Page 1

OPTIVIEW

TM

REMOTE CONTROL CENTER

INSTALLATION, OPERATION & SERVICE

OPTIVIEW™ REMOTE CONTROL CENTER

New Release

Form 50.40-OM2 (601)

00497VIP

Page 2

IMPORTANT!

READ BEFORE PROCEEDING!

GENERAL SAFETY GUIDELINES

This equipment is a relatively complicated apparatus.

During installation, operation, maintenance or service,

individuals may be exposed to certain components or

conditions including, but not limited to: refrigerants,

oils, materials under pressure, rotating components,

and both high and low voltage. Each of these items

has the potential, if misused or handled improperly,

to cause bodily injury or death. It is the obligation

and responsibility of operating/service personnel to

identify and recognize these inherent hazards, protect

themselves, and proceed safely in completing their

tasks. Failure to comply with any of these requirements

could result in serious damage to the equipment and

the property in which it is situated, as well as severe

personal injury or death to themselves and people

at the site.

This document is intended for use by owner-authorized

operating/service personnel. It is expected that this

individual possesses independent training that will

enable them to perform their assigned tasks properly

and safely. It is essential that, prior to performing

any task on this equipment, this individual shall have

read and understood this document and any referenced

materials. This individual shall also be familiar with and

comply with all applicable governmental standards and

regulations pertaining to the task in question.

SAFETY SYMBOLS

The following symbols are used in this document to alert the reader to areas of potential hazard:

DANGER indicates an imminently

hazardous situation which, if not

avoided, will result in death or serious injury.

CAUTION identifies a hazard

which could lead to damage to the

machine, damage to other equipment and/or environmental pollution. Usually an instruction will

be given, togeth e r wit h a brief

explanation.

WARNING indicates a potentially

hazardous situation which, if not

avoided, could result in death or

NOTE is used to highlight additional

information which may be helpful

to you.

serious injury.

External wiring, unless specied as an optional connection in the manufacturer’s product

line, is not to be connected inside the micro panel cabinet. Devices such as relays, switches,

transducers and controls may not be installed inside the micro panel. No external

wiring is allowed to be run through the micro panel. All wiring must be in accordance

with YORK’s published specications and must be performed only by qualied YORK

personnel. YORK will not be responsible for damages/problems resulting from improper

connections to the controls or application of improper control signals. Failure to follow

this will void the manufacturer’s warranty and cause serious damage to property or

injury to persons.

YORK INTERNATIONAL2

Page 3

CHANGEABILITY OF THIS DOCUMENT

FORM 50.40-OM2

In complying with YORK’s policy for continuous

product improvement, the information contained in

this document is subject to change without notice.

While YORK makes no commitment to update or

provide current information automatically to the

manual owner, that information, if applicable, can be

obtained by contacting the nearest YORK Applied

Systems Service ofce.

It is the responsibility of operating/service personnel

as to the applicability of these documents to the

equipment in question. If there is any question in

the mind of operating/service personnel as to the

ap plicability of these do cuments, then, prior to

working on the equipment, they should verify with

the owner whether the equipment has been modied

and if current literature is available.

3YORK INTERNATIONAL

Page 4

TABLE OF CONTENTS

SECTION 1 PRODUCT DESCRIPTION ....................................................................... 8

Chiller/Condensing Control Panel(s) .......................................................... 9

SECTION 2 INSTALLATION........................................................................................ 10

Mounting ..................................................................................................10

Installation Checklist ................................................................................ 10

Wiring ................................................................................................... 10

Lan Transient Installation ......................................................................... 14

Eprom Compatibility ................................................................................ 14

Troubleshooting .......................................................................................14

Safety ................................................................................................... 14

Proper Installation Practices ..................................................................... 15

SECTION 3 OPERATION............................................................................................. 18

OptiView Remote Control Center ............................................................. 18

Screen Descriptions and Usage................................................................. 19

Home Screen............................................................................................. 22

Unit Screen ..........................................................................................24

Systems Screen............................................................................... 29

Individual System Screen.......................................................... 32

Hours/Starts Screen ........................................................................ 34

Options Screen ...............................................................................36

Trending Screen .............................................................................38

Trend Setup Screen................................................................... 40

Setpoints Screen ............................................................................. 44

History Screen ................................................................................ 47

History Details Screen .............................................................. 48

RCC Setpoints Screen ......................................................................... 49

RCC Setup Screen .......................................................................... 50

Comms Screen .......................................................................... 52

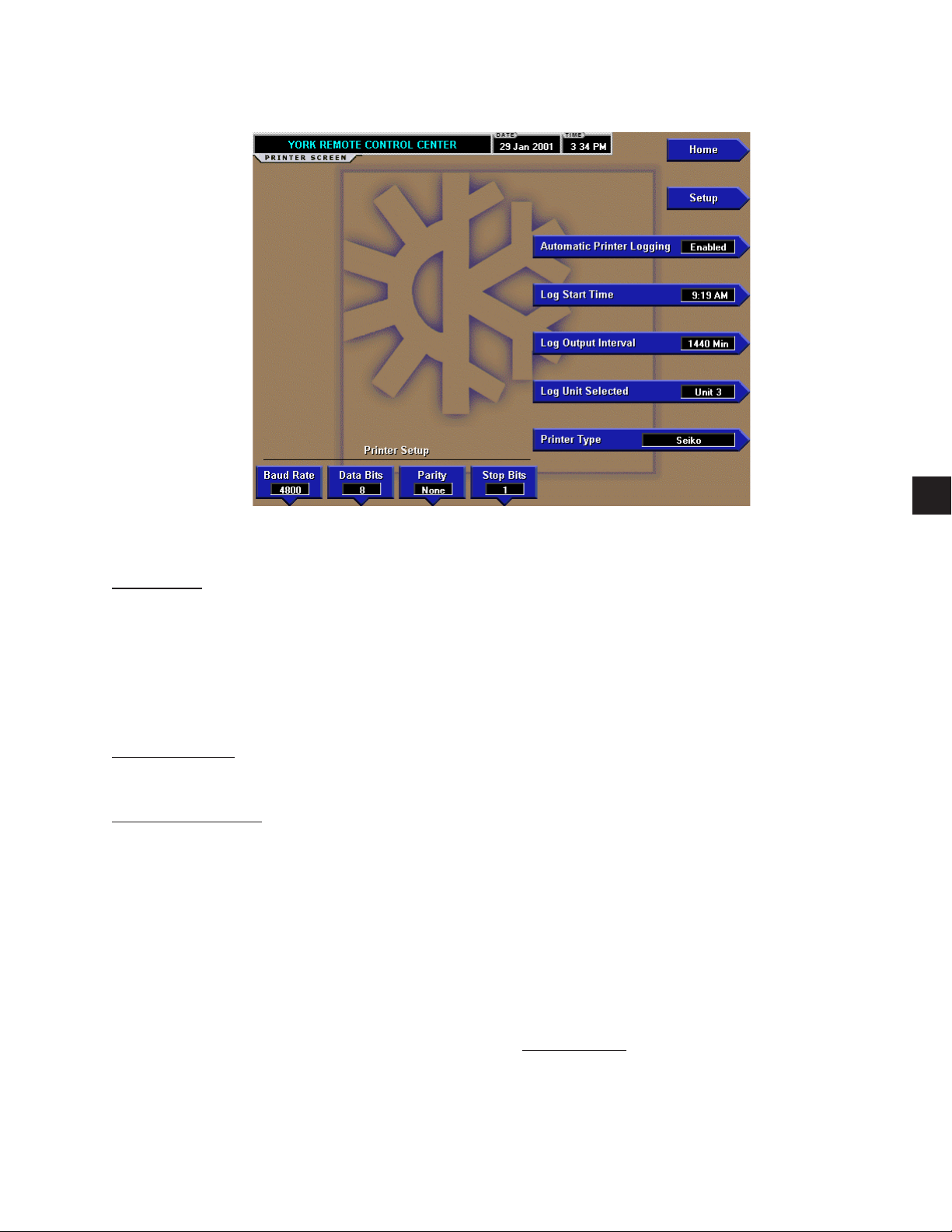

Printer Screen ............................................................................53

Diagnostics Screen ....................................................................54

Diagnostics (I/O) Screen ..................................................... 55

Diagnostics (RCC Comms) Screen ..................................... 56

Display Messages ..................................................................................... 58

SECTION 4 PRINTERS ............................................................................................... 59

SECTION 5 SERVICE ................................................................................................. 65

Introduction............................................................................................... 65

YORK INTERNATIONAL4

Page 5

FORM 50.40-OM2

System Architecture.................................................................................. 66

Microboard................................................................................................ 68

Microboard Program Jumpers .................................................................. 76

Microboard Program Switches .................................................................78

Liquid Crystal Display.............................................................................. 81

Display Interface Board ............................................................................ 87

Display Backlight Inverter Board ............................................................. 89

Keypad .................................................................................................... 91

Power Supply............................................................................................ 94

Ofine Diagnostics & Troubleshooting.................................................... 96

Main Diagnostics ...................................................................................... 97

Keypad Test............................................................................................... 98

Display Test .............................................................................................. 99

Bit Pattern Test ....................................................................................... 100

Serial Inputs / Outputs Tests ................................................................... 101

Digital Inputs / Outputs Tests ................................................................. 103

Analog Inputs Test ..................................................................................104

System Commissioning Checklist .......................................................... 105

SECTION 6 PART NUMBER AND RENEWAL PARTS........................................... 106

LIST OF TABLES

TABLE 1 – Required Software Version of the Chiller/Condensing Unit Eproms .......... 11

TABLE 2 – Program Jumpers ......................................................................................... 76

TABLE 3 – Program Switches ........................................................................................78

TABLE 4 – Part Number ...............................................................................................106

TABLE 5 – Renewal Parts ............................................................................................106

5YORK INTERNATIONAL

Page 6

LIST OF FIGURES

FIG. 1 – EU DECLARATION OF CONFORMITY ............... 7

FIG. 2 – FIELD WIRING ................................................... 12

FIG. 3 – CONTROL INSTALLATION ................................ 16

FIG. 4 – GROUNDING ..................................................... 16

FIG. 5 – SEPARATE CONDUIT INSTALLATION .............. 17

FIG. 6 – POWER & GROUND WIRE CONNECTIONS.... 17

FIG. 7 – OPTIVIEW REMOTE CONTROL CENTER ....... 18

FIG. 8 – SCREEN NAVIGATION LAYOUT ....................... 20

FIG. 9 – HOME SCREEN ................................................. 22

FIG. 10 – UNIT SCREEN ................................................... 24

FIG. 11 – SYSTEMS SCREEN .......................................... 29

FIG. 12 – INDIVIDUAL SYSTEM SCREEN........................ 32

FIG. 13 – HOURS AND STARTS SCREEN ....................... 34

FIG. 14 – OPTIONS SCREEN ........................................... 36

FIG. 15 – TRENDING SCREEN ......................................... 38

FIG. 16 – TRENDING SETUP SCREEN ............................ 40

FIG. 17 – SETPOINTS SCREEN ....................................... 44

FIG. 18 – HISTORY SCREEN............................................ 47

FIG. 19 – HISTORY DETAILS SCREEN ............................ 48

FIG. 20 – RCC SETPOINTS SCREEN .............................. 49

FIG. 21 – RCC SETUP SCREEN ....................................... 50

FIG. 22 – COMMS SCREEN .............................................. 52

FIG. 23 – PRINTER SCREEN ............................................ 53

FIG. 24 – DIAGNOSTICS SCREEN ................................... 54

FIG. 25 – DIAGNOSTICS I/O SCREEN ............................. 55

FIG. 26 – DIAGNOSTICS RCC COMMS SCREEN ........... 56

FIG. 27 – PRINTERS ......................................................... 59

FIG. 28 – EXAMPLE PRINTOUT (OPERATING DATA)...... 63

FIG. 29 – EXAMPLE PRINTOUT (HISTORY HEADER) .... 64

FIG. 30 – CONTROL CENTER BLOCK DIAGRAM ........... 67

FIG. 31 – MICROBOARD ................................................... 73

FIG. 32 – FLASH MEMORY CARD.................................... 74

FIG. 33 – BLOCK DIAGRAM, MICROBOARD .................. 75

FIG. 34 – MICROBOARD LAMP DIMMER CIRCUIT ......... 78

FIG. 35 – SERIAL DATA COMMUNICATIONS PORTS...... 79

FIG. 36 – CONFIGURABLE ANALOG INPUTS ................. 80

FIG. 37 – DISPLAY, MOUNTING........................................ 84

FIG. 38 – LCD TYPICAL CONTROL SIGNAL TIMING ...... 84

FIG. 39 – LG SEMICON LP104V2 DISPLAY ASSEMBLY - 85

FIG. 40 – SHARP LQ10D367 DISPLAY ASSEMBLY - ...... 85

FIG. 41 – SHARP LQ10D367 BACKLIGHT LAMP

REPLACEMENT ................................................ 86

FIG. 42 – LG SEMICON LP104V2 BACKLIGHT LAMP

REPLACEMENT................................................. 86

FIG. 43 – DISPLAY INTERFACE BOARD .......................... 88

FIG. 44 – DISPLAY BACKLIGHT INVERTER BOARD....... 90

FIG. 45 – KEYPAD ............................................................. 92

FIG. 46 – DIAGRAM, KEYPAD........................................... 93

FIG. 47 – BLOCK DIAGRAM, DC POWER DISTRIBUTION. 95

FIG. 48 – MAIN DIAGNOSTIC SCREEN ........................... 97

FIG. 49 – KEYPAD TEST SCREEN ................................... 98

FIG. 50 – DISPLAY TEST SCREEN................................... 99

FIG. 51 – BIT PATTERNS TEST SCREEN....................... 100

FIG. 52 – SERIAL INPUTS/OUTPUTS TESTS SCREEN 101

FIG. 53 – DIGITAL INPUTS/OUTPUTS TESTS SCREEN 103

FIG. 54 – ANALOG INPUTS TEST SCREEN .................. 104

FIG. 55 – FRONT OF OPTIVIEW RCC ............................ 107

FIG.56 – INSIDE OF OPTIVIEW RCC ............................ 107

FIG.57 – INSIDE DOOR OF OPTIVIEW RCC ................ 108

FIG.58 – LOCATION OF FUSE, F1 & F2 ........................ 109

YORK INTERNATIONAL6

Page 7

FORM 50.40-OM2

FIG. 1 – EU DECLARATION OF CONFORMITY

7YORK INTERNATIONAL

Page 8

Product Description

SECTION 1 – PRODUCT DESCRIPTION

The YORK OptiView Remote Control Center is a

microprocessor based control system capable of

remotely monitoring certain chillers and condensing

units. It can monitor and individually control 1 to 8 of

these chiller/condensing units.

The panel comes congured with a full screen color

LCD Graphic Display mounted in the middle of a

keypad interface. The graphic display allows the

presentation of the current information all at once. In

addition, the operator may view a graphical representation of several operating parameters. For the novice

user, the locations of various parameters are clearly and

intuitively marked. Instructions for specic operations

are provided on many of the screens.

The graphic display also allows information to be

represented in Imperial units (temperatures in °F and

pressures in PSIG or PSID) or SI units (temperatures in

°C and pressures in BARG or BARD).

All values that are modiable at the Remote Control

Center are recorded in memory and preserved even

through a power failure condition. During operation, the

chillers are continually polled and the user is advised of

the operating conditions by various status and warning

messages. A complete listing of shutdown, status, and

warning messages is within the chiller/condensing

unit’s operation manual.

If the chiller/condensing unit is in remote control mode

the OptiView Remote Control Center provides the

capability to program the following:

1. Start Command

2. Stop Command

3. Local Setpoint

4. Local Control Range

5. Daily/Holiday Schedule

6. Current or Load Limit Setpoint

The Remote Control Center is also designed to enable

the user to obtain chiller/condensing unit printouts

directly from this panel.

This equipment has been tested and

found to comply with the limits for

a Class A digital device, pursuant

to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is

operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency

energy and, if not installed and

used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in

a residential area is likely to cause

harmful interference in which case

the user will be required to correct

the interference at his own expense.

YORK INTERNATIONAL8

Page 9

FORM 50.40-OM2

CHILLER/CONDENSING CONTROL PANEL(S)

All communication with the chiller/condensing units

will occur over a single RS-485 port. Reference Figure

2 and the Installation instructions.

When the OptiView RCC is first turned on it will

initialize by requesting current data and history buffer

information from the units connected. After the history

buffers are lled, only current data will be continuously

requested. Every eight hours the OptiView RCC will reinitialize. If the control panel updates the history buffer

(a safety shutdown has occurred), the control panel

will send the chiller shutdown data to the OptiView

RCC upon receipt of the next valid OptiView RCC

transmission. The OptiView RCC will recognize that

a safety shutdown has occurred by the Update History

Buffer bit being set. If this bit is ever 1, the data dump is

assumed to be a shutdown data dump and the OptiView

RCC will update its history buffers with the new data

and start a printout of the transmitted data through its

RS232 port. If the OptiView RCC had been requesting

another type of data dump (i.e. a daily schedule dump),

the OptiView RCC will repeat its request on the next

transmission.

While at the Home Screen, the OptiView RCC will

communicate with each unit in order. Once a unit has

been selected by entering the Unit Screen or any screen

below it, that unit will be polled between every unit

in order. This will allow the selected unit to update its

information quickly while still maintaining information

for the Home Screen.

A command string is used to indicate what data the

OptiView RCC is requesting and to modify control data

in the chiller control panel. If the chiller/condensing

unit is in remote control mode then its Local Set

Point, Local Range, Daily Schedule, Holiday, Start

/ Stop Command, and Current / Load Limit can be

programmed from the OptiView RCC. The OptiView

RCC will send a command string once any of these are

modied at the OptiView RCC. If the OptiView RCC

sends a Stop command, the chiller/condensing unit will

turn off. If the OptiView RCC sends a start command,

the chiller/condensing unit will be allowed to run if all

the other run requirements of the unit are made.

A chiller/condensing unit that is in remote control

mode will use local control (set points and start / stop

information), if a valid transmission has not been

received for 5 minutes from the OptiView RCC. The

remote commands will be used again once a valid

new transmission has been processed. The OptiView

RCC will display an error message indicating the

communications problem when such a condition

occurs.

A general status message for each unit is displayed

on the Home Screen. The messages displayed will

include communications status. Not Initialized will

be displayed upon power-up for all units until the

OptiView RCC begins to poll and receive data from

that unit. Initializing… will be displayed while the

OptiView RCC is polling a unit for all current, schedule,

and history data the rst time after power-up. Loss of

Comms will be displayed after 5 minutes have elapsed

with no response from a previously initialized unit. If

any of these messages is displayed, the unit’s button

will be disabled not allowing it to be selected.

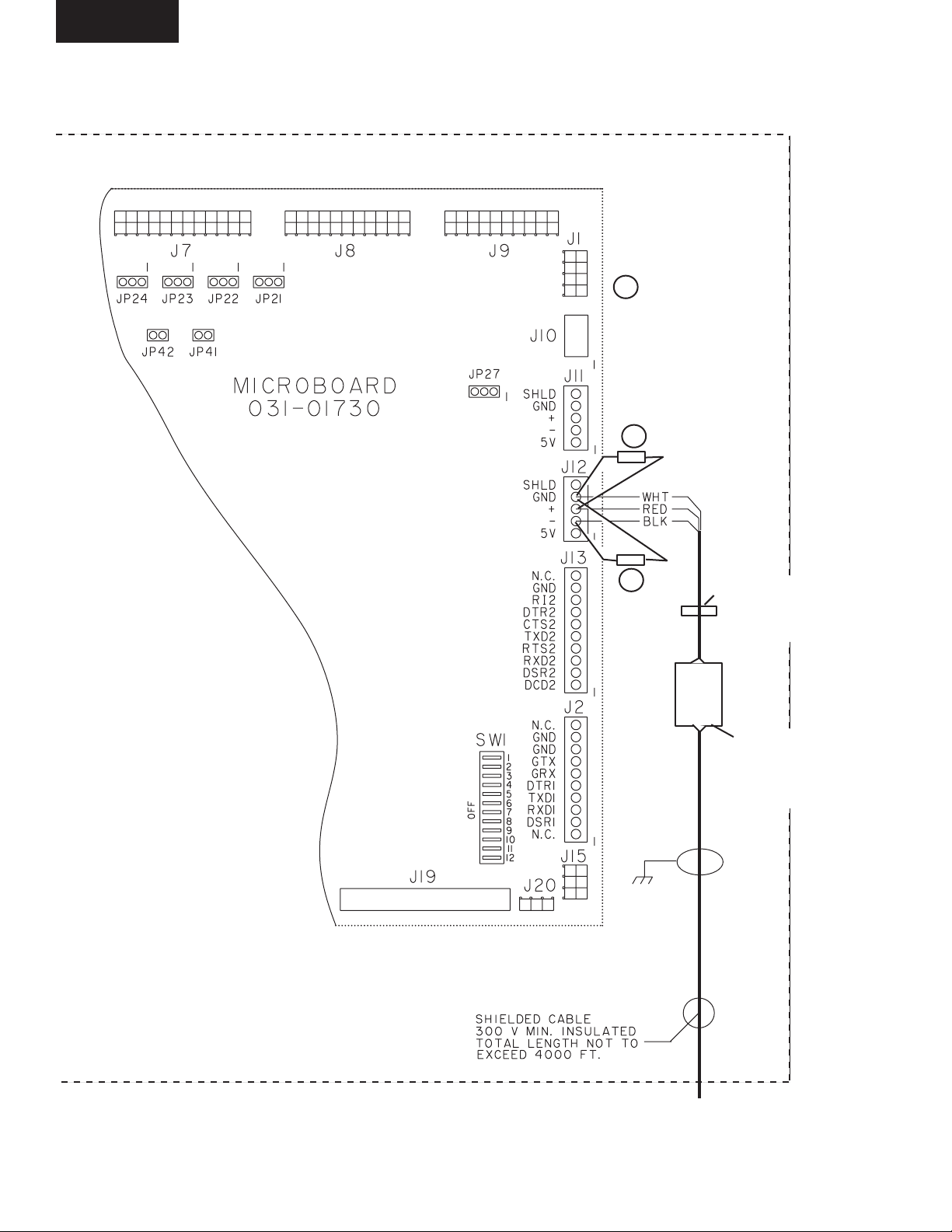

The Control Center Microboard (J12) communicates

with this board via a 0/+5VDC serial data communications link. If this communications link does not operate

properly, correct Microboard J12 serial port operation

can be veried using the Serial Inputs and Outputs

diagnostic procedure in the “Service” section of this

book.

1

9YORK INTERNATIONAL

Page 10

Installation

SECTION 2 – INSTALLATION

MOUNTING

Mount the Remote Control Center at a level that

provides for easy viewing of the color graphic display

by all users. Securely mount it at the desired location.

The panel may be mounted away from the chiller as far

as 4000 ft. (1219 m.) of wiring will allow.

INSTALLATION CHECKLIST

(Reference Fig. 2 for wiring)

• A communications cable must connect the OptiView

RCC to the chiller/condenser control panel. This

cable should be a three-conductor with foil shield

and drain wire, 20 awg or larger wire, 300v, 80 Deg.

C, UL Style 2464, UL listed and CSA approved.

Three sources are Alpha 5463, Belden 9364, or

Quabbin 0220. The cable length (sum of lengths of

all cables) must not exceed 4000 ft. (1219 m.). The

cable is user supplied.

• Obtain ferrite (part number 025-35154-000) from

the cloth bag found in the OptiView RCC and

install it as shown on Fig. 2. This must be installed

to meet FCC and CE requirements.

• Make sure that the Transient Voltage Suppressors are

installed at J12. One is installed from “+” to “GND”

and one is installed from “-” to “GND”.

• At J12 of the OptiView RCC, red wire on RS485(+),

black wire on RS485(-) and white wire on Ground.

• At the OptiView RCC, connect the shield to the

panel.

• Use a tie wrap between the J12 connector and the

Ferrite (part number 025-35154-000) to secure the

shielded cable to the OptiView RCC. The tie wrap

can help prevent the wires from being accidentally

pulled out of the J12 connector by someone working

in the panel or by the weight of the ferrite.

• Install a LAN transient protection module at the

chiller/condenser control panel and connect the

cable according to the type of control panel.

• Make sure the correct EPROM is installed at the

chiller/condenser control panel(s). See Table 1.

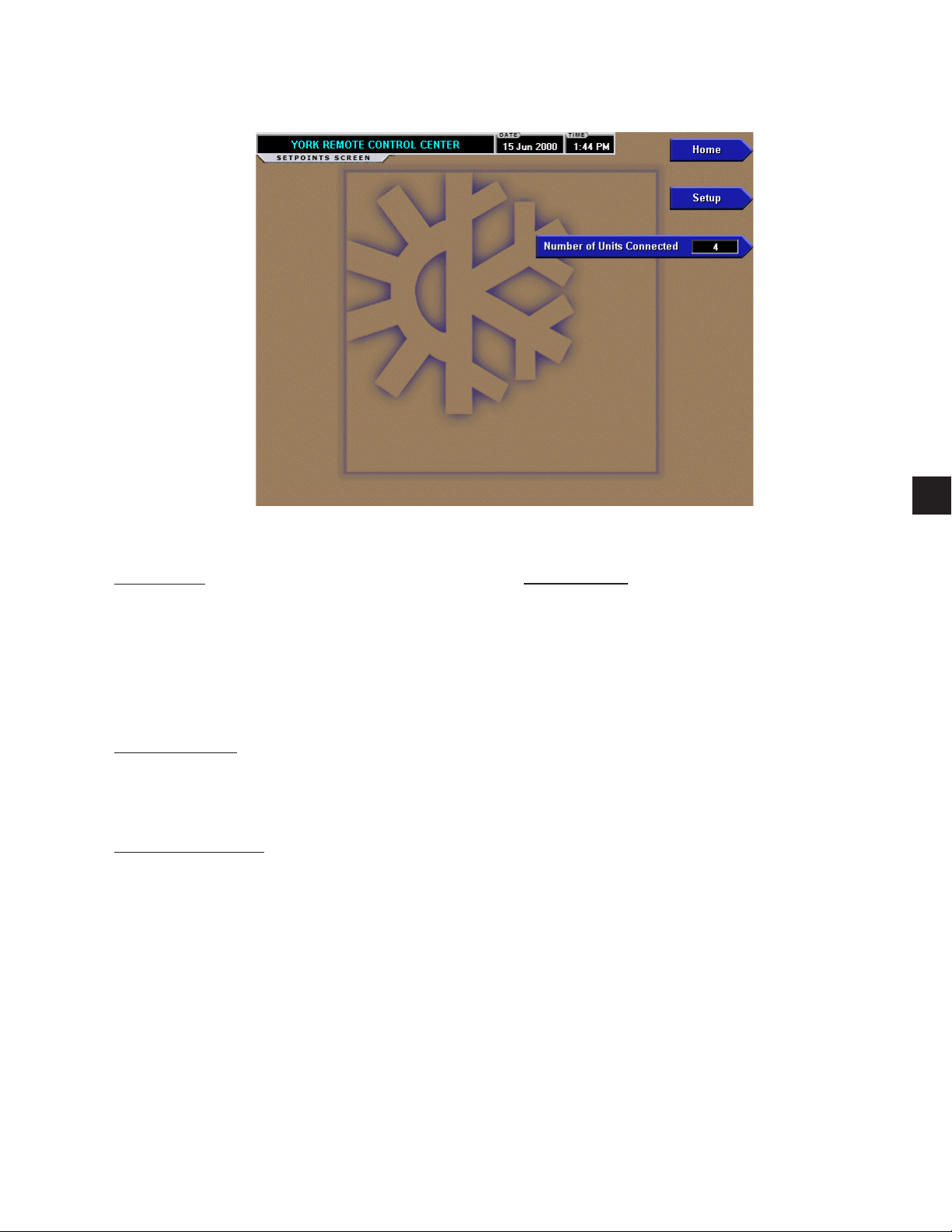

• From the Setpoints Screen of the OptiView RCC,

enter the Number of Units Connected (Maximum

value allowed is 8).

• At the chiller/condenser control panel that uses

a rotary switch to set the ID, use a small screw

driver to rotate the rotary switch so that the arrow

points at the number that coincides with the Unit’s

Identication number (ID#). Unit 1 - Unit 8 coincide

to rotary switches 0 - 7. Otherwise program the

panel’s ID through keypad entry.

Never skip an ID#. For example, if

you have four units then they must be

identied from ID#0 - ID#3.

• At the chiller/condenser unit’s control panel, select

the type of control mode. Select REMOTE only if

remote control is desired. Select LOCAL to only

monitor this unit.

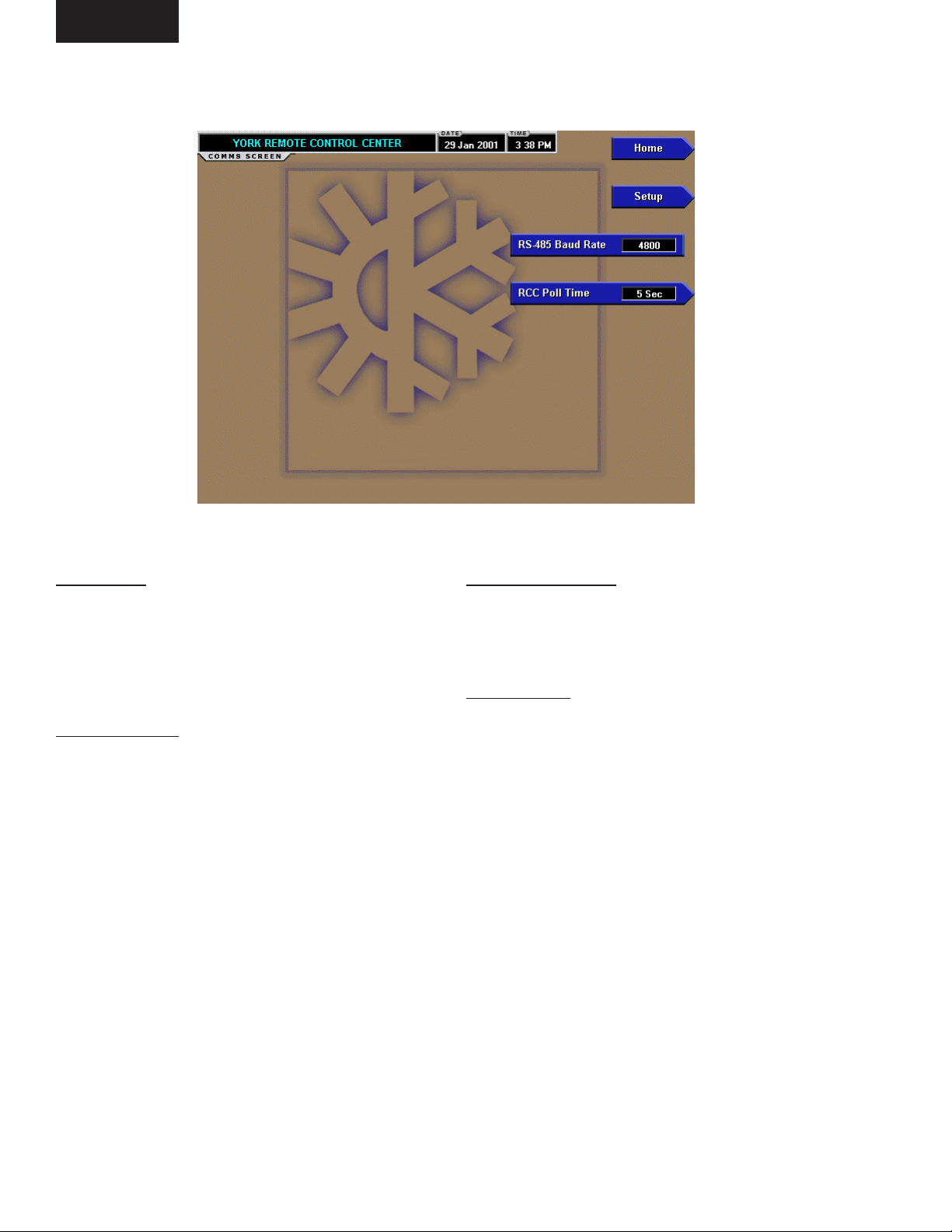

• From the Comms Screen of the OptiView RCC,

enter the RCC Poll Time. This is how often (time

in seconds) to request data. This time should be set

long enough to allow for receiving the data.

WIRING

A communications cable must connect the chiller to the

remote panel. This cable should be a three-conductor

with foil shield and drain wire, 20 awg or larger sized

wire, 300v, 80 Deg. C, U.L. Style 2464, U.L. listed

and CSA approved. Three sources are Alpha 5463,

Belden 9364, or Quabbin 0220. The cable length (sum

of lengths of all cables) must not exceed 4000 ft.

(1219 m.).

Never run the communication cable in

close proximity to any power wiring.

For best results, it should be run in

dedicated, grounded conduit. See

Proper Installation Practices.

YORK INTERNATIONAL10

Page 11

FORM 50.40-OM2

REQUIRED SOFTWARE VERSION OF THE

CHILLER / CONDENSING UNIT EPROMS

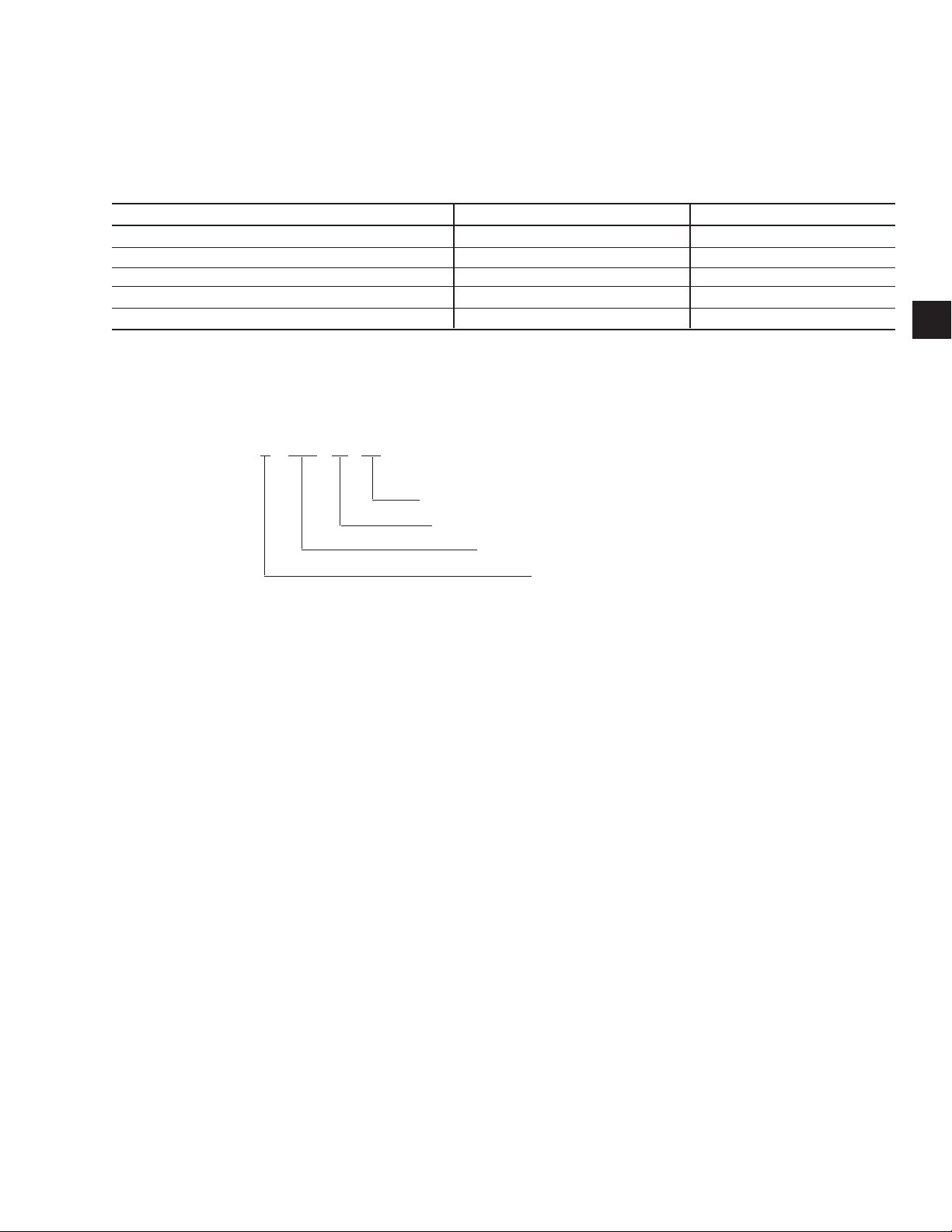

TABLE 1 – REQUIRED SOFTWARE VERSION OF THE CHILLER/CONDENSING UNIT EPROMS

UNIT TYPE EPROM PART NO. VERSION

YCAL / YCUL w/microboard 031-01314-000 031-02011-001 C.MMC.01.05

YCAL / YCUL w/microboard 031-02050-000 031-02049-001 C.MMC.03.02

YCAS - F 2 Compressors 031-01798-001 C.ACS.09.03

YCAS - F 3 & 4 Compressors 031-01798-002 C.ACS.10.02

YCAR 2 Compressors 031-02013-001 C.RCP.23.02

The software version is printed on a label adhered to the EPROM chip’s surface. A revision level higher than the one

listed in the table is acceptable. An example version code is as follows:

C. ACS. 09. XX.

2

Revision Level. Increments 01, 02 etc.

Product Code

YCAS (RCP = YCAR, MMC =YCAL/YCUL)

Commercial

11YORK INTERNATIONAL

Page 12

Tie Wrap (To help

keep wires

connected)

Ferrite

(025-35154-000)

(FCC & CE

Requirement)

A

A

A

Transient Voltage

Suppressor

(031-02076-000)

(Factory Installed)

Installation

OPTIVIEW REMOTE CONTROL CENTER

FIG. 2 – FIELD WIRING OPTIVIEW RCC PANEL

LD06725

YORK INTERNATIONAL12

Page 13

SHLD

BLK

SHLD

RED

(TOTAL NOT TO

EXCEED 8)

WHT

BLK

SHLD

RED

FROM

OPTIVIEW RCC

WHT

BLK

RED

WHT

(COMPONENT

SIDE UP)

(COMPONENT

SIDE DOWN)

(COMPONENT

SIDE DOWN)

X

X

CUT PINS

AS SHORT

AS POSSIBLE

X

X

CUT PINS

AS SHORT

AS POSSIBLE

FORM 50.40-OM2

2

FIG. 2 – FIELD WIRING OPTIVIEW RCC PANEL (CONT.)

LD06726

13YORK INTERNATIONAL

Page 14

Installation

LAN TRANSIENT INSTALLATION

The properly installed Lan Transient Protection Module,

(part number 031-01586-000) will limit the voltage

levels seen by the chiller control panel’s RS-485 driver

while allowing normal RS-485 network operation under

non-transient conditions. For installation of the module

refer to Fig. 2 and the specic installation instructions

for the microboard.

Unit Microboard 031-01314-000 and

031-02050-001:

Step 1: Label all wires, cables, or components con-

nected to TB1.

Step 2: Carefully loosen each terminal of TB1. Remove

all wires, cables, or components. Be extremely careful

to not allow them to short together or to the enclosure.

Step 3: Refer to the Module. Replace all wires,

cables, or components taken from TB1 into the correct terminals of the Module terminal strip J1 being

extremely careful to not allow them to short together

or to the enclosure.

Step 4: Carefully tighten all screws on the Module

Terminal strip J1.

Step 5: Orient the Module as shown (component side

down) and cut the unused pins. Insert the four P1

Module pins into TB1 as shown.

Step 6: Carefully tighten each terminal of TB1. Double

check all wiring to the Module before closing up.

Unit Microboard 031-01095-000:

Step 1: Label all wires, cables, or components con-

nected to TB7.

Step 2: Carefully loosen each terminal of TB7. Remove

all wires, cables, or components. Be extremely careful

to not allow them to short together or to the enclosure.

Step 3: Replace all wires, cables, or components taken

from TB7 into the Module terminal strip J1 being

extremely careful to not allow them to short together

or to the enclosure.

Step 4: Carefully tighten all screws on the Module

Terminal strip J1.

Step 5: Orient the Module as shown (component side

up) and insert all six P1 Module pins into TB7 as

shown.

Step 6: Carefully tighten each terminal of TB7. Double

check all wiring to the Module before closing up.

EPROM COMPATIBILITY

Since the concept and design of the OptiView Remote

Control Center may have occurred after the original

EPROM (software) for the chiller/condenser control

panel, the EPROM may need to be replaced with

one that allows for OptiView Remote Control Center

operation. See Table 1.

TROUBLESHOOTING

From the Home Screen you can determine if you are

communicating to the chiller/condensing unit.

If the message Not Initialized.. remains shown on this

screen, proper communication between the panels has

not occurred and you will need to troubleshoot.

Step 1: If you are trying to communicate with more

than one unit, simplify the troubleshooting by isolating

the communication to one unit at a time. Remove any

wiring to a secondary unit and from the Setpoints

Screen of the OptiView RCC, enter one as the Number

of Units Connected and at the chiller/condenser control

panel set it’s ID to zero.

Step 2: Check if there is any communication problem

occurring on the Diagnostic RCC Comms Screen. See

the description of this screen.

You could also check that the RX3 I/O communication

activity LED on the OptiView Main Processor Board is

blinking as it receives data from the chiller/condensing

unit’s control panel. A steady lit RX3 LED is a sign of

improper wiring. If the RX3 LED is not blinking check

the wiring and the installation of the Lan Transient

Protection Module. If everything is properly connected

replace the 485 driver on the chiller/condenser

microboard (part number 031-02074-000).

SAFETY

It is recommended that all maintenance and service

repair work be performed by experienced personnel.

There must be recognition of the potential hazards

that can exist. Those hazards may include (but are

not limited to):

YORK INTERNATIONAL14

Page 15

FORM 50.40-OM2

There can be electrical circuitry that

presents an electrocution hazard. Be

sure that the sources of all power

supplies have been properly isolated

and secured before attempting any

service related activities.

External wiring, unless specied as

an optional connection in the manufacturer’s product line, is not to be

connected inside the OptiView Remote

Control Center cabinet. Devices such

as relays, switches, transducers and

controls may not be installed inside

the OptiView Remote Control Center.

No external wiring is allowed to be

run through the OptiView Remote

Control Center. All wiring must be in

accordance with YORK’s published

specications and must be performed

only by qualified YORK personnel.

YORK will not be responsible for

damages/problems resulting from

improper connections to the controls

or application of improper control

signals. Failure to follow this will

void the manufacturer’s warranty and

cause serious damage to property or

injury to persons.

PROPER INSTALLATION PRACTICES

Earlier relay systems were virtually immune to radio

frequency interference (RFI), electromagnetic interference (EMI), and ground loop currents. Installation

consisted of hooking up the point-to-point wiring and

sizing the wire properly.

In an electronic system, improper installation will

cause problems that outweigh the benets of electronic

control. Electronic equipment is susceptible to RFI,

EMI, and ground loop currents which can cause equipment shutdowns, processor memory and program loss,

erratic behavior, and false readings. Manufacturers of

industrial electronic equipment take into consideration

the effects of RFI, EMI, and ground loop currents and

incorporate protection of the electronics in their designs.

These manufacturers require that certain installation

precautions be taken to protect the electronics from

these effects. All electronic equipment must be viewed

as sensitive instrumentation and therefore requires

careful attention to proper installation procedures.

There are a few basics, that if followed, will result in

a trouble-free installation. The National Electric Code

(N.E.C.) is a guideline for safe wiring practices, but

it does not deal with procedures used for electronic

control installation. Use the following procedures for

electronic equipment installation. These procedures are

to be used in conjunction with the N.E.C.

Wire Sizing

Size supply wires one size larger than required for

amperage draw to reduce instantaneous voltage dips

caused by large loads such as heaters, contactors

and solenoids. Sudden dips in voltage can cause the

processor to momentarily malfunction or cause a

complete reset of the control system. If the wire is

loaded to its maximum capacity, the voltage dips are

much larger, and the potential for a malfunction is

very high. If the wire is sized one size larger than

required, the voltage dips are smaller than in a fully

loaded supply wire, and the potential for malfunction

is much lower.

The NEC code requires specic wire sizes to be used

based on current draw. An example would be to use

#14 gauge wire for circuits up to 15 amp or #12 gauge

wire for circuits of up to 20 amp. Therefore, when

connecting the power feed circuit to an electronic

industrial control, use #12 gauge wire for a maximum

current draw of 15 amp and #10 wire for a maximum

current draw of 20 amp.

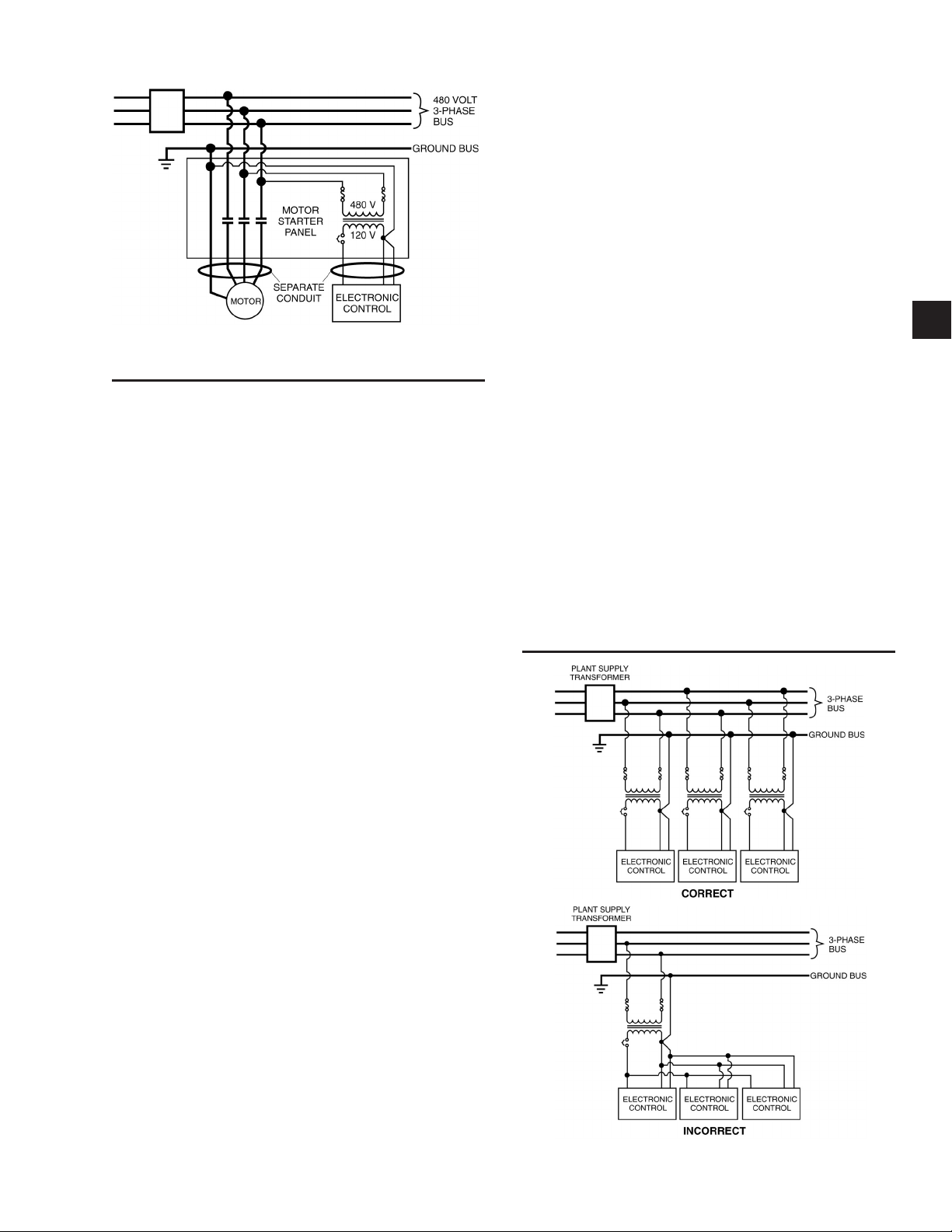

Voltage Source (Figure 3)

Selecting the voltage source is extremely important

for proper operation of electronic equipment in

an industrial environment. Standard procedure for

electronic instrumentation is to provide a “clean”

separate source voltage in order to prevent EMI, from

other equipment in the plant, from interfering with

the operation of the electronic equipment. Connecting

electronic equipment to a breaker panel (also known as

lighting panels and fuse panels) subjects the electronic

equipment to noise generated by other devices connected to the breaker panel. This noise is known as

electromagnetic interference (EMI). EMI ows on

the wires that are common to a circuit. EMI cannot

travel easily through transformers and therefore can

be isolated from selected circuits. Use a control

transformer to isolate the electronic control panel from

other equipment in the plant that generate EMI.

2

15YORK INTERNATIONAL

Page 16

Installation

equipment in the plant on the same circuits will ground

themselves to the ground stake causing large ground

ow at the electronic equipment.

LD06728

LD06727

FIG. 3 – CONTROL INSTALLATION

Grounding

Grounding is the most important factor for successful

operation. Electronic equipment reacts to very small

currents and must have a good ground in order to

operate properly. The NEC states that control equipment

may be grounded by using the rigid conduit as a

conductor. This is not acceptable for electronic control

equipment. Conduit is a poor conductor compared

to a copper wire. Copper grounds are required for

proper operation.

Ground Wire Size (Figure 4)

The ground wire must be the same size as the supply

wires or one size smaller as a minimum. The three

phase power brought into the plant must also have a

ground wire, making a total of four wires. In many

installations that are having electronic control problems,

this essential wire is usually missing. A good ground

circuit must be continuous from the plant source

transformer to the electronic control panel for proper

operation. Driving a ground stake at the electronic

control will cause additional problems since other

FIG 4 – GROUNDING

Wiring Practices (Figure 5)

Do not mix wires of different voltages in conduit. For

an example refer to Figure 5. The motor voltage is 480

volts and the panel control power is 120 volts. The 480

volt circuit must be run from the motor starter to the

motor in its own conduit. The 120 volt circuit must

be run from the motor starter control transformer to

the control panel in its own separate conduit. If the

two circuits are run in the same conduit, transients on

the 480 volt circuit will be inducted into the 120 volt

circuit causing functional problems with the electronic

control. Dividers must be used in wire way systems

(conduit trays) to separate unlike voltages. The same

rule applies for 120 volt wires and 220 volt wires.

Also, never run low voltage wires in the same conduit

with 120 volt wires.

Never run any wires through an electronic control

panel that do not relate to the function of the panel.

Electronic control panels should never be used as

a junction box. These wires may be carrying large

transients that will interfere with the operation of

the control.

When running conduit to an electronic control panel,

note that the access holes (knockouts) are strategically

placed so that the eld wiring does not interfere with

the electronics in the panel. Never allow eld wiring to

come in close proximity with the controller boards

since this will almost always cause problems.

YORK INTERNATIONAL16

Page 17

LD06738

FIG. 5 – SEPARATE CONDUIT INSTALLATION

Do not drill a control panel to locate conduit connections. Drilling can cause metal chips to land in the

electronics and create a short circuit. If you must drill

the panel, take the following precautions:

1. Call the panel manufacturer, if possible, before

drilling the panel to be sure you are entering the

panel at the right place.

2. Cover the electronics with plastic. Tape the plastic

to the board with masking or electrical tape.

3. Place masking tape or duct tape on the inside of

the panel at the point of drill bit entry.

FORM 50.40-OM2

Never run refrigerant, water or brine tubing inside

an electronic control panel. A leak could damage or in

some cases totally destroy the electronics.

If the electronic control panel has a starter built into

the same panel, be sure to run the higher voltage

wires where indicated by the manufacturer. EMI

from the wires can interfere with the electronics if run

too close to the circuitry.

Never daisy-chain or parallel-connect power or

ground wires to electronic control panels. Each

electronic control panel must have its own supply

wires back to the power source. Multiple electronic

control panels on the same power wires create current

surges in the supply wires which can cause controller

malfunctions. Daisy-chaining ground wires allows

ground loop currents to ow between electronic control

panels which also causes malfunctions. (See Figure 6)

It is very important to read the installation instructions

thoroughly before beginning the project. Make sure you

have drawings and instructions with your equipment.

If not, call the manufacturer and have them send you

the proper instructions. Following correct wiring

procedures will ensure proper installation of your

electronic equipment.

2

4. Remove all of the remaining chips from the panel

before removing the protective plastic.

When routing conduit to the top of an electronic control

panel, condensation must be taken into consideration.

Water can condense in the conduit and run into the panel

causing catastrophic failure. Route the conduit to the

sides or bottom of the panel and use a conduit drain.

If the conduit must be routed to the top of the panel,

use a sealable conduit tting which is poured with a

sealer after the wires have been pulled, terminated and

the control functions have been checked. A conduit

entering the top of the enclosure must have an

“O” ring-type tting between the conduit and the

enclosure, so that if water gets on top of the enclosure,

it cannot run in between the conduit and the enclosure.

This is extremely important in outdoor applications.

Never add relays, starters, timers, transformers,

etc. inside an electronic control panel without rst

contacting the manufacturer. Contact arcing and

EMI emitted from these devices can interfere with the

electronics. If you need to add these devices contact the

manufacturer for the proper device types and placement.

LD06739

LD06740

FIG. 6 – POWER & GROUND WIRE CONNECTIONS

17YORK INTERNATIONAL

Page 18

Operation

SECTION 3 – OPERATION

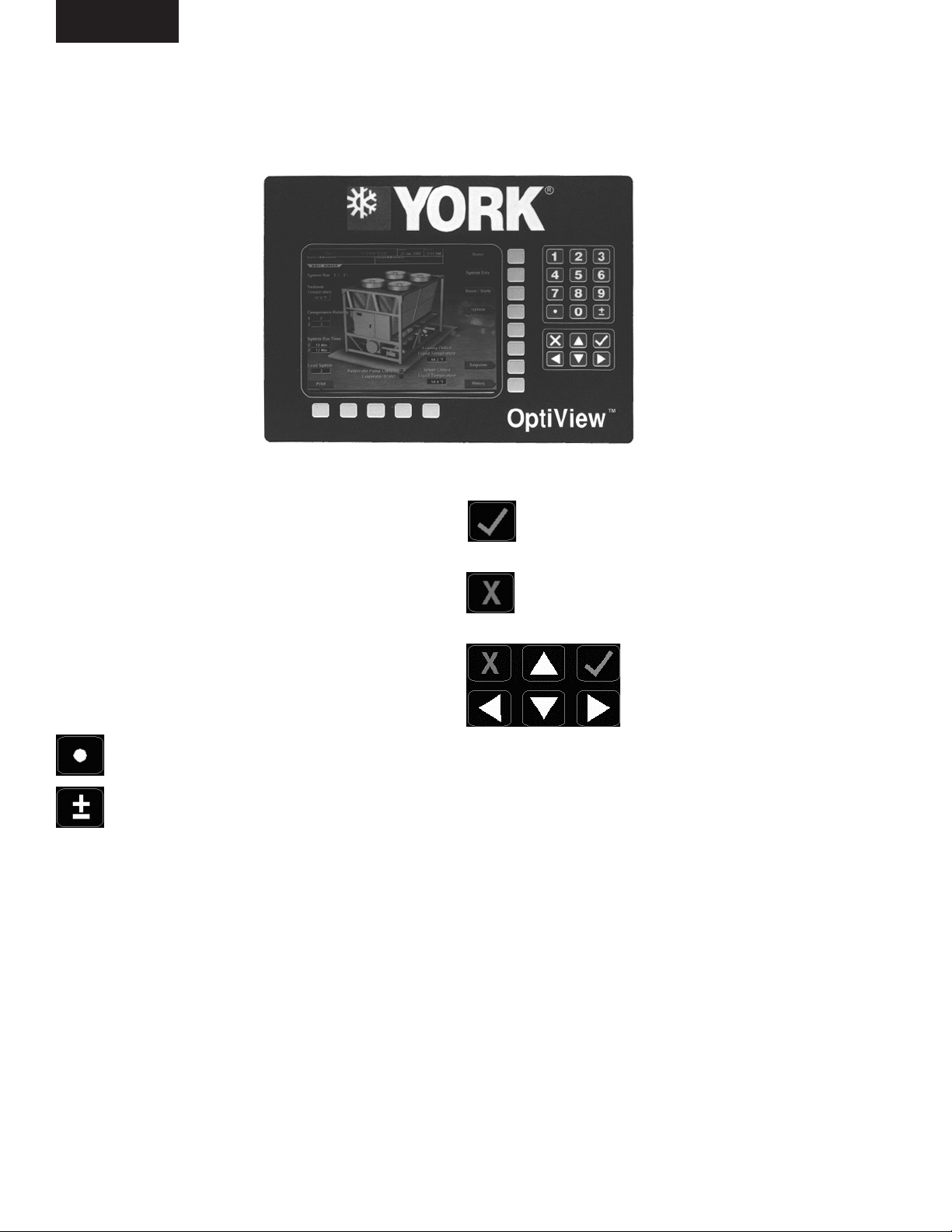

OPTIVIEW REMOTE CONTROL CENTER

FIG. 7

The OptiView Remote Control Center display is

highlighted by a full screen graphics display. This

display is nested within a standard keypad, and is

surrounded by “soft” keys which are redened based

on the currently displayed screen. Eight buttons are

available on the right side of the panel, and are primarily

used for navigation between the system screens. At the

base of the display are 5 additional buttons. The area

to the right of the keypad is used for data entry with a

standard numeric keypad provided for entry of system

setpoints and limits.

The Decimal key is used prior to entering

decimal values.

A +/- key has also been provided to allow entry

of negative values and AM/PM selection during

time entry.

00500VIP

In order to accept changes made to the chiller

setpoints, the Check key is provided as a

universal ‘Enter’ key or ‘Accept’’ symbol.

In order to reject entry of a setpoint or dismiss

an entry form, the ‘X’ key is provided as a

universal ‘Cancel’ symbol.

Cursor Arrow keys are provided to allow movement on

screens which contain a large

amount of entry data. In addition, these keys can be used

to scroll through history and

event logs.

YORK INTERNATIONAL18

Page 19

SCREEN DESCRIPTIONS AND USAGE

FORM 50.40-OM2

OVERVIEW

The new graphical display on each control panel allows

a wide variety of information to be presented to the

user. Each screen description in this document will

begin with a section entitled Overview which will

describe the graphical elements on the screen and

give a short summary of the functions available. Each

element on the screen will then be categorized into

three distinct groups: Display Only, Programmable, and

Navigation. Below is a short description of what types

of information are included in these groups.

DISPLAY ONLY

Values in this group are read-only parameters of

information about chiller operation. This type of

information may be represented by a numerical value,

a text string, or an LED image. For numerical values, if

the monitored parameter is above the normal operating

range, the high limit value will be displayed along with

the ‘>’ symbol; if it is below the normal operating range,

the low limit value will be displayed along with the

‘<’ symbol. In some cases, the value may be rendered

invalid by other conditions and the display will use

X’s to indicate this.

PROGRAMMABLE

Values in this group are available for change by the

user if the chiller/condensing unit is in remote mode.

If there are no values that can be changed then “None”

is shown.

Setpoint / Change Schedule

On screens containing programmable setpoints, a key

with one of these labels will be visible. This key allows

the user to modify setpoints on that screen.

Setpoints

1. Press the desired setpoint key. A dialog box appears

displaying the present value, the upper and lower

limits of the programmable range, and the default

value.

2. If the dialog box begins with the word “ENTER”,

use the numeric keys to enter the desired value.

Leading zeroes are not necessary. If a decimal point

is necessary, press the ‘•’ key (i.e. 45.0).

Pressing the ▲ key, sets the entry value to the

default for that setpoint. Pressing the ▼ key, clears

the present entry. The ◄ key is a backspace key and

causes the entry point to move back one space.

If the dialog box begins with “SELECT”, use the ◄

and ► keys to select the desired value.

If the previously dened setpoint is desired, press

the ‘X’ (Cancel) key to dismiss the dialog box.

3. Press the ‘ü’ (Enter) key.

If the value is within range, it is accepted and the

dialog box disappears. The chiller will begin to

operate based on the new programmed value. If

out of range, the value will not be accepted and the

user is prompted to try again.

Manual Controls

So m e keys are used to perform manual control

functions. These may initiate/terminate processes

such as a report.

Free Cursor

On screens containing many setpoints, a specic “soft”

key may not be assigned to each setpoint value. A

soft key will be assigned to enable the cursor arrow

keys below the numeric keypad which are used to

“highlight” the desired setpoint eld. At this point,

the ‘ü’ key is pressed to bring up a dialog prompting

the user to enter a new setpoint value. The ‘X’ key

cancels cursor mode. (See “Change Schedule” from

the Setpoints Screen for an example.)

3

Setpoint values are used to control chillers/condensing

units and other devices connected to the units. Setpoints

can fall into several categories. They could be numeric

values (such as 45.0°F for the Leaving Chilled Liquid

Temperature), or they could Enable/Yes or Disable/No

a feature or function.

Regardless of which setpoint is being programmed, the

following procedure applies:

NAVIGATION

In order to maximize the amount of values which the

panel can display to the user, and in order to place

those values in context, multiple screens have been

designed to describe each unit’s operation. In order

to move from one screen to the next, navigation keys

have been dened. These keys allow the user to either

19YORK INTERNATIONAL

Page 20

Operation

move “forward” to a sub-screen of the present screen,

or move “backward” to the previous screen. Except

for the Home Screen display, the upper-right “soft”

key will always return the user to the Home Screen.

Navigating with “soft” keys is as simple as pressing the

key next to the label containing the name of the desired

screen. The system will immediately refresh the display

with the graphics for that screen. Following is a layout

of all the screens and how they are connected.

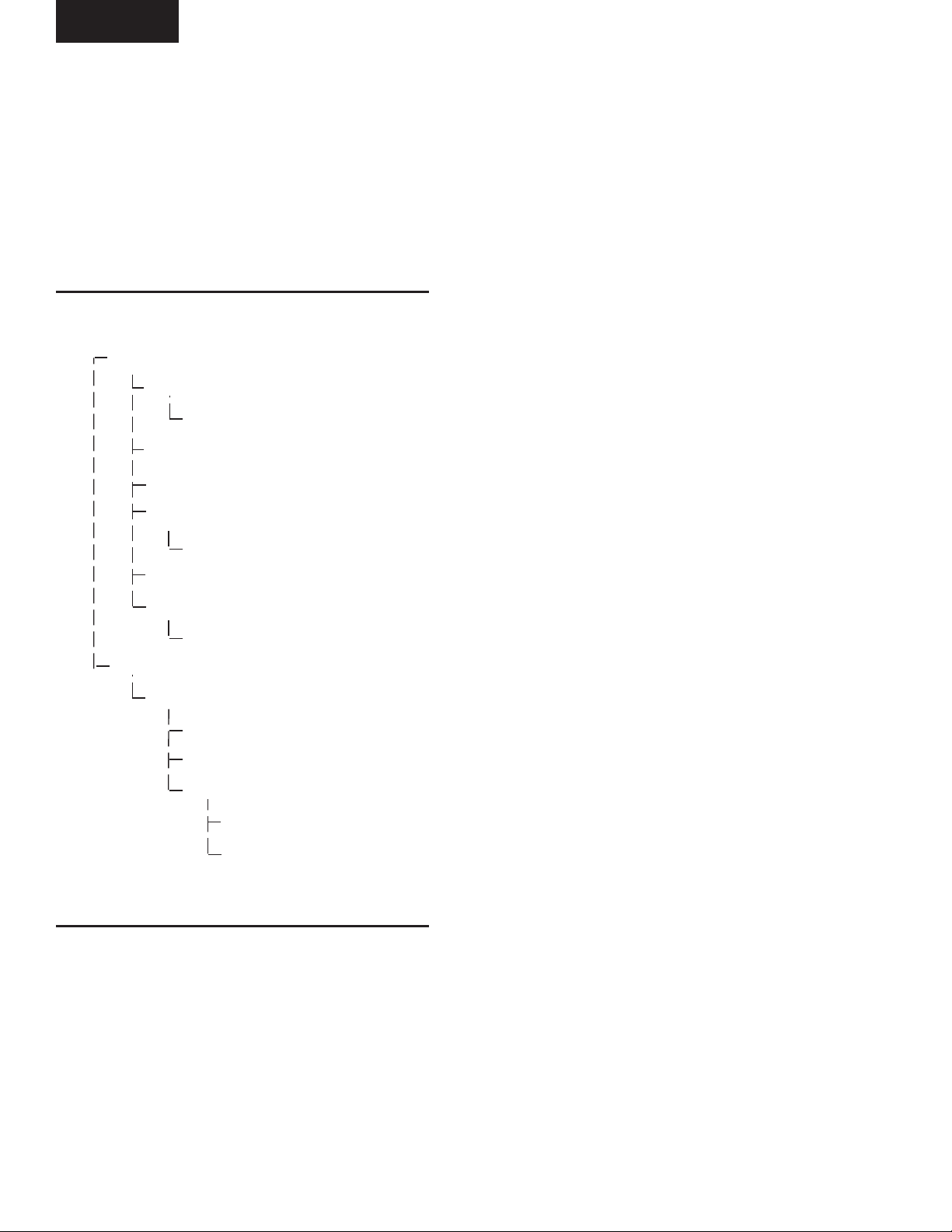

Home (page 22)

Unit Data (page 24)

System Data (page 29)

Individual System (page 32)

Hours/Starts (page 34)

Options (page 36)

Trending (page 38)

Trend Setup (page 40)

Setpoints (page 44)

History (page 47)

History Details (page 48)

RCC Setpoints (page 49)

RCC Setup (page 50)

Comms (page 52)

Printer (page 53)

Diagnostics (page 54)

Diagnostics (I/O) (page 55)

Diag. (RCC Comms) (page 56)

FIG. 8 – SCREEN NAVIGATION LAYOUT

This section of the manual will describe each screen

in the order they are accessed as shown in this screen

navigation layout.

YORK INTERNATIONAL20

Page 21

FORM 50.40-OM2

This page intentionally left blank to maintain formatting

3

21YORK INTERNATIONAL

Page 22

Operation

HOME SCREEN

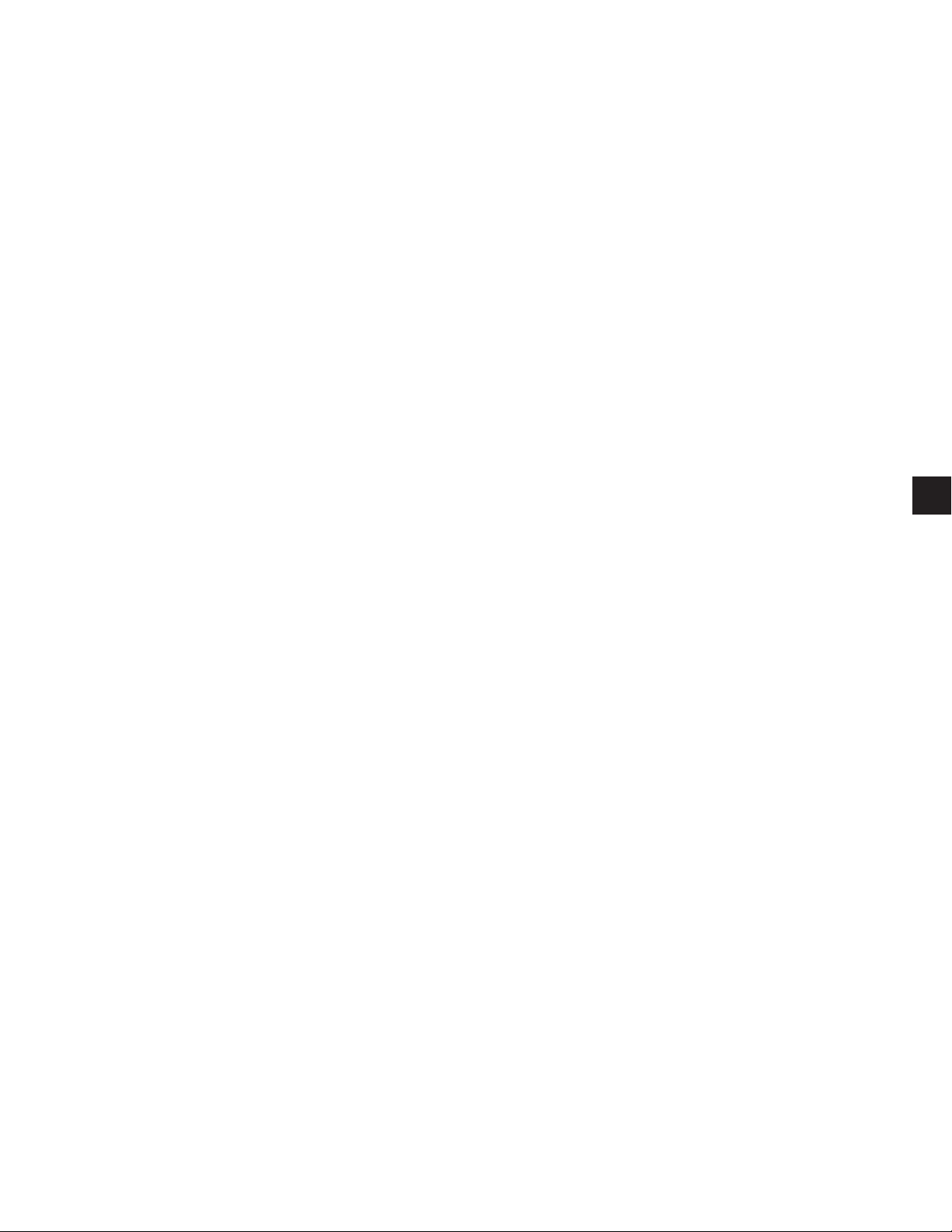

FIG. 9 – HOME SCREEN - EXAMPLE

OVERVIEW

When the OptiView Remote Control Center is powered

on, the above default display appears. This screen gives

a general overview of the operating status of each unit

connected to the OptiView Remote Control Center. The

data and control of an individual unit is accessed from

the Home Screen display. Fig. 9 is an example that

shows eight units were programmed.

DISPLAY ONLY

Unit Control Temperature

Displays the temperature of what the unit is using for

control such as leaving chilled liquid temperature.

This is not shown if suction pressure is being used

for control.

Unit Type

Displays the type of chiller the unit is.

Unit Status

Displays a general status message for the unit. The

general status message will include communications

status, running status, and fault status, etc. Following is

a complete listing of the general status messages:

00499VIPC

this message is displayed, the unit’s button will be

disabled, not allowing it to be selected.

• Initializing… will be displayed while the OptiView

Remote Control Center is polling a unit for all

current, schedule, and history data the rst time

after power-up. While this message is displayed,

the unit’s button will be disabled not allowing it

to be selected.

• Loss of Comms will be displayed after 5 minutes

have elapsed with no response from a previously

initialized unit. While this message is displayed,

the unit’s button will be disabled not allowing it

to be selected.

• Running will be displayed when at least 1 system is

running on a unit with no faults on any system. This

message will be displayed even if the chiller is in any

kind of limiting as long as there are no faults present.

While this message is displayed, the unit’s button

will be enabled allowing it to be selected.

• Not Running will be displayed when no systems

on the unit are running for a non-fault reason but

can run when demand requires. This would be

for the No Cool Load state. While this message

is displayed, the unit’s button will be enabled

allowing it to be selected.

• Not Initialized will be displayed upon power-up for

all units until the OptiView Remote Control Center

begins to poll and receive data from that unit. While

• Faulted will be displayed when no systems on

the unit are running and there is a fault on one or

more systems or a unit fault. While this message

YORK INTERNATIONAL22

Page 23

FORM 50.40-OM2

is displayed, the unit’s button will be enabled

allowing it to be selected.

• Running / Faulted will be displayed when at least

one system on the unit is running and at least one

system is faulted. While this message is displayed,

the unit’s button will be enabled allowing it to

be selected.

• Cannot Run will be displayed for any non-fault

condition preventing the entire chiller from running. This would include such things as the daily

schedule, unit switch, all system switches, run

perm, etc. While this message is displayed, the

unit’s button will be enabled allowing it to be

selected.

Unit Run Indicator (LED)

Is ON when the unit is running.

Average Ambient Temperature

Displays the average Ambient Air Temperature of all

the units connected.

PROGRAMMABLE

None

NAVIGATION

Unit #

A detailed view of data relevant to the specied (#) unit.

If the “Not Initialized” status message is displayed,

the unit’s button will be disabled, not allowing it to

be selected.

Setpoints

This screen provides the gateway to many of the

OptiView Remote Control Center’s general setup

parameters such as Date/Time, Comm Setup, Printer

Setup, etc.

3

23YORK INTERNATIONAL

Page 24

Operation

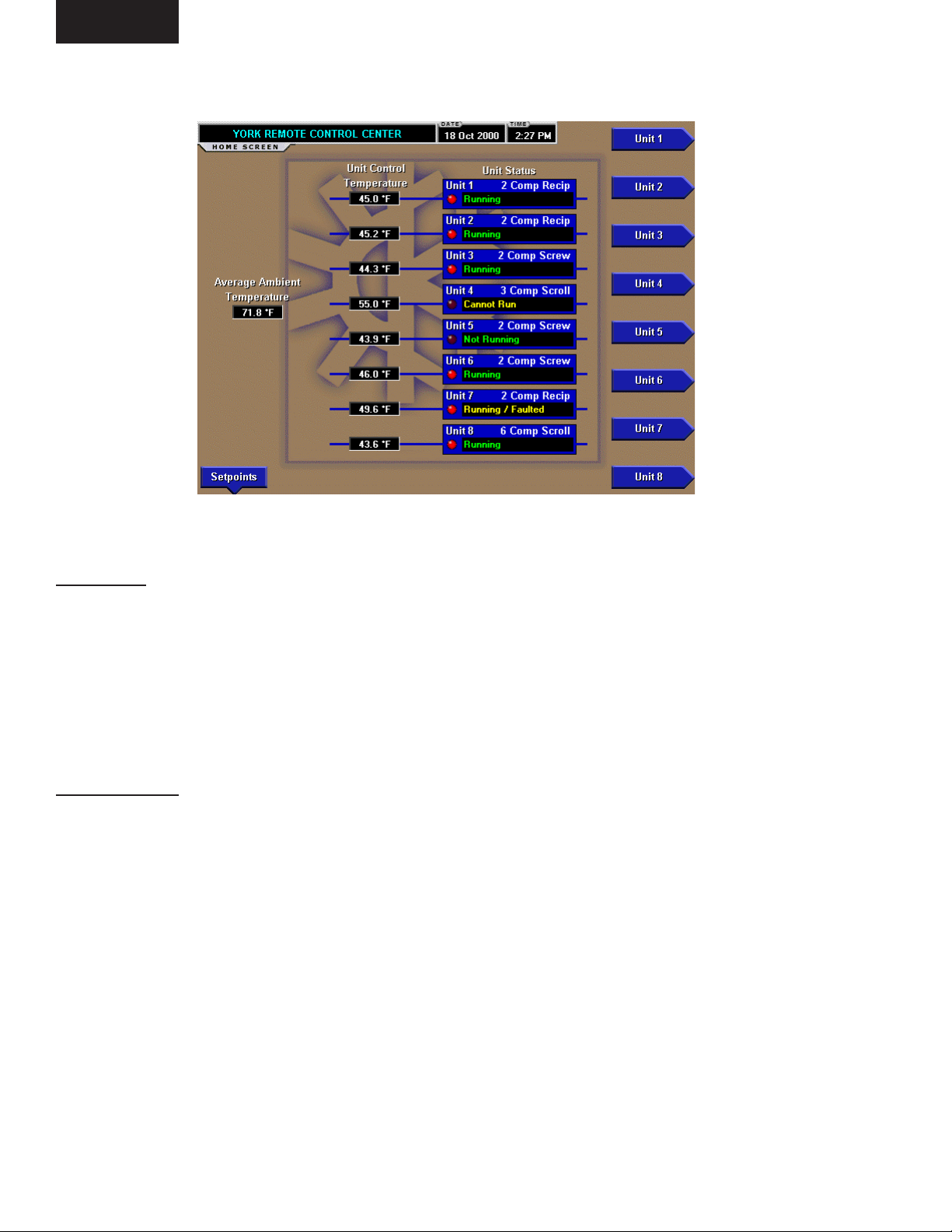

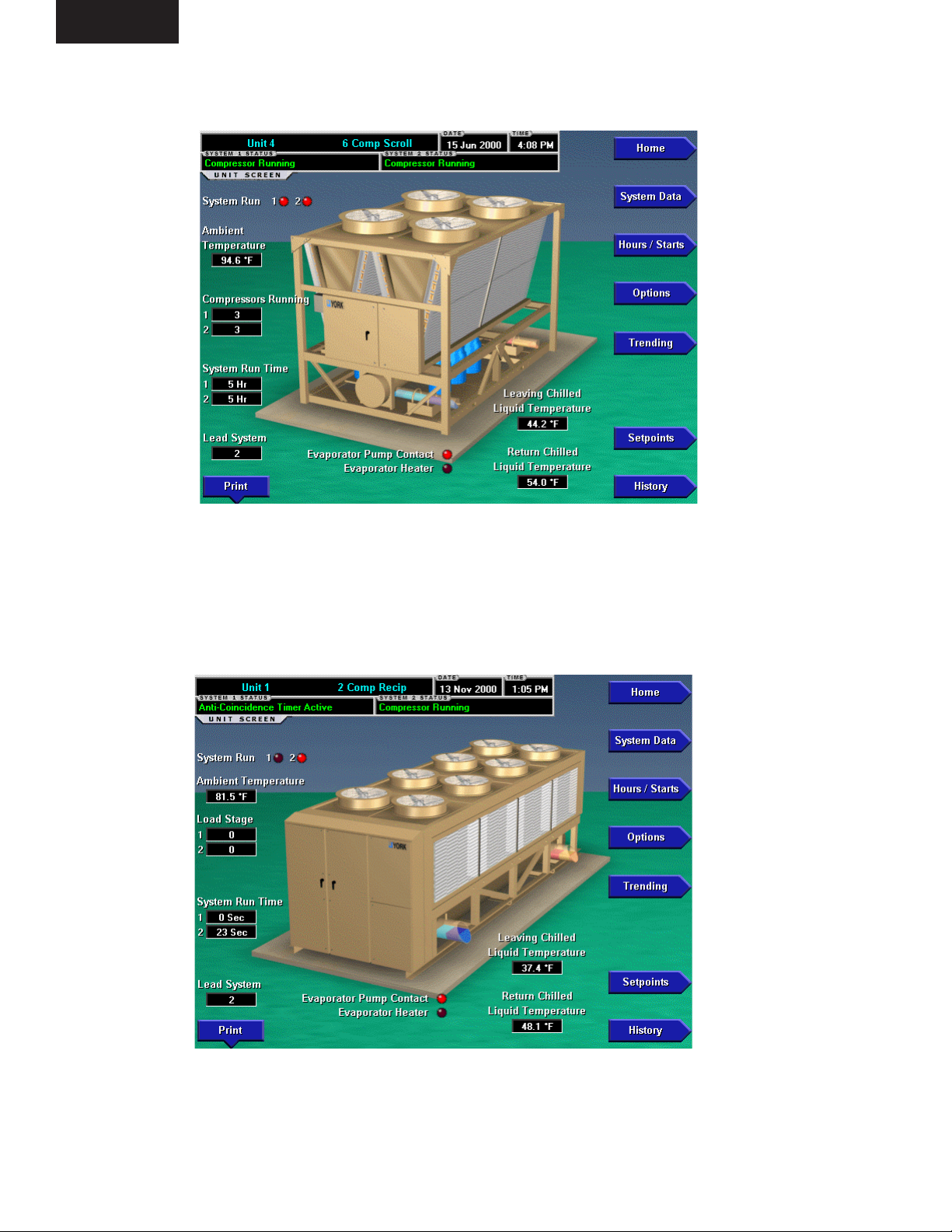

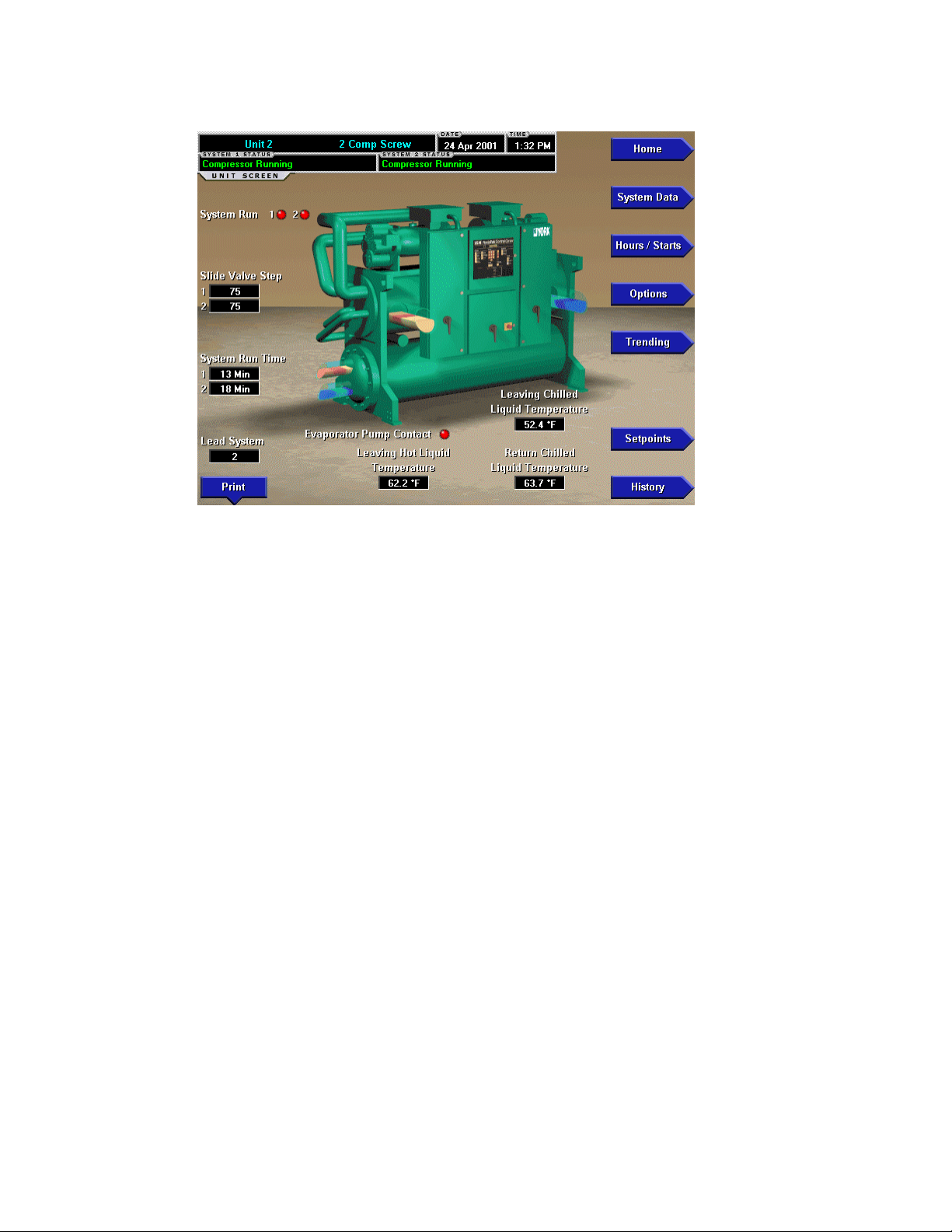

UNIT SCREEN - EXAMPLES

FIG. 10A – YCAL CHILLER

00569VIPC

FIG. 10B – YCAR CHILLER

00570VIPC

YORK INTERNATIONAL24

Page 25

UNIT SCREEN - EXAMPLES

FORM 50.40-OM2

FIG. 10C – YCAS CHILLER

3

00571VIPC

FIG. 10D – YCUL CONDENSING UNIT

00572VIPC

25YORK INTERNATIONAL

Page 26

UNIT SCREEN - EXAMPLES

FIG. 10E – YCWS CHILLER

00573VIPC

YORK INTERNATIONAL26

Page 27

UNIT SCREEN

FORM 50.40-OM2

OVERVIEW

This screen is accessed from the Home Screen. The

primary values of the chiller or condensing unit which

must be monitored and controlled are shown on this

screen. The data available depends on the type of unit.

This screen display depicts a visual representation of

the unit itself. Animation indicates chilled liquid ow

and condenser fans running.

DISPLAY ONLY

Systems Statuses

Displays the individual refrigerant systems operational

statuses. The messages displayed include running

status, cooling demand, fault status, external cycling

device status, load limiting, and anti-recycle timer

status. The status message that is displayed on the

microprocessor is represented here.

System Run (LED)

Is ON when the individual refrigerant systems compres-

sor is running. If any of these are ON, the fans will be

animated to show that they are running.

Slide Valve Step (If Screw)

Displays the individual refrigerant systems slide valve

step.

Load Stage (If Recip)

Indicates the number of solenoids on the compressor of

a YCAR unit that are de-energized and loaded.

Return Chilled Liquid Temperature

Displays the temperature of the liquid as it enters

the evaporator.

Discharge Air Temperature

Displays the discharge air temperature leaving the

evaporator when the condensing unit is programmed

for Discharge Air control.

Systems Suction Pressure

Displays the suction pressure for each individual system

on a condensing unit when the unit was programmed

for Suction Pressure control.

Ambient Temperature

Displays the outdoor Ambient Air Temperature.

PROGRAMMABLE

Print

Init i a t e s a printout of current system operating

parameters for the currently selected unit.

Cancel Print

Terminates the printing in process. This key is only

visible while printing is in process.

NAVIGATION

Home

Causes an instant return to the Home Screen.

Number Of Compressors Running (If a system has

more than one)

Displays how many compressors are running on the unit.

System Run Time

Displays the individual refrigerant systems logged run

time since the last compressor start, in days (Days),

hours (Hr), minutes (Min) or seconds (Sec).

Lead System

This message indicates which system is in the lead.

Evaporator Pump Contact (LED)

Is ON when the evaporator pump signal from the

microprocessor is on. If this is ON, the chilled liquid

will be animated to show that it is owing.

Evaporator Heater (LED)

Is ON when the evaporator heater signal from the

microprocessor is on.

Leaving Chilled Liquid Temperature

Displays the temperature of the liquid as it leaves

the evaporator.

System Data

Used to provide additional system information.

Hours/Starts

This screen shows the cumulative operating hours and

start count of each compressor.

Options

Used to provide information of the options that were

programmed at the Unit Control Panel.

Trending

This screen provides the user a view of trending data on

selected parameters of this chiller/condensing unit.

Setpoints

This screen provides a single location to program the

unit setpoints for the selected unit.

History

This screen provides access to a snapshot of system data

at each of the last 4-6 shutdown conditions.

27YORK INTERNATIONAL

Page 28

Operation

This page intentionally left blank.

YORK INTERNATIONAL28

Page 29

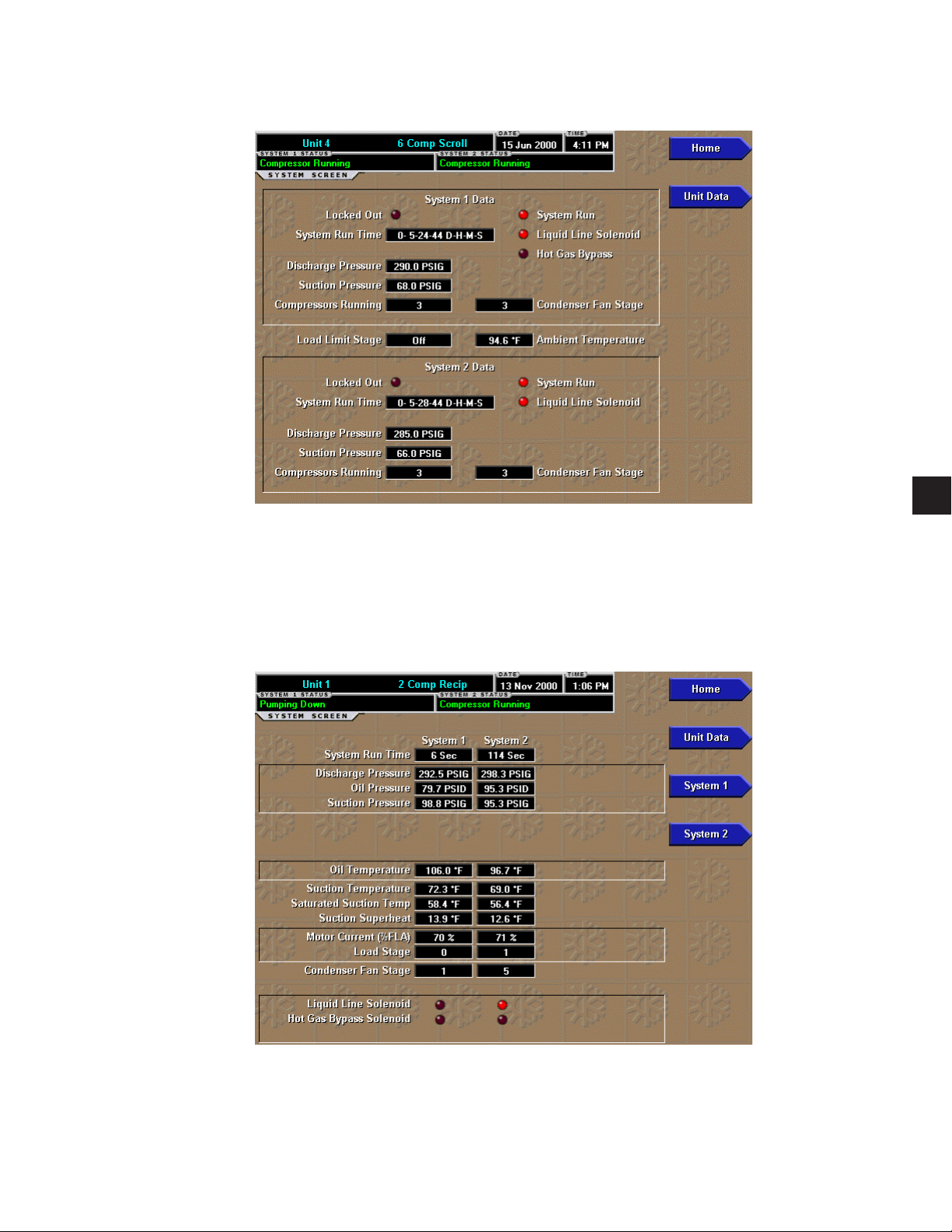

SYSTEMS SCREEN - EXAMPLES

FORM 50.40-OM2

FIG. 11A – YCAL CHILLER

3

00505VIPC

FIG. 11B – YCAR CHILLER

00506VIPC

29YORK INTERNATIONAL

Page 30

Operation

SYSTEMS SCREEN - EXAMPLES

FIG. 11C – YCAS CHILLER

00507VIPC

FIG. 11D – YCUL CONDENSING UNIT

00508VIPC

Page 31

SYSTEMS SCREEN

OVERVIEW

This screen is accessed from the Unit Screen. A chiller

can consist of separate refrigerant circuits. Each

refrigerant circuit is referred to as a system. This

screen shows system specic information for each of

the unit’s refrigerant systems. This information can

vary according to the type of chiller. Reference the

chiller’s Installation, Operation, Maintenance Manual

(IOM) for details.

DISPLAY ONLY

System Status

Displays this refrigerant systems operational status.

The messages displayed include running status, cooling

demand, fault status, external cycling device status,

load limiting, and antirecycle timer status. The status

message that is displayed on the Unit’s microprocessor

is represented here.

System Run (LED)

Displays this refrigerant systems operational status. Is

ON when the system is running.

Locked Out (LED)

Is ON when a system is locked out on a fault requiring

a manual reset at the chiller or condenser unit micro

panel.

System Run Time

Displays the amount of time the system has run.

Compressors Running

(If more than one compressor per circuit)

Indicates the number of compressors running

Load Limit Stage

Indicates which stage of Load Limiting a unit is in.

Load Stage

Indicates the number of solenoids on the compressor of

a YCAR unit that are de-energized and loaded.

Condenser Fan Stage

Displays the stage of condenser fan operation on the

system.

Cooler Inlet Refrigerant temperature (Only if in

R-407c mode)

Displays the refrigerant temperature at the inlet of

the cooler.

Liquid Line Solenoid (LED)

Is ON when the Liquid Line Solenoid Valve is energized/

open.

Economizer Solenoid (LED)

Is ON when the economizer Thermal Expansion Valve

Solenoid is energized/open.

Oil Cooling Solenoid (LED)

Is ON when the Oil Cooling Solenoid Valve is energized/

open.

3

Temperatures and pressures are either measured directly

by transducers and temperature sensors, or computed

from these measurements. Depending on the type of

chiller, the following temperatures and pressures could

be displayed:

• Discharge Pressure • Oil Pressure

• Suction Pressure • Oil Temperature

• Discharge Temperature • Suction Superheat

• Saturated Discharge Temperature

• Discharge Superheat

• Suction Temperature

• Saturated Suction Temperature

Motor Current (%FLA)

This displays the motor current of the system in percent

of full load amps.

Slide Valve Step (If screw)

This indicates the compressor slide valve step.

Compressor Heater (LED)

Is ON when the compressor heater is on.

Hot Gas Bypass (LED)

Is ON when the hot gas bypass valve is open.

PROGRAMMABLE

None

NAVIGATION

Home

Causes an instant return to the Home Screen.

Unit Data

Causes an instant return to the Unit Screen of the

selected unit.

System #

A detailed view of the specied (#) system information.

Page 32

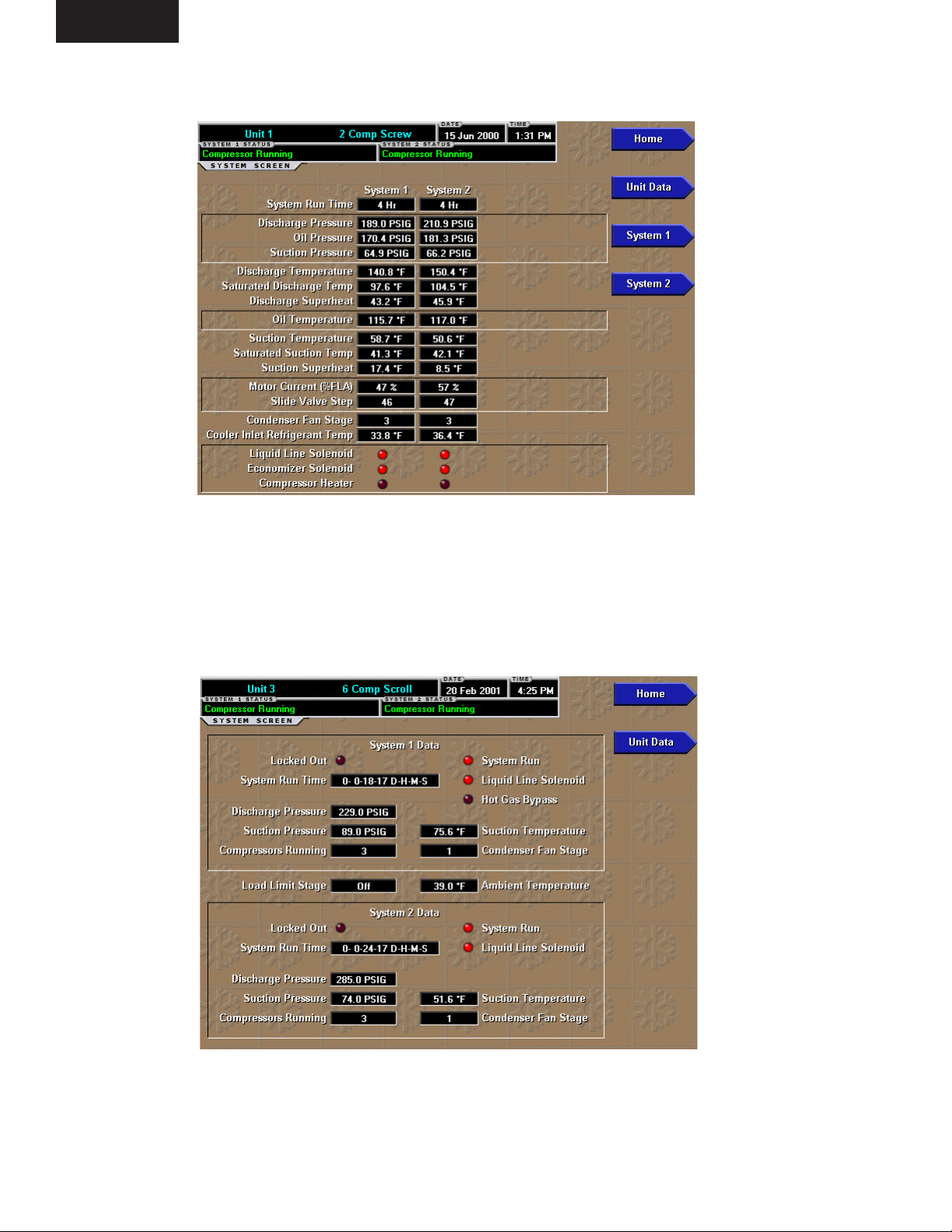

Operation

INDIVIDUAL SYSTEM SCREEN

FIG. 12A – YCAS CHILLER

00509VIPC

FIG. 12B – YCAR CHILLER

00510VIPC

YORK INTERNATIONAL32

Page 33

FORM 50.40-OM2

OVERVIEW

This screen is accessible from the SYSTEM screen

when there is much data to view about an individual

system. It displays data only from the selected system.

Reference the chiller’s Installation, Operation, Maintenance Manual (IOM) for details about the data.

Depending on the type of chiller, the following data

might be displayed:

DISPLAY ONLY

The following system information is displayed at the

top of the screen:

Locked Out (LED)s

System Run Time

System Run (LED)

Liquid Line Solenoid (LED)

The following discharge readings are grouped together

and displayed:

Discharge Pressure

Saturated Discharge Temperature

Discharge Temperature

Discharge Superheat

The following miscellaneous readings are grouped

together and displayed:

Motor Current (%FLA)

Slide Valve Step or Load Stage

Pressure Ratio

Ambient Temperature

The following miscellaneous information is displayed

separately:

Economizer Solenoid (LED)

Hot Gas Bypass Solenoid (LED)

Oil Cooling Solenoid (LED)

Condenser Fan Stage

PROGRAMMABLE

None

3

NAVIGATION

Home

Causes an instant return to the Home Screen.

Unit Data

Causes an instant return to the Unit Screen.

The following suction readings are grouped together

and displayed:

Suction Pressure

Saturated Suction Temperature

Suction Temperature

Suction Superheat

The following oil readings are grouped together and

displayed:

Oil Pressure

Low Differential Oil Pressure

High Differential Oil Pressure

Oil Temperature

System Data

Causes an instant return to the System Screen.

33YORK INTERNATIONAL

Page 34

Operation

HOURS AND STARTS SCREEN

FIG. 13A – YCAL CHILLER

00511VIPC

FIG. 13B – YCAS CHILLER

00512VIPC

YORK INTERNATIONAL34

Page 35

FORM 50.40-OM2

OVERVIEW

This screen, accessed from the UNIT screen, displays

the total operating hours and the total number of starts

for all systems on the unit.

DISPLAY ONLY

Total Starts

Displays the number of times the compressor has

been started.

Operating Hours

Displays the number of hours the compressor has

run.

PROGRAMMABLE

None

NAVIGATION

Home

Causes an instant return to the Home Screen.

Unit Data

Causes an instant return to the Unit Screen.

3

35YORK INTERNATIONAL

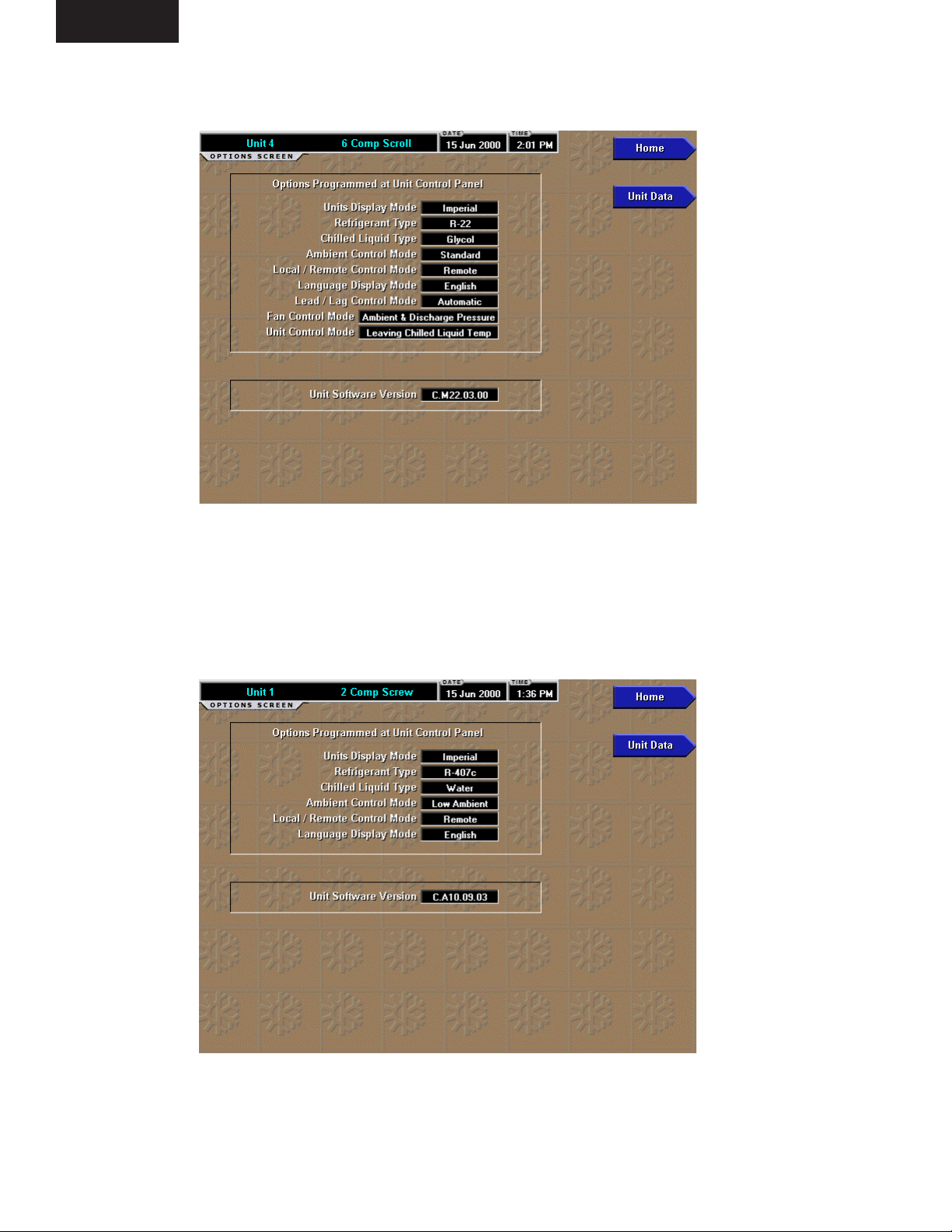

Page 36

Operation

OPTIONS SCREEN

FIG. 14A – YCAL CHILLER

00513VIPC

FIG. 14B – YCAS CHILLER / YCAR CHILLER

00514VIPC

YORK INTERNATIONAL36

Page 37

FORM 50.40-OM2

OVERVIEW

This screen, accessed from the UNIT screen, displays

all the dip switch settings and other programmable

options at the chiller micro panel. These items can only

be changed at the chiller micro panel and not at the

OptiView Control Center. Depending on the type of

chiller, the following data might be displayed:

DISPLAY ONLY

Units Display Mode

The units selected at the OptiView Remote Control

Center, either Imperial or SI, is displayed. In Imperial

Units temperatures will be in °F and pressures will be

in PSIG or PSID. In SI units temperatures will be in °C

and pressures will be in BARG or BARD.

The values at the OptiView Remote

Control Center will be displayed in

the units that are selected on it’s

Setpoints screen regardless of what is

programmed at the chiller/condensing

unit.

Language Display Mode

The language selected at the chiller micro panel (i.e.

English) is displayed.

Lead/Lag Control Mode

The Lead/Lag control at the chiller micro panel is

displayed, either Automatic or Manual. This control

is used to select which compressor starts. See the unit’s

Installation, Operation and Maintenance Manual for

a description.

Fan Control Mode

The fan control at the unit’s micro panel is displayed,

either Discharge Pressure or Ambient and Discharge

Pressure.

Unit Control Mode

What the chiller/condensing unit control is based on

is displayed, either Leaving Liquid, Return Liquid,

Suction Pressure, or Discharge Air Temperature.

Unit Software Version

The software version of the EPROMS at the chiller/

condensing unit’s micro panel .

3

Refrigerant Type

The refrigerant, either R-407C or R-22, selected at the

chiller micro panel is displayed.

Chilled Liquid Type

The cooling mode, either Water or Glycol, selected at

the chiller micro panel is displayed.

Ambient Control Mode

The ambient mode, either Standard or Low Ambient,

selected at the chiller micro panel is displayed.

Local/Remote Control Mode

The control mode selected at the chiller micro panel,

either Local or Remote, is displayed.

PROGRAMMABLE

None

NAVIGATION

Home

Causes an instant return to the Home Screen.

Unit Data

Causes an instant return to the Unit Screen.

37YORK INTERNATIONAL

Page 38

Operation

TRENDING SCREEN

FIG. 15 TRENDING

OVERVIEW

This screen is accessed from the UNIT screen. As many

as six Operator selected parameters can be plotted in

an X/Y graph format. The X-Axis is scaled per the

selected Data Collection Interval and displayed in a

time of day or elapsed time format, as selected with

the X-axis toggle key. The Y-Axis is scaled for each

parameter per the selected minimum and maximum

value for each parameter. Analog parameters are scaled

in pressure, temperature, volts, amps, hertz or time.

Digital on/off parameters are scaled as zero (off) and

one (on). Only one Y-Axis label is displayed at a time.

The Y-Axis Toggle Key is used to toggle the Y-Axis

labels through the different parameters. The Y-Axis

label that is being displayed is identied at the top of the

graph. All parameters are displayed simultaneously. For

identication, each plotted parameter and associated

Y-Axis labeling is color coordinated.

The parameters are sampled at the selected Data

Collection Interval and plotted using 450 data points

across the X-Axis. If the actual value of the sampled

parameter is less than the Y-Axis label minimum for

that parameter, the value will be plotted at the minimum

value. Similarly, if the actual value is greater than the

Y-Axis label maximum for that parameter, the value

will be plotted at the maximum value.

00574VIPC

There are two types of charts that can be created: ONE

SCREEN or CONTINUOUS. When the plotting has

reached the end of the X-Axis, one of the following

will occur, depending on which is selected: If ONE

SCREEN has been selected, the trending stops and the

data is frozen. If CONTINUOUS has been selected,

the oldest data is dropped from the left-hand side of the

graph at the next Data Collection Interval. Thereafter,

the oldest data is dropped from left-hand side of the

graph at each Data Collection Interval.

Only parameters from the selected Unit are trended.

The same parameters that have been selected for a Unit,

will be selected by default for the next selected Unit.

When on the Home screen, a Unit is not selected and

any trending is stopped. Trending is also stopped if a

power failure occurs while it is running. After trending

is stopped, the last screen of data that was collected will

be displayed on the trending screen and the START key

must be pressed to initiate a new trend screen.

DISPLAY ONLY

This screen allows the user to view the graphical

trending of the selected parameters and is also a

gateway to the graph setup screens.

YORK INTERNATIONAL38

Page 39

FORM 50.40-OM2

A red screen with the words “TREND

MAX MUST BE > TREND MIN”

will appear if the Y-Axis minimum

has been programmed to a value that

is greater than the Y-Axis maximum

for any parameter. If this appears,

proceed to the Trend Setup Screen to

change the values.

PROGRAMMABLE

Start

Pressing this key clears the graph, starts a new graph

and begins the trending. The trending will continue

until the STOP key is pressed, the Home screen is

displayed, or a power failure occurs. This key is only

available if trending is stopped.

Stop

Pressing this key stops the trending. The trend data

is frozen on the display until another graph is started

with the START key. The Stop key is only available

if trending is running.

X-Axis

This key toggles the X-Axis labels of the graph.

Each key press alternates the scaling between time of

day and elapsed time. The Time of Day scaling is in

24-hour format. The Elapsed Time scaling is the time

elapsed since the START key was pressed, starting

the trending.

NAVIGATION

Home

Causes a return to the Home Screen.

Unit Data

Causes a return to the Unit Screen.

Trend Setup

Only displayed if the trending is stopped. Causes

a jump to a sub-screen for conguring the trending

display.

3

Y-Axis

This key toggles the Y-Axis labels of the graph. Each

key press changes the label to another of the selected

parameters.

39YORK INTERNATIONAL

Page 40

Operation

TREND SETUP SCREEN

FIG. 16 TREND SETUP

OVERVIEW

This screen is accessed from the Trending screen.

This screen is used to congure the trending screen.

The parameters to be trended are selected from the

Common Slots Screen or Common Slots Master list

and entered as Slot Numbers for Data Points 1 through

6. The Y-Axis minimum and maximum values for each

parameter are entered as Data Point Min and Data Point

Max for Data Points 1 through 6. The interval at which

all the parameters are sampled is selected as the Data

Collection Interval.

DISPLAY ONLY

None

PROGRAMMABLE

Chart Type

Selects either CONTINUOUS or ONE SCREEN type

of graph.

Collection Interval

Selects the interval at which the parameters are sampled.

There are 450 data points displayed across the X-Axis

of the graph. Each point represents the instantaneous

value of the parameter. The user selects the time

interval between these points. This is called the DATA

00575VIPC

COLLECTION INTERVAL, or the interval at which

the parameter is sampled. This interval is programmable

over the range of 1 second to 3600 seconds (1 hour), in

one second increments. The selected interval not only

determines the sample interval, but also the full screen

time display. The full screen time display is a result

of the selected interval in seconds, multiplied by the 450

data points. For example, if the Data Collection Interval

is programmed for 900 seconds, the parameter would

be sampled every 900 seconds, with the last 112.5 hours

(4.7 days) of data viewable on the screen. Therefore, the

selected interval is a compromise between resolution

and full screen time display. Select the desired Data

Collection Interval as follows:

1. Determine the desired time interval (in seconds),

between data samples.

2. Calculate the full screen time display as follows:

• 450 x Data Collection Interval = full screen

seconds

• full screen seconds / 60 = full screen minutes

• full screen minutes / 60 = full screen hours

• full screen hours / 24 = full screen days

3. Decide if the resultant sample interval and full

screen display meet the requirements. If not, select

a different sample interval.

YORK INTERNATIONAL40

Page 41

FORM 50.40-OM2

Select

This key is used to enter the slot numbers and the

minimum and maximum Y-Axis values of each parameter to be trended. Pressing this key places a yellow

box around Data Point 1 Slot Number. Use the ▲ and

▼ navigation keys to place the box around the value of

Data Points 1 through 6 to be changed. With the desired

value selected, press the ‘4’ (Enter) key. A dialog box

is displayed permitting data entry.

Data Point Slot # (1-6)

Use the SELECT key as described above and enter

the slot number from the Trend Common Slots Screen

of the desired parameter to be trended. The selected

parameter description will be displayed for the Data

Point. Setting this slot number to zero will disable

trending for that particular Data Point. Any or all points

can be disabled.

Data Point Min (1-6)

Only displayed if the Associated Slot Number is not

Zero. This is the minimum value displayed for the

Y-Axis. Selecting a parameter for a Data Point sets

this to the default value, which is the lowest value

allowed for that parameter. It can be changed to a

value that provides a more appropriate resolution for

the parameter being monitored. To change, use the

SELECT key as described above and enter the desired

value. The value must always be set to a value less

than the Data Point Max. Otherwise, a red graph is

displayed on the Trend Screen with the words “TREND

MAX MUST BE > TREND MIN”. If the parameter

selected for this data point is a digital type (on/off),

this value must be set to zero (0). Zero indicates the

OFF state.

Data Point Max (1-6)

Only displayed if the associated slot number is not zero.

This is the maximum value displayed for the Y-Axis.

Selecting a parameter for a Data Point sets this to the

default value, which is the highest value allowed for that

parameter. It can be changed to a value that provides a more

appropriate resolution for the parameter being monitored.

To change, use the SELECT key as described above and

enter the desired value. The value must always be set to

a value greater than the Data Point Min. Otherwise, a red

graph is displayed on the Trend Screen with the words

“TREND MAX MUST BE > TREND MIN”. There are

20 Y-axis divisions. If a MIN-MAX span is selected that is

not evenly divided by 20, the Program will automatically

select the next higher MAX value that makes the span

evenly divided by 20. For example, if 0.0 is selected as

the MIN, and 69.0 as the MAX, the Program will insert

70.0 as the MAX value. If the parameter selected for this

data point is a digital type (on/off), this value must be set

to one (1). One indicates the on state.

3

NAVIGATION

Home

Causes a return to the Home Screen.

Unit Data

Causes a return to the Unit Screen.

Trending

Causes a return to the Trending Screen.

Slot Numbers

Causes a jump to the Trend Common Slots Screen.

The slot numbers of the most commonly monitored

parameters are listed on this screen. The parameters

are arranged to make it easier to nd the slot number

of the desired parameter to plot.

41YORK INTERNATIONAL

Page 42

This page intentionally left blank.

YORK INTERNATIONAL42

Page 43

FORM 50.40-OM2

This page intentionally left blank.

43YORK INTERNATIONAL

Page 44

Operation

SETPOINTS SCREEN - EXAMPLES

FIG. 17A – YCAL CHILLER

00515VIPC

FIG. 17B – YCAS CHILLER

00516VIPC

YORK INTERNATIONAL44

Page 45

FORM 50.40-OM2

FIG. 17C – YCAR CHILLER

00517VIPC

3

45YORK INTERNATIONAL

Page 46

Operation

SETPOINTS SCREEN

OVERVIEW

This screen, accessed from the Unit screen, provides a

convenient location for programming the most common

setpoints involved in the chiller/condensing unit control.