Page 1

Instruction

DR232/DR242

Manual

Hybrid Recorder

(Expandable Type)

IM DR232-01E

IM DR232-01E

9th Edition

Page 2

Foreword

Notes

Thank you for purchasing the YOKOGAWA Hybrid Recorder DR232 or DR242.

This User’s Manual contains useful information regarding the instrument’s functions and

operating procedures, as well as precautions that should be observed during use. To ensure proper

use of the instrument, please read this manual thoroughly before operating the instrument.

Keep the manual in a safe place for quick reference whenever a question arises.

The following manual is provided with the instrument in addition to this manual.

Manual Name Manual No.

DR231/DR232/DR241/DR242 Communication Interface IMDR231-11E

• DARWIN is a system comprising a number of data-acquisition equipment components. In the

course of system growth, new models, software, various input/output modules and optional

features are added to the family to enhance the systems expandability and flexibility. You can

check the versions of your equipment and software by referring to the style number (Sn) and

release number (Rn) respectively which are shown on the nameplate of the main unit.

When configuring a system, you must confirm that the style number of each component unit and

software meets the following requirements:

1 the style number of each input/output module must be the same as or lower than that of the

main unit or subunit to which the module is connected.

2 the release number of a dedicated software package must be the same or higher than the style

number of the main unit or subunit where the package is installed and where it performs

control.

Any equipment/software not meeting these requirements might have incompatible areas with

your system configuration.

In this manual, equipment of style S8 is explained.

For unsupported functions as classified by the style number, see the next page.

• The contents of this manual are subject to change without prior notice as a result of

improvements in the instrument’s performance and functions.

• Every effort has been made in the preparation of this manual to ensure the accuracy of its

contents. However, should you have any questions or find any errors, please contact your

nearest YOKOGAWA representative as listed on the back cover of this manual.

• Copying or reproduction of all or any part of the contents of this manual without

YOKOGAWA’s permission is strictly prohibited.

Trademarks

DOS and Windows are registered trademarks of Microsoft Corporation.

IBM is a registered trademark of International Business Machines Corporation.

Revisions

1st Edition: January 1996

2nd Edition: February 1996

3rd Edition: June 1996

4th Edition: November 1996

5th Edition: March 1997

6th Edition: November 1997

7th Edition: November 1998

8th Edition: June 2000

9th Edition: October 2000

Disk No. RE04

9th Edition: October 2000 (YK)

All Rights Reserved, Copyright 1996 Yokogawa Electric Corporation

IM DR232-01E

1

Page 3

Unsupported Functions As Classified by the Style Number

The following functions are not available for style number S1

• Computation function (including remote RJC)

• Saving and reading of measured data, computated data and set-up data (FDD function)

• Summer/Winter time

• RS-422-A/RS-485 cs£munication module

• Pulse input module

• mA, Strain and AC input module

• Extender module and Extender base

• Report function

• Ethernet module

• Digital input module

• Flag and group reset functions (for /M1 option)

• The measuring of active power and apparent power on CH3 to CH6 for power monitor module.

The following functions are not available for style number S2

• Summer/Winter time

• RS-422-A/RS-485 communication module

• Pulse input nodule

• mA, Strain and AC input module

• Extender module and Extender base

• Report function

• Ethernet module

• Digital input module

• Flag and group reset functions (for /M1 option)

• The measuring of active power and apparent power on CH3 to CH6 for power monitor module.

The following functions are not available for style number S3

• Pulse input module

• mA, Strain and AC input module

• Extender module and Extender base

• Report function

• Ethernet module

• Digital input module

• Flag and group reset functions (for /M1 option)

• The measuring of active power and apparent power on CH3 to CH6 for power monitor module.

The following functions are not available for style number S4 and S5

• mA, Strain and AC input module

• Extender module and Extender base

• Report function

• Ethernet module

• Digital input module

• Flag and group reset functions (for /M1 option)

• The measuring of active power and apparent power on CH3 to CH6 for power monitor module.

Products with style number S6 is not sold.

The following functions are not available for style number S7

• Ethernet module

• Digital input module

• Flag and group reset functions (for /M1 option)

• The measuring of active power and apparent power on CH3 to CH6 for power monitor module.

2

IM DR232-01E

Page 4

Checking the Contents of the Package

Unpack the box and check the contents before operating the instrument. In case the wrong

instrument or accessories have been delivered, or if some accessories are not present, or if they

seem abnormal, contact the dealer from which you purchased them. Furthermore, please contact a

Yokogawa representative to order any of parts as follows.

Main Unit DR232/DR242

Check that the model and suffix code given on the name plate are according to your order.

Model and Suffix Codes

Model Suffix Code Description

DR232 ....................... Hybrid recorder, desktop type

DR242 ....................... Hybrid recorder, panel-mount type

Memory -0 .................... No memory

-1 .................... 3.5inch Floppy disk drive

Software 0 ................. Without data acquisition software

2 ................. With data acquisition software

Input Type -00 ............ Always “-00”

Power Supply -1 ......... 100-240VAC

Power Cord D ......... 3-pin inlet w/UL, CSA cable* (Part No. A1006WD)

F ......... 3-pin inlet w/VDE cable* (Part No. A1009WD)

R ......... 3-pin inlet w/SAA cable* (Part No. A1024WD)

S ......... 3-pin inlet w/BS cable* (Part No. A1023WD)

W ........ 3-pin inlet with screw conversion terminal**

* For DR232 only

**For DR242 only

Options /M1 . Mathematical Func.

/M3 . Report Func.

/H1 .. Internal illumination

/D2 .. deg F Display

Subunit DS400/DS600

NO. (Instrument Number), Style number (equipment) and Release number

(software package)

Please refer to these numbers when contacting the dealer.

Check that the model and suffix code given on the name plate are according to your order.

Model and Suffix Codes

Model Suffix Code Description

DS400 ....................... 4-module connection subunit

DS600 ....................... 6-module connection subunit

Type 00 ................... always 00

Power Supply -1 ............. 100-240VAC

-2 ............. 12-28V DC

Power Cord D ......... 3-pin inlet w/UL, CSA cable (Part No. A1006WD)

F ......... 3-pin inlet w/VDE cable (Part No. A1009WD)

R ......... 3-pin inlet w/SAA cable (Part No. A1024WD)

S ......... 3-pin inlet w/BS cable (Part No. A1023WD)

W ........ 3-pin inlet with screw conversion terminal (when power supply suffix code is

-1)

Y ......... 2-pin inlet with round-type connector (when power supply suffix code is -2)

NO. (Instrument Number) and Style number (equipment)

Please quote these numbers when contacting the dealer.

IM DR232-01E

3

Page 5

Checking the Contents of the Package

Input Modules

Check that the model code given on the name plate is according to your order.

Model Codes

Model Description

DU100-11 10-channel universal input module, screw type terminal

DU100-21 20-channel universal input module, screw type terminal

DU100-31 30-channel universal input module, screw type terminal

DU100-12 10-channel universal input module, clamp type terminal

DU100-22 20-channel universal input module, clamp type terminal

DU100-32 30-channel universal input module, clamp type terminal

DU200-11 10-channel DCV/TC/DI input module, screw type terminal

DU200-21 20-channel DCV/TC/DI input module, screw type terminal

DU200-31 30-channel DCV/TC/DI input module, screw type terminal

DU200-12 10-channel DCV/TC/DI input module, clamp type terminal

DU200-22 20-channel DCV/TC/DI input module, clamp type terminal

DU200-32 30-channel DCV/TC/DI input module, clamp type terminal

DU300-11 10-channel, mA-input module with screw terminals

DU300-12 10-channel, mA-input module with clamp terminals

DU400-12 Power monitor module for single-phase use

DU400-22 Power monitor module for three-phase use

DU500-12 10-channel, strain input module with 120-Ω bridge resistors

DU500-22 10-channel, strain input module with 350-Ω bridge resistors

DU500-32 10-channel, strain input module with NDIS terminals

DU600-11 10-channel, pulse input module with screw terminals

DU700-11 10-channel, digital input module with screw terminal

I/O Terminal Modules

NO. (Instrument Number)

Please quote this instrument number when contacting the dealer.

Check that model code given on the name plate is according to your order.

Model Codes

Model Description

DT100-11 DI/DO module, screw type terminal

DT200-11 Alarm module (4 transfer contacts), screw type terminal

DT200-21 Alarm module (10 make contacts), screw type terminal

DT300-11 GP-IB module

DT300-21 RS-232-C module, D-sub terminal

DT300-31 RS-422-A/RS-485 module

DT300-41 Ethernet module

NO. (Instrument Number) and Style number (equipment)

Please quote these numbers when contacting the dealer.

4

IM DR232-01E

Page 6

Standard Accessories

Checking the Contents of the Package

Name Part No. Q’ty Description

1. Power cord see page 2, 3 1

2. Fuse A1350EF 1 Timelag 2.5A 250V, for DR232/242, in case of

3. DC power supply A1105JC 1 Only for the subunit models whose power supply

terminal connector code is “-2”

4. Ribbon cassette B9627AZ 1 10 colors (for DR232/242)

5. Chart paper B9627AY 1 Length: 30m, 25mm grid (for DR232/DR242)

6. Mounting brackets B9900CW 1 x 2 for DR242

7. Clamp filter A1197MN 1 When power supply code is -1

8. User’s Manual IMDR232-01E 1 this manual (for DR232/242)

9. User’s Manual IMDR231-11E 1 Communication Interface manual (for DR232/242)

10.

Data acquisition software

1.One of these power cord types is supplied according

to the instrument's suffix code

DP120-13 Only for models whose software code is “-2”

DR232 located in fuse holder

D

2. 4.3. 5.

F

6. 7.

S

8.

9.

R

10.

IM DR232-01E

5

Page 7

Checking the Contents of the Package

Optional Accessories

Name Model Description

Extender module DV100-011

Extender base DV100-012

Extension cable DV200-000 Length: 0.5m

Extension cable DV200-001 Length: 1m

Extension cable DV200-002 Length: 2m

Extension cable DV200-005 Length: 5m

Extension cable DV200-010 Length: 10m

Extension cable DV200-020 Length: 20m

Extension cable DV200-050 Length: 50m

Extension cable DV200-100 Length: 100m

Extension cable DV200-200 Length: 200m

Extension cable DV200-300 Length: 300m

Extension cable DV200-400 Length: 400m

Extension cable DV200-500 Length: 500m

Shunt resistance DV300-011 10Ω, for screw

Shunt resistance DV300-012 10Ω, for clamp

Shunt resistance DV300-101 100Ω, for screw

Shunt resistance DV300-102 100Ω, for clamp

Shunt resistance DV300-251 250Ω, for screw

Shunt resistance DV300-252 250Ω, for clamp

Rack mount kit DV400-011 for DS400/600

Rack mount kit DV400-013 for DR232

Power cable DV400-051 between DR232/242 and DS400/600

Strain conversion cable DV450-001

Cable adapter DV250-001 For expanding cable

AC adapter DV500-001 2-pin inlet w/UL, CSA cable (Part No. B9988YA) for

AC adapter DV500-002 2-pin inlet w/VDE cable (Part No. B9988YB) for

AC adapter DV500-003 2-pin inlet w/SAA cable (Part No. B9988YC) for

AC adapter DV500-004 2-pin inlet w/BS cable (Part No. B9988YD) for

DC100/DA100/DS400/DS600 DC power supply model

DC100/DA100/DS400/DS600 DC power supply model

DC100/DA100/DS400/DS600 DC power supply model

DC100/DA100/DS400/DS600 DC power supply model

Optional Software

Spares

Name Model Description

DAQ 32 DP120-13 Windows 95/98 and Windows NT

DAQ 32 Plus DP320-13 Windows 95/98 and Windows NT

Name Part No. Min. Q’ty Description

Ribbon cassette B9627AZ 1 10 colors

Chart paper B9627RY 10 Length 30 m, grid 10mm

B9627AY 10 Length 30 m, grid 25mm

6

IM DR232-01E

Page 8

Safety Precautions

This instrument is an IEC safety class I instrument (provided with terminal for protective

grounding).

The following general safety precautions must be observed during all phases of operation, service

and repair of this instrument. If this instrument is used in a manner not sepecified in this manual,

the protection provided by this instrument may be impaired. Also, YOKOGAWA Electric

Corporation assumes no liability for the customer’s failure to comply with these requirements.

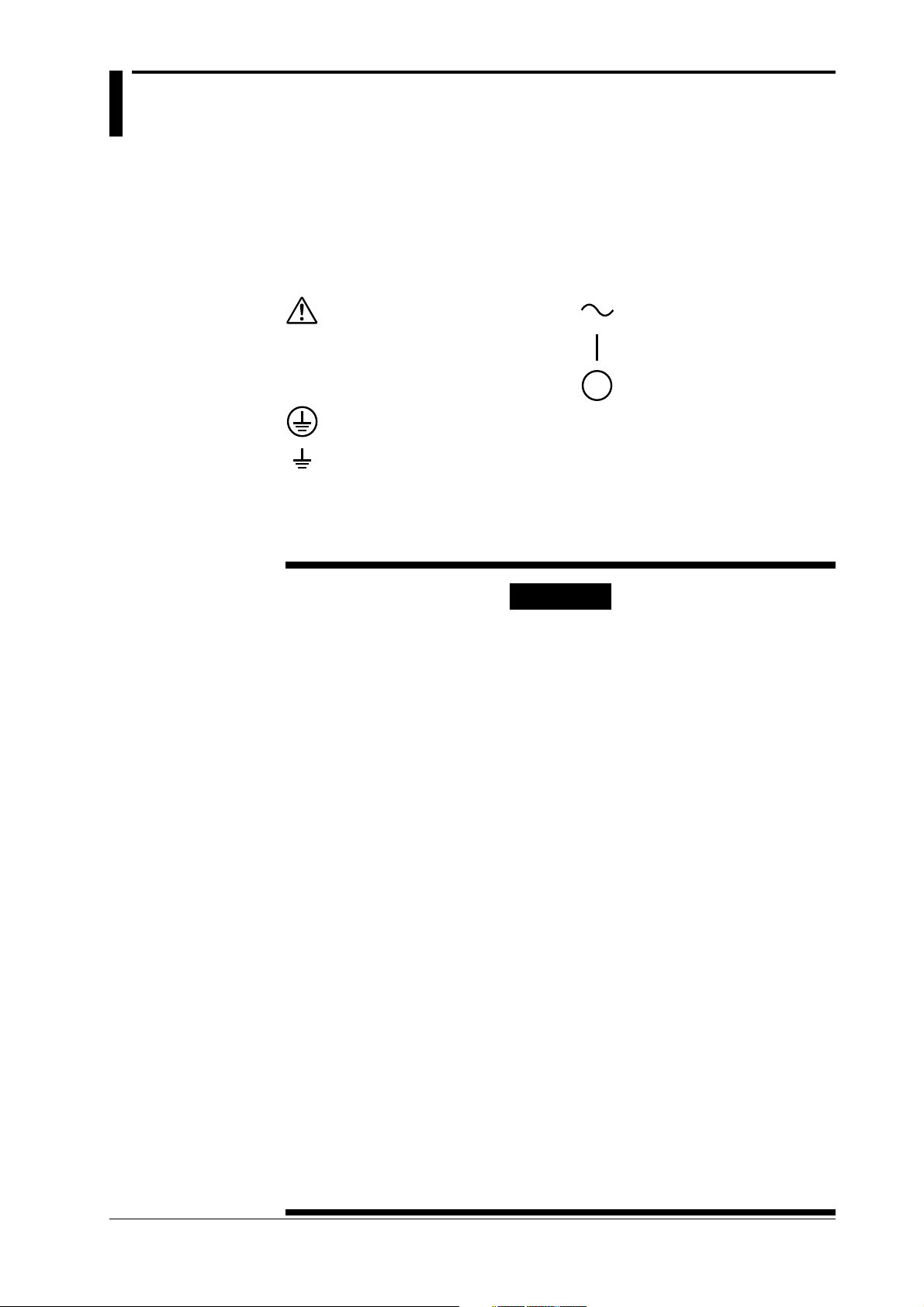

The following symbols are used on this instrument.

To avoid injury, death of personnel

or damage to the instrument, the

operator must refer to an explanation

in the User’s Manual or Service

Manual.

Protective grounding terminal.

Function grounding terminal. This

terminal should not be used as a

“Protective grounding terminal”.

Make sure to comply with the following safety precautions. Not complying might

result in injury, death of personnel or damage to the instrument.

Alternating current.

ON(power).

OFF(power).

WARNING

Power Supply

Ensure the source voltage matches the voltage of the power supply

before turning ON the power.

Power Cord and Plug

To prevent an electric shock or fire, be sure to use the power cord

supplied by YOKOGAWA. The main power plug must be plugged in an

outlet with protective grounding terminal. Do not invalidate protection by

using an extension cord without protective grounding.

Protective Grounding

Make sure to connect the protective grounding to prevent an electric

shock before turning ON the power.

Necessity of Protective Grounding

Never cut off the internal or external protective grounding wire or

disconnect the wiring of protective grounding terminal. Doing so poses a

potential shock hazard.

Defect of Protective Grounding and Fuse

Do not operate the instrument when protective grounding or fuse might be

defective.

Do not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable liquids or

vapors. Operation of any electrical instrument in such an environment

constitutes a safety hazard.

Fuse

To prevent a fire, make sure to use fuses with specified standard(current,

voltage, type). Before replacing the fuse, turn OFF the power and

disconnect the power source. Do not use a different fuse or short-circuit

the fuse holder.

Do not Remove any Covers

There are some areas with high voltages. Do not remove any cover if the

power supply is connected. The cover should be removed by qualified

personnel only.

External Connection

To ground securely, connect the protective grounding before connecting

to measurement or control unit.

IM DR232-01E

7

Page 9

How to Use this Manual

This User’s Manual consists of the following twelve chapters and Index.

Chapter Title Description

Chapter 1 System Configuration Explains the position of the DR within DARWIN, its

Chapter 2 Functions Explains the functions of the DR. Operating

Chapter 3 Installation and Wiring Describes cautions for use, explains how to install and

Chapter 4 Setting the Monitor Mode Explains the display in the monitor mode.

Display

Chapter 5 Setting the Input Type/ Explains the operations when setting the input type,

Recording Span/ recording span and linear scaling function.

Linear Scaling

Chapter 6 Setting the Recording Explains the operations when setting recording

Conditions conditions such as the recording mode, channels,

Chapter 7 Executing Recording Explains how to start and stop recording.

Chapter 8 Setting, Displaying and Explains how to set an alarm and what to do when an

Recording Alarms alarm occurs.

Chapter 9 Event/Action Function and Explains how to operate the event/action function,.

Other Functions how to copy recording information, how to reset

Chapter 10 Basic Settings (SET UP) Explains functions which usually do not need to be

Chapter 11 Saving/Reading Measured, Explains how to save measured data, computed data

Computed and Set-up Data and set-up data to the internal RAM disk or floppy

Chapter 12 Executing Computation Explains the computation function (optional).

(Available with the /M1 Model)

Chapter 13 Trouble-Shooting and Explains maintenance procedures, error messages and

Maintenance calibration procedures.

Chapter 14 Specifications Explains specifications for all features of DR.

Index Gives the index in main menu and alphabetic order.

configuration, etc..

procedures are not explained here.

wire the DR, the power cord, how to switch ON/OFF

the DR, how to set the date/time, explains the noise

filter, etc..

recording interval, chart speed, recording span, and

recording format.

alarms, how to reset the timer, how to use the keylock, and how to use the external in-/output function.

changed, and how to set

disk and read them into the instrument.

8

IM DR232-01E

Page 10

Conventions Used in this Manual

Used Symbols

The following symbol marks are used to attract the operator’s attention.

Affixed to the DR232/242, indicating that for safety, the operator should

refer to the appropriate User’s Manual. For a list of the User’s Manuals,

refer to page 1.

Describes precautions that should be observed to prevent the danger of

injury or death to the user.

Describes precautions that should be observed to prevent damage to the

DR232/242.

Note

Provides information that is important for proper operation of the DR232/

242.

Indicates the relevant panel keys and indicators to carry out

the operation.

The procedure is explained by a flow diagram. For the

meaning of each operation, refer to the example below. The

operating procedures are given with the assumption that you

are not familiar with the operation. Thus, it may not be

necessary to carry out all the steps when changing settings.

Describes settings and restrictions relating to the operation.

IM DR232-01E

9

Page 11

Contents

Foreword .................................................................................................................................................................................. 1

Checking the Contents of the Package ..................................................................................................................... 3

Safety Precautions .............................................................................................................................................................. 7

How to Use this Manual .................................................................................................................................................... 8

Conventions Used in this Manual ................................................................................................................................9

List of Menus and Set-up Data .................................................................................................................................... 13

Chapter 1 System Configuration

1.1 About DARWIN ................................................................................................................................... 1-1

1.2 Product Overview .................................................................................................................................1-2

1.3 Names of Parts ...................................................................................................................................... 1-4

1.4 Floppy Disk ........................................................................................................................................ 1-11

Chapter 2 Functions

2.1 Display Functions .................................................................................................................................2-1

2.2 Measurement Input Functions .............................................................................................................. 2-3

2.3 Recording Functions ............................................................................................................................. 2-5

2.4 Alarm Function ................................................................................................................................... 2-13

2.5 Standard Computation Functions ....................................................................................................... 2-16

2.6 Other Functions .................................................................................................................................. 2-17

Chapter 3 Installation and Wiring

3.1 General Precautions for Installation ..................................................................................................... 3-1

3.2 How to Install ....................................................................................................................................... 3-2

3.3 How to Connect the Input/Output Modules ......................................................................................... 3-7

3.4 Installing the Chart and Ribbon Cassette ............................................................................................. 3-9

3.5 Connecting the Interface Cables ......................................................................................................... 3-14

3.6 Connecting the Extension Cables- ......................................................................................................3-19

3.7 Connecting the Signal Lines ............................................................................................................... 3-20

3.8 Connecting an Extension Module to Extension Bases .......................................................................3-28

3.9 Connecting the Power Cord and Turning the Power ON/OFF ...........................................................3-30

3.10 Setting the Date and Time .................................................................................................................. 3-35

3.11 Countering Noise................................................................................................................................3-36

Chapter 4 Setting the Monitor Mode Display

4.1 Using the AUTO Display......................................................................................................................4-1

4.2 Using the MANUAL Display ...............................................................................................................4-4

4.3 Using the PAGE Display ...................................................................................................................... 4-6

4.4 Using the ALARM SEARCH Display .................................................................................................4-7

4.5 Using the BARGRAPH Display...........................................................................................................4-9

4.6 Using the ALARM STATUS Display.................................................................................................4-10

4.7 Using the RELAY STATUS Display .................................................................................................. 4-11

4.8 Using the CLOCK (Data & Time) Display ........................................................................................ 4-13

Chapter 5 Setting the Input Type/Recording/Span/Linear Scalling

5.1 Setting the Type of Input and Recording Span .....................................................................................5-1

5.2 Setting Linear Scaling and the Recording Span ................................................................................... 5-4

5.3 Configuring the Input Range and Recording Span or the Linear Scaling of a Power Monitoring

Channel .................................................................................................................................................5-6

5.4 Configuring the Measuring Range and Recording Span or the Linear Scaling of a Strain Input

Channel ...............................................................................................................................................5-10

10

IM DR232-01E

Page 12

5.5 Performing Initial Balancing/Initialization on a Strain Input Channel...............................................5-12

5.6 Configuring the Pulse Input Channel ................................................................................................. 5-13

Chapter 6 Setting the Recording Conditions

6.1 Setting the Recording Mode, Engineering Unit, Recording Channel and Recording Interval ............ 6-1

6.2 Setting the Chart Speed ........................................................................................................................ 6-4

6.3 Setting Recording Zones and Partially Expanded Recording .............................................................. 6-6

6.4 Setting Tag, Digital Printout and Manual Printout ............................................................................... 6-8

6.5 Setting the Alarm Printout ..................................................................................................................6-10

6.6 Setting Scale Printout, List Printout and List Format .........................................................................6-12

6.7 Entering Messages, Headers and Title................................................................................................6-14

6.8 Setting Match Time, Moving Average, Interpolation and Groups...................................................... 6-16

Contents

1

2

3

Chapter 7 Executing Recording

7.1 Starting Dot Printing, Digital Printing and Printing in Logging Mode ................................................7-1

7.2 Starting Manual Printing, List Printing and Header Printing ............................................................... 7-2

7.3 Starting Message Printing .....................................................................................................................7-3

7.4 Printing Set-up Lists .............................................................................................................................7-4

Chapter 8 Setting, Displaying and Recording Alarms

8.1 Setting Alarms and Relays (including internal switches) .....................................................................8-1

8.2 Alarm Display and Printing ..................................................................................................................8-4

Chapter 9 Event/Action Function and Other Functions

9.1 Setting Event/Action Functions ............................................................................................................ 9-1

9.2 Copying .............................................................................................................................................. 9-12

9.3 Alarm Acknowledgment, Alarm Reset, Timer Reset, Keylock, and Message Printout .....................9-14

9.4 Clearing Alarm/Message Buffers, Displaying Module/Communications Information, Structuring

System Modules, and Initializing Information ...................................................................................9-16

9.5 Fail/Chart End Output, and Remote Control Signal Input ................................................................. 9-18

9.6 Summer/Winter Time ......................................................................................................................... 9-19

Chapter 10 Basicn Settings (SET UP)

10.1 Selecting Adjustment of Dot-Printing Position or Scan Interval........................................................10-1

10.2 Setting Recording Format................................................................................................................... 10-3

10.3 Select Alarm Interval/Hysteresis/Hold/A/D Converter Integration Time/Filter ................................. 10-7

10.4 Setting Operation Mode of Relay/Internal Switch .............................................................................10-9

10.5 Setting Burn-out/Reference Junction Compensation ....................................................................... 10-12

10.6 Setting Recording Colors.................................................................................................................. 10-14

10.7 Setting Key Lock .............................................................................................................................. 10-15

10.8 Setting FUNC/FUNC3 Menu ........................................................................................................... 10-17

10.9 Setting SET/SET3 Menu ..................................................................................................................10-20

10.10 Selecting Display Update Interval, Registering Details Set/Selected with SET UP Menu, and

Terminating SET UP Menu .............................................................................................................. 10-24

10.11 Selecting the temperature unit from °C or °F (option) ..................................................................... 10-25

10.12 Working with the Report Function ................................................................................................... 10-27

Chapter 11 Saving/Reading Measured, Computed and Set-up Data

11.1 Saving Measured and Computed Data ............................................................................................... 11-1

11.2 Reading Measured and Computed Data .............................................................................................11-7

11.3 Saving Set-up Data ........................................................................................................................... 11-10

11.4 Reading Set-up Data......................................................................................................................... 11-12

11.5 Copying a Data File.......................................................................................................................... 11-15

11.6 Copying in ASCII Format.................................................................................................................11-17

IM DR232-01E

4

5

6

7

8

9

10

11

12

13

14

Index

11

Page 13

Contents

11.7 Deleting a Data File.......................................................................................................................... 11-20

11.8 Displaying RAM Disk and Floppy Disk Information ...................................................................... 11-21

11.9 Initializing the RAM Disk ................................................................................................................ 11-23

11.10 Formatting a Floppy Disk .................................................................................................................11-24

Chapter 12 Executing Computation (Available with the /M1 Model)

12.1 Overview of the Computation Function .............................................................................................12-1

12.2 Setting a Computation Equation.........................................................................................................12-4

12.3 Setting a Constant...............................................................................................................................12-7

12.4 Starting/Stopping Computation .......................................................................................................... 12-8

12.5 Setting Actions to be Carried out in Case of Computation Error and Setting the Time Axis for TLOG

SUM..................................................................................................................................................12-12

Chapter 13 Trouble-shooting and Maintenance

13.1 Periodic Maintenance and Recommended Parts Replacement Period ...............................................13-1

13.2 Replacing the Fuse.............................................................................................................................. 13-2

13.3 Troubleshooting ..................................................................................................................................13-3

13.4 Error Codes.........................................................................................................................................13-4

13.5 Calibration ..........................................................................................................................................13-6

Chapter 14 Specifications

14.1 Specifications of DR232/DR242 and DS400/DS600.........................................................................14-1

14.2 Universal Input Module and DCV/TC/DI Input Module .................................................................14-11

14.3 Specifications of mA-input Module .................................................................................................14-14

14.4 Specifications of Power Monitor Module ........................................................................................ 14-16

14.5 Specifications of Strain Input Module..............................................................................................14-20

14.6 Specifications of Pulse Input Module............................................................................................... 14-22

14.7 Specifications of Digital Input Module ............................................................................................14-24

14.8 Alarm Module................................................................................................................................... 14-26

14.9 DI/DO Module.................................................................................................................................. 14-27

14.10 Communication Interface Module ....................................................................................................14-29

14.11 Specifications of Extension Module and Extension Base ................................................................ 14-32

14.12 Dimensional Drawings ..................................................................................................................... 14-33

INDEX

12

IM DR232-01E

Page 14

List of Menus and Set-up Data

The following is a list of set-up data, procedures to switch to different setting modes, and setting

menu.

Measurement Condition Settings

Parameters Procedure Selecting menu Reference

Input type, span, linear RANGE key 001-01:VOLT/2V Chapter 5

1

Chart Speed Settings

Recording Settings

scaling*

Units SET key*

Moving average

Measurement cycle*

A/D integration time*1Turn ON power while pressing the DISP key

1

Filter*

*1: Make sure that the total number of setting changes, including calibrations and restructuring, does not

surpass 100000.

*2: Procedure varies according to the menu configuration of the SET key (see section 10.9).

Parameters Procedure Selecting menu Reference

Chart speed 1 CHART key CHART Section 6.2

Chart speed 2

*: Procedure varies according to the menu configuration of the SET key (see section 10.9).

Press the SET key for about three seconds

1

Turn ON power while pressing the DISP key

Turn ON power while pressing the DISP key

Press the SET key for about three seconds*

2

SET=UNIT Section 6.1

*2SET=MOVE AVE Section 6.8

SET UP= Section 10.1

SCAN INTVL

SET UP=A/D INTG Section 10.3

SET UP=FILTER Section 10.3

SET=CHART2 Section 6.2

Display Settings

Parameters Procedure Selecting menu Reference

Logging/Analog trend SET key* SET=SYSTEM Section 6.1

switch, dot-printing cycle

Recording channel SET key* SET=TREND Section 6.1

Recording zone

Partial compression

Tag

Channel to digital print,

number of rows to print

Channel to manual print

Alarm print

Channel to print scale

values

Channel to list print

Items to list print

Message

Header

Title

Interpolation

Adjust dot-printing

position

Recording format

Dot-print color

*: Procedure varies according to the menu configuration of the SET key (see section 10.9).

Parameters Procedure Selecting menu Reference

Switch display DISP key and MODE key -------- Chapter 4

Display update interval Turn ON power while pressing the SET UP=DISPLAY Section 10.10

Press the SET key for about three seconds*

Press the SET key for about three seconds*

Press the SET key for about three seconds*

Press the SET key for about three seconds*

Press the SET key for about three seconds*

Press the SET key for about three seconds*

Press the SET key for about three seconds*

Press the SET key for about three seconds*

Press the SET key for about three seconds*

Press the SET key for about three seconds*

Press the SET key for about three seconds*

Press the SET key for about three seconds*

Press the SET key for about three seconds*

Turn ON power while pressing the DISP key

Turn ON power while pressing the DISP key

Turn ON power while pressing the DISP key

DISP key

SET=ZONE Section 6.3

SET=PERTIAL Section 6.3

SET=TAG Section 6.4

SET=DIGITAL PR Section 6.4

SET=MANUAL PR Section 6.4

SET=ALARM PR Section 6.5

SET=SCALE PR Section 6.6

SET=LIST PR Section 6.6

SET=LIST FMT Section 6.6

SET=MESSAGE Section 6.7

SET=HEADER Section 6.7

SET=TITLE Section 6.7

SET=INTERPOL Section 6.8

SET UP=PRN ADJ Section 10.1

SET UP=RECORD Section 10.2

SET UP=COLOR Section 10.6

Alarm Settings

IM DR232-01E

Parameters Procedure Selecting menu Reference

Alarm, alarm output ALARM key 001-01:1/OFF Section 8.1

relay

Alarm

interval/hysteresis/hold

Execute alarm FUNC key* ALARM ACK Section 9.3

acknowledge

Reset alarm FUNC key* ALARM RST Section 9.3

Clear alarm buffer

*: Procedure varies according to the menu configuration of the FUNC key (see section 10.8).

Turn ON power while pressing the DISP key

Press the FUNC key for about three seconds*

SET UP=ALARM Section 10.3

ALM BUF CLEAR Section 9.4

13

Page 15

List of Menus and Set-up Data

Computation Settings

Parameters Procedure Selecting menu Reference

Computation equation SET key* SET=MATH Section 12.2

Constant SET key* SET=CONST Section 12.3

Perform computation FUNC key** MATH START Section 12.4

Clear measured data and FUNC key** MATH CLR START Section 12.4

perform computation

Stop computation FUNC key** MATH STOP Section 12.4

Clear incomplete FUNC key** MATH ACK Section 12.4

measurement status

Handling of computation

error/time axis setting of

TLOG SUM

*: Procedure varies according to the menu configuration of the SET key (see section 10.9).

**: Procedure varies according to the menu configuration of the FUNC key (see section 10.8).

Turn ON power while pressing the DISP key

Settings for Saving/Loading Measured/Setup Data (Floppy Disk)

Parameters Procedure Selecting menu Reference

Save/Load measured data SET key* SET=MEMORY

Save/Load set-up data SET key* SET=FLOPPY

of SET mode

Copy measured data SET key* SET=MEMORY Section 11.5

between built-in RAM

disk and floppy disk

Convert data and copy SET key* SET=MEMORY Section 11.6

Initialize built-in RAM SET key* SET=MEMORY Section 11.9

disk

Initialize floppy disk SET key* SET=MEMORY Section 11.10

Save/Load set-up data Turn ON power while pressing the DISP SET UP=FLOPPY

of SET UP mode key

*: Procedure varies according to the menu configuration of the SET key (see section 10.9).

SET UP=MATH Section 12.5

Section 11.1, 11.2

Section 11.2, 11.3

Section 11.3, 11.4

Perform Printing

Other Settings

14

Parameters Procedure Selecting menu Reference

Perform manual print PRINT key MAN PR START Section 7.2

Perform list print PRINT key LIST START Section 7.2

Perform header print PRINT key HEADER START Section 7.2

Perform message print FUNC key* MSG PRINT Section 7.3

Perform setup list print

*: Procedure varies according to the menu configuration of the FUNC key (see section 10.8).

Parameters Procedure Selecting menu Reference

Timer SET key* SET=TIMER Section 6.1

Event/Action SET key* SET=LOGIC Section 9.1

Copy between channels SET key* SET=COPY Section 9.2

Match time

Group

Relay, internal switch

operation mode

Burnout

Reference junction

compensation

Key lock

Menu configuration

of FUNC key FUNC PARM

Menu configuration

of SET key

Report function

Reset timer FUNC key** TIMER RESET Section 9.3

Lock keys FUNC key** KEY LOCK ON Section 9.3

Start report FUNC key** REPORT START Section 10.12

Stop report FUNC key** REPORT STOP Section 10.12

Start report print FUNC key** REPORT RECALL Section 10.12

Stop report print FUNC key** REPORT PRINT Section 10.12

Clear message buffer

Display module settings

Display communication

settings

Initialize setting

information

*: Procedure varies according to the menu configuration of the SET key (see section 10.9).

**: Procedure varies according to the menu configuration of the FUNC key (see section 10.8).

Press the FUNC key for about three seconds*

Press the SET key for about three seconds*

Press the SET key for about three seconds*

Turn ON power while pressing the DISP key

Turn ON power while pressing the DISP key

Turn ON power while pressing the DISP key

Turn ON power while pressing the DISP key

Turn ON power while pressing the DISP key

Turn ON power while pressing the DISP key

Turn ON power while pressing the DISP key

Press the FUNC key for about three seconds**

Press the FUNC key for about three seconds**

Press the FUNC key for about three seconds**

Press the FUNC key for about three seconds**

S/U LIST START Section 7.4

SET=MATCH TIME Section 6.8

SET=GROUP Section 6.8

SET UP=RELAY Section 10.4

SET UP=BURN OUTSection 10.5

SET UP=RJC Section 10.5

SET UP=LOCK Section 10.7

SET UP= Section 10.8

SET UP=SET PARM Section 10.9

SET UP=REPORT Section 10.12

START

START

MSG BUF CLEAR Section 9.4

MODULE INF Section 9.4

COMM INF Section 9.4

RAM INIT Section 9.4

IM DR232-01E

Page 16

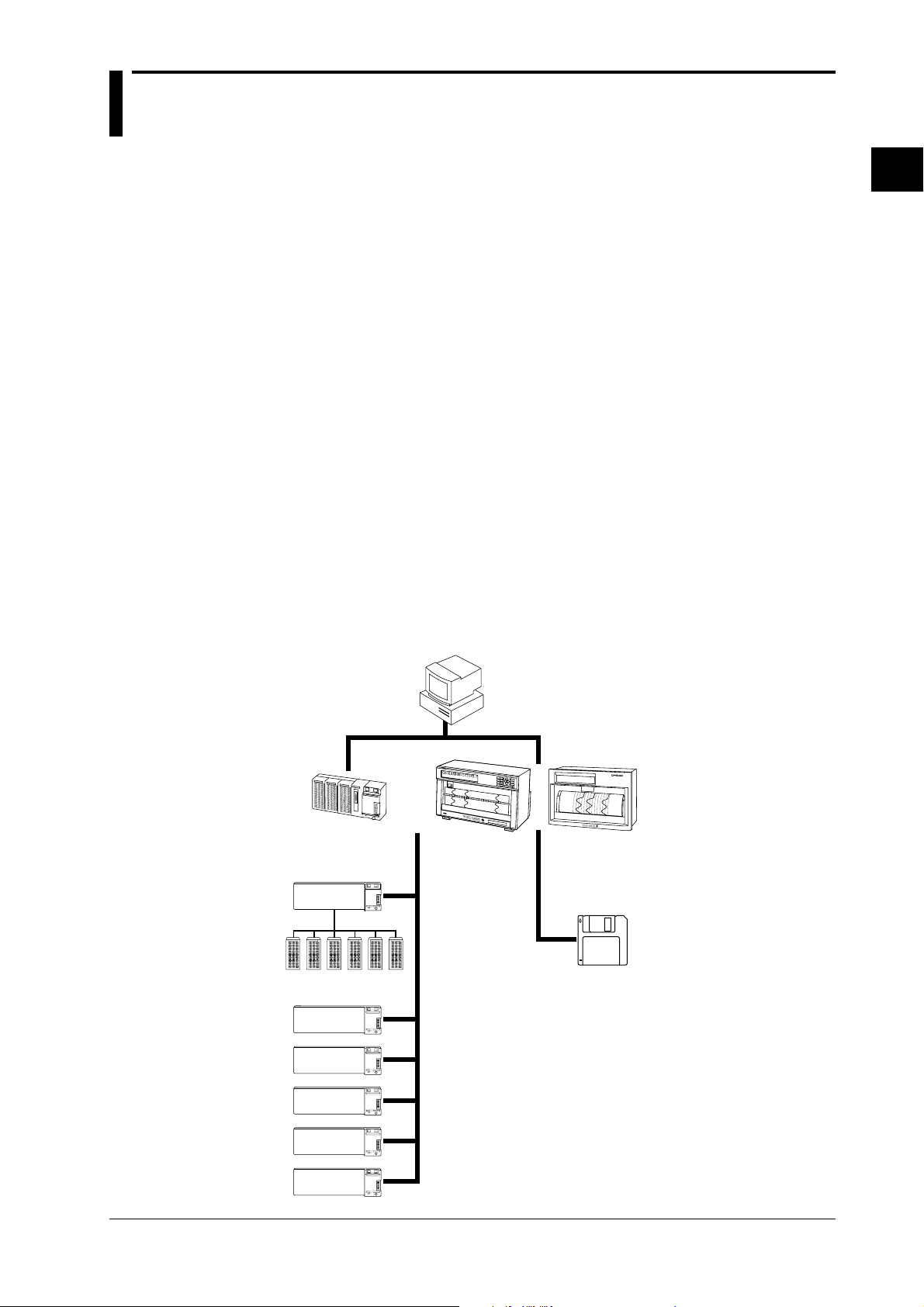

1.1 About DARWIN

Created from a completely new concept that is based on modular architecture, this group of next

generation data acquisition systems is called DARWIN (Data Acquistion and Recording

Windows).

Today many data acquisition networks are increasingly being linked together. More than ever

before, large volume, high speed, accurate, easy-to-use communication functions are essential in

many disciplines.

In the world of measurement and control where the number of measurement points has increased

sharply, the ability to acquire information from a large number of points easily and economically

is crucial. Interfacing to a personal computer allows simplified utilization of the information

while improving quality and efficiency.

DARWIN is based on a unique, new concept to meet these needs. The art of measurement is

revolutionized by DARWIN which integrates functions of conventional recording and data

logging.

Most existing data acquisition equipment has been the all-in-one type in which the measurement

section and display/recording section are contained in one box. While this simplifies operation on

the one hand, it is difficult to adapt to changes in the measurement environment and also makes

expansion difficult.

DARWIN uses a data acquisition engine and remote I/O modules which are completely separate

from each other. It is an entirely new product line which quickly and flexibly copes with various

restrictive conditions and changes in specifications.

Supported by a personal computer, a whole line-up can be created starting with the data

acquisition systems DA series which performs data logging. For example, using a printer as the

output device, the equipment becomes a hybrid recorder (DR series).

Two models are available in the DR series: the DR230 and DR240. The DR 230 is a desk-top

hybrid recorder, and the DR240 is a panel-mount hybrid recorder (component type).

1

System Configuration

Personal

computer

DA100

Subunit

Input/output

modules

D

Extension cables

(max. length 500m)

CH=001 RANGE=TC TYPE-T

0

0

1

0

0

6

0

0

2

0

1

1

0

0

7

0

0

3

0

1

2

0

0

8

0

0

4

0

1

3

0

0

9

0

0

5

0

1

4

0

1

0

0

1

5

DR240DR230

0

1

6

0

1

7

0

1

8

0

1

9

0

2

0

FD

H

y

b

r

i

d

R

e

c

o

r

d

e

r

0

2

1

0

2

6

0

2

2

0

2

7

0

2

3

0

2

8

0

2

4

0

2

9

0

2

5

0

3

0

IM DR232-01E

1-1

Page 17

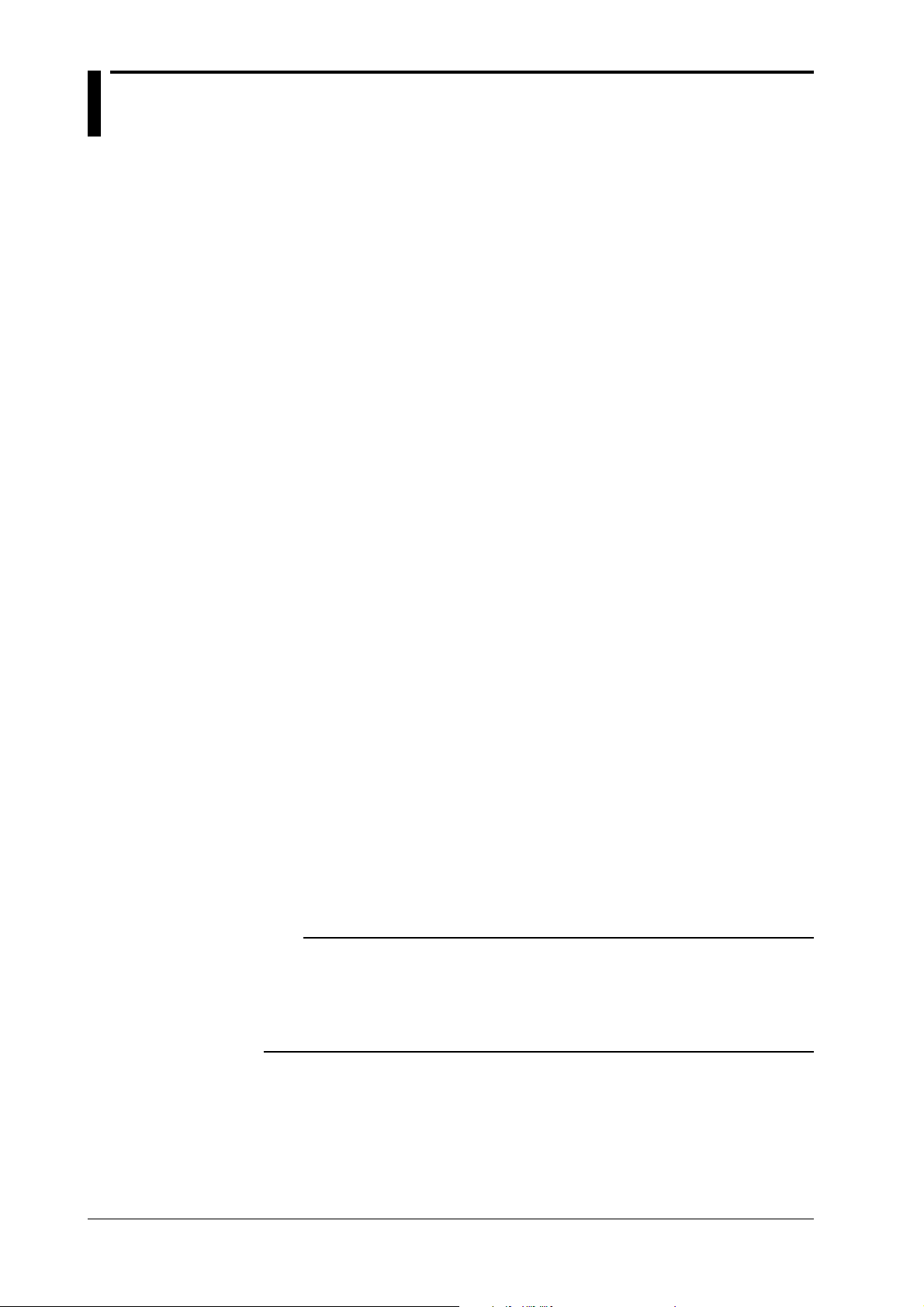

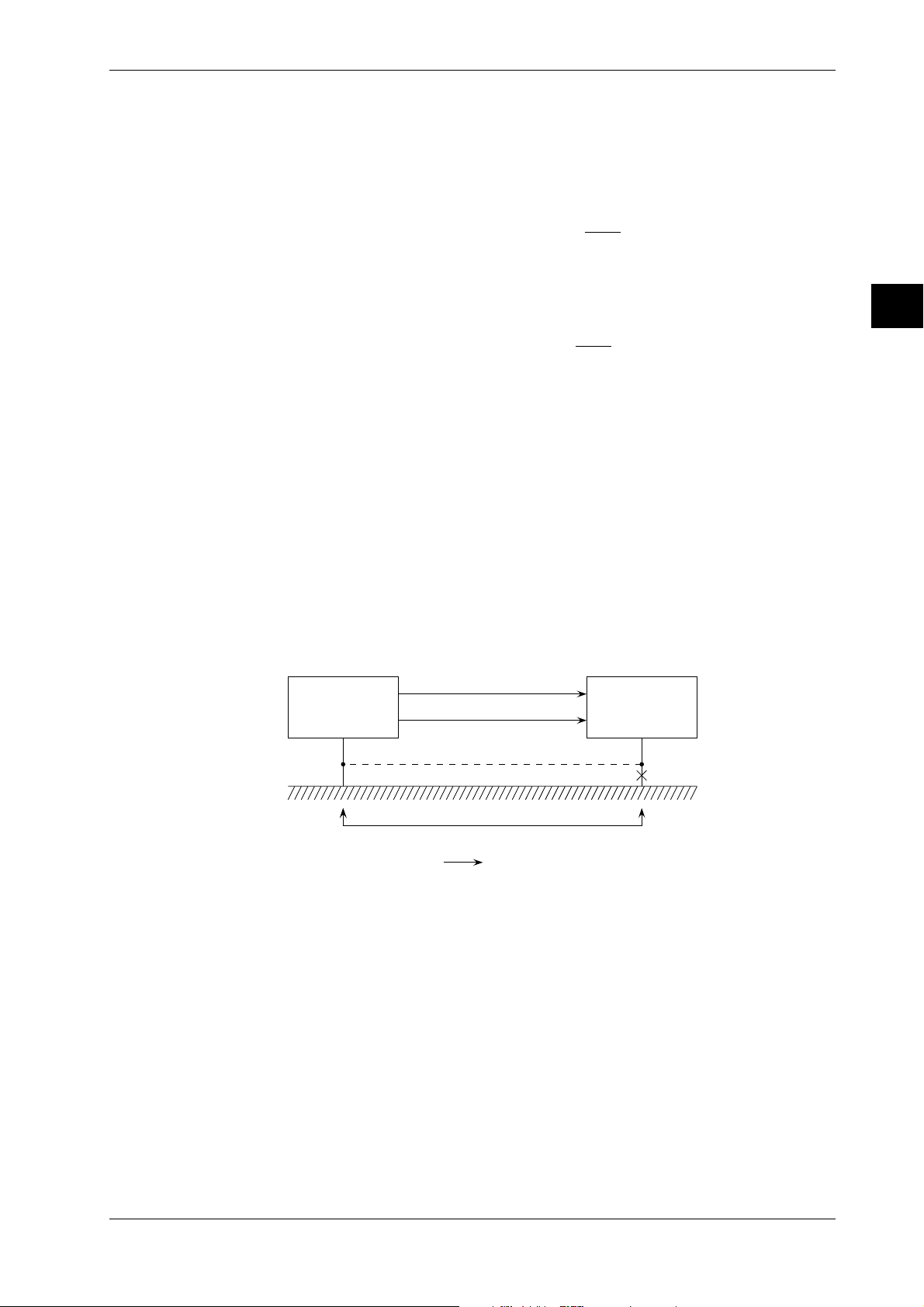

1.2 Product Overview

This product is a hybrid recorder which can record and measure from small-scale 10-ch data up to

widely distributed 300-ch multi-point data.

The number of measurement points can be expanded up to a maximum of 300-ch by connecting

up to six subunits (DS400/DS600) to a main unit (DR232/242). Using dedicated extension cables

between units, interconnections can be extended up to 500 m. Since measured objects scattered

over a wide area can be wired fast and with a minimum of wiring, a flexible, extensive

measurement system can be configured. The input modules to be incorporated in the DR232/242

or DS400/600 can be selected from the following, to suit your measurement conditions:

• Universal input module and DCV/TC/DI input module

Temperature, DC voltage and contact signals can be measured, but cannot be connected to the

main unit.

• mA-input Module

This module can directly measure DC currents ranging from -20 mA to 20 mA since it contains

shunt resistors. It cannot be connected to a system's main unit.

• Power Monitor Module

This module can measure the effective voltage, effective current, active power, reactive power,

apparent power, frequency, power factor and phase angle for an AC voltage or AC current input.

It is available in either a single-phase or three-phase model. This module cannot be connected to

a system's main unit.

• Strain Input Module

This module can measure strain. It is available in either a model with built-in 120- or 350-Ω

bridge resistors or a model with NDIS terminals where bridge resistors are connected externally.

The module cannot be connected to a system's main unit.

• Pulse Input Module

This module can measure pulses. It cannot be connected to a system's main unit.

• Digital input module

This module can measure contact signals. It cannot be connected to a system’s main unit.

• Communication interface module

This module is necessary when communicating with a personal computer. Measurement

conditions can be set and data acquired via the communication interface (GP-IB, RS-232-C, etc.)

of this dule. This module can only be connected to the main unit.

• Alarm module

This module can output alarm signals as contact signals. The module can be connected to the

main unit or the subunit.

• DI/DO module

This module allows a signal to be output in the case of alarm, failure, or chart end and a remote

control signal for the product to be input. The module can be connected to the main unit or the

subunit but only one module in all units.

1-2

Note

When the following handling is done, it is necessary to carry out “system construction” to operate the

instrument correctly. After executing system construction, confirm the module information. For details,

see page 9-16.

• Connection (including addition or replacement)/removal of subunits, or unit number setting (see page 3-

7)

• Mounting (including addition or replacement)/removal of modules

IM DR232-01E

Page 18

Connection example

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b -/B +/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b-/B+/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b-/B+/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b-/B+/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b-/B+/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b -/B +/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b -/B +/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b-/B+/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b-/B+/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b -/B +/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b-/B+/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b -/B +/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b -/B +/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b -/B +/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b-/B+/A

CH

1

CH

2

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

CH

9

CH

10

b-/B+/A

SUB UNIT

POWER

STATUS

POWER

STATUS

POWER

100-240V 50/60Hz 55VA MAX

STATUS

100-240V 50/60Hz 70VA MAX

SUB UNIT

100-240V 50/60Hz 70VA MAX

SUB UNIT

Subunit

DS600

Subunit

DS600

Subunit

DS400

Extension cable

10ch Universal Input module

10ch Universal Input module

10ch Universal Input module

Up to 6 subunits

can be connected

Main unit DR232/DR242

1.2 Product Overview

1

System Configuration

IM DR232-01E

1-3

Page 19

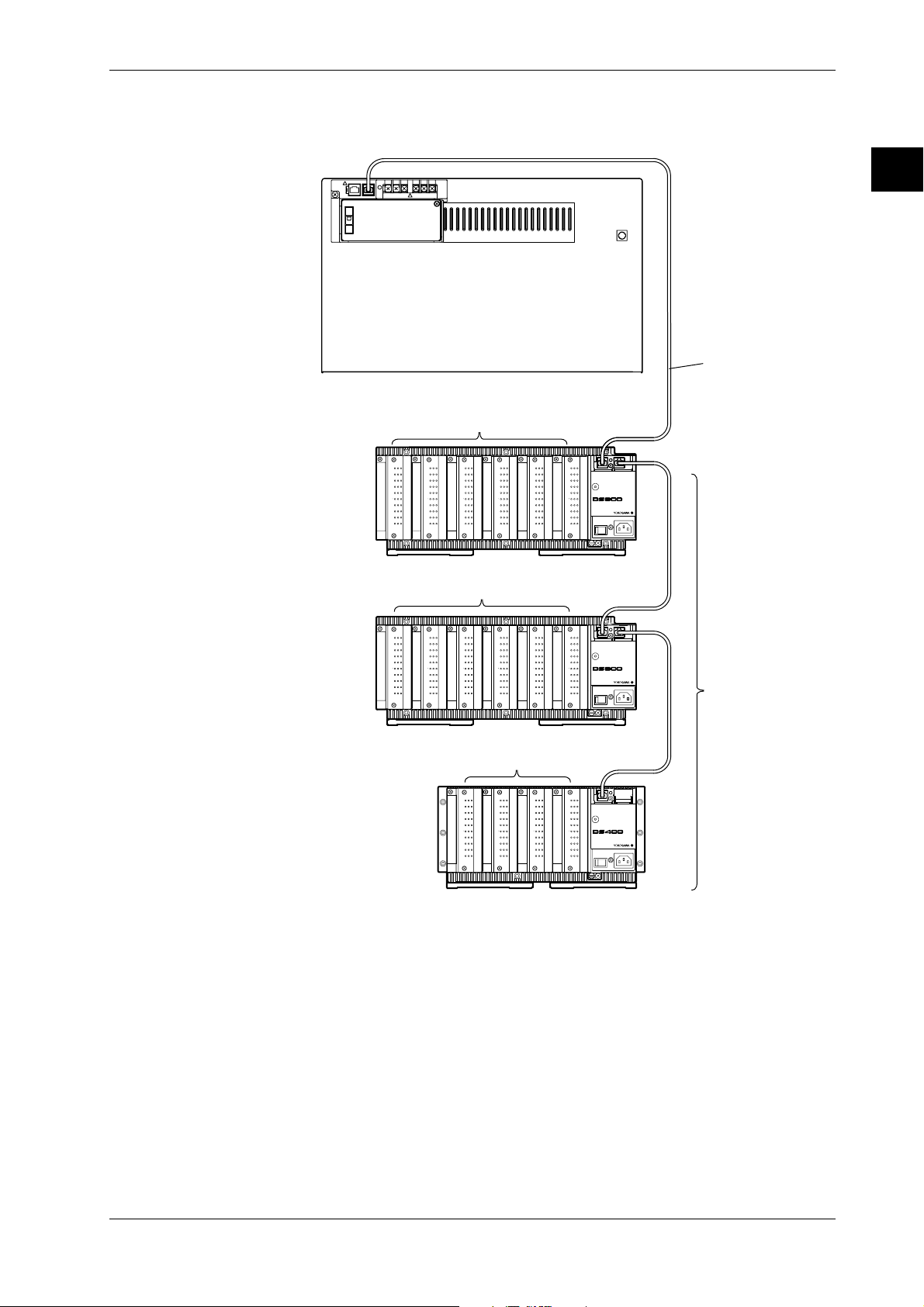

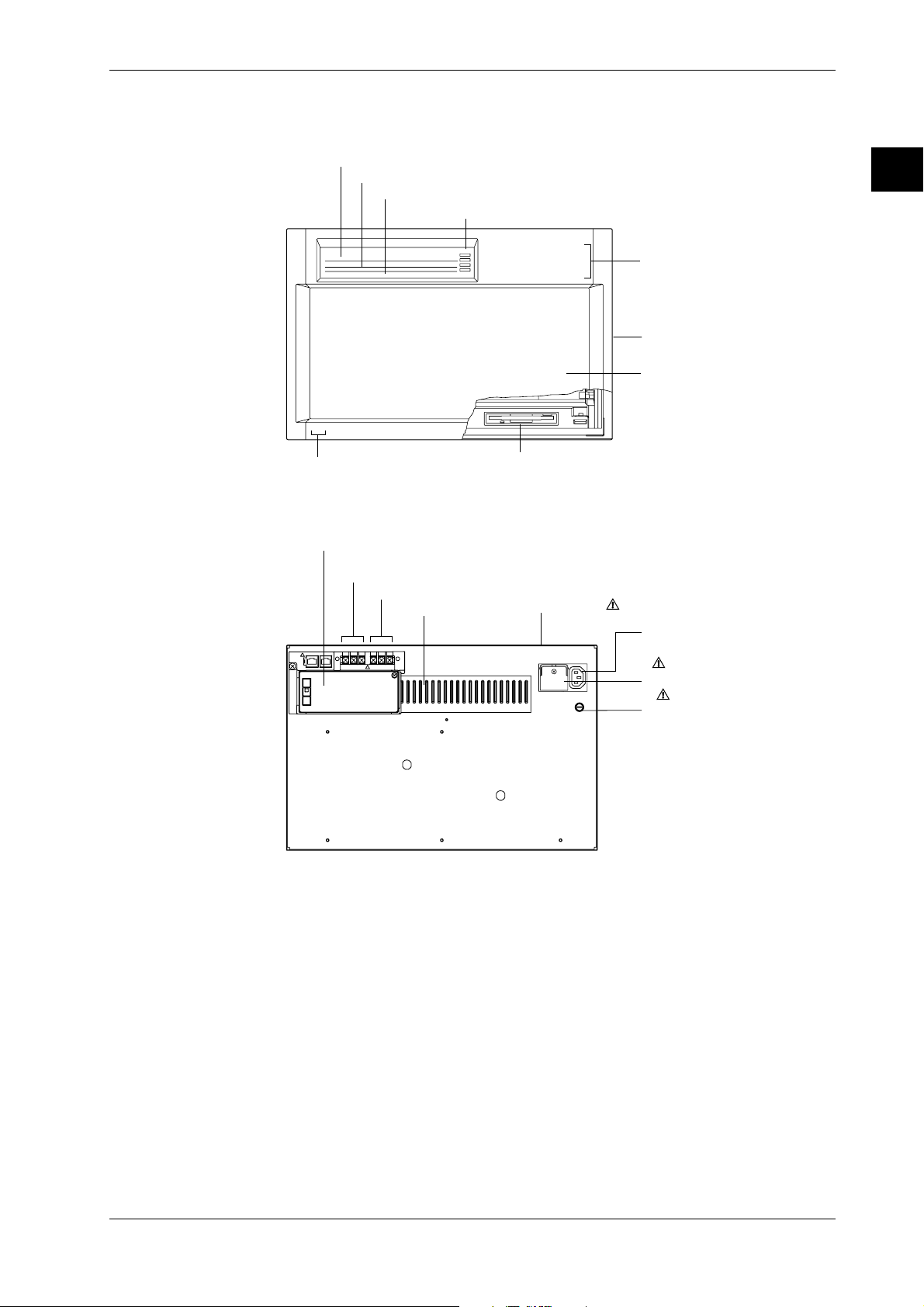

1.3 Names of Parts

DR232 Main Unit (desk-top hybrid recorder)

Front

Main display (See chapter 4.)

Sub-display 1 (See chapter 4.)

Sub-display 2 (See chapter 4.)

Status indicator

Operation panel

(See chapters 3 to 12.)

Handle to open/close

the front door

Front door

Power switch (See page 3-22)

Rear

Vacant slot with cover

(for communication interface,

alarm, or DI/DO modules)

Failure output terminals

Chart end output terminals

Heat sink fins

Floppy disk drive (Only for DR232-1)

Power fuse ( See page 13-2)

AC outlet(Au xiliary

for DS400/DS600

: See page 3-29)

Power connector

( See page 3-29)

Function grounding

terminal

1-4

IM DR232-01E

Page 20

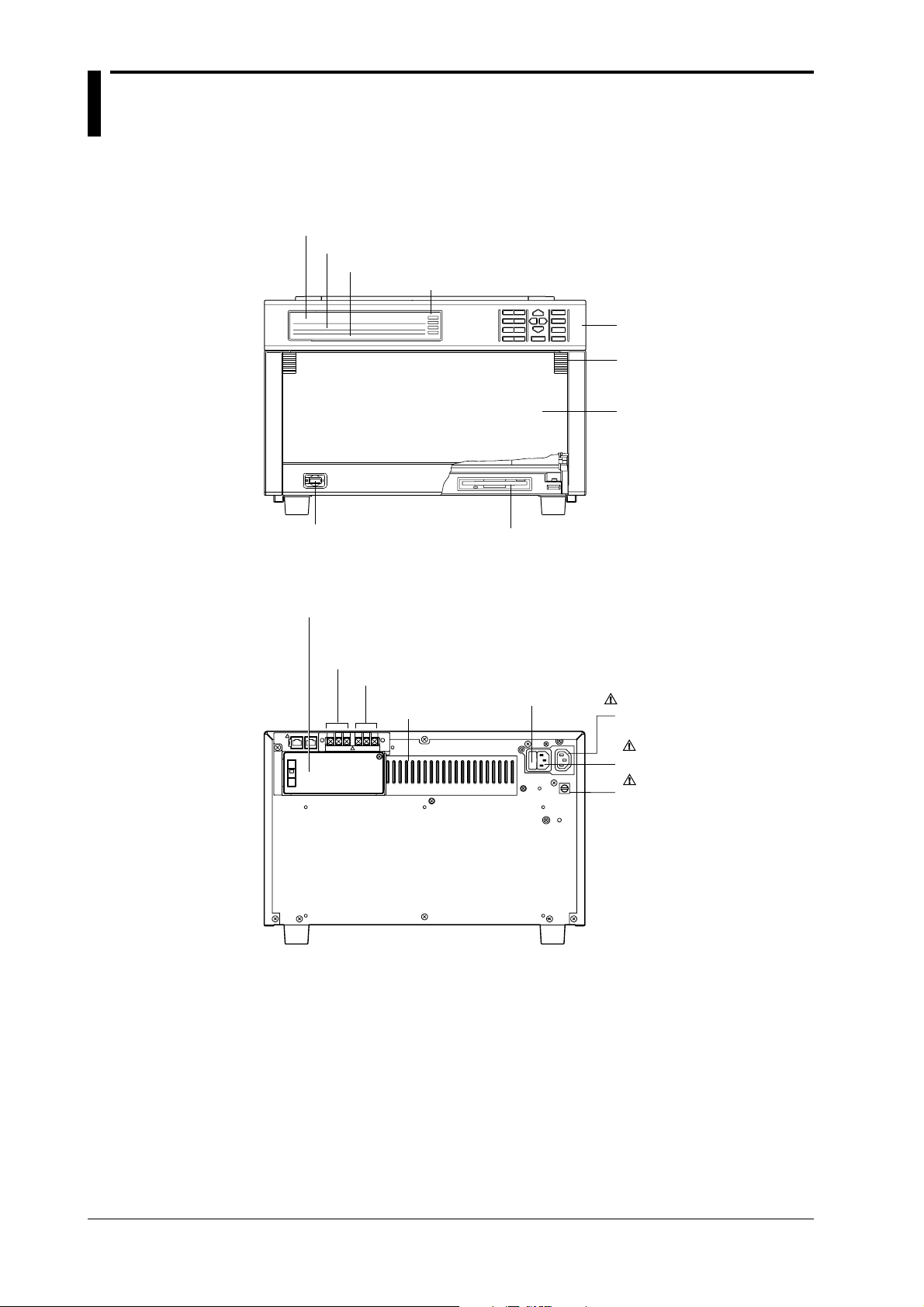

DR242 Main Unit (panel-mount hybrid recorder)

Main display (See chapter 4.)

Sub-display 1 (See chapter 4.)

Sub-display 2 (See chapter 4.)

Status indicator

Operation panel

(Located behind the front door.

See chapters 3 to 12.)

Handle to open/close

the front door

Front door

Power switch

(Located inside the front door. See page 3-22.)

Floppy disk drive (Only for /DR242-1)

Heat sink fins

Power terminals with a cover

( See page 3-30)

Vacant slot with cover

(for communication interface, alarm, or DI/DO modules)

Failure output terminals

Chart end output terminals

Power fuse (See page 13-2)

(located in the main unit)

Function grounding

terminal

AC outlet(Auxiliary

for DS400/DS600

: See page 3-30)

Front

1.3 Names of Parts

1

System Configuration

Rear

IM DR232-01E

1-5

Page 21

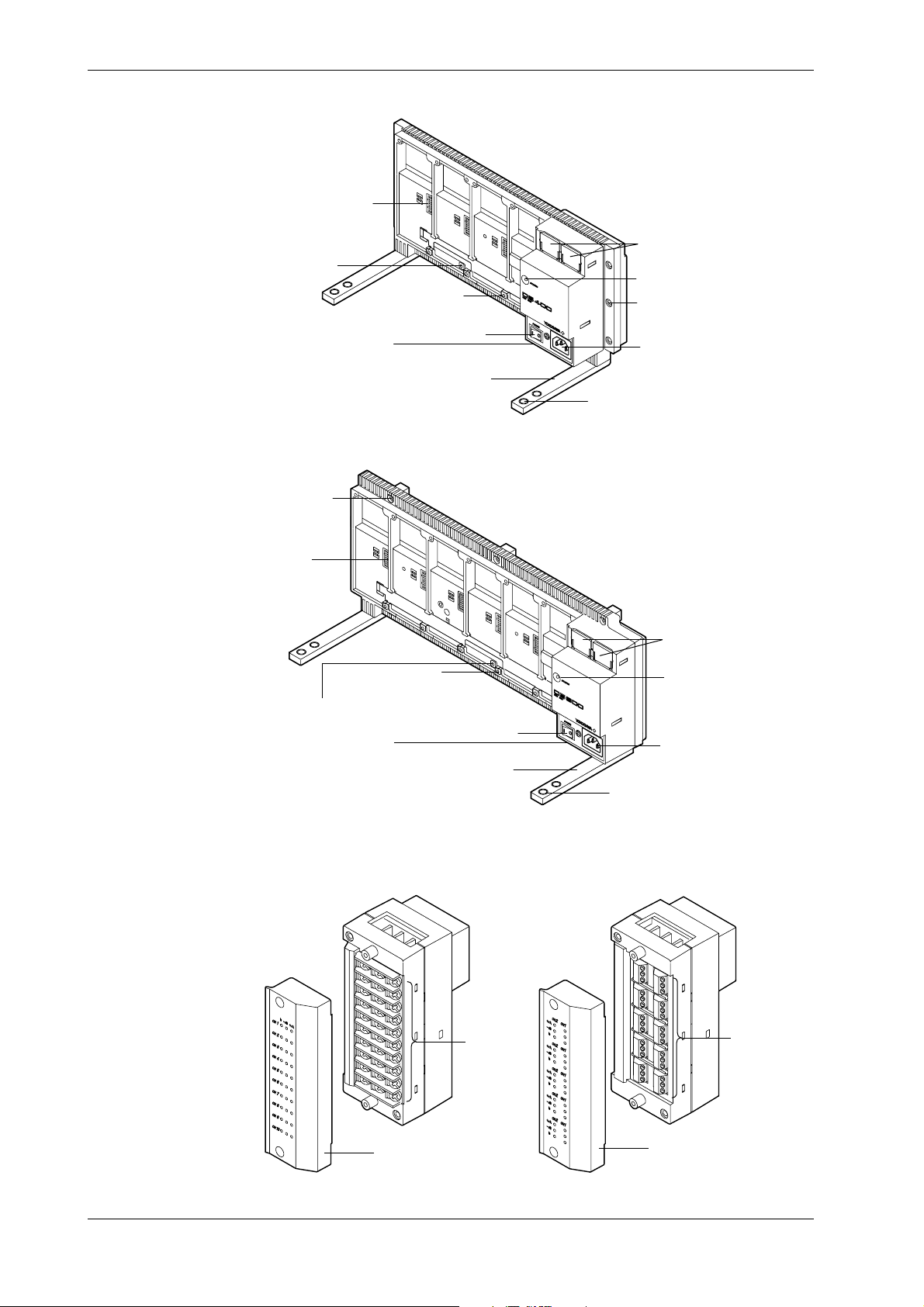

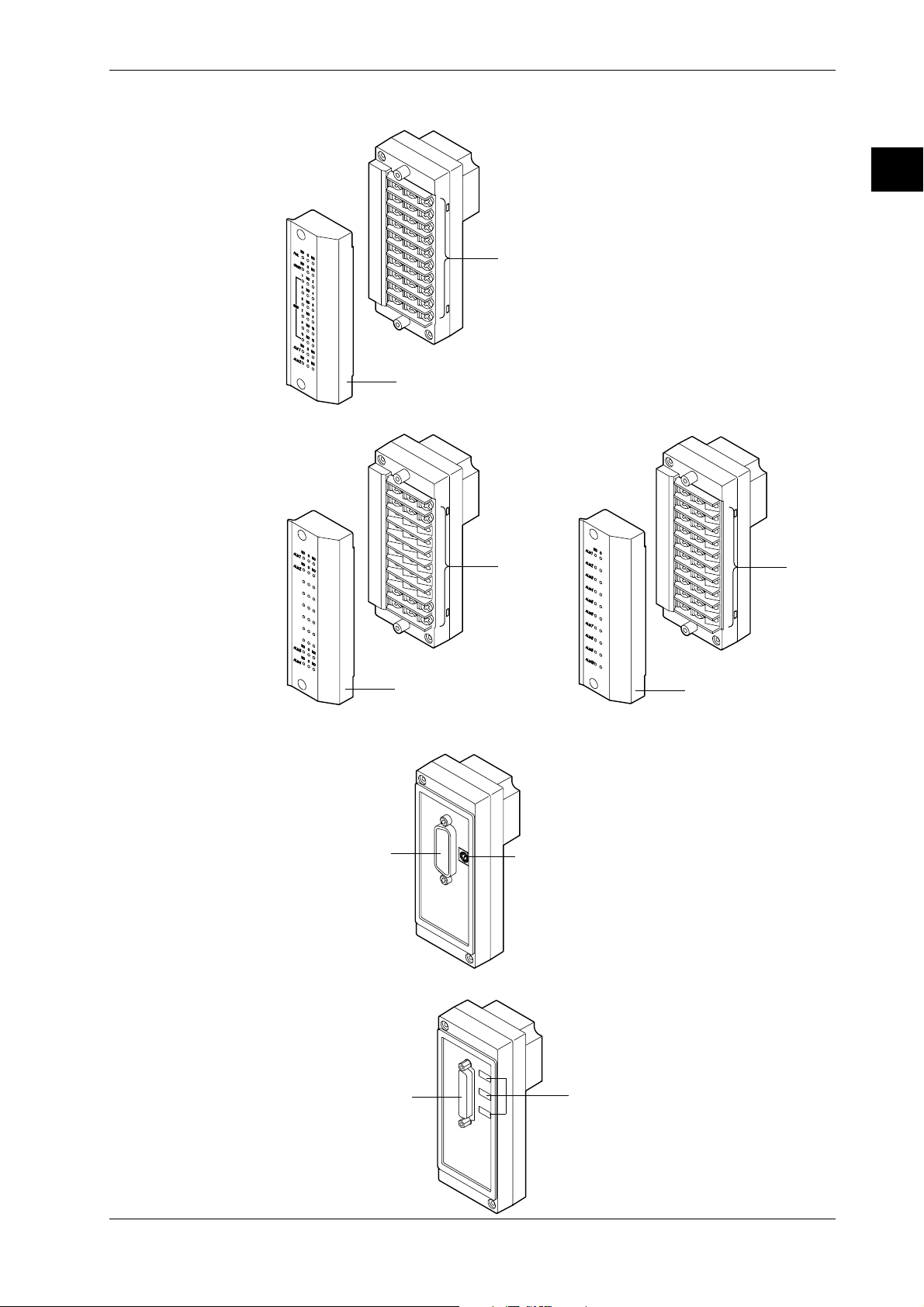

1.3 Names of Parts

Subunit DS400

Subunit DS600

Module connector

Switch to set the

unit number

Screw holes for

module installation

Function grounding

terminal (below power switch)

Installation

holes

Power switch

Lid covering the extension

cable connector

Status indicator

Installation holes

Power connector

Feet

Holes for fastening the feet

Input modules

Module

connector

Screw holes for

module installation

Switch to set

the unit number

Function grounding

terminal (below power switch)

Power switch

Feet

10-ch Universal input module (DU100-11/DU100-12)

DU100-11

DU100-12

Lid covering the

extension cable

connector

Status indicator

Power connector

Holes for fastening

the feet

1-6

Screw

terminal

Cover

The 20-ch Universal input modules (DU100-21/DU100-22) and the 30-ch Universal input modules

(DU100-31/DU100-31) are similar to the ones shown above.

Cover

Clamp

terminal

IM DR232-01E

Page 22

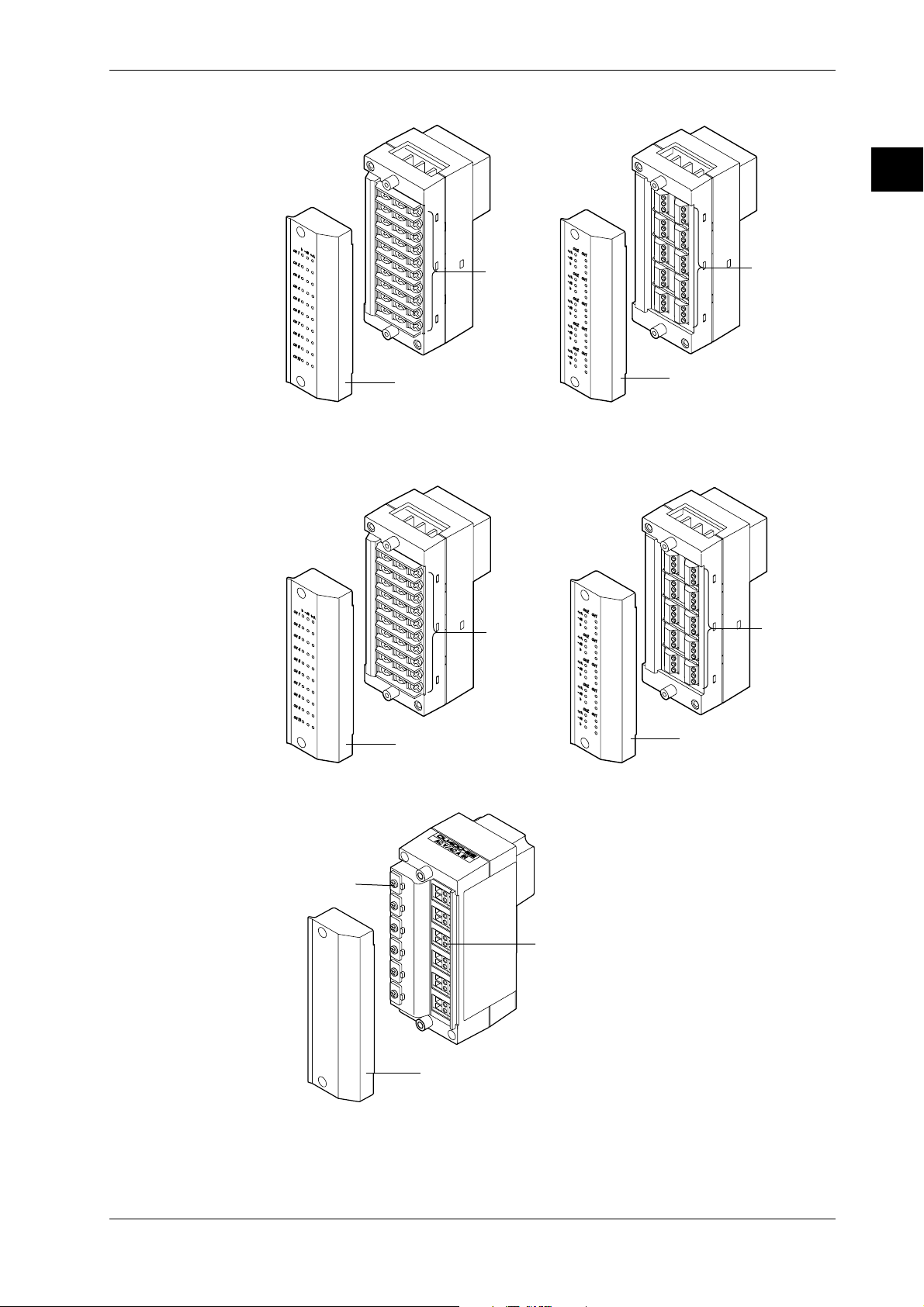

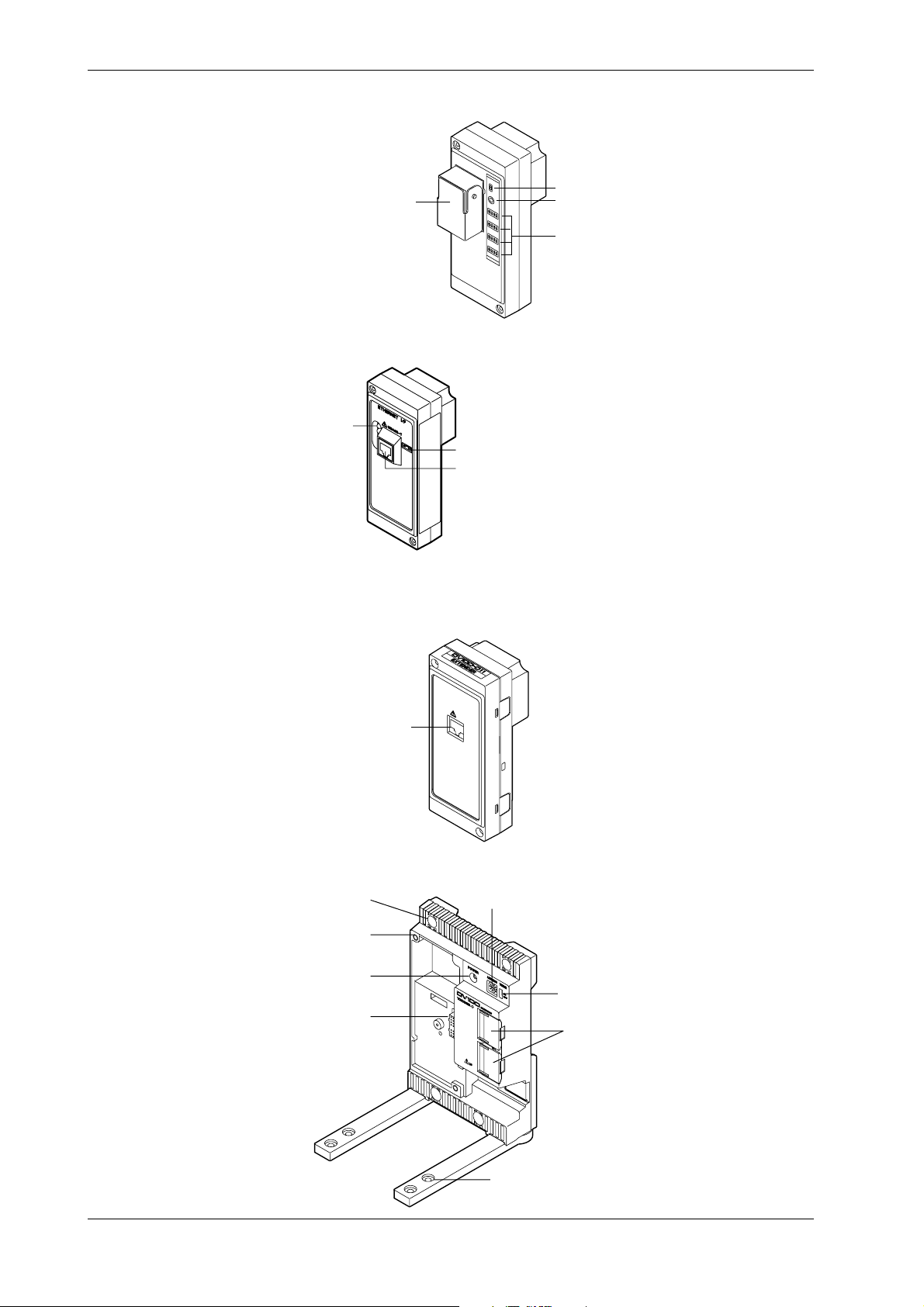

10-ch DCV/TC/DI input module (DU200-11/DU200-12)

1.3 Names of Parts

DU200-11

Screw

terminal

Cover

The 20-ch DCV/TC/DI input modules (DU200-21/DU200-22) and the 30-ch DCV/TC/DI input modules

(DU200-31/DU200-31) are similar to the ones shown above.

DU200-12

Clamp

terminal

Cover

mA input module (DU300-11/DU300-12)

1

System Configuration

Cover

AC input module (DU400-12/22)

Wire clip

Cover

Screw

terminal

Clamp

terminal

Cover

Clamp terminal

IM DR232-01E

1-7

Page 23

1.3 Names of Parts

Strain input module (DU500-12/DU500-13/DU500-14)

Gauge method setup switch

Pulse input module (DU600-11)

DU500-12/DU500-13

Cover

DU500-14

NDI terminal

Clamp terminal

Screw terminal

Cover

Digital input module (DU700-11)

Cover

Screw

terminal

1-8

IM DR232-01E

Page 24

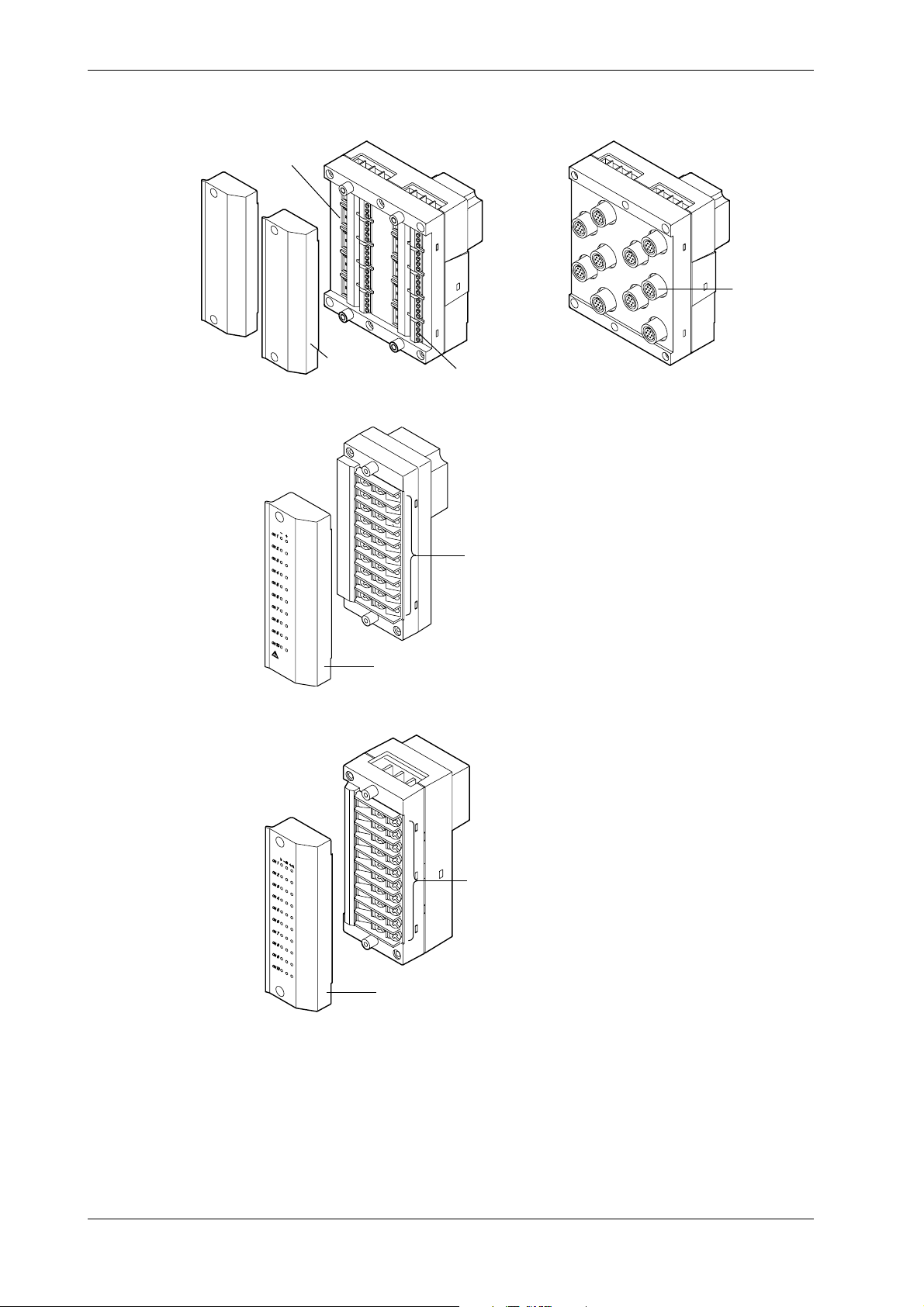

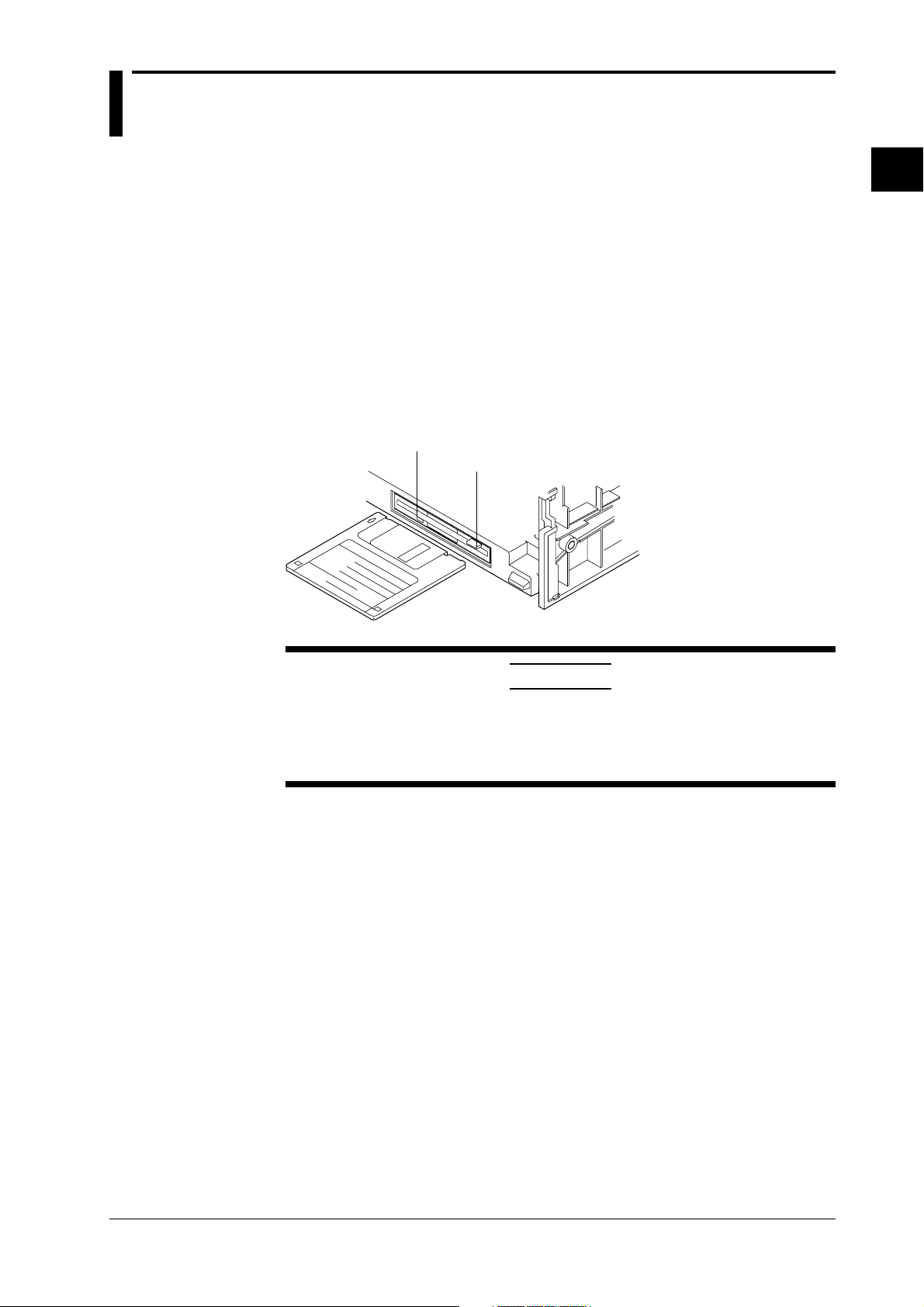

I/O Terminal Modules

1.3 Names of Parts

DI/DO module (DT100-11)

1

System Configuration

Screw terminal

Cover

Alarm module (DT200-11/DT200-21)

DT200-11

Communication Module

GP-IB module (DT300-11)

GP-IB connector

Cover

Screw

terminal

Switch to set

the address

DT200-21

Screw

terminal

Cover

IM DR232-01E

RS-232-C module (DT300-21)

RS-232-C connector

Switches to set

communication parameters

1-9

Page 25

1.3 Names of Parts

RS-422-A/RS-485 Module (DT300-31)

RS-422-A/RS-485 terminal

Ethernet module (DT300-41)

Status indicator

Switch to set mode

10BASE-T port

ON/OFF switch of built-in terminating resistor

LED

Switches to set

communication parameters

Extender Module/Extender Base

Extender Module (DV100-011)

Extension cable connector

Extender Base (DV100-012)

Inatallation

holes

Screw holes for

module installation

Power indicator

Module connector

EXTENDER

I/F

I/F

Slot number setup switch

Terminator on/off switch

Lid covering the extension

1-10

Holes for fastening the feet

IM DR232-01E

Page 26

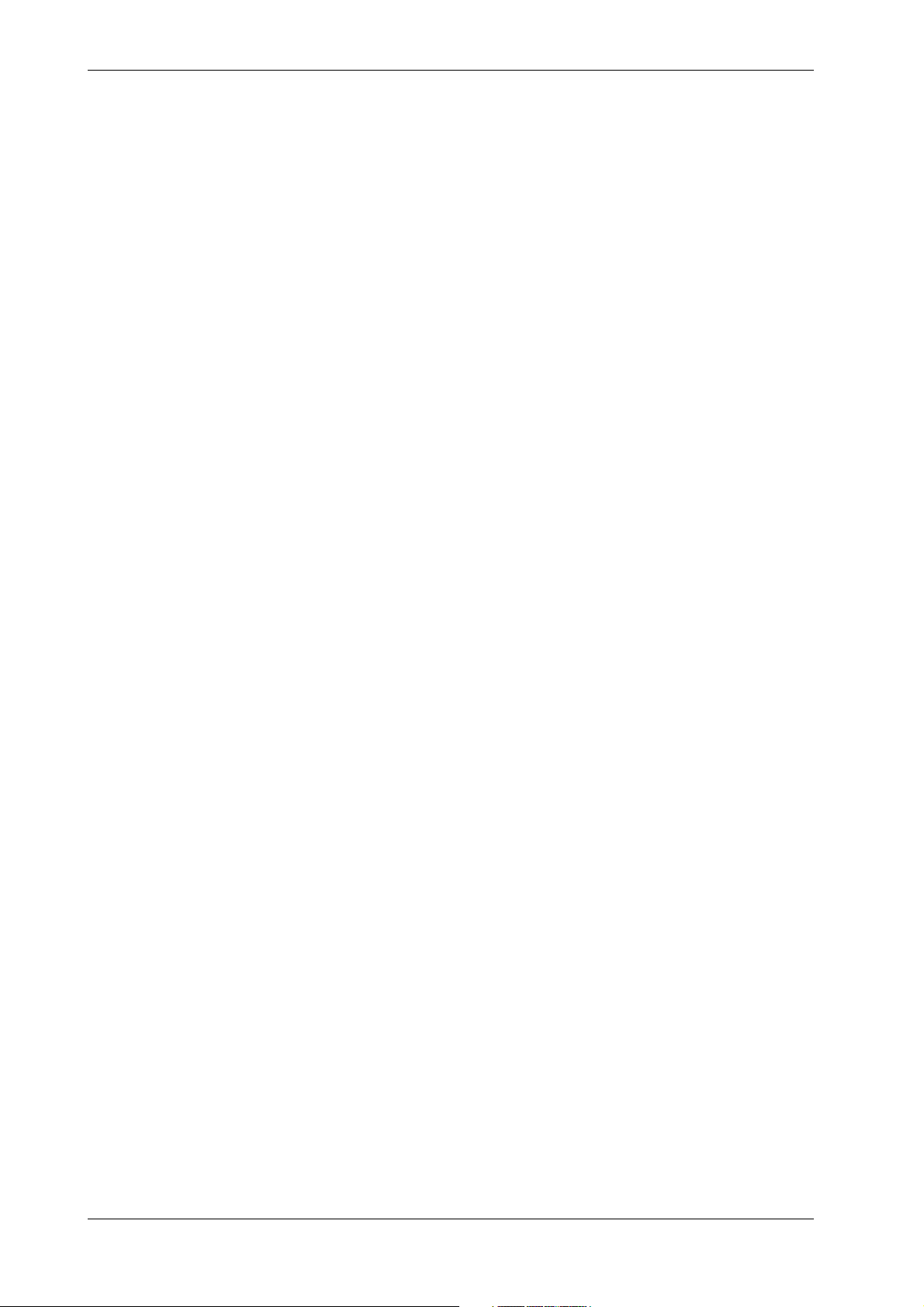

1.4 Floppy Disk

A floppy disk drive is provided with the DR232-1 and DR242-1.

Applicable Floppy Disks

3. 5-inch floppy disks can be used for this instrument. They can also be formatted on this

instrument.

• 2HD type: 1.2 MB or 1.44 MB (MS-DOS format)

• 2DD type; 720 MB (MS-DOS format)

Inserting a Floppy Disk into the Drive

Insert the floppy disk into the floppy disk drive, shutter side first and with the label face up.

Make sure that the floppy disk is inserted until the eject button pops up.

Removing the Floppy Disk from the Drive

Make sure that the access indicator is not lit, then push the eject button to remove the floppy disk.

access indicator

eject button

1

System Configuration

CAUTION

If the floppy disk is removed when the access indicator is still lit, damage to

the magnetic head of the floppy disk drive or to data saved on the floppy

disk may result. Before removing the floppy disk, always make sure that

the access indicator is OFF.

General Precautions Regarding Handling of Floppy Disk

For general precautions regarding handling of floppy disks, refer to the instruction manual

provided with the disk.

IM DR232-01E

1-11

Page 27

2.1 Display Functions

The inter-active front panel display consists of three rows. The first row is the main display, and

the second and third row are sub-display 1 and 2 respectively.

Monitor Mode and Status Display

Monitor Mode

• Auto Mode

This mode can be set for the main display, sub-display 1 and sub-display 2. Measurement

values of all channels will be consecutively displayed with update interval.

• Manual Mode

This mode can be set for the main display, sub-display 1 and sub-display 2. Measurement

values of a single channel will be displayed. The display update interval is the same as the

measurement interval (refer to page 2-4).

• Manual Mode

This mode can be set for the main display. When choosing this display, the measurement values

of 5 consecutive channels will be displayed as a page using also sub-display 1 and 2. The

display update interval is the same as the measurement interval (refer to page 2-4).

• Alarm Search Mode

This mode can be set for the main display, sub-display 1 and sub-display 2. Channels at which

an alarm occurred will be searched for and their measurement values displayed. The display

update interval is 2 seconds.

• Bargraph Mode

This mode can be set for sub-display 1. Measurement values which are shown on the main

display will be shown as a bargraph. The display update interval is the same as the interval of

the main display.

• Alarm Status Mode

This mode can be set for sub-display 1 and 2. The display will show per channel whether or not

an alarm occurred (refer to page 2-13). On one display the alarm status of a maximum of 30

channels can be monitored (depending on the number of input channels). The display update

interval is 0.5 seconds.

• Relay Status Mode

This mode can be set for sub-display 1 and 2. The display will show the operating status of

internal switches/alarm output relays (refer to page 2-13). On one display a maximum of 30

relay statuses can be monitored. The display update interval is 1 second.

• Clock Mode

This mode can only be set for sub-display 2. The current date and time are shown.

• Displaying the Selected Mode

To the right of sub-display 1 the currently selected display mode is shown for a specific

display.

2

Functions

IM DR232-01E

Status Display

Indicators at the right side of the display will light up to show that recording is in progress (refer

to page 2-5), alarms are occuring (refer to page 2-13), keys are locked (refer to page 2-17) and

chart needs to be replaced (refer to page 2-18).

Remote/Local Status Display

The status of remote/local control will be show on sub-display 2. Keys cannot be operated in

remote control.

2-1

Page 28

2.1 Display Functions

Display for Setting the Type of Input, Computation and Recording Conditions

Menus for setting each of the following functions will be displayed.

• measurement input functions (refer to page 2-3)

• recording functions (refer to page 2-5)

• alarm functions (refer to page 2-13)

• calculation functions (refer to page 2-16)

• event/action function, key-lock function and external in/output function (refer to page 2-17, 18)

Display for Setting Fundamental Functions

Menus for performing fundamental settings will be displayed.

2-2

IM DR232-01E

Page 29

2.2 Measurement Input Functions

Input Type

DC Voltage

Measurements can be done after selecting the measurement range per channel. The minimum

range is 20mV, the maximum range is 50V.

Thermocouple

Measurements can be done after selecting the type of thermocouple per channel. The available

types are R, S, B, K, E, J, T, L, U, N, W and KPvsAU7FE.

Reference Junction Compensation (RJC) can be set to either use Internal RJC (INT) or External

RJC (EXT) per channel.

Burnout function can be set OFF per channel or it can be selected in which direction the trend line

will move if burnout occurs (right or left)

Resistance Temperature Detector

Measurements can be done after selecting the type of resistance temperature detector (RTD) per

channel. The available 17 types are Pt100(1mA), Pt100(2mA), JPt100(1mA), JPt100(2mA),

Pt50(2mA), Ni100(1mA)SAMA, Ni100(1mA)DIN, Ni120(1mA), J263*B, Cu10GE, Cu10L&N,

Cu10WEED, Cu10BAILEY, Pt100 (1mA) high resolution, Pt100 (2mA) high resolution, JPt100

(1mA) high resolution and JPt100 (2mA) high resolution.

Contact Input

The type of contact input can be selected from voltage level input or contact input, and recording

can be set ON or OFF per channel. In case of the voltage level input a voltage level up to 2.4V

results in recording OFF, whereas a voltage level of 2.4V or more results in recording ON.

2

Functions

DC Currents

DC currents ranging from -20 mA to 20 mA can be measured by means of the built-in 250-Ω

shunt resistors.

AC Voltages/Currents

The effective voltage, effective current, active power, reactive power, apparent power, frequency,

power factor and phase angle can be measured. The measuring range is common to all terminals.

The input terminals of the module with this input mode, unlike those of modules with other input

modes, are not consistent with a setup screen in terms of the channel number.

Strain

The module for this input mode supports the single-gauge, single-gauge three-wire (not yet

supported by the DU500-14 module), adjacent-side two-gauge, opposed-side two-gauge and fourgauge methods. If you have connected any new strain gauge or changed the measuring range, go

through initial balancing before starting measurement.

Pulses

The module for this input mode can measure the number of pulses per second on a channel basis

or detect the on/off states by means of any variations occurring in the instantaneous value every

second. Once you connect the pulse input module, you can sum up values without the need for

the computing function.

Skipping Input Channels

This function allows skipping measurement, recording and display of channels you are not using.

Measurement, recording and display will not be done for the skipped channels.

Reference Junction Compensation (RJC)

This function is to be used when measuring temperatures using thermocouples. The voltage

generated by a thermocouple depends on the temperature of the spot of measurement and the

reference junction temperature. Reference junction compensation is a function which

compensates the temperature at the side of the measurement instrument to 0 degrees C.

To compensate for the environmental temperature an internal circuit can be selected, or

compensation by a fixed compensation voltage value (external) can be set.

IM DR232-01E

2-3

Page 30

2.2 Measurement Input Functions

Scan Interval

• The duration of time (one scan) in which the measurement of all channels is carried out, is

called the scan interval.

• This interval can be set to any value from 0.5 second to 60 seconds. The shortest is 300 ch/500

ms (varies with the shortest measurement period of the input module).

A/D Integration Time

This instrument measures the input signal after putting it through an A/D converter. In order to

minimize the noise imposed on the input signal, specific integration times exist.

The integration time can be selected from 20ms (50Hz), 16.7ms (60Hz) and 100ms (10Hz).

When “AUTO” is selected, the integration time will be automatically decided according to the 50/

60Hz frequency of the power supply.

AUTO does not function if the instrument is the subunit (DS400/DS600) of the DC power supply

model (Selecting “AUTO” will set the A/D integration time to 20 ms (50 Hz)). If you are using

the instrument on a 60-Hz power supply, set the A/D integration time to 16.7 ms (60Hz).

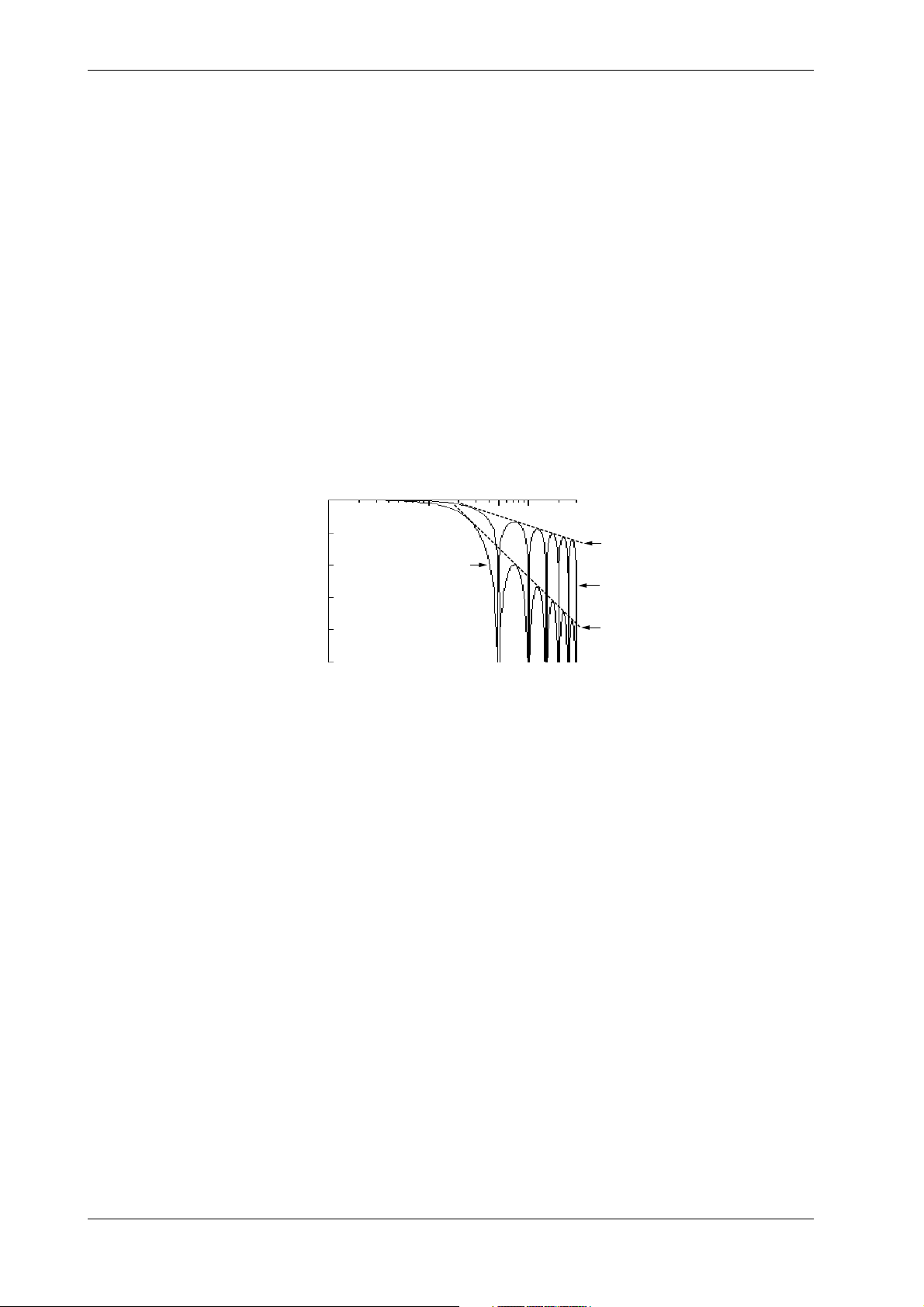

Input Filter

A filter can be set ON/OFF to reduce normal mode noise. Effects on normal mode noise are as

follows depending on the filter being ON/OFF (theoretical values).

0dB

1Hz

Frequency

10Hz

50Hz

100Hz

300Hz

–20dB

–40dB

–60dB

Attenuation

–80dB

–100dB

Slope:–20dB/dec

Filter ON

Filter OFF

Slope:–60dB/dec

2-4

IM DR232-01E

Page 31

2.3 Recording Functions

Chart Speed

The speed at which the chart moves when performing trend recording can be selected from any

value between 1 to 1500mm/h.

Two types of chart speeds can be set. When you are not using the Event/Action function, which

will be described later on in this manual, chart speed 1 will be valid. When the Event/Action

function is being used, you can select whether chart speed 1 will change to speed 2 according to

the event status.

Recording Mode

Two types of recording modes are available; analog trend and logging mode. The default setting

is analog trend mode.

Analog Trend Mode (refer to the next page for a recording example)

Trend Recording (Dot recording)

The recording principle is that, according to measurement data and recording conditions, the

correct position on the chart will be decided and on that position the dot will be printed. Trend

recording conditions consist of the following.

• chart speed

• channels to be recorded

• recording color (refer to page 2-8)

• recording interval (refer to page 2-8)

• recording span (refer to page 2-9)

• recording zone (refer to page 2-9)

• partially expanded recording (refer to page 2-10)

• interpolation function (refer to page 2-10)

2

Functions

Digital Printout

Measurement data will be printed as numerical values. Digital printout conditions consist of the

following.

• channels to be recorded

• recording interval (refer to page 2-8)

• the number of channels to be recorded on the same line (refer to page 2-7)

Logging Mode

In this mode measurement data are only printed as numerical values. Logging recording

conditions consist of the following.

• channels to be recorded

• the recording direction (vertical or horizontal)

• recording interval (refer to page 2-8)

IM DR232-01E

2-5

Page 32

2.3 Recording Functions

Recording Example

The numbers in parentheses refer to reference pages.

Trend recording (Page 2-5)

Reference point of scale

(Page 2-7)

Scaled value

(Page 2-9)

Alarm release mark

(Page 2-12)

Alarm occurrence mark

(Page 2-12)

Right margin

Reference position of

Chart speed

(Page 2-5)

Starting time

of dot

recording

(Page 2-7)

Ending time of

previons dot

recording

(Page 2-7)

dot recording start

(Page 2-7)

Channel No. or tag of

dot recording

2-6

Manual Printout

Starting date/time

(Page 2-12)

of manual printout

Channel No. or tag

of manual printout

Digital printout

(Page 2-5)

Message

(Page 2-12)

Titlle

(Page 2-12)

Chart speed

(Page 2-5)

Starting date/time

Header

(Page 2-12)

of Digital printout

IM DR232-01E

Left margin

Page 33

Recording Format

2.3 Recording Functions

You can modify the recording format of measurement values according to your own preferences.

The following selections are available.

Items common for Analog Trend and Logging mode

Printing Channel No. or Tag

When printing measurement values, the corresponding channel number or a preset tag can be

recorded with it. This selection will also affect the display the same way. The number of

characters of a tag which will be printed out, can be selected too.

2

Items for Analog Trend Mode

Printing Starting/Stopping Time of Recording

You can select whether to print the time of starting/stopping the recording (refer to page 2-9) on

the right side of the chart. The first time recording starts after the power has been turned ON, only

the starting time will be printed. After that, the current starting time will be printed together with

the stopping time of the previous recording. To the right of the starting time a bar will be printed

as a reference point to the time of starting.

Selecting the Number of Columns for Digital Printouts

You can select how many columns (where one column equals data of one channel) will be used in

one line for printing out measurement data.

Selection of the Pitch of Channel Printouts

You can select at which distance the channel numbers (or tags) will be printed. You can also

select this printout OFF. When tags have been selected, this distance applies to the tag printout.

Selection of the Pitch of Title Printouts

You can select at which distances the title will be repeatedly printed. You can also select this

printout OFF.

Selection of the Scaled Values Printout

You can select the printing pattern for scaled values (refer to page 2-9). You can also select this

printout OFF.

Selection of the Reference Point of Scaled Values

You can select whether or not to print a reference point for the positions of the scaled values.

Items for Logging Mode

Selection of the Recording Direction (Horizontal/Vertical)

You can select whether printouts will occur in horizontal or vertical direction,

Example of a printout in horizontal direction

Functions

IM DR232-01E

Example of a printout in vertical direction

2-7

Page 34

2.3 Recording Functions

Recording Colors

Recording Interval

In the trend recording the color of the recording can be selected per channel. The colors which can

be selected are black, purple, redish purple, navy blue, red, blue, brown, green, orange and

yellowish green.

The recording color of the numerical values in the logging mode is purple only.

The time during which one scan of trend recording or numerical printout is carried out is called

the recording interval.

Recording interval for trend recording

This recording interval can be selected from AUTO or FIX.

AUTO

The recording interval is decided automatically depending on the measurement (scan) interval

and chart speed in order prevent the dots from overlapping. However, in cases where this

calculation would render the recording interval smaller than the scan interval, the recording

interval will equal the scan interval.

Recording interval = Scan interval × N

where N is an integer satisfying N

fixed.

Example: when scan interval is 2s; chart speed is 100mm/h

then N ≤ 720 / (2 × 100) = 3.6

The closest matching integer is 3.

Accordingly, the recording interval becomes 2 × 3 = 6s.

≤ 720 / (scan interval × chart speed). 720 is

FIX

Recording is carried out at an interval which is the same as the scan interval (2 to 60s)

regardless of the chart speed.

Recording interval for digital printouts