Page 1

User’s

Manual

Dissolved Oxygen Metering System

Model DO30G

Dissolved Oxygen Sensor

IM 12J5B3-01E

IM 12J5B3-01E

4th Edition

Page 2

Introduction

The DO30G Dissolved Oxygen Sensor bases its principle of measurement on the galvanic-cell

method. The sensor is specically suited for continuous measurement of oxygen dissolved in

water.

Topics and information that need your special attention in handling the product are given in the

text of this manual along with cautionary notes, such as a warning or caution, depending on their

importance. Strictly observe these items from the standpoint of safety and prevention of equipment damage. For a notation, such as a warning also indicated on the product, there is an alert

mark in the manual.

1. Conrming the Specications

The standard specication DO30G dissolved oxygen sensor is used to build the dissolved oxy-

gen metering system.

The DO30G sensor cable has the prescribed length. The conguration of the crimp-on terminals

are either pin-type, M4 ring-type or fork-type.

Upon arrival of the purchased product, carefully unpack it and make sure the product is completely free from any damage that may have occurred during transport. Also check the model

code indicated on the nameplate attached to the sensor cable to make sure that you received the

correct sensor. For the meaning of the model code, refer to subsection 1.2.2 on page 1-3.

Note: The model and sufx code of the sensor with standard specications is as follows.

DO30G-NN-50-

- ( : User specied alphanumeric)

i

2. Information Covered by This Manual

This manual covers all of the information on handling the DO30G Dissolved Oxygen Sensor

(Style B), such as instructions on installation, inspection, and maintenance and service.

Note : When system components other than DO30G have to be mentioned, descriptions of the basic system assumes that the

DO402G Dissolved Oxygen Converter is used.

Refer to the instruction manual for information on the converter connecting holders with the

DO30G and how to connect sensor cables.

Note that the instruction manuals listed in the following table are for the associated equipment

used with the EXA

Manuals for Associated Equipment Used with the EXA DO Dissolved Oxygen Metering Syatem

Model Title of Manual Manual No.

DO402G Dissolved Oxygen Converter IM 12J05D02-01E

DO202

FLXA21 2-wire Liquid Analyzer IM 12A01A02-01E

DO30G Dissolvecl Oxygen Sensor IM 12J5B3-01E

PH8HG Guide Pipe IM 12B7M2-01E

PB350G Angled Floating Ball Holder IM 19H1E1-01E

DOX8HS Immersion Type Holder (Style B) IM 19H1D2-01E

PH8PU1 Cleaning Pump/Tank IM 19C1E1-01E

WTB10-DO

Note: Only the basic system of basic components are listed on the front panel.

Refer to respective instruction manual for information on recorders, annunciators and other instruments.

DO Dissolved Oxygen Metering System.

2-wire Dissolved Oxygen Transmitter

Relay Terminal Box IM 12J05W02-01E

IM 12J05C01-01E

Media No. IM 12J5B3-01E (CD) 4th Edition:Apr.2011 (YK)

All Rights Reserved Copyright © 1996, Yokogawa Electric Corporation

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 3

u For the safe use of this equipment

CAUTION

WARNING

IMPORTANT

(1) About This Manual

• This manual should be passed on the end user.

• The contents of this manual are subject to change without prior notice.

• The contents of this manual shall not be reproduced or copied, in part or in whole, without

permission.

• This manual explains the functions contained in this product, but does not warrant that they

are suitable for the particular purpose of the user.

• Every effort has been made to ensure accuracy in the preparation of this manual. However,

when you realize mistaken expressions or omissions, please contact the nearest Yokogawa

representative or sales ofce.

• This manual does not cover the special specications. This manual may be left unchanged

on any change of specication, construction or parts when the change does not affect the

functions or performance of the product.

• If the product is not used in a manner specied in this manual, the safety of this product may

be impaired.

(2) SafetyandModicationPrecautions

ii

• Follow the safety precautions in this manual when using the product to ensure protection

and safety of the human body, the product and the system containing the product.

(3) The following safety symbols are used on the product as well as in this manual.

The following safety symbols are used in this manual.

Identies instructions that must be observed in order to avoid physical injury and electric

shock or death of the operator.

Identies instructions that must be observed in order to prevent the software or hardware

from being damaged or the system from becoming faulty.

Identies important information required to understand operations or functions.

TIP

SEE

ALSO

Identies additional information.

Identies a source to be referred to.

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 4

u After-sales Warranty

l Do not modify the product.

l

During the warranty period, for repair under warranty carry or send the product to the local

sales representative or service ofce. Yokogawa will replace or repair any damaged parts and

return the product to you.

l

Before returning a product for repair under warranty, provide us with the model name and serial

number and a description of the problem. Any diagrams or data explaining the problem would

also be appreciated.

l If we replace the product with a new one, we won't provide you with a repair report.

l

Yokogawa warrants the product for the period stated in the pre-purchase quotation. Yokogawa

shall conduct dened warranty service based on its standard. When the customer site is

located outside of the service area, a fee for dispatching the maintenance engineer will be

charged to the customer.

l

In the following cases, customer will be charged repair fee regardless of warranty period.

• Failure of components which are out of scope of warranty stated in instruction manual.

• Failure caused by usage of software, hardware or auxiliary equipment, which Yokogawa did

not supply.

iii

• Failure due to improper or insufcient maintenance by user.

• Failure due to abuse, misuse or modication which Yokogawa does not authorize.

• Failure due to power supply (voltage, frequency) being outside specications or abnormal.

• Failure caused by any usage out of scope of recommended usage.

• Any damage from re, earthquake, storms and oods, lightning, disturbances, riots, warfare,

radiation and other natural changes.

l

Yokogawa does not warrant conformance with the specic application at the user site.

Yokogawa will not bear direct/indirect responsibility for damage due to a specic application.

l

Yokogawa will not bear responsibility when user congures the product into systems or resells

the product.

l

Maintenance service and supplying repair parts will be covered for ve years after the

production ends. For repair for this product, please contact the nearest sales ofce described

in this instruction manual.

IM 12J5B3-01E 4th Edition : Apr 05,2011

Page 5

Blank Page

Page 6

Dissolved Oxygen Metering System

Model DO30G

Dissolved Oxygen Sensor

IM12J5B3-01E4thEdition

CONTENTS

Introduction ..............................................................................................................i

u For the safe use of this equipment

u After-sales Warranty

.........................................................................................iii

...................................................................ii

1. General ...................................................................................................... 1-1

1.1 Features ............................................................................................................1-1

1.2 Specications

1.2.1 Standard Specications .....................................................................1-2

1.2.2 Model and Sufx Codes .....................................................................1-3

1.2.3 External View and Dimensions ..........................................................1-4

....................................................................................................1-2

2. Components and Their Functions .......................................................... 2-1

3. Installing the Sensor and Connecting the Cable .................................. 3-1

3.1 PreparingforInstallation ................................................................................. 3-1

3.1.1 Removal of Parts for Transportation and Storage ............................ 3-1

3.1.2 Inspecting the Permeable Membrane ...............................................3-1

3.2 Installation .........................................................................................................3-2

3.2.1 Selecting the Measurement Point ...................................................... 3-2

3.2.2 Selecting the Sensor Holder ..............................................................3-2

3.2.3 Asembling the Sensor in the Holder ..................................................3-4

3.3 Connecting the Sensor Cable ..........................................................................3-4

4. Maintenance .............................................................................................. 4-1

4.1 Routine Inspection ............................................................................................4-1

4.1.1 Inspecting the Permeable Membrane (Degree of Contamination) ...4-1

4.1.2 Checking of Membrane Assembly Locknut .......................................4-1

4.2 Inspection If Failure Occurs .............................................................................4-2

4.2.1 Inspecting the Permeable-membrane Assembly (for Damage) ........4-2

4.2.2 Checking of RTD in the Sensor ......................................................... 4-4

4.2.3 Judgment of Lead Electrode Fault ..................................................... 4-4

4.3 Expendables,SparePartsandMaintenanceParts ....................................... 4-4

4.3.1 DOX8A Maintenance Parts (Expendables) Kit ..................................4-4

4.3.2 Parts That Should Be Kept on Hand .................................................. 4-5

Appendix1"HowtoRemovetheDO30GMembraneProtectiveCap" ................................... A-1

CustomerMaintenancePartsList(DO30G) ...................................................................CMPL12J5B3-01E

CustomerMaintenancePartsList(DOX8A) ..............................................................CMPL12J05B03-12E

Revision Record ............................................................................................................................................... i

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 7

Blank Page

Page 8

<1. General>

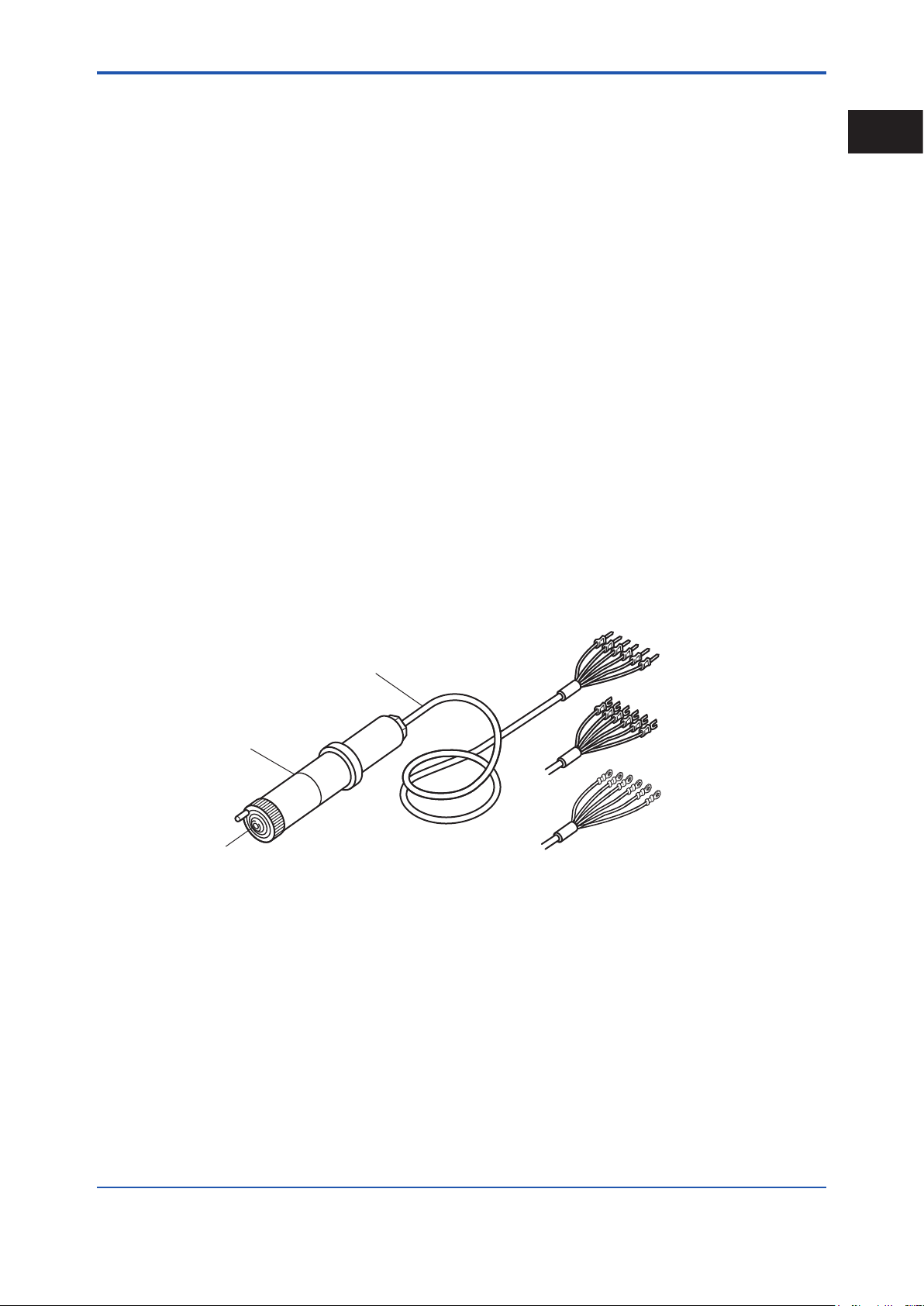

F01.ai

Sensor cable

Sensor unit

Permeable-membrane

assembly

Pin-type crimping

terminals

Fork-type crimping

terminals

M4 ring-type crimping

terminals

1. General

1-1

1

1.1 Features

• The sensor maintains stable characteristics over a prolonged period.

It stabilizes in a initial time for electrolysis of approximately a half a day.

The sensor has a structure less susceptible to the effects of deterioration in an electrolyte or

contamination of the permeable membrane. Consequently, you can make precise measurements in a variety of processes.

• You can choose the desired measurement point according to the nature of the solution being measured.

You can submerse the DO30G Dissolved Oxygen Sensor to a depth of 3 m and then put it in

regular use (the sensor can withstand a pressure of up to 100 kPa). The sensor can be assembled into a immersion type holder or a oating ball holder. The sensor, when assembled

in the immersion type holder, allows automatic cleaning of the sensor with jet-sprayed water

or air at regular intervals.

• The sensor is easy to service and very economical.

Dissolved oxygen sensors usually deteriorate with time and ultimately come to the end of

their service life. For the DO30G Dissolved Oxygen Sensor, only those parts whose service

lives are relatively short, such as the membrane, may be replaced. Thus, running costs can

be reduced. In addition, servicing and maintaining the sensor requires no special skills and

is done quickly.

2

3

4

Figure 1.1 External View of the DO30G Dissolved Oxygen Sensor

Note: The crimping terminals used on the sensor cables are either pin-type, M4 ring-type or fork-type depending on specications.

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 9

<1. General>

1-2

IM 12J5B3-01E

1.2 Specications

1.2.1 StandardSpecications

Object of Measurement: Concentration of oxygen dissolved in solution (water)

Principle of Measurement: Galvanic-cell method

Measurement Range: 0 to 20 ppm, 0 to 20 mg/l, or 0 to 100% (saturation)

Note: The measurement range must be entered through the dissolved oxygen converter.

Resistance Temperture Detector (RTD) :

Pt 1000

Construction: Sensor unit : Rigid PVC, SUS304

O-ring: Nitrile rubber

Permeable membrane: Fluoro-resin [FEP]

Cable shielding : Heat-resistant exible PVC

Outlet of cable : Polycarbonate resin

Sensor Cable: Length : 3 m, 5 m, 10 m, 15 m, or 20 m

(specied when ordering)

Crimping terminal conguration : Pin-type, M4 Ring-type or

Fork-type (specied when ordering )

Weight: Approx. 0.3 kg + 0.12 × N kg N: cable length

(e.g. for cable length of 5 m, approx. 0.9 kg)

Temperature of Solution Under Measurement (SUM) :

max. 0 to 40 °C

Flow rate of SUM: No less than 20 cm/s (recommended to prevent the sensor

from trapping bubbles that are the source of error in

measurements)

Pressure of SUM: Narmally : 0 to 30 kPa

Maximum applicable : 100 kPa

[Characteristics]

Repeatability:

Temperature Compensation Error:

Within ±3% FS

(including sensor) for a ±5 °C change in the range of 0 to 40 °C

Response Time : Within 2 minutes (90% response)

(including sensor)

0.1 mg/l or 3% FS, whichever is greater (including sensor)

4th Edition : Apr 05,2011

Page 10

<1. General>

Model

DO30G

DO sensor

–

Always -NN

-NN

Membrane

thickness

50 Mm

-50

Cable terminal

Cable length

3m

5m

10m

15m

20m

-03

-05

-10

-15

-20

Option

Code

Suffix Code Description

Pin terminal *1

Fork terminal

M4 ring terminal *2

*1 Select pin terminal for DO402G, DO202, and FLXA21.

When terminal box is used, select WTB10-DO3.

*2 Used to connection to FLXA21.

When terminal box is used, select WTB10-DO4.

-PN

-FK

-FL

Model

DOX8A

Parts set for

maintenance

(for membrane

thickness of 50 µm)

Sensor

For membrane

replacing type sensor

-M

–

Style B

*

B

Option

Code

Suffix Code

Description

Model

DOX8W

Calibration set

Option

Code

Suffix Code Description

*

A

1.2.2 ModelandSufxCodes

1-3

• DO Sensor

•DOX8APartsSetforMaintenance

1

2

3

4

A set of zero-adjusting reagent and maintenance parts

<Contents>

Zero adjusting reagent (sodium sulte 500 g) ... 1 bottle

Membrane assembly

(for membrane thickness of 50 μm) .................3 sets

Electrolyte for sensor (50 ml) ............................. 1 bottle

Syringe for replacing electrolyte .................................. 1

Polish for silver electrode (30 g) ........................ 1 bottle

Polyethylene beaker (200 ml) ...................................... 1

•DOX8WCalibrationSet(optional)

This is necessary if the span calibration is to be done using a saturated dissolved oxygen solution. It is not necessary for air calibration.

<Contents>

Air pump, stirrer, stirring element, bubbler, clamp, beaker, and thermometer.

Note: The calibration set can be used in common regardless of the type of holder.

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 11

<1. General>

ø26

ø30

ø36

ø6.5

Approx.

80

L

38.5

46

10

108

• Dissolved-oxygen sensor with

pin terminals

13

11 12 14 15 16

Model and Suffix Codes

DO30G - NN - 50 - 03 - PN

DO30G - NN - 50 - 05 - PN

DO30G - NN - 50 - 10 - PN

DO30G - NN - 50 - 15 - PN

DO30G - NN - 50 - 20 - PN

L

3 000

5 000

10 000

15 000

20 000

Weight (kg)

Approx. 0.6

Approx. 0.8

Approx. 1.4

Approx. 2.0

Approx. 2.6

• Dissolved-oxygen sensor with

fork terminals

• Dissolved-oxygen sensor with

ring terminals

Model and Suffix Codes

DO30G - NN - 50 - 03 - FK

DO30G - NN - 50 - 05 - FK

DO30G - NN - 50 - 10 - FK

DO30G - NN - 50 - 15 - FK

DO30G - NN - 50 - 20 - FK

L

3 000

5 000

10 000

15 000

20 000

Weight (kg)

Approx. 0.6

Approx. 0.8

Approx. 1.4

Approx. 2.0

Approx. 2.6

L

3 000

5 000

10 000

15 000

20 000

Weight (kg)

Approx. 0.6

Approx. 0.8

Approx. 1.4

Approx. 2.0

Approx. 2.6

Unit: mm

Pin terminals

Fork terminals

Ring terminals

Terminal asign

13 IE

15 RE

11 T1

12 T2

14 Shield

16 Liquid earth

Model and Suffix Codes

DO30G - NN - 50 - 03 - FL

DO30G - NN - 50 - 05 - FL

DO30G - NN - 50 - 10 - FL

DO30G - NN - 50 - 15 - FL

DO30G - NN - 50 - 20 - FL

13111214 15 16

13111214 15 16

1.2.3 External View and Dimensions

1-4

Note: Select pin terminasl for systems using the DO402G/FLXA21 dissolved oxygen converter.

When using with FLXA21, M4 ring terminals is recommended.

Figure 1.2 External View and Dimensions of DO30G Dissolved Oxygen Sensor

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 12

<2. Components and Their Functions>

Sensor cable

Carries the detected signal to

the dissolved oxygen converter.

The desired cable length can be

chosen from 3, 5, 10, 15, or 20m.

You can choose either pin-type, M4

ring-type or fork-type terminals.

Permeable-membrane

assembly locknut

Sensor unit

Generates both an electrolytic current signal

proportional to the amount of oxygen that

passes through the permeable membrane

and a temperature signal for compensation.

O-ring

Lead electrode

Permeable-membrane assembly

Silver electrode

Temperature Detector

Cutaway View of the Sensor Tip

F03.ai

CAUTION

2. Components and Their Functions

2-1

1

2

3

4

Figure 2.1 Components and Their Functions of DO30G Dissolved Oxygen Sensor

Do not loosen the permeable-membrane assembly locknut except when replacing the assembly.

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 13

Blank Page

Page 14

<3. Installing the Sensor and Connecting the Cable>

Permeable-membrane assembly locknut

Make sure the locknut is not loose.

Permeable membrane

Make sure the membrane is free

from any wrinkling or damage.

F04.ai

3. Installing the Sensor and

Connecting the Cable

3-1

1

2

3.1 PreparingforInstallation

3.1.1 RemovalofPartsforTransportationandStorage

A cap to prevent the membrane from being damaged when transporting the sensor is mounted at

the tip of the DO30G Dissolved Oxygen Sensor. When installing the sensor, remove this protec-

tive cap (See Appendix 1.).

3.1.2 InspectingthePermeableMembrane

Any wrinkling or damage to the permeable membrane may lead to a failure to take normal measurements. Make sure the membrane is free from any wrinkling or damage.

Also check that the membrane assembly locknut is not loose. If any wrinkling or damage is found,

replace the membrane assembly with a new assembly unless such damage is slight.

3

4

Figure3.1 InspectionofPermeable-membraneAssembly

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 15

<3. Installing the Sensor and Connecting the Cable>

3-2

IM 12J5B3-01E

Stopper

Guide pipe

Dissolved oxygen sensor

Sensor cable

Mounting pipe

(Outer diameter of 60.5 mm)

F05.ai

3.2 Installation

Normally, the DO30G Dissolved Oxygen Sensor is assembled into the PH8HG Guide Pipe,

PB350G Angled Floating Ball Holder or DOX8HS Immersion Type Holder and submersed to the

point best suited to obtain precise measurement results. This section explains how to select the

measurement point and sensor holder.

3.2.1 SelectingtheMeasurementPoint

Normally, a location that meets the following requirements may be selected as the measurement

point.

l The measured value is representative among the values available for the solu-

tion under measurement (SUM).

Avoid choosing a location where the solution is unevenly distributed, since heavy hunting may

result in the measured value. Also, avoid locations where bubbles occur frequently.

l Thetemperatureandowratecomplywiththeoperatingconditionsrequired

of the sensor and holder.

Note that, if a measured solution running at a high ow rate contains particles of sand, the permeable membrane of the sensor may be damaged.

Do not install the sensor at a depth greater than 3 m.

3.2.2 Selecting the Sensor Holder

Each holder or tting where the DO30G Dissolved Oxygen Sensor is assembled has the following characteristics.

Choose a holder that suits the liquid to be measured and the measurement location.

[PH8HGGuidePipe]

The holder is made of PVC resin and is 2 m long. The sensor is suspended down inside the cylindrical barrel of the holder. This pipe is conveniently suited for the measurement of a solution free

from bubbles or pollutants.

Figure3.2 SuspensionofDissolvedOxygenSensorUsingPH8HGGuidePipe

4th Edition : Apr 05,2011

Page 16

<3. Installing the Sensor and Connecting the Cable>

Arm assembly

Sensor cable

Float

Mounting bracket

Fix the bracket to a nominal 50 A

pipe (OD of 60.5 mm) or a

horizontal surface (floor, the

edge of a solution tank, etc.).

F06.ai

Cleaning-utility pipe

Sensor cable

Dissolved oxygen sensor

Jet cleaner

F07.ai

[PB350GAngledFloatingBallHolder]

3-3

The tting is designed to contain the sensor in a sphere that oats on a liquid. This tting is immune to large variations in the liquid level. Since the wet part is smooth and less susceptible to

catching ocs, the sensor does not trap rubbish that mixes in with the SUM (Related description: See Subsection 3.2.3). The oat is supported by an arm and does not move away from the

measurement point even if the SUM is owing.

When using this holder the membrane damage detector function in the converter can be activated.

Figure3.3 SuspensionofDissolvedOxygenSensorUsingPB350GAngledFloatingBallHolder

1

2

3

4

[DOX8HS(StyleB)ImmersionTypeHolder]

The holder holds the sensor at an angle of 45°. Consequently, bubbles will not stick to the permeable membranne. Any pollutants in the SUM can be automatically cleaned off at regular intervals

using a jet-spray water (air) cleaner.

Figure3.4 SuspensionofDissolvedOxygenSensorUsingDOX8HSImmersionTypeHolder

(withJetCleaner)

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 17

<3. Installing the Sensor and Connecting the Cable>

CAUTION

Stopper

F07-1.ai

F08.ai

IE T1 T2 SE RE S

131721 11 12 14 15 16

13 11 12 14 15 16

(*1)

Dissolved oxygen

converter terminals for

connection to sensor

cable

Sensor cable

Jumper

*1: Liquid earth to detect membrane failure.

This function is available when using

PB350G/PB360G float type holder.

Connect only when using this function.

3.2.3 Asembling the Sensor in the Holder

For details on how to assmble the sensor in the holder or tting, see the appropriate instruction

manual for each holder or tting.

Exercise care not to contaminate or wet the tip of the sensor cable when assembling the sensor.

If you will not begin wiring the sensor cable immediately, take the protective measures necessary

to prevent the assembly from being damaged.

SensormountinginthecasewhereocsandothermatterarecontainedintheSUM

3-4

The stopper projecting from the membrane assembly locknut serves to prevent the membrane

from being in contact with the ground and thus being damaged. If there are ocs in the SUM, the

stopper may become clogged. Thus, assemble the sensor to the holder so that the stopper is

positioned downstream in the SUM.

3.3 Connecting the Sensor Cable

The cable of the dissolved oxygen sensor must be connected to the terminals of the dissolved

oxygen converter. For information on connections, refer to the following instruction manu-

als: DO402G Dissolved Oxygen Converter (IM 12J05D02-01E), the DO202/FLXA21 2-wire

Transmitter instruction manual (IM 12J05C01-01E/IM 12A01A02-01E) or WTB10-DO

Terminal Box (IM 12J05W02-01E).

Relay

Figure3.5 ConnectionofSensorCable

Now the explanation on the installation and wiring is completed. For details on operation during

startup or for regular operation after the entire measuring system is brought into operation, refer

to the DO402G Dissolved Oxygen Converter instruction manual (IM 12J05D02-01E), the DO202/

FLXA21 2-wire Transmitter instruction manual (IM 12J05C01-01E/IM 12A01A02-01E). The main-

tenance and service of the dissolved oxygen sensor is explained in Section 4 that follows.

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 18

<4. Maintenance>

CAUTION

4. Maintenance

This section describes the inspection and maintenance procedure applicable to just the dissolved oxygen sensor alone. For comprehensive inspection and tuning of the measuring system, such as calibration, see the DO402G Dissolved Oxygen Converter instruction manual (IM

12J05D02-01E), the DO202/FLXA21 2-wire Transmitter instruction manual (IM 12J05C01-01E/

IM 12A01A02-01E).

4-1

1

2

3

4.1 Routine Inspection

4.1.1 InspectingthePermeableMembrane(Degreeof

Contamination)

An inspection (visual) of the permeable membrane must be made whenever the sensor is calibrated. Any dirt on the membrane will adversely affect your measurements. If the dirt is spread

over the membrane, dip the membrane into clean water and gently wipe the dirt off with a soft

cloth or lint-free paper. If the dirt will not come off easily, apply a neutral detergent to the membrane so it will be easier to remove the dirt. Clean the membrane with clean water. Finally, make

sure the permeable-membrane assembly locknut is not loose.

Exercise care to avoid wrinkling or damaging the permeable membrane during inspection.

Wrinkling and other damage prevent normal membrane operation.

4.1.2 CheckingofMembraneAssemblyLocknut

At every calibration, check that the membrane assembly locknut is not loose. If it is, retighten it.

In addition, if a phenomenon which is considered to be due to a change in the electrolyte qual-

ity (e.g., showing extremely low measured values) is observed after the locknut is retightened,

replace the electrolyte according to the directions in Subsection 4.2.1.

4

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 19

<4. Maintenance>

4-2

IM 12J5B3-01E

CAUTION

4.2 Inspection If Failure Occurs

If the electrolyte and/or lead electrode within the sensor unit deteriorates and ultimately completes its service life, anomalies, such as the failure to make a span adjustment, will occur. This

section deals especially with the inspection and service of the dissolved oxygen sensor needed if

any anomaly is found in a detected signal. If you fail to pinpoint the cause of failure to a particular

location, follow the instructions in Section 4.2.1 and subsequent sections in sequence. One or

more of the following measures are necessary to remedy the failure.

• Replacement of electrolyte/permeable-membrane assembly

• Replacement of sensor unit

4.2.1 InspectingthePermeable-membraneAssembly(for

Damage)

Note : When the membrane is used in the oat holder, the converter membrane damage detector function can be used. This function

generates an "E4" error message if the membrane is damaged.

Check the permeable-membrane assembly for possible wrinkling or damage. Also, check that

the permeable-membrane assembly locknut is not loose. If the locknut is securely tightened and

the membrane is normal (no wrinkling or damage is found), proceed to the instruction procedure

in Section 4.2.2. If the locknut is loosen or the membrane is wrinkled or damaged, replace the

electrolyte and the permeable-membrane assembly (including the O-ring seal) as well.

[Electrolyte/permeable-membraneassemblyreplacementprocedure]

When replacing the electrolyte and permeable-membrane assembly, you must provide a syringe

and beaker that are used to replace the electrolyte and an abrasive and gauze to polish the silver

electrodes. Provide these materials along with the spare electrolyte solution and assembly used

in the replacement.

PrecautionsinHandlingtheElectrolyte

The potassium-hydroxide electrolyte (KOH) is a highly alkaline solution containing potassium

hydroxide as the major constituent. Exercise extreme care to protect your body from contact

with the solution and to prevent the solution from getting into your eyes. Should your skin or eyes

become exposed to the solution, immediately wash the exposed area with clean water. If the

solution gets in your eyes, consult an eye doctor after ushing them with water. The electrolyte

is a colorless corrosive and, therefore, there is the risk of its being mishandled. Never leave any

residual solution in the syringe.

(1) After having removed the dissolved oxygen sensor from the holder, clean dirt off the wet

part.

(2) Loosen the locknut and remove the permeable-membrane assembly. Also, remove the O-

ring.

4th Edition : Apr 05,2011

Page 20

<4. Maintenance>

Sensor unit

Place a beaker

underneath to catch the

draining electrolyte.

Silver electrode

Syringe

Inlet for refilling electrolyte

Needle (syringe needle)

Insert the syringe needle into

the inlet for refilling electrolyte

and force air inside.

F09.ai

Surface of the silver electrode

Apply a drop of electrolyte when

installing the permeable-membrane

assembly.

Fill with electrolyte

and then remove

approximately 1 ml.

Syringe

Inlet for injecting electrolyte

O-ring

F10.ai

(3) Completely drain the electrolyte within the sensor unit. Tilt the sensor tip downward and then

use the syringe to force air into the inlet for relling the electrolyte. Position the beaker so it

will catch any of the electrolyte that drains through the gaps around the silver electrode.

Figure 4.1 Draining the Electrolyte

(4) Hold the sensor level and polish the silver electrode.

Apply an abrasive (alumina) to wet gauze and polish the surface of the silver electrode until

it becomes glossy. After nishing polishing, completely wipe off any abrasive that remains

on the electrode.

4-3

1

2

3

4

(5) Make sure the sealed surfaces are free from dust. Install a new O-ring.

(6) Inject 8 ml of electrolyte into the sensor body with the syringe (see Figure 4.2).

Note: Always use an electrolyte prepared by Yokogawa for exclusive use with the DO30G.

First, ll the sensor with the electrolyte (approx. 9 ml) and then remove approximately 1 ml

so that a layer of air is present inside the sensor body.

(7) Install the permeable-membrane assembly.

It is strictly not possible to allow a layer of air to form between the membrane and the sil-

ver electrode. To prevent such a layer from forming, rst apply a drop of electrolyte to the

surface of the silver electrode. Lightly press the permeable-membrane assembly so that the

O-ring touches the groove on the inside. Tighten the locknut fully without letting the assembly turn.

Figure 4.2 Injecting the Electrolyte

All these steps complete the inspection procedure for the permeable-membrane assembly. By

way of precaution, make sure the membrane is free from wrinkling. Note that a stable detection

signal is not possible right after relling with the electrolyte. Make a zero or span adjustment approximately a half a day or longer after relling. It may indicate a minus value for about 10 min-

utes zero adjustment.

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 21

<4. Maintenance>

4-4

IM 12J5B3-01E

4.2.2 Checking of RTD in the Sensor

The resistance temperature detector (RTD) incorporated in the DO30G sensor is a Pt 1000 Ω

RTD. This Pt 1000 Ω RTD indicates a resistance value of about 1097 Ω at 25 °C. Check the RTD

by measuring the resistance value between conductors 11 (T1) and 12 (T2). If the resistance

value differs greatly from the above value, the sensor must be replaced.

4.2.3 JudgmentofLeadElectrodeFault

If no failure is found in the checks in Subsections 4.2.1 and 4.2.2, the cause of the problem may

be the end of the service life of the lead electrode or a loose connection of the conductors. In

either case, the sensor must be replaced.

[ServiceLifeofLeadElectrode]

The lead electrode mounted in the sensor body gradually erodes due to battery action. When

span adjustment becomes impossible for a sensor which has been used in succession over a

long period even if the electrolyte/membrane assembly has been replaced, it shows that the lead

electrode has reached the end of its service life. The service life of the lead electrode varies with

the temperature of the SUM or the amount of dissolved oxygen. Under general operating conditions, it should be approximately three to four years.

4.3 Expendables,SparePartsand

MaintenanceParts

This section presents the general information on spare parts that the manufacturer recommends

you to provide and on materials that are used in maintenance and service. When procuring these

parts or materials, also refer to the Customer Maintenance Parts List (CMPL) at the end of this

manual.

4.3.1 DOX8AMaintenanceParts(Expendables)Kit

The DOX8A Maintenance Parts Kit contains, as a set, spare parts for the expendables that need

to be replaced within one year after the start of use of the DO30G Dissolved Oxygen Sensor, the

materials that are used during replacement, and a reagent that is used to prepare the calibration

solution for zero adjustment.

Note: There are two different DOX8A Maintenance Parts Kit available: style A and style B.

Be sure to use a style B membrane assembly (membrane thickness: 50 μm) for a EXA DO dissolved oxygen metering system.

4th Edition : Apr 05,2011

Page 22

<4. Maintenance>

Table4.1ItemsContainedintheDOX8AMaintenancePartsKit

4-5

Item PartNo. Qty Remarks

Electrolyte K9171DN 50 ml

Permeable-membrane

assembly / O-ring

Reagent for preparing calibration solution (for zero adjust-

ment)

sodium sulte (Na

5-ml syringe (without needle)

Needle

200-ml beaker L9825AF 1

Abrasive for silver electrode

(alumina)

2SO3

)

K9171HM

L9920BR

L9827NH

L9827NG11

K9088PE

3 sets

500 g

30 g

Must be replaced periodically, either once every 6 to 8

months or if a span adjustment is not possible. Eight to 9

ml are consumed with each replacement.

Normally, these parts must be replaced at the same time

that the sensor is relled with electrolyte. If the sensor is used in a slurry solution, these parts may require

replacement more often due to abrasion or damage.

Calibration must be carried out at a predetermined

interval (the frequency of calibration varies depending

on the operating conditions). Calibration must also be

performed when, for example, the electrolyte is replaced.

Approximately 15 grams of the reagent is needed to prepare 1 liter of the calibration solution for zero adjustment.

Used when replacing the electrolyte.

Used when calibration is carried out or when the electrolyte is replaced.

When the permeable-membrane assembly is replaced,

the silver electrode must be polished until it becomes

glossy. Only an extremely marginal amount (approx. 0.5

mg) of the abrasive is consumed with each polishing.

4.3.2 PartsThatShouldBeKeptonHand

1

2

3

4

Even parts with a long service life are not completely free from possible failure. It is recommended that users have on hand spare parts for those parts which, if they become defective, will make

it impossible to continue measurement.

[MembraneAssemblyLocknut(partnumber:K9171CH)]

It is recommended that users have spare parts for the locknut on hand in preparation for possible

failure.

[SpareSensorAssembly]

If the sensor assembly remains unused over a prolonged period, the electrolyte may change in

quality or some anomalies may occur in the permeable membrane. Consequently, these materials must be replaced with new ones before you can use the sensor. Although it is desirable

that users always try to avoid storing the sensor assembly for long periods, the manufacturer

recommends that users keep a spare part on hand for the sensor assembly in anticipation of an

unexpected failure. Do not store the sensor with the electrolyte removed. Otherwise, any residual

electrolyte may become concentrated, harming the lead electrode or other mechanisms. If the

sensor must be stored with the electrolyte removed, completely clean the inside of the sensor

with clean water (repeat injecting and draining the water several times) before it is stored.

Note: If the sensor is stored without the electrolyte, repeat injecting and draining the electrolyte several times before you reuse it.

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 23

Blank Page

Page 24

<Appendix 1.>

CAUTION

Prohibited action 1

No good

No good

Prohibited action 2

DO30G

Protective cap

A-1

Appendix 1. How to Remove the DO30G Membrane Protective

Cap

A black rubber cap is attached to the tip of the DO30G to protect the membrane.

Pulling off the cap forcefully causes a negative pressure inside the protective cap, because the

protective cap sticks to the DO30G, and may stretch the membrane or damage it.

Furthermore, removing the cap by twisting it may loosen the membrane assembly and affect the

measurement results.

Please read the following notes and removal procedure in advance in order to prevent damage

and loosening of the membrane assembly from occurring.

1. Prohibited actions

2. How to Remove Protective Cap

Figure 1 Do not pull off the cap forcefully

When taking out of the package, a black rubber cap is attached the DO30G shown below.

Figure 3 Condition after taking out of the package

Figure 2 Do not pull off the cap twisting the cap

counterclockwise.

IM 12J5B3-01E

3rd Edition : May 28,2010

Page 25

<Appendix 1.>

Protective

cap

Stick or the like

with a diameter of

0.1 to 0.2 mm

Push it beneath the protective cap

and up to the tip of the sensor.

DO30G tip

Protective cap

Maintain the space.

Turn it clockwise slowly.

A-2

When using a stick or the like.

(1) As shown in the gure 4, insert a

stick or the like between the DO30G

and protective cap. Be careful not to

damage the DO30G main body.

Figure 4 Insert a stick or the like between the

DO30G

(2) Push it in so that enough air space

is created between the DO30G and

protective cap.

When an appropriate stick or the

like is not available.

(1) Hold the protective cap while holding the

DO30G as shown in the gure 7.

Figure 7 Hold the DO30G and protective cap.

(2) Remove the protective cap by turning it

clockwise slowly.

Figure 5 Push a stick or the like beneath the

protective cap to create air space.

Figure 6 Pull off the protective cap while

maintaining the air space.

Figure 8 Remove the protective cap by turning it

clockwise slowly

IM 12J5B3-01E

3rd Edition : May 28,2010

Page 26

Customer

2

3

1

Dissolved Oxygen Metering System

Maintenance

PartsList

DO30G

Dissolved Oxygen Sensor

Item Part No. Qty Description

1 — 1 Dissolved oxygen sensor

2 K9171CH 1 Box nut assembly

3 K9171HM 1 Membrane / O-ring

Model SufxCode Option Code Description

DO30G

— -NN

Membrane thickness -50

Cable length

Cable terminal

…………………… ……………………

……………………

……………………

03

-

-05

-10

-15

-20

……………………

……………………

……………………

……………………

……………………

……………………

-PN

……………………

-FK

……………………

-FL

Dissolved oxygen sensor

Always - NN

50 µm

3 m

5 m

10 m

15 m

20 m

Pin terminal

Fork terminal

M4 ring terminal

(Refer to table of below "Model & Code")

All Rights Reserved, Copyright © 1996, Yokogawa Electric Corporation.

Subject to change without notice.

CMPL12J5B3-01E

3rd Edition : Oct,2010

Page 27

Customer

1

2

3

4

78

9

65

10

200

150

100

50

Item Part No. Qty Description

1 L9825AF 1 200 ml Beaker

2 L9920BR 1 Reagent (for zero calibration)

3 K9088PE 1 Polishing Powder

4 K9171HK 1 Spare Parts & Service Tool

5 K9171DN 1 Electrolyte

6 K9171HM 3 Membrane / O-Ring Set

7 G9303NM 1 O-Ring

8 K9171CS 1 Membrane Assembly (50 mm)

9 L9827NG 1 Needle

10 L9827NH 1 5 ml Sylinge

Maintenance

Parts List

Model DOX8A-M*B

Accessory for EXA DO

All Rights Reserved, Copyright © 1996, Yokogawa Electric Corporation.

Subject to change without notice.

CMPL 12J05B03-12E

2nd Edition : Feb. 2006 (YK)

Page 28

Revision Record

l Title : Model DO30G Dissolved Oxygen Sensor

l Manual No. : IM 12J5B3-01E

Edition Date Remark(s)

1st Nov. 1996 Newly published

2nd May 2007 Fully revised

3rd Mar. 2010 MS-code of DOX8A, DOX8W added to Section 1.2.2.

CMPL 12J05B03-12E(2) added for DOX8A.

4th Apr. 2011 Over all revised.

P. i, FLXA21 and DO202 manual no. added to documnents to

be refered.

P. 1-1, Stabilized time in a initial time for electrolysis modied.

M4 ring terminal added to Figure 1.1.

P. 1-2, M4 ring-type terminal added to specications.

P. 1-3, FLXA21 added to MS-code.

P. 1-4, M4 ring terminal added to Figure 1.2.

P. 2-1, M4 ring terminal added to Figure 2.1.

P. 3-1, Addition of Appendix 1 to be refered for section

3.1.1 "Removal of Parts for Transportation and

Storage."

P. 3-4, FLXA21 and DO202 manual no. added to section 3.3

"Connecting the Sensor Cable."

P. 4-1, FLXA21 and DO202 manual no. added to section 4

"Maintenance."

P. 4-3, Stabilized time in a initial time for electrolysis modied.

Appendix 1 "H ow to R emo ve the DO30G Mem bra ne

Protective Cap" added to end of this manual.

CMPL 12J5B3-01E revised to 3rd edition (M4 ring terminal

added)..

i

IM 12J5B3-01E

4th Edition : Apr 05,2011

Page 29

Blank Page

Loading...

Loading...