Page 1

User’s

Manual

Model DM8

Vibration Type Density Meter

IM 12T03A01-02E

R

IM 12T03A01-02E

3rd Edition

Page 2

Blank Page

Page 3

INTRODUCTION

This manual describes the specifi cations, installation, operation, maintenance, and trouble-

shooting for the Model DM8 Vibration Type Density Meter. To use this manual correctly, read

this manual thoroughly.

For the Model VD6SM Sampling System, refer to IM 12T3S1-01E.

<INTRODUCTION>

i

Media No. IM 12T03A01-02E 3rd Edition : Jun. 2012 (YK)

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation

IM 12T03A01-02E

Page 4

ii

<INTRODUCTION>

For the safe use of this equipment

Safety, Protection, and Modifi

• In order to protect the system controlled by the product and the product itself and ensure safe

operation, observe the safety precautions described in this user’s manual. We assume no liability

for safety if users fail to observe these instructions when operating the product.

• If this instrument is used in a manner not specifi ed in this user’s manual, the protection provided

by this instrument may be impaired.

• Be sure to use the spare parts approved by Yokogawa Electric Corporation (hereafter simply

referred to as YOKOGAWA) when replacing parts or consumables.

• Modifi cation of the product is strictly prohibited.

• The following symbols are used in the product and user’s manual to indicate that there are

precautions for safety:

Notes on Handling User’s Manuals

• Please hand over the user’s manuals to your end users so that they can keep the user’s manuals

on hand for convenient reference.

• Please read the information thoroughly before using the product.

• The purpose of these user’s manuals is not to warrant that the product is well suited to any

particular purpose but rather to describe the functional details of the product.

cation of the Product

• No part of the user’s manuals may be transferred or reproduced without prior written consent

from YOKOGAWA.

• YOKOGAWA reserves the right to make improvements in the user’s manuals and product at any

time, without notice or obligation.

• If you have any questions, or you find mistakes or omissions in the user’s manuals, please

contact our sales representative or your local distributor.

Warning and Disclaimer

The product is provided on an “as is” basis. YOKOGAWA shall have neither liability nor responsibility

to any person or entity with respect to any direct or indirect loss or damage arising from using the

product or any defect of the product that YOKOGAWA can not predict in advance.

IM 12T03A01-02E

Page 5

Symbol Marks

Throughout this user’s manual, you will fi nd several different types of symbols are used to identify dif-

ferent sections of text. This section describes these icons.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

IMPORTANT

<INTRODUCTION>

iii

Indicates that operating the hardware or software in this manner may damage it or lead to system

failure.

NOTE

Draws attention to information essential for understanding the operation and features.

Tip

This symbol gives information that complements the current topic.

SEE ALSO

This symbol identifi

es a source to be referred to.

IM 12T03A01-02E

Page 6

iv

<INTRODUCTION>

After-sales Warranty

Do not modify the product.

During the warranty period, for repair under warranty consult the local sales

representative or service offi

parts. Before consulting for repair under warranty, provide us with the model

name and serial number and a description of the problem. Any diagrams or

data explaining the problem would also be appreciated.

If we replace the product with a new one, we won’t provide you with a repair report.

Yokogawa warrants the product for the period stated in the pre-purchase quotation Yokogawa

shall conduct defi ned warranty service based on its standard. When the customer site is located

outside of the service area, a fee for dispatching the maintenance engineer will be charged to the

customer.

In the following cases, customer will be charged repair fee regardless of war-

ranty period.

ce. Yokogawa will replace or repair any damaged

• Failure of components which are out of scope of warranty stated in instruction manual.

• Failure caused by usage of software, hardware or auxiliary equipment, which Yokogawa Electric

did not supply.

• Failure due to improper or insuffi cient maintenance by user.

• Failure due to modifi cation, misuse or outside-of-specifi cations operation which Yokogawa does

not authorize.

• Failure due to power supply (voltage, frequency) being outside specifi cations or abnormal.

• Failure caused by any usage out of scope of recommended usage.

• Any damage from fi re, earthquake, storms and fl oods, lightning, disturbances, riots, warfare,

radiation and other natural changes.

Yokogawa does not warrant conformance with the specifi c application at the

user site. Yokogawa will not bear direct/indirect responsibility for damage due

to a specifi c application.

Yokogawa Electric will not bear responsibility when the user confi gures the

product into systems or resells the product.

Maintenance service and supplying repair parts will be covered for fi ve years

after the production ends. For repair for this product, please contact the nearest sales offi ce described in this instruction manual.

IM 12T03A01-02E

Page 7

<CONTENTS>

Model DM8

Vibration Type Density Meter

IM 12T03A01-02E 3rd Edition

CONTENTS

INTRODUCTION ...................................................................................................i

For the safe use of this equipment ...................................................................ii

After-sales Warranty ..........................................................................................iv

1. GENERAL .................................................................................................. 1-1

1.1 Standard Specifi cations ...................................................................................1-1

1.1.1 General Specifi cations ....................................................................... 1-1

1.1.2 Detector ..............................................................................................1-2

1.1.3 Converter Model DM8C ..................................................................... 1-3

1.1.4 Special Cable Model DM8W .............................................................. 1-5

1.1.5 Standard Accessories ........................................................................ 1-5

1.2 Models and Suffi x Codes .................................................................................1-6

1.2.1 General Purpose Detector ................................................................. 1-6

1.2.2 Flameproof Detector .......................................................................... 1-6

1.2.3 Sanitary Use Detector ........................................................................ 1-6

1.2.4 Converter ...........................................................................................1-6

1.2.5 Special Cable ..................................................................................... 1-6

1.3 External Dimensions ........................................................................................ 1-7

1.3.1 Detector ..............................................................................................1-7

1.3.2 Converter Model DM8C ..................................................................... 1-9

1.3.3 Special Cable Model DM8W ............................................................1-10

1.4 Cautions in Handling Flameproof, Explosionproof Instruments .............. 1-11

1.4.1 Outline of Explosionproof Instruments ............................................. 1-11

1.4.2 Labeling the Explosionproof Specifi cations ..................................... 1-11

1.4.3 Installation Area and Ambient Conditions ........................................1-12

1.4.4 External Wiring Work ....................................................................... 1-12

1.4.5 Maintenance Procedure .................................................................. 1-12

1.4.6 Repairs ............................................................................................. 1-12

v

2. PRINCIPLES OF OPERATION ................................................................. 2-1

2.1 Measuring Principle .......................................................................................... 2-1

2.1.1 Density Detector ................................................................................ 2-1

2.1.2 Density Converter .............................................................................. 2-2

2.2 Main Components ............................................................................................. 2-3

2.2.1 Density Detector ................................................................................ 2-3

IM 12T03A01-02E

Page 8

vi

<CONTENTS>

2.2.2 Density Converter .............................................................................. 2-4

3. INSTALLATION, PIPING AND WIRING .................................................... 3-1

3.1 Installation of Density Detector ....................................................................... 3-1

3.1.1 Mounting Density Detector ................................................................ 3-1

3.1.2 Sampling Unit for Vibration Type Density Meter ................................ 3-2

3.2 Installation of Density Converter .................................................................... 3-6

3.2.1 Installation Area.................................................................................. 3-6

3.2.2 Installation of Density Converter ........................................................ 3-6

3.3 Piping ............................................................................................................... 3-10

3.3.1 Sample Liquid Conduit .....................................................................3-10

3.3.2 Air Piping for Maintenance ............................................................... 3-11

3.3.3 Steam Piping .................................................................................... 3-11

3.3.4 Piping for Air Purge .......................................................................... 3-12

3.4 Wiring ............................................................................................................... 3-13

3.4.1 Wiring between Detector and Converter .........................................3-14

3.4.2 Wiring for Analog Output Signal ....................................................... 3-16

3.4.3 Wiring for Digital Output Signal ........................................................ 3-16

3.4.4 Wiring for Abnormal Status Contact Output ..................................... 3-16

3.4.5 Wiring for Power Supply ..................................................................3-16

3.4.6 Wiring for Grounding ........................................................................ 3-16

4. OPERATION .............................................................................................. 4-1

4.1 Component Names and Function ................................................................... 4-1

4.1.1 Density Detector ................................................................................ 4-1

4.1.2 Density Converter .............................................................................. 4-2

4.2 Operation ........................................................................................................... 4-3

4.2.1 Operation Mode ................................................................................. 4-3

4.3 Preparation for Measurement .......................................................................... 4-7

4.3.1 Check for Piping ................................................................................. 4-7

4.3.2 Check for Wiring................................................................................. 4-7

4.3.3 Measuring Liquid Flow ....................................................................... 4-7

4.3.4 Turning ON the Power ....................................................................... 4-8

4.3.5 Data Input ........................................................................................... 4-8

4.3.6 Pressure Compensation .................................................................... 4-9

4.4 Calibration ......................................................................................................... 4-9

4.4.1 Calibration with Standard Solution .................................................. 4-10

4.4.2 Calibration with a Sample ................................................................ 4-11

4.4.3 Calibration Error ............................................................................... 4-11

4.5 Operation ......................................................................................................... 4-12

4.5.1 Operation Procedure ....................................................................... 4-12

4.5.2 Check of Measured Density Value................................................... 4-12

4.5.3 Shutdown ......................................................................................... 4-12

5. MAINTENANCE ......................................................................................... 5-1

IM 12T03A01-02E

Page 9

<CONTENTS>

5.1 Daily Inspection/Maintenance ......................................................................... 5-1

5.1.1 Cleaning the Vibrator in the Detector ................................................. 5-1

5.1.2 Exchange of Desiccant in the Detector ............................................. 5-1

5.2 Troubleshooting ................................................................................................ 5-2

5.2.1 Checking the Vibrators .......................................................................5-2

5.2.2 Checking the RTD ..............................................................................5-2

5.2.3 Checking the Oscillation Amplifi er .....................................................5-2

Customer Maintenance Parts List .......................................... CMPL 12T3E1-01E

Customer Maintenance Parts List .......................................... CMPL 12T3H1-01E

Revision Information ...............................................................................................i

vii

IM 12T03A01-02E

Page 10

Blank Page

Page 11

< 1. GENERAL >

1. GENERAL

Density is one of the fundamental physical quantities required when the property or composition of

a liquid sample is being determined in industrial processes. Especially, density measurement of a

sample liquid is indispensable in many industries such as electric manufactures, chemical industries,

oil refi neries and food-related applications.

The Model DM8 Vibration Type Density Meter is a higher reliable meter full of operation and

maintenance functions. The meter consists of a detector and a converter. The detector has a vibrator

and an RTD (resistance temperature detector), and outputs detected density signal (frequency) and

temperature signal (voltage) to the converter. The converter is equipped with a microprocessor to

convert the frequency signals from the detector into density values and display them. It also calculates

the density at the reference temperature according to these signals and digitally displays them.

Moreover, the converter outputs digital transmission signals besides analog transmission signals and

is further provided with a variety of functions such as one-touch calibration, selfdiagnosis.

1.1 Standard Specifi cations

1.1.1 General Specifi cations

Measurement object: Liquid density

Measurement principle: Vibration density measurement

Measurement range:

Density: 0.5 to 2.0 g/cm

Temperature: –10 to 100 °C

Distance between Detector and Converter: Up to 2 km

Power supply: 90 to 132 V AC or 180 to 264 V AC, 50/60 Hz

Power consumption: 20 VA

3

1-1

Characteristics

(overall characteristics after combing the detector and the converter)

Repeatability: 5 x10

1 % of span (for analog output)

Linearity: ±0.5 % of span (when span is 0.2 g/cm

±1 % of span (when span is more than 0.2 g/cm

Temperature characteristics: ±0.5 % of span/±10 °C (Compensating error for changes in the

measuring liquid temperature and detector temperature)

Flow characteristics: ±0.1 % of span in the range of 0 to 5 l/min

Pressure characteristics: ±0.0005 g/cm

Viscosity error: ±0.1 % of span in the range of 0 to 1500 cP

–4

g/cm3 (for digital output)

3

/±98 kPa change

3

or less)

3

)

IM 12T03A01-02E

Page 12

1-2

< 1. GENERAL >

1.1.2 Detector

(1) General Purpose Detector Model VD6D

Detector construction: Non-explosion protection, rain-proof construction

Case material: Cast Aluminum alloy

Case coating: Epoxy resin, baked fi nish

Case color: Jade green (equivalent to Munsell 7.5BG4/1.5)

Wetted part materials:

Base: SUS316

Vibrator: SUS316 or Ni (Au Brazing: BAu·4)

Measuring liquid temperature: –10 to 100 °C

Measuring liquid pressure: 2 MPa G or less

Maximum pressure: 4.9 MPa G

Steam tracing: Available

Process connection: Rc1/4

Electrical connection: G3/4

Mounting: 2-inch. pipe mounting

Ambient temperature: –10 to 50 °C

Weight: Approx. 12 kg

(2) Flameproof (Explosionproof) Detector Model VD6DF

Detector construction: TIIS; d2G3 or FM; Class I, Division 1, Groups C and D, Flameproof

construction

Process connection: Rc1/4 or 1/4NPT female (only for VD6DF-*B/FM)

Electrical connection: G3/4 or 3/4NPSM female (only for VD6DF-*B/FM)

Specifi cations are the same as for the (1) General Purpose Detector except for the above

construction.

(3) Sanitary Use Detector Model VD6DS

Process connection: Special joint for connection to JIS 6A (6 mm dia.) pipe (within gasket)

Wetted part materials: Added to the standard model

Gasket: Tefl on

O-Ring: Viton

Stream tracing: Not available

Specifi cations are the same as for the (1) General Purpose Detector except for the above two items.

Temperature detector protecting tubes are detachable.

Note: These detectors cannot be used with highly corrosive liquids and solutions likely to stick

to sensors. If it is desired to be applied to solutions containing slurry or sludge, consult with

YOKOGAWA. For measuring NaOH solutions, use sensors with a nickel vibrator.

IM 12T03A01-02E

Page 13

< 1. GENERAL >

1.1.3 Converter Model DM8C

Display: Digital display, fi ve digits LED

Display contents:

Density (g/cm

Density (g/cm

Measuring liquid temperature (°C)

Set density value for the calibration liquid (g/cm

Temperature coeffi cient set value for the calibration liquid (x10

Output signal set value (%) (displayed on call)

Setting for output range low limit (g/cm

Setting for output range high limit (g/cm

Reference temperature (center temperature) set value (°C) (displayed on call)

Temperature coeffi cient set value for the measuring liquid (x10

Fault contents display

Output signal:

Analog output: 4 to 20 mA DC (load resistance 550 Ω or less), and 0 to 1 V DC (load

resistance 250 kΩ or more), isolated output.

Density (g/cm

Digital output: RS-232-C

(1) Communication specifi cations

3

) after conversion to reference temperature (center temperature)

3

) at the measuring temperature

3

) (displayed on call)

–5

g/cm3/°C) (displayed on call)

3

) (displayed on call)

3

) (displayed on call)

–5

g/cm3/°C) (displayed on call)

3

) after conversion to the reference temperature

1-3

• Asynchronous system

Start bit; 1 bit, Stop bit; 2 bit, Parity; none

• Baud rate; 1200 bps

• Data format; ASCII, Data length; 8 bit

• Wiring system; Two-wire system (output only)

(2) Output signal

• Transmitting contents

Measured data; Density (g/cm

3

) after conversion to the reference temperature, density (g/cm3) at

the measured temperature, measured liquid temperature (°C)

Calibration state; calibration start, error No., calibration end

Failure alarm; error No.

• Signal level

Output voltage; ON; 9 ±3 V, OFF; -9 ±3 V

Output impedance; 300 Ω

IM 12T03A01-02E

Page 14

1-4

< 1. GENERAL >

• Output format

Measured data

# * . * * * * _ * . * * * * _ * * * . * C

Calibration status

space space

(Note) Data are output in the order of density (data converted into that at a reference

temperature), density (at measuring temperature), and measuring liquid temperature.

Hold data (data immediately before entering the mode) is output during the time of

calibration or maintenance mode. However, holding is released immediately after

calibration or maintenance mode.

# CALIBRATION _ START C

(Note) Nothing is output during calibration. However, when a parameter error occurs, output

becomes as follows.

# CALIBRATION _ END C

Fail alarm

# ERROR - * _ ERROR - * C

(Note) When multiple errors occur, each error No. for the respective errors is output.

space

# ERROR - *C

space

space

RLF

RLF

RLF

(*: 5 or 6)

RLF

RLF

Example: # ERROR - 1 _ ERROR - 3 C

space

RLF

Output signal span: 0.05 to 0.5 g/cm3 settable

Reference temperature set range: 0 to 100 °C (in increments or decrements of 1 °C)

Contact output on failure: One point. Contact closed on failure or power failure. Contact open

when normal.

Permissible voltage: 220 V DC, 250 V AC

Permissible current: 2A (resistive load)

Permissible contact power: 60 W

Fault detecting contents: Detector failure and converter failure

Failure output:

Analog signal: Falls down to about –10 % of the output signal span

Digital signal: Error message outputs

Output signal hold: Holds in the CAL. or Maintenance mode.

Settable range for temperature coeffi cient: 0 to 0.002 g/cm

3

/°C

Calibration procedure: One-touch calibration by strong calibration liquid density

(onepoint calibration)

Ambient temperature: –10 to 55 °C

Power supply: 90 to 132 V AC or 180 to 264 V AC, 50/60 Hz

IM 12T03A01-02E

Page 15

< 1. GENERAL >

Case construction: Dust and rain proof construction

Coating color: Door: Equivalent to Munsell 2.8GY6.4/0.9

Case: Equivalent to Munsell 2.0GY3.1/0.5

Coating fi nish: Baked fi nish epoxy resin

Mounting: To panel, wall or 2-inch pipe

Air purge connector: Rc1/8, Rc1/4, or 1/4NPT female is also optionally available

Electrical connection: Five holes, 27 mm dia.

Attached with four plastic waterproof plugs equivalent to JIS A15, and one

plastic waterproof plug equivalent to JIS A20.

Weight: Approx. 7.5 kg

1.1.4 Special Cable Model DM8W

Type: Six-conductor double shield cable

Insulator: Polyethylene

Sheath: Polyvinyl chloride

Insulation resistance: 1000 MΩ/km

Conductor resistance: 15.31 Ω/km

Finished O.D.: 15.8 mm

Weight: Approx. 0.3 kg/m

1-5

1.1.5 Standard Accessories

Syringe (for injecting standard

solution or solvenet)

Brush (for cleaning the detector) 1 pcs

Allen wrench for terminal box 1 pcs

Allen wrench for locking the cover 1 pcs

O-Ring 1 bag

Silica gel 2 packs

Fuse for the converter (3A) 1 pcs for Converter (DM8C)

1 pcs

for Detector (VD6)

IM 12T03A01-02E

Page 16

1-6

< 1. GENERAL >

1.2 Models and Suffi x Codes

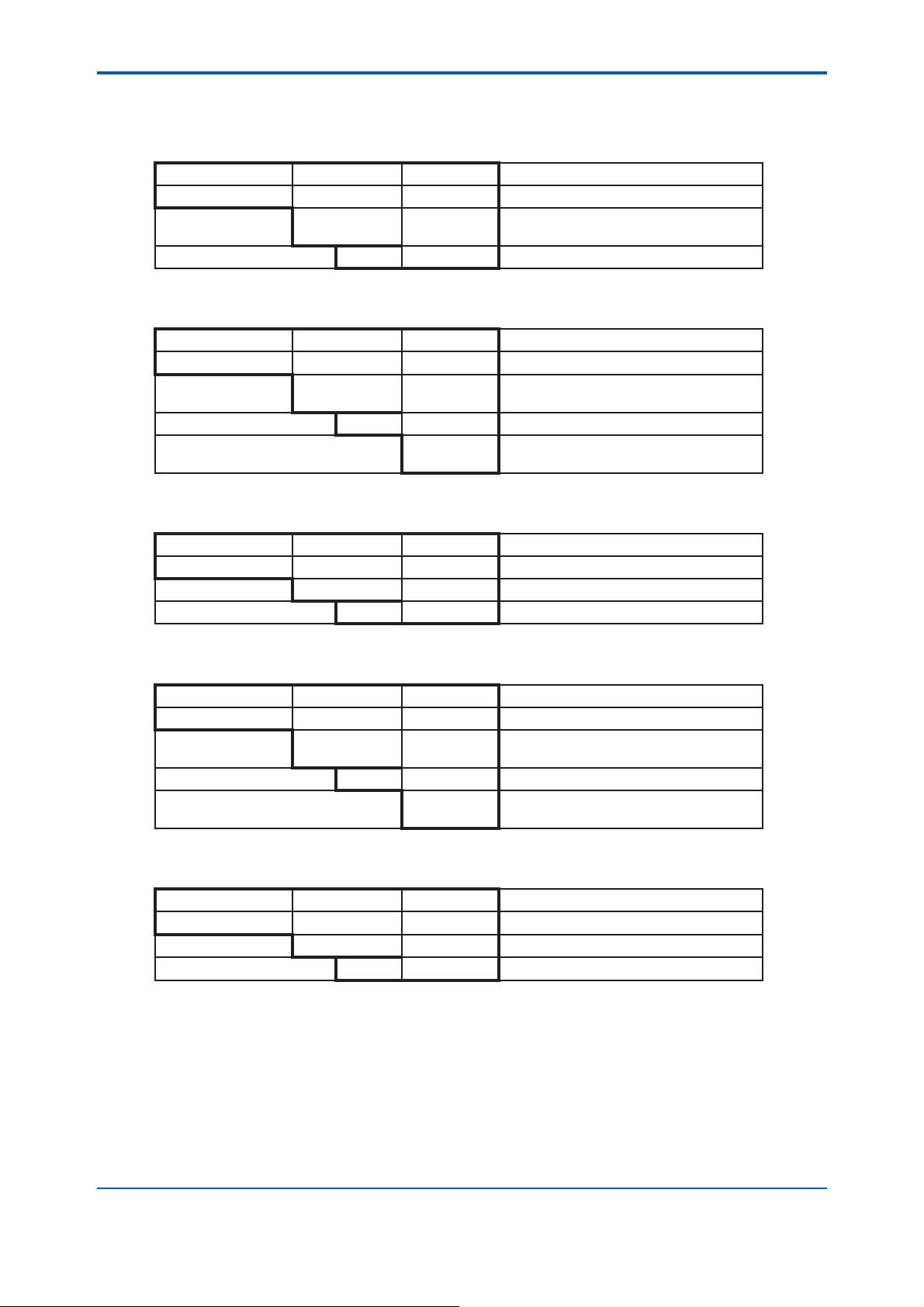

1.2.1 General Purpose Detector

Model Suffi x Code Option Code Description

VD6D ••••••••••••••••••••• •••••••••••••••••• General purpose detector

Vibrator material -S3

-N1

— *B •••••••••••••••••• Style B

1.2.2 Flameproof Detector

Model Suffi x Code Option Code Description

VD6DF ••••••••••••••••••••• •••••••••••••••••• Flameproof detector

Vibrator material -S3

-N1

— *B •••••••••••••••••• Style B

(Option) /FM NEC Class I,Division 1,Group C and D,

••••••••••••••••••

••••••••••••••••••

••••••••••••••••••

••••••••••••••••••

SUS316

Ni

SUS316

Ni

explosionproof

1.2.3 Sanitary Use Detector

Model Suffi x Code Option Code Description

VD6DS ••••••••••••••••••••• •••••••••••••••••• Sanitary use detector

Vibrator material -S3 •••••••••••••••••• SUS316

— *B •••••••••••••••••• Style B

1.2.4 Converter

Model Suffi x Code Option Code Description

DM8C ••••••••••••••••••••• •••••••••••••••••• Converter

Power supply -A1

— *C •••••••••••••••••• Style C

(Option)

Air purge connector

-A2

1.2.5 Special Cable

Model Suffi x Code Option Code Description

DM8W ••••••••••••••••••••• •••••••••••••••••• Special cable

Cable length

— *A •••••••••••••••••• Style A

-L

••••••••••••••••••

••••••••••••••••••

/AP1

/AP2

•••••••••••••••••• Length (unit: m)

90 to 132V AC, 50/60Hz

180 to 264V AC, 50/60Hz

Rc1/4

1/4NPT female

(Note) Enter the cable length in “-L in m.”

[Example] L0050 for 50 m

L0100 for 100 m

L2000 for 2 km

IM 12T03A01-02E

Page 17

< 1. GENERAL >

1.3 External Dimensions

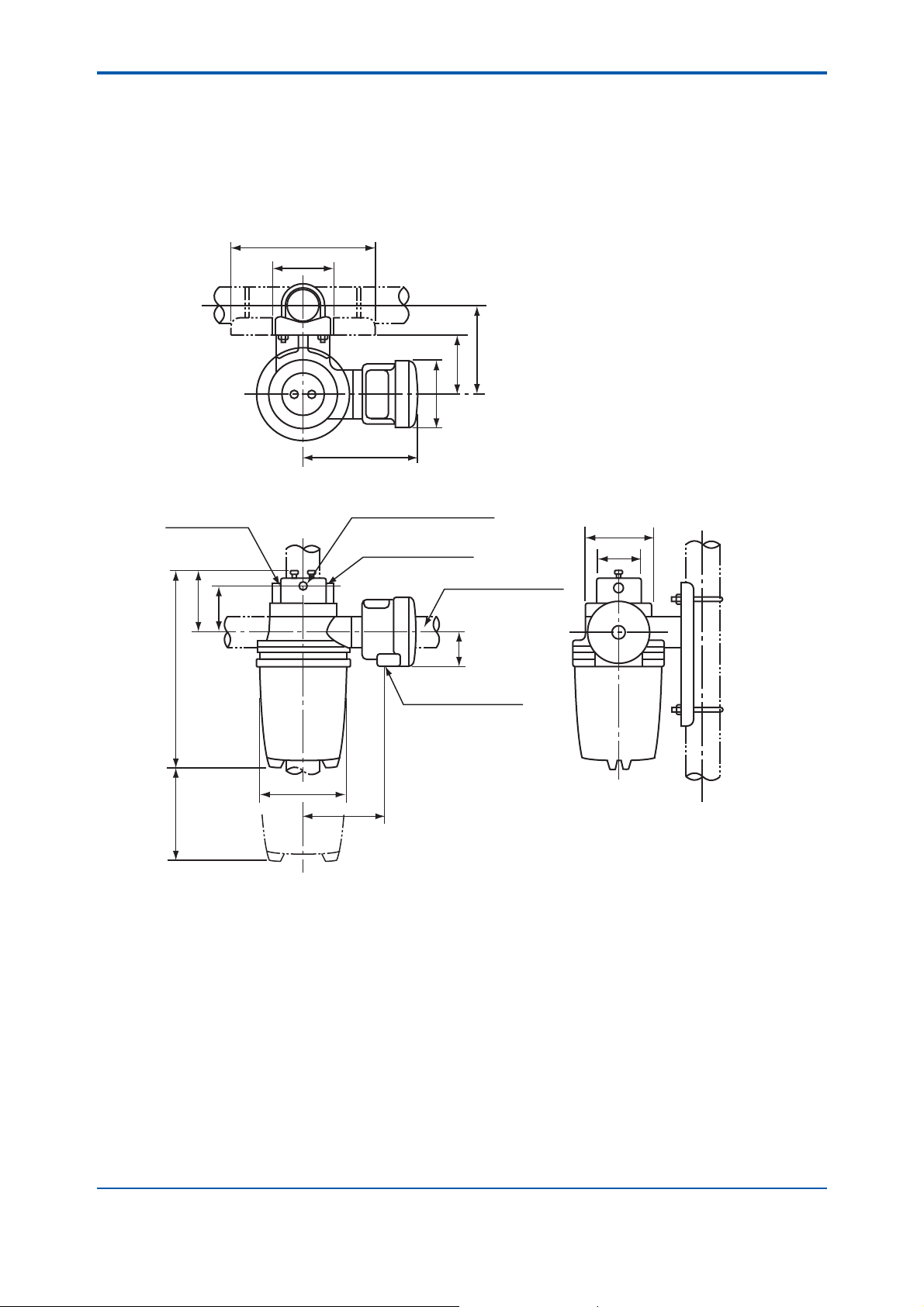

1.3.1 Detector

General Purpose and Flameproof Detector Models VD6D and VD6DF

246

100

153

104

ø110

192

1-7

Unit : mm

Sample lnlet

Rc1/4

342

200

100

*1

78

ø160

Steam Connection Rc1/4

*1

Steam Outlet Rc1/4

*1

2-inch Pipe

(Horizontal or Vertical)

Electrical Wiring Port

G3/4

146

ø116

ø74

58

*2

For VD6DF-*B/FM

*1: 1/4NPT

*2: 3/4NPSM

IM 12T03A01-02E

Page 18

1-8

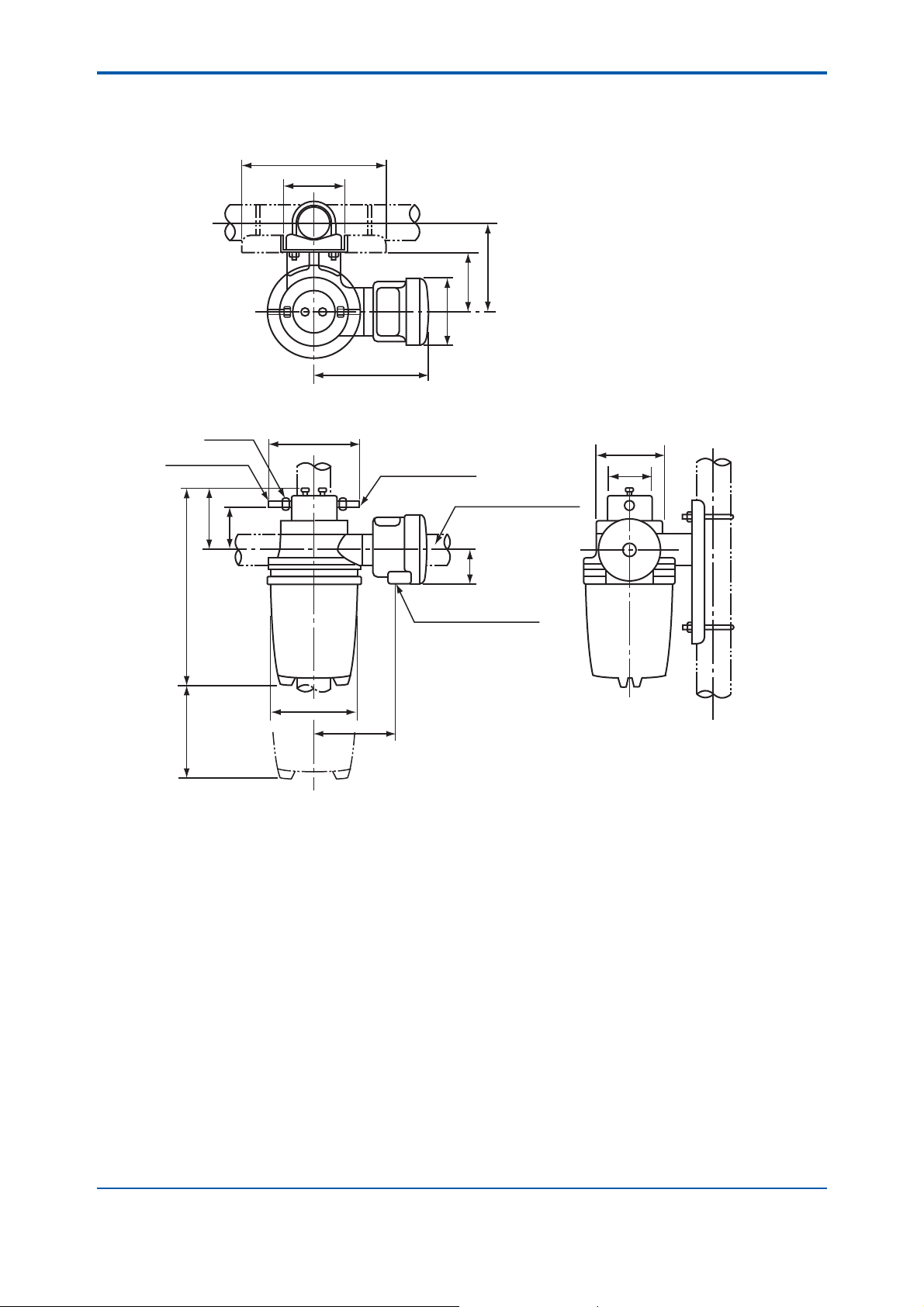

< 1. GENERAL >

Sanitary Use Detector Model VD6DS

246

100

Unit : mm

153

104

ø110

192

Gland

Sample lnlet *

103

73

345

200

166

ø160

Sample Output *

146

ø116

ø74

2-inch Pipe

(Horizontal or Vertical)

58

Electrical Wiring Port

G3/4

* The ends of sample inlet and outlet are connected with 1/8-inch

pipe in welding. The pipe may be removed by loosing the gland.

IM 12T03A01-02E

Page 19

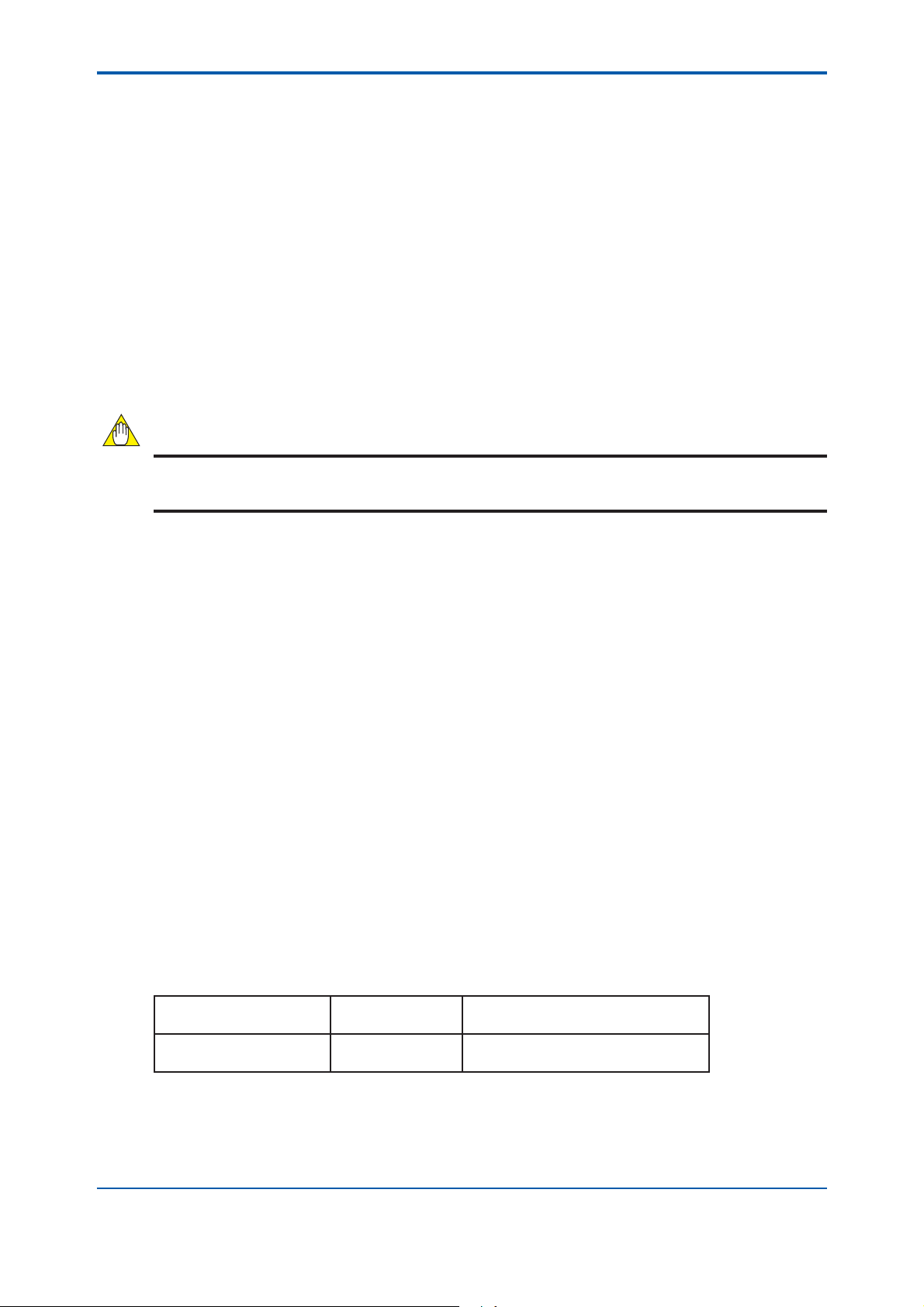

< 1. GENERAL >

1.3.2 Converter Model DM8C

1-9

Wiring port holes (5-ø27)

(with rubber plugs)

Purge air outlet

(with seal sheet)

Mounting pipe

(2-inch pipe)

183

240

288

14

200

34 34 34 34

*: When option code is specified, Rc1/4 or 1/4 NPT female connector is attached.

Mounting bracket (applicable with any mounting

method to panels, walls or pipes)

Mounting panel thickness

Max. 12

31 35

23

Purge air inlet Rc1/8 *

Pipe mounting bracket

138

116

272

Unit: mm

Panel cutout dimensions

212±1 222

Wall mounting hole drilling dimensions

2-ø9 holes or M8 screws

275±1

IM 12T03A01-02E

Page 20

1-10

< 1. GENERAL >

1.3.3 Special Cable Model DM8W

Unit : mm

Density detector

130(from A)

B4

WHITE

GRAY

A2

RED

A3

BLUE

YELLOW

A5

GREEN

BROWN

(Note) Cable length is specified by the suffix code of “-L”, is specified in meter.

e.g. for 50 m, -L0050

for 100 m, -L0100

for 2 km, -L2000

60(from A)

B5

110(from A)

110(from A)

A4

(from A)

110(from A)

A6

60

60(from A)

Specified length

by “-L”

(Note)

AB

ø15.8

(from B)100

Density converter

(from B)

80

(from B)

120

(from B)

(from B)100

B4

WHITE

B5

GRAY

110

(from B)90

(from B)80

A2

RED

A3

BLUE

A4

YELLOW

A5

GREEN

A6

BROWN

IM 12T03A01-02E

Page 21

< 1. GENERAL >

1-11

1.4 Cautions in Handling Flameproof, Explosionproof Instruments

1.4.1 Outline of Explosionproof Instruments

Specifi cations of “Explosionproof Instruments” conform to the regulations of relevant public

organizations.

Model DM8 Vibration Type Liquid Density Meter consists of a density detector and a density converter.

Model VD6DF density detector, explosionproof instrument, can be installed in hazardous area where

explosive gases may be generated.

It should be noted, however, that the method of installation, ambient conditions, and the handling of

these instruments must conform to the regulations of relevant public organizations. The applicable

explosionproof regulations and the cautions marked on the analyzer shall be strictly observed when

using Model VD6DF in a hazardous location.

CAUTION

Model VD6D and Model VD6DS Density Detector, which are not “explosionproof instrumment”,

cannot be installed in hazardous location.

Model VD6DF density detector has either TIIS or FM fl ameproof type of explosionproof specifi cations.

The TIIS type has passed tests conducted by a public authority in accordance with the Labor Safety

and Health Law (Japan) which regulates domestic explosionproof electrical equipment. The FM type

has been certifi ed to have an explosionproof construction meeting the requirements of NEC (National

Electrical Code) by Factory Mutual Research Corporation, U.S.A. (FM), a testing organization. It also

conforms to requirements of OSHA (Occupational Safety and Health Act, U.S.A.).

Items 1.4.2 to 1.4.6 cover general cautions in using the Model VD6DF density detector. For further

details, see the following publications:

• For TIIS fl ameproof requirements

‘RECOMMENDED PRACTICE’ for Electrical Equipments for Use in Explosive Gas Atmosphere

published by The Research Institute of Industrial Safety, Ministry of Labor.

• For FM Flameproof requirements

National Electrical Code, Chapter 5, Special Occupancies.

1.4.2 Labeling the Explosionproof Specifi cations

TIIS Flameproof type of explosion-protected construction

The Model VD6DF density detector is labeled data plate on which type of the explosion-protection

constructions, approval number, symbols for the type and working ambient temperature range.

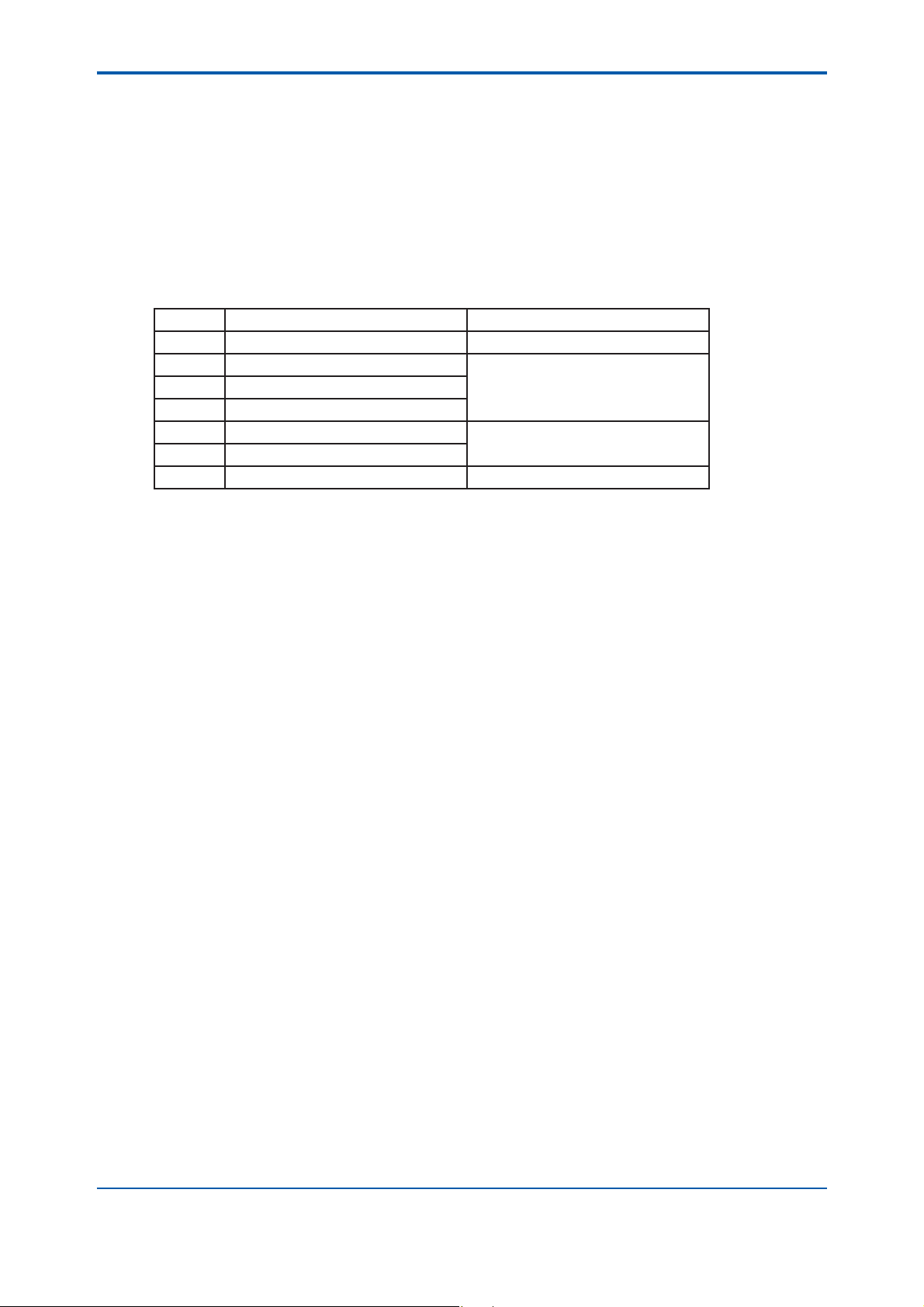

Table 4.1 TIIS Flameproof Type (Explosionproof) Construction of Vibration Density Detector

Model and codes Type Approval No.

Model VD6DF-N1

Model VD6DF-S3

FM Explosionproof Specifi cations

The Model VD6DF density detectors complying with FM explosionproof specifi cations is labeled data

plate which is marked with an approval mark, classifi cation of hazardous location, working ambient

temperature range, and handling cautions.

No. T21726

No. T21727

Symbol for the type (including

explosion class and ignition group)

d2G3

d2G3

IM 12T03A01-02E

Page 22

1-12

< 1. GENERAL >

1.4.3 Installation Area and Ambient Conditions

Model VD6DF density detector can be installed in hazardous area where specifi ed gases are present.

However, do not install the detector at the place where explosive gases may be continuously present,

and in which the gas concentration is continuous or for long period, equal to or more than, the lowest

gas explosion limit.

Environmental conditions at the installation site are very important to the detector.

Before installing the detector, check the temperature, humidity and altitude of the site.

The conditions shall not exceed the specifi ed ranges. The temperature range (-10 to 50 °C) in

indicated on the data plate, and the altitude shall be 1000 meters or less above sea level and the

relative humidity range 45 to 85 %.

1.4.4 External Wiring Work

External wiring for fl ameproof detector shall be carried out according to the fl ameproof metal conduit

wiring. For TIIS explosionproof specifi cations, the fl ameproof packing type is used for leading external

cables.

1.4.5 Maintenance Procedure

Do not remove the detector cover in a hazardous area unless power is OFF. However, if detector

maintenance with power on is unavoidable, a gas detector check should fi rst be made to determine

whether a hazardous atmosphere exits in the installation area.

1.4.6 Repairs

The following points must be observed during repairs.

The detector must be restored to their original conditions, electrically and mechanically to maintain

their fl ameproof properties.

The gaps, path lengths and mechanical strength of enclosures are important factors in establishing

fl ameproof properties. Therefore, service staff should be careful not to damage point surfaces and not

to shock enclosures.

IM 12T03A01-02E

Page 23

< 2. PRINCIPLES OF OPERATION >

2. PRINCIPLES OF OPERATION

2.1 Measuring Principle

2.1.1 Density Detector

Model VD6D Density Detector is a vibration type density meter. Measuring principle is that the lateral

free oscillation of a pipe is a function of the density of the liquid contained in the pipe.

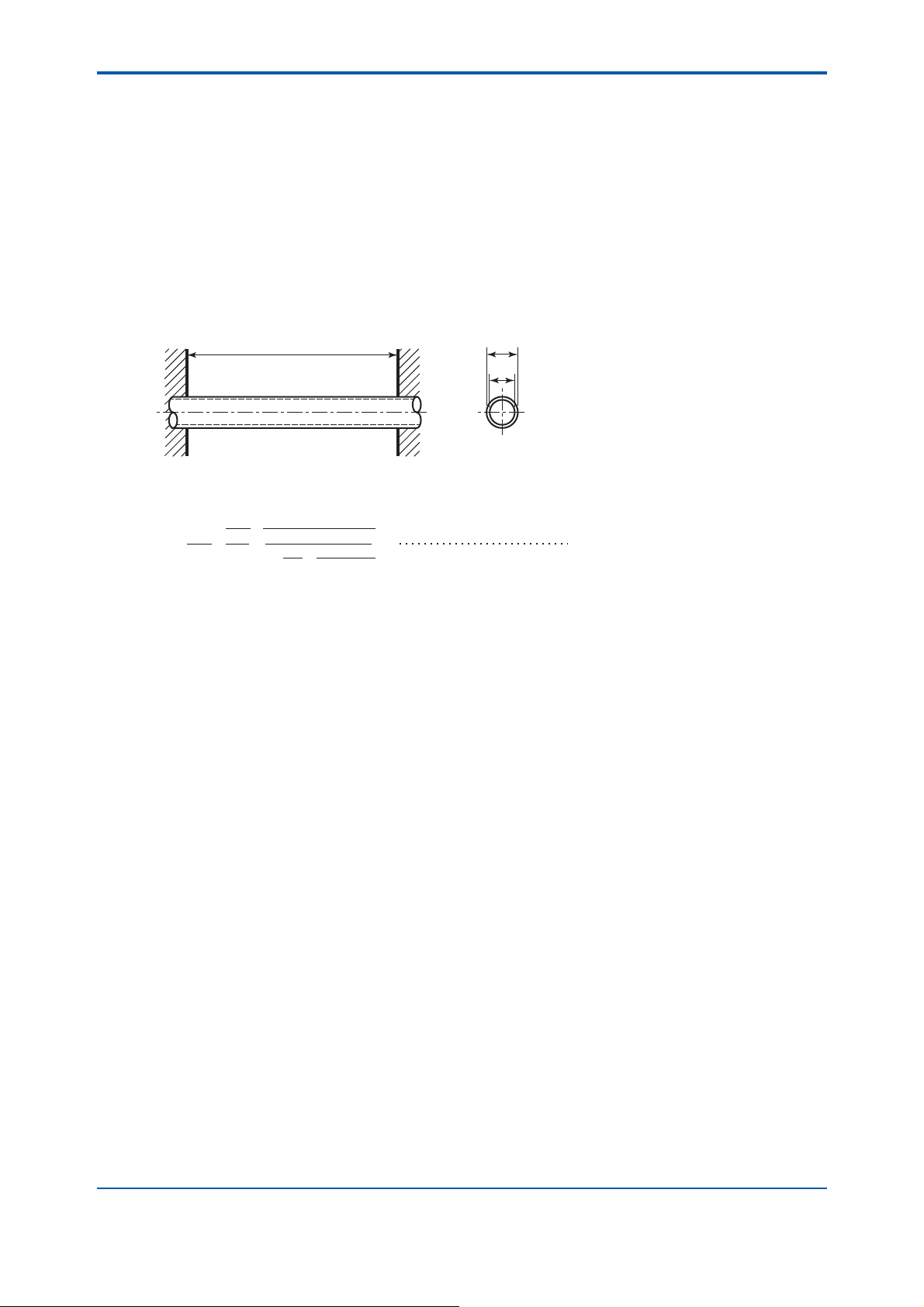

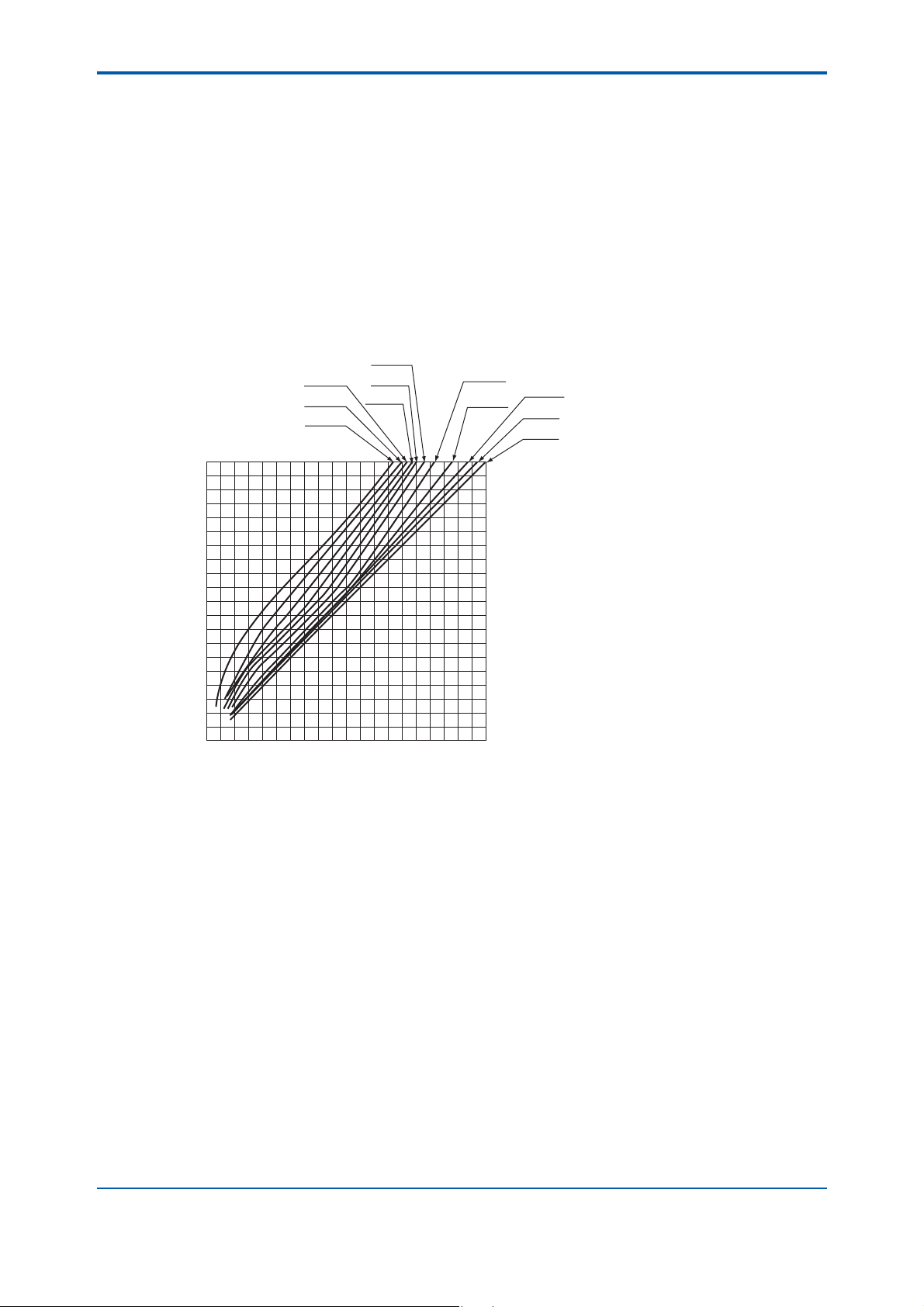

Assuming that the pipe is fi lled with a liquid as shown in Figure 2.1, the lateral free oscillation of the

pipe can be shown as the following equation:

2-1

D

1

D

2

Joint

l

Joint

Figure 2.1 Pipe Filled with Liquid

2

C

E

fx =

2

4 l

fx : Free transfers oscillation frequency for ρx [Hz]

C : Constant determined by oscillation mode

l : Oscillating pipe length [m]

E : Young's modulus of pipe [kg/m

ρ

: Density of pipe material [kg/cm3]

l

ρ

: Density of liquid measured [kg/cm3]

x

: Pipe outside diameter [m]

D

1

D

: Pipe inside diameter [m]

2

¥ ¥

ρ

l

D

ρ

1 + x

ρ

2

+ D

1

2

l

x

2

D

2

2

2

D

- D

1

2

3

]

(1)

In equation (1), the values other than fx and ρx are determined by the pipe material and construction.

Thus, the density ρx of the liquid can be obtained by measuring the free transfers oscillation frequency

fx.

IM 12T03A01-02E

Page 24

2-2

< 2. PRINCIPLES OF OPERATION >

2.1.2 Density Converter

The density converter computes the liquid density using the oscillation frequency signal and voltage of

the temperature.

Each value of l, E, ρ

of fx is also a function of temperature. To obtain the correct density, the factors A

, D1, D2 or rx in equation (1) is a function of liquid temperature, hence the value

1

and B

(t)

depending

(t)

temperature should be previously compensated for the temperature as follows.

A

=

f

x

(t)

1 + ρx B

¥

where, A

B

A

B1 = B / 300

T : Liquid temperature (°C)

(t)

= A1 ( 1.0060 - 1.9814 x 10-4T - 9.7683 x 10-8T2 )

(t)

= B1 { 1 + 4.5 x 10-5 ( T - 30 ) }

(t)

= ( A + 131072 ) / 100

(t)

(2)

(Note) Both A and B are constants of the detector which has inherent values.

From equation (2) and (3), the density ρ

2

A

(t)

- 1

{ }

f

x

B

(t)

can be obtained.

x

(3)ρx =

The ρx in equation (3) represents the liquid density at measuring temperature. The density ρTB at the

reference temperature can be obtained by the following equation (4):

ρTB = ρx + α ( Tx - TB )

α : Temperature coefficient of density for measuring liquid (g/cm3/°C)

Tx : Liquid temperature at density measurement (°C)

TB : Reference temperature (°C)

(4)

IM 12T03A01-02E

Page 25

< 2. PRINCIPLES OF OPERATION >

2.2 Main Components

2.2.1 Density Detector

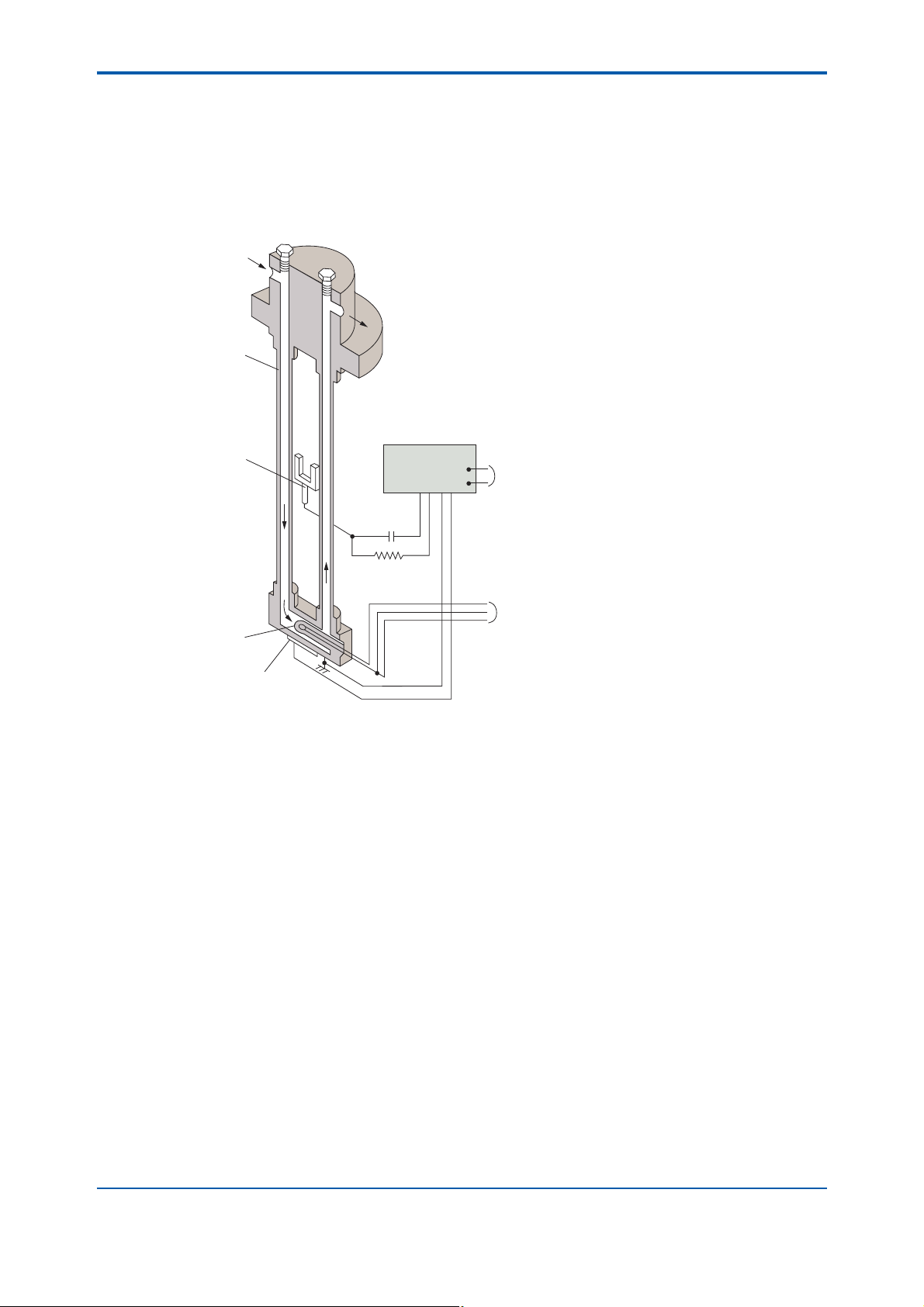

Figure 2.2 is a schematic diagram of the density detector.

As shown in the fi gure, the density detector consists mainly of a vibrator assembly, a capacitance

pickup electrode, and an amplifi er.

Sample

Vibrator

Pick-up electrode

Preamplifier

Density signal

2-3

Temperature signal

Temperature

measuring element

Piezo-electric element

Vibrator cross sectional view of Density Detector

Figure 2.2 Schematic Diagram of Density Detector

The vibrator assembly consists of a sample path formed by connecting the ends of two thin tubular

vibrators whose upper ends are connected to a base. The connector incorporates an RTD to measure

the sample liquid temperature. The vibrator assembly also contains a piezoelectric element to

maintain vibration corresponding to the sample liquid density.

The capacitance pickup electrode installed between the two vibrating pipes detects the lateral

oscillation frequency of the vibrator.

The amplifi er converts the output of the capacitance pickup electrode into an AC voltage to amplify

it. This frequency signal is, together with the temperature signal from the RTD, transmitted to the

converter. A part of the frequency signal is fed back to the piezoelectric element to maintain the

vibrator oscillation.

IM 12T03A01-02E

Page 26

2-4

< 2. PRINCIPLES OF OPERATION >

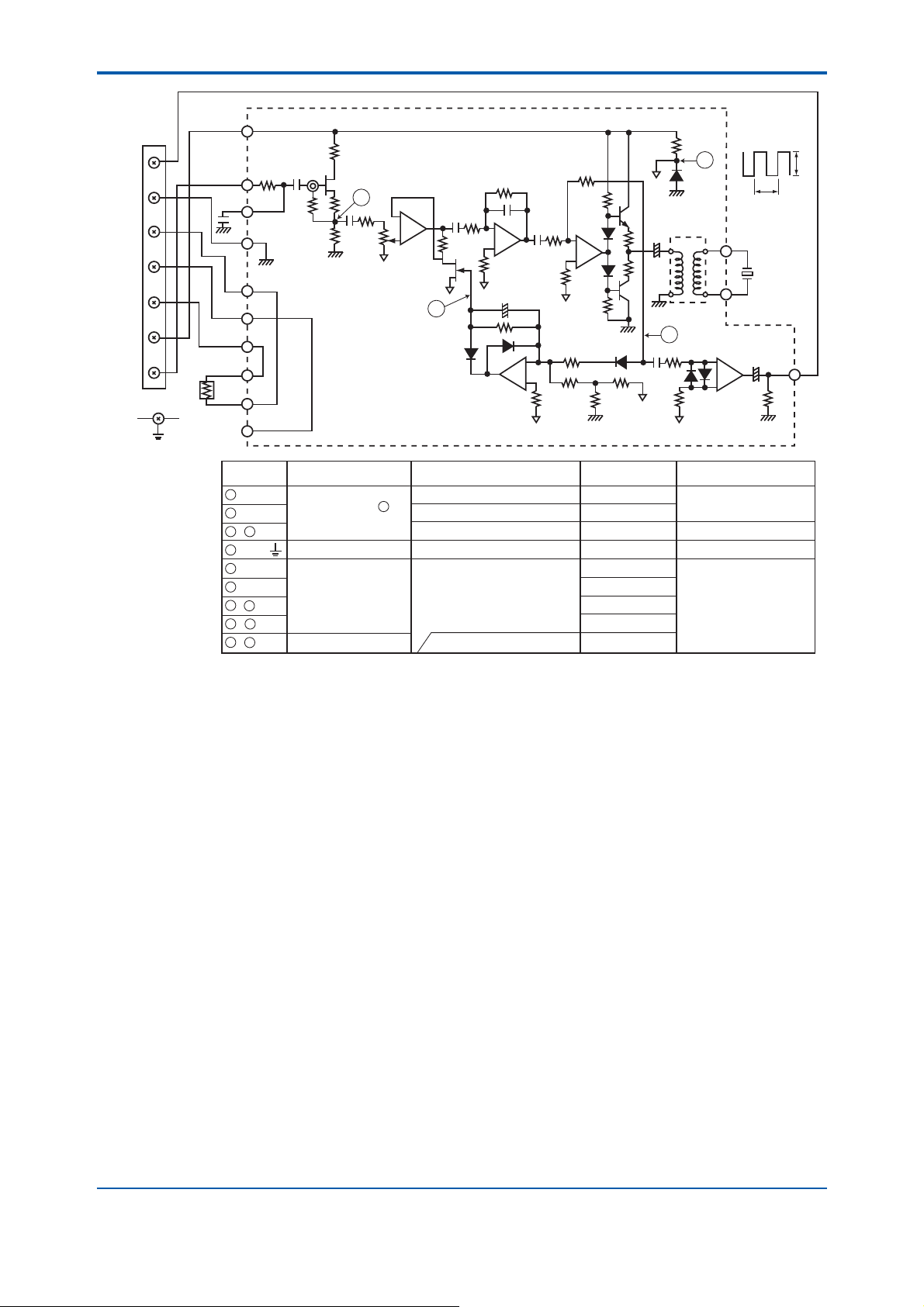

2.2.2 Density Converter

Figure 2.3 is a block diagram of the density converter.

As shown in the diagram, the density converter receives the density signal (frequency) F

and

ρ

temperature signal (voltage) VT from the density detector and fi nally outputs a 4 to 20 mA analog

signal and 0 to 1 V DC signal corresponding to the liquid density converted to that at reference

temperature. The digital signals of densities at measuring temperature and reference temperature,

and measuring temperature and measuring temperature value are also output. The converter circuit

comprises three printed circuit boards. Changing displayed items or setting constants are performed

by keys or transfer switches on the front panel.

Frequency of Density (Fx)

Temp. Signal

(RT)

0 to 1 V

4 to 20 mA

TD

Digital Output

R/V

Ref. temp. Span

Ref. temp. Zero

Multiplexer

Reference frequency

Multiplexer

200 V

V/I

Zero

Span

Integrator

V/F

Driver

PC

PC

PC

COUNTER

P.W.

Modulation

Serial

Communication

Controller

CPU

Memory

ROM

RAM

EEPROM

Key &

Display

Controller

W.D.T.

Key

Fail Alarm

PC

Figure 2.3 Block Diagram of Density Converter

LED

IM 12T03A01-02E

Page 27

< 3. INSTALLATION, PIPING AND WIRING >

3-1

3. INSTALLATION, PIPING AND WIRING

Model DM8 vibration type density meter consists of a density detector and a density converter. The

density detector is generally installed in fi eld and sampling piping is made to conduct measuring

liquid. The density converter is generally installed in the vicinity of the density detector. It must not

be installed in hazardous area. It can be installed in a control room, though it is far away from the

detector, receiving digital signal.

3.1 Installation of Density Detector

The density detector is shipped with a sampling unit if it is specifi ed. For the detector without the

sampling unit, user should install sampling device suitable to measuring system.

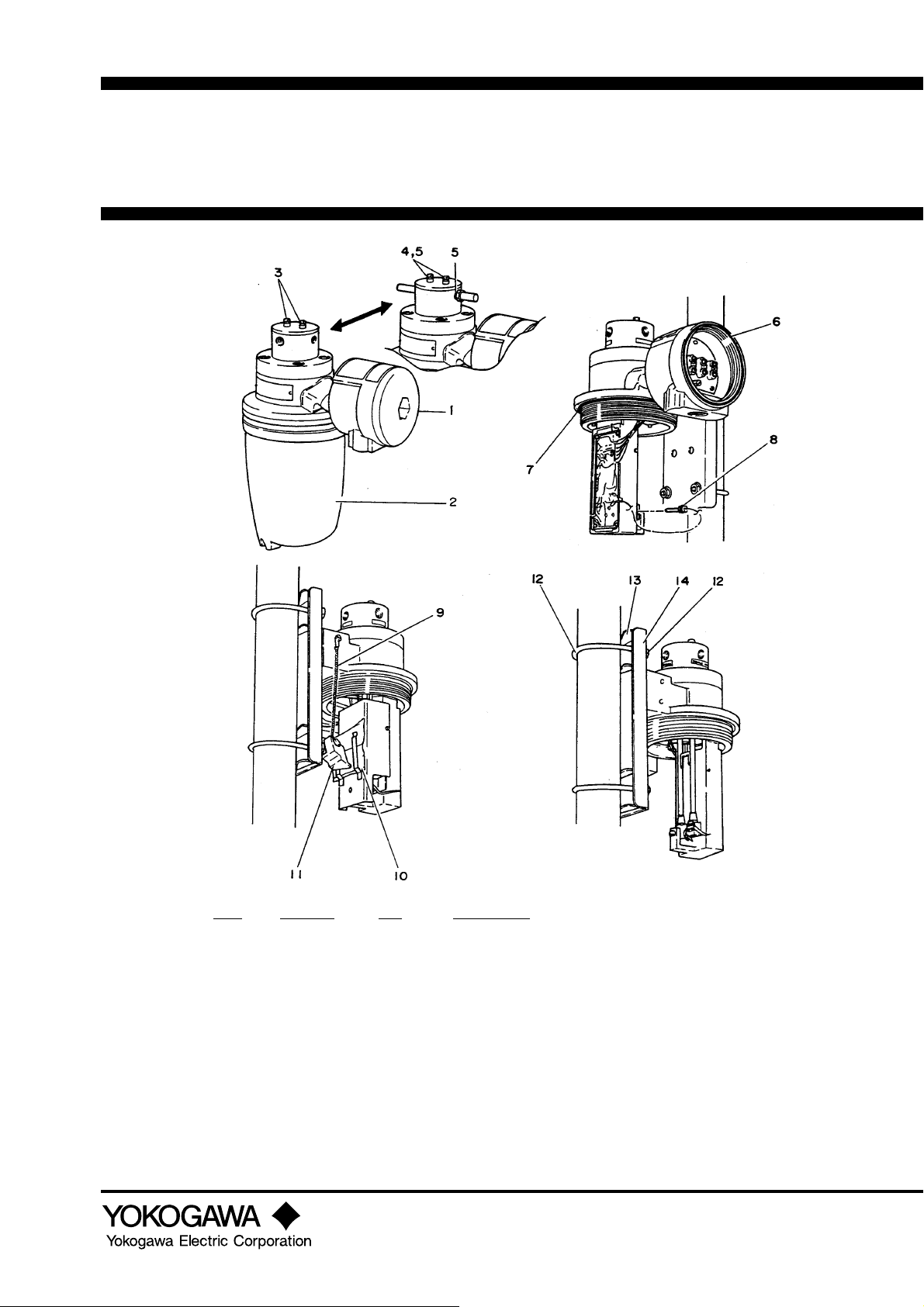

3.1.1 Mounting Density Detector

The detector (without the sampling unit) should be installed vertically (note). The pipe mounting

bracket is applicable to vertical or horizontal pipe (JIS 50A) as shown in Figure 3.1 and 3.2.

(Note) The detector should be installed vertically to keep the vibrator pipe vertical.

(1) Pipe Mounting

The pipe mounting bracket is attached to the detector to mount it on a vertical pipe. For mounting on

a horizontal pipe, remove the mounting bracket from the detector to turn it 90° and fi x it again to the

detector. Figure 3.1 shows installation on a vertical pipe and Figure 3.2 shows on a horizontal pipe.

Figure 3.1 Installation on a Vertical Pipe

Figure 3.2 Installation on a Horizontal Pipe

IM 12T03A01-02E

Page 28

3-2

< 3. INSTALLATION, PIPING AND WIRING >

(2) Bracket Mounting

This bracket is not the pipe mounting bracket. Release the four bolts (with spring washers) to remove

the pipe mounting bracket from the detector. Using the four bolts and spring washers, fi x the detector

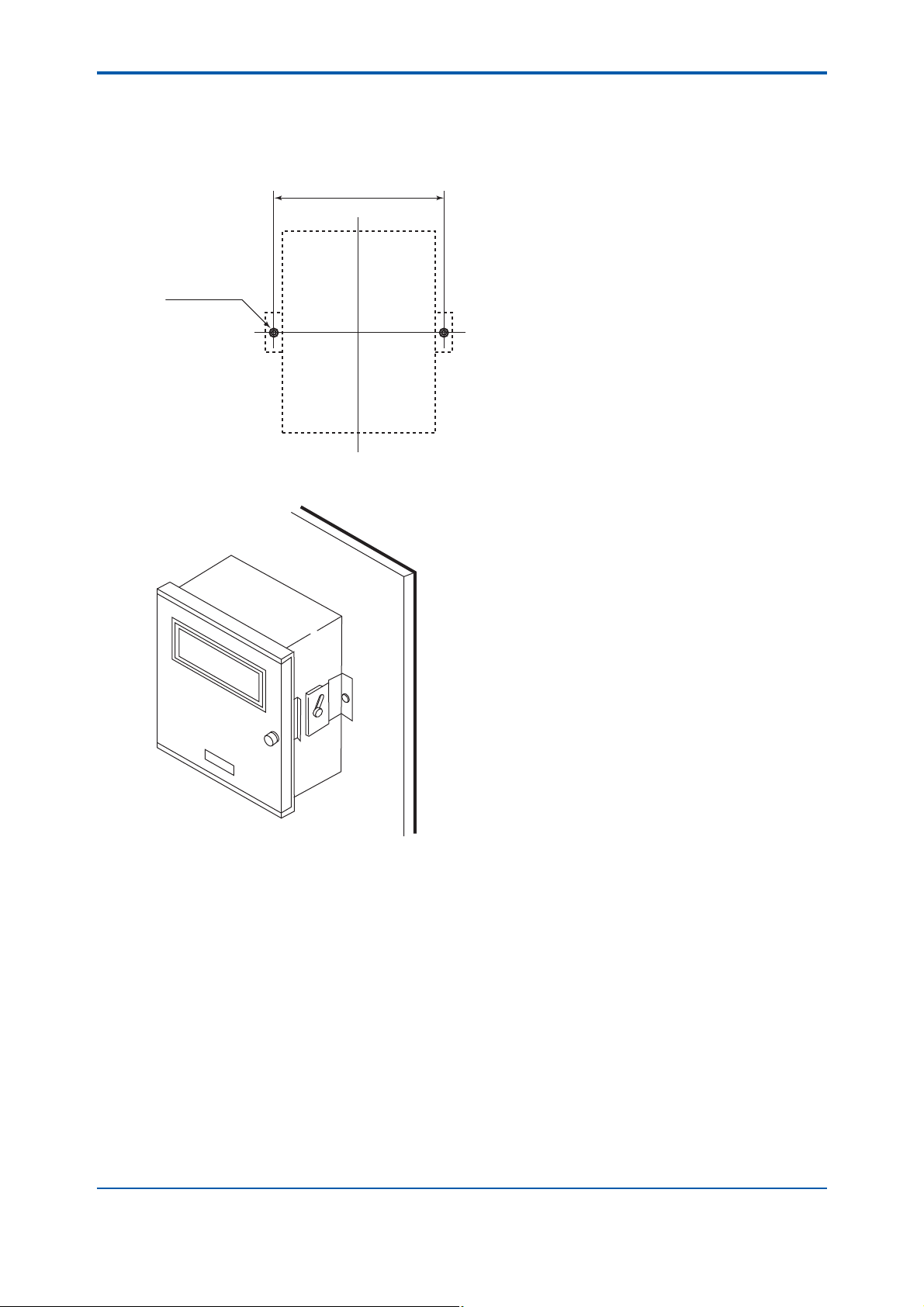

on the bracket as shown in Figure 3.4. Figure 3.3 shows position of holes to be drilled on the bracket.

Unit: mm

70 ±0.2

4-ø9 Holes

40 ±0.2

Figure 3.3 Position of Holes on the Bracket

Density detector

Figure 3.4 Mounting on the Bracket

3.1.2 Sampling Unit for Vibration Type Density Meter

This section describes a sampling that is provided by user for the density meter.

The sampling equipment is equipped with valves, a thermometer, a fl owmeter, etc., and is located

near to process pipe and the density detector.

The sampling equipment is used to provide good condition to measure liquid density, easy to monitor

measuring and maintenance condition such as calibration and cleaning the vibrator.

Install the sampling equipment according to the following. For details of piping from process to the

equipment, refer to the section 3.3.

IM 12T03A01-02E

Page 29

< 3. INSTALLATION, PIPING AND WIRING >

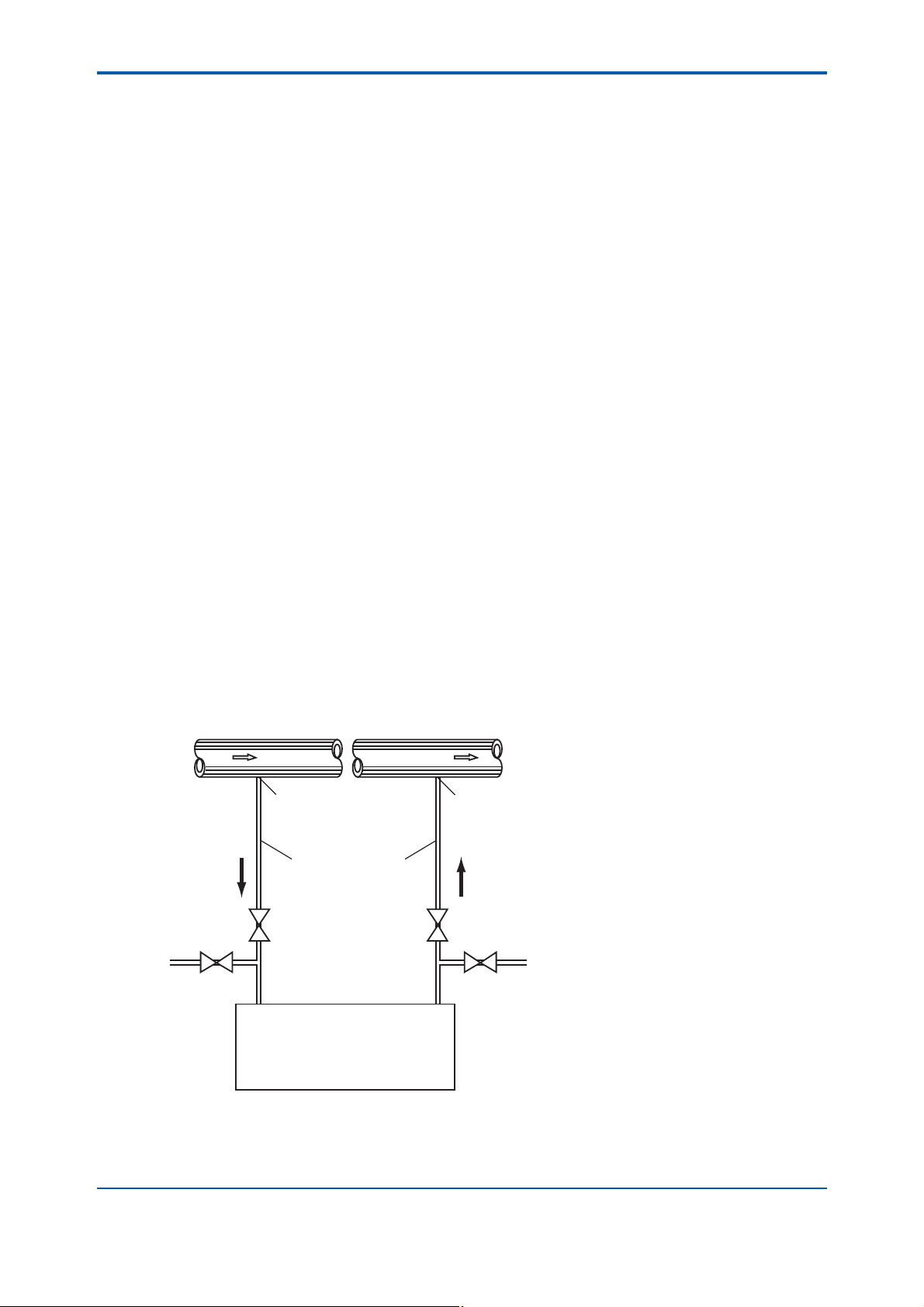

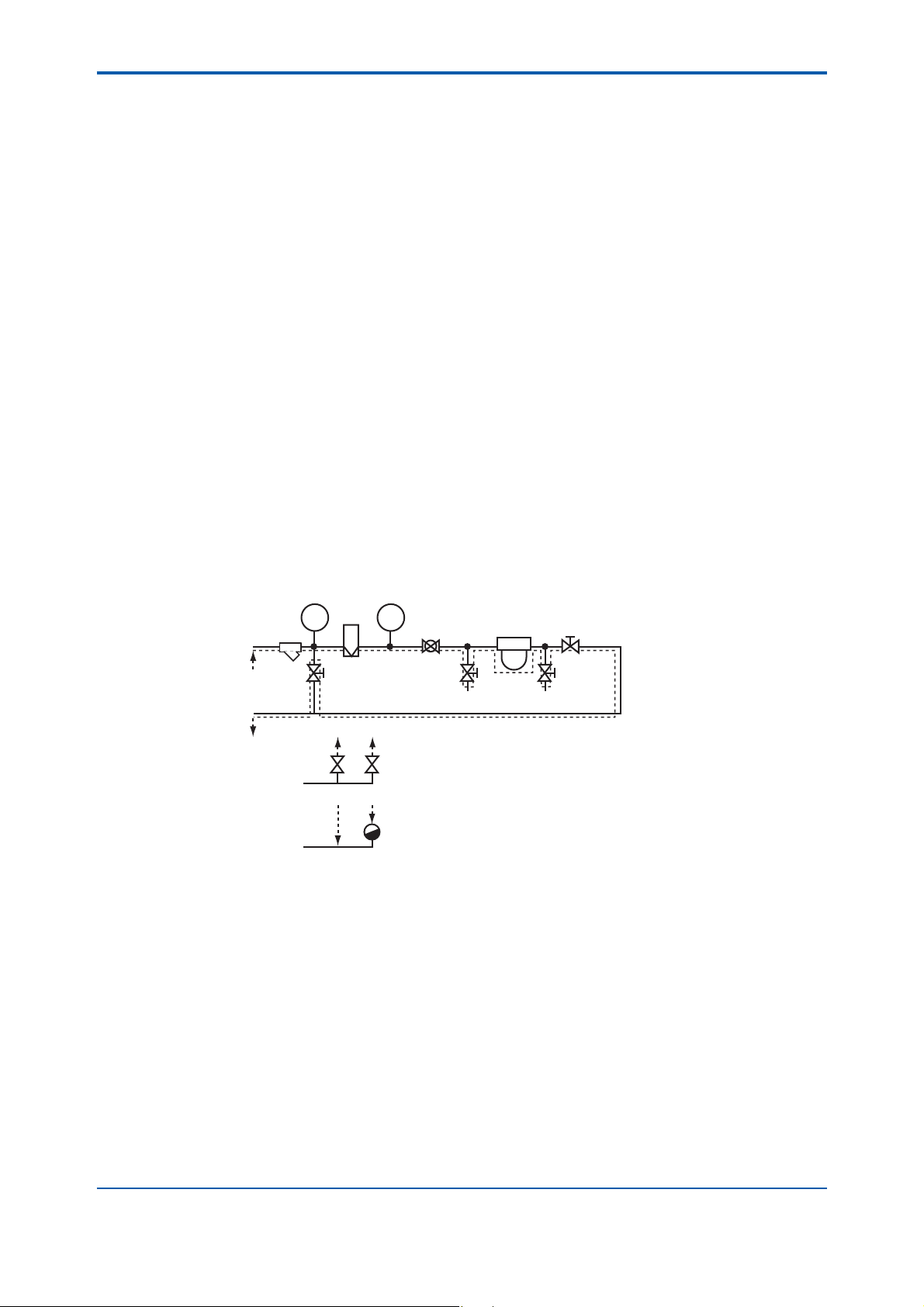

(1) Flow Diagram

Figure 3.5 shows a fl ow diagram of a typical sampling equipment. Model VD6SM sampling unit of

Yokogawa is also designed according to this diagram.

FM

SAMPLE IN

a

SAMPLE OUT

a'

STEAM IN

CONDENSATE OUT

TI

F

NV1

b

b'

V1

PI

a

a'

Element specifications

V2

ST1

F: Strainer body; SUS316

Element; SUS316, or Ni (option)

PI: Pressure gauge, 0 to 1MPa or 0 to 2MPa, SUS316

TI: Thermometer. 0 to 100 °C or 0 to 150 °C, SUS316

FM: Flowmeter, tapered metal tube flowmeter, 1 to 10 l/min, SUS316

BV1: Ball valve, SUS316

NV1 to 4: Needle valve, SUS316

DD: Density detector

V1, V2: Valve

ST1: Steam trap

DD

NV2

NV4BV1

NV3

Figure 3.5 Flow Diagram

3-3

In Figure 3.5, each element of the sampling equipment is shown F (fi lter) is usually 80 meshes,

prevents a solid from entering into the sampling line. TI (thermometer), FM (fl owmeter) and PI

(pressure gauge) are necessary to monitor measuring liquid. NV1 (needle valve) is required to control

fl ow rate of a sample liquid. BV1 (ball valve) and NV4 (needle valve) are used for stopping measuring

liquid when the vibrator is cleaned or calibration is performed using standard solution. (The needle

valve is also used for adjusting fl ow rate.) NV2 (needle valve) and NV3 (needle valve) are used for

draining liquid from the vibrator or for picking up sample for manual analysis.

When viscosity of a measuring liquid is to be lowered, for example, the pour point of measuring

liquid is high, arrange the density detector and the liquid pipe should be warmed individually. Steam

pipe can be connected to the density detector and the liquid pipe can also be traced by steam pipe.

V1 (“stop” valve) is to supply the steam to the density detector and V2 (“stop” valve) is to supply the

steam to tracing pipe. ST1 (steam trap) is used to drain condensed water.

(Note 1) Kind of valve used in the sampling equipment varies with the purpose of use. This

instruction manual gives a detailed name of equipment (for example, ball valve) used for

limited purpose, and shows a general name within “ ” when equipment type is not restricted (for

example “stop” valve).

(Note 2) Density Detectors of Model VD6D (general purpose type) and VD6DF (fl ameproof) have

steam pipe connections, however, Model VD6DS (sanitary use) has not the connections.

(Note 3) Model VD6SM sampling unit, a product of Yokogawa, is applied to Model VD6D (general

purpose type) or Model VD6DF (fl ameproof type). It is not recommended for the Model VD6DS

(sanitary use) used for food.

IM 12T03A01-02E

Page 30

3-4

< 3. INSTALLATION, PIPING AND WIRING >

Density meter sampling unit

Anchor bolt

Drain pit

Concrete base

Figure 3.6 Installation Example for Sampling Unit (Model VD6SM)

(2) Note of Designing a Density Meter Sampling Unit

• Minimize liquid pipe length to improve response.

• Design the piping not to allow air bubbles to remain in the pipe which may cause an error.

• Piping should not have sharp bending where solids may accumulate.

• Maintenance such as cleaning should be made easily.

• Select element material most suitable for measuring liquid. Especially, for foodstuff

measurement, the selection should be done strictly.

(3) Installation of a Density Meter Sampling Unit

For the density detector with the sampling unit or with the sampling equipment user provided,

installing place must

• be near to sample tap on the main pipe.

• be free from vibration

• meet the ambient conditions specifi ed by the hazardous area (when the detector is model

VD6DF fl ameproof type).

Moreover, the sampling unit should be fi xed to a concrete base drained well.

IM 12T03A01-02E

Page 31

< 3. INSTALLATION, PIPING AND WIRING >

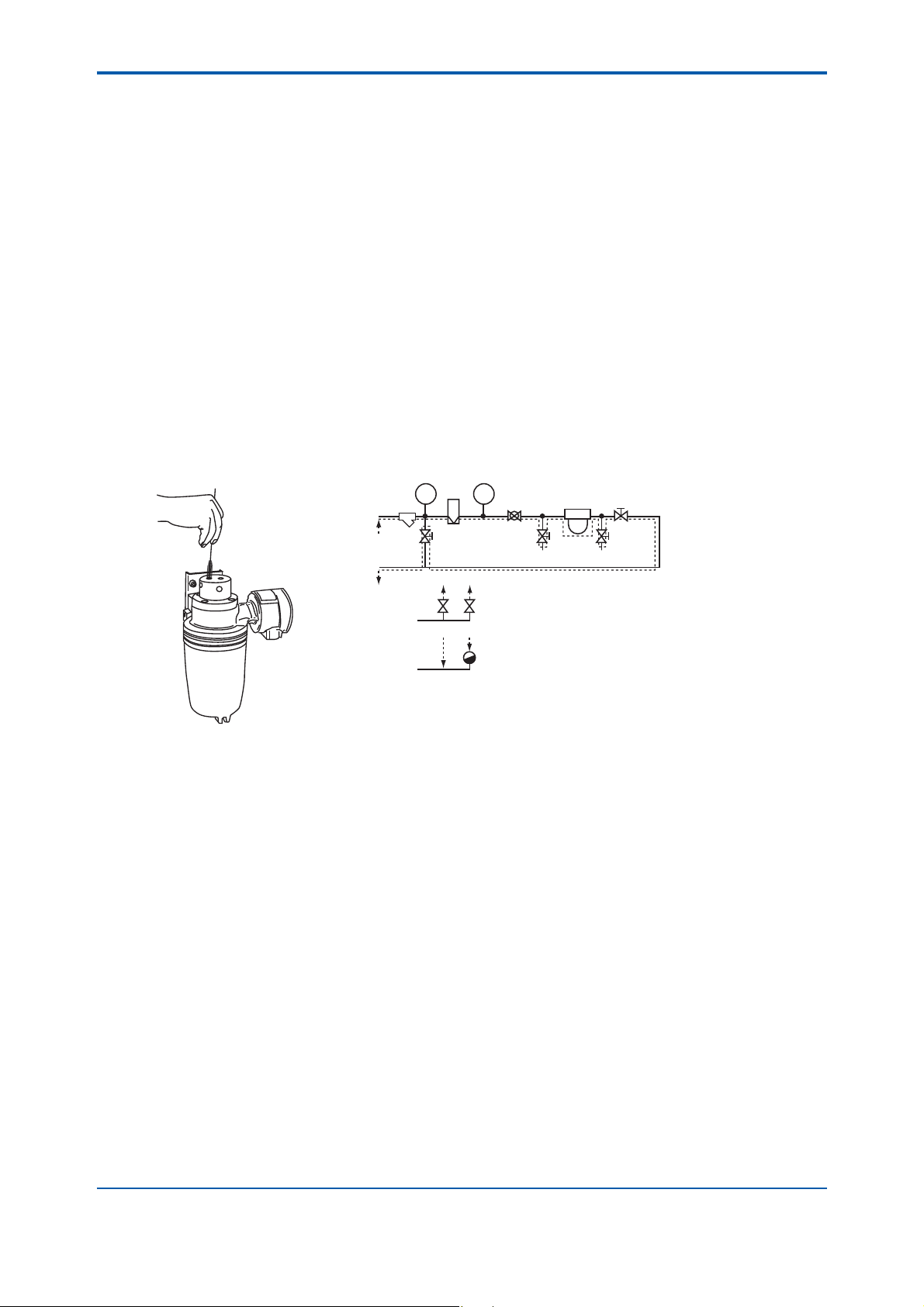

(4) Removing a Packing Sheet for Transportation from the Density Detector

The vibrator is fi xed to the amplifi er case to avoid being damaged during transportation.

Remove the rubber sheet used for the fi xing. The rubber sheet is inserted between the case and

the coupler of the vibrator assembly. Remove the sheet according the steps below. For component

names, refer to the section 4.1.1.

(a) Remove the lock with a hexagonal bar wrench. Release the cover by turning it counterclockwise

and pull it down not to touch the internal assembly.

(b) Remove the cover (with desiccant) from the vibrator.

CAUTION

The vibrator tube has extremely thin wall, hence must be carefully handled.

Since assembling the vibrator tube requires special skill, the exchange of the vibrator should be made

by Yokogawa.

(c) Release the lock-screw for the vibrator turning the screw counterclockwise completely with a fl at

chip screw driver. Turn it enough, if not, the vibrator may touch the screw during measurement

causing an error. In addition, pay attention not to bend or damage the vibrator because it is made

of a thin pipe.

3-5

(d) Pull out the rubber sheet avoiding applying force to the vibrator (refer to Figure 3.7).

Lock-screw

Use flat blade screw-driver

to turn this screw fully counterclockwise.

Pull rubber sheet

in this direction

Rubber sheet

Pull out this rubber sheet

after loosening the set screw.

Figure 3.7 How to Remove the Rubber Sheet

(e) Remount the cover removed in the item (b). Also remount the cover in the item (a) to the case

and lock it.

Now the removing the rubber sheet fi nishes. Keep the rubber sheet which is necessary for

transportation of the density converter.

IM 12T03A01-02E

Page 32

3-6

< 3. INSTALLATION, PIPING AND WIRING >

3.2 Installation of Density Converter

3.2.1 Installation Area

The density converter should be installed in the place described below;

(1) The vicinity of the sampling unit where maintenance or calibration is made easy. The density

converter is designed dustproof and rainproof structure so that it can be installed outdoors.

However, when it is used with the Model VD6DF fl ameproof detector, it cannot be installed the

hazardous area, must be installed in the nonhazardous area. Further, when digital output signal

is used for a receiver, able length between the converter and the receiver should be 10 m or less.

(2) Free from vibration.

Vibration may cause illegal contact in electric circuits.

(3) Avoiding from direct sunshine.

This instrument can be used in an ambient temperature of -10 to 55 °C. However, direct

sunshine in summer may heat the instrument over the range.

(4) Free from corrosive gases and dusts.

The structure of this converter is dustproof and rainproof. However, for maintenance (with

opening front door of the converter), installation in better environment is recommended. For the

same reason, the following (5) and (6) are conditions for selecting installation area.

(5) Avoiding excessive humidity.

(6) Avoiding wide temperature variation.

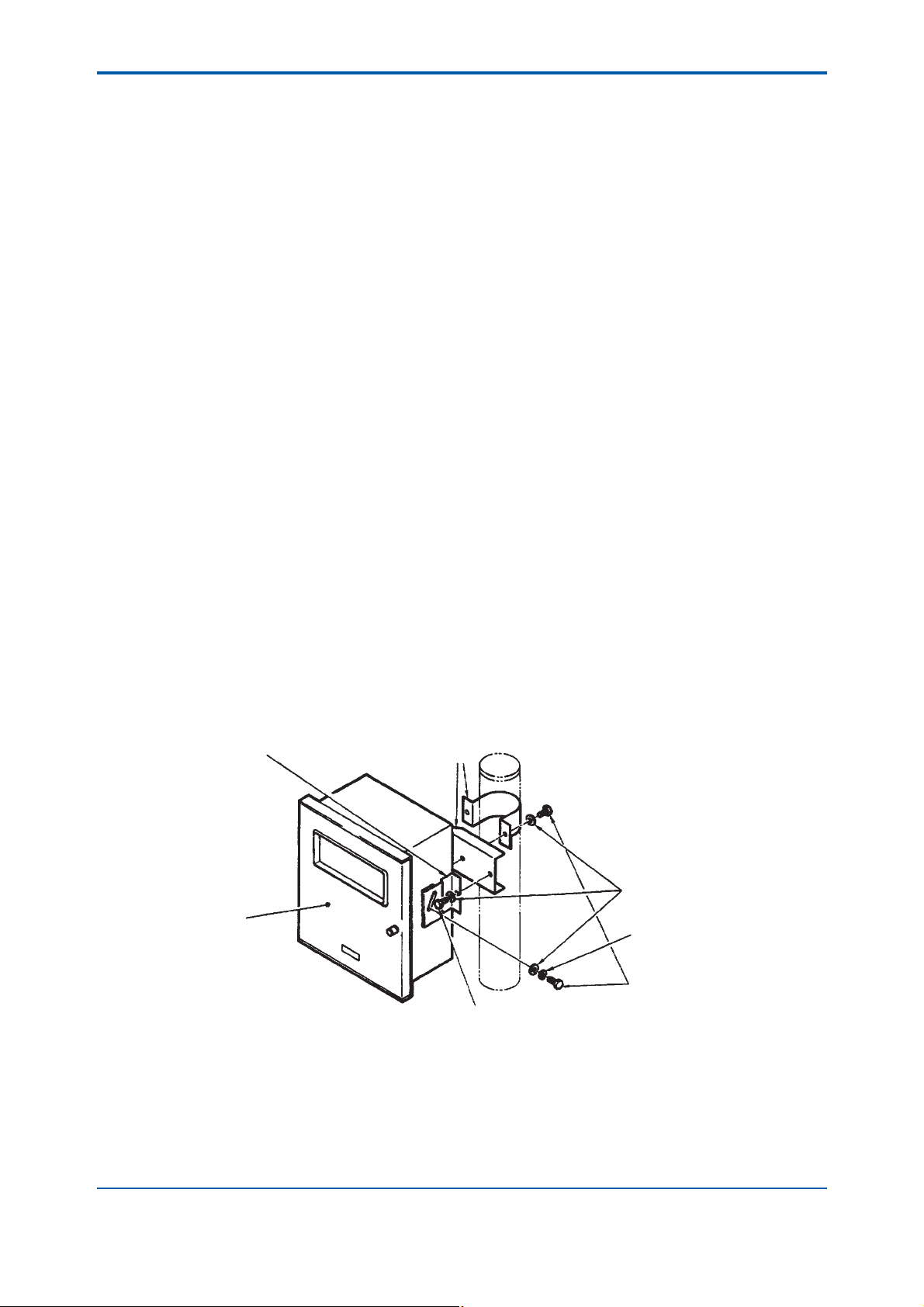

3.2.2 Installation of Density Converter

The density converter can be installed on a panel or a wall or 2-inch pipe. The pipe should be vertical

to fi x the mounting bracket on it (see Figure 3.8).

(Note) Mounting attitude is free from the converter performance. Mounting should be made of the

following procedures.

Mounting bracket

Converter

Pipe mounting

hardware

Washer

Spring washer

Bolt (M8x10)

Figure 3.8 Pipe Mounting

IM 12T03A01-02E

Bolt (M8x14)

Page 33

< 3. INSTALLATION, PIPING AND WIRING >

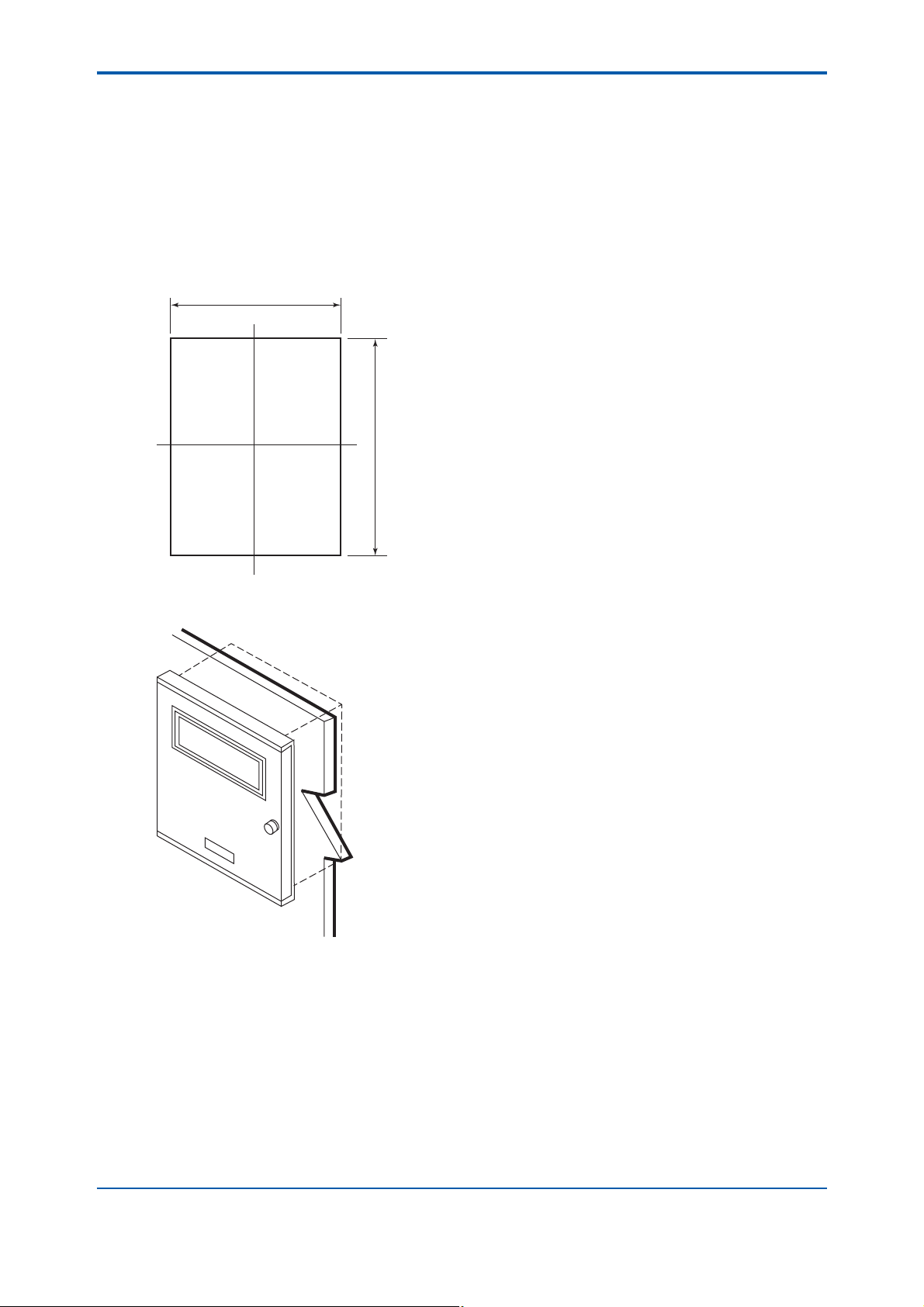

(1) Panel Mounting

The pipe mounting bracket should be removed from the converter before panel mounting.

Panel cutout dimensions are shown in Figure 3.9.

Before inserting the converter into front of the panel, remove the clumping brackets from both sides of

the converter case. After the case is inserted into a panel, remount the clumping brackets on the same

pace to hold the converter on the panel.

Figure 3.10 illustrates that the converter is mounted on a panel.

3-7

212 ±1

275 ±1

Figure 3.9 Panel Cutout Dimensions

Unit: mm

Figure 3.10 Panel Mounting

IM 12T03A01-02E

Page 34

3-8

(2) Wall Mounting

Remove the pipe mounting bracket from the converter before wall mounting. Make two holes for 8 mm

screws in a wall as illustrated in Figure 3.11.

< 3. INSTALLATION, PIPING AND WIRING >

222

2-M8 Screws

Figure 3.11 Holes for Wall Mounting

Unit: mm

Figure 3.12 Wall Mounting

Using two mounting brackets, mount the converter on the wall (see Figure 3.12).

IM 12T03A01-02E

Page 35

< 3. INSTALLATION, PIPING AND WIRING >

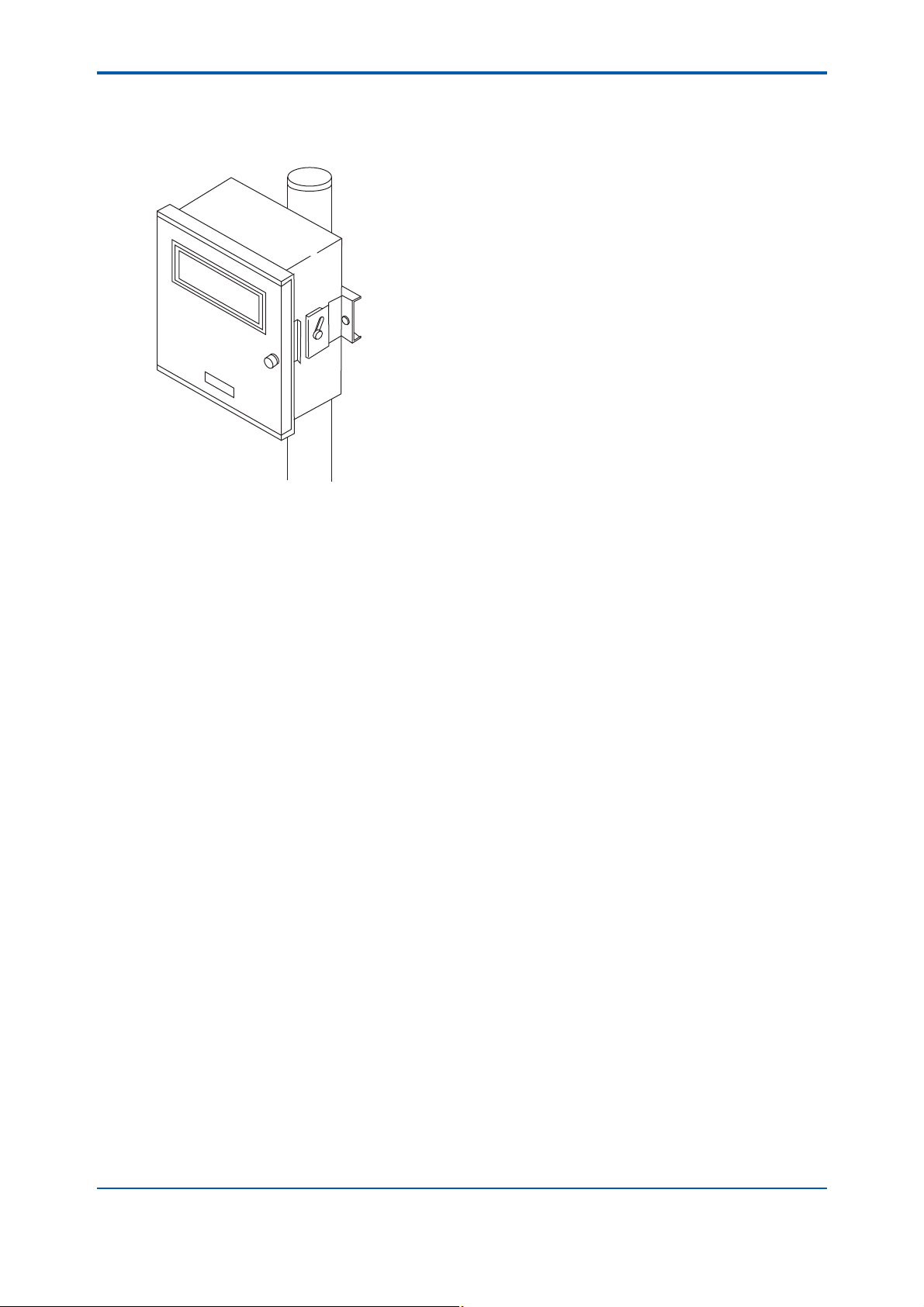

(3) Pipe Mounting

Mounting bracket is applied to the pipe of nominal size 50A (diameter 60.5 mm). As shown in Figure

3.13 mount the converter on the vertical pipe (inclination causes no problem).

Figure 3.13 Pipe Mounting

3-9

IM 12T03A01-02E

Page 36

3-10

< 3. INSTALLATION, PIPING AND WIRING >

3.3 Piping

The vibration type density meter requires the following piping;

(1) Sample liquid conduit

(2) Air piping for maintenance

(3) Steam piping

(4) Piping for air purge

Sample liquid conduit is a pipe to conduct measuring liquid to the density detector. Air piping for

maintenance is to obtain air to blow away liquid from the vibrator at maintenance (vibrator cleaning,

calibration with standard solution). Steam piping which is installed according to requirement is to

obtain a steam to heat the sample liquid conduit. Air purge piping is necessary when the converter is

installed in dusty environment.

The sample liquid conduit referred here indicates pipes between the main process pipe and the

sampling equipment. For piping within the sampling equipment, refer to Section 3.1.2.

3.3.1 Sample Liquid Conduit

This piping conducts the measuring liquid to the sampling unit. The main process pipe should have

two sampling taps (sample inlet and sample return) as shown in Figure 3.14. The sample conduit

from the sample inlet is connected to ‘SAMPLE IN’ of the sampling unit and the other conduit from the

sample return to ‘SAMPLE OUT’ of the sampling unit.

The piping procedure is as follows:

(1) Select the tap locations for the sample inlet and the sample return to make the pressure

difference between them become at least 0.1 MPa.

(2) The pipe length between the sample inlet and the SAMPLE IN should not exceed 10 m. Use

stainless steel pipe of nominal diameter 15 mm or Sch 40 to 80.

(3) Install stop valves and drain valves near the sampling unit.

Main process pipe line

(Pressure at inlet)

P

in

Sample conduits

(10 m max.)

Tap valve Stop valve

Drain valve Drain valve

P

(Pressure at outlet)

out

2 MPa > Pin

3

+ 0.1 MPa)

out

Figure 3.14 Sample Liquid Conduits

(4) Avoid sharp bending of the pipe to prevent accumulation of sludge.

IM 12T03A01-02E

Sampling unit

for vibration type density meter

Page 37

< 3. INSTALLATION, PIPING AND WIRING >

3-11

Sampling unit

Sampling line

Figure 3.15 Example of Wrong Piping

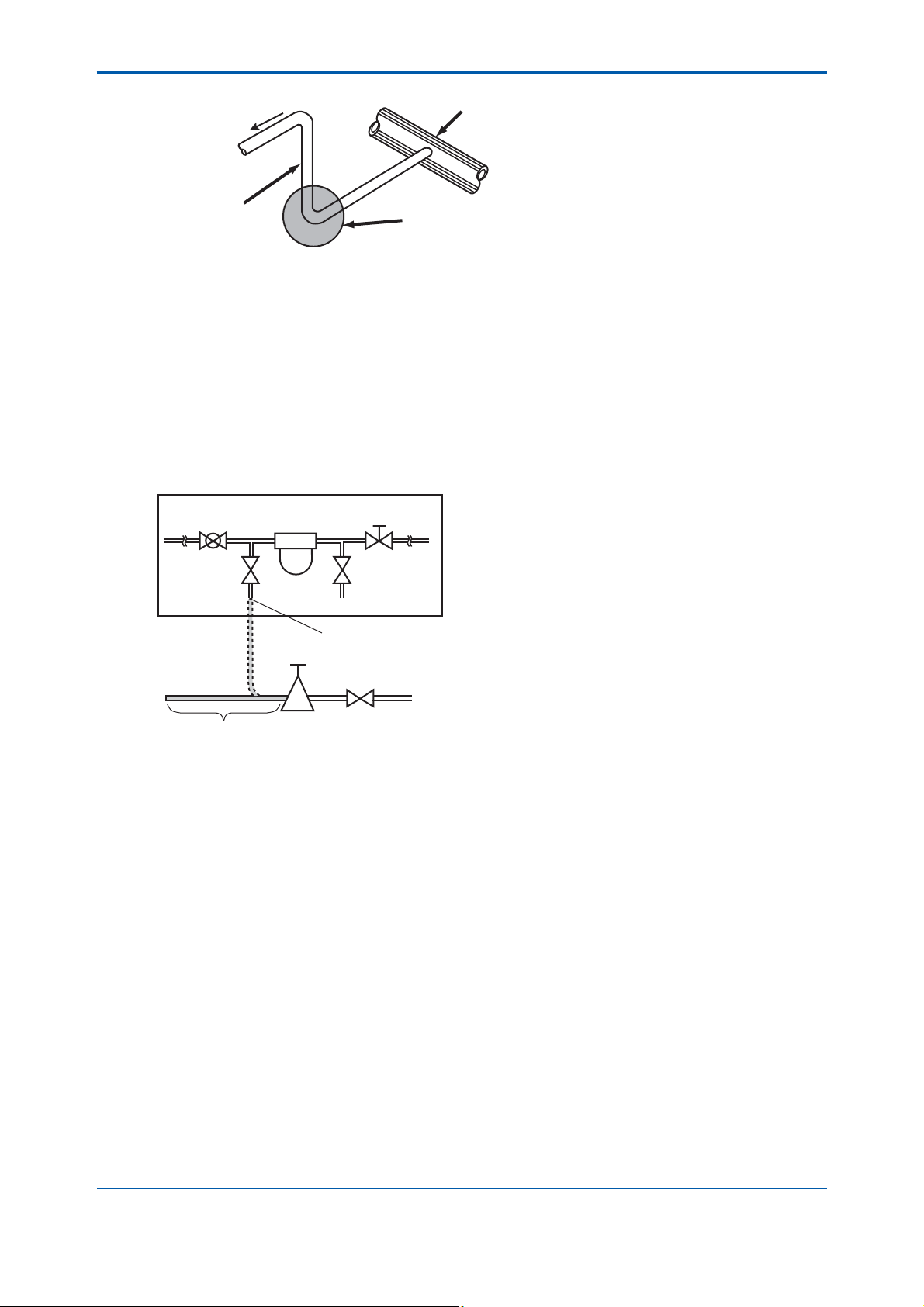

3.3.2 Air Piping for Maintenance

When cleaning the vibrator or calibrating the meter with standard solution, blow away liquid from the

vibrator by air pressure. Air should be clean and dried with 0.3 to 0.5 MPa G.

Mount a ‘stop’ valve and a ‘pressure regulator’ on the pipe from the air source, and fi x a fl exible tube

with a copper tube with outside diameter 10 mm should be provided for connecting with the detector.

Connect the air pipe to the sampling unit only for cleaning the vibrator or calibration with the standard

solution.

Sampling unit

BV1 DD NV4

Main pipe

Sludge is likely to collect here.

Flexible tube

Figure 3.16 Air Piping for Maintenance

3.3.3 Steam Piping

This is installed to heat measuring liquid whose pour point is high, and to decrease its viscosity. The

sampling unit with steam trace pipes should be used for this purpose.

Connect a pipe from steam source to the sampling unit ‘STEAM IN’ inlet. The sample liquid conduit

also should have a steam tracer pipe. Steam of pressure 0.3 to 0.5 MPa and temperature of 140 to

160 °C is preferable.

Installing the tracer pipe for the sample liquid conduit should be performed after pressure retentive

and leak test of the conduit.

Notes for the tracer piping are as follows.

Reducing

valve

NV3NV2

Connect when cleaning the density detector

Air supply 300 to 500 kPa G

Stop valve

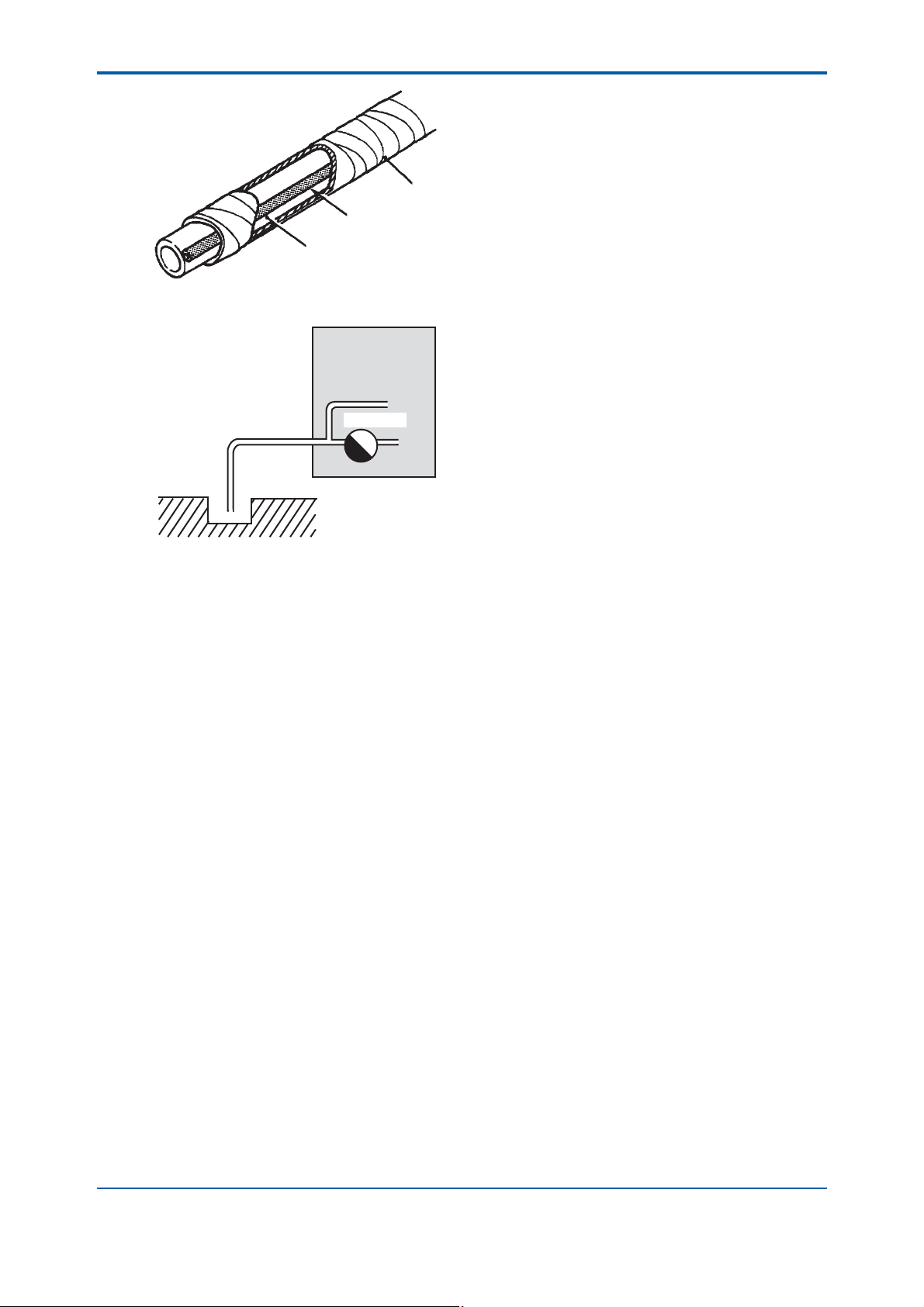

(1) The tracer pipe of the sample liquid conduit should be installed such that the entire conduit can

be heated. The pipe should also be covered with insulating material (see Figure 3.17).

(2) The steam trap discharge outlet should be open to the atmosphere (see Figure 3.18).

IM 12T03A01-02E

Page 38

3-12

< 3. INSTALLATION, PIPING AND WIRING >

Heat insulating material

Trace pipe

Sampling line

Figure 3.17 Steam Tracer Pipe

Steam trap

Sampling unit

Drain pit

Figure 3.18 Piping at Steam Trap Discharge Outlet

3.3.4 Piping for Air Purge

If the density converter is installed in dusty environment, air purging is recommended.

Air purge should be performed continuously by clean dried air with pressure of 50 kPa G. Size Ø6

x Ø4 mm copper or stainless pipe should be used to connect air source to the purge air inlet of the

converter.

The air inlet is Rc1/8 female connection. If specifi ed, a connector for an Rc1/4 female or 1/4NPT

female screw is provided.

IM 12T03A01-02E

Page 39

< 3. INSTALLATION, PIPING AND WIRING >

3.4 Wiring

The vibration type density meter requires the following wirings:

(1) Wiring between analog output signal

(2) Wiring for analog output signal

(3) Wiring for digital output signal (10 m or less length is recommended).

(4) Wiring for contact output for abnormal status

(5) Wiring for power supplying

(6) Wiring for grounding

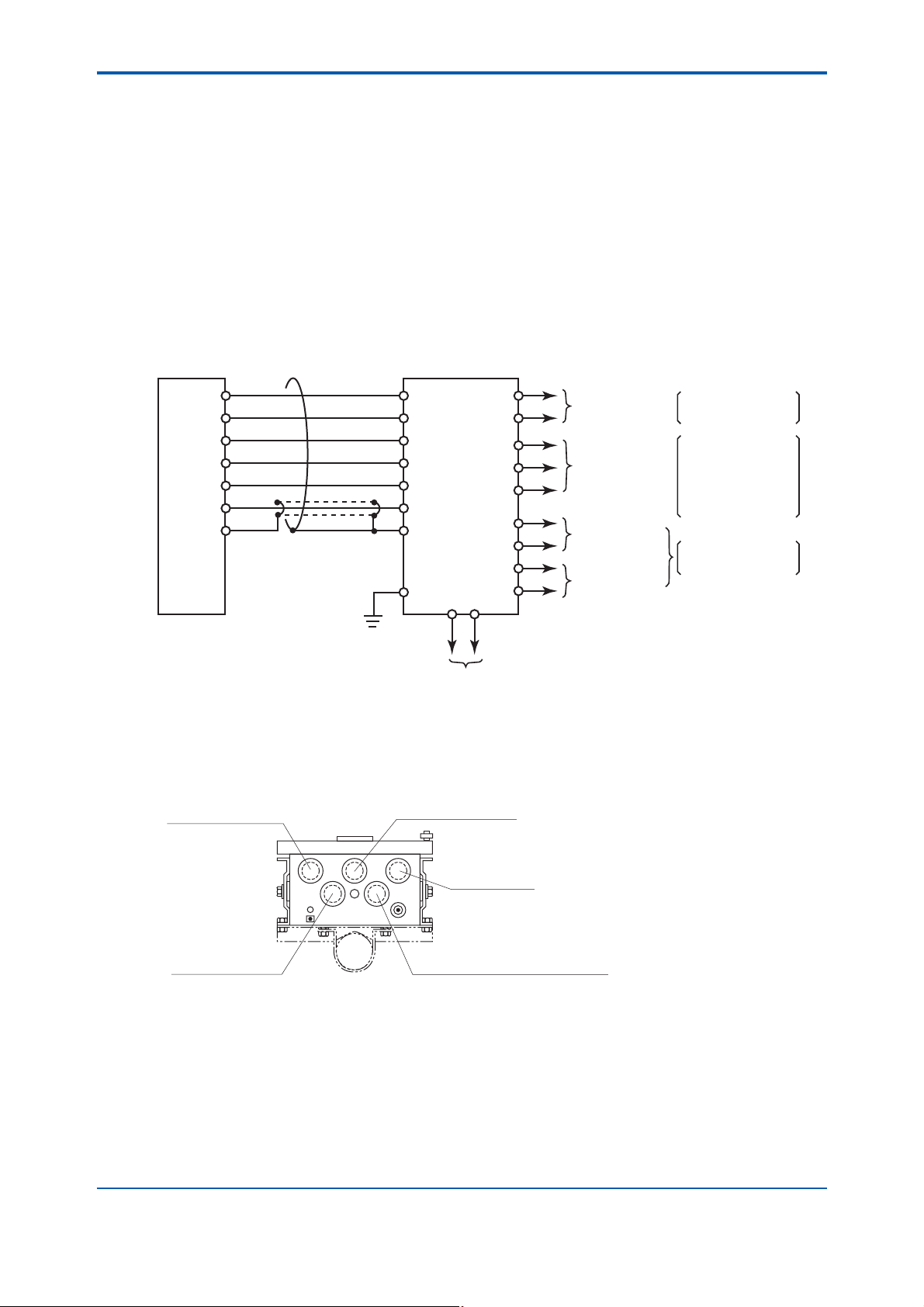

Figure 3.19 is a diagram of these wirings.

Detector Special cable Converter

A2

A3

A4

A6

A5

B4

B5

RED

BLUE

YELLOW

BROWN

GREEN

WHITE

GRAY

A2

A3

A4

A6

A5

B4

B5

G

L1 L2

N.C

SG

RD

TD

C

+

-

Alarm

RS-232-C signal

0 to 1 V DC

+

-

4 to 20 mA DC

Closed when a

failure is detected or

the power fails.

Density signal after being

converted to the reference

temperature state

Density signal before being

converted to the reference

temperature state

7HPSHUDWXUHVLJQDO

Density signal after being

converted to the reference

temperature state

3-13

Power supply

Figure 3.19 Wiring Diagram

The cable inlet of the density detector is located at the bottom of the terminal box. The density

converter has fi ve cable inlets and their size is 27 mm. A cable can pass any inlet of them (one cable

to one inlet). Figure 3.20 shows an example of allocated inlets.

Analog output signal

Inlet of special cable

Power supply

Contact output for abnormal statusDigital output signal

Figure 3.20 Cable Inlet of Density Converter

IM 12T03A01-02E

Page 40

3-14

< 3. INSTALLATION, PIPING AND WIRING >

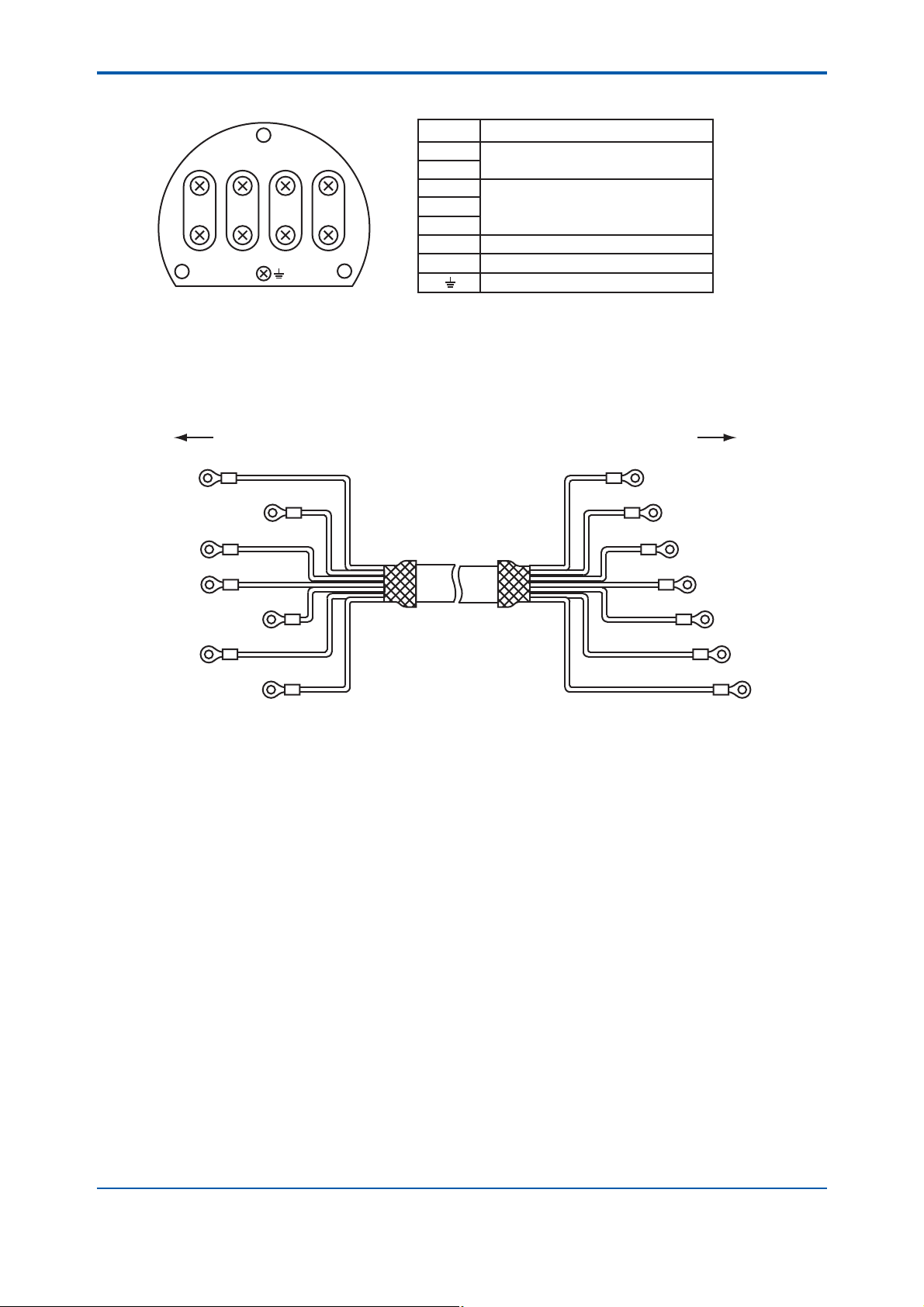

Figure 3.21 shows terminal arrangement of the density detector.

Terminals Function

B4

B5

A2 A3 A5 B4

A4 A6 B5

A2

A3

A4

A5

A6

Figure 3.21 Terminal Arrangement of Density Detector

3.4.1 Wiring between Detector and Converter

This wiring is to be carried out with special cable of specifi ed length. The cable is terminated as

illustrated in Figure 3.22. Pay attention not to stain or wet terminated.

Output Frequency

Temperature Sensor

Power Supply for Pre-amp

Impressed Voltage for Pick-up Electrode

Earth Terminal

Density detector

B4

WHITE

B5

GRAY

A2

RED

A3

BLUE

A4

YELLOW

A5

GREEN

A6

BROWN

Figure 3.22 DM8W Cable

(Connection to Density Detector)

Remove the cover of the terminal box, using the spanner in accessories, and insert the special cable

into the cable inlet. Connect each conductor to the respective terminals.

A fl exible fi tting is used at the inlet of the density detector (note) and the cable from the detector runs

though metal conduit to the duct. For Model VD6DF explosionproof detector, wiring should be made

complying with the Recommended Practice.

Density converter

B4

WHITE

B5

GRAY

A2

RED

A3

BLUE

A4

YELLOW

A5

GREEN

A6

BROWN

The explosionproof fl exible fi tting for wiring should be used at the cable inlet (G3/4 female) of the

detector.

IM 12T03A01-02E

(Note) The fl exible fi tting is not inevitable. The Detector not moved for usual check or maintenance

does not require the fl exible tube.

Page 41

< 3. INSTALLATION, PIPING AND WIRING >

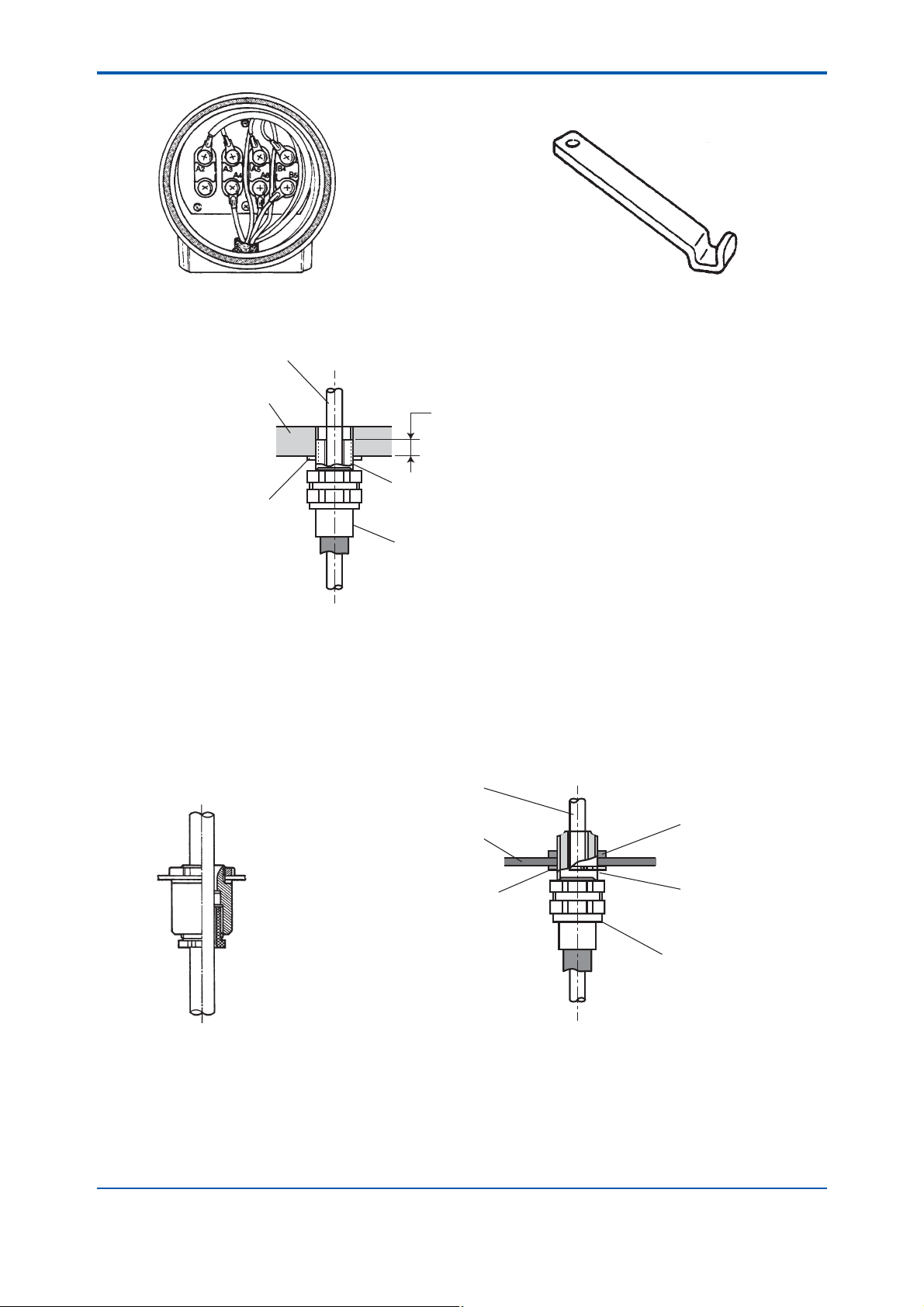

Figure 3.23 Wiring to Density Detector Terminals Figure 3.24 Spanner for Open/

closing Terminal Box Cover

Cable

Terminal box case

Be sure to screw in

at least 12 mm (5 threads)

G3/4 screw (TIIS explosionproof)

Lock nut

3/4NPSM (FM explosionproof)

3-15

Figure 3.25 Explosionproof Flexible Fitting

(Connection to Density Converter)

The density converter is installed in fi eld or indoors (control room). The connector for passing through

cable should be sealed for air purge. The connector with a ring packing as shown in Figure 3.26

should be used, or the inlet of metal conduit is fi lled with silicon sealing compound. Duct or protective

pipe for the cable should be provided to prevent the cable from damage.

Explosionproof flaxible fitting

Cable

Converter case

Lock nut

Nut

G3/4 screw

Flaxible fitting

Figure 3.26 Packing Gland

Figure 3.27 Cable Inlet for Metal Conduit

Type Connector for

Passing through Cable

Take the special cable into the converter from the leftmost inlet and connect the each conductor to the

respective terminals.

IM 12T03A01-02E

Page 42

3-16

< 3. INSTALLATION, PIPING AND WIRING >

3.4.2 Wiring for Analog Output Signal

Output signal of 4 to 20 mA DC output (load resistance 550 Ω or less) and 0 to 1 V DC (load

resistance 250 kΩ or more) are provided. Carry out either or both of wirings as necessary.

Shielded 2-conductor (for one signal) or 4-conductor (for two signals) cable are used for wiring. For

connecting the cable to the converter, remove the sheath of conductor about 50 mm from its end, and

attach a solderless lug for M4 screw omit. The shield of the cable should be grounded at the receiving

unit.

Wiring method (metal conduit and others) is same as that of Section 3.4.1.

3.4.3 Wiring for Digital Output Signal

The Model DM8C density converter outputs digital signals through RS-232C interface besides analog

signal (for details of digital signal, refer to “Standard Specifi cations” in Chapter 1).

When using this signal, use a shielded 3-conductor cable for wiring. Cable length from the converter

to a receiving unit should be 10 m or less.

Cable termination is same as that of Section 3.4.2, however, remove the sheath of conductor 80 mm

from the end.

Wiring method is also same as that of Section 3.4.1.

3.4.4 Wiring for Abnormal Status Contact Output

When an error (see Table 4.2) occurs with an abnormality in the density measuring system, a contact

signal is output.

For wiring of this contact output, use 2-conductor cable. When connecting the cable to the converter,

remove the sheath of conductor 80 mm from its end and attach a solderless terminal for M4 screw.

Wiring method is same as that of Section 3.4.1.

3.4.5 Wiring for Power Supply

This wiring is to supply the converter with power.

Use shielded 2-conductor cable for wiring. Cable termination and wiring method are the same as

those for analog output signal in Section 3.4.2.

3.4.6 Wiring for Grounding

As a rule, the case of the density detector and the density converter should be earthed.

The grounding terminal of the detector is located on the base for the mounting bracket, and of the

converter, on the bottom of the case. Perform wiring so that ground resistance is 100 Ω or less

(Class D) using a wire of 2 mm

2

nominal cross-sectional area.

IM 12T03A01-02E

Page 43

< 4. OPERATION >

4. OPERATION

4.1 Component Names and Function

4.1.1 Density Detector

4-1

Vibrator assembly

Terminal box

Terminal box cover

Cover

Figure 4.1 Density Detector

Lock

Vibrators

Piezoelectric

element

Lock-screw

(Keep loose during detector operation)

Case

Capacitance

pickup electrode

Oscillation

amplifier

Coupler

IM 12T03A01-02E

Page 44

4-2

< 4. OPERATION >

4.1.2 Density Converter

Data Display: Function No. and data are displayed.

Front door

Data sheet

)81&7,211RNH\

Function No. display Data display

Fastener (Nyratch)

Internal assembly fixing screw

(for transportation)

,1&5ŸNH\

Increases the number of a

flashing digit.

6(7NH\

Used to enter a displayed

data.

6+,)7ŹNH\

3UHVVHGWKLNH\GLVSOD\HG

number flashes. Flashing

digit shifts right with every

SUHVVLQJRIWKHNH\

Mode transfer switch

DSPL (measuring mode):

0RGHIRUQRUPDORSHUDWLRQ,QWKLVPRGHGHQVLW\DWWKHUHIHUHQFH

WHPSHUDWXUHGHQVLW\DWPHDVXULQJWHPSHUDWXUHRUPHDVXULQJ

temperature value is displayed by transferring function No.

CAL (calibration mode):

Mode for calibration

MAINT (maintenance mode):

0RGHIRUFKHFNRIRSHUDWLQJFRQGLWLRQVHWWLQJDGHWHFWRUFRQVWDQW

a reference temperature.

Figure 4.2 Component Names of Density Converter

Cover of terminal board

IM 12T03A01-02E

Page 45

< 4. OPERATION >

4.2 Operation

4.2.1 Operation Mode

Operation of the Model DM8 vibration type density meter ruled by the mode as shown in Table 4.1.

Measuring mode (DSPL), calibration mode (CAL) and maintenance mode (MAINT) are transferred

with the mode transfer switch.

Table 4.1 Operation Modes and Function No.

4-3

MODE SW

Measuring

mode

(DSPL)

Calibration

mode (CAL)

Maintenance

mode

(MAINT)

FUNCTION

NO.

No display

1

2

3

4

5

6

7

8

9

A

1.

2.

3.

4.

5.

6.

7.

8.

9.

A.

B.

C.

D.

Contents Display

Displays density (at reference temperature)

Displays density (measured value)

Displays measuring liquid temperature

Sets density of calibration solution 1

Sets temperature of calibration solution 1

Sets temperature coeffi cient of calibratio solution 1

Starts calibration 1 (press SET key)

Sets density of calibration solution 2

Sets temperature of calibration solution 2

Sets temperature coeffi cient of calibratio solution 2

Starts calibration 2 (press SET key)

Canceles protect (enter 77)

Displays frequency (density)

Displays frequency (temperature)

Checks output signal

Checks LED (press SET key)

Sets low limit of the output range

Sets high limit of the output range

Sets reference temperature of measuring liquid

Sets temperature coeffi cient of measuring liquid

Sets detector constant A

Sets detector constant B

Displays detector calibration coeffi cient C (span)

Displays detector calibration coeffi cient D (zero)

3

g/cm

3

g/cm

°C

. g/cm

. °C

-5

–x10

(displays density after calibration)

CAL-1

g/cm3/°C

. g/cm

. °C

-5

–x10

(displays density after calibration)

CAL-2

g/cm3/°C

7 7

Hz

Hz

%

- LED - (fl ash 5 times)

. g/cm

. g/cm

. °C

-5

–x10

g/cm3/°C

3

3

3

3

(1) Measuring mode (DSPL): Mode for normal operation

An analog output in this mode is density value at the reference temperature.

Moreover, density value at measuring liquid temperature and temperature of measuring liquid

are digitally output. The density value at the reference temperature (without function No. display),

the density value at measuring liquid temperature (No.1) or the measuring liquid temperature

(No.2) can be displayed by selecting function No. Use FUNCTION key to select the FUNCTION

No.

(2) Calibration mode (CAL): Mode for calibration. Sets or specifi es data required for

calibration.

During this mode the analog and digital outputs are held (at the values just before the holding).

However, digital data output stops during calibration function No. ‘6’ or ‘A’.

When calibration computation ends holding is released and measured data are again output until

function No. ‘6’ or ‘A’ is transferred to another No.

IM 12T03A01-02E

Page 46

4-4

< 4. OPERATION >

Digital signal (Note 1)

Measuring mode (DSPL)

Maintenance mode (1)

(MAINT)

Transfer to

Calibration mode

Calibration start

While in calibration

computation

Calibration end

Calibration mode

function No. transfer

Calibration mode (CAL)

or waiting for mode

transfer

Function No.

transfer (2)

Maintenance mode (3)

(MAINT)

Measuring mode (DSPL)

Note 1: The density value after temperature conversion, density value at the measuring temperature and measuring liquid

temperature are transmitted in digital form. (Only the density value after temperature conversion is transmitted in analog form.)

Note 2: The density converter displays CAL-1 or CAL-2.

Measured

value

(1)

Hold

Output stop

Measured

value

(2)

(3)

Measured

value

Hold

(Note2)

Measured

value

Hold

Measured

value

Measured

value

Measured

value

Analog signal

(1)

Hold

(2)

(3)

Measured

value

Hold

Hold

Measured

value

Figure 4.3 Digital and Analog Signal Output Statuses

Eight function Nos. from ‘3’ to ‘A’ are provided in the calibration mode (see Table 4.1). Among

them, ‘6’ and ‘A’ are to specify the calibration computation and others are to input data required

for the calibration.

Function No. ‘3’: Sets density of calibration solution 1

3

Density value (g/cm

) of a calibration solution for one-point calibration or 1st calibration of two-

point calibration can be input. The input density is a data at the reference temperature.

(Note) If relation between temperature and density is well known, a density at a temperature

can be set. However, the density data at the reference temperature is recommended to

achieve accurate calibration.

Function No. ‘4’: Sets temperature of calibration solution 1

Input the temperature of the calibration solution 1 of which density at the reference temperature

is set at ‘3’.

Function No. ‘5’: Sets temperature coeffi cient of calibratio solution 1

3

Enter the value which is -100000 times the temperature coeffi cient (g/cm

/°C) of the liquid for

calibration 1.

(Note) The temperature coeffi cient -0.00086 g/cm3/°C becomes the value 086.

Function No. ‘6’: Starts calibration 1 (press SET key)

(Note) For calibration procedure, refer to Section 4.4.

IM 12T03A01-02E

Pressing “SET” key executes calibration computation, or also executes the fi rst calibration of the

two-point calibration.

Page 47

< 4. OPERATION >

Function No. ‘7’: Sets density of calibration solution 2

3

Density data (g/cm

) for the 2nd calibration (calibration solution 2) of two-point calibration can be

input. As a rule, the input density is data at the same reference temperature as that of ‘4’.

(Note) If relation between temperature and density is well known, a density at a temperature can

be input. However, the density data at the reference temperature which is same as that of

‘4’ is recommended to achieve accurate calibration.

Function No. ‘8’: Sets temperature of calibration solution 2

Enter the temperature of calibration solution 2 of which density at the reference temperature is

set at ‘7’.

Function No. ‘9’: Sets temperature coeffi cient of calibratio solution 2

3

Enter the value which is -100000 times the temperature coeffi cient (g/cm

/°C) of the calibration

solution 2.

Function No. ‘A’: Starts calibration 2 (press SET key)

Pressing “SET” key executes 2nd calibration computation of two-point calibration.

(3) Maintenance mode (MAINT): Mode for adjusting and checking operating conditions.

During this mode, analog and digital outputs are held (at the value just before holding).

4-5

Function No. in maintenance mode is from ‘1.’ to ‘D.’ (see table 4.1).

Function No. ‘1.’: Canceles protect (enter 77)

Function to avoid data changing due to carelessness. When “0” is displayed, a function No. is

not entered. To release the protection, display “77” and press “SET” key. When protecting again,

display any number other than “77” (for example 78) and press “SET” key. This operation is

invalid unless some operation is made after the protection release (for example, setting function

No. ‘2’).

Function No. ‘2.’: Displays frequency (density)

Checks operation of this converter. Frequency corresponding to measured density are

displayed. When the converter is normal, the frequency ranges from 600 to 700 Hz to 1000 or

1500 Hz.

(Note) Displayed frequency varies with measured density, liquid temperature and detector

3

constant. If density is 0.5 to 2.0 g/cm

, temperature is 25 °C, detector constant (A) is 17074

and detector constant (B) is 36384, the frequency is 640 to 1400 Hz for normal operation.

Function No. ‘3.’: Displays frequency (temperature)

Checks operation of this converter. A frequency signal converted from liquid temperature voltage

is displayed. If temperature is 25 °C, the frequency is about 25000 to 35000 Hz for normal

operation.

Function No. ‘4.’: Checks output signal

Checks zero point and span of an analog output signal.

(Note) The data at shipping is described in a data sheet in the converter.

Function No. ‘5.’: Checks LED (press SET key)

Function to check LED data display. When “SET” key is pressed, all displays fl ash fi ve times if it

is normal.

Function No. ‘6.’: Sets low limit of the output range

3

Sets a low limit density value (g/cm

) of an analog output range.

IM 12T03A01-02E

Page 48

4-6

< 4. OPERATION >

Function No. ‘7.’: Sets high limit of the output range

3

Sets a high limit density value (g/cm

) of an analog output range.

(Note) Difference between high and low limit value should be 0.05 g/cm3 or more. If an

inadequate value is set, the function No. returns to ‘6.’ operations of ‘6.’ and ‘7.’ are related;

when setting is made at ‘6.’ setting should also be made at ‘7.’.

Function No. ‘8.’: Sets reference temperature of measuring liquid

Sets a reference temperature (°C) of measuring solution.

Function No. ‘9.’: Sets temperature coeffi cient of measuring liquid

5

Sets the value which is -1 x 10

(= -100000) times the temperature coeffi cient of measuring

solution (g/cm3/°C) to change it to plus integer.

(Note) Purifi ed water is an exception; its maximum density is at approx. 4 °C.

Generally, temperature coeffi cients of any liquids are minus number.

Function No. ‘A.’: Sets detector constant A

Sets the detector constant A. Since the detector constant A is an inherent characteristic of the

detector, this is indicated in each detector.

(Note) Detector constant A changes with each calibration.

Function No. ‘B.’: Sets detector constant B

Sets the detector constant B. Since the detector constant B is also an inherent characteristic of

the detector, this is indicated in each detector.