Page 1

User’s

Manual

Model AC4/AC8 Automatic Calibration Unit

For Use With AV550G

Oxygen Analyzer Averaging Converter

I. Introduction.................................................................................................3

II. Overview......................................................................................................3

2.1 Models AC4/AC8 Multi-Channel Automatic Calibration ...............................................................3

III. Installation ...................................................................................................3

3.1 Location ..........................................................................................................................................3

3.2 Mounting .........................................................................................................................................3

3.3 Gas Sources ...................................................................................................................................4

3.4 Piping ..............................................................................................................................................5

IV. Wiring ..........................................................................................................6

4.1 Wiring the AC4/AC8 to the AV550G Averaging Unit ......................................................................6

4.2 Pressure Switch, M1133AR, Set Point Procedure .........................................................................6

V. Initial Flow Rate Set-Up ............................................................................. 7

5.1 Checking for Leaks .........................................................................................................................7

5.2 Setting for Reference Air Flow........................................................................................................7

5.3 Balancing Pressure Drops in the Cal Lines ...................................................................................8

5.4 Calibration Check ...........................................................................................................................9

VI. Programming .............................................................................................. 9

VII. Set-Up Menus for Calibration from the AV550G Averaging Unit ........... 9

7.1 Modes .............................................................................................................................................9

7.1.2 Calibration Setup Mode .............................................................................................................10

7.1.3 Zero Gas Concentration ............................................................................................................10

7.1.4 Span Gas Concentration ...........................................................................................................10

VIII. Maintenance ............................................................................................. 12

IX. Trouble shooting ....................................................................................... 12

9.1 Typical Calibration Problems ........................................................................................................12

X. Spare Parts and Accessories ..................................................................13

10.1 Spare Parts .................................................................................................................................13

10.2 Accessories ...............................................................................................................................14

10.2.1 Zero Gas Regulator, M1132ZX ........................................................................................15

10.2.2 Pressure Regulator, M1132KD ........................................................................................15

10.2.3 Pressure Gauge, M1132CG ............................................................................................15

10.2.4 Zero Gas Pressure Switch, M1133AR .............................................................................16

10.2.5 Fuses, M1132HG .............................................................................................................16

Appendix A Wiring Diagram AC4 to AV550 to ZR22G ..................................17

Appendix B Wiring Diagram AC8 to AV550 to ZR22G ..................................19

IM 11M6D2-02E-A

2nd Edition

Page 2

Page 3

3

IMPORTANT

NOTE

AUTO CALIBRATION UNIT FOR AV 550G

AC44 Channel System

AC88 Channel System

ENCLOSURE

-4 NEMA 4

-5 NEMA 4X

PL UM BING

-C Copper tubing , brass fittings

-S Stainless steel tubing and fittin gs

REFE RENCE AIR FLOW METER

-R*U Refere nce air flow meter

OPTIONS

/SCT Stainless Steel Tag

NOTE

IMPORTANT

I. INTRODUCTION

This manual details the operating instruction for the Yokogawa Model AC4/AC8 Automatic Calibration Unit, and the

integration with the AV550G Zirconia Oxygen Averaging

Converter.

The maximum input pressure for the span and zero gases is 35

psig. Exceeding 35 psig may result in damage to the AC4/AC8.

II. OVERVIEW

The AC4/AC8 Automatic Calibration System is designed to

work with the AV550G Oxygen Averaging Converter, providing accurate, automatic or semi-automatic calibration of the

ZR22 Zirconia Oxide Detector. The AC4/AC8 is assembled

with plumbing, flow control hardware and internal solenoid

wiring necessary to calibrate up to four or eight probes

respectively. The end user need only provide plumbing to the

individual probes, calibration gases, and interconnection wiring between the calibration unit and the converter.

Initial setup of the auto cal unit is further simplified by the

use of manual overrides for all solenoids. The overrides,

coupled with the flow regulation for each probe, allow for

fast balancing of each calibration line. Each probe also has

its own flow meter and flow control for the reference air flow.

2.1 Models AC4/AC8 Multi-Channel Automatic

Calibration

UStandard Specifications

Operating Pressure: 20 psi

Maximum Pressure: 35 psi

Flow meter range: 0.15 to 1 LPM (separate flow meter

for cal gas and reference air)

Flow rate: Cal Gas – 0.6 LPM;

Reference Air – 0.8 LPM

Cal tubing: 1/4” copper (standard);

1/4: stainless steel (optional)

Gas connection: 1/4” FNPT

Voltage: 110 VAC, 50/60 Hz (standard)

Ambient temp.: 80°C (176°F) maximum

Weight: Approximately 40 lbs (18 kg)

Construction: Outdoor installation (Indirect sunlight)

Enclosure: NEMA 4 or NEMA 4X

Reference gas

Consumption: 0.8 LPM per probe

Cal Gas Consumption

(Zero & Span): 0.6 LPM per probe,

during calibration only

Instrument air is used for both span calibration gas and

reference air.

Model and code

III. INSTALLATION

3.1 LOCATION

The following guidelines should be used when selecting a

location for the auto-calibration unit.

1. The unit must be easily accessible for maintenance and

inspections.

2. The unit must be near the ZR22 probes as practical. This

will minimize the length and amount of tubing required for

plumbing.

3. Ambient temperature will not exceed 80°C (176°F).

4. Humidity is moderate and no corrosive gases are present.

5. Minimal presence of vibration.

6. Availability of 120 VAC and clean, dry instrument air.

7. Adequate spacing for reference and zero gas plumbing.

8. Not positioned in direct sunlight.

If ambient atmosphere contains corrosive gases or high dust,

the use of air purging is recommended.

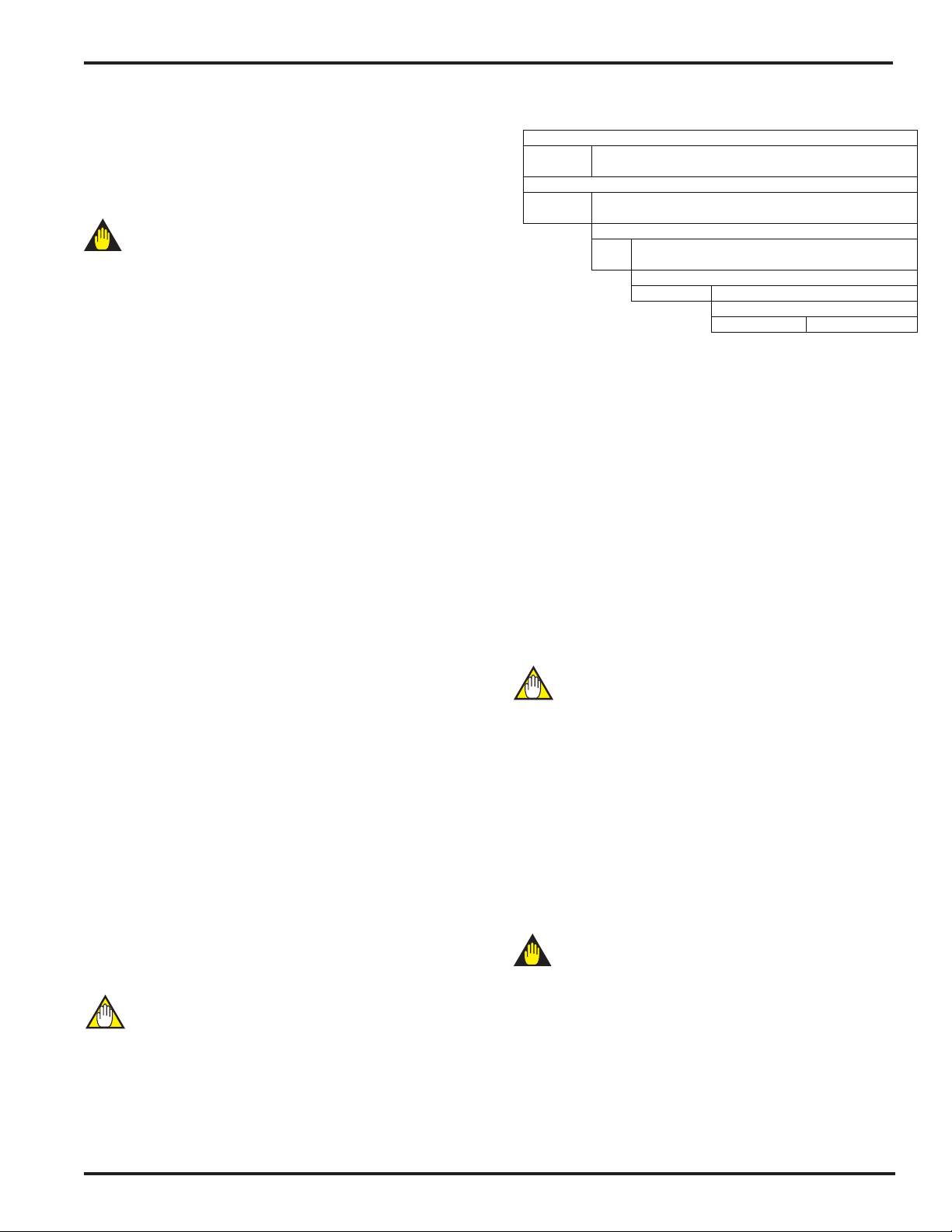

3.2 MOUNTING

The unit is designed for wall mounting by securing the four

standoffs with bolts. Allow for sufficient space to connect the

copper or stainless steel lines to both sides of the enclosure.

Input gases (zero calibration gas and instrument air) are

connected to the left side, while all probe connections (cal

lines and reference air) are on the right side, when facing the

unit. Refer to Figure 1 for mounting dimensions and required

clearances.

Care must be taken to mount the unit as level as possible to

ensure the accuracy of the flow rates. If the unit is not level, the

flow rates will not be accurate!

IM 11M6D2-02E-A

Page 4

4

NOTE

IMPORTANT

Figure 3.1: AC4/AC8 Dimensional Drawing

3.3 GAS SOURCES

Zero Gas

Typically, 1% oxygen balanced in nitrogen is used, however,

an oxygen mixture between 0.5% and 8% is acceptable.

NEVER USE PURE NITROGEN FOR ZERO CALIBRATION GAS. A compressed gas cylinder containing the zero

gas is fitted with a dual stage regulator. Zero calibration gas

cylinders with regulators may be purchased from a local

compressed gas supplier. Follow the operation and safety instructions as supplied from your gas supplier. The maximum

pressure of the calibration unit is 35 psi.

The compressed gas cylinder must have the same CGA connection fitting as the dual stage regulator (see accessories).

Span Gas

Typically, a clean dry air source is recommended, such as

instrument air (20.6% oxygen). An in-line filter is recommended to remove any moisture or dirt prior to the calibration unit. A regulator must be attached to the instrument air

source in order to reduce the flow to an appropriate pressure

(35 psig max) prior to reaching the calibration unit.

Reference Air

The reference air is the same air as the span gas. Thus, the

reference air is also clean dry instrument air. Unlike span gas,

which is use only during calibration, reference air flows to

the back side of the zirconium cell and should be used at all

times.

When the instrument air has a nitrogen backup (used for air

failure), instrument air for the reference gas should not be used.

In this instance the probe must use either bottled air (20.6%

oxygen balanced in nitrogen) or natural convection for reference

air flow.

IM 11M6D2-02E-A

Page 5

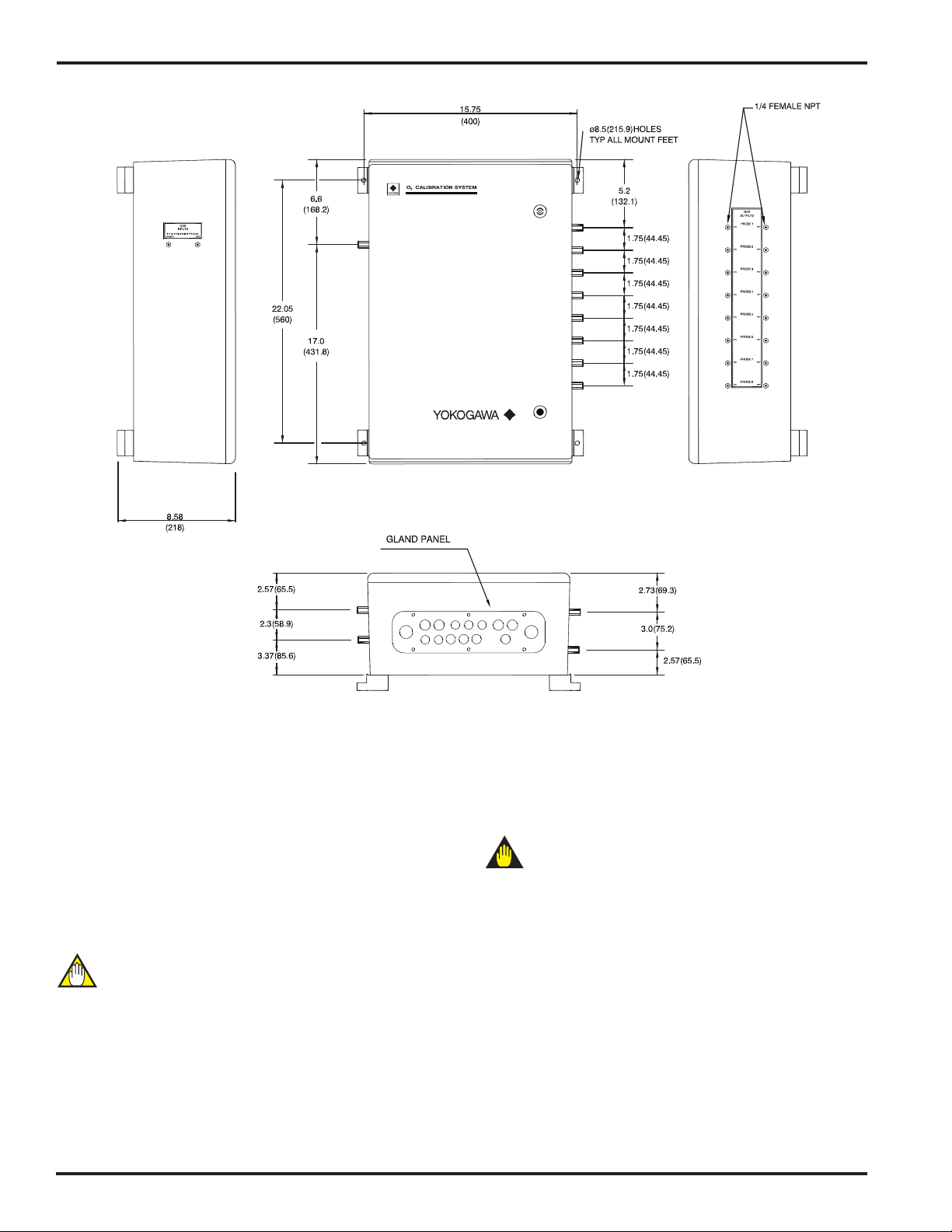

3.4 PIPING

PCDE?Q

A?J

E?Q

/-2ĥ

DCK?JCLNR

/-2ĥDCK?JCLNR

WMIME?U?

O2 CALIBRATION SYSTEM

LCK?2V

INSTRUMENT AIR

ZERO GAS

35 psig MAX

PROBE 1

PROBE 2

PROBE 3

PROBE 4

PROBE 5

PROBE 6

PROBE 7

PROBE 8

NOTE

IMPORTANT

5

Figure 3.2

Piping Gases to the Auto Cal Unit

Piping (or tubing) is required from the instrument air line and

zero gas cylinder to the calibration unit. Standard tubing is _”

O.D. (Outside Diameter) copper or stainless steel. Stainless

steel is preferred, as it is less likely to develop leaks. The

separate tubing for both the instrument air and zero gas are

connected to the two separate 1/4” FNPT brass or stainless

fittings on the LEFT side of the calibration unit.

Piping Gases to ZR22 Probes

The tubing to the ZR22 probes is run from the RIGHT side of

the calibration unit to each of the ZR22 probes as shown in

Figure 2. Quarter inch (1/4”) tubing should be used between

the auto cal unit and the probes. It is important to note 1)

the reference air tubing is connected to the REF IN port

at the probe; 2) cal gas tubing is connected to the CAL

IN port on the probe. The REF IN and CAL GAS ports are

located on the bottom of the ZR22 probe junction box. The

check gas and reference air ports require a 1/4” FNPT fitting.

Flexible stainless steel hose is recommended for the connection

between the ZR22 and the tubing.

This will allow for probe movement due to thermal expansion of

the duct.

To prevent leakage, all compression fittings should be installed

per manufacturer’s recommendations. In addition to this, a

check valve is usually installed on the cal gas inlet of the ZR22

probe to protect the cal tubing from moisture contamination.

IM 11M6D2-02E-A

Page 6

6

NOTE

WARNING

Pressure

Switch

Relay

Calibratio n

Status

Cal Gas

Pressure

OK ?

Relay Deenergized

and

CLOS ED

Pressure Switch

OPEN

Relay Energi zed and

OPEN

Pressure Switch

CLOS ED

CALIBRATE

YES

NO

STAR T

DO NOT

CALIBRATE

Pressure Switch Used as Input to Relay

Calibration

Using

Pressure Switch AND Relay

IV. WIRING

4.1 Wiring the AC4/AC8 to the AV550G Averaging unit

Please refer to appendix A for the system configuration

drawing.

Solenoid, Relay and Pressure Switch wiring connections

The AC4/AC8 uses 120VAC, 60 Hz for all solenoids. Although two internal 1 amp fuses are provided for the ±120

VAC terminal, an external 5 amp circuit breaker is recommended. Included with each fuse is an LED that is activated

when the fuse is blown. Recommended wiring is 14AWG,

run in conduit. If conduit is not used, wiring should have a

suitable jacket to meet environmental and regulatory codes.

The AC4 unit requires a maximum of 8 conductors, whereas

the AC8 requires 12 conductors.

A 120 VAC relay (included with NEMA 4 enclosure), shown at terminal K1, is required at the AV550G if a pressure switch is used.

This prevents noise caused by a low voltage pressure switch

signal from being run in the same cable as the 120 VAC solenoid

signal.

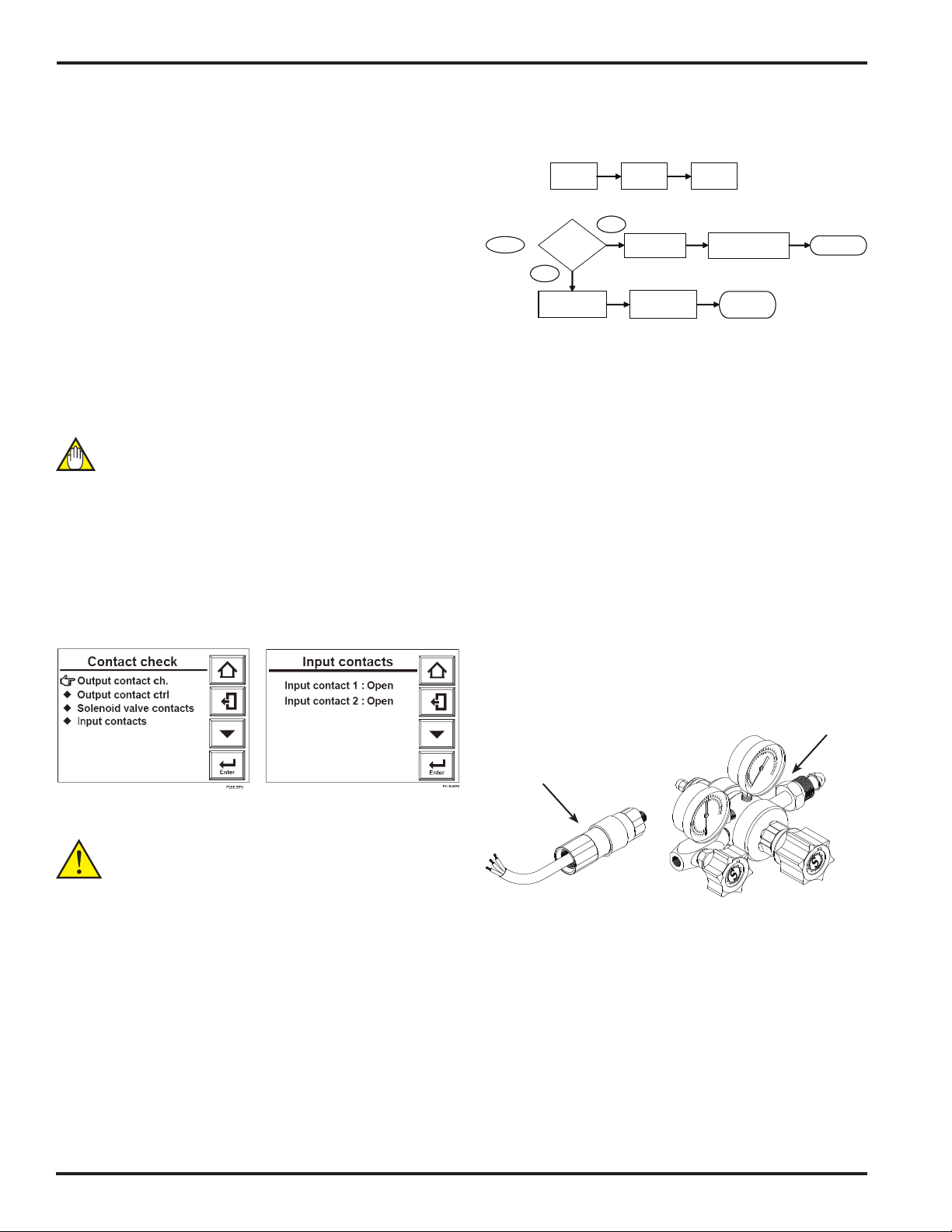

Figure 4.2: Calibration Using Pressure Switch and Relay Flow

Chart

The recommended pressure switch configuration is to the

high pressure side of the zero gas regulator. This is preferred

because it gives the earliest warning of a decrease in zero

gas pressure. The switch is threaded into the high pressure purge port of the dual stage regulator on the zero gas

cylinder.

4.2 Pressure Switch, M1133AR, Set Point Procedure

The relay is prewired as NORMALLY CLOSED (NC) to

contact input #1 at the control card (terminal 7 and 9) of the

AV550G.

Figure 4.1 AV550G Input Contact Screen

When the relay is deactivated, the unit will not calibrate. The

relay remains closed unless a 120 VAC source is connected to

energize it. Terminal 7 of the relay provides 120 VAC. Neutral

voltage is connected to terminal 2 of the relay from the AC4/AC8

calibration unit.

The relay switch is designed to OPEN when energized as

depicted in the flow diagram shown in Figure 4.2. A pressure

switch input completes the 120 VAC signal used to energize

the relay, which is wired at the calibration unit as Normally

Open (NO), where Open = Low or Zero tank pressure. The

AC4/AC8 unit is prewired with the jumper in place, so that

the relay will be energized and OPEN. However, if the pressure switch input is used, then remove the jumper between

the terminals labeled PS at the calibration unit’s terminal

strip, and attach the pressure switch. The pressure switch is

wired as normally open.

For the AC4/AC8 Autocal units, a gas pressure set point is

used to indicate that the calibration gas (zero gas) is low.

Pressure Switch M1133AR is a cylindrical style pressure

switch which uses a diaphragm or piston sensor to detect a

pressure change. The recommended set point is 200 psi on

the fall. At the predetermined set point, a SPST switch actuates, converting a pressure signal into an electrical signal.

M1132ZX Dual

Stage Regulator

M1133AR

Pressure Switch

Figure 4.3: Pressure Switch and Dual Stage Regulator

The following procedure is required to adjust the set point:

1. Thread the pressure switch into the high pressure gauge

port on the regulator.

2. With power disconnected, slide the cover on the switch

toward the electrical termination while twisting it to overcome friction.

3. Connect the power to the terminal or leads.

4. Insert a flat head screwdriver (1/8”) into the adjustment

slot and turn counterclockwise to increase the setting or

clockwise to decrease the setting.

IM 11M6D2-02E-A

Page 7

7

NOTE

CH ANNEL MANIFOLD

WIT H MANU AL

OVERRIDE AN D

FLOW ADJU STER

M1132BY (4 Channel)

M1132BZ (8 Channe l)

For setting on fall, apply pressure equal to normal system

operating pressure. Reduce source pressure to set point

value. Turn the adjustment clockwise until switch “clicks”

[circuit across N.C. (black) and COM (white) closes]. For

setting on rise, apply desired pressure and turn adjustment

left until switch “clicks” [circuit across N.O. (red) and COM

(white) terminal closes].

5. After completing adjustments, slide the cover closed over

the adjustment compartment. Recheck the set point value.

6. Wire the pressure switch Normally Open to the AC4/AC8

terminals at the calibration unit that are labeled PS. Remove

the jumper across the PS terminals.

V. INITIAL FLOW RATE SETUP

5.1 CHECKING FOR LEAKS

Before considering your calibration unit operational, it is a

good idea to check for leaks along the full distance of the cal

line tubing. Additionally, perform a cal check to confirm that

the gases are plumbed correctly to each probe.

1. Plug all the cal and reference air lines at the probes. This

requires disconnecting the fitting at the ZR22 Probe and

plugging the tubing.

2. Set the flow rate of the Zero Gas and Instrument Air to 20

psig using the regulators.

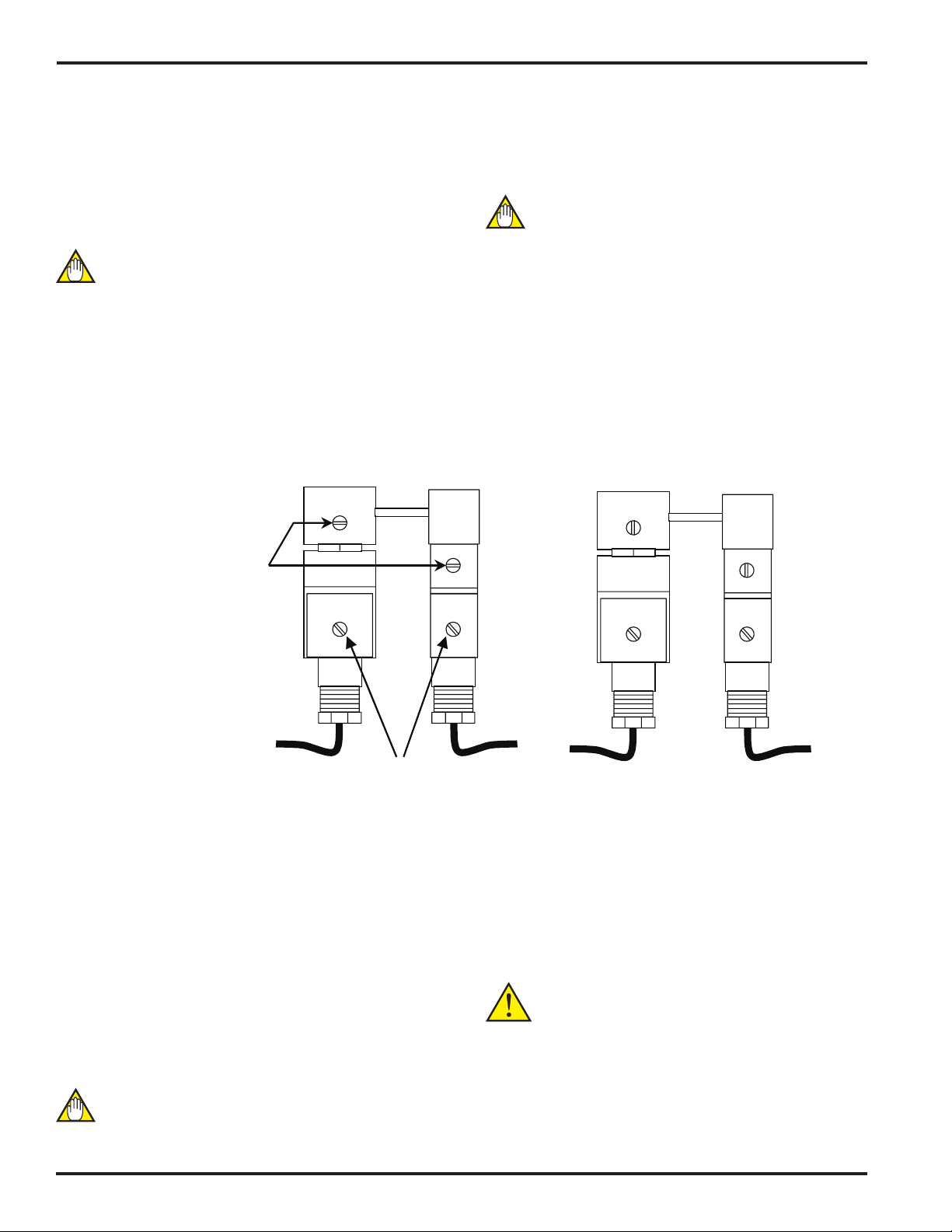

3. Locate the block solenoid shown in Figure 5. Using a flat

tip screwdriver, turn the manual override screw on the block

solenoid to the 90º position as shown in Figure 5.2.

4. Turn the channel solenoid valve’s manual override screw

to the horizontal, or ON (NOT NORMAL) position for Uall

probes in use. See Figure 5.1 and 5.3.

5. Apply leak detection spray on all compression fittings and

bends of the cal line tubing for all probes. Spray both the

reference air and cal gas line(s).

6. Inspect the full length of the cal lines to determine if there

is a leak. Repair any leaks.

7. After repairing the leaks, if any, turn all probe channel

solenoids and the block solenoid to the NORMAL position as

shown in Figure 5.2 and 5.3.

8. Unplug tubing at the ZR22 probe(s) and reconnect.

5.2 SETTING REFERENCE AIR FLOW

Locate the reference flow air meters in Figure 5.1. Adjust the

black flow adjustment knob on each reference air flow meter

to 0.8 LPM (800cc/min).

Reference air flow should be adjusted before the calibration

adjustments are made.

Figure 5.1 AC8 Parts Listing

IM 11M6D2-02E-A

Page 8

8

NOTE

ZERO/SPA N

SOLENOID

BLOCK

SOLENOID

MOUNTING

SCREWS

NORMAL

FOR NORMAL OPERATION AND

MANUAL OVERIDE, SCREWS

MUST BE IN THE POSITIONS

SHOWN

ZERO/SPA N

SOLENOID

BLOCK

SOLENOID

OVERRIDE

NOTE

NOTE

WARNING

5.3 BALANCING PRESSURE DROPS IN THE CAL LINES

For accurate calibrations, the auto cal system must provide a

fixed flow of zero gas and span gas (0.6 LPM pr 600cc/min).

To do this, the pressure drop from the AC4/AC8 to each

probe must be the same regardless of the length of tubing

run or number of probes. To balance the pressure drops,

perform the following steps:

Perform all adjustments with a flat tip screwdriver.

1. Ensure gas and instrument air are plumbed to the auto cal

unit. Pressure should be set at 20 psig ± 2 psig.

2. Locate the block solenoid shown in Figures 5.1 and 5.3.

Using a flat tip screwdriver, turn the manual override screw

on the block solenoid to the vertical position, as shown in

Figure 5.2.

6. Turn the manual override on the channel solenoid for the

probe to the OFF (normal) position.

7. Repeat steps 4, 5, and 6 for the remainder of the probes

that are being used.

DO NOT use the cal gas flow meter’s adjustment knob to make

this flow rate adjustment. Use the individual channel’s flow

adjustment screw to adjust for varying pressure drops in the

tubing runs.

8. After all flow rates have been set manually to 1 LPM, turn

the channel solenoid for the probe with the longest tubing

run back ON to the manual override position – making sure

all others are OFF (normal position shown in Figure 5.3). Turn

the cal gas flow meter’s adjustment knob to 0.6 LPM (600cc/

min).

Figure 5.2: Zero and Block Solenoid

3. Locate the cal gas flow meter in Figure 5.1. Turn the

black adjuster knob to the maximum open position. This fully

opens the cal gas regulator, allowing precise adjustments of

flow rates.

4. Locate the channel solenoid valve for the probe with the

longest tubing run in Figure 5.1. Turn the manual override

screw to the horizontal, or ON position. Refer to Figure 5.3.

5. Each channel has its own flow adjustment screw located

on the channel solenoid valve as shown in Figure 5.3. Adjust the flow adjustment screw for the probe so that the flow

rate shown on the cal gas flow meter is 1 LPM (1000 cc/min).

DO NOT use the cal gas flow meter’s adjustment knob to make

this flow rate adjustment. If necessary, increase the air pressure.

9. Turn the manual override screw (Figure 5.3) on the zero/

span solenoid (three way solenoid) to the 90º position. This

starts the flow of the zero gas. Adjust the needle valve to

the left of the three-way solenoid so that the flow rate is 0.6

LPM (600cc/min). If 0.6 LPM is difficult to obtain, it will be

necessary to slightly increase the zero gas pressure to the

unit.

Do not adjust the cal gas flow meter or the flow adjustment

screw on the individual channel solenoids.

10. Confirm that all channel solenoid overrides for all used

probed are turned back to the normal position as shown in

Figure 5.3.

IM 11M6D2-02E-A

Page 9

11. Turn the block solenoid and the zero/span solenoid to

WARNING

NORMAL OPERATION OVERRIDE

MOUNTING SCREW

FLOW ADJUSTMENT SCREW (PRESET)

FOR NORMAL

OPERATION THE

MANUAL

OVERRIDE SCREW

MUST BE IN THE

VERTICAL

POSITION

FOR OVERRIDE

THE MANUAL

OVERRIDE SCREW

MUST BE IN THE

HORIZONTA L

POSITION

Item Initial value

Mode Manual

Points Span-Zero

Zero gas conc. 1.00%

Span gas con. 21.00%

Hold time 3 min. 00 sec.

Cal. time 3 min. 00 sec.

Interval 1 days 00 hrs

Starting date yy01mm01dd01

Starting time hh00mm00

CAUTION

the normal position.

If reference air is used during calibration, the reference air must

remain ON after calibration.

Figure 5.3: Typical Channel Solenoid

5.4 CAL CHECK

The purpose of performing a cal check at this time is to confirm that the calibration gas and reference air are plumbed

correctly for each probe, along with confirming that enough

time was allowed for the cal gas to flow at the probe’s cell

tip. Refer to the AV550G Instruction Manual for calibration

codes and procedures.

VI. PROGRAMMING

All programming for the AV550G Averaging Unit is done

through the display module. Please refer to the AV550G

Instruction Manual, IM 11M12D01-01E, Section 9 for additional details. The following is a brief description of setup

procedures.

The ZR22G Probe is calibrated by applying two known gas

standards. In most applications the zero gas is around 1%

oxygen with the balance nitrogen. The span gas is instrument air (20.95 % oxygen).

9

Figure 6.1

VII. SET-UP PROCEDURES

7.1 Mode

There are three calibration modes (for zero and span calibration: manual mode, semi-automatic mode (started from the

display or started by contact input) using preset calibration

time and stabilization (settling) time, and auto calibration

at preset intervals. Restrictions related to each mode are

described here.

-When [Manual Mode] is selected:

In this mode, only Manual calibration can be performed.

(Contact input used to start semi-auto calibration has no effect). Auto calibration does not start at auto calibration start

time.

-When [Semi-Auto Mode] is selected:

In this mode, manual calibration or semi-automatic

calibration can be performed.

Auto calibration does not start at auto calibration

start time.

-When [Auto Mode] is selected:

Any calibration mode is valid.

The zero gas concentration must be certified so the exact

concentration can be programmed into the AV550G memory.

Calibration values required for full auto-calibration operations

are stored in the menu of the AV550G.

For additional information refer to Chapter 8 of the AV550G

manual for a full explanation of all parameters.

Shipping time default setting for zero gas is 1% oxygen and

for span gas is 21%. Figure 6.1

Indication check mode of [Auto] cannot coexist with [Auto]

Calibration mode. Therefore, if the mode of indication Check is

set to [Auto], you cannot set the mode of Calibration to [Auto],

and vice versa.

<Setting Procedure>

1) From the basic panel display, if you touch the Setup key,

the [Execution/Setup] display appears. Select [Maintenance].

2) From the [Maintenance] display, select [CalibrationSetup]

the [Mode] amd you can selct Manual, Semi-Auto, or Auto in

the selection drop down that appears. Figure 7.1.

IM 11M6D2-02E-A

Page 10

10

NOTE

Figure 7.1 Calibration Mode Setting

7.1.3 Zero Gas Concentration

This sets the oxygen concentration of the zero gas used for

calibration. Enter the value from the label of the corresponding gas bottle.

7.1.4 Span Gas Concentration

This sets the oxygen concentration of the span gas used for

calibration. When the instrument air supply is used as the

span gas, enter 21% O2.

When the instrument air supply is to be used as a span gas, cool

the gas to -20ºC below the dew point to remove moisture, oil

mist and dust from the air. If this air purification is not performed, the accuracy of the calibration may be affected.

7.1.2 Calibration Setup Procedure

Either Span or Zero or both calibrations can be performed.

Normally select both: Span-Zero.

<Setting Procedure>

From [Maintenance]‡ [Calibration setup] display, select

[Points], then a selection window opens and Span-Zero,

Span or Zero may be selected. Figure 7.2

Figure 7.2 Procedures for Setting Calibration Mode.

<Setting Procedure>

1) From the [Calibration setup] display, select [Zero gas

conc.], and the numerical data entry is display is displayed.

Enter the oxygen concentration of the zero gas used for calibration. For example, enter 0.98 vol% O2 as [00098].

2) From the [Calibration setup] display, select [Span gas

conc.], and the numerical data entry is display is displayed.

Enter the oxygen concentration of the span gas used for

calibration. For example, enter 21 vol% O2 as [02100].

3) Calibration time setting

If the mode is [Man]:

Select [Hold time]. This is the output stabilization (settling)

time required from calibration end until measurement is

reentered. During this time, the calibration gas is switched to

measurement gas and the measurement gas is allowed time

to stabilize. Setting range is from 00 min. to 60 min 59 sec.

The analog outputs of individual channels which are under

calibration remain Output Hold status from the start of calibration until the end of the stabilization (settling) time, and

their output is not included in the averaging group calculations during this time.

If the mode is in [Semi-Auto]:

In addition to the above [Hold] output stabilization (settling)

time, there is also a [Cal. Time] setting. This is the setting

time from when calibration gas flow is started until calibration is performed. The same time setting is used for both

Zero and Span calibration. Setting range is from 00 min. to

60 min 59sec. Calibration time and stabilization time, and

analog output status are shown on the calibration timing

chart of Figure 7.3 below. For solenoid valve (SV) piping and

wiring refer to Section 5 of AV550G manual.

IM 11M6D2-02E-A

Page 11

11

Cal start in

Chan 1 Span CAL

CAL time

Chan 1 Zero CAL

CAL time

Chan 1output hold

Stabilization

Chan 1 output hold

Chan 2 Span CAL

CAL time

Chan2 Zero Cal

CAL time

Chan 2 output hold

Stabilization

Chan 2 output hold

Average output

SV-Chan 1 contact

offon

SV- Chan 2 contact

offon

SV- Chan 2 contact

span gas on zero gas on span gas on zero gas on

Chan 2 removed from averageChan 1 removed from average

CAL start

NOTE

Figure 7.3

If the mode is [Auto]:

In addition to the above [Hold] output stabilization (settling)

time [Cal. Time] setting, there is also Cal. [Interval], [Start

date] and [Start time]. The Automatic Calibration Interval can

be set in the range 00 days 00 hrs to 255 days 23 hrs once

Auto Calibration starts. It is performed for all installed channels, so the interval needs to be larger than the sum of span

and zero calibration times plus settling tines for all channels.

The Start date and Start time are for the first calibration in

the Auto Calibration cycle (repeated at the calibration interval). To set 2004 June 21 at 1:30 pm, set Start date to:

YY: 04, MM: 06, DD: 21 and Start time to HH: 13, MM: 30.

<Setting Procedure>

1) From the [Calibration Setup] display, select [Timing] and

the display shown in Figure 7.4 appears. In this example,

[Mode] is set to [Auto].

2) Select items and enter numerical values as required.

Figure 7.4 Calibration time setting

When setting, keep the following points in mind:

1) When calibration is to be started by a contact input signal,

the contact input signal on the [Input Contacts] display

needs to be defined and enabled.

2) The starting of Auto Calibration may be delayed by the

status of the channel to be calibrated, or by the status of

other channels, as explained by table 7.1.

IM 11M6D2-02E-A

Page 12

12

other

commands

Purging

the

channel

Man. Cal.

SemiAuto

AutoCal

X

X

Wait

X

X

Wait

X

X

Wait

X

X

Wait

X: Cannot perform calibration

Wait: Wait until other command finishes before starting calibration

X

X

Wait

X

X

X

X

X

X

X

X

X

Other

channel

CAL

Indication

check in

other channel

Blowback in

other

channel

Maintenance CAL chan.

in warmup

status

CAL chan.

in ERR

status

CAL chan.

now

disabled

IMPORTANT

3) If the calibration interval is shorter than the sum of the

stabilization time plus calibration time, the second calibration start time will conflict with the first calibration. In such a

case, the second calibration will not be conducted. (When

both zero and span calibrations are to be performed, the

calibration time is double that required for a single (zero or

span) calibration).

4) If the (Calibration) Interval is et to DD: 00, HH: 00 then

auto Calibration will not be performed.

5) If the start date is set before the current date, then Auto

Calibration will not start.

6) [Cal. Time] of [Calibration timing] display will be equalized

to [Check time] of [Semi-auto ind. Chk] display

Table 7.1 When Auto Calibration conflict with Other Commands

VIII. MAINTENANCE

Because of the AC4/AC8 unit’s simplified construction, no

routine maintenance is required, other than replacing the

calibration gas when necessary. When cal gas cylinders are

changed refer back to Section 7.1.2 Calibration Setup Procedure. Failure to perform the Calibration Setup Procedure

upon replacing cal gases will result in an error in the zero

correction values. When changing gases it is also necessary

to check the zero gas flow rate.

It is recommended that periodic inspections are performed

to insure a sufficient supply of calibration gases when the

pressure switch input is not used. Also, periodic checks

verify that the flow rate of the calibration gases, to the individual oxygen detector probes have not been accidentally

changed. It is important that the zero gases flow at a rate of

0.6 LPM (600mL/min.), while the reference air (instrument air)

flows at 0.8 LPM (800mL/min).

Refer to Section 10 of this manual for a listing of spare parts

for the AC4/AC8.

IX. TROUBLESHOOTING

9.1 TYPICAL CALIBRATION PROBLEMS

1) Gas does not flow to the probe.

• If reference air is used, then the reference air ow meters

should show 0.8 LPM at all times. If the reference air flow

meters do not show 0.8 LPM, then confirm that the instrument air has been turned on by checking the regulator gauge

(10to 35 psi).

• Conrm override screws are in the NORMAL mode for the

block solenoid and all channel solenoids.

• Turn block solenoid to the manual position. Cal gas ow

meter should show 0.6 LPM. If cal gas flow meter shows 0

LPM, turn the black knob on the flow meter to open the flow

meter. Set flow rates for all probes as according to procedures shown in Section 5 of this manual.

2) Flow meter will not go to 0.8 LPM for reference air.

• Turn the ow rate adjustment knob only, NOT the override

screw.

• Only one channel should be in the manual override position. All other probes should be in the normal position.

• Check the pressure regulator at the gas source. If the

pressure is below 14 psi, increase pressure in increments

of 5 psi, and adjust reference flow meters. DO NOT increase pressure to greater than 35 psi. If more than 35 psi

is needed, attempt to move the calibration box closer to the

probes, without compromising safety or the ambient operating temperature of the auto cal unit.

• Tubing outside diameter (O.D.) should not be greater than

1/4” .Tubing runs should not be in a T position, and should

remain separate for each probe.

• Check for leaks at compression ttings. All NPT ttings

should have Teflon tape on the threads to prevent leaks.

3) Flow meter will not go up to 0.6 LPM for cal gas.

• Same solution as above, except make adjustment to the

cal gas flow meter.

4) Wrong gas flowing to the probe.

• Conrm that gases are plumbed correctly at the left side of

the calibration unit.

• Turn the override screw on the three-way solenoid to the

normal position.

• Perform a cal check in semi auto calibration mode. (See

Section 5).

When performing an actual automatic or semi automatic calibration, and a calibration alarm occurs, it is necessary to reset

the channel. Instead, recalibrate the channel to remove the calibration alarm. For additional troubleshooting procedures, refer

to the AV550G manual, Section 12.

IM 11M6D2-02E-A

Page 13

X. SPARE PARTS AND ACCESSORIES

CH ANNEL MANIFOLD

WIT H MANU AL

OVERRIDE AN D

FLOW ADJU STER

M1132BY (4 Channel)

M1132BZ (8 Channel)

10.1 SPARE PARTS

Refer to figure 10.1 for a list of replacement parts for the AC4/ AC8 Auto Calibration Unit.

13

Figure 10.1

1. Zero/Span Solenoid M1132GM

2. Channel Manifold M1133BY (4 CHANNEL)

M1133BZ (8 CHANNEL)

3. Needle Valve M1132GK (BRASS)

M1132BX (STAINLESS STEEL)

4. Reference /Cal Gas Flow Meters M1132CC (BRASS)

M1132ZC (STAINLESS STEEL)

IM 11M6D2-02E-A

Page 14

14

NOTE

10.2 ACCESSORIES

10.2.1 Zero Gas Regulator, M1132ZX

This regulator controls the gas pressure of the zero gas cylinders before it reaches the calibration unit. The dual stage regulator is highly recommended for services which require a near constant delivery pressure as the calibration source decays (See

M1133AR). Air diffusion and absorption, desorption and off gassing are minimized because of its stainless steel construction.

This regulator is used on a “zero gas” cylinder with a CGA 580 connection. The Cylinder connection must be CGA580 (used for <5%

oxygen balanced in nitrogen).

FRONT ISOMETRIC

Figure 10.2 Zero Gas Regulator, M1132ZX

Maximum Inlet Pressure: 3,000 psig

Operating Temperature Range: -40ºF to 200 ºF

Bonnet Vents: 1/8” NPTF

Inlet/Outlet Connection: CGA 580 with 1/4” NPTM

Purge Ports: 1/4” NPT Female

Weight: 4.7 lbs (1.75 kg)

Material of Construction: Body - 316L Stainless Steel

Diaphragm - 316L Stainless Steel

Seat/Seal – Tetzel/Teflon, Kel-F

Gauges - 316L Stainless Steel

Bonnet – brass, nickel-plated

Delivery pressure Range: 2 to 75 psig

Flow Capacity Air: 300 scfh

Gauges: Delivery, 0 to 100 psig;

Cylinder pressure, 0 to 3,000 psig

2” diameter

IM 11M6D2-02E-A

Page 15

10.2.2 Pressure Regulator, M1132KD

This general purpose regulator is used to adjust the pressure of instrument air entering the AC4/AC8. Figure 10.4

15

Figure 10.4 Pressure Regulator, M1132KD

Flow Capacity: 20 SCFM (33.6m_/hr) at 100 psig supply – 20 psig outlet

Exhaust Capacity: 0.1 SCFM (0.17m_/hr) – downstream pressure 5 psig above set point

Sensitivity: 1” of water

Effect of Supply Pressure Variation: Less than 0.2 psig for 25 psi change

Maximum Supply Pressure: 250 psig

Air Consumption: Less than 6 SCFM

Output Range: 0 to 60 psi

Port Size: 1/4” NPT

Materials: Body – Die cast aluminum alloy; Diaphragm – Nitrile elastomer

and nylon fabric; Trim – Brass, zinc plated steel, acetyl

Weight: 4.0 lbs (1.8 kg)

10.2.3 Pressure Gauge, M1132ME

The purpose of this gauge is to indicate the pressure of instrument air entering into the AC4/AC8. Figure 10.5

Figure 10.5 Reference Air Gauge, M1132ME

Gauge Size: 2” (50mm)

Measuring Range: 0 to 60 psi

Connection: 1/4” FNPT

Weight: 0.5 lbs (0.2 kg)

IM 11M6D2-02E-A

Page 16

16

10.2.4 Zero Pressure Switch, M1133AR, Figure 10.2.6

The pressure switch is used to alert the Operator via a contact input that the zero gas cylinder needs to be replaced before the

cylinder is empty. The recommended connection is to the high pressure side of the zero gas regulator. Refer to Figure 4.1.

Figure 10.2.6 Zero Pressure Switch, M1133AR

Adjustable Set 30 to 575 psi on fall;

Point Ranges: 50 to 600 psi on rise.

Dead Band: 8 to 60 psi

Over Range: 2,500 psi

Proof Pressure: 3,000 psi

Storage Temperature: -40ºF to 180ºF (-40 ºC to 82 ºC)

Ambient Temperature: 0 ºF to 160 ºF (-18 ºC to 71 ºC)

Set Point Repeatability: 1% of span

Switch Output: One SPDT (either NC or NO)

Electrical Rating: Rated to 5 amps resistive and 15 amps inductive (75% PF), at 125 and 120 VAC, 1/4” HP

Enclosure: Aluminum with irradiate finish rated for 100 hours of salt spray

Electrical Connection: One SPDT output; 1/4” NPTF, 5ft cable

Pressure Connection: 1/8” NPTM

Mounting: NPTM pressure connection

Weight: 12oz (340g)

Approvals: UL 508 listed, E42272; CSA C22.2, No 14-1987: LR 9690

10.2.5 Fuses, M1132HG

Two fuses are imbedded in the power supply input terminals of the AC4 and AC8 calibration units.

Current Rating: 1 amp

Slow Blow Time: 100% - 4hours maximum

135% - 1 hour maximum

200% - 5 second maximum

Size: 1’4” O.D. x 1 1/4” L

Approvals: UL Listed, CSA approved

IM 11M6D2-02E-A

Page 17

APPENDIX A

17

IM 11M6D2-02E-A

Page 18

18

IM 11M6D2-02E-A

Page 19

APPENDIX B

19

IM 11M6D2-02E-A

Page 20

20

IM 11M6D2-02E-A

Loading...

Loading...