Page 1

User’s

Manual

AQ7270 Series

OTDR

IM 735020-01E

7th Edition

Page 2

Product Registration

Thank you for purchasing YOKOGAWA products.

YOKOGAWA provides registered users with a variety of information and

services.

Please allow us to serve you best by completing the product registration

form accessible from our homepage.

http://tmi.yokogawa.com/

PIM 103-03E

Page 3

Foreword

Notes

Thank you for purchasing the AQ7270 Series (AQ7270/AQ7275) OTDR (Optical Time

Domain Reflectometer).

This user’s manual contains useful information about the instrument’s functions and

operating procedures and the handling precautions of the AQ7270 Series OTDR.

To ensure correct use, please read this manual thoroughly before beginning operation.

After reading the manual, keep it in a convenient location for quick reference whenever a

question arises during operation.

Three manuals, including this one, are provided as manuals for the AQ7270 Series

OTDR. Please read all of them.

Manual Title Manual No. Description

AQ7270 Series OTDR User’s Manual IM 735020-01E This manual. Explains all functions

and procedures of the AQ7270/

AQ7275 excluding the remote

control functions.

AQ7270 Series OTDR IM 735020-02E Explains briefly the functions

Operation Guide and basic operations.

AQ7270 Series OTDR Communication IM 735020-17E Explains the functions for

Interface User’s Manual controlling the AQ7270/AQ7275

using comm

unication commands.

• The contents of this manual are subject to change without prior notice as a result of

continuing improvements to the instrument’s performance and functions. The figures

given in this manual may differ from those that actually appear on your screen.

•

Every effort has been made in the preparation of this manual t

o ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact your nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without

YOKOGA

WA’s permission is strictly prohibited.

Trademarks

• The fiber Xplorer is the registered trademark of Yokogawa Electric Corporation.

• Microsoft, Windows, and Windows XP are either registered trademarks or trademarks

of Microsoft Corporation in the United States and/or other countries.

• Adobe and Acrobat are trademarks of

• For purposes of this manual, the TM and ® symbols do not accompany their

respective trademark names or registered trademark names.

• Other company and product names are trademarks or registered trademarks of their

respective holders.

Revisions

• 1st Edition: December 2006

• 2nd Edition: January 2007

• 3rd Edition:

• 4th Edition:

• 5th Edition:

• 6th Edition:

• 7th Edition: September 2011

7th Edition : September 2011 (YMI)

All Rights Reserved, Copyright © 2006, Yokogawa Electric Corporation

All Rights Reserved, Copyright © 2011, Yokogawa Meters & Instruments Corporation

IM 735020-01E

December 2007

February 2008

December 2008

June 2009

Adobe Systems Incorporated.

i

Page 4

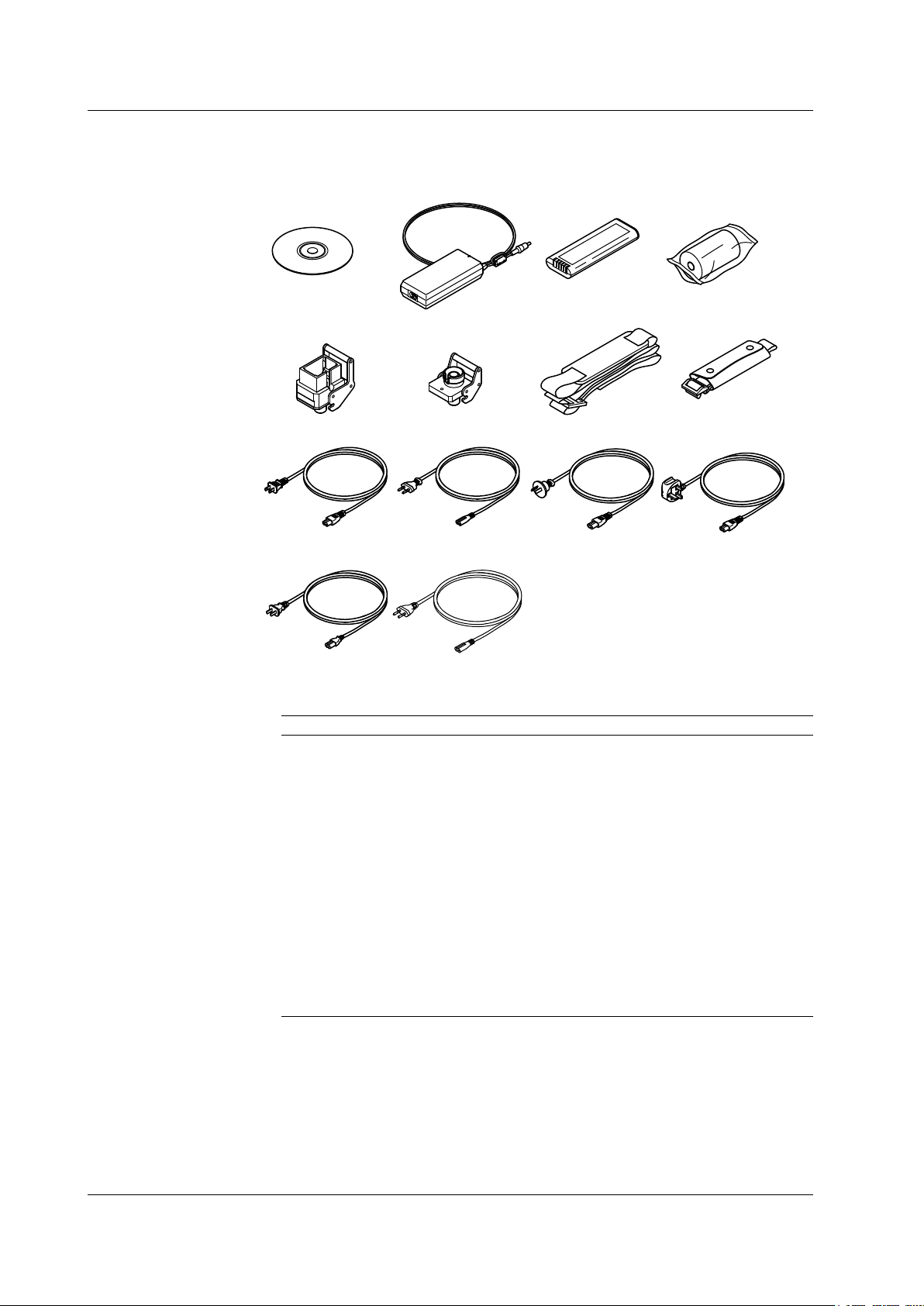

Checking the Contents of the Package

Unpack the box and check the contents before operating the instrument.

If some of the contents are not correct or missing or if there is physical damage, contact

the dealer from which you purchased them.

AQ7270 Series

MODEL

AQ7270

MODEL Suffix Code Description

735020

1550 nm, 32 dB

735021 1650 nm, 30 dB

735022 1310/1550 nm, 34/32 dB

735023 1310/1550 nm, 40/38 dB

735024 1550/1625 nm, 38/35 dB

735025 1310/1490/1550 nm, 34/30/32 dB

735026 1310/1550/1625 nm, 34/32/28 dB

735027 1310/1550/1650 nm, 34/32/30 dB

735028 1310/1550/1625 nm, 40/38/35 dB

735029 850/1300 nm, 22.5/24 dB (GI (62.5/125

735030

AQ7275

MODEL Suffix Code Description

735031

1650 nm, 30 dB

(15dB if the suffix code is /PN)

735032 1310/1550 nm, 34/32 dB

(36/34 dB if the suffix code is /DR)

735033 1310/1550 nm, 40/38 dB

(23/21dB if the suffix code is /PN)

735034 1310/1550 nm, 43/41 dB

735035 1310/1490/1550 nm, 34/30/32 dB

735036 1310/1550/1625 nm, 40/38/33 dB

(23/21/16dB if the suffix code is /PN)

735037 1310/1550/1650 nm, 40/38/30 dB

735038 1310/1550/1625 nm, 40/38/36 dB

(23/21/16dB if the suffix code is /PN)

735040 850/1300 nm, 22.5/24 dB (GI (62.5/125

735041 850/1300 nm, 22.5/24 dB (GI (62.5/125mm))

850/1300 nm, 22.5/24 dB (GI (62.5/125mm))

1310/1550 nm, 34/32 dB

1310/1550 nm, 40/38 dB

21.5/23 dB (GI (50/125mm))

1310/1550 nm, 40/38 dB

m))

m

m))

m

ii

IM 735020-01E

Page 5

Checking the Contents of the Package

AQ7270/AQ7275

MODEL Suffix Code Description

Optical connector -SCC SC connector (fixed)

-FCC FC Connector (fixed)

-ASC Angled PC SC Connector *

-NON No universal adapter

-USC SC universal adapter

-UFC FC universal adapter

Language -HE English

-HC Chinese/English

-HK Korean/English

-HR Russian/English

Power cord -D UL/CSA standard Max. rated voltage: 125 V

-F VDE standard Max. rated votlage: 250 V

-R AS standard Max. rated votlage: 250 V

-Q BS standard Max. rated votlage: 250 V

-H GB standard Max. rated votlage: 250 V

-P EK standard Max. rated votlage: 250 V

Options /PM Optical power monitor function *

/SLS Stability Light source function *

/LS Light source function *

/VLS Visible Light source function *

/PL Internal printer and LAN (Ethernet interface)

/DF Dummy fiber (SMF) *

/SB Shoulder belt

/DR Dynamic range expansion (2 dB) *

/PN

PON measurement*8 (firmware version 2.07 or later)

*1 Supported by the SMF port of the 735031 to 735038, 735040 and 735041, or supported by

the visible light source output port of the 735031 to 735035 and 735038.

2

Not supported by 735021, 735029 and 735031, and the MMF of 735030, 735040 and 735041

*

3

*

Not supported by 735020 to 735030, and 735040

4

*

Not supported by 735029, 735032, 735033 and 735037, and the MMF of 735030 and 735040

5

*

Supported by 735031 to 735035 and 735038

6

*

Not supported by 735029, 735030, 735040 and 735041

7

*

Supported by 735032

8

*

Supported by 735031, 735033, 735036 and 735038

1

2

3

4

5

6

7

IM 735020-01E

• No. (Instrument No.)

When contacting the dealer from which you purchased the instrument, please give

them this number.

iii

Page 6

Power cord

UL/CSA St’d

A1068WD

*1 Included if the suffix code is /PL.

*2 Included if the suffix code is -USC.

*3 Included if the suffix code is -UFC.

*4 Included if the suffix code is /SB.

Power cord

VDE St’d

A1071WD

Power cord

AS St’d

A1070WD

Power cord

BS St’d

A1069WD

Power cord

GB St’d

A1076WD

AQ7270 Series OTDR

User’s Manual

B8070TH

AC adapter

739870-D/F/R/Q/H/P

Battery pack

739880

Printer roll paper

A9010ZP

*1

Universal connector

(SC)

SU2005A-SCC

*2

Universal connector

(FC)

SU2005A-FCC

*3

Hand belt

B8070CX

Shoulder belt

*4

B8070CY

Power cord

EK St’d

A1078WD

Checking the Contents of the Package

Standard Accessories

The standard accessories below are supplied with the instrument.

Optional Accessories (Sold Separately)

The optional accessories below are available for purchase separately.

Name Part Number Notes

Soft carrying case 738960 Soft case

Emulation software 735070 Waveform analysis application

Printer roll paper A9010ZP 80 mm width × 25 m roll: 10 rolls per

unit

Battery pack(reserve) 739880

External Large Capacity Battery 739881 Attached Connecting Cord and Battery

case

Universal adapter(SC) SU2005A-SCC SC type

Universal adapter(FC) SU2005A-FCC FC type

Shoulder belt B8070CY

AC adapter(reserve) 739870-D UL/CSA standard

739870-F VDE standard

739870-R AS standard

739870-Q BS standard

739870-H GB standard, Complied with CCC

739870-P EK standard

iv

IM 735020-01E

Page 7

Safety Precautions

Ni-MH

To use the instrument safely and effectively, be sure to observe the precautions given in

the user’s manual.

The following symbols are used on this instrument.

Warning: handle with care. Refer to the user’s manual or service manual.

This symbol appears on dangerous locations on the instrument which require

special instructions for proper handling or use. The same symbol appears in the

corresponding place in the manual to identify those instructions.

Hazard, radiation of laser apparatus

Direct current

Stand-by (power)

Recycle

Double insulation mark (equipment protected throughout by double insulation or

reinforced insulation)

IM 735020-01E

v

Page 8

Safety Precautions

Make sure to comply with the precautions below. Not complying might result in

injury or death, or damage to the instrument.

WARNING

Use the Correct Power Supply

Before connecting the power cord, ensure that the source voltage matches the

rated supply voltage of the AC adapter and that it is within the maximum rated

voltage of the provided power cord.

Use the Correct Power Cord

Use only the power cord that comes with the instrument. Do not use it for other

devices.

Use the Correct AC Adapter

Use only the AC adapter specified for the instrument. Do not use it for other

devices.

Use Only the Designated Battery pack

Use only the battery pack specified for the instrument. Do not use it for other

devices.

Use only this instrument or a charger specified by YOKOGAWA to charge the

battery pack. If the fast charge does not finish after three hours or more, stop

charging the battery pack immediately.

Because the electrolyte solution inside the battery pack is alkaline, harm can be

done to the clothes or skin, if the battery pack leaks or explodes and the solution

comes in contact. If the electrolyte solution enters the eye, it can cause blindness.

In such cases, do not rub the eye. Rinse thoroughly with water and immediately

consult your eye doctor.

To prevent the possibility of electric shock and accidents, always turn OFF the

power switch and remove the AC adapter power supply from the instrument when

replacing the battery pack.

Do not throw the battery pack into fire or apply heat to it. This can cause dangerous

explosions or spraying of the electrolytes.

Do Not Look at the Laser Light

Do not look at the laser’s direct ray, reflected ray from a mirror, or indirect ray

without the proper protective eyewear. In addition, avoid being exposed to the laser

light. It can cause blindness or damage to the eye.

Do Not Operate in an Explosive Atmosphere

Do not use the thermocouple in a location where any flammable or explosive gas/

vapor is present. Operation in such an environment constitutes a safety hazard.

Do Not Remove Covers

The covers should be removed by YOKOGAWA’s qualified personnel only.

Opening the cover is dangerous, because some areas inside the instrument

have high voltages.

Carrying and Moving the Instrument

Remove all power cords and connection cables from the main unit before moving

the instrument. When carrying the instrument, hold it firmly by the handle.

Also, if storage media is inserted into the instrument, always remove the storage

media before carrying or moving the instrument. Never leave the media inserted

when carrying or moving. The storage media can become damaged.

Apply Correct Signals to the Optical Connectors (PORT1 and PORT2)

Do not apply light that is —5 dBm or greater to the AQ7270/AQ7275 optical

connectors (PORT1 and PORT2).

Doing so may damage the AQ7270/AQ7275.

vi

IM 735020-01E

Page 9

CAUTION

When Measuring with the Same Wavelength as the Communication Light

Most instrument models use the same wavelength for measurement as is

used for communication. If communication light is present in an optical fiber

being measured, this has an affect on the communication itself. Take sufficient

precautions to avoid interruption of communications. The measurements by the

instrument may also be incorrect, therefore the measuring environment (presence

or absence of communication light, etc.) should be carefully considered.

When Measuring with a Wavelength Different from the Communication Light

(1625/1650 nm)

When there is communication light in the fiber under test, use a wavelength

different from the communication light for measurement.

If no cutoff filter of 1625 nm or 1650 nm is installed in an instrument connected to

the system under test, or depending on the instrument’s lightfastness power rating

or characteristics of the cutoff filter such as its attenuation, the pulse light output

from the instrument can, in the worst case, damage the instrument. Check that an

appropriate cutoff filter is installed and that there is no problem with the instrument’

s ratings, then take sufficient caution during use.

Safety Precautions

When Using the Angled PC SC Connector (Suffix Code:-ASC)

•

Use the same type of angled PC SC connector for the connected optical fiber

cable as well.

The ferrule end of the angled PC SC connector is polished to an angle.

I

other types of connectors are used, the end face of the connector may become

f

damaged.

• You can replace the

AQ7270/AQ7275 connector, but only with an SC type.

See below for operating environment limitations.

CAUTION

This product is a Class A (for industrial environments) product. Operation of this

product in a residential area may cause radio interference in which case the user

will be required to correct the interference.

IM 735020-01E

vii

Page 10

Safety Precautions

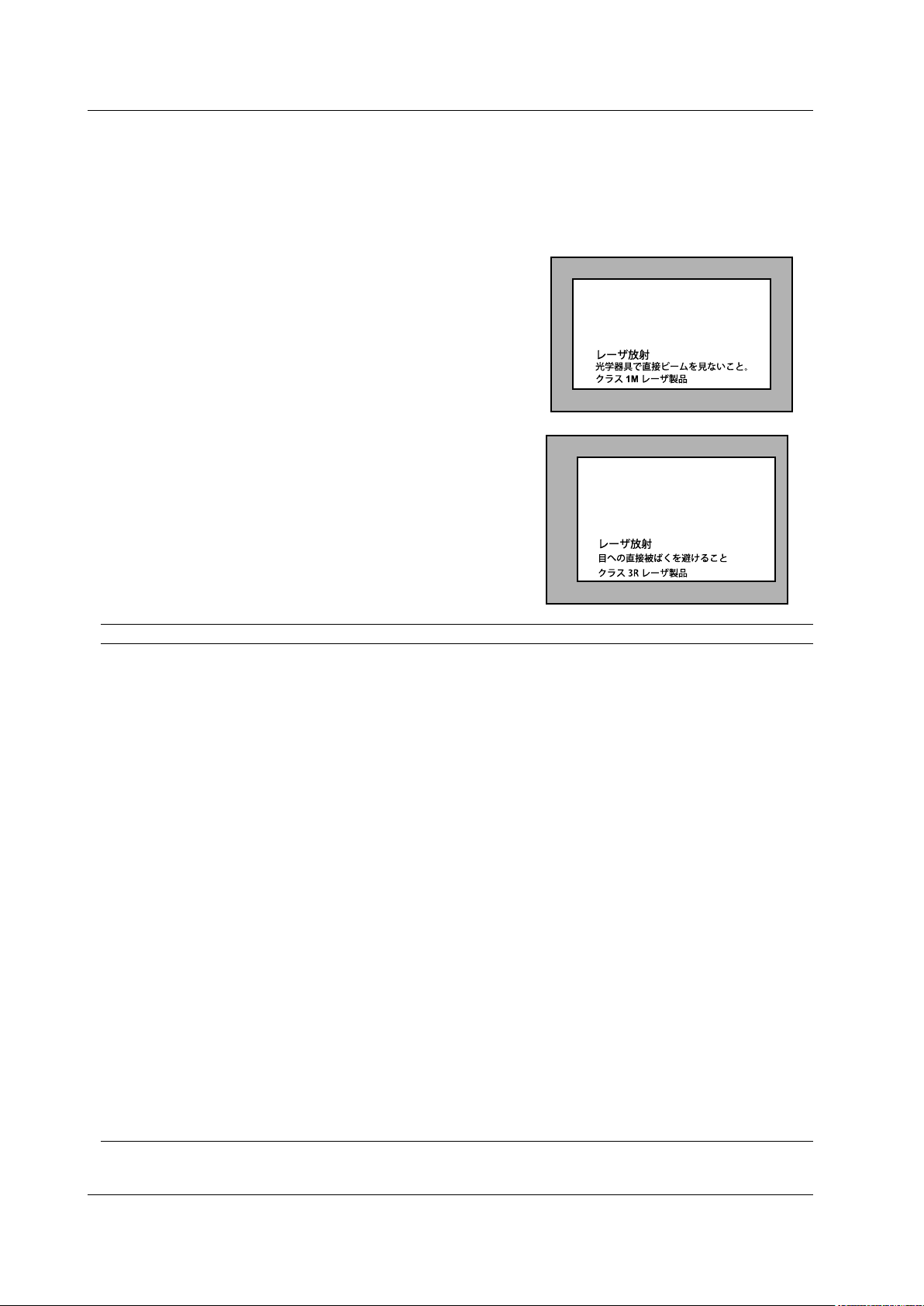

INVISIBLE LASER RADIATION

DO NOT VIEW DIRECTY WITH

OPTICAL INSTRUMENTS

CLASS 1M LASER PRODUCT

(IEC 60825-1:2007)

Laser Class 1M Label

If the laser output is observed at a distance of

100mm or less from the laser beam emitting

part by means of optical method (loupe,

magnifying glass, microscope, etc.), this may

cause eye injury.

VISIBLE LASER RADIATION

AVOID DIRECT EYE EXPOSURE

CLASS 3R LASER PRODUCT

(IEC 60825-1:2007)

MAX OUTPUT WAVELENGTH

5mW 650±20nm

Laser Class 3R Label

Avoid direct eye exposure

Safety Precautions for Laser Products

This instrument uses a laser light source. This instrument is a Class 1M laser product

as defined by IEC60825-1 Safety of Laser Products-Part 1: Equipment Classification,

Requirements and User’s Guide. In addition, the AQ7270/AQ7275 complies with

21 CFR 1040.10 except for the items that deviate from the standard as a result of

complying with Laser Notice No.50 dated on June 24, 2007.

MODEL Class Center Wavelength Output Power

735020 1M 1550nm CW: ≤5mW@1550nm

PULSE: ≤200mW@1550nm

PULSEwidth:≤20us@1550nm(dutycycle:≤2.5%)

735021 1M 1650nm CW: ≤5mW@1650nm

PULSE: ≤32mW@1650nm

PULSEwidth:≤20us@1650nm(dutycycle:≤2.5%)

735022 1M 1310/1550nm CW: ≤5mW@1310/1550nm

PULSE: ≤200mW@1310/1550nm

PULSEwidth:≤20us@1310/1550nm(dutycycle:≤2.5%)

735023 1M 1310/1550nm CW: ≤5mW@1310/1550nm

PULSE: ≤200mW@1310/1550nm

PULSEwidth:≤20us@1310/1550nm(dutycycle:≤2.5%)

735024 1M 1550/1625nm CW: ≤5mW@1550/1625nm

PULSE: ≤200mW@1550/1625nm

PULSEwidth:≤20us@1550/1625nm(dutycycle:≤2.5%)

735025 1M 1310/1490/1550nm CW: ≤5mW@1310/1490/1550nm

PULSE: ≤200mW@1310/1490/1550nm

PULSEwidth:≤20us@1310/1490/1550nm(dutycycle:≤2.5%)

735026 1M 1310/1550/1625nm CW: ≤5mW@1310/1550/1625nm

PULSE: ≤200mW@1310/1550/1625nm

PULSEwidth:≤20us@1310/1550/1625nm(dutycycle:≤2.5%)

735027 1M 1310/1550/1650nm CW: ≤5mW@1310/1550/1650nm

PULSE: ≤200mW@1310/1550nm

PULSE: ≤32mW@1650nm

PULSEwidth:≤20us@1310/1550/1650nm(dutycycle:≤2.5%)

735028 1M 1310/1550/1625nm CW: ≤5mW@1310/1550/1625nm

PULSE: ≤200mW@1310/1550/1625nm

PULSEwidth:≤20us@1310/1550/1625nm(dutycycle:≤2.5%)

viii

IM 735020-01E

Page 11

Safety Precautions

MODEL Class Center Wavelength Output Power

735029 1M 850/1300nm PULSE: ≤50mW@850nm

≤100mW@1300nm

PULSEwidth:≤1us@850nm(dutycycle:≤5%)

≤5us@1300nm(dutycycle:≤0.6%)

735030 1M 850/1300nm PULSE: ≤50mW@850nm

≤100mW@1300nm

PULSEwidth:≤1us@850nm(dutycycle:≤5%)

≤5us@1300nm(dutycycle:≤0.6%)

1310/1550nm CW: ≤5mW@1310/1550nm

PULSE: ≤200mW@1310/1550nm

PULSEwidth:≤20us@1310/1550nm(dutycycle:≤2.5%)

735031 1M 1650nm CW: ≤5mW@1650nm

PULSE: ≤32mW@1650nm

PULSEwidth:≤20us@1650nm(dutycycle:≤2.5%)

3R 650nm CW: ≤5mW@650nm

735032 1M 1310/1550nm CW: ≤5mW@1310/1550nm

PULSE: ≤200mW@1310/1550nm

PULSEwidth:≤20us@1310/1550nm(dutycycle:≤2.5%)

3R 650nm CW: ≤5mW@650nm

735033 1M 1310/1550nm CW: ≤5mW@1310/1550nm

PULSE: ≤200mW@1310/1550nm

PULSEwidth:≤20us@1310/1550nm(dutycycle:≤2.5%)

3R 650nm CW: ≤5mW@650nm

735034 1M 1310/1550nm CW: ≤5mW@1310/1550nm

PULSE: ≤200mW@1310/1550nm

PULSEwidth:≤20us@1310/1550nm(dutycycle:≤2.5%)

3R 650nm CW: ≤5mW@650nm

735035 1M 1310/1490/1550nm CW: ≤5mW@1310/1490/1550nm

PULSE: ≤200mW@1310/1490/1550nm

PULSEwidth:≤20us@1310/1490/1550nm(dutycycle:≤2.5%)

3R 650nm CW: ≤5mW@650nm

735036 1M 1310/1550/1625nm CW: ≤5mW@1310/1550/1625nm

PULSE: ≤200mW@1310/1550/1625nm

PULSEwidth:≤20us@1310/1550/1625nm(dutycycle:≤2.5%)

735037 1M 1310/1550/1650nm CW: ≤5mW@1310/1550/1650nm

PULSE: ≤200mW@1310/1550nm

PULSE: ≤32mW@1650nm

PULSEwidth:≤20us@1310/1550/1650nm(dutycycle:≤2.5%)

735038 1M 1310/1550/1625nm CW: ≤5mW@1310/1550/1625nm

PULSE: ≤200mW@1310/1550/1625nm

PULSEwidth:≤20us@1310/1550/1625nm(dutycycle:≤2.5%)

3R 650nm CW: ≤5mW@650nm

735040 1M 850/1300nm PULSE: ≤50mW@850nm,PULSE:≤100mW@1300nm

PULSEwidth:≤1us@850nm(dutycycle:≤5%)

≤5us@1300nm(dutycycle:≤0.6%)

1310/1550nm CW: ≤5mW@1310/1550nm

PULSE: ≤200mW@1310/1550nm

PULSEwidth:≤20us@1310/1550nm(dutycycle:≤2.5%)

735041 1M 850/1300nm PULSE: ≤50mW@850nm,PULSE:≤100mW@1300nm

PULSEwidth:≤1us@850nm(dutycycle:≤5%)

≤5us@1300nm(dutycycle:≤0.6%)

1310/1550nm CW: ≤5mW@1310/1550nm

PULSE: ≤200mW@1310/1550nm

PULSEwidth:≤20us@1310/1550nm(dutycycle:≤2.5%)

IM 735020-01E

If the instrument is used in a manner not specified in this manual, the protection provided

by the instrument may be impaired. Yokogawa Electric Corporation assumes no liability

for the customer’s failure to comply with these requirements.

ix

Page 12

Waste Electrical and Electronic Equipment

Waste Electrical and Electronic Equipment (WEEE), Directive 2002/96/EC

(This directive is only valid in the EU.)

This product complies with the WEEE Directive (2002/96/EC) marking

requirement. This marking indicates that you must not discard this electrical/

electronic product in domestic household waste.

Product Category

With reference to the equipment types in the WEEE directive Annex 1, this

product is classified as a “Monitoring and Control instrumentation” product.

Do not

dispose in domestic household waste. When disposing products in the EU,

contact your local Yokogawa Europe B. V. office.

x

IM 735020-01E

Page 13

Symbols and Notation Used in This Manual

Safety Markings

The following markings are used in this manual.

Improper handling or use can lead to injury to the user or damage

to the instrument. This symbol appears on the instrument to indicate

that the user must refer to the users manual for special instructions.

The same symbol appears in the corresponding place in the user’

s manual to identify those instructions. In the manual, the symbol is

used in conjunction with the word “WARNING” or “CAUTION.”

WARNING

CAUTION

Calls attention to information that is important for proper operation of

Note

Calls attention to actions or conditions that could cause serious or

fatal injury to the user, and precautions that can be taken to prevent

such occurrences.

Calls attention to actions or conditions that could cause light injury

to the user or damage to the instrument or the user’s data, and

precautions that can be taken to prevent such occurrences.

the instrument.

Notations Used on Pages Describing Operating Procedures

On pages that describe the operating procedures in chapters 4 through 19, the following

displayed characters, and terminology are used to distinguish the procedures from their

explanations.

Procedure

Explanation

Carry out the procedure according to the step numbers. All

procedures are written with inexperienced users in mind; experienced

users may not need to carry out all the steps.

This section describes the setup items and the limitations regarding

the procedures. It may not give a detailed explanation of the function.

For a detailed explanation of the function, see chapter 2.

Unit

IM 735020-01E

Displayed Characters and Terminology Used in the Procedural

Explanations

Panel Keys and Soft keys

Bold characters used in the procedural explanations indicate characters that are marked on the

panel keys or the characters of the soft keys or menus displayed on the screen.

k Denotes 1000. Example: 12 kg, 100 kHz

xi

Page 14

Contents

Checking the Contents of the Package.............................................................................................ii

Safety Precautions ............................................................................................................................v

Waste Electrical and Electronic Equipment ......................................................................................x

Symbols and Notation Used in This Manual ....................................................................................xi

Chapter 1 Names and Functions of Parts

1.1 Front Panel ....................................................................................................................... 1-1

1.2 Rear Panel ....................................................................................................................... 1-2

1.3 Side Panel ........................................................................................................................

1.4 Display ..............................................................................................................................

Chapter 2 Measurement Overview

2.1 MeasurementConguration ............................................................................................. 2-1

2.2 Measurement Procedure .................................................................................................. 2-4

2.3 Viewing the Optical Pulse Measurement W

2.4 Distance Measurement ...................................................................................................2-11

Chapter 3 Measurement Preparation

3.1 Connecting the Power Supply .......................................................................................... 3-1

3.2 Connecting the Optical Fiber Cable ................................................................................. 3-5

3.3 Setting the Date and T

3.4 Loading the Printer Roll Paper (Option) ........................................................................... 3-9

3.5 Connecting the USB Interface ........................................................................................ 3-10

3.6 Connecting the Ethernet Interface (Option) .....................................................................3-1

3.7 Attaching the Belt ........................................................................................................... 3-12

ime ................................................................................................ 3-7

1-3

1-5

aveform ........................................................ 2-9

1

Chapter 4 Setting the Optical Pulse Measurement Conditions (Simple Full Auto

Mode)

4.1 Selecting the Test Wavelength ......................................................................................... 4-1

4.2 Selecting the Approximation Method ................................................................................ 4-3

4.3 Setting Other Items ......................................................................................................

.... 4-4

Chapter 5 Setting the Optical Pulse Measurement Conditions (Measurement

Wizard Mode)

5.1 Setting the Measurement Conditions ............................................................................... 5-1

5.2 Setting the Analysis Conditions ........................................................................................ 5-8

5.3 Setting

5.4 Setting the File ......................................................................................................

theDetectionConditionsofReectionandLossWaveforms .............................5-11

......... 5-16

Chapter 6 Setting the Optical Pulse Measurement Conditions (Detail Mode

(Manually Setting All Items))

6.1 Setting the Measurement Conditions ............................................................................... 6-1

6.2 Setting the Analysis Conditions ...................................................................................... 6-16

6.3 Setting the Multi Wavelength Measurement Conditions .................................................

6.4 Setting the Multi Wavelength

Analysis Conditions .......................................................... 6-25

6-22

xii

IM 735020-01E

Page 15

Contents

Index

App

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Chapter 7 Executing the Optical Pulse Measurement (Acquiring Waveforms)

7.1 Realtime Measurement .................................................................................................... 7-1

7.2 Averaging Measurement .................................................................................................. 7-5

7.3 Displaying the Measurement Conditions .......................................................................... 7-7

7.4 High Resolution Measurement of the Selected Location ................................................. 7-8

7.5 Measuring Multicore Fiber ...............................................................................................7-11

7.6 Warm-up Measurement .................................................................................................. 7-28

Chapter 8 Zooming the Waveform

8.1 Zooming the Display ......................................................................................................... 8-1

8.2 Moving the Waveform ....................................................................................................... 8-2

8.3 Initializing the Waveform Display ......................................................................................

8.4 Auto Zoom the Waveform Display ....................................................................................

8-3

8-4

Chapter 9 Macro Measurement

9.1 CreatingtheMeasurementConditions(DeningtheMacroConditions) ......................... 9-1

9.2 Saving the Macro Measurement Results ......................................................................... 9-3

9.3 Loading the Measurement Conditions .............................................................................. 9-9

9.4 Executing the Macro .......................................................................................................

9.5 Saving/Loading Macro Conditions .................................................................................. 9-13

Chapter 10 Measuring the Distance

10.1 Marker and Cursor Operation ......................................................................................... 10-1

10.2 Measuring the Distance .................................................................................................. 10-9

10.3 Moving the Measurement Reference ........................................................................... 10-12

Chapter 11 Measuring the Splice and Return Loss

11.1 Measuring the Splice Loss ..............................................................................................11-1

11.2 Measurement Taking the Adjacent Splice Loss into Consideration .................................11-7

11.3 Measuring

theReturnLossandReectionLevel ............................................................11-9

Chapter 12 Editing the Event List

12.1 Viewing the Measured Results ....................................................................................... 12-1

12.2 Editing the Waveform ..................................................................................................... 12-3

12.3 Editing the List ..............................................................................................................

Chapter 13 Detail Analysis of the Measured Waveform

13.1 Displaying the Multiple Waveforms ................................................................................ 13-1

13.2 2-Way Trace ................................................................................................................... 13-4

13.3 Difference W

13.4 Section Analysis ......................................................................................................

13.5 Fixing the Waveform

aveform ...................................................................................................... 13-9

..................................................................................................... 13-14

Chapter 14 Optical Power Monitoring (Option)

14.1 Calibration before the Measurement .............................................................................. 14-1

14.2 Setting the Reference ..................................................................................................... 14-2

14.3 Selecting the Display Unit .............................................................................................. 14-3

14.4 Selecting the W

14.5 Setting the Offset .......................................................................................................

14.6 Set the Threshold Level

avelength ...............................................................................................

.................................................................................................. 14-6

9-11

.

12-14

..... 13-12

14-4

..... 14-5

IM 735020-01E

xiii

Page 16

Contents

Chapter 15 Light Source Operation (Option)

15.1 Light and Stabilized Light Source ................................................................................... 15-1

15.2 Visible Light Source ........................................................................................................ 15-3

Chapter 16 Checking Fiber End Faces

16.1 Using Fiber Inspection Probes to View the Status of Optional Fiber End Faces. .......... 16-1

Chapter 17 Multi Core Trace Comparison

17.1 Measuring Optical Pulses before Work and after Work .................................................. 17-1

17.2 ConguringtheCoreInformation ................................................................................. 17-10

17.3 Setting Measurement Conditions ................................................................................. 17-15

17.4 Setting

Analysis Conditions ..........................................................................................

Chapter 18 Saving, Loading, and Printing Files

18.1 Loading and Saving Files ............................................................................................... 18-1

18.2 Deleting or Copying the Files ......................................................................................... 18-8

18.3 Renaming the File ........................................................................................................

18.4 Creating, Deleting, and Copying Folders ..................................................................... 18-14

18.5 Printing ......................................................................................................

18.6 Entering Characters ..................................................................................................... 18-21

18.7 Creating Labels ......................................................................................................

18.8 Initializing (formatting) the internal memory ................................................................. 18-29

...................

......

17-16

18-12

18-18

18-23

Chapter 19 Other Settings

19.1 Setting the System ......................................................................................................... 19-1

19.2 Setting the Display ......................................................................................................... 19-9

19.3 Setting the Network (/PL Option)

19.4 Network File T

19.5 Cable

InstallationCompletionNotication .................................................................... 19-23

ransfers ................................................................................................. 19-22

.................................................................................. 19-18

Chapter 20 Troubleshooting, Maintenance, and Inspection

20.1 Troubleshooting .............................................................................................................. 20-1

20.2 Error Messages .............................................................................................................. 20-2

20.3 Self T

20.4 Updating the Firmware ................................................................................................... 20-8

20.5 Mechanical Inspection .................................................................................................. 20-10

20.6 Checking the Operation .................................................................................................20-1

20.7 Replacing the Battery Pack ..........................................................................................

20.8 Replacing the Optical

20.9 Routine Maintenance ................................................................................................... 20-17

20.10 Storage Precautions ..................................................................................................... 20-18

20.11

Recommended Replacement Parts .............................................................................

20.12 Calibration ....................................................................................................................

est .......................................................................................................................... 20-7

Adapter

...................................................................................... 20-15

Chapter 21 Specications

21.1 Models ............................................................................................................................ 21-1

21.2 Optical Section ............................................................................................................... 21-2

21.3 General

21.4 External Dimensions .................................................................................................... 21-10

Specications ................................................................................................... 21-8

1

20-12

20-19

20-20

xiv

IM 735020-01E

Page 17

Appendix

Index

App

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Contents

Appendix 1 Terminology ........................................................................................................ App-1

Appendix 2 Key Assignments for the USB104 Keyboard ......................................................App-6

Appendix3

Exampleofleinput/output ................................................................................ App-7

Index

IM 735020-01E

xv

Page 18

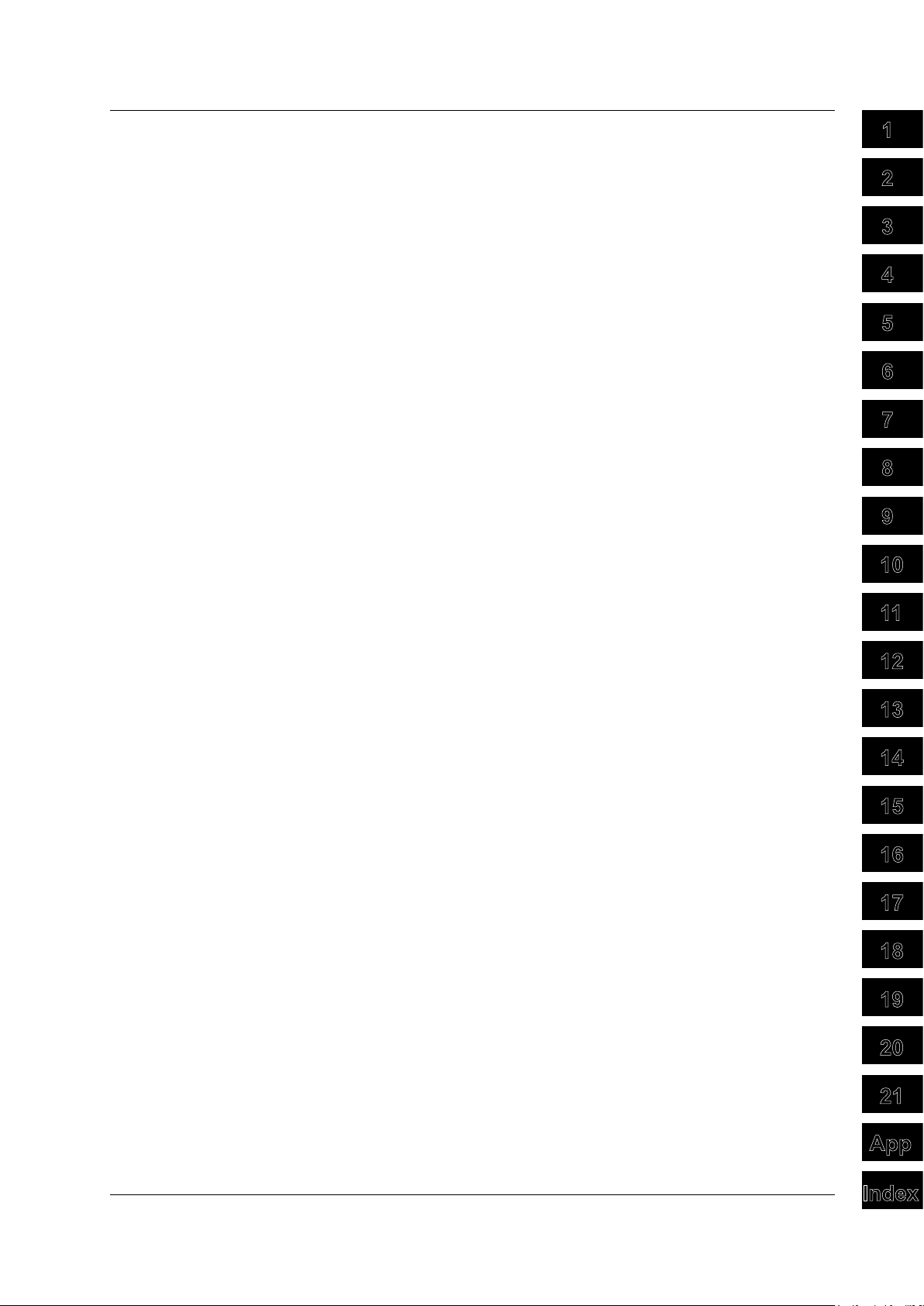

1

OPTICAL INPUT

MENU

F 1

F 2

F 3

F 4

F 5

ESC

FILE

SCALE

ENTER

SETUP

REAL

TIME

AVG

CHARGE

ON

1

2 3

4

5 6

7

8

9

10

11

12

13

14

15

Chapter 1 Names and Functions of Parts

1.1 Front Panel

Names and Functions of Parts

IM 735020-01E

Number Name Function

1 LCD Displays the measured waveforms, measurement

conditions, etc.

2 ESC key Cancels an operation or returns to the previous display.

3 FILE key Operate files and print waveforms.

Some also used as soft keys.

4 CHARGE lamp Lights (green) while the battery pack is fast charging.

Turns OFF when the battery pack is finished fast charging.

Blinks (green) if the battery pack cannot be fast charged.

5 POWER switch Turns the instrument on/off

6 POWER lamp Illuminates while the instrument is turned on (green).

When the battery level is low (red).

7 AVERAGE key Starts or stop the averaging measurement.

8 REALTIME key Starts or stop the realtime measurement.

9 SETUP key Sets measurement conditions and system configuration.

Also used to change the event detection conditions for

event analysis.

Arrow keys Moves, expands, and reduces waveforms, moves cursors,

10

etc.

11 ENTER key Confirms the operation

12 SCALE key Expands, reduces, and moves waveforms.

13 Rotary knob Moves cursors and markers, sets values, etc.

14 MENU key Returns to the initial screen at startup.

(Selects OTDR, optical power monitor, light source, and

one-button measurement.)

15 Soft keys Executes functions that are assigned to the soft keys

displayed at the right edge of the LCD.

1-1

Page 19

1.2 Rear Panel

1

Number Name Function

1 Stand Tilts the instrument.

Note

• The /PL option does not come with a stand.

• Do not use the stand as a handle to carry the AQ7270/AQ7275.

• Use the stand only to tilt the AQ7270/AQ7275.

• If you are tilting the AQ7270/AQ7275, check that the stand is fixed in place.

1-2

IM 735020-01E

Page 20

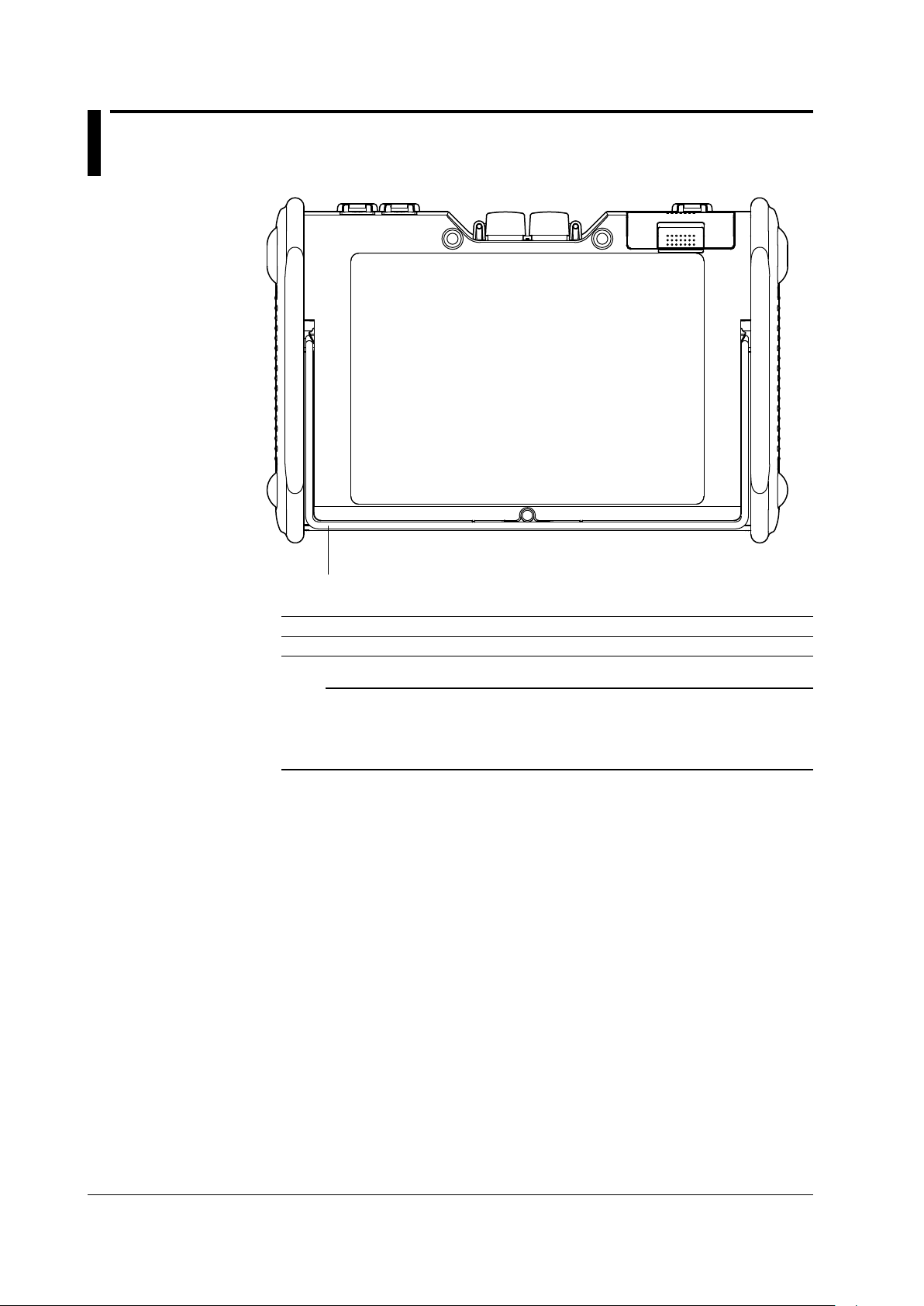

1

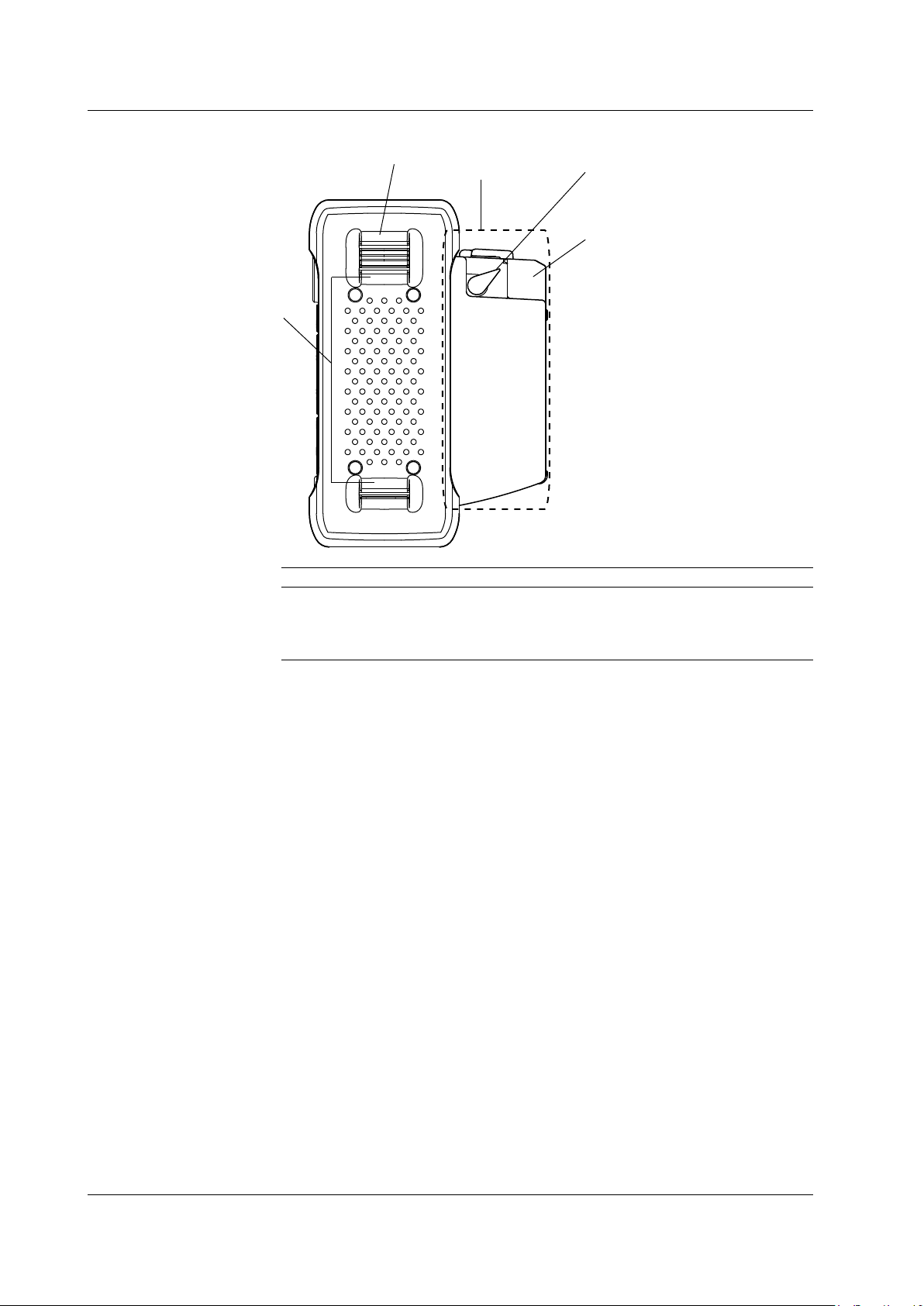

1.3 Side Panel

1

2

3

4

5

6

78

/PL Option

Top View

Names and Functions of Parts

Number Name Function

1 DC power connector Connects the AC adapter.

2 Optical connector Connects the optical fiber cable. *1

3 USB 1.1 connector (Type A) Connects a USB memory, USB printer,

the USB104 keyboard etc.

4 USB 1.1 connector (Type B)

5 Internal printer Prints waveforms and event lists.(/PL option)

6 Printer paper feed button Feeds the paper.(/PL option)

7 Ethernet connector Used for remote control.(/PL option)

8 Battery pack storage Stores the battery pack.

*1 The /PM option supports only PORT1. PORT2 (MMF) and 1650-nm wavelength are not

supported.

Used for remote control, storage, etc.

IM 735020-01E

1-3

Page 21

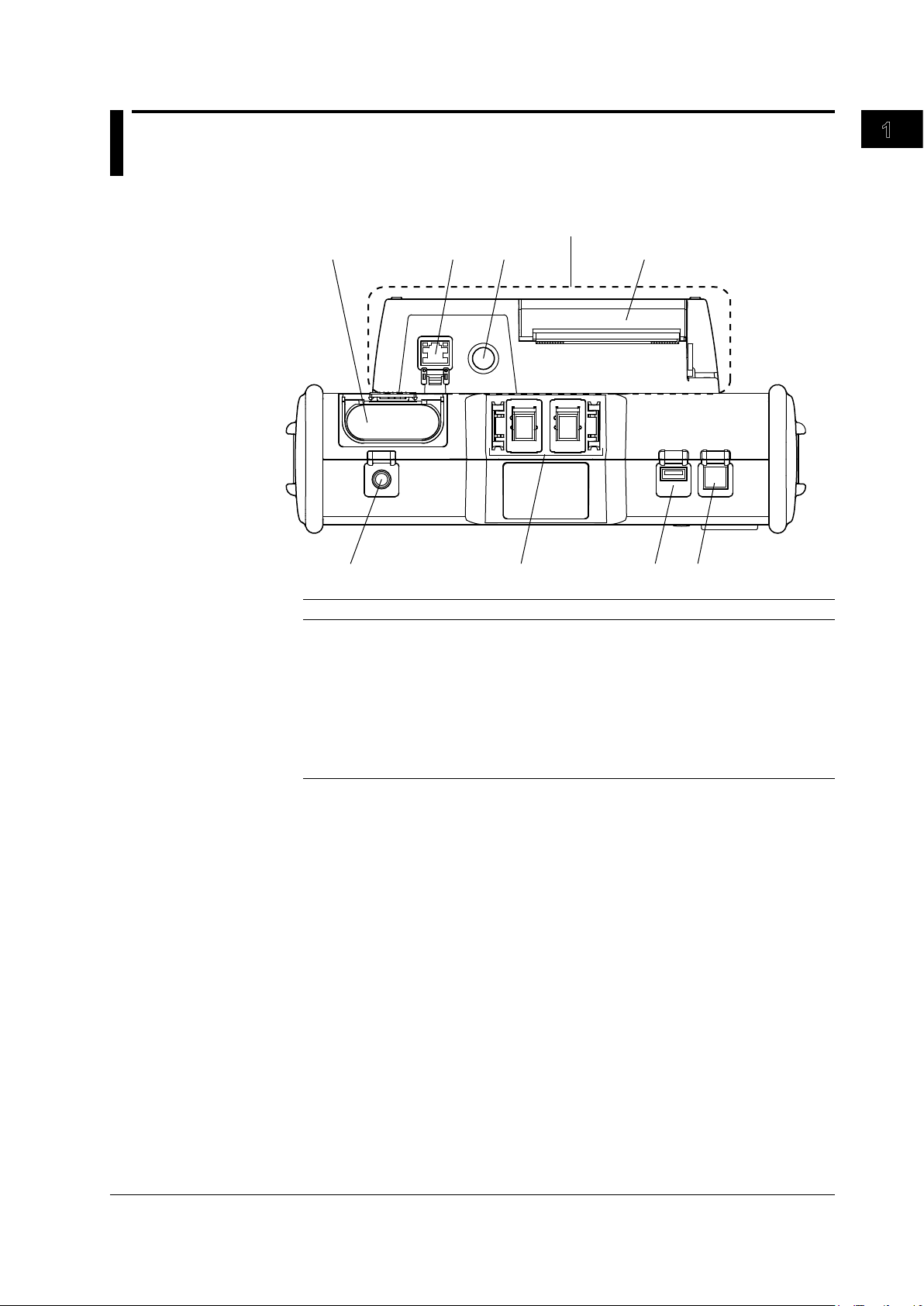

1

2

3

4

/PL option

1.3 Side Panel

Right View

Number Name Function

1 Printer cover Stores the paper.

2 Lock lever Fixes the printer cover in place.

3 Shoulder belt bracket Attaches the shoulder belt.

4 Hand belt bracket Attaches the hand belt.

1-4

IM 735020-01E

Page 22

1

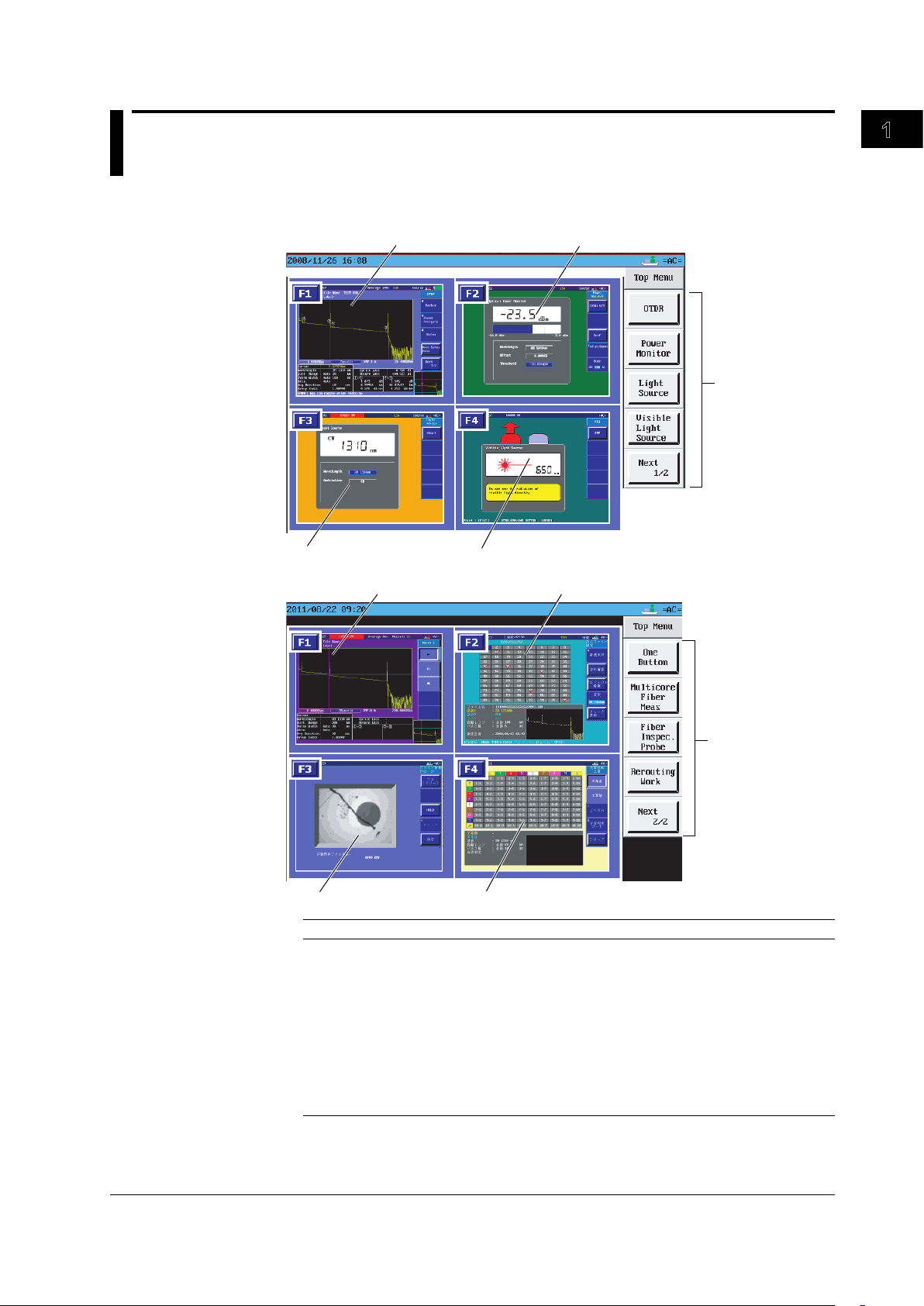

1.4 Display

1

2

3

4

5

5

6

7

8

9

Top Menu

Names and Functions of Parts

Number Function

1 Optical pulse measurement (OTDR) screen.

2 Optical power monitor screen (/PM option).

3 Light source screen (/LS /SLS option).

4 Visible Light source screen (/VLS option).

5 Displays the soft key menu.

6 One-button measurement screen.

7 multicore fiber measurement (

8 Displays the fiber inspection probe screen.

Displays the Multi Core Trace Comparison (main view) screen (firmware versions 3.01

9

and later).

main view display) screen.

IM 735020-01E

1-5

Page 23

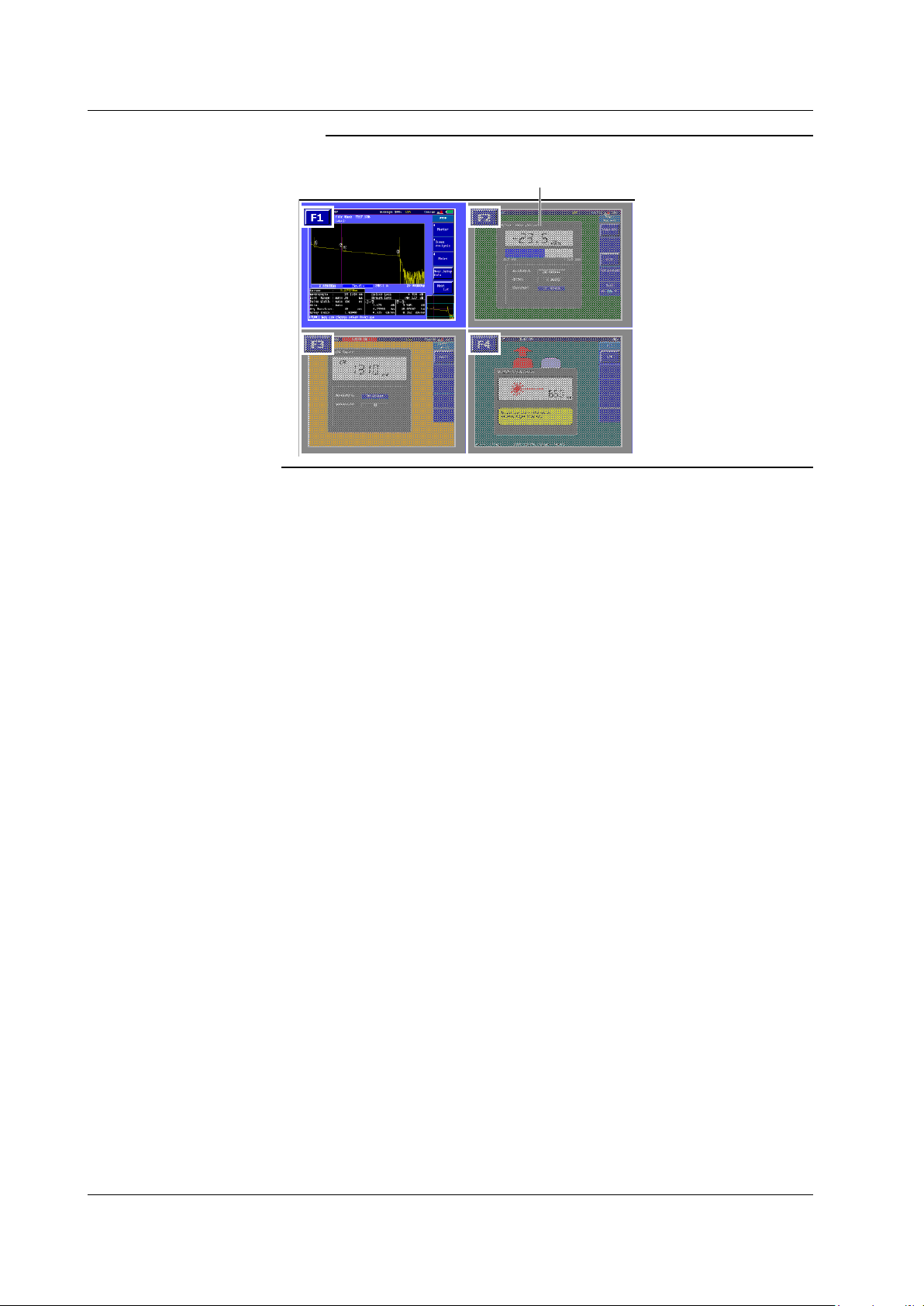

A shaded area

1.4 Display

Note

Displays a shaded area when the option is not installed (firmware version 3.01 or later).

1-6

IM 735020-01E

Page 24

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1516 17

18

19

20

21

22

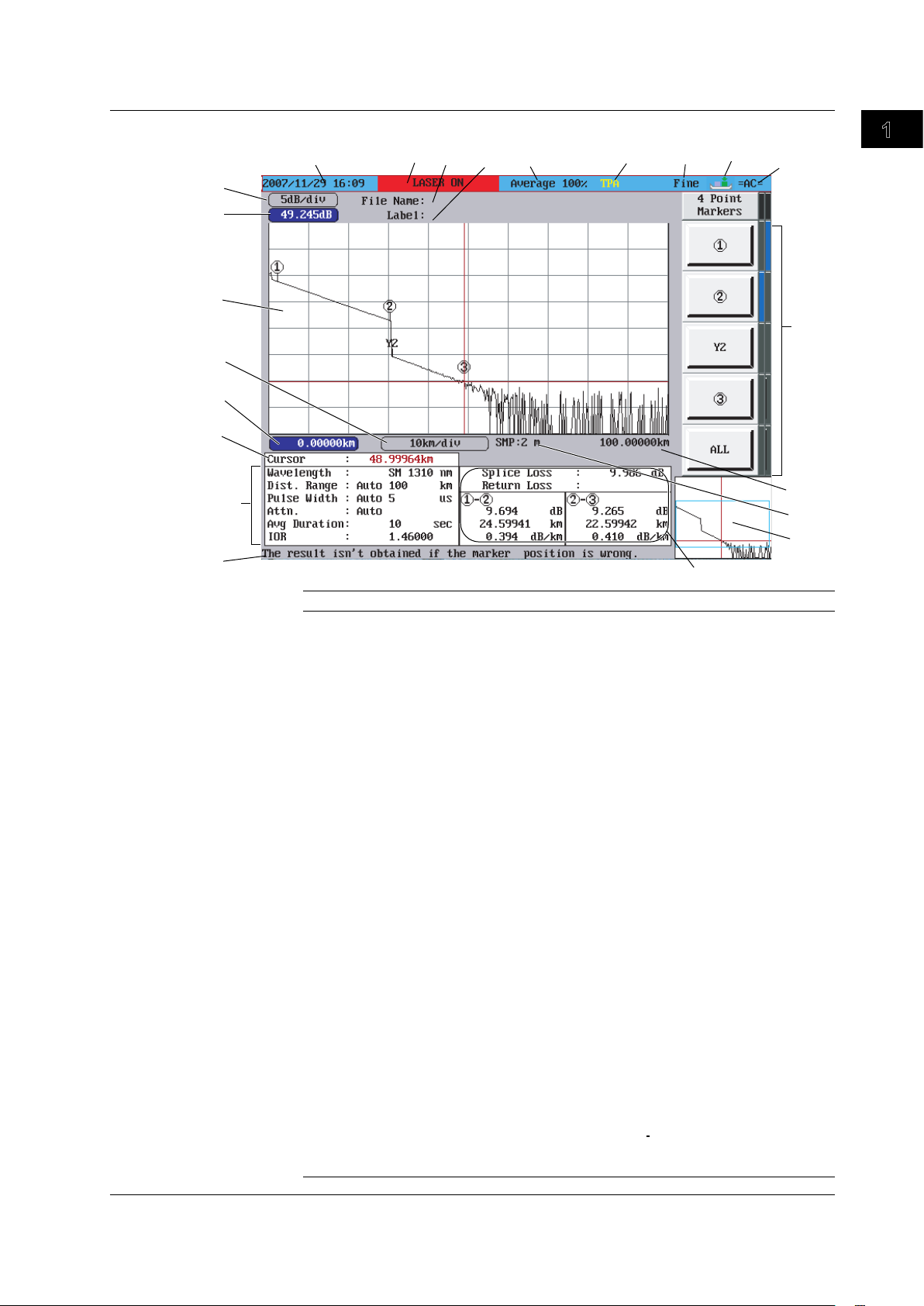

1.4 Display

Optical Pulse Measurement (OTDR)

Names and Functions of Parts

Number Function

1 Displays the value per scale mark on the vertical axis.

2 Shows the display start level of the vertical axis (top edge of the waveform display area)

3 Waveform display area

4 Displays the value per scale mark on the horizontal axis.

5 Shows the display start distance of the horizontal axis (left edge of the waveform display

area)

6 Displays the distance from the measurement reference point of the horizontal axis to the

cursor position.

7 Displays the measurement conditions.

8 Displays an explanation of the function

9 Displays the computed result of the measured data.

10 Displays the full screen of the waveform display area. The section displayed in the

waveform display area is indicated with a frame (overview).When adjusting the scale

using Zoom or Shift, the color of the frame is different. When you press Shift, the word

“SHIFT” is displayed at the upper right of the overview screen.

11 Displays the sampling resolution.

12

Shows the display end distance of the horizontal axis (right edge of the waveform

display area)

13 Displays the soft key menu.

14 Displays the type of power in use (battery pack or AC adapter)

15 Displays the cursor movement setting.

16 Displays the approximation method.

17 Displays in red the connector in which the optical pulse is output.

18 Displays the progress of the averaging measurement (AVE).Displays a bar graph

indicating the progress in the

19 Label area. The name of the next file to be saved blinks if auto save is turned ON.

20 Displays the operating status of the instrument.

While the optical pulse output is ON: “LASER ON” is indicated and the text ckground

blinks.

While the optical pulse output is OFF: Operation mode (Simple (Full Auto),

measurement Wizard, Detail, or Multi WL)

21 Displays the year, month, day, and time.

22 FILE name area

text background.

IM 735020-01E

1-7

Page 25

1 2

3

4

1 2

3

1.4 Display

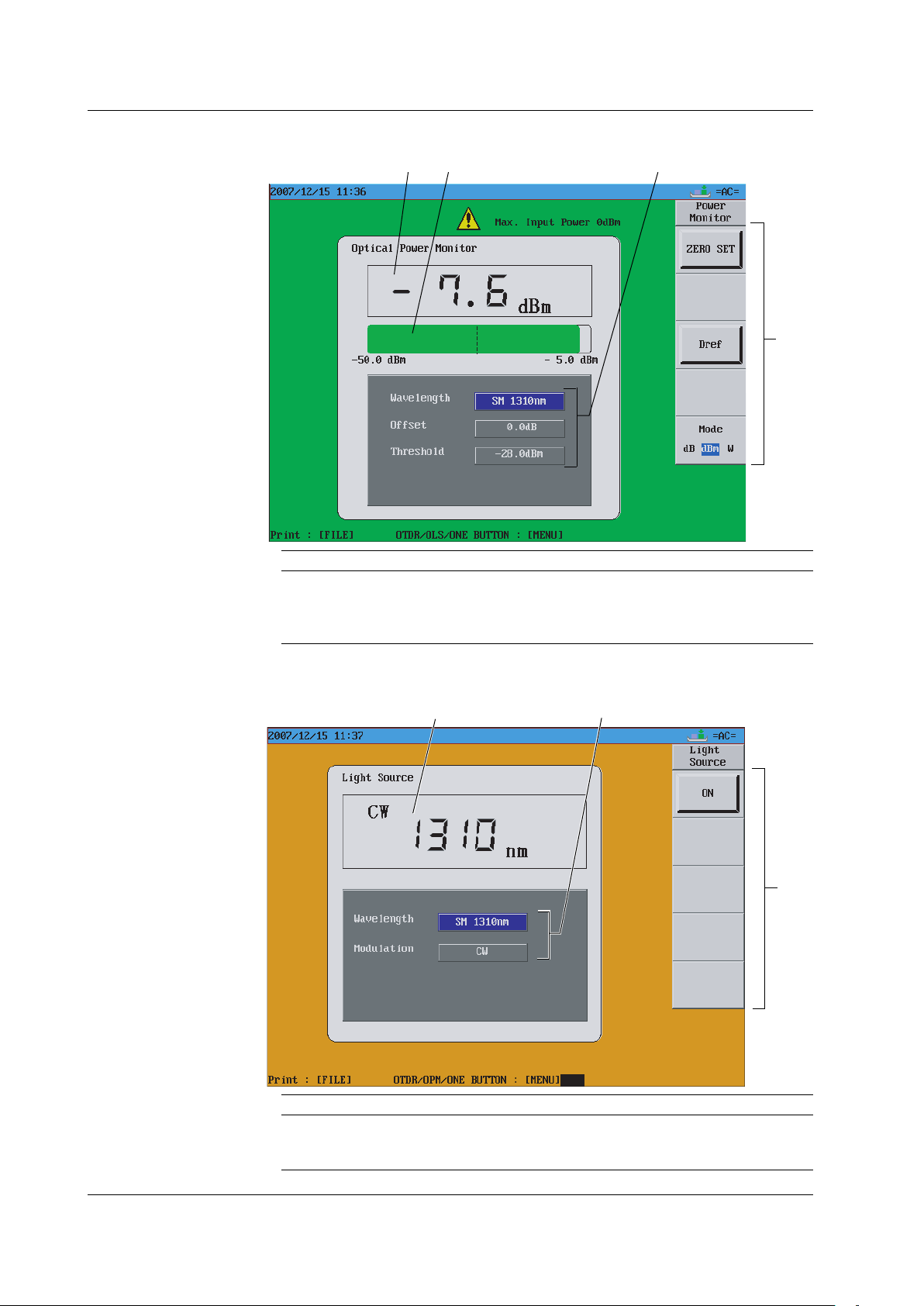

Optical Power Monitor(/PM option)

Number Function

1 Displays numerically the optical input power value.

2 Displays a graph of the optical input power value.

3 Measurement condition display area

4 Soft key menu

Light Source(/LS, /SLS option)

1-8

Number Function

1 Displays the wavelength value.

2 Measurement condition display area

3 Soft key menu

IM 735020-01E

Page 26

1

1

2

1

2

1.4 Display

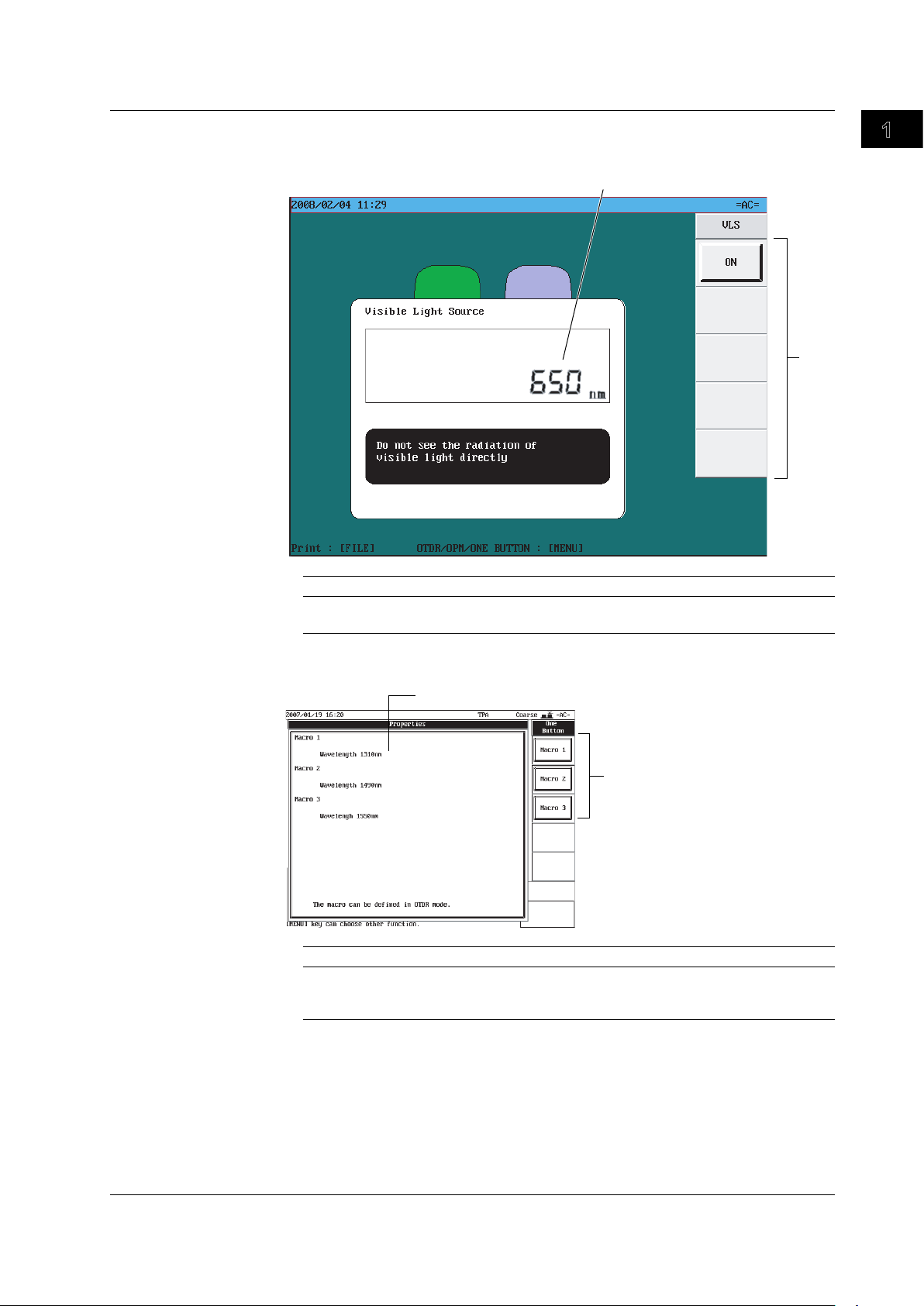

Visible Light source (/VLS option)

Number Function

1 Displays the wavelength value.

2 Soft key menu

Names and Functions of Parts

One-Button Measurement

Number Function

1 Displays the contents of the macro that is being defined (used to enter the macro while

viewing the contents).

2 Soft key menu

IM 735020-01E

1-9

Page 27

1

2

1

2

3

4

1.4 Display

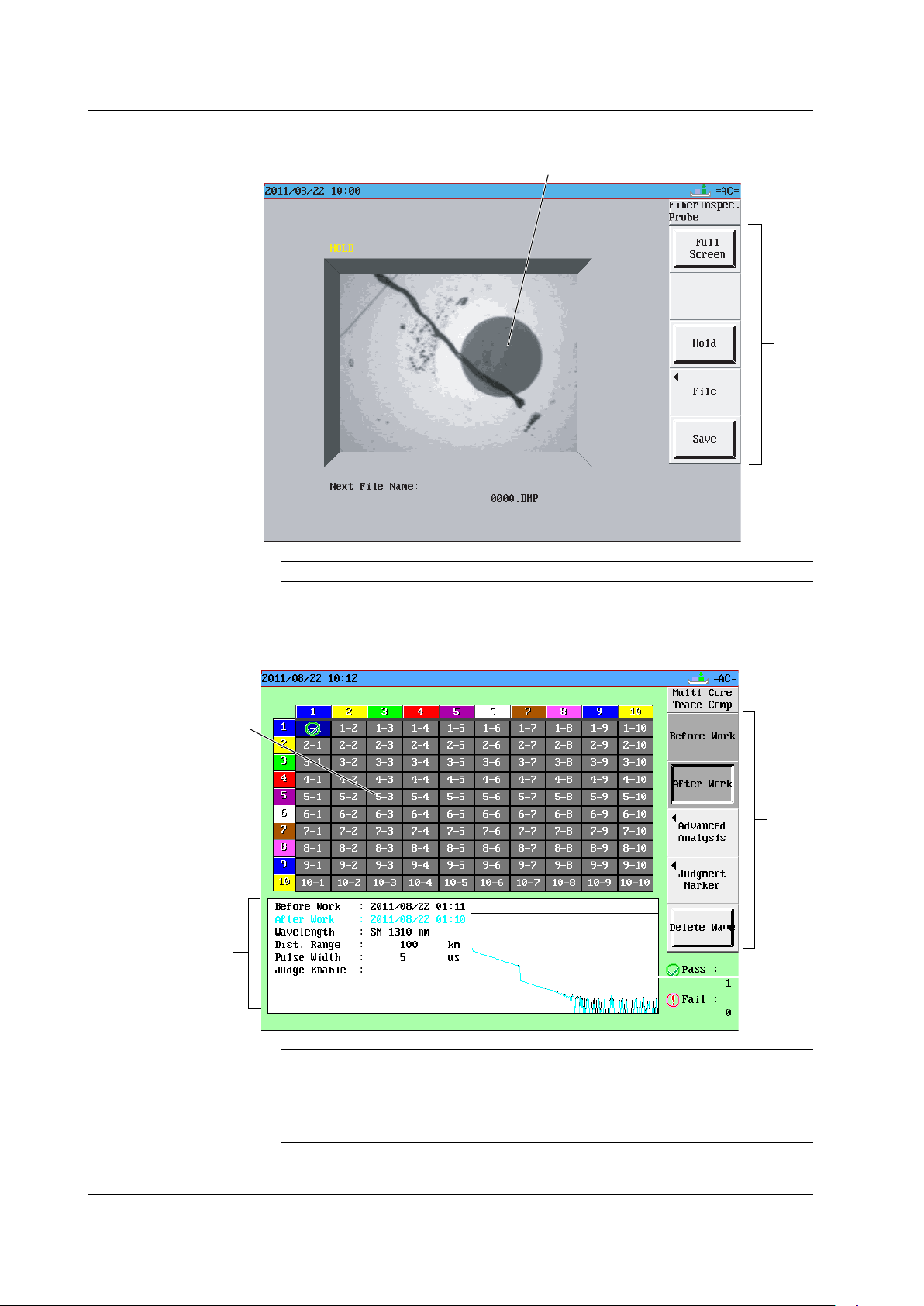

Fiber Inspection Probe

Number Function

1 Displays the fiber inspection probe screen.

2 Soft key menu

Multi Core Trace Comparison (Firmware Versions 3.01 and Later)

Number Function

1 Displays the number of the core of the optical fiber cable under measurement.

2 Displays the soft key menu.

3 Displays the information of the cell that the cursor is at.

4 Displays the waveform before work and the waveform after work at the same time.

1-10

IM 735020-01E

Page 28

2

1

Telephone

pole

Closure

Optical fiber cable

Telephone

exchanges

Measurement in

cable installations

AQ7270/AQ7275 OTDR

Consumer

Corporate user

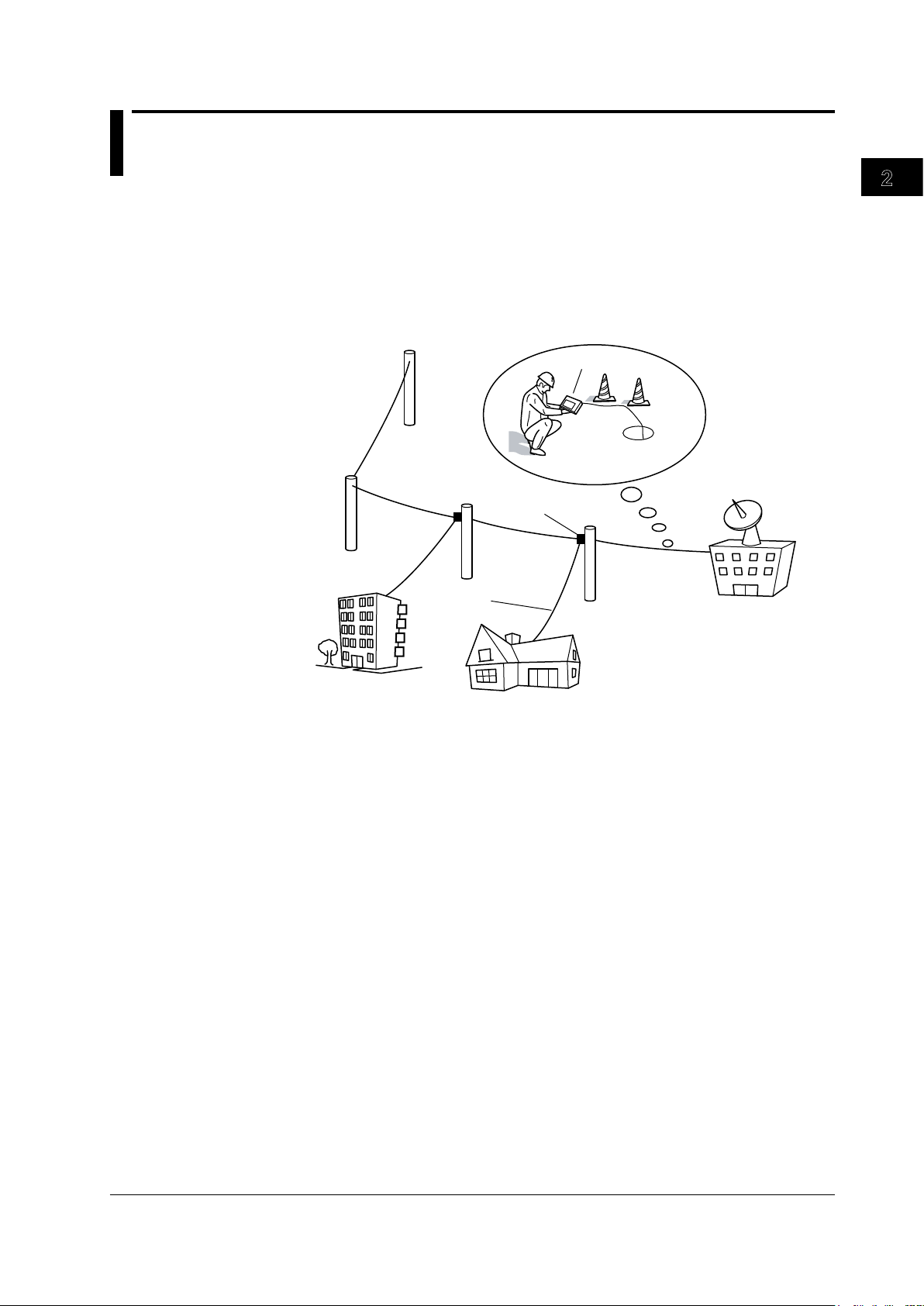

Chapter 2

Measurement Overview

2.1 Measurement Configuration

Overview of the AQ7270/AQ7275

The AQ7270/AQ7275 is an optical time domain reflectometer that measures optical

fiber lengths and losses and identifies failure locations. It is mainly used in the optical

fiber installation and maintenance servicing of access networks (communications links

between telephone exchanges and telephone poles) and user networks (communications

links between user sites and telephone poles). The light source and optical power

monitor functions can also be used as options.

Measurement Overview

Analysis Using the Emulation Software

The waveform data that is measured by the AQ7270/AQ7275 can be analyzed on your

PC using the AQ7932 OTDR emulation software (version 3.0 or later). The software

comes with a report creation wizard that is convenient in creating construction reports.

Precautions for Measurement

When Measuring with the Same Wavelength as the Communication Light

Most instrument models use the same wavelength for measurement as is used for

communication. If communication light is present in an optical fiber being measured, this

has an affect on the communication itself. Take sufficient precautions to avoid interruption

of communications. The measurements by the instrument may also be incorrect,

therefore the measuring environment (presence or absence of communication light, etc.)

should be carefully considered. For details on fiber-in-use alarm function, see section 6.1.

When Measuring with a Wavelength Different from Communication Light

(1625/1650 nm)

When there is communication light in the fiber under test, use a wavelength different from

the communication light for measurement.

IM 735020-01E

The instrument is designed to allow measurement that impacts communication as

little as possible in such cases, but be sure to install a cutoff filter of 1625 nm or 1650

nm in system under test. If measurements are taken without a cutoff filter installed,

communications can be affected and measurements may not be correct. Always check

the configuration of the system under test before use (presence or absence of an

appropriate cutoff filter, attenuation characteristics, etc.).

2-1

Page 29

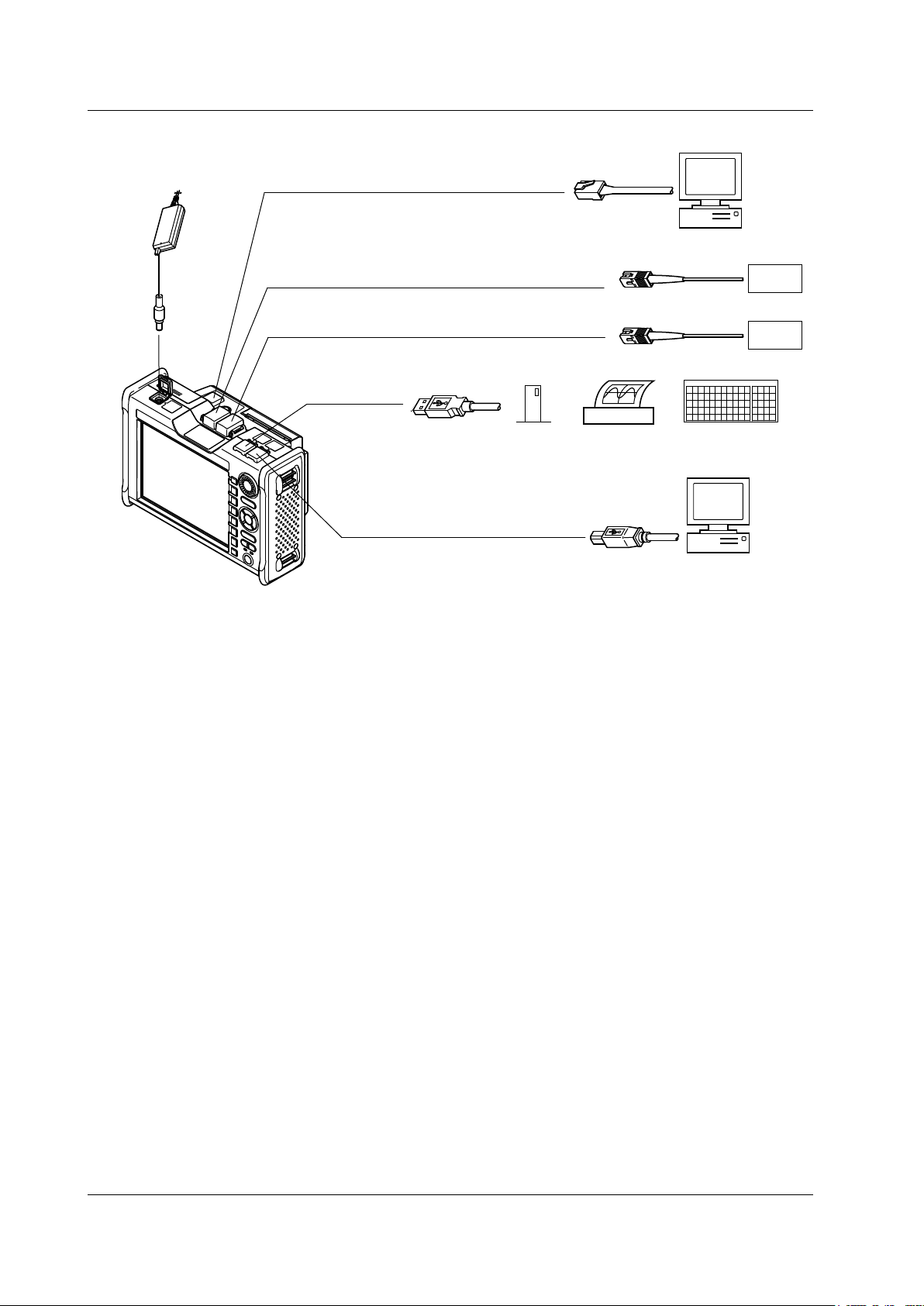

Ethernet connector (remote control)

PC

PC

USB connector

(remote control and storage)

USB printer

USB connector

USB memory

DUT

Optical connector PORT2

(wavelength *1: 650 nm, 850 nm, 1300 nm, and 1650 nm)

Optical connector PORT1

(wavelength *2: 1310 nm, 1490 nm, 1550 nm, and 1625 nm)

DUT

AC adapter

The 735021 and 735031 output 1650 nm from PORT1. The 735029 outputs 850 nm and 1300 nm from PORT1.

The /PM option supports only PORT1. PORT2 (MMF) and 1650-nm wavelength are not supported.

*1

USB104 keyboard

The 735036 outputs 1650 nm from PORT2.

*2

2.1 Measurement Configuration

Configuration of Peripheral Devices

2-2

IM 735020-01E

Page 30

2

1

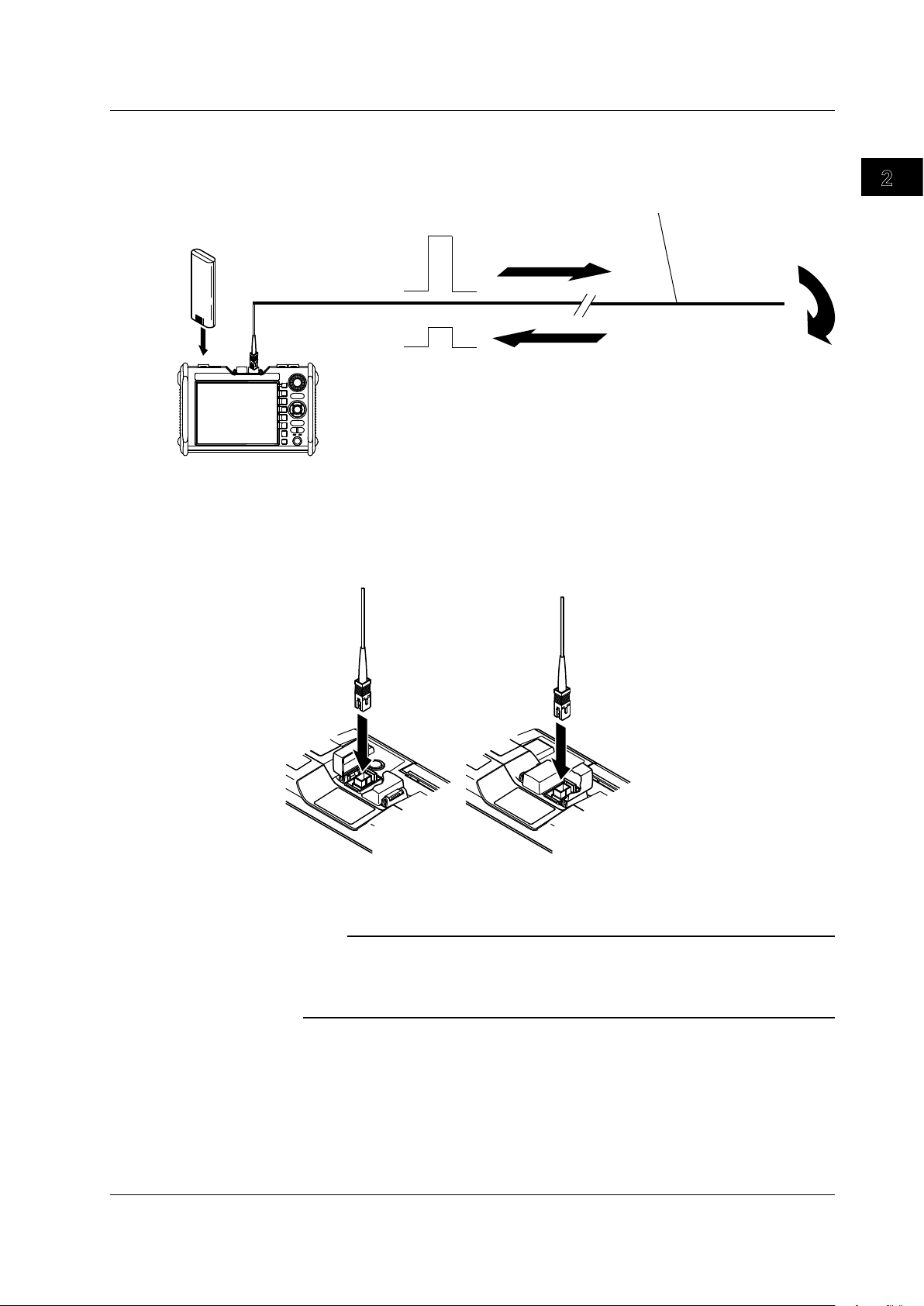

Optical Pulse Measurement (OTDR) Configuration

Reflection point

Battery pack

Optical fiber cable

under measurement

Optical pulse

output

Return ray due

to reflection

* Do not bend the optical fiber cable.

[PORT1][PORT2]

Install the battery pack and connect the optical fiber cable under measurement.

There are two optical connectors on the top panel of the AQ7270/AQ7275.Because the

connector that delivers the optical pulse is fixed depending on the wavelength, connect

the cable to the appropriate connector according to the condition of the optical fiber

cable to be measured. You can view the indicator shown on the display (see page 1-5) to

choose the appropriate connector.

2.1 Measurement Configuration

Measurement Overview

This also applies when using the optional optical power monitor or light source function.

Note

• The 735021 outputs 1650 nm from PORT1.

• The 735029 outputs 850 nm and 1300 nm from PORT1.

• The /PM option supports only PORT1. PORT2 (MMF) and 1650-nm wavelength are not

supported.

When Using the Angled PC SC Connector (Suffix Code:-ASC)

• Use the same type of angled PC SC connector for the connected optical fiber cable

as well.

The ferrule end of the angled PC SC connector is polished to

If other types of connectors are used, the end face of the connector may become

damaged.

• You can replace the

an angle.

AQ7270/AQ7275 connector, but only with an SC type.

IM 735020-01E

2-3

Page 31

2.2 Measurement Procedure

Measurement Preparation

Measurement Condition Setup

(Select from the Following Three)

Waveform Display Conditions

Connect the power supply and turn it ON/OFF

Connect the optical fiber cables

Set the date and time

Load the printer paper

When setting only the wavelength

and using auto setup for other

items (full auto mode)

When setting measurement

conditions using the wizard

(measurement wizard mode)

When specifying all items

(detail mode)

• Expand or reduce

• Move the waveform

• Display the grid and information

Waveform Analysis

• Measure the distance

• Measure the splice loss and return loss

• Editing the waveform

• Analyze multiple waveforms

Waveform Printing and Storage

• Print the display image

• Save various types of data

Section 3.1

Section 3.2

Section 3.3

Section 3.4

Chapter 4

Chapter 5

Chapter 6

Section 8.1

Section 8.2

Section 19.2

Section 18.5

Sections 18.1 to 18.4

One-Button

Measurement

Select a macro

and execute

Section 9.3

Waveform Acquisition

• Realtime measurement

• Averaging measurement

Section 7.1

Section 7.2

Multicore Fiber

Measurement

Create a project

and execute

Section 7.5

Chapter 10

Chapter 11

Section 12.2

Chapter 13

Flow of Operation

The figure below is provided to familiarize the first-time user with the general flow of the

AQ7270/AQ7275 operation. For details on each item, see the relevant section or chapter.

2-4

IM 735020-01E

Page 32

2

1

2.2 Measurement Procedure

One-Button Measurement <<For procedures, see section 9.3.>>

If you enter the settings such as the optical pulse measurement conditions, waveform

acquisition mode, and data format for storage in advance, you can carry out the

measurement and storage through a single-step operation. If you enter multiple sets

of settings such as the wavelengths to be measured, you can carry out measurements

sequentially using different measurement conditions through one-step operation.

Easy Setting of Measurement Conditions

There are three modes for setting the measurement conditions: Detail, Measurement

Wizard, and Full Auto.

In Detail mode, the user sets each measurement condition as in the past.

In Measurement Wizard mode, a wizard is displayed when the user sets each

measurement condition. This feature is convenient for users that are not used to the

work.

In Full Auto mode, all optical pulse measurement conditions are automatically set when

you select the wavelength to be measured, and the measured waveform is displayed.

This feature is convenient when you are not sure about the installation conditions of the

optical fiber cable.

Waveform Acquisition and Measurement Using Markers and Cursors

The AQ7270/AQ7275 has the following two measurement functions.

• Acquire the waveform

• Position markers or cursors on the acquired waveform and measure the values.

Measurement Overview

Multi Wavelength Measurement <<For procedures, see section 6.3 and 6.4.>>

The multi wavelength measurement is performed on the following wavelengths: 850nm,

1300nm, 1310 nm, 1490 nm, 1550 nm, and 1625 nm.

Measurement at multiple wavelengths can be carried out continuously.

The number of wavelengths that can be measured and waveforms that can be displayed

differs depending on the model (up to 3 waveforms).

Measuring Multicore Fiber <<For procedures, see section 7.5.>>

Specialized screens (Main View Screen) and menus for multicore fiber measurements

appear, enabling you to efficiently measure multicore fibers without data loss.

IM 735020-01E

2-5

Page 33

Measurement Preparation

Configure the core information

Configure settings such as the number of cores

and how to assign numbers.

Set the measurement conditions

Set conditions such as the wavelength and

the distance range.

Set the analysis conditions

Set conditions such as the group refraction

index and the reference waveform (before work).

Section 17.2

Section 17.3

Section 17.4

Measurements before Work

Measure the optical pulse

Measure cores numbered 1 to 100 (maximum)

in order.

Section 17.1

Measurements after Work

Measure the optical pulse (core number 1)

Measure core number 1.

Check the measured waveform

Perform a visual check of the core number 1

waveform and the waveform before work

(the reference).

Analyze the measured waveform

(if necessary)

Use markers or line markers to perform

calculations on the core number 1 waveform,

and check the events as numeric values.

Measure the optical pulse

(core number 2 and greater)

Repeat the checks listed above for cores

numbered 2 to 100 (maximum).

Section 17.1

Section 17.1

Section 17.1

2.2 Measurement Procedure

Multi Core Trace Comparison (Firmware Versions 3.01 and Later)

<<For procedures, see chapter 17.>>

When installed fibers are moved because of road work or other external factors, you can

efficiently perform measurements by using this function.

The following three measurement methods are available, each of which checks the

quality of the optical pulse measurement waveform after work.

•

Visual check of the waveform before work and the waveform a

• Visual check using a waveform of one fiber within the same tape as the reference

• Automatic pass/fail judgment using pass/fail markers

Visual Check of the Waveform before Work and the Waveform after Work

fter work

2-6

IM 735020-01E

Page 34

2

1

Measurement Preparation

Configure the core information

Configure settings such as the number of

cores and how to assign numbers.

Set the measurement conditions

Set conditions such as the wavelength and

the distance range.

Set the analysis conditions

Set conditions such as the group refraction

index and the reference waveform (tapes a to j).

Section 17.2

Section 17.3

Section 17.4

Measurements before Work

Measure the optical pulse

Measure 12 tapes worth of waveforms—

the cores numbered 1a to 12a (maximum) of

the tape ID—in order (in this example, tape a is

the reference waveform).

Section 17.1

Measurements after Work

Measure the optical pulse (1a of tape 1)

Measure the core numbered 1a of tape 1.

Check the measured waveform

Perform a visual check of the core number 1a

waveform of tape 1 and the waveform

before work (the reference).

Analyze the measured waveform

(if necessary)

Use markers or line markers to perform

calculations on the core number 1a waveform

of tape 1, and check the events as numeric

values.

Measure the optical pulse

(1b and greater of tape 1)

Perform a visual check of the core number 1b

waveform and the core number 1a waveform

of tape 1 (the reference is tape a).

Perform the same visual check using the 1c

and greater waveforms and the 1a waveform.

Measure the optical pulse

(tape 2 and greater)

Repeat the checks listed above.

Section 17.1

Section 17.1

Section 17.1

Section 17.1

2.2 Measurement Procedure

Visual Check Using a Waveform of One Fiber within the Same Tape as the

Reference

Measurement Overview

IM 735020-01E

2-7

Page 35

Measurement Preparation

Configure the core information

Configure settings such as the number of

cores and how to assign numbers.

Set the measurement conditions

Set conditions such as the wavelength

and the distance range.

Configure the pass/fail markers

Position markers above the events

(2 markers, 4 markers, or 5 markers method),

set the threshold levels, and configure other

settings.

Section 17.2

Section 17.3

Section 17.4

Measurements after Work

Measure the optical pulse

Measure cores numbered 1 to 100 (maximum)

in order.

Each time that the measurement of a core is

completed, the AQ7270/AQ7275 automatically

performs a pass/fail measurement and displays

the results on the screen.

Section 17.1

2.2 Measurement Procedure

Automatic pass/fail judgment using pass/fail markers

2-8

IM 735020-01E

Page 36

2

1

2.3 Viewing the Optical Pulse Measurement

Incident ray

Backscattering

light

Fused

connection

point

Connector

connection

point

Bending

Open end

Near-end reflection

Splice loss due to fusion

Approximation line

Reflection due to

Connector Connection

Loss due to bending

Open end reflection

(Fresnel reflection)

Dynamic range(SNR=1)

Small

material

Incident ray

Backscattering

light

Optical fiber cable

Waveform

Measurement Overview

An optical pulse that enters the optical fiber cable incurs loss due to reflection at the

connection points, etc. The measured result is displayed with the distance along the

horizontal axis and loss level along the vertical axis. Waveform refers to the display of

this result on the AQ7270/AQ7275. The losses and reflections detected on the waveform

are called events.

Near-End Reflection

A reflection occurs in the connection point between the AQ7270/AQ7275 and the

connector for the optical fiber cable. This section also includes the internal reflection of

the OTDR. Losses and reflections of the connection points cannot be detected in the

section in which this reflection is detected. This section is called a near-end dead zone.

If the near-end reflection affects the measurement of a short distance, connect a dummy

fiber provided as an option to clear the effects.

Loss by the Optical Fiber Cable due to Rayleigh Scattering

When light propagates through the optical fiber cable, a phenomenon called Rayleigh

Scattering occurs due to the nonuniformity of the density or constituents of materials

smaller than the wavelength unit. The scattered light that is transmitted opposite to the

direction of propagation is called backscattering light.

IM 735020-01E

2-9

Page 37

Optical fiber cable

Optical fiber cable

Gap

Connector

Glass Air

Incident ray (100%)

Reflected ray (3%)

Light

(97%)

Measurement

waveform

Noise peak

2.6 dB

RMS level of noise

Dynamic range

(SNR=1)

2.3 Viewing the Optical Pulse Measurement Waveform

Splice Loss due to Fusion

Because the unevenness in the density or constituents of the materials in the fused

section becomes large, the loss due to Rayleigh Scattering increases, and a splice loss

occurs.

Reflection due to Connector Connection

Unlike the fused section, a slight gap occurs in the connection section of connectors.

Because the group refraction index changes in this gap, a reflection occurs causing a

loss.

Fresnel Reflection at the Far End of the Optical Fiber Cable

Fresnel reflection occurs at the location where the optical fiber cable is broken or a

location where the group refraction index changes such as the far end of the cable (glass

and air) when light enters the cable. If the end face of the optical fiber cable is vertical,

approximately

%(–14.7dB)oftheincidentlightpowerisreflected.

3

Dynamic Range

2-10

The backscattering light level that the AQ7270/AQ7275 can measure.

IM 735020-01E

Page 38

2

1

2.4 Distance Measurement

Accuracy

The AQ7270/AQ7275 calculates the distance (L) by measuring the time until the

transmitted light pulse returns and using the equation indicated below.

L = C×T/(2N) [m]

C:

The speed of light travelling through a vacuum.

The time from when the pulse is transmitted until the light returns.

T:

N: Group refraction index

The reason why the equation divides by 2 is because the round-trip time of the optical

pulse is measured.

An error will occur in the distance measurement unless an accurate group refraction

index is specified.

Group Refraction Index Settings

The following group refraction indexes are assigned according to the wavelength on the

AQ7270/AQ7275.

850 nm: 1.46000

1300 nm: 1.46000

1310 nm:

1490 nm: 1.46000

1550 nm:

1625 nm: 1.46000

1650 nm: 1.46000

The selectable range is 1.30000 to 1.79999.

For the accurate group refraction index, check with the manufacturer of the optical fiber

cable.

1.46000

1.46000

Measurement Overview

Optical Fiber Cable Length and Distance Range

Select a distance range that is longer than the optical fiber cable you want to measure. If

the distance range is longer, the measurement time also increases accordingly.

Cable Length Distance Range

Unknown Auto

0 to 400 m 500 m

400 m to 800 m 1 km

800 m to 1.6 km 2 km

1.6 km to 4 km 5 km

4 km to 8 km 10 km

8 km to 16 km 20 km

16 km to 40 km 50 km

40 km to 80 km 100 km

80 km to 160 km 200 km

160 km to 240 km 300 km

IM 735020-01E

2-11

Page 39

Pulse width

Event dead zone

Attenuation dead zone

1.5 dB

2.4 Distance Measurement

Selectable Pulse Widths for the Distance Measurement

The pulse width has the following characteristics.

Short pulse width: Allows events (reflection point and loss) that are close together

to be measured separately. However, long distance cannot be

measured.

Long pulse width: Long distance can be measured. However, multiple events that

are close together may appear as a single event.

Distance Range Selectable Pulse Widths

500 m 3 ns, 10 ns, 20 ns, 50 ns, 100 ns, 200 ns, 500 ns

1 km 3 ns, 10 ns, 20 ns, 50 ns, 100 ns, 200 ns, 500 ns, 1 ms

2 km 3 ns, 10 ns, 20 ns, 50 ns, 100 ns, 200 ns, 500 ns, 1 ms

5 km 3 ns, 10 ns, 20 ns, 50 ns, 100 ns, 200 ns, 500 ns, 1 ms

10 km, 20 km 3 ns, 10 ns, 20 ns, 50 ns, 100 ns, 200 ns, 500 ns, 1 ms

50 km or longer 3 ns, 10 ns, 20 ns, 50 ns, 100 ns, 200 ns, 500 ns, 1 ms, 2 ms, 5 ms,

10 ms, 20 ms

If the wavelength is 850 nm, you cannot use 3ns, 2 ms, 5 ms, 10 ms, and 20 ms(3 ns is available

on the 735041).

If the wavelength is 1300 nm, you cannot use 3ns, 10 ms and 20 ms (3 ns is available on the

735041)

.

Dead Zone in Which the Distance Cannot Be Measured

The locations where measurements cannot be made due to the effects of connection

point of connectors, etc. The following types of dead zones are available.

• Event dead zone

Area in which two reflections that are close together cannot be separated.

defined by a pulse width whose level is 1.5 dB less than the peak value.

• Attenuation dead zone

A zone in which the splice loss cannot be measured due to a l

A zone

arge reflection nearby.

2-12

IM 735020-01E

Page 40

2

1

Optical fiber cable

under measurement

Dummy fiber

Location of event

occurrence

* Do not bend the optical fiber cable.

Small reflection hidden behind a large reflection

2.4 Distance Measurement

Circumventing the Near-End Dead Zone Using a Dummy Fiber

Losses and reflections of the connection points cannot be detected in the section in

which a near-end reflection is detected. When measuring a short distance, connect the

dummy fiber to move the events that are hidden behind the near-end reflection by the

length of the dummy fiber.

Measurement Overview

Note

The AQ7270/AQ7275 OTDR product series allow a 100-m dummy fiber to be built in (/DF

option).

IM 735020-01E

2-13

Page 41

3

2

1

Chapter 3 Measurement Preparation

3.1 Connecting the Power Supply

Using the AC Adapter

WARNING

Make sure that you observe the following points before connecting the AC adapter.

Failure to do so may cause electric shock or damage to the instrument.

• Check that the AQ7270/AQ7275 is turned OFF before connec

adapter.

• Use only the power cord supplied by YOKOGA

• Before connecting the power cord, ensure that the source voltage matches the

rated supply voltage of the AC adapter and that it is within the maximum rated

voltage of the provided power cord.

•

Use only the AC adapter specified for the instrument.

When unplugging the power cord from the outlet, never pull the cord itself.

•

Always hold and pull by the plug. If the power cord is damaged, contact your

dealer for replacement.

•

Do not plug or unplug the AC adapter while the instrument is t

• If you are using the instrument for an extended time with the AC adapter

connected, remove the battery pack from the instrument.

• If you are not going to use the instrument for an extended time, unplug the

power cord of the

• Be sure nothing is placed on top of the AC adapter or power c

generating objects come in contact with them.

• If an AC outlet that matches the power cord provided is unava

the instrument.

AC adapter from the outlet.

WA for the instrument.

ting the AC

urned ON.

ord or let heat

ilable, do not use

Measurement Preparation

IM 735020-01E

3-1

Page 42

POWER lamp

CHARGE lamp

Green: Running

Red: Low battery level

Green: Fast charging in progress

Green(blinking): Fast charging not started

• The battery pack is not loaded correctly in the AQ7270/AQ7275.

• Battery pack temperature not within the allowable range

for fast charging.

• The battery pack is in the preliminary charging condition

because the battery charge is too low for fast charging.

Check that the battery pack is loaded correctly. If the green lamp does not

illuminate even after 2 or 3 hours passes with the AC adapter connected,

the battery pack may be broken or reduced life.

3.1 Connecting the Power Supply

Connect the power cord to the AC adapter.

1.

Connect the AC adapter plug to the instrument.

2.

Connect the power plug to the outlet.

3.

Note

If the DC power connector cover comes off, bend the axis section of the cover and attach it.

Turning the Power ON

4.

Press the power switch on the front panel of the instrument. The POWER lamp

illuminates.

3-2

IM 735020-01E

Page 43

3

2

1

Using the Battery Pack

Put the battery pack string way in

the dented section in the back.

Push up

Pull out

WARNING

• Do not remove or insert the battery pack while being charged with the AC

• To prevent problems with the

•

Charge the battery pack using the instrument. Be sure to observe the

1.

2.

3.

4.

5.

3.1 Connecting the Power Supply

adapter.

battery pack, periodically check the physical

appearance for cracks, deformation, and leaks.

environmental conditions when charging the battery pack. Otherwise, leaks,

overheating, smoke, explosion, or fire may occur

Push up the battery pack cover lock.

Pull out the battery pack cover while pushing the lock up.

Insert the battery pack. Pay attention to the direction.

Put the battery pack string way in the dented section in the back.

Close the battery pack cover and securely lock the battery pack cover.

.

Measurement Preparation

Note

• Charge the battery pack in advance when using it for the first time or after long periods of

non-use. The remaining battery charge may be low due to self-discharging.

• If you attempt to charge a battery pack that is overly discharged, the battery pack enters the

preliminary charging condition* and it may take about 2 hours for the fast charging to start.

• The AQ7270/AQ7275 draws minute current even if the power switch is turned OFF. If you

do not plan to use the AQ7270/AQ7275 for longer than a week, we recommend that you

remove the battery pack from the AQ7270/AQ7275. If you do not use the AQ7270/AQ7275

for a long time with the battery pack loaded, the battery pack may become overdischarged.

* For a description of the preliminary charging condition, see “Charging Conditions of the

Battery Pack.”

IM 735020-01E

3-3

Page 44

3.1 Connecting the Power Supply

Explanation

Charging Conditions of the Battery Pack

There are four charging operations

• Preliminary Charging

This function is designed to reactivate a battery pack that is overly discharged or

deactivated due to temperatures lower than the specifications’ allowable range

(when engaged, the CHARGE lamp blinks green). If the battery pack is overly

discharged, the preliminary charge can take two hours or more. When preliminary

charging is complete, fast charging begins automatically

•

Fast Charging

Normally (under standard operating conditions with a problem-free battery pack),

fast charging begins simultaneously when powering with the

chargingcharges

charging takes approximately two hours, depending on the original battery level

and environmental conditions.

• Top-of

This function engages immediately after fast charging, and runs on a three-

hour

provided by the fast charging function). When fast charging finishes, the CHARGE

lamp goes out and the battery pack will be charged continuously for three hours.

Charging of the battery pack is complete after five hours: two hours of fast charging

and three hours of top-off charging.

•

Maintenance Charging

This function compensates for the battery pack’s self-discharging. If the

battery pack continues to be powered by the

maintenance charging will be employed to compensate for self-discharging (when

engaged, the CHARGE lamp is turned OFF).

.

AC adapter

thebatterypacktoupto80–90%ofitsfullcapacity.Fast

f Charging

timertobringthechargeupto100%(theremainingamountofchargenot

AC adapter after top-off charging,

. Fast

Note

The CHARGE lamp also blinks green if the battery pack is not installed or if the temperature is

outside the allowable range for fast charging.

Warm-up

Allow the instrument to warm up for at least 30 minutes after turning ON the power.

Sufficient warm-up produces more accurate measurements.

Overdischarging

If you do not use the AQ7270/AQ7275 for a long time with the battery pack loaded, the

battery pack may become overdischarged.

Please note that this can lead to reduced life of the battery pack.

If not using the AQ7270/AQ7275 for one week or more, prevent overdischarging by

charging the battery pack, removing it from the AQ7270/AQ7275, then storing it away

from

sunlight

more, compensate for self-discharging by charging it with the instrument once a month.

ina10–30°Cenvironment.Whenstoringthebatterypackforonemonthor

3-4

IM 735020-01E

Page 45

3

2

1

3.2 Connecting the Optical Fiber Cable

Good example

Cleaning the Connector End Face of the Optical Fiber Cable

Clean the connector end face of the optical fiber cable under measurement before

connecting it to the AQ7270/AQ7275. If dust is adhered to the connector end face, it

may damage the optical connector of the AQ7270/AQ7275. If this happens, the AQ7270/

AQ7275 will not be able to make correct measurements.

Press the connector end face of the optical fiber cable firmly against the cleaning

1.

surface of the cleaner.

Turn the cable around once with the end face pressed against the cleaner.

2.

Rub the end face against the cleaner.

3.

Repeat steps 1 to 3.

4.

Measurement Preparation

Note

• If you do not press the connector end face of the optical fiber cable firmly against the

cleaner, the end face may not be cleaned completely.

• You can purchase an optical fiber connector cleaner from NTT-AT corporation.

Connecting the Optical Fiber Cable to the AQ7270/AQ7275

Open the optical connector cover at the top of the AQ7270/AQ7275.

1.

Match the direction of the optical fiber cable connector to the optical connector,

2.

and insert it.

IM 735020-01E

3-5

Page 46

Optical pulse output indicator

Bad example

3.2 Connecting the Optical Fiber Cable

Note

The connector to which the cable is to be connected varies depending on the wavelength.

•

Connect the cable to the connector that is indicated by the red indicator at the top of the

AQ7270/AQ7275 display.

•

Power monitor measurement uses only POR

CAUTION

When connecting the optical fiber cable connector, insert it vertically and slowly