Page 1

User’s

Manual

AQ7260 OTDR

Yokogawa Electric Corporation

IM 813920300-01E

2nd Edition

Page 2

Preface

Thank you for purchasing the AQ7260. The AQ7260 is a compact optical time domain

reflectometer with various functions and is designed to measure loss and detect faults in

optical fibers.

This user's manual refers to AQ7260 OTDR which software version is 2.00 or later.

Before using the AQ7260 (hereafter referred to as the instrument), please read this

manual thoroughly. In particular, the “Safety Precautions” given at the beginning of this

manual should be read to gain a full understanding of the instrument.

After reading, please keep this manual in a safe place so that it can be referred to anytime

it is required.

PREFACE

Caution

Refer

This user's manual refers to AQ7260 OTDR which software version is 2.00 or later.

Procedure of checking software version, refer to page 10-4.

• Copying or reproduction of all or any part of the contents of this manual without

permission is strictly prohibited.

• The contents of this manual are subject to change without prior notice.

• Every effort has been made in the preparation of this manual. However, should

you find any errors or lack of descriptions, please contact the agent from whom the

instrument was purchased.

• This instrument falls under the category of goods (or technology) restricted by the

Foreign Exchange and Foreign Trade Law. Thus, in accordance with this law and

before exporting this instrument permission must be obtained from the government

of Japan.

TIP

yThe instrument uses Linux and Microwindows.

Linux is a trademark or a registered trademark of Linus Torvalds in U.S.A. and

other countries.

This product includes open source software. For the procedure of obtaining the source

y

code, contact your nearest YOKOGAWA dealer.

I

Page 3

WARRANTY

Warranty

• The warranty period is one year from the date of purchase.

• Should breakdown occur during the warranty period, repairs shall be made free of

charge according to the warranty policy.

• Breakdown arising from operating mistakes or modifications performed by the user

or breakdown/damage caused by natural disasters shall be exempt from this

warranty policy, even if it occurs during the warranty period.

• A certificate of compliance to guarantee the designed quality accompanies

YOKOGAWA products.

Prior to shipment, every YOKOGAWA product undergoes strict inspections that are

carried out according to its quality assurance system. However, should breakdown

occur arising from defects in manufacturing or accidents during transport, please

contact the agent from whom the product was purchased.

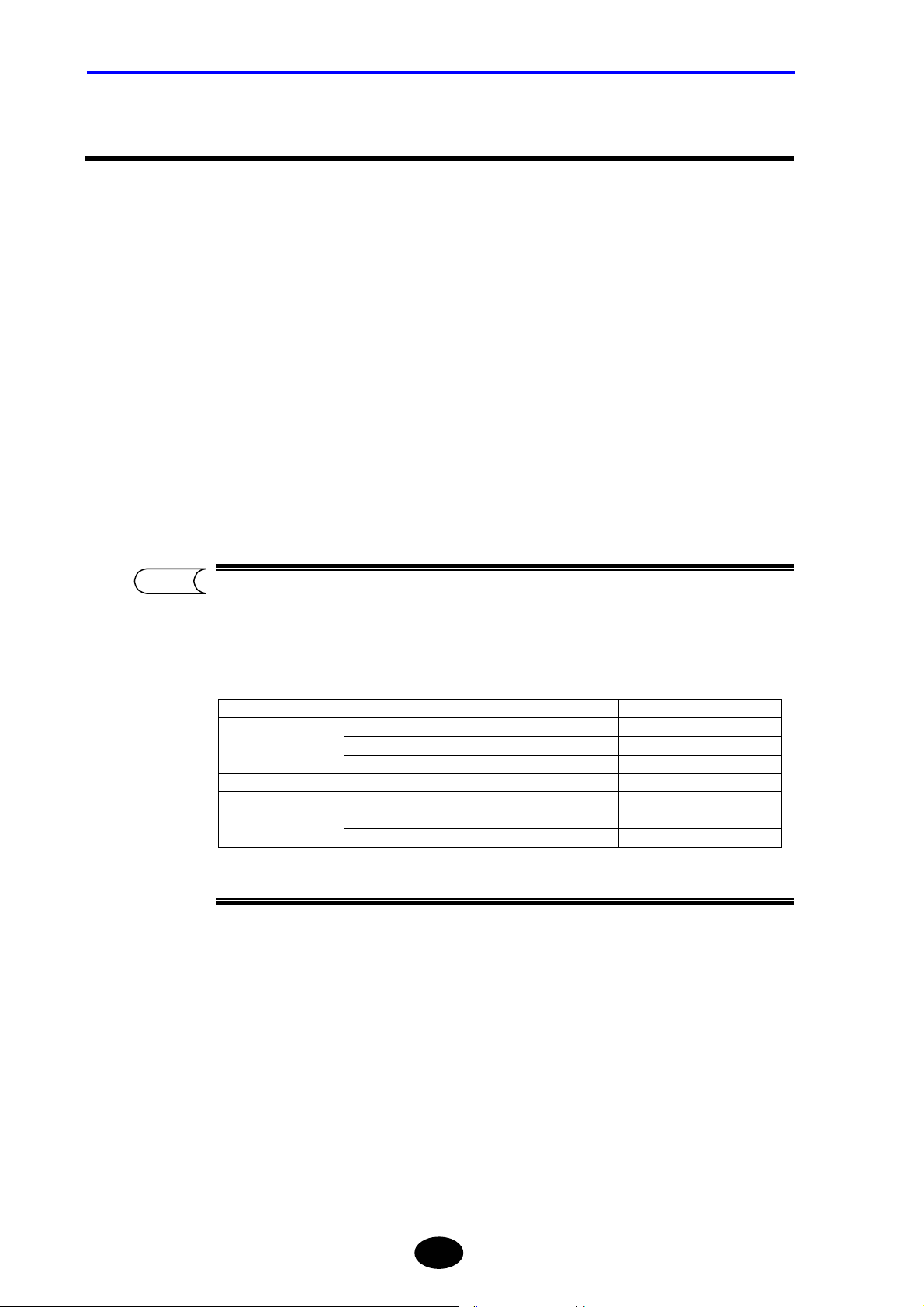

TIP

y Recommended recalibration period is 1 year. Inquiry of about recalibration,

please contact the agent from whom the instrument was purchased.

y The following parts are consumable parts and are not subject to the warranty

period.

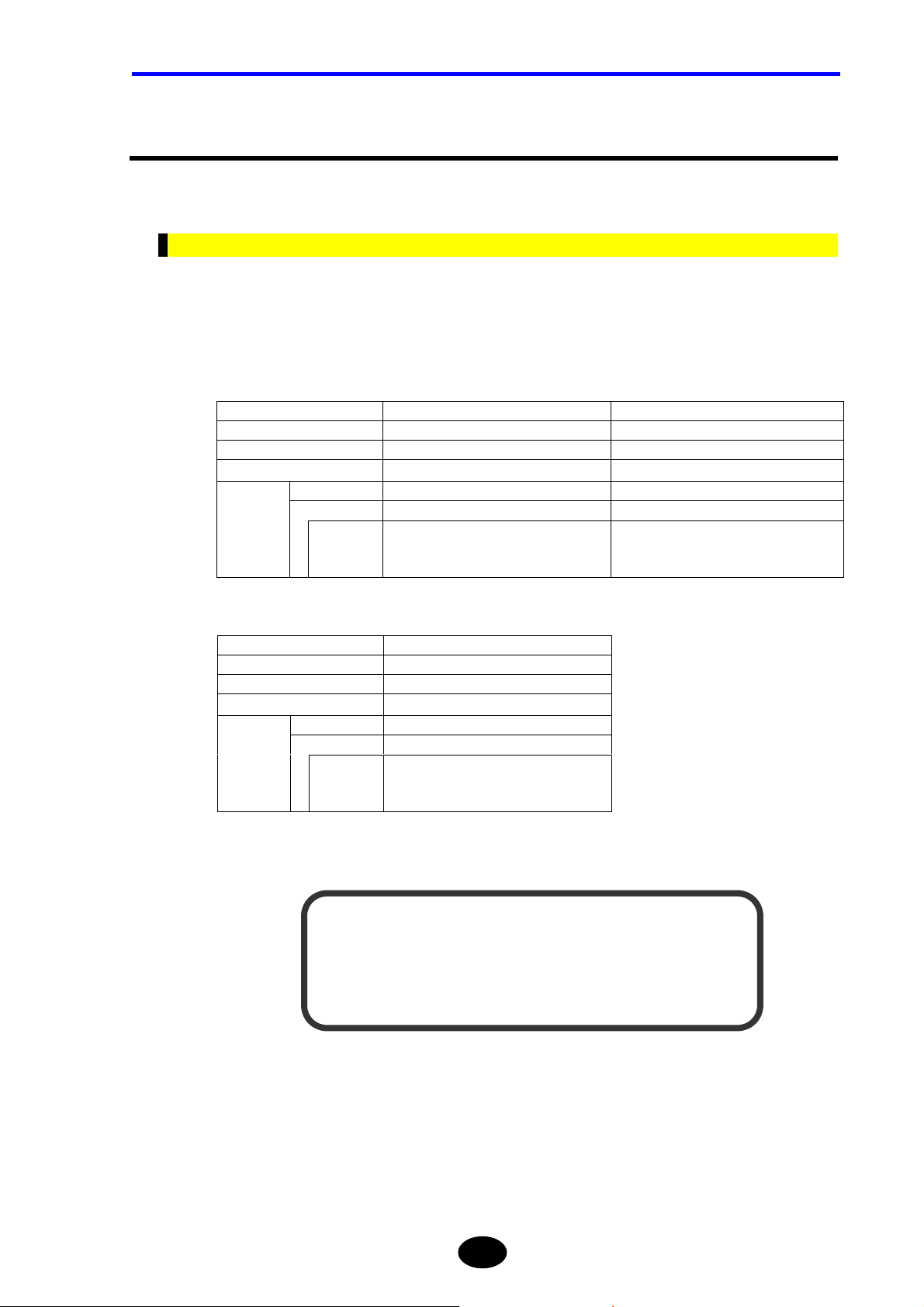

product name Part name Life span

Liquid Crystal Display (LCD) panel 3 years

Main Frame

Optical Module Ferrule on the connector 1 year

Expansion

unit

*1: Each life span depends on the environmental conditions and frequency of use.

Battery pack 1 year

Back up battery 5 years

Printer

FDD 3 years

*1

Equivalent to 3,000 roll of

printer paper.

II

Page 4

CONVENTIONS USED IN THIS MANUAL

Conventions Used in this Manual

Safety Graphic Marks

The following graphic marks are given in this manual to ensure the safe use of this

instrument and to prevent injury and property damage. Before operating the instrument,

please read the following carefully to gain thorough understanding.

The following graphic marks indicate the degree of danger and damage that may

occur as a result of improper handling.

WARNING

Indicates a potentially hazardous situation that may possibly result in death or serious injury in the event of

improper handling.

CAUTION

Indicates a potentially hazardous situation that may result in moderate injury or property damage in the

event of improper handling.

The degree of danger and damage is indicated by the following graphic symbols.

“U” indicates a warning or caution.

This example indicates fire warning.

“{” indicates a prohibited operation.

This example indicates that disassembly is prohibited.

“z” indicates an obligatory operation.

This example indicates that the AC adapter must be removed from the power outlet.

III

Page 5

CONVENTIONS USED IN THIS MANUAL

Other Graphic Marks

Caution

This is called a caution mark. It indicates an operation or procedure that requires

special care or a point to be observed regarding handling of the instrument.

TIP

This is called a TIP mark. It indicates information that is useful for operation of the

instrument.

Refer

This is called a reference mark. It indicates the reference page for the contents or

terms used in this manual.

The following symbols are used on this instrument.

Direct current.

Alternating current.

Danger, Caution

Danger, risk of electronic shock.

Equipment protected throughout by DOUBLE INSULATION

or REINFORCED INSULATION

IV

Page 6

Safety Precautions

This section must be read to ensure safe use of the instrument. After reading, keep this

manual in a safe place so that it can be referred to anytime it is required.

For Safe Use of Laser Products

This instrument uses a laser light source and as such, falls into the category of “class 1M

laser product” specified by “EN60825-1:1994 +A2:2001 Safety of Laser Products-Part 1:

Equipment Classification, Requirements and User’s Guide

And the laser products comply with 21CFR1040.10 except for deviations pursuant to Laser

Notice No.50, dated May 27 2001.

Optical module AQ7261 AQ7264

Laser type FP-Laser InGaAsP FP-Laser InGaAsP

Laser class 1M 1M

Center wavelength 1310nm, 1550nm 1310nm, 1550nm

power

PULSE

CW --------------------- ≤1mW@1310nm, 1550nm Output

PULSE ≤100mW@1310nm, 1550nm ≤100mW@1310nm, 1550nm

WIDTH

”.

≤20µs@1310nm(duty:≤1.6%)

≤20µs@1550nm(duty:≤1.6%)

SAFETY PRECAUTIONS

≤20µs@1310nm(duty:≤1.6%)

≤20µs@1550nm(duty:≤1.6%)

50µs@1550nm(duty:≤0.8%)

Optical module AQ7265

Laser type FP-Laser InGaAsP

Laser class 1M

Center wavelength 1310nm, 1550nm

power

PULSE

CW ≤1mW@1310nm, 1550nm Output

PULSE ≤100mW@1310nm, 1550nm

≤20µs@1310nm(duty:≤1.6%)

WIDTH

DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS

≤20µs@1550nm(duty:≤1.6%)

50µs@1550nm(duty:≤0.8%)

INVISIBLE LASER RADIATION

CLASS 1M LASER PRODUCT

V

Page 7

SAFETY PRECAUTIONS

WARNING

Invisible laser beam is output from the emitter section. The emitter section is located on the

top panel.

A message “LASER ON” is displayed while a laser beam is emitted.

Class 1M laser

invisible radiation when LASER ON.

*1

Viewing the laser output with certain optical instruments (for example, eye loupes,

magnifiers and microscopes) within a distance of 100mm may pose eye hazard.

*1: When measuring or Light source function ON

These laser beams cannot be seen by the human eye. Should the beams enter the eyes,

they may be seriously damaged, resulting in excessive deterioration of eyesight. To

prevent such accidents, the following points must be strictly observed.

• Never emit laser beam if no optical fiber is connected to the emitter section.

• When disconnecting the optical fiber from the emitter section, stop emission first.

• While laser beam is output, never stare into the emitter section nor the end of the

optical fiber that is connected to the emitter section.

Do not disassemble or modify the instrument, since high-power laser beams may be output

when doing so.

If repair is necessary due to breakdown, contact the agent from whom the instrument was

purchased. Repair is allowed by qualified personnel only.

VI

Page 8

Notes on Power Supply

The instrument can be powered by the following two methods.

• AC adapter (supplied with the instrument)

• Battery pack (Model name : 3UR18650F-2)

SAFETY PRECAUTIONS

Refer

For details on use of power supply, refer to page 3-3.

Before connecting the instrument to the power, read the safety precautions given below.

AC adapter

CAUTION

Do not connect or disconnect the power cord while the instrument is powered ON.

Doing so may result in breakdown.

VII

Page 9

SAFETY PRECAUTIONS

Battery Pack

WARNING

If the battery fluid leaks from the battery pack and enters the eyes, immediately wash with

clean water, such as tap water, (never rub the eyes) and consult a doctor. Failure to do so

may cause damage to the eyes.

The instrument and battery pack must be kept out of the reach of children.

If the battery fluid leaks and adheres to skin or clothes, immediately wash with clean water,

such as tap water. Adhesion to the skin may produce irritation.

VIII

Page 10

SAFETY PRECAUTIONS

CAUTION

Do not disassemble or modify the battery pack. The battery pack has built-in safety and

protective functions designed to prevent danger. If these functions are damaged, the

battery fluid may leak from the battery pack, resulting in heat generation, smoke, explosion

or fire.

Do not connect the “+” and “−” terminals of the battery pack with metal objects like a wire.

In addition, do not carry the battery pack or store it near metal necklaces or hairpins. Doing

so may short-circuit the battery pack. This may cause excessive current flow, resulting in

leakage, heat generation, smoke, explosion or fire, or may cause the metal objects,

necklaces or hairpins to generate heat.

Do not put the battery pack into a fire or heat it. Doing so may melt insulating materials,

damage the protective circuit, or cause the battery fluid to catch fire, resulting in leakage,

heat generation, smoke, explosion or fire.

Do not use or leave the battery pack near a fire or hot objects such as stoves. Doing so

may cause short-circuit in the battery pack, resulting in battery fluid leakage, heat

generation, smoke, explosion or fire.

Do not put the battery pack under any water, including seawater, or let it get wet. If the

built-in protective circuit is damaged, the battery pack will be charged with abnormal current

or voltage. This may cause a chemical reaction inside the battery pack, resulting in battery

fluid leakage, heat generation, smoke, explosion or fire.

Do not charge the battery pack near a fire or under very hot sunshine. If it gets hot, the

protective device will initiate to prevent danger, hindering charging, or it gets damaged

causing charging with abnormal current or voltage. Such charging may cause a chemical

reaction inside the battery pack, resulting in battery fluid leakage, heat generation, smoke,

explosion or fire.

Charging of the battery pack must be performed on this instrument under the specified

charging conditions. If charging is performed in an environment that does not conform to

the specified charging conditions (e.g. at excessively high temperatures, with higher

voltage/current than the specified, using a modified charger), the battery pack may be

excessively charged, or charged with abnormal current. Such charging may cause an

abnormal chemical reaction inside the battery pack, resulting in battery fluid leakage, heat

generation, smoke, explosion or fire.

Do not pierce the battery pack with a nail, hit it with a hammer, or stamp on it. Doing so

may damage or deform the battery pack. This may cause short-circuit inside the battery

pack, resulting in battery fluid leakage, heat generation, smoke, explosion or fire.

Do not cause any excessive impact to the battery pack or throw it. Doing so may result in

battery fluid leakage, heat generation, smoke, explosion or fire.

Furthermore, if the built-in protective circuit is damaged, the battery pack will be charged

with abnormal current or voltage. This may cause an abnormal chemical reaction inside the

battery pack, resulting in battery fluid leakage, heat generation, smoke, explosion or fire.

Do not solder directly on the battery pack. Doing so may melt insulating materials, damage

the protective circuit, resulting in battery fluid leakage, heat generation, smoke, explosion

or fire.

Do not use the battery pack if it shows excessive damage or deformation. Using it in such

condition may result in battery fluid leakage, heat generation, smoke, explosion or fire.

IX

Page 11

SAFETY PRECAUTIONS

CAUTION

The battery pack must only be used for this instrument.

If charging is not complete even if the specified charging time has elapsed, stop charging.

Continuing to charge the battery pack may result in battery fluid leakage, heat generation,

smoke, explosion or fire.

Do not put the battery pack in a microwave oven or high-pressure container. The battery

pack may be heated rapidly or may no longer be airtight, resulting in battery fluid leakage,

heat generation, smoke, explosion or fire.

If battery fluid leakage or an odd smell is detected, immediately take the battery pack away

from the heat source. Leaving it in such condition may cause the battery fluid to catch fire,

resulting in smoke, explosion or fire.

If odd smells, heat generation, discoloration or deformation are noticed during use,

charging or storage of the battery pack, disconnect it from the instrument or charger, and

do not use it. Continuing to use it in such conditions may result in battery fluid leakage,

heat generation, smoke, explosion or fire.

Do not use or leave the battery pack in strong direct sunlight or in places like inside an

automobile under very strong sunshine. Doing so may result in battery fluid leakage, heat

generation or smoke. It also may deteriorate the performance or life of the battery pack.

The battery pack has a built-in protective circuit designed to prevent danger. So, do not use

the battery pack in places where static electricity that is likely to damage the protective

device is generated. Using the battery pack in such places may damage the protective

device, resulting in battery fluid leakage, heat generation, smoke, explosion or fire.

The battery pack can be charged in the following temperature range. Charging the battery

pack outside this range may cause battery fluid leakage, heat generation or breakdown. It

may also deteriorate the performance or life of the battery pack. Allowed charging

temperature range: 5°C to 30°C

If rust, odd smells, heat generation or any other abnormality are found when using the

instrument for the first time following purchase, stop its use and contact the agent from

whom the instrument was purchased.

X

Page 12

Notes on Operating Environment and Conditions

Restrictions Regarding Operating Environment

WARNING

Take care not to let water enter the instrument or to allow it to get wet.

Failure to observe this may result in fire, electric shock or breakdown.

Restrictions Regarding Operating Conditions

WARNING

The power cord specified by YOKOGAWA must be used.

SAFETY PRECAUTIONS

Use of any other power cord may result in fire, electric shock or accident.

XI

Page 13

SAFETY PRECAUTIONS

Notes on Installation

For Personnel Performing Installation

WARNING

CAUTION

Do not connect the instrument to an AC outlet using an extension power cord.

Doing so may result in heat generation or fire.

Do not dissemble or modify the instrument.

Doing so may result in electric shock, fire or accident.

Do not expose the instrument to water splashes.

Failure to observe this may result in electric shock, fire or accident.

Do not allow the terminals to short-circuit.

Failure to observe this may result in fire or breakdown.

When using an AC adapter, make sure that it is inserted into the AC outlet properly.

If the power plug comes into contact with metal objects, fire or electric shock may result.

When carrying out work with the instrument on your shoulders, take care not to let it drop.

Failure to observe this may result in injury or breakdown.

XII

Page 14

SAFETY PRECAUTIONS

Restricted and Prohibited Items Regarding Operating Environment and

Conditions

WARNING

Do not insert metal bars or such like into gaps on the instrument.

Doing so may result in fire, electric shock or accident.

CAUTION

Keep the power cord away from heaters etc.

Failure to observe this may result in electric shock.

Do not connect or disconnect the power plug with wet hands.

Doing so may result in electric shock.

Do not place the instrument in humid or dusty areas.

Doing so may result in electric shock or breakdown.

Do not place the instrument on an unstable surface like a shaky table or slope.

The instrument may drop or turn over, causing injury.

Do not place the instrument in areas where there is excessive vibration or impact.

The instrument may drop or turn over, causing injury.

When disconnecting the power cord, always hold the plug and pull it out.

Pulling the power cord may damage the cord, resulting in fire or electric shock.

Do not place the instrument in direct sunlight or in places like inside a car under the very

hot sunshine.

Placing the instrument in such places may cause the temperature inside the instrument to

rise, resulting in breakdown.

XIII

Page 15

SAFETY PRECAUTIONS

Prohibited Items Regarding Installation Method

WARNING

CAUTION

Notes on Handling

Do not place heavy objects on the power cord, heat or pull it, and do not modify the power

cord.

Doing so may damage the cord, resulting in fire or electric shock.

Before transferring the instrument to another site, make sure that the power plug is

removed from the AC outlet and all the external connecting cables are disconnected.

Failure to observe this may damage the cord, resulting in fire or electric shock.

The instrument must be handled according to the procedures given in this manual.

Warning marks (“WARNING”, “CAUTION”) must be strictly observed.

WARNING

Do not leave metal objects or containers of liquid, such as water, near the instrument.

Strong wind may turn over the container spilling the water or cause metal objects to hit the

instrument, resulting in fire, electric shock or breakdown.

Do not modify the power cord, bend, twist or pull it excessively.

Failure to observe this may result in fire or electric shock.

Before plugging in or removing connectors from the instrument, make sure that the

instrument is powered OFF.

Failure to observe this may result in fire, electric shock or breakdown.

Do not disassemble or modify the instrument.

Doing so may result in fire, electric shock or accident.

Do not allow the terminals of the battery pack to get wet.

Failure to observe this may result in rust, fire or electric shock.

XIV

Page 16

SAFETY PRECAUTIONS

CAUTION

When closing panels and covers, take care not to trap your fingers.

If you are not going to use the instrument for a long period of time, the power plug must be

removed from the AC outlet for safety reasons. It must also be removed in the event of

thunderstorms.

Failure to observe this may result in fire, electric shock or breakdown.

Do not use the instrument at -10°C or lower temperatures.

Operation of the indicators cannot be guaranteed.

Do not allow short-circuiting of the battery pack’s terminals with metal objects.

Failure to observe this may result in fire or breakdown.

Caution

If this instrument is used in a manner not specified in this manual, the protection

provided by this instrument may be impaired.

Notes on Maintenance and Inspection

Periodic maintenance and inspection of the instrument are recommended. For enquiries

regarding maintenance and inspection, contact the agent from whom the instrument was

purchased.

CAUTION

Take care not to let dust or dirt collect inside the instrument.

Collection of dust or dirt inside the instrument may result in fire or breakdown.

XV

Page 17

SAFETY PRECAUTIONS

Actions to be Taken in Case of Abnormalities

WARNING

Do not repair the instrument even though the instrument becomes faulty.

Doing so may result in electric shock or injury. In addition, the instrument repaired by the

user without permission will be exempt from the warranty.

Should the instrument be dropped or damaged, turn OFF the power switch on the

instrument, disconnect the power plug from the AC outlet and then contact your agent from

whom the instrument was purchased.

Continuing to use it may result in fire, electric shock or breakdown.

Should foreign items enter the instrument, turn OFF the power switch on the instrument,

disconnect the power plug from the AC outlet and then contact your agent from whom the

instrument was purchased.

Continuing to use it may result in fire, electric shock or breakdown.

Should smoke or odd smells be detected, turn OFF the power switch on the instrument,

disconnect the power plug from the AC outlet and then contact your agent from whom the

instrument was purchased.

Failure to observe this may result in fire, electric shock or breakdown.

If the power cord is damaged, contact the agent for replacement.

Continuing to use it may result in fire or electric shock.

Notes on Disposal

WARNING

When disposing of the instrument, do not put it into a fire.

Doing so may cause explosion, resulting in fire or burns.

CAUTION

The instrument uses a lithium battery for memory backup and a gallium arsenide battery

for the light source module. In addition, the liquid crystal display panel contains fluorescent

tubes.

So, disposal of the instrument must be carried out according to the laws and regulations of

the country and local authorities.

XVI

Page 18

Other Precautions

Notes on Backup Battery

CAUTION

SAFETY PRECAUTIONS

The instrument uses a lithium battery for memory backup. The instrument may malfunction

suddenly due to battery life, therefore, early replacement of the battery is recommended.

The life of the battery is approximately five years.

Refer

For details on replacement of the backup battery, refer to page 1-25.

Notes on LCD Panel

CAUTION

This instrument uses a liquid crystal display panel. The display panel gradually becomes

unclear due to the backlight life. The LCD panel needs to be replaced when it becomes

unclear.

The life of the LCD panel is approximately three years.

Please contact the agent when the panel is no longer clear.

XVII

Page 19

CONTENTS

Structure of this Manual

Chapter 1 BEFORE USING THE INSTRUMENT

Explains the names and functions of each part of the instrument, and how to carry out

daily maintenance.

Chapter 2 BEFORE STARTING MEASUREMENT

Explains how to set up the instrument.

Chapter 3 PERFORMING MEASUREMENTS

Explains how to set measurement conditions and how to measure optical fiber cables.

Chapter 4 ENTERING CHARACTERS

Explains how to enter label and file names.

Chapter 5 EDITING AUTOMATIC SEARCH RESULTS

The instrument has a function that detects events in the measurement results

automatically at the end of measurement. This chapter explains how to edit the detection

results.

Chapter 6 FILE OPERATION

Explains how to use (e.g. open, delete) files saved to a storage medium.

Chapter 7 USING USEFUL FUNCTIONS

This instrument has various useful functions. This chapter explains these functions.

Chapter 8 USING OPTIONS AND EXTERNAL DEVICES

Explains how to use options and external devices (e.g. USB printer) and how to control the

instrument from a personal computer.

Chapter 9 SPECIFICATIONS

Explains the specification of the instrument itself, optical module and options.

Chapter 10 APPENDIX

Explains corrective actions to be carried out in case of breakdown. Also provides a list of

technical terms regarding the instrument.

XVIII

Page 20

CONTENTS

Contents

Preface..................................................................................................... I

Warranty................................................................................................. II

Conventions Used in this Manual ....................................................... III

Safety Graphic Marks .............................................................................................................III

Other Graphic Marks .............................................................................................................IV

Safety Precautions ................................................................................V

For Safe Use of Laser Products ............................................................................................. V

Notes on Power Supply ........................................................................................................ VII

Notes on Operating Environment and Conditions.................................................................. XI

Notes on Installation ............................................................................................................. XII

Other Precautions...............................................................................................................XVII

Structure of this Manual...................................................................XVIII

Chapter 1 BEFORE USING THE INSTRUMENT............................................................ XVIII

Chapter 2 BEFORE STARTING MEASUREMENT......................................................... XVIII

Chapter 3 PERFORMING MEASUREMENTS................................................................ XVIII

Chapter 4 ENTERING CHARACTERS ...........................................................................XVIII

Chapter 5 EDITING AUTOMATIC SEARCH RESULTS .................................................. XVIII

Chapter 6 FILE OPERATION..........................................................................................XVIII

Chapter 7 USING USEFUL FUNCTIONS.......................................................................XVIII

Chapter 8 USING OPTIONS AND EXTERNAL DEVICES.............................................. XVIII

Chapter 9 SPECIFICATIONS.......................................................................................... XVIII

Chapter 10 APPENDIX ...................................................................................................XVIII

Contents..............................................................................................XIX

Chapter 1 BEFORE USING THE INSTRUMENT .............................. 1-1

1.1 What is the AQ7260? .................................................................................1-2

1.2 Installation, Storage and Transport..........................................................1-3

Unpacking and Receiving Inspection................................................................................... 1-3

Notes on Storage................................................................................................................. 1-4

Notes on Transport..............................................................................................................1-5

1.3 Power Supply.............................................................................................1-7

XIX

Page 21

CONTENTS

1.4 Daily Maintenance.....................................................................................1-8

Cleaning the Exterior of the Instrument ................................................................................ 1-8

Cleaning the Optical Connector ...........................................................................................1-9

Cleaning the Optical Adapter.............................................................................................. 1-11

1.5 Replacing the Optical Module................................................................1-12

Removing the Optical Module ............................................................................................1-12

Attaching a New Optical Module ........................................................................................ 1-14

1.6 Replacing the Optical Adapter ...............................................................1-16

Removing the Optical Adapter............................................................................................1-16

Attaching a New Optical Adapter........................................................................................1-17

1.7 Replacing the Battery Pack....................................................................1-19

Removing the Battery Pack................................................................................................1-19

Attaching a New Battery Pack............................................................................................1-21

1.8 Charging the Battery Pack ..................................................................... 1-23

1.9 Replacing the Backup Battery................................................................1-25

1.10 Names of Instrument Parts..................................................................... 1-28

Front View ..........................................................................................................................1-28

Rear View...........................................................................................................................1-30

Top View.............................................................................................................................1-32

Right Side View..................................................................................................................1-33

Accessories........................................................................................................................1-34

Options...............................................................................................................................1-35

1.11 Screen Display.........................................................................................1-36

Description of Screen Display ............................................................................................1-36

Meaning of Each Part of the Trace..................................................................................... 1-40

1.12 Notes Before Performing Measurement................................................ 1-42

When Using AQ7261 / AQ7264 / AQ7265..........................................................................1-42

Chapter 2 BEFORE STARTING MEASUREMENT ...........................2-1

2.1 Changing System Settings.......................................................................2-2

Displaying the Setting Change Window ...............................................................................2-3

Changing Settings................................................................................................................2-4

Restoring the Default System Settings............................................................................... 2-38

Chapter 3 PERFORMING MEASUREMENTS...................................3-1

3.1 Flow of Measurement Steps..................................................................... 3-2

3.2 Turning ON the Power [Step 1].................................................................3-3

When Using AC Power.........................................................................................................3-4

When Using the Battery Pack ..............................................................................................3-5

XX

Page 22

CONTENTS

3.3 Warming Up the Instrument [Step 2]........................................................3-6

3.4 Connecting an Optical Fiber to the Instrument [Step 3] ......................3-7

Cleaning the Optical Connector and Adapter....................................................................... 3-7

Connecting the Optical Fiber ............................................................................................... 3-8

3.5 Setting the Measurement Conditions/Auto Search Conditions

[Step 4] .......................................................................................................3-9

Displaying the Measurement Condition Change Window .................................................. 3-10

Changing the Measurement Conditions ............................................................................ 3-12

Changing the Measured Data Auto Saving Conditions...................................................... 3-33

Changing the Auto Search Conditions............................................................................... 3-35

Notes on Changing of Measurement Conditions / Auto Search Conditions ....................... 3-50

Restoring the Default Measurement Conditions / Auto Search Conditions ........................ 3-52

3.6 Setting the File Name/Location to Store the File [Step 5].....................3-53

3.7 Measuring an Optical Fiber [Step 6].......................................................3-54

Performing Real Time Measurement................................................................................. 3-55

Performing Average Measurement .................................................................................... 3-56

When the Trace Contains a Lot of Noise........................................................................... 3-59

3.8 Checking the Measured Data [Step 7]....................................................3-64

Basic Operations ............................................................................................................... 3-64

When “AUTO” is Selected for “EVENT SEARCH” ............................................................. 3-68

When “MANUAL” is Selected for “EVENT SEARCH” ........................................................ 3-71

3.9 Recording the Measured Data [Step 8] ..................................................3-88

Saving the Measured Data ................................................................................................ 3-88

Printing the Measured Data ............................................................................................. 3-104

3.10 Turning OFF the Power [Step 9] ...........................................................3-107

Turning OFF the Power ................................................................................................... 3-107

Disconnecting the Optical Fiber....................................................................................... 3-108

Chapter 4 ENTERING CHARACTERS.............................................. 4-1

4.1 Entering Characters...................................................................................4-2

Displaying the Label Input Window...................................................................................... 4-3

Entering a Label .................................................................................................................. 4-4

4.2 Editing Characters.....................................................................................4-7

Deleting a Character............................................................................................................4-7

Changing a Character ......................................................................................................... 4-8

Adding a Character..............................................................................................................4-9

Chapter 5 EDITING AUTOMATIC SEARCH RESULTS.................... 5-1

5.1 Editing an Event .........................................................................................5-2

XXI

Page 23

CONTENTS

Inserting an Event ................................................................................................................5-3

Deleting an Event.................................................................................................................5-6

Moving an Event ..................................................................................................................5-9

5.2 Editing an Event Marker ......................................................................... 5-12

5.3 Editing the Event List..............................................................................5-15

Displaying the List Edit Window .........................................................................................5-16

Editing the Event List..........................................................................................................5-18

5.4 Attaching a Comment to an Event.........................................................5-23

5.5 Changing the Conditions and Performing Auto Search Again............5-25

Displaying the Auto Search Condition Change Window..................................................... 5-26

Changing the Auto Search Conditions................................................................................5-28

Notes on Changing of Auto Search Conditions ..................................................................5-38

Chapter 6 FILE OPERATION.............................................................6-1

6.1 File Operation............................................................................................6-2

Saving a File ........................................................................................................................6-2

Recalling a File.....................................................................................................................6-3

Deleting a File ......................................................................................................................6-7

Printing a File .....................................................................................................................6-12

Copying a File ....................................................................................................................6-18

6.2 Using the Utility Functions.....................................................................6-22

Initializing a Drive ...............................................................................................................6-23

Deleting a Folder................................................................................................................6-25

Creating a Folder ...............................................................................................................6-27

Copying a Folder................................................................................................................6-30

Chapter 7 USING USEFUL FUNCTIONS..........................................7-1

7.1 Initializing the Vertical-/Horizontal-Axis Scales......................................7-2

7.2 Displaying Approximate Lines.................................................................7-3

For Traces that Have Been Auto Searched ..........................................................................7-4

For Traces that Have Not Been Auto Searched ...................................................................7-6

7.3 Using the Cursor Link Function...............................................................7-7

For Traces that Have Been Auto Searched ..........................................................................7-8

For Traces that Have Not Been Auto Searched .................................................................7-10

7.4 Using the Label Fixed Form Input Function.......................................... 7-11

7.5 Using the Label Auto Increment Function ............................................7-13

7.6 Entering Various Information for the Measured Trace......................... 7-16

Displaying the Detailed Information Input Window .............................................................7-17

Entering Detailed Information.............................................................................................7-18

XXII

Page 24

CONTENTS

7.7 Changing the Distance Reference ..........................................................7-27

For Traces that Have Been Auto Searched ....................................................................... 7-28

For Traces that Have Not Been Auto Searched................................................................. 7-31

7.8 Using the Event Fix Function .................................................................7-33

7.9 Using the Section Analysis Function.....................................................7-36

7.10 Manipulating Two or More Traces ..........................................................7-39

Displaying Multiple Traces................................................................................................. 7-40

Displaying the Subtract Trace of Two Traces..................................................................... 7-43

Merging Two Traces .......................................................................................................... 7-45

7.11 Using the Light Source Function............................................................7-47

Displaying the Light Source Function Window................................................................... 7-48

Changing the Wavelength and Modulation Frequency ...................................................... 7-49

Emitting a Laser................................................................................................................. 7-51

Turn off a Laser ................................................................................................................. 7-51

7.12 Making a Measurement Continuously Changing the Wavelengths.....7-52

Chapter 8 USING OPTIONS AND EXTERNAL DEVICES................ 8-1

8.1 Using Options ............................................................................................8-2

Option Unit........................................................................................................................... 8-3

8.2 Using External Devices.............................................................................8-9

USB Keyboard................................................................................................................... 8-10

PCMCIA Memory Card...................................................................................................... 8-13

USB Printer........................................................................................................................ 8-16

USB Storage Medium........................................................................................................ 8-21

8.3 Operating the Instrument from a Personal Computer..........................8-22

Operation by using RS-232C............................................................................................. 8-23

Operation by using GP-IB.................................................................................................. 8-29

Control Commands............................................................................................................ 8-35

Request Commands.......................................................................................................... 8-47

Return Value Format.......................................................................................................... 8-59

Command Input Examples (RS-232C) .............................................................................. 8-61

Chapter 9 SPECIFICATIONS ............................................................ 9-1

9.1 Specifications of main frame....................................................................9-2

9.2 Specifications of optical modules............................................................9-4

9.3 Specifications of optional units................................................................9-7

9.4 Outside view drawings..............................................................................9-8

AQ7260 OTDR .................................................................................................................... 9-9

AQ7261 SMF MODULE..................................................................................................... 9-10

XXIII

Page 25

CONTENTS

AQ7264 SMF MODULE ..................................................................................................... 9-11

AQ7265 SMF MODULE .....................................................................................................9-12

PRINTER/FDD UNIT..........................................................................................................9-13

PRINTER UNIT ..................................................................................................................9-14

Chapter 10 APPENDIX ....................................................................10-1

10.1 Software Upgrade....................................................................................10-2

10.2 Troubleshooting ......................................................................................10-5

When the Instrument Appears Faulty................................................................................. 10-5

When the Problem Cannot Be Solved................................................................................ 10-7

10.3 Glossary...................................................................................................10-8

Attenuation .........................................................................................................................10-8

Attenuation dead zone .......................................................................................................10-8

Back scattering ray.............................................................................................................10-8

Connection point ................................................................................................................10-9

Dead zone..........................................................................................................................10-9

Distance measuring accuracy ............................................................................................10-9

Distance range ...................................................................................................................10-9

Dynamic range .................................................................................................................10-10

Event dead zone ..............................................................................................................10-10

Event list...........................................................................................................................10-10

Event note ........................................................................................................................10-10

Far end............................................................................................................................. 10-11

Fault location.................................................................................................................... 10-11

Filter ................................................................................................................................. 10-11

Format.............................................................................................................................. 10-11

Fresnel reflection.............................................................................................................. 10-11

Group index......................................................................................................................10-12

Label ................................................................................................................................10-12

Least squares approximate (LSA).................................................................................... 10-12

Near end ..........................................................................................................................10-12

OTDR ............................................................................................................................... 10-12

Pulse width.......................................................................................................................10-13

Real time measurement ...................................................................................................10-13

Reflection point ................................................................................................................10-13

Resolution ........................................................................................................................10-13

Return loss .......................................................................................................................10-14

S/N ...................................................................................................................................10-14

Sampling count ................................................................................................................10-14

Sampling resolution.......................................................................................................... 10-14

XXIV

Page 26

CONTENTS

Secondary reflection........................................................................................................ 10-15

Spatial resolution ............................................................................................................. 10-15

Splice loss........................................................................................................................ 10-15

Two Point Approximate (TPA) .......................................................................................... 10-15

XXV

Page 27

Page 28

Chapter 1

BEFORE USING THE INSTRUMENT

1.1 What is the AQ7260? ............................................................................................... 1-2

1.2 Installation, Storage and Transport........................................................................... 1-3

1.3 Power Supply...........................................................................................................1-7

1.4 Daily Maintenance.................................................................................................... 1-8

1.5 Replacing the Optical Module................................................................................. 1-12

1.6 Replacing the Optical Adapter................................................................................1-16

1.7 Replacing the Battery Pack.................................................................................... 1-19

1.8 Charging the Battery Pack...................................................................................... 1-23

1.9 Replacing the Backup Battery................................................................................ 1-25

1.10 Names of Instrument Parts..................................................................................... 1-28

1.11 Screen Display....................................................................................................... 1-36

1.12 Notes Before Performing Measurement................................................................. 1-42

Page 29

Chapter 1 BEFORE USING THE INSTRUMENT

1.1 What is the AQ7260?

This instrument emits a light pulse into an optical fiber and searches faults from the end of

the fiber, then calculates transmission loss effectively by detecting back scattering rays

caused by Rayleigh scattering inside the fiber, and rays reflecting at connection points and

fault points.

Since the optical section comes in a module, an appropriate optical module can be

selected according to the wavelength and type of optical fiber to be used.

This instrument also can be used for light source depend on the mounted optical module.

1-2

Page 30

Chapter 1 BEFORE USING THE INSTRUMENT

1.2 Installation, Storage and Transport

This section explains points to be observed when installing, storing or transporting the

instrument.

Unpacking and Receiving I n spection

Prior to shipment, the instrument has undergone strict mechanical and electrical

inspection to ensure its correct operation. On delivery, immediately unpack and check the

instrument for any damage that might have occurred during transport.

Mechanical Inspection

After the instrument is unpacked, check the appearance, operation of each switch and

connector, and check for any damage or defects that might have occurred during

transport. In addition check that all the accessories are present and correct.

TIP

It is recommended that packing materials, such as corrugated boxes and

cushioning materials, be kept in a safe place so that they can be reused when

transporting the instrument again.

Operation Inspection

If no defects are found by mechanical inspection, check the instrument to see whether it

conforms to the specifications.

When Damage or Defects are Found

If damage or non-conformation to the specifications is found during mechanical or

operation inspection, contact the agent from whom the instrument was purchased.

1-3

Page 31

Chapter 1 BEFORE USING THE INSTRUMENT

Notes on Storage

This section explains points to be observed when storing the instrument for a long period

of time.

Notes Before Storage

Dust, fingerprints, dirt and stains etc. collected on the instrument must be wiped off with a

piece of cloth.

Carry out operation inspection to check that the instrument operates correctly.

Refer

For the method of cleaning the exterior of the instrument, refer to page 1-8.

Storage Conditions

When storing the instrument, make sure it is stored under the following environmental

conditions.

• Temperature −20 to 60°C

• Humidity 95%RH or less (No condensation allowed)

• Temperature/humidity does not change excessively throughout the day.

• Areas where the instrument will not be exposed to direct sunlight

• Areas where there is little dust

• Low-humidity areas where no water drops are generated or collect on the instrument

• Areas where the instrument will not be exposed to active gases or oxidized.

Caution

Refer

If you are not going to use the instrument for a long period of time, store it with the

battery pack removed. Furthermore, when storing the instrument outside the above

temperature range, make sure that the battery pack is removed.

For the method of removing the battery pack, refer to page 1-19.

Notes When Re-Using the Instrument

When using the instrument again after storing it for a long period of time, first carry out

operation inspection to check that the instrument operates correctly.

1-4

Page 32

Notes on Transport

This section explains points to be observed when transporting the instrument.

Repacking

To repack the instrument, the packing materials used to deliver the instrument must be

used. If they have been discarded or damaged, pack the instrument as explained below.

1. Wrap the instrument with a thick vinyl sheet to prevent entry of dust.

2. Place cushioning material on projecting parts on the bottom and front/rear

panels of the instrument to protect them.

3. Prepare a corrugated, wooden or aluminum box that is large enough to

accommodate the instrument and allows 10 to 15 cm space between the surface

of each part of the instrument (top, bottom, front, rear, right/left panels) and the

sides of the box.

Chapter 1 BEFORE USING THE INSTRUMENT

4. Put shock-absorbent materials at the bottom of the box to absorb shocks, such

as vibration.

5. Place the instrument in the center of the box and fill the spaces (between the

box’s internal surface and each surface of the instrument: top, front, rear,

right/left panels) with shock absorbent materials.

6. Secure the outside of the box with packing cord, adhesive tape or bands.

Caution

TIP

The instrument must be packed so that any impact or vibration on the instrume nt is

50G or less. If the instrument is exposed to impact or vibration exceeding 50G, the

instrument may get damaged. In particular, take care not to let any excessive

pressure be exerted on the LCD.

It is recommended that packing materials used to deliver the instrument be kept in

a safe place. Using these materials will facilitate packing work when transporting

the instrument.

1-5

Page 33

Chapter 1 BEFORE USING THE INSTRUMENT

Transport

During transport, make sure that vibration is avoided and the required storage conditions

are satisfied.

Refer

Caution

For details on the storage conditions, refer to pa ge 1-4.

When the battery pack is transport by using aircraft. Pleas each package contains

12 battery pack or less. However, airlines refuse transport battery packs. Please

inquire to the airline in advance.

1-6

Page 34

1.3 Power Supply

The instrument can run on AC power (AC battery is supplied with the instrument) or

battery pack.

The AC adapter must be connected to an AC power outlet (100 to 240 V, 50/60Hz).

Necessary measures must be taken to prevent the following.

• Accident by electric shock

• Internal damage of the instrument by abnormal voltage

Chapter 1 BEFORE USING THE INSTRUMENT

1-7

Page 35

Chapter 1 BEFORE USING THE INSTRUMENT

1.4 Daily Maintenance

The instrument can be used for many years if daily maintenance is carried out properly.

Daily maintenance is also important to prevent trouble and breakdowns.

This section explains how to clean the following items.

• Exterior of the instrument

• Optical connector

• Optical adapter

Cleaning the Exterior of the Instrument

Wet a cloth with lukewarm water, squeeze it thoroughly, wipe the LCD and exterior of the

instrument with it, and then wipe the instrument with dry cloth.

Caution

•Before carrying out daily maintenance, make sure that the power is turned OFF.

•Do not use chemicals such as thinner, benzene and alcohol. Use of such

chemicals may cause deterioration or discoloration of the exterior of the instrument.

•To prevent entry of water into the instrument, the wet cloth must be firmly

squeezed before it is used to wipe the exterior.

1-8

Page 36

Cleaning the Optical Connector

The end of the optical connector must be kept clean at all times. Collection of dust or dirt

on the end may damage the optical adapter of the instrument, hindering correct

measurement.

This section explains how to clean the end of the optical connector by taking a FC

connector as an example.

1. Place the end of the optical connector perpendicular to the cleaner’s cleaning

surface.

2. With the end of the optical connector pushed against the cleaning surface, turn

it approximately one turn.

3. Then, slide the end of the optical connector.

Chapter 1 BEFORE USING THE INSTRUMENT

4. Repeat steps 2 to 3 to clean the end of the optical connector.

Caution

When cleaning the optical connector, make sure that it is pushed against the

cleaner firmly. If not, the optical connector may not be cleaned sufficiently.

1-9

Page 37

Chapter 1 BEFORE USING THE INSTRUMENT

TIP

•To check the condition of the end of the optical connector, use of a surface check

microscope (x200 to x400) is helpful.

•Various cleaners designed for optical fiber cables are available, including

“OPTICAL FIBER CONNECT OR CLEANER” man ufa ctured by NTT-ME.

CLETOP reel-type A SC, FC, ST, DIN, D4

CLETOP reel-type B MT, Biconic

CLETOP spare tape ---------CLETOP stick-type ----------

Product Name Appropriate Connector Types

1-10

Page 38

Cleaning the Optical Adapter

This section explains how to clean the optical adapter.

1. Make sure that the power to the instrument is turned OFF.

WARNING

Never clean the instrument if the power is ON. Laser beams are invisible to the naked

eye, but if they enter the eyes, they may cause impaired eyesight.

Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

Chapter 1 BEFORE USING THE INSTRUMENT

Refer

For the method of turning OFF the power , refer to page 3-107.

2. Slide the optical connector cover on the top of the instrument to open it.

3. Clean the outer surface inside the optical adapter using a special cleaning stick.

Also clean the end of the optical fiber with a special cleaning stick.

Special cleaner

CLETOP

Stick-Type

Cover of

optical fiber

cable connector

Front shell

TIP

Various cleaners designed for optical adapters are available, including “CLETOP

Stick-Type” manufactured by NTT-ME.

1-11

Page 39

Chapter 1 BEFORE USING THE INSTRUMENT

1.5 Replacing the Optical Module

This section explains how to replace the optical module with a new one.

Removing the Optical Module

Caution

Refer

The optical module cannot be replaced if the expansion unit is conn ected.

For the method of removing the expansion unit, refer to page 8-5.

1. Make sure that the power to the instrument is turned OFF.

WARNING

Do not replace the optical module while the instrument is powered ON.

Failure to observe this may result in electric shock or breakdown.

Refer

For the method of turning OFF the power , refer to page 3-107.

1-12

Page 40

Chapter 1 BEFORE USING THE INSTRUMENT

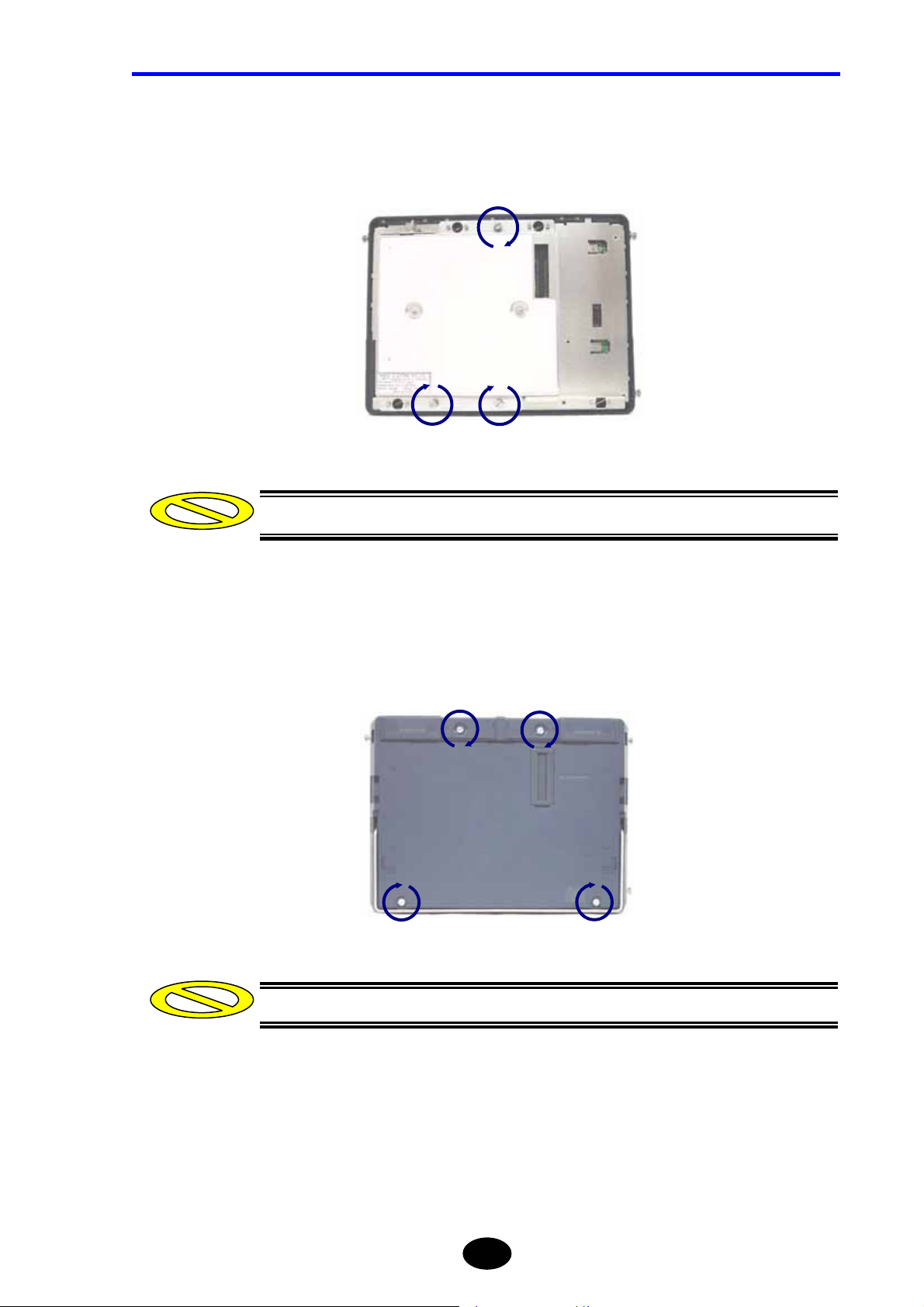

2. Remove the optical module cover.

Loosen the four screws shown below counter-clockwise.

3. Lift the optical module cover straight to remove it.

4. Remove the optical module.

Loosen the three screws shown below counter-clockwise. Then, pull out the optical

module as shown below to remove it.

knob

knob

CAUTION

OPTICAL

MODULE

When removing the optical module, lift the two knobs slowly at the same time to detach

them. Never shake it sideways or remove it by force.

Doing so may damage the connector.

Take care not to touch the connector on the optical module or the one on the instrument.

Doing so may result in breakdown.

1-13

Page 41

Chapter 1 BEFORE USING THE INSTRUMENT

Attaching a New Optical Module

This section explains how to attach a new optical module. It is assumed that the optical

module and its cover have been removed.

1. Make sure that the power to the instrument is turned OFF.

WARNING

Do not replace the optical module while the instrument is powered ON.

Failure to observe this may result in electric shock or breakdown.

Refer

For the method of turning OFF the power , refer to page 3-107.

2. Connect the optical module’s connector to the one on the optical module.

CAUTION

When attaching the optical module, insert the connector slowly. Never shake the connector

sideways or insert it by force.

Doing so may damage the connector.

1-14

Page 42

Chapter 1 BEFORE USING THE INSTRUMENT

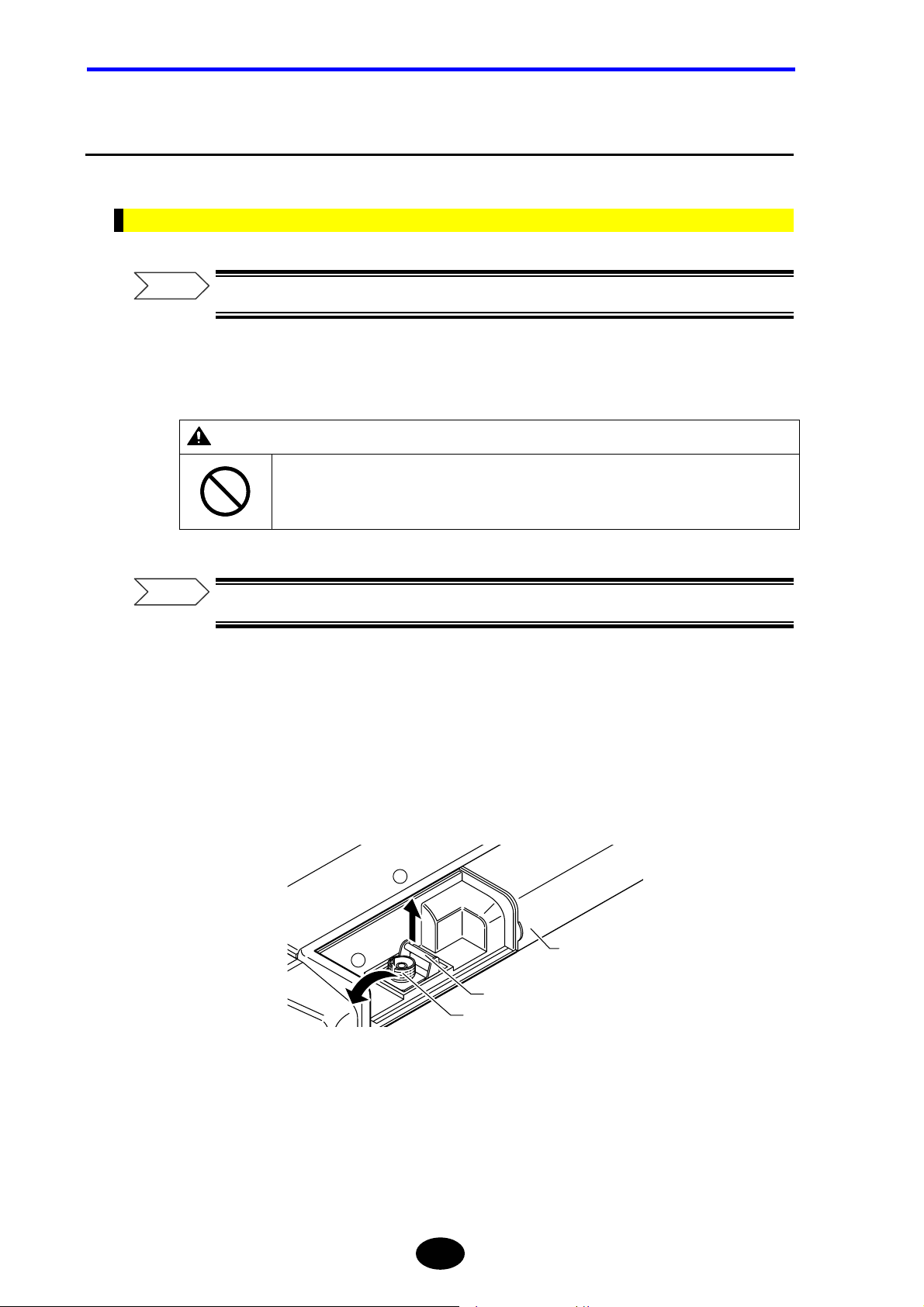

3. Fix the optical module.

Tighten the three screws shown below clockwise to secure the optical module.

Caution

Make sure that the screws are tightened firmly.

4. Attach the optical module cover.

Tighten the four screws shown below clockwise.

Caution

Make sure that the screws are tightened firmly.

1-15

Page 43

Chapter 1 BEFORE USING THE INSTRUMENT

1.6 Replacing the Optical Adapter

This section explains how to replace the optical adapter with a new one.

Removing the Optical Adapter

Refer

Refer to the Cautions given on page 1-18.

1. Make sure that the power to the instrument is turned OFF.

WARNING

Do not replace the optical adapter while the power to the instrument is ON.

Should the laser emit and enter the eyes, they may be seriously damaged or loss of

eyesight may result.

Refer

For the method of turning OFF the power , refer to page 3-107.

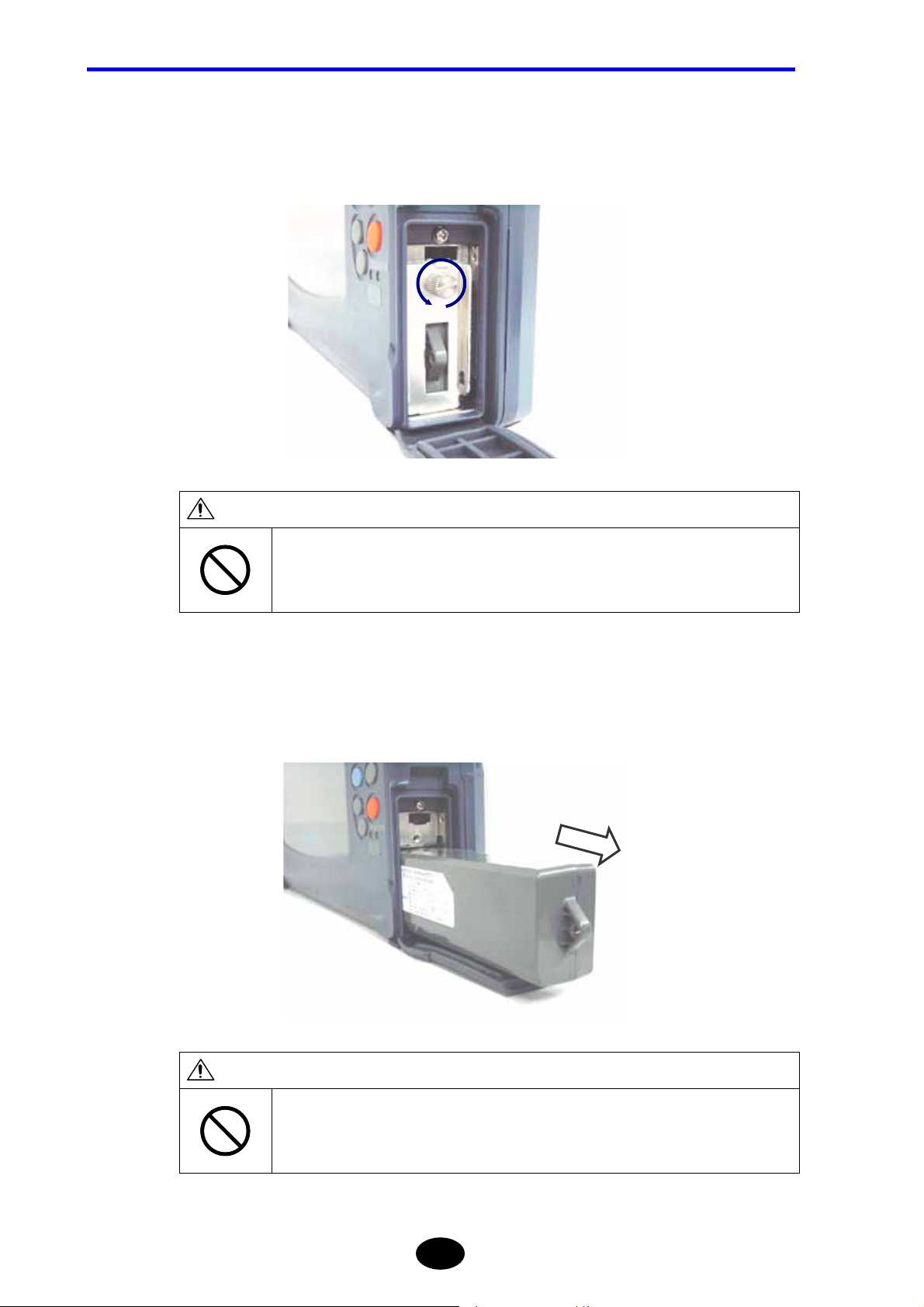

2. Slide the optical connector cover on the top of the instrument to open it.

3. Push the optical adapter’s lock lever inward to unlock the adapter.

4. Lift the adapter to pull it out.

2

1

Lock lever

Front shell

Cover of

optical fiber

cable connector

1-16

Page 44

Attaching a New Optical Adapter

Chapter 1 BEFORE USING THE INSTRUMENT

Refer

Refer to the Cautions given on page 1-18.

1. Make sure that the power to the instrument is turned OFF.

WARNING

Do not replace the optical adapter while the power to the instrument is ON.

Should the laser emit and enter the eyes, they may be seriously damaged or loss of

eyesight may result.

Refer

For the method of turning OFF the power , refer to page 3-107.

2. Slide the optical connector cover on the top of the instrument to open it.

3. Insert the new optical adapter straight into the rear shell.

4. Push the optical adapter’s lock lever outward to lock the adapter.

1-17

Page 45

Chapter 1 BEFORE USING THE INSTRUMENT

CAUTION

• Take care not to damage the end of the optical fiberl.

If the end of the optical fiber is damaged, correct measurement may no longer be

possible or the optical fiber to be measured may also be damaged.

• When removing/inserting the optical adapter, it must be removed/inserted slowly.

Shaking it sideways or removing/inserting by force may not only damage the optical

adapter, but also damage the ferrule on the optical connector.

1-18

Page 46

Chapter 1 BEFORE USING THE INSTRUMENT

1.7 Replacing the Batter y Pack

This section explains how to replace the battery pack with a new one.

Removing the Battery Pack

1. Make sure that the power to the instrument is turned OFF.

WARNING

Do not replace the battery pack while the power to the instrument is ON.

Failure to observe this may result in electric shock or breakdown.

Refer

For the method of turning OFF the power , refer to page 3-107.

2. Open the battery pack protecting rubber.

1-19

Page 47

Chapter 1 BEFORE USING THE INSTRUMENT

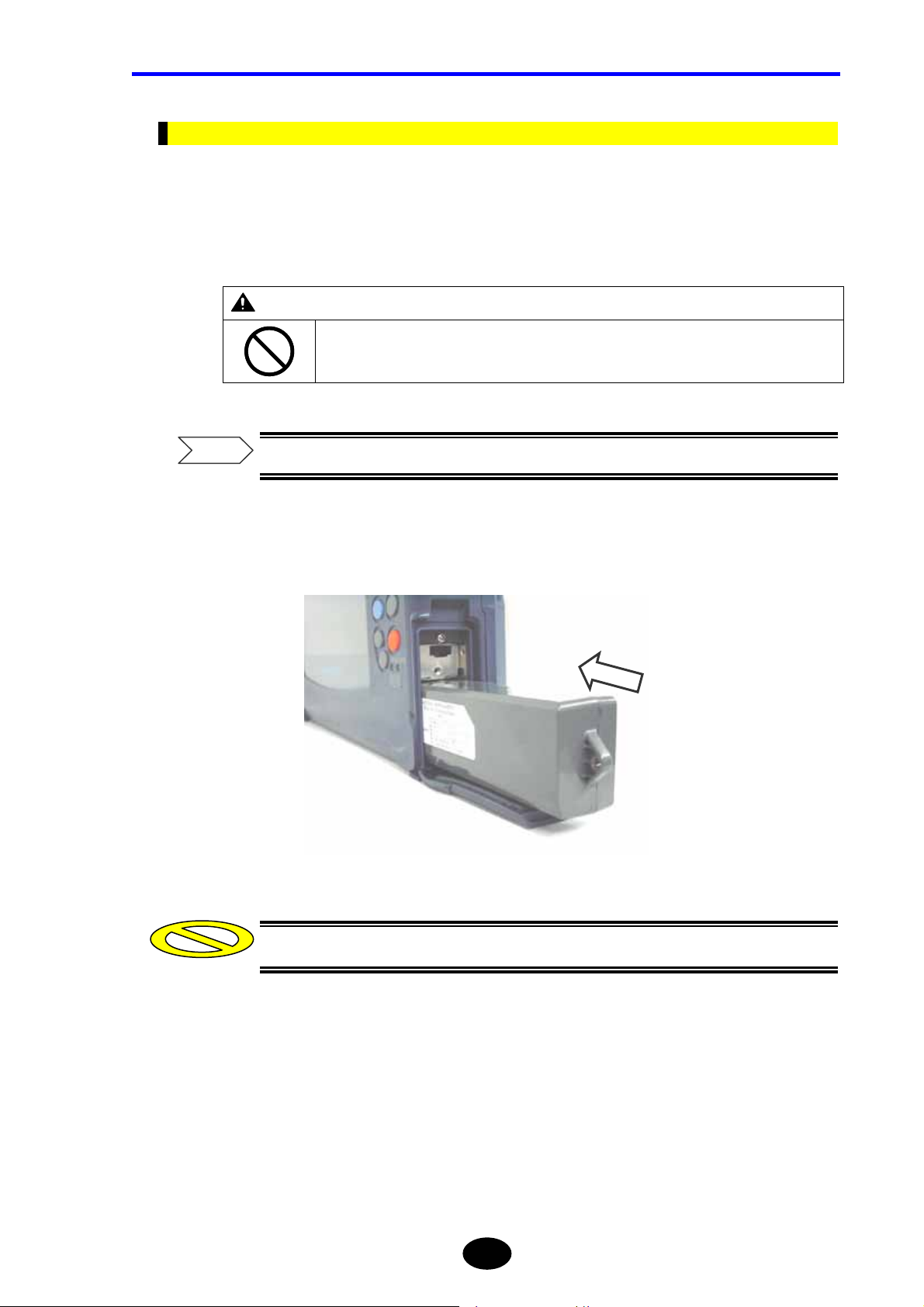

3. Remove the battery pack bracket.

Loosen the screw shown below counter-clockwise to remove the bracket.

CAUTION

When removing the bracket, make sure that the right side of the instrument is not facing

the floor.

Doing so may cause the battery pack to drop, resulting in damage.

4. Remove the battery pack.

CAUTION

Do not touch the electrodes on the removed battery pack.

Doing so may result in breakdown.

1-20

Page 48

Attaching a New Battery Pack

This section explains how to attach a new battery pack. It is assumed that the battery pack

bracket has been removed.

1. Make sure that the power to the instrument is turned OFF.

WARNING

Do not replace the battery pack while the power to the instrument is ON.

Failure to observe this may result in electric shock or breakdown.

Chapter 1 BEFORE USING THE INSTRUMENT

Refer

For the method of turning OFF the power , refer to page 3-107.

2. Insert a new battery pack into the instrument.

Caution

Make sure that the battery pack is inserted in the correct direction.

1-21

Page 49

Chapter 1 BEFORE USING THE INSTRUMENT

3. Attach the battery pack bracket.

Tighten the screw shown below clockwise to secure the bracket.

Caution

Make sure that the screw is tightened firmly.

4. Close the battery pack protecting rubber.

CAUTION

Make sure that the battery pack protecting rubber is closed firmly.

Failure to observe this may result in breakdown.

1-22

Page 50

Chapter 1 BEFORE USING THE INSTRUMENT

1.8 Charging the Battery Pack

This section explains how to charge the battery pack.

When there is insufficient power in the battery pack, charge it as explained below.

Caution

Charging of the battery pack must be performed at temperatures of 5°C to 35°C.

Charging outside this temperature range may not only deteriorate the battery

pack’s performance or shorten its life, but in the worst case may also prevent start

of charging. The CHARGE LED blinks if charging is not yet started.

The remaining power in the battery pack can be seen on the power indicato r

located in the lower right corner of the screen.

Fully charged Insufficient remaining power

The following message appears when there is insuff icient power in the battery

pack.

Low battery.

Please use AC adapter,

or replace the charged battery.

Push any key.

Take the required actions according to the above message. If the required actions

are not taken within a few minutes following the appearance of the above message,

the following message will appear and the power will be turned OFF automatically.

When the battery pack is heated, the instrument prevents to cha rg e the battery. If

the battery pack is heated. Please remove the battery pack. After the temperature

become cool to room temperature and insert battery pack.

Low battery.

OTDR will shutdown in 10 sec.

1-23

Page 51

Chapter 1 BEFORE USING THE INSTRUMENT

Refer

For the method of removing the battery pack, refer to page1-19.

1. Make sure that the power to the instrument is turned OFF.

Refer

For the method of turning OFF the power , refer to page 3-107.

2. With the battery pack installed in the instrument, connect the AC adapter to the

instrument.

Refer

•For the method of attaching the battery pack, refer to page 1-21.

•For the method of connecting the AC adapter, refer to page 3-4.

3. Insert the AC adapter’s power plug into an AC power outlet.

Charging of the battery pack will start.

CAUTION

Do not insert the AC adapter’s power plug into an AC power outlet if the power to the

instrument is ON.

TIP

The CHARGE LED will be lit steadily while the battery pack is charged, and will go

out when charging is complete.

Failure to observe this may result in breakdown.

1-24

Page 52

Chapter 1 BEFORE USING THE INSTRUMENT

1.9 Replacing the Backup Battery

This section explains how to replace the backup battery with a new one.

The backup battery must be replaced with a new one periodically, since it may cause

sudden malfunctions due to its battery life even though the instrument is working properly.

The backup battery must be replaced approximately every five years.

Caution

•When the backup battery is replaced, the date and time will be initialized.

•The battery model “CR2032” must be used.

1. Make sure that the power to the instrument is turned OFF.

WARNING

Do not replace the backup battery while the power to the instrument is ON.

Failure to observe this may result in electric shock or breakdown.

Refer

For the method of turning OFF the power , refer to page 3-107.

2. Remove the optical module cover and then remove the optical module.

Refer

For the method of removing the optical module and its cover, refer to page 1-12.

1-25

Page 53

Chapter 1 BEFORE USING THE INSTRUMENT

3. Remove the battery.

3-1. Slide the battery as shown below.

3-2. Pull up the battery

Caution

When removing the backup battery, take care not to short-circuit the instrument.

4. Insert a new battery.

Caution

Make sure that the battery is inserted in the correct direction. The printing board

side is minus.

1-26

Page 54

Chapter 1 BEFORE USING THE INSTRUMENT

5. Attach the optical module and then attach its cover.

Refer

For the method of attaching the optical module and its cover, refer to page 1-12.

CAUTION

The instrument uses a lithium battery for memory backup.

So, disposal of the instrument must be carried out according to the laws and regulations of

the country and local authorities.

1-27

Page 55

Chapter 1 BEFORE USING THE INSTRUMENT

1.10 Names of Instrument Parts

This section explains the name and function of each part of the instrument (front, rear, top

and right side panels). It also explains standard accessories and options.

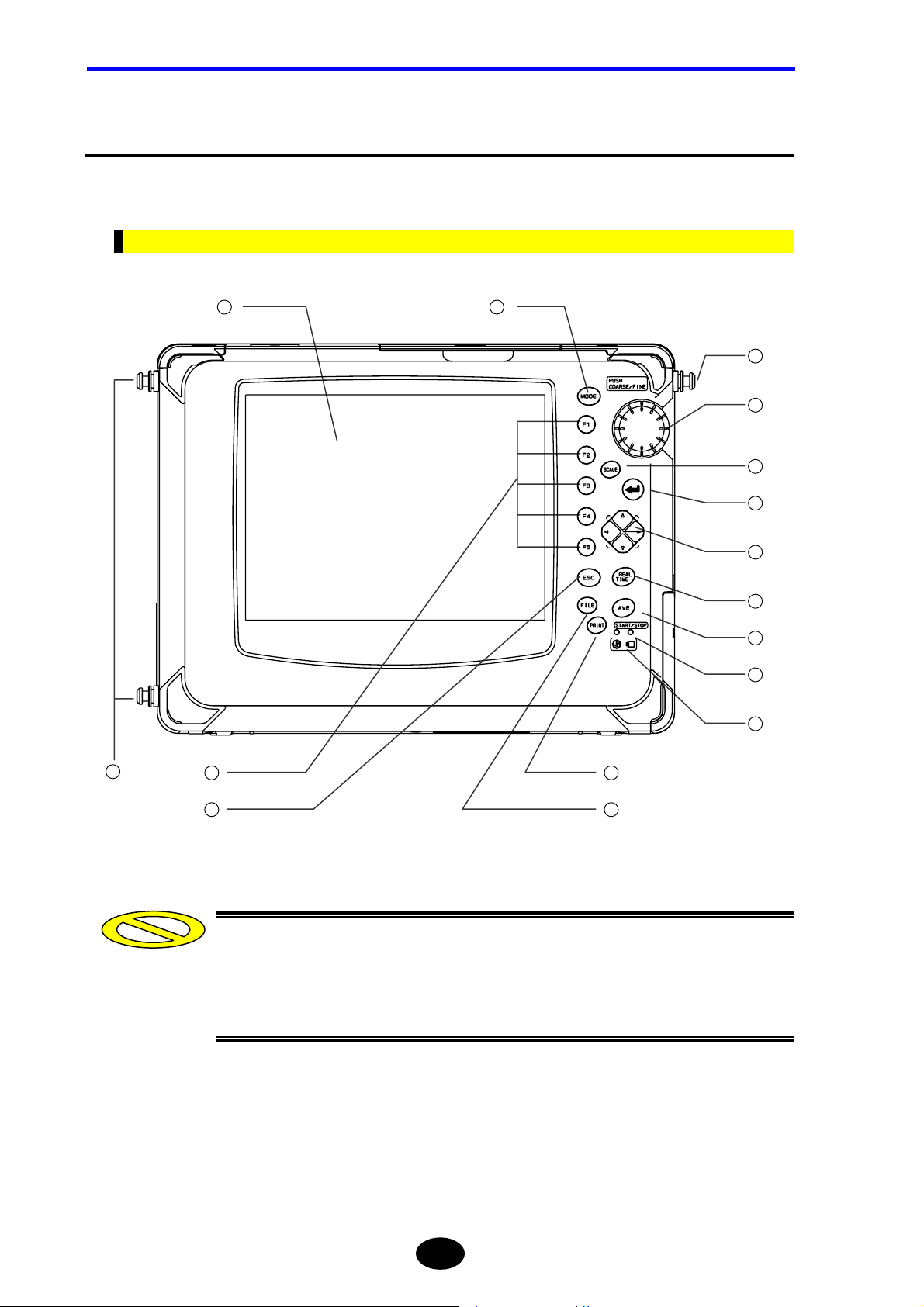

Front View

1

2

13

3

4

5

6

7

8

14

15

13

12

9

1011

Caution

The instrument uses a color LCD (hereafter called LCD). A filter plate is attached to

the front surface of the LCD for protection. However, if the filter plate is exposed to

strong impact, it may crack or the LCD itself may be damaged, so speci al care

must be taken when handling it.

1-28

Page 56

Chapter 1 BEFORE USING THE INSTRUMENT

No. Name Description

1

LCD 8.4-inch color TFT (640 x 480 dots). Measured trace, measurement

conditions and measured values are displayed.

2

MODE key Used to switch the operation mode.

3

Rotary knob Used to move the distance cursor or increase/decrease entered values.

Holding down the key will allow you to move the distance cursor at

different speeds.

4

SCALE key Used to enlarge/reduce the trace size or shift the trace.

5

ENTER key Used to confirm entered values etc.

6

Arrow key Used to move the trace, enlarge/reduce the trace size, or change

entered values.

7

REAL TIME key Starts/stops real-time measurement.

8

AVERAGE key Starts/stops average measurement.

9

PRINT key Prints out the information displayed on the screen.

10

FILE key Used for file operation (saving, deleting, recalling).

11

ESC key Used to cancel the operation or restore the previous screen contents.

12

Function keys Performs the function inscribed on each key.

13

Shoulder belt fixture Used to attach a shoulder belt to the instrument.

14

CHARGE LED Lit while the battery pack is charged.

When the battery pack is full charged, the LED is off.

15

POWER LED Lit while the power to the instrument is ON.

Conventions Used in This Manual

In this manual, each key is expressed as follows.

Example

It blinks if the battery pack has not been charged or if it is in critical

condition.

When the instrument is running on the battery pack, this LED turns from

green to red when there is insufficient power in the battery pack.

[key name]

[ENTER]

1-29

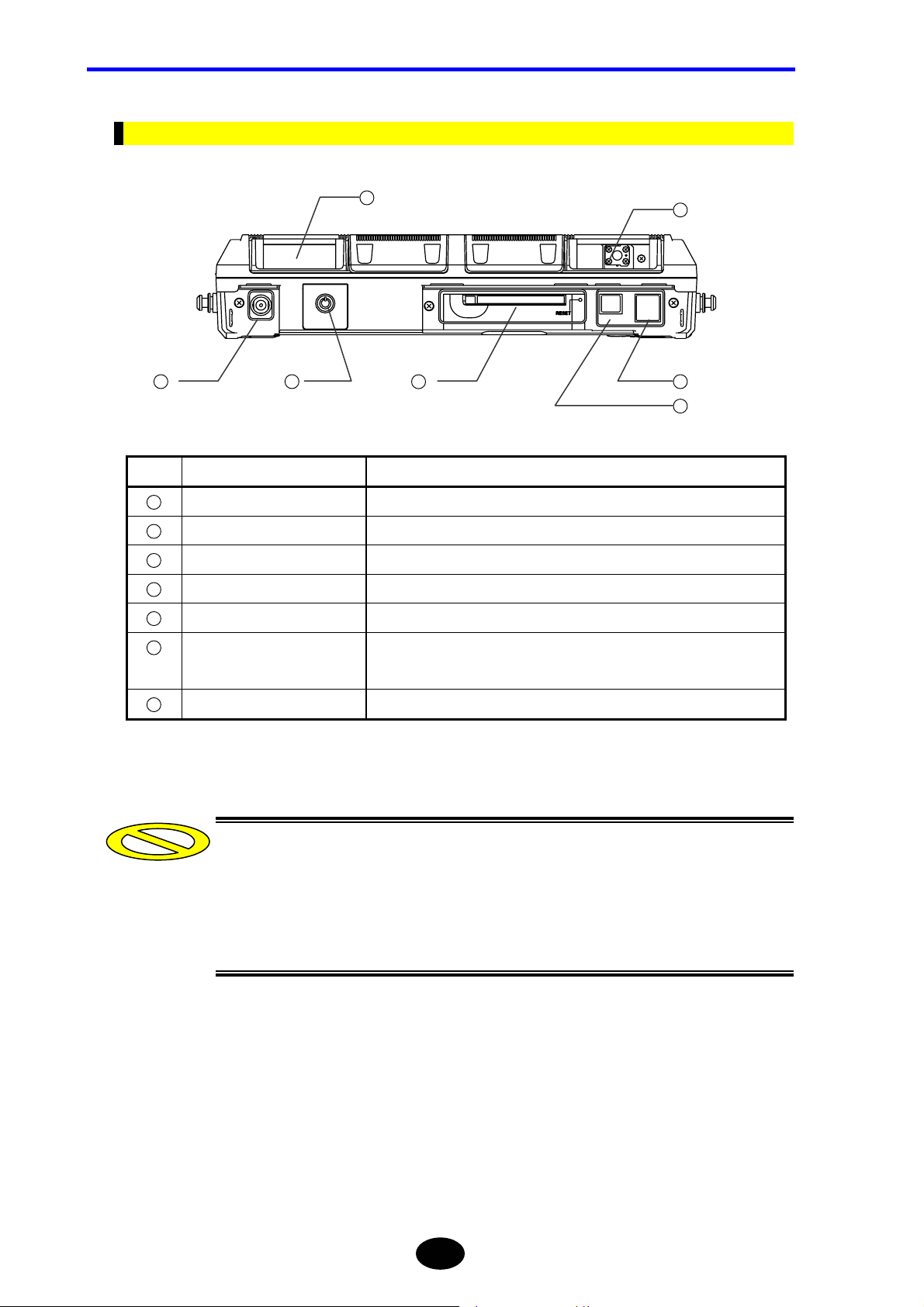

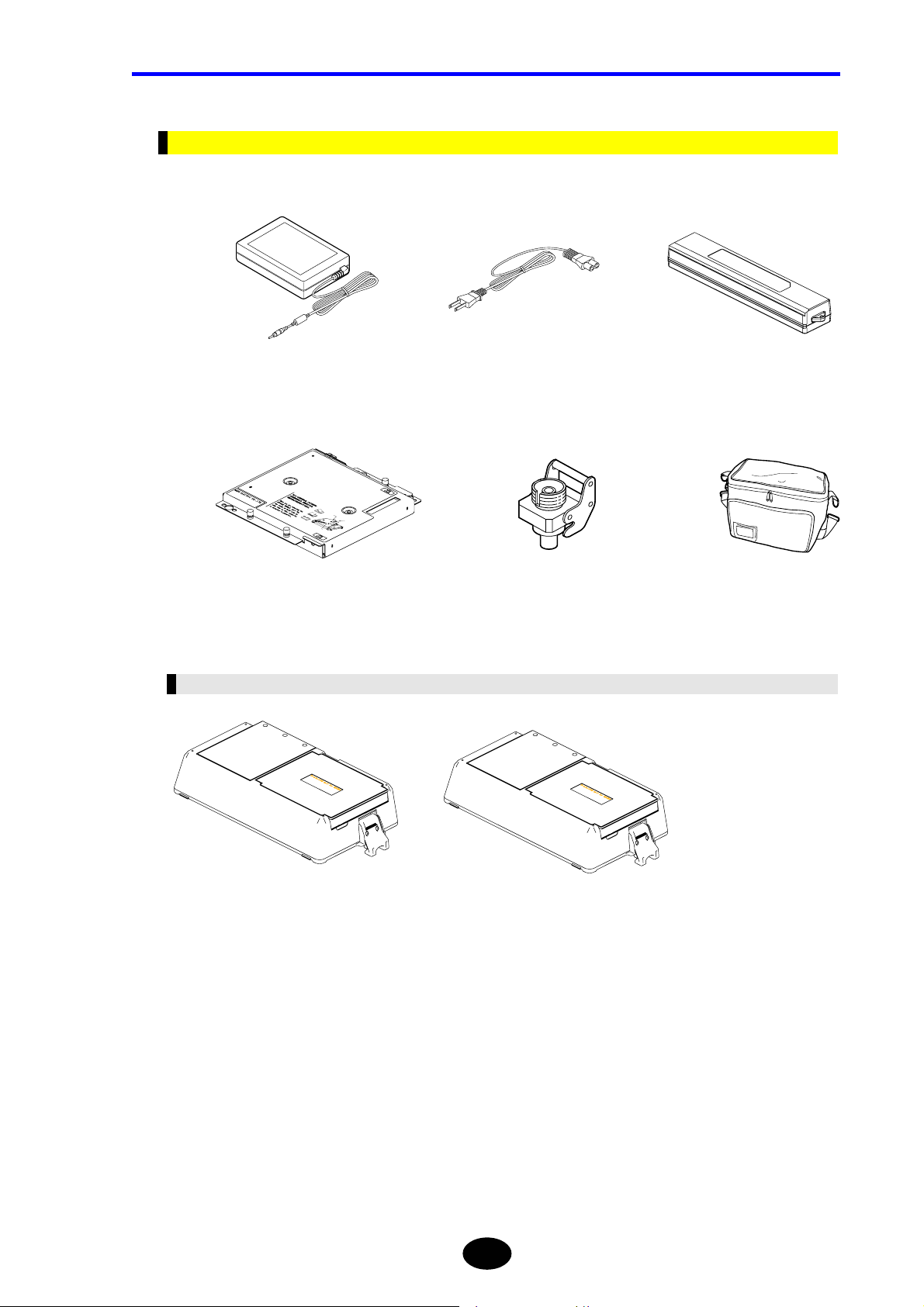

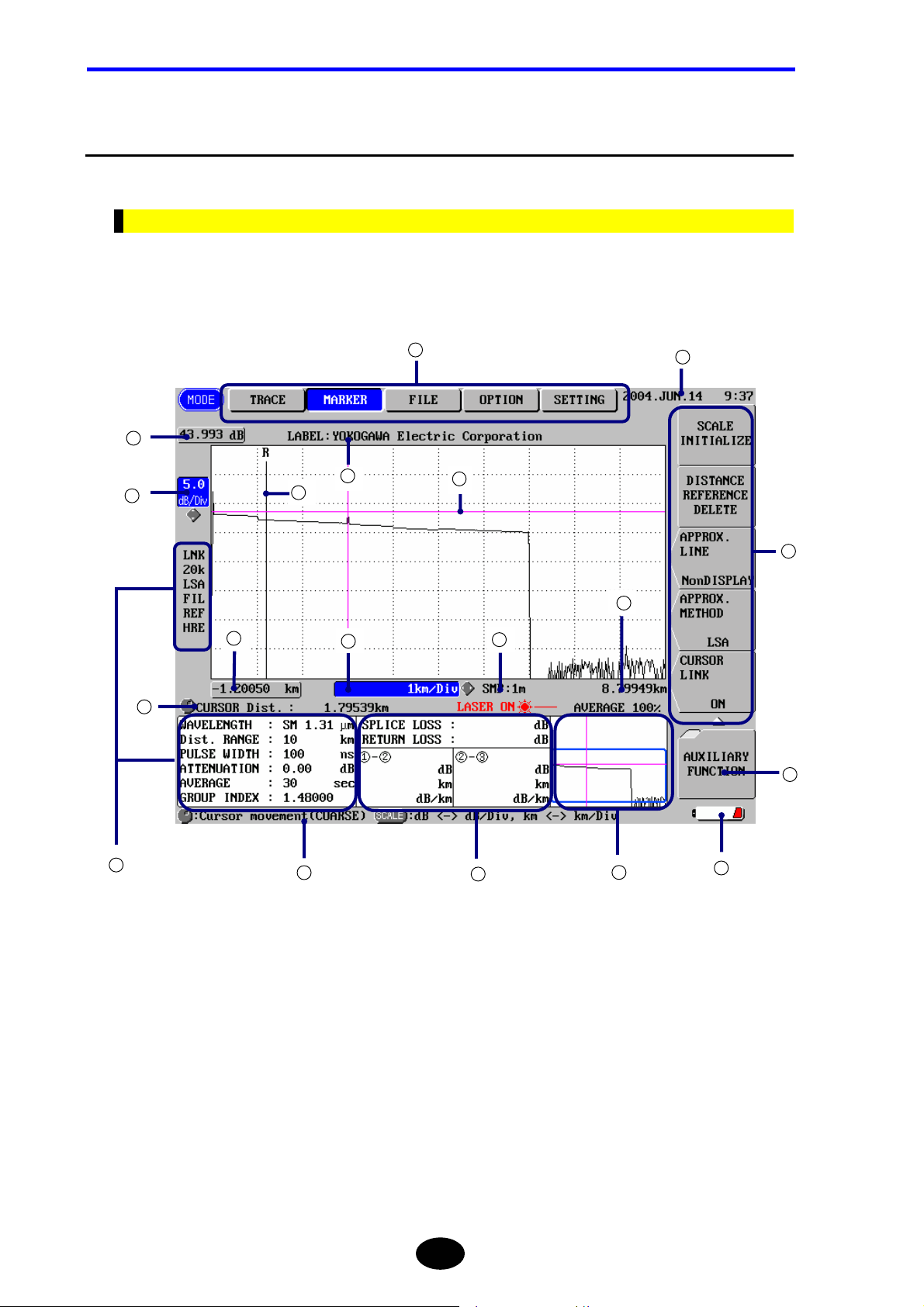

Page 57