Page 1

User ’s

Manual

AQ6370D

Optical Spectrum Analyzer

IM AQ6370D-01EN

5th Edition

Page 2

Product Registration

Thank you for purchasing YOKOGAWA products.

YOKOGAWA provides registered users with a variety of information and services.

Please allow us to serve you best by completing the product registration form

accessible from our website.

http://tmi.yokogawa.com/

PIM 103-04E

Page 3

List of Manuals

Thank you for purchasing the AQ6370D Optical Spectrum Analyzer. This instrument

enables high speed measurement of the optical properties of LD and LED light sources,

optical amps, and other devices. To improve ease of use, it includes mouse-based user

operation and a brand-new zoom function.

This user’s manual describes the instrument’s functions, operating procedures, and

handling precautions, and provides other important information for use of the instrument.

For correct operation, please read this manual thoroughly before use. After reading this

manual, keep it in a convenient location for quick reference in the event a question arises

during operation.

The following manuals, including this one, are provided as manuals for the AQ6370D.

Please read all manuals.

Manual Title Manual No. Description

AQ6370D

Optical Spectrum Analyzer

User’s Manual

AQ6370C/AQ6370D/AQ6373/

AQ6373B/AQ6375/AQ6375B

Optical Spectrum Analyzer

Remote Control User’s Manual

AQ6370D

Optical Spectrum Analyzer

Getting Started Guide

Model AQ6370D-01

AQ6370D Optical Spectrum

Analyzer Limited model

IM AQ6370D-01EN The manual is located on the CD included

in your package (pdf format). Explains

all functions and operating procedures of

the AQ6370D except remote control and

program functions.

IM AQ6370C-17EN The manual is located on the CD included

in your package (pdf format).Explains

functions for controlling the instrument with

communication commands and program

functions.

IM AQ6370D-02EN This manual. Explains the handling

precautions, installation procedure,

component names, and specifications of

the AQ6370D.

IM AQ6370D-51EN Explains the specifications of the limited

model of the AQ6370D.

The “EN” in the manual number is the language code.

Notes

Trademarks

Contact information of Yokogawa offices worldwide is provided on the following sheet.

Document Description Description

PIM 113-01Z2 List of worldwide contacts

• The contents of this manual are subject to change without prior notice as a result

of improvements in the instrument’s performance and functions. Display contents

illustrated in this manual may differ slightly from what actually appears on your screen.

• Every effort has been made in the preparation of this manual to ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact your nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without the

permission of YOKOGAWA is strictly prohibited.

• Microsoft and Windows are registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries.

• Adobe and Acrobat are registered trademarks or trademarks of Adobe Systems

incorporated.

• In this manual, the ® and TM symbols do not accompany their respective registered

trademark or trademark names.

• Other company and product names are registered trademarks or trademarks of their

respective companies.

5th Edition: October 2017 (YMI)

All Rights Reserved, Copyright © 2014 Yokogawa Test & Measurement Corporation

IM AQ6370D-01EN

i

Page 4

Revisions

• 1st Edition: April 2014

• 2nd Edition: July 2014

• 3rd Edition: July 2015

• 4th Edition: May 2017

• 5th Edition: October 2017

ii

IM AQ6370D-01EN

Page 5

Conventions Used in This Manual

Safety Markings

The following markings are used in this manual.

Improper handling or use can lead to injury to the user or damage

to the instrument. This symbol appears on the instrument to indicate

that the user must refer to the userʼs manual for special instructions.

The same symbol appears in the corresponding place in the user's

manual to identify those instructions. In the manual, the symbol is

used in conjunction with the word “WARNING” or “CAUTION.”

WARNING

CAUTION

Note

Calls attention to actions or conditions that could cause serious or

fatal injury to the user, and precautions that can be taken to prevent

such occurrences.

Calls attentions to actions or conditions that could cause light injury to

the user or damage to the instrument or user’s data, and precautions

that can be taken to prevent such occurrences.

Calls attention to information that is important for proper operation of

the instrument.

Notations Used on Pages Describing Operating Procedures

On pages that describe the operating procedures in Chapter 3 through 11, the following

notations are used to distinguish the procedures from their explanations.

Procedure

Explanation

This subsection contains the operating procedure used to carry out

the function described in the current chapter. The procedures are

written with inexperienced users in mind; experienced users may not

need to carry out all the steps.

This subsection describes the setup parameters and the limitations on

the procedures. It may not give a detailed explanation of the function.

For a detailed explanation of the function, see chapter 2.

Unit

IM AQ6370D-01EN

Notations Used in the Procedures

Panel Keys and Soft keys

Bold characters used in the procedural explanations indicate characters that are marked on the

panel keys or the characters of the soft keys displayed on the screen menu.

k: Denotes “1000.” Example: 100 kS/s

K: Denotes “1024.” Example: 459 KB (file data size)

iii

Page 6

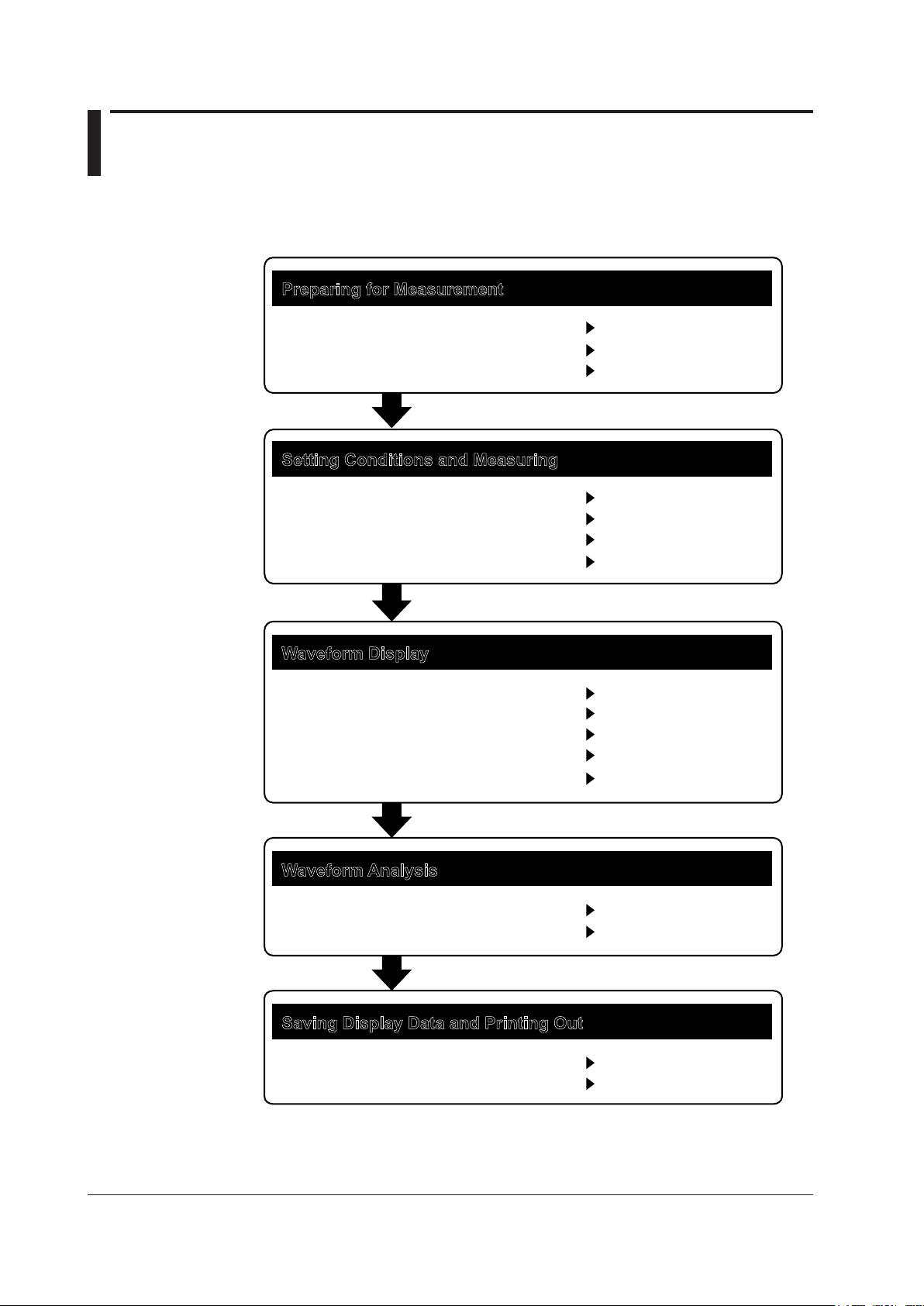

Flow of Operation

The figure below is provided to familarize the first-time user with the general flow of this

instrument operation. For a description of each item, see the relevant section or chapter.

Preparing for Measurement

Installing the Instrument

Turning the Power ON/OFF

Wavelength Calibration

Setting Conditions and Measuring

Auto Sweep Setting and Measurement

Other Settings

Measurement Start (Sweep)

External Trigger Measurement

Waveform Display

Waveform Display

Displaying Calculated Waveforms

Displaying Power Density

Marker Display

Searching

Section 3.1

Section 3.4

Section 3.7

Section 5.1

Sections 5.2 to 5.12

Section 5.13

Section 5.16

Sections 6.1 to 6.4

Section 6.5

Section 6.8

Section 6.9

Sections 6.13 and 6.14

Waveform Analysis

Waveform Analysis

GO/NO-GO Judgment

Sections 7.1 to 7.9

Section 7.12

Saving Display Data and Printing Out

Storage Media

Saving Data

iv

Section 8.1

Sections 8.2 to 8.10

IM AQ6370D-01EN

Page 7

Contents

List of Manuals ...................................................................................................................................i

Conventions Used in This Manual ................................................................................................... iii

Flow of Operation.............................................................................................................................iv

1

2

Chapter 1 Part Names and Functions

1.1 Front Panel ....................................................................................................................... 1-1

1.2 Rear Panel ....................................................................................................................... 1-2

1.3 Panel Keys and Knobs ..................................................................................................... 1-3

1.4 LCD Screen ...................................................................................................................... 1-6

Chapter 2 Functions

2.1 System Structure .............................................................................................................. 2-1

2.2 Measurement ................................................................................................................... 2-2

2.3 Waveform Display ........................................................................................................... 2-7

2.4 Analysis .......................................................................................................................... 2-12

2.5 Other .............................................................................................................................. 2-14

Chapter 3 Preparing for Measurement

3.1 Installing the Instrument ................................................................................................... 3-1

3.2 Attaching the Connector Adapter ..................................................................................... 3-3

3.3 Connecting the Device ..................................................................................................... 3-5

3.4 Turning the Power ON/OFF .............................................................................................. 3-7

3.5 Connecting the DUT ....................................................................................................... 3-12

3.6 Alignment Adjustment ..................................................................................................... 3-14

3.7 Wavelength Calibration .................................................................................................. 3-18

3.8 Resolution Calibration .................................................................................................... 3-23

3.9 Important Points During Measurement ........................................................................... 3-27

3

4

5

6

7

8

9

Chapter 4 Common Operations

4.1 Description of Soft Keys ................................................................................................... 4-1

4.2 Using the Mouse and External Keyboard ......................................................................... 4-3

4.3 Entering Numerical Values and Strings ............................................................................ 4-5

4.4 Screen Display ................................................................................................................. 4-7

4.5 Setting the Date and Time ................................................................................................ 4-8

Chapter 5 Measurement

5.1 Auto Measurement ........................................................................................................... 5-1

5.2 Horizontal/Vertical Axis Settings ....................................................................................... 5-2

5.3 Sub Scale ......................................................................................................................... 5-7

5.4 Setting the Reference Level ............................................................................................5-11

5.5 Center Wavelength (Center Frequency) Setting ............................................................ 5-15

5.6 Sweep Width Settings .................................................................................................... 5-20

5.7 Wavelength (Frequency) Resolution Settings ................................................................ 5-24

5.8 Sampling Point/Interval Settings .................................................................................... 5-27

5.9 Sensitivity Settings ......................................................................................................... 5-29

5.10 Sweep Speed Settings ................................................................................................... 5-31

5.11 Averaging Times Setting................................................................................................. 5-32

5.12 Trace Settings ................................................................................................................ 5-33

5.13 Measurement Start (Sweep) .......................................................................................... 5-35

IM AQ6370C-01EN

10

11

App

Index

v

Page 8

Contents

5.14 Specifying a Sweep Range ............................................................................................ 5-37

5.15 Pulse Light Measurement ............................................................................................... 5-38

5.16 External Trigger Measurement ....................................................................................... 5-44

5.17 Trigger Output ................................................................................................................ 5-48

5.18 Smoothing ...................................................................................................................... 5-49

5.19 Analog Out ..................................................................................................................... 5-50

Chapter 6 Waveform Display

6.1 Zooming In/Out on Waveforms ......................................................................................... 6-1

6.2 Wavelength Updating/Fixing ............................................................................................. 6-8

6.3 MAX/MIN HOLD Display ................................................................................................ 6-10

6.4 Sweep Average ...............................................................................................................6-11

6.5 Displaying Calculated Waveforms .................................................................................. 6-13

6.6 Normalized Display ....................................................................................................... 6-19

6.7 Curve Fitting .................................................................................................................. 6-20

6.8 Power Density Trace ..................................................................................................... 6-26

6.9 Marker Display ............................................................................................................... 6-27

6.10 Displaying a Split Screen ............................................................................................... 6-43

6.11 Noise Mask ..................................................................................................................... 6-45

6.12 Copying and Clearing Traces ......................................................................................... 6-47

6.13 Single Search ................................................................................................................. 6-49

6.14 Multi Search ................................................................................................................... 6-53

Chapter 7 Analysis

7.1 Spectrum Width Measurement ......................................................................................... 7-1

7.2 Notch Width Measurement ............................................................................................... 7-4

7.3 SMSR Measurement ........................................................................................................ 7-6

7.4 POWER Measurement ..................................................................................................... 7-8

7.5 DFB-LD, FP-LD, and LED Measurement ......................................................................... 7-9

7.6 PMD Measurement ........................................................................................................ 7-10

7.7 WDM Transmission Signal Analysis ............................................................................... 7-12

7.8 Optical Amp Gain and NF Measurement ........................................................................ 7-19

7.9 Optical Filter Characteristics Measurement ................................................................... 7-26

7.10 Editing the Grid Table ..................................................................................................... 7-35

7.11 Measurement of Level Fluctuations in Single-Wavelength Light (0 nm Sweeping) ........ 7-39

7.12 Go/No-Go Judgment (Template) .................................................................................... 7-42

7.13 Specifying an Analysis Range ........................................................................................ 7-54

7.14 Correcting Displayed Values .......................................................................................... 7-57

7.15 Analysis Data Logging .................................................................................................... 7-60

Chapter 8 Saving/Loading Data

8.1 USB Storage Media .......................................................................................................... 8-1

8.2 Temporarily Saving and Redisplaying Traces to and from Internal Memory .................... 8-2

8.3 Saving/Loading Displayed Data ....................................................................................... 8-6

8.4 Saving/Loading Displayed Data(All Trace) ..................................................................... 8-22

8.5 Saving/Loading Setting Data .......................................................................................... 8-28

8.6 Saving/Loading Analysis Results Data ........................................................................... 8-33

8.7 Saving/Loading Program Data ....................................................................................... 8-40

8.8 Saving Screen Image Data ............................................................................................ 8-46

8.9 Saving/Loading Template Data....................................................................................... 8-50

8.10 Saving and Loading Logging Data ................................................................................. 8-56

8.11 Creating Files ................................................................................................................. 8-62

vi

IM AQ6370C-01EN

Page 9

Contents

Chapter 9 Other Operations

9.1 Registering Soft keys ....................................................................................................... 9-1

9.2 Data Initialization .............................................................................................................. 9-2

9.3 Help ................................................................................................................................ 9-16

9.4 Registering and Loading Character Strings ................................................................... 9-17

9.5 Locking Keys .................................................................................................................. 9-18

9.6 Other Settings ................................................................................................................ 9-20

9.7 Displaying System Information ....................................................................................... 9-25

Chapter 10 Maintenance

10.1 Updating the Firmware ................................................................................................... 10-1

10.2 Mechanical Inspection .................................................................................................... 10-4

10.3 Operational Inspection ................................................................................................... 10-5

10.4 Inspection of Wavelength Accuracy ................................................................................ 10-6

10.5 Inspection of Level Accuracy .......................................................................................... 10-7

10.6 Replacing Fuses ............................................................................................................. 10-8

10.7 Daily Maintenance .......................................................................................................... 10-9

10.8 Care during Storage ......................................................................................................10-11

10.9 Recommended Replacement Parts ............................................................................. 10-12

10.10 Warning Display Function ............................................................................................. 10-13

Chapter 11 Specications

11.1 Specications ..................................................................................................................11-1

11.2 External Dimensions .......................................................................................................11-4

1

2

3

4

5

6

7

Appendix

Index

Appendix 1 GRID Table for WDM Wevelength ....................................................................... App-1

Appendix 2 Data Calculation Algorithms for Spectrum Widths ............................................... App-2

Appendix 3 Details of Each Analytical Functions ................................................................. App-11

Appendix 4 Detailed Explanations of WDM Analysis Function ............................................. App-19

Appendix 5 Details of Optical Amplifier Analysis Function ...................................................App-30

Appendix 6 Details of Optical Filter Analysis Function ......................................................... App-33

Appendix 7 Soft Key Tree Diagram ...................................................................................... App-50

Appendix 8 END USER LICENSE AGREEMENT ................................................................ App-69

8

9

10

11

App

Index

IM AQ6370C-01EN

vii

Page 10

3 4

9 10

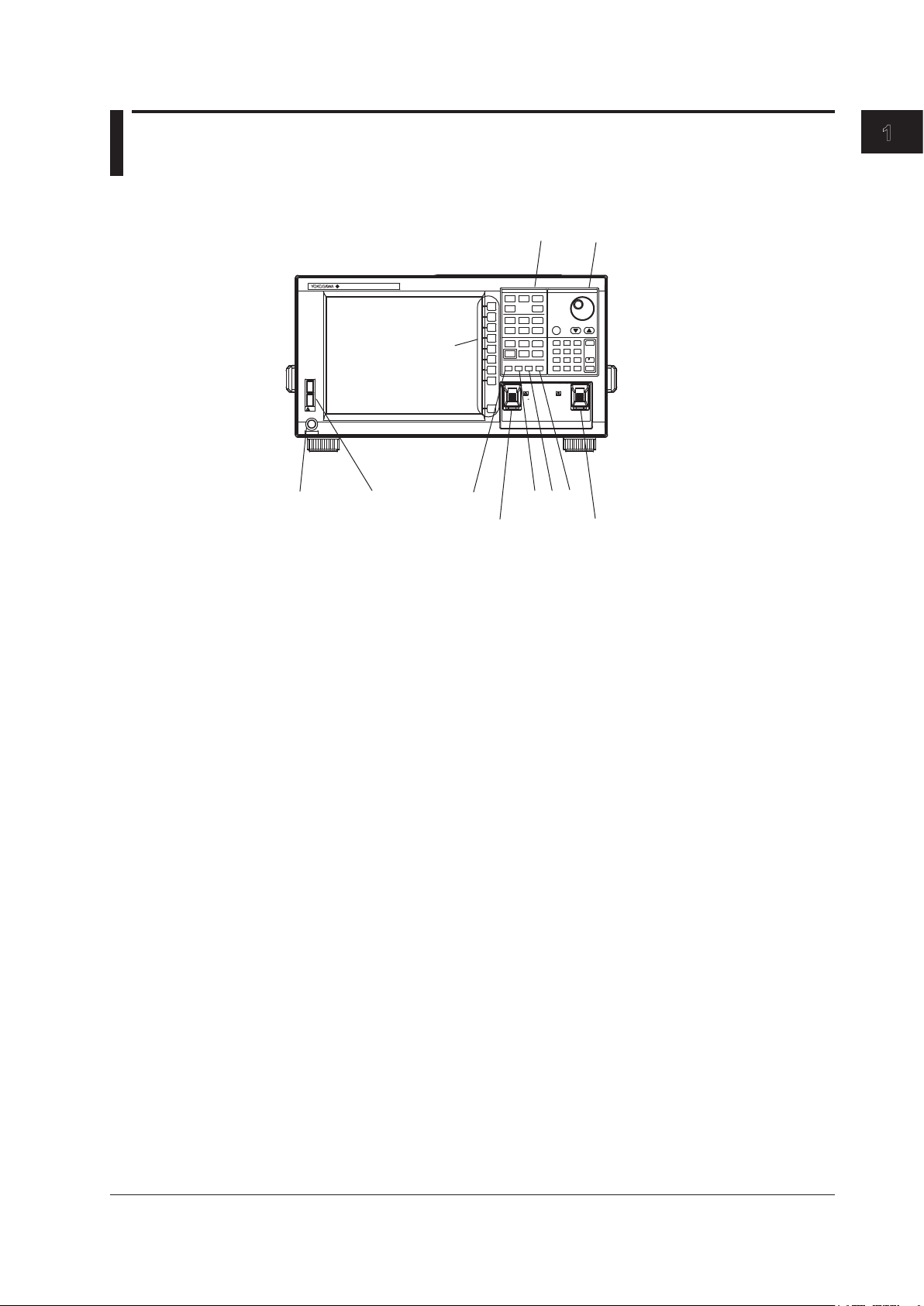

Chapter 1 Part Names and Functions

1.1 Front Panel

Front Panel

USB

POWER

5 6 7 8

No. Name Function

1 LCD display Displays measured waveform, measurement conditions,

2 Soft key section Used to execute the functions assigned to the soft keys on

3 FUNCTION section Used to enter settings pertaining to all measurements

4 DATA ENTRY section Used for measurement condition parameter input, label

5 POWER Used to start and shut down the instrument.

6 USB interface Used to connect USB storage media

7 UNDO/LOCAL See the following table(1.3 Panel keys and Knobs)

8 HELP Used to check the contents of the soft key menu displayed

9 OPTICAL INPUT Optical input connector

10 CALIBRATION OUTPUT Reference light source optical output connector used for

11 COPY Save the screen as an image file.

12 PRESET Clears all internal settings of the AQ6370D except for the

AQ6370D

OPTICAL SPECTRUM ANALYZER

1 2

DATA ENTRY

FUNCTION

SPAN

LEVEL

CENTER

SWEEP

ZOOM

DISPLAY

SETUP

TRACE

PEAK

COARSE

ANALYSIS

MARKER

SEARCH

USER

FILE

MEMORY

ADVANCE

PROGRAM

SYSTEM

OREMOTE

UNDO/

PRESET

HELP

COPY

LOCAL

OPTICAL INPUT

(

)

600 1700nm

7

8

5

4

1 2 3

.

0

CALIBRATION

OUTPUT

BACK

9

SPASE

6

m/

ENTER

nm/

-

ENTER

11 12

measurement values, etc.

the right side of the LCD display

(sweep, measurement conditions, data analysis, and

various functions)

input, etc.

on the screen.

alignment adjustments and wavelength calibration (when

the built-in light source specification is -L1)

remote interface (ETHERNET, GP-IB, and RS232) settings.

1

Part Names and Functions

IM AQ6370D-01EN

1-1

Page 11

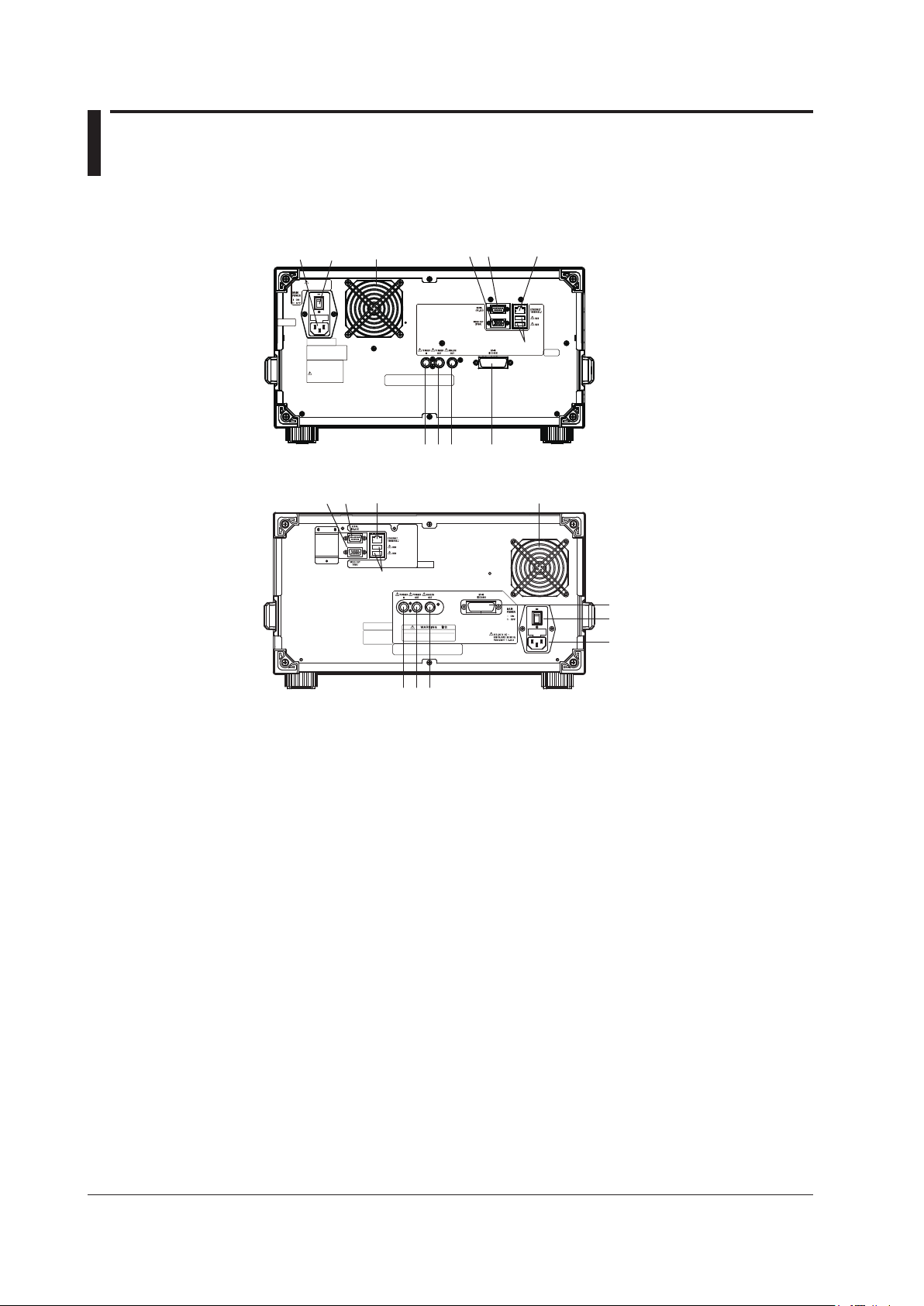

1.2 Rear Panel

2

3

4

5

6

AQ6370D-02, A6370D-12, A6370D-22

Rear Panel

11

56

7 8

3 4

2

1

AQ6370D-01, A6370D-10, A6370D-20

7

8 9

10

9

10

11

1

No. Name Function

1 GP-IB GP-IB port for controlling this unit through an external

computer

2 TRIGGER IN Input connector for synchronous signals for the

synchronous measurement function with the Tunable Laser

Source

3 TRIGGER OUT Output connector for synchronous signals for the

synchronous measurement function with the Tunable Laser

Source

4 ANALOG OUT Analog output

5 MAIN POWER Used to turn the main power ON/OFF

6 Power cord connector Connect the power cord to this connector

7 VIDEO OUT (SVGA) Analog RGB video signal (SVGA-compliant) interface

8 SERIAL RS-232 interface

9 ETHERNET Ethernet Interface (10/100BASE-TX)

10 USB interface Used to connect USB storage media or USB mouse

11 Exhaust holes

1-2

IM AQ6370D-01EN

Page 12

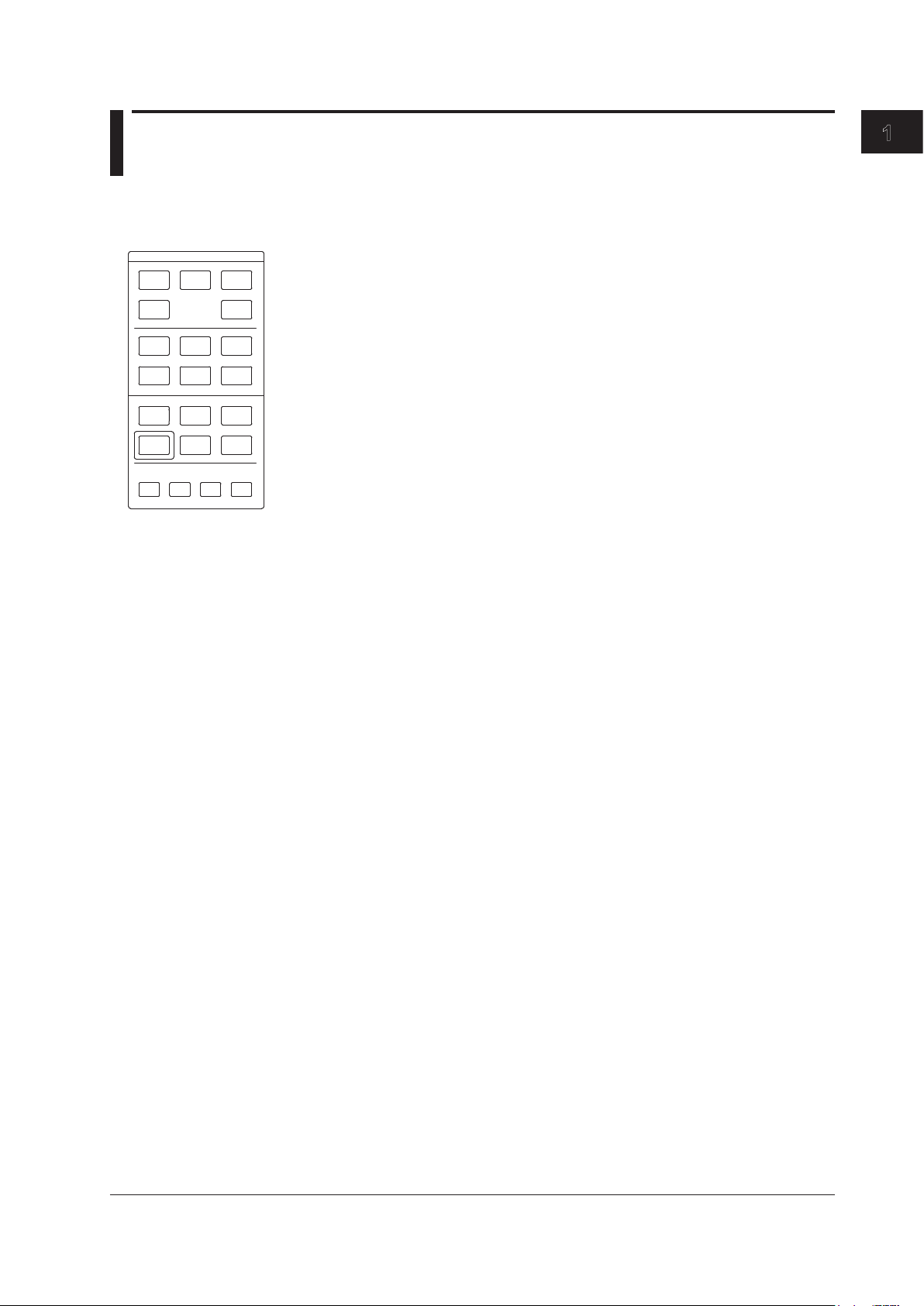

1.3 Panel Keys and Knobs

FUNCTION

FUNCTION Section

The FUNCTION section contains 17 function keys and 4 auxiliary keys. When you press

a function key, information about the function is displayed on the soft key menu located

CENTER

SWEEP

SETUP

MARKER

USER

PROGRAM

OREMOTE

UNDO/

LOCAL

SPAN

DISPLAY

PEAK

SEARCH

MEMORY

ADVANCE

HELP

COPY

LEVEL

ZOOM

TRACE

ANALYSIS

FILE

SYSTEM

PRESET

on the right side of the LCD display.

SWEEP

The SWEEP key contains functions related to sweeping. When you press the SWEEP

key, the soft key menu for sweeping appears.

CENTER

The CENTER key contains functions related to setting the center wavelength and center

frequency for measurements. The soft key functions change depending on whether the

screen display mode is wavelength display mode or frequency display mode.

SPAN

The SPAN key contains functions pertaining to settings for the wavelength span or

frequency span being measured. The soft key functions change according to whether the

screen display mode is wavelength display mode or frequency display mode.

1

Part Names and Functions

LEVEL

The LEVEL key contains functions related to level axis settings.When you press the

LEVEL key, the soft key menu for setting reference level appears.

SETUP

The SETUP key contains functions related to measurement condition settings.

ZOOM

The ZOOM key contains the zoom function, which allows the user to freely enlarge or

reduce a measured waveform in order to check a small area of the measured waveform,

or to check the overall waveform.

This key is used to set the waveform enlarged/reduced display conditions.

DISPLAY

The DISPLAY key contains functions related to screen display.This key is used to set the

screen to upper/lower 2-split display mode (split mode).

TRACE

The TRACE key contains functions related to trace mode settings.

MARKER

The MARKER key contains functions related to markers.

IM AQ6370D-01EN

PEAK SEARCH

The PEAK SEARCH key contains functions for searching for peaks and bottoms in

measured waveforms.

ANALYSIS

The ANALYSIS key contains functions related to measured waveform analysis.

1-3

Page 13

1.3 Panel keys and Knobs

MEMORY

The MEMORY key contains functions for writing the contents of the active trace to the

unit’s internal memory. When you press the MEMORY key, the traces and memory list

screen (soft key menu) are displayed. A memory number may be entered in the DATA

ENTRY section, or selected using the rotary knob or arrow keys.

FILE

The FILE key contains functions for saving and loading waveform data, program data,

and the like to and from USB storage media (USB memory/HDD).

PROGRAM

The PROGRAM key contains the soft keys related to program functions for controlling

measurements through a program.

SYSTEM

The SYSTEM key contains system-related functions such as monochromator adjusting

optical alignment, wavelength adjustment, hardware setup, and setting initialization.

ADVANCE

The ADVANCE key contains functions for setting reference data used to make

comparison judgments on measured data and for logging analysis data.

USER

Frequently used soft keys can be registered on the soft key menu in the USER key.

Registering frequently used soft keys in the USER key allows you to execute frequently

used functions in a small number of steps.

COPY

The COPY key is used to output the measurement screen to the internal printer or a file.

When you press the COPY key, the measured waveforms and lists displayed on the

screen are output to the internal printer or a file.

PRESET

The PRESET key clears all internal settings of the AQ6370D except for the remote

interface (ETHERNET, GP-IB, and RS232) settings.

UNDO/LOCAL

The key’s function changes depending on the status of the instrument when the UNDO/

LOCAL key is pressed. The following table shows the key’s functions.

Status of Instrument Function

UNDO action is allowed If the UNDO key is pressed after changing parameter settings,

changing or deleting data, etc., the previous action (change,

deletion, etc.) is canceled and the state preceding that action

is restored.

During user key registration If the UNDO key is pressed during user key registration,

registration mode is canceled and the soft key menu which

appeared when the SYSTEM key was pressed is displayed

again.

During remote control by external

PC (Remote light is on)

Changes the state from the remote state back to the local

state. The remote light turns off.

HELP

When you press the HELP key, a soft key menu of the currently displayed screen is

displayed explanations.

Soft keys for selecting the “MORE INFO” which indicate additional information are

displayed by some soft keys in HELP screen.

1-4

IM AQ6370D-01EN

Page 14

1.3 Panel keys and Knobs

DATA ENTRY

DATA ENTRY Section

This unit allows you to enter measurement conditions and various other parameters

through the DATA ENTRY section. Three different entry methods can be used in the

DATA ENTRY section, the rotary knob, the arrow keys, and the numeric keypad.

Rotary knob

When you press a soft key which has a parameter, the current setting is displayed in

the parameter entry window. Turning the rotary knob raises or lowers the numeric value

COARSE

7

4

1

0

9

8

5

6

3

2

.

-

shown in the parameter entry window (turn clockwise to increase and counterclockwise

to decrease), and the internal setting changes at the same time.

Note that if the COARSE key is on (lamp on), the numeric value increase/decrease step

BACK

SPASE

will be larger.

m/

ENTER

Arrow keys (▲, ▼)

nm/

ENTER

Pressing the ▲ key has the same effect as turning the rotary knob clockwise. Likewise,

pressing the ▼ key has the same effect as turning the rotary knob counterclockwise.

Holding an arrow key down for 0.5 second or longer activates auto-repeat.

If the multi-marker function has been selected, the arrow keys can be used to scroll the

marker value display in the data area.

COARSE Key

You can raise the digit of settings being entered or the increase/decrease step for

numerical values.

Each time you press this key the setting toggles between ON and OFF. When ON, the

lamp lights.

1

Part Names and Functions

Numeric keypad

You can enter numerical values directly into the parameter input window by pressing

keys of the numeric keypad.

After you have pressed a parameter soft key to display the current setting in the

parameter display area, you can press a numeric keypad key to display the numeric

keypad input area including the entered numeric value.

If the value entered with the numeric keypad is not in the allowed value range, the

nearest allowed value will be set.

μm/ENTER Key and nm/ENTER Key

Enters values input using the numeric keypad or the parameter input window.

Use one or the other key if entering a parameter value with a particular unit.

If a parameter does not have a unit associated with it, you can use either the μm/ENTER

key or the nm/ENTER key.

BACK SPACE Key

Use this key if you make an error when inputting values with the numeric keypad. The

last entered (right-most) character is removed, allowing entry of the correct character.

By holding the BACK SPACE key down, you can erase the entire entry in the numeric

keypad input area and make the numeric keypad input area disappear, returning it to the

condition preceding numeric keypad input.

IM AQ6370D-01EN

1-5

Page 15

1.4 LCD Screen

1

2

3

4

5

6

7 8 9 10

11 12

13

14 15

16

17

19

20

23

18

21

22

No. Function

1 Data area

2 Measurement conditions area

3

4 Displays level axis scale per DIV

5

6 Displays reference level

7 Label area (56 characters)

8 Displays wavelength resolution

9 Displays measurement sensitivity

10 Displays averaging times

11 Displays the number of measurement samples

12 Displays date and time

13 Displays each trace status

14

15 Displays the statuses of main settings

16 Displays wavelength axis scale per DIV

17 Displays sweep status

(Displayed when any of the measurement conditions are changed.)

(Displayed when measurement is not correctly carried out.)

(Only displayed when ZOOM function is used)

(When a setting is ON, its display is depressed, or is displayed with white on black

background if the display colors are black and white.)

(RPT=Repeat; SGL=Single; STP=Stop)

1-6

IM AQ6370D-01EN

Page 16

1.4 LCD Screen

No. Function

18 Displays soft key menu

(Displays markers and data analysis results.)

19 Parameter display area

20 Parameter input area

21 OVERVIEW display screen

(Only displayed when ZOOM function is used.)

22 Displays sub-scale

23 This appears when a resolution calibration has been performed.

1

Part Names and Functions

IM AQ6370D-01EN

1-7

Page 17

1

Chapter 2 Functions

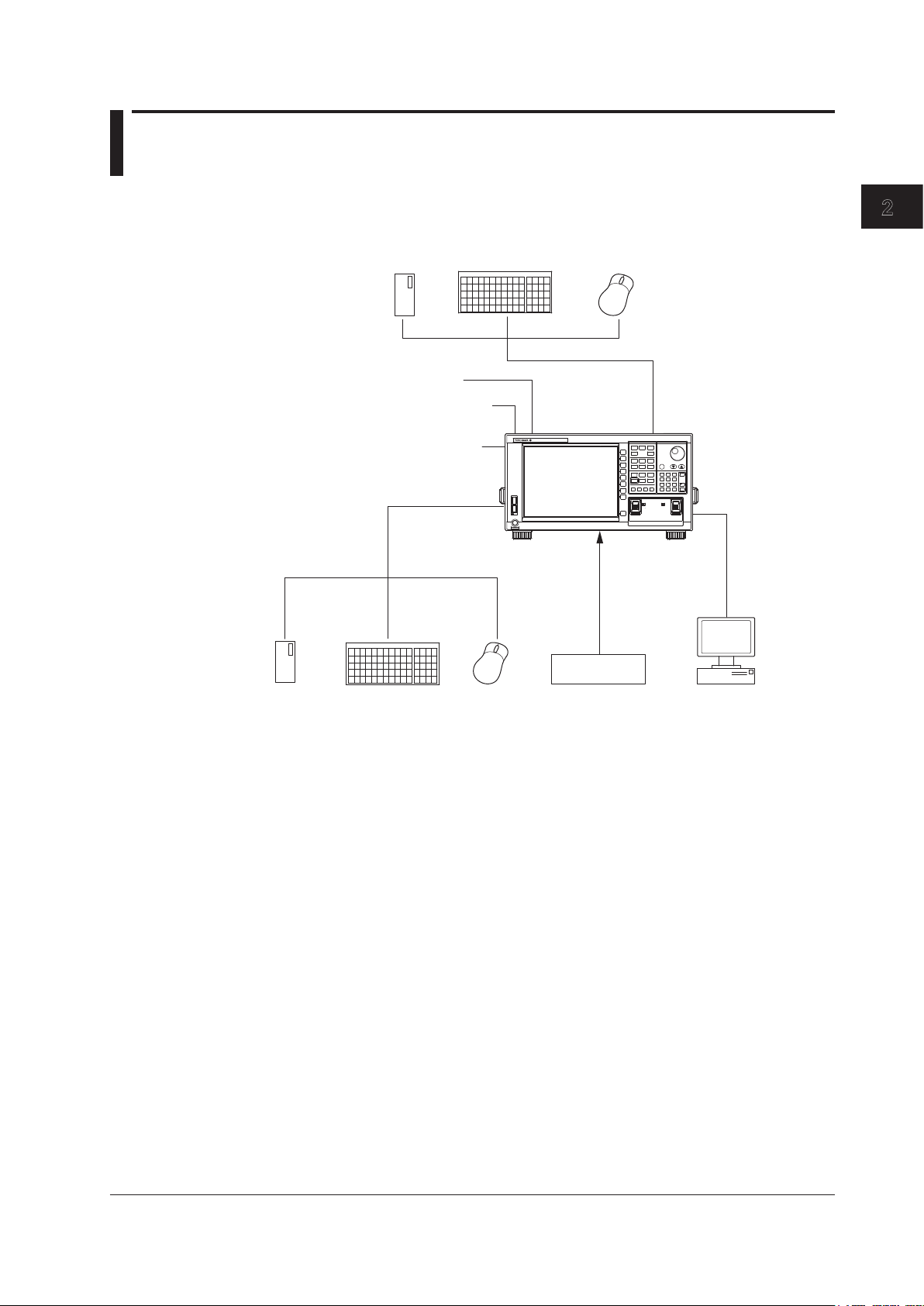

Ethernet interface

USB storage

medium

USB storage

2.1 System Structure

System Structure

medium

USB keyboard

Analog output

External trigger input

Video signal output

trigger output

2

Functions

USB mouse

OPTICAL SPECTRUM ANALYZER

AQ6370

USB

POWER

DATA ENTRY

FUNCTION

SPAN

LEVEL

CENTER

SWEEP

ZOOM

DISPLAY

SETUP

TRACE

PEAK

COARSE

ANALYSIS

MARKER

SEARCH

BACK

9

7

8

USER

FILE

SPASE

MEMORY

5

4

6

ADVANCE

PROGRAM

SYSTEM

m/

1 2 3

OREMOTE

UNDO/

LOCAL

ENTER

nm/

.

FEED

-

HELP

0

COPY

ENTER

OPTICAL INPUT

CALIBRATION

(

)

600 1700nm

OUTPUT

GP-IB interface

RS-232 interface

USB 101 keyboard

USB mouse

Control target

PC

IM AQ6370D-01EN

2-1

Page 18

2.2 Measurement

Alignment Adjustment <<See section 3.6 for the operating procedure>>

This function allows adjustment of the optical axis of the instrument’s built-in

monochromator (spectroscope).

The instrument’s optical performance is not guaranteed until the alignment adjustment

function has been executed. Failure to perform this adjustment can result in distortion

of measured waveforms. After alignment adjustment has been executed, wavelength

calibration is also subsequently performed automatically. If you are using the instrument

for the first time or using it after it has been severely shaken while being moved, perform

the alignment adjustment procedure after warm-up ends.

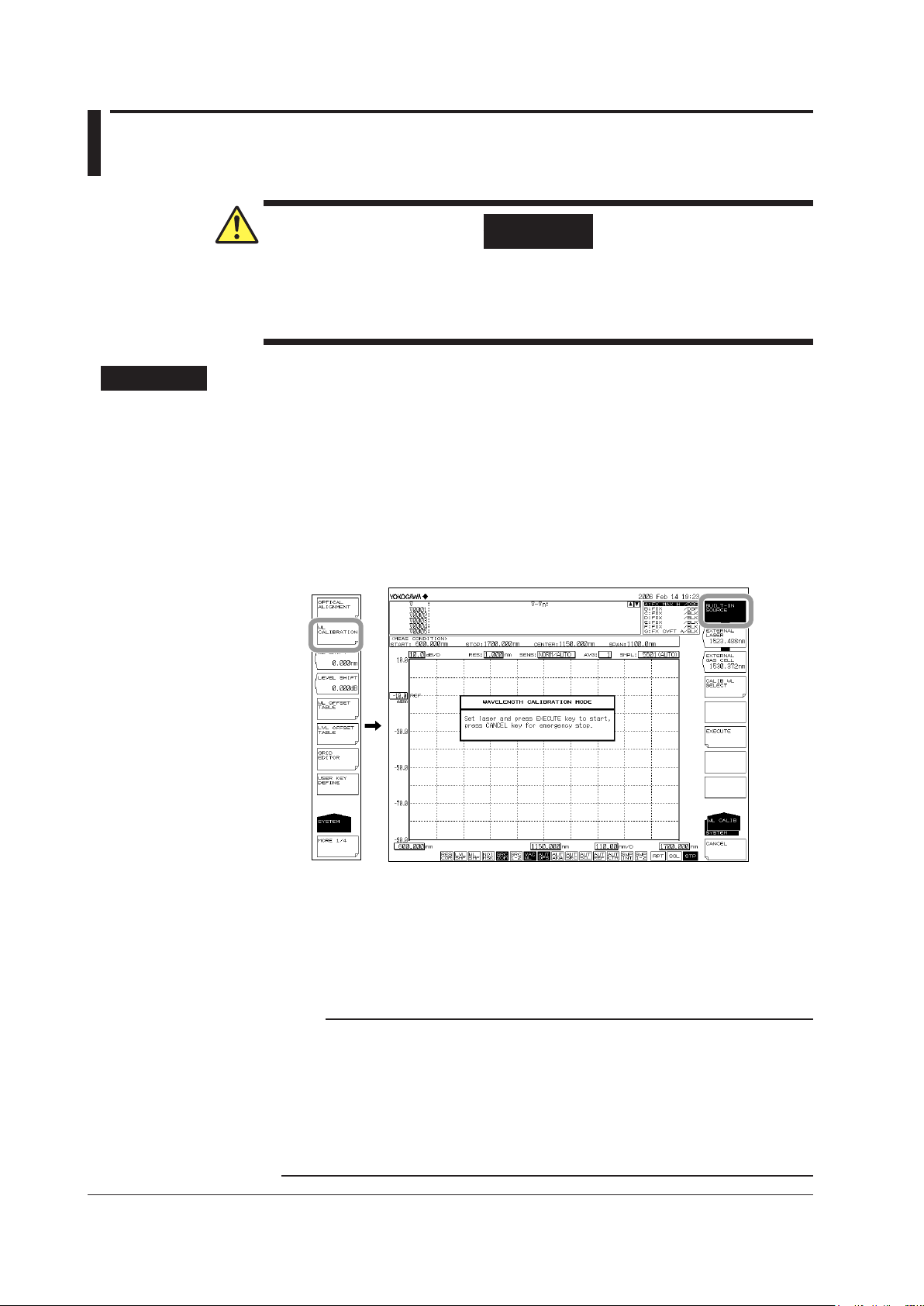

Wavelength Calibration <<See section 3.7 for the operating procedure>>

Wavelength calibration can be performed using the internal reference light source (when

the built-in light source specification is -L1) or an external light source.

Resolution Calibration <<See section 3.8 for the operating procedure>>

Typically the filter response of an optical spectrum analyzer is not rectangular, and

thus the resolution bandwidth differs slightly from the equivalent noise bandwidth. This

difference becomes prominent especially when the wavelength resolution is high (e.g.,

0.05 nm or less). The resolution calibration function measures the equivalent noise

bandwidth at each resolution setting and internally sets the resolution bandwidth to the

result. The resolution bandwidth appears in parentheses in each of the resolution soft

keys on the resolution screen. The resolution bandwidth accuracy affects the results of

noise measurements and the results of optical power measurements of wideband light

sources. In detail, the resolution bandwidth is used when the following analysis and

computation functions are executed. For details, see pages 3-25 and 3-26.

• WDM analysis

• EDFA-NF (optical amp gain, NF measurement)

• Power analysis

• OSNR and total power of DFB-LD analysis

• Total power of FP-LD analysis

• Total power of LED analysis

• Power density markers, Integrated power markers

Auto Measurement <<See section 5.1 for the operating procedure>>

This function automatically sets the optimal measuring conditions for the input light and

displays the spectrum waveform. This function is useful when the characteristics of the

input light are not well known.

The wavelength range of input light that can be auto-measured is 1200–1670 nm.

The measurement conditions that are set automatically are as follows.

1. Span (SPAN)

2. Center wavelength (CENTER)

3. Reference level (REF LEVEL)

4. Resolution (RESOLUTION)

Other measuring conditions (sensitivity, averaging times, number of sampling points,

and interval settings) are set to their defaults. The horizontal and vertical axes of the

displayed spectrum waveform are zoomed to an appropriate degree.

Single Sweep <<See section 5.13 for the operating procedure>>

This function executes a single sweep or forcibly stops a sweep operation.

2-2

IM AQ6370D-01EN

Page 19

1

Repeat Sweep <<See section 5.13 for the operating procedure>>

This function performs repeat sweeping or forcibly stops a sweep operation. It enables

repeated, real-time measurement of waveforms.

2.2 Measurement

Sweeping between Markers << See section 5.14 for the operating procedure >>

This function enables sweeping between two specified waveform line markers. You can

sweep any desired area on screen.

Segment Measurement <<See section 5.13 for the operating procedure>>

This function allows you to divide up items to be measured in units of previously specified

segments.

Allows measurement delimited by segments (portions).

Smoothing << See section 5.18 for the operating procedure >>

This function attenuates the noise in the measured waveform. By using the Smoothing

function, areas on the waveform with a large amount of noise can be “smoothed out”

when measured.

One-Action Keys <<See sections 5.4 to 5.6 for the operating procedure>>

This is the general name for a key that uses data from the active trace waveform (the

currently displayed waveform) to set measurement conditions.

Setting conditions requires that a waveform is displayed for the active trace.

One-Action Key Name Description

PEAK → REF LEVEL Sets the peak level of the measured waveform of the active trace as

the reference level.

MARKER→ REF LEVEL Sets the moving marker level as the reference level.

PEAK→CENTER Sets the peak wavelength or the peak frequency of the active trace

measurement waveform to center wavelength or center frequency.

MEAN WL→CENTER Sets THRESH 3 dB center wavelength or center frequency of the

active trace measured waveform to center wavelength or center

frequency.

VIEW→MEAS Sets the currently displayed ZOOM scale as the measurement scale

(CENTER, START, STOP, SPAN) for the next sweep.

MARKER →CENTER Sets the wavelength of the moving marker to center wavelength or

center frequency.

Δλ→SPAN Sets the sweep width as six times the RMS 20 dB width of the

active trace measurement waveform.

MKR L1-L2 →SPAN Sets spacing between line markers 1 and 2 for sweep width.

PEAK→ZOOM CTR Sets the peak wavelength of the active trace measurement

waveform to center wavelength or center frequency of zoom display.

MARKER →ZOOM CTR Sets the wavelength of the moving marker to center wavelength or

center frequency of zoom display.

MKR L1-L2 →ZOOM SPAN Sets spacing between line markers 1 and 2 for sweep width of zoom

display.

2

Functions

IM AQ6370D-01EN

2-3

Page 20

2.2 Measurement

Switching between Vacuum Wavelength and Air Wavelength

<<See section 5.2 for the operating procedure>>

This function switches the measured wavelength to either a vacuum wavelength or an air

wavelength.

Measurement can be performed in either air or vacuum wavelength mode.

Switching between Wavelength and Frequency

<<See section 5.2 for the operating procedure>>

This function switches the horizontal axis display to wavelength or frequency.

You can display either the wavelengths or frequencies of marker values and analysis

results.

Averaging <<See section 5.11 for the operating procedure>>

This function performs multiple measurements and displays the average values.

The function is used in cases such as: when the light source’s level is fluctuating; when

measuring a modulated signal of several kHz or less; when the waveform is disrupted

and difficult to measure; when it is necessary to obtain even higher measurement

sensitivity.

Power Density Display <<See section 7.4 for the operating procedure>>

The power per 1 nm is called the power density.

The level axis of the AQ6370D indicates the absolute power per wavelength resolution.

For example, if the resolution is set to 0.1 nm, the power per 0.1 nm will be displayed.

Since the optical spectrum of such devices as a gas laser or a laser diode is narrower

than the wavelength resolution of the instrument, the entire power is accommodated

within the band of a resolution. Therefore, the measured power (peak level) is equal

to the total power of the light source. This instrument has been calibrated to display

accurate power under such conditions.

On the other hand, natural light or lights such as fluorescent lamps or LEDs, have,

in many cases, optical spectrums wider than the wavelength resolution set for the

instrument. Therefore, if the instrument measures these lights, measured power will vary,

depending on the resolution setting.

In order to deal with this issue, the instrument is equipped with the dBm dBm/nm soft key

to allow the level axis displays to switch from the absolute power (dBm, mW, μW, nW,

pW) per resolution to power density (dBm/nm, mW/nm, μW/nm, nW/nm, pW/nm).

In the case of power density displays, a measured value is converted to power per 1 nm.

Therefore, whatever resolution is used for measurement, certain measured values will

always be available.

For information on the use of dBm and dBm/nm, see “Power Density Display” in section

5.2, “Horizontal/Vertical Axis Settings.”

The trace computation function can be used to display the power density in the specified

bandwidth within the range of 0.1 nm to 10 nm (see section 6.8).

Note

Specifications such as level accuracy, measurement level range, and level linearity of the

instrument are provided for the absolute power display.

2-4

IM AQ6370D-01EN

Page 21

1

2.2 Measurement

External Trigger Measurement <<See section 5.16 for the operating procedure>>

This function performs measurement in synchronization with an external trigger signal.

The SMPL TRG IN terminal is an input terminal on the TTL level and in positive/

negative logic (which can be set by the <EXT TRIGGER SETTING> key). The SMPL

TRG IN terminal is an input terminal for TTL level, positive/negative logic signals. The

measurement points (wavelength/frequency) are incremented each time edges of input

external trigger signals are detected. Thus, sweeping stops when a number of external

trigger signals equaling the specified number of sampling points is input. (However,

when the REPEAT sweep is performed, the sweep will be repeated until the STOP key is

pressed or until trigger signals are no longer input.)

The delay time (from the time when a trigger signal is detected until the time when the

sampling is performed) specific to the instrument is about 20 µs. Supply the trigger

signal at a timing appropriate for the measurement sensitivity. An optional delay time can

be set to this specific delay time. With the DELAY key of the EXT TRIGGER SETTING

key, the 0.0 µs to 1000.0 µs range can be set in units of 0.1 µs.

Note that after the measurement points are set, input trigger signals during the

movement to the next measurement point are ignored. The time varies depending on the

measurement wavelength band and the number of sampling points (sampling intervals).

Since the SMPL TRG IN terminal is pulled up internally, it can be set to the HIGH level

while it is in the open state and to the LOW level while it is in the GND short state.

2

Functions

Sweep Trigger <<See section 5.16 for the operating procedure>>

This function performs a single sweep measurement based on an externally input trigger

signal.

The instrument starts a single sweep measurement by allowing sweep trigger signals on

the TTL level and in negative logic to enter the TRGGER IN terminal at the back of the

instrument.

The signal logic of the sweep trigger input signals is fixed to negative logic, which cannot

be changed.

The pulse width of sweep trigger signals must be 5 ms or more.

The action when entering a sweep trigger is the same as that for the SWEEP key or

SINGLE key.

The sweep trigger function detects sweep trigger signals by polling in certain cycles.

Thus, the time after a sweep trigger signal is input until the sweep starts will fluctuate in

the range of 5 ms.

Trigger Output <<See section 5.17 for the operating procedure>>

This function outputs trigger signals from the trigger output terminal on the rear panel of

the instrument (only during sweeping).

IM AQ6370D-01EN

2-5

Page 22

2.2 Measurement

Analog Out <<See section 5.19 for the operating procedure>>

An analog voltage is output from the ANALOG OUT terminal on the rear panel of the

main unit according to the input light.

The temporal changes in the input light can be measured by an oscilloscope.

However, to enable this output, the sensitivity setting must be NORM/HOLD.

When set to NORM/HOLD, the RANGE is switched relative to the REF LEVEL without

implementing the AUTORANGE function. Therefore, if the level of the input light is high,

the output voltage level is saturated.

The saturation level and noise level varies depending on the REF level.

The table below shows the relationship between the REF level and the saturation level.

REF LEVEL(dBm or dBm/nm) Saturation Level * (dBm)

REF > 0 23 dBm or more

0 < = REF > -10 13 dBm or more

-10 < = REF > -20 3 dBm or more

-20 < = REF > -30 -7 dBm or more

-30 < = REF -17 dBm or more

* At wavelength 1450 to 1620 nm

ANALOG OUT Output Specifications

Output saturation voltage +6 V or more, +8 V or less

Bandwidth 10 kHz or more

Load 1 kΩ or more

Correcting the Wavelength Resolution

<<See section 5.7 for the operating procedure>>

Since the wavelength resolution function is set according to the monochromator slit

width, the setting resolution and actual resolution may not match. If the resolution is set

to 0.1 nm, the actual resolution will be 0.09 nm for a 1450 nm wavelength, and 0.07 nm

for a 1550 nm wavelength.

If the Resolution Correction function is turned ON, measured data is processed by the

software so that it matches the set resolution.

In the following cases, the resolution correction function has no effect even when turned

ON.

• When the set resolution is 0.02 nm

• When the measured wavelength is 1400 nm or less

Turn OFF the resolution correction function when performing measurement for which the

level accuracy is guaranteed.

2-6

IM AQ6370D-01EN

Page 23

1

2.3 Waveform Display

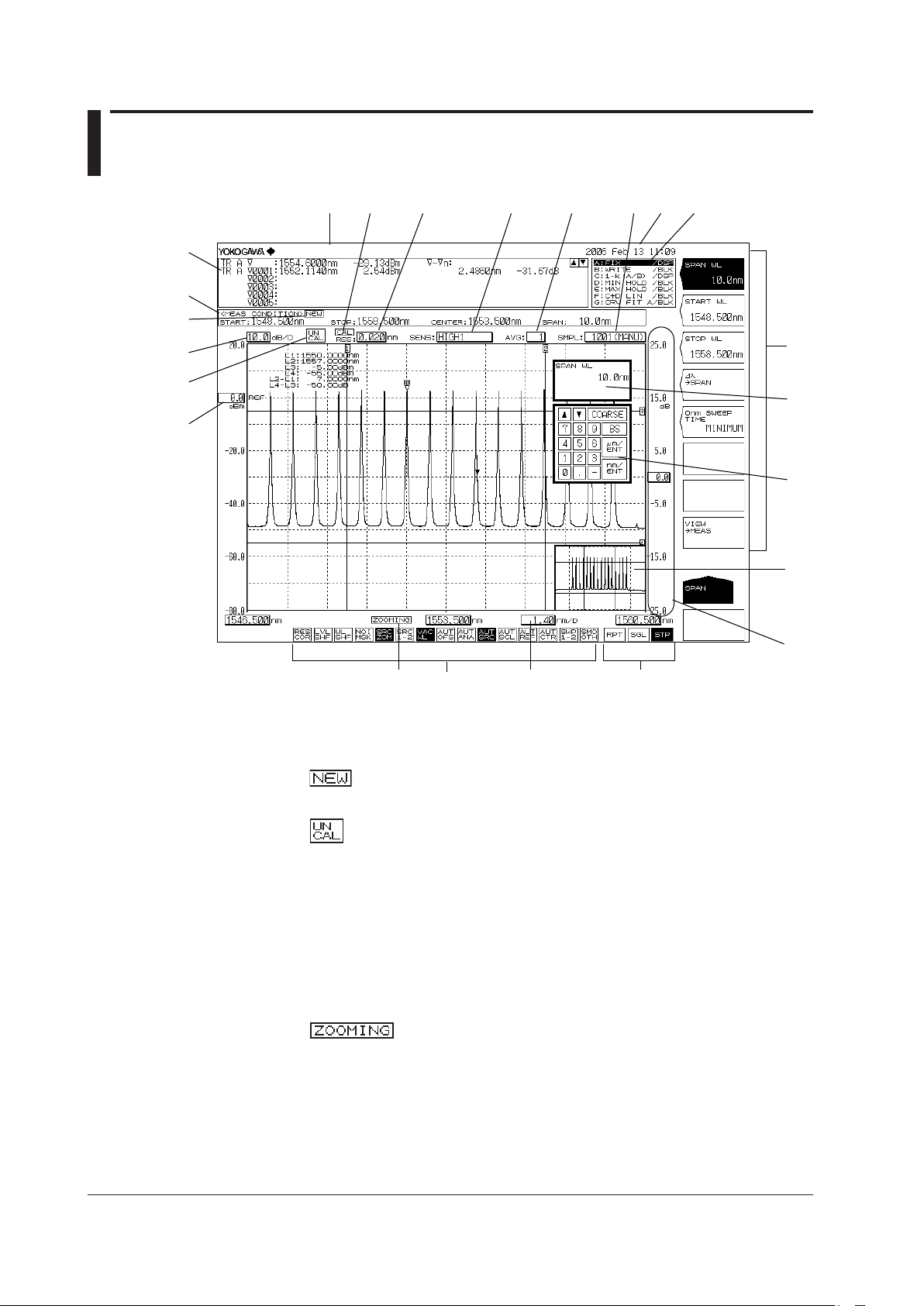

Zoom <<See section 6.1 for the operating procedure>>

This function allows you to zoom freely in and out on measured waveforms.

You can easily zoom an area simply by selecting it with the mouse. Drag the mouse over

an area of the displayed waveform to zoom in on the area. ZOOMING is displayed at the

bottom of the screen to indicate that the screen is displaying a zoomed area. You can

also zoom in and out with key operations.

Overview <<See section 6.1 for the operating procedure>>

This function displays an overview window at the very bottom of the waveform display

area. The overview window is displayed when the waveform display is enlarged or

reduced using the zoom function. (Only displayed when a zoom is performed.)

You can easily check which part of the measured waveform is zoomed. The overview

window can be shown or hidden, and you can change its position and size.

Trace <<See section 5.12 for the operating procedure>>

A trace shows a waveform and measurement conditions. The instrument has a total of

seven independent traces (A through G). Multiple traces can be displayed at the same

time on the waveform screen. In addition, display ON/OFF and mode settings can be set

separately for each trace.

Traces can be set to the following modes.

• WRITE mode Section 6.2

• FIX mode Section 6.2

• MAX/MIN HOLD mode Section 6.3

• ROLL AVG mode Section 6.4

• CALCULATE mode Section 6.5 to Section 6.9

The following explains each of the modes.

2

Functions

IM AQ6370D-01EN

WRITE Mode

Waveform data are written during sweeping.

When a trace is set to WRITE mode, waveform data are written during measurement,

and the data are updated. Traces used in measurements are normally set to WRITE

mode. The trace display at the side of the data area changes to “WRITE.”

FIX Mode

Fixes the data; does not write waveform data.

When a trace is set to FIX mode, its waveform data are not overwritten even when

measurement is performed. Therefore, the waveform on the screen is not overwritten. If

you want to fix the waveform data of a trace, set the trace to FIX mode. The trace display

at the side of the data area changes to “FIX.”

2-7

Page 24

2.3 Waveform Display

MAX/MIN HOLD Mode (Maximum/Minimum Value Detection Mode)

ROLL AVG Mode (Rolling Average Mode)

CALCULATE Mode (Calculation Results Display)

Writes the maximum/minimum values of the waveform data for each sweep.

When a trace is set to MAX/MIN HOLD mode, each time a sweep is performed, the data

at the individual measurement points are compared with prior measurements, and the

measurement with the higher level (MAX HOLD) or lower level (MIN HOLD) is written.

If you want to measure the maximum or minimum value of a waveform which changes

each time a sweep is performed, set the trace you want to measure to MAX/MIN HOLD

mode and perform REPEAT sweeping.

The trace display at the side of the data area appears as “MAX HOLD” or “MIN HOLD”.

Note that the NOISE MASK soft key setting applies when a waveform is displayed, and

is not affected when a maximum or minimum value is detected.

Writes the rolling average values of the waveform data during each sweep.

When a trace is set to ROLL AVG mode, each time measurement is performed the rolling

average of the current measurement and past measurements is calculated, and the

measurement data are updated. The number of averagings is set in the range of 2 to

100. The trace display at the side of the data area changes to “ROLL AVG”.

Writes the results of calculations performed between data from different traces.

When a trace is set to CALCULATE mode, subtraction between data from different

traces, normalized display, power display per specified bandwidth, or curve-fit display

is performed according to the set CALCULATE mode. Note that CALCULATE mode

can only be set for traces C, F, and G. Also, the available calculations vary from trace to

trace. For more information, see chapter 6.

Normalized Display Function <<See section 6.6 for the operating procedure>>

This function is one of the trace CALCULATE modes. It normalizes and displays the

trace data.

With normalized display, normalization is performed and the waveform is displayed with

the waveform peak set to 1 if the sub-scale is linear, or set to 0 dB if the sub-scale is

LOG. One trace can be normalized, either trace A, B, or C. If both traces selected for

calculation are set to “BLANK”, then the sub-scale is displayed on the left side of the

screen. Otherwise it is displayed on the right side. The calculation results are displayed

in the sub-scale. The trace display at the side of the data area changes to “NORM @”.

Curve Fit <<See section 6.7 for the operating procedure>>

Makes an approximation of the specified trace waveform. The result is written to TRACE G.

Calculations are applied to data from the peak to the threshold value. The threshold

value is set in the range of 0 to 99 dB (steps of 1). The trace display at the side of the

data area changes to “CRV FIT @.”

Peak Curve Fit <<See section 6.7 for the operating procedure>>

Makes an approximation of the specified trace waveform. The result is written to TRACE G.

Calculations are applied to mode peaks at or above the threshold value. The threshold

value is set in the range of 0 to 99 dB (steps of 1). The trace display at the side of the

data area changes to “PKCVFIT @”.

2-8

IM AQ6370D-01EN

Page 25

1

2.3 Waveform Display

Power Density Trace <<See section 6.8 for the operating procedure>>

Computes the power density in the specified bandwidth and writes the results in Trace F.

The target trace is a single trace selected from Traces A to E.

You can set the bandwidth in the range from 0.1 nm to 10 nm in 0.1 nm steps. The trace

display at the side of the data area shows "PWR/NBW @".

Marker Functions <<See section 6.9 for the operating procedure>>

Marker functions can be used to easily measure wavelength differences and level

differences, and to search for peak wavelengths, peak levels, and spectrum widths.

There are markers, line markers, and advanced markers.

Markers

A total of 1025 markers (one moving marker and 1024 fixed markers) are provided.

Moving markers can be moved to an arbitrary wavelength using the rotary knob, arrow

keys, or numeric key pad. You can also drag the markers with the mouse. Moving

markers can be moved over a waveform to display the marker values (wavelength

and level value) in the data area. If a moving marker is fixed in an arbitrary position, it

changes to a fixed marker.

Fixed markers are markers fixed to a number on which the moving marker was set. Fixed

markers are assigned marker numbers in order starting from 001. You can enter an

arbitrary number using the rotary knob, arrow keys, or numeric key pad. A number up to

1024 can be set. When multiple fixed markers are set, it is possible to display wavelength

differences and level differences between a given marker and adjacent markers.

2

Functions

Line Markers

There are four line markers––two wavelength line markers and two level line markers.

Wavelength line markers show wavelength and wavelength difference, and level line

markers show level values and level difference. Also, you can use line markers to specify

a sweep or analysis range.

Advanced Markers

There are four advanced markers.

There are three types of advanced markers: moving marker, power density marker, and

integrated power marker. Advanced markers can be placed on any of the waveforms

from trace A to G.

Each marker can be moved to an arbitrary wavelength using the rotary knob, arrow keys,

or numeric keypad.

You can also drag the markers with the mouse.

Moreover, you can use the search function to move the marker to the peak of the target

waveform.

Advanced markers measure the following values.

• Moving markers

Moving markers move along the waveform and show marker values (wavelength and

level) in the data area.

They are the same as the moving markers described above, except they do not have

the fixed marker function.

IM AQ6370D-01EN

• Power density markers

Power density markers move along the waveform and show marker values (power

values per normalization bandwidth) in the data area.

• Integrated power markers

Integrated power markers move along the waveform and show marker values

(integrated power value over the specified wavelength range) in the data area.

2-9

Page 26

2.3 Waveform Display

Single Search

• PEAK SEARCH

A peak search (a search for the maximum value) is performed on the marker trace

waveform.

An advanced marker is displayed at the peak point, and the marker value is displayed

in the data area.

If the peak level is off the screen, its marker is displayed at the top or bottom edge of

the screen. Even in this situation, the correct marker value is displayed.

After the measurement has been completed, you can use the rotary knob to move

the moving marker.

You can use the arrow keys to scroll through the data area.

• BOTTOM SEARCH

A bottom search (a search for the minimum value) is performed on the marker trace

waveform.

An advanced marker is displayed at the bottom point, and the marker value is

displayed in the data area.

If the bottom is off the screen, its marker is displayed at the top or bottom edge of the

screen. Even in this situation, the correct marker value is displayed.

After the measurement has been completed, you can use the rotary knob to move the

moving marker. You can use the arrow keys to scroll through the data area.

• NEXT LEVEL SEARCH

On the marker trace waveform, the advanced marker at the peak or bottom is set to

the next peak (local maximum value) or bottom (local minimum value).

If such peak or bottom is not found, a warning appears.

WARNING 103: No data in active trace

• NEXT SEARCH RIGHT

On the marker trace waveform, the advanced marker at the peak or bottom is set to

the peak (local maximum value) or bottom (local minimum value) on its right.

If such peak or bottom is not found, a warning appears.

WARNING 103: No data in active trace

• NEXT SEARCH LEFT

On the marker trace waveform, the advanced marker at the peak or bottom is set to

the peak (local maximum value) or bottom (local minimum value) on its left.

If such peak or bottom is not found, a warning appears.

WARNING 103: No data in active trace

Displaying Wavelength Difference and Level Difference

This function places a fixed marker and measures the wavelength difference and level

difference compared to a moving marker.

Note

For details, see the explanation in section 6.9, “Displaying Markers.”

Displaying Line Markers

When line markers are displayed, the marker values are shown in the upper left part of

the waveform area.

When both wavelength line markers 1 and 2 are displayed, or both level line markers

3 and 4 are displayed, the wavelength difference (L2-L1) or level difference (L4-L3) is

shown below the marker values.

2-10

Note

For details, see the explanation in section 6.9, “Displaying Markers.”

IM AQ6370D-01EN

Page 27

1

2.3 Waveform Display

Split Display <<See section 6.10 for the operating procedure>>

You can split the screen into an upper and lower display (SPLIT mode).

You can assign trace waveforms to either the upper or lower split.

TRACE A UP/LOW

This function is used to set whether to put trace A on top or on bottom during upper/lower

split display. If you select UP, it is assigned to the top. (Default) If you select LOW, it is

assigned to the bottom.

Noise Mask <<See section 6.11 for the operating procedure>>

This key is used to display a waveform so that parts of the waveform at or below the

set value are masked. In addition, when a noise mask value is set, the waveform is

overwritten in real time.

When you press the NOISE MASK soft key, the current noise mask value is displayed in

the noise mask value setting screen. The allowed settings for the noise mask setting are

OFF (-210 dBm), and the range from -100 to 0 dBm (fine: in steps of 1; coarse: in steps

of 10).

Peak/Bottom Search <<See sections 6.13 and 6.14 for the operating procedure>>

The peak/bottom search function has two search modes: single, in which a single peak

or a single bottom of the measured waveform’s level are detected, and multi, in which

multiple peaks and bottoms are detected in a single search. Markers are displayed at the

peak and bottom points. You can also detect the next level peak or bottom.

There is also an auto search function that automatically performs peak/bottom searches

during each sweep. This is useful when you want to observe the changes to the peak

and bottom levels during repeat sweeping.

2

Functions

IM AQ6370D-01EN

2-11

Page 28

2.4 Analysis

Spectrum Width Analysis <<See section 7.1 for the operating procedure>>

You can display the spectrum width and center wavelength using the following four types

of calculation.

• THRESH method

• ENVELOPE method

• RMS method

• PEAK RMS method

<See appendix 2, “Spectrum Width Data Calculation Algorithms” for a description of the

spectrum width analysis algorithms and parameters.>

Notch Width Measurement <<See section 7.2 for the operating procedure>>

With notch width measurement, it is possible to measure pass band width / notch

width from the measured waveform of a filter with V-character type or U-character type

wavelength characteristics.

<For a description of the notch width analysis algorithm and parameters, see appendix 2,

“Data Calculation Algorithms for Spectrum Widths.”>

Device Analysis <<See sections 7.3 and 7.4 for the operating procedure>>

Light source parameters can be analyzed from the measured waveform of each light

source (DFB-LD, FP-LD, LED).

DFB-LD SMSR Measurement

The side-mode suppression ratio (SMSR) can be measured from the DFB-LD measured

waveform.

FP-LD and LED TOTAL POWER Measurement

Optical power can be measured by integrating the measured waveform level

measurements.

PMD Measurement <<See section 7.6 for the operating procedure>>

It is possible to measure the polarization mode dispersion (PMD) of a DUT (such as

an optical fiber) by using the instrument in combination with an analyzer, polarization

controller, polarizer, and an amplified spontaneous emission (ASE) light source, highoutput LED light source, or other wideband light source.

WDM Analysis <<See section 7.7 for the operating procedure>>

You can analyze WDM transmission signals. You can also measure OSNR of a DWDM

transmission system with 50 GHz spacing. Measurements of WDM signal wavelength,

level, wavelength interval, and OSNR can be made collectively on up to 1024 channels,

and the analysis results can be displayed in a data table.

Optical Amp Analysis <<See section 7.8 for the operating procedure>>

Measurement can be performed of the optical amp gain and noise figure from measured

waveform of the signal light going into the optical amp, as well as the measured

waveform of the output light leaving the optical amp.

2-12

IM AQ6370D-01EN

Page 29

1

Optical Filter Characteristics Measurement

<<See section 7.9 for the operating procedure>>

Optical filter characteristics can be measured from the measured waveform of the light

input to the optical filter from the light source, as well as from the measured waveform

light output from the optical filter.

Analysis can be performed not only on optical filters with only one mode, but also multimode WDM filters.

Measurement of Level Fluctuations in Single-Wavelength Light

<<See section 7.11 for the operating procedure>>

This function is used to measure changes over time in the level of a specific wavelength

level. The sweep width is set to 0 nm, and measurement of the single-wavelength light is

taken. The horizontal axis is the time axes. It is useful for purposes such as optical axis

alignment when a light source is input to an optical fiber.

Template <<See section 7.12 for the operating procedure>>

The template function compares preset reference data (template data) with a measured

waveform. In addition, if a function for displaying the target spectrum (target line) on the

measurement screen is used, the target spectrum can be referenced while adjusting the

optical axis of an optical device.

2.4 Analysis

2

Functions

The following three templates are provided.

• Upper limit line

• Lower limit line

• Target line

Go/No Go Judgment <<See section 7.12 for the operating procedure>>

The Go/No Go test function compares the active trace waveform against reference data

(template data) preset by the user, and performs a test on the measured waveform (Go/

No Go test).

The template function can be used effectively in situations such as pass/fail tests on

production lines.

Analysis between Line Markers

<<See section 7.13 for the operating procedure>>

You can specify an analysis range with line markers. Analysis is performed in the range

outlined by the two line markers.

Analysis in the Zoom Area <<See section 7.13 for the operating procedure>>

You can specify the zoomed area as the analysis range.

For example, there is a zoom area power measurement function. This function calculates

totalized power between display scales. It is effective for purposes such as ASE

evaluation on optical amplifiers.

Analysis Data Logging <<See section 7.15 for the operating procedure>>

The analysis data logging function measures and records WDM analysis, DFB-LD

analysis, and peak data at regular intervals. The recorded data can be shown on the

screen in tables or graphs. In addition, the contents in tables can be saved to a file in

CSV format.

The following types of data are recorded for WDM analysis and peaks.

• WDM analysis: Wavelength, level, SNR (signal-to-noise ratio)

• Peak: Wavelength, level

IM AQ6370D-01EN

2-13

Page 30

2.5 Other

Using the USB Mouse <<See section 4.2 for the operating procedure>>

With a connected USB mouse you can perform the same operations as with the

instrument’s panel keys. Also, if you move the mouse pointer over the item in the menu

screen that you wish to select and click it, the instrument responds exactly as if you had

pressed the corresponding soft key.

The USB mouse is connected to the connector on the front panel of the instrument.

Registering Soft Keys <<See section 9.1 for the operating procedure>>

Frequently used soft keys can be registered in the soft key menu.

Registering soft keys reduces the steps needed to execute their functions. Twenty-four

soft keys can be registered. By default, all keys are unregistered.

Data Initialization <<See section 9.2 for the operating procedure>>

You can restore all settings to their factory defaults.

The parameter setting values and data of each function are initialized.

Help <<See section 9.3 for the operating procedure>>

Displays an explanation of the soft key menus.

Certain soft keys have additional help text (“MORE INFO”). MORE INFO contains

detailed explanations of the corresponding soft keys.

Locking Keys <<See section 9.5 for the operating procedure>>

This function locks key input temporarily to prevent users from operating the AQ6370D

through the keys. Even when the keys are locked, soft keys registered as USER keys

can be used for operation.

Remote (Separate Manual)

An external device can be connected to the instrument through the GP-IB port or another

port to remotely control the instrument. This function requires a special connector cable

for connecting with the external device. For details, see the separate user’s manual,

“Remote/Program Function.”

Program (Separate Manual)

The program function allows you to control an external instrument without using a PC.

The function uses Ethernet, RS-232, or GP-IB. For details, see the separate user’s

manual, “Remote/Program Function.”

2-14

IM AQ6370D-01EN

Page 31

1

2

Chapter 3 Preparing for Measurement

3.1 Installing the Instrument

WARNING

• This instrument is designed to be used indoors. Do not install or use it outdoors.

• Install the instrument so that you can immediately remove the power cord if an

abnormal or dangerous condition occurs.

• The instrument has a built-in reference light source for wavelength calibration,

and infrared light is always being output from the optical output connector. Never

look into the optical output connector. Infrared light entering the eyes can cause

severe injury and loss of vision.

CAUTION

Do Not Apply Shock to the Instrument

Non-horizontal orientation, and do not drop the instrument from a height of 2 cm

or more. This can adversely affect the accuracy of the internal monochromator

and inhibit performance. Take great care when transporting the instrument, and

use packaging with a shock absorbing capacity that is greater than or equal to the

packaging used upon shipment from the factory.

Never use inferior packaging materials that are unable to sufficiently absorb

vibrations and shocks occurring during transport. This can adversely affect the

accuracy of the internal monochromator and inhibit performance.

3

Preparing for Measurement

When unpacking

When the instrument is packaged in a box and moved, prevent condensation by

allowing sufficient time for the instrument to acclimatize before removing it from the

box.

Installation Conditions

Install the instrument so that the following conditions are met.

Flat Horizontal Location

Place the instrument in a stable location that is flat in all directions. If the instrument is

used in an unstable or angled surface, the accuracy of the internal monochromator can

be compromised.

Location without Vibration

Do not install the instrument in a location subject to vibration. Use in a location that

experiences large vibrations can lead to instability of operation, measurement stopping

before completion, or notable decreases in accuracy of the wavelength and level axes.

Well Ventilated Location

Ventilation holes are present at the sides and rear of the instrument. To keep the

internal temperature from rising, always maintain a gap of 200 mm or more between the

ventilation holes and the installation surfaces.

IM AQ6370D-01EN

3-1

Page 32

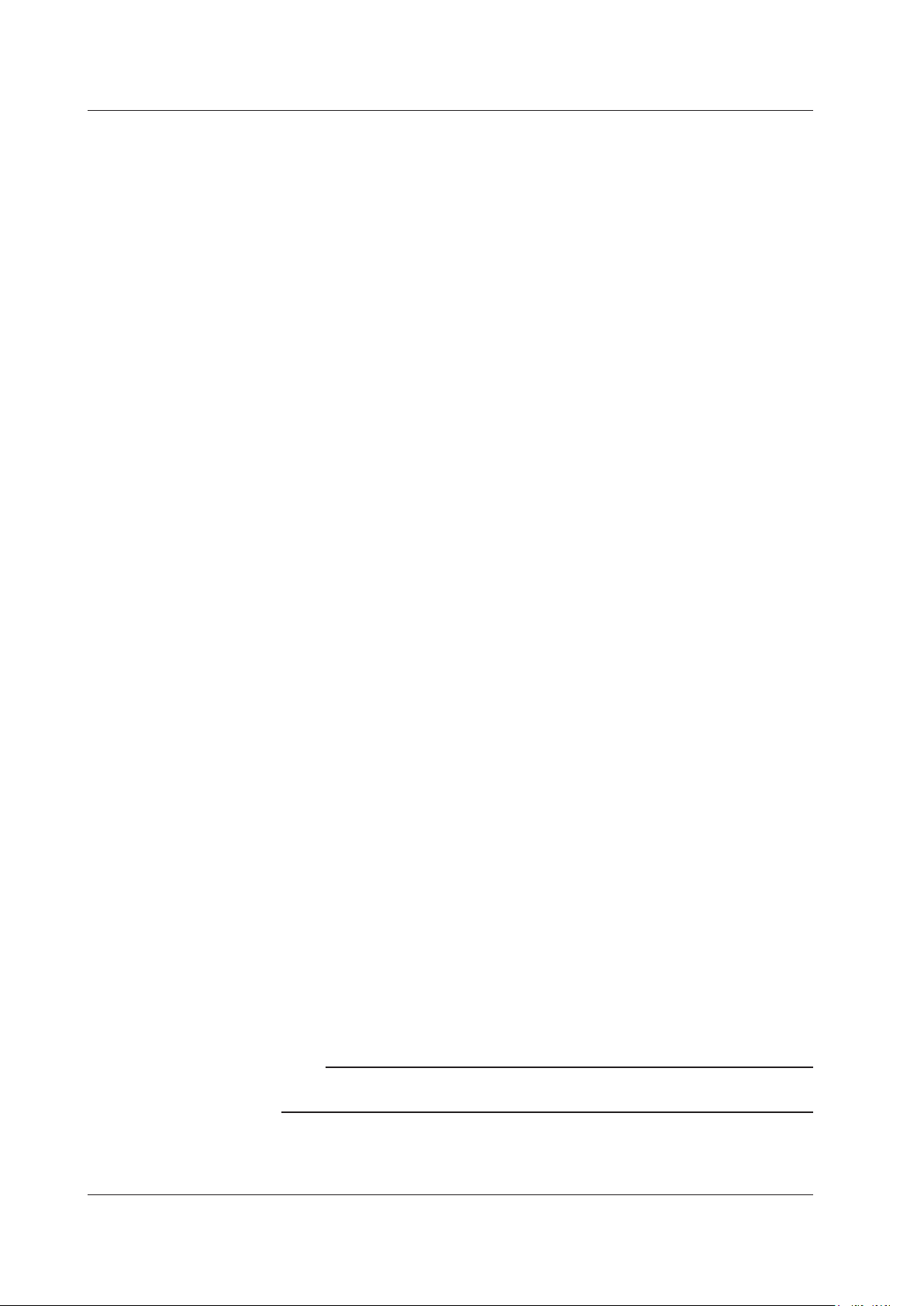

Inlet holes (also on the bottom panel)

3.1 Installing the Instrument

Also be sure to maintain sufficient clearance for connecting measurement cables.

20 cm or more

20 cm or

more

20 cm or

more

Ambient Temperature and Humidity

Ambient temperature: 5 to 35°C

Ambient humidity: 80% RH or lower (no condensation present)

Note

Condensation may occur if the instrument is moved to another place where the ambient

temperature is higher, or if the temperature changes rapidly. In such cases, allow sufficient time

for the instrument to adjust to the ambient temperature before use.

When the instrument is packaged in a box and moved, prevent condensation by allowing

sufficient time for the instrument to acclimatize before removing it from the box.

Do Not Install the Instrument in the Following Places

• Outdoors.

• Dangerous locations where flammable or explosive gasses, vapors, or dust is present,

or where the possibility of explosions or fires exists.

• In direct sunlight or near heat sources.

• Where an excessive amount of soot, steam, dust, or corrosive gas is present.

• Location where mechanical vibration is high.

• In an unstable place.

• Where the instrument is exposed to water or other liquids.

20 cm or

more

General Handling Precautions

• Do Not Place Anything on Top of the Instrument

Never stack instruments or place any other objects on top of the instrument, especially

those containing water. Doing so can lead to malfunction.

• Take Proper Care When Carrying the Instrument

The instrument should always be carried by two people. Hold the instrument by the

handles on the sides of the case. The instrument weighs approximately 19 kg. Take

precautions against injuries when carrying it.

remove the power cable, and confirm that no other cables are connected before

carrying the instrument.

• Clean the Instrument Properly

When removing dirt from the case or operation panel, disconnect the power to the

circuits under test and the instrument, remove the instrument’s power cord from the

power outlet, then wipe gently with a clean, dry cloth. Do not use volatile chemicals

since this might cause discoloring and deformation.

3-2

Also, always turn the power switch OFF,

IM AQ6370D-01EN

Page 33

1

2

3.2 Attaching the Connector Adapter

Attach the optional connector adapter before using the instrument.

WARNING

Always turn the power OFF before replacing the connector adapter. The instrument

has a built-in reference light source for wavelength calibration (when the built-in

light source specification is -L1), and infrared light is always being output from the

optical output connector. Never look into the optical output connector. Infrared light

entering the eyes can cause severe injury and loss of vision.

CAUTION