Page 1

User ’s

Manual

AQ6360

Optical Spectrum Analyzer

Getting Started Guide

IM AQ6360-02EN

1st Edition

Page 2

Product Registration

Thank you for purchasing YOKOGAWA products.

YOKOGAWA provides registered users with a variety of information and services.

Please allow us to serve you best by completing the product registration form

accessible from our website.

http://tmi.yokogawa.com/

PIM 103-04E

Page 3

List of Manuals

Thank you for purchasing the AQ6360 Optical Spectrum Analyzer. This instrument

enables high speed measurement of the optical properties of LD and LED light sources,

optical amps, and other devices.

This getting started guide primarily explains the handling precautions and basic

operations of this instrument. For correct operation, please read this manual thoroughly

before use. After reading this manual, keep it in a convenient location for quick reference

in the event a question arises during operation.

The following manuals, including this one, are provided as manuals for the AQ6360.

Please read all manuals.

Manual Title Manual No. Description

AQ6360

Optical Spectrum Analyzer

User’s Manual

AQ6360

Optical Spectrum Analyzer

Getting Started Guide

AQ6360

Optical Spectrum Analyzer

Remote Control User’s Manual

Model AQ6360-01

AQ6360 Optical Spectrum

Analyzer Limited model

User’s Manual

AQ6360

Optical Spectrum Analyzer

IM AQ6360-01EN The manual is located on the CD included

in your package (pdf format). Explains

all functions and operating procedures of

the AQ6360 except remote control and

program functions.

IM AQ6360-02EN This manual. This guide explains

the handling precautions, installation

procedure, basic operations, and

specifications of this instrument.

IM AQ6360-17EN The manual is located on the CD included

in your package (pdf format).Explains

functions for controlling the instrument with

communication commands and program

functions.

IM AQ6360-51EN Explains the specifications of the limited

model of the AQ6360.

IM AQ6360-92Z1 A document for China.

The “EN” in the manual number is the language code.

Notes

Contact information of Yokogawa offices worldwide is provided on the following sheet.

Document Description Description

PIM 113-01Z2 List of worldwide contacts

• The contents of this manual are subject to change without prior notice as a result

of improvements in the instrument’s performance and functions. Display contents

illustrated in this manual may differ slightly from what actually appears on your screen.

• Every effort has been made in the preparation of this manual to ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact your nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without the

permission of YOKOGAWA is strictly prohibited.

1st Edition: April 2018 (YMI)

All Rights Reserved, Copyright © 2018 Yokogawa Test & Measurement Corporation

IM AQ6360-02EN

i

Page 4

Trademarks

Revisions

• Microsoft and Windows are registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries.

• Adobe and Acrobat are registered trademarks or trademarks of Adobe Systems

incorporated.

• In this manual, the ® and TM symbols do not accompany their respective registered

trademark or trademark names.

• Other company and product names are registered trademarks or trademarks of their

respective companies.

• 1st Edition: April 2018

ii

IM AQ6360-02EN

Page 5

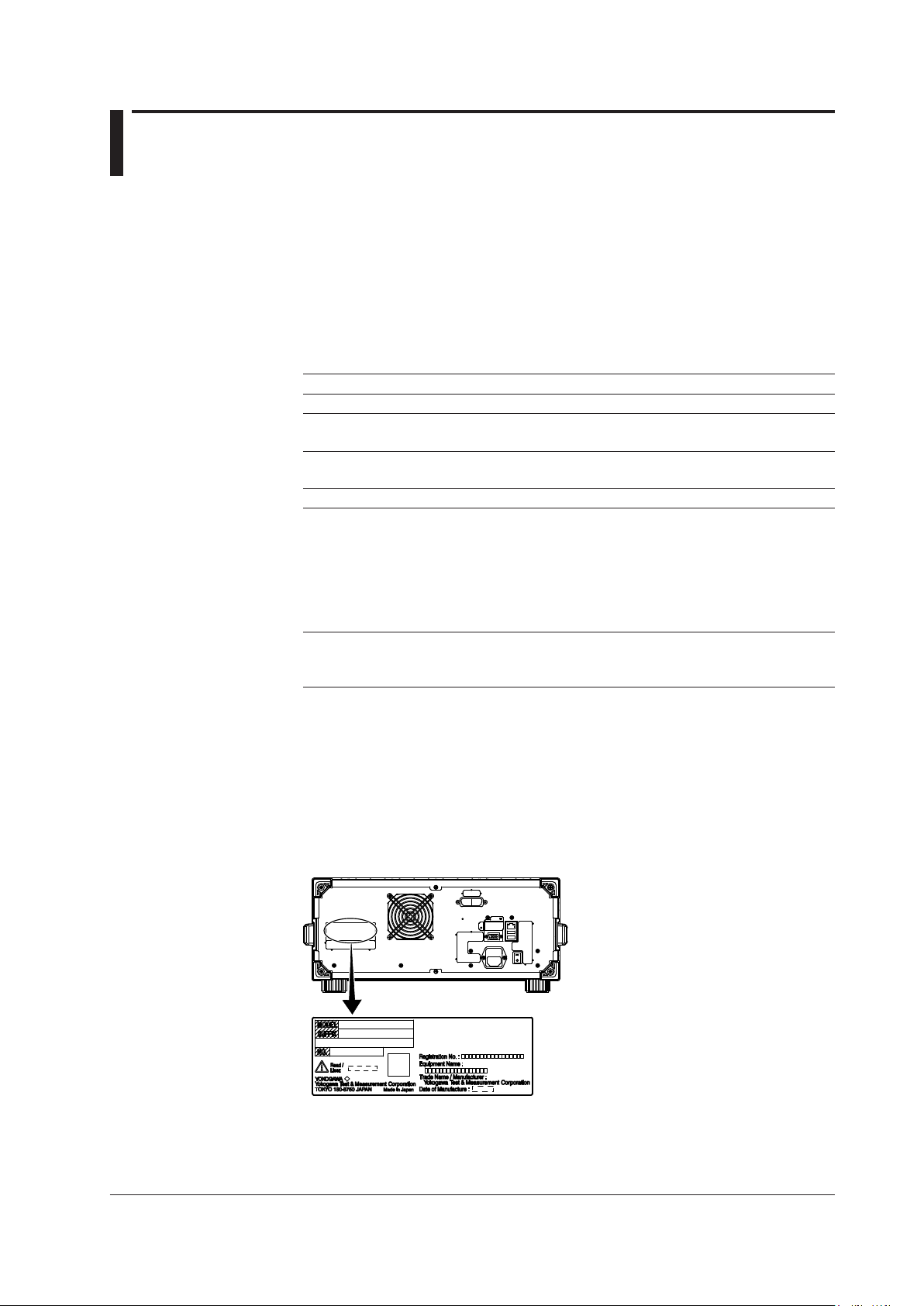

Checking the Contents of the Package

After opening the package, check the following items before beginning use. If any of

the contents are incorrect, missing, or appear to be abnormal, please contact your

YOKOGAWA dealer or representative.

AQ6360 Main Unit

Check that the model and suffix on the name plate on the rear of the instrument

match those of your order. When contacting the dealer from which you purchased the

instrument, please give them the instrument number.

MODEL Suffix Description

AQ6360 AQ6360 Optical Spectrum Analyzer

Spec.Code -10 Standard Model

-01 Limited Model

Optical Connector -FC AQ9447(FC) Connector Adapter

(Optical Input) -SC AQ9447(SC) Connector Adapter

Display -D1 Built-in Display

Power Cord

-F VDE/Korean Standard, Rated Voltage: 250 V

-R Australian Standard, Rated Voltage: 250 V

-Q British Standard, Rated Voltage: 250 V

-H Chinese Standard, Rated Voltage: 250 V

-N Brazilian Standard, Rated Voltage: 250 V

Options

Built-in Light Source /LFC Wavelength Reference Source (FC Connector

/LSC Wavelength Reference Source (SC Connector

1 Already attached to the optical input of the AQ6360 front panel.

2 Make sure that the attached power cord meets the designated standards of the country and

area that you are using it in.

3 Already attached to the calibration light source output of the AQ6360 front panel.

For products whose suffix code contains “Z,” an exclusive manual may be included.

Please read it along with the standard manual.

2

-D UL/CSA Standard and PSE Compliant, Rated

Voltage: 125 V

1

1

3

)

3

)

• No. (Instrument Number)

When contacting the dealer from which you purchased the instrument, please give

them the instrument number.

IM AQ6360-02EN

iii

Page 6

Checking the Contents of the Package

Standard Accessories

Part Name Model or Part No. Quantity Specifications and Notes

Power cord

A1009WD VDE/Korean Standard, Rated Voltage: 250 V

A1024WD Australian Standard, Rated Voltage: 250 V

A1054WD British Standard, Rated Voltage: 250 V

A1064WD Chinese Standard, Rated Voltage: 250 V

A1088WD Brazilian Standard, Rated Voltage: 250 V

Rubber feet A9088ZM 2 1 A9088ZM sheet

Manuals

Printed Manuals IM AQ6360-02EN 1 Getting Started Guide

IM AQ6360-51EN 1 Accompanying the limited model only

IM AQ6360-92Z1 1 Document for China

PIM 113-01Z2 1 List of worldwide contacts

Manual CD A1025US 1 Contains PDFs of the user’s manuals (For

Standard accessories are not covered by warranty of this instrument.

1 Make sure that the attached power cord meets the designated standards of the country and

1

A1006WD 1 UL/CSA Standard and PSE Compliant,

area that you are using it in.

Optional Accessories (Sold Separately)

Part Name Model/Part Number Specifications

AQ9447 connector adapter 810804602-FCC FC type (for optical input)

810804602-SCC SC type (for optical input)

AQ9441 universal adapter 813917321-FCC FC type (for calibration light source output)

813917321-SCC SC type (for calibration light source output)

Optional accessories (sold separately) are not covered by warranty of this instrument.

Rated Voltage: 125 V

the types of manuals that CD contains,

see Manual CD below.)

Manual CD

The English directory in the manual CD contains the PDF files shown below. The CD

also contains Japanese manuals.

File Name Manual Title Manual No.

IMAQ6360-01EN AQ6360 Optical Spectrum Analyzer

User’s Manual

IMAQ6360-17EN AQ6360

Optical Spectrum Analyzer

Remote Control User’s Manual

IM AQ6360-01EN

IM AQ6360-17EN

To view the PDF files above, you need Adobe Reader.

iv

IM AQ6360-02EN

Page 7

Conventions Used in This Manual

Safety Markings

The following markings are used in this manual.

Improper handling or use can lead to injury to the user or damage

to the instrument. This symbol appears on the instrument to indicate

that the user must refer to the user’s manual for special instructions.

The same symbol appears in the corresponding place in the user’s

manual to identify those instructions. In the manual, the symbol is

used in conjunction with the word “WARNING” or “CAUTION.”

WARNING

CAUTION

Calls attention to actions or conditions that could cause serious or

fatal injury to the user, and precautions that can be taken to prevent

such occurrences.

Calls attentions to actions or conditions that could cause light injury to

the user or damage to the instrument or user’s data, and precautions

that can be taken to prevent such occurrences.

French

AVERTISSEMENT

ATTENTION

Calls attention to information that is important for proper operation of

Note

Attire l’attention sur des gestes ou des conditions

Attire l’attention sur des gestes ou des conditions

susceptibles de provoquer des blessures graves (voire

mortelles), et sur les précautions de sécurité pouvant

prévenir de tels accidents.

susceptibles de provoquer des blessures légères ou

d’endommager l’instrument ou les données de l’utilisateur,

et sur les précautions de sécurité susceptibles de prévenir

de tels accidents.

the instrument.

IM AQ6360-02EN

v

Page 8

Conventions Used in This Manual

Notations Used on Pages Describing Operating Procedures

On pages that describe the operating procedures, the following notations are used to

distinguish the procedures from their explanations.

Unit

Procedure

Explanation

This subsection contains the operating procedure used to carry out

the function described in the current chapter. The procedures are

written with inexperienced users in mind; experienced users may not

need to carry out all the steps.

This subsection describes the setup parameters and the limitations

on the procedures.

Characters and Terminology Used in Procedural Explanations

Bold alphanumeric characters in procedural explanations indicate characters appearing near

panel controls and characters of the control menu items shown on the screen.

k: Denotes “1000.” Example: 100 kS/s

K: Denotes “1024.” Example: 459 KB (file data size)

vi

IM AQ6360-02EN

Page 9

Safety Precautions

This product is designed to be used by a person with specialized knowledge.

This instrument is an IEC protection class I instrument (provided with terminal for

protective earth grounding).

The general safety precautions described herein must be observed during all phases

of operation. If the instrument is used in a manner not specified in this manual, the

protection provided by the instrument may be impaired.

This manual is an essential part of the product; keep it in a safe place for future

reference. YOKOGAWA assumes no liability for the customer’s failure to comply with

these requirements.

The following symbols are used on this instrument.

Warning: handle with care. Refer to the user’s manual or service manual.

This symbol appears on dangerous locations on the instrument which require

special instructions for proper handling or use. The same symbol appears in the

corresponding place in the manual to identify those instructions.

Alternating current

ON(power)

OFF(power)

French

Avertissement : À manipuler délicatement.

Toujours se reporter aux manuels d’utilisation et d’entretien. Ce symbole a été

apposé aux endroits dangereux de l’instrument pour lesquels des consignes

spéciales d’utilisation ou de manipulation ont été émises. Le même symbole

apparaît à l’endroit correspondant du manuel pour identifier les consignes qui s’y

rapportent.

Courant alternatif

Marche (alimentation)

Arrêt (alimentation)

IM AQ6360-02EN

vii

Page 10

Safety Precautions

Failure to comply with the precautions below could lead to injury or death or

damage to the instrument.

WARNING

Use the Instrument Only for Its Intended Purpose

The optical measuring instrument is designed to measure the optical characteristics

of light sources and evaluate their performance. Do not use this instrument for

anything other than as an optical measuring instrument.

Check the Physical Appearance

Do not use the instrument if there is a problem with its physical appearance.

Use the Correct Power Supply

Before connecting the power cord, ensure that the source voltage matches the

rated supply voltage of the instrument and that it is within the maximum rated

voltage of the provided power cord.

Use the Correct Power Cord and Plug

To prevent the possibility of electric shock or fire, be sure to use the power cord

supplied by YOKOGAWA. The main power plug must be plugged into an outlet with

a protective earth terminal. Do not disable this protection by using an extension

cord without protective earth grounding.

Also, do not use the power cord that came with the instrument on any other device.

Connect the Protective Grounding Terminal

Make sure to connect the protective earth to prevent electric shock before turning

ON the power. The power cord that comes with the instrument is a three-prong type

power cord. Connect the power cord to a properly grounded three-prong outlet.

Do not Impair the Protective Grounding

Never cut off the internal or external protective earth wire or disconnect the wiring

of the protective earth terminal. Doing so poses a potential shock hazerd.

Do Not Use When the Protection Functions Are Defective

Before using this instrument, check that the protection functions, such as the

protective grounding and fuse, are working properly. If you suspect a defect, do not

use the instrument.

Reference light source output light (/LFC, /LSC option)

The instrument has a built-in reference light source for wavelength calibration, and

infrared light is always being output from the optical output connector. Never look

into the optical output connector. Infrared light entering the eyes can cause severe

injury and loss of vision.

Do not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable liquids or vapors.

Operation in such environments constitutes a safety hazard.

Do not Remove the Covers or Disassemble or Alter the Instrument

Only qualified YOKOGAWA personnel may remove the covers and disassemble or

alter the instrument.

Opening the cover is dangerous, because some areas inside the instrument have

high voltages.

viii

IM AQ6360-02EN

Page 11

Installation Location

• This instrument is designed to be used indoors. Do not install or use it outdoors.

• Install the instrument so that you can immediately remove the power cord if an

abnormal or dangerous condition occurs.

Manual CD

• Never play this manual CD, which contains the user’s manuals, in an audio CD

player. Doing so may cause loss of hearing or speaker damage due to the large

sounds that may be produced.

CAUTION

Operating Environment Limitations

This product is a Class A (for industrial environment) product. Operation of this

product in a residential area may cause radio interference in which case the user is

required to correct the interference.

French

AVERTISSEMENT

Safety Precautions

Utiliser l’instrument aux seules fins prévues

Cet instrument de mesure optique est prévu pour mesurer les caractéristiques

optiques des sources lumineuses et évaluer leur performance. Ne pas utiliser cet

instrument à d’autres fins que celles de mesure optique.

Inspecter l’apparence physique

Ne pas utiliser l’instrument si son intégrité physique semble être compromise.

Vérifier l’alimentation

Avant de brancher le cordon d’alimentation, vérifier que la tension source

correspond à la tension d’alimentation nominale du AQ6360 et qu’elle est

compatible avec la tension nominale maximale du cordon d’alimentation.

Utiliser le cordon d’alimentation et la fiche adaptés

Pour éviter tout risque de choc électrique ou d’incendie, toujours utiliser le cordon

d’alimentation fourni par YOKOGAWA. La fiche doit être branchée sur une prise

secteur raccordée à la terre. En cas d’utilisation d’une rallonge, celle-ci doit être

impérativement reliée à la terre. Ne pas utiliser le cordon d’alimentation fourni avec

l’instrument pour tout autre appareil.

Brancher la prise de terre

Avant de mettre l’instrument sous tension, penser à brancher la prise de terre pour

éviter tout choc électrique. Le cordon d’alimentation livré avec l’instrument est doté

de trois broches.

Brancher le cordon d’alimentation sur une prise de courant à trois plots et mise à la

terre.

IM AQ6360-02EN

Ne pas entraver la mise à la terre de protection

Ne jamais neutraliser le fil de terre interne ou externe, ni débrancher la borne

de mise à la terre. Cela pourrait entraîner un choc électrique ou endommager

l’instrument.

ix

Page 12

Safety Precautions

Ne pas utiliser lorsque les fonctions de protection sont défectueuses

Avant d’utiliser l’instrument, vérifier que les fonctions de protection, telles que

le raccordement à la terre et le fusible, fonctionnent correctement. En cas de

dysfonctionnement possible, ne pas utiliser l’instrument.

Source de lumière de référence (/LFC, /LSC option)

Cet instrument dispose d’une source de lumière de référence intégrée pour les

ajustements d’alignement. La lumière infrarouge est toujours émise depuis le

connecteur de sortie optique. Ne regardez jamais directement dans le connecteur

de sortie optique. La lumière infrarouge risquerait de gravement vous blesser ou de

provoquer une perte de vision.

Ne pas utiliser dans un environnement explosif

Ne pas utiliser l’instrument en présence de gaz ou de vapeurs inflammables. Cela

pourrait être extrêmement dangereux.

Ne pas retirer le capot, ni démonter ou modifier l’instrument

Seul le personnel YOKOGAWA qualifié est habilité à retirer le capot et à démonter

ou modifier l’instrument. Certains composants à l’intérieur de l’instrument sont à

haute tension et par conséquent, représentent un danger.

Installer et utiliser l’instrument aux emplacements appropriés

• Ne pas installer, ni utiliser l’instrument à l’extérieur ou dans des lieux exposés à

la pluie ou à l’eau.

• Installer l’instrument de manière à pourvoir immédiatement le débrancher du

secteur en cas de fonctionnement anormal ou dangereux.

Manuel CD

• Ce CD contient les manuels d’utilisation. Ne jamais insérer ce CD dans

un lecteur de CD audio. Cela pourrait entraîner une perte d’audition ou

l’endommagement des enceintes en raison du volume potentiellement élevé des

sons produits.

ATTENTION

Limitations relatives à l’environnement opérationnel

Ce produit est un produit de classe A (pour environnements industriels). L’utilisation

de ce produit dans un zone résidentielle peut entraîner une interférence radio que

l’utilisateur sera tenu de rectifier.

x

IM AQ6360-02EN

Page 13

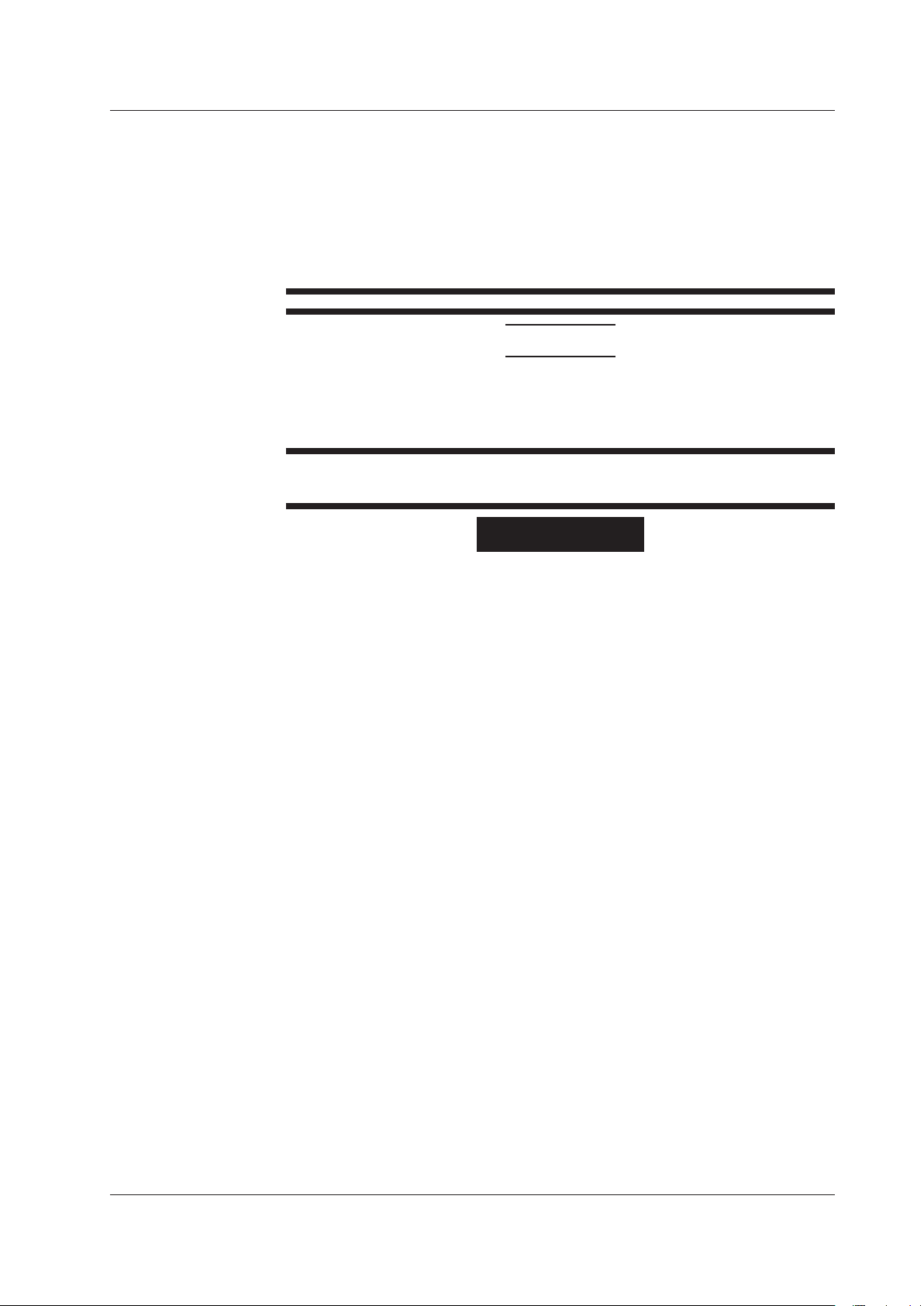

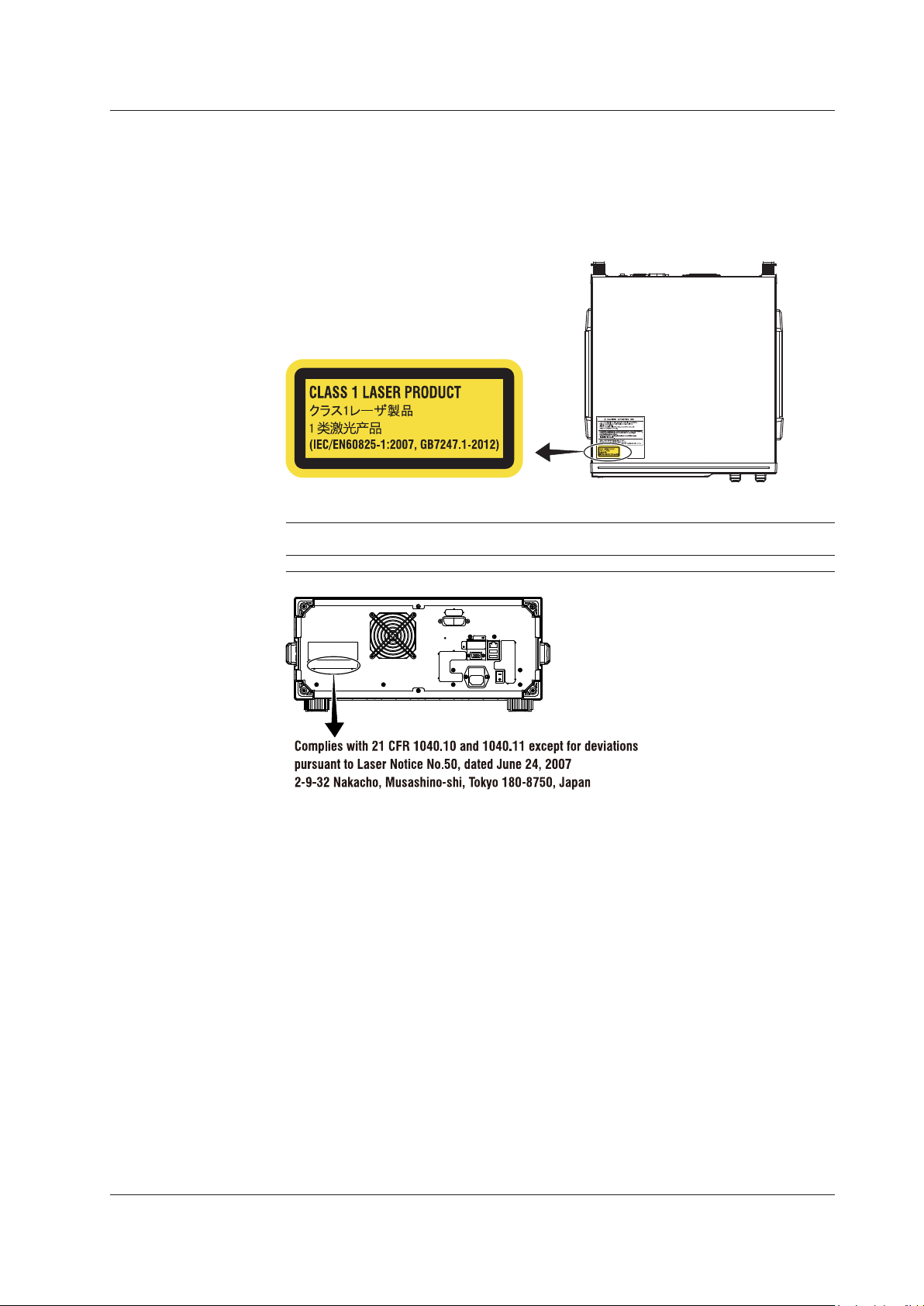

Safety Precautions for Laser Products (/LFC, /LSC option)

This instrument uses a laser light source. This instrument is a Class 1 laser product

as defined by IEC/EN 60825-1:2007 Safety of Laser Products-Part 1: Equipment

Classification, Requirements and User’s Guide. In addition, this instrument complies with

21 CFR 1040.10 and 1040.11 except for deviations pursuant to Laser Notice No. 50,

dated June 24, 2007.

Laser Class 1 Label

Information about the Laser Light Source Used

Class Laser Type Wavelength Maximum

Output Power

1 EE-LED 1.53 µm 0.04 mW 9 µm CW 0.1

Diameter of

Mode Field

Safety Precautions

Repetation

Rate

Numerical

Aperture

IM AQ6360-02EN

xi

Page 14

Regulations and Sales in Each Country or Region

Waste Electrical and Electronic Equipment

Waste Electrical and Electronic Equipment (WEEE)

(This directive is valid only in the EU.)

This product complies with the WEEE Directive marking requirement. This

marking indicates that you must not discard this electrical/electronic product in

domestic household waste.

Product Category

With reference to the equipment types in the WEEE directive, this product is

classified as a “Monitoring and control instruments” product.

When disposing of products in the EU, contact your local Yokogawa Europe B.V.

office. Do not dispose in domestic household waste.

EU Battery Directive

EU Battery Directive

(This directive is valid only in the EU.)

Batteries are included in this product. This marking indicates they shall be sorted

out and collected as ordained in the EU battery directive.

Battery type: Lithium battery

You cannot replace batteries by yourself. When you need to replace batteries,

contact your local Yokogawa Europe B.V. office.

Authorized Representative in the EEA

Yokogawa Europe B.V. is the authorized representative of Yokogawa Test &

Measurement Corporation for this product in the EEA. To contact Yokogawa Europe B.V.,

see the separate list of worldwide contacts, PIM 113-01Z2.

xii

IM AQ6360-02EN

Page 15

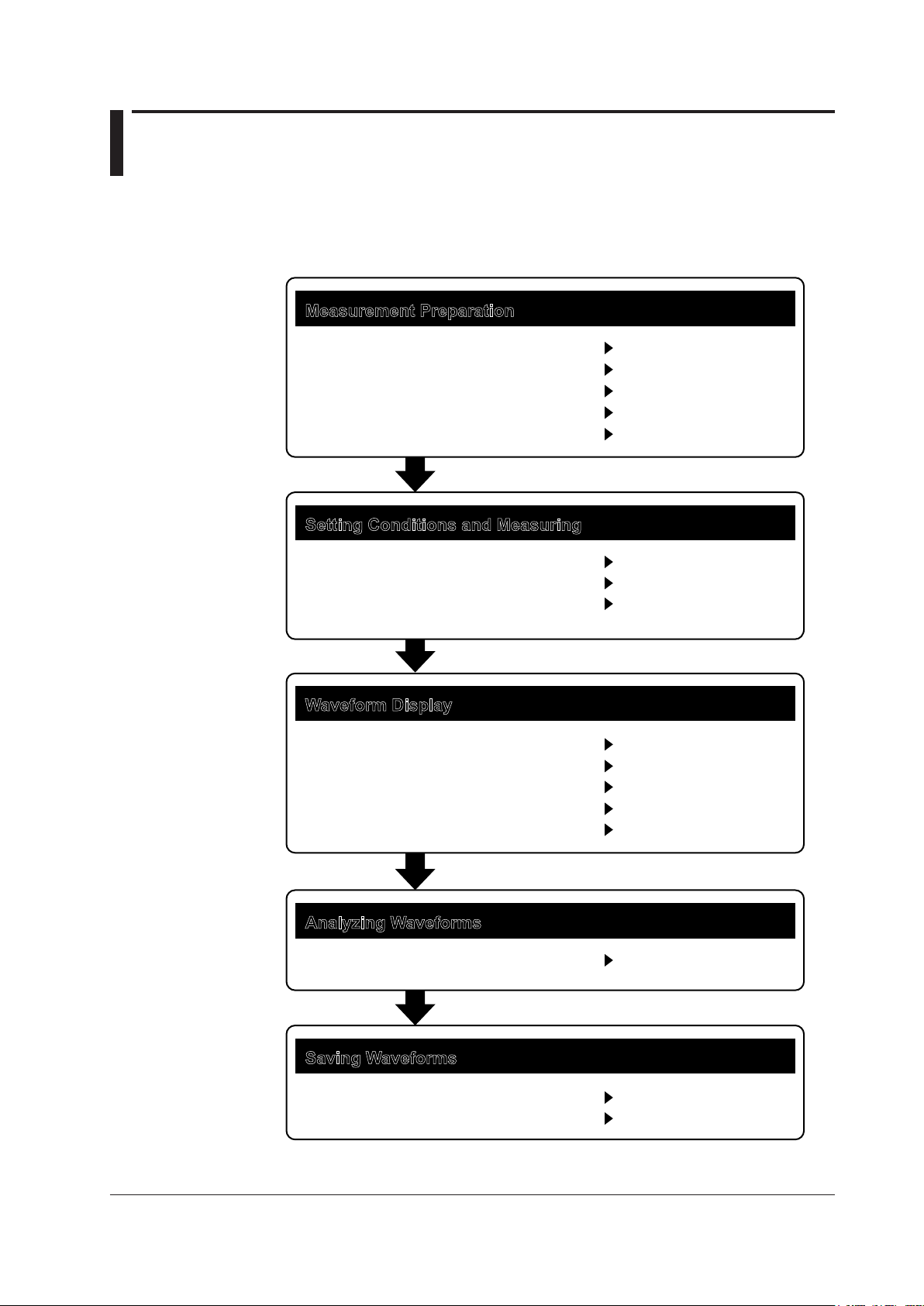

Flow of Operation

* IM AQ6360-01EN

The figure below is provided to familarize the first-time user with the general flow of this

instrument operation. For the details of each item, see the relevant section in IM AQ636001EN or IM AQ6360-02EN.

Measurement Preparation

Installing the Instrument

Turning the Power On and Off

Connecting the DUT

Wavelength Calibration

Resolution Calibration

Setting Conditions and Measuring

Auto Sweep Setting and Measurement

Other Settings

Starting a Measurement (Sweep)

Waveform Display

Displaying Waveforms

Displaying Calculated Waveforms

Displaying Power Spectral Density

Displaying Markers

Searching

Section 2.1

Section 2.4

Section 2.5

Section 2.1*

Section 2.2*

Section 3.1*

Sections 3.2* to 3.12*

Section 3.13*

Sections 4.1* to 4.4*

Section 4.5*

Section 4.8*

Section 4.9*

Sections 4.13* and 4.14*

IM AQ6360-02EN

Analyzing Waveforms

Waveform Analysis

Saving Waveforms

Storage Device

Saving Data

Sections 5.1* to 5.9*

Section 6.1*

Sections 6.2* to 6.7*

xiii

Page 16

xiv

IM AQ6360-02EN

Page 17

Contents

1

List of Manuals ...................................................................................................................................i

Checking the Contents of the Package............................................................................................ iii

Conventions Used in This Manual ....................................................................................................v

Safety Precautions .......................................................................................................................... vii

Regulations and Sales in Each Country or Region ......................................................................... xii

Flow of Operation........................................................................................................................... xiii

Chapter 1 Part Names and Functions

1.1 Front Panel ....................................................................................................................... 1-1

1.2 Rear Panel ....................................................................................................................... 1-2

1.3 LCD Screen ...................................................................................................................... 1-3

Chapter 2 Preparing for Measurement

2.1 Installing the Instrument ................................................................................................... 2-1

2.2 Attaching the Connector Adapter ..................................................................................... 2-5

2.3 Connecting the Device ..................................................................................................... 2-8

2.4 Turning the Power ON/OFF ............................................................................................ 2-10

2.5 Connecting the DUT ....................................................................................................... 2-17

Chapter 3 Common Operations

3.1 Touch Panel Operations ................................................................................................... 3-1

3.2 Menu Operations .............................................................................................................. 3-4

3.3 Entering Numerical Values and Strings .......................................................................... 3-12

3.4 Using the Mouse and External Keyboard ....................................................................... 3-14

3.5 Setting the Date and Time .............................................................................................. 3-16

2

3

4

5

App

Chapter 4 Maintenance

4.1 Updating the Firmware ..................................................................................................... 4-1

4.2 Mechanical Inspection ...................................................................................................... 4-4

4.3 Inspection of Wavelength Accuracy .................................................................................. 4-5

4.4 Inspection of Level Accuracy ............................................................................................ 4-6

4.5 Replacing Fuses ............................................................................................................... 4-7

4.6 Daily Maintenance ............................................................................................................ 4-8

4.7 Care during Storage ........................................................................................................4-11

4.8 Recommended Replacement Parts ............................................................................... 4-12

4.9 Disposal .......................................................................................................................... 4-13

4.10 Warning Display Function ............................................................................................... 4-14

Chapter 5 Specications

5.1 Specications ................................................................................................................... 5-1

5.2 External Dimensions ........................................................................................................ 5-4

Appendix

Appendix 1 MICROSOFT SOFTWARE LICENSE TERMS ...................................................App-1

IM AQ6360-02EN

xv

Page 18

1

2

3 4 5

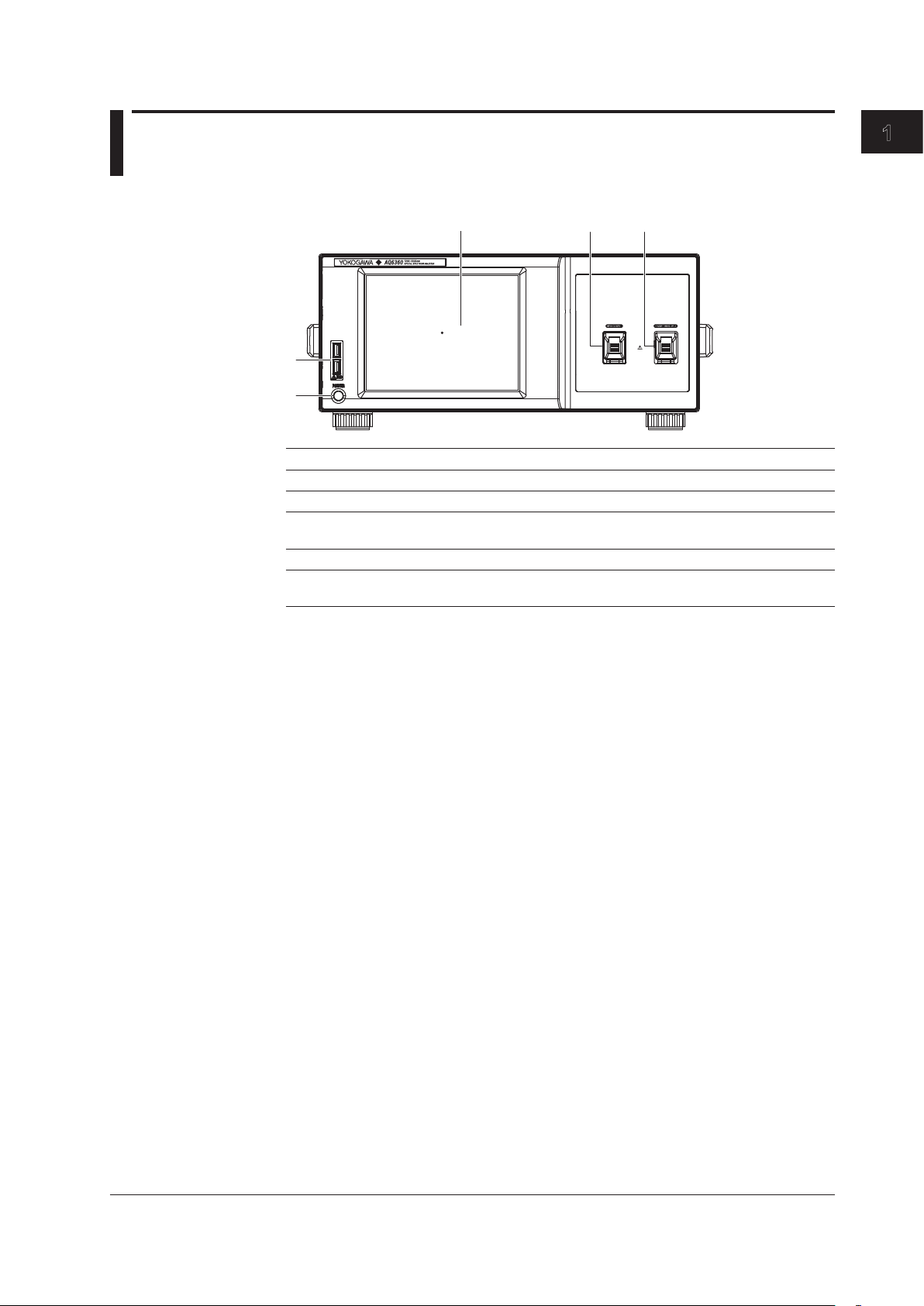

Chapter 1 Part Names and Functions

1.1 Front Panel

No. Name Function

1 POWER Used to start and shut down the instrument.

2 USB interface Used to connect USB storage media

3 LCD display Displays measured waveform, measurement conditions,

4 OPTICAL INPUT Optical input connector

5 CALIBRATION OUTPUT An optical output connector for the reference light source

1

Part Names and Functions

measurement values, etc.

used in wavelength calibration (/LFC, /LSC option)

IM AQ6360-02EN

1-1

Page 19

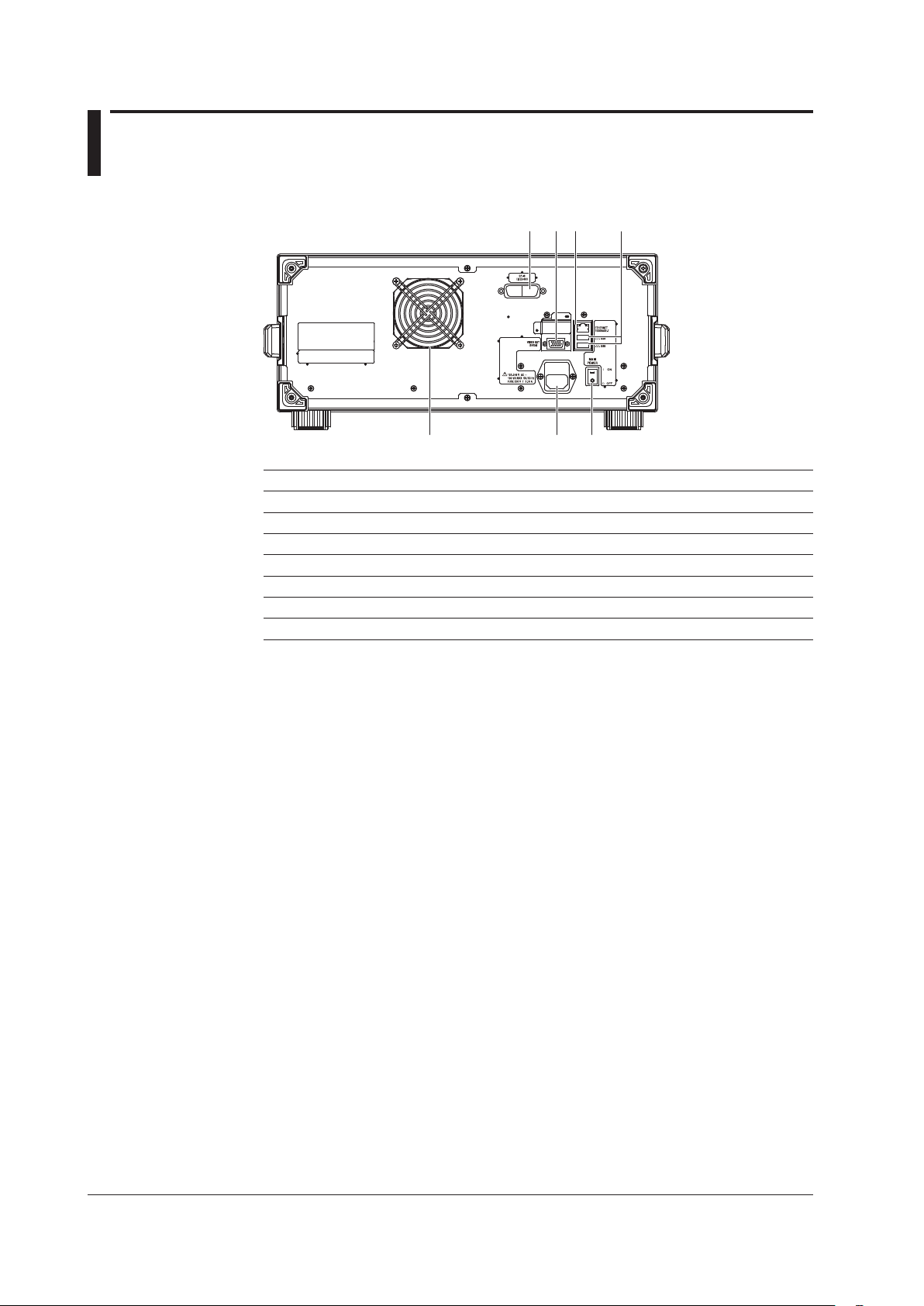

1.2 Rear Panel

1 2 3 4

56

7

No. Name Function

1 GP-IB A GP-IB port for controlling the instrument from a PC

2 VIDEO OUT (SVGA) Analog RGB video signal (SVGA-compliant) interface

3 ETHERNET Ethernet Interface

4 USB interface Used to connect USB storage media or USB mouse

5 MAIN POWER Used to turn the main power ON/OFF

6 Power cord connector Connect the power cord to this connector

7 Exhaust holes Keeps the internal temperature from rising

1-2

IM AQ6360-02EN

Page 20

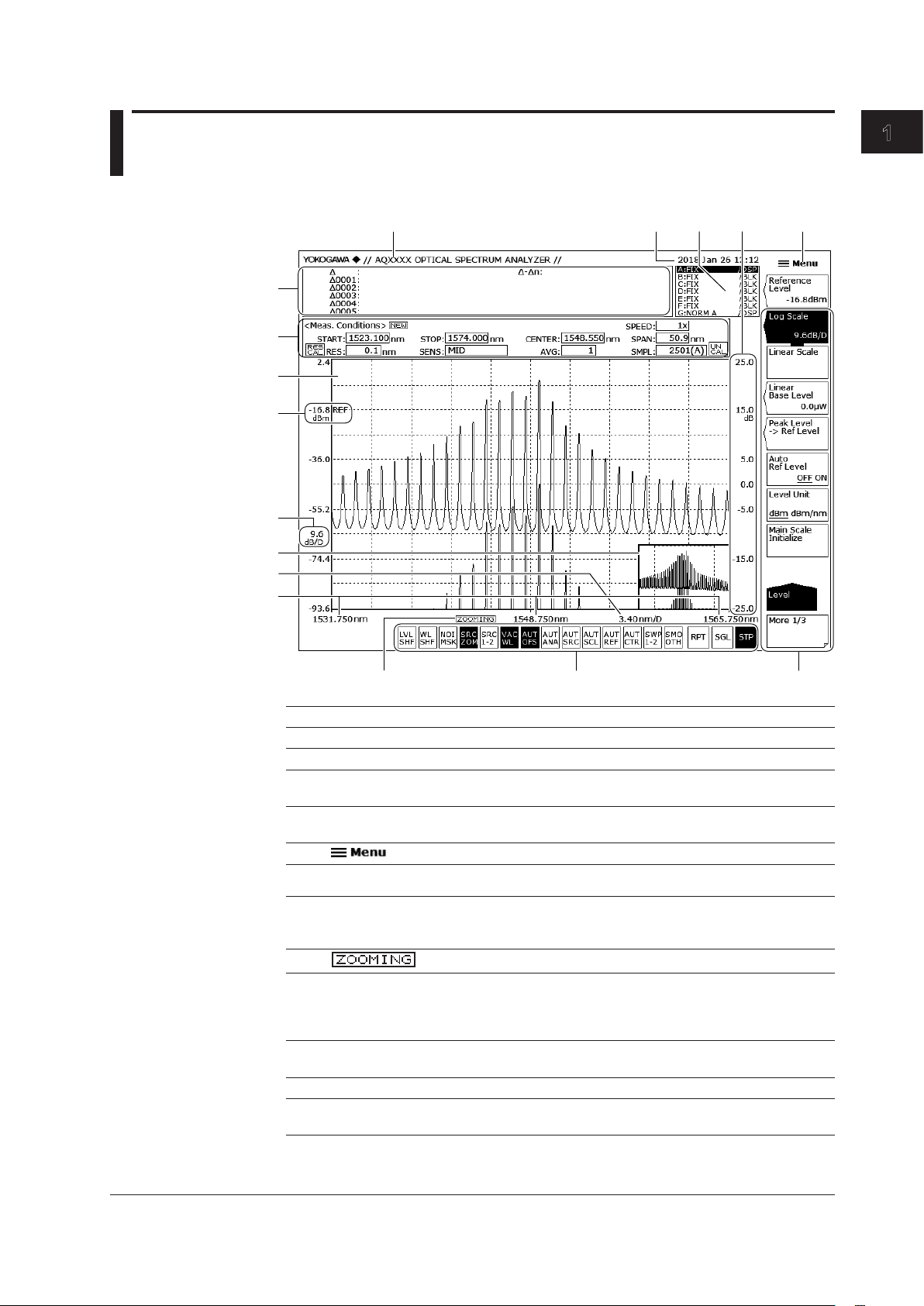

1.3 LCD Screen

1 2 3 5

78

10

11

12

13

14

15

16

6

4

1

Part Names and Functions

9

No. Name Function See

1 Label area Up to 56 characters Section 3.3

2 Year, month, day, time Section 3.5

3 Trace setting area Displays the status of each trace. Tap to display the

setup screen.

4 Subscale Displays relative levels of differential waveforms

5

6 Function menu For configuring various settings. Section 3.2

7 Shortcut keys Shortcuts to frequently used settings. You can

8

9 Wavelength/frequency Displays the start wavelength (frequency), center

10 Wavelength axis scale Displays the wavelength axis scale per division.

11 Overview screen Appears only when the zoom feature is in use. Section 4.1*

12 Level axis scale Displays the level axis scale per division.

and normalized waveforms.

Displays the Main Menu window. Section 3.2

quickly specify settings by simply tapping them.

When a setting is on, the shortcut key is highlighted.

Appears when the zoom feature is in use. Section 4.1*

wavelength (frequency), and stop wavelength

(frequency) of the zoom function.

You can set them directly by tapping the values.

You can set it directly by tapping the value.

You can set it directly by tapping the value.

Section 3.12*,

Chapter 4*

Section 3.3*

Section 3.2

Section 4.1*

Section 4.1*

Section 3.2*

IM AQ6360-02EN

1-3

Page 21

1.3 LCD Screen

No. Name Function See

13 Reference level Displays the reference level. You can change the

vertical display position of the reference level.

You can set it directly by tapping the value.

14 Waveform display area Displays waveforms. Waveforms can be zoomed

using touch panel operation.

15 Measurement

conditions area

START Displays and sets the start wavelength or start

STOP Displays and sets the stop wavelength or stop

CENTER Displays and sets the center wavelength or center

SPAN Displays and sets the sweep span Section 3.6*

SPEED Displays and sets the sweep speed Section 3.10*

RES Displays and sets the resolution Section 3.7*

SENSE Displays and sets the measurement sensitivity Section 3.9*

AVG Displays and sets the average count Section 3.11*

SMPL Displays and sets the sample count Section 3.8*

16 Data area Displays marker values and analysis results. If there

You can set a parameter directly by tapping within

the frame of the value.

frequency

frequency

frequency

Appears when measurement conditions are

changed.

Appears when a resolution calibration has been

performed.

Displayed when the span, sample count, or

resolution setting is inappropriate.

are five or more data values, you can drag the data

area to scroll.

Section 3.4*

Section 3.1,

Chapter 4*

Section 3.2

Section 3.5*

Section 3.5*

Section 3.5*

Chapter 3*

Section 2.2*

Section 3.7*

Chapter 4*,

Chapter 5*

* See the relevant chapter or section in IM AQ6360-01EN.

For details on touch panel operation and menu operation, see chapter 3, “Common

Operations.”

1-4

IM AQ6360-02EN

Page 22

1

Chapter 2 Preparing for Measurement

2.1 Installing the Instrument

WARNING

• This instrument is designed to be used indoors. Do not install or use it outdoors.

• Install the instrument so that you can immediately remove the power cord if an

abnormal or dangerous condition occurs.

• This instrument has a built-in reference light source for wavelength calibration (/

LFC, /LSC option) and transmits infrared light from the optical output connector

at all times. Never look into the optical output connector. Infrared light entering

the eyes can cause severe injury and loss of vision.

CAUTION

Do Not Apply Shock to the Instrument

Non-horizontal orientation, and do not drop the instrument from a height of 2 cm

or more. This can adversely affect the accuracy of the internal monochromator

and inhibit performance. Take great care when transporting the instrument, and

use packaging with a shock absorbing capacity that is greater than or equal to the

packaging used upon shipment from the factory.

Never use inferior packaging materials that are unable to sufficiently absorb

vibrations and shocks occurring during transport. This can adversely affect the

accuracy of the internal monochromator and inhibit performance.

2

Preparing for Measurement

When unpacking

When the instrument is packaged in a box and moved, prevent condensation by

allowing sufficient time for the instrument to acclimatize before removing it from the

box.

French

AVERTISSEMENT

• L’instrument est prévu pour une utilisation en intérieur. Ne pas l’installer, ni l’utiliser

à l’extérieur.

• Installer l’instrument de manière à pourvoir immédiatement le débrancher du

secteur en cas de fonctionnement anormal ou dangereux.

• Cet instrument dispose d’une source de lumière de référence intégrée pour les

ajustements d’alignement (/LFC, /LSC option). La lumière infrarouge est toujours

émise depuis le connecteur de sortie optique. Ne regardez jamais directement

dans le connecteur de sortie optique. La lumière infrarouge risquerait de

gravement vous blesser ou de provoquer une perte de vision.

IM AQ6360-02EN

2-1

Page 23

2.1 Installing the Instrument

ATTENTION

Ne pas heurter l’instrument

En position non horizontale et ne faites pas chuter l’instrument d’une hauteur de

2 cm ou plus. Cela risquerait d’endommager la précision du monochromateur

interne et les performances de l’instrument.

Transportez l’instrument avec maintes précautions et utilisez un emballage d’une

capacité d’absorption supérieure ou égale à celle de l’emballage utilisé pour la

livraison depuis l’usine.

N’utilisez jamais de matériaux d’emballage de qualité inférieure, incapables

d’absorber correctement les vibrations et les chocs survenant au cours du

transport.

Cela risquerait d’endommager la précision du monochromateur interne et les

performances de l’instrument.

Déballage

Lorsque l’instrument est emballé dans un carton et transporté, évitez toute

condensation en le laissant s’adapter aux conditions environnementales

suffisamment longtemps avant de le retirer du carton.

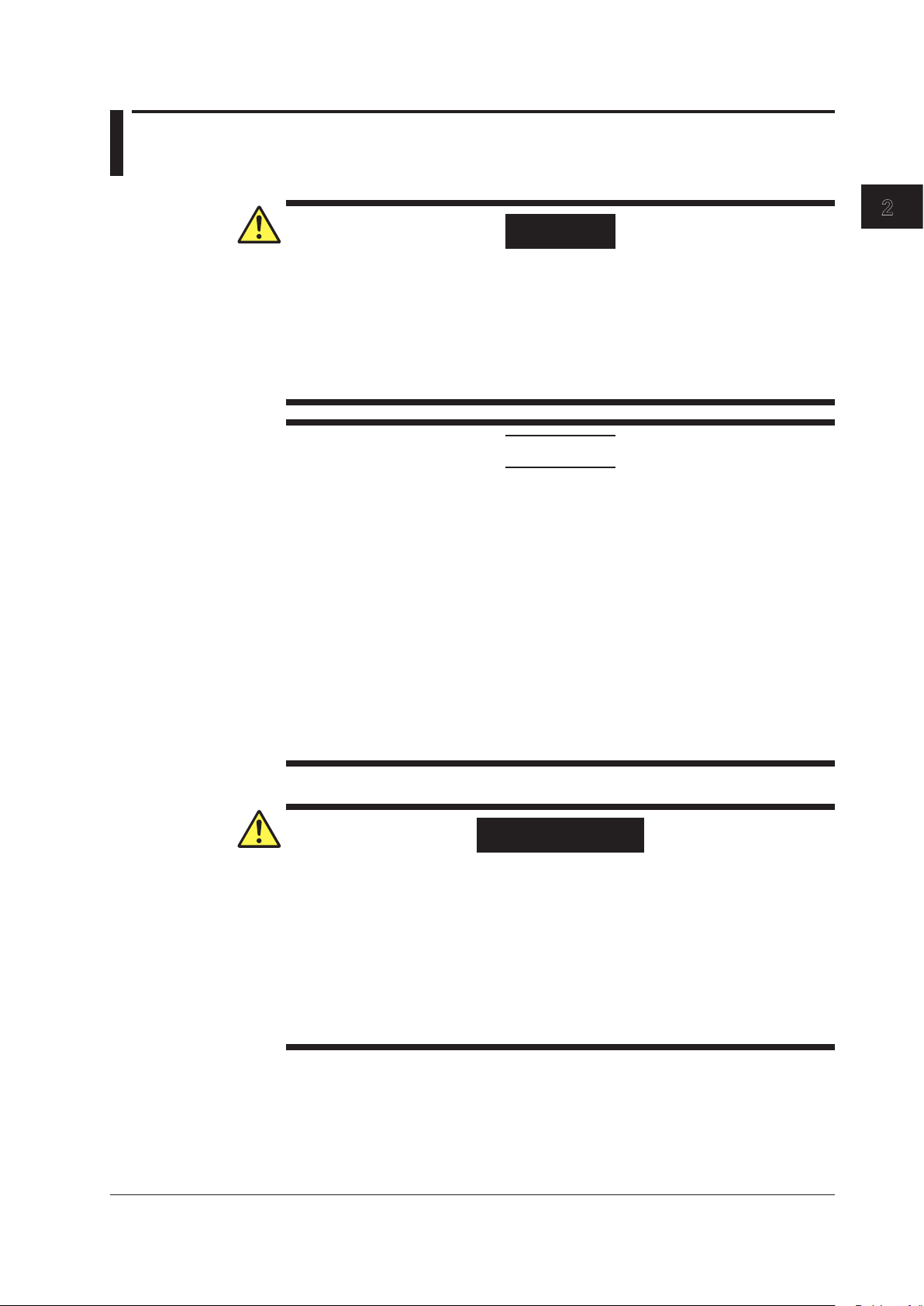

Installation Conditions

Install the instrument so that the following conditions are met.

Flat Horizontal Location

Place the instrument in a stable location that is flat in all directions. If the instrument is

used in an unstable or angled surface, the accuracy of the internal monochromator can

be compromised.

Location without Vibration

Do not install the instrument in a location subject to vibration. Use in a location that

experiences large vibrations can lead to instability of operation, measurement stopping

before completion, or notable decreases in accuracy of the wavelength and level axes.

Well Ventilated Location

Ventilation holes are present at the sides and rear of the instrument. To keep the

internal temperature from rising, always maintain a gap of 200 mm or more between the

ventilation holes and the installation surfaces.

2-2

IM AQ6360-02EN

Page 24

1

Inlet holes (also on the bottom panel)

2.1 Installing the Instrument

Also be sure to maintain sufficient clearance for connecting measurement cables.

20 cm or

more

20 cm or more

20 cm or

more

20 cm or

more

Ambient Temperature and Humidity

Ambient temperature: 5 to 35°C

Ambient humidity: 20%RH to 85%RH (no condensation present)

Note

Condensation may occur if the instrument is moved to another place where the ambient

temperature is higher, or if the temperature changes rapidly. In such cases, allow sufficient time

for the instrument to adjust to the ambient temperature before use.

When the instrument is packaged in a box and moved, prevent condensation by allowing

sufficient time for the instrument to acclimatize before removing it from the box.

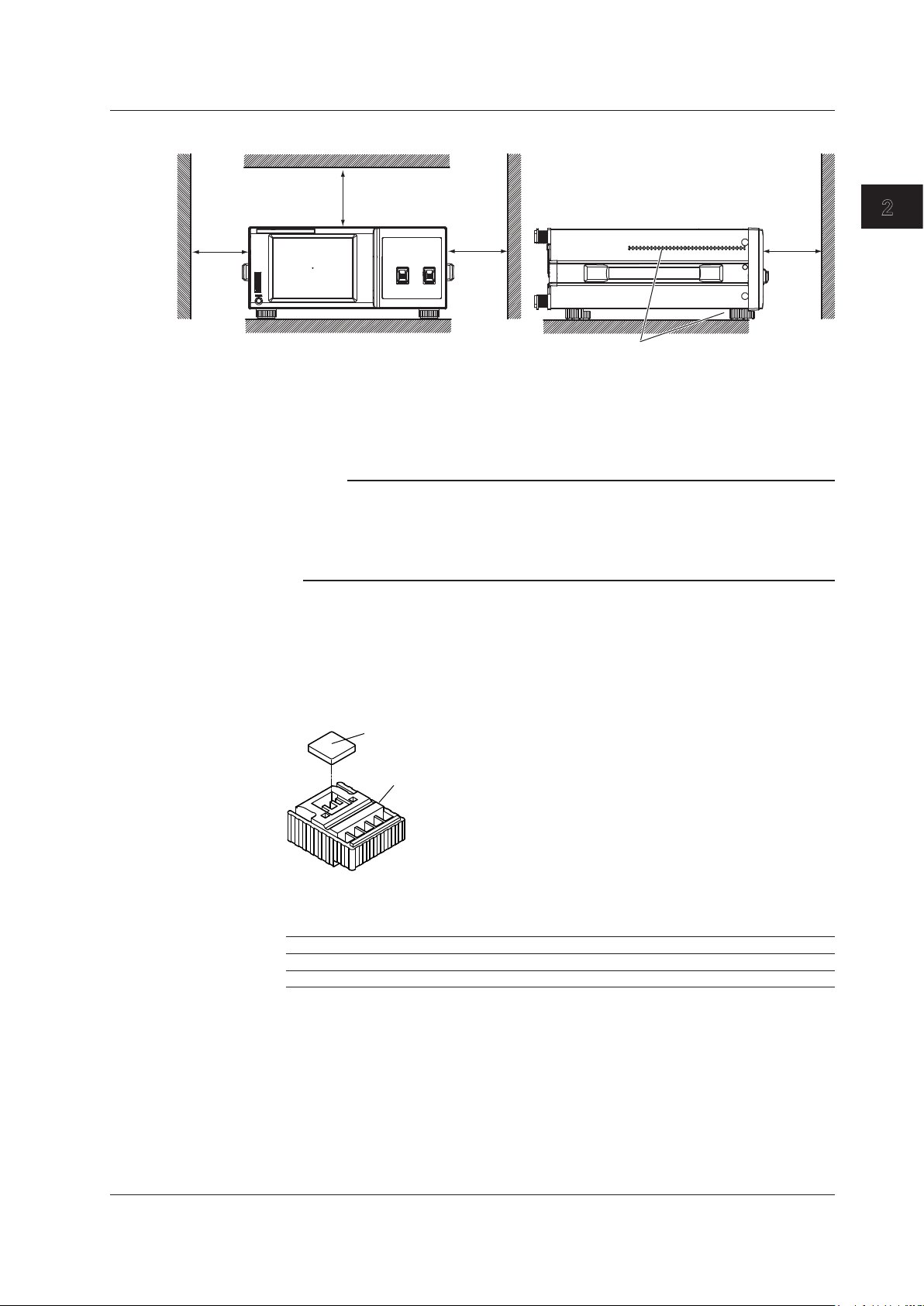

Flat, Even Surface

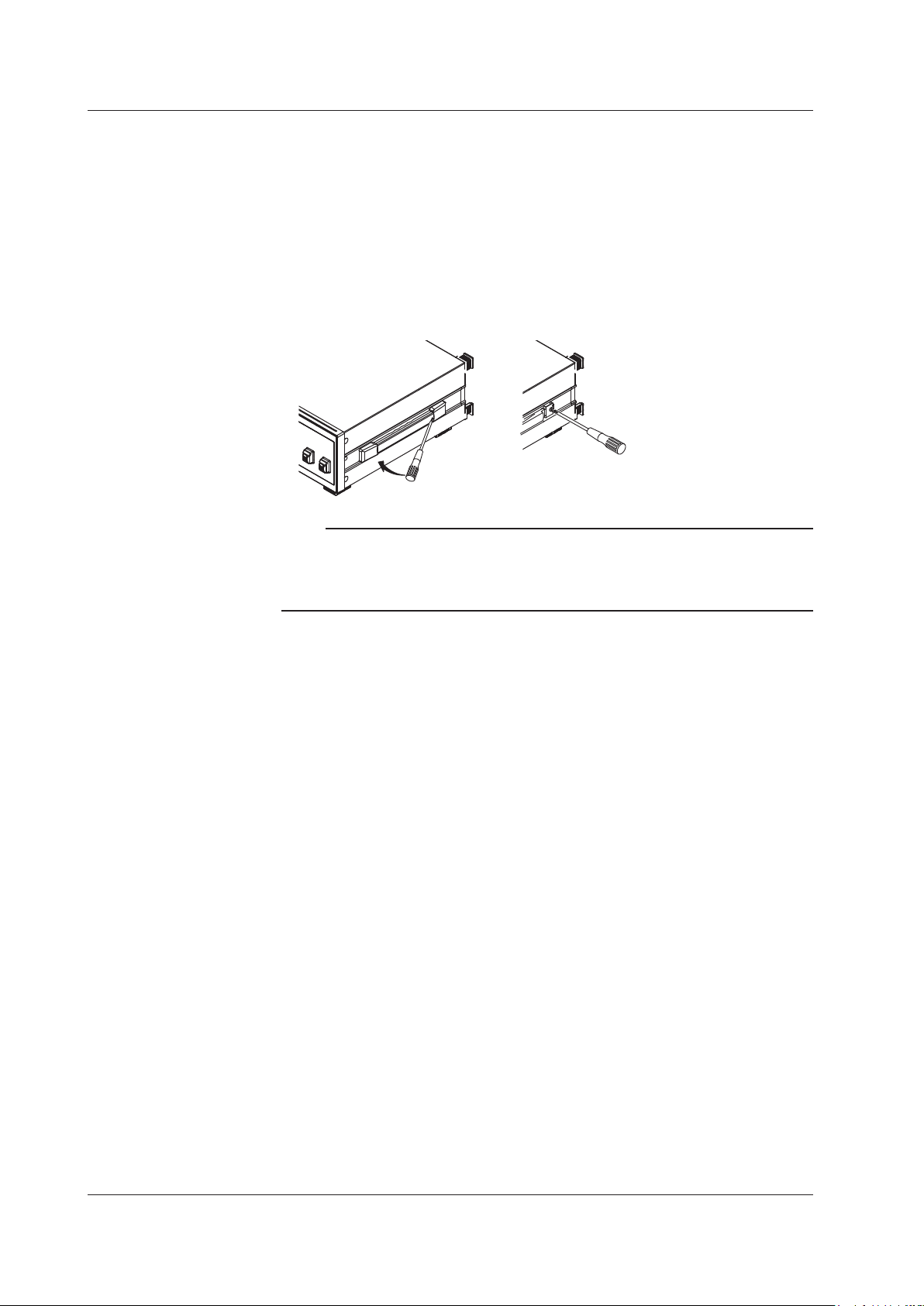

Install the instrument with the correct orientation on a stable, horizontal surface. If the

instrument is installed in a horizontal position, rubber stoppers can be attached to the

feet at the rear of the instrument to prevent the instrument from sliding. One set of rubber

stoppers (two stoppers) are included with the instrument.

2

Preparing for Measurement

Rack Mounting

Rubber stoppers

A9088ZM

Feet at the rear of the instrument

To rack-mount the instrument, use the separately sold rack mount kit.

Product Name Model

Rack Mounting Kit for EIA Single 751535-E4

Rack Mounting Kit for JIS Single 751535-J4

IM AQ6360-02EN

2-3

Page 25

2.1 Installing the Instrument

An outline of the mounting procedure is given below. For detailed instructions, see the

manual that is included with the rack mount kit.

Remove the handles from both sides of the instrument.

1.

Remove the four feet from the bottom of the instrument.

2.

Remove the four seals the rack mount attachment holes on each side of the

3.

instrument near the front.

Place seals over the feet and handle attachment holes.

4.

Attach the rack mount kit to the instrument.

5.

Mount the instrument on a rack.

6.

Note

• When rack-mounting the instrument, allow at least 10 cm of space around the inlet and

exhaust holes to prevent internal heating.

• Make sure to provide adequate support from the bottom of the instrument. The support

should not block the inlet and exhaust holes.

Do Not Install the Instrument in the Following Places

• Outdoors.

• Dangerous locations where flammable or explosive gasses, vapors, or dust is present,

or where the possibility of explosions or fires exists.

• In direct sunlight or near heat sources.

• Where an excessive amount of soot, steam, dust, or corrosive gas is present.

• Location where mechanical vibration is high.

• In an unstable place.

• Where the instrument is exposed to water or other liquids.

General Handling Precautions

• Take Proper Care When Carrying the Instrument

Hold the instrument by the handles on the sides of the case. The instrument weighs

approximately 15.5 kg. Take precautions against injuries when carrying it.

turn the power switch OFF, remove the power cable, and confirm that no other cables

are connected before carrying the instrument.

• Do Not Place Anything on Top of the Instrument

Never stack instruments or place any other objects on top of the instrument, especially

those containing water. Doing so can lead to malfunction.

• Clean the Instrument Properly

When removing dirt from the case or the LCD, disconnect the power to the circuits

under test and the instrument, remove the instrument’s power cord from the power

outlet, then wipe gently with a clean, dry cloth. Do not use volatile chemicals since this

might cause discoloring and deformation.

Also, always

2-4

IM AQ6360-02EN

Page 26

1

2.2 Attaching the Connector Adapter

Attach the optional connector adapter before using the instrument.

WARNING

Always turn the power OFF before replacing the connector adapter. This instrument

has a built-in reference light source for wavelength calibration (/LFC, /LSC option)

and transmits infrared light from the optical output connector at all times. Never

look into the optical output connector. Infrared light entering the eyes can cause

severe injury and loss of vision.

CAUTION

• As there may be dust adhering to calibration output, be sure to clean it before

attaching the connector adapter.

• Do not exhale or blow compressed air into the monochromator from the optical

input. Doing so may allow dust or other materials to enter the monochromator,

adversely affecting its optical performance. Also, if debris is adhering to the

optical components inside the monochromator when a strong light source is

input, the monochromator may be damaged.

• When attaching or removing the connector adapter, carefully insert it

perpendicularly to the ferrule so as not to damage the ferrule end.

• Moving the connector adapter to the right or left or inserting it forcefully can

damage the ferrule or the connector adapter.

2

Preparing for Measurement

French

AVERTISSEMENT

Toujours éteindre l’avant de remplacer l’adaptateur de connecteur.

Cet instrument dispose d’une source de lumière de référence intégrée pour les

ajustements d’alignement (/LFC, /LSC option). La lumière infrarouge est toujours

émise depuis le connecteur de sortie optique. Ne regardez jamais directement

dans le connecteur de sortie optique. La lumière infrarouge risquerait de gravement

vous blesser ou de provoquer une perte de vision.

IM AQ6360-02EN

2-5

Page 27

2.2 Attaching the Connector Adapter

ATTENTION

• Comme il peut y avoir de la poussière adhérant à la sortie d’étalonnage,

assurez-vous de le nettoyer avant de fixer l’adaptateur de connecteur.

• Ne pas expirer ou souffler de l’air comprimé dans le monochromateur de l’entrée

optique. Cela pourrait permettre à la poussière ou d’autres matériaux pour

entrer dans le monochromateur, nuire à ses performances optiques. En outre,

si des débris adhère aux composants optiques à l’intérieur du monochromateur

quand une forte source de lumière est entrée, le monochromateur peut être

endommagé.

• Lors de la fixation ou du retrait de l’adaptateur de connecteur, insérer

soigneusement perpendiculairement à la virole de manière à ne pas

endommager l’extrémité virole.

• Déplacement de l’adaptateur de connecteur vers la droite ou vers la gauche

ou en l’insérant de force peut endommager la virole ou de l’adaptateur de

connecteur.

A connector adapter is required for connecting the optical connector to the AQ6360.

On products whose optical connector (optical input) specification is -FC or -SC and those

with an /LFC or /LSC option, connector adapters come attached to the optical input and

calibration light source output on the instrument’s front panel.

On products without these options, attach a connector adapter appropriate for the optical

connector.

Note

Attachment Procedure

1.

2.

3.

4.

5.

A different connector adapter is used for OPTICAL INPUT and CALIBRATION OUTPUT. Make

sure not to use the wrong connector adapter.

Confirm that the power is OFF.

Open the optical connector cover at the front of the instrument.

Clean the ferrule edge of the optical I/O section using a swab soaked with a small

amount of pure alcohol.

Insert the connector adapter all the way in.

Push the connector adapter’s lock lever down.

The adapter has been attached correctly if the groove in the lock lever interlocks with the

latch pin of the optical input/output section.

2-6

IM AQ6360-02EN

Page 28

1

Removal Procedure

Panel

Optical input

Connector

SC type

SC type

2.2 Attaching the Connector Adapter

Confirm that the power is OFF.

1.

Turn the connector adapter’s lock lever up. The lock lever’s lock is released.

2.

Pull the connector adapter all the way out.

3.

Close the optical connector cover at the front of the instrument.

4.

2

Preparing for Measurement

Explanation

Types of Connector Adapter

The connector adapter for internal reference light output (AQ9441) comes in the following

two types.

FC type

The optical input connector adapter (AQ9447) comes in the following two types.

section

Ferrule

Latch pin

adapter

Lock lever

Attached

Optical Connectors Types

IM AQ6360-02EN

FC type

The instrument can use FC or SC type optical connectors.

Cap

FC type optical

connector

Cap

SC type optical

connector

2-7

Page 29

2.3 Connecting the Device

Connecting the Mouse

You can use a USB or PS/2 mouse.

Supported USB Mouse

The instrument can support a USB HID Class Ver. 1.1 compliant mouse (with wheel).

Connections

Connect a USB mouse to one of the USB interfaces on the front or rear panel of the

instrument.

Confirm that MAIN POWER switch on the rear panel is OFF.

1.

Orient the mouse connector so that it matches the orientation of the interface,

2.

then insert the connector.

Note

• There are 2 USB interfaces each on front and rear panels, but do not connect more than

one mouse at a time.

• In addition to a USB mouse, the USB interfaces can be used to connect USB storage and

keyboards.

For information on operations using the mouse, see section 3.4.

Connecting a Keyboard

You can connect a keyboard for entering file names, comments, and other items. The

instrument features and settings are mapped to the keys on the keyboard, so you

can use the keyboard to perform the same operations that you can perform using the

instrument’s menus.

Supported Keyboards

The instrument supports any 101 English USB keyboard.

Connecting

Connect a USB keyboard to one of the USB interfaces on the front or rear panel of the

instrument.

Confirm that the MAIN POWER switch on the rear panel is OFF.

1.

Orient the mouse connector so that it matches the orientation of the interface,

2.

Note

• There are 2 USB interfaces each on front and rear panels, but do not connect more than

• In addition to a USB keyboard, the USB interfaces can be used to connect USB storage and

then insert the connector.

one keyboard at a time.

a USB mouse.

2-8

For information on operations using the keyboard, see section 3.4.

IM AQ6360-02EN

Page 30

1

Connecting a USB Storage Device

Supported USB Storage Devices

The instrument supports USB memory (USB card adapters).

You cannot use a USB storage device not recognized by the instrument. If the USB

storage device’s drive is partitioned, only the primary partition (F:) is recognized. If there

are two or more USB storage devices, only the first connected device is recognized.

If you restart the instrument, it the USB storage devices that were connected will still be

recognized.

Connections

Connect the USB storage device to the USB connector on the front panel of the

instrument.

2.3 Connecting the Device

2

Preparing for Measurement

Removing

USB connector

See section 6.1 in IM AQ6360-01EN. (You will use the Remove USB Storage function

menu.)

CAUTION

Do not remove the USB storage device or turn the power OFF while the USB

storage device access indicator is blinking. This can damage the data on the device

or the device itself.

French

ATTENTION

Ne retirez pas le dispositif de stockage USB et ne coupez pas l’alimentation

lorsque le voyant d’accès au dispositif de stockage USB clignote. Cela risquerait

d’endommager le dispositif ou les données se trouvant sur ce dernier.

Connecting with Other Devices

The GP-IB interface or Ethernet interface can be used to connect external devices to this

instrument. For details, see the Remote Control User’s Manual, IM AQ6360-17EN.

Note

Before connecting a GP-IB instrument, such as an external computer, or a LCD monitor or

other display to the instrument, check the wiring, and be sure to turn OFF the power to the

instrument and the instruments to be connected first.

Leaving the power ON while making connections can damage the equipment.

IM AQ6360-02EN

2-9

Page 31

2.4 Turning the Power ON/OFF

Before Connecting the Power

Take the following precautions before turning on the power supply. Failure to do so can

result in electric shock or damage to instruments.

WARNING

• Before connecting the power cord, ensure that the power supply source voltage

matches the rated supply voltage of the instrument and that it is within the

maximum rated voltage of the provided power cord.

• Check that the instrument’s power switch is OFF before connecting the power

cord.

• To prevent electric shock or fire, be sure to use the power cord for the instrument

that is supplied by YOKOGAWA.

• Make sure to connect protective earth grounding to prevent electric shock.

Connect the power cord to a three-prong power outlet with a protective earth

terminal.

• Do not use an extension cord without protective earth ground. Otherwise, the

protection function will be compromised.

• If an AC outlet that conforms to the supplied power cord is unavailable and you

cannot ground the instrument, do not use the instrument.

French

AVERTISSEMENT

• Avant de brancher le cordon d’alimentation, vérifiez que la tension de la source

d’alimentation correspond à la tension d’alimentation nominale de l’instrument

et qu’elle est compatible avec la tension nominale maximale du cordon

d’alimentation fourni.

• Vérifiez que l’interrupteur d’alimentation de l’instrument est sur OFF avant de

brancher le cordon d’alimentation.

• Pour éviter tout risque de choc électrique ou d’incendie, utiliser exclusivement le

cordon d’alimentation fourni par YOKOGAWA et prévu pour l’instrument.

• Relier l’instrument à la terre pour éviter tout risque de choc électrique. Brancher

le cordon d’alimentation sur une prise de courant à trois plots reliée à la terre.

• N’utilisez pas de rallonge si celle-ci n’est pas reliée à la terre, car la fonction de

protection serait compromise.

• En l’absence de prise secteur conforme au cordon d’alimentation et dans

l’impossibilité de mettre l’instrument à la terre, ne pas utiliser l’instrument.

2-10

IM AQ6360-02EN

Page 32

1

Preparing to Turn ON the Power

The AQ6360 has a MAIN POWER switch for turning the main power ON/OFF, and a

POWER switch for starting and shutting down the instrument. The POWER switch is a

push-button switch; press once to turn it ON and press again to turn it OFF.

• Confirm that the MAIN POWER switch on the rear panel of the instrument is OFF.

• Connect the power cord plug to the power connector on the rear panel.

• Connect the other end of the cord to an outlet that meets the following conditions. Use

a grounded three-prong outlet.

Item

Rated supply voltage* 100 VAC to 240 VAC

Permitted supply voltage range 90 VAC to 264 VAC

Rated power supply frequency 50/60 Hz

Permitted supply frequency range 48 Hz to 63 Hz

Maximum power consumption Approx. 100 VA

* This instrument can use a 100 V or a 200 V power supply. The maximum rated voltage differs

according to the type of power cord. Before you use the instrument, check that the voltage

supplied to it is less than or equal to the maximum rated voltage of the power cord provided

with it (see page iii for the maximum voltage rating).

CAUTION

2.4 Turning the Power ON/OFF

2

Preparing for Measurement

Do not input a strong light source to the instrument when turning the power ON. If a

strong light source is input, the optical section can be damaged.

French

ATTENTION

Ne retirez pas le dispositif de stockage USB et ne coupez pas l’alimentation

lorsque le voyant d’accès au dispositif de stockage USB clignote. Cela risquerait

d’endommager le dispositif ou les données se trouvant sur ce dernier.

Power On and Screen Display

Connect the power cord to the power cord connector on the back side of the

1.

instrument.

Three-prong outlet

Power cord

(accessory)

IM AQ6360-02EN

2-11

Page 33

2.4 Turning the Power ON/OFF

Turn ON the MAIN POWER switch on the rear panel of the instrument. The

2.

POWER switch on the front panel of the instrument lights orange.

Wait a few seconds after step 2, and then press the POWER switch on the front

3.

panel of the instrument. The color of the switch turns from orange to green. The

operating system starts up, and initialization of the instrument begins.

The instrument will not start for a few seconds immediately after step 2 even if you press the

POWER switch.

The initialization screen appears, and the internal initialization process starts. STEP

1/9 through STEP 9/9 are displayed in the lower right part of the screen to indicate the

progress of initialization.

CAUTION

Do not press the POWER or MAIN POWER switches while initialization is in

progress. Doing so can cause malfunction.

French

ATTENTION

N’appuyez pas sur les interrupteurs POWER ou MAIN POWER pendant

l’initialisation. Cela pourrait provoquer des dysfonctionnements.

2-12

IM AQ6360-02EN

Page 34

1

2.4 Turning the Power ON/OFF

Operations Performed When the power is Turned On

When the initialization finishes successfully, the following measurement screen appears.

Appears only on models

with an /LFC or /LSC

option (with built-in

reference light source).

On models with an /LFC or /LSC option (with built-in reference light source), a message

prompting you to execute wavelength calibration appears. The message that appears is

shown below.

For this instrument to meet its specifications, a Wavelength Calibration must be

performed. Please perform according to the guidelines below.

2

Preparing for Measurement

Wavelength Calibration

Please perform a Wavelength Calibration after a 1-hour warm-up and before

starting a measurement. Unless the Wavelength Calibration is carried out, the

wavelength accuracy of this instrument cannot be guaranteed.

For details on wavelength calibration, see section 2.1 in IM AQ6360-01EN.

When the Power-on Operation Does Not Finish Normally

Turn off the power switch, and check that :

• The instrument is installed properly. See section 2.1, "Installing the Instrument."

• The power cord is connected properly. See the previous page.

If the instrument still does not work properly, contact your nearest YOKOGAWA dealer for

repairs.

If a memory error or other errors occur during initialization, initialization is cancelled at

the step in which the error occurs (STEP @/9, where @ is a number from 1 to 9). Then,

the screen changes to the measurement screen, and a warning message is displayed.

If this occurs, repairs are necessary. Contact your nearest YOKOGAWA dealer

immediately.

Note

The instrument retains the measurement conditions, the function menu state, the waveforms

that it is showing, and so on. When the power is turned ON, the state of the instrument prior to

the last shut down is restored. When the power is turned ON for the first time, the instrument

starts up in the factory default state.

IM AQ6360-02EN

2-13

Page 35

2.4 Turning the Power ON/OFF

Turning the Power OFF

CAUTION

French

ATTENTION

Do not cut the power to the instrument with the MAIN POWER switch on the rear

panel when an operation is in progress. The operating system configuration file will

not be backed up, possibly resulting in malfunctions upon start up the next time the

instrument is turned ON. Be sure to follow the procedure below to shut down the

instrument.

Lorsque l’instrument est en cours de fonctionnement, ne coupez pas son

alimentation à l’aide de l’interrupteur MAIN POWER situé sur le panneau arrière.

Le fichier de configuration du système d’exploitation ne serait pas sauvegardé, ce

qui entraînerait probablement des dysfonctionnements à la prochaine mise sous

tension de l’instrument. Suivez toujours la procédure ci-dessous.

Veiller à suivre la procédure ci-dessous pour arrêter l’instrument.

2-14

IM AQ6360-02EN

Page 36

1

2.4 Turning the Power ON/OFF

Press the POWER switch on the instrument’s front panel. A shutdown confirmation

1.

message appears, and Yes and No keys appear in the function menu.

Tap Yes. The message “AQ6360 is shutting down Please wait.....” appears, and

2.

the shutdown procedure begins.

If you do not want to shut down, tap No. The screen returns to the previous

screen.

After the POWER switch changes from green to orange, turn OFF the MAIN

3.

POWER switch on the rear panel of the instrument.

Shutdown is also possible by selecting SYSTEM from the Main Menu window.

Tap . The Main Menu window appears.

1.

Tap SYSTEM.

2.

Tap More to display the More 4/4 function menu.

3.

Tap Shut Down.

4.

Tap Yes. The shutdown procedure begins.

5.

After the POWER switch changes from green to orange, turn OFF the MAIN

6.

POWER switch on the rear panel of the instrument.

2

Preparing for Measurement

Note

If for some reason the instrument fails to shut down normally, hold down the

for approximately four seconds or longer to force standby mode. Note that the operating system

configuration file will not be backed up, possibly resulting in malfunctions upon start up the next

time the instrument is turned on.

POWER

switch

IM AQ6360-02EN

2-15

Page 37

2.4 Turning the Power ON/OFF

Explanation

Screen when the instrument was not shut down

If the shutdown procedure was not performed after the previous session, the following

message appears after start up.

Function failure may occur if the instrument is not shut down. When turning OFF the

power, always perform the shut down procedure.

Tap the screen to clear this message.

2-16

IM AQ6360-02EN

Page 38

1

2.5 Connecting the DUT

WARNING

Do not look at the optical fiber laser light that you are measuring or point the laser

at another person’s eye. Doing so may cause eye damage or impair one’s health.

CAUTION

• Before connecting an optical fiber to the instrument, make sure that the start-up

initialization process has finished. If a strong light source is input during start-up,

the optical section can be damaged.

• Be sure to clean the tip of the optical fiber’s optical connector before connecting.

• As there may be dust adhering to calibration output, be sure to clean it before

connecting optical fiber.

• Do not try to forcefully attach the optical fiber’s optical connector with the plug

inserted at a slanted angle. Doing so may damage the instrument’s optical

connector’s components or the connector itself.

• Before connecting the input light, make sure that it does not exceed the

AQ6360’s maximum rated level. If input light exceeding the maximum rated level

is introduced, the optical section may be damaged.

• Do not exhale or blow compressed air into the monochromator from the optical

input. Doing so may allow dust or other materials to enter the monochromator,

adversely affecting its optical performance. Also, if debris is adhering to the

optical components inside the monochromator when a strong light source is

input, the monochromator may be damaged.

• Press the optical connector hard against the cleaning surface of the special

cleaner to clean it. If it is not pressed hard against the cleaning surface, it may

not be possible to properly clean the optical connector.

2

Preparing for Measurement

French

AVERTISSEMENT

Ne regardez pas directement la lumière du laser à fibre optique et ne pointez pas

le laser vers le yeux d’une tierce personne, pour ne pas provoquer de blessures ou

de dommages oculaires.

IM AQ6360-02EN

2-17

Page 39

2.5 Connecting the DUT

ATTENTION

• Avant de connecter l’instrument à une fibre optique, vérifiez que la procédure

d’initialisation de démarrage est terminée. Si vous connectez une source de

lumière puissante au démarrage, la section optique risque d’être endommagée.

• Veillez à nettoyer l’extrémité du connecteur de la fibre optique avant le

raccordement.

• Comme il peut y avoir de la poussière adhérant à la sortie d’étalonnage,

assurez-vous de le nettoyer avant de fixer l’adaptateur de connecteur.

• Ne forcez pas le connecteur de la fibre optique dans la fiche en l’insérant de

manière inclinée. Vous risqueriez de l’endommager ou d’endommager ses

composants.

• Avant de connecter la lumière d’entrée, vérifiez qu’elle ne dépasse la valeur

nominale maximale de l’analyseur AQ6370D, car si tel était le cas, la section

optique pourrait être endommagée.

• Ne pas expirer ou souffler de l’air comprimé dans le monochromateur de l’entrée

optique. Cela pourrait permettre à la poussière ou d’autres matériaux pour

entrer dans le monochromateur, nuire à ses performances optiques. En outre,

si des débris adhère aux composants optiques à l’intérieur du monochromateur

quand une forte source de lumière est entrée, le monochromateur peut être

endommagé.

• Appuyez fermement le connecteur optique sur la surface nettoyante du

nettoyeur. Si vous n’appuyez pas fermement, le connecteur optique risque de ne

pas être correctement nettoyé.

Cleaning the Optical Fiber End Face

Firmly press the connector end face of the optical fiber against the cleaning

1.

While pressing the end face against the cleaner, turn it once.

2.

While pressing the end face against the cleaner, move it.

3.

Repeat steps 1 to 3.

4.

Note

• If you do not firmly press the connector end face of the optical fiber against the cleaner, the

• You can purchase an optical fiber connector cleaner from NTT-AT Corporation.

surface of the cleaner.

end face may not be cleaned completely.

2-18

IM AQ6360-02EN

Page 40

1

Connecting Optical Fibers

Light source

Optical fiber

Open the instrument’s optical input connector cover.

5.

Connect the optical fiber’s optical connector to the optical input connector on the

6.

instrument.

Setting the optical fiber connector

Tap . The Main Menu window appears.

7.

Tap SETUP. The function menu appears.

8.

Tap More 1/2.

9.

Tap Fiber Connector. NORM and ANGLED toggles each time you tap the menu.

10.

Set ANGLED if the optical fiber under test is APC (angle lap PC). Otherwise, set

NORM.

Note

• If you set Fiber Connector to ANGLED, is displayed in the measurement

conditions area.

• The instrument's measurement accuracy specification is for when Fiber Connector is set to

NORM.

2.5 Connecting the DUT

2

Preparing for Measurement

Connecting the DUT (Light Source)

Clean the top of the optical connector on the other end of the optical fiber with a

11.

Connect the optical connector on the other end of the optical fiber to the optical

12.

Measuring System

Explanation

Optical Connectors Types

The instrument can use FC or SC type optical connectors.

fiber cleaner.

connector on the DUT.

AQ6360

IM AQ6360-02EN

Cap

FC type optical

connector

Cap

SC type optical

connector

2-19

Page 41

1

2

Pinch out Pinch in

Chapter 3 Common Operations

3.1 Touch Panel Operations

Basic Touch Panel Operations

The basic touch panel operations are described below.

Tap

Tap refers to the act of gently hitting the screen with your finger.

This is used to select a menu, enter data, and so on.

Drag

Drag refers to the act of pressing your finger against the screen and sliding your finger.

This is used to move the displayed waveform or marker position.

Pinch Out and Pinch In

Pinch out refers to the act of pressing two fingers against the screen and spreading them

apart. Pinch in refers to the act of pressing two fingers against the screen and drawing

them together.

On a screen displaying waveforms, you can pinch out to zoom in and pinch in to zoom

out.

3

Common Operations

Note

For operations using a mouse or external keyboard, see section 3.4, “Using the Mouse and

External Keyboard.”

IM AQ6360-02EN

3-1

Page 42

Operation tool window

1 2 3 4

3.1 Touch Panel Operations

Displayed Waveform Operation

Waveforms can be moved or zoomed using touch panel operation.

Moving a Waveform

With the waveform displayed on the screen, drag the waveform display area in any

direction.

• Dragging vertically or horizontally limits the movement to vertical or horizontal

movement.

• When a waveform is moved vertically, the reference level also changes in sync.

• When a waveform is moved horizontally, the zoom center wavelength (center

frequency), the zoom start wavelength (start frequency), and the zoom stop

wavelength (stop frequency) also change in sync.

Zooming a Waveform

Operation Tool Window

With the waveform displayed on the screen, pinch out or pinch in the waveform display

area in any direction.

• Pinching out or pinching in vertically or horizontally limits the zoom operation to

vertical or horizontal zoom.

• When a waveform is zoomed vertically, the log scale (linear scale) changes in sync.

• When a waveform is zoomed horizontally, the displayed sweep span changes in sync.

When you move or zoom a waveform using touch panel operation, a scale operation

tool window appears. For details on the operation tool window, see section 3.2, “Menu

Operations.”

3-2

1 Returns to the state before the waveform was moved or zoomed (horizontal direction only).

2 Returns to the state before the waveform was moved or zoomed (vertical direction only).

3 Moves the waveform vertically so that the peak wavelength at the reference level.

4 Moves the waveform horizontally so that the peak wavelength at the zoom center wavelength

(center frequency).

IM AQ6360-02EN

Page 43

1

2

Marker Operation

▼: Moving marker

Dotted line for dragging

Line markers

3.1 Touch Panel Operations

When you tap the moving marker, a vertical dotted line appears at the marker. You can

move the moving marker by dragging this line horizontally.

3

Common Operations

You can move a line marker by dragging the line marker line.

Key Lock

This instrument allows the operation of keys other than the registered user keys to be

locked to prevent operation mistakes by the user. For details, see section 7.6, “Locking

the Keys” in IM AQ6360-01EN.

IM AQ6360-02EN

3-3

Page 44

3.2 Menu Operations

Function menu

Procedure

Function Menus

Function menus can be used to set all the functions of this instrument. You use the Main

Menu window to switch the functions displayed in a function menu.

Tap in the upper right of the screen. The Main Menu window appears.

1.

Tap the key of the function you want to configure. The function menu items on the

2.

right side of the screen change.

If there are several function menus, the next menu appears each time you tap the

key. You can also tap More in the function menu to change to the next menu.

Tap the appropriate function menu key.

3.

The value assigned to the key is selected, or the action assigned to it is executed.

Then the Main Menu closes.

You can also close the Main Menu window by tapping

at the upper right.

Main Menu window

3-4

IM AQ6360-02EN

Page 45

1

2

TRACE SETTINGS Window

TRACE SETTINGS Window

Select the active

trace.

Trace setting area

The TRACE SETTINGS window allows you to quickly configure the trace functions. You

can also set them using the function menus.

Tap the trace setting area in the upper right of the screen. The TRACE SETTINGS

1.

window appears.

Tap the item you want to set.

2.

You can move the TRACE SETTINGS window by dragging the title area.

To close the TRACE SETTINGS window, tap

3.2 Menu Operations

3

.

Common Operations

Set the write mode

or calculation mode.

Shows and hides

waveforms

IM AQ6360-02EN

3-5

Page 46

Displays the moving or advanced

Displays wavelength line markers and

3.2 Menu Operations

List Display

Measurement Condition Area Example (when setting the resolution)

A list is displayed when you tap a setting in the measurement condition area or waveform

display area.

To clear the list, tap an area outside the list.

You can quickly set measurement conditions. You can also set them using the function

menus.

Tap within the frame of a value in the measurement condition area.

1.

A list of values appears.

Tap the item you want to set.

2.

Note

• When you tap a setting that requires a value to be entered, a parameter input window

appears. For details, see section 3.3, “Entering Numerical Values and Strings.”

• A list is also displayed for settings not in the measurement condition area if the settings

require a value to be selected from several options.

• If settings do not fit in the list, a scroll bar appears at the right of the list. Hidden settings can

be displayed by dragging a setting in the list or the scroll bar.

Waveform Display Area Example (pop-up list)

You can quickly configure the marker display and other functions related to the displayed

waveform. You can also set them using the function menus.

Tap any area in the waveform display area. When using a mouse, right-click.

1.

A pop-up list appears where you tapped.

Tap the item you want to set to select it.

2.

marker and the operation tool window

the operation tool window

Pop-up list

Displays level line markers and the

operation tool window

Executes the currently set analysis

3-6

Displays the operation tool window

IM AQ6360-02EN

Page 47

1

2

Operation Tool Window

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

You can quickly change waveform display, marker, and other settings. You can also set

them using the function menus.

Tap the waveform display area to display a pop-up list.

1.

On the list, tap Marker, X Line Marker, Y Line Marker, or Scale.

2.

An operation tool window for the selected function appears.

An operation tool window is displayed also when you tap a moving marker or drag

Tap the item you want to set.

3.

To close the operation tool window, tap

a displayed waveform.

3.2 Menu Operations

3

Common Operations

.

Normal moving marker

Advanced marker

Pop-up list

Wavelength line marker

Level line marker

Scale

Shortcut Keys

The states of frequently used settings are displayed below the waveform display area at

all times.

You can change the following settings by tapping them. You can also set them using the

function menus.

1 Set the amount of level shift. 10 Turn on or off the auto scaling of the

subscale.

2 Set the amount of wavelength shift. 11 Turn on or off the auto configuration of the

reference level.

3 Set the noise mask value. 12 Turn on or off the auto configuration of the

center wavelength or center frequency.

4 Turn on or off the zoom area analysis/

search.

5 Turn on or off the inter-line marker analysis/

search.

6 Switch between vacuum wavelength and air

wavelength.

7 Turn on or off auto offset. 16 Start a single sweep.

8 Turn on or off auto analysis. 17 Stop sweeping.

9 Turn on or off auto search.

13 Turn on or off the inter-line marker sweep.

14 Turn on or off smoothing.

15 Start a repeat sweep.

IM AQ6360-02EN

3-7

Page 48

3.2 Menu Operations

Explanation

Main Menu Window

The Main Menu window consists of 15 keys for selecting the functions displayed in a

function menu, keys for starting and stopping measurements, and four keys for auxiliary

functions.

AUTO

Executes auto measurement.

REPEAT, SINGLE, STOP

Tap SINGLE or REPEAT to start a measurement and STOP to stop the measurement.

SWEEP

Contains sweep functions. A menu for setting auto setup and repeat sweep will appear.

CENTER

The CENTER key contains functions for setting the center wavelength and center

frequency for making measurements. The content of function menus changes depending

on whether the screen display mode is wavelength display or frequency display.

SPAN

The SPAN key contains functions for setting the wavelength span or frequency span

(sweep span) to be measured.

The content of function menus changes depending on whether the screen display mode

is wavelength display or frequency display.

LEVEL

Contains functions for level axis settings. A menu for setting the reference level will

appear.

SETUP

Contains functions for measurement condition settings.

ZOOM

Contains measurement waveform zoom functions.

A menu for setting waveform zoom display conditions will appear.

DISPLAY

Contains screen display functions.

A menu for setting split display and labels will appear.

TRACE

Contains trace mode functions.

3-8

MARKER

Contains marker display functions.

PEAK SEARCH

Contains functions for searching measurement waveform peaks and bottoms.

IM AQ6360-02EN

Page 49

1

2

3.2 Menu Operations

ANALYSIS

Contains measurement waveform analysis functions.

FILE

Contains functions for saving and loading waveform data from USB storage memory.

PROGRAM

Contains functions for controlling measurements using programs.

SYSTEM

Contains system functions. (Wavelength calibration, initialization of settings)

USER

Frequently used function menus can be registered to user keys. By registering them, you

can execute them with less steps.

COPY

Outputs measurement waveforms or lists shown on the screen to files.

PRESET

Clears all the internal information of the instrument except for the remote interface

(ETHERNET, GP-IB).

3

Common Operations

UNDO/LOCAL

The function varies depending on the state the instrument is in when you tap UNDO/

LOCAL.

The following table shows the UNDO/LOCAL functions depending on the instrument

states.

Status of Instrument Function

UNDO action is allowed If you tap UNDO immediately after changing a parameter

setting or changing or deleting data, the previous operation is

canceled, and the instrument returns to the previous state.

During user key registration If you tap UNDO while registering a user key, the registration

mode is canceled, and the function menu that was displayed

when you tapped SYSTEM appears again.