25” AVENGER COULTER

OPERATORS MANUAL

WITH PARTS IDENTIFICATION

2565-419_REV_E 07/2013

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website: www.yetterco.com

E-mail: info@yetterco.com

FOREWORD

You’ve just joined an exclusive but rapidly growing

club.

For our part, we want to welcome you to the group

and thank you for buying a Yetter Avenger Coulter.

This is a unique and revolutionary new product.

We hope your new Avenger coulter will help you

achieve both increased productivity and increased

efficiency so that you may generate more profit.

This operator’s manual has been designed into

four major sections.

Foreword, Safety Precautions, Installation and

Operation.

Throughout the manual references may be made

to left side and right side. These terms are used

as viewed from the operator’s seat facing the front

of the tractor.

This SAFETY ALERT SYMBOL

indicates important safety messages

in the manual. When you see this symbol, be

alert to the possibility of PERSONAL INJURY

and carefully read the message that follows.

The word NOTE is used to convey information that

is out of context with the manual text. It contains

special information such as specifications,

techniques, reference information of a

supplementary nature.

The word IMPORTANT is used in the text when

immediate damage will occur to the machine due

to improper technique or operation. Important will

apply to the same information as specified by note

only of an immediate and urgent nature.

It is the responsibility of the user to read the

operator’s manual and comply with the safe and

correct operating procedure and to lubricate and

maintain the product according to the maintenance

schedule in the operator’s manual.

The user is responsible for inspecting his machine

and for having parts repaired or replaced when

continued use of the product would cause damage

or excessive wear to the other parts.

It is the user’s responsibility to deliver his machine

to the Yetter dealer who sold him the product for

service or replacement of defective parts which

are covered by the warranty policy.

IMPORTANT: When raising 3 pt. Toolbars watch

tractor tire clearance. EXAMPLE: In most cases 3

pt. hitches require a cat. 2 or cat. 3 quick hitch

coupler to offset toolbar away from tractor tires.

YETTER MANUFACTURING CO.

309/776-4111

800/447-5777

309/776-3222 (FAX)

WARRANTY POLICY

Yetter Manufacturing warrants all products manufactured and sold by it against defects in material. This

warranty being expressly limited to replacement at the factory of such parts or products as will appear to

be defective after inspection. This warranty does not obligate the Company to bear cost of labor in

replacement of parts. It is the policy of the company to make improvements without incurring obligations

to add them to any unit already sold. No warranty is made or authorized to be made, other than herein set

forth. This warranty is in effect for one year after purchase.

Model Number:_________________________

Dealer :_______________________________

Yetter Manufacturing warrants its own products only and cannot be responsible for damage to

equipment on which mounted.

2

SAFETY

A brief description of signal words that may be used in this manual:

CAUTION: Used as a general reminder of good safety practices or to direct attention to unsafe practices.

WARNING: Denotes a specific potential hazard.

DANGER: Denotes the most serious specific potential hazard.

SAFETY PRECAUTIONS

You can make your farm a safer place to live and work if you observe the safety precautions given. Study

these precautions carefully and insist that they be followed by those working with you and for you.

Finally, remember this: an accident is usually caused by someone’s carelessness, neglect or oversight.

WARNING

Never clean, lubricate or adjust a machine that is in motion. Always lower or block the implement before

performing service.

If the machine must be serviced in the raised position, jack or block it up to prevent it from accidentally

falling and injuring someone.

Do not allow riders on the tractor or implement.

Use speeds and caution dictated by the terrain being traversed. Do not operate on any slope steep enough

to cause tipping or loss of control.

Be sure all personnel are clear of the immediate area before operating.

Read and understand the operator’s manual and require all other persons who will operate the equipment to

do the same.

Be familiar with all tractor and implement controls and be prepared to stop engine and implements quickly in

an emergency.

CAUTION

Consult your implement and tractor operator’s manual for correct and safe operating practices.

Beware of towed implement width and allow safe clearance.

FAILURE TO HEED MAY RESULT IN PERSONAL INJURY OR DEATH.

3

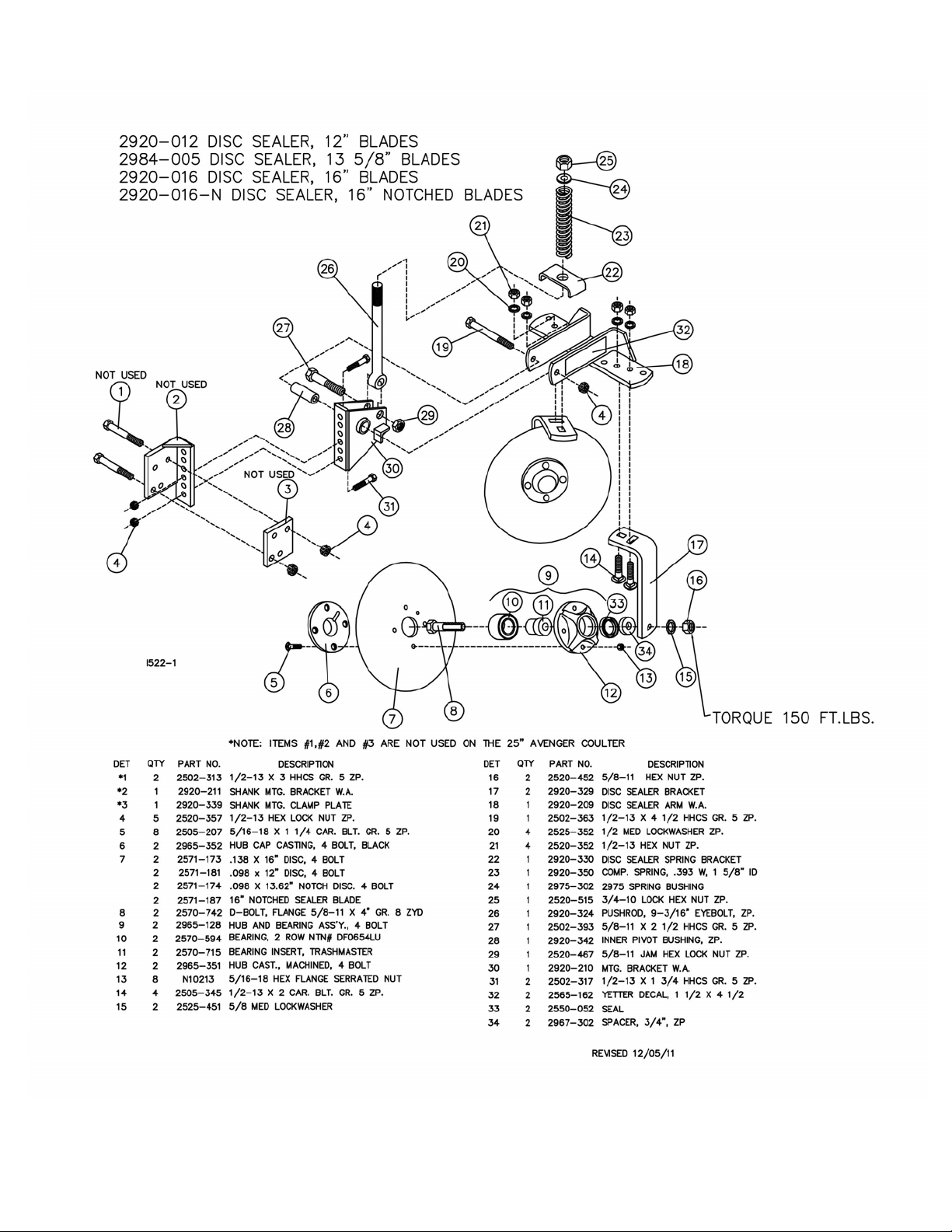

GENERAL INFORMATION

Examine all equipment carefully for damage or shortages.

2986-125 Avenger with Standard Mount

2986-124 – Avenger Main Arm Box

2986-126 – Avenger Standard Mount Kit

2571-200 – 25” Coulter Blade

2986-122 Avenger with 4 X 4 Mount

2986-124 – Avenger Main Arm Box

2986-123 – Avenger 4 X 4 Mount Kit

2571-200 – 25” Coulter Blade

NOTE: Right hand coulter can be converted to left hand coulter and left hand coulter can be converted to

right hand coulter.

Optional Equipment Available: 2986-108 – Skid Shoe Kit.

2920-012 – 12” Smooth Disc Sealer Kit

2984-005 – 13 5/8” Notched Disc Sealer Kit

2920-016 – 16” Smooth Disc Sealer Kit

2984-009 – Sealing Wheel Kit

2920-016-N – 16” Notched Disc Sealer Kit

Lubricate all bearings and moving parts as you assemble and see that they work freely.

NOTE: When you are behind the coulter looking forward, the right hand coulter is assembled with the blade to

the right hand of the arm assembly. The left hand coulter is assembled with the blade to the left hand of the arm

assembly.

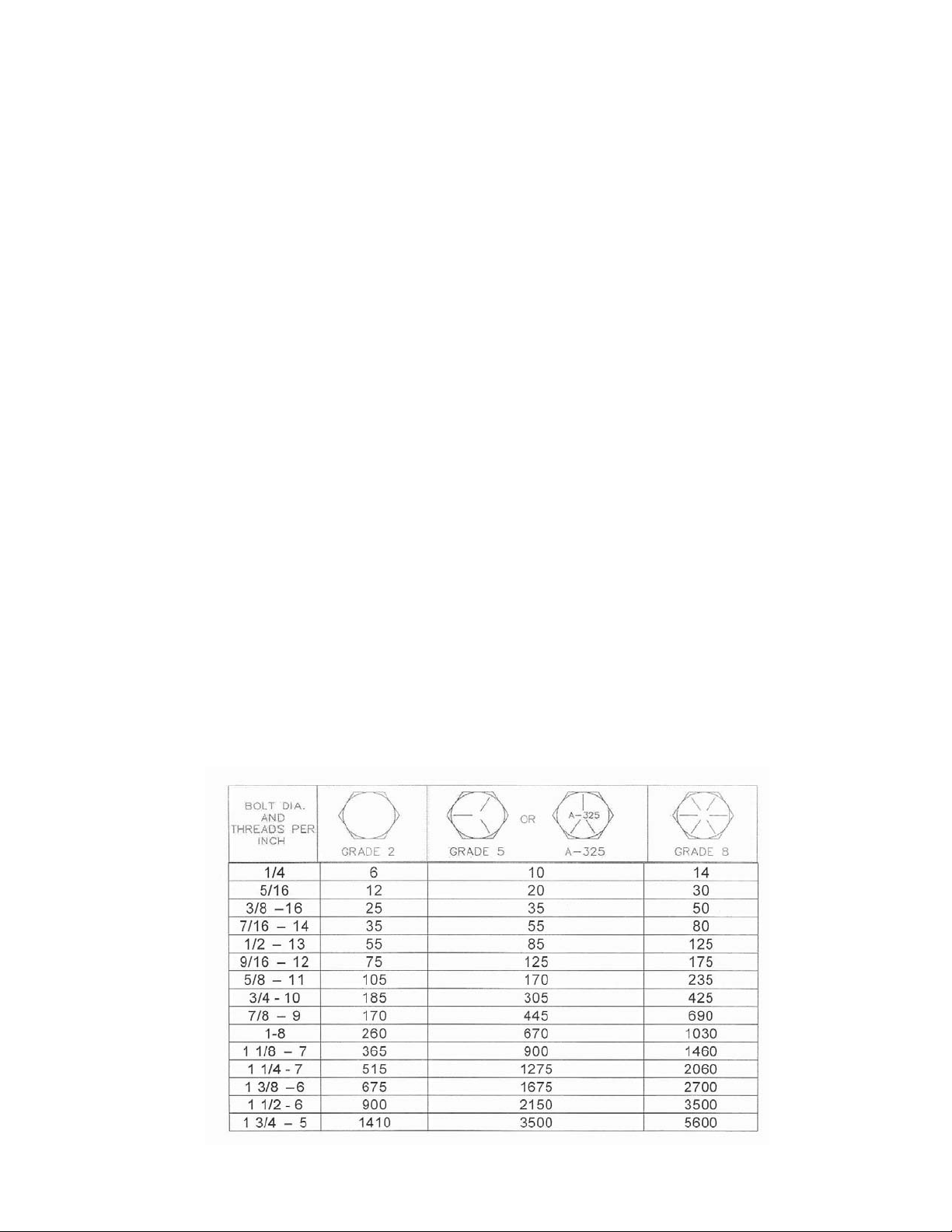

READ THESE INSTRUCTIONS FIRST:

1. Improperly tightened bolts will result in damage, breakage, expense, and down time.

2. Always replace bolts with the specified grade and type.

3. Torque properly before first use of the machine and every 2-4 hours of use until you are sure bolts are staying

tight.

4. The chart below is a guide for proper torque. Use it unless a specified torque is called out elsewhere in the

manual.

5. Torque is the force you apply to the wrench handle or the cheater bar, times the length of the handle or bar.

6. Use a torque wrench whenever possible.

The following table shows torque in ft. lbs.

4

ASSEMBLY INSTRUCTIONS

The Avenger coulter is designed to mount to rectangular toolbars in three sizes: 5” x 7”, 6” x 6”or 7” x 7”.

WARNING:

lockups.

Never work under the toolbar while in a raised position without using safety

WARNING:

The Avenger coulter can be mounted to the toolbar using different techniques. One way is to

mount the main arm assembly to the toolbar and then attach the components one at a time. Another way is

to completely assemble the avenger coulter before attaching to the toolbar frame.

NOTE: To aid the assembly of the opener, it is recommended that a stand be constructed to temporarily

attach the opener and hold it in an upright position.

CAUTION:

techniques while handling and or maneuvering the coulter during assembly is very important.

Failure to do so may lead to personal injury or death.

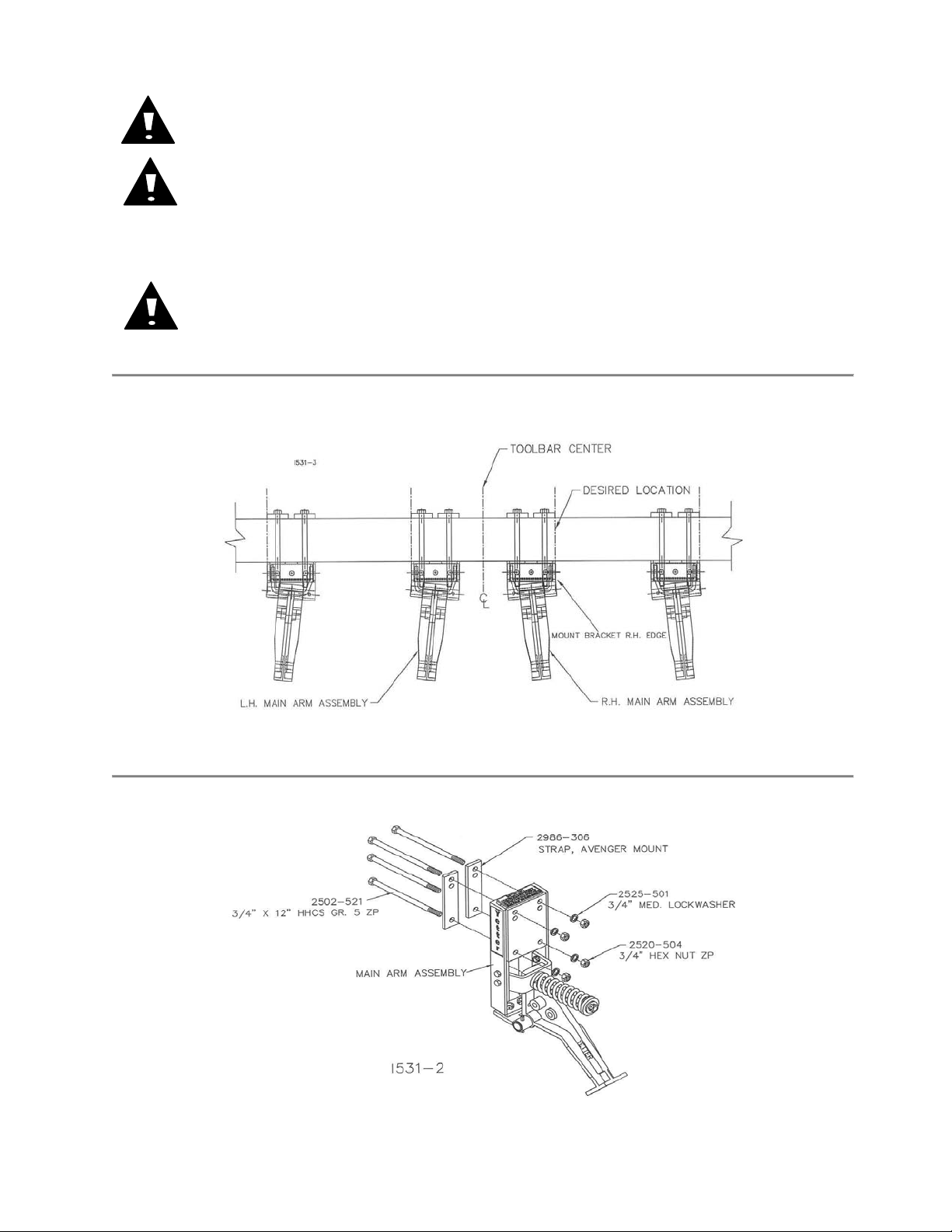

STEP 1. Mark the toolbar frame as to the location that each coulter is to be mounted. Right hand

assemblies are usually mounted on the right hand side of the toolbar and the left hand assemblies are

mounted on the left hand side of the toolbar.

Use extreme caution, the blade is sharp and may cause bodily injury.

The Avenger coulter and its components are very heavy. Extra attention to lifting

NOTE: The coulter blade is in line with the edge of the mount bracket, for a reference use the edge of the

mounting bracket (right hand edge for a right hand and left hand edge for a left hand) to align with the mark

on the toolbar so that the coulters are mounted at the desired spacing.

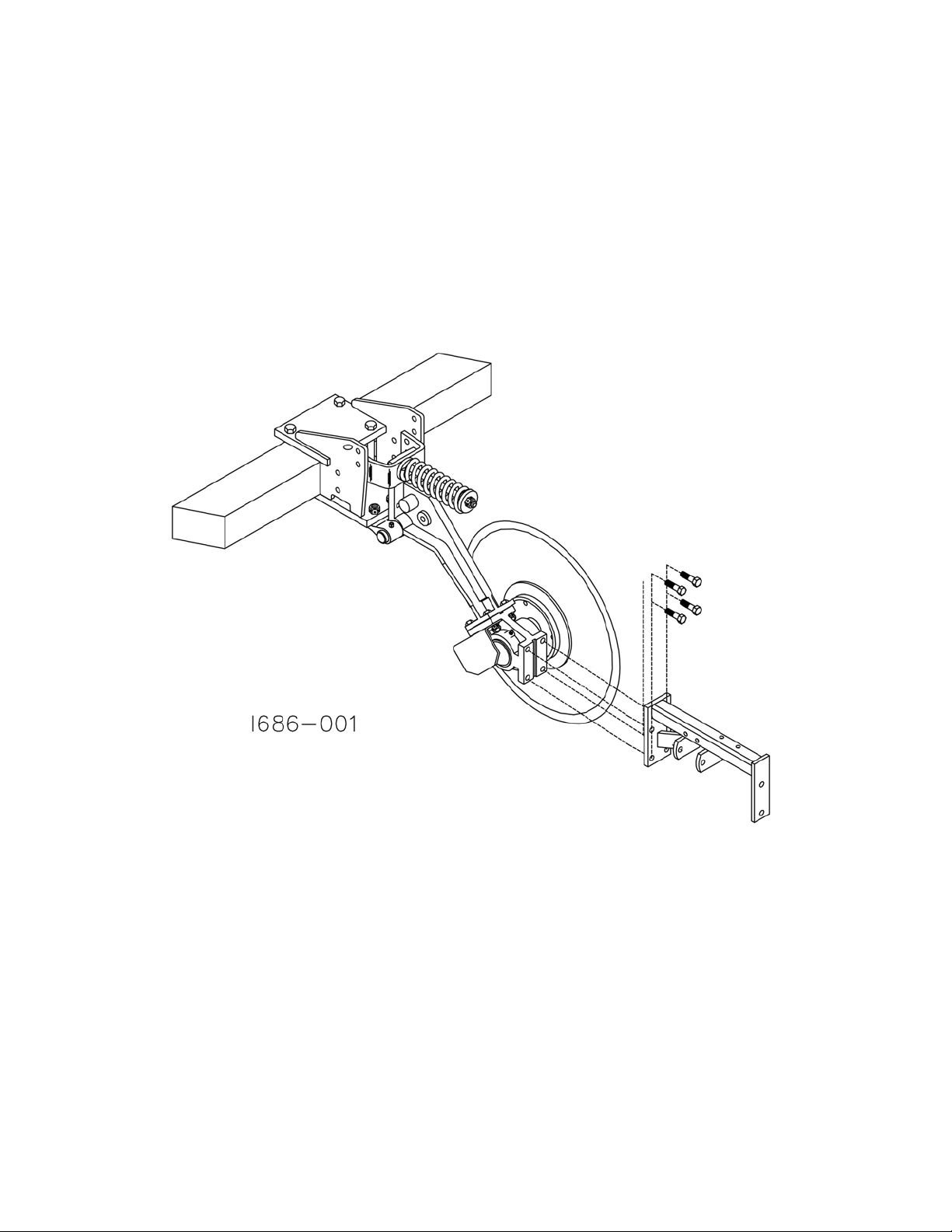

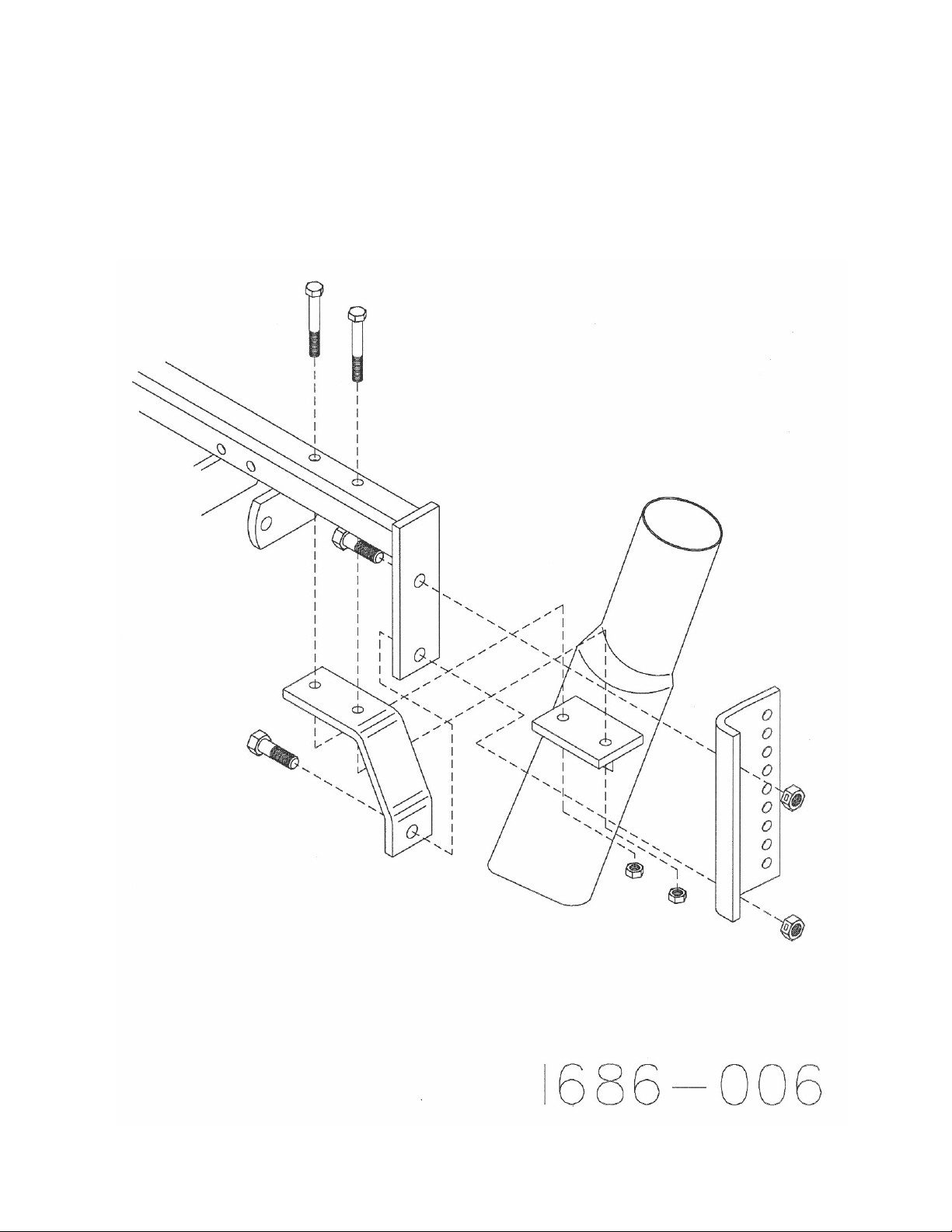

STEP 2. Attach the main arm assembly to the toolbar using 2) 2986-306 mounting straps, 4) ¾” x 12” hex

head bolts, ¾” lock washers and ¾” hex nuts.

5

ASSEMBLY INSTRUCTIONS

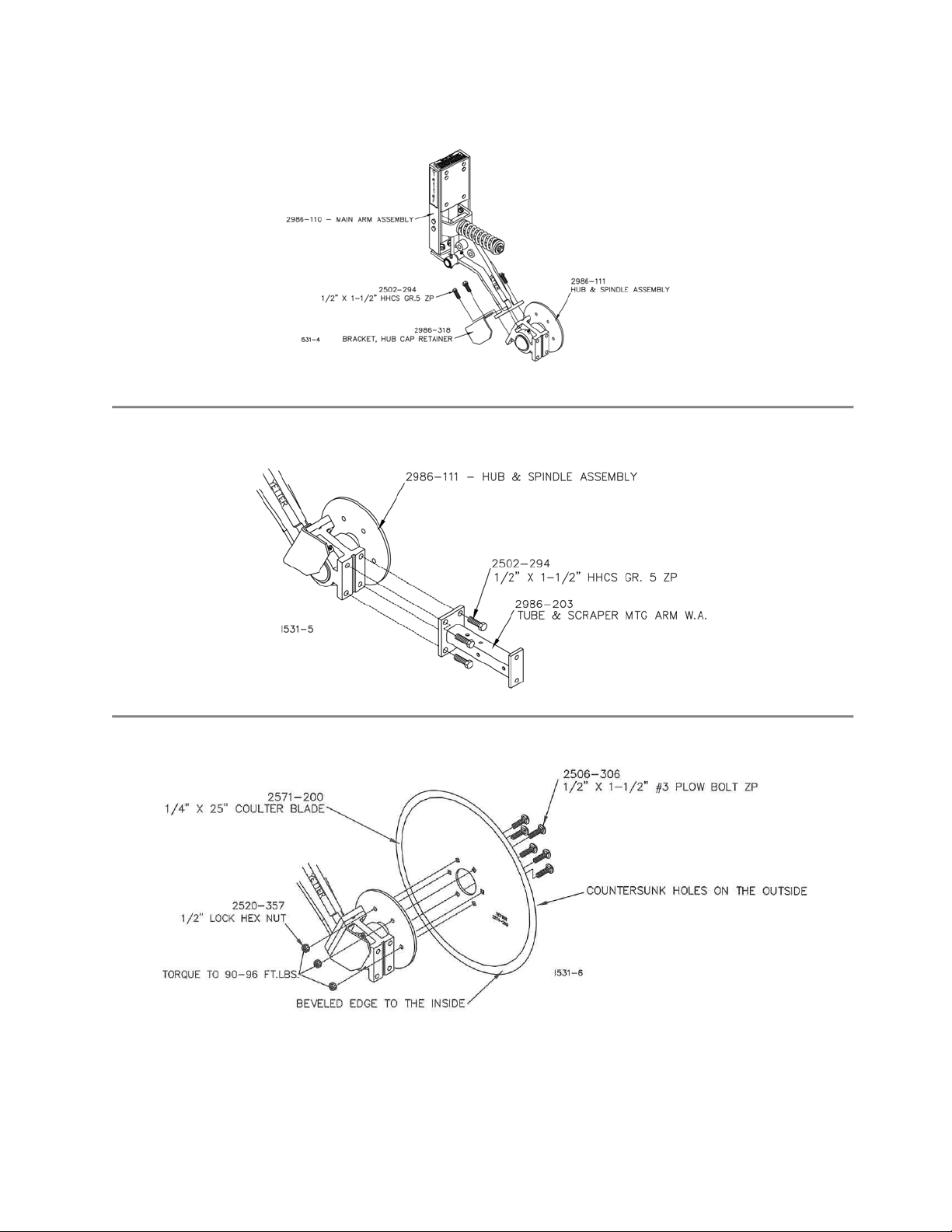

STEP 3. Attach the 2986-111 hub and spindle assembly and the 2986-318 hub cap retainer to the 2986-

110 main arm assembly using 4) ½” x 1-1/2” hex head bolts. The spindle hub will be mounted on the right

hand side for a right hand coulter and on the left hand side for a left hand coulter.

STEP 4. Attach the 2986-203 tube and scraper mount arm to the 2986-111 hub assembly using 4) ½” x

1-1/2” hex head bolts.

STEP 5. Attach the 2571-200 – 25” coulter blade to the 2986-111 hub and spindle using 6) ½” x 1 ½” plow

bolts and ½” hex lock nuts. Tighten buts to 90-96 ft. lbs. of torque.

6

ASSEMBLY INSTRUCTIONS

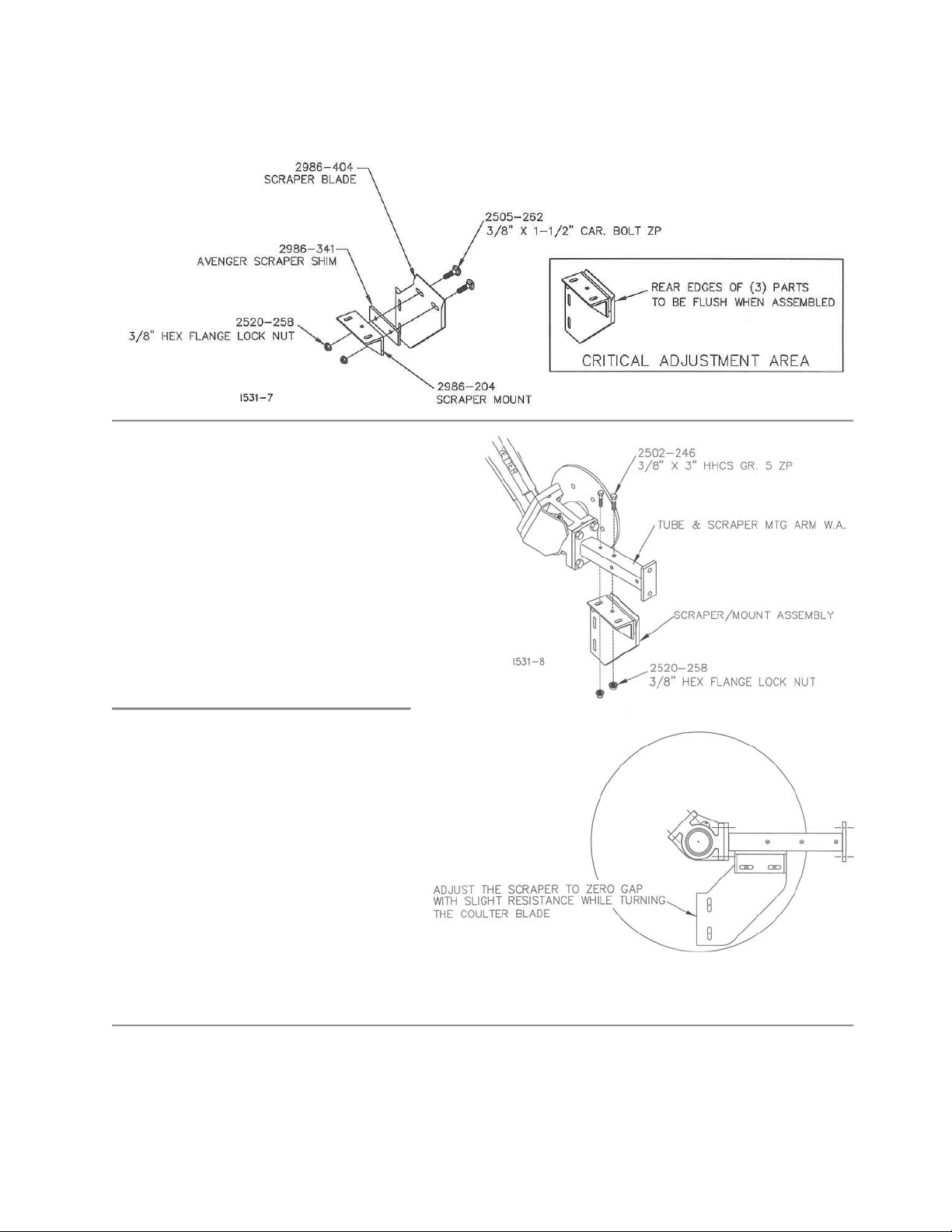

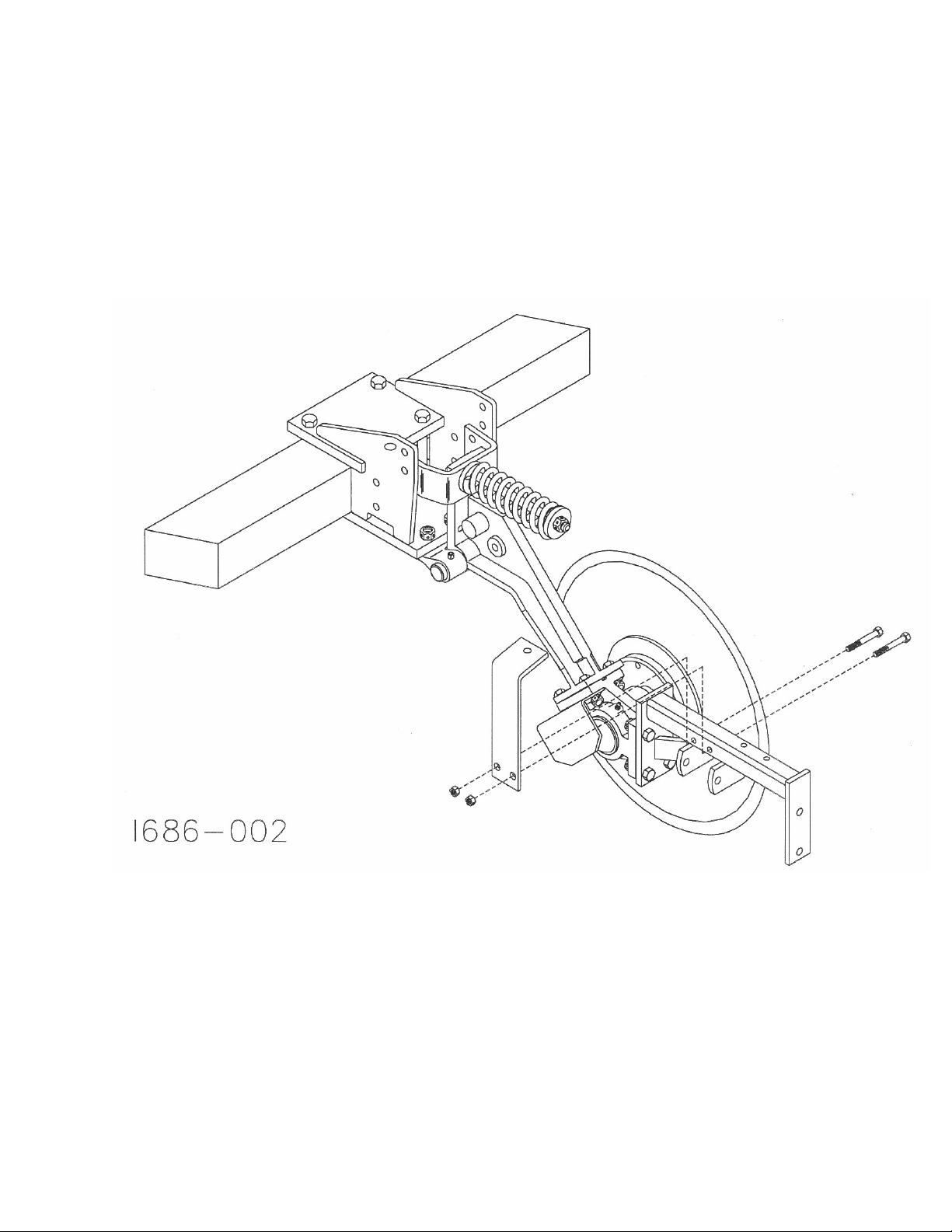

STEP 6. Assemble the 2986-404 scraper, 2986-341 shim and 2986-204 scraper mount w.a. using 2) 3/8” x

1 ½” smooth head carriage bolts and 3/8” flanged hex lock nuts. Adjust the scraper to the mount so that the

rear edges are flush with each other.

STEP 7. Attach the scraper and mount

assembly (from step 6) to the scraper

mounting arm using 2) 3/8” x 3” bolts and

3/8” flange lock nuts.

NOTE: Adjust the 2986-404 scraper to the

2571-200 blade . There should be zero

tolerance gap between the front edge of

the scraper and the blade, but the blade

should be able to turn with only slight

resistance.

CRITICAL ADJUSTMENT AREA

7

ASSEMBLY INSTRUCTIONS

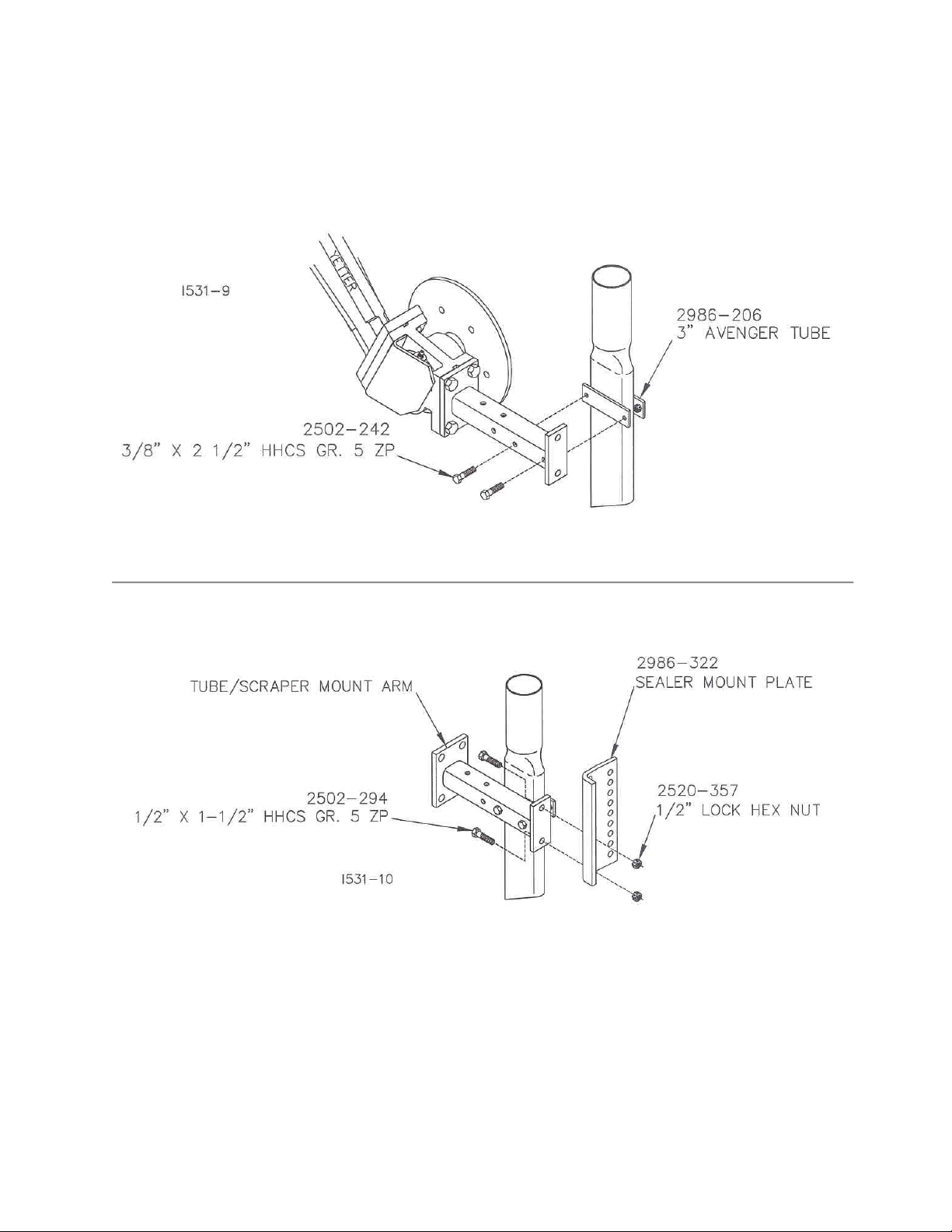

STEP 8. Attach the 2986-206 3” Avenger tube to the 2986-203 tube/scraper mount arm using 2) 3/8” x 2 ½”

bolts. Insert the bolts through the two most rear holes of the mount arm.

STEP 9. Attach the 2986-322 sealer mount plate to the 2986-203 tube scraper mount arm using 2) ½” x 1

½” hex head bolts and ½” lock nuts.

8

ASSEMBLY

2986-120 SPRING LOADED SCRAPER

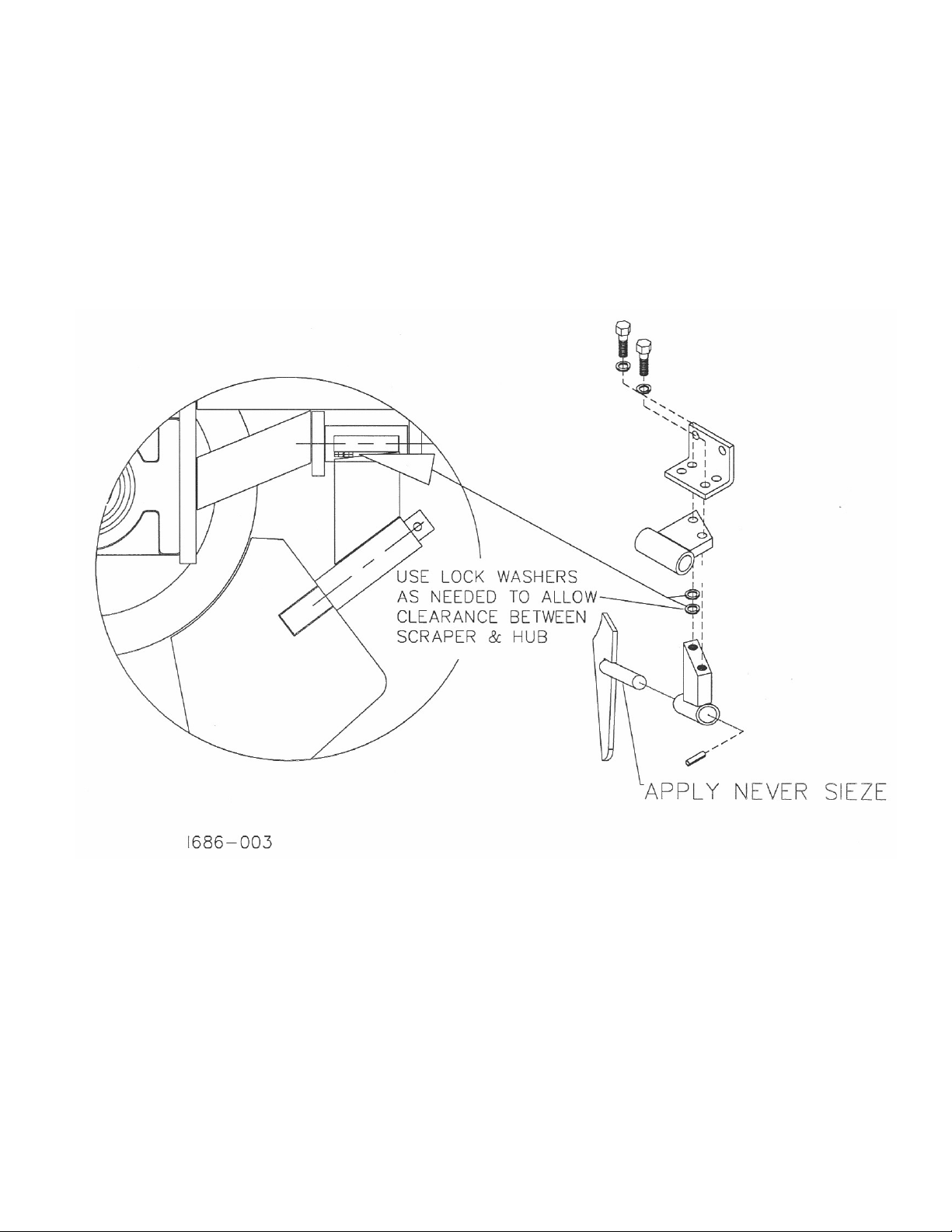

Step 1. Attach the 2986-218 knife arm to the coulter hub using the 4) 1/2” x

1-1/2” bolts.

9

ASSEMBLY

2986-120 SPRING LOADED SCRAPER

Step 2. Attach the 2986-343 spring adjustment to the knife arm using the 2)

3/8” x 3” bolts and flange nuts.

10

ASSEMBLY

2986-120 SPRING LOADED SCRAPER

Step 3. Assemble the 2986-215 scraper blade to the 2986-216 lower pivot,

apply never seize to the shaft and secure with the roll pin. Attach the 2986345 spring anchor and the 2986-217 upper knife pivot to the 2986-216 lower

knife pivot using 2) 3/8” x 1-1/2” bolts and lock washers.

11

ASSEMBLY

2986-120 SPRING LOADED SCRAPER

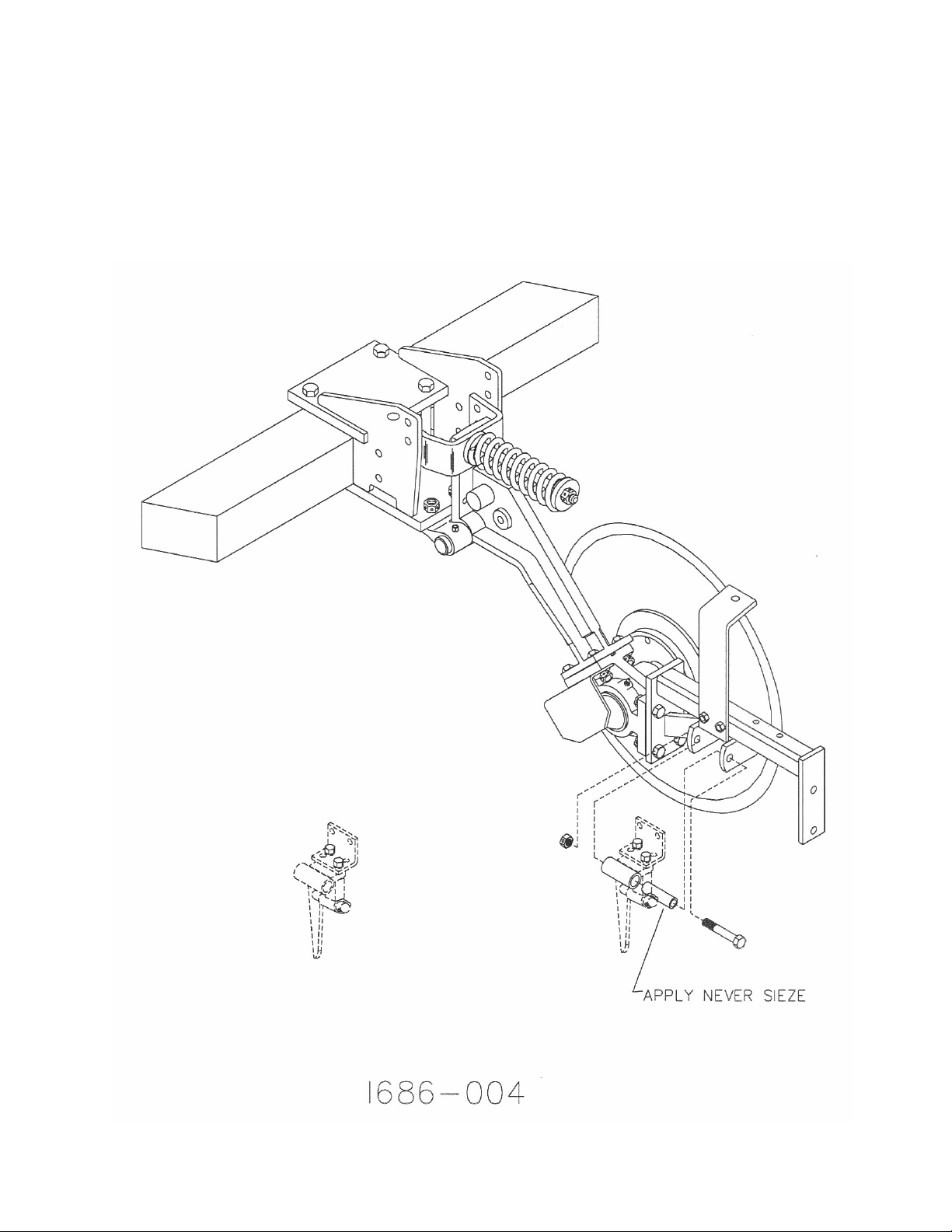

Step 4. Attach the knife assembly to the knife arm using the 1/2” x 4” bolt,

2986-346 bushing and lock nut.

12

ASSEMBLY

2986-120 SPRING LOADED SCRAPER

Step 5. Attach the springs to the 2986-221 adjustment block using the 2)

7/16” x 1-1/4” bolts and lock washer. Attach the springs to the knife

assembly then attach the spring adjustment assembly to the 2986-343

adjustment plate using the 1) 7/16” x 4-1/2” bolt, washer & hex nut.

Apply never seize

13

Step 5A.

ASSEMLBY

2986-120 SPRING LOADED SCRAPER

14

ASSEMBLY

2986-120 SPRING LOADED SCRAPER

Step 6. Attach the 3” Liquid tube and the 2986-344 knife arm brace to the

knife arm using 2) 3/8” x 3-1/4” bolts, 2) 1/2” x 1-3/4” bolts and lock nuts.

15

Step 6A.

•

ASSEMBLY

2986-120 SPRING LOADED SCRAPER

16

ASSEMBLY INSTRUCTIONS

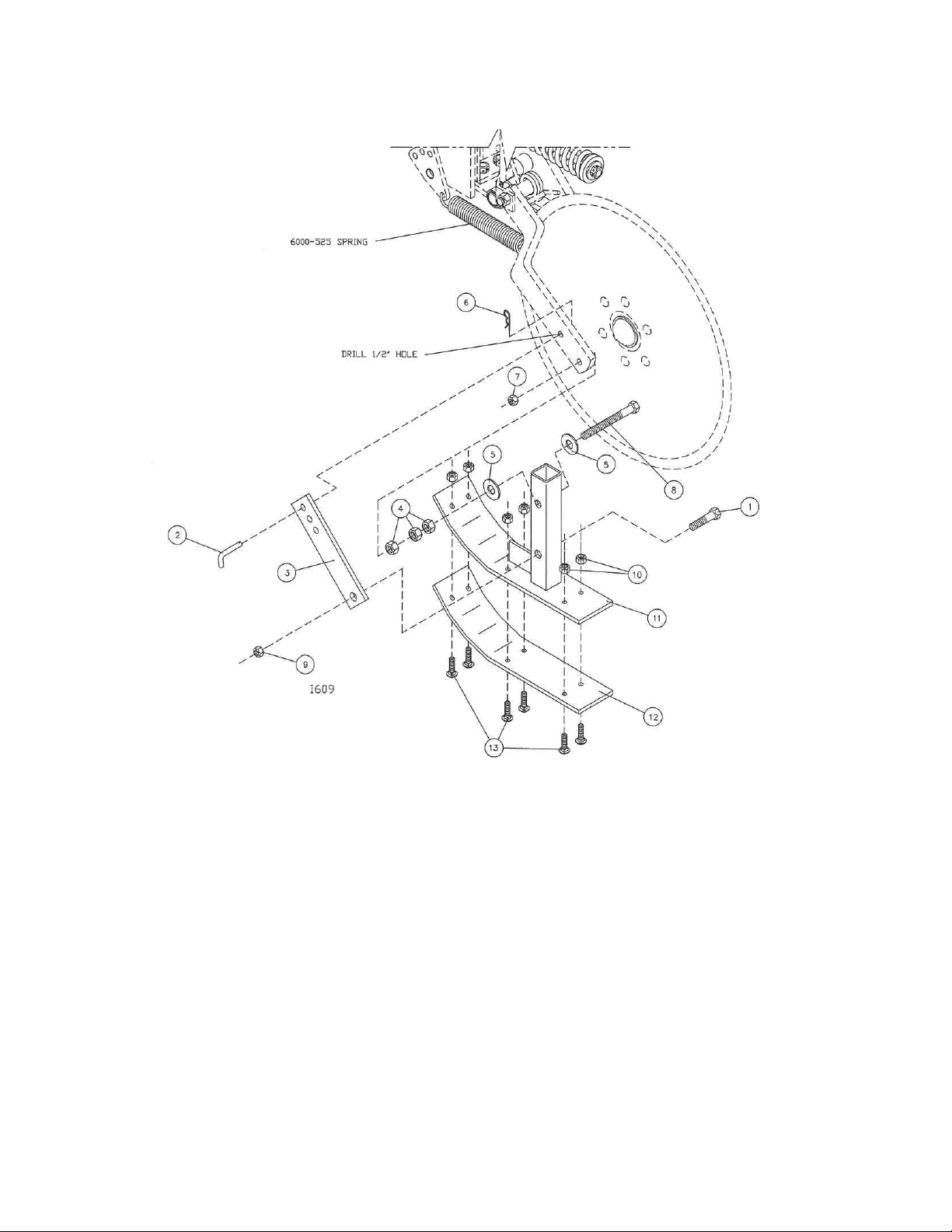

OPTIONAL EQUIPMENT

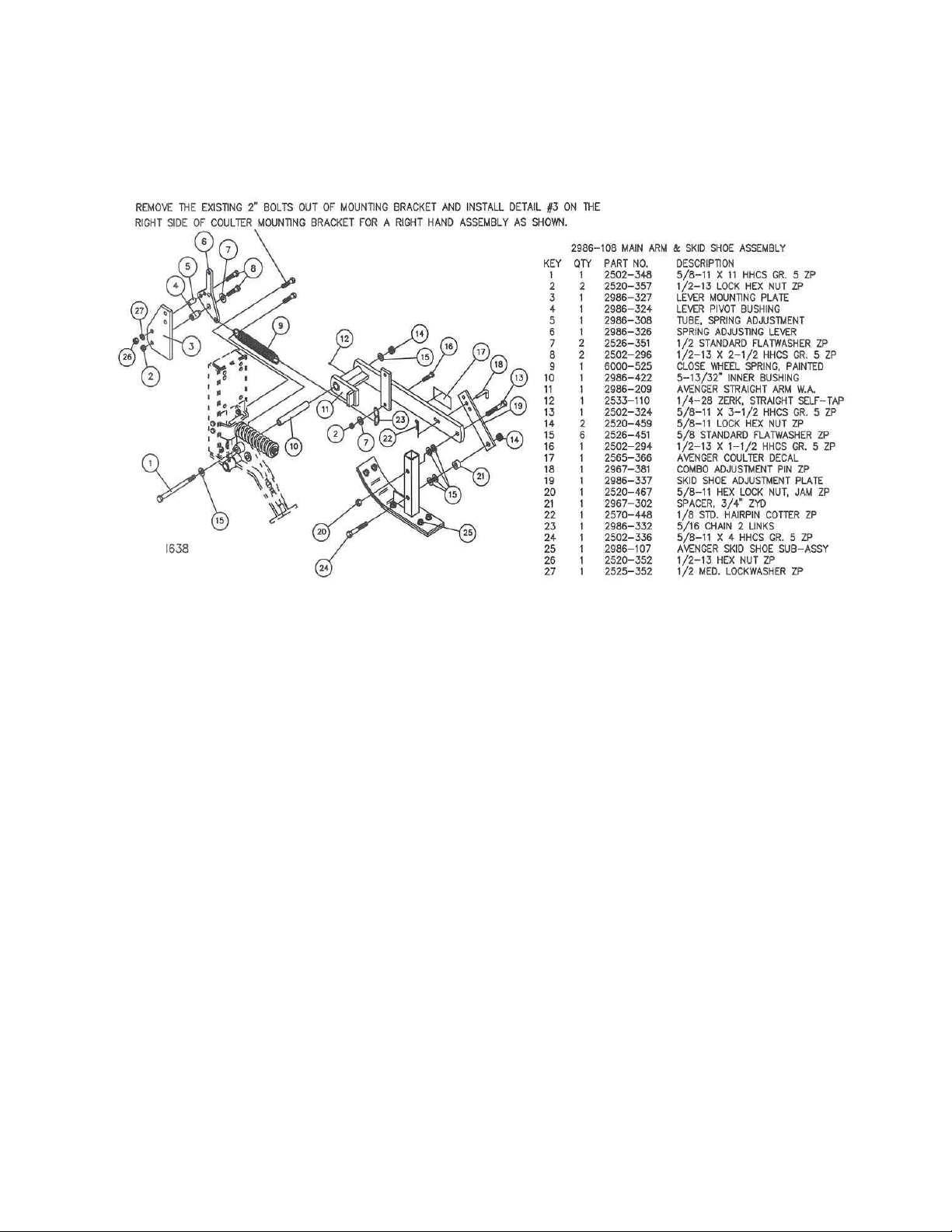

Assembly of 2986-108 Skid Shoe Kit.

The Skid Shoe can be attached to both R.H. and L.H. coulter assemblies. Begin by removing (2) ½” x 2”

bolts from the 2986-423 spring stop and save for the next step. Remove the bolts from the R.H. side when

working on a R.H. coulter or the bolts from the L.H. side when working on a L.H. coulter. Attach the 2986327 to the spring stop using (2) ½” x 2” hex head bolts and reusing the locknuts that were saved from the

previous step. Next, attach the grease zerk 2533-110 to the arm 2986-209 and also insert bushing 2986422 (pre-lube bushing before installing) and attach to the 25” Coulter assembly using (1) 5/8” x 11” hex

head bolt, (2) 5/8” flat washers and 5/8” hex lock nut. Attach the chain to the lower hole in the arm using (1)

½” x 1 ½” hex head bolt, ½” flat washer and ½” hex lock nut. Hook the 6000-525 spring to the chain link and

hook the other end into 2986-326 Spring Adjust Lever. Attach the adjustment lever to Lever Mounting Plate

first using a ½” x 2 ½” hex head bolt, 2986-324 bushing and ½” hex lock nut in the lower hole and using a ½”

x 2 ½” bolt, tube spacer and ½” lock nut in the upper hole. Now attach the Skid Shoe adjustment plate

2986-337 to the Skid Shoe Assembly 2987-107 using (1) 5/8” x 4” hex head bolt, (2) 5/8” flat washers, ¾”

spacer and (1) 5/8” hex lock nut. Fasten the Skid Shoe Assembly to the arm 2986-209 using (1) 5/8” x 3 ½”

hex head bolt, (2) 5/8” flat washers and (1) 5/8” hex lock jam nut.

Adjust. Set the shoe to the blade, equally front and back. Start with no gap between the blade and shoe.

Set the shoe just touching the blade.

17

ASSEMBLY INSTRUCTIONS

OPTIONAL EQUIPMENT

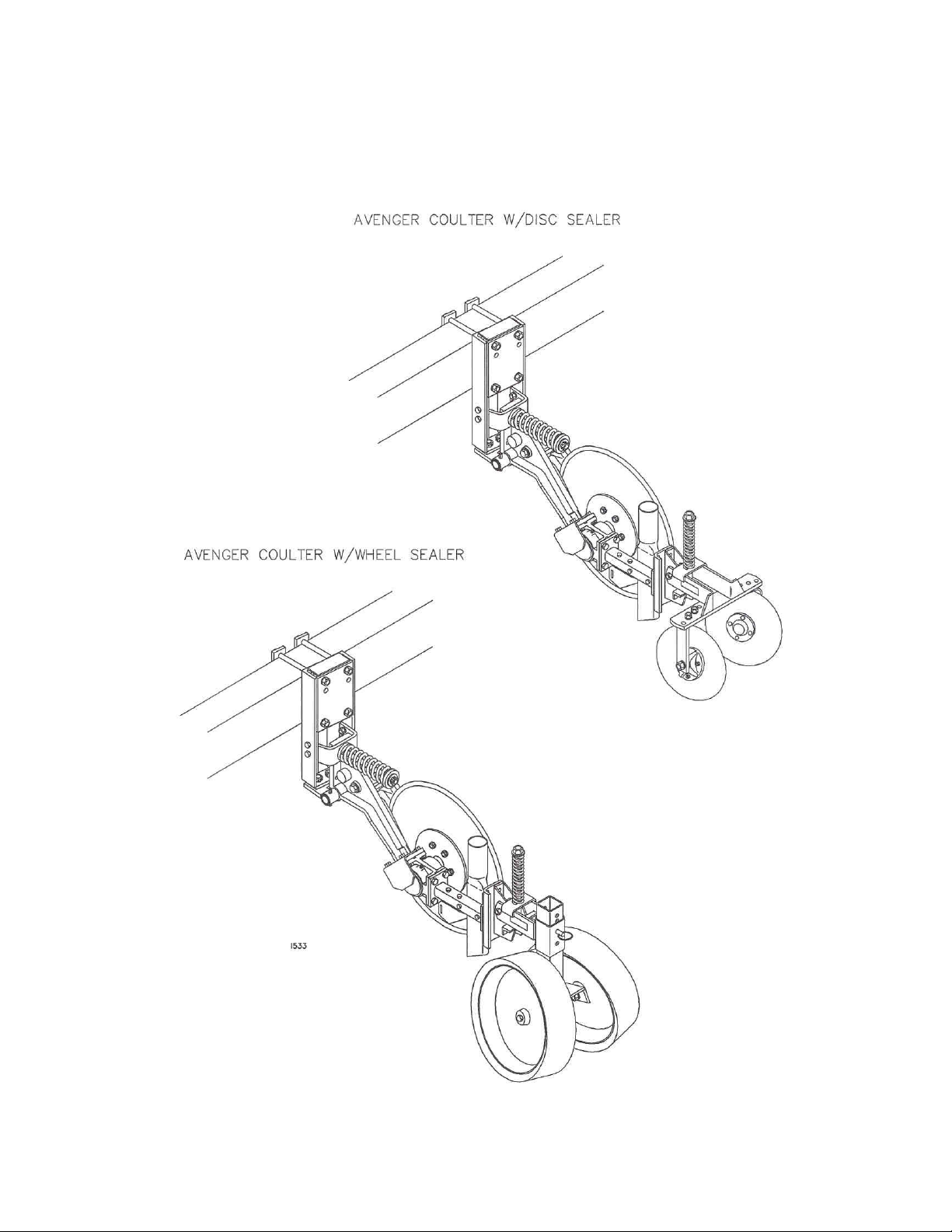

Attach optional sealing equipment to the Avenger at the sealer mount bracket using hardware that is

supplied with the sealing equipment kit. For proper operation of the closing system in field adjustments will

be required initially and as soil conditions change.

18

OPERATION

Yetter Model 2986 25” coulter is designed to inject liquid material 4”-8” deep below the

surface. Depth of operation of the coulter will vary depending on your particular

application.

IMPORTANT: For proper operation, the toolbar frame must operate level (for and aft) and at the

correct height, usually 22” – 25” while in operation.

In hard no-till conditions the desired operating depth may not be possible. Tighten the

spring pressure adjustment to obtain maximum depth if spring is flexing rather than lower

the toolbar frame below the 22” minimum recommended setting.

Toolbar weight may limit operating depth in hard soil conditions, ballast weight can be

added to the toolbar frame. Example, 200 lb. per coulter may be required to get desired

depth and obtain toolbar frame height of 22”-25”.

Coulter operating depth is affected by spring tension, toolbar height, levelness of toolbar

and soil conditions. As soil conditions change, toolbar settings and coulter adjustments

will need to be changed as well.

Toolbar gauge wheel kits are recommended for use with the Avenger coulter because of

toolbar frame height being very critical.

1. Set/mount coulter blades to run vertical to the soil. Operation depth and blade wear can

be affected if coulter is mounted crooked or if toolbar is not level side to side.

2. After a few hours use, check all bolts and setscrews for tightness and proper torque

settings.

3. After a day of use (10-12 hours), check coulter hubs for loose bearings. There should

be no end play in the hub bearings to allow it to wobble. If necessary, remove hub cap

and cotter pin, adjust slotted nut to remove wobble, recommended torque of 13 ft/lbs,

re-insert cotter pin and replace hub cap. If the wobble or looseness can not be

corrected, the bearings, cups and seal will need to be replaced. DO NOT RE-USE

WORN OR DAMAGED PARTS.

19

OPERATION

TOOLBAR FRAME HEIGHT ADJUSTMENT

Figure A. The toolbar frames are equally 22”-25” off the ground. To ensure that frame heights are equal, it

is important that measurements are taken. The tube frames should be parallel with the soil surface.

Figure B. The hitch is set too low while the toolbar frames are not equal distance from the soil surface.

NOTE: The illustrations are intended to show that the settings are critical. Tool frame levelness and

height adjustment are very important settings for correct performance of the coulters.

20

OPERATION INSTRUCTIONS

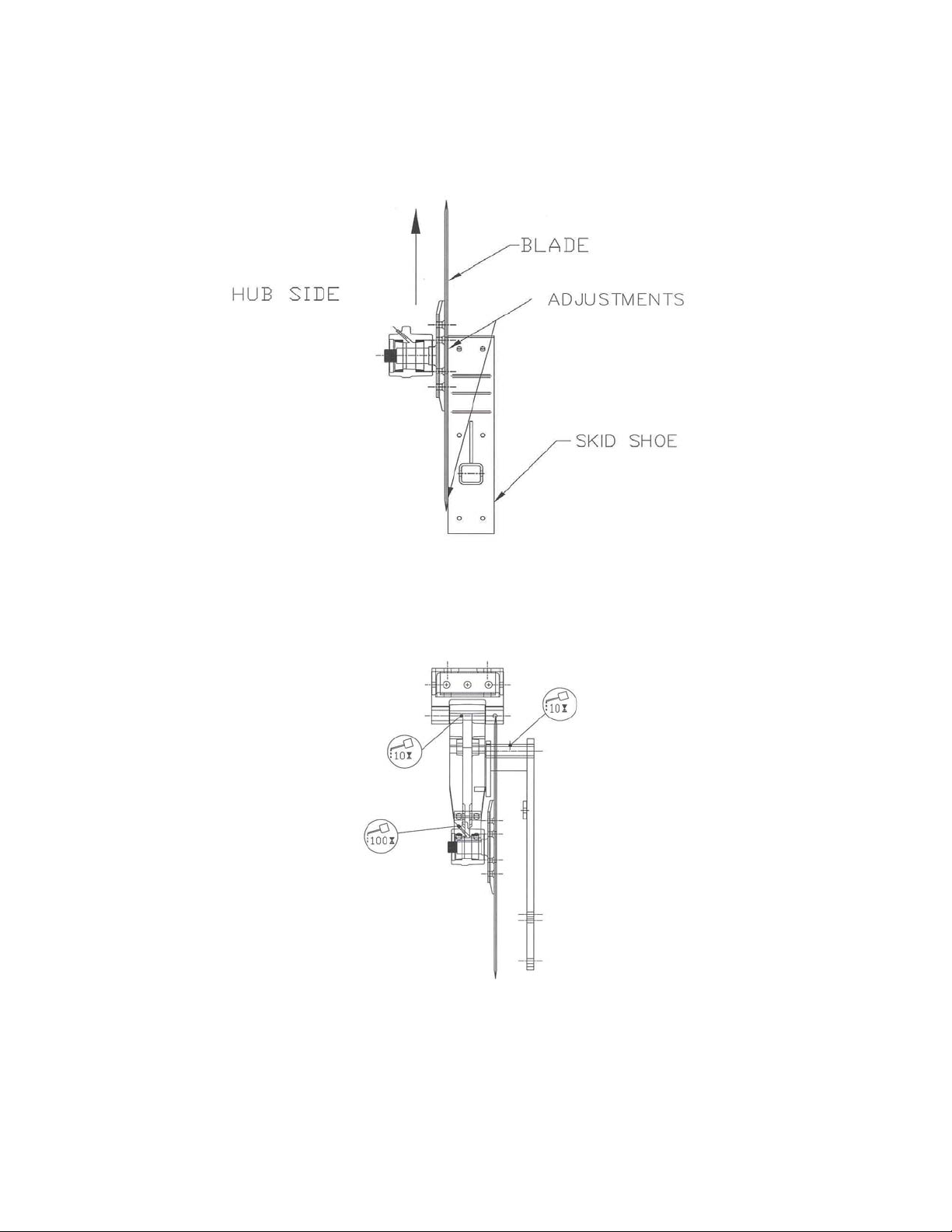

RIGHT HAND ASSEMBLY

DIRECTION OF TRAVEL

1. Adjust the shoe the same front and back.

2. Start with no gap between the blade and shoe.

3. Set the shoe just touching the blade.

OPERATION MAINTENANCE

LUBRICATION: Each coulter is equipped with (3) grease zerks. To ensure longevity and reliability of

the coulter, the recommended lubrication schedule should be followed using general purpose grease at

hourly intervals indicated on symbol.

21

OPERATION MAINTENANCE

BEARING ADJUSTMENT:

1. Raise the toolbar until the blade is clear of the ground. Place a safety stand under the toolbar.

Remove the blade. Remove the hub cap, cotter pin, slotted nut, washer and spacer from the

spindle shaft assembly.

2. Pull the coulter spindle shaft assembly from the hub. Remove bearing cones and seal.

3. Wash the old grease from the hub, bearing cups, coulter spindle shaft, seal and bearing cones.

Inspect the condition of bearing cups, cones and seal. Replace if necessary.

4. Apply #2 multi-purpose lithium grease on each bearing. Make sure the space around each roller is

filled. Lubricate the bearing cups.

5. Position the bearing in the cup and install the seal. Lubricate the seal lips and proceed with reassembly of the removed parts including the blade. Blade bolt torque is 90 to 96 ft/lbs.

6. Tighten the slotted nut to 10 to 15 ft/lbs. or until a definite drag is felt when the blade is turned by

hand. Back off the nut one slot position to line up the cotter pin hole with a slot. Secure the nut with

a new cotter pin.

SCRAPER WEAR:

The lower portion of the scraper and tube are subject to wear during operation. The rate of wear will

depend on a variety of factors and in abrasive hard soil conditions the wear will be more rapid.

NOTE: In certain areas, replacement scrapers should be kept in stock, replacing worn scrapers as

needed.

22

MAINTENANCE

BEARING ASSEMBLY AND LUBRICATION

Practice Safety

Understand and practice safe service procedures before doing work. Follow ALL the

operating, maintenance and safety information in the equipment operator manual. Clear

the area of bystanders, especially small children, when performing any maintenance or

adjustments. Keep work area clean and dry. Use adequate lighting for the job. Use only

tools, jacks and hoists of sufficient capacity for the job.

Never lubricate, service, or adjust machine while it is moving. Keep hands, feet, and

clothing from power-driven moving and rotating parts. Disengage all power and operate

controls to relieve pressure. Lower equipment to the ground and stop the engine.

Remove the key. Wait for all moving parts to stop before servicing, adjusting, repairing or

unplugging.

Securely support any machine elements with blocks or safety stands that must be raised

for service work.

Keep all parts in good condition and properly installed. Fix damaged equipment

immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris.

Make sure all guards are in place and properly secured when maintenance work is

completed.

Assembly

23

MAINTENANCE

NOTE: Be certain to align the grease fitting with the slot in the wheel and the hubcap so

that the grease can flow freely.

24

MAINTENANCE

Grease must fill this

Hubcap cavity.

25

MAINTENANCE

Lubrication

CAUTION: To help prevent serious injury or death to you or others caused by

unexpected movement, service machine on a level surface. Lower machine to

ground or sufficiently lock or block raised machine before servicing. If machine

is connected to tractor, engage parking brake and place transmission in

"PARK", shut off engine and remove key. If machine is detached from tractor,

block wheels and use shop stands to prevent movement.

CAUTION: Do not clean, lubricate, or adjust machine while in motion.

Use grease based on NLGI consistency numbers and the expected air temperature

range during the service interval.

Use a multi-purpose lithium, water resistant, moderate speed, and NLGI grade #2

grease.

Other greases may be used if they meet the following NLGI Performance

Classification: GC-LB

IMPORTANT: Some types of grease thickener are not compatible with others.

Consult your grease supplier before mixing different types of grease.

Alternative Lubricants

Conditions in certain geographical areas may require special lubricants and lubrication

practices which do not appear in the operator's manual. If there are any questions,

consult Yetter Manufacturing Co. to obtain latest information and recommendation.

PART # DESCRIPTION OUNCES OF GREASE

2967-404 13” TAPER TOOTH R.M. WHEEL 1.12 OZ

2967-602 13” SHARK TOOTH R.M. WHEEL 1.12 OZ

2967-186 FLOATER WHEEL KIT W/R.M. WHEEL 2.08 OZ

2967-596 HEAVY DUTY OR BEVEL R.M. WHEEL

W/ FLOATER WHEEL KIT

2.40 OZ

Storing Lubricants

Your machine can operate at top efficiency only if clean lubricants are used.

Use clean containers to handle all lubricants.

Store them in an area protected from dust, moisture and other contaminants.

26

MAINTENANCE

Lubrication Symbols

Lubricate with grease at hourly interval indicated on symbol.

Lubrication Intervals

IMPORTANT: The recommended service intervals are based on normal conditions;

severe or unusual conditions may require more frequent lubrication.

Perform each lubrication and service procedure at the beginning and end of each

season.

Clean grease fittings before using grease gun, to avoid injecting dirt and grit into the

bearing. Replace any lost or broken fittings immediately. If a fitting fails to take grease,

remove and clean thoroughly, replace fitting if necessary. Also check for failure of

adjoining parts.

BEARING REPLACEMENT INSTALLATION

1. When assembling the spoke wheels, bearing assembly and hubcap, be sure to

align the grease transfer hole in the spoke wheel with the groove in the hubcap

and hole in the hub to allow grease passage.

2. Assemble the wheels, hubs and caps

3. Grease the wheel/hub/bearing assembly.

27

MAINTENANCE

Storing the Equipment

Store the machine in an area away from human activity

Store machine in RAISED position.

Install service locks on all wheel cylinders.

At the end of the season, the machine should be thoroughly inspected and prepared for

storage. Repair or replace any worn or damaged components to prevent down time at the

start of the next season. Store machine under cover with all parts in operating condition.

• Clean machine thoroughly to remove all dirt, debris and crop residue, which would

hold moisture and cause rusting.

• Inspect machine for worn or broken parts. See your Yetter Farm Equipment dealer

during the off-season so that parts or service can be acquired when machine is not

needed in the field.

• Lubricate bearings as outlined in the Lubrication section

• Paint all parts which are chipped or worn and require repainting.

• Store machine in a clean, dry place with the planting unit out of the sun.

• If the machine cannot be stored inside, cover with a waterproof tarpaulin and tie

securely in place.

Do not allow children to play on or around the machine

28

PARTS IDENTIFICATION

Right Hand Assembly Shown

29

PARTS IDENTIFICATION

30

PARTS IDENTIFICATION

KEY QTY. PART NUMBER DESCRIPTION

1 1 2550-065 HUB CAP, WILTON #909912-1

2 1 2986-329 MACH. CASTLE NUT 1 ¼-12

3 1 2531-124 3/16 X 2 COTTER PIN

4 1 2526-562 1 17/64 ID X 2 ¼ OD X 10 GA. MB BLK

5 2 2550-057 BEARING, KOYO #2788R

6 1 2986-403 MOUNTING HUB

1 2533-110 ¼-28 ZERK STRAIGHT SELF-TAP

2 2550-056 CUP, KOYO #2729

7 1 2550-058 SEAL, CR #17699

8 1 2986-402 25” COULTER SPINDLE

NOTE: Detail #2 is to be torqued to between 12 and 15 ft/lbs.

31

PARTS IDENTIFICATION

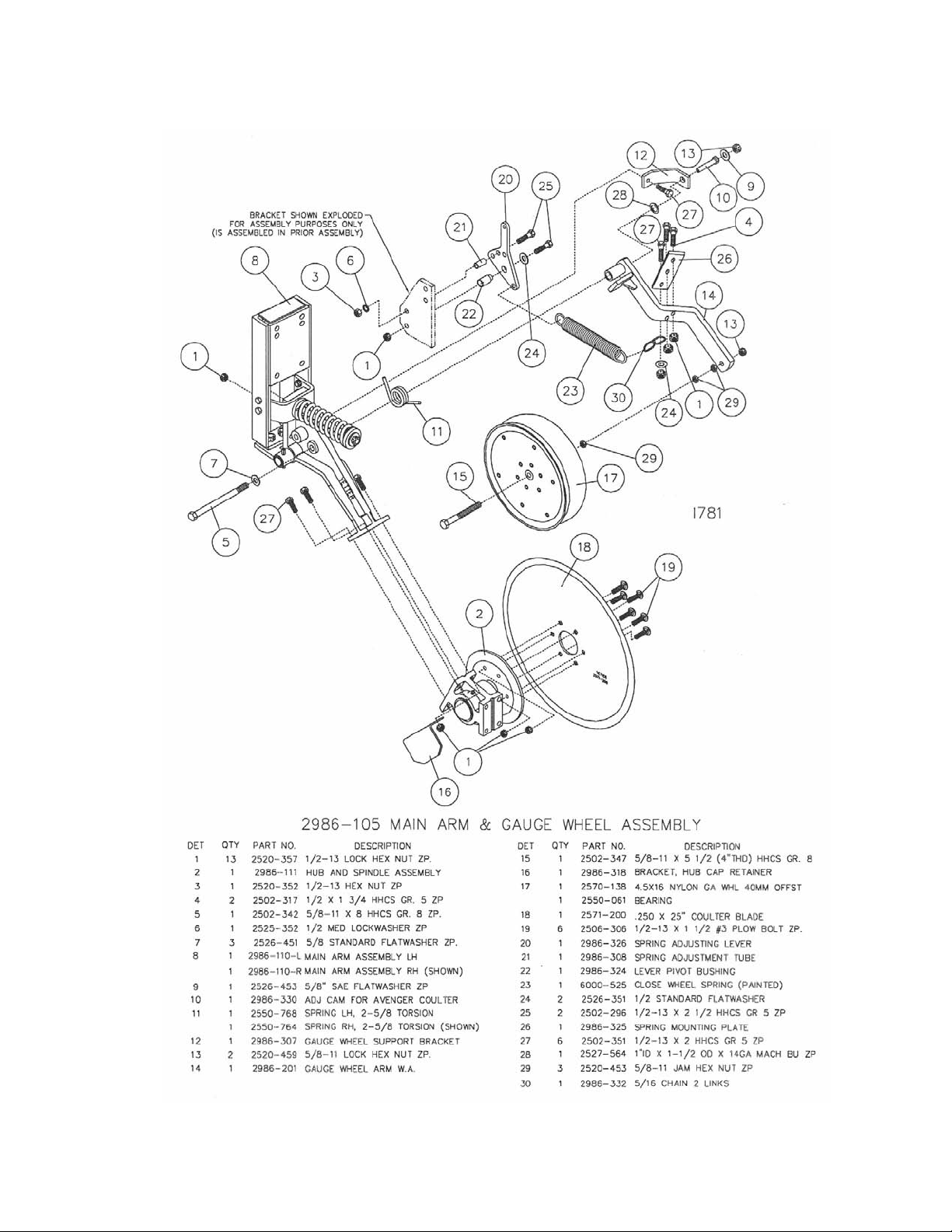

2986-108 MAIN ARM & SKID SHOE ASSEMBLY

KEY QTY. PART NUMBER DESCRIPTION

1 1 2502-348 5/8-11 X 11 HHCS GR 5 ZYD

2 2 2520-357 ½-13 HEX LOCK NUT ZYD

3 1 2986-327 LEVER MOUNTING PLATE

4 1 2986-324 LEVER PIVOT BUSHING

5 1 2986-308 TUBE, SPRING ADJUSTMENT

6 1 2986-326 SPRING ADJUSTING LEVER

7 2 2526-351 ½ STANDARD FLAT WASHER ZYD

8 2 2502-296 ½-13 X 2 ½ HHCS GR 5 ZYD

9 1 6000-525 CLOSE WHEEL SPRING, PAINTED

10 1 2986-422 5 13/32” INNER BUSHING

11 1 2986-209 AVENGER STRAIGHT ARM W .A.

12 1 2533-110 ¼-28 ZERK, STRAIGHT SEFL-TAP

13 1 2502-324 5/8-11 X 3 ½ HHCS GR 5 ZYD

14 2 2520-459 5/8-11 HEX LOCK NUT ZYD

15 6 2526-451 5/8 STANDARD FLAT W ASHER ZYD

16 1 2502-294 ½-13 X 1 ½ HHCS GR 5 ZYD

17 1 2565-366 AVENGER COULTER DECAL

18 1 2967-381 COMBO ADJUSTMENT PIN ZYD

19 1 2986-337 SKID SHOE ADJUSTMENT PLATE

20 1 2520-467 5/8-11 HEX LOCK JAM NUT ZYD

21 1 2967-302 SPACER, ¾ ZYD

22 1 2570-448 1/8 STD. HAIRPIN COTTER ZYD

23 1 2986-332 5/16 CHAIN 2 LINKS

24 1 2502-336 5/8-11 X 4 HHCS GR 5 ZYD

25 1 2986-208 AVENGER SKID SHOE W .A.

26 1 2520-352 ½-13 HEX NUT ZYD

27 1 2525-352 ½ MED. LOCK WASHER ZYD

28 1 2986-340 4 1/4" POLY SKID SHOE

29 6 N10213 5/16-18 HEX FLANGE SERRATED NUT

30 6 2505-206 5/16-16 X 1 CAR BOLT GR 5 ZYD

32

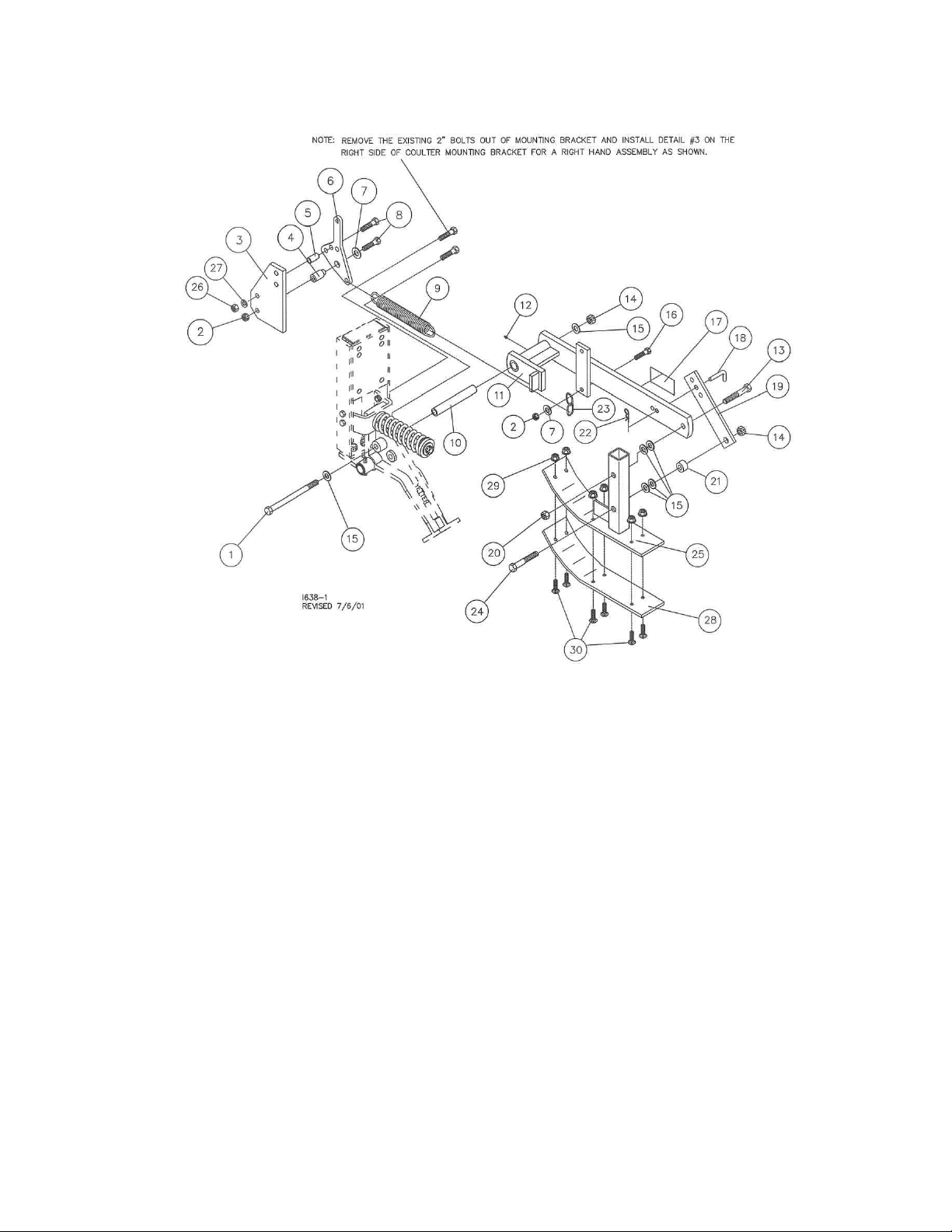

PARTS IDENTIFICATION

FOR COULTERS BUILT PRIOR TO 6-01-01

33

PARTS IDENTIFICATION

FOR COULTERS BUILT PRIOR TO 6-01-01

2986-104 AVENGER SKID SHOE

Key Qty. Part No. Description

1 1 2502-324 5/8-11 x 3-1/2 HHCS Gr. 5 ZP

2 1 2965-305 Pin, Furrowing Attachment ZYD

3 1 2986-337 Skid Shoe Adjustment Plate

4 3 2520-453 5/8-11 Jam Hex Nut ZP

5 2 2526-451 5/8 Std. Flat washer ZP

6 1 2570-448 1/8 Std. Hairpin Cotter ZP

7 1 2520-467 5/8-11 Hex Locknut, Jam ZP

8 1 2502-347 5/8-11 x 5-1/2 HHCS Gr. 8, 4”Thd.

9 1 2520-459 5/8-11 Lock Hex Nut ZP

10 6 N10213 5/16-18 Hex Flange Serrated Nut

11 1 2986-208 Avenger Skid Shoe W.A.

12 1 2986-340 4-1/4” Poly Skid Shoe

13 6 2505-206 5/16-18 x 1 Car. Bolt Gr. 5 ZP

34

PARTS IDENTIFICATION

35

PARTS IDENTIFICATION

36

PARTS IDENTIFICATION

37

PARTS IDENTIFICATION

38

TROUBLESHOOTING

Problem

25" coulter blade creates soil disruption.

Slot cut by 25" coulter blade fills and overflows

with material.

Inadequate 25" coulter blade depth.

Slot made by 25" blade remains open.

Optional sealer forces liquid out of trench.

Inadequate slot being made by 25" coulter blade.

Coulter plugging.

Breakage or excessive damage to blades.

Solution

Add optional skid shoe kit 2986-108

Increase skid shoe spring tension.

Make sure maximum coulter operating depth is

reached (8”).

Cut back volume of the material which is being

applied.

Increase ground speed.

Tighten down pressure spring.

Add 2550-771 10” poly helper spring.

Add additional ballast. Example: 200# per

coulter. Operate toolbar height 22”-25”

Install optional disc sealer 12” 2920-012, 16”

2930-012, 2920-016, 2920-016-N, or optional

wheel sealer 2984-009.

Decrease disc sealer spring tension.

Readjust blade angle.

Adjust disc arm side to side to space disc blade

further from trench.

Increase depth of the 25” blade.

Sharpen or replace 25” coulter blade.

Adjust scraper to touch flat against the blade.

Replace scraper

Avoid turning with blades in the ground.

Avoid operating in frozen ground.

Reduce speed in rocks or other adverse

conditions.

39

Our name

Is getting known

Just a few years ago, Yetter products were sold primarily

to the Midwest only. Then we embarked on a program of

expansion and moved into the East, the South, the West and

now north into Canada. We’re even getting orders from as

far away as Australia and Africa.

So, when you buy Yetter products . . .you’re buying a name

that’s recognized. A name that’s known and respected. A name

that’s become a part of American agriculture and has become

synonymous with quality and satisfaction in the field of

conservation tillage.

Thank you.

YETTER MANUFACTURING CO.

Colchester, IL 62326-0358 309/776-4111

Toll Free 800/447-5777

Fax 309/776-3222

Website: www.yetterco.com

E-mail: info@yetterco.com

2565-419_REV_E

07/13

40

Loading...

Loading...