Yetter 8500-027, 8500-032, 8500-038, 8500-043, 8500-048 Owner's Manual

OWNER’S MANUAL

8500 SERIES HEAD CART

ALL MODELS

2565-799_B 02/2019

Yetter Manufacturing

Founded 1930

Colchester, IL 62326

Call: (309)776-4111

Fax: (309)776-3222

Website: www.yetterco.com

Email: info@yetterco.com

FOREWORD

WARRANTY

You’ve just joined an exclusive but rapidly

growing club. For our part, we want to

welcome you to the group and thank you for

buying a Yetter product.

We hope your new Yetter products will help

you achieve two goals: increase your

productivity and increase your efficiency so

that you may generate more profit.

This SAFETY ALERT SYMBOL

indicates important safety

messages in the manual. When

you see this symbol, be alert to the

possibility of PERSONAL INJURY and

carefully read the message that follows.

The word NOTE is used to convey

information that is out of context with the

manual text. It contains special information

such as specifications, techniques and

reference information of a supplementary

nature.

The word IMPORTANT is used in the text

when immediate danger will occur to the

machine due to improper technique or

operation.

It is the responsibility of the user to read the

owner’s manual, comply with safe and

correct operating procedure, and to

lubricate and maintain the product

according to the information listed in the

owner’s manual.

The user is responsible for inspecting their

machine and for having parts repaired or

replaced when it is damaged or worn.

Continued use of a damaged or worn part

can cause injury or more extensive damage

to the machine.

If you have any questions regarding the

information given in this manual, consult

your local Yetter dealer or contact:

Yetter Manufacturing Co.

(309)776-4111

(800)447-5777

Website: www.yetterco.com

Email: info@yetterco.com

Yetter Manufacturing warrants all products manufactured and sold by it against defects

in material. This warry being expressly limited to replacement at the factory of such parts

or products that appear to be defective after inspection. The warranty does not obligate

Yetter Manufacturing to bear the cost of labor in replacement of parts. It is the policy of

the Company to make improvements without incurring obligations to add them to any

unit sold prior. No warranty is made, or authorized to be made, other than herein set

forth. This warranty is in effect for one year after purchase.

Dealer:__________________________

Yetter Manufacturing warrants its own products and cannot be held responsible

for damages to equipment on which they are mounted.

2

TABLE OF CONTENTS

SAFETY .................................................................................................. 4-5

GENERAL INFORMATION ..................................................................... 6-8

BOLT TORQUE .......................................................................................... 9

SET-UP ............................................................................................... 10-11

OPERATION ....................................................................................... 12-13

MAINTENANCE ....................................................................................... 14

PART IDENTIFICATION ..................................................................... 15-34

3

SAFETY INFORMATION

BE ALERT!

YOUR SAFETY IS INVOLVED

It is the responsibility of the owner, operator, or supervisor to know and instruct

everyone using this machine at the time of initial assignment and at least annually

thereafter, of the proper operation, precautions, and work hazard which exist in the

operation of the machine in accordance with OSHA regulations.

SAFETY IS NO ACCIDENT

The following safety instructions combines with common sense will save your

equipment from needless damage and the operator from unnecessary exposure

to personal hazard. Pay special attention to the caution notes in the text. Review

this manual each year and with new and experience operators.

1. Read and understand the operator’s manual before operating this machine.

Failure to do so is considered a misuse of the equipment.

2. Make sure equipment is secure before use.

3. Always keep children away from equipment while in operation.

4. Make sure everyone that is not directly involved with the operation is clear of the

work area before use.

5. Be sure all safety devices, shield, and guards are in place and functional before

beginning operation

6. Shut off all power to the unit prior to adjustment, servicing, or cleaning.

7. Keep hands, feet, and clothing away from moving parts. It is a good idea to

remove all jewelry before starting the operation.

8. Visually inspect the machine periodically during operation for signs of excessive

vibration, loose fasteners, and unusual noises.

4

SAFETY INFORMATION

During Operation

• Regulate speed to field conditions. Maintain complete control at all times.

• Never lubricate equipment when in operation.

• Use extreme care when operating close to ditches, fences, or on hillsides.

• Do no leave towing vehicle unattended with engine running.

• Do no adjust the transporter with the head positioned over the unit.

Before Operation

• Secure the transport chains to towing vehicle before transporting. DO NOT

transport without the chains.

• Check for proper function of all available transport lights. Make sure that all

reflectors are clean and in place on the machine.

• This implement may not be equipped with brakes. Ensure that the towing vehicle

has adequate weight and braking capacity to tow this unit.

• Before transporting, secure the head with straps. Replace damaged or worn

straps, and avoid putting straps over rough or sharp surfaces. Use appropriate

number and capacity rating.

During Transport

• Comply with state and local laws governing highway safety when moving

machinery.

• Use transport lights as required by local laws to adequately warn operators of

other vehicles.

• Use good judgement when transporting equipment on highways. Regulate speed

to road conditions and maintain complete control.

• Slow down before making sharp turns to avoid tipping. Drive slowly over rough

ground and side slops.

• It is probable that this implement is taller, wider, and longer than the towing

vehicle. Become aware of and avoid all obstacles and hazards in the travel path

of the equipment such as power lines, ditches, etc.

5

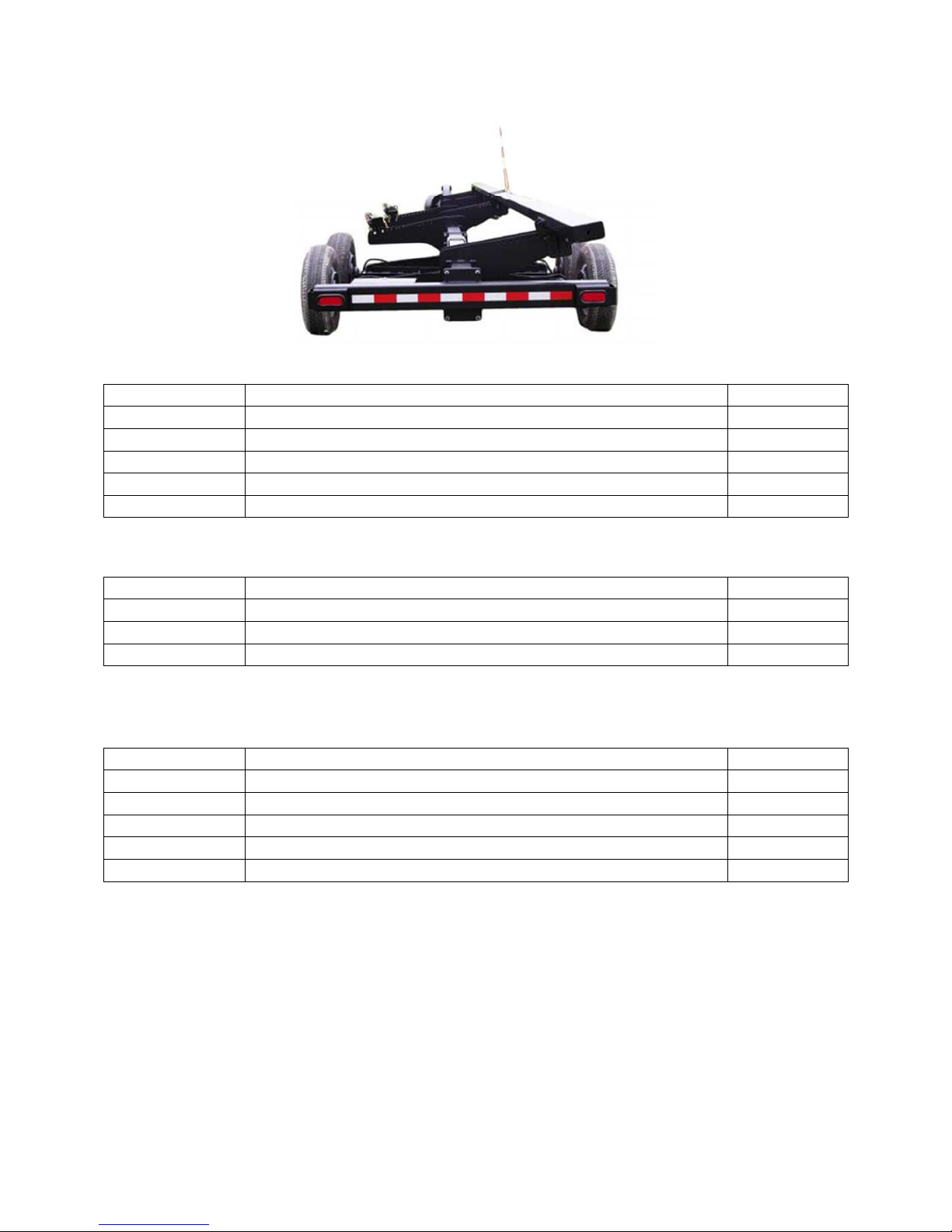

GENERAL INFORMATION

Model No.

Description

Est. Wt.

Model No.

Description

Est. Wt.

Model No.

Description

Est. Wt.

8500 Series Head Cart Trailers

8500-027 27’ Head Cart 3260 lbs

8500-032 32’ Head Cart 4103 lbs

8500-038 38’ Head Cart 4358 lbs

8500-043 43’ Head Cart 4741 lbs

8500-048 48’ Head Cart 4970 lbs

Optional Equipment

8500-001 Marker Pole 3 lbs

8500-144 Ball Hitch 2-5/16” 10 lbs

8500-166 Drop Pin Hitch 14 lbs

Service Kits

8500-120 Rear Bearing and Drum Replacement Kit (1 Per Wheel) 40 lbs

8500-121 Lugnut and Stud Replacement Kit (1 Per Wheel) 4 lbs

8500-122 Front and Rear Bearing Replacement Kit (1 Per Wheel) 7 lbs

8500-123 Brake Replacement Kit (1 Per Axle) 10 lbs

8500-124 Front Bearing and Hub Replacement Kit (1 Per Wheel) 26 lbs

6

GENERAL INFORMATION

8500 Series Head Cart Trailers

• Central beam design with adjustable truss supports

• Spare cutter bar storage

• Dual 12” rest brackets to fit any header platform with tool-

less adjustments

• Drum brakes on rear axle(s)

• Front and rear torsion axles providing a smooth ride

• Molded front fenders protecting head and truck from road

debris

• Tongue rotates around to main beam for easy winter storage

and shipment

• 24” of telescoping hitch adjustment

• Dual safety chains with standard clevis hitch. Options for

drop-pin and ball hitch attachments

• LED lights and seven pin bladed receptacle for standard

towing vehicles

• Full length DOT reflective tape

• Tool box – 17 ¾” x 8” x 7”

• Full width rear light support brackets

• Durable black powder coat finish

• Made in the USA, manufactured and shipped from Macomb,

IL

7

GENERAL INFORMATION

8500

-

027 8500

-

032 8500

-

038 8500

-

043 8500

-

048

Overall Length (in)

Overall Width (in)

Overall Height (in)

Unloaded Weight (lb)

Max Gross Weight (lb)

Max Usable Weight (lb)

Max Drawbar Pull (lb)

Chassis Style

Axle Configuration

Axle Stud Pattern

Tire Size

Max Tire PSI

Electric Brakes

Over Run Brakes

Cutter Bar Storage

Lights

Front Fenders

Accessory Box

License Plate Lights

Rear Fenders

Marker Pole Kit

8500 Series Head Cart Trailers

Technical Specifications

429 489 561 621 681

102 102 102 102 102

44 44 44 44 44

3260 4103 4391 4741 4970

12000 18000 18000 18000 18000

8740 13897 13609 13259 13030

17600 17600 17600 17600 17600

Single Beam Single Beam Single Beam Single Beam Single Beam

Single Tandem Tandem Tandem Tandem

8 x 6.5” BC 8 x 6.5” BC 8 x 6.5” BC 8 x 6.5” BC 8 x 6.5” BC

8-14.5 LT 14

Standard

Standard

Standard

Standard

Standard

Standard

Wire Leads Only Wire Leads Only Wire Leads Only Wire Leads Only Wire Leads Only

Optional

Optional

PLY

8-14.5 LT 14

65 65 65 65 65

Standard

Standard

Standard

Standard

Standard

Standard

Optional

Optional

PLY

8-14.5 LT 14

Standard

Standard

Standard

Standard

Standard

Standard

Optional

Optional

PLY

8-14.5 LT 14

Standard

Standard

Standard

Standard

Standard

Standard

Optional

Optional

PLY

8-14.5 LT 14

Standard

Standard

Standard

Standard

Standard

Standard

Optional

Optional

PLY

8

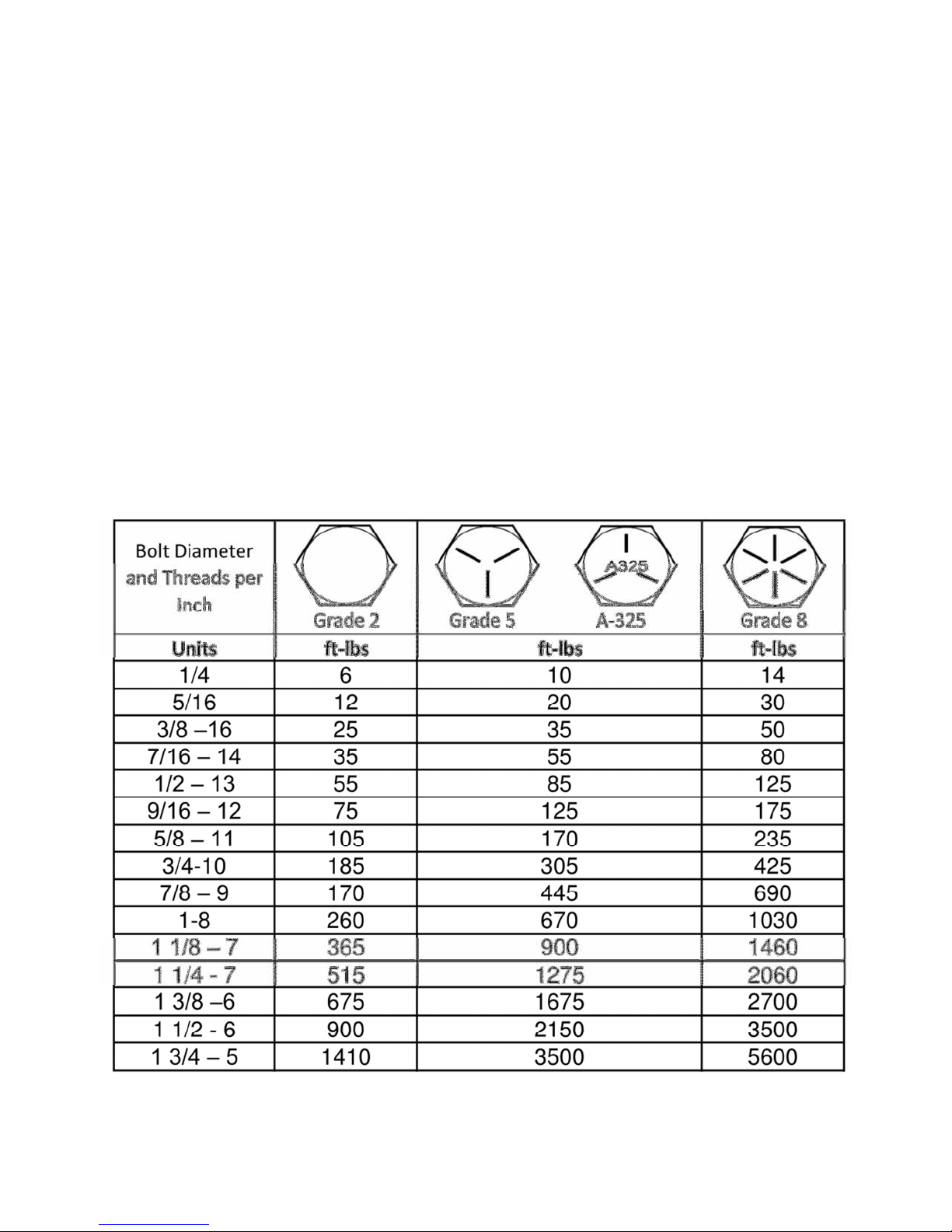

BOLT TORQUE

Important: Over tightening hardware can cause as much damage as under tightening.

Tightening hardware beyond the recommended range can reduce it shock load

capacity.

All hardware used on the 8500 Series Head Cart is Grade 5 unless otherwise specified.

If hardware must be replaced, be sure to replace it with hardware of equal size,

strength, and thread type.

The chart below is a guide for proper torque. Use it unless a specified torque

value is given elsewhere in the manual.

Torque is the force you apply to the wrench handle times the length of the handle.

Use a torque wrench wherever possible

The following table shows torque in ft-lbs for coarse thread hardware.

9

SET UP INSTRUCTIONS

1

2

3

4 5

6

7 8

6.5” BC

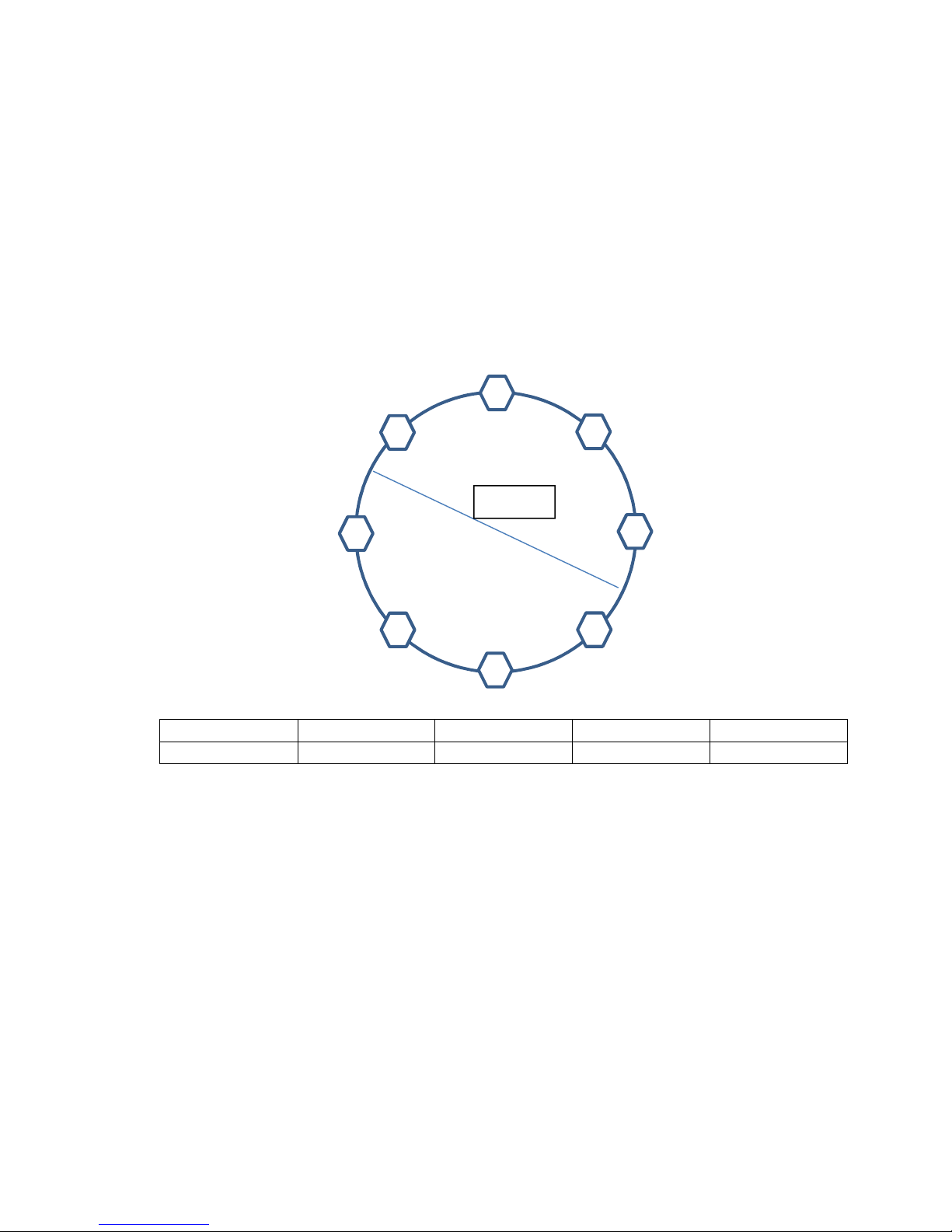

Tires and Wheels

1. Using a safe lifting device and jack stands rated at a minimum of 2500 lbs, raise

the frame at least 16 ½” high

2. Install wheels and tires onto the axles and secure with provided lug nuts. Refer to

the table below for torque sequence and value.

• Start all lug nuts by hand to prevent cross threading

• Tighten nuts in the sequence shown below

• Lug nuts should be torqued before first road use and after each wheel

removal. Check and re-torque after the first 50 miles. A periodic check

during regular service is recommended.

Wheel Size Stud Size 1st Stage 2nd Stage 3rd Stage

14.5 X 7 9/16” 25 lb-ft 70 lb-ft 130 lb-ft

10

SET UP INSTRUCTIONS

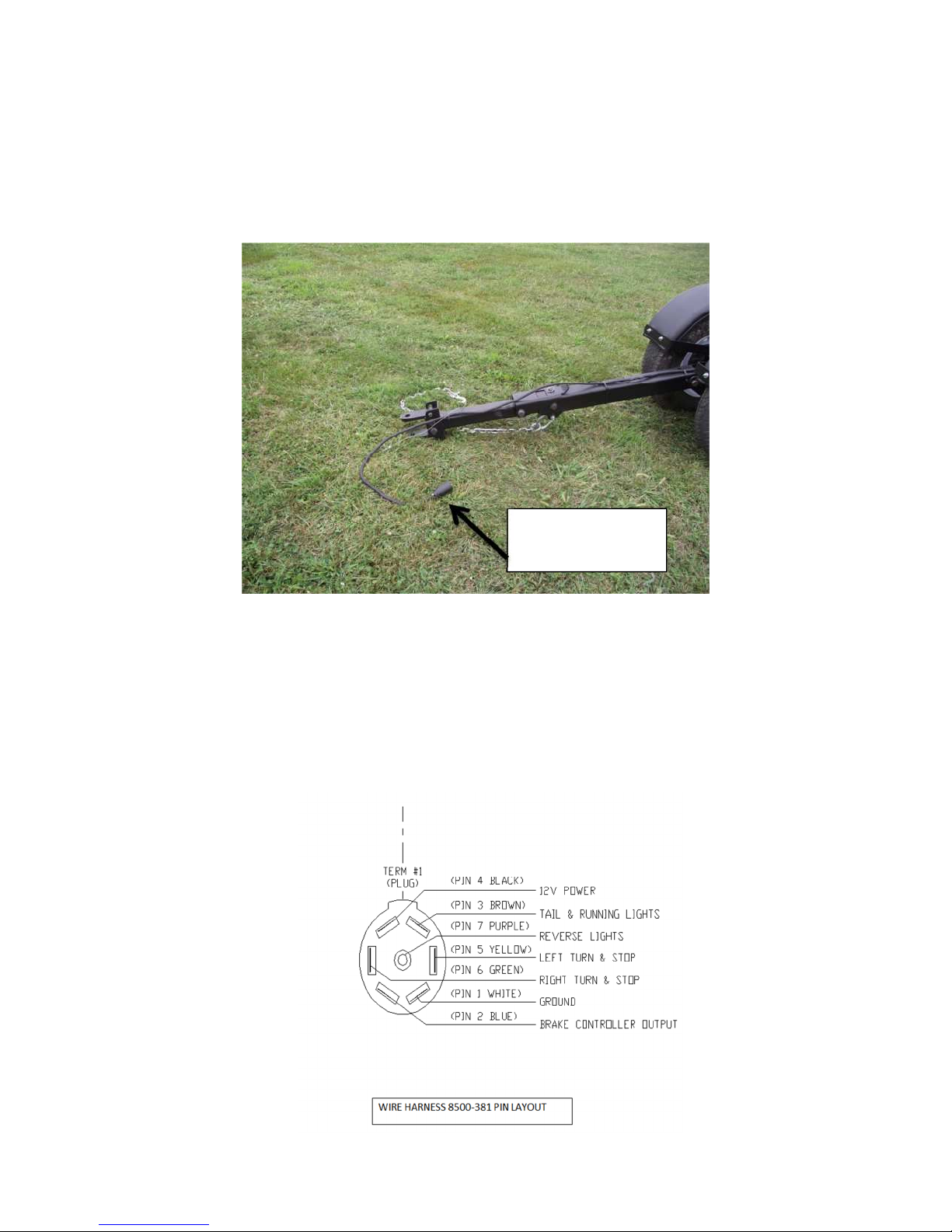

ATTACH TO

Test Lights

Make sure no wires are pinched or cut during installation.

Keep all wires concealed to prevent them from getting caught on obstructions.

Attach 8500 Head Cart and wiring harness to tow vehicle to test the lights.

Check the following:

• Tail lights

• Brake lights

• Left and right turn signals with and without brakes applied

TOW VEHICLE

Note: If any of the light tests fail, check wiring harness on tow vehicle for proper

wiring.

11

OPERATION

Hitching

1. Position towing vehicle in front of header transport. Lift tongue latch handle and

extended inner tongue extension enough to attach to vehicle drawbar using a ¾”

minimum diameter hitch pin and lock in place. Back-up towing vehicle to re-latch

tongue.

2. Cross transport chains and connect to towing vehicle.

Note: Before hitching the header transport to any vehicle drawbar, be sure the pin

hole is located close enough to the rear of the vehicle drawbar to allow the

header transport tongue clevis to swing 90 degrees right or left of the centerline

without interference.

Note: When hitching, be sure not to pinch wire harness. Position the wire harness

away from all pinch points and any areas that may wear the harness.

CAUTION: BE SURE TRANSPORT TONGUE IS LATCHED

BEFORE TRANSPORTING, OTHERWISE JARRING COULD

OCCUR WHEN STOPPING UNIT, CAUSING A SUDDEN SHIFT OF

LOAD.

CAUTION: ALWAYS USE TRANSPORT CHAINS WHEN

TRANSPORTING IMPLEMENTS. FAILURE TO USE TRANSPORT

CHAIN COULD CAUSE PERSONAL INJURY OR DAMAGE IF

IMPLEMENT BECOMES DISENGAGED.

12

Loading...

Loading...