Page 1

6010 PLANTER UNIT

OPERATOR’S MANUAL

PARTS IDENTIFICATION

2565-724_REV_B ● 05/2013

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website: www.yetterco.com

E-mail: info@yetterco.com

&

Page 2

FOREWORD

You’ve just joined an exclusive but rapidly

growing club.

For our part, we want to welcome you to the

group and thank you for buying a Yetter product.

We hope your new Yetter products will help you

achieve both goals-increase your productivity and

increase your efficiency so that you may generate

more profit.

This operator’s manual has been designed into

four major sections: Foreword, Safety

Precautions, Installation Instructions and Parts

Breakdown.

This SAFETY ALERT SYMBOL

indicates important safety messages in

the manual. When you see this

symbol, be alert to the possibility of

PERSONAL INJURY and carefully

read the message that follows.

The word NOTE is used to convey information

that is out of context with the manual text. It

contains special information such as

specifications, techniques and reference

information of a supplementary nature.

The word IMPORTANT is used in the text when

immediate damage will occur to the machine due

to improper technique or operation. Important will

apply to the same information as specified by

note only of an immediate and urgent nature.

It is the responsibility of the user to read the

operator’s manual and comply with the safe and

correct operating procedure and to lubricate and

maintain the product according to the

maintenance schedule in the operator’s manual.

The user is responsible for inspecting his

machine and for having parts repaired or

replaced when continued use of the product

would cause damage or excessive wear to the

other parts.

It is the user’s responsibility to deliver his

machine to the Yetter dealer who sold him the

product for service or replacement of defective

parts, which are covered by the warranty policy.

If you are unable to understand or follow the

instructions provided in this publication, consult

your local Yetter dealer or contact:

YETTER MANUFACTURING CO.

309/776-4111

800/447-5777

309/776-3222 (FAX)

Website: www.yetterco.com

E-mail: info@yetterco.com

WARRANTY

Yetter Manufacturing warrants all products manufactured and sold by it against defects in material. This

warranty being expressly limited to replacement at the factory of such parts or products as shall appear to

be defective after inspection. This warranty does not obligate the Company to bear cost of labor in

replacement of parts. It is the policy of the Company to make improvements without incurring obligations to

add them to any unit already sold. No warranty is made or authorized to be made, other than herein set

forth. This warranty is in effect for one year after purchase.

Dealer ___________________________________________________

Yetter Manufacturing warrants its own products only and cannot be responsible for damages to

equipment on which mounted.

2

Page 3

SAFETY PRECAUTIONS

You can make your farm a safer place to live and work if you observe the safety precautions given. Study these

precautions carefully and insist those working with you and for you follow the precautions.

Finally, remember this an accident is usually caused by someone’s carelessness, neglect or oversight.

A brief description of signal words that may be used in this manual:

CAUTION: Used as a general reminder of good safety practices or to direct attention to unsafe practices.

WARNING: Denotes a specific potential hazard.

DANGER: Denotes the most serious specific potential hazard.

CAUTION

Consult your implement and tractor operator’s manual for correct and safe operating practices. Be aware of towed

implement width and allow safe clearance.

CAUTION: SAFETY SIGNS

Safety decals are placed on the implement to alert the operator and others to the risk of personal injury or unsafe

operation during normal operations and servicing.

1. The safety decals must be kept clean and in good condition to ensure that they are legible.

2. Safety decals must be replaced if they are missing or illegible.

3. When components are replaced during repair or servicing, check that the new components include the necessary

safety signs.

4. Replacement safety decals may be obtained from your local dealer.

WARNING

Read these instructions carefully to acquaint yourself with the Equipment. Working with unfamiliar equipment can lead

to accidents.

Safety shields must always be in place during operation.

Never park the equipment on a steep incline or leave the equipment running unattended.

Never clean, lubricate or adjust a machine that is in motion. Always replace safety shields after servicing.

Do not allow children to operate this equipment.

Do not allow riders on the equipment.

Use speed and caution dictated by the terrain being traversed. Do not operate on any slope steep enough to cause

tipping or loss of control.

Be sure all personnel are clear of the immediate area before operating.

Read and understand the operator’s manual and require all other persons who will operate the equipment to do the

same.

If operating on public roadways, where legal, be certain all lighting is operating properly and observe all traffic laws.

Beware of increased stopping distances and control effort when operating with implements attached.

Be familiar with all controls and be prepared to stop engine and equipment quickly in an emergency.

If seed or seed treatment is dusty or dirty, wear full-face respirator.

FAILURE TO HEED MAY RESULT IN PERSONAL INJURY OR DEATH.

3

Page 4

TABLE OF CONTENTS

PAGE

FORWARD/WARRANTY……………………………………………………….2

SAFETY INFORMATION……….………………………………………..……..3

TABLE OF CONTENTS……..….………………………………………..……..4

GENERAL INFORMATION/BOLT TORQUE…………………………..……..5

HITCH ASSEMBLY INSTRUCTIONS/PARTS IDENTIFICATION…….…6-7

PLANTING UNIT ASSEMBLY

INSTRUCTIONS……………………………………………………………….8-13

SMV EMBLEM INSTALLATION………………………………………………14

LIGHT KIT INSTALLATION…………….……………………………………..15

OPERATING THE PLANTER……………………….……………………..16-22

PARKING STAND INSTALLATION……………….………………………….18

PREDELIVERY LUBRICATION……………………………………………23-24

STORAGE………………………………………………………………………..25

PARTS IDENTIFICATION…………………………..………………………26-34

TROUBLESHOOTING………………………………………………………….35

4

Page 5

GENERAL INFORMATION

To achieve maximum performance, this machine must be assembled as outlined in this instruction manual.

The planter operator’s manual will NOT include attachment assembly information. Please keep a copy of this

instruction available for future attachment assembly.

Information in this instruction manual is divided into sections. These sections are identified at the top of each page.

Read all assembly instructions and carefully observe illustrations.

Leave bolts loose until parts or attachments are completely assembled. Then tighten bolts to torques shown in the

following chart unless otherwise specified. It is important that bolts are tight. Loose bolts can cause breakage of parts.

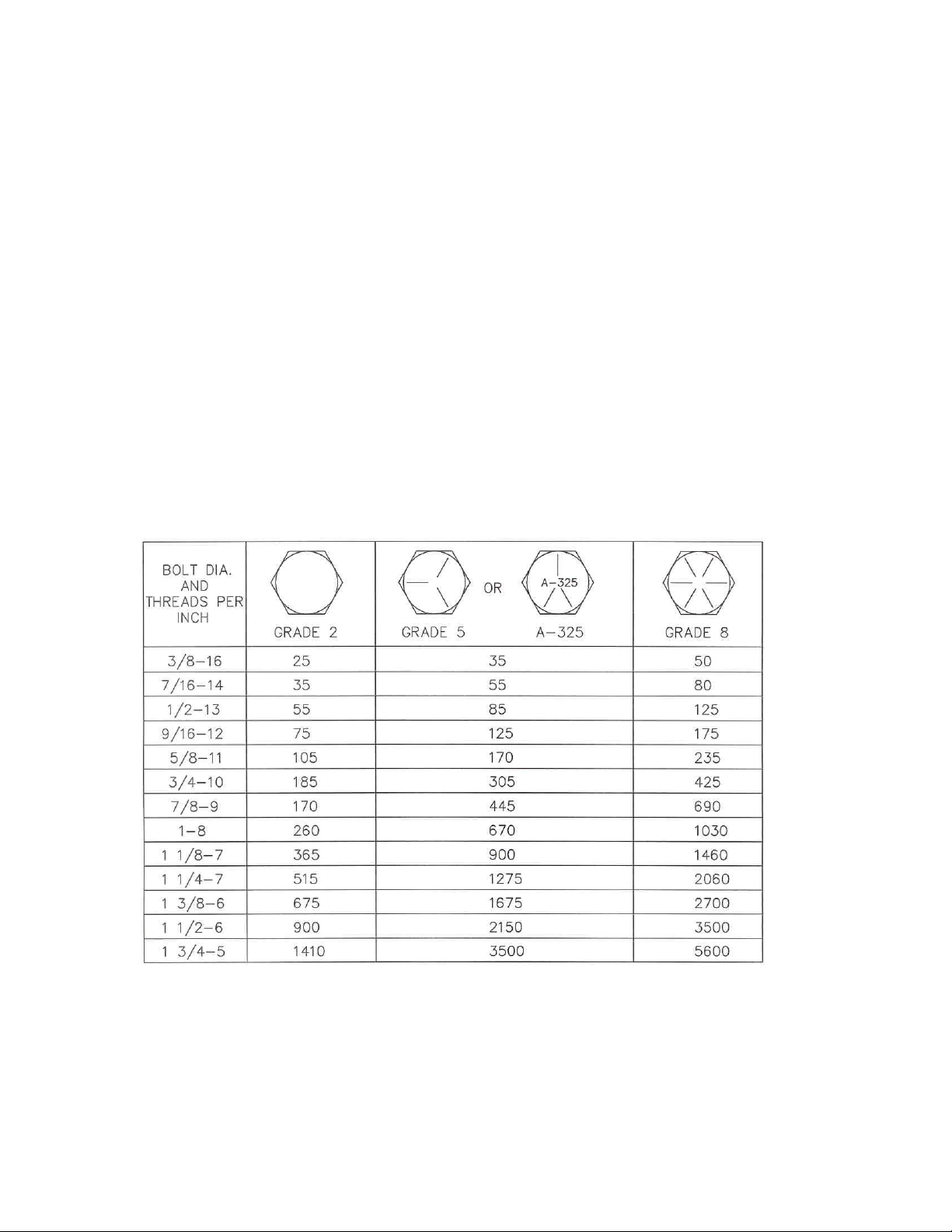

BOLT TORQUE

READ THESE INSTRUCTIONS FIRST:

1. Improperly tightened bolts will result in damage, breakage, expense, and down time.

2. Always replace bolts with the specified grade and type.

3. Torque properly before first use of the machine and every 2-4 hours of use until you are sure bolts

are staying tight.

4. The chart below is a guide for proper torque. Use it unless a specified torque is called out

elsewhere in the manual.

5. Torque is the force you apply to the wrench handle or the cheater bar, times the length of the

handle or bar.

6. Use a torque wrench whenever possible.

The following table shows torque in ft. lbs.

Lubricate all bearings and moving parts as assembled and make certain that they work freely.

5

Page 6

ASSEMBLY INSTRUCTIONS

B

C

D F

G

K

J

K

Step 1. Place the toolbar on two assembly stands approximately 28 inches above the floor or ground.

A

H

E

FRONT VIEW OF HITCH ASSEMBLY

Step 2. Bolt the center mast brackets (A) together using the 1” x 4-1/2” bolt, upper hitch pipe, lock washer and hex nut

(B). Also, attach the 6010-303 hitch pin in the lower hole of the upper hitch plates with ¼ x 2 roll pin and 1/8” hairpin

cotter.

Step 3. Bolt the 4) mount straps (C) to the center hitch assembly using 4) ¾” x 2” bolts, lock washers and hex nuts (D).

Step 4. Bolt the lower left hitch plate (E) to the end of the mount straps (C) and through the lower hole of the right hand

support bracket (H) using the ¾” x 2-1/2” bolts, lock washers and hex nuts (F).

Step 5. Bolt the lower right hitch plate (G) to the end of the mount straps (C) and through the lower hole of the right

hand support bracket (I) using the ¾” x 2-1/2” bolts, lock washers and hex nuts (F).

Step 6. Bolt the 7/8” lift pins (J) through the lower hitch plates and attach using the 6010-302 bushing and the lock

washer and hex nut included with the lift pins.

Step 7. Bolt both the support brackets (H) & (I) to the toolbar using the 5/8-11 x 4 x 5-1/2 u-bolts (K), lock washers and

hex nuts.

A

I

D

H

E

G

LEFT HAND TOP VIEW OF HITCH ASSEMBLY RIGHT HAND VIEW OF HITCH ASSEMBLY

6

Page 7

PARTS IDENTIFICATION

6010-010 – CAT I HITCH KIT

7

Page 8

PLANTING UNIT ASSEMBLY

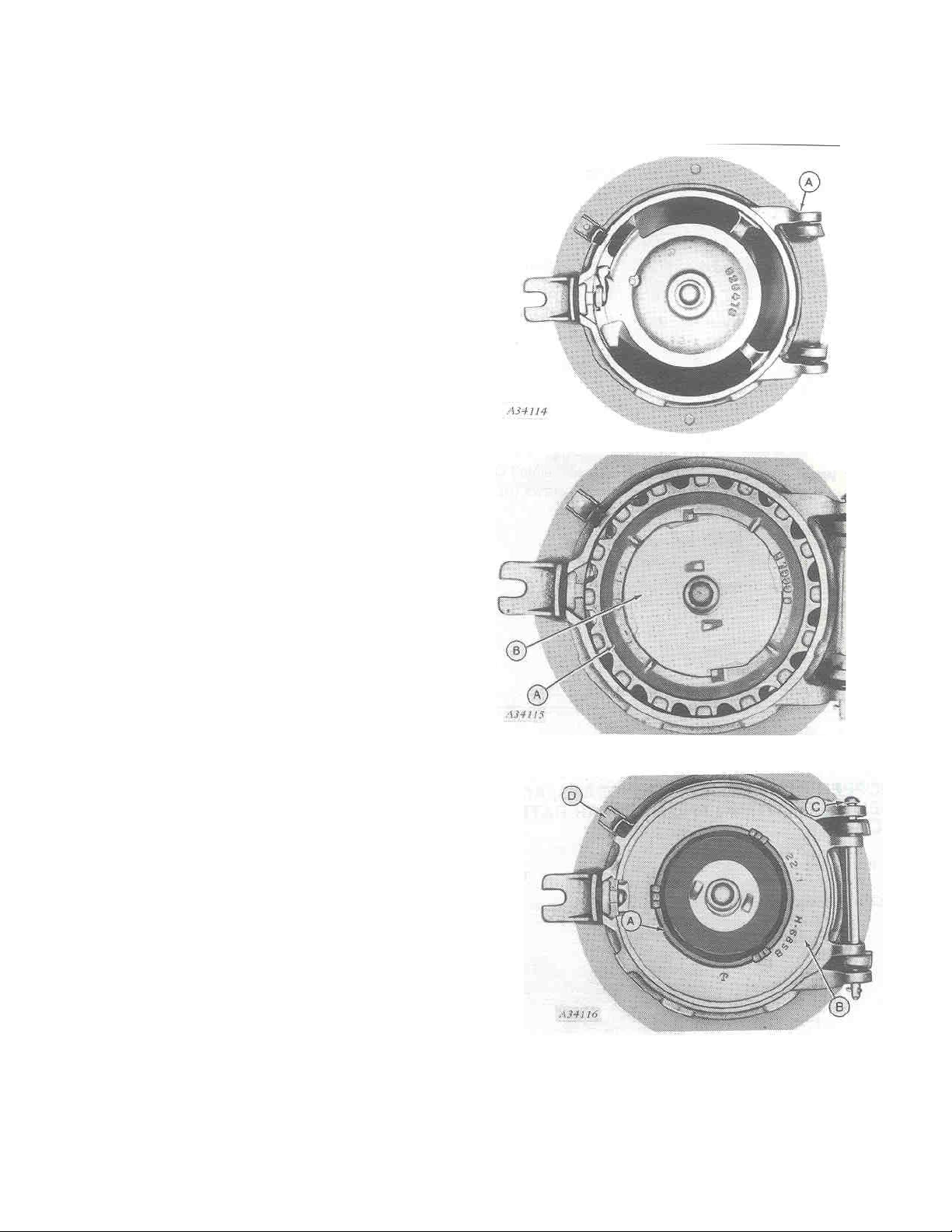

HOPPER BOTTOM-CORN, SOYBEANS,

ACID DELINTED COTTON AND

REGULAR-RATE SORGHUM.

1. Install cutoff (A) in hopper bottom.

NOTE: Be sure cutoff is bottomed in hopper

bottom ring as shown above.

2. Install seed plate (A) and drive plate (B).

3. Install drive plate retainer in floor plate

with retainer (A).

4. Install complete floor plate (B).

5. Secure cutoff and complete floor plate

assembly to hopper bottom with hinge

pin (C) and cotter pin.

6. Hold parts in place with floor plate spring

(D).

8

Page 9

PLANTING UNIT ASSEMBLY

7. When planting corn, soybeans, or aciddelinted cotton with the fiber glass

hopper, remove cap screws (A) from

hopper bottom.

8. Insert ¼ x 3-1/4” bolts (A) through

hopper bottom (thread end inside of

hopper).

9. Install baffle plate (A) on bolts and

secure with springs, flat washers and

lock nuts (B).

9

Page 10

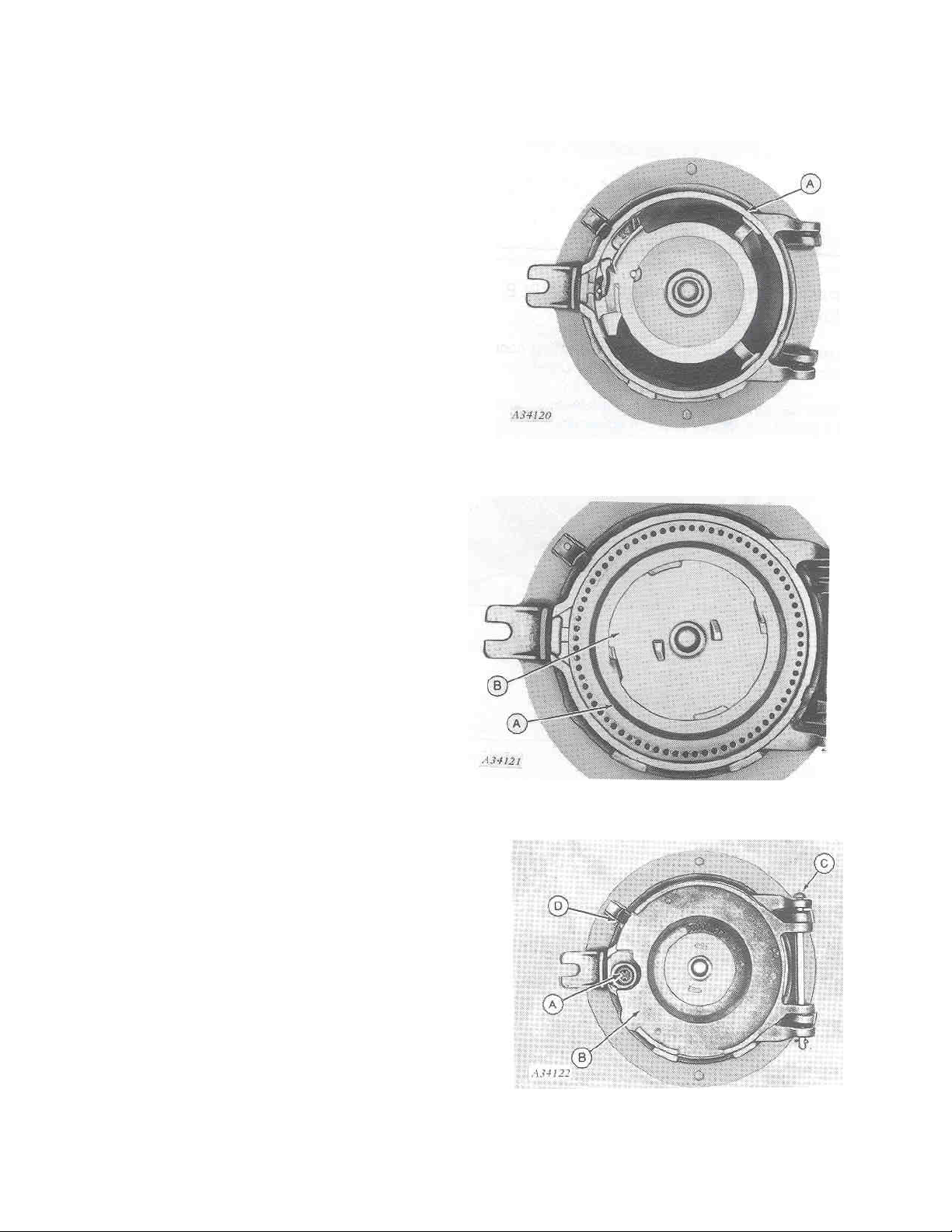

PLANTING UNIT ASSEMBLY

HOPPER BOTTOM-BEETS, LOW-RATE

SORGHUM OR CUCUMBER

1. Install cutoff (A) in hopper bottom.

NOTE: Be certain cutoff is bottomed in

hopper bottom ring.

2. Install seed plate (A) and drive

plate (B).

3. Install false ring (A).

4. Install complete floor plate (B).

5. Secure cutoff and complete floor plate

assembly to hopper bottom with hinge

pin (C) and cotter pin.

6. Hold parts in place with floor plate

spring (D).

10

Page 11

PLANTING UNIT ASSEMBLY

HOPPER BOTTOM-PEANUTS OR EDIBLE

BEANS

1. Install peanut cutoff (A) and floor plate

(B) on hopper bottom and secure with

hinge pin (C) and cotter pin.

2. Install recommended peanut seed plate

on peanut cutoff with center locator and

bolt.

NOTE: Center locator has left-hand thread.

3. Install drive plate (A) on seed plate.

4. Close floor plate (A) and secure

with spring (B).

11

Page 12

PLANTING UNIT ASSEMBLY

HOPPER BOTTOM-SOYBEANS AND

COTTON SEED (ACID, FLAME, ZIP OR

MECHANICALLY DELINTED)

NOTE: Stirring rod (A) must be removed

when planting soybeans or acid delinted

cotton to prevent hard driving.

1. Install cutoff (A) and floor plate (B) on

hopper bottom and secure with hinge pin

(C) and cotter pin. Seat bottom under floor

plate spring (D).

Be certain cell filter springs ride

directly over cells in seed plate.

2. Install seed plate (A).

3. Close hopper floor plate and secure under

floor plate spring (A).

12

Page 13

PLANTING UNIT ASSEMBLY

1. Install lid and hopper on planting units. Pull latch past locating lug and rotate

forward when installing hopper. Secure hopper with latch.

13

Page 14

SMV EMBLEM INSTALLATION

14

Page 15

OPTIONAL

LIGHT KIT INSTALLATION

3400-175

15

Page 16

OPERATING THE PLANTER

NOTE: Be sure seed tube (A) is installed in clip (B) as shown at right.

16

Double-Disk Seed Opener

Page 17

OPERATING THE PLANTER

B

DRILLING DISTANCES

Four sprockets are shipped with each unit; 11-, 14-, 20and 22-tooth sprockets. These sprockets will give the

seed spacing shown on the following page.

The 14-tooth sprocket (A) and 20-tooth sprocket (B) are

shipped in place. If other sprocket combinations are

desired, remove cap screw (C) and remove sprockets

from storage position.

APPROXIMATE DRILLING DISTANCE IN INCHES

C

A

NOTE: The 9-tooth sprocket is not available to order.

To obtain the one to one ratio, use two 14-tooth or two 20-tooth sprockets on the same planter. This

can be done by pooling the sprockets from two planters or by ordering extra sprockets.

The drilling distances may be doubled by using the extended distance attachment.

See Extended Drilling Attachment in the Attachment section.

In rough field conditions, reduce travel speed to insure proper seed plate cell fill.

Do not exceed the maximum plating speeds in the drilling distance chart or seeds will bounce out of

seed plate cells while planting. Vegetable plating also requires smooth seedbed preparation.

17

Page 18

ATTACHMENT ASSEMBLY INSTRUCTIONS

PARKING STAND ASSEMBLY

18

Page 19

OPERATING THE PLANTER

A

B

C

A B

LEVELING

Drive tractor and planter on level ground.

Adjust planter frame to 16 inches (405 mm)

above ground.

CHANGING PLANTING DEPTH

The press wheel gauges the planting

depth. The adjustment is from surface

plating to 3-1/2 in. (90 mm) deep.

To adjust depth, pull out adjustment stop

(A) and turn depth control cam (B) to

position desired. The numbers on the

depth control cam are only to be used as a

guide. Release the handle to lock cam in

position.

Depth control cam should rest against the

stop (A) in planting position. If the cam

does not rest on the stop, loosen the jam

nut (B) on the down pressure spring and

loosen the down pressure spring bolt (C)

until the depth cam is resting on the stop.

Tighten jam nut.

19

Page 20

OPERATING THE PLANTER

Two holes (B) and (C) in the main chain

housing (A) permit finer adjustment. To

increase the planting depth slightly with the

adjustment stop pin in hole (B) proceed as

follows:

Insert the adjustment stop pin into hole (D)

and turn to the left until it locks the depth

control cam in position in hole (C) in the

chain housing.

To decrease the planting depth slightly with

the adjustment stop pin set in hole (B)

proceed as follows:

Insert the adjustment stop pin into hole (E)

and turn to the right until it locks the depth

control cam in position in hole (C) in the

chain housing.

ADJUSTING PRESS WHEEL DOWN FORCE

ON SQUARE TOOLBAR

Raise planter to transport position.

Adjust unit down pressure by changing position

of spring adjusting arms.

Place a ¾ in. open-end wrench on end of

adjusting arm, remove pin (A) and move arm to

desired position. The bottom hole (B) is

maximum down pressure.

20

Page 21

OPERATING THE PLANTER

A

CENTERING PRESS WHEEL

If press wheel (A) does not track directly behind seed opener (B), loosen round head bolts

(C) behind drive chain housing.

Align press wheel so drive chain housing is at right angle to the toolbar. Tighten round

head bolts.

If press wheel frame becomes

loose, loosen jam nut on bolt

(A) and tighten bolt. Tighten

jam nut. If press wheel does

not float, loosen jam nut and

bolt (A). Tighten jam nut.

21

Page 22

PLANT POPULATION

APPROXIMATE PLANT POPULATION PER ACRE

OPERATING THE PLANTER

CHECKING PLANT POPULATION

22

Page 23

PREDELIVERY LUBRICATION

PREDELIVERY LUBRICATION

Note that lubrication intervals are identical to those appearing in the operator’s manual.

Regardless of recommended intervals, lubricate the planter before delivery at every point

shown in the charts with multi-purpose lubricant or an equivalent SAE multi-purpose type

grease.

When you deliver the planter, the time interval information will remind you to tell your

customer of the importance of lubrication intervals recommended in the planter operator’s

manual.

If any grease fittings are missing, replace them immediately. Clean fittings thoroughly

before using grease gun.

LUBRICATION SYMBOLS

Lubricate with general purpose grease at hourly interval indicated on

symbol.

Pack wheel bearings with axle grease at hourly interval indicated on symbol.

Lubricate with SAE 10W oil at hourly interval indicated on the symbol.

ALTERNATIVE LUBRICANTS

Conditions in certain geographical areas may require special lubricants and lubrication

practices which do not appear in this manual. If you have any questions, consult you

dealer to obtain the latest information and recommendations.

23

Page 24

LUBRICATION

ROLLER CHAIN LUBRICATION

The most effective roller chain lubrication routine varies, depending on the environmental

conditions and/or conditions of the chain. The obvious goal is to maintain complete

freedom at every chain link joint.

For best results, DO NOT lubricate roller chains if operating in dusty conditions.

Lubrication will only tend to pull additional grit into the critical pivot areas, restring free

chain movement.

If operating in clean and/or moist conditions, lubricate the roller chains with PT508 chain

lube spray (or equivalent) at intervals sufficient to maintain free chain movement.

When roller chains remain unused for several days, moisture in the air will accumulate on

the chain causing the chain to rust. This can and will become serious enough in time to

cause the chain joints to become stiff, restricting their normal free movement. While very

difficult to detect, this stiffness can encourage the chains to operate abnormally and

disturb the smooth rotation of important meter components causing a deterioration in

performance.

If the planter is not to be used for several days, thoroughly lubricate the chains with

PT508 chain lube at the beginning of the idle period. If the roller chains have become

rusty or stiff during the idle period, lubricate prior to continued usage and operate or

“work” the chains sufficiently to insure all chain joints move freely before normal planter

operation is resumed.

SPECIAL LUBRICATNS FOR SEED HOPPERS

IMPORTANT: With plate type hoppers, sprinkle a teaspoon of powdered graphite

over the top of the seed twice a day.

24

Page 25

STORAGE

BEGINNING OF THE SEASON SERVICE

Before using the planter after it has been stored, inspect the seed hoppers for cleanliness

to be certain the seed will flow from hoppers freely.

Thoroughly inspect the planter unit for loose parts and adjust as necessary.

Clean any dirt or grease that may have accumulated on moving parts, gears and chains

before operating the planter. This will prevent abrasive action that could cause excessive

wear.

When roller chains remain unused for several days, moisture in the air will accumulate on

the chain, causing the chain to rust. This can, and will, become serious enough in time to

cause the chain joints to become stiff, restricting the normal free movement. While very

difficult to detect, this stiffness can encourage the chains to operate abnormally and

disturb the smooth rotation of important meter components, causing deterioration in

performance.

If the planter is not used for several days, or if oil has been removed from chains, etc.

while cleaning the planter, thoroughly lubricate chains with multipurpose spray lube.

END OF THE SEASON SERVICE

When planting is completed for one season, store the planter under cover with all parts in

operating condition.

Paint all parts which are chipped or worn and require repainting.

Clean the planter thoroughly to remove dirt and trash which would hold moisture and

cause rusting.

Lubricate the planter as outlined in the Lubrication section and grease exposed cylinder

rods.

If the planter is not to be used for several days, or if oil has been removed from chains,

etc. while cleaning the planter, thoroughly lubricate chains with Multipurpose Spray Lube

at the beginning of the idle period. If roller chains have become rusty or stiff during the

idle period, lubricate prior to continued usage and operate or “work” chains sufficiently to

insure all chain joints move freely before normal planter operation is resumed.

Empty and clean seed hoppers.

Clean insecticide and/or herbicide hopper thoroughly as various chemicals may

deteriorate the system components.

Inspect the planter for worn or broken parts. See your dealer during the off season so

that parts or service can be acquired when the planter is not needed in the field.

Store the units in a clean, dry place, with the press wheel out of the sun and off of the

floor. Do not let the unit rest on the press wheel in storage, as this will reduce its life.

25

Page 26

PARTS IDENTIFICATION

SEED HOPPER ASSEMBLY

1. 1 6010-300 LID, HOPPER

2. 1 6010-301 SEED HOPPER, 71 ROW UNIT

4. 1 6010-369 SPRING

5. 1 6010-393 PLATE

6. 2 2502-105 ¼-20 X ¾ HHCS GR 5 ZYD

2 2520-151 ¼-20 HEX NUT ZYD

7. 4 2502-200 5/16-18 X ¾ HHCS GR 2 ZYD

4 2525-201 5/16 MED LOCK WASHER ZYD

4 2526-201 5/16 STANDARD FLAT WASHER ZYD

26

KEY QTY. PART NO. DESCRIPTION

3. 1 6010-414 1/8 X ½ RIVET

8. 1 6010-401 SPRING LOCKING PIN

9. 1 6010-370 PIN

Page 27

PARTS IDENTIFICATION

PARALLEL ARMS AND TOOLBAR SUPPORTS

KEY QTY. PART NO. DESCRIPTION

1. 8 6010-398 BUSHING

2. 4 2502-294 ½-13 X 1-1/2 HHCS GR 5 ZYD.

4 2525-352 ½ MED LOCK WASHER ZYD.

4 2520-352 ½-13 HEX NUT ZYD.

4 2526-352 ½ SAE FLAT WASHER ZYD.

3. 2 2502-294 ½-13 X 1-1/2 HHCS GR 5 ZYD.

2 2520-357 ½-13 HEX LOCK NUT ZYD.

2 2526-352 ½ SAE FLAT WASHER ZYD.

2 6010-397 BUSHING

4. 2 2570-758 5/8-11 U-BOLT (2-1/2”)

2 2570-602 5/8-11 U-BOLT (3”)

2 2570-588 5/8-11 U-BOLT (4”)

2 2570-626 5/8-11 U-BOLT (7”)

5. 4 2525-451 5/8 MED LOCK WASHER ZYD.

6. 1 6010-342 R.H. SUPPORT (SHOWN)

1 6010-343 L.H. SUPPORT

7. 1 6010-325 ARM, L.H. (SHOWN)

1 6010-324 ARM, R.H.

8. 2 6010-401 SPRING LOCKING PIN

9. 1 2531-107 1/8 X 1 COTTER PIN ZYD.

10. 2 6010-391 PIN

11. 2 6010-341 ARM

12. 2 6010-390 SPRING

13. 4 2520-452 5/8-11 HEX NUT ZYD.

27

Page 28

PARTS IDENTIFICATION

HOPPER DRIVE CASE ASSEMBLY

AND DEPTH ADJUSTMENT CAM

KEY QTY. PART NO. DESCRIPTION

1. 2 6010-311 7/16” JAM NUT ZYD.

2. 1 6010-387 SHIELD

3. 1 6010-373 BRACE

4. 1 6010-371 1-1/8” SLEEVE

6. 1 6010-382 HOUSING

7. 1 6010-354 CAM

8. 1 6010-352 STOP

9. 1 2530-154 1/4 X 1 COTTER PIN ZYD.

10. 1 6010-358 SPRING

11. 1 6010-359 SPACER

12. 1 2526-301 7/16” STD. FLAT WASHER ZYD.

13. 1 6010-314 7/16-14 X 2-1/2” HHCS GR 2 ZYD.

15. 1 6010-372 SLEEVE

16. 1 6010-317 7/16-14 X 5-1/4 HHCS GR 5 ZYD.

1 2525-301 7/16 MED LOCK WASHER ZYD.

17. 1 6010-383

18. 1 6010-379 EXTENSION SPRING

19. 2 6010-377 CHAIN SPROCKET, 7 TOOTH

20. 2 2526-253 3/8 SAE FLAT WASHER ZYD.

21. 1 6010-334 LINK CHAIN, TYPE 65, 86 LINKS

22. 1 6010-362 CHAIN SPROCKET, 11 TOOTH

1 6010-363 CHAIN SPROCKET, 14 TOOTH

1 6010-364 CHAIN SPROCKET, 20 TOOTH

1 6010-365 CHAIN SPROCKET, 22 TOOTH

28

POP RIVET 3/16 DIA.

KEY QTY. PART NO. DESCRIPTION

23. 3 2526-352 ½ SAE FLAT WASHER ZYD.

24. 3 2502-281 7/16-14 X ¾ HFLHCS GR5 ZYD

2 2525-301 7/16 MED LOCK WASHER ZYD.

25. 4 6010-400 POP RIVET

26. 1 6010-356 SPRING

27 1 6010-357 SPRING

28. 1 6010-335 COVER ASSEMBLY

29. 6010-336 HOUSING (INCLUDES #6 & #15)

30. 2 6010-310 7/16-14 X 1-1/2 CARBLT GR5 Z

2 2525-301 7/16 MED LOCK WASHER ZYD.

2 2520-303 7/16-14 HEX NUT ZYD.

32. 1 2531-107 1/8 X 1 COTTER PIN ZYD.

33. 1 6010-380 BUSHING

34. 2 6010-410 SNAP RING

35. 1 6010-381 IDLER ASSEMBLY

40. 1 6010-315 7/16-14 X 1-1/2 HHCS GR 5 ZYD

1 2525-301 7/16 MED LOCK WASHER ZYD.

2 2526-352 ½ SAE FLAT WASHERS ZYD.

1 2520-303 7/16-14 HEX NUT ZYD.

41. 1 6010-320 ¼ X 7/8 SET SCREW

42. 1 2520-151 ¼-20 HEX NUT ZYD

43. 1 6010-378 THRUST WASHER

Page 29

PARTS IDENTIFICATION

BAFFLE AND ACID DELINTED COTTON, BEANS,

REGULAR RATE MAIZE AND CORN

KEY QTY. PART NO. DESCRIPTION

1. 2 6010-406 ¼-20 HEX LOCK NUT ZYD

2. 2 2526-151 ¼ STANDARD FLAT WASHER ZYD

3. 2 6010-413 COMPRESSION SPRING

4. 1 6010-389 PLATE

5. 2 6010-316 ¼-20 X 3-1/4 HHCS GR 2 ZYD

29

Page 30

PARTS IDENTIFICATION

SPRING, PLUG AND ANCHOR

KEY QTY. PART NO. DESCRIPTION

1. 1 2502-372 ½-13 X 6-1/2” HHCS GR 5 ZYD.

1 2525-352 ½ MED LOCK WASHER ZYD.

1 2520-352 ½-13 HEX NUT ZYD.

2. 3 6010-396 ½ HRND FLAT WASHER

3. 2 6010-398 BUSHING

4. 1 6010-313 7/16-14 X 3 HHCS GR 5 ZYD.

5. 1 6010-355 ANCHOR

6. 1 2520-303 7/16-14 HEX NUT ZYD.

7. 1 6010-399 PLUG

8. 1 6010-347 SPRING

9. 1 6010-333 SPRING ASSEMBLY

30

Page 31

PARTS IDENTIFICATION

SEED BOOT, DISK AND BEARING ASSEMBLY

KEY QTY. PART NO. DESCRIPTION

18. 2 6010-395 DISK, 12” X .079”

19. 1 6010-408 CASE

20. 1 6010-346 BALL BEARING

21. 1 6010-404 SCREW, 5/8 X 1, R.H.

1 6010-405 SCREW, 5/8 X 1, L.H.

22. 1 6010-344 CASE, R.H.

1 6010-345 CASE, L.H.

23. 12 6010-312 ¼ X 1/2 RIVET

24. 2 6010-321 WASHER, 29/64 X ¾ X .035

25. 1 6010-339 BLADE, R.H.

1 6010-340 BLADE, L.H.

26. 1 6010-318 7/16-14 X 4-3/4 HHCS GR 2 ZYD.

1 2520-303 7/16-14 HEX NUT ZYD.

27. 2 2526-301 7/16 STD FLAT WASHER ZYD.

28. 2 6010-367 SCRAPER

29. 2 6010-411 SUPPORT

30. 2 2502-237 3/8-16 X 1 HHCS GR 5 ZYD.

2 2525-251 3/8 MED LOCK WASHER ZYD.

2 2520-251 3/8-16 HEX NUT ZYD.

37. 2 6010-407 DRAIN PLUG

31

Page 32

PARTS IDENTIFICATION

SEED BOOT AND DRIVE

KEY QTY. PART NO. DESCRIPTION

1. 2 2533-110 ¼ STRAIGHT SELF-TAP ZERK

2. 1 6010-388 BOLT

3. 1 6010-350 GEAR

6. 1 6010-337 TUBE (CORN OR PEANUT)

7. 4 6010-323 WASHER, 21/32 X 15/16 X .036

8. 1 6010-384 WASHER, .627 X 1-3/16 X 3/32

9. 1 6010-360 HUB, DRIVEN SPROCKET

10. 1 6010-363 CHAIN SPROCKET, 14 TOOTH

11. 1 2526-352 ½ SAE FLAT WASHER ZYD.

12. 1 2502-281 7/16-14 x ¾ HFLHCS GR 5 ZYD

1 2525-301 7/16 MED LOCK WASHER ZYD.

13. 2 6010-409 SEAL

14. 1 6010-338 LATCH

15. 1 2530-107 1/8 X 1 COTTER PIN ZYD

16. 1 6010-368 SPRING

17. 1 2526-253 3/8 SAE FLAT WASHER ZYD

18. 1 6010-372 SLEEVE, 1-15/32”

19. 1 6010-366 BUSHING

20. 1 6010-371 SLEEVE, 1-1/8”

KEY QTY. PART NO. DESCRIPTION

21. 1 6010-402 1/8 STRAIGHT SELF-TAP ZERK

22. 1 6010-375 SCRAPER, R.H. INSIDE

1 6010-376 SCRAPER, L.H. INSIDE

23. 4 6010-398 BUSHING

24. 1 2502-293 ½-13 X 1-1/4 HHCS GR 5 ZYD.

1 2520-356 ½-13 HEX JAM NUT ZYD.

25. 1 6010-351 STUD

26. 1 6010-322 WASHER, 33/64 X 7/8 X .048

27. 1 6010-329 RING GEAR AND PINION

28. 1 2502-372 ½-13 X 6-1/2 HHCS GR 5 ZYD.

1 2525-352 ½ MED LOCK WASHER ZYD.

1 6010-396 WASHER, 17/32 X 1-1/4 X .063

1 2520-352 ½-13 HEX LOCK NUT

29. 1 2502-371 ½-13 X 7 HHCS GR 5 ZYD.

1 2525-352 ½ MED LOCK WASHER ZYD.

1 6010-396 WASHER, 17/32 X 1-1/4 X .063

1 2520-352 ½-13 HEX LOCK NUT

30. 1 6010-392 DOUBLE DISK SEED OPENER

32

Page 33

PARTS IDENTIFICATION

CORN CUTOFF FOR SEED HOPPER

KEY QTY. PART NO. DESCRIPTION

1. 1 6010-328 CAP

2. 1 6010-319 ¼ X ¾ SCREW

3. 1 6010-326 GATE

4. 1 6010-413 COMPRESSION SPRING

5. 1 6010-327 KNOCKER

6. 1 6010-412 WHEEL

7. 1 6010-348 DEFLECTOR

8. 1 6010-374 BOTTOM, CORN

9. 1 6010-332 PLATE, CORN

10. 1 6010-337 TUBE

11. 1 6010-330 RETAINER

12. 1 6010-361 PLATE

13. 1 6010-331 PLATE, STEEL, FLAT ON BOTH SIDES

15. 1 ……….. SEED PLATE (NOT SUPPLIED)

33

Page 34

PARTS IDENTIFICATION

PRESS WHEEL AND TIRES

KEY QTY. PART NO. DESCRIPTION

3. 1 6010-385 TIRE, 4 X 16 CHEVRON (SUB FOR N10065)

6. 4 2502-200 5/16-18 X ¾ HHCS GR 2 ZYD

4 2520-205 5/16 HEX LOCK NUT ZYD.

7. 2 6010-394 RIM

8. 4 2502-200 5/16-18 X ¾ HHCS GR 2

4 2525-201 5/16 MED LOCK WASHER ZYD

9. 1 6010-353 HUB

10. 1 6010-386 WASHER

11. 1 6010-403 BALL BEARING

12. 1 6010-349 HUB

34

Page 35

Problem

Inaccurate drop

Planting more seed in some

rows than in others

Too many skips.

Depth adjusting cam does not

rest against stop in planting

position.

Runners plugging

TROUBLESHOOTING

Cause

Wrong seed plate

Floor plate turned wrong side

up or wrong false ring used.

Knocker worn or not working

freely

Chain on wrong sprockets

Planting too fast

Cut-off worn

Weak cut-off spring

Wrong seed plate or false ring

in one hopper

Hopper not secured tightly.

Seed hoppers nearly empty

Obstruction in seed plate

Excessive speed

Down pressure spring too

tight.

Planter not running level

Allowing planter to roll

backward when lowering

Solution

Select proper seed plate

Turn floor plate over or select

proper false ring.

Replace knocker. (Under cutoff cap)

Refer to charts.

Plant slower

Replace cut-off

Replace spring

Select right seed plate or false

ring to match

Secure with latch.

Fill hoppers.

Remove obstruction.

Slow down to recommended

speed.

Loosen down pressure spring.

Level planter

Lower planter only when

tractor is moving forward.

35

Page 36

Our name

Is getting known

Just a few years ago, Yetter products were sold primarily to the

Midwest only. Then we embarked on a program of expansion and

moved into the East, the South, the West and now north into Canada.

We’re even getting orders from as far away as Australia and Africa.

So, when you buy Yetter products . . .you’re buying a name that’s

recognized. A name that’s known and respected. A name that’s

become a part of American agriculture and has become synonymous

with quality and satisfaction in the field of conservation tillage.

Thank you.

YETTER MANUFACTURING CO.

Colchester, IL 62326-0358 • 309/776-4111

Toll Free 800/447-5777

Fax 309/776-3222

Website: WWW.YETTERCO.COM

E-MAIL: INFO@YETTERCO.COM

2565-724_REV_B • 05/13

36

Loading...

Loading...