Page 1

6000-002 CLOSE WHEEL ATTACHMENT ASSEMBLY

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website: www.yetterco.com

E-mail: info@yetterco.com

Page 2

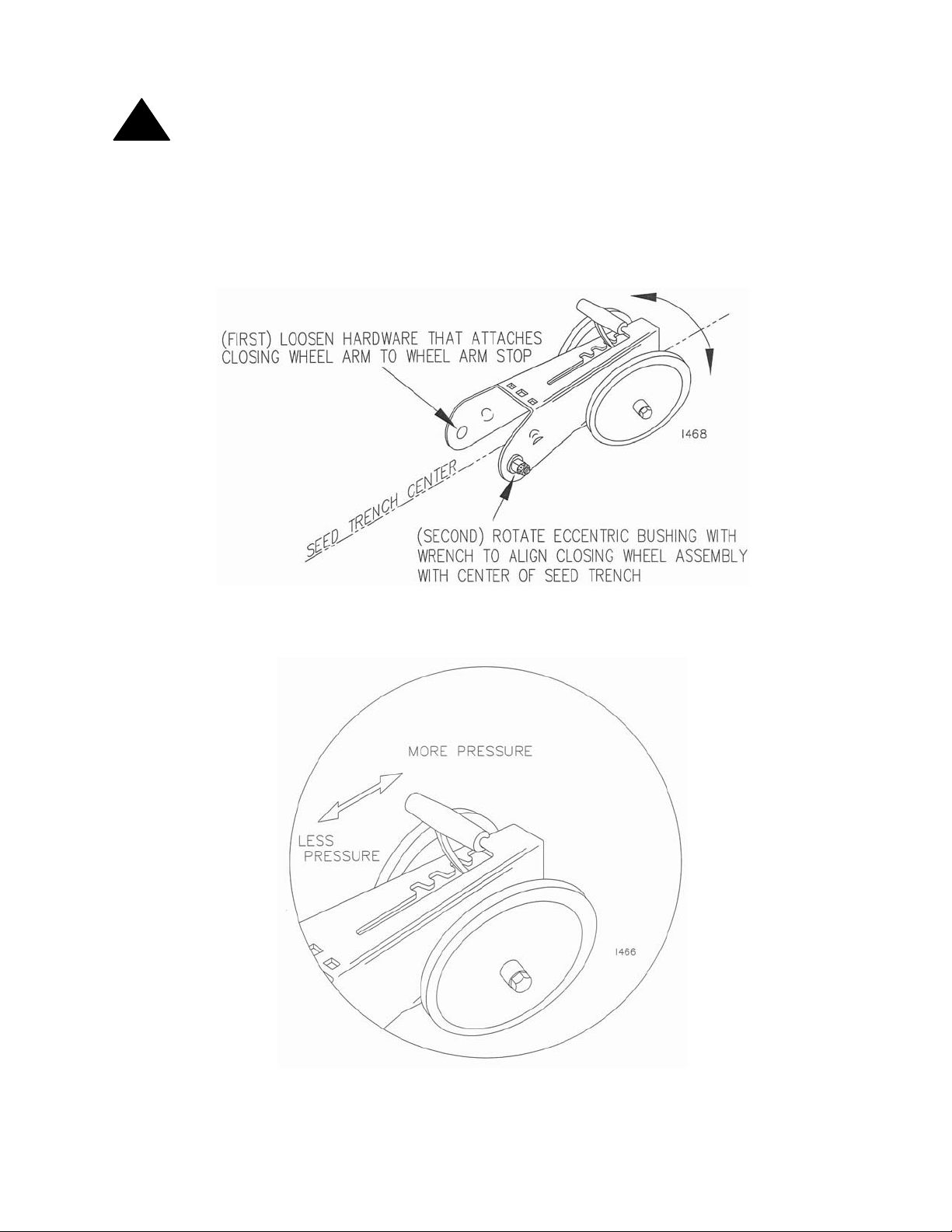

“V” CLOSING WHEEL ADJUSTMENT

WARNING: Raise planter to transport position and install all safety locks before

adjusting closing wheels.

Angled closing wheels trail behind the seed opener to close the seed trench left by the opener. Adjusting

spring pressure permits proper firming of the soil beside the seed rather than directly above it. An eccentric

bushing allows centering the closing wheel on the row to properly apply pressure on both sides of the seed

when closing the trench. When adjusted properly, the closing wheels are centered, tighten the bolts holding

the closing wheel to the row unit.

(CLOSING WHEEL ASSEMBLY SHOWN NOT ASSEMBLED TO ROW UNIT FOR VISUAL CLARITY)

After setting the planter depth to the correct depth, check the operation of the closing wheels. The closing

wheels must apply enough down pressure to close the seed trench and insure good seed to soil contact. If

the seed trench is not being closed properly increase the closing wheel pressure by moving the closing

wheel lever rearward.

Closing wheels must not sink into the soil too deeply or the seed placement could be adversely affected,

especially when planting shallow. If the closing wheels are applying too much pressure and the seed is

being moved by the closing wheels, decrease by moving the lever forward.

Light soils usually require less down pressure, heavy soils more.

2

Page 3

In certain conditions, seed to soil contact and residue flow can be improved by spacing the closing wheels

further apart and/or staggering them. to space them further apart, remove the bolt and nut holding the

closing wheel to the closing wheel arm, place 5/8” washers (not provided) between the closing wheel and

the arm and re-assemble the closing wheel to the arm.

Two mounting holes for each closing wheel are provided in the closing wheel arm. To stagger the closing

wheels, remove one closing wheel from the arm and re-assemble it in the other hole in the closing wheel

arm.

LUBRICATION

Oil the closing wheel bushings weekly with a general-purpose oil.

(CLOSING WHEEL ASSEMBLY SHOWN NOT ASSEMBLED TO ROW UNIT FOR VISUAL CLARITY)

3

Page 4

Problem

Closing wheel(s) leave

severe imprint in soil.

Closing wheel(s) not

firming soil around seed.

Closing wheel running on

top of seed trench.

TROUBLESHOOTING

Cause

Too much closing wheel

down pressure.

Insufficient closing wheel

pressure.

Closing wheels not

centered.

PARTS IDENTIFICATION

Solution

Reduce closing wheel

pressure.

Increase closing wheel

pressure.

Rotate eccentric

bushing(s) to center

closing wheels.

2565-402 – 6/06

4

Loading...

Loading...