Yetter 5000-050A, 5000-051A, 5000-052A Owner's Manual

5000 SERIES STALK DEVASTATOR

DRAGO GT MODEL CORN HEADS

OWNER’S MANUAL

PART IDENTIFICATION

2565-969 06/2019

YETTER MANUFACTURING CO.

Founded 1930

Colchester, IL 62326

Toll free: (800)447-5777.

Fax: (309)776-3222

Website: yetterco.com

E-mail: info@yetterco.com

WARRANTY

Yetter Manufacturing warrants all products manufactured and sold by it against defects in material. This

warranty being expressly limited to replacement at the factory of such parts or products as shall appear to be

defective after inspection. This warranty does not obligate the Company to bear cost of labor in replacement

of parts. It is the policy of the Company to make improvements without incurring obligations to add them to

any unit already sold. No warranty is made or authorized to be made, other than herein set forth. This

warranty is in effect for one year after purchase.

DEALER: ________________________________________

Yetter Manufacturing warrants its own products only and cannot be responsible for damages to

equipment on which mounted.

TABLE OF CONTENTS

FOREWARD....................................................... 2

WARRANTY....................................................... 2

SAFETY INFORMATION................................ 3 – 5

TORQUE............................................................ 6

BILL OF MATERIALS & TOOLS NEEDED.............. 7

ASSEMBLY INSTRUCTIONS........................ 8 – 14

LOCK UP / OPERATION................................... 15

PART IDENTIFICATION............................ 16 – 22

You’ve just joined an exclusive but rapidly

growing club.

For our part, we want to welcome you to the

group and thank you for buying a Yetter product.

We hope your new Yetter products will help you

achieve both goals-increase your productivity and

increase your efficiency so that you may generate

more profit.

This operator’s manual has been designed into 4

major sections: Foreword, Safety Precautions,

Installation Instructions and Parts

Breakdown.

This SAFETY ALERT SYMBOL indicates

important safety messages in the

manual. When you see this symbol, be

alert to the possibility of PERSONAL INJURY &

carefully read the message that follows.

The word NOTE is used to convey information

that is out of context with the manual text. It

contains special information such as

specifications, techniques and reference

information of a supplementary nature.

The word IMPORTANT is used in the text when

immediate damage will occur to the machine due

to improper technique or operation.

Important will apply to the same information as

specified by note only of an immediate and

urgent nature.

2

FOREWORD

It is the responsibility of the user to read the

operator’s manual and comply with the safe and

correct operating procedure and to lubricate and

maintain the product according to the

maintenance schedule in the operator’s manual.

The user is responsible for inspecting his

machine and for having parts repaired or

replaced when continued use of the product

would cause damage or excessive wear to the

other parts.

It is the user’s responsibility to deliver his

machine to the Yetter dealer who sold him the

product for service or replacement of defective

parts, which are covered by the warranty policy.

If you are unable to understand or follow the

instructions provided in this publication, consult

your local Yetter dealer or contact:

YETTER MANUFACTURING CO.

309/776-4111

800/447-5777

309/776-3222 (FAX)

Website: www.yetterco.com

E-mail: info@yetterco.com

BE ALERT!

YOUR SAFETY IS INVOLVED

WATCH FOR THIS SYMBOL. IT POINTS OUT IMPORTANT SAFETY

PRECAUTIONS. IT MEANS “ATTENTION – BE ALERT!”

It is your responsibility as an owner, operator, or supervision to know and

instruct everyone using this machine at the time of initial assignment and at

least annually thereafter, of the proper operation, precautions, and work

hazards which exist in the operation of the machine in accordance with

OSHA regulations.

Safety Is No Accident

The following safety instructions, combined with common sense, will

save your equipment from needless damage and the operator from

unnecessary exposure to personal hazard. Pay special attention to

the caution notes in the text. Review this manual at least once a year

with all operators.

1. Read and understand the operator’s manual before operating this machine.

Failure to do so is considered a misuse of the equipment.

2. Make sure equipment is secure before operating.

3. Always keep children away from equipment when operating.

4. Make sure everyone that is not directly involved with the operation is out of the

work area before beginning operation.

5. Make sure all safety devices, shields, and guards are in place and functional

before beginning operation

6. Shut off all power to adjust, service, or clean.

7. Keep hands, feet, and clothing away from moving parts. It is a good idea to

remove all jewelry before operating.

8. Inspect the machine periodically during operation for signs of excessive wear,

loose fasteners, and unusual noises.

3

PLEASE READ, VERY IMPORTANT

SECURE CORN HEADER AGAINST UNWANTED

LOWERING BY APPLYING THE LOCKING

MECHANISM ON THE HYDRAULIC CYLINDERS!

1. Attach head to combine, lock head to combine

2. Raise the head off the ground and engage safety stop on the

feeder house cylinder.

3. Turn off combine engine and remove the key

FOLLOW ALL INSTRUCTIONS GIVEN BY THE COMBINE

MANUFACTURER

4

PLEASE READ, VERY IMPORTANT

Subject to the size and weight of the corn header, one

or two additional hydraulic cylinders may be required.

The combine manufacturer generally keeps

corresponding kits readily available for dealers.

Subject to the design of the corn header and the

carrying capacity of different combines, the steering

axle may require the fitting of additional weights and

the rear tires be filled with ballast.

FOLLOW ALL INSTRUCTIONS GIVEN BY THE COMBINE

MANUFACTURER

5

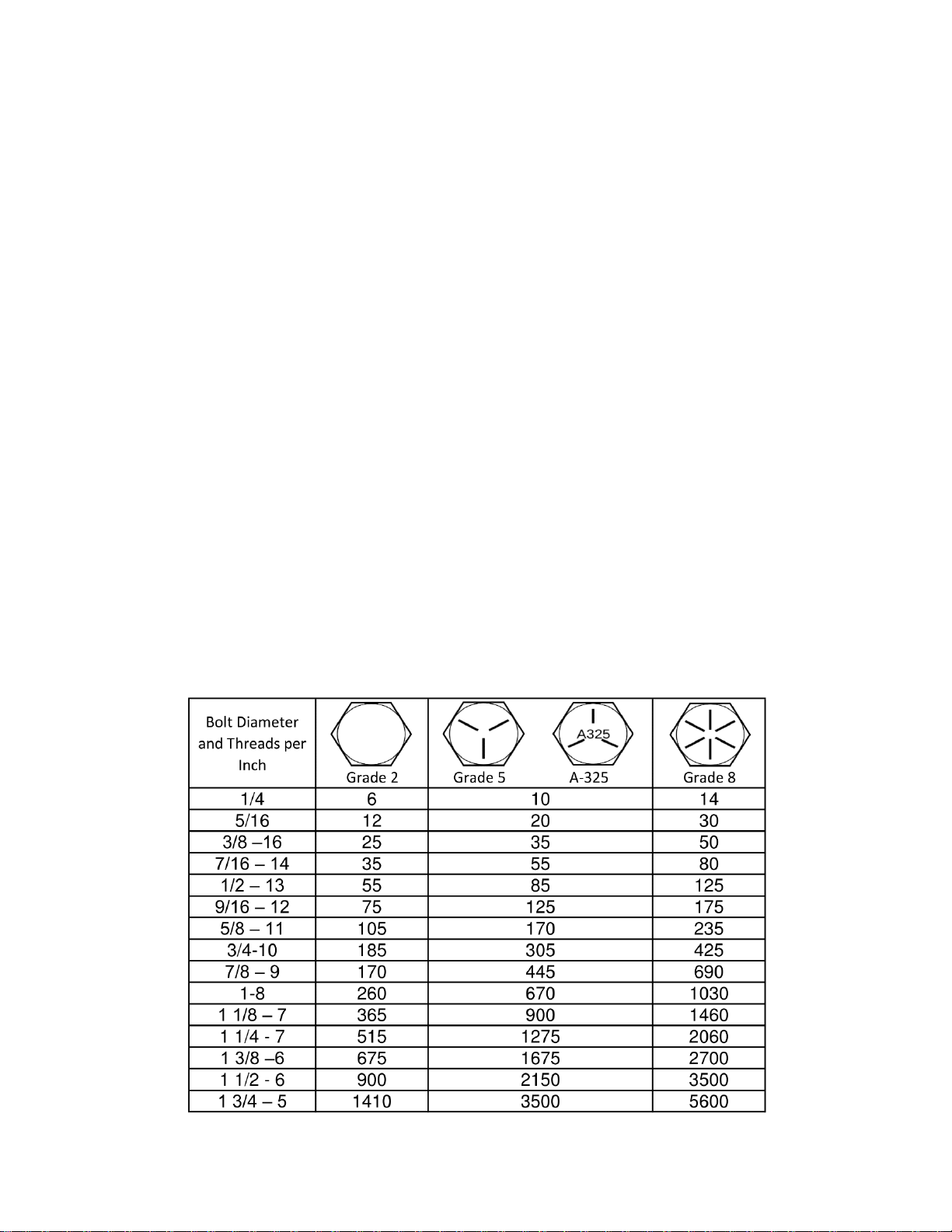

BOLT TORQUE

Important: Over-tightening hardware can cause just as much damage as

under-tightening. Tightening hardware beyond the recommended range

can reduce its shock load capacity.

All hardware on the 5000 Devastator is either Grade 5 or Grade 8, unless

otherwise noted. Grade 5 cap screws are marked with three radial lines on

the head. Grade 8 cap screws are marked with six radial lines on the head.

If hardware must be replaced, be sure to replace it with hardware of equal

size, strength and thread type. Refer to the torque values chart when

tightening hardware.

The chart below is a guide for proper torque. Use it unless a specified

torque is called out elsewhere in the manual.

Torque is the force applied to the end of the handle or cheater bar, times

the length of the handle or bar.

Use a torque wrench wherever possible

The following table shows torque in ft.-lbs. for coarse thread hardware.

6

Loading...

Loading...