Page 1

3600 SERIES

FERTILIZER TOOLBAR

FOR SELF PROPELLED SPRAYERS

OPERATOR’S MANUAL

PART IDENTIFICATION

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website: www.yetterco.com

E-mail: info@yetterco.com

Page 2

FOREWORD

You’ve just joined an exclusive but rapidly

growing club.

For our part, we want to welcome you to the

group and thank you for buying a Yetter product.

We hope your new Yetter products will help you

achieve both goals-increase your productivity and

increase your efficiency so that you may generate

more profit.

This operator’s manual has been designed into

four major sections: Foreword, Safety

Precautions, Installation Instructions and Parts

Breakdown.

This SAFETY ALERT SYMBOL

indicates important safety messages in

the manual. When you see this

symbol, be alert to the possibility of

PERSONAL INJURY and carefully

read the message that follows.

The word NOTE is used to convey information

that is out of context with the manual text. It

contains special information such as

specifications, techniques and reference

information of a supplementary nature.

The word IMPORTANT is used in the text when

immediate damage will occur to the machine due

to improper technique or operation. Important will

apply to the same information as specified by

note only of an immediate and urgent nature.

It is the responsibility of the user to read the

operator’s manual and comply with the safe and

correct operating procedure and to lubricate and

maintain the product according to the

maintenance schedule in the operator’s manual.

The user is responsible for inspecting his

machine and for having parts repaired or

replaced when continued use of the product

would cause damage or excessive wear to the

other parts.

It is the user’s responsibility to deliver his

machine to the Yetter dealer who sold him the

product for service or replacement of defective

parts, which are covered by the warranty policy.

If you are unable to understand or follow the

instructions provided in this publication, consult

your local Yetter dealer or contact:

YETTER MANUFACTURING CO.

309/776-4111

800/447-5777

309/776-3222 (FAX)

Website: www.yetterco.com

E-mail: info@yetterco.com

WARRANTY

Yetter Manufacturing warrants all products manufactured and sold by it against defects in material. This

warranty being expressly limited to replacement at the factory of such parts or products as shall appear to

be defective after inspection. This warranty does not obligate the Company to bear cost of labor in

replacement of parts. It is the policy of the Company to make improvements without incurring obligations to

add them to any unit already sold. No warranty is made or authorized to be made, other than herein set

forth. This warranty is in effect for one year after purchase.

Dealer ___________________________________________________

Yetter Manufacturing warrants its own products only and cannot be responsible for damages to

equipment on which mounted.

2

Page 3

SAFETY PRECAUTIONS

You can make your farm a safer place to live and work if you observe the safety precautions given. Study these

precautions carefully and insist those working with you and for you follow the precautions.

Finally, remember this an accident is usually caused by someone’s carelessness, neglect or oversight.

A brief description of signal words that may be used in this manual:

CAUTION: Used as a general reminder of good safety practices or to direct attention to unsafe practices.

WARNING: Denotes a specific potential hazard.

DANGER: Denotes the most serious specific potential hazard.

CAUTION

Consult your implement and tractor operator’s manual for correct and safe operating practices. Be aware of towed

implement width and allow safe clearance.

CAUTION: SAFETY SIGNS

Safety decals are placed on the implement to alert the operator and others to the risk of personal injury or unsafe

operation during normal operations and servicing.

1. The safety decals must be kept clean and in good condition to ensure that they are legible.

2. Safety decals must be replaced if they are missing or illegible.

3. When components are replaced during repair or servicing, check that the new components include the necessary

safety signs.

4. Replacement safety decals may be obtained from your local dealer.

WARNING

Read these instructions carefully to acquaint yourself with the Equipment. Working with unfamiliar equipment can lead

to accidents.

Never park the equipment on a steep incline or leave the equipment running unattended.

Never clean, lubricate or adjust a machine that is in motion.

Always check that straps are secure.

Make sure latches are in pinned position when moving equipment.

Do not allow children to operate this equipment.

Do not allow riders on the equipment, trailer and/or pick-up.

Use speed and caution dictated by the terrain being traversed. Do not operate on any slope steep enough to cause

tipping or loss of control.

Read and understand the operator’s manual and require all other persons who will operate the equipment to do the

same.

If operating on public roadways, where legal, be certain all lighting is operating properly and observe all traffic laws.

Beware of increased stopping distances and control effort when operating with implements attached.

Be familiar with all controls and be prepared to stop equipment quickly in an emergency.

FAILURE TO HEED MAY RESULT IN PERSONAL INJURY OR DEATH.

3

Page 4

ASSEMBLY

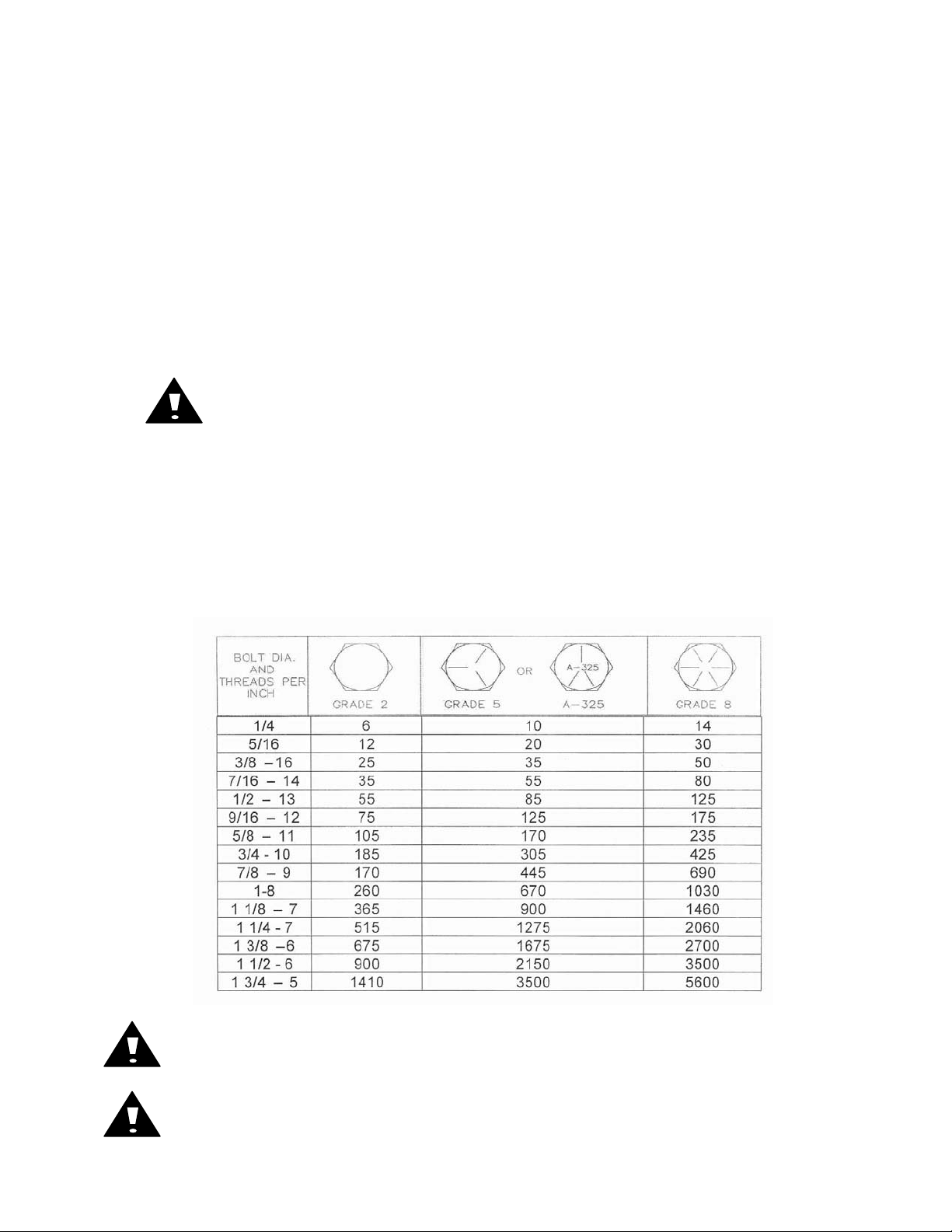

BOLT TORQUE

Mounting bolts and hardware

Before operating the FERTILIZER TOOLBAR for the first time, check to be sure that all

hardware is tight. Check all hardware again after approximately 50 hours of operation

and at the beginning of each planting season.

All hardware used on the FERTILIZER TOOLBAR is Grade 5 unless otherwise noted.

Grade 5 cap screws are marked with three radial lines on the head. If hardware must be

replaced, be sure to replace it with hardware of equal size, strength and thread type.

Refer to the torque values chart when tightening hardware.

Important: Over tightening hardware can cause as much damage as when

under tightening. Tightening hardware beyond the recommended range can

reduce its shock load capacity.

The chart below is a guide for proper torque. Use it unless a specified torque is called out

elsewhere in the manual.

Torque is the force you apply to the wrench handle or the cheater bar, times the length of the

handle or bar.

Use a torque wrench whenever possible.

The following table shows torque in ft. lbs. for coarse thread hardware.

Lubricate all bearings and moving parts as assembled and make certain that they work freely.

WARNING: Never work around the toolbar/implement while in a raised position without using

so may lead to personal injury.

4

safety lockups.

CAUTION: The FERTILIZER TOOLBAR and its attachments are very heavy. Pay extra attention

to lifting techniques while handling and or maneuvering the opener during assembly. Failure to do

Page 5

JD 4710/4720 SELF-PROPELLED SPRAYER FERTILIZER TOOLBAR

SELF-PROPELLED SPRAYER FERTILIZER TOOLBAR

Suggested list of items not

- Solution Filter, Flow Meter, Valves, Hoses, Quick Coupler and Fittings

provided by YETTER Manufacturing Co.

5

Page 6

SELF-PROPELLED SPRAYER FERTILIZER TOOLBAR

-Numbered labels 1-12, quantity 3 sets

-Plugs JD #38H1445 for hydraulic hoses, quantity 20

-Caps JD #38H1414 for hydraulic manifold, quantity 12

-Hydraulic hose-4@127

” and 4@97” with end to fit JD#38H1159 adapter,

#T77814 O-ring and end to fit –6 JIC.

Suggested list of items not

provided by YETTER Manufacturing Co.

6

Page 7

SELF-PROPELLED SPRAYER FERTILIZER TOOLBAR

-Numbered labels 1-8, quantity 2 sets to

Identify the foam marker hoses.

Suggested list of items not provided by YETTER Manufacturing Co.

• Wiring Harness

• 37 Pin female receptacle quantity 01

• 37 Pin male connector quantity 02

• Sensor connector JD# 57M7796 quantity 01

• Flow meter connector JD# 57M7257 quantity 01

• 3 Pin weather pack connector quantity = # of section

• Control valves

Yetter Manufacturing Company reserves the right to alter equipment specifications without notice or obligation. Yetter Manufacturing

Company offers the information contained in this guide in good faith. However, the use of the information provided is beyond the

control of Yetter Manufacturing Company and in no case shall Yetter Manufacturing Company or any seller of its products be

responsible for any damages that may occur from the use of this information. The user shall assume all such risks. Due to the

equipment and specifications involved, the possibility of error does exist. If you discover such an error, please notify Yetter

Manufacturing Company as soon as possible so that it can be corrected. This list was compiled from customer suggestions based on

their individual needs and preferences.

7

Page 8

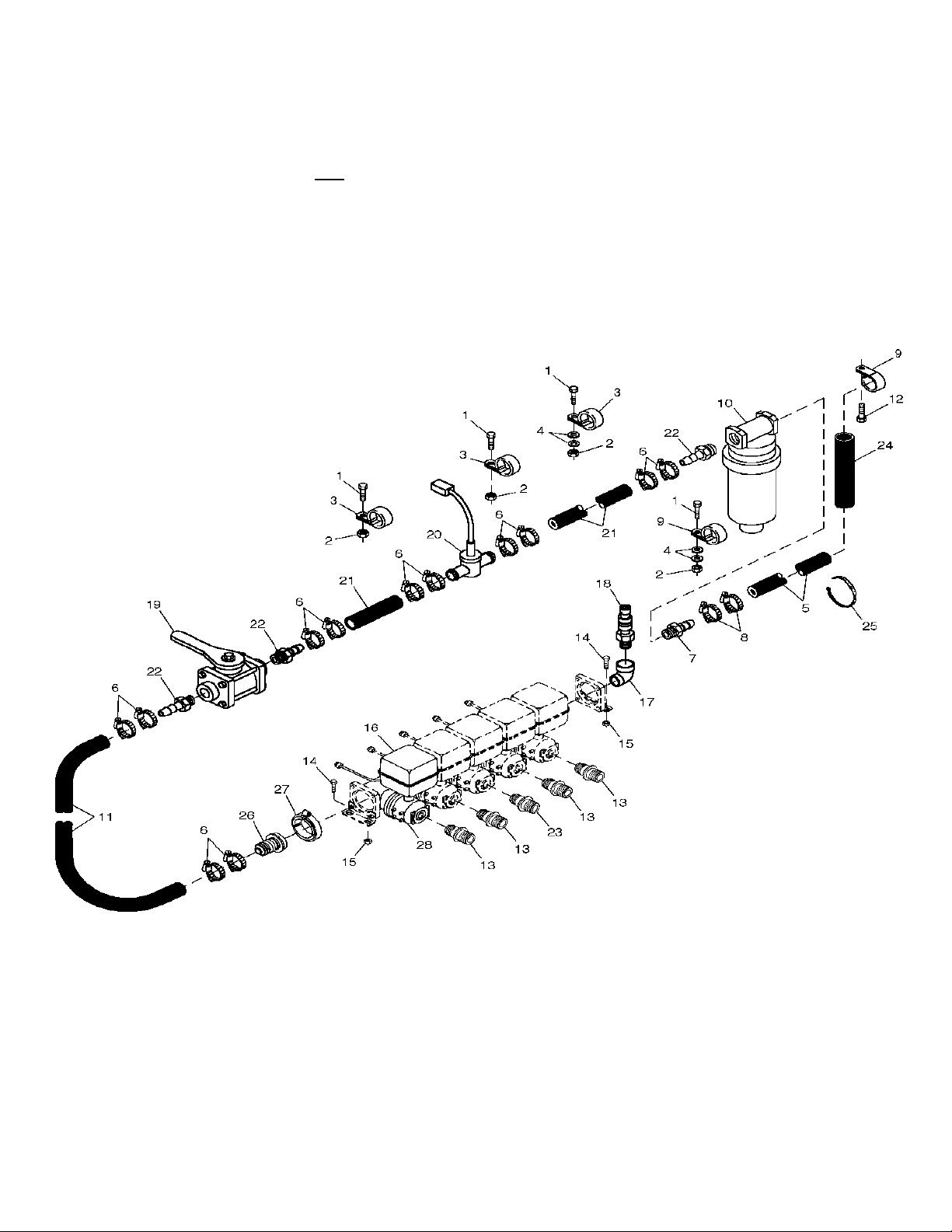

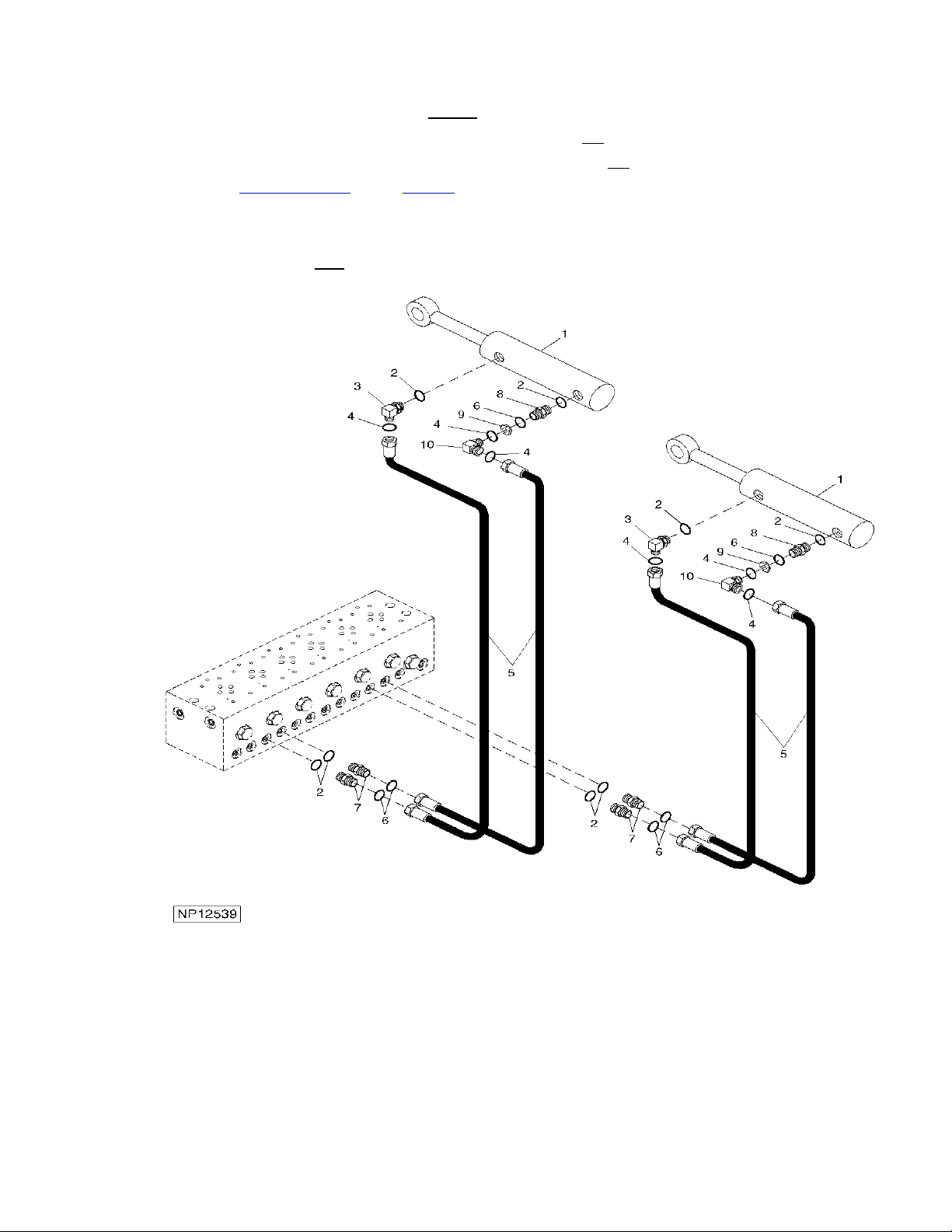

PARTS IDENTIFICATION

8

Page 9

PARTS IDENTIFICATION

9

Page 10

PARTS IDENTIFICATION

10

Page 11

PARTS IDENTIFICATION

IMPORTANT: When the toolbar is in the folded position the lock pin 3600-345 must not bind in

the wing stop plate 3600-344. The pin must be adjusted with shims and correctly positioned by

moving the pin assembly on the slotted holes of the 3600-223 pin lock bracket. When the lock pin

is not being held down with the transport lock striker 3600-204, the spring should be to pull the

lock pin up out of the lock plate. Use never-seize to aid the pin to move freely.

11

Page 12

PARTS IDENTIFICATION

12

Page 13

PARTS IDENTIFICATION

13

Page 14

PARTS IDENTIFICATION

14

Page 15

PARTS IDENTIFICATION

15

Page 16

PARTS IDENTIFICATION

16

Page 17

LIGHT KIT LOCATIONS

17

Page 18

SAFETY

WARNING: Before performing any work on a sprayer, be sure to clean and

neutralize the sprayer.

CAUTION: Pesticides are hazardous and can poison causing serious injury or

death to you or others. During application of hazardous pesticides, pesticide

residue can build up on the inside or outside of the machine. Clean machine according to

use instructions of hazardous pesticides. Refer to product label.

TROUBLESHOOTING

COMPONENT

Solution System

High low flow valve

Boom section shut off valves

Check valves

Boom and suction strainers

Hose clamps

Solution hoses

SprayStar Monitor

Wiring harness

Flow meter

Pressure transducer

Plumbing

Boom plumbing

Nozzle bodies

Nozzle tips

Nozzle screens

CHECK FOR

Leaks/corroded/operation

Leaks/corroded/operation

Leaks/corroded/operation

Leaks/plugged/ripped

Loose/worn/missing

Collapsed/worn

Worn/Broken/corroded

Clean/Calibrate

Leaks/performance/calibrate

Leaks/corroded

Leaks/cracks/corroded

Calibrate/worn

Plugged/missing/ripped

MAINTENANCE

1. After washing, spray machine down with Spray Master Equipment coating (N205703-U.S.,

N207338-CAN.) to protect from chemicals and allow for future ease of cleaning.

2. Add 20-30 gallons of appropriate solution mixture of RV antifreeze for the desired temperatures.

18

Page 19

NOTES

19

Page 20

Our name

Is getting known

Just a few years ago, Yetter products were sold primarily to the

Midwest only. Then we embarked on a program of expansion and

moved into the East, the South, the West and now north into Canada.

We’re even getting orders from as far away as Australia and Africa.

So, when you buy Yetter products . . .you’re buying a name that’s

recognized. A name that’s known and respected. A name that’s

become a part of American agriculture and has become synonymous

with quality and satisfaction in the field of conservation tillage.

Thank you.

YETTER MANUFACTURING CO.

Colchester, IL 62326-0358 • 309/776-4111

Toll Free 800/447-5777

Fax 309/776-3222

Website: WWW.YETTERCO.COM

E-MAIL: INFO@YETTERCO.COM

2565-691_REV_A • 03/09

20

Loading...

Loading...