Page 1

3400 & 3500 SERIES

TOOLBAR ROTARY HOE

PATENTED

2565-118_REV_E

OPERATOR’S MANUAL

PART IDENTIFICATION

•

02/12

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website: www.yetterco.com

E-mail: info@yetterco.com

Page 2

FOREWORD

You’ve just joined an exclusive but rapidly

growing club.

For our part, we want to welcome you to the

group and thank you for buying a Yetter product.

We hope your new Yetter implement will help you

achieve both increased productivity and

increased efficiency so that you may generate

more profit. This operator’s manual has been

designed into six major sections.

Foreword, Safety Precautions, assembly

instructions, Operation, parts identification and

troubleshooting.

It is important the owner/operator knows the

implement model number and serial number.

Write the serial and model number in the space

provided and use it in all correspondence when

referring to the implement.

Throughout the manual references may be made

to left side and right side. These terms are used

as viewed from the operator’s seat facing the

front of the tractor.

This SAFETY ALERT SYMBOL indicates

important safety messages in the manual.

When you see this symbol, be alert to the

possibility of PERSONAL INJURY and carefully

read the message that follows.

YETTER MANUFACTURING CO.

309/776-4111

800/447-5777

309/776-3222 (FAX)

Website: www.yetterco.com

E-mail: info@yetterco.com

WARRANTY POLICY

Yetter Manufacturing warrants all products manufactured and sold by it against defects in material. This warranty being

expressly limited to replacement at the factory of such parts or products as will appear to be defective after inspection.

This warranty does not obligate the Company to bear cost of labor in replacement of parts. It is the policy of the

company to make improvements without incurring obligations to add them to any unit already sold. No warranty is

made or authorized to be made, other than herein set forth. This warranty is in effect for one year after purchase.

Model Number:_________________________

Serial Number:_________________________

Dealer :___________________

The serial and model numbers are located on the top of the left hitch plate.

Yetter Manufacturing warrants its own products only and cannot be responsible for damage to

equipment on which mounted.

2

The word NOTE is used to convey information

that is out of context with the manual text. It

contains special information such as

specifications, techniques, reference information

and other information of a supplementary nature.

The word IMPORTANT is used in the text when

immediate damage will occur to the machine due

to improper technique or operation. Important will

apply to the same information as specified by

note only of an immediate and urgent nature.

It is the responsibility of the user to read the

operator’s manual and comply with the safe and

correct operating procedure and to lubricate and

maintain the product according to the

maintenance schedule in the operator’s manual.

The user is responsible for inspecting his

machine and for having parts repaired or

replaced when continued use of the product

would cause damage or excessive wear to the

other parts.

It is the user’s responsibility to deliver his

machine to the Yetter dealer who sold

him the product for service or

replacement of defective parts that are covered

by the warranty policy.

If you are unable to understand or follow the

instructions provided in the publication, consult

you local Yetter dealer or contact:

Page 3

SAFETY PRECAUTIONS

You can make your farm a safer place to live and work if you observe the safety precautions given. Study

these precautions carefully and insist that those working with you and for you follow them.

Finally, remember this: an accident is usually caused by someone’s carelessness, neglect or oversight.

DANGER

Inspect and replace worn or frayed hydraulic hose, keep all connections tight. Escaping hydraulic fluid

under pressure can have sufficient force to penetrate the skin and cause serious personal injury. Fluid

escaping from a small hole can be almost invisible. Use a piece of cardboard or wood rather than the

hands to search for suspected leaks.

CAUTION

Consult your implement and tractor operator’s manual for correct and safe operating practices. Be aware of

towed implement width and allow safe clearance.

CAUTION: SAFETY SIGNS

Safety decals are placed on the implement to alert the operator and others to the risk of personal injury or

unsafe operation during normal operations and servicing.

1. The safety decals must be kept clean and in good condition to ensure that they are legible.

2. Safety decals must be replaced if they are missing or illegible.

3. When components are replaced during repair or servicing, check that the new components include

the necessary safety signs.

4. Replacement safety decals may be obtained from your local Yetter dealer.

WARNING

Never clean, lubricate or adjust a machine that is in motion. Always install the transport lock pins and bracket when

transporting for any length of time or on public roadways.

If required to service unit in raised position, be sure to install all transport lock pins and locking bracket.

Be sure the implement is securely locked in the 3-point quick hitch before operating.

Do not allow children to operate this equipment.

Do not allow riders on the tractor or implement.

Use speeds and caution dictated by the terrain being traversed. Do not operate on any slope steep enough to cause

tipping or loss of control.

Be sure all personnel are clear of the immediate area before operating.

Read and understand the operator’s manual and require all other persons who will operate the equipment to do the

same.

In operating on public roadways, where legal, be certain all lighting is operating properly and observe all traffic laws.

Ensure slow moving vehicle emblem on tractor is visible.

Beware of increased stopping distances and control effort when operating with implements attached.

Be familiar with all tractor and implement controls and be prepared to stop engine and implements quickly in an

emergency.

FAILURE TO HEED MAY RESULT IN PERSONAL INJURY OR DEATH

3

Page 4

3400 MODEL SPECIFICATIONS

MODEL NO. OF TOOLBAR APPROX.

NO. SECTIONS LENGTH WEIGHT

3412-101 3 149” (12’5”) 1250#

3415-101 4 184” (15’4”) 1600#

3421-101 6 254” (21’2”) 2400#

3428-101 8 338” (28’2”) 3050#

3430-101 8 366” (30’6”) 3300#

3434-101 8 408” (34’) 3700#

3400 ROW COVERAGES

3412-101 12’ 3 SECTION HOE

42” ROWS – 3 ROWS WITH 21” OVERLAP

40” ROWS – 3 ROWS WITH 29” OVERLAP

38” ROWS – 3 ROWS WITH 33” OVERLAP

36” ROWS – 4 ROWS WITH 3” OVERLAP

34” ROWS – 4 ROWS WITH 11” OVERLAP

32” ROWS – 4 ROWS WITH 19” OVERLAP

30” ROWS – 4 ROWS WITH 27” OVERLAP

28” ROWS – 5 ROWS WITH 7” OVERLAP

26” ROWS – 5 ROWS WITH 17” OVERLAP

24” ROWS – 6 ROWS WITH 3” OVERLAP

22” ROWS – 6 ROWS WITH 15” OVERLAP

20” ROWS – 7 ROWS WITH 7” OVERLAP

3421-101 21’ 6 SECTION HOE

42” ROWS – 6 ROWS WITH NO OVERLAP

40” ROWS – 6 ROWS WITH 12” OVERLAP

38” ROWS – 6 ROWS WITH 24” OVERLAP

36” ROWS – 7 ROWS WITH NO OVERLAP

34” ROWS – 7 ROWS WITH 14” OVERLAP

32” ROWS – 7 ROWS WITH 28” OVERLAP

30” ROWS – 8 ROWS WITH 12” OVERLAP

28” ROWS – 9 ROWS WITH NO OVERLAP

26” ROWS – 9 ROWS WITH 18” OVERLAP

24” ROWS – 10 ROWS WITH 12” OVERLAP

22” ROWS – 11 ROWS WITH 10” OVERLAP

20” ROWS – 12 ROWS WITH 12” OVERLAP

3430-101 30’ 8 SECTION HOE

42” ROWS – 8 ROWS WITH 28” OVERLAP

40” ROWS – 9 ROWS WITH 4” OVERLAP

38” ROWS – 9 ROWS WITH 22” OVERLAP

36” ROWS – 10 ROWS WITH NO OVERLAP

34” ROWS – 10 ROWS WITH 24” OVERLAP

32” ROWS – 11 ROWS WITH 12” OVERLAP

30” ROWS – 12 ROWS WITH 4” OVERLAP

28” ROWS – 13 ROWS WITH NO OVERLAP

26” ROWS – 14 ROWS WITH NO OVERLAP

24” ROWS – 15 ROWS WITH 4” OVERLAP

22” ROWS – 16 ROWS WITH 12” OVERLAP

20” ROWS – 18 ROWS WITH 4” OVERLAP

3415-101 15’ 4 SECTION HOE

42” ROWS – 4 ROWS WITH 14” OVERLAP

40” ROWS – 4 ROWS WITH 22” OVERLAP

38” ROWS – 4 ROWS WITH 30” OVERLAP

36” ROWS – 5 ROWS WITH 2” OVERLAP

34” ROWS – 5 ROWS WITH 12” OVERLAP

32” ROWS – 5 ROWS WITH 22” OVERLAP

30” ROWS – 6 ROWS WITH 2” OVERLAP

28” ROWS – 6 ROWS WITH 14” OVERLAP

26” ROWS – 7 ROWS WITH NO OVERLAP

24” ROWS – 7 ROWS WITH 14” OVERLAP

22” ROWS – 8 ROWS WITH 6” OVERLAP

20” ROWS – 9 ROWS WITH 2” OVERLAP

3428-101 28’ 8 SECTION HOE

42” ROWS – 8 ROWS WITH NO OVERLAP

40” ROWS – 8 ROWS WITH 16” OVERLAP

38” ROWS – 8 ROWS WITH 32” OVERLAP

36” ROWS – 9 ROWS WITH 12” OVERLAP

34” ROWS – 9 ROWS WITH 30” OVERLAP

32” ROWS – 10 ROWS WITH 16” OVERLAP

30” ROWS – 11 ROWS WITH 6” OVERLAP

28” ROWS – 12 ROWS WITH NO OVERLAP

26” ROWS – 12 ROWS WITH 24” OVERLAP

24” ROWS – 14 ROWS WITH NO OVERLAP

22” ROWS – 15 ROWS WITH 6” OVERLAP

20” ROWS – 16 ROWS WITH 16” OVERLAP

3434-101 34’ 8 SECTION HOE

42” ROWS – 9 ROWS WITH 28” OVERLAP

40” ROWS – 10 ROWS WITH 6” OVERLAP

38” ROWS – 10 ROWS WITH 26” OVERLAP

36” ROWS – 11 ROWS WITH 10” OVERLAP

34” ROWS – 11 ROWS WITH 32” OVERLAP

32” ROWS – 12 ROWS WITH 22” OVERLAP

30” ROWS – 13 ROWS WITH 16” OVERLAP

28” ROWS – 14 ROWS WITH 14” OVERLAP

26” ROWS – 15 ROWS WITH 14” OVERLAP

24” ROWS – 16 ROWS WITH 22” OVERLAP

22” ROWS – 18 ROWS WITH 10” OVERLAP

20” ROWS – 20 ROWS WITH 6” OVERLAP

4

Page 5

3500 MODEL SPECIFICATIONS

MODEL NO. OF TOOLBAR TOOLBAR APPROX.

NO. SECTIONS LENGTH LENGTH WEIGHT

(OPEN) (FOLDED)

3521-101 4 252” (21’) 130” (10’10”) 3100#

3528-101 8 336” (28’) 184” (14’4”) 3850#

3530-101 8 364” (30’2”) 186” (15’6”) 4100#

3534-101 8 406” (33’10”) 207” (17’3”) 4500#

3541-101 9 490” (40’10”) 249” (20’9”) 5000#

3546-101 9 550” (45’10”) 309” (25’10”) 5500#

3554-101 12 650” (54’2”) 340” (28’4”) 8400#

3560-101 13 726” (60’6”) 389” (32’5”) 10,000#

3500 ROW COVERAGES

3521-101 21’ 4 SECTION HOE

42” ROWS – 6 ROWS WITH NO OVERLAP

40” ROWS – 6 ROWS WITH 12” OVERLAP

38” ROWS – 6 ROWS WITH 24” OVERLAP

36” ROWS – 7 ROWS WITH NO OVERLAP

34” ROWS – 7 ROWS WITH 14” OVERLAP

32” ROWS – 7 ROWS WITH 28” OVERLAP

30” ROWS – 8 ROWS WITH 12” OVERLAP

28” ROWS – 9 ROWS WITH NO OVERLAP

26” ROWS – 9 ROWS WITH 18” OVERLAP

24” ROWS – 10 ROWS WITH 12” OVERLAP

22” ROWS – 11 ROWS WITH 10” OVERLAP

20” ROWS – 12 ROWS WITH 12” OVERLAP

3530-101 30’ 8 SECTION HOE

42” ROWS – 8 ROWS WITH 28” OVERLAP

40” ROWS – 9 ROWS WITH 4” OVERLAP

38” ROWS – 9 ROWS WITH 22” OVERLAP

36” ROWS – 10 ROWS WITH NO OVERLAP

34” ROWS – 10 ROWS WITH 24” OVERLAP

32” ROWS – 11 ROWS WITH 12” OVERLAP

30” ROWS – 12 ROWS WITH 4” OVERLAP

28” ROWS – 13 ROWS WITH NO OVERLAP

26” ROWS – 14 ROWS WITH NO OVERLAP

24” ROWS – 15 ROWS WITH 4” OVERLAP

22” ROWS – 16 ROWS WITH 12” OVERLAP

20” ROWS – 18 ROWS WITH 4” OVERLAP

3541-101 41’ 9 SECTION HOE

42” ROWS – 11 ROWS WITH 28” OVERLAP

40” ROWS – 12 ROWS WITH 10” OVERLAP

38” ROWS – 12 ROWS WITH 34” OVERLAP

36” ROWS – 13 ROWS WITH 22” OVERLAP

34” ROWS – 14 ROWS WITH 14” OVERLAP

32” ROWS – 15 ROWS WITH 10” OVERLAP

30” ROWS – 16 ROWS WITH 10” OVERLAP

28” ROWS – 17 ROWS WITH 14” OVERLAP

26” ROWS – 18 ROWS WITH 22” OVERLAP

24” ROWS – 20 ROWS WITH 10” OVERLAP

22” ROWS – 22 ROWS WITH 6” OVERLAP

20” ROWS – 24 ROWS WITH 10” OVERLAP

3554-101 54’ 12 SECTION HOE 3560-101 60 13 SECTION HOE

42” ROWS – 15 ROWS WITH 20” OVERLAP 42” ROWS – 18 ROWS WITH 6” OVERLAP

40” ROWS – 16 ROWS WITH 10” OVERLAP 40” ROWS – 18 ROWS WITH 23” OVERLAP

38” ROWS – 17 ROWS WITH 4” OVERLAP 38” ROWS – 20 ROWS WITH 2” OVERLAP

36” ROWS – 18 ROWS WITH 2” OVERLAP 36” ROWS – 20 ROWS WITH 21” OVERLAP

34” ROWS – 19 ROWS WITH 4” OVERLAP 34” ROWS – 22 ROWS WITH 6” OVERLAP

32” ROWS – 20 ROWS WITH 10” OVERLAP 32” ROWS – 22 ROWS WITH 27” OVERLAP

30” ROWS – 21 ROWS WITH 20” OVERLAP 30” ROWS – 24 ROWS WITH 18” OVERLAP

28” ROWS – 23 ROWS WITH 6” OVERLAP 28” ROWS – 26 ROWS WITH 13” OVERLAP

26” ROWS – 25 ROWS WITH NO OVERLAP 26” ROWS – 28 ROWS WITH 12” OVERLAP

24” ROWS – 27 ROWS WITH 2” OVERLAP 24” ROWS – 30 ROWS WITH 15” OVERLAP

22” ROWS – 29 ROWS WITH 12” OVERLAP 22” ROWS – 34 ROWS WITH 0” OVERLAP

20” ROWS – 32 ROWS WITH 10” OVERLAP 20” ROWS – 36 ROWS WITH 13” OVERLAP

3528-101 28’ 8 SECTION HOE

42” ROWS – 8 ROWS WITH NO OVERLAP

40” ROWS – 8 ROWS WITH 16” OVERLAP

38” ROWS – 8 ROWS WITH 32” OVERLAP

36” ROWS – 9 ROWS WITH 12” OVERLAP

34” ROWS – 9 ROWS WITH 30” OVERLAP

32” ROWS – 10 ROWS WITH 16” OVERLAP

30” ROWS – 11 ROWS WITH 6” OVERLAP

28” ROWS – 12 ROWS WITH NO OVERLAP

26” ROWS – 12 ROWS WITH 24” OVERLAP

24” ROWS – 14 ROWS WITH NO OVERLAP

22” ROWS – 15 ROWS WITH 6” OVERLAP

20” ROWS – 16 ROWS WITH 16” OVERLAP

3534-101 34’ 8 SECTION HOE

42” ROWS – 9 ROWS WITH 28” OVERLAP

40” ROWS – 10 ROWS WITH 6” OVERLAP

38” ROWS – 10 ROWS WITH 26” OVERLAP

36” ROWS – 11 ROWS WITH 10” OVERLAP

34” ROWS – 11 ROWS WITH 32” OVERLAP

32” ROWS – 12 ROWS WITH 22” OVERLAP

30” ROWS – 13 ROWS WITH 16” OVERLAP

28” ROWS – 14 ROWS WITH 14” OVERLAP

26” ROWS – 15 ROWS WITH 14” OVERLAP

24” ROWS – 16 ROWS WITH 22” OVERLAP

22” ROWS – 18 ROWS WITH 10” OVERLAP

20” ROWS – 20 ROWS WITH 6” OVERLAP

3546-101 46’ 9 SECTION HOE

42” ROWS – 12 ROWS WITH 4” OVERLAP

40” ROWS – 13 ROWS WITH 30” OVERLAP

38” ROWS – 14 ROWS WITH 16” OVERLAP

36” ROWS – 15 ROWS WITH 10” OVERLAP

34” ROWS – 17 ROWS WITH NO OVERLAP

32” ROWS – 17 ROWS WITH 6” OVERLAP

30” ROWS – 18 ROWS WITH 10” OVERLAP

28” ROWS – 19 ROWS WITH 18” OVERLAP

26” ROWS – 21 ROWS WITH 4” OVERLAP

24” ROWS – 22 ROWS WITH 22” OVERLAP

22” ROWS – 25 ROWS WITH NO OVERLAP

20” ROWS – 27 ROWS WITH 10” OVERLAP

5

Page 6

ASSEMBLY AND PARTS IDENTIFICATION

6

Page 7

ASSEMBLY AND PARTS IDENTIFICATION

7

Page 8

ASSEMBLY AND PARTS IDENTIFICATION

8

Page 9

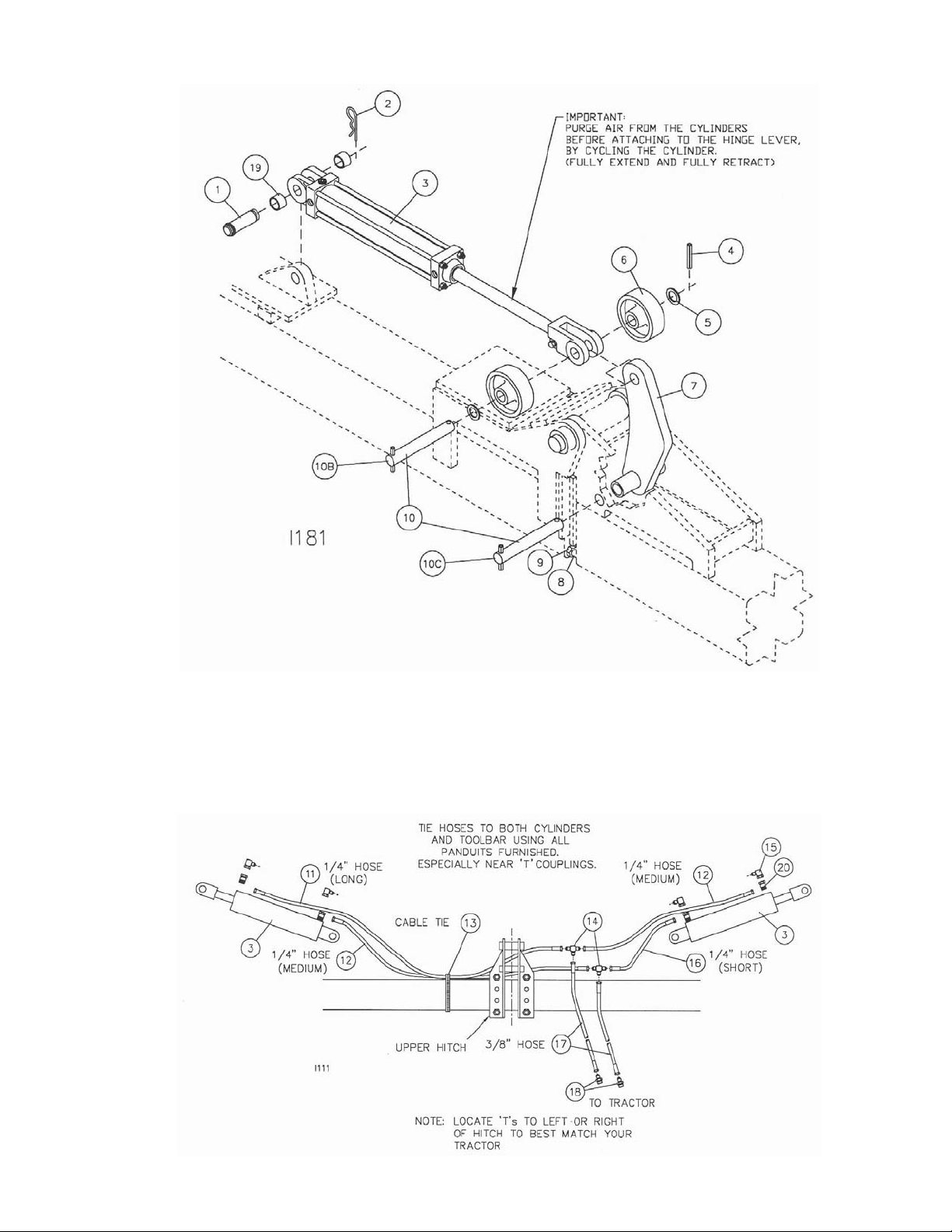

3500 SERIES

HYDRAULIC ASSEMBLY

ASSEMBLE HINGE LEVERS AS FOLLOWS

1. Drive a 3/8” x 2-1/2” roll pin into one end of each of 4 hinge pins.

2. On one wing of hoe assemble 1” washer on hinge pin, push pin thru near hole in hinge,

insert hinge lever, push pin thru other hole in hinge, assemble another 1” washer and roll

pin.

3. On other end of hinge lever assemble a 1” washer on hinge pin, put thru a wheel, push

rod clevis of a hydraulic cylinder, hinge lever, other side of clevis, wheel, washer, and

secure with another 3/8” roll pin.

4. On the butt end of cylinder remove 1 hairpin clip and the clevis pin, extend the cylinder

and fasten to the cylinder bracket with the clevis pin and the hairpin clip. Check spacing

between hinge lever and hinge bushing; (opposite zerk) and set to 1/8” to 3/16” spacing

by removing clevis pin and turning cylinder into or out of the rod end clevis. Tighten

clevis-clamping bolt.

5. Repeat 2, 3, and 4 for the remaining wing.

6. Lubricate the o-ring on each of the restricted 90-degree fittings and install into the cylinder

ports. DO NOT OVER TIGHTEN AND DISTORT THE METAL BACK-UP WASHER.

Position the fitting by turning it out (counter clockwise) to a maximum of one complete

turn and tighten the jam-nut.

7. There are four hose sizes as follows:

1. ¼” hose (short) 1 pc.

2. ¼” hose (medium) 2 pcs.

3. ¼” hose (long) 1 pc.

4. 3/8” hose, 2 pcs.

8. Connect a short and medium hose on opposite arms of a “T” fitting.

9. Connect a medium and long hose on opposite arms of a second “T”.

10. Position the short hose assembly on the toolbar with “T” on the operators left of the hitch

assembly, position the long hose assembly in the same manner, connect short hose ends

to the inner ports, the longer assembly to outer ports.

11. Connect the 4ft. 3/8” hoses to the remaining “T” ports and tighten ALL connections.

Adapters are provided for the hoses to connect to standard ¾-16 straight thread quick

coupler tips such as Case-IH part no. 1285718* or Deere part no. AR945222.

12. Using the cable ties furnished, tie the outer port hoses to the lower ends of each cylinder

and the hose to the toolbar on each side of the “T”s and at 2 to 3 foot intervals between.

13. IMPORTANT: Be sure to cycle the hydraulic cylinders before attaching them to the

folding wings. This removes air from the hoses and insures smooth wing operation.

CAUTION

STAND CLEAR OF FOLDING WINGS!

9

Page 10

HYDRAULIC ASSEMBLY

KEY QTY. PART NO. DESCRIPTION

1 2 2515-172 CLEVIS PIN FOR (3X16 & 4X16) CYLINDERS

3554-303 CLEVIS PIN FOR 5 X 16 CYLINDERS

2 4 2570-465 7 GA. X 3-3/4 HAIRPIN COTTER ZYD.

3 2 3500-387 3” X 16” ASAE CYLINDER, 1-1/4” ROD DIA., PAINTED

(3500 SERIES EXCEPT 3541 & 3546)

3500-388 4” X 16” ASAE CYLINDER (3541 & 3546)

2515-826 5” X 16” SAE-35016 CYLINDER, (54’ & 60’)

4 8 2530-208 3/8” X 2-1/2” ROLL PIN ZYD.

5 12 2527-564 1” ID X 1-1/2” OD X 14 GA. MACH BUSHING ZYD.

4 2527-561 1-1/4 ID X 2-1/4 OD X 14 GA. MACH BUSHING ZYD. (54’& 60’)

6 4 3500-390 HINGE WHEEL (1” ID X 4-3/8 OD)

4 3554-204 54’ HINGE WHEEL W.A. (54’ & 60’)(1.25 ID X 4.5 OD)

7 2 3500-226 HEAVY HINGE LEVER W.A. (1” PIVOT HOLES)

2 3560-200 60’ HINGE LEVER W.A. (1.5” AND 1.25” PIVOT HOLES)

2 3554-205 54 FT. HINGE LEVER W.A. (1” ID BUSHING, 1.25 CYL CLV)

8 4 2520-543 7/8-9 JAM HEX NUT ZYD.

9 4 2502-604 7/8-9 X 3-1/2” THREAD. TO HEAD TAP BOLT GR. 2 ZYD.

10 4 3500-308 HINGE PIN (1” D. X 8-3/4 LONG)

2 3560-301 60’ HINGE PIN UPPER (1.25 D. X 9.75 LONG)

10B 2 3554-310 HINGE LEVER PIN UPPER, (54’ & 60’)(1.25” D. X 8.75” LONG)

10C 2 3560-300 HINGE LEVER PIN LOWER, (54’ & 60’)(1.5” D. X 8.75” LONG)

11 1 2515-358 HOSE, ¼” X 50” W/-6 JIC ENDS (3521)

1 2515-362 HOSE, ¼” X 75” W/-6 JIC ENDS (3528 & 3530)

1 2515-364 HOSE, ¼” X 90” W/-6 JIC ENDS (3530 & 3534)

1 2515-366 HOSE, ¼” X 110” W/-6 JIC ENDS (3541)

1 2515-367 HOSE, ¼” X 135” W/-6 JIC ENDS (3546)

1 2515-397 HOSE, ¼” X 160” W/-6 JIC ENDS (3554)

1 2515-372 HOSE, ¼ X 200” (3560)

12 2 2515-356 HOSE, ¼” X 35” W/-6 JIC ENDS (3521)

2 2515-358 HOSE, ¼” X 50” W/-6 JIC ENDS (3528)

2 2515-360 HOSE, ¼” X 65” W/-6 JIC ENDS (3530)

2 2515-362 HOSE, ¼” X 75” W/-6 JIC ENDS (3534)

2 2515-365 HOSE, ¼” X 100” W/-6 JIC ENDS (3541)

2 2515-367 HOSE, ¼” X 135” W/-6 JIC ENDS (3546)

2 2515-387 HOSE, ¼” X 150” W/-6 JIC ENDS (3554)

2 2515-371 HOSE, ¼ X 180” (3560)

13 4 2515-405 CABLE TIES (3521)

6 CABLE TIES (3528, 3530)

8 CABLE TIES (3534)

10 CABLE TIES (3541, 3546)

12 CABLE TIES (3554, 3560)

14 2 2515-326 TEE FITTING, –6/-6/-6 JIC

15 4 2515-330 90 DEG FITTING, ¾” SAE TO –6 JIC, RESTRICTED

16 1 2515-353 HOSE, ¼” X 35” W/-6 JIC ENDS (3521)

1 2515-356 HOSE, ¼” X 50” W/-6 JIC ENDS (3528)

1 2515-358 HOSE, ¼” X 65” W/-6 JIC ENDS (3530)

1 2515-360 HOSE, ¼” X 75” W/-6 JIC ENDS (3534)

1 2515-365 HOSE, ¼” X 100” W/-6 JIC ENDS (3541)

1 2515-365 HOSE, ¼” X 100” W/-6 JIC ENDS (3546)

1 2515-366 HOSE, ¼” X 110” W/-6 JIC ENDS (3554)

1 2515-367 HOSE, ¼ X 135” (3560)

17 2 2515-386 HOSE, 3/8” X 50” W/-6 JIC ENDS

18 2 2515-327 ADAPTER, ¾ SAE TO –6 JIC

19 4 1000-361 13/16” UPPER SLEEVE, ZP. (54 FT. ONLY)

20 4 2515-827 REDUCER, (3554 & 3560)

3 X 16 SEAL KIT ROCKFORD/HYDRO-LINE 2515-338

COMMAND 2515-128(BLACK & YELLOW PISTON SEAL)

MONARCH 2515-338

PRINCE 1-1/8” ROD 2515-103

PRINCE 1-1/4” ROD 2515-265

4 X 16 SEAL KIT ROCKFORD/HYDRO-LINE 2515-468

COMMAND 2515-144

MONARCH 2515-170

5 X 16 SEAL KIT PRINCE 2515-171

10

Page 11

HYDRAULIC ASSEMBLY

FIGURE 1

11

Page 12

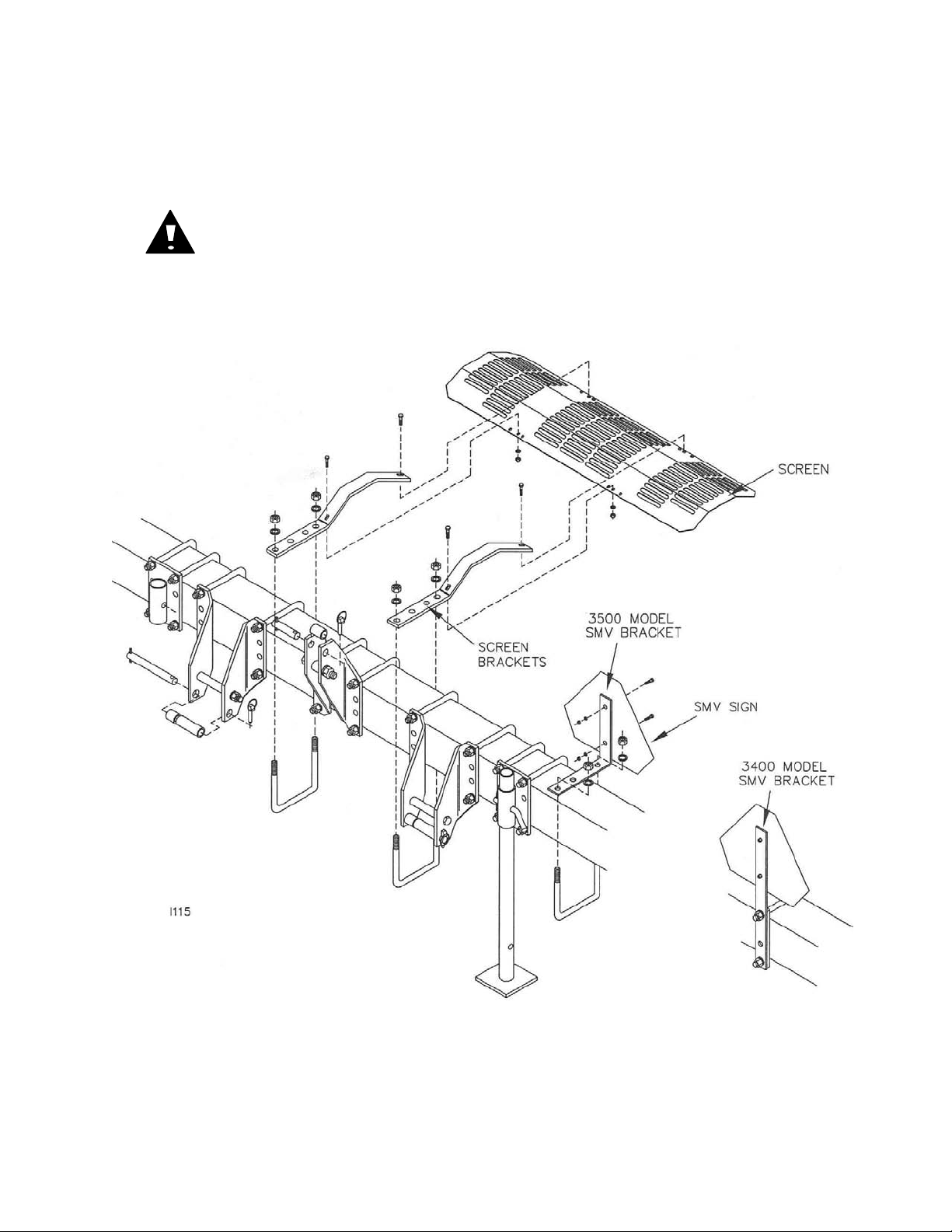

ASSEMBLY

SCREEN ASSEMBLY

1. Assemble the screen brackets to the screen with four 3/8 x 1” bolts, lock washers,

and nuts.

2. Mount the screen assembly to the main frame as shown with two u-bolts, lock

washers, and nuts. Additional screens can be ordered if desired.

CAUTION: DO NOT OPERATE ROTARY HOE UNLESS SCREEN IS

SECURED AND PROPERLY INSTALLED.

SMV ASSEMBLY

1. Mount SMV emblem as shown with point of triangle up as near operators left of

center as possible. Face so emblem is visible from rear of equipment.

12

Page 13

ASSEMBLY

GAUGE WHEELS

Frame gauge wheels maintain the rotary hoe frame at a constant level in respect to the

ground contour, which helps insure uniform penetration of the hoe wheels. Recommended

tire size 7.50 x 14 or equivalent.

Mount the frame gauge wheels as shown, location each wheel an equal distance from the

center of the main frame. Gauge wheels should run outside the tractor wheel tracks.

To tighten wheel bearing, remove the hubcap and cotter pin. Tighten the slotted nut until

there is a slight drag on the bearing, while turning the wheel. Then loosen or back off the

slotted nut one slot and insert the cotter pin. There should be a slight drag on the bearing

following adjustment. Reinstall the hubcap.

CAUTION: ON 3500 MODELS, BEFORE ACTIVATING FOLDING HINGE

CHECK FOR OBSTRUCTIONS, ESPECIALLY CHECK GAUGE WHEEL

POSITIONS TO BE SURE THAT GAUGE WHEELS ARE SET TO CLEAR

TRACTOR AND OPERATOR.

CAUTION: CLEAR ALL PERSONNEL FROM AREA BEFORE FOLDING

OR UN-FOLDING TOOLBAR.

13

Page 14

OPERATION

ROTARY HOE PREPARATION

BOLTS AND NUTS:

Before starting to work, check all nuts and bolts for tightness.

HOE WHEELS:

Check all hoe wheels for straightness. Replace if necessary.

NOTE: ¼” of “RUNOUT” is acceptable.

LUBRICATION:

The basic Rotary Hoe requires no lubrication. If your hoe is equipped with gauge

wheels, repack the wheel bearings once a year with multi purpose lithium base

grease. On transport, axle straps need to be greased. Hinges on folding hoes

should be greased regularly.

TRACTOR PREPARATION

WHEEL SPACING:

Set the tractor wheels for the desired row spacing so the wheels are centered

between the rows. The distance from center of tractor to the center of the tire should

be the same on each side. Refer to your tractor operator’s manual for correct

inflation and ballast information of the tractor.

SWAY BLOCKS:

Place the sway blocks in the wide setting during transport to prevent any swaying of

the hoe.

DRAWBAR POSITION:

Place the drawbar in the short, center position to provide maximum clearance

between rear of drawbar and rotary hoe.

LIFT LINKS:

Adjust the length of lift links to maximum length. Refer to Tractor Operator’s Manual.

Keep an adequate distance between the tractor tires and rotary hoe toolbar.

If your hoe is equipped with gauge wheels, adjust the lift link pins to allow lateral float.

If gauge wheels are not used, adjust prevent any lateral float movement.

14

Page 15

ATTACHING ROTARY HOE TO TRACTOR

HITCH ASSEMBLY

The rotary hoe is shipped with mast and hitch pin bushings assembled for CAT III or IV hitches.

Remove bushings as required of your tractor.

Place sleeves and spacers in position to fit your hitch. The lower hitch plates are adjustable to fit your

tractor’s spacing.

CAUTION: BEFORE ATTACHING ROTARY HOE TO TRACTOR, BE

SURE HITCH PINS ARE COMPLETELY ASSEMBLED TO MATCH YOUR

TRACTOR HITCH.

TRACTOR WITHOUT QUICK COUPLER:

Attach rotary hoe to tractor with draft links to lower hitches.

Adjust the center link or extend the draft links to make hookup easier. Raise parking stand and place

in upper position.

TRACTOR WITH QUICK COUPLER:

Lower the 3-point hitch so the upper jaw of the Quick Coupler passes under the

spacer between the hoe mast plates. This allows lower jaws to pass under the hoe

hitch pins. Back tractor up until coupler jaws are under their respective pins and raise

hitch.

CAUTION: MAKE CERTAIN THAT CENTER LINK AND QUICK COUPLER

ARE LOCKED AND LOCK PINS ARE PROPERLY INSTALLED BEFORE

MOVING ROTARY HOE.

15

Page 16

FIELD OPERATION

PRE-OPERATION CHECK LIST:

Use this checklist each time you operate the hoe in the field. It will help you obtain

satisfactory field operation quickly.

1. Tractor sway blocks in upper position.

2. Center link adjusted for level frame in field operation.

3. Tractor lift links set in lateral float.

4. Tractor rockshaft control lever set in “zero”

5. Check hoe for loose or missing parts. Tighten hardware where necessary.

6. Bent hoe teeth straightened or replaced.

7. Hitch pins fastened and correct spacers used.

8. Quick couplers locked.

9. Adequate ballast added to front of tractor.

IMPORTANT: NEVER BACK UP WITH ROTARY HOE IN THE GROUND.

NEVER TURN WITH THE HOE IN ITS DOWN POSITION.

OPERATING SPEED:

An operating speed of 5 to 8 mph will normally provide the best results. Higher speeds

tend to increase the teeth penetration.

MAIN FRAME HEIGHT:

The mainframe height during field operation will normally be about 22 inches to bottom of

frame.

Without gauge wheels, set the tractor rockshaft control lever to obtain the desired frame

height.

With frame gauge wheels, put the rockshaft control lever all the way forward to lock “it” in

the float position, which will enable the frame gauge wheels to maintain the frame at a

uniform height from the ground.

LEVELING MAIN FRAME

Adjust lift links and center link as necessary to make hoe level and perpendicular to the

ground.

Before activating/folding hinge check for obstructions, especially check gauge wheel

positions to ascertain proper tractor and cab clearance.

NOTE: If gauge wheels are to be used, make leveling adjustments after gauge wheels

are installed.

16

Page 17

FIELD OPERATION

PARKING THE ROTARY HOES

3400 HOES

Lower the parking stand. Lower rotary hoe and loosen center link if necessary. Release

the latch levers and quick coupler, or raise center link latch handle and remove hitch pins,

then move tractor.

3500 HOES

Fold wings to the down position unless rear parking stand is used. Lower the parking

stands. Lower the rotary hoe and loosen center link if necessary. Release the latch

levers and quick coupler, or raise center link latch handle and remove hitch pins, then

drive tractor away.

CAUTION: NEVER UNHOOK FROM A FOLDED ROTARY HOE UNLESS REAR

PARKING STANDS ARE USED.

TRANSPORTING THE HOES

3400 HOES

To change from field to transport position, raise the hoe. Make certain the SMV symbol is

in place before transporting. DO NOT exceed 15 mph during transport.

3500 HOES

To change from field to transport position, raise the hoe, and then fold. Make certain

there is adequate clearance for the wings to fold without hitting obstructions. Check

gauge wheel positions for adequate tractor and cab clearance. Make certain the SMV

symbol is in place. DO NOT exceed 15 mph during transport.

CAUTION: STAND CLEAR OF FOLDING WING!

CAUTION: ALWAYS FOLLOW ALL STATE, FEDERAL, AND LOCAL LAWS

WHEN TRANSPORTING ROTARY HOE ON PUBLIC ROADS.

17

Page 18

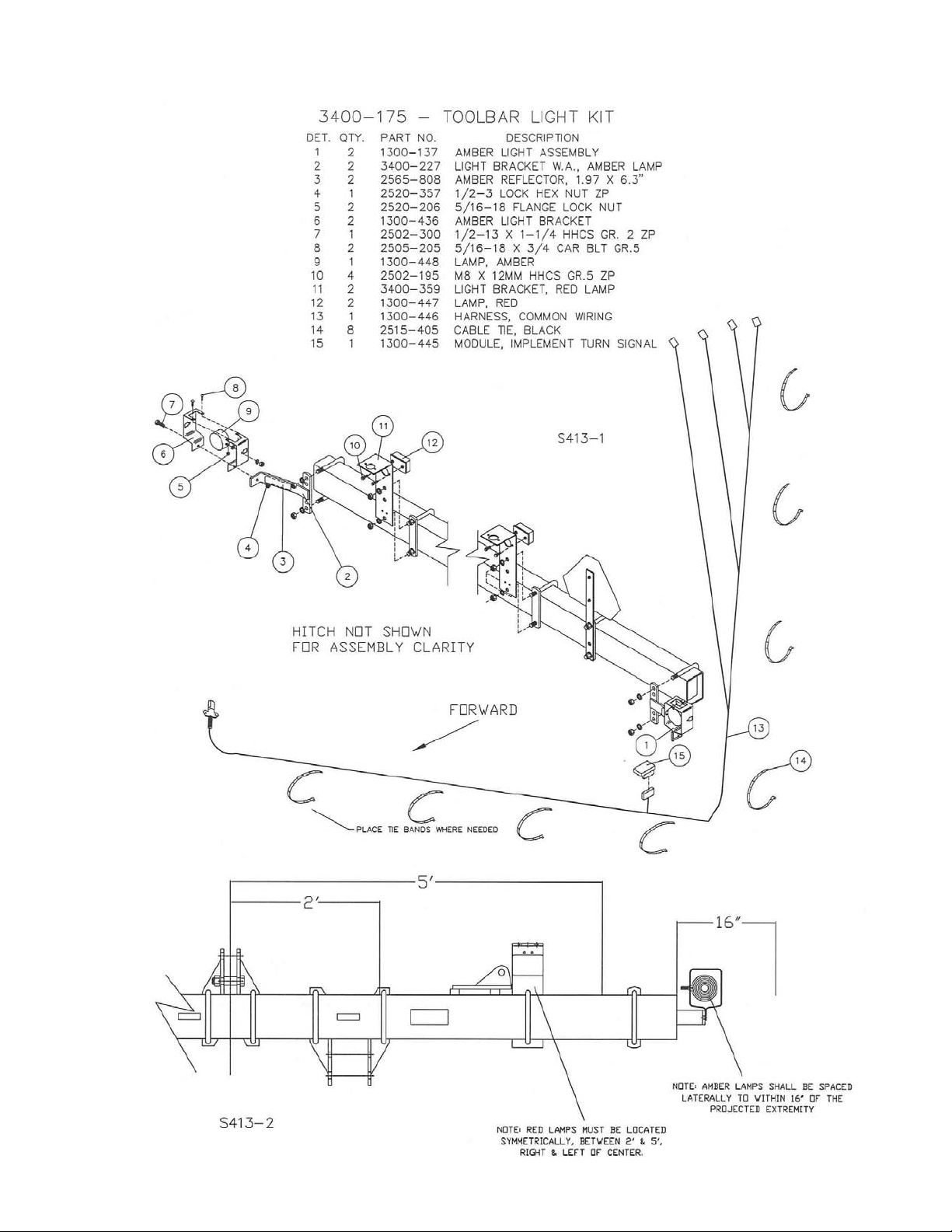

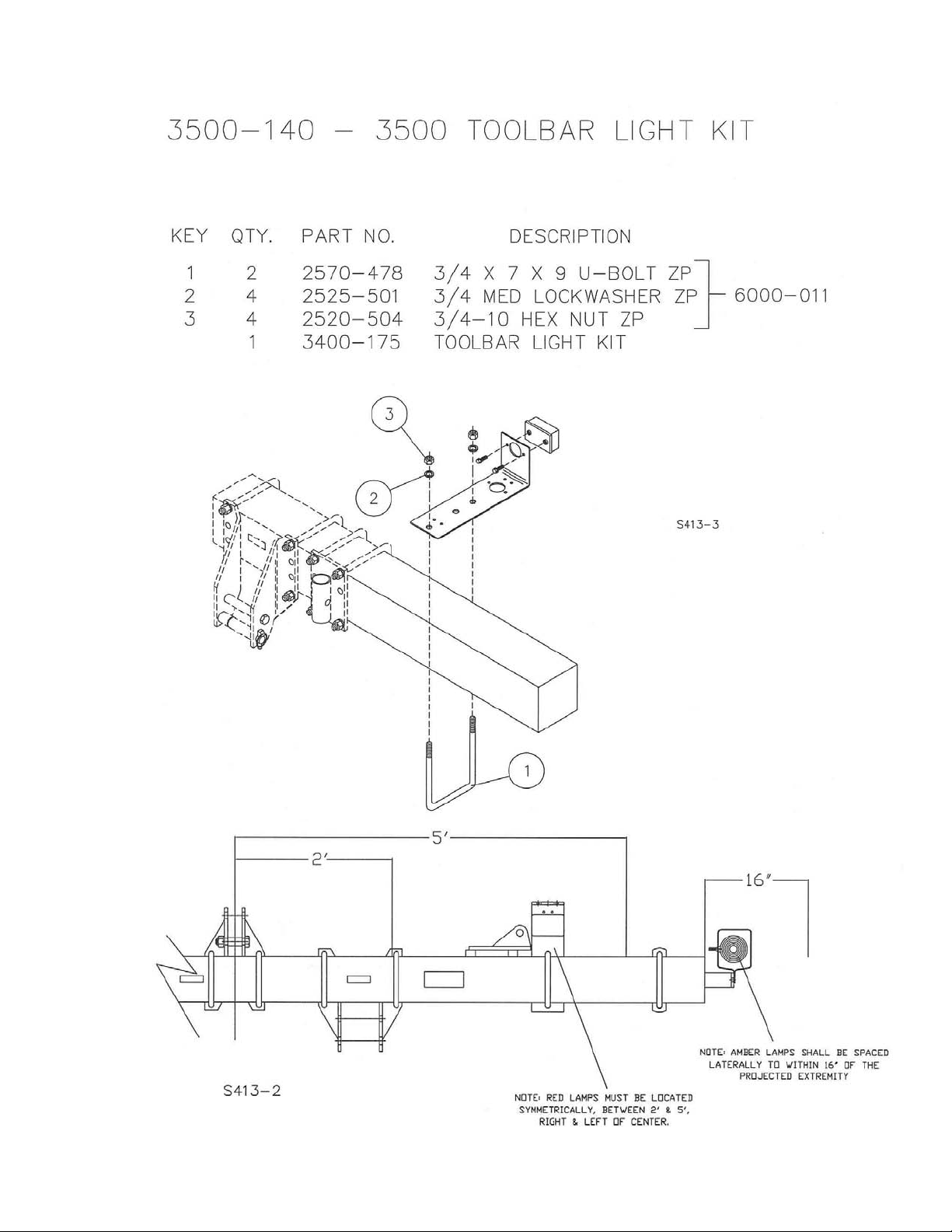

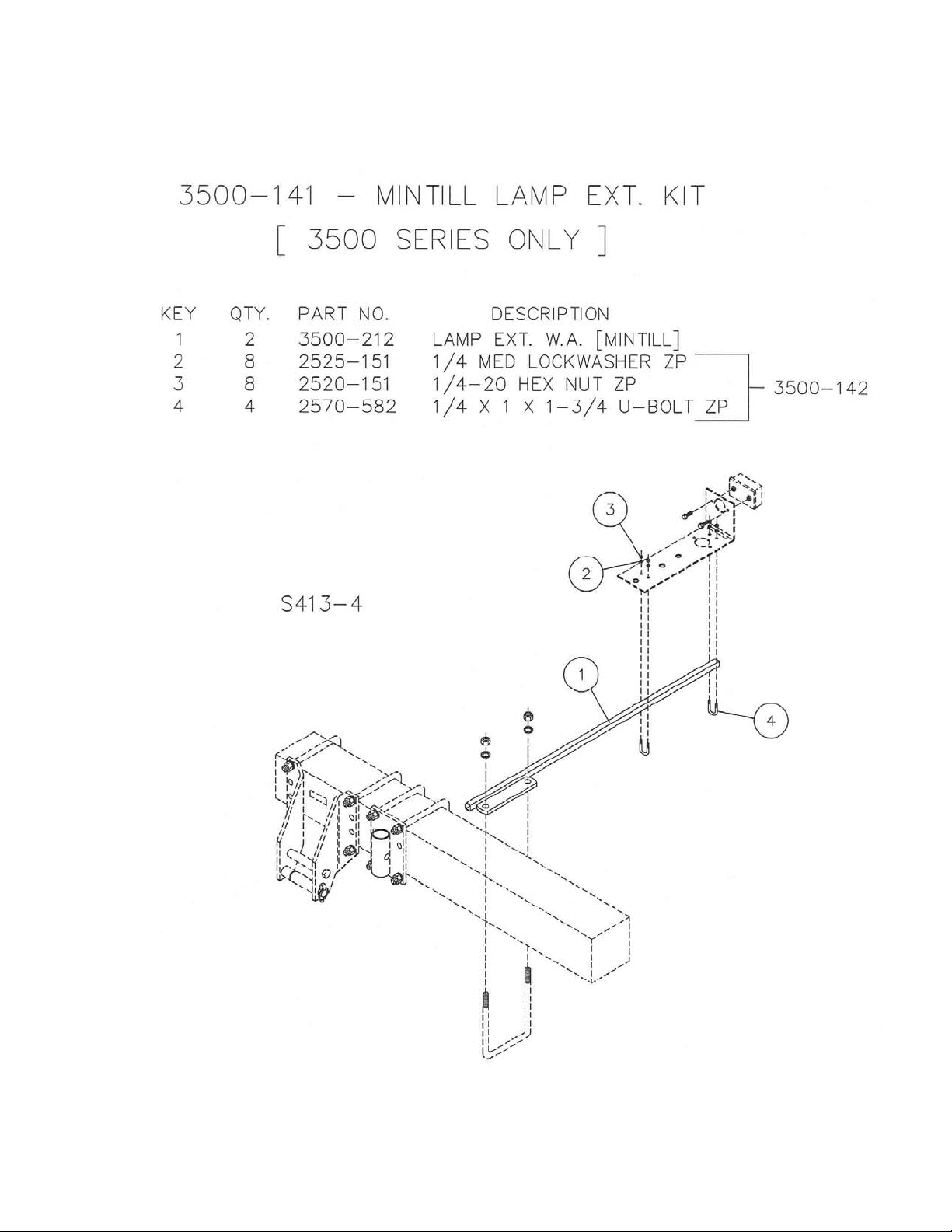

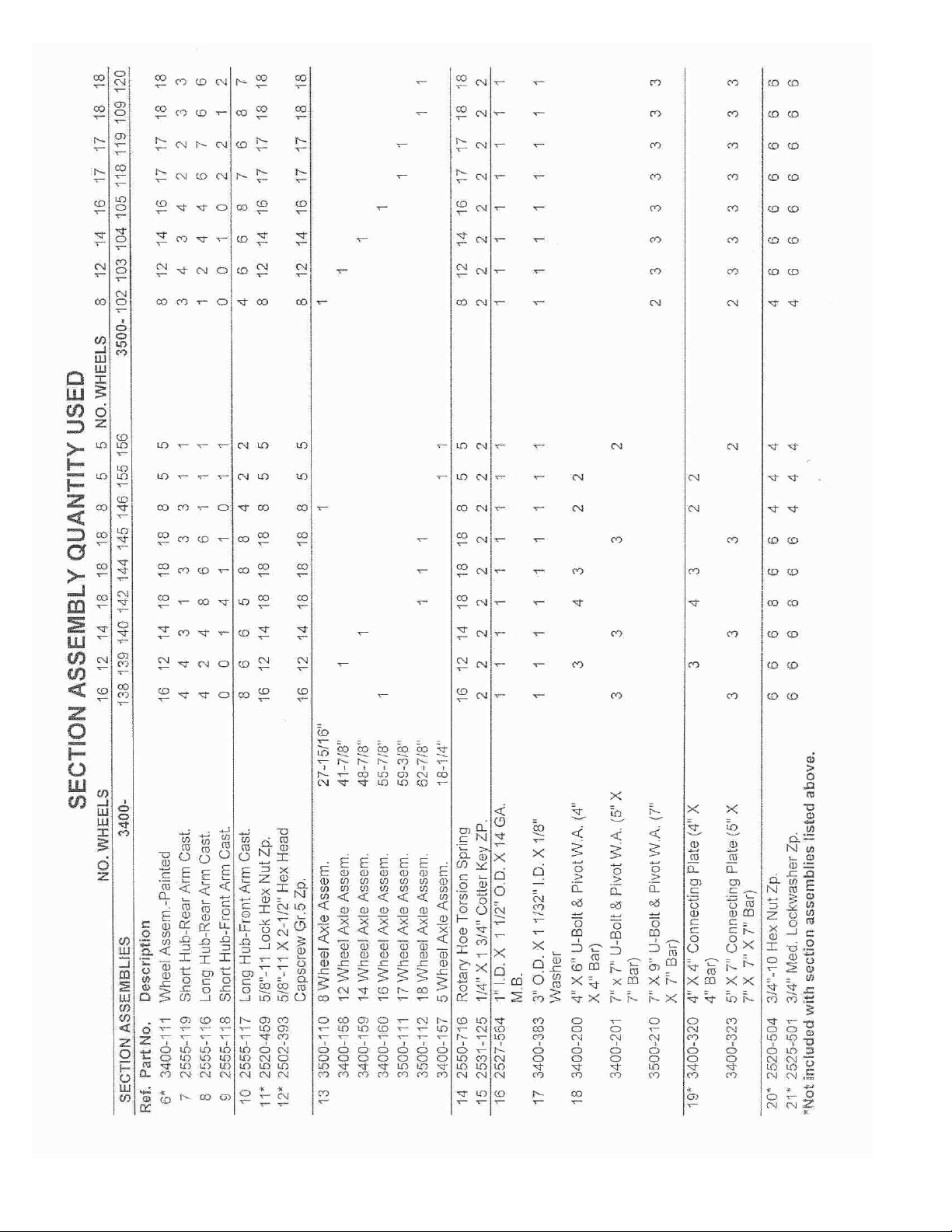

PARTS IDENTIFICATION

18

Page 19

PARTS IDENTIFICATION

19

Page 20

PARTS IDENTIFICATION

20

Page 21

PARTS IDENTIFICATION

21

Page 22

PARTS IDENTIFICATION

22

Page 23

PARTS IDENTIFICATION

23

Page 24

PARTS IDENTIFICATION

24

Page 25

PARTS IDENTIFICATION

25

Page 26

26

Page 27

27

Page 28

I112-001-3

28

Page 29

MIN-TILL CONVERSION

This conversion kit increases the separation of the two rows of rotary hoe wheels improved

residue flow through.

1. Attach “stop” casting to each rear wheel arm with small u-bolt.

2. Remove hoe wheel from existing rear arm.

3. Attach arm extension casting to rear arms with existing wheel bolt and nut.

4. Attach hoe wheel to end to extension casting with bolt and lock nut supplied.

CAUTION: On the 3500 Series Folding Hoes that are being equipped with

the Mill-Till Conversion Kit (3400-170), the helper spring kit (3400-172)

must be added to the seven min-till arms above the OSHA screen in the

folding position. Failure to add helper spring will cause damage to the

OSHA screen.

29

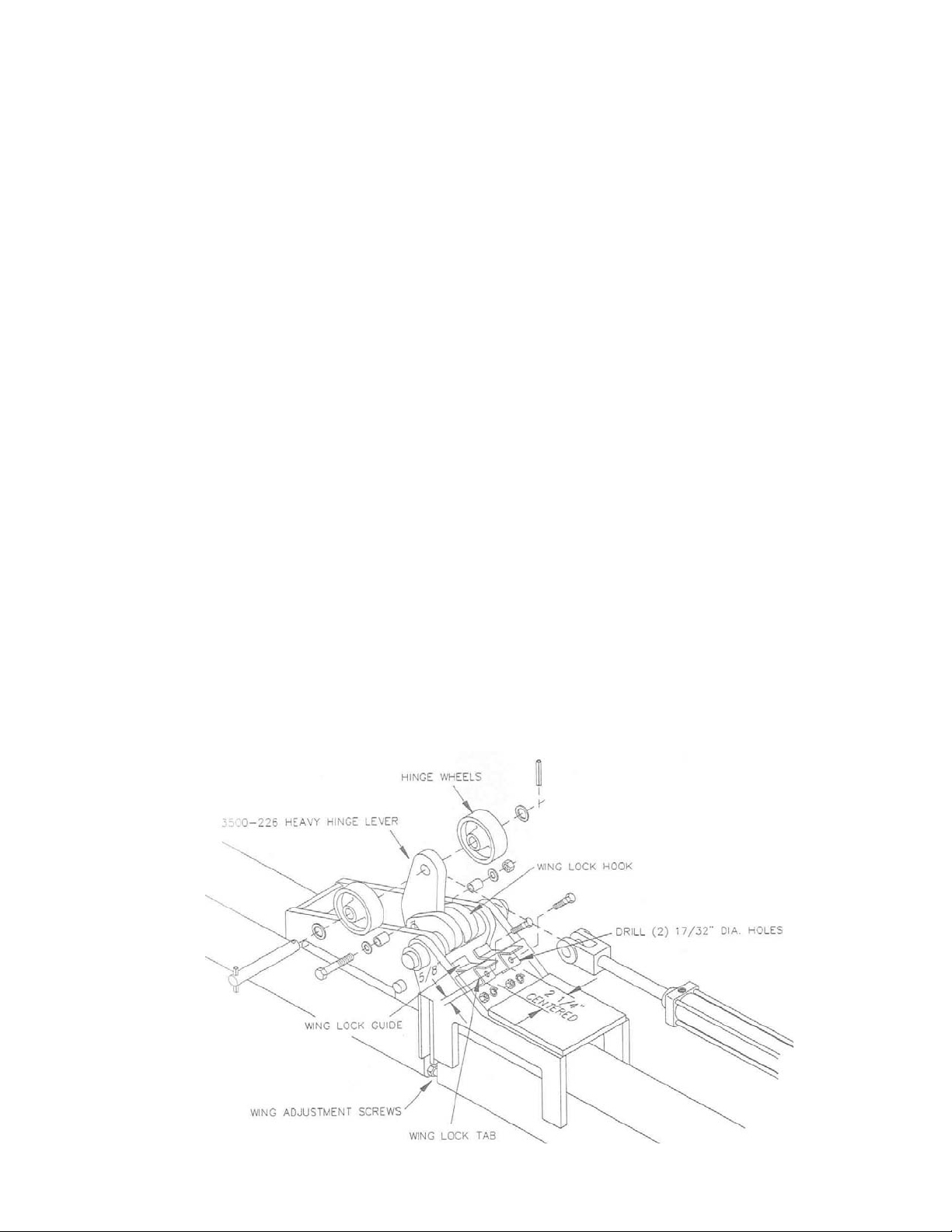

Page 30

INSTALLATION INSTRUCTIONS

3500-107 Wing Lock Kit is designed to

fit Yetter 21’, 28’, 30’, 34’, 41’, 46’ and

54’ Rotary Hoe Flat Folding Toolbars.

To prevent wings from floating up in

certain operating conditions the Yetter

Wing Lock Kit will hold the wings in

horizontal position when desired. To

allow the wings to float, simply retract

the wing lift cylinders slightly. This

allows complete operator control from

the tractor seat to let the wings float up

or to lock them down.

INSTALLATION:

1. Remove hinge levers and replace

with 4100-205 hinge lever on 41’

hoes unless hinge levers have a

21/32” dia. hole added to mount

wing lock hooks.

2. Drill (2) 17/32” dia. holes (as shown)

in hinge wheel ramp on each side of

toolbar. (Holes are in strap after

3/1/82 mfg.)

3. Mount wing lock guides and wing

lock tabs (as shown) with ½-13 x 11/2” hex head cap screws, lock

washers, and nuts.

WING LOCK KIT

4. Mount wing lock hooks on hinge

levers (as shown) using 3500-386

bushing, 5/8-11 x 4” hex head cap

screw, flat washers, and lock nut.

Be sure hooks pivot freely after bolt

is tightened.

5. Level the wings with the lower

existing screw adjustment to hold

the wings straight with the center

section.

6. Cycle cylinders, disconnected from

hinge lever, to remove air from

hydraulic system before folding

wings.

7. Assemble cylinder and hinge wheels

as shown.

8. Extend the wing lift cylinders until

they bottom out. NOTE: This will

cause the wing lock hooks to yield

slightly as they are stretched into

position.

9. Fold wings a few times slowly while

watching the wing lock hooks to be

sure they are operating properly.

30

Page 31

PARTS IDENTIFICATION

3500-107 – WING LOCK KIT

KEY QTY. PART NO. DESCRIPTION

1 4 3500-374 WING LOCK HOOK, 1”

2 4 3500-377 WING LOCK GUIDE

3 4 3500-378 WING LOCK TAB

4 4 3500-386 BUSHING, 7/8 O.D. X .635 I.D. X 1-1/16

5 2 2502-336 5/8-11 X 4” HHCS GR 5 ZYD.

6 4 2502-301 ½-13 X 1-1/2 HHCS GR 2 ZYD.

7 4 2526-451 5/8 STD FLATWASHER ZYD.

8 2 2520-459 5/8-11 HEX LOCK NUT ZYD.

9 4 2520-352 ½-13 HEX NUT ZYD.

10 4 2525-352 ½ MED LOCKWASHER ZYD.

3500-135 – REAR PARKING STAND ASSEMBLY

KEY QTY. PART NO. DESCRIPTION

1 2 2570-478 ¾ X 7 X 9 U-BOLT ZYD.

2 2 3500-229 REAR PARKING STAND BRKT.

3 4 2525-501 ¾ MED LOCKWASHER ZYD.

4 4 2520-504 ¾-10 HEX NUT ZYD.

5 2 2502-336 5/8-11 X 4” HHCS GR 5 ZYD.

6 2 3500-230 REAR PARKING STAND W.A.

7 2 3500-384 PIVOT BUSHING, PARK STAND

8 2 2525-451 5/8 MED LOCKWASHER ZYD.

9 2 2520-452 5/8-11 HEX NUT ZYD.

10 2 3500-333 STAND PIN

11 2 2570-465 7 GA. HAIRPIN COTTER ZYD.

31

Page 32

PARTS IDENTIFICACTION

32

Page 33

PARTS IDENTIFICATION

3560-112

33

Page 34

PARTS IDENTIFICATION

INSTALLATION INSTRUCTIONS

1. Install trash guard to arm casting with trash

guard tip towards rear of hoe using ¼ u-bolts,

nuts and lock washers as shown. NOTE: Do

Not tighten bolts at this time.

2. Set depth of hoe and adjust trash guards.

Recommended setting: Tip of trash guard

should be 1” to 1-1/2” from ground, depending

on field conditions when hoe wheel is

penetrating.

3. Tighten all u-bolts after adjusted.

4. The trash guard does not work on the Min-till

Arm Extension Kit.

3400-147 – TRASH GUARD ASSEMBLY

KEY QTY. PART NO. DESCRIPTION

1 1 3400-225 TRASH GUARD W.A.

2 2 2570-481 TRASH GUARD U-BOLT

3 4 2525-151 ¼ MED LOCKWASHER ZYD.

4 4 2520-151 ¼-20 HEX NUT ZYD.

INSTALLATION INSTRUCTIONS

1. Install the torsion spring (#5) and anchor spring

(#6) over existing spring and axle. Hook to spring

bracket (#7).

2. Assemble the spring clamp casting (#3) and clamp

plate (#2) to spring using 5/16 x 1” bolt and nut

inserted in clamp casting. Preset lower hook 2” to

3” in front of arm that it is being installed on.

Tighten clamp then pull hook up on arm and spring

tension is preset.

3400-172 – HELPER SPRING SHIP ASSEMBLY

KEY QTY. PART NO. DESCRIPTION

1 1 2502-198 5/16-18 X 1 HHCS GR 5 ZYD.

2 1 3400-391 CLAMP PLATE

3 1 3400-392 CLAMP

4 1 2520-205 5/16-18 LOCK HEX NUT ZYD.

5 1 3400-393 TORSION SPRING

6 1 3400-394 ANCHOR SPRING

7 1 3400-375 SPRING BRACKET

34

Page 35

Problem

Premature bearing failure

Rotary hoe arm bending or breaking

3500 Series Wings float up

Hydraulic cylinders fail to operate

properly (3500 model only)

Rotary hoe wheels plug with trash

materials

Hoe wheels won't penetrate

Rotary hoe wheels are too aggressive

TROUBLE SHOOTING

Cause

Excessive strain on the hoe wheel

bearings

Excessive strain on the arms and

wheels

Air in system

Gauge wheels not properly adjusted

Wing deflection not properly adjusted

Hinge levers not properly installed

Hydraulic system improperly installed

Air in system

Blocked restrictors

Excessive trash conditions

Hard soil conditions

Rotary hoe wheels running too fast

Rotary hoe wheels running too deep

Solution

Don't turn with rotary hoe wheels on

the ground

Store the rotary hoe inside to help

protect the bearings from freezing

weather, moisture, blowing sand, and

dirt

Keep all wheel bolts tight. Check

rotary hoe wheels for loose rivets and

bent teeth. Check for bent arm

castings

Don't turn with the rotary hoe wheels

on the ground

Don't back the rotary hoe with wheels

on the ground

Check for air in hydraulic system and

purge system

Check proper adjustment of wing

gauge wheels

Maintain center tool bar height above

or parallel with outer wings

Check assembly of hinge levers

Install 3500-107 Wing Lock Kit

Check for correct assembly of the

hydraulic system

Check for air in the hydraulic system

and purge system

Check restrictors for malfunctions

Decrease operating depth of hoe

wheels and increase ground speed to

create momentum so the hoe wheels

may clean themselves

On softer, mellow soils, decrease

operating depth so that hoe wheels

do not pickup trash material

Install optional Min-Till Conversion

Kit, (3412-3434-125)(3541or3546-

125)

Install optional trash guard (part no.

3400-147)

Lower tool bar to maximize

aggressiveness of rotary hoe

Lengthen center link on tractor to tilt

tool bar back to increase spring

tension

Install optional helper spring (part no.

3400-150)

Slow tractor ground speed

Decrease operating depth of rotary

hoe wheels

Install toolbar gauge wheels except

on model 3412 and 3415

35

Page 36

Our name

Is getting known

Just a few years ago, Yetter products were sold primarily to the

Midwest only. Then we embarked on a program of expansion and

moved into the East, the South, the West and now north into Canada.

We’re even getting orders from as far away as Australia and Africa.

So, when you buy Yetter products . . .you’re buying a name that’s

recognized. A name that’s known and respected. A name that’s

become a part of American agriculture and has become synonymous

with quality and satisfaction in the field of conservation tillage.

Thank you.

YETTER MANUFACTURING CO.

Colchester, IL 62326-0358 • 309/776-4111

Toll Free 800/447-5777

Fax 309/776-3222

Website: WWW.YETTERCO.COM

E-MAIL: INFO@YETTERCO.COM

2565-118_REV_E • 02/12

36

Loading...

Loading...