Page 1

GENERATION III COULTER

MODEL 2995

SET-UP & PARTS MANUAL

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website: www.yetterco.com

E-mail: info@yetterco.com

2565-490_REV_D ● 07/13

Page 2

FOREWORD

You’ve just joined an exclusive but rapidly

growing club.

For our part, we want to welcome you to the

group and thank you for buying a Yetter product.

We hope your new Yetter products will help you

achieve both goals-increase your productivity and

increase your efficiency so that you may generate

more profit.

This operator’s manual has been designed into

four major sections: Foreword, Safety

Precautions, Installation Instructions and Parts

Breakdown.

This SAFETY ALERT SYMBOL

indicates important safety messages in

the manual. When you see this symbol, be alert

to the possibility of PERSONAL INJURY and

carefully read the message that follows.

The word NOTE is used to convey information

that is out of context with the manual text. It

contains special information such as

specifications, techniques and reference

information of a supplementary nature.

The word IMPORTANT is used in the text when

immediate damage will occur to the machine due

to improper technique or operation. Important will

apply to the same information as specified by

note only of an immediate and urgent nature.

It is the responsibility of the user to read the

operator’s manual and comply with the safe and

correct operating procedure and to lubricate and

maintain the product according to the

maintenance schedule in the operator’s manual.

The user is responsible for inspecting his

machine and for having parts repaired or

replaced when continued use of the product

would cause damage or excessive wear to the

other parts.

It is the user’s responsibility to deliver his

machine to the Yetter dealer who sold him the

product for service or replacement of defective

parts, which are covered by the warranty policy.

If you are unable to understand or follow the

instructions provided in this publication, consult

your local Yetter dealer or contact:

YETTER MANUFACTURING CO.

309/776-4111

800/447-5777

309/776-3222 (FAX)

Website: www.yetterco.com

E-mail: info@yetterco.com

WARRANTY

Yetter Manufacturing warrants all products manufactured and sold by it against defects in material. This

warranty being expressly limited to replacement at the factory of such parts or products as shall appear to

be defective after inspection. This warranty does not obligate the Company to bear cost of labor in

replacement of parts. It is the policy of the Company to make improvements without incurring obligations to

add them to any unit already sold. No warranty is made or authorized to be made, other than herein set

forth. This warranty is in effect for one year after purchase.

Dealer ___________________________________________________

Yetter Manufacturing warrants its own products only and cannot be responsible for damages to

equipment on which mounted.

2

Page 3

SAFETY

A brief description of signal words that may be used in this manual:

CAUTION: Used as a general reminder of good safety practices or to direct attention to unsafe

practices.

WARNING: Denotes a specific potential hazard.

DANGER: Denotes the most serious specific potential hazard.

SAFETY PRECAUTIONS

You can make your farm a safer place to live and work if you observe the safety precautions given. Study

these precautions carefully and insist that they be followed by those working with you and for you.

Finally, remember this: an accident is usually caused by someone’s carelessness, neglect, or oversight.

WARNING

Never clean, lubricate or adjust a machine that is in motion. Always lower or block the implement before

performing service.

If machine must be serviced in the raised position, jack or block it up to prevent it from accidentally falling

and injuring someone.

Do not allow riders on the tractor or implement.

Use speeds and caution dictated by the terrain being traversed. Do not operate on any slope steep enough

to cause tipping or loss of control.

Be sure all personnel are clear of the immediate area before operating.

Read and understand the operator’s manual and require all other persons who will operate the equipment

to do the same.

Be familiar with all tractor and implement controls and be prepared to stop engine and implements quickly in

an emergency.

CAUTION

Consult your implement and tractor operator’s manual for correct and safe operating practices.

Beware of towed implement width and allow safe clearance.

FAILURE TO HEED MAY RESULT IN PERSONAL INJURY OR DEATH.

3

Page 4

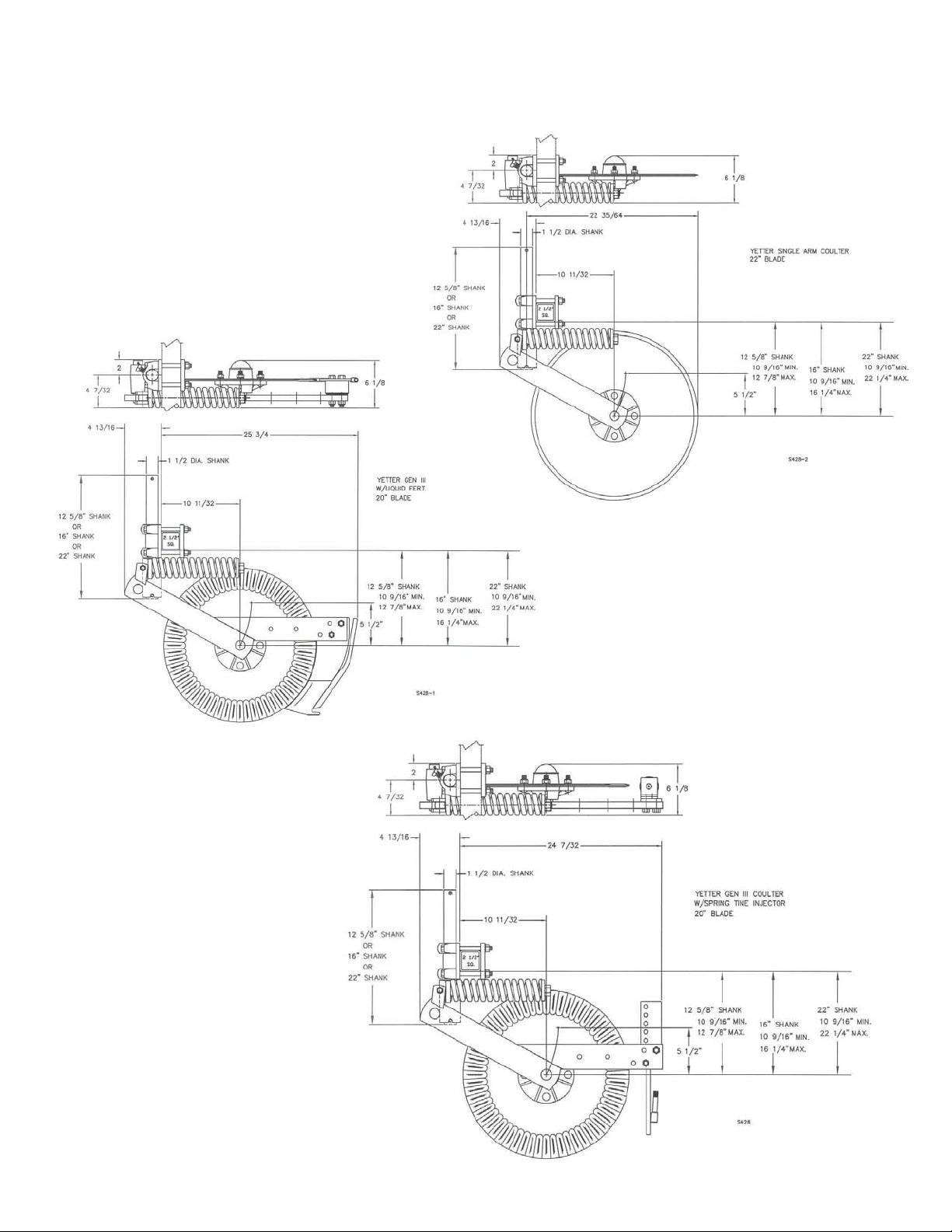

YETTER MODEL 2995

GENERATION III COULTER

2995-012 – FERTILIZER COULTER ASSEMBLY, RH

2995-012-L – FERTILIZER COULTER ASSEMBLY, LH

2995-140 – COULTER ASSEMBLY, RH

2995-140-L – COULTER ASSEMBLY, LH

CLAMPS

(DIMENSIONS ARE INCHES HORIZONTAL X VERTICAL)

Part No. Description

2975-151 Clamp Kit, 3 X 6 Bar

2990-153 Clamp Kit, 2” Sq. Bar

2990-154 Clamp Kit, 2 1/2” Sq. Bar

2990-155 Clamp Kit, 2 x 6 Bar

2990-156 Clamp Kit, 4 x 4 Bar

2990-157 Clamp Kit, 5 x 7 Bar

2990-158 Clamp Kit, 7 x 7 Bar

2990-159 Clamp Kit, 3” Dmd Bar

2990-160 Clamp Kit, 3 1/2” Dmd Bar

2990-161 Clamp Kit, 3 x 7 Bar

2990-162 Clamp Kit, 2 1/2” Sq., 1/2” Spacer

2990-163 Clamp Kit, 3” Sq. Bar

2990-166 Clamp Kit, 2 1/4”,2 1/2” Dmd Bar

2990-171 Clamp Kit, 3 x 4 Bar

2990-172 Clamp Kit, 4 x 6 Bar

2990-173 Clamp Kit, 6 x 4 Bar

2990-174 Clamp Kit, 7 x 5 Bar

2990-175 Clamp Kit, 7 x 4 Bar

2990-181 Clamp Kit, 4 x 10 Special

2990-182 Clamp Kit, 4 x 7 Bar

2999-120 Clamp, Air Seeder

6300-105 Clamp Kit, 5 x 5 Bar

FERTILIZER KNIVES

17” BLADE

Dry Fertilizer Knife 2975-116

Liquid Fertilizer Knife 2975-220

Suspension Rear Fertilizer Knife 2975-219

Seeder Knife 2977-203

Liquid Side Knife, Left 2995-122

Liquid Side Knife, Right 2995-123

Dry Side Knife, Left 2995-124

Dry Side Knife, Right 2995-125

Spring Mount Liquid Fertilizer Injection Kit – 2995-109 – For 17” and 20”

Spring Mount Dry Fertilizer Injection Kit – 2995-130 – For 17” and 20”

BLADES

PART NO. DESCRIPTION

2571-164 14-5/8” Wave Blade (8 Wave)

2571-166 14-5/8” 25 Multi-Wave Blade

2571-153 16” Bubble Flute Blade

2571-161 16” Ripple Blade

2571-156 16” Wavy Blade (8 Wave)

2571-162 16” 13 Wave Blade

2571-172 16” Multi-Wave Blade (25 Wave)

2571-206 16” Smooth Blade

2571-158 17” Ripple Blade

2571-165 17” Notched Smooth Blade

OPTIONAL EQUIPMENT

2975-120 Gauge Wheel Kit

2970-133 Knife Scraper 17”

2976-133 Knife Scraper 20”

4

SHANKS

(TOTAL LENGTH OF SHANK IN INCHES)

Part No. Description

2990-208 Shank, 12 5/8” Long, 3” Offset

2990-221 Shank, 27” Long, 3” Offset

2990-310 Shank, 12 5/8”

2990-318 Shank, 16”

2990-328 Shank, 26”

2990-342 Shank, 18” Long, 3/4” Offset

2990-350 Shank, 27 1/8”

2990-353 Shank, 22” Long, 3/4” Offset

2990-354 Shank, 18” Long, 5 1/2” Offset

2990-370 Shank, 30” Long, Straight

2990-377 Shank, 15” Long, 5 1/2” Offset

3010-303 Shank, 22”, Straight

3011-302 Shank, 22” Long, 5 1/2” Offset

6300-331 Shank, 19” Long, 3/4” Offset

20” BLADE

2996-201 Dry Knife

2996-200 Liquid Knife

2996-203 Liquid Suspension Knife

2996-114 Liquid Side Knife, Left

2996-115 Liquid Side Knife, Right

2996-116 Dry Side Knife, Left

2996-117 Dry Side Knife, Right

PART NO. DESCRIPTION

2571-156 18” Wavy Blade (8 Wave)

2571-155 18” 13 Wave Blade

2571-179 18” Multi-Wave Blade (25 Wave)

2571-169 18” Smooth Blade

2571-076 20” Ripple Blade

2571-178 20” Smooth Blade

2571-198 20” Notched Blade

2571-201 20” Notched Bubble Blade

2571-202 20” Multi-Wave Blade (25 Wave)

2571-196

6200-107 V-Close Wheel Kit

2920-022 Press Wheel Kit

2920-021 16” Disc Sealer

22” Smooth Blade-(Cutting Coulter Only)

Page 5

SINGLE ARM COULTERS

5

Page 6

INSTALLATION

1. Assembly 3/8 x 2-1/2” roll pin into hole closest to end of 1-1/2” diameter shank, leaving

approximately equal amount protruding out each side. Note: offset shanks require

that you perform step 2 first then step 1.

2. Insert lock collar into pivot casting and slide shank up through casting and lock collar.

If you wish to lock coulter from pivoting, slide roll pin into slots in casting. If you wish

to let coulter pivot, do not align roll pin with casting slots, but slide shank up till roll pin

contacts casting surface. Install and tighten 5/8 x 1” setscrew in lock collar to 110 ft.

lb. torque maximum.

3. Mount 17” blade loosely to hub using four 1/2 x 1-1/2” carriage bolts, lock washers and

nuts.

4. Mount fertilizer knife and spacer block to rear support arm using two 1/2 bolts lock

nuts. Place shims between 2995-309 – Spacer Block and support arm as required to

align knife point with blade.

5. Center blade on hub by rotating blade and watching clearance between knife and

blade. Slide blade on hub as required until clearance varies no more than 1/8” when

blade is rotated one complete revolution. Tighten four 1/2” nuts. If blade-wobble is

excessive, check for burrs on hub mounting surface and remove if necessary.

6. Adjust knife clearance to blade as close as possible. The high point of the blade

should just clear the knife as blade is rotated. Be sure blade rotates freely then

tighten two 1/2” locknuts to 120 ft. lb. Re-check clearance, by rotating blade one full

revolution, after all bolts are tightened.

7. Assemble clamp components loosely to planter front bar as shown in parts view of

appropriate clamp.

8. Position coulter clamps either toward the inside or outside of the planter openers on

each side of the planter to equalize draft. Tighten four 1/2” nuts to secure the clamps.

9. Install coulters on planter by inserting shank up through clamps and tightening 5/8 x 1”

setscrews.

10. Install 5/16 x 2-1/2” cotter pins in all vertical 1-1/2” diameter shanks. This cotter pin

prevents loss of coulter should the clamp setscrews work loose. Cotter pin can be

installed between clamp castings or on top, above top casting depending on the

shank.

11. Set coulter depth by loosening setscrews in clamp castings. For John Deere 7000

front fold planters there may not be enough up adjustment to operate coulter at proper

depth, not more than hub deep. Not all toolbars on John Deere planters operate at

the same height. If necessary, cut off top of 1/12” diameter shank to allow proper

adjustment.

6

Page 7

INSTALLATION

12. On John Deere 7000 front fold planters there are two hoses that may interfere with

coulter operation. Loosen hydraulic fittings and swivel hoses up out of the way to

provide clearance when coulter flexes up.

13. If you have elected to let coulter swivel, set lock collar to allow swivel in one or both

directions as required. If you have elected to hold coulter rigid, set coulter straight

with the direction of travel. Tighten set screw to 110 ft. lb. torque maximum.

14. Set spring tension by adjusting 3/4” lock nut until 1/8” of threads are exposed above

the nut. Tighten 3/4” locknut if greater spring pre-load is required. NOTE: This will

reduce vertical movement of coulter.

15. NEVER mount coulters under planter drive shaft to allow coulter blades to contact

shaft when an obstacle is struck. Coulters must be mounted so blade can always flex

up and clear drive shaft.

NOTE: Dry fertilizer must be free of chunks greater that 1/4” in size to prevent

plugging. Yetter recommends using screened fertilizer or running fertilizer

through screen when hoppers are filled. Clean hoppers thoroughly at the

beginning of season to prevent plugging problems.

The rubber dry fertilizer tube may appear to be ‘stretched’ when the planter is in

the transport position. This does not affect operation of the planter and should

not be detrimental to the fertilizer tube.

OPERATION

Yetter Model Generation III fertilizer coulters are designed to apply fertilizer 3” to 5” deep.

See your fertilizer dealer for recommended depth and distance away from row for your

particular fertilizer. A popular placement setting is 2” below and 2” away from the seed.

High deposit rates require the fertilizer to be placed farther away from the row to avoid

crop “burn”.

The coulter can be set up to swivel or not swivel as required. By not allowing the coulter

to swivel, the distance between seed and fertilizer varies less when planting on contour.

When mounting Model Generation III coulters on 3-point or 2-point hitch planters, the

coulters should be set up to swivel, particularly if a 4-wheel drive tractor is used. This

reduces the side load on the coulter during operation. It is preferable to allow the coulter

to swivel.

IMPORTANT: For proper operation, the planter frame must operate level and at the

correct height, usually 20” – 22” while in operation.

In hard no-till conditions the desired operating depth may not be possible. Tighten spring

nut to maintain depth if spring is flexing rather than lower coulter to obtain maximum

depth.

Planter weight may limit operating depth in hard conditions, particularly with mounted or

semi-mounted planters. Be sure planter has enough weight to keep drive wheels on the

ground during operation or plant populations can be drastically affected.

7

Page 8

OPERATION

1. Set coulter blades to run vertical to ground. Operation depth and blade wear can be affected if coulter

is mounted crooked. If coulters are set-up to not swivel be sure they run straight with the direction of

travel.

2. After a few hours use, check all bolts and setscrews for tightness.

3. After a few days use, check coulter hubs for loose bearings. There should be no end play in the hub

bearings to allow it to wobble. If necessary, remove hub cap and cotter pin, adjust slotted nut to

remove wobble, re-insert cotter pin and replace hub cap.

4. KNIFE ADJUSTMENT IS CRITICAL. Adjust knife-blade clearance regularly, see page 9.

An optional knife scraper, Part #2970-133 or 2976-133 is available to reduce the frequency of

adjustment on the fertilizer coulter knife. In addition this allows better operation in tough conditions

such as freshly disked soils with abundant trash in the top four inches of loose soil.

NOTE: A ‘bump’ will appear behind knife scraper, on blade where protected, this must be ground off

periodically to maintain correct knife-blade clearance.

5. BLADE WEAR can affect operation in loose trash conditions. If knife adjustment does not stop

plugging problems, it may be necessary to replace blade.

6. Dry fertilizer must be free of chunks greater that 1/4” in size to prevent plugging. Yetter

recommends using screened fertilizer or running fertilizer through screen when hoppers are

filled. Clean hoppers thoroughly at the beginning of season to prevent plugging problems.

NOTE: The rubber dry fertilizer tube may appear to be ‘stretched’ when the planter is in the

transport position. This does not affect operation of the planter and should not be detrimental

to the fertilizer tube.

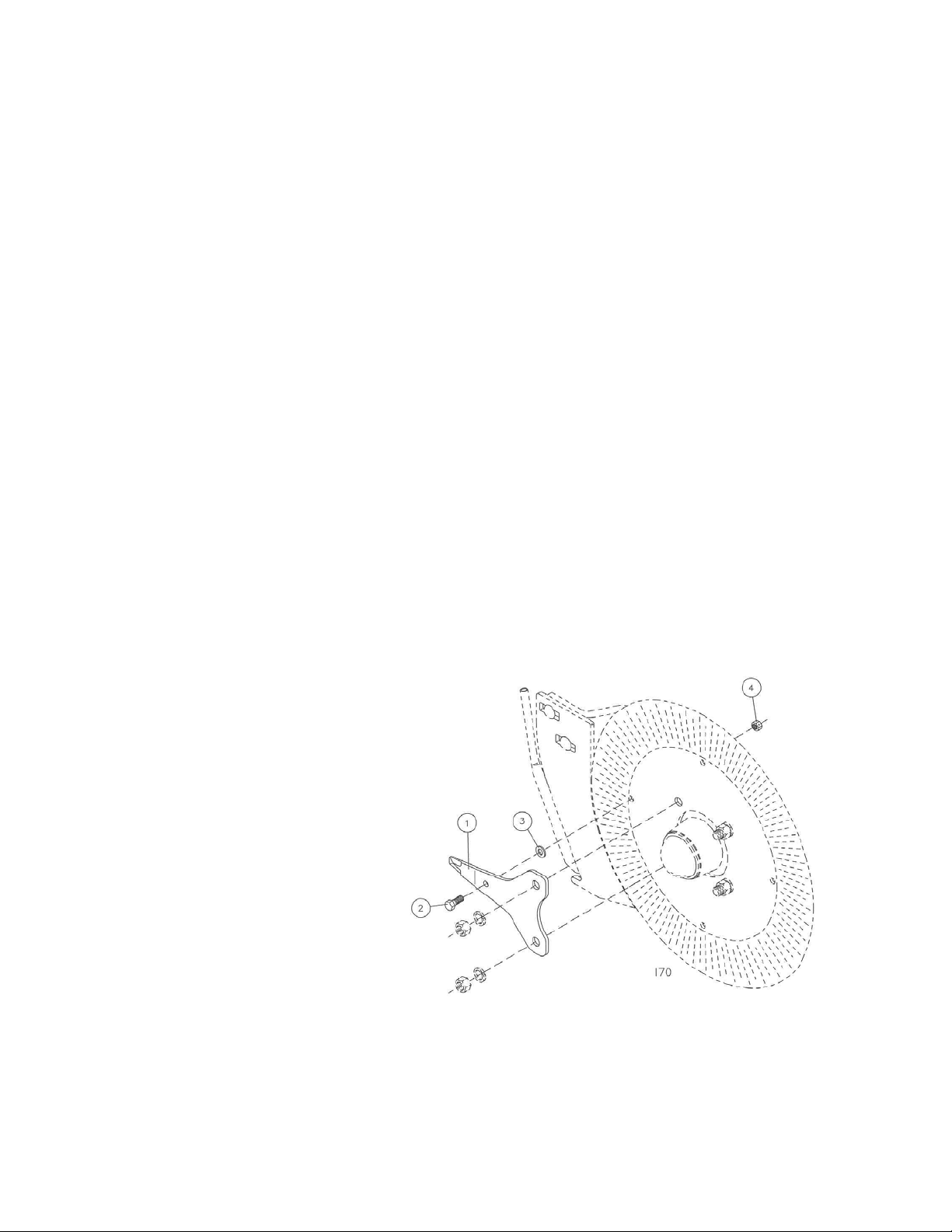

2970-133 17” Knife Scraper

Key Qty. Part No. Description

1 1 2970-353 Double Edge Knife Scraper

2 1 2502-199 5/16-18 x 3/4 HHCS Gr. 5 ZP

3 1 2526-201 5/16 Std. Flat washer ZP

4 1 2520-205 5/16-18 Lock Hex Nut ZP

2976-133 20” Knife Scraper

Key Qty. Part No. Description

1 1 2976-353 Double Edge Knife Scraper

2 1 2502-199 5/16-18 x 3/4 HHCS Gr. 5 ZP

3 1 2526-201 5/16 Std. Flat washer ZP

4 1 2520-205 5/16-18 Lock Hex Nut ZP

8

Page 9

MAINTENANCE

LUBRICATION

DANGER: Always install safety lock-ups or lower the planter to the ground before working on the

machine. Lubricate at frequency indicated with a multi-purpose type grease.

DANGER: Always install all safety lock-ups and safety lock pins before working under the toolbar.

1. Raise the toolbar until is clear off the ground. Remove the gauge wheel and the blade. Remove the

hubcap, cotter pin, slotted nut and washer from the spindle shaft assembly.

2. Pull the coulter spindle shaft assembly from the hub. Remove bearing cones and cups and discard if bearings

are being replaced. Clean hub and dry. Remove bearings only and not cups of re-packing.

3. Wash the old grease from the hub, bearing cups, coulter spindle shaft, seal, and bearing cones. Inspect the

condition of bearing cups and cones.

4. Apply #2 multi-purpose lithium grease on each bearing. Make sure the space around each roller is filled.

Lubricate the bearing cups.

5. Position the bearing in the cup and install the seal. Lubricate the seal lips and proceed with re-assembly of the

removed parts including the blade. Blade bolt torque is 90 to 96 ft. lbs.

6. Install outer bearing, washer, and slotted nut. Tighten the slotted nut to 150 in. lbs. while rotating the blade or

until a definite drag is felt when the blade is turned by hand. Tighten the nut one slot position to line up the

cotter pin hole with a slot. Secure the nut with a new cotter pin.

9

Page 10

KNIFE ADJUSTMENT

The adjustment of knife clearance to the blade is critical to trouble free operation of the fertilizer coulter, in

certain conditions the coulter can “plug” in just a few feet if not correctly adjusted.

1. The disc blade must run concentric. Adjust by loosening four hub nuts and centering the blade.

2. Set knife to rub slightly on blade, especially at bottom of knife. See illustrations above. Tighten lock

nuts securely.

10

Page 11

PARTS IDENTIFICATION

11

Page 12

PARTS IDENTIFICATION

12

Page 13

PARTS IDENTIFICATION

13

Page 14

PARTS IDENTIFICATION

14

Page 15

PARTS IDENTIFICATION

ITEM #24 – DIFFERENT BLADE OPTIONS

PART NO. DESCRIPTION

2571-164 14-5/8” Wave Blade (8 Wave)

2571-167 14-5/8” 25 Multi-Wave Blade

2571-154 16” Bubble Flute Blade

2571-163 16” Ripple Blade

2571-156 16” Wavy Blade (8 Wave)

2571-164 16” 13 Wave Blade

2571-172 16” Multi-Wave Blade (25 Wave)

2571-206 16” Smooth Blade

2571-158 17” Ripple Blade

2571-165 17” Notched Smooth Blade

PART NO. DESCRIPTION

2571-156 18” Wavy Blade (8 Wave)

2571-155 18” 13 Wave Blade

2571-179 18” Multi-Wave Blade (25 Wave)

2571-169 18” Smooth Blade

2571-076 20” Ripple Blade

2571-178 20” Smooth Blade

2571-198 20” Notched Blade

2571-201 20” Notched Bubble Blade

2571-203 20” Multi-Wave Blade (25 Wave)

2571-196 22” Smooth Blade

15

Page 16

PARTS IDENTIFICATION

SIDE KNIFE KITS

2995-122 Liquid Side Knife Assy., L.H. 2995-124 Dry Side Knife Assy., L.H.

2995-123 Liquid Side Knife Assy., R.H. 2995-125 Dry Side Knife Assy., R.H.

To be used with 2571-165 or 2571-169 blades only.

2996-114 LH 5-1/2” Liq Side Knife Assy. 2996-116 LH 5-1/2” Dry Side Knife Assy.

2996-115 RH 5-1/2” Liq Side Knife Assy. 2996-117 RH 5-1/2” Dry Side Knife Assy.

To be used with 2571-178 blade only.

Key Qty. Part No. Description

1 3 2502-351 1/2-13 x 2 HHCS Gr. 5 ZP

2 1 2995-316 Side Knife Shim, 1/8”, ZP

3 3 2995-315 Side Knife Shim, 16 Ga., ZP

4 1 2995-314 Side Knife Brkt., 2995

5 1 2502-362 1/2-13 x 5 HHCS Gr. 5 ZP

6 1 2995-121 Liquid Side Knife Assy., R.H. (Shown)

1 2995-120 Liquid Side Knife Assy., L.H.

1 2995-200 Dry Side Knife W.A., L.H.

1 2995-201 Dry Side Knife W.A., R.H.

1 3000-123 LH 5-1/2” Liq Side Knife S.A.

1 3000-124 RH 5-1/2” Liq Side Knife S.A.

1 3000-234 LH 5-1/2” Dry Side Knife W.A.

1 3000-235 RH 5-1/2” Dry Side Knife W.A.

7 3 2520-357 1/2-13 Lock Hex Nut ZP

8 2 2520-352 1/2-13 Hex Nut ZP

16

Page 17

PARTS IDENTIFICATION

2995-109 SPRING MOUNT LIQ. FERT. INJECTOR KIT

Key Qty. Part No. Description

1 2 2502-294 1/2-13 x 1-1/2 HHCS Gr. 5 ZP

2 1 2502-292 1/2-13 x 1 HHCS Gr. 5 ZP

3 5 2525-352 1/2 Med. Lock washer ZP

4 1 2995-301 Injector Mount Plate

5 1 2975-389 Adjustment Plate, Injector

6 4 2520-352 1/2-13 Hex Nut ZP

7 1 2995-131 Spring Injector Assembly

8 1 2515-311 3” Nipple, 1/4 NPT Stainless Steel

9 1 2995-212 Injector Rod W.A., 1/2-13

10 2 2505-344 1/2-13 x 1-3/4 Car. Bolt Gr. 5 ZP

11 2 2970-319 Knife Shim, 1/8”, ZP

12 1 2970-320 Knife Shim, 16 GA., ZP

13 1 2520-356 1/2-13 Jam Hex Nut ZP

14 1 2995-320 Spacer, Injector

17

Page 18

PARTS IDENTIFICATION

2995-130 SPRING MOUNT DRY INJECTOR KIT

Key Qty. Part No. Description

1 5 2525-352 1/2 Med. Lock washer ZP

2 4 2520-352 1/2-13 Hex Nut ZP

3 2 2502-294 1/2-13 x 1 1/2 HHCS Gr. 5 ZP

4 1 2502-292 1/2-13 x 1 HHCS Gr. 5 ZP

5 1 2995-301 Injector Mount Plate

6 1 2975-389 Adjustment Plate, Injector

7 1 2995-131 Injector Spring Assembly

8 1 2515-547 Dry Fertilizer Adapter, PVC

9 1 2995-213 Spring Tine Dry Injector W.A.

10 2 2505-344 1/2-13 x 1-3/4 Car. Bolt Gr. 5 ZP

11 2 2970-319 Knife Shim, 1/8”, ZP

12 1 2970-320 Knife Shim, 16 Ga., ZP

13 1 2520-356 1/2-13 Jam Hex Nut

14 1 2995-320 Spacer, Injector

18

Page 19

PARTS IDENTIFICATION

2990-159 Clamp Kit, 3” Diamond Bar

Key Qty. Part No. Description

1 4 2502-369 1/2-13 x 8” HHCS Gr. 5 ZP

2 2 2990-314 Clamp Plate, 4” Sq. or 3” Diamond

3 2 2970-326 Adaptor, 3” Sq. Diamond Bar

4 2 2990-360 Clamp Casting, Drilled

5 2 2503-379 5/8-11 x 1” Sq. HCPSS Gr. 5 ZP

6 4 2520-357 1/2-13 Lock Hex Nut ZP

Key Qty. Part No. Description

1 4 2502-374 1/2-13 x 9” HHCS Gr. 5 ZP

2 2 2990-316 Clamp Plate, 3-1/2” Diamond Bar

3 2 2970-327 Adaptor, 3-1/2” Sq. Diamond Bar

4 2 2990-360 Clamp Casting, Drilled

5 2 2503-379 5/8-11 x 1” Sq. HCPSS Gr. 5 ZP

6 4 2520-357 1/2-13 Lock Hex Nut ZP

2990-160 Clamp Kit, 3-1/2” Diamond Bar

2990-166 Clamp Kit, 2-1/4,2-1/2 Diamond Bar

Key Qty. Part No. Description

1 4 2502-371 1/2-13 x 7” HHCS Gr. 5 ZP

2 2 2990-348 Clamp Plate, 2-1/4, 2-1/2 Diamond Bar

3 2 2990-349 Adaptor, 2-1/4, 2-1/2 Diamond Bar

4 2 2990-360 Clamp Casting, Drilled

5 2 2503-379 5/8-11 x 1” Sq. HCPSS Gr. 5 ZP

6 4 2520-357 1/2-13 Lock Hex Nut ZP

19

Page 20

PARTS IDENTIFICATION

2990-154 Clamp Kit, 2-1/2” Sq. Bar 2990-155 Clamp Kit, 2 x 6 Bar

Key Qty. Part No. Description Key Qty. Part No. Description

1 4 2502-368 1/2-13 x 5-1/2” HHCS GR. 5 ZP 1 4 2502-362 1/2-13 X 5” HHCS GR. 5 ZP

2 2 2990-313 Clamp Plate, 2-1/2 Square Bar 2 2 2975-363 Clamp Plate, Universal

3 2 2990-360 Clamp Casting, Drilled 3 2 2990-360 Clamp Casting, Drilled

4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP 4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP

5 4 2520-357 1/2-13 Hex Lock Nut ZP 5 4 2520-357 1/2-13 Hex Lock Nut ZP

2990-156 Clamp Kit, 4 x 4 Bar 2990-157 Clamp Kit, 5 x 7 Bar

Key Qty. Part No. Description Key Qty. Part No. Description

1 4 2502-371 1/2-13 x 7” HHCS GR. 5 ZP 1 4 2502-369 1/2-13 X 8” HHCS GR. 5 ZP

2 2 2990-314 Clamp Plate, 4” Sq. & 3” Diamond Bar 2 2 2990-315 Clamp Plate, 5 x 7 or 7x 7 Bar

3 2 2990-360 Clamp Casting, Drilled 3 2 2990-360 Clamp Casting, Drilled

4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP 4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP

5 4 2520-357 1/2-13 Hex Lock Nut ZP 5 4 2520-357 1/2-13 Hex Lock Nut ZP

2990-158 Clamp Kit, 7 x 7 Bar 2990-161 Clamp Kit, 3 x 7 Bar

Key Qty. Part No. Description Key Qty. Part No. Description

1 4 2502-376 1/2-13 x 10” HHCS GR. 5 ZP 1 4 2502-373 1/2-13 X 6” HHCS GR. 5 ZP

2 2 2990-315 Clamp Plate, 5 x 7 or 7 x 7 Bar 2 2 2990-315 Clamp Plate, 5 x 7 or 7 x 7 Bar

3 2 2990-360 Clamp Casting, Drilled 3 2 2990-360 Clamp Casting, Drilled

4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP 4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP

5 4 2520-357 1/2-13 Hex Lock Nut ZP 5 4 2520-357 1/2-13 Hex Lock Nut ZP

2990-163 Clamp Kit, 3 x 3 Bar 2990-171 Clamp Kit, 3 x 4 Bar

Key Qty. Part No. Description Key Qty. Part No. Description

1 4 2502-373 1/2-13 x 6” HHCS GR. 5 ZP 1 4 2502-373 1/2-13 X 6” HHCS GR. 5 ZP

2 2 2990-339 Clamp Plate, 3” Square Bar 2 2 2990-314 Clamp Plate, 4” Sq. & 3” Dmd

3 2 2990-360 Clamp Casting, Drilled 3 2 2990-360 Clamp Casting, Drilled

4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP 4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP

5 4 2520-357 1/2-13 Hex Lock Nut ZP 5 4 2520-357 1/2-13 Hex Lock Nut ZP

20

Page 21

PARTS IDENTIFICATION

2975-151 Clamp Kit, 3 x 6 Bar 2990-172 Clamp Kit, 4 x 6 Bar

Key Qty. Part No. Description Key Qty. Part No. Description

1 4 2502-373 1/2-13 x 6” HHCS GR. 5 ZP 1 4 2502-371 1/2-13 X 7” HHCS GR. 5 Zp

2 2 2975-363 Clamp Plate, Universal 2 2 2975-363 Clamp Plate, Universal

3 2 2990-360 Clamp Casting, Drilled 3 2 2990-360 Clamp Casting, Drilled

4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP 4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP

5 4 2520-357 1/2-13 Hex Lock Nut ZP 5 4 2520-357 1/2-13 Hex Lock Nut ZP

2990-173 Clamp Kit, 6 x 4 Bar 2990-174 Clamp Kit, 7 x 5 Bar

Key Qty. Part No. Description Key Qty. Part No. Description

1 4 2502-374 1/2-13 x 9” HHCS GR. 5 ZP 1 4 2502-376 1/2-13 X 10” HHCS GR. 5 ZP

2 2 2990-314 Clamp Plate, 4” Sq. & 3” Diamond Bar 2 2 2975-367 Clamp Plate, 5 Sq. Bar

3 2 2990-360 Clamp Casting, Drilled 3 2 2990-360 Clamp Casting, Drilled

4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP 4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP

5 4 2520-357 1/2-13 Hex Lock Nut ZP 5 4 2520-357 1/2-13 Hex Lock Nut ZP

2990-175 Clamp Kit, 7 x 4 Bar

Key Qty. Part No. Description Key Qty. Part No. Description

1 4 2502-376 1/2-13 x 10” HHCS GR. 5 ZP 1 4 2502-371 1/2-13 X 7” HHCS GR. 5 ZP

2 2 2990-314 Clamp Plate, 4” Sq. 3” Diamond Bar 2 2 2990-315 Clamp Plate, 5 x 7 or 7 x 7 Bar

3 2 2990-360 Clamp Casting, Drilled 3 2 2990-360 Clamp Casting, Drilled

4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP 4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP

5 4 2520-357 1/2-13 Hex Lock Nut ZP 5 4 2520-357 1/2-13 Hex Lock Nut ZP

2990-182 Clamp Kit, 4 x 7 Bar

6300-105 Clamp Kit, 5 x 5 Bar

Key Qty. Part No. Description

1 4 2502-369 1/2-13 x 8” HHCS GR. 5 ZP

2 2 2975-367 Clamp Plate, 5” Square Bar

3 2 2990-360 Clamp Casting, Drilled

4 2 2503-379 5/8-11 x 1 Sq. HCPSS Gr. 5 ZP

5 4 2520-357 1/2-13 Hex Lock Nut ZP

21

Page 22

Problem

Setting coulter

Trash plugging

Blade not penetrating

Spring not deflecting

Fertilizer too deep

Fertilizer too shallow

Fertilizer will not flow

Blade not rotating properly

TROUBLESHOOTING

Cause

Planter not set correctly

Excessive knife-blade

clearance

Knife not correctly aligned

behind blade

Insufficient coulter spring

pressure

Coulter incorrectly installed

Excessive spring pressure

Spring not deflecting

Coulter incorrectly installed

Lack of depth control

Planter frame too low

Blade not penetrating

Coulter incorrectly installed

Plugged fertilizer tubes

Loose soil

Solution

Ensure that in operation the

planter frame is at correct

height (20”-22”) and level the

toolbar. See opposite page.

Check and adjust knife-blade

clearance. See page 9.

Use shims to align knife

behind blade

Tighten coulter spring locknut

down 1” further

Adjust height of coulter by

sliding shank down

Back off coulter spring locknut

to 1/8” of thread exposed

Back off coulter spring locknut

to 1/8” of thread exposed

Adjust height of coulter by

sliding shank up

Install gauge wheel kit, part

no. 2975-120

Raise planter frame to correct

height

Tighten coulter spring locknut

down 1” further

Adjust height of coulter by

sliding shank down

Check for plugged fertilizer

tube openings on knife

Check for plugged fertilizer

delivery tubes on planter

Coulter works best in firmer

soil conditions

22

Page 23

NOTES

23

Page 24

Our name

Is getting known

Just a few years ago, Yetter products were sold

primarily to the Midwest only. Then we embarked on a

program of expansion and moved into the East, the

South, the West and now north into Canada. We’re even

getting orders from as far away as Australia and Africa.

So, when you buy Yetter products . . .you’re buying a

name that’s recognized. A name that’s known and

respected. A name that’s become a part of American

agriculture and has become synonymous with quality and

satisfaction in the field of conservation tillage.

Thank you.

YETTER MANUFACTURING CO.

Colchester, IL 62326-0358 309/776-4111

Toll Free 800/447-5777

Fax 309/776-3222

Website: www.yetterco.com

E-mail: info@yetterco.com

2565-490_REV_D

07/13

24

Loading...

Loading...