Y-E Data YD-380 Maintenance Manual

VY·E

DATA

HALF

MAINTENANCE

YD-380

HEIGHT,

5.25

INCH

HIGH

FLEXIBLE

MANUAL

DENSITY,

DISK

DOUBLE

DRIVE

SIDED

Contents

Check

the

of

this

revision

manual

number when

may

be

changed

placing

September

FDL-523006

without

an

order.

notice.

1983

REV.

A

Revisions

Date

..

~ptember

.

-

--

-

--

---

-

-

-

-

83

Rev.

A

Description

First

Edition

Revised

Pages

~ote:

I~"

('21

publication

----~e

~=~e

~

-.

disk.

YD-380

5.25

may

inch

be

referred

flexible

disk

to

may

as

simply

be

referred

a

"drive".

to

as

simply

YD-380

Maintenance Manual

TABLEOFCONTENTS

Page

1.0

2.0

3.0

4.0

INTRODUCTION

MAINTENANCE

2.1

Maintenance Tool

2.2

Maintenance

2.3

2.4

Test

Exerciser

PREVENTIVE

3.1

General

3.2

Visual

3.3

Cleaning

SERVICE

TOOLS

Equipment

MAINTENANCE

Check

CHECKS,

AND

TEST

EQUIPMENT

List

Supplies

REPLACEMENT

List

AND

ADJUSTMENT

1

1

1

2

2

2

3

3

3

3

4

Maintenance

4.1

4.2

4.3

4.4

4.5

4.6

PWB

Index

Track

Write

Media

In

Use

Level

1

Sensor Assembly

00

Sensor

Protect

Assembly

Sensor

Sensor Assembly

Lamp

Assembly

Assembly

5

6

9

11

12

14

TABLEOFCONTENTS

Page

5.0

6.0

~Aintenance

4.7

4.8

4.9

4.10

4.11.

4.12

4.13

4.14

Carrier

Index

Drive

Head Load

Front

Front

Stepper

Head/Carriage

Level. 2

Assembly

Lamp

Motor Assembly (on Motor

Lever

Bezel

Assembly

PARTS/ASSEMBLIES

TEST

POINT/CONNECTOR

Assembly (on Motor

Solenoid

Assembly

PHYSICAL

PIN

LOCATIONS

ASSIGNMENTS

Control

Control

PWB)

PWB)

15

16

17

18

21

U

23

24

30

35 .

7.0

8.0

9.0

10.0

SPARE

PARTS

SCHEMATIC

EXPLODED

USINGACLEANING

LIST

DIAGRAMS

VIEW

DISK

38

39

42

43

1.0

INTRODUCTION

This

DATA

Included

ment

engineers.

2.0

MAINTENANCE

The

supplies,

2.1

Maintenance

Phillips

manual

YD-380

is

procedures,

following

test

Screwdriver

describes

two

sided,

information

and

TOOLS

Tools

TOOL

AND

tables

equipment and

List

the

high

also

TEST

list

(for

maintenance

density,

on

service

adjustment

EQUIPMENT

the

maintenance

exerciser

M3)

and

5.25

checks,

instructions

tools,

for

Y-E

141034-01

operation

inch

Floppy

removal and

for

maintenance

the

YO-38D.

DATE

PIN

of

the

Disk

replace-

customers'

Y-E

Drive.

Phillips

Flat

Cutters

Needle Nose

Tweezers

CE

Disk

Cleaning

Wrench

Hex

Wrench

Hex

Screwdriver

Head

Disk

Screwdriver

Pliers

1.27

1.5

mm

mm

(for

M2.6)

141627-01

141035-01

141039-01

141040-01

141042-01

145173-01

145174-01

140266-03

140266-01

2.2

Maintenance

Supplies

2.3

Tie

Wrap

Test

Equipment

Test

Multimeter

Electronic

Oscilloscope*

*

For

Supplies

(TY-23M,

Equipment

Counter*

use

at

Kitagawa)

Maintenance

Level

Y-E

DATA

031005-01

2

PIN

2.4

Exerciser

Equipment

Exerciser

Y-E

DATA

YD-164T

PIN

3

.0

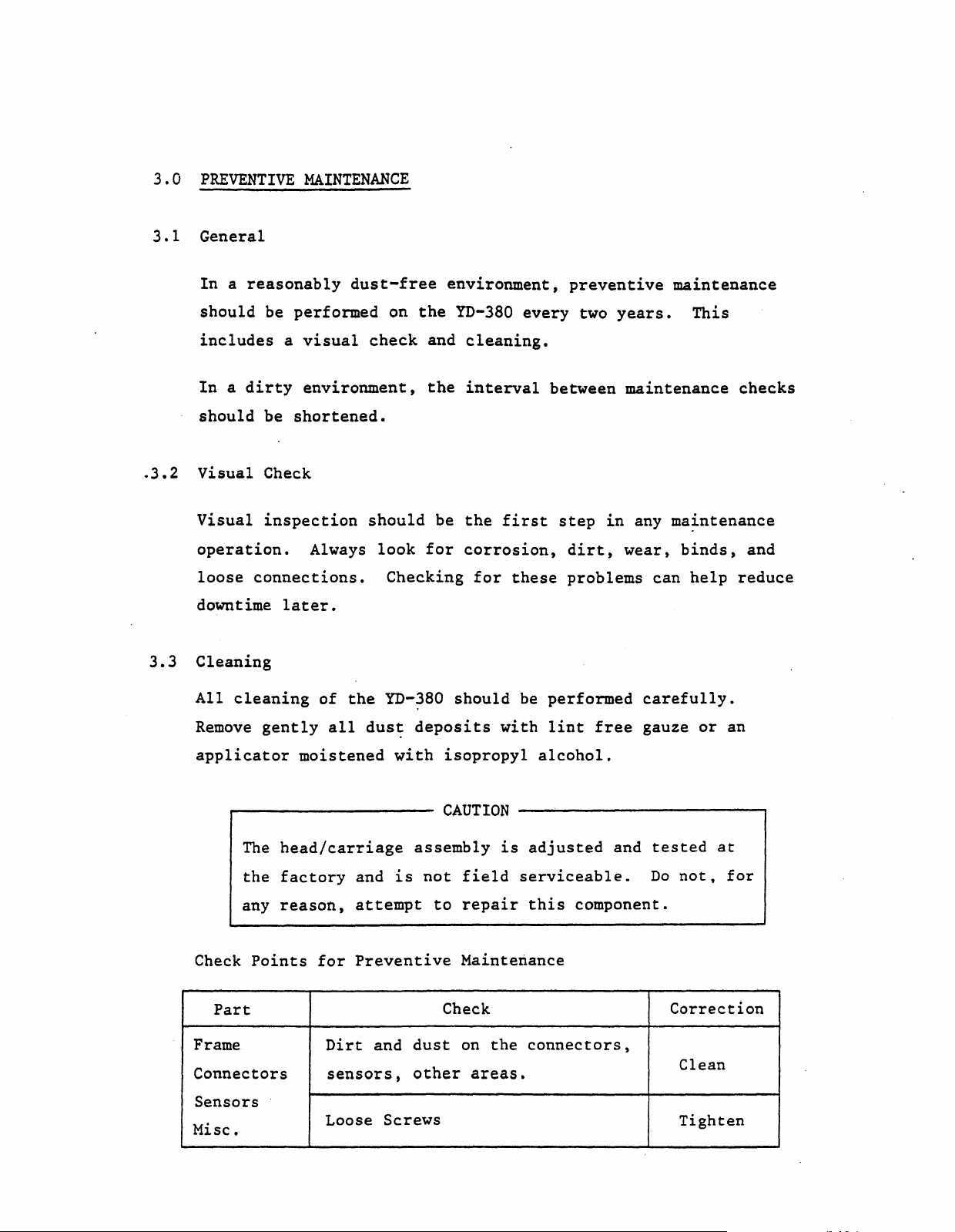

PREVENTIVE

MAINTENANCE

.

3.2

3.3

3.1

General

Inareasonably

should

includes

Inadirty

should

Visual

Visual

operation.

loose

downtime

be

performed

a

visual

environment,

be

shortened

Check

inspection

Always

connections.

later.

Cleaning

dust-free

on

check

•

should

look

Checking

environment,

the

YD-380

and

cleaning.

the

interval

be

the

for

corrosion,

for

every

first

these

preventive

two

between

step

dirt,

problems

maintenance

years.

maintenance

in

any

ma~ntenance

wear,

can

This

binds,

help

checks

and

reduce

All

cleaning

Remove

gently

applicator

The

the

any

Check

Points

Part

Frame

Connectors

Sensors

Misc.

of

the

all

dus~

moistened

head/carriage

factory

reason,

for

Dirt

and

attempt

Preventive

and

sensors,

Loose

YD-380

deposits

with

assembly

is

not

dust

other

Screws

should

isopropyl

CAUTION

field

to

repair

Maintenance

Check

the

on

areas.

be

performed

with

lint

alcohol.

is

adjusted

serviceable.

this

connectors,

carefully.

free

and

gauze

tested

Do

component.

or

an

at

not,

for

Correction

Clean

Tighten

4.0

SERVICE

CHECKS,

REPLACEMENTS

AND

ADJUSTMENTS

This

assemblies

two

Levell:

Level

Level

chapter

maintenance

2:

1

4.1

4.2

4.3

4.4

4.5

4.6

Level 2

4.7

contains

listed

Can

be

Special

PWB

Index

Track

Write

Media

In

Use

Carrier

below.

levels:

performed

training

Sensor

00

Sensor

Protect

Sensor

Lamp

detailed

Note

Sensor

maintenance

that

without

and

tools

the

list

special

required.

procedures

is

separated

training

or

for

the

into

tools.

Note:

4.8

4.9

4.10

4.11

4.12

4.13

4.14

Index

Drive

Head Load

Front

Front

Stepper

Head/Carriage

Refer

Chapter

Chapter9for

to

Lamp

Motor (on Motor

Lever

Bezel

Chapter

6

for

(on Motor

Solenoid

Assembly

5

for

Test

Exploded View.

Points/Connector

Control

Control

Parts/Assemblies

PWB)

PWB)

Pin

Locations,

Assignments and

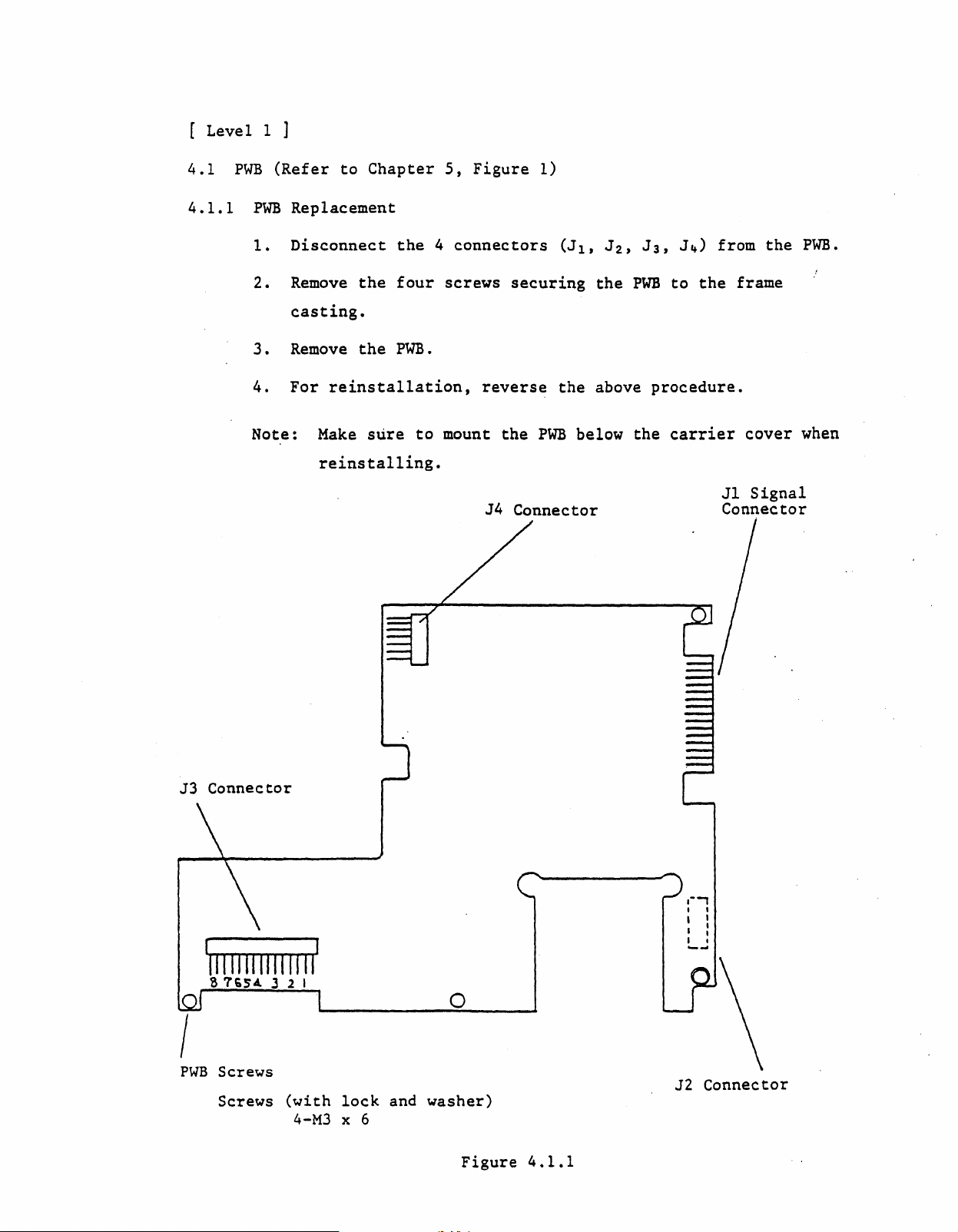

[

Levell]

4.1

4.1.1

PWB

PWB

1.

2.

3.

4.

Note:

(Refer

Replacement

Disconnect

Remove

casting.

Remove

For

to

reinstallation,

Make

reinstalling.

Chapter

the

the

four

the

PWB.

sure

5,

4

connectors

screws

to

mount

Figure

securing

reverse

the

J4

1)

(J1,

the

PWB

below

Connector

J2'

the

PWBtothe

above

the

J3,

J4)

procedure.

carrier

from

the

frame

cover

Jl

Signal

Connector

PWB.

when

J3

Connector

I

PWB

Screws

Screws

(with

4-M3

lock

x 6

and

o

washer)

Figure

4.1.1

,--,

I ,

, I

, :

I ,

--

J2

Connector

4.2

Index

Sensor

Assembly

(Refer

to

Chapter

5,

Figure

3)

4.2.1

4.4.2

Service

1.

2.

Replacement

1.

2.

3.

4.'

Check~

Power

Without

and

check

All

and G

the

vol

Remove

Remove

4.2.2)

Take

cover.

Lift,

out

up

up

the

inserting

for

tage

the

J3

connector

the

'

the

drive.

a

(GND).

at

PWB

carrier

lead

a

to

0.5

Next,

the

same

(Refer

clamps

disk,

V

between

insert

points

to

4.1)

housing

cover

slightly

move

6.

screws

the

lever

the

a

disk

should

(Refer

and remove

and

to

PWB

connector

and

be

2.5

to

pullout

lock

close

Page

to'

the

the

position

the

5.25

9,

figure

carrier

leads.

J3

door;

V'.

Pin

5.

6.

7.

8.

9.

Note:

Remove

Take

bly,

Take

and

sensor

When

lead

For

Perform

out

and remove

out

as

clamping

insulation.

reinstallation,

Make

arm

the

In

the

the

shown

assembly

a

service

sure

securing

the

Use Lamp.

screws

the

screws

in

figure

by

pushing

the

leads,

check.

front

the

for

the

front

to

CAUTION

reverse

Ready/Off

lever

the

4.4.1,

be

(See

edge

Write

in

front

and

remove

the

careful

the

above

4.l.l)

of

the

plate

lever

carrier

Protect

the

direction

not

procedure.

carrier

does

and

Sensor

write

to

damage

plate

not

carrier

assembly.

assembly,

protect

indicated.

the

spring

come

in

assem-

contact

with

the

leads.

Carrier

Spring

Plate

Front

Bezel

Side

Index

(with

Sensor

lock

M3x6)

Screw

and

washer,

Collet

Connector

Number

Guide

J3

---t--~

Connector

Housing

Figure

~ssignment

4.2.1

Lead Clamp

Collet

Shaft

Figure

4.2.2

Connector

No.

1

2 Head Load

3

4

5

6

7

8 Media

Stepper

Drive

Write

In

Use

Index

Track

Part

Solenoid

Motor

Protect

Lamp

Sensor

00

Sensor

Sensor

Sensor

4.2.3

Adjustment

1.

Loosen

2.

Power

3.

Connect

up

the

the

an

Index

Sensor

drive.

oscilloscope

screws

to

the

one

PWB

quarter

test

turn.

points

lA,

1B,

3.

Connect

connect

Set

the

INPUT

VERT

INVERT

TIME/DIV

VOLTS/DIV

4.

Insert

5.

Load

head/carriage

tion

signal

channell

the

external

oscilloscope

COUPLING

MODE

(CH

2)

(CHI,

a

CE

Disk

the

read/write

until

the

from TP3) and

to

controls

MODE

CH2)

and

heads

assembly

timing

PWB

TP

scope

AC

ADD

ON

0.1

100

turn

to

between

the

first

lA,

trigger

as

follows:

ms

mV

the

front

against

track

the

channel

the

2.

start

part

to

TP3.

lever

disk

Adjust

of

the

2

of

to

to

and

the

the

index

TP

lock

step

sensor

sweep

IB, and

position.

t~e

posi-

(index

burst

(TP

lA,

Index

Burst

(TP1A,TP1B)

Note:

TP

Signal

Signal

To

delay

front

lB)

is

within

(TP3)--------~

-600

Figure

the

bezel

Ind~x

(see

Burst,

Page

to

,....

4.2.3

9,

1400

move

figure

~s.

.,,..

-600

the

4.2.1).

1 _

to

1400~s

J

sensor

towards

the

6.

Verify

the

first

at

side

that

peak

0 and

the

of

1,

timing

the

track

between':the

index

02

and

burst

track

start

is

68.

of

between

the

-600

sweep and

to

1400

~s

4.3

4.3.1

,

Track

Service

1.

2.

3.

4.

00

Sensor

Check

Power up

Step

inner

Check

a.

b.

Power

the

stop.

the

Track

The

between

Track

The

between 0

the

Assembly

1,

Track

the

drive.·

head/carriage

following:

00 Lamp:

voltage

00

voltage

drive

across

1.0

and

Sensor:

across

and

down

(Refer

00

1.7

0.5

Sensor

(Resets

assembly

PWB

V.

PWB

v.

and

up

to

Chapter

memo~ies

to

a

J3-A12 and G

J3-A13 and G

again.

(Resets

5,

Figure

in

PWB)

position

(GND)

(GND)

4)

near

should

should

PWB

the

be

be

memories)

5.

Check

a.

Service

1.

With power

to

2.

Power up

3.

When

move

be

4.

Move

step

of

the

Track

The

voltage

"between

Check

the

outer

power

inwards

at

Low

the

outward.

2.4

to

following:.

00

Sensor:

across

2.5

and

2,

Track

off,

the

is

level

head/carriage

5.25

move

stop.

drive.

applied,

slightly.

(0

The

v.

PWB

5.25

00

Sensor

the

the

The

to

0.4

assembly

voltage

J3-A13 and

V.

Position

head/carriage

head/carriage

Track

V).

should

00

five

change

G(GND)

Check

assembly

assembly

signal

steps

to

should

(Jl-26)

inward

a High

all

should

and one

level

be

the

way

should

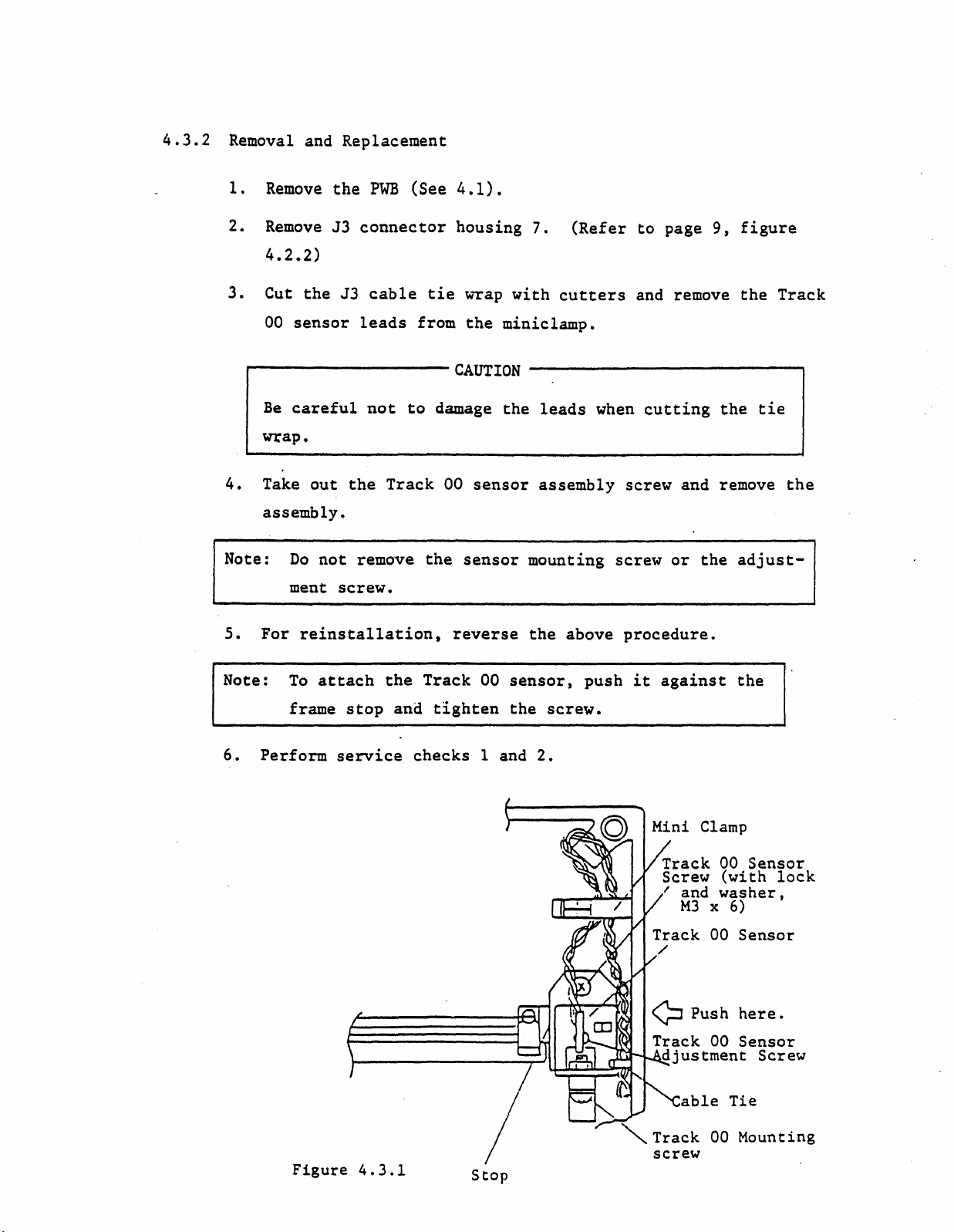

4.3.2

Removal and Replacement

1.

2.

Remove

Remove

the

PWB

J3

connector

(See

4.2.2)

3.

Cut

the

J3

00

sensor

cable

leads

tie

from

4.1).

housing

wrap

the

miniclamp•

7.

with

(Refer

cutters

to

page

9,

and remove

figure

the

Track

...----------

Be

wrap.

4.

Take

assembly.

Note:

5.

For

Note:

6.

Perform

careful

out

Do

not

ment

not

the

remove

screw.

reinstallation,

To

attach

frame

stop

service

to

Track

the

and

checks

CAUTION

damage

00

the

reverse

Track

tighten

the

sensor

sensor

00

1 and

--------------,

leads

when

assembly

mounting screw

the

above

sensor,

the

push

screw.

2.

cutting

the

screw and remove

or

the

adjust-

procedure.

it

against

the

tie

the

Figure

4.3.1

Stop

Track

Screw

I and

""

Track 00 Mounting

M3

able

00

(with

washer,

x

6)

00

Sensor

Tie

screw

Sensor

lock

4.4

Write

Protect

Sensor

(See

Chapter

5,

Figure

3)

4.4.1

Service

1.

Power up

2.

Check

a.

b.

3.

Check

withawrite

in

a.

Check

the

drive.

the

following

Write

The

between

Write

The

Protect

voltage

1.0

Protect

voltage.

between 0 and

the

following

protect

the

drive

Write

The

voltage

and

Protect

with

Lamp:

across

and

1.7

Sensor:

across

0.5

withawrite

seal

the

front

Sensor:

across

no

disk

J3-A8 and G

v.

J3-A9 and G

V.

over

J3-A9 and G

the

lever

in

the

(GND)

(GND)

protected

write

in

lock

(GND)

drive.

should

should

d~sk

protect

position.

should

be

be

(a

disk

notch)

be

4.4.2

between

Removal and

1.

Remove

2.

Remove

figure

3.

Remove

4.

5.

6.

Lift

Remove

Take

(two

the

locations)

out

and remove

2.5

and

Replac~ment

the

PWB

(See

housing

4 from

4.2.2).

the

carrier

tabs

from

and remove

the

In

Use

Lamp

the

screws

the

front

5.25

4.1).

the

cover

the

for

lever

V.

J3

connector.

screws and remove

carrier

the

the

front

and

and

write

leads.

lever,

carrier

(See page

the

protect

and

carrier

assembly.

9,

carrier

lead

cover.

clamps

assembly,

Loading...

Loading...