Page 1

欧州安全規格対応ACサーボドライブ

Σ-miniシリーズ

取扱説明書

サーボモータ SGMM

サーボパック SGDF

製品を安全にお使い頂くために,本書を必ずお読みください。

また,本書をお手元に保管していただくとともに,最終的に本製品をご使用になる

ユーザー様のお手元に確実に届けられるよう,お取り計らい願います。

AC Servo Drive Conforming to EN Standard

Σ-mini Series

INSTRUCTIONS

SGMM Servomotors

SGDF SERVOPACK

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

MANUAL NO. TOB-S800-27B

Page 2

INTRODUCTION

J Manual Contents

This manual consists of Japanese Version and English Version.

D Japanese Version: Described on pages J - 1 to J - 20.

D English Version: Described on pages E - 1 to E - 21.

Use the Japanese Version or English Version as needed.

J User Instructions

Use these instructions for the following jobs:

D Checking v-Series Servo drive on delivery

D Installing v-Series Servo drive

D Wiring v-Series Servo drive

D Operating v-Series Servo drive

D Inspecting and maintenance of v-Series Servo drive

ii

Page 3

CONTENTS

Σ SERIES AC SERVODRIVE INSTRUCTIONS E - 1..............

NOTES FOR SAFE OPERATION E - 3..................................

1 CHECKING ON DELIVERY E - 5.............................

2 LIST OF STANDARD COMBINATION E - 7...................

3 CABLE SPECIFICATIONS E - 7.............................

4 INSTALLATION E - 8.......................................

4.1 Transportation E - 8.............................................

4.2 Installing the Servomotor E - 8....................................

4.3 Installing the SERVOPACK E - 9..................................

5 WIRING E - 10..............................................

5.1 Typical Configuration E - 10.......................................

5.2 Flowchart for Peripheral Device Selection E - 12.....................

5.3 Wiring Precautions E - 15.........................................

6 OPERATION E - 16..........................................

7 INSPECTION AND MAINTENANCE E - 17.....................

7.1 Servomotor E - 17................................................

7.2 SERVOPACK E - 17..............................................

8 MEASURES TO SATISFY THE EMC DIRECTIVE E - 19.........

8.1 Applicable Servomotors E - 19.....................................

8.2 Applicable Noise Filter E - 19......................................

8.3 Applicable Power Supply E - 19....................................

8.4 Motor Cables E - 19..............................................

8.5 Encoder Cables E - 20............................................

8.6 Control I/O E - 20................................................

v

Page 4

8.7 Digital Operator and Monitoring by Personal Computer E - 20..........

8.8 Cable Core E - 20................................................

8.9 Wiring Examples E - 21...........................................

vi

Page 5

INSTRUCTIONS

Σ SERIES AC SERVODRIVE

CONTENTS

Σ SERIES AC SERVODRIVE INSTRUCTIONS E - 1

NOTES FOR SAFE OPERATION E - 3...................

1 CHECKING ON DELIVERY E - 5..............

2 LIST OF STANDARD COMBINATION E - 7.....

3 CABLE SPECIFICATIONS E - 7...............

4 INSTALLATION E - 8.........................

4.1 Transportation E - 8................................

4.2 Installing the Servomotor E - 8......................

4.3 Installing the SERVOPACK E - 9.....................

5 WIRING E - 10...............................

5.1 Typical Configuration E - 10..........................

5.2 Flowchart for Peripheral Device Selection E - 12........

5.3 Wiring Precautions E - 15............................

6 OPERATION E - 16...........................

7 INSPECTION AND MAINTENANCE E - 17.......

7.1 Servomotor E - 17..................................

7.2 SERVOPACK E - 17................................

8 MEASURES TO SATISFY THE EMC

DIRECTIVE E - 19............................

8.1 Applicable Servomotors E - 19.......................

8.2 Applicable Noise Filter E - 19.........................

8.3 Applicable Power Supply E - 19......................

8.4 Motor Cables E - 19.................................

8.5 Encoder Cables E - 20..............................

8.6 Control I/O E - 20...................................

8.7 Digital Operator and Monitoring by Personal Computer E - 20

8.8 Cable Core E - 20..................................

8.9 Wiring Examples E - 21..............................

E-1

Page 6

This instruction manual covers AC servo drive Σ series SERVOPACK.

The AC Servo Drives consist primarily of AC Servomotors and their controllers, SER-

VOPACKS.

To properly use the AC servo drive Σ series, read this manual thoroughly and retain

for easy reference for inspections and maintenance etc.

Reference materials are listed below:

Manual Titles

Σ Series SGMM/SGDF USER’S MANUAL

Digital Operator Type JUSP-OP02A-3 OPERATION MANUAL

Software for Personal Computer Monitoring OPERATION MANUAL

AC Servomotor INSTRUCTIONS

Manual No.

SIE-S800-27

TOE-S800-15.3

SIE-S800-15.5

TOE-C231-2

General Precautions

S Some drawings in this manual are shown with the protective cover or shields removed, in order to

describe the detail with more clarity. Make sure all covers and shields are replaced before operating this product.

S Some drawings in this manual are shown as typical example and may differ from the shipped

product.

S This manual may be modified when necessary because of improvement of the product, modifi-

cation or changes in specifications.

Such modification is made as a revision by renewing the manual No.

S To order a copy of this manual, if your copy has been damaged or lost, contact your YASKAWA

representative listed on the last page stating the manual No. on the front cover.

S YASKAWA is not responsible for accidents or damages due to any modification of the product

made by the user since that will void our guarantee.

E-2

Page 7

NOTES FOR SAFE OPERATION

Read this manual thoroughly before installation, operation, maintenance or inspection of the AC Servo

Drives. In this manual, the NOTES FOR SAFE OPERATION are classified as “WARNING” or “CAUTION”.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious per-

sonal injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

personal injury and/or damage to the equipment.

In some instances, items described in

follow these important items.

(WIRING)

D Grounding must be in accordance with the national code and consistent with sound local practic-

es.

Failure to observe this warning may lead to electric shock or fire.

(OPERATION)

D Never touch any rotating motor parts during operation.

Failure to observe this warning may result in personal injury.

(INSPECTION AND MAINTENANCE)

D Do not touch areas inside the SERVOPACK.

Electrical shock may result.

D After turning OFF power, wait at least five minutes before servicing the product.

Otherwise, residual electric charges may result in electric shock.

CAUTION

WARNING

may also result in a serious accident. In either case,

E-3

Page 8

CAUTION

(RECEIVING)

D Use the specified combination of Servomotor and SERVOPACK.

Failure to observe this caution may lead to fire or failure.

(STORAGE AND TRANSPORTATION)

D If disinfectants or insecticides must be used to treat packing materials such as wooden frames,

pallets, or plywood, the packing materials must be treated before the product is packaged, and

methods other than fumigation must be used.

Example: Heat treatment, where materials are kiln−dried to a core temperature of

56°C for 30 minutes or more.

Ifthe electronic products,which includestand−alone productsand productsinstalled inmachines, arepacked

with fumigated wooden materials, the electrical components may be greatly damaged by the gases or fumes

resulting from the fumigation process. In particular, disinfectants containing halogen, which includes chlorine, fluorine, bromine, or iodine can contribute to the erosion of the capacitors.

(INSTALLATION)

D Never use the equipment where it may be exposed to splashes of water, corrosive or flammable

gases, or near flammable materials.

Failure to observe this caution may lead to electric shock or fire.

(WIRING)

D Do not connect three-phase power supply to output terminals U V and W .

Failure to observe this caution may lead to personal injury or fire.

D Make sure that screws on the power supply and motor output terminals are securely tightened.

Failure to observe this caution can result in a fire.

(OPERATION)

D To avoid inadvertent accidents, run the Servomotor only in test run (without load).

Failure to observe this caution may result in personal injury.

D Before starting operation with a load connected, set up user constants suitable for the machine.

Starting operation without setting up user constants may lead to overrun failure.

D Before starting operation with a load connected, make sure emergency-stop procedures are in

place.

Failure to observe this caution may result in personal injury.

D During operation, do not touch the heat sink.

Failure to observe this caution may result in burns.

(INSPECTION AND MAINTENANCE)

D Do not disassemble the Servomotor or the SERVOPACK.

Failure to observe this caution may result in electric shock or personal injury.

D Never change wiring while power is ON.

Failure to observe this caution may result in electric shock or personal injury.

E-4

Page 9

1 CHECKING ON DELIVERY

When Σ-Series products are delivered, check the following items:

Check Items

Check if the delivered products are the

ones you ordered.

Check if the motor shaft rotates smoothly.

Check for damage.

Check screws for looseness.

If any of the above items are faulty or incorrect, contact the dealer from which you purchased

the products or your nearest local sales representative.

Remarks

Checkthetypes marked on the nameplates of Servomotor and SERVOPACK (see the table on the next page).

Ifthemotor shaft is smoothly turned by hand,itis normal. However,

if the motor has brakes, it cannot be turned manually.

Checkthe overall appearance,and check fordamage or scratches resulting from transportation.

Check for looseness by using a screwdriver as necessary.

E-5

Page 10

1CHECKING ON DELIVERY

Servomotors

Appearance

Σ-Series

SGMM Servomotor

Nameplate

Rated output

Servomotor model

Serial number

Rated speed

Rated output

current

Manufacturing

date

Type

Standard Servomotors

SGMM

−A1

C

3

1

Σ Series

SGMM Servomotor

Rated output

10 W B3:3W

:

A1

20 W B5:5W

A2

:

30 W B9:10 W

A3

:

Power supply

C: 24 VDC

S: EN safety standards, 24 VDC

Encoder specifications

2048P/R incremental encoder

3:

F: 1024 P/R incremental encoder

Design revision order

Shaft specifications

Straight without key

2

:

3

Straight with flat seat

:

Option

C

With brake (24V)

:

Servomotors with Reduction Gears

SGMM

−A1

C

3

J

Σ Series

SGMM Servomotor

Rated output

10 W

:

A1

A2

20 W

:

30 W

A3

:

Power supply

C: 24 VDC

S: EN safety standards, 24 VDC

Encoder specifications

2048P/R incremental encoder

3:

With reduction gear

Deceleration rate

A: 1/5

B: 1/16

C: 1/25

Shaft specifications

Straight without key

2

:

Straight with flat seat

3

:

Option

C

With brake (24V)

:

2

j

1

2

j

SERVOPACKS

SGDFA1CS

DC24V

SERVOPACK

CN3

RDY

ALM

CN4

CN2/PG

CN1/IO

Σ-Series SGDF

SERVOPACK

C

N

5

SERVOPACK model

1.2

Serial number

Applicable

power supply

AC-OUTPUT

Applicable

motor capacity

SGDF

Σ Series

SGDF SERVOPACK

Rated output

10 W B3:3W

A1

:

A2

20 W B5:5W

:

A3

30 W B9:10 W

:

Power supply

C: 24 VDC

Type

S: Speed/torque control

P: Position control

− A1

C

S

E-6

Page 11

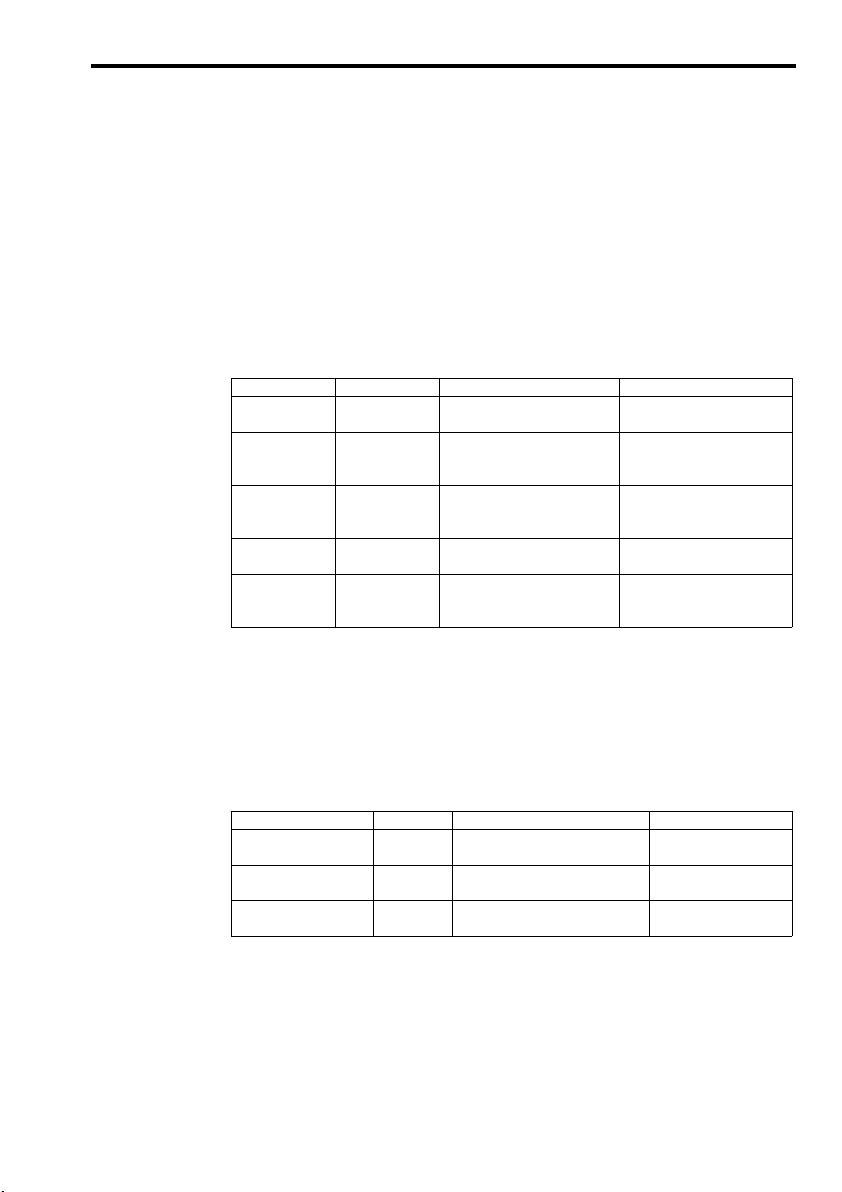

2 LIST OF STANDARD COMBINATION

W

A

to

Combination of SERVOPACK, Servomotor and Accessories

SERVOPACK

Type

SGDF-

10 W

20 W

30 W

3W

5W

10W

A1Cj

A2Cj

A3Cj

B3Cj

B3Cj

B3Cj

Applicable

Servomotor

SGMM-A1jj

SGMM-A2jj

SGMM-A3jj

SGMM-A3jj

SGMM-A3jj

SGMM-A3jj

* 1 Values at rated load.

* 2 Braking characteristics at 25

* 3 Yaskawa recommends noise filter manufactured by Tokin Corp. Contact Yaskawasales representa-

tive.

* 4 Power supply capacity required for maximum load.

Power Supply

Capacity per

SERVOPACK*

W

28

MCCB or

1

Capacity *

5

Fuse

A

42

60

22

24

30

°C : 200% for 2s or above, 700% for 0.01s

2

LF-205A

3 CABLE SPECIFICATIONS

The rated current and cable size of the SERVOPACK external terminals are shown in below.

Select cable specifications and size according to the operating environment and current capac-

ity.

SERVOPACK

Type

SGDF-

A1Cj

A2Cj

A3Cj

B3Cj

B5Cj

B9Cj

Main Circuit Power Input Terminal*

24VDC, GND,

Rated Current

(Arms)

1.2

Cable Spec.

(mm

0.5 min.

1.7

2.3

0.9

1.0

1.2

Recommended Noise

Type

Filter*

3

Spec.

Single-phase

200V, 5A

or above.

1

Motor Connection Terminals*

2

)

Rated Current

(Arms)

2.1

2.0

2.9

1.3

1.3

1.9

Magnetic

Contactor

HI-11J

(20A)or

equivalent

U, V, W,

2

*

Power

Supply

Capacity

to

SERVOPACK *

W

220

300

130

140

Cable Spec

2

)

(mm

4

1

* 1 The cable specifications are selected under conditions of three cables per bundle at 40°C ambient

temperature, with the rated current flowing.

* 2 Be sure to use Yaskawacables. For details, refer to 5.2 “Flowchart for Peripheral Device Selection”.

E-7

Page 12

4INSTALLATION

4 INSTALLATION

4.1 Transportation

4.2 Installing the Servomotor

J Installation direction

J Precautions for installation

J Installation sites:

D Do not lift or carry the Servomotor by the (encoder and/or motor) cables.

It may break the wire.

D Gently place the Servomotor when installing.

AC Servomotor can be installed either horizontally or vertically.

This is a precision equipment, therefore, avoid impacts

on motor or output shaft.

The Servomotor is designed for indoor use. Install Servomotor in an environment which meets

the following conditions:

D Free from corrosive and explosive gases

D Well-ventilated and free from dust and moisture

D Ambient temperature of 0 to 40°C

D Relative humidity of 20% to 80% (non-condensing)

D Inspection and cleaning can be performed easily

E-8

Page 13

Installing the SERVOPACK

3

4.

J Installation direction

D Mount the unit vertically on wall using the mounting holes on the baseplate, with main ter-

minals at the bottom.

D Since SERVOPACK is a self-cooling unit, supply enough space for cooling.

D If SERVOPACKS are mounted side by side, temperature may rise because of the uneven

temperature inside the panel. Therefore, provide a fan/fans above the SERVOPACK blow-

ing down on the units.

4.3 Installing the SERVOPACK

Fan 50 mm or more

30 mm

10 mm

or more

or more

J Installation sites:

Situation

When installed in a control panel

When installed near a heating unit

When installed near a source of vibration

Wheninstalled in aplacereceiving corrosive gases

Others

Fan

50 mm or more

Notes on Installation

Design the control panel size, unit layout, and cooling method so

that the temperature around the periphery of the SERVOPACK

does not exceed 50

Suppress radiation heat from the heating unit and a temperature

rise caused by convection so that the temperature around the periphery of the SERVOPACK does not exceed 50°C.

Install a vibration isolator underneath the SERVOPACK to prevent it from receiving vibration.

Corrosive gases do not immediately affect the SERVOPACK but

will eventually cause contactor-related devices to malfunction.

Take appropriate action to prevent corrosive gases.

Avoidinstallation inahot and humid place orwhereexcessive dust

or iron powder is present in the air.

°C.

40°C or below is preferable to maintain the reliability over a long period.

E-9

Page 14

5WIRING

5 WIRING

5.1 Typical Configuration

Before wiring, turn OFF the power ON/OFF switch and post a notice of“No Conduction.” Only an

electrical expert can perform the wiring.

E-10

Page 15

5.1 Typical Configuration

Molded-case circuit

breaker (MCCB)

Used to protect

power supply line.

Shuts the circuit

OFF when

overcurrent is

detected.

Noise filter

Used to eliminate external

noise from power supply line.

Magnetic contactor

Turns the Servo

ON or OFF.

Use a surge

suppressor for

the magnetic

contactor.

Model:

HI-Series

Molded-case

circuit breaker

Noise

filter

Power supply:

Single-phase

200 or 100 VAC

Host controller

The SGDF Servopack can be

used with most host controllers.

MEMOCON GL120/GL130 PLC

with Motion Control Module

Digital Operator

Personal computer

Connecting cable: JZSP-CFS01 to 03

Encoder cable

Allows the user to

set user constants

or operation

references and

display operation

status or alarm

status. Personal

computers can also

be used.

JUSP-OP02A-3

AC/DC power supply

Supplies Servopack

with 24 VDC.

Magnetic

contactor

AC/DC

power

supply

Power supply

ground line

Motor cable

E-11

Page 16

5WIRING

5.2 Flowchart for Peripheral Device Selection

Peripheral Device Selection Flowchart

Start peripheral device

selection

1) Select motor cables

SGMM-AjC/

SGMM-BjC

SGMM-AjC

Without brake/

With brake?

Without brake

With connector at

both ends/Cable only?

With connector at both ends

Select one of the following

according to cable length.

1m

→ JZSP-CFM00-01

3m→ JZSP-CFM00-03

5m→ JZSP-CFM00-05

SGMM-BjC

Select one of the following

according to cable length.

1m→ JZSP-CFM09-01

3m→ JZSP-CFM09-03

5m→ JZSP-CFM09-05

Select connector kit.

Servo side:

JZSP-CFM9-1

Motor side:

JZSP-CFM9-2

With connector at

both ends/Cable only?

Select one of the following

according to cable length.

1m→ JZSP-CFM01-01

3m→ JZSP-CFM01-03

5m→ JZSP-CFM01-05

With brake

With connector at

both ends/Cable only?

Cable only

Select one of the following

according to cable length.

1m→ JZSP-CFM10-01

3m→ JZSP-CFM10-03

5m→ JZSP-CFM10-05

With connector at both ends Cable only

Select one of the following

according to cable length.

1m→ JZSP-CFM09-01

3m→ JZSP-CFM09-03

5m→ JZSP-CFM09-05

With connector at both ends

Cable only

Select one of the following

according to cable length.

1m→ JZSP-CFM19-01

3m→ JZSP-CFM19-03

5m→ JZSP-CFM19-05

Select connector kit.

Servo side:

JZSP-CFM9-1

Motor side:

JZSP-CFM9-3

E-12

Select connector kit.

Servo side:

JZSP-CFM9-1

Motor side:

JZSP-CFM9-4

Page 17

2) Select encoder cable

SGMM-AjC

Select one of the following

according to cable length.

JZSP-CFP00-01

1m

3m

JZSP-CFP00-03

5m

JZSP-CFP00-05

Connector

at both ends

SGMM-AjC/

SGMM-BjC

SGMM-BjC

Select one of the following

according to cable length.

1m

3m

5m

Connector

at both

ends

JZSP-CFP01-01

JZSP-CFP01-03

JZSP-CFP01-05

Standard

Specifications/

European

Specifications

Standard

Specifications

Servopack

end with

connector

Servopack end

with connector

Select one of the following

according to cable length.

1m

3m

5m

5.2 Flowchart for Peripheral Device Selection

Select according to details provided

in 8.5 Encoder Cables.

Cable

//

only

Cable only

Select one of the following

according to cable length.

JZSP-CFP09-01

JZSP-VFP10-01

JZSP-VFP10-03

JZSP-VFP10-05

1m

3m

5m

JZSP-CFP09-03

JZSP-CFP09-05

EN

standard

Select connector kit

for motor side.

SGMM-AjC:

JZSP-CFP9-1

SGMM-BjC:

JZSP-CFP9-2

E-13

Select connector kit.

¯ Servopack side

JZSP-VFP9

¯ Motor side

SGMM-AjC:

JZSP-CFP9-1

SGMM-BjC:

JZSP-CFP9-2

Page 18

5WIRING

3) Select CN1 connector for

reference input.

Connector kit /

One cable end without connector

Connector kit One cable end

Connector kit

JZSP-VFP9

4) Select connector kit for power

supply:

5) Select SERVOPACK power supply

Power supply: 220 W min.

6) Select power supply circuit

breaker (MCCB) and noise filter

Capacity: 3 A

7) Use a magnetic contactor and

surge suppressor

JZSP-CFG9

End peripheral device selection

without connector

Cable with CN1

connector and one end

without connector

1m

JZSP-VFI01-01

3m

JZSP-VFI01-03

E-14

Page 19

5.3 Wiring Precautions

J Grounding wire

D In conformance with local electrical codes, ground the SERVOPACK’ s grounding terminal

.

D Be sure to connect the grounding wire of the Servomotor to

D Never share the grounding cable or grounding rod with welders, power equipment, or other

high-voltage devices. Separate the grounding cable from wiring of high-voltage equip-

ments.

D Make the grounding wire as short as possible. As for cable size, see Par. 3.

D If two or more SERVOPACKS are used, ground them as shown in (a) below.

Avoid methods (b) and (c).

5.3 Wiring Precautions

of the SERVOPACK.

GOOD

(a)

POOR

(b)

POOR

(c)

J Power supply

D Supply 24VDC for power supply.

D Do not connect three-phase power to output terminals U V W.Failure to observe this caution

may damage the SERVOPACK.

D Take care to prevent power line wiring or output wiring from touching or being enclosed

inside the case.

J Noise control

D If the speed signal line is affected by noise, malfunction may result.

• Separate power cables from control cables.

• Make the speed signal line as short as possible and use twisted-pair wires.

D Never use a noise filter (for power input) for motor circuit. If peripheral devices malfunc-

tion due to the noise from SERVOPACK, insert a noise filter (for output, type LF-310KA,

made by Tokin Corp.) between motor and SERVOPACK.

E-15

Page 20

6OPERATION

6 OPERATION

J Conducting test run for Servomotor without load

When Servomotor is operated without load, set the speed loop gain (user constant Cn-04) to

40 or less. (Factory setting is 80)

Speed loop gain(user constant Cn-04) is determined by the following conditions:

Load inertia ≥motor inertia ×3

Therefore, when motor is rotated without load (without load inertia) or load inertia is small,

if the value has been kept at the factory setting, the motor may oscillate.

To avoid this, make sure to set the value of Cn-04 (speed loop gain) to 40 or less and then servo

ON.

J Conducting test run with Servomotor connected to machine

SERVOPACK initial user constants setting is performed supposing the normal operation

conditions.

Before test run, set up user constants suitable for the machine.

Failure to set up the user constants initial setting may result in machine overrun or breakdown.

As for the setting procedures and methods, refer to “Digital Operator Operation

Manual.”

J Check items during test run

The following items should be checked during the test run.

D Unusual vibration

D Abnormal noise

D Excessive temperature rise

E-16

Page 21

7 INSPECTION AND MAINTENANCE

7.1 Servomotor

For inspection and maintenance of Servomotors, follow the simple, daily inspection procedures in

the table below.

The AC Servomotors are brushless. Simple, daily inspection is sufficient. The inspection and main-

tenance frequencies in the table are only guidelines. Increase or decrease the frequency to suit the

operating conditions and environment.

7.1 Servomotor

Item

Vibration and

noise

Appearance

Insulation resistance measurement

Replace oil seal

Overhaul

* Measure across the Servomotor FG (Green/Yellow) and the U-phase (Red), V-phase (White), or

W-phase (Blue) power lead.

7.2 SERVOPACK

The SERVOPACK contains highly reliable parts and daily inspection is not required. Carry out the

inspections and maintenance in the table below once every year.

Item

Clean unit interior and circuit boards

Loose screws

Defective parts in unit or

on circuit boards.

Frequency

Daily

According to degree of contamination

At least once a

year

At least once every 5,000 hours

At least once every 20,000 hours

or 5 years

Frequency

At least once

a year

At least once

a year

At least once

a year

Procedure

Touch and listen.

Clean with cloth or compressed

air.

Disconnect SERVOPACK and

test insulation resistance at 500 V.

Must exceed 10 MΩ.*

Remove servomotor from machine and replace oil seal.

Contact your YASKAWA representative.

Procedure

Check for dust, dirt, and oil on the surfaces.

Check for loose terminal block and

connector screws.

Check for discoloration, damage or

discontinuities due to heating.

Comments

Levels higher than normal?

Contact your YASKAWA representative if the insulation resistance is below 10 MΩ.

Applies only to motors with oil

seal.

The customer should not disassemble and clean the Servomotor.

Remedy

Cleanwith compressedair.

Tighten any loose screws.

Contact your YASKAWA

representative.

E-17

Page 22

7INSPECTION AND MAINTENANCE

J Part replacement schedule

The following parts are subject to mechanical wear or deterioration over time. To avoid failure,

replace these parts at the frequency indicated.

Part

Smoothing Capacitor

Relays

Fuse

Electrolytic Capacitor on

Circuit Board

Note: Operating Conditions:

Ambient Temperature: annual average 30

Load Factor: 80% max.

Operation Rate: 20 hours/day max.

Standard Replacement

Period

7 to 8 years

---

10 years

5 years

°C

Replacement Method

Test. Replace with new part if necessary.

Test. Replace if necessary.

Replace with new part.

Test. Replace with new part if necessary.

E-18

Page 23

8.1 Applicable Servomotors

8 MEASURES TO SATISFY THE EMC DIRECTIVE

This section describes the measures required for SERVOPACKS to conform to EMC Directive

(EN55011, EN50082-2).

8.1 Applicable Servomotors

Use a Yaskawa Servomotor conforming to EN standards.

D Servomotor Models: SGMM-A1S312 (10 W)

SGMM-A2S312 (20 W)

SGMM-A3S312 (30 W)

8.2 Applicable Noise Filter

Use the following noise filter.

Make sure to ground the noise filter properly.

Model

Manufacturer

8.3 Applicable Power Supply

Use a power supply conforming to EN standards.

Make sure to ground the power supply properly.

Recommended power supply is as follows:

Model

Manufacturer

8.4 Motor Cables

The maximum cable length is 5 m (16.7 feet).

MYB-1206-33

NEMIC-LAMBDA K.K

PLEY24HSZ-PU

ETA ELECTRIC IND. Co., Ltd

E-19

Page 24

8MEASURES TO SATISFY THE EMC DIRECTIVE

8.5 Encoder Cables

Use an encoder cable with connector at both ends.

The maximum cable length is 5 m (16.7 feet). Select one of the following according to

cable length.

1 m: JZSP-VFP00-01

3 m: JZSP-VFP00-03

5 m: JZSP-VFP00-05

8.6 Control I/O

Use cables with CN1 connectors for control I/O. When using connector kits, use shielded

cable for the CN1 cable and make sure to ground between the cable shield and connector

case. Connect the shield at the host controller properly.

8.7 Digital Operator and Monitoring by Personal Computer

Use the Digital Operator or personal computer (for monitoring) for trial operation only.

Disconnect them during normal operation.

8.8 Cable Core

Model

Manufacturer

ESD-SR-25

Tokin Corp.

The cable line and line position where the core is attached is as follows:

Cable Line

Line Position

Encoder Line

Servopack end

Motor end

E-20

Servopack end

Motor Line

Page 25

8.9 Wiring Examples

The following diagram shows the wiring conditions conforming to EMC Directive. The

noise filter and the core are shown in the diagram.

8.9 Wiring Examples

Earth Plate/Shield Box

Power Supply

200 VAC

Single-phase

FG

2 m (78.7 in)

Power Supply

Noise

Filter

Clamp

Clamps: Fix and ground the cable shield using a piece of conductive metal.

AC/DC

Output: 24 VDC

Symbol

1

2

3

4

5

Controller cable

Motor cable

Encoder cable

AC Line cable

DC Line cable

SERVOPACK

24 VDC

, GND

FG

Name

SGDF-

CN1

Clamp

Controller

U, V, W

CN2

Core

ClampClamp

Core

Core

5 m (196.8 in)

Specification

Shield cable (0.5 m) (19.6 in)

Shield cable (5 m) (196.8 in)

Shield cable (5 m) (196.8 in)

Shield cable (2 m) (78.7 in)

Shield cable (0.5 m) (19.6 in)

Servomotor

SGMN-

Motor

Encoder

E-21

Page 26

AC Servo Drive Conforming to EN Standard

Σ-mini Series

INSTRUCTIONS

IRUMA BUSINESS CENTER (SOLUTION CENTER)

480, Kamifujisawa, Iruma, Saitama 358-8555, Japan

Phone 81-4-2962-5151 Fax 81-4-2962-6138

http://www.yaskawa.co.jp

YASKAWA AMERICA, INC.

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone 1-800-YASKAWA (927-5292) or 1-847-887-7000 Fax 1-847-887-7310

http://www.yaskawa.com

YASKAWA ELÉTRICO DO BRASIL LTDA.

Avenida Piraporinha 777, Diadema, São Paulo, 09950-000, Brasil

Phone 55-11-3585-1100 Fax 55-11-3585-1187

http://www.yaskawa.com.br

YASKAWA EUROPE GmbH

Hauptstraβe 185, Eschborn 65760, Germany

Phone 49-6196-569-300 Fax 49-6196-569-398

http://www.yaskawa.eu.com

YASKAWA ELECTRIC KOREA CORPORATION

9F, Kyobo Securities Bldg. 26-4, Yeouido-dong, Yeongdeungpo-gu, Seoul, 150-737, Korea

Phone 82-2-784-7844 Fax 82-2-784-8495

http://www.yaskawa.co.kr

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

151 Lorong Chuan, #04-02A, New Tech Park 556741, Singapore

Phone 65-6282-3003 Fax 65-6289-3003

http://www.yaskawa.com.sg

YASKAWA ELECTRIC (CHINA) CO., LTD.

12F, Carlton Bld., No.21 HuangHe Road, HuangPu District, Shanghai 200003, China

Phone 86-21-5385-2200 Fax 86-21-5385-3299

http://www.yaskawa.com.cn

YASKAWA ELECTRIC (CHINA) CO., LTD. BEIJING OFFICE

Room 1011, Tower W3 Oriental Plaza, No.1 East Chang An Ave.,

Dong Cheng District, Beijing 100738, China

Phone 86-10-8518-4086 Fax 86-10-8518-4082

YASKAWA ELECTRIC TAIWAN CORPORATION

9F, 16, Nanking E. Rd., Sec. 3, Taipei 104, Taiwan

Phone 886-2-2502-5003 Fax 886-2-2505-1280

YASKAWA ELECTRIC CORPORATION

In the event that the end user of this product is to be the military and said product is to be employed in any weapons systems or the manufacture

thereof, the export will fall under the relevant regulations as stipulated in the Foreign Exchange and Foreign Trade Regulations. Therefore, be sure to

follow all procedures and submit all relevant documentation according to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications and improvements.

© 1999-2014 YASKAWA ELECTRIC CORPORATION. All rights reserved.

MANUAL NO. TOB-S800-27B

Published in Japan February 2014 99-2

13-6-9

15

-0

Loading...

Loading...