Page 1

ACサーボパック

Σ-IIシリーズ

取扱説明書

MECHATROLINKインタフェースモジュール

形式:JUSP-NS100

対象サーボパック形式:SGDH-E-

製品を安全にお使い頂くために,本書を必ずお読みください。

また,本書をお手元に保管していただくとともに,最終的に本製品をご使用になる

ユーザー様のお手元に確実に届けられるよう,お取り計らい願います。

AC SERVOPACK

Σ-II Series

INSTRUCTIONS

MECHATROLINK Interface Module

Model: JUSP-NS100

Applicable SERVOPACK Model: SGDH-E-

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

MANUAL NO. TOB-C718-4C

Page 2

Copyright © 2001

本書の内容の一部または全部を,当社の文書による許可なしに,転載または複製する

ことは,固くお断りします。

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is

constantly striving to improve its high-quality products, the information contained in this

manual is subject to change without notice. Every precaution has been taken in the preparation

of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained

in this publication.

株式会社 安川電機

YASKAWA ELECTRIC CORPORATION

Page 3

はじめに

■ 本書の構成

この取扱説明書は,日本語編と英語編で構成しています。

•

日本語編: J-1 ページ ~ J-25 ページに掲載

•

英語編: E-1 ページ ~ E-25 ページに掲載

必要に応じて,ご活用ください。

■ 本書の対象読者

本書は下記の方々を対象読者としています。

•

Σ-II シリーズ サーボパックの到着時の点検を行う方

•

Σ-II シリーズ サーボパックの盤組み込みや配線を行う方

•

Σ-II シリーズ サーボパックの操作や運転を行う方

•

Σ-II シリーズ サーボパックの保守や点検を行う方

INTRODUCTION

Manual Contents

■

This manual consists of Japanese Version and English Version.

• Japanese Version: Described on pages J-1 to J-25.

• English Version: Described on pages E-1 to E-25.

Use the Japanese Version or English Version as needed.

User Instructions

■

Use these instructions for the following jobs:

•

Checking Σ-II Series SERVOPACK on delivery

•

Installing Σ-II Series SERVOPACK

•

Wiring Σ-II Series SERVOPACK

•

Operating Σ-II Series SERVOPACK

•

Inspecting and maintenance of Σ-II Series SERVOPACK

iii

Page 4

CONTENTS

Σ-II Series

MECHATROLINK Interface Module - - - - - - - - - - - - - - E-1

SYMBOLS FOR SAFE OPERATION

NOTES FOR SAFE OPERATION

- - - - - - - - - - - - - - - - - - - - - - - E-4

- - - - - - - - - - - - - - - - - - - - - - - - - E-4

1

2

3

4

5

6

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-8

PAR TS

CHECKING ON DELIVERY

2.1

Checking Items

2.2

Appearance and Nameplate

2.3

Type Designation

2.4

Mounting NS100 Module

INSTALLATION

3.1

Storage

3.2

Installation Sites

3.3

Orientation

3.4

Installation Precations

WIRING

4.1

MECHATROLINK Connection Example

4.2

Precautions on Wiring

OPERATION

5.1

Precautions at Test Run

5.2

Precautions at Operation

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-14

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-14

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-15

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-17

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-20

- - - - - - - - - - - - - - - - - - - - - - - E-9

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-10

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-11

- - - - - - - - - - - - - - - - - - - - - - - - - E-11

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-15

- - - - - - - - - - - - - - - - - - - - - - - - - - - E-16

- - - - - - - - - - - - - - - - - - - - - - - - - - - E-19

- - - - - - - - - - - - - - - - - - - - - - - - - E-20

- - - - - - - - - - - - - - - - - - - - - - - - E-21

INSPECTION AND MAINTENANCE

- - - - - - - - - - - - - - - - - - - - - - E-10

- - - - - - - - - - - - - - E-18

- - - - - - - - - - - - - - - - E-22

7

MEASURES TO SATISFY THE EMC DIRECTIVE

7.1

MECHATROLINK Communication Cable

7.2

Fully Closed Encoder Cable

7.3

The Core on the Cable

7.4

Cable Clamp

7.5

Wiring Examples

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-24

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-25

v

- - - - - - - - - - - - - - - - - - - - - - E-23

- - - - - - - - - - - - - - - - - - - - - - - - - - E-23

- - - - - - E-23

- - - - - - - - - - - - - E-23

Page 5

INSTRUCTIONS

Series

Σ-II

MECHATROLINK Interface Module

Σ-II Series MECHATROLINK Interface Module

SYMBOLS FOR SAFE OPERATION

NOTES FOR SAFE OPERATION

1

2

3

4

5

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-8

PAR TS

CHECKING ON DELIVERY

2.1

Checking Items

2.2

Appearance and Nameplate

2.3

Type Designation

2.4

Mounting NS100 Module

INSTALLATION

3.1

Storage

3.2

Installation Sites

3.3

Orientation

3.4

Installation Precations

WIRING

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-17

4.1

MECHATROLINK Connection Example

4.2

Precautions on Wiring

OPERATION

5.1

Precautions at Test Run

5.2

Precautions at Operation

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-10

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-11

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-14

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-14

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-15

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-15

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-20

- - - - - - - - - - - - - - - - - - - - - - - E-9

- - - - - - - - - - - - - - - - - - - - - - - - - E-11

- - - - - - - - - - - - - - - - - - - - - - - - - - - E-16

- - - - - - - - - - - - - - - - - - - - - - - - - - - E-19

- - - - - - - - - - - - - - - - - - - - - - - - - E-20

- - - - - - - - - - - - - - - - - - - - - - - - E-21

- - - - - - - - - - - - - - - - - - - - - - - E-4

- - - - - - - - - - - - - - - - - - - - - - - - - E-4

- - - - - - - - - - - - - - - - - - - - - - E-10

- - - - - - - - - - - - - - E-18

- - - - - - - - - - - E-1

6

INSPECTION AND MAINTENANCE

E-1

- - - - - - - - - - - - - - - - E-22

Page 6

7

MEASURES TO SATISFY THE EMC DIRECTIVE

7.1

MECHATROLINK Communication Cable

7.2

Fully Closed Encoder Cable

7.3

The Core on the Cable

7.4

Cable Clamp

7.5

Wiring Examples

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-24

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-25

- - - - - - - - - - - - - - - - - - - - - - E-23

- - - - - - - - - - - - - - - - - - - - - - - - - - E-23

- - - - - - E-23

- - - - - - - - - - - - - E-23

E-2

Page 7

This instruction manual covers Σ-II series SGDH MECHATROLINK Interface Module

(hereinafter called NS100 Module), which is an application module to be connected to Σ-II

series SGDH SERVOPACK for MECHATROLINK.

To properly use the application module, read this manual thoroughly and retain for easy ref-

erence for inspections and maintenance etc.

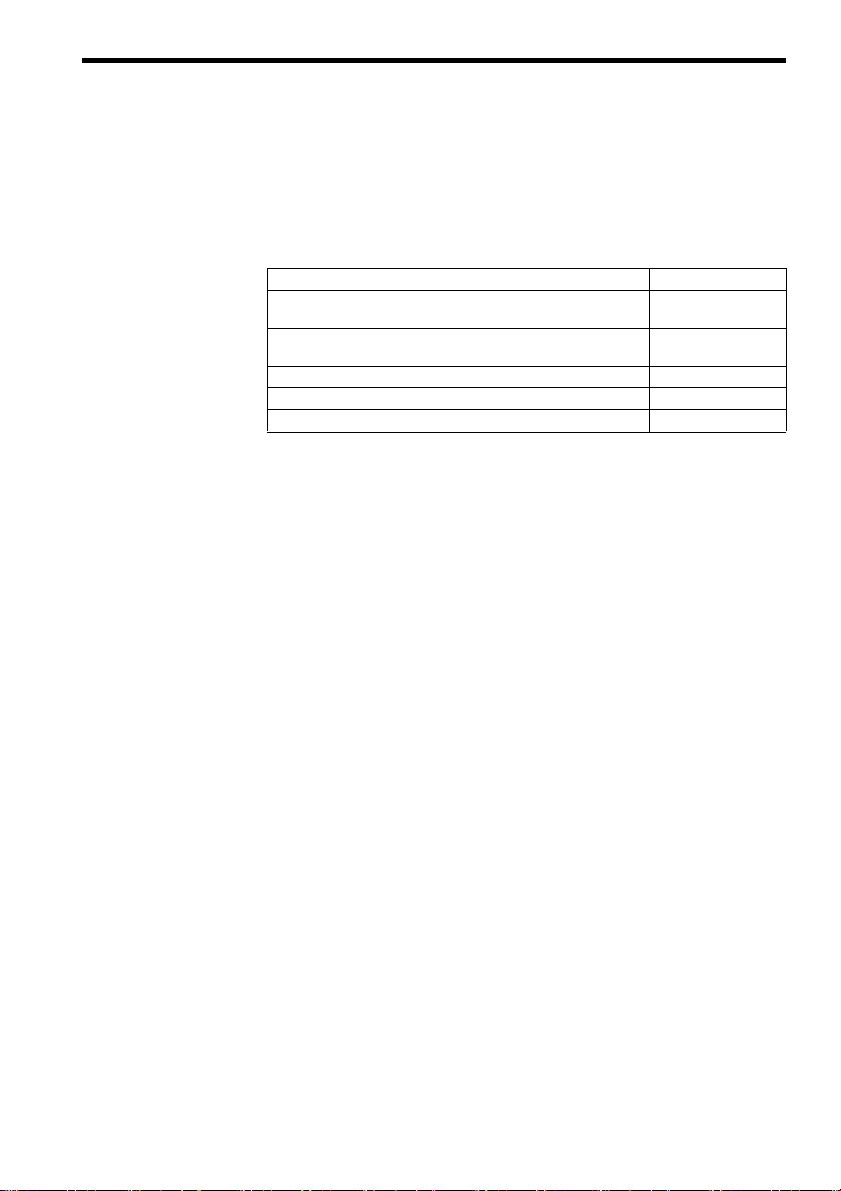

Reference materials are listed below:

Manual Titles manual No.

Σ-II series SGMH/SGDH User’s Manual

Servo Selection and Data Sheets

Σ-II series SGMH/SGDH User’s Manual

Design and Maintenance

Σ-II series SGDH MECHATROLINK Interface Module User’s Manual SIE-C718-4

AC SERVOMOTOR INSTRUCTIONS TOE-C231-2

Σ-II series SGDH Instruction Manual TOB-S800-32

SIE-S800-32.1

SIE-S800-32.2

E-3

Page 8

SYMBOLS FOR SAFE OPERATION

In this manual, the NOTES FOR SAFE OPERATION are classified as “WARNING” or

“CAUTION”. The following symbols are used.

WARNING

CAUTION

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious personal injury.

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate personal injury and/or damage to the equipment.

In some instances, items described in may also result in a serious accident.

In either case, follow these important items.

NOTES FOR SAFE OPERATION

Read this manual thoroughly before installation, operation, maintenance or inspection of the

AC Servo Drives.

CHECKING ON DELIVERY

• Do not apply or use the NS100 Module in conjunction with SGDH SERVOPACK

version 12.

There is a potential for an unintended servomotor brake release with the NS100 Module in

connection with the SGDH SERVOPACK version 12 and in connection with Σ-II motors

with holding brakes.

AN UNINTENDED RELEASE COULD RESULT IN INJURY TO PERSONS OR

EQUIPMENT IN CLOSE PROXIMITY TO ANY MECHINERY CONTROLLED BY

THE SERVO SYSTEM.

IN CLOSE PROXIMITY TO ANY MACHINERY CONTROLLED BY THE SERVO

SYSTEM.

In this product combination the motor holding brake will release 3 seconds after power is

supplied to the SGDH SERVOPACK even though the SERVOPACK is disabled (SERVO

ON signal is OFF).

CAUTION

WARNING

(Ref.No.)

E-9

E-4

Page 9

CAUTION

• There is a limitation in the combination of the software version of the SGDH SER-

VOPACK and the software version of the NS100 Module.

When the software version of the SGDH SERVOPACK is 11 or lower: Applicable to

all the versions of the NS100

When the software version of the SGDH SERVOPACK is 12 or higher: Applicable

to version 7 or higher of the NS100

When the wrong combination is used, an alarm A.BF SYSTEM ERROR (operation error)

may occur.

• When SGDH SERVOPACK is used with a NS100 Module mounted, the parame-

ters are automatically set so that the NS100 Module can be operated from the first

power ON.

For details of parameter setting methods, refer to Σ-II Series SGM/SGDH User’s Manual

Desine and Maintenance (SIE-S800-32.2).

INSTALLATION

CAUTION

• Never use the equipment where it may be exposed to splashes of water, corrosive

or flammable gases, or near flammable materials.

Failure to observe this caution may result in electric shock or fire.

WIRING

WARNING

• SERVOPACK grounding must be in accordance with the national code and consis-

tent with sound local practices.

Failure to observe this warning may result in electric shock or fire.

(Ref.No.)

E-9

E-10

(Ref.No.)

E-14

(Ref.No.)

E-17

CAUTION

• Do not connect three-phase power supply to SERVOPACK output terminals U, V,

and W.

Failure to observe this caution may lead to personal injury or fire.

• Securely tighten screws on the power supply and motor output terminals.

Failure to observe this caution may result in a fire.

E-5

(Ref.No.)

E-17

E-17

Page 10

OPERATION

CAUTION

• To avoid inadvertent accidents, run the servomotor only in test run (without load).

Failure to observe this caution may result in personal injury.

• Before starting operation with a load connected, set up parameters suitable for the

machine.

Starting operation without setting up parameters may result in machine overrun or failure.

• Before starting operation with a load connected, make sure emergency-stop proce-

dures are in place.

Failure to observe this caution may result in personal injury.

• During operation, do not touch the SERVOPACK’S heatsink.

Failure to observe this caution may result in burns.

INSPECTION AND MAINTENANCE

WARNING

• Never touch the inside of the SERVOPACKs.

Failure to observe this warning may result in electric shock.

• Never open the terminal cover while power is ON, and never turn ON power when

the terminal cover is open.

Failure to observe this warning may result in electric shock.

• After turning OFF power, wait at least five minutes before servicing the product.

Otherwise, residual electric charges may result in electric shock.

(Ref.No.)

E-20

E-20

E-20

E-21

(Ref.No.)

E-22

E-22

E-22

CAUTION

• Never change wiring while power is ON.

Failure to observe this caution may result in electric shock or personal injury.

E-6

(Ref.No.)

E-22

Page 11

General Precautions

Note the following to ensure safe application.

• Some drawings in this manual are shown with the protective cover or shields removed, in order to

describe the detail with more clarity. Make sure all covers and shields are replaced before operating this

product.

• Some drawings in this manual are shown as typical example and may differ from the shipped

product.

• This manual may be modified when necessary because of improvement of the product, modification or

changes in specifications.

Such modification is made as a revision by renewing the manual No.

• To order a copy of this manual, if your copy has been damaged or lost, contact your YASKAWA representative listed on the last page stating the manual No. on the front cover.

• YASKAWA is not responsible for accidents or damages due to any modification of the product made by

the user since that will void our guarantee.

WARNING LABEL

NS100

5

S

W

1

A

R

S

W

2

C

N

6

A

SERVOPACK warning label position

Disconnect all power and wait 5 min.

WARNING

before servcing. May cause electric shock.

Do not touch heat sink when power is ON.

CAUTION

May cause burn.

Use proper grounding techniques.

YASKAWA

SERVOPACK

SGDH- 200 V

C

N

6

B

C

N

4

SERVOPACK Warning Label and Grounding Mark Position

E-7

Page 12

1 PARTS

The NS100 Module parts names are as follows:

NS100

S

W

1

A

R

S

W

2

C

A

6

A

C

A

6

B

C

A

4

Ground wire for connecting to SERVOPACK

Rotary switch (SW1) for MECHATROLINK station

address settings

LED (A) for alarm

LED (R) for MECHATROLINK communication

DIP switch (SW2) for MECHATROLINK

communication settings

Nameplate with operation module type and serial

No.

MECHATROLINK communication connectors

(CN6A and CN6B)

Fully closed encoder signal connector (CN4)

E-8

Page 13

2 CHECKING ON DELIVERY

• Do not apply or use the NS100 Module in conjunction with the SGDH NS100 SERVOPACK

version 12.

There is a potential for an unintended servomotor brake release with the NS100 Module in connection

with the SGDH SERVOPACK version 12 and in connection with Σ-II motors with holding brakes.

AN UNINTENDED RELEASE COULD RESULT IN INJURY TO PERSONS OR EQUIPMENT IN

CLOSE PROXIMITY TO ANY MECHINERY CONTROLLED BY THE SERVO SYSTEM.

IN CLOSE PROXIMITY TO ANY MACHINERY CONTROLLED BY THE SERVO SYSTEM.

In this product combination the motor holding brake will release 3 seconds after power is supplied to the

SGDH SERVOPACK even though the SERVOPACK is disabled (SERVO ON signal is OFF).

Note: The brake release above occurs only when the software version 12 of

the SGDH SERVOPACK and any versions of the NS100 Module are

used together. It does not occur when only the SGDH SERVOPACK

is used or is used with any application modules other than the NS100

Module.

Check the software version of the SGDH SERVOPACK on the front

face underneath the model number or in the parameter Fn012.

Version tool:

∗∗∗ 12

Monitor mode: Fn012.

2

WARNING

The lower two digits of the software version

CHECKING ON DELIVERY

CAUTION

• There is a limitation in the combination of the software version of the SGDH SERVOPACK and

the software version of the NS100 Module.

When the software version of the SGDH SERVOPACK is 11 or lower: Applicable to all the ver-

sions of the NS100 Module

When the software version of the SGDH SERVOPACK is 12 or higher: Applicable to version 7

or higher of the NS100 Module

When the wrong combination is used, an alarm A.BF SYSTEM ERROR (operation error) may occur.

Note: Check the software version as follows:

Software version of the SGDH SERVOPACK: Lower two digit of the

version tool

Software version of the NS100 Module: Lower two digits of the version number in the nameplate

E-9

∗∗∗ 12

∗∗∗ 07

Page 14

• When SGDH SERVOPACK is used with a NS100 Module mounted, the parameters are auto-

matically set so that the NS100 Module can be operated from the first power ON.

For details of parameter setting methods, refer to Σ-II Series SGM/SGDH User’s Manual Desine and

Maintenance (SIE-S800-32.2).

2.1 Checking Items

When Σ-II Series products are delivered, check the following items:

Check Items Remarks

Check if the delivered products

are the ones you ordered.

Check if the motor shaft rotates

smoothly.

Check for damage. Check the overall appearance, and check for damage or scratches

Check if SERVOPACK is the

type applicable for NS100 Module?

If any of the above items are faulty or incorrect, contact the dealer from which you pur-

chased the products or your nearest local sales representative.

2.2 Appearance and Nameplate

CAUTION

Check the types marked on the nameplates of the NS100 Module.

If the motor shaft is smoothly turned by hand, it is normal. However, if the motor has brakes, it cannot be turned manually.

resulting from transportation.

Check the nameplate of SERVOPACK.

SERVOPACK Type

SGDH

-E-

c d

“SGDH” in c, and “E” in d

NS100

S

W

1

A

R

S

W

2

C

N

6

A

C

N

6

B

C

N

4

NS100 module

Order Number Protection class

SERVOPACK 1P1X

MECHATROLINK APPLICATION MODULE

MODEL JUSP-NS100 VER. 01000

CE marking

UL marking

E-10

Page 15

2.3 Type Designation

2

CHECKING ON DELIVERY

SERVOPACK peripheral device

Model

NS10: MECHATROLINLK interface

Design revision order

2.4 Mounting NS100 Module

Mount a NS100 Module on a SGDH SERVOPACK in the following manner. Provide the

screws for connecting ground wire as shown below.

Mounting

Method

Base

mounted

Rack

mounted

Duct

ventilated

SERVOPACK Type Screw Remarks

SGDH-A3 to 02BE

SGDH-A3 to 10AE

SGDH-15 to 50AE

SGDH-05 to 50DE

SGDH-60 to 1EAE

SGDH-60 to 1EDE

SGDH-A3 to 02BE-R

SGDH-A3 to 50AE-R

SGDH-05 to 50DE-R

SGDH-60 to 1EAE-P

SGDH-60 to 1EDE-P

1. Remove the connector cover mounted on CN10 of SERVOPACK.

SERVOPACK

JUSP

M3

×10 round head screws

(with spring washer and

plain washer)

M4

×10 round head screws

(with spring washer and

plain washer)

M4

×8 round head screws

(with spring washer and

plain washer)

M4

×6 round head screws

(with spring washer and

plain washer)

M4

×8 round head screws

(with spring washer and

plain washer)

YASKAWA

SERVOPACK

SGDH-

MODE/SET

DATA/

CHARGE

POWER

CN10

0

Connector

cover

-

NS10

Attachments.

Attachments.

Use the screw of the front panel.

Attachments.

Note: Make sure that spring washers and

plain washers are used for mounting.

(Otherwise, the screw for connecting

ground wire sticks out from the other

side of the flange, and the SERVO PACK cannot be mounted properly.)

Use the screw of the front panel.

E-11

Page 16

2. Mount a NS100 Module.

Connector (to SERVOPACK)

CN10

YASKAWA

SERVOPACK

SGDH-

3. For grounding, connect a ground wire of the NS100 Module to the marked “G” on the

SERVOPACK.

Ground wire

YASKAWA

SGDH-

G

SERVOPACK

NS100

DATA/

MODE/SET

CHARGE

POWER

For SERVOPACK (30 W to 5.0 kW)

G

YASKAWA

SERVOPACK 200 V

SGDH-

NS100

For SERVOPACK (6.0 kW to 7.5 kW)

E-12

Ground wire

Page 17

2

CHECKING ON DELIVERY

The appearance of SERVOPACK with application module properly mounted is shown

below

YASKAWA

SERVOPACK

SGDH-

NS100

S

W

1

A

R

S

W

2

C

N

6

A

C

N

6

B

C

N

4

E-13

Page 18

3 INSTALLATION

Σ-II Series SGDH SERVOPACK is a base-mount type servo controller. Incorrect installation

will cause problems. Always observe the installation instructions described below.

• Never use the equipment where it may be exposed to splashes of water, corrosive or flamma-

ble gases, or near flammable materials.

Failure to observe this caution may lead to electric shock or fire.

3.1 Storage

When the SERVOPACK is to be stored with the power cable disconnected, store it in the fol-

lowing temperature range:

Between -20 to +85°C

YASKAWA

SERVOPACK

SGDH- 200 V

CAUTION

NS100

S

W

1

A

R

S

W

2

C

N

6

A

C

N

6

B

C

N

4

S

-II Series

SGDH SERVOPACK with NS100 Module Mounted

E-14

Page 19

3.2 Installation Sites

For installation sites, use proper care with the following notes.

When installed in a control panel Design the control panel size, unit layout, and cooling method

When installed near a heating unit Suppress radiation heat from the heating unit and a tempera-

When installed near a source of

vibration

When installed in a place receiving

corrosive gases

Others Avoid installation in a hot and humid place or where excessive

3.3 Orientation

Install the SERVOPACK perpendicular to the wall as shown in the figure below.

The SERVOPACK must be orientated as shown in the figure.

Firmly secure the SERVOPACK through two to four mounting holes depending on the SER-

VOPACK capacity.

Situation Notes on Installation

so that the temperature around the periphery of the SERVOPACK does not exceed 55°C.

ture rise caused by convection so that the temperature around

the periphery of the SERVOPACK does not exceed 55°C.

Install a vibration isolator underneath the SERVOPACK to

prevent it from receiving vibration.

Corrosive gases do not immediately affect the SERVOPACK

but will eventually cause contactor-related devices to malfunction. Take appropriate action to protect against corrosive gases.

dust or iron powder is present in the air. Install in a place

where the altitude is 1000 m or less.

3

INSTALLATION

MADE IN JAPAN

Ventilation

E-15

Mounting face

Page 20

3.4 Installation Precations

When installing multiple SERVOPACKs side by side in a control panel, observe the follow-

ing installation method:

FAN FAN

5.0 mm (2in.) or more

10 mm (0.4in.) or more

30 mm (1.2in.) or more

5.0 mm (2in.) or more

Front Panel

Install SERVOPACK perpendicular to the wall so that the front panel (digital operator

mounted face) faces outward.

Cooling

Provide sufficient space around each SERVOPACK to allow cooling by fan and natural con-

vection.

Where mounted side by side

When installing SERVOPACKs side by side, provide at least 10mm (0.4in.) space between

them and at least 50mm (2in.) space above and below them as shown in the figure above.

Install cooling fans above the SERVOPACKs to prevent the temperature around each SER-

VOPACK from increasing excessively and also to maintain the temperature inside the con-

trol panel evenly.

Environments in Control Panel

Maintain the following conditions inside the control panel:

• Ambient temperature for SERVOPACK: 0 to 55°C

• Humidity: 90%RH or less

• Vibration: 4.9 m/s

• Condensation and freezing: None

• Ambient temperature to ensure long-term reliability: 45°C or less

• Altitude of 1000 m max.

2

E-16

Page 21

4 WIRING

4

WIRING

This section shows a standard example for connecting Σ-II series products to peripheral devices

and briefly explains how to connect each peripheral device.

WARNING

• SERVOPACK grounding must be in accordance with the national code and consistent with

sound local practices.

Failure to observe this warning may lead to electric shock or fire.

CAUTION

(WIRING)

• Do not connect three-phase power supply to SERVOPACK output terminals U, V and W.

Failure to observe this caution may lead to personal injury or fire.

• Securely tighten screws on the power supply and motor output terminals.

Failure to observe this caution can result in a fire.

For the following wiring, refer to Σ-II series SGMH/SGDH User ’s Manual Design and Main-

tenance (SIE-S800-32.2) and Σ-II series SGDH MECHATROLINK Interface Module User’s

Manual (SIE-C718-4).

• Main circuit wiring

• I/O signal wiring

• Encoder wiring

• Example of connections

E-17

Page 22

4.1 MECHATROLINK Connection Example

An example of MECHATROLINK connection is shown below.

Host controller

PS-03

YASKAWA

SGDH-

SERVOPACK

MP920 CPU-01 SVB-01 D1-01 DO-01

POWER

SW1

DC 24 V

12345678

LRST

RUN

INIT

-TEST

MULTI

FLASH

M. RST

ON OFF

PORT2

PORT2

TB1

+24 V

0 V

PORT1

FG

CN1

SG

NS100

RLY OUT

Motion controller

MP910, MP920, MP930,

Note: The total length of cable should be “L1 + L2 + ••• Ln≤50m”

CN1

CN1

RUN RUN

STATUS

PDY

RUN

ALM

ERF

BAT

ALM

PRT

PRT2

FUSE

TRK

CN2

CN2

CN1

...

L2 Ln

YASKAWA

SERVOPACK

SGDH-

NS100

Up to 15 sations can be connected.

L1

YASKAWA

SGDH-

SERVOPACK

NS100

E-18

Page 23

4.2 Precautions on Wiring

Take note the following precautions at wiring.

Connectable Maximum Number of Stations

Up to 15 slave stations can be connected.

Cables

Use the following cables.

Cable Type Length (m)

MECHATROLINK Communication Cable

(With connector on both ends)

For other peripheral devices, refer to Σ-II series SGMH/SGDH User’s Manual Design

and Maintenance (SIE-S800-32.2) and Σ-II series SGDH MECHATROLINK Interface

Module User’s Manual (SIE-C718-4).

Total cable length

The total cable length should be 50 m and less.

(Station 1 + Station 2 + ••• Station ≤ 50 m)

JEPMC-W6000-A3

JEPMC-W6000-A5

JEPMC-W6000-01

4

WIRING

0.3

0.5

1.0

Terminator

Be sure to install the following terminator on SERVOPACK of terminal station.

Terminator Type

MECHATROLINK Communication Terminator JEPMC-W6020

E-19

Page 24

5 OPERATION

This section provides precautions at test run and operation. For instructions on test run and

operation, refer to Σ-II series SGMH/SGDH User’s Manual Design and Maintenance (SIE-

S800-32.2) and Σ-II series SGDH MECHATROLINK Interface Module User’s Manual (SIE-

C718-4).

5.1 Precautions at Test Run

• To avoid inadvertent accidents, run the servomotor only in test run (without load).

Failure to observe this caution may result in personal injury.

• Before starting operation with a load connected, set up parameters suitable for the machine.

Starting operation without setting up parameters may lead to overrun failure.

• Before starting operation with a connected load, make sure emergency-stop procedures are in

place.

Failure to observe this caution may result in personal injury.

Conducting Test Run for Servomotor without Load

When servomotor is operated without load, set the load inertia (parameter Pn103) to 0.

(Factory setting is 0)

When servomotor is rotated without load (without load inertia), if the value has been set to

other than 0, the servomotor may oscillate.

To avoid this, make sure to set the load inertia to 0 and then servo ON.

CAUTION

Conducting Test Run with Servomotor Connected to Machine

SERVOPACK initial parameters setting is performed assuming normal operation conditions.

Before test run, set up parameters suitable for the machine.

Failure to set up the parameters initial setting may result in machine overrun or breakdown.

As for the setting procedures and methods, refer to Σ-II Series SGMH/SGDH User’s

Manual Design and Maintenance (SIE-S800-32.2).

Check Item during Test Run

The following items should be checked during test run.

• Unusual vibration

• Abnormal noise

• Excessive temperature rise

E-20

Page 25

5.2 Precautions at Operation

• During operation, do not touch the SERVOPACK’S heatsink.

Failure to observe this caution may result in burns.

CAUTION

5

OPERATION

E-21

Page 26

6 INSPECTION AND MAINTENANCE

This section describes the basic inspections and maintenance. If any failure occures on SER-

VOPACK, refer to Σ-II Series SGMH/SGDH User’s Manual Design and Maintenace Section

10.2 Troubleshooting (SIE-S800-32.2) and Σ-II Series SGDH MECHATROLINK Interface

Module User’s Manual (SIE-C718-4). Contact your Yaskawa representative if the problem can-

not be solved by the procedures described.

WARNING

• Be sure to turn OFF power before inspection or maintenance.

Otherwise, electric shock may result.

• Never open the terminal cover while power is ON, and never turn ON power when the terminal

cover is open.

Otherwise, electric shock may result.

• After turning OFF power, wait at least five minutes before servicing the product.

Otherwise, residual electric charges may result in electric shock.

CAUTION

• Never change wiring while power is ON.

Failure to observe this caution may result in electric shock or personal injury.

E-22

Page 27

7

MEASURES TO SATISFY THE EMC DIRECTIVE

7 MEASURES TO SATISFY THE EMC DIRECTIVE

This section describes the measures required for MECHATROLINK Interface Module to con-

form to EMC Directive (EN50081-2, EN50082-2).

7.1 MECHATROLINK Communication Cable

For serial communication (CN6A, CN6B) connector, use the connector for special use.

Max. cable length is 50 m.

Use the twisted pair shielded cable.

7.2 Fully Closed Encoder Cable

For fully closed encoder (CN4) connector, use the following connector.

Use the twisted pair shielded cable.

Connector: 54306-2011 (Made by Molex Japan Co., Ltd.)

Connector case: 54331-0201 (Made by Molex Japan Co., Ltd.)

7.3 The Core on the Cable

Attach the core on the cable as shown below:

Core Model ESD-SR-25

Quantity 1

Turn 2

Manufacturer Tokin.Corp.

Cable

Core

Cable line and the line position where the core are attached are shown below.

Cable Name Mounting Position of Core

MECHATROLINK Communication Cable Near the host controller and SERVOPACK side

Fully Closed Encoder Cable Near the SERVOPACK side

E-23

Page 28

7.4 Cable Clamp

Fix and ground the cable shield using a piece of conductive metal.

<Example of Cable Clamp>

SERVOPACK side

Cable

Clamp

Ground plate

Cable

Shield (cable sheath stripped)

Fix and ground the cable shield

using a piece of conductive metal.

Remove paint on mounting surface.

E-24

Page 29

7.5 Wiring Examples

The following diagrams show the wiring example. Before wiring, turn OFF the Power ON/

OFF switch and post a notice of “No Conduction”. Only an electrical expert can perform the

wiring. The noise filter and the core are shown in the diagram.

7

MEASURES TO SATISFY THE EMC DIRECTIVE

<REQUIRED EN SPECIFICATIONS>

Three-phase

400 V

Main

power

supply

Control

power

supply

Signal-phase

200 VAC

Clamp

Clamp

Noise

filter 1

Note: 1. Clamp: Secure cable shields and ground for conductive metal parts.

2. Make sure that the grounding plate are securely connected to the grounding.

3. Remove the paint from the grounding plate to insure a good Earth connection for filter,

SERVOPACK, clamp, etc.

Noise

filter 2

AC/DC

converter

Grounding plate/Box

Control box

CN1

SGDH

SERVOPACK

L1, L2, L3

A1, A2

U, V, W, CN2

Clamp Clamp Clamp Clamp

Moter

Encoder

Servomotor

I/F module

JUSP-NS100

CoreCore

Core

Core Core

CN6A

Core

CN6B

Core

Core

Open

Host controller

CoreCore

E-25

Page 30

AC SERVOPACK

Σ-II Series

INSTRUCTIONS

MECHATROLINK Interface Module

IRUMA BUSINESS CENTER (SOLUTION CENTER)

480, Kamifujisawa, Iruma, Saitama 358-8555, Japan

Phone 81-4-2962-5151 Fax 81-4-2962-6138

http://www.yaskawa.co.jp

YASKAWA AMERICA, INC.

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone 1-800-YASKAWA (927-5292) or 1-847-887-7000 Fax 1-847-887-7310

http://www.yaskawa.com

YASKAWA ELÉTRICO DO BRASIL LTDA.

Avenida Piraporinha 777, Diadema, São Paulo, 09950-000, Brasil

Phone 55-11-3585-1100 Fax 55-11-3585-1187

http://www.yaskawa.com.br

YASKAWA EUROPE GmbH

Hauptstraβe 185, Eschborn 65760, Germany

Phone 49-6196-569-300 Fax 49-6196-569-398

http://www.yaskawa.eu.com

YASKAWA ELECTRIC KOREA CORPORATION

9F, Kyobo Securities Bldg. 26-4, Yeouido-dong, Yeongdeungpo-gu, Seoul, 150-737, Korea

Phone 82-2-784-7844 Fax 82-2-784-8495

http://www.yaskawa.co.kr

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

151 Lorong Chuan, #04-02A, New Tech Park 556741, Singapore

Phone 65-6282-3003 Fax 65-6289-3003

http://www.yaskawa.com.sg

YASKAWA ELECTRIC (CHINA) CO., LTD.

12F, Carlton Bld., No.21 HuangHe Road, HuangPu District, Shanghai 200003, China

Phone 86-21-5385-2200 Fax 86-21-5385-3299

http://www.yaskawa.com.cn

YASKAWA ELECTRIC (CHINA) CO., LTD. BEIJING OFFICE

Room 1011, Tower W3 Oriental Plaza, No.1 East Chang An Ave.,

Dong Cheng District, Beijing 100738, China

Phone 86-10-8518-4086 Fax 86-10-8518-4082

YASKAWA ELECTRIC TAIWAN CORPORATION

9F, 16, Nanking E. Rd., Sec. 3, Taipei 104, Taiwan

Phone 886-2-2502-5003 Fax 886-2-2505-1280

YASKAWA ELECTRIC CORPORATION

In the event that the end user of this product is to be the military and said product is to be employed in any weapons systems or the manufacture

thereof, the export will fall under the relevant regulations as stipulated in the Foreign Exchange and Foreign Trade Regulations. Therefore, be sure to

follow all procedures and submit all relevant documentation according to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications and improvements.

© 1999-2014 YASKAWA ELECTRIC CORPORATION. All rights reserved.

MANUAL NO. TOB-C718-4C

Published in Japan January 2014 99-3

13-6-9

15

-0

Page 31

한국 전파법에 관한 주의사항

韓国電波法に関連する注意事項

Precautions for Korean Radio Waves Act

针对韩国电波法的注意事项

기종별 사용자 안내문

A급 기기

( 업무용 방송 통신기 자재 )

이 기기는 업무용 (A 급 ) 전자파 적합 기기로서 판매자

또는 , 사용자는 이 점을 주의하시기 바라며 , 가정외의

지역에서 사용하는 것을 목적으로 합니다 .

사용자 안내문

Loading...

Loading...