Page 1

Low Harmonic Drive for HVAC Applications

Z1000U HVAC MATRIX Drive

Programming Manual

Type: CIMR-ZU

Models:

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

200 V Class: 7.5 to 75 kW (10 to 100 HP ND)

400 V Class: 5.5 to 260 kW (7.5 to 350 HP ND)

MANUAL NO. SIEP C710636 10C

Parameter Details

Periodic Inspection &

Maintenance

Parameter List

MEMOBUS/Modbus

Communications

B

1

C

2

D

A

E

B

Page 2

Copyright © 2014 YASKAWA ELECTRIC CORPORATION. All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means,

mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of Yaskawa. No patent

liability is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly

striving to improve its high-quality products, the information contained in this manual is subject to change without notice.

Every precaution has been taken in the preparation of this manual. Yaskawa assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Page 3

Table of Contents

1. PARAMETER DETAILS ................................................................................... 9

1.1 A: Initialization........................................................................................................... 10

A1: Initialization ....................................................................................................................... 10

A2: User Parameters............................................................................................................... 14

1.2 b: Application............................................................................................................. 16

b1: Operation Mode Selection................................................................................................. 16

b2: DC Injection Braking.......................................................................................................... 21

b3: Speed Search.................................................................................................................... 23

b4: Timer Function .................................................................................................................. 30

b5: PID Control........................................................................................................................ 31

b8: Energy Saving ................................................................................................................... 44

1.3 C: Tuning.................................................................................................................... 46

C1: Acceleration and Deceleration Times ............................................................................... 46

C2: S-Curve Characteristics.................................................................................................... 47

C4: Torque Compensation ...................................................................................................... 48

C6: Carrier Frequency............................................................................................................. 49

Rated Current Depending on Carrier Frequency .................................................................... 50

C7: Voltage Adjustment........................................................................................................... 51

1.4 d: Reference Settings ............................................................................................... 52

d1: Frequency Reference........................................................................................................ 52

d2: Frequency Upper/Lower Limits ......................................................................................... 53

d3: Jump Frequency................................................................................................................ 54

d4: Frequency Reference Hold and Up/Down 2 Function....................................................... 55

d6: Field Weakening................................................................................................................ 56

d7: Offset Frequency............................................................................................................... 57

1.5 E: Motor Parameters ................................................................................................. 58

E1: V/f Pattern for Motor 1....................................................................................................... 58

E2: Motor 1 Parameters .......................................................................................................... 62

E5: PM Motor Settings ............................................................................................................ 64

1.6 F: Option Settings ..................................................................................................... 67

F2: Analog Input Card Settings ............................................................................................... 67

F3: Digital Input Card Settings ................................................................................................ 67

F4: Analog Monitor Card Settings ........................................................................................... 68

F5: Digital Output Card Settings.............................................................................................. 69

F6 and F7: Communication Option Card................................................................................. 69

CC-Link Parameters................................................................................................................ 71

MECHATROLINK Parameters ................................................................................................ 71

PROFIBUS-DP Parameters .................................................................................................... 73

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

3

Page 4

Table of Contents

CANopen Parameters ....................................................................................................................... 73

BACnet Parameters .......................................................................................................................... 74

DeviceNet Parameters

Modbus TCP/IP Parameters ............................................................................................................. 76

PROFINET Parameters..................................................................................................................... 76

EtherNet/IP Parameters ................................................................................................................... 76

...................................................................................................................... 74

1.7 H: Terminal Functions.........................................................................................................78

H1: Multi-Function Digital Inputs ....................................................................................................... 78

H2: Multi-Function Digital Outputs..................................................................................................... 87

H3: Multi-Function Analog Inputs ...................................................................................................... 98

H4: Multi-Function Analog Outputs ................................................................................................. 103

H5: Serial Communication (APOGEE FLN, BACnet, MEMOBUS/Modbus,

and Metasys N2)............................................................................................................................ 105

1.8 L: Protection Functions ....................................................................................................106

L1: Motor Protection ........................................................................................................................ 106

L2: Momentary Power Loss Ride-Thru............................................................................................ 109

L3: Stall Prevention ......................................................................................................................... 111

L4: Speed Detection........................................................................................................................ 116

L5: Fault Restart.............................................................................................................................. 117

L6: Torque Detection....................................................................................................................... 120

L8: Drive Protection......................................................................................................................... 123

L9: Drive Protection 2...................................................................................................................... 128

1.9 n: Special Adjustments.....................................................................................................129

n1: Hunting Prevention.................................................................................................................... 129

n3: High Slip Braking (HSB) and Overexcitation Braking................................................................ 130

n8: PM Motor Control Tuning .......................................................................................................... 130

1.10 o: Operator-Related Settings ...........................................................................................133

o1: HOA Keypad Display Selection................................................................................................. 133

o2: HOA Keypad Functions............................................................................................................. 136

o3: Copy Function ........................................................................................................................... 137

o4: Maintenance Monitor Settings................................................................................................... 138

1.11 S: Special Parameters.......................................................................................................141

S1: Dynamic Audible Noise Control Function ................................................................................. 141

S2: Sequence Timers...................................................................................................................... 142

S3: Secondary PI (PI2) Control ....................................................................................................... 146

S4: Bypass Operation ..................................................................................................................... 150

S5: HOA Keypad Parameters ......................................................................................................... 156

S6: Phase Order Selections ............................................................................................................ 159

1.12 T: Motor Tuning .................................................................................................................160

T1: Parameter Settings during Induction Motor Auto-Tuning .......................................................... 160

T2: Parameter Settings during PM Motor Auto-Tuning ................................................................... 161

1.13 U: Monitor Parameters......................................................................................................164

U1: Operation Status Monitors ........................................................................................................ 164

U2: Fault Trace................................................................................................................................ 164

U3: Fault History.............................................................................................................................. 164

U4: Maintenance Monitors .............................................................................................................. 164

U5: PID Monitors ............................................................................................................................. 164

U6: Operation Status Monitors ........................................................................................................ 164

U9: Power Monitors......................................................................................................................... 164

4

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

Page 5

Table of Contents

2. PERIODIC INSPECTION & MAINTENANCE ...................................................... 165

2.1 Section Safety

....................................................................................................................166

2.2 Inspection ..........................................................................................................................168

Recommended Daily Inspection...................................................................................................... 168

Recommended Periodic Inspection................................................................................................. 169

Storage Guidelines.......................................................................................................................... 170

2.3 Periodic Maintenance .......................................................................................................171

Replacement Parts.......................................................................................................................... 171

2.4 HOA Keypad Battery Replacement..................................................................................173

Replacing the Battery ...................................................................................................................... 173

2.5 Drive Cooling Fans............................................................................................................174

Number of Cooling Fans ................................................................................................................. 174

Cooling Fan Component Names ..................................................................................................... 175

Drive Cooling Fan Replacement: Models 2o0028 to 2o0130 and 4o0011 to 4o0124 ................ 176

Drive Cooling Fan Replacement: Models 2o0154, 2o0192, 4o0156, and 4o0180 ..................... 178

Drive Cooling Fan Replacement: Models 2o0248 and 4o0216 to 4o0414 .................................. 182

Installing the Cooling Fan................................................................................................................ 183

2.6 Drive Replacement ............................................................................................................188

Serviceable Parts ............................................................................................................................ 188

Terminal Board................................................................................................................................ 188

Replacing the Drive ......................................................................................................................... 188

A. PARAMETER LIST............................................................................................... 191

A.1 Understanding Parameter Descriptions..........................................................................192

Control Modes, Symbols, and Terms .............................................................................................. 192

A.2 Parameter Groups .............................................................................................................193

A.3 A: Initialization Parameters ..............................................................................................194

A1: Initialization ............................................................................................................................... 194

A2: User Parameters....................................................................................................................... 194

A.4 b: Application.....................................................................................................................195

b1: Operation Mode Selection......................................................................................................... 195

b2: DC Injection Braking.................................................................................................................. 196

b3: Speed Search............................................................................................................................ 196

b4: Timer Function .......................................................................................................................... 198

b5: PID Control................................................................................................................................ 198

b8: Energy Saving ........................................................................................................................... 201

A.5 C: Tuning............................................................................................................................202

C1: Acceleration and Deceleration Times ....................................................................................... 202

C2: S-Curve Characteristics............................................................................................................ 202

C4: Torque Compensation .............................................................................................................. 202

C6: Carrier Frequency..................................................................................................................... 203

C7: Voltage Adjustment................................................................................................................... 203

A.6 d: References.....................................................................................................................204

d1: Frequency Reference................................................................................................................ 204

d2: Frequency Upper/Lower Limits ................................................................................................. 204

d3: Jump Frequency........................................................................................................................ 205

d4: Frequency Reference Hold Function......................................................................................... 205

d6: Field Weakening........................................................................................................................ 205

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

5

Page 6

Table of Contents

d7: Offset Frequency....................................................................................................................... 206

A.7 E: Motor Parameters

E1: V/f Pattern for Motor 1............................................................................................................... 207

E2: Motor 1 Parameters .................................................................................................................. 208

E5: PM Motor Settings .................................................................................................................... 208

.........................................................................................................207

A.8 F: Option Settings .............................................................................................................210

F2: Analog Input Card Settings (AI-A3)........................................................................................... 210

F3: Digital Input Card Settings (DI-A3)............................................................................................ 210

F4: Analog Monitor Card Settings (AO-A3) ..................................................................................... 210

F5: Digital Output Card Settings (DO-A3) ....................................................................................... 211

F6, F7: Communication Option Card Settings................................................................................. 211

A.9 H Parameters: Multi-Function Terminals ........................................................................217

H1: Multi-Function Digital Inputs ..................................................................................................... 217

H2: Multi-Function Digital Outputs................................................................................................... 221

H3: Multi-Function Analog Inputs .................................................................................................... 223

H4: Analog Outputs ......................................................................................................................... 225

H5: MEMOBUS/Modbus Serial Communication ............................................................................. 226

A.10 L: Protection Function ......................................................................................................228

L1: Motor Protection ........................................................................................................................ 228

L2: Momentary Power Loss Ride-Thru............................................................................................ 229

L3: Stall Prevention ......................................................................................................................... 229

L4: Speed Detection........................................................................................................................ 230

L5: Fault Restart.............................................................................................................................. 231

L6: Torque Detection....................................................................................................................... 231

L8: Drive Protection......................................................................................................................... 232

L9: Drive Protection 2...................................................................................................................... 233

A.11 n: Special Adjustment.......................................................................................................234

n1: Hunting Prevention.................................................................................................................... 234

n3: Overexcitation Braking .............................................................................................................. 234

n8: PM Motor Control Tuning .......................................................................................................... 234

A.12 o: Operator-Related Settings ...........................................................................................236

o1: HOA Keypad Display Selection................................................................................................. 236

o2: HOA Keypad Functions............................................................................................................. 237

o3: Copy Function ........................................................................................................................... 238

o4: Maintenance Monitor Settings................................................................................................... 238

A.13 S: Special Application.......................................................................................................239

S1: Dynamic Noise Control Function .............................................................................................. 239

S2: Sequence Timers...................................................................................................................... 239

S3: Secondary PI (PI2) Control ....................................................................................................... 241

S4: Bypass Operation ..................................................................................................................... 243

S5: HOA Keypad Parameters ......................................................................................................... 243

S6: Z1000U Protection .................................................................................................................... 243

A.14 T: Motor Tuning .................................................................................................................245

T1: Induction Motor Auto-Tuning..................................................................................................... 245

T2: PM Motor Auto-Tuning .............................................................................................................. 246

A.15 U: Monitors.........................................................................................................................248

U1: Operation Status Monitors ........................................................................................................ 248

U2: Fault Trace................................................................................................................................ 250

U3: Fault History.............................................................................................................................. 251

U4: Maintenance Monitors .............................................................................................................. 252

6

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

Page 7

Table of Contents

U5: PID Monitors ............................................................................................................................. 254

U6: Operation Status Monitors ........................................................................................................ 255

U9: Power Monitors

......................................................................................................................... 256

A.16 Control Mode Dependent Parameter Default Values .....................................................257

A1-02 (Control Mode) Dependent Parameters................................................................................ 257

A.17 V/f Pattern Default Values.................................................................................................258

A.18 Defaults by Drive Model....................................................................................................259

A.19 Parameters Changed by Motor Code Selection (for PM Motors)..................................263

Yaskawa SMRA Series SPM Motor ................................................................................................ 263

Yaskawa SSR1 Series IPM Motor (For Derated Torque)................................................................ 264

Yaskawa SST4 Series IPM Motor (For Constant Torque) .............................................................. 270

B. MEMOBUS/MODBUS COMMUNICATIONS........................................................ 279

B.1 MEMOBUS/Modbus Configuration ..................................................................................280

B.2 Communication Specifications........................................................................................281

B.3 Connecting to a Network ..................................................................................................282

Network Cable Connection.............................................................................................................. 282

Wiring Diagram for Multiple Connections ........................................................................................ 283

Network Termination ....................................................................................................................... 284

B.4 MEMOBUS/Modbus Setup Parameters ...........................................................................285

MEMOBUS/Modbus Serial Communication.................................................................................... 285

B.5 Drive Operations by MEMOBUS/Modbus........................................................................289

Observing the Drive Operation........................................................................................................ 289

B.6 Communications Timing...................................................................................................290

Command Messages from Master to Drive..................................................................................... 290

Response Messages from Drive to Master ..................................................................................... 290

B.7 Message Format ................................................................................................................291

Message Content ............................................................................................................................ 291

Slave Address ................................................................................................................................. 291

Function Code ................................................................................................................................. 291

Data................................................................................................................................................. 291

Error Check ..................................................................................................................................... 291

B.8 Message Examples ...........................................................................................................293

Reading Drive MEMOBUS/Modbus Register Contents .................................................................. 293

Loopback Test................................................................................................................................. 293

Writing to Multiple Registers............................................................................................................ 294

B.9 MEMOBUS/Modbus Data Table........................................................................................295

Command Data ............................................................................................................................... 295

Monitor Data.................................................................................................................................... 296

Broadcast Messages....................................................................................................................... 308

Fault Trace Contents....................................................................................................................... 308

Alarm Register Contents ................................................................................................................. 310

B.10 Enter Command.................................................................................................................311

Enter Command Types ................................................................................................................... 311

B.11 Communication Errors .....................................................................................................312

MEMOBUS/Modbus Error Codes.................................................................................................... 312

Slave Not Responding..................................................................................................................... 312

B.12 Self-Diagnostics ................................................................................................................313

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

7

Page 8

Table of Contents

INDEX ................................................................................................................... 315

8

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

Page 9

1

Parameter Details

1.1 A: INITIALIZATION................................................................................................10

1.2 B: APPLICATION

1.3 C: TUNING..............................................................................................................46

1.4 D: REFERENCE SETTINGS..................................................................................52

1.5 E: MOTOR PARAMETERS....................................................................................58

1.6 F: OPTION SETTINGS...........................................................................................67

1.7 H: TERMINAL FUNCTIONS...................................................................................78

1.8 L: PROTECTION FUNCTIONS............................................................................106

1.9 N: SPECIAL ADJUSTMENTS..............................................................................129

1.10 O: OPERATOR-RELATED SETTINGS................................................................133

1.11 S: SPECIAL PARAMETERS................................................................................141

1.12 T: MOTOR TUNING..............................................................................................160

1.13 U: MONITOR PARAMETERS..............................................................................164

...................................................................................................16

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

9

Page 10

1.1 A: Initialization

1.1 A: Initialization

The initialization group contains parameters associated with initial drive setup, including parameters involving the display

language, access levels, initialization, and password.

u

A1: Initialization

A1-00: Language Selection

n

Selects the display language for the HOA keypad.

Note: This parameter is not reset when the drive is initialized using parameter A1-03.

No. Parameter Name Setting Range Default

A1-00 Language Selection 0, 1, 3, 5, 6 0

Setting 0: English

Setting 1: Japanese

Setting 3: French

Setting 5: Spanish

Setting 6: Portuguese

A1-01: Access Level Selection

n

Allows or restricts access to drive parameters.

No. Parameter Name Setting Range Default

A1-01 Access Level Selection 0 to 2 2

Setting 0: Operation Only

A1-01, A1-04, and Drive Mode can be accessed and set. All U monitor parameters can be accessed. Parameters that are set

in A2-01 to A2-32 can be accessed in Setup Mode. Verify Mode, Setup Mode, and Auto-Tuning Mode cannot be accessed.

Setting 1: User Parameters

A1-00, A1-01, A1-04, and Drive Mode can be accessed and set. All U monitor parameters can be accessed. Parameters that

are set in A2-01 through A2-32 can be accessed in Setup Mode. Verify Mode and Auto-Tuning Mode cannot be accessed.

Setting 2: Advanced Access Level (A)

All parameters can be viewed and edited.

Notes on Parameter Access

• If the drive parameters are password protected by A1-04 and A1-05, parameters A1-01 through A1-03, A1-07, and A2-01

through A2-32 cannot be modified.

•

If a digital input terminal programmed for “Program lockout” (H1-oo = 1B) is enabled, parameter values cannot be

modified, even if A1-01 is set to 1 or 2.

• If parameters are changed via serial communication, it will not be possible to edit or change parameter settings with the

HOA keypad until an Enter command is issued to the drive from the serial communication.

A1-02: Control Method Selection

n

Selects the Control Method (also referred to as the control mode) that the drive uses to operate the motor. Parameter A1-02

determines the control mode for the motor.

Note: When changing control modes, all parameter settings depending upon the setting of A1-02 will be reset to the default.

No. Parameter Name Setting Range Default

A1-02 Control Method Selection 0, 5 0

Setting 0: V/f Control for Induction Motors

Use this mode for simple speed control and for multiple motor applications with low demands to dynamic response or speed

accuracy. The speed control range is 1:40.

10

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

Page 11

1.1 A: Initialization

Setting 5: Open Loop Vector Control for PM

Use this mode when running a PM motor in variable torque applications that benefit from energy efficiency. The drive can

control an SPM or IPM motor with a speed range of 1:20 in this control mode.

A1-03: Initialize Parameters

n

Resets parameters to default values. After initialization, the setting for A1-03 automatically returns to 0.

No. Parameter Name Setting Range Default

A1-03 Initialize Parameters

Setting 0: No Initialize

Setting 1110: User Initialize

0, 1110, 2220,

3330, 3410, 3420

0

Resets parameters to the values selected by the user as User Settings. User Settings are stored when parameter o2-03 is set to

“1: Set defaults”.

Note: User Initialization resets all parameters to a user-defined set of default values previously saved to the drive. Set parameter o2-03 to 2 to

Setting 2220: 2-Wire Initialization

clear the user-defined default values.

Resets parameters except parameters listed in Table 1.1 to default settings with digital inputs S1 and S2 configured as Forward

run and Reverse run, respectively. Refer to Setting 40, 41: Forward Run, Reverse Run Command for 2-Wire Sequence on

page 84 for more information on digital input functions.

Setting 3330: 3-Wire Initialization

Resets parameters to default settings with digital inputs S1, S2, and S5 configured as Run, Stop, and Forward/Reverse

respectively. Refer to Setting 0: 3-Wire Sequence on page 79 for more information on digital input functions.

Setting 3410: HVAC Initialization

Resets parameters to default settings. The following parameters are not reset:

H1-03: b1 (Customer Safeties)

H1-04: b2 (BAS Interlock)

H1-05: AF (Emergency Override Forward Run)

H2-03: b2 (BAS Interlock Relay Contact)

Note: After performing an HVAC Initialization, H1-03 to H1-05 and H2-03 will be displayed in the Modified Parameters list.

Setting 3420: OEM Bypass Initialization

Resets parameters to default settings. The following parameters are not reset:

H1-03: A7 (BP Customer Safeties)

H1-04: A6 (BP BAS Interlock)

H1-05: A4 (Emergency Override)

H1-06: AE (BP Bypass Run)

H2-01: A4 (BP Drive Relay)

H2-02: A5 (BP Bypass Relay)

H2-03: A6 (BP BAS Interlock)

o1-16: 2 (Drive/Bypass)

Note: After performing an OEM Bypass Initialization, H1-03 to H1-05, H2-01 to H2-03, and o1-16 will be displayed in the Modified Parameters

list.

Notes on Parameter Initialization

The parameters shown in Table 1.1 will not be reset when the drive is initialized by setting A1-03 = 2220 or 3330. Although

the control mode in A1-02 is not reset when A1-03 is set to 2220 or 3330, it may change when an application preset is selected.

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

11

Parameter Details

1

Page 12

- MODE -

U1-01= 0.00Hz

U1-02= 0.00Hz

U1-03= 0.00 A

DRV

Freq Ref (AI)

Rdy

FWD

LSEQ

LREF

-PRMSETInitialization

Select Language

PRG

A1-00= 0

← →

FWD

← →

-PRMSETSelect Language

English

PRG

FWD

A1-00= 0 *0*

← →

-PRMSET-

A1- 04 = 0

(0~9999)

“0”

PRG

Enter Password

FWD

OFF

← →

-PRMSET-

A1- 05 = 0

(0~9999)

“0”

PRG

Select Password

FWD

← →

-PRMSET-

A1- 05 = 0000

(0~9999)

“0”

PRG

Select Password

FWD

0

1.1 A: Initialization

Table 1.1 Parameters Not Changed by Drive Initialization

No. Parameter Name

A1-00 Language Selection

A1-02 Control Method Selection

E1-03 V/f Pattern Selection

F6-08 Communication Parameter Reset

L8-35 Installation Selection

o2-04 Drive Model Selection

A1-04, A1-05: Password and Password Setting

n

Parameter

A1-04

enters the password when the drive is locked; parameter A1-05 is a hidden parameter that sets the password.

No. Parameter Name Setting Range Default

A1-04 Password

A1-05 Password Setting

0000 to 9999 0000

How to Use the Password

The user can set a password in parameter A1-05 to restrict access to the drive. The password must be entered to A1-04 to

unlock parameter access (i.e., parameter setting A1-04 must match the value programmed into A1-05). The following

parameters cannot be viewed or edited until the value entered to A1-04 correctly matches the value set to A1-05: A1-01, A1-02,

A1-03, A1-06, and A2-01 through A2-33.

The instructions below demonstrate how to set password “1234”. An explanation follows on how to enter that password to

unlock the parameters.

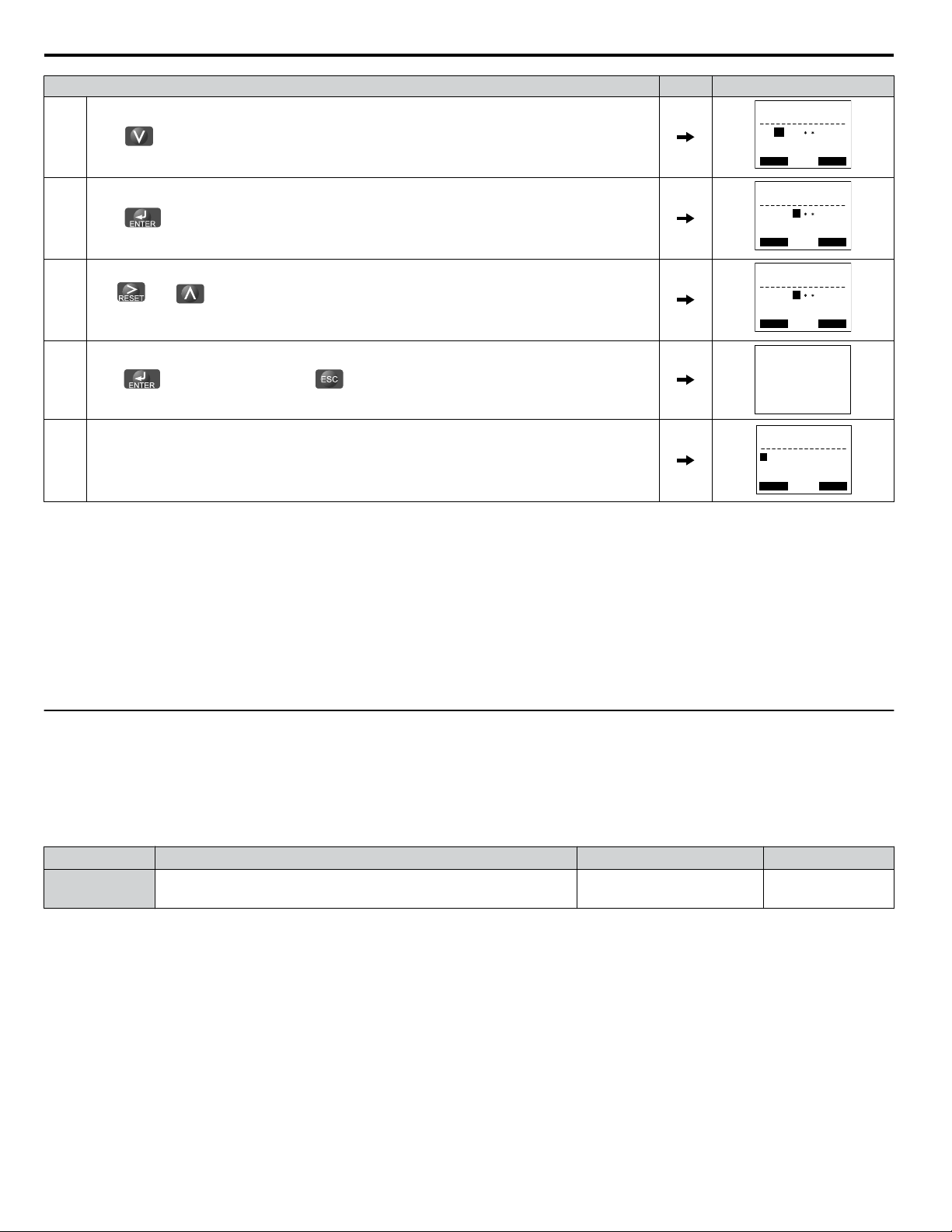

Table 1.2 Setting the Password for Parameter Lock

Step Display/Result

1. Turn on the power to the drive. The initial display appears.

- MODE - PRG

Programming

2.

Press

or until the Parameter Setting Mode screen appears.

HELP

FWD

DATA

3.

4.

5.

6.

7.

12

Press

to enter the parameter menu tree.

Select the flashing digits by pressing

Select A1-04 by pressing .

Press while holding down

Note:

A1-05 is hidden and will not display by pressing only .

Press .

F1

F2

,

, or

.

at the same time. A1-05 will appear.

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

Page 13

← →

-PRMSET-

A1- 05 = 1234

(0~9999)

“0”

PRG

Select Password

FWD

4

← →

-PRMSET-

A1- 05 = 0

(0~9999)

“0”

PRG

Select Password

FWD

← →

-PRMSET- PRG

Control Method

FWD

A1-02= 0

0

V/f Control

-PRMSETInitialization

Select Language

PRG

A1-00= 0

← →

FWD

← →

-PRMSETSelect Language

English

PRG

FWD

A1-00= 0 *0*

← →

-PRMSET-

A1- 04 = 0

(0~9999)

“0”

PRG

Enter Password

FWD

← →

-PRMSET- PRG

Enter Password

FWD

A1-04= 1234

V/f Control

4

← →

-PRMSET-

A1- 04 = 0

(0~9999)

“0”

PRG

Enter Password

FWD

1.1 A: Initialization

Step Display/Result

8.

9.

F1

Use

Press to save what was entered.

F2

,

, and to enter the password.

,

10. The display automatically returns to the display shown in step 6.

Table 1.3 Check if A1-02 is Locked (continuing from step 10 above)

Step Display/Result

1.

Press to display A1-02.

2.

Press , making sure that the setting values cannot be changed.

3.

Press to return to the first display.

Entry Accepted

- MODE - PRG

Programming

FWD

HELP

DATA

Table 1.4 Enter the Password to Unlock Parameters (continuing from step 3 above)

1.

Press to enter the parameter setup display.

2.

Press

3.

Press to scroll to A1-04 and .

F1

F2

,

to select the flashing digits as shown.

,

4. Enter the password “1234”.

5.

Press to save the new password.

Step Display/Result

Entry Accepted

Parameter Details

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

6. Drive returns to the parameter display.

1

13

Page 14

← →

-PRMSET- PRG

Control Method

FWD

A1-02= 0

0

V/f Control

← →

-PRMSET- PRG

Control Method

FWD

A1-02=

0

V/f Control

0

← →

-PRMSET- PRG

Control Method

FWD

A1-02=

0

PM OpenLoop Vect

5

-PRMSETInitialization

Select Language

PRG

A1-00= 0

← →

FWD

1.1 A: Initialization

Step Display/Result

7.

Press

8.

Press

Use and to change the value if desired (though changing the control mode at this point is

9.

not typically done).

and scroll to A1-02.

to display the value set to A1-02. If the first “0” blinks, parameter settings are unlocked.

10.

Press to save the setting, or press to return to the previous display without saving changes.

Entry Accepted

11. The display automatically returns to the parameter display.

Note: 1. Parameter settings can be edited after entering the correct password.

2. Performing a 2-Wire or 3-Wire initialization resets the password to “0000”.

A1-06: Application Preset

n

Several Application Presets are available to facilitate drive setup for commonly used applications. Selecting one of these

Application

Presets

automatically assigns functions to the input and output terminals and sets a predefined group of parameters

to values appropriate for the selected application.

In addition, the parameters most likely to be changed are assigned to the group of User Parameters, A2-01 through A2-16.

User Parameters are part of the Setup Group, which provides quicker access by eliminating the need to scroll through multiple

menus.

u

A2: User Parameters

A2-01 to A2-32: User Parameters 1 to 32

n

The user can select up to 32 parameters and assign them to parameters A2-01 through A2-32 to provide quicker access by

eliminating the need to scroll through multiple menus. The User Parameter list can also save the most recently edited

parameters.

No. Parameter Name Setting Range Default

A2-01 to A2-32 User Parameters 1 to 32 A1-00 to S6-07

<1> This setting is the default setting of the Setup Mode parameters. Refer to TOEPC71063610 User Manual Section 4 for details.

<2> A1-06 determines how the setting of user parameters A2-01 through A2-32 are changed.

Determined by

A1-06

Saving User Parameters

To save specific parameters to A2-01 through A2-32, set parameter A1-01 to 2 to allow access to all parameters, then enter

the parameter number to one of the A2-oo

parameters to assign it to the list of User Parameters. Finally, set A1-01 to 1 to

restrict access so users can only set and refer to the parameters saved as User Parameters.

14

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

<1>

<2>

Page 15

1.1 A: Initialization

A2-33: User Parameter Automatic Selection

n

Determines whether recently edited parameters are saved to the second half of the User Parameters (A2-17 to A2-32) for

quicker access.

No. Parameter Name Setting Range Default

A2-33 User Parameter Automatic Selection 0, 1

Setting 0: Do not save list of recently edited parameters

Determined by

A1-06

Set A2-33 to 0 to manually select the parameters listed in the User Parameter group.

Setting 1: Save list of recently edited parameters

Set A2-33 to 1 to automatically save recently edited parameters to A2-17 through A2-32. A total of 16 parameters are saved

with the most recently edited parameter set to A2-17, the second most recently to A2-18, and so on. Access the User Parameters

using the Setup Mode of the HOA keypad.

Note: User parameters are listed from A2-27 to A2-32. Parameters A2-01 to A2-26 are already listed as defined by default when in Setup Mode.

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

Parameter Details

1

15

Page 16

Drive

A1 Analog Input 1

0 to 10 V

AC Analog input common

2 k

+V

10.5 V, 20 mA power supply

A2 Analog Input 2

A3 Analog Input 3

Drive

A1 Analog Input 1

AC Analog input common

+V

10.5 V, 20 mA power supply

A2 Analog Input 2

A3 Analog Input 3

4 k

-10 to 10 V

OR

Customer

+/- 10 V

Supply

+10 V

-10 V

Common

1.2 b: Application

1.2 b: Application

u

b1: Operation Mode Selection

b1-01: Frequency Reference Selection for AUTO Mode

n

Selects the frequency reference source 1.

Note: If a Run command is input to the drive, but the frequency reference entered is 0 or below the minimum frequency, the AUTO or HAND

Setting 0: HOA Keypad

Using this setting, the frequency reference can be input using the HOA keypad.

Setting 1: Terminals (analog input terminals)

Using

Voltage Input

Voltage input can be used at any of the three analog input terminals. Make the settings as described in Table 1.5 for the input

used.

Terminal Signal Level

A1

A2

A3

indicator LED on the HOA keypad will light and the OFF indicator will flash.

No. Parameter Name Setting Range Default

b1-01 Frequency Reference Selection for AUTO Mode 0 to 3 1

this setting, an analog frequency reference can be entered as a voltage or current signal from terminals A1, A2, or A3.

Table 1.5 Analog Input Settings for Frequency Reference Using Voltage Signals

Parameter Settings

Signal Level

Selection

0 to 10 Vdc H3-01 = 0

-10 to +10 Vdc H3-01 = 1

0 to 10 Vdc H3-09 = 0

-10 to +10 Vdc H3-09 = 1

0 to 10 Vdc H3-05 = 0

-10 to +10 Vdc H3-05 = 1

Function Selection Gain Bias

(Frequency Reference Bias)

H3-02 = 0

H3-10 = 0

(Frequency Reference Bias)

H3-06 = 0

(Frequency Reference Bias)

H3-03 H3-04 –

H3-11 H3-12

H3-07 H3-08

Set jumper S1 on the terminal

board to

Set DIP switch S4 on the

terminal board to “AI”.

Notes

“V” for voltage input.

Figure 1.1 Setting the Frequency Reference as a Voltage Signal at Terminal A1

Current Input

Input terminals, A1, A2, and A3 can accept a current input signal. Refer to Table 1.6 for an example to set terminal A2 for

current input.

Terminal

16

A2

Signal

Level

4 to 20 mA H3-09 = 2

0 to 20 mA H3-09 = 3

Table 1.6 Analog Input Settings for Frequency Reference Using a Current Signal

Signal Level

Selection

Function

Selection

H3-10 = 0

(Frequency Bias)

Parameter Settings

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

Gain Bias

H3-11 H3-12

Notes

Make sure to set jumper S1 on the

terminal board to “I” for current

input.

Page 17

Drive

A1 Analog Input 1

0 or 4 to 20 mA

AC Analog input common

+V

10.5 V, 20 mA power supply

A2 Analog Input 2

A3 Analog Input 3

Jumper S1

A1/A2/A3

Voltage/Current

Selection

V

I

A1 A2 A3

1.2 b: Application

Figure 1.2 Setting the Frequency Reference as a Current Signal to Terminal A2

Switching between Main/Auxiliary Frequency References

The

frequency

reference input can be switched between the analog terminals A1, A2, and A3 using multi-speed inputs. Refer

to Multi-Step Speed Selection on page 52 for details on using this function.

Setting 2: Serial Communication (APOGEE FLN, BACnet, MEMOBUS/Modbus, Metasys N2)

This setting requires entering the frequency reference via the RS-422/RS-485 serial communications port (control terminals

R+, R-, S+, and S-). Refer to MEMOBUS/Modbus Configuration on page 280 for instructions.

Setting 3: Option card

This setting requires entering the frequency reference via an option board plugged into connector CN5-A on the drive control

board. Consult the option board manual for instructions on integrating the drive with the communication system.

Note: If the frequency reference source is set for Option PCB (b1-01 = 3), but an option board is not installed, an oPE05 operation error will be

b1-02: Run Command Selection for AUTO Mode

n

displayed on the digital operator and the drive will not run.

Determines the Run command selection for AUTO mode.

No. Parameter Name Setting Range Default

b1-02 Run Command Selection for AUTO Mode 1 to 3 1

Setting 1: Control Circuit Terminal

This setting requires entering the Run command via the digital input terminals using one of following sequences:

• 2-Wire sequence 1:

Two inputs (FWD/Stop-REV/Stop). Set A1-03 to 2220 to initialize the drive and preset terminals S1 and S2 to these

functions. This is the default setting of the drive. Refer to

Setting 40, 41: Forward Run, Reverse Run Command for 2-

Wire Sequence on page 84.

• 2-Wire sequence 2:

Two inputs (Start/Stop-FWD/REV). Refer to Setting 42, 43: Run and Direction Command for 2-Wire Sequence 2 on

page 84.

• 3-Wire sequence:

Three inputs (Start-Stop-FWD/REV). Set A1-03 to 3330 to initialize the drive and preset terminals S1, S2, and S5 to these

functions. Refer to Setting 0: 3-Wire Sequence on page 79.

Setting 2: Serial Communication (APOGEE FLN, BACnet, MEMOBUS/Modbus, Metasys N2)

This setting requires entering the Run command via serial communications by connecting the RS-422/RS-485 serial

communication cable to control terminals R+, R-, S+, and S- on the terminal block. Refer to MEMOBUS/Modbus

Configuration on page 280 for instructions.

Setting 3: Option Card

This setting requires entering the Run command via the communication option board by plugging a communication option

board into the CN5 port on the control PCB. Refer to the option card manual for instructions on integrating the drive into the

communication system.

Note: If b1-02 is set to 3, but an option card is not installed in CN5, an oPE05 operation error will be displayed on the HOA keypad and the drive

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

will not run.

Parameter Details

1

17

Page 18

1.2 b: Application

b1-03: Stopping Method Selection

n

Selects how the drive stops the motor when the Run command is removed or when a Stop command is entered.

No. Parameter Name Setting Range Default

b1-03 Stopping Method Selection 0 to 3 1

Setting 0: Ramp to Stop

When the Run command is removed, the drive will decelerate the motor to stop. The deceleration rate is determined by the

active deceleration time. The default deceleration time is set to parameter C1-02.

When the output frequency falls below the level set in parameter b2-01, the drive will start DC injection or Zero Speed Control

depending on the selected control mode.

Setting 1: Coast to Stop

When the Run command is removed, the drive will shut off its output and the motor will coast (uncontrolled deceleration) to

stop. The stopping time is determined by the inertia and the friction in the driven system.

Run

command

Output

frequency

ON OFF

Drive output is shut off

Motor speed

Figure 1.3 Coast to Stop

Note: After

stop is initiated, any subsequent Run command entered will be ignored until the minimum baseblock time (L2-03) has expired. Do

a

not enter Run command until it has come to a complete stop. Use DC Injection at Start (Refer to b2-03: DC Injection Braking Time at

Start on page 22) or Speed Search (Refer to b3: Speed Search on page 23) to restart the motor before it has completely stopped.

Setting 2: DC Injection Braking to Stop

When the Run command is removed, the drive will enter baseblock (turn off its output) for the minimum baseblock time

(L2-03). When the minimum baseblock time has expired, the drive will inject the amount DC current set in parameter b2-02

into the motor windings to brake the motor. The stopping time in DC Injection Braking to Stop is significantly faster compared

to Coast to Stop.

Note: This function is not available in OLV/PM control mode (A1-02 = 5).

Run

command

Output

frequency

Motor speed

ON OFF

DC Injection Braking

with the current set in

Motor coasts

b2-02

Minimum Baseblock

Time (

L2-03)

Figure 1.4 DC Injection Braking to Stop

DC Injection Braking time is determined by the value set to b2-04 and the output frequency at the time the Run command is

removed. It can be calculated by:

18

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

Page 19

DC Injection brake time

(b2-04) x 10 x Output frequency

Max. output frequency (E1-04)

=

DC Injection braking time

Min output

frequency

100%

(Max output

frequency)

Output frequency

when Stop command

was entered

Run wait time t

Active deceleration time

Momentary Power Loss

Minimum Baseblock

Time (L2-03)

b2-04×10

b2-04

1.2 b: Application

10%

Output frequency when

Stop command was entered

100%

(Maximum output

frequency)

Figure 1.5 DC Injection Braking Time Depending on Output Frequency

Note: If an overcurrent (oC) fault occurs during DC Injection Braking to Stop, increase the momentary power loss minimum baseblock time

(L2-03) until the fault no longer occurs.

Setting 3: Coast with Timer

the

When

Run command is removed, the drive will turn off its output and the motor will coast to stop. The drive will not start

if a Run command is input before the time t (C1-02) has expired. Cycle the Run command that was activated during time t

after t has expired to start the drive.

The wait time t is

Run command

Output

frequency

determined by the output frequency when the Run command is removed and by the active deceleration time.

ON ON ONOFF OFF

Drive output shut off

Run wait time t

Figure 1.6 Coast with Timer

Figure 1.7 Run Wait Time Depending on Output Frequency

b1-04: Reverse Operation Selection

n

Enables and disables Reverse operation. For some applications, reverse motor rotation is not appropriate and may cause

problems (e.g., air handling units, pumps, etc.).

No. Parameter Name Setting Range Default

b1-04 Reverse Operation Selection 0, 1 1

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

Parameter Details

1

19

Page 20

1.2 b: Application

Setting 0: Reverse Enabled

Possible to operate the motor in both forward and reverse directions.

Setting 1: Reverse Disabled

Drive disregards a Reverse run command or a negative frequency reference.

b1-06: Digital Input Reading

n

Defines how the digital inputs are read. The inputs are acted upon every 1 ms or 2 ms depending upon the setting.

No. Name Setting Range Default

b1-06 Digital Input Reading 0, 1 1

Setting 0: Read once (1 ms scan)

The state

of a digital input is read once. If the state has changed, the input command is immediately processed. With this setting

the drive responds more quickly to digital inputs, but a noisy signal could cause erroneous operation.

Setting 1: Read twice (2 ms scan)

The state of a digital input is read twice. The input command is processed only if the state does not change during the double

reading. This reading process is slower than the “Read once” process, but it is more resistant to noisy signals.

b1-08: Run Command Selection in Programming Mode

n

As a safety precaution, the drive will not normally respond to a Run command input when the HOA keypad is being used to

adjust parameters in Programming Mode (Verify Menu, Setup Mode, Parameter Settings Mode, and Auto-Tuning Mode). If

required by the application, set b1-08 to allow the drive to run while in Programming Mode.

No. Parameter Name Setting Range Default

b1-08 Run Command Selection in Programming Mode 0 to 2 0

Setting 0: Run Command Is Not Accepted in Programming Mode

A Run command is not accepted while the HOA keypad is in Programming Mode.

Setting 1: Run Command Is Accepted in Programming Mode

A Run command is accepted in any HOA keypad mode.

Setting 2: Prohibit Entering Programming Mode during Run

It is not possible to enter the Programming Mode as long as the drive output is active. The Programming Mode cannot be

displayed during Run.

b1-11: Drive Delay Time Setting

n

If a time is set to b1-11, the drive will delay executing a Run command until the set time has expired. During Drive Delay

Time execution, the HOA keypad will display “WrUn”. Both Alarm and Run indicators will blink while the drive waits to

execute the Run command.

No. Parameter Name Setting Range Default

b1-11 Drive Delay Time Setting 0 to 600 s 0

b1-14: Phase Order Selection

n

Sets the phase order for drive output terminals U/T1, V/T2, and W/T3.

Switching motor phases will reverse the direction of the motor.

No. Parameter Name Setting Range Default

b1-14 Phase Order Selection 0, 1 0

Setting 0: Standard

Setting 1: Switch Phase Order

The direction of the motor is reversed.

b1-17: Run Command at Power Up

n

Determines whether an external Run command that is active during power up will start the drive.

20

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

Page 21

1.2 b: Application

No. Parameter Name Setting Range Default

b1-17 Run Command at Power Up 0, 1 1

Setting 0: Disregarded

A new Run command must be issued after power up. Cycle the Run command to start the drive.

Note: For safety reasons, the drive is initially programmed not to accept a Run command at power up (b1-17 = 0). If a Run command is issued at

Setting 1: Allowed

power up, the RUN indicator LED will flash quickly.

The motor will start immediately after a power up if a Run command is already enabled.

WARNING! Sudden Movement Hazard. If b1-17 is set to 1 and an external Run command is active during power up, the motor will begin

rotating as soon as the power is switched on. Proper precautions must be taken to ensure that the area around the motor is safe prior to

powering up the drive. Failure to comply may cause serious injury.

b1-24: Commercial Power Operation Switching Selection

n

When the output frequency matches the power supply frequency (60 Hz), the PWM switching operation stops and switches

to operation with a direct commercial power supply connection.

Note: 1. Switching can be enabled when an inductive motor is being driven in V/f or OLV control modes.

2. Current value may change when a switch is made.

3. Verify that the induction motor can be driven with the commercial power supply (e.g., the rated voltage and rated speed) prior to enabling

the commercial power switching selection.

No. Parameter Name Setting Range Default

b1-24 Commercial Power Switching Selection 0, 1 0

Setting 0: Disabled

A voltage will be output with PWM switching operation regardless of the output frequency.

Setting 1: Enabled

When the deviation between the output frequency and the power supply frequency is less than or equal to the commercial

power switching output frequency coincidence level (b1-26), the PWM switching operation stops and switches to operation

with a direct commercial power supply connection.

Operation with a direct commercial power supply continues until the deviation between the output frequency and the power

supply frequency is greater than or equal to the commercial power switching output frequency coincidence/non-coincidence

level (b1-25 + b1-26).

b1-25/b1-26: Commercial Power Supply Operation Cancellation Level/Switching Level

n

These parameters set the value in 0.1 Hz increments at which commercial power supply switching selection is enabled and

disabled.

Entering Eco Mode

When the deviation between the output frequency and the power supply frequency becomes equal to or less than the setting

values of b1-26, an output frequency coincidence condition exists. The drive will operate in commercial power switching

mode. If the drive will not switch to commercial power supply switching mode, set b1-26.

Exiting Eco Mode

When

the deviation between the output frequency and the power supply frequency becomes equal to or greater than the setting

value of b1-25 + b1-26, the drive will operate in PWM switching mode. If commercial power switching mode and PWM

switching mode are repeated frequently, increase the setting value of b1-25.

Note: The drive will not switch to commercial power switching mode when L3-06, Stall Prevention Level during Run, is exceeded and L3-05,

Stall Prevention Selection during Run, is enabled.

No. Parameter Name Setting Range Default

b1-25 Commercial Power Supply Operation Cancellation Level 0.4 to 6.0 Hz 1.0 Hz

b1-26 Commercial Power Supply Operation Switching Level 0.0 to 3.0 Hz 0.2 Hz

u

b2: DC Injection Braking

These parameters determine operation of the DC Injection Braking and Zero Speed Control features.

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

Parameter Details

1

21

Page 22

1.2 b: Application

b2-01: Zero Speed Level (DC Injection Braking Start Frequency)

n

Active when “Ramp to Stop” is selected as the stopping method (b1-03 = 0).

No. Name Setting Range Default

b2-01 Zero Speed Level (DC Injection Braking Start Frequency) 0.0 to 10.0 Hz

Determined by

A1-02

The function triggered by parameter b2-01 depends on the control mode that has been selected.

V/f and OLV/PM (A1-02 = 0, 5)

For these control modes, parameter b2-01 sets the starting frequency for DC Injection Braking at Stop. When the output

frequency falls below the setting of b2-01, DC Injection Braking is enabled for the time set in parameter b2-04.

DC Injection

Braking

Time

b2-04

Output

frequency

Figure 1.8 DC Injection Braking at Stop for V/f

b2-01

Note: If

b2-02: DC Injection Braking Current

n

to the E1-09 value.

is set to a smaller value than E1-09 (Minimum Output Frequency), then DC Injection Braking will begin when the frequency falls

E1-09 Min. Frequency

b2-01 Zero Speed Level

Sets the DC Injection Braking current as a percentage of the drive rated current.

No. Name Setting Range Default

b2-02 DC Injection Braking Current 0 to 100% 50%

The level of DC Injection Braking current affects the strength of the magnetic field attempting to lock the motor shaft.

Increasing the

current level will increase the amount of heat generated by the motor windings. Do not set this parameter higher

than the level necessary to hold the motor shaft.

b2-03: DC Injection Braking Time at Start

n

Sets the time of DC Injection Braking at start. Used to stop a coasting motor before restarting it or to apply braking torque at

start. Disabled when set to 0.00 s.

No. Name Setting Range Default

b2-03 DC Injection Braking Time at Start 0.00 to 10.00 s 0.00 s

Note: Before starting an uncontrolled rotating motor (e.g., a fan motor driven by windmill effect), use DC Injection or Speed Search to stop the

b2-04: DC Injection Braking Time at Stop

n

Sets

the

motor or detect motor speed before starting it. Otherwise, motor stalling and other faults can occur.

time of DC Injection Braking at stop. Used to completely stop a motor with high inertia load after ramp down. Increase

the value if the motor still coasts by inertia after it should have stopped. Disabled when set to 0.00 s.

No. Name Setting Range Default

b2-04 DC Injection Braking Time at Stop 0.00 to 10.00 s 0.00 s

b2-09: Motor Pre-Heat Current 2

n

Determines the percentage of motor rated output current that will be used for the motor pre-heat function. This function can

be useful in applications where the motor sits for extended periods of time in humid conditions. Motor pre-heating can only

be initiated by closing a digital input programmed as a Motor Pre-Heat 2 (H1-oo = 50).

No. Name Setting Range Default

b2-09 Motor Pre-Heat Current 2 0 to 100% 5%

22

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

Page 23

AC Power supply

Output frequency

Minimum Baseblock Time (L2-03)

b3-05

Run command

Output

frequency

Minimum Baseblock

Time (L2-03)

b3-05

1.2 b: Application

u

b3: Speed Search

The Speed Search function allows the drive to detect the speed of a rotating motor shaft that is driven by external forces and

start the motor operation directly from the detected speed without first stopping the machine.

Example: When a momentary loss of power occurs, the drive output shuts off and the motor coasts. When power returns, the

drive can find the speed of the coasting motor and restart it directly.

Enabling Speed Search for PM motors only requires setting parameter b3-01 to 1. The drive offers current detection and speed

estimation Speed Search for induction motors. Parameter b3-24 selects the speed search method for induction motors. Both

methods and relevant parameters are explained below.

Speed Search start timing differs depending on whether operation is after a momentary power loss (L2-01 = 1 or 2) or after

the Speed Search at start (b3-01 = 1). The operation timing of the Speed Search after a momentary power loss is shown in

Figure 1.9. The operation timing after the Speed Search at start is shown in Figure 1.10.

After restoring power, the Speed Search operation remains in baseblock status for at least the time set in b3-05. However,

Speed Search will not start if the time set in L2-03, Minimum Baseblock Time, does not pass after the power stops. When

induced voltage remains in the motor, the Speed Search operation starts after the time set in b3-05 without waiting for the time

set in L2-03.

When performing a speed search operation at start, the speed search operation will start after waiting for the longer of the

times set

Search operation starts after the time set in b3-05 without waiting for the time set in L2-03.

n

Current Detection Speed Search 2 is for use with IM motors. The current set in b3-31 is applied and the speed is detected

based

Speed Search. If the output current during the Speed Search operation is larger than the setting value of b3-32, reduce the

frequency for the deceleration time set in b3-03. After motor speed estimation is completed, the speed is accelerated or

decelerated to the frequency reference.

Figure 1.9 Timing Chart for Speed Search after Recovery from Momentary Power Loss

in b3-05 and L2-03 after the Run command input is received. When induced voltage remains in the motor, the Speed

Figure 1.10 Timing Chart for Speed Search at Start

Current Detection Speed Search 2 (b3-24 = 2)

the current flow to the motor. The speed then accelerates or decelerates to the frequency reference after completing

on

Parameter Details

1

YASKAWA ELECTRIC SIEP C710636 10C Z1000U HVAC MATRIX Drive Programming Manual

23

Page 24

1.2 b: Application

Speed Estimation Speed Search (b3-24 = 1)

n

A

Speed

Estimation Speed Search estimates the motor speed while the motor is coasting and then restarts operation. The speed

then accelerates or decelerates to the frequency reference after completing Speed Search.

This method can be used for a single induction motor connected to a drive. Do not use this method if the motor is one or more

frame size smaller than the drive, at motor speeds above 200 Hz, or when using a single drive to operate more than one motor.

Speed Search Activation

n

Speed Search can be activated using any of the methods 1 through 5 described below. Select the Speed Search type in parameter

b3-24 independent of the activation method.

Method 1. Automatically activate Speed Search with every Run command. Set b3-01, Speed Search Selection at Start, to 1

(Enabled). External Speed Search commands are ignored.

Method 2. Activate Speed Search using the digital input terminals.

Use the input functions for H1-oo in Table 1.7.

Table 1.7 Speed Search Activation by Digital Inputs

Setting Description b3-24 = 1 b3-24 = 2

61

62

External Search

Command 1

External Search

Command 2

Activate Speed Estimation

Speed Search

Closed: Activate Current Detection Speed Search from the

maximum output frequency (E1-04).

Closed: Activate Current Detection Speed Search from the

frequency reference.

To activate Speed Search by a digital input, the input must be set together with the Run command or the Run command must

be entered after giving the Speed Search command.

Method 3. After automatic fault restart.

When the number of maximum fault restarts in parameter L5-01 is set higher than 0, the drive will automatically perform

Speed Search as specified by b3-24 following a fault.

Method 4. After momentary power loss.

This mode

requires that the Power Loss Ride-Thru function is enabled during CPU operation (L2-01 = 1 or 2). Refer to L2-01:

Momentary Power Loss Operation Selection on page 109.

Method 5. After external baseblock is released.

The drive will resume the operation starting with Speed Search if the Run command is present and the output frequency is

above the minimum frequency when the Baseblock command (H1-oo = 8 or 9) is released.

Rotation Direction Detection Conditions for Backspin

n

Backspin occurs when the motor rotates in the opposite direction from the rotation direction command. Specify the speed

search direction when power is recovered after a momentary power loss in applications in which backspin can occur, such as

for an oil pump when backspin may occur due to the weight of the oil after a momentary power loss. The search starts from

the rotation direction specified in the direction command when the momentary power loss time is short. The search starts from

the opposite direction of the direction specified in the direction command when the momentary power loss time is long. The

rotation for the Speed Search is determined as follows:

[t] is the time from the momentary power loss to recovery.

• 0 ≤ t < b3-50: The search is started in the direction specified by the direction command.