Page 1

Z1000U HVAC MATRIX Bypass

Low Harmonic Drive Bypass for HVAC Applications

Technical Manual

Type: Z1D1

Models:

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

208 V: 7.5 to 75 HP

480 V: 7.5 to 350 HP

Receiving

Mechanical Installation

Electrical Installation

Start-Up Programming &

Operation

Programming

Diagnostics &

Troubleshooting

Periodic Inspection &

Maintenance

Specifications

Parameter List

BACnet Communications

MEMOBUS/Modbus

Communications

1

2

3

4

5

6

7

A

B

C

D

MANUAL NO. SIEP YAIZ1D 01A

Apogee FLN Network

Protocol

Metasys N2 Network

Protocol

Standards Compliance

Quick Reference Sheet

E

F

G

H

Page 2

Copyright © 2015 YASKAWA AMERICA, INC. All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means,

mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of Yaskawa. No patent

liability is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly

striving to improve its high-quality products, the information contained in this manual is subject to change without notice.

Every precaution has been taken in the preparation of this manual. Yaskawa assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Page 3

Quick Start Procedure

u

This procedure is a supplement to other documentation supplied with this equipment and guides the user in properly wiring

the Z1000U Bypass and motor.

WARNING! Read and adhere to all safety messages contained in this manual prior to performing this procedure. When installing the system

be sure to follow good wiring practices and all applicable codes. Ensure that the mounting of the various components are secure and that

the environment, such as extreme dampness, poor ventilation etc. will not cause system degradation. Please read this cheat sheet and

other documentation provided with the bypass thoroughly before attempting any installation.

The setup procedure begins on the next page.

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

3

Page 4

4

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 5

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

5

Page 6

6

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 7

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

7

Page 8

8

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 9

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

9

Page 10

10

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 11

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

11

Page 12

12

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 13

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

13

Page 14

14

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 15

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

15

Page 16

16

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 17

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

17

Page 18

18

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 19

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

19

Page 20

20

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 21

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

21

Page 22

22

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 23

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

23

Page 24

24

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 25

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

25

Page 26

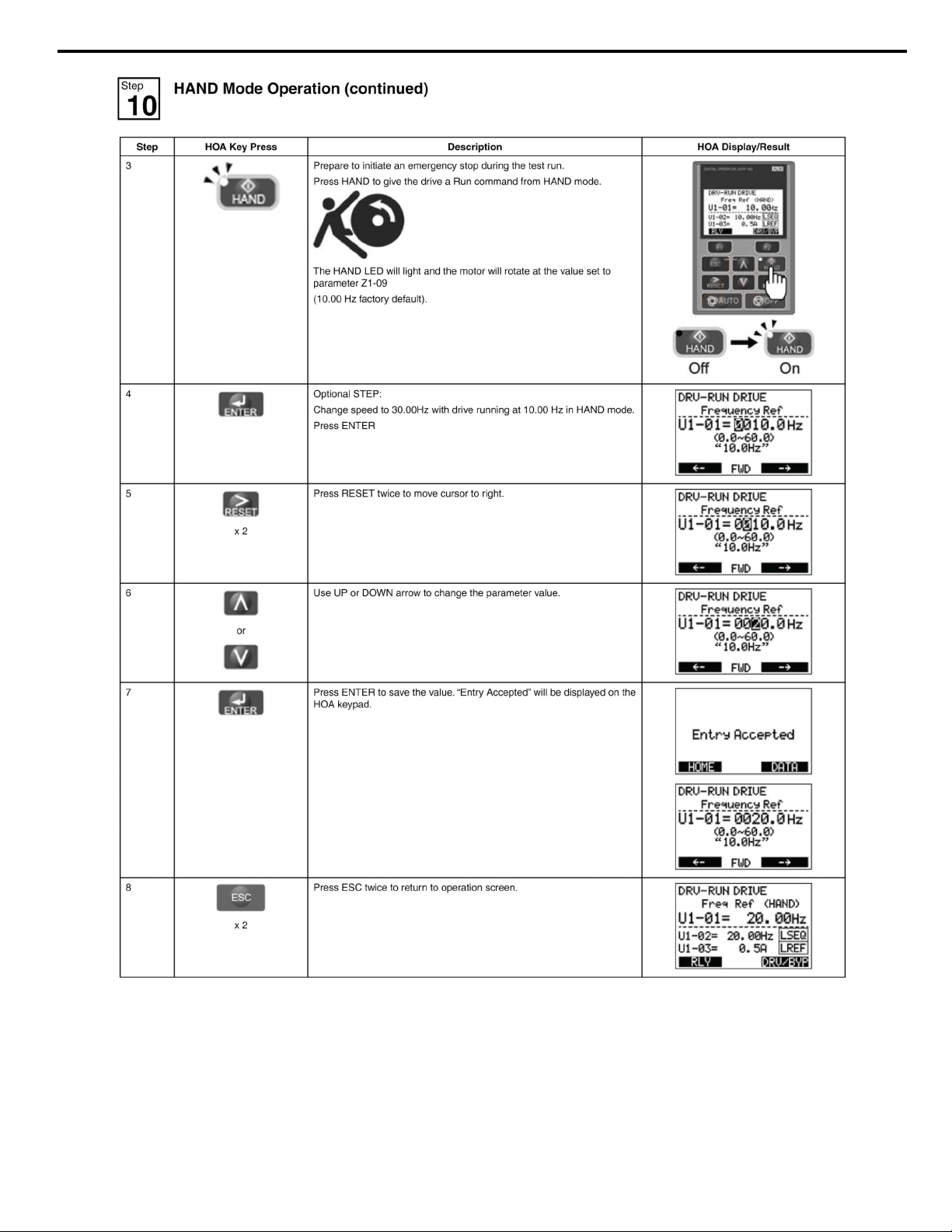

operation mode.

26

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 27

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

27

Page 28

28

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 29

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

29

Page 30

30

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 31

desired

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

31

Page 32

32

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 33

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

33

Page 34

34

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 35

Table of Contents

QUICK START PROCEDURE.......................................................................... 3

i. PREFACE & GENERAL SAFETY.................................................................. 45

i.1 Preface ....................................................................................................................... 46

Product Description ................................................................................................................. 46

Applicable Documentation....................................................................................................... 46

Symbols................................................................................................................................... 46

Terms and Abbreviations ........................................................................................................ 47

Trademarks ............................................................................................................................. 47

i.2 General Safety ........................................................................................................... 48

Supplemental Safety Information ............................................................................................ 48

Safety Messages..................................................................................................................... 49

General Application Precautions ............................................................................................. 50

Motor Application Precautions................................................................................................. 51

Drive Label Warning Example................................................................................................. 52

Bypass Label Warning Example ............................................................................................. 53

Warranty Information............................................................................................................... 54

1. RECEIVING .................................................................................................... 55

1.1 Section Safety............................................................................................................ 56

1.2 General Description .................................................................................................. 57

Control Mode Details............................................................................................................... 57

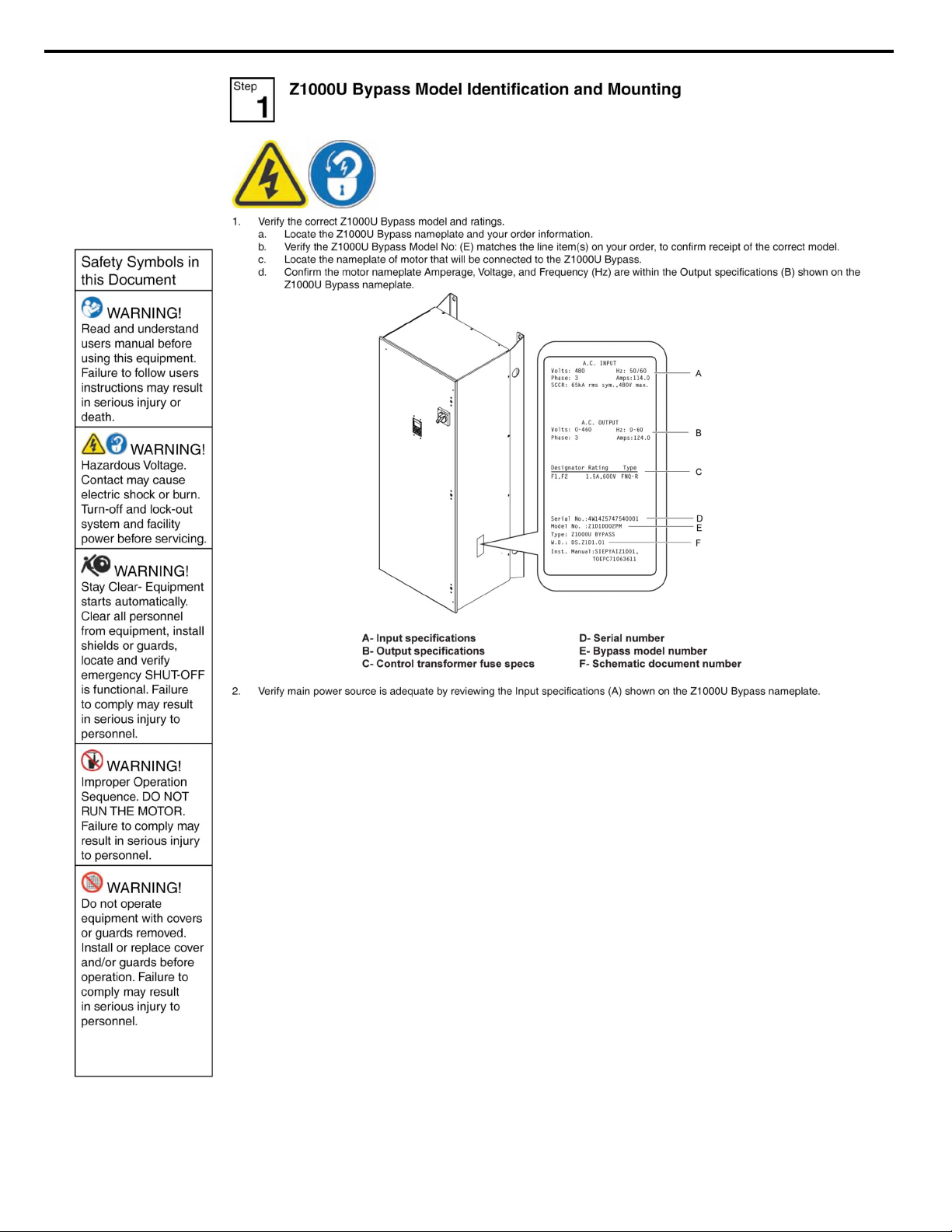

1.3 Model Numbers and Nameplate Checks ................................................................. 58

Drive Nameplate...................................................................................................................... 58

Bypass Nameplate .................................................................................................................. 59

Bypass Enclosures.................................................................................................................. 61

Bypass Product Options.......................................................................................................... 61

1.4 Bypass Component Names...................................................................................... 62

1.5 Bypass Component Descriptions............................................................................ 63

Bypass Front Control Panel .................................................................................................... 63

Bypass Internal Components .................................................................................................. 63

Front Views of Drive ................................................................................................................ 66

2. MECHANICAL INSTALLATION..................................................................... 67

2.1 Section Safety............................................................................................................ 68

2.2 Mechanical Installation ............................................................................................. 70

Installation Environment .......................................................................................................... 70

YASKAWA

SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

35

Page 36

Table of Contents

Installation Orientation and Spacing.................................................................................................. 71

Exterior and Mounting Dimensions ................................................................................................... 71

3. ELECTRICAL INSTALLATION .............................................................................. 73

3.1 Section Safety......................................................................................................................74

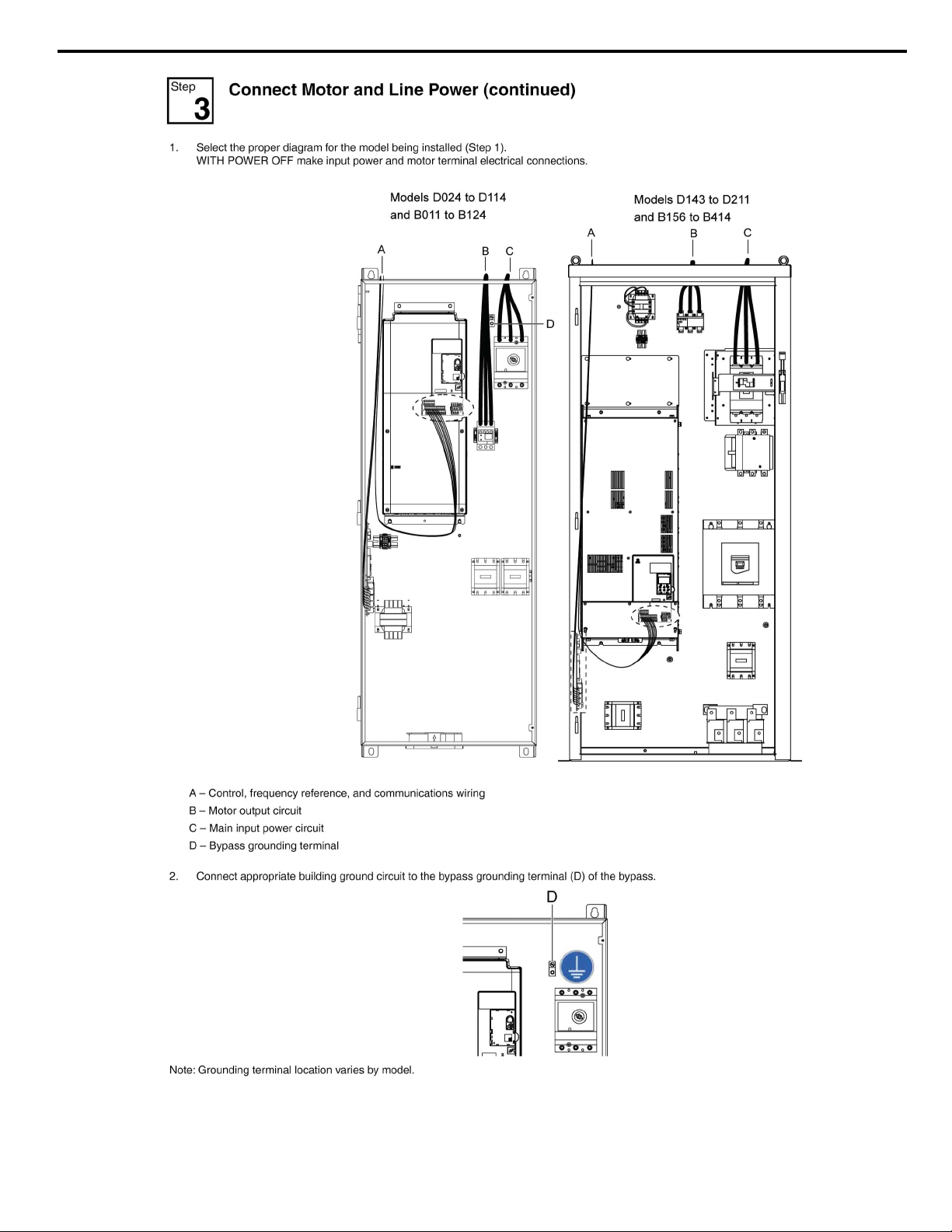

3.2 Standard Connection Diagram...........................................................................................76

3.3 Main Circuit Wiring..............................................................................................................80

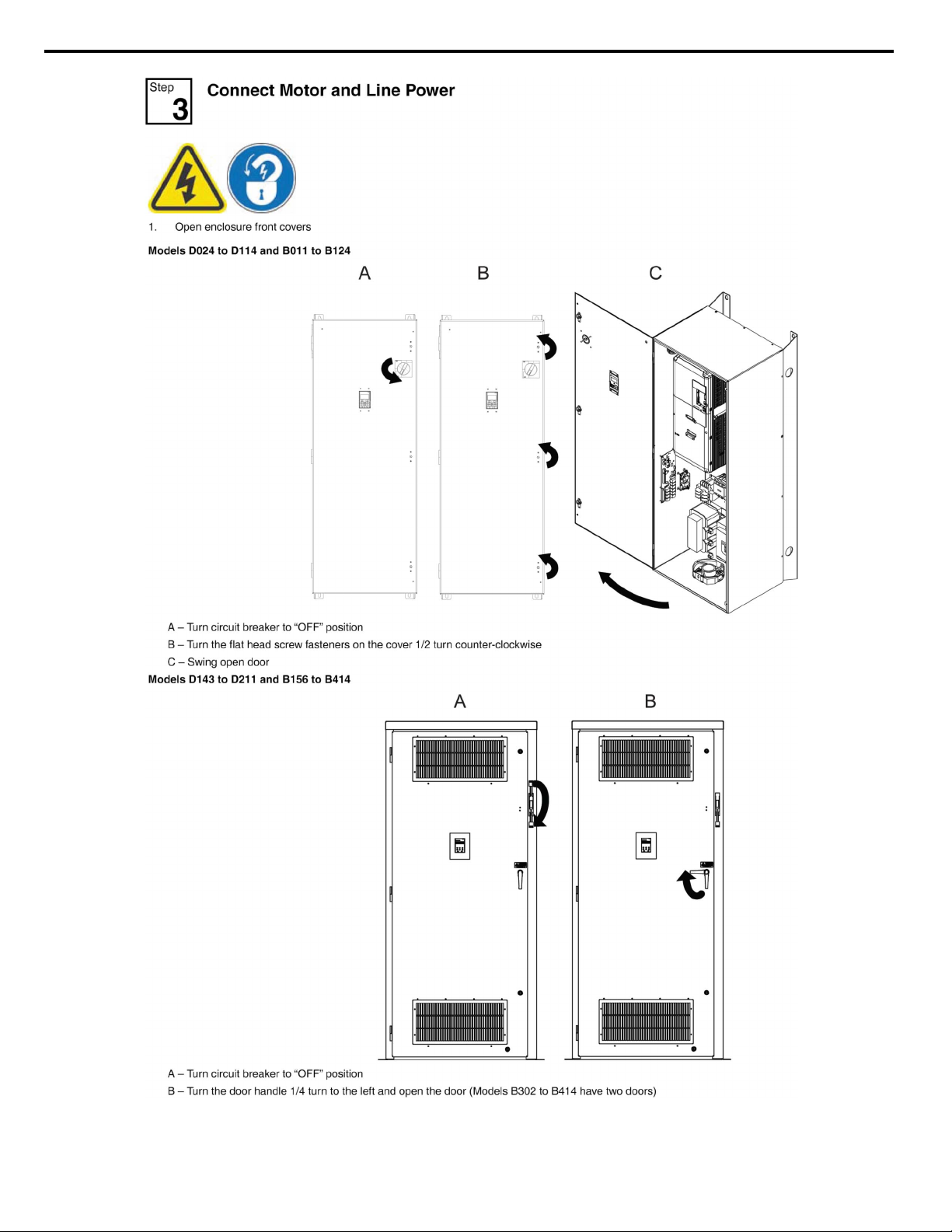

Opening the Bypass Enclosure ......................................................................................................... 80

Bypass Main Circuit Terminal Block Configuration ........................................................................... 84

3.4 Input and Output Power Wiring Connections...................................................................85

Factory Recommended Branch Circuit Protection ............................................................................ 85

Main Circuit Terminal Functions........................................................................................................ 86

Wire Gauge and Tightening Torque Specifications........................................................................... 86

Main Input Circuit and Motor Wiring .................................................................................................. 88

Wiring the Main Input Circuit ............................................................................................................. 93

3.5 Control Circuit Wiring .........................................................................................................96

Control Circuit Connection Diagram.................................................................................................. 96

Control Circuit Terminal Block Functions .......................................................................................... 96

Bypass Analog Outputs..................................................................................................................... 97

Serial Communications ..................................................................................................................... 98

Drive Cover Removal ........................................................................................................................ 99

Drives in Bypass Models D024 to D114 and B011 and B124 ........................................................... 99

Drives in Bypass Models D143 to D211 and B156 to B414 ............................................................ 100

Removing/Reattaching the Front Cover .......................................................................................... 100

Wiring the Drive Control Circuit Terminal ........................................................................................ 102

Switches and Jumpers on the Terminal Board................................................................................ 104

3.6 Bypass and Drive Control I/O Connections....................................................................105

Terminals A1, A2, and A3 Input Signal Selection............................................................................ 105

Terminal AM/FM Signal Selection ................................................................................................... 105

MEMOBUS/Modbus Termination .................................................................................................... 106

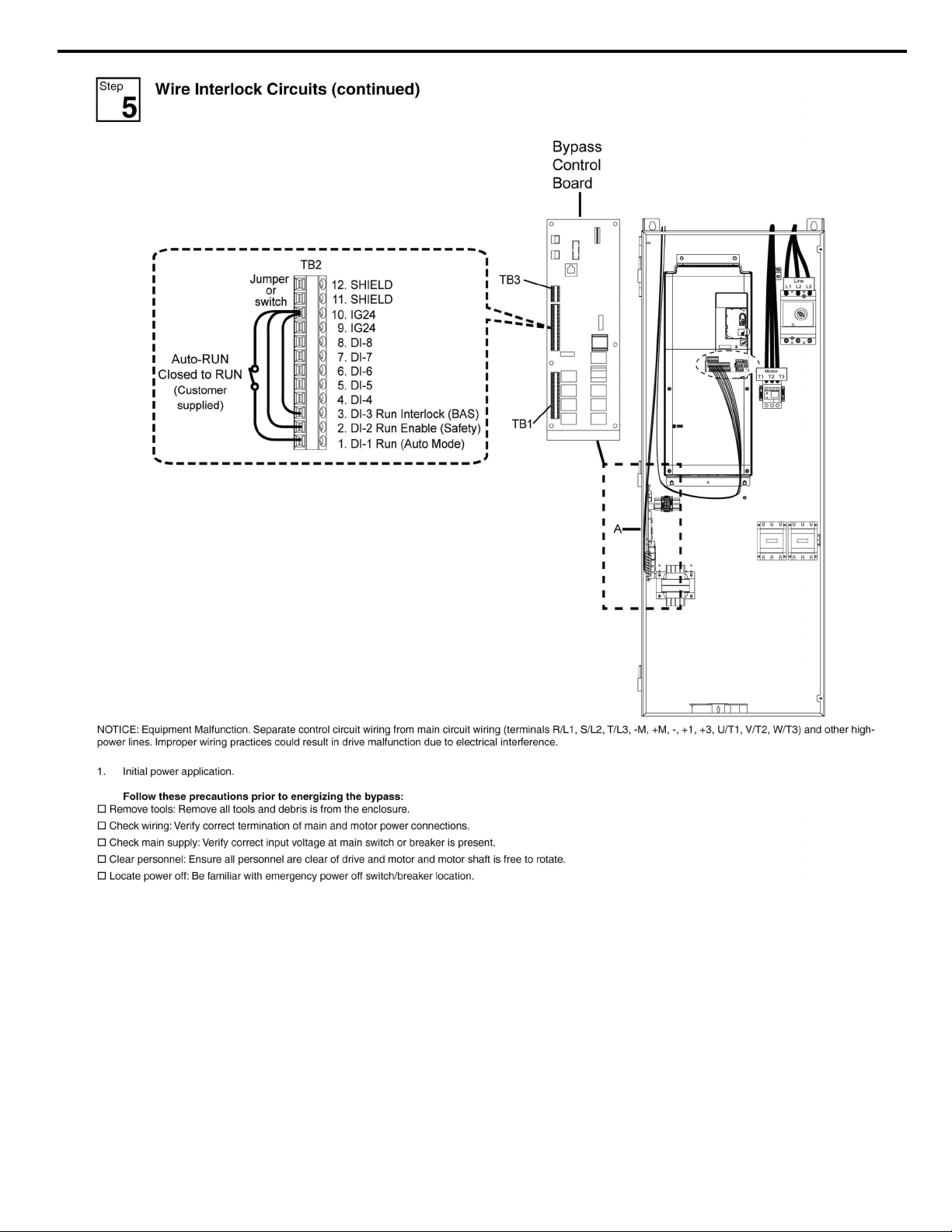

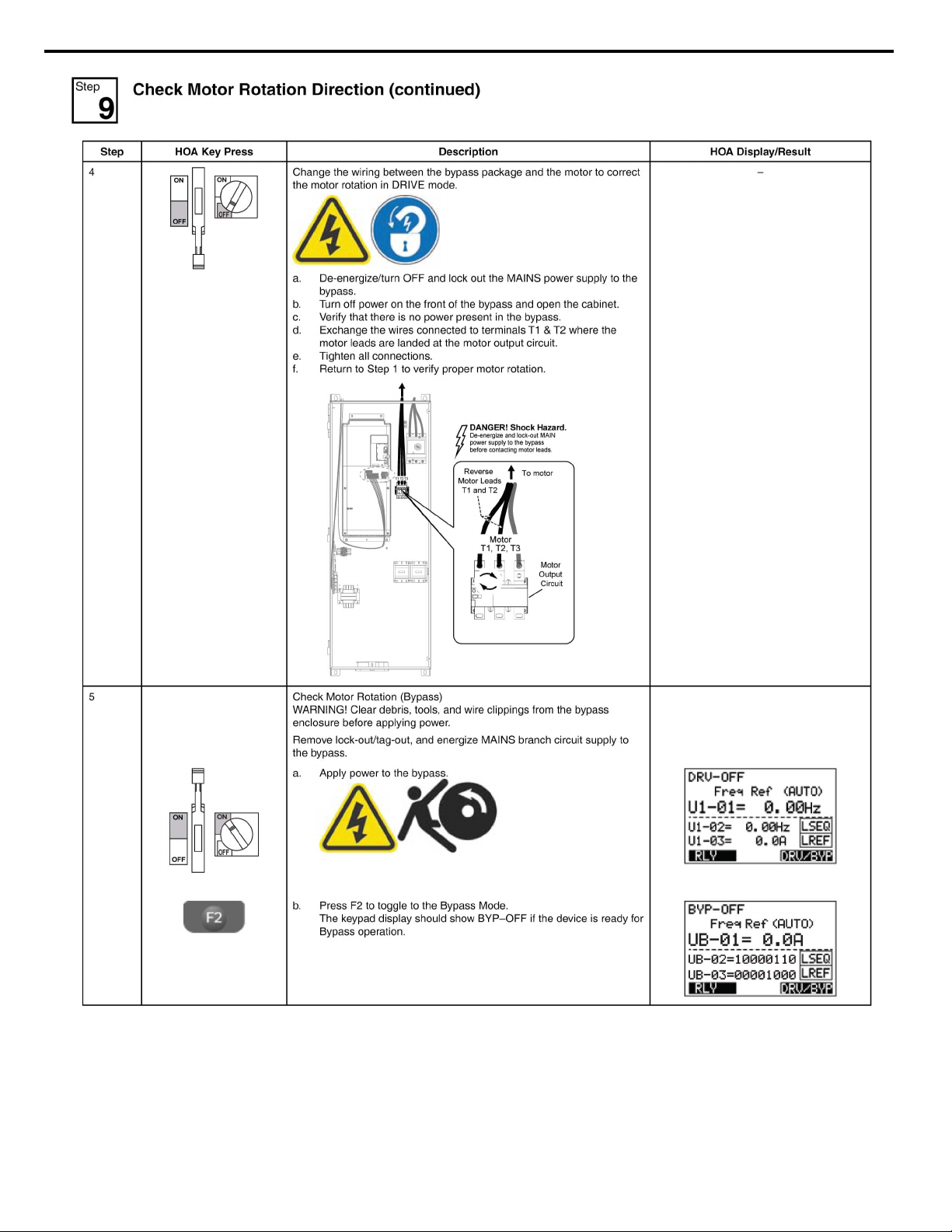

3.7 External Interlock ..............................................................................................................107

Annunciation Contact Outputs......................................................................................................... 107

Building Automation System Run/Stop Circuit ................................................................................ 107

Safety Interlock Circuit .................................................................................................................... 107

Building Automation System Interlock Circuit (Drive and Bypass Enable Input)............................. 107

Remote Transfer to Bypass............................................................................................................. 108

Smoke Purge Operation.................................................................................................................. 108

Spare Multi-Function Digital Inputs ................................................................................................. 108

4. START-UP PROGRAMMING & OPERATION..................................................... 109

4.1 Section Safety....................................................................................................................110

4.2 Using the HOA Keypad .....................................................................................................111

HOA Keypad Keys and Displays..................................................................................................... 111

LCD Display .................................................................................................................................... 112

Bypass Control Board LEDs............................................................................................................ 113

ALARM (ALM) LED Displays........................................................................................................... 114

AUTO LED and HAND LED Indications .......................................................................................... 114

HOA Keypad Menu Structure.......................................................................................................... 116

HOA Keypad Parameter Display (Drive Off) ................................................................................... 116

4.3 The Drive and Programming Modes................................................................................118

36

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 37

Table of Contents

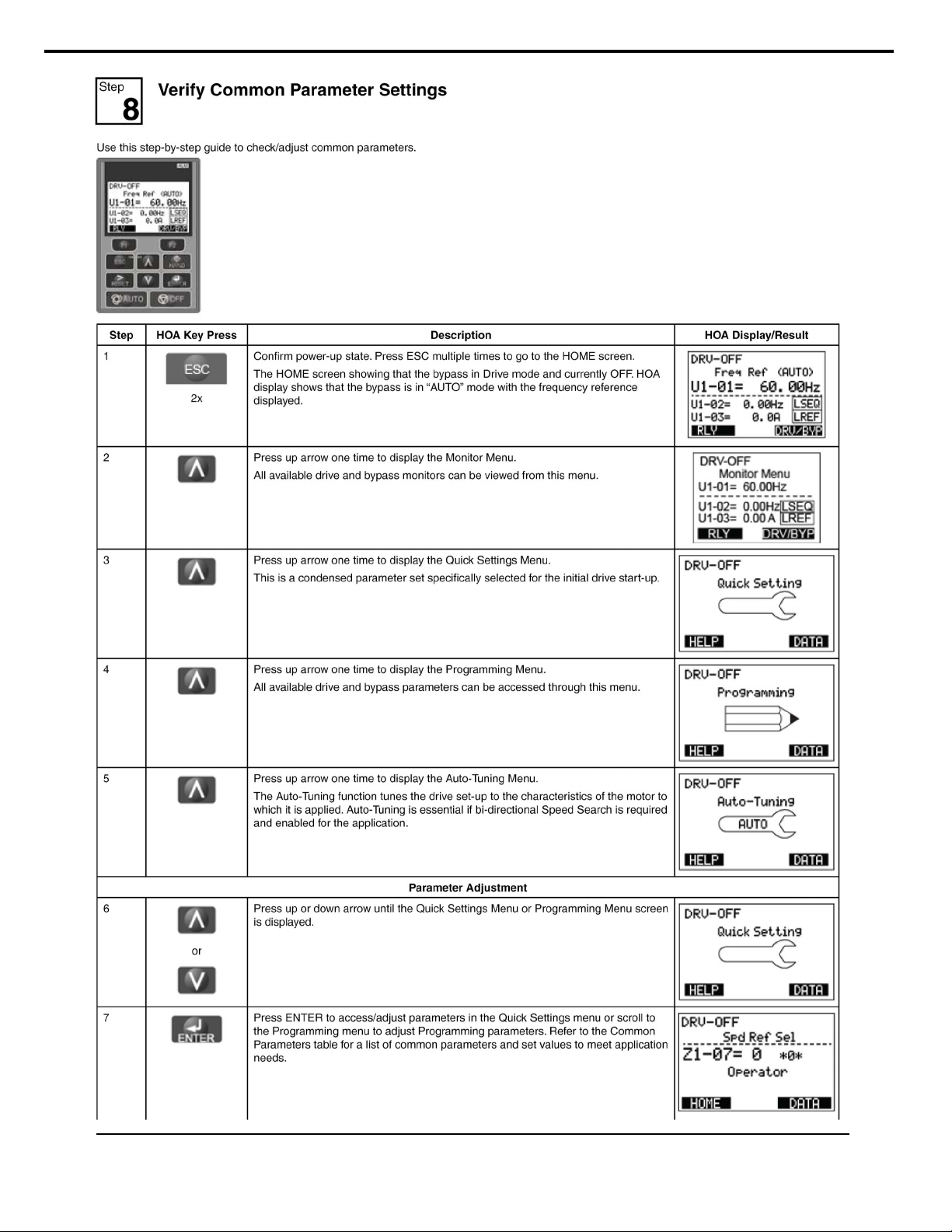

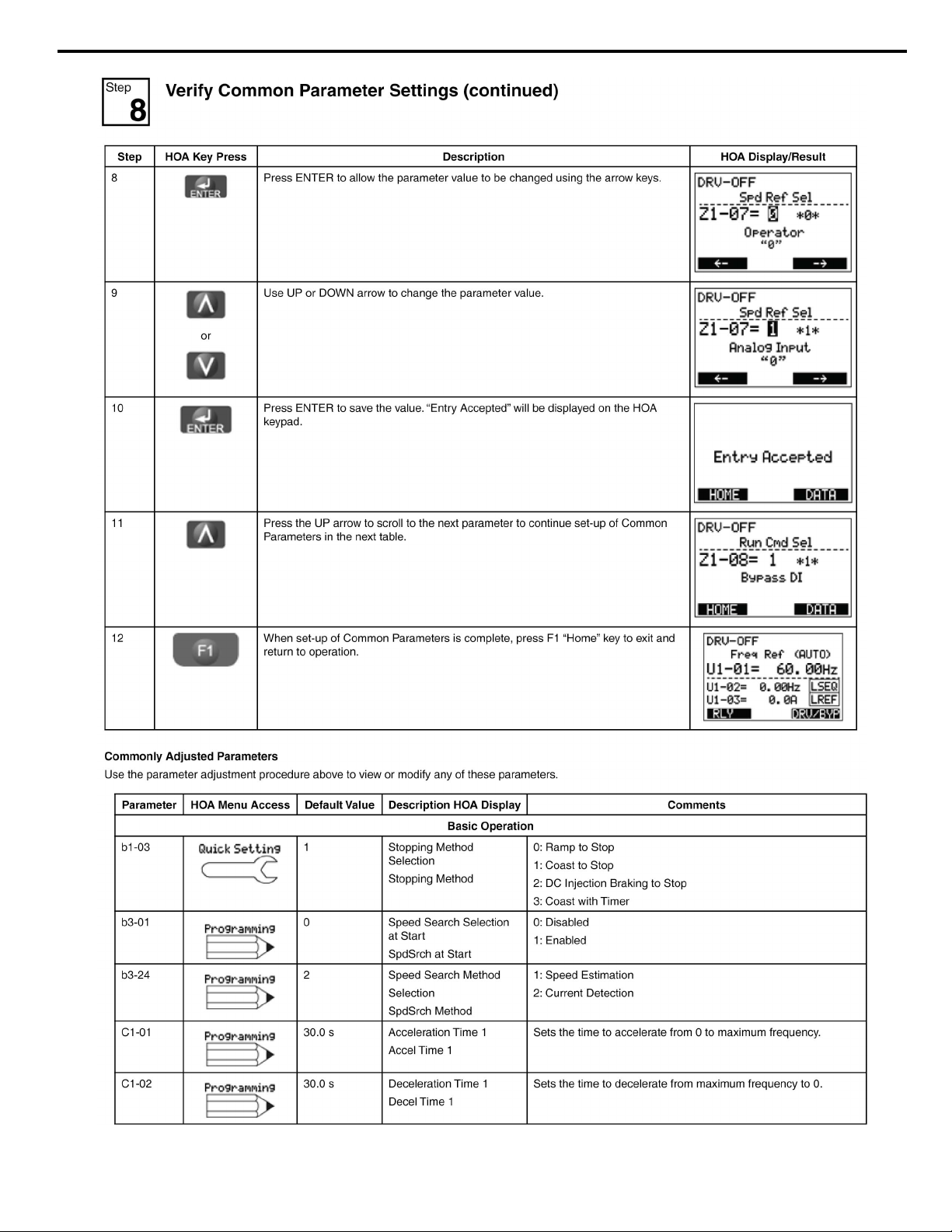

Changing Parameter Settings or Values ......................................................................................... 118

Verifying Parameter Changes: Modified Constants ........................................................................ 119

Simplified Setup Using the Quick Setting Group............................................................................. 120

4.4 Powering Up the Drive ......................................................................................................122

Powering Up the Drive and Operation Status Display..................................................................... 122

4.5 Application Selection........................................................................................................123

Setting 1: Fan Application ............................................................................................................... 123

Setting 2: Fan with PID Control Application .................................................................................... 123

Setting 3: Return Fan with PID Control Application......................................................................... 123

Setting 4: Cooling Tower Fan Application ....................................................................................... 124

Setting 5: Cooling Tower Fan with PID Control Application ............................................................ 124

Setting 6: Pump (Secondary) Application........................................................................................ 125

Setting 7: Pump with PID Control Application ................................................................................. 125

4.6 Auto-Tuning .......................................................................................................................126

Types of Auto-Tuning ...................................................................................................................... 126

Before Auto-Tuning the Drive.......................................................................................................... 126

Auto-Tuning Interruption and Fault Codes ...................................................................................... 127

Auto-Tuning Operation Example ..................................................................................................... 127

T1: Parameter Settings during Induction Motor Auto-Tuning .......................................................... 129

5. PROGRAMMING .................................................................................................. 131

5.1 A: Initialization...................................................................................................................132

A1: Initialization ............................................................................................................................... 132

5.2 b: Application.....................................................................................................................133

b1: Operation Mode Selection......................................................................................................... 133

b2: DC Injection Braking and Short Circuit Braking......................................................................... 135

b3: Speed Search............................................................................................................................ 136

b5: PID Control................................................................................................................................ 142

5.3 C: Tuning............................................................................................................................153

C1: Acceleration and Deceleration Times ....................................................................................... 153

C2: S-Curve Characteristics............................................................................................................ 153

C4: Torque Compensation .............................................................................................................. 154

C6: Carrier Frequency..................................................................................................................... 154

C7: Voltage Adjustment................................................................................................................... 155

5.4 d: Reference Settings .......................................................................................................156

d1: Frequency Reference................................................................................................................ 156

d2: Frequency Upper/Lower Limits ................................................................................................. 157

d3: Jump Frequency........................................................................................................................ 158

5.5 E: Motor Parameters .........................................................................................................159

E1: V/f Pattern for Motor 1............................................................................................................... 159

E2: Motor 1 Parameters .................................................................................................................. 163

5.6 F: Options...........................................................................................................................164

F6: Drive/Bypass Communications ................................................................................................. 164

5.7 H: Terminal Functions.......................................................................................................165

H1: Multi-Function Digital Inputs ..................................................................................................... 165

H2: Multi-Function Digital Outputs................................................................................................... 167

H3: Multi-Function Analog Inputs .................................................................................................... 174

H4: Multi-Function Analog Outputs ................................................................................................. 180

5.8 L: Protection Functions ....................................................................................................182

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

37

Page 38

Table of Contents

L1: Motor Protection ........................................................................................................................ 182

L2: Momentary Power Loss Ride-Thru............................................................................................ 183

L3: Stall Prevention ......................................................................................................................... 184

L4: Reference Detection.................................................................................................................. 186

L5: Fault Restart.............................................................................................................................. 187

L6: Torque Detection....................................................................................................................... 190

L8: Drive Protection......................................................................................................................... 192

5.9 n: Special Adjustments.....................................................................................................194

n1: Hunting Prevention.................................................................................................................... 194

n3: Overexcitation Braking .............................................................................................................. 194

5.10 o: Operator-Related Settings ...........................................................................................195

o1: HOA Keypad Display Selection................................................................................................. 195

o2: HOA Keypad Functions............................................................................................................. 196

o4: Maintenance Monitor Settings................................................................................................... 196

5.11 S: Special Parameters.......................................................................................................198

S1: Dynamic Audible Noise Control Function ................................................................................. 198

S2: Sequence Timers...................................................................................................................... 199

Examples of Sequence Timers ....................................................................................................... 201

5.12 T: Motor Tuning .................................................................................................................205

5.13 U: Monitor Parameters......................................................................................................206

UB: Bypass Monitors....................................................................................................................... 206

U1: Operation Status Monitors ........................................................................................................ 206

U2: Fault Trace................................................................................................................................ 206

U3: Fault History.............................................................................................................................. 206

U4: Maintenance Monitors .............................................................................................................. 206

U5: PID Monitors ............................................................................................................................. 206

U9: Power Monitors......................................................................................................................... 206

5.14 Z: Bypass Parameters.......................................................................................................207

Z1: Bypass Control System............................................................................................................. 207

Z2: Bypass Control Input/Output ..................................................................................................... 216

Z3: Bypass Control Communication................................................................................................ 220

Z4: Ethernet Option Bypass Control................................................................................................ 223

6. DIAGNOSTICS & TROUBLESHOOTING ............................................................ 227

6.1 Section Safety....................................................................................................................228

6.2 Motor Performance Fine-Tuning......................................................................................230

Fine-Tuning V/f Control ................................................................................................................... 230

Parameters to Minimize Motor Hunting and Oscillation .................................................................. 230

6.3 Drive Alarms, Faults, and Errors .....................................................................................231

Types of Alarms, Faults, and Errors................................................................................................ 231

Alarm and Error Displays ................................................................................................................ 232

6.4 Fault Detection ..................................................................................................................235

Fault Displays, Causes, and Possible Solutions ............................................................................. 235

6.5 Alarm Detection.................................................................................................................251

Alarm Codes, Causes, and Possible Solutions ............................................................................... 251

6.6 Operator Programming Errors .........................................................................................259

Operator Programming Error Codes, Causes, and Possible Solutions........................................... 259

6.7 Auto-Tuning Fault Detection ............................................................................................262

38

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 39

Table of Contents

Auto-Tuning Codes, Causes, and Possible Solutions..................................................................... 262

6.8 Diagnosing and Resetting Faults.....................................................................................264

Fault Occurs Simultaneously with Power Loss ............................................................................... 264

If the Drive Still has Power After a Fault Occurs ............................................................................. 264

Viewing Fault Trace Data After Fault .............................................................................................. 264

Fault Reset Methods ....................................................................................................................... 264

6.9 Troubleshooting without Fault Display...........................................................................266

Common Problems.......................................................................................................................... 266

Cannot Change Parameter Settings ............................................................................................... 266

Motor Does Not Rotate Properly after Pressing AUTO Button or after Entering External Run

Command ...................................................................................................................................... 267

Motor is Too Hot.............................................................................................................................. 269

oPE02 Error Occurs When Lowering the Motor Rated Current Setting .......................................... 270

Motor Stalls during Acceleration or Acceleration Time is Too Long................................................ 270

Drive Frequency Reference Differs from the Controller Frequency Reference Command ............. 270

Excessive Motor Oscillation and Erratic Rotation............................................................................ 271

Deceleration Takes Longer than Expected ..................................................................................... 271

Noise From Drive or Motor Cables When the Drive is Powered On ............................................... 271

Ground Fault Circuit Interrupter (GFCI) Trips During Run .............................................................. 271

Connected Machinery Vibrates When Motor Rotates ..................................................................... 271

PID Output Fault.............................................................................................................................. 272

Motor Rotates after the Drive Output is Shut Off (Motor Rotates During DC Injection Braking) ..... 272

Output Frequency is Not as High as Frequency Reference............................................................ 272

Sound from Motor............................................................................................................................ 273

Motor Does Not Restart after Power Loss....................................................................................... 273

The Safety Controller Does Not Recognize Safe Disable Monitor Output Signals (Terminals DM

+ and DM-) ..................................................................................................................................... 273

7. PERIODIC INSPECTION & MAINTENANCE....................................................... 275

7.1 Section Safety....................................................................................................................276

7.2 Inspection ..........................................................................................................................278

Recommended Daily Inspection...................................................................................................... 278

Recommended Periodic Inspection................................................................................................. 279

7.3 Periodic Maintenance .......................................................................................................281

Replacement Parts.......................................................................................................................... 281

7.4 HOA Keypad Battery Replacement..................................................................................283

Real-Time Clock Adjustment........................................................................................................... 283

7.5 Drive Cooling Fans............................................................................................................285

Number of Cooling Fans ................................................................................................................. 285

Drive Cooling Fan Component Names............................................................................................ 285

Cooling Fan Replacement: 2o0028 to 2o0130 and 4o0011 to 4o0124 ...................................... 287

Cooling Fan Replacement: 2o0154, 2o0192, 4o0156, and 4o0180 ........................................... 289

Cooling Fan Replacement: 2o0248 and 4o0240 to 4o0414 ........................................................ 293

Installing the Cooling Fan................................................................................................................ 295

A. SPECIFICATIONS ................................................................................................ 299

A.1 Power Ratings ...................................................................................................................300

Three-Phase 208 Vac Models D024 to D211.................................................................................. 300

Three-Phase 480 Vac Models B011 to B077 .................................................................................. 301

Three-Phase 480 Vac Models B096 to B414 .................................................................................. 302

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

39

Page 40

Table of Contents

A.2 Drive Specifications ..........................................................................................................303

A.3 Drive Derating Data ...........................................................................................................304

Carrier Frequency Derating............................................................................................................. 304

A.4 Bypass Options .................................................................................................................305

Option B .......................................................................................................................................... 305

Option D .......................................................................................................................................... 305

Option G .......................................................................................................................................... 305

Option K (Control) ........................................................................................................................... 305

Option K (Power)............................................................................................................................. 305

Option L........................................................................................................................................... 305

Option N .......................................................................................................................................... 305

Option W (Control) .......................................................................................................................... 305

Option W (Power)............................................................................................................................ 305

Option Z........................................................................................................................................... 305

B. PARAMETER LIST............................................................................................... 307

B.1 Parameter Groups .............................................................................................................308

Parameters Listed in Dark Gray Rows ............................................................................................ 309

B.2 A: Initialization Parameters ..............................................................................................310

A1: Initialization ............................................................................................................................... 310

B.3 b: Application.....................................................................................................................311

b1: Operation Mode Selection......................................................................................................... 311

b2: DC Injection Braking.................................................................................................................. 311

b3: Speed Search............................................................................................................................ 312

b5: PID Control................................................................................................................................ 313

b8: Energy Saving ........................................................................................................................... 315

B.4 C: Tuning............................................................................................................................316

C1: Acceleration and Deceleration Times ....................................................................................... 316

C2: S-Curve Characteristics............................................................................................................ 316

C4: Torque Compensation .............................................................................................................. 316

C6: Carrier Frequency..................................................................................................................... 317

C7: Voltage Adjustment................................................................................................................... 317

B.5 d: References.....................................................................................................................318

d1: Frequency Reference................................................................................................................ 318

d2: Frequency Upper/Lower Limits ................................................................................................. 318

d3: Jump Frequency........................................................................................................................ 318

d4: Frequency Reference Hold Function......................................................................................... 319

d7: Offset Frequency....................................................................................................................... 319

B.6 E: Motor Parameters .........................................................................................................320

E1: V/f Pattern for Motor 1............................................................................................................... 320

E2: Motor 1 Parameters .................................................................................................................. 321

B.7 F: Options...........................................................................................................................322

F6: Drive/Bypass Communications ................................................................................................. 322

B.8 H Parameters: Multi-Function Terminals ........................................................................323

H1: Multi-Function Digital Inputs ..................................................................................................... 323

H2: Multi-Function Digital Outputs................................................................................................... 325

H3: Multi-Function Analog Inputs .................................................................................................... 326

H4: Analog Outputs ......................................................................................................................... 328

H5: MEMOBUS/Modbus Serial Communication ............................................................................. 329

40

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 41

Table of Contents

B.9 L: Protection Function ......................................................................................................330

L1: Motor Protection ........................................................................................................................ 330

L2: Momentary Power Loss Ride-Thru............................................................................................ 330

L3: Stall Prevention ......................................................................................................................... 331

L4: Speed Detection........................................................................................................................ 331

L5: Fault Restart.............................................................................................................................. 332

L6: Torque Detection....................................................................................................................... 332

L8: Drive Protection......................................................................................................................... 333

B.10 n: Special Adjustment.......................................................................................................334

n1: Hunting Prevention.................................................................................................................... 334

n3: Overexcitation Braking .............................................................................................................. 334

B.11 o: Operator-Related Settings ...........................................................................................335

o1: HOA Keypad Display Selection................................................................................................. 335

o2: HOA Keypad Functions............................................................................................................. 335

o4: Maintenance Monitor Settings................................................................................................... 336

B.12 S: HVAC Function..............................................................................................................337

S1: Dynamic Noise Control Function .............................................................................................. 337

S2: Sequence Timers...................................................................................................................... 337

B.13 T: Motor Tuning .................................................................................................................340

T1: Induction Motor Auto-Tuning..................................................................................................... 340

B.14 U: Monitors.........................................................................................................................341

UB: Bypass Control Monitors .......................................................................................................... 341

U1: Operation Status Monitors ........................................................................................................ 342

U2: Fault Trace................................................................................................................................ 344

U3: Fault History.............................................................................................................................. 345

U4: Maintenance Monitors .............................................................................................................. 347

U5: PID Monitors ............................................................................................................................. 348

U9: Power Monitors......................................................................................................................... 349

B.15 Z: Bypass Parameters.......................................................................................................350

Z1: Bypass Control System............................................................................................................. 350

Z2: Bypass Control Input/Output ..................................................................................................... 353

Z3: Bypass Control Communication................................................................................................ 354

Z4: Bypass Control Option Boards.................................................................................................. 355

B.16 Defaults by Drive Model....................................................................................................358

C. BACNET COMMUNICATIONS ............................................................................ 361

C.1 BACnet Configuration.......................................................................................................362

C.2 Communication Specifications........................................................................................363

C.3 Connecting to a Network ..................................................................................................364

Network Cable Connection.............................................................................................................. 364

Wiring Diagram for Multiple Connections ........................................................................................ 365

Network Termination ....................................................................................................................... 365

C.4 BACnet Setup Parameters................................................................................................366

BACnet Serial Communication........................................................................................................ 366

C.5 Bypass Operations by BACnet ........................................................................................368

Observing the Bypass Operation .................................................................................................... 368

Controlling the Bypass .................................................................................................................... 368

C.6 BACnet Objects Supported ..............................................................................................369

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

41

Page 42

Table of Contents

Present Value Access ..................................................................................................................... 369

Supported Properties of Objects ..................................................................................................... 369

Analog Input Objects ....................................................................................................................... 370

Analog Output Objects .................................................................................................................... 370

Analog Value Objects...................................................................................................................... 370

Binary Input Objects ........................................................................................................................ 371

Binary Output Objects ..................................................................................................................... 372

Binary Value Objects....................................................................................................................... 372

Device Object .................................................................................................................................. 374

C.7 Accessing Bypass Parameters and the Enter Command .............................................376

Reading Bypass Parameters........................................................................................................... 376

Writing Bypass Parameters............................................................................................................. 376

Enter Command .............................................................................................................................. 376

C.8 Communication Errors .....................................................................................................377

C.9 BACnet Protocol Implementation Conformance Statement..........................................378

D. MEMOBUS/MODBUS COMMUNICATIONS........................................................ 381

D.1 MEMOBUS/Modbus Configuration ..................................................................................382

D.2 Communication Specifications........................................................................................383

D.3 Connecting to a Network ..................................................................................................384

Network Cable Connection.............................................................................................................. 384

Wiring Diagram for Multiple Connections ........................................................................................ 385

Network Termination ....................................................................................................................... 385

D.4 MEMOBUS/Modbus Setup Parameters ...........................................................................386

MEMOBUS/Modbus Serial Communication.................................................................................... 386

D.5 Bypass Operations by MEMOBUS/Modbus....................................................................388

Observing the Bypass Operation .................................................................................................... 388

D.6 Communications Timing...................................................................................................389

Command Messages from Master to Bypass ................................................................................. 389

Response Messages from Bypass to Master.................................................................................. 389

D.7 Message Format ................................................................................................................390

Message Content ............................................................................................................................ 390

Slave Address ................................................................................................................................. 390

Function Code ................................................................................................................................. 390

Data................................................................................................................................................. 390

Error Check ..................................................................................................................................... 390

D.8 Message Examples ...........................................................................................................392

Reading Drive MEMOBUS/Modbus Register Contents .................................................................. 392

Loopback Test................................................................................................................................. 392

Writing to Multiple Registers............................................................................................................ 393

D.9 MEMOBUS/Modbus Data Table........................................................................................394

Command Data ............................................................................................................................... 394

Monitor Data.................................................................................................................................... 395

Broadcast Messages....................................................................................................................... 407

Fault Trace Contents....................................................................................................................... 408

Bypass Fault Codes ........................................................................................................................ 410

Alarm Register Contents ................................................................................................................. 410

D.10 Enter Command.................................................................................................................412

Enter Command Behavior ............................................................................................................... 412

42

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 43

Table of Contents

D.11 Communication Errors .....................................................................................................413

MEMOBUS/Modbus Error Codes.................................................................................................... 413

Slave Not Responding..................................................................................................................... 413

E. APOGEE FLN NETWORK PROTOCOL.............................................................. 415

E.1 APOGEE FLN Set-Up.........................................................................................................416

Bypass Parameter Settings for APOGEE FLN Communications.................................................... 416

E.2 Connecting to a Network ..................................................................................................417

Network Cable Connection.............................................................................................................. 417

Wiring Diagram for Multiple Connections ........................................................................................ 418

Network Termination ....................................................................................................................... 418

Recommended Cable...................................................................................................................... 418

E.3 Slope and Intercept Conversion ......................................................................................419

Drive Controlled Feedback.............................................................................................................. 419

Field Panel Controlled Feedback .................................................................................................... 419

Other Functionality .......................................................................................................................... 420

E.4 APOGEE FLN Point List Summary ..................................................................................421

E.5 Cable Loss Configuration and Behavior.........................................................................425

Drive Behavior at Loss of Communication ...................................................................................... 425

Apogee FLN Points ......................................................................................................................... 425

E.6 Mailbox Function...............................................................................................................427

Mailbox Function Points .................................................................................................................. 427

E.7 Fault Codes........................................................................................................................428

Communications Fault..................................................................................................................... 428

Bypass Faults–Apogee FLN Configuration ..................................................................................... 428

F. METASYS N2 NETWORK PROTOCOL .............................................................. 431

F.1 N2 Specifications and Configuration...............................................................................432

F.2 Connecting to a Network..................................................................................................433

Network Cable Connection.............................................................................................................. 433

Wiring Diagram for Multiple Connections ........................................................................................ 434

Network Termination ....................................................................................................................... 434

F.3 N2 Setup Parameters ........................................................................................................435

N2 Serial Communication................................................................................................................ 435

F.4 Bypass Operations by N2.................................................................................................437

Observing the Bypass Operation .................................................................................................... 437

Controlling the Bypass .................................................................................................................... 437

F.5 Communications Timing...................................................................................................441

Command Messages from Master to Bypass ................................................................................. 441

Response Messages from Bypass to Master.................................................................................. 441

F.6 Metasys N2 Point Database..............................................................................................442

Metasys N2 Analog Input (AI) Summary ......................................................................................... 442

Metasys N2 Analog Output (AO) Summary .................................................................................... 443

Metasys N2 Binary Input (BI) Summary .......................................................................................... 443

Metasys N2 Binary Output (BO) Summary ..................................................................................... 444

F.7 Mailbox Function...............................................................................................................445

Reading Drive Parameters .............................................................................................................. 445

Writing Drive Parameters ................................................................................................................ 445

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

43

Page 44

Table of Contents

G. STANDARDS COMPLIANCE .............................................................................. 447

G.1 Section Safety....................................................................................................................448

G.2 UL/cUL Standards .............................................................................................................450

UL Standards Compliance .............................................................................................................. 450

H. QUICK REFERENCE SHEET .............................................................................. 451

H.1 Z1000U Bypass and Motor Specifications ......................................................................452

Z1000U Bypass Specifications........................................................................................................ 452

Motor Specifications ........................................................................................................................ 452

H.2 Basic Parameter Settings .................................................................................................453

Quick Setting Parameters ............................................................................................................... 453

Motor Setup..................................................................................................................................... 453

Multi-Function Digital Inputs ............................................................................................................ 453

Analog Inputs .................................................................................................................................. 453

Multi-Function Digital Outputs ......................................................................................................... 454

Monitor Outputs............................................................................................................................... 454

H.3 User Setting Table.............................................................................................................455

INDEX ................................................................................................................... 461

44

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 45

i

Preface & General Safety

This section provides safety messages pertinent to this product that, if not heeded, may result in fatality,

personal injury, or equipment damage. Yaskawa is not responsible for the consequences of ignoring

these instructions.

i.1 PREFACE...............................................................................................................46

i.2 GENERAL SAFETY...............................................................................................48

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

45

Page 46

TERMSTERMS

i.1 Preface

i.1 Preface

Yaskawa manufactures products used as components in a wide variety of industrial systems and equipment. The selection and

application of Yaskawa products remain the responsibility of the equipment manufacturer or end user. Yaskawa accepts no

responsibility for the way its products are incorporated into the final system design. Under no circumstances should any

Yaskawa product be incorporated into any product or design as the exclusive or sole safety control. Without exception, all

controls should be designed to detect faults dynamically and fail safely under all circumstances. All systems or equipment

designed to incorporate a product manufactured by Yaskawa must be supplied to the end user with appropriate warnings and

instructions as to the safe use and operation of that part. Any warnings provided by Yaskawa must be promptly provided to

the end user. Yaskawa offers an express warranty only as to the quality of its products in conforming to standards and

specifications published in the Yaskawa manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS OFFERED.

Yaskawa assumes no liability for any personal injury, property damage, losses, or claims arising from misapplication of its

products.

This manual is designed to ensure correct and suitable application of the Z1000U Bypass. Read this manual before attempting

to install, operate, maintain, or inspect the bypass unit and keep it in a safe, convenient location for future reference. Be sure

you understand all precautions and safety information before attempting application.

u

Product Description

The Z1000U MATRIX HVAC Bypass combines excellent harmonic mitigation, input power factor control, and energy saving

capabilities in a design specifically suited for use in HVAC building automation applications that require reliable motor control.

The bypass package provides a Z1000U MATRIX drive in a NEMA rated enclosure with a 2-contactor style bypass to allow

motor operation from the drive or across the line. The Z1000U MATRIX drive incorporates MATRIX technology to directly

convert input AC voltage to output AC voltage. The Z1000U MATRIX drive offers real choices and benefits for green HVAC

applications.

The Z1000U features HVAC application-specific software macros, a Hand/Off/Auto LCD keypad, and a real time clock for

system accuracy. Popular building automation communication protocols BACnet, Siemens APOGEE, Johnson Controls

Metasys, and MEMOBUS/ Modbus are embedded in the drive.

u

Applicable Documentation

The following manuals are available for the Z1000U MATRIX Bypass:

Z1000U HVAC MATRIX Bypass Technical Manual

Read this manual first. This manual is packaged together with the product and contains basic information

required to install and wire the bypass. It also gives detailed information on fault diagnostics, parameter

settings, and serial communication specifications. The purpose of this manual is to prepare the Z1000U

Bypass for a trial run with an application and for basic operation. This manual is also available for

download on the Yaskawa documentation website, www.yaskawa.com.

Z1000U HVAC MATRIX Drive User Manual

This manual contains detailed information on fault diagnostics, parameter settings, and BACnet

specifications. The most recent version of this manual is available for download on our documentation

website, www.yaskawa.com.

Z1000U HVAC MATRIX Drive Programming Manual

This manual provides detailed information on parameter settings, drive functions, and MEMOBUS/

Modbus specifications. Use this manual to expand drive functionality and to take advantage of higher

performance features. The most recent version of this manual is available for download on our

documentation website, www.yaskawa.com.

u

Symbols

Note: Indicates a supplement or precaution that does not cause drive damage.

Indicates a term or definition used in this manual.

46

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 47

TERMSTERMS

i.1 Preface

u

Terms and Abbreviations

• Bypass: Yaskawa Z1000U MATRIX Bypass

• Drive: Yaskawa Z1000U-Series Drive

• H: Hexadecimal Number Format

• IGBT: Insulated Gate Bipolar Transistor

• kbps: Kilobits per Second

• MAC: Media Access Control

• r/min: Revolutions per Minute

• V/f: V/f Control

u

Trademarks

This manual may describe trademarked equipment, which is the property of other companies. These trademarks are the property

of the registered owner companies and may include the following:

• BACnet is a trademark of the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE).

•

APOGEE™ FLN, trademark of Siemens Building Technologies, Inc.

• Metasys®, trademark of Johnson Controls Inc.

• Modbus®, trademark of Schneider Automation, Inc.

• LONWORKS®, trademark of Echelon Corporation

• Other companies and product names mentioned in this manual are trademarks of those companies.

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

47

Page 48

i.2 General Safety

i.2 General Safety

u

Supplemental Safety Information

General Precautions

• The diagrams in this manual may be indicated without covers or safety shields to show details. Replace the covers or shields before

operating the drive and run the drive according to the instructions described in this manual.

• Any illustrations, photographs, or examples used in this manual are provided as examples only and may not apply to all products to

which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of the manual may be changed without notice

to improve the product and/or the manual.

• When ordering a new copy of the manual due to damage or loss, contact your Yaskawa representative or the nearest Yaskawa sales

office and provide the manual number shown on the front cover.

• If nameplate becomes worn or damaged, order a replacement from your Yaskawa representative or the nearest Yaskawa sales office.

WARNING

Read and understand this manual before installing, operating or servicing this drive. The drive must be installed according

to this manual and local codes.

The following conventions are used to indicate safety messages in this manual. Failure to heed these messages could result

in serious or fatal injury or damage to the products or to related equipment and systems.

DANGER

Indicates a hazardous situation, which, if not avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation, which, if not avoided, could result in death or serious injury.

WARNING! may also be indicated by a bold key word embedded in the text followed by an italicized safety message.

CAUTION

Indicates a hazardous situation, which, if not avoided, could result in minor or moderate injury.

CAUTION! may also be indicated by a bold key word embedded in the text followed by an italicized safety message.

NOTICE

Indicates a property damage message.

NOTICE: may also be indicated by a bold key word embedded in the text followed by an italicized safety message.

48

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

Page 49

i.2 General Safety

u

Safety Messages

WARNING

Heed the safety messages in this manual.

Failure to comply could result in death or serious injury.

The operating company is responsible for any injuries or equipment damage resulting from failure to heed the warnings in

this manual.

Sudden Movement Hazard

System may start unexpectedly upon application of power, resulting in death or serious injury.

Clear all personnel from the drive, motor and machine area before applying power. Secure covers, couplings, shaft keys and

machine loads before applying power to the drive.

Electrical Shock Hazard

Do not connect or disconnect wiring while the power is on.

Failure to comply could result in death or serious injury.

Before servicing, disconnect all power to the equipment. The internal capacitor remains charged even after the power supply

is turned off. The charge indicator LED will extinguish when the DC bus voltage is below 50 Vdc. To prevent electric shock,

wait for at least the time specified on the warning label, once all indicators are OFF, measure for unsafe voltages to confirm

the drive is safe prior to servicing.

Do not attempt to modify or alter the drive in any way not explained in this manual.

Failure to comply could result in death or serious injury.

Yaskawa is not responsible for any modification of the product made by the user. This product must not be modified.

Do not allow unqualified personnel to use equipment.

Failure to comply could result in death or serious injury.

Maintenance, inspection, and replacement of parts must be performed only by authorized personnel familiar with installation,

adjustment and maintenance of AC drives.

Do not remove covers or touch circuit boards while the power is on.

Failure to comply could result in death or serious injury.

Make sure the protective earthing conductor complies with technical standards and local safety regulations.

Because the leakage current exceeds 3.5 mA, IEC/EN 61800-5-1 states that either the power supply must be automatically

disconnected in case of discontinuity of the protective earthing conductor or a protective earthing conductor with a crosssection of at least 10 mm2 (Cu) or 16 mm2 (Al) must be used. Failure to comply may result in death or serious injury.

Always use appropriate equipment for Ground Fault Circuit Interrupters (GFCIs).

The drive can cause a residual current with a DC component in the protective earthing conductor. Where a residual current

operated protective or monitoring device is used for protection in case of direct or indirect contact, always use a type B GFCI

according to IEC/EN 60755.

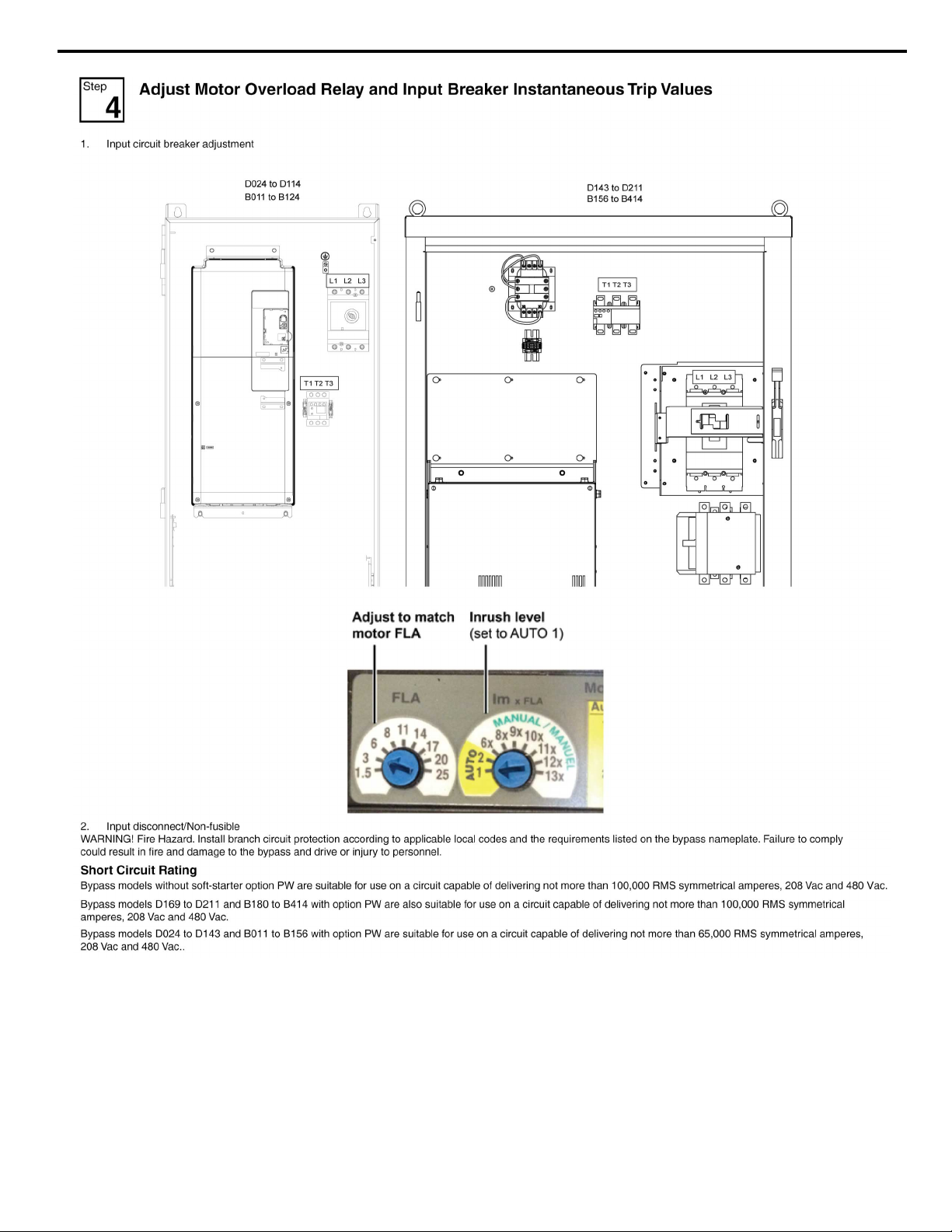

Fire Hazard

Branch Circuit protection is required to be installed according to applicable local codes and the requirements listed on the

bypass nameplate. Failure to comply could result in fire and damage to the bypass and drive or injury to personnel. Bypass

models without soft-starter option PW are suitable for use on a circuit capable of delivering not more than 100,000 RMS

symmetrical amperes, 208 Vac and 480 Vac. Bypass models D169 to D211 and B180 to B414 with option PW are also

suitable for use on a circuit capable of delivering not more than 100,000 RMS symmetrical amperes, 208 Vac and 480 Vac.

Bypass models D024 to D143 and B011 to B156 with option PW are suitable for use on a circuit capable of delivering not

more than 65,000 RMS symmetrical amperes, 208 Vac and 480 Vac.

Do not use an improper voltage source.

Failure to comply could result in death or serious injury by fire.

Verify that the rated voltage of the drive matches the voltage of the incoming power supply before applying power.

YASKAWA SIEP YAIZ1D 01A Z1000U HVAC MATRIX Drive Bypass Technical Manual

49

Page 50

i.2 General Safety

NOTICE

Observe proper electrostatic discharge procedures (ESD) when handling the drive and circuit boards.

Failure to comply may result in ESD damage to the drive circuitry.