YASKAWA AC Drive Z1000

AC Drive for HVAC Fan and Pump

User Manual

Type: CIMR-ZU

Models:

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

600 V Class: 2 to 250 HP

MANUAL NO. TOEP YAIZ1U 03A

Receiving

Mechanical Installation

Electrical Installation

Start-Up Programming &

Operation

Troubleshooting

Peripheral Devices &

Options

Specifications

Parameter List

BACnet Communications

Standards Compliance

Quick Reference Sheet

1

2

3

4

5

6

A

B

C

D

E

Copyright © 2014 YASKAWA AMERICA, INC. All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means,

mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of Yaskawa. No patent

liability is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly

striving to improve its high-quality products, the information contained in this manual is subject to change without notice.

Every precaution has been taken in the preparation of this manual. Yaskawa assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Table of Contents

i. PREFACE & GENERAL SAFETY.................................................................. 11

i.1 Preface ....................................................................................................................... 12

Applicable Documentation....................................................................................................... 12

Symbols................................................................................................................................... 12

Terms and Abbreviations ........................................................................................................ 12

i.2 General Safety ........................................................................................................... 13

Supplemental Safety Information ............................................................................................ 13

Safety Messages..................................................................................................................... 14

General Application Precautions ............................................................................................. 15

Motor Application Precautions................................................................................................. 17

Drive Label Warning Example................................................................................................. 20

Warranty Information............................................................................................................... 20

1. RECEIVING .................................................................................................... 21

1.1 Section Safety............................................................................................................ 22

1.2 General Description .................................................................................................. 23

Z1000 Model Selection............................................................................................................ 23

Control Mode Selection ........................................................................................................... 23

1.3 Model Number and Nameplate Check ..................................................................... 25

Drive Nameplate...................................................................................................................... 25

1.4 Drive Models and Enclosure Types......................................................................... 27

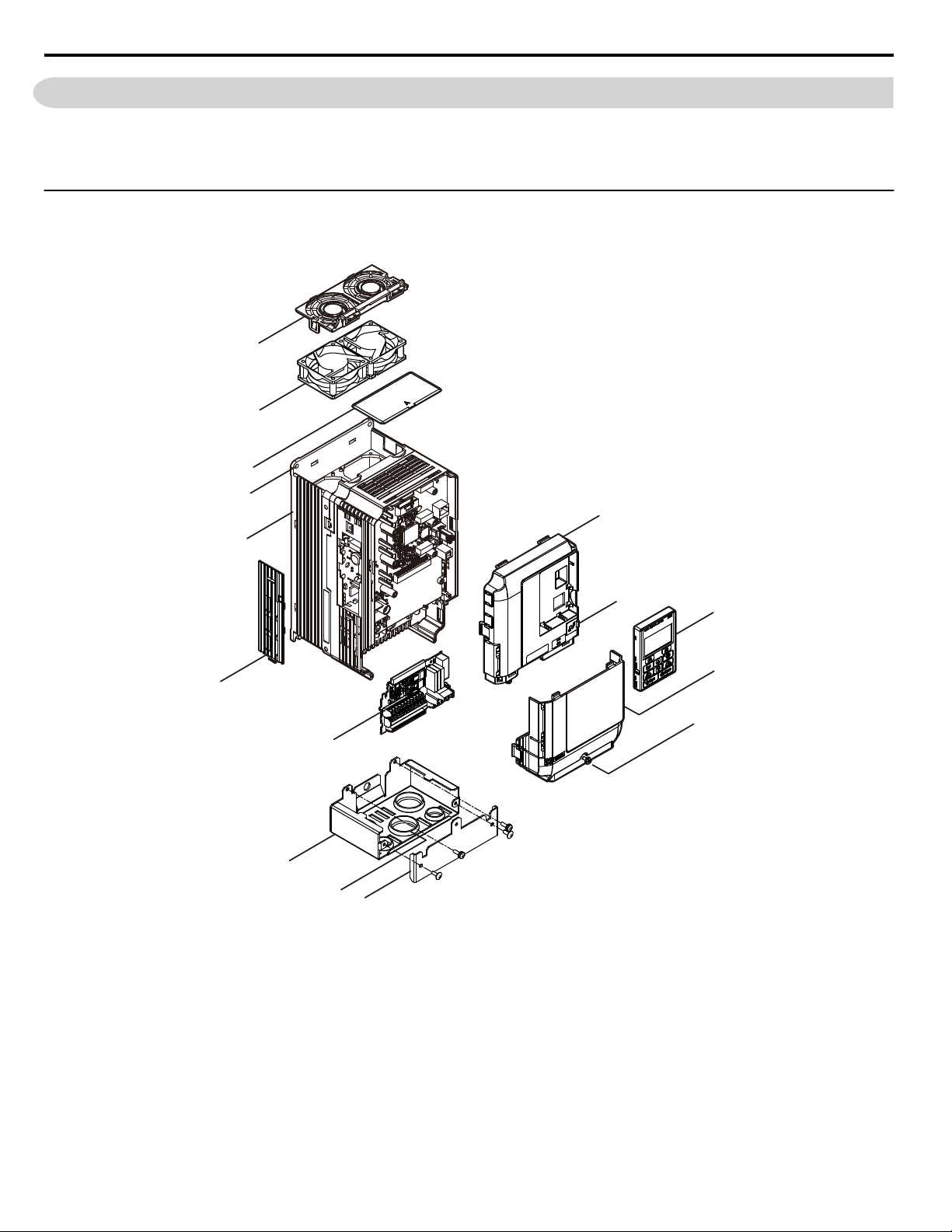

1.5 Component Names.................................................................................................... 28

IP20/NEMA Type 1 Enclosure................................................................................................. 28

IP00/Open Type Enclosure ..................................................................................................... 31

Front Views ............................................................................................................................. 33

2. MECHANICAL INSTALLATION..................................................................... 35

2.1 Section Safety............................................................................................................ 36

2.2 Mechanical Installation ............................................................................................. 38

Installation Environment .......................................................................................................... 38

Installation Orientation and Spacing........................................................................................ 38

HOA Keypad Remote Usage .................................................................................................. 40

Exterior and Mounting Dimensions ......................................................................................... 44

2.3 Flange Type Enclosure (NEMA 12 Backside) Dimensions & Heat Loss .............. 49

Flange Type Models 5A0003 and 5A0004 .............................................................................. 49

Flange Type Models 5A0006 and 5A0009 .............................................................................. 51

Flange Type Model 5A0011 .................................................................................................... 53

YASKAWA ELECTRIC

TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

3

Table of Contents

Flange Type Models 5A0017 and 5A0022 ........................................................................................ 55

Flange Type Models 5A0027 and 5A0032 ........................................................................................ 57

Flange Type Models 5A0041 and 5A0052 ........................................................................................ 59

Flange Type Models 5A0062 to 5A0099 ........................................................................................... 61

Flange Type Models 5A0125 and 5A0145 ........................................................................................ 63

Flange Type Models 5A0192 and 5A0242 ........................................................................................ 65

3. ELECTRICAL INSTALLATION .............................................................................. 67

3.1 Section Safety......................................................................................................................68

3.2 Standard Connection Diagram...........................................................................................70

3.3 Main Circuit Connection Diagram......................................................................................73

Three-Phase 600 V Class Models 5A0003 to 5A0032...................................................................... 73

Three-Phase 600 V Class Models 5A0041 and 5A0052................................................................... 73

Three-Phase 600 V Class Models 5A0062 to 5A0099...................................................................... 74

Three-Phase 600 V Class Models 5A0125 to 5A0242...................................................................... 74

3.4 Terminal Block Configuration ............................................................................................75

3.5 Terminal Cover ....................................................................................................................76

Models 5A0003 to 5A0032 (IP20/NEMA Type 1 Enclosure)............................................................. 76

Models 5A0125 to 5A0242 (IP00/Open Type Enclosure) ................................................................. 77

3.6 HOA Keypad and Front Cover............................................................................................78

Removing/Reattaching the HOA Keypad .......................................................................................... 78

Removing/Reattaching the Front Cover ............................................................................................ 78

3.7 Top Protective Cover ..........................................................................................................79

Removing the Top Protective Cover ................................................................................................. 79

Reattaching the Top Protective Cover .............................................................................................. 79

3.8 Main Circuit Wiring..............................................................................................................80

Main Circuit Terminal Functions........................................................................................................ 80

Protecting Main Circuit Terminals ..................................................................................................... 80

Main Circuit Wire Gauges and Tightening Torque ............................................................................ 81

Main Circuit Terminal and Motor Wiring ............................................................................................ 84

3.9 Control Circuit Wiring .........................................................................................................86

Control Circuit Connection Diagram.................................................................................................. 86

Control Circuit Connections............................................................................................................... 86

Terminal Configuration ...................................................................................................................... 88

Wiring the Control Circuit Terminal ................................................................................................... 89

Switches and Jumpers on the Terminal Board.................................................................................. 91

3.10 Control I/O Connections .....................................................................................................92

Sinking/Sourcing Mode for Digital Inputs .......................................................................................... 92

Input Signal Selection for Terminals A1 and A2................................................................................ 93

Terminal A2 Input Signal Selection ................................................................................................... 93

Terminal FM/AM Signal Selection ..................................................................................................... 94

MEMOBUS/Modbus Termination ...................................................................................................... 94

3.11 Connect to a PC...................................................................................................................95

3.12 External Interlock ................................................................................................................96

Drive Ready....................................................................................................................................... 96

3.13 Wiring Checklist ..................................................................................................................97

4. START-UP PROGRAMMING & OPERATION....................................................... 99

4

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

Table of Contents

4.1 Section Safety....................................................................................................................100

4.2 Using the HOA Keypad .....................................................................................................101

Keys and Displays........................................................................................................................... 101

LCD Display .................................................................................................................................... 102

ALARM (ALM) LED Displays........................................................................................................... 103

AUTO LED and HAND LED Indications .......................................................................................... 103

Menu Structure for HOA Keypad..................................................................................................... 105

4.3 The Drive, Programming, and Clock Adjustment Modes ..............................................106

Real-Time Clock (RTC) ................................................................................................................... 106

Clock Adjustment ............................................................................................................................ 106

Changing Parameter Settings or Values ......................................................................................... 109

Verifying Parameter Changes: Verify Menu .................................................................................... 110

Simplified Setup Using the Setup Group......................................................................................... 111

4.4 Start-Up Flowcharts ..........................................................................................................113

Flowchart A: Basic Start-Up and Motor Tuning ............................................................................... 114

Subchart A-1: Simple Motor Setup Using V/f Control...................................................................... 115

Subchart A-2: Operation with Permanent Magnet Motors............................................................... 116

4.5 Powering Up the Drive ......................................................................................................117

Powering Up the Drive and Operation Status Display..................................................................... 117

4.6 Application Selection........................................................................................................118

HVAC Application Parameters ........................................................................................................ 118

Setting 1: Fan Application ............................................................................................................... 118

Setting 2: Fan with PI Control Application ....................................................................................... 119

Setting 3: Return Fan with PI Control Application ........................................................................... 119

Setting 4: Cooling Tower Fan Application ....................................................................................... 119

Setting 5: Cooling Tower Fan with PI Control Application............................................................... 120

Setting 6: Pump (Secondary) Application........................................................................................ 120

Setting 7: Pump with PI Control Application.................................................................................... 120

4.7 Basic Drive Setup Adjustments .......................................................................................121

4.8 Auto-Tuning .......................................................................................................................136

Types of Auto-Tuning ...................................................................................................................... 136

Before Auto-Tuning the Drive.......................................................................................................... 137

Auto-Tuning Interruption and Fault Codes ...................................................................................... 138

Auto-Tuning Operation Example ..................................................................................................... 138

T1: Parameter Settings during Induction Motor Auto-Tuning .......................................................... 140

T2: Parameter Settings during PM Motor Auto-Tuning ................................................................... 141

4.9 No-Load Operation Test Run............................................................................................144

No-Load Operation Test Run .......................................................................................................... 144

4.10 Test Run with Load Connected........................................................................................145

Test Run with the Load Connected ................................................................................................. 145

4.11 Verifying Parameter Settings and Backing Up Changes...............................................146

Backing Up Parameter Values: o2-03 ............................................................................................. 146

Parameter Access Level: A1-01...................................................................................................... 146

Password Settings: A1-04, A1-05 ................................................................................................... 146

Copy Function ................................................................................................................................. 147

4.12 Test Run Checklist ............................................................................................................148

4.13 Advanced Drive Setup Adjustments ...............................................................................149

U1: Operation Status Monitors ........................................................................................................ 187

U2: Fault Trace................................................................................................................................ 187

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

5

Table of Contents

U3: Fault History.............................................................................................................................. 187

U4: Maintenance Monitors .............................................................................................................. 187

U5: PI Monitors................................................................................................................................ 187

U6: Operation Status Monitors ........................................................................................................ 187

5. TROUBLESHOOTING.......................................................................................... 189

5.1 Section Safety....................................................................................................................190

5.2 Motor Performance Fine-Tuning......................................................................................192

Fine-Tuning V/f Control ................................................................................................................... 192

Fine-Tuning Open Loop Vector Control for PM Motors................................................................... 192

Parameters to Minimize Motor Hunting and Oscillation .................................................................. 193

5.3 Drive Alarms, Faults, and Errors .....................................................................................194

Types of Alarms, Faults, and Errors................................................................................................ 194

Alarm and Error Displays ................................................................................................................ 195

5.4 Fault Detection ..................................................................................................................198

Fault Displays, Causes, and Possible Solutions ............................................................................. 198

5.5 Alarm Detection.................................................................................................................211

Alarm Codes, Causes, and Possible Solutions ............................................................................... 211

5.6 Programming Errors .........................................................................................................218

Operator Programming Error Codes, Causes, and Possible Solutions........................................... 218

5.7 Auto-Tuning Fault Detection ............................................................................................222

Auto-Tuning Codes, Causes, and Possible Solutions..................................................................... 222

5.8 Copy Function Related Displays .....................................................................................224

Tasks, Errors, and Troubleshooting ................................................................................................ 224

5.9 Diagnosing and Resetting Faults.....................................................................................226

Fault Occurs Simultaneously with Power Loss ............................................................................... 226

If the Drive Still has Power After a Fault Occurs ............................................................................. 226

Viewing Fault Trace Data After Fault .............................................................................................. 226

Fault Reset Methods ....................................................................................................................... 227

5.10 Troubleshooting without Fault Display...........................................................................228

Common Problems.......................................................................................................................... 228

Cannot Change Parameter Settings ............................................................................................... 228

Motor Does Not Rotate Properly after Pressing AUTO Button or after Entering External Run

Command ...................................................................................................................................... 229

Motor is Too Hot.............................................................................................................................. 230

oPE02 Error Occurs When Lowering the Motor Rated Current Setting .......................................... 231

Motor Stalls during Acceleration or Acceleration Time is Too Long................................................ 231

Drive Frequency Reference Differs from the Controller Frequency Reference Command ............. 232

Excessive Motor Oscillation and Erratic Rotation............................................................................ 232

Deceleration Takes Longer than Expected ..................................................................................... 232

Noise From Drive or Motor Cables When the Drive is Powered On ............................................... 232

Ground Fault Circuit Interrupter (GFCI) Trips During Run .............................................................. 232

Connected Machinery Vibrates When Motor Rotates ..................................................................... 233

PI Output Fault ................................................................................................................................ 233

Motor Rotates after the Drive Output is Shut Off (Motor Rotates During DC Injection Braking) ..... 233

Output Frequency is Not as High as Frequency Reference............................................................ 234

Sound from Motor............................................................................................................................ 234

Unstable Motor Speed when Using PM .......................................................................................... 234

Motor Does Not Restart after Power Loss....................................................................................... 234

6

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

Table of Contents

6. PERIPHERAL DEVICES & OPTIONS ................................................................. 235

6.1 Section Safety....................................................................................................................236

6.2 Drive Options and Peripheral Devices ............................................................................238

6.3 Connecting Peripheral Devices .......................................................................................239

6.4 Option Installation.............................................................................................................240

Prior to Installing the Option ............................................................................................................ 240

Communication Option Installation Example................................................................................... 241

6.5 Installing Peripheral Devices ...........................................................................................244

Installing a Molded Case Circuit Breaker (MCCB) or Ground Fault Circuit Interrupter (GFCI) ....... 244

Installing a Magnetic Contactor at the Power Supply Side.............................................................. 244

Connecting an AC Reactor.............................................................................................................. 245

Connecting a Surge Absorber ......................................................................................................... 245

Connecting a Noise Filter ................................................................................................................ 245

Installing Input Fuses ...................................................................................................................... 247

Attachment for External Heatsink Mounting .................................................................................... 248

Installing a Motor Thermal Overload (oL) Relay on the Drive Output ............................................. 248

A. SPECIFICATIONS ................................................................................................ 249

A.1 Power Ratings ...................................................................................................................250

Three-Phase 600 V Class Drive Models 5A0003 to 5A0032 .......................................................... 250

Three-Phase 600 V Class Drive Models 5A0041 to 5A0099 .......................................................... 251

Three-Phase 600 V Class Drive Models 5A0125 to 5A0242 .......................................................... 252

A.2 Drive Specifications ..........................................................................................................253

A.3 Drive Watt Loss Data ........................................................................................................255

A.4 Drive Derating Data ...........................................................................................................256

Rated Current Depending on Carrier Frequency ............................................................................ 256

Carrier Frequency Derating............................................................................................................. 257

Temperature Derating ..................................................................................................................... 259

Altitude Derating.............................................................................................................................. 260

B. PARAMETER LIST............................................................................................... 261

B.1 A: Initialization Parameters ..............................................................................................262

A1: Initialization ............................................................................................................................... 262

A2: User Parameters....................................................................................................................... 263

B.2 b: Application.....................................................................................................................264

b1: Operation Mode Selection......................................................................................................... 264

b2: DC Injection Braking and Short Circuit Braking......................................................................... 264

b3: Speed Search............................................................................................................................ 265

b4: Timer Function .......................................................................................................................... 266

b5: PI Control .................................................................................................................................. 266

b8: Energy Saving ........................................................................................................................... 269

B.3 C: Tuning............................................................................................................................270

C1: Acceleration and Deceleration Times ....................................................................................... 270

C2: S-Curve Characteristics............................................................................................................ 270

C4: Torque Compensation .............................................................................................................. 270

C6: Carrier Frequency..................................................................................................................... 271

B.4 d: References.....................................................................................................................272

d1: Frequency Reference................................................................................................................ 272

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

7

Table of Contents

d2: Frequency Upper/Lower Limits ................................................................................................. 272

d3: Jump Frequency........................................................................................................................ 273

d4: Frequency Reference Hold Function......................................................................................... 273

d6: Field Weakening........................................................................................................................ 273

d7: Offset Frequency....................................................................................................................... 274

B.5 E: Motor Parameters .........................................................................................................275

E1: V/f Pattern for Motor 1............................................................................................................... 275

E2: Motor Parameters ..................................................................................................................... 276

E5: PM Motor Settings .................................................................................................................... 276

B.6 F: Communication Option Parameters............................................................................278

F6, F7: Communication Option Card............................................................................................... 278

B.7 H Parameters: Multi-Function Terminals ........................................................................281

H1: Multi-Function Digital Inputs ..................................................................................................... 281

H2: Multi-Function Digital Outputs................................................................................................... 285

H3: Multi-Function Analog Inputs .................................................................................................... 287

H4: Analog Outputs ......................................................................................................................... 288

H5: MEMOBUS/Modbus Serial Communication ............................................................................. 289

B.8 L: Protection Function ......................................................................................................290

L1: Motor Protection ........................................................................................................................ 290

L2: Momentary Power Loss Ride-Thru............................................................................................ 290

L3: Stall Prevention ......................................................................................................................... 291

L4: Speed Detection........................................................................................................................ 293

L5: Fault Restart.............................................................................................................................. 293

L6: Torque Detection....................................................................................................................... 294

L8: Drive Protection......................................................................................................................... 294

B.9 n: Special Adjustment.......................................................................................................296

n1: Hunting Prevention.................................................................................................................... 296

n3: High Slip Braking (HSB) and Overexcitation Braking................................................................ 296

n8: PM Motor Control Tuning .......................................................................................................... 297

B.10 o: Operator-Related Settings ...........................................................................................298

o1: HOA Keypad Display Selection................................................................................................. 298

o2: HOA Keypad Functions............................................................................................................. 299

o3: Copy Function ........................................................................................................................... 300

o4: Maintenance Monitor Settings................................................................................................... 300

B.11 S: Special Application.......................................................................................................301

S1: Dynamic Noise Control Function .............................................................................................. 301

S2: Sequence Timers...................................................................................................................... 301

S3: Secondary PI (PI2) Control ....................................................................................................... 303

S4: Bypass Operation ..................................................................................................................... 305

S5: HOA Keypad Parameters ......................................................................................................... 305

S6: Z1000 Protection....................................................................................................................... 306

B.12 T: Motor Tuning .................................................................................................................307

T1: Induction Motor Auto-Tuning..................................................................................................... 307

T2: PM Motor Auto-Tuning .............................................................................................................. 307

B.13 U: Monitors.........................................................................................................................309

U1: Operation Status Monitors ........................................................................................................ 309

U2: Fault Trace................................................................................................................................ 310

U3: Fault History.............................................................................................................................. 311

U4: Maintenance Monitors .............................................................................................................. 313

U5: PI Monitors................................................................................................................................ 314

8

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

Table of Contents

U6: Operation Status Monitors ........................................................................................................ 315

C. BACNET COMMUNICATIONS ............................................................................ 317

C.1 BACnet Configuration.......................................................................................................318

C.2 Communication Specifications........................................................................................319

C.3 Connecting to a Network ..................................................................................................320

Network Cable Connection.............................................................................................................. 320

Wiring Diagram for Multiple Connections ........................................................................................ 321

Network Termination ....................................................................................................................... 321

C.4 BACnet Setup Parameters................................................................................................322

BACnet Serial Communication........................................................................................................ 322

C.5 Drive Operations by BACnet ............................................................................................326

Observing the Drive Operation........................................................................................................ 326

Controlling the Drive........................................................................................................................ 326

C.6 Communications Timing...................................................................................................327

Command Messages from Master to Drive..................................................................................... 327

Response Messages from Drive to Master ..................................................................................... 327

C.7 BACnet Objects Supported ..............................................................................................328

Present Value Access ..................................................................................................................... 328

Supported Properties of Objects ..................................................................................................... 328

Analog Input Objects ....................................................................................................................... 329

Analog Output Objects .................................................................................................................... 329

Analog Value Objects...................................................................................................................... 329

Binary Input Objects ........................................................................................................................ 330

Binary Output Objects ..................................................................................................................... 331

Binary Value Objects....................................................................................................................... 331

Device Object .................................................................................................................................. 332

C.8 Accessing Drive Parameters and the Enter Command .................................................333

Reading Drive Parameters .............................................................................................................. 333

Writing Drive Parameters ................................................................................................................ 333

Enter Command .............................................................................................................................. 333

C.9 Communication Errors .....................................................................................................334

C.10 Self-Diagnostics ................................................................................................................335

C.11 BACnet Protocol Implementation Conformance Statement..........................................336

D. STANDARDS COMPLIANCE .............................................................................. 339

D.1 Section Safety....................................................................................................................340

D.2 European Standards .........................................................................................................342

CE Low Voltage Directive Compliance............................................................................................ 342

D.3 UL and CSA Standards .....................................................................................................344

UL Standards Compliance .............................................................................................................. 344

CSA Standards Compliance............................................................................................................ 349

Drive Motor Overload Protection ..................................................................................................... 349

Precautionary Notes on External Heatsink (IP00/Open Type Enclosure) ....................................... 351

E. QUICK REFERENCE SHEET .............................................................................. 353

E.1 Drive and Motor Specifications........................................................................................354

Drive Specifications......................................................................................................................... 354

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

9

Table of Contents

Motor Specifications ........................................................................................................................ 354

E.2 Basic Parameter Settings .................................................................................................355

Basic Setup ..................................................................................................................................... 355

Motor Setup..................................................................................................................................... 355

Multi-Function Digital Inputs ............................................................................................................ 355

Analog Inputs .................................................................................................................................. 355

Multi-Function Digital Outputs ......................................................................................................... 356

Monitor Outputs............................................................................................................................... 356

E.3 User Setting Table.............................................................................................................357

INDEX ................................................................................................................... 363

10

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

i

Preface & General Safety

This section provides safety messages pertinent to this product that, if not heeded, may result in fatality,

personal injury, or equipment damage. Yaskawa is not responsible for the consequences of ignoring

these instructions.

i.1 PREFACE...............................................................................................................12

i.2 GENERAL SAFETY...............................................................................................13

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

11

F2F1

ESC

M M

AUTO OFF

ENTERRESET

ALM

DIGITAL OPERATOR JVOP-183

HAND

TERMSTERMS

TERMSTERMS

i.1 Preface

i.1 Preface

Yaskawa manufactures products used as components in a wide variety of industrial systems and equipment. The selection and

application of Yaskawa products remain the responsibility of the equipment manufacturer or end user. Yaskawa accepts no

responsibility for the way its products are incorporated into the final system design. Under no circumstances should any

Yaskawa product be incorporated into any product or design as the exclusive or sole safety control. Without exception, all

controls should be designed to detect faults dynamically and fail safely under all circumstances. All systems or equipment

designed to incorporate a product manufactured by Yaskawa must be supplied to the end user with appropriate warnings and

instructions as to the safe use and operation of that part. Any warnings provided by Yaskawa must be promptly provided to

the end user. Yaskawa offers an express warranty only as to the quality of its products in conforming to standards and

specifications published in the Yaskawa manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS OFFERED.

Yaskawa assumes no liability for any personal injury, property damage, losses, or claims arising from misapplication of its

products.

This manual is designed to ensure correct and suitable application of Z1000-series drives. Read this manual before attempting

to install, operate, maintain, or inspect a drive and keep it in a safe, convenient location for future reference. Be sure you

understand all precautions and safety information before attempting application.

u

Applicable Documentation

The following manuals are available for Z1000-series drives (600 V models):

Z1000-Series AC Drive Safety Precautions Manual (600 V Models): TOEPYAIZ1U02

This manual is packaged together with the product and contains essential safety information and simplified information for

the Z1000-series 600 V class AC drive. This document also provides basic instructions on mechanical installation, a

connection diagram, main circuit and control circuit connections, switch and jumper configuration, basic troubleshooting,

standards compliance and fusing, drive specifications and an abbreviated parameter list.

Z1000-Series AC Drive User Manual (600 V Models): TOEPYAIZ1U03

Read this manual first. This manual contains basic information required to install and wire the drive. It also gives detailed

information on fault diagnostics, parameter settings, and BACnet specifications. The purpose of this manual is to prepare

the drive for a trial run with an application and for basic operation. This manual is available for download on our

documentation website, www.yaskawa.com.

Z1000-Series AC Drive Programming Manual (600 V Models): SIEPYAIZ1U03

This manual provides detailed information on parameter settings, drive functions, maintenance, and MEMOBUS/Modbus

specifications. Use this manual to expand drive functionality. This manual is available for download on our documentation

website, www.yaskawa.com.

u

Symbols

Note: Indicates a supplement or precaution that does not cause drive damage.

Indicates a term or definition used in this manual.

u

Terms and Abbreviations

• Drive: Yaskawa Z1000-Series Drive

• Digital Operator: Hand Off Auto (HOA) Keypad JVOP-183

• H: Hexadecimal Number Format

• IGBT: Insulated Gate Bipolar Transistor

• kbps: Kilobits per Second

• MAC: Media Access Control

• r/min: Revolutions per Minute

• V/f: V/f Control

• OLV/PM: Open Loop Vector Control for PM

• PM motor: Permanent Magnet Synchronous motor (an abbreviation for IPM motor or SPM motor)

• IPM motor: Interior Permanent Magnet Motor (e.g., Yaskawa SSR1 Series and SST4 Series motors)

• SPM motor: Surface mounted Permanent Magnet Motor (e.g., Yaskawa SMRA Series motors)

12

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

i.2 General Safety

i.2 General Safety

u

Supplemental Safety Information

General Precautions

• The diagrams in this manual may be indicated without covers or safety shields to show details. Replace the covers or shields before

operating the drive and run the drive according to the instructions described in this manual.

• Any illustrations, photographs, or examples used in this manual are provided as examples only and may not apply to all products to

which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of the manual may be changed without notice

to improve the product and/or the manual.

• When ordering a new copy of the manual due to damage or loss, contact your Yaskawa representative or the nearest Yaskawa sales

office and provide the manual number shown on the front cover.

• If nameplate becomes worn or damaged, order a replacement from your Yaskawa representative or the nearest Yaskawa sales office.

WARNING

Read and understand this manual before installing, operating or servicing this drive. The drive must be installed according

to this manual and local codes.

The following conventions are used to indicate safety messages in this manual. Failure to heed these messages could result

in serious or fatal injury or damage to the products or to related equipment and systems.

DANGER

Indicates a hazardous situation, which, if not avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation, which, if not avoided, could result in death or serious injury.

WARNING! may also be indicated by a bold key word embedded in the text followed by an italicized safety message.

CAUTION

Indicates a hazardous situation, which, if not avoided, could result in minor or moderate injury.

CAUTION! may also be indicated by a bold key word embedded in the text followed by an italicized safety message.

NOTICE

Indicates a property damage message.

NOTICE: may also be indicated by a bold key word embedded in the text followed by an italicized safety message.

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

13

i.2 General Safety

u

Safety Messages

DANGER

Heed the safety messages in this manual.

Failure to comply will result in death or serious injury.

The operating company is responsible for any injuries or equipment damage resulting from failure to heed the warnings in

this manual.

Electrical Shock Hazard

Before servicing, disconnect all power to the equipment. The internal capacitor remains charged even after the power

supply is turned off. The charge indicator LED will extinguish when the DC bus voltage is below 50 Vdc. To prevent electric

shock, wait for at least the time specified on the warning label, once all indicators are OFF, measure for unsafe voltages to

confirm the drive is safe prior to servicing.

Failure to comply will result in death or serious injury.

WARNING

Sudden Movement Hazard

System may start unexpectedly upon application of power, resulting in death or serious injury.

Clear all personnel from the drive, motor and machine area before applying power. Secure covers, couplings, shaft keys and

machine loads before applying power to the drive.

Unpredictable equipment operation may result in death or serious injury.

Take special note of custom I/O programming in the drive before attempting to operate equipment.

Electrical Shock Hazard

Do not attempt to modify or alter the drive in any way not explained in this manual.

Failure to comply could result in death or serious injury.

Yaskawa is not responsible for any modification of the product made by the user. This product must not be modified.

Do not allow unqualified personnel to use equipment.

Failure to comply could result in death or serious injury.

Maintenance, inspection, and replacement of parts must be performed only by authorized personnel familiar with installation,

adjustment and maintenance of AC drives.

Do not remove covers or touch circuit boards while the power is on.

Failure to comply could result in death or serious injury.

Make sure the protective earthing conductor complies with technical standards and local safety regulations.

Because the leakage current exceeds 3.5 mA, IEC/EN 61800-5-1 states that either the power supply must be automatically

disconnected in case of discontinuity of the protective earthing conductor or a protective earthing conductor with a crosssection of at least 10 mm2 (Cu) or 16 mm2 (Al) must be used. Failure to comply may result in death or serious injury.

Always use appropriate equipment for Ground Fault Circuit Interrupters (GFCIs).

The drive can cause a residual current with a DC component in the protective earthing conductor. Where a residual current

operated protective or monitoring device is used for protection in case of direct or indirect contact, always use a type B GFCI

according to IEC/EN 60755.

Fire Hazard

Do not use an improper voltage source.

Failure to comply could result in death or serious injury by fire.

Verify that the rated voltage of the drive matches the voltage of the incoming power supply before applying power.

14

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

i.2 General Safety

WARNING

Install adequate branch circuit protection according to applicable local codes and this Installation Manual. Failure

to comply could result in fire and damage to the drive or injury to personnel.

The device is suitable for use on a circuit capable of delivering not more than 100,000 RMS symmetrical amperes, 600 Vac

maximum (600 V class) when protected by branch circuit protection devices specified in this document.

Branch circuit protection shall be provided by any of the following: Non-time delay Class J, T, or CC fuses sized at 300%

of the drive input rating, or Time delay Class J, T, or CC fuses sized at 175% of the drive input rating, or MCCB sized at

200% maximum of the drive input rating.

Crush Hazard

Do not use this drive in lifting applications without installing external safety circuitry to prevent accidental dropping

of the load.

The drive does not possess built-in load drop protection for lifting applications.

Failure to comply could result in death or serious injury from falling loads.

Install electrical and/or mechanical safety circuit mechanisms independent of drive circuitry.

CAUTION

Crush Hazard

Do not carry the drive by the front cover.

Failure to comply may result in minor or moderate injury from the main body of the drive falling.

NOTICE

Observe proper electrostatic discharge procedures (ESD) when handling the drive and circuit boards.

Failure to comply may result in ESD damage to the drive circuitry.

Do not perform a withstand voltage test on any part of the drive.

Failure to comply could result in damage to the sensitive devices within the drive.

Do not operate damaged equipment.

Failure to comply could result in further damage to the equipment.

Do not connect or operate any equipment with visible damage or missing parts.

If a fuse is blown or a Ground Fault Circuit Interrupter (GFCI) is tripped, check the wiring and the selection of the

peripheral devices.

Contact your supplier if the cause cannot be identified after checking the above.

Do not restart the drive immediately operate the peripheral devices if a fuse is blown or a GFCI is tripped.

Check the wiring and the selection of peripheral devices to identify the cause. Contact your supplier before restarting the

drive or the peripheral devices if the cause cannot be identified.

Do not expose the drive to halogen group disinfectants.

Failure to comply may cause damage to the electrical components in the drive.

Do not pack the drive in wooden materials that have been fumigated or sterilized.

Do not sterilize the entire package after the product is packed.

u

General Application Precautions

Selection

n

Installing a Reactor

Use an AC reactor or DC link choke in the following situations:

• to suppress harmonic current.

• to smooth peak current that results from capacitor switching.

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

15

i.2 General Safety

• when the power supply is above 600 kVA.

• when the drive is running from a power supply system with thyristor converters.

Note: A DC link choke is built in to drive models 5A0041 to 5A0242.

4000

Power supply harmonics

reactor required

Power Supply

Capacity (kVA)

600

0

Drive Capacity (kVA)

Figure i.1 Installing a Reactor

Reactor

unnecessary

60 400

Drive Capacity

For specialized motors, make sure that the motor rated current is less than the rated output current for the drive.

When running more than one motor in parallel from a single drive, the capacity of the drive should be larger than [total motor

rated current × 1.1].

Starting Torque

The overload rating for the drive determines the starting and accelerating characteristics of the motor. Expect lower torque

than when running from line power. To get more starting torque, use a larger drive or increase both the motor and drive capacity.

Emergency Stop

During a drive fault condition, the output shuts off but the motor does not stop immediately. A mechanical brake may be

required when it is necessary to stop the motor faster than the ability of the Fast Stop function of the drive.

Options

NOTICE: The B1, B2, ⊖, ⊕1, ⊕2, and ⊕3 terminals are used to connect optional drive-specific compatible devices only. Connecting non-

Yaskawa-approved devices to these terminals may damage the drive.

Repetitive Starting/Stopping

Laundry machines, punching presses, and other applications with frequent starts and stops often approach 150% of their rated

current values. Heat stress generated from repetitive high current will shorten the life span of the IGBTs.

Yaskawa recommends lowering the carrier frequency, particularly when audible noise is not a concern. It is beneficial to

reduce the load, increase the acceleration and deceleration times, or switch to a larger drive to help keep peak current levels

under 150%. Be sure to check the peak current levels when starting and stopping repeatedly during the initial test run, and

make adjustments accordingly.

Installation

n

Enclosure Panels

Keep the drive in a clean environment by installing the drive in an enclosure panel or selecting an installation area free of

airborne dust, lint, and oil mist. Be sure to leave the required space between drives to provide for cooling, and take proper

measures so the ambient temperature remains within allowable limits and keep flammable materials away from the drive.

Yaskawa offers protective designs for drives that must be used in areas subjected to oil mist and excessive vibration. Contact

Yaskawa or your Yaskawa agent for details.

Installation Direction

NOTICE: Install the drive upright as specified in the manual. Refer to Mechanical Installation on page 38 for more information on

installation. Failure to comply may damage the drive due to improper cooling.

Settings

n

Motor Code

When using OLV/PM, set the proper motor code to parameter E5-01 before performing a trial run.

Upper Limits

NOTICE: The drive is capable of running the motor up to 400 Hz. Be sure to set the upper limit for the frequency of the drive to prevent the

possible danger of accidentally operating equipment at higher than rated speed. The default setting for the maximum output frequency is

60 Hz.

16

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

i.2 General Safety

DC Injection Braking

NOTICE: Excessive current during DC Injection Braking and excessive duration of DC Injection Braking can cause motor overheat.

Acceleration/Deceleration Times

Acceleration and deceleration times are affected by the amount of torque generated by the motor, the load torque, and the

inertia moment. Set a longer accel/decel time when Stall Prevention is enabled. The accel/decel times are lengthened for as

long as the Stall Prevention function is in operation. Install one of the available braking options or increase the capacity of the

drive for faster acceleration and deceleration.

General Handling

n

Wiring Check

NOTICE: Do not connect power supply lines to output terminals U/T1, V/T2, or W/T3. Failure to comply will destroy the drive. Be sure to

perform a final check of all sequence wiring and other connections before turning on the power and also check for short circuits on the

control terminals, which may damage the drive.

Selecting a Circuit Breaker or Circuit Interrupter

Yaskawa recommends installing a Ground Fault Circuit Interrupter (GFCI) to the power supply side. The GFCI should be

designed for use with AC drives (e.g., Type B according to IEC/EN 60755).

Select a Molded Case Circuit Breaker (MCCB) or GFCI with a rated current 1.5 to 2 times higher than the drive rated input

current to avoid nuisance trips caused by harmonics in the drive input current.

Magnetic Contactor Installation

WARNING! Fire Hazard. Shut off the drive with a magnetic contactor (MC) when a fault occurs in any external equipment such as braking

resistors. Failure to comply may cause resistor overheating, fire, and injury to personnel.

NOTICE: To get the full performance life out of the electrolytic capacitors and circuit relays, refrain from switching the drive power supply

off and on more than once every 30 minutes. Frequent use can damage the drive. Use the drive to stop and start the motor.

Inspection and Maintenance

WARNING! Electrical Shock Hazard. Capacitors in the drive do not immediately discharge after shutting off the power. Wait for at least the

amount of time specified on the drive before touching any components after shutting off the power. Failure to comply may cause injury to

personnel from electrical shock.

WARNING! Electrical Shock Hazard. When a drive is running a PM motor, voltage continues to be generated at the motor terminals after

the drive is shut off while the motor coasts to stop. Take the precautions described below to prevent shock and injury:

∙ In applications where the machine can still rotate after the drive has fully stopped a load, install a switch to the drive output side to disconnect

the motor and the drive.

∙ Do not allow an external force to rotate the motor beyond the maximum allowable speed or to rotate the motor when the drive has been

shut off.

∙ Wait for at least the time specified on the warning label after opening the load switch on the output side before inspecting the drive or

performing any maintenance.

∙ Do not open and close the load switch while the motor is running.

∙ If the motor is coasting, make sure the power to the drive is turned on and the drive output has completely stopped before closing the load

switch.

WARNING! Burn Hazard. Because the heatsink can get very hot during operation, take proper precautions to prevent burns. When replacing

the cooling fan, shut off the power and wait at least 15 minutes to be sure that the heatsink has cooled down. Failure to comply may cause

burn injury to personnel.

Wiring

Yaskawa recommends using ring terminals on all drive models. Use only the tools recommended by the terminal manufacturer

for crimping.

Transporting the Drive

NOTICE: Never steam clean the drive. During transport, keep the drive from coming into contact with salts, fluorine, bromine, phthalate

ester, and other such harmful chemicals.

u

Motor Application Precautions

Standard Induction Motors

n

Low-Speed Range

The cooling fan of a standard motor should sufficiently cool the motor at the rated speed. As the self-cooling capability of

such a motor reduces with the speed, applying full torque at low speed will possibly damage the motor. Reduce the load torque

as the motor slows to prevent motor damage from overheat. Figure i.2 shows the allowable load characteristics for a Yaskawa

standard motor. Use a motor designed specifically for operation with a drive when 100% continuous torque is needed at low

speeds.

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

17

50

3 6

60

60

70

80

90

100

25% ED (or 15 min)

40% ED (or 20 min)

60% ED (or 40 min)

Frequency (Hz)

Continuous operation

Torque

(%)

20

i.2 General Safety

Figure i.2 Allowable Load Characteristics for a Yaskawa Motor

Insulation Tolerance

NOTICE: Consider motor voltage tolerance levels and motor insulation in applications with an input voltage of over 440 V or particularly

long wiring distances.

High-Speed Operation

NOTICE: Problems may occur with the motor bearings and dynamic balance of the machine when operating a motor beyond its rated speed.

Contact the motor or machine manufacturer.

Torque Characteristics

Torque characteristics differ compared to operating the motor directly from line power. The user should have a full

understanding of the load torque characteristics for the application.

Vibration and Shock

The drive allows selection of high carrier PWM control and low carrier PWM. Selecting high carrier PWM can help reduce

motor oscillation.

• Take particular caution when adding a variable speed drive to an application running a motor from line power at a constant

speed. If resonance occurs, install shock-absorbing rubber around the base of the motor and enable the Jump frequency

selection to prevent continuous operation in the resonant frequency range.

• Mechanical resonance can occur with long motor shafts and in applications such as turbines, blowers, and fans with high

inertia loads. Use Closed Loop Vector Control when these applications experience mechanical resonance problems.

Audible Noise

The audible noise of the motor varies based on the carrier frequency setting. However, drive current derating may be required.

When using a high carrier frequency, audible noise from the motor is comparable to the motor noise generated when running

from line power.

Synchronous Motors

n

• Contact Yaskawa or a Yaskawa agent when planning to use a synchronous motor not endorsed by Yaskawa.

• Use a standard induction motor when running multiple synchronous motors simultaneously. A single drive does not have

this capability.

• A synchronous motor may rotate slightly in the opposite direction of the Run command at start depending on parameter

settings and rotor position.

• The amount of generated starting torque differs depending on the control mode and motor type. Set up the motor with the

drive after verifying the starting torque, allowable load characteristics, impact load tolerance, and speed control range.

Contact Yaskawa or a Yaskawa agent when planning to use a motor that does not fall within these specifications:

• In Open Loop Vector Control for PM motors, braking torque is less than 125% when running between 20% and 100% speed.

Braking torque drops to less than 50% when running at less than 20% speed.

• In Open Loop Vector Control for PM motors, the allowable load inertia moment is approximately 50 times higher than the

motor inertia moment.

Contact Yaskawa or a Yaskawa agent for questions concerning applications with a larger inertia moment.

• To restart a coasting motor rotating below 100 Hz, use the Speed Search function if the motor cable is not too long. If the

motor cable is relatively long, stop the motor using Short Circuit Braking.

18

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

i.2 General Safety

Specialized Motors

n

Multi-Pole Motor

The rated current of a multi-pole motor differs from that of a standard motor, so be sure to check the maximum current when

selecting a drive. Always stop the motor before switching between the number of motor poles. The motor will coast to stop if

a regen overvoltage (ov) fault occurs or if overcurrent (oC) protection is triggered.

Submersible Motor

The rated current of a submersible motor is greater than that of a standard motor, so select the drive capacity accordingly. Use

a motor cable large enough to avoid decreasing the maximum torque level from voltage drop caused by a long motor cable.

Explosion-Proof Motor

The motor and the drive must be tested together to be certified as explosion-proof. The drive is not designed for explosionproof areas.

When attaching an encoder to an explosion-proof motor, make sure the encoder is also explosion-proof. Use an insulating

signal converter to connect the encoder signal lines to the speed feedback option card.

Geared Motor

Make sure that the gear and the lubricant are rated for the desired speed range to avoid gear damage when operating at low

speeds or very high speeds. Consult with the manufacturer for applications that require operation outside the rated speed range

of the motor or gear box.

Single-Phase Motor

Variable speed drives are not designed to operate with single phase motors. Using capacitors to start the motor causes excessive

current to flow and can damage drive components. A split-phase start or a repulsion start can burn out the starter coils because

the internal centrifugal switch is not activated. The drive is for use with three-phase motors only.

Motor with Brake

Take caution when using the drive to operate a motor with a built-in holding brake. If the brake is connected to the output side

of the drive, it may not release at start due to low voltage levels, so be sure to install a separate power supply for the motor

brake. Note that motors with built-in brakes tend to generate a fair amount of noise when running at low speeds.

Notes on Power Transmission Machinery

n

Installing an AC drive in machinery that was previously connected directly to the power supply will allow the machine to

operate at variable speeds. Continuous operation outside of the rated speeds can wear on lubrication material in gear boxes

and other power transmission parts. Make sure that lubrication is sufficient within the entire speed range to avoid machine

damage. Note that operation above the rated speed can increase the noise generated by the machine.

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

19

Warning Label

600V 3Phase 5.5kW/3.7kW

F2F1

ESC

M M

AUTO OFF

ENTERRESET

ALM

DIGITAL OPERATOR JVOP-183

HAND

i.2 General Safety

u

Drive Label Warning Example

Always heed the warning information listed in Figure i.3 in the position shown in Figure i.4.

WARNING

Risk of electric shock.

●

Read manual before installing.

●

Wait 5 minutes for capacitor

discharge after disconnecting

power supply.

●

To conform to requirements,

make sure to ground the supply

neutral for 400V class.

●

After opening the manual switch

between the drive and motor,

please wait 5 minutes before

inspecting, performing

maintenance or wiring the drive.

Hot surfaces

●

Top and Side surfaces may

become hot. Do not touch.

Figure i.3 Warning Information Example

Figure i.4 Warning Information Position

u

Warranty Information

Restrictions

n

The drive is not designed or manufactured for use in devices or systems that may directly affect or threaten human lives or

health.

Customers who intend to use the product described in this manual for devices or systems relating to transportation, health

care, space aviation, atomic power, electric power, or in underwater applications must first contact their Yaskawa

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

representatives or the nearest Yaskawa sales office.

WARNING! Injury to Personnel. This product has been manufactured under strict quality-control guidelines. However, if this product is to

be installed in any location where failure of this product could involve or result in a life-and-death situation or loss of human life or in a facility

where failure may cause a serious accident or physical injury, safety devices must be installed to minimize the likelihood of any accident.

20

1

Receiving

This chapter explains how to inspect the drive upon receipt, and gives an overview of the different

enclosure types and components.

1.1 SECTION SAFETY.................................................................................................22

1.2 GENERAL DESCRIPTION.....................................................................................23

1.3 MODEL NUMBER AND NAMEPLATE CHECK....................................................25

1.4 DRIVE MODELS AND ENCLOSURE TYPES........................................................27

1.5 COMPONENT NAMES...........................................................................................28

YASKAWA ELECTRIC TOEP YAIZ1U 03A YASKAWA AC Drive – Z1000 User Manual

21

1.1 Section Safety

1.1 Section Safety

CAUTION

Do not carry the drive by the front cover or the terminal cover.

Failure to comply may cause the main body of the drive to fall, resulting in minor or moderate injury.

NOTICE

Observe proper electrostatic discharge procedures (ESD) when handling the drive and circuit boards.

Failure to comply may result in ESD damage to the drive circuitry.