YASKAWA MOTOMAN-MH50, MOTOMAN-MH80, YR-MH00050-D, YR-MH00080-B, YR-MH00080-D INSTRUCTIONS FOR ZEROING FUNCTION

...Page 1

MOTOMAN-MH50/ MH50-35/ MH80/ MS80

1 of 51

OPTIONS

INSTRUCTIONS

FOR ZEROING FUNCTION

TYPE:

YR-MH00050-B**/ YR-MH00050-D** (ZEROING SPECIFICATION)

YR-MH00080-B**/ YR-MH00080-D** (ZEROING SPECIFICATION)

YR-MS00080-B** (ZEROING SPECIFICATION)

Upon receipt of the product and prior to initial operation, read these instructions thoroughly, and retain

for future reference.

MOTOMAN INSTRUCTIONS

MOTOMAN-MH50 INSTRUCTIONS

MOTOMAN-MH50-35 INSTRUCTIONS

MOTOMAN-MH80 INSTRUCTIONS

MOTOMAN-MS80 INSTRUCTIONS

DX100 INSTRUCTIONS

DX100 OPERATOR’S MANUAL

DX100 MAINTENANCE MANUAL

The DX100 operator’s manual above corresponds to specific usage.

Be sure to use the appropriate manual.

Part Number: 163471-1CD

Revision: 1

MANUAL NO.

HW1481050

3

Page 2

MH50/MH50-35/MH80/

2 of 51

MS80 Zeroing

163471-1CD

Copyright © 2016, 2012 YASKAWA America, Inc.

Terms of Use and Copyright Notice

All rights reserved. This manual is freely available as a service to

YASKAWA customers to assist in the operation of Motoman robots,

related equipment and software This manual is copyrighted property of

YASKAWA and may not be sold or redistributed in any way. You are

welcome to copy this document to your computer or mobile device for

easy access but you may not copy the PDF files to another website, blog,

cloud storage site or any other means of storing or distributing online

content.

Printed in the United States of America

First Printing, 2016

YASKAWA America, Inc.

Motoman Robotics Division

100 Automation Way

Miamisburg, OH 45342

Phone: 937-847-6200

www.motoman.com

ii

HW1481050

Page 3

163471-1CD

MANDATORY

CAUTION

3 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

• This instruction manual is intended to explain mainly on the

mechanical part of the MOTOMAN-MH50, MH50-35, MH80, MS80

for the application to the actual operation and for proper

maintenance and inspection. It describes on safety and handling,

details on specifications, necessary items on maintenance and

inspection, to explain operating instructions and maintenance

procedures. Be sure to read and understand this instruction manual

thoroughly before installing and operating the manipulator.

• General items related to safety are listed in Chapter 1: Safety of the

DX100 Instructions. To ensure correct and safe operation, carefully

read the DX100 Instructions before reading this manual.

• Some drawings in this manual are shown with the protective covers

or shields removed for clarity. Be sure all covers and shields are

replaced before operating this product.

• The drawings and photos in this manual are representative

examples and differences may exist between them and the

delivered product.

• YASKAWA may modify this model without notice when necessary

due to product improvements, modifications, or changes in

specifications.

If such modification is made, the manual number will also be

revised.

• If your copy of the manual is damaged or lost, contact a YASKAWA

representative to order a new copy. The representatives are listed

on the back cover. Be sure to tell the representative the manual

number listed on the front cover.

• YASKAWA is not responsible for incidents arising from unauthorized

modification of its products. Unauthorized modification voids your

product's warranty.

iii

HW1481050

Page 4

MH50/MH50-35/MH80/

4 of 51

MS80 Zeroing

163471-1CD

We suggest that you obtain and review a copy of the ANSI/RIA National

Safety Standard for Industrial Robots and Robot Systems (ANSI/RIA

R15.06-2012). You can obtain this document from the Robotic Industries

Association (RIA) at the following address:

Robotic Industries Association

900 Victors Way

P.O. Box 3724

Ann Arbor, Michigan 48106

TEL: (734) 994-6088

FAX: (734) 994-3338

www.roboticsonline.com

Ultimately, well-trained personnel are the best safeguard against

accidents and damage that can result from improper operation of the

equipment. The customer is responsible for providing adequately trained

personnel to operate, program, and maintain the equipment. NEVER

ALLOW UNTRAINED PERSONNEL TO OPERATE, PROGRAM, OR

REPAIR THE EQUIPMENT!

We recommend approved YASKAWA training courses for all personnel

involved with the operation, programming, or repair of the equipment.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications.

iv

HW1481050

Page 5

163471-1CD

WARNING

CAUTION

MANDATORY

PROHIBITED

NOTE

DANGER

5 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

Notes for Safe Operation

Notes for Safe Operation

Read this manual carefully before installation, operation, maintenance, or

inspection of the DX100.

In this manual, the Notes for Safe Operation are classified as “DANGER”,

“WARNING”, “CAUTION”, “MANDATORY”, or “PROHIBITED”.

DANGER

Indicates an imminent hazardous

situation which, if not avoided, could

result in death or serious injury to

personnel.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury to

personnel.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury to

personnel and damage to equipment.

It may also be used to alert against

unsafe practices.

Always be sure to follow explicitly the

items listed under this heading.

Must never be performed.

Even items described as “CAUTION” may result in a serious accident in

some situations.

At any rate, be sure to follow these important items.

To ensure safe and efficient operation at all times, be sure to

follow all instructions, even if not designated as “DANGER”,

“CAUTION” and “WARNING”.

• Maintenance and inspection must be performed by specified

personnel.

Failure to observe this caution may result in electric shock or injury.

• For disassembly or repair, contact your YASKAWA representative.

• Do not remove the motor, and do not release the brake.

Failure to observe these safety precautions may result in death or

serious injury from unexpected turning of the manipulator's arm.

v

HW1481050

Page 6

MH50/MH50-35/MH80/

WARNING

TURN

6 of 51

MS80 Zeroing

163471-1CD

Notes for Safe Operation

• Before operating the manipulator, check that servo power is turned

OFF pressing the emergency stop buttons on the front door of the

DX100 and the programming pendant.

When the servo power is turned OFF, the SERVO ON LED on the

programming pendant is turned OFF.

Injury or damage to machinery may result if the emergency stop circuit

cannot stop the manipulator during an emergency. The manipulator

should not be used if the emergency stop buttons do not function.

Figure 1: Emergency Stop Button

• Once the emergency stop button is released, clear the cell of all

items which could interfere with the operation of the manipulator.

Then turn the servo power ON.

Injury may result from unintentional or unexpected manipulator motion.

Figure 2: Release of Emergency Stop

• Observe the following precautions when performing teaching

operations within the P-point maximum envelope of the

manipulator:

– Be sure to use a lockout device to the safeguarding when going

inside. Also, display the sign that the operation is being

performed inside the safeguarding and make sure no one closes

the safeguarding.

– View the manipulator from the front whenever possible.

– Always follow the predetermined operating procedure.

– Keep in mind the emergency response measures against the

manipulator’s unexpected motion toward you.

– Ensure that you have a safe place to retreat in case of

emergency.

Improper or unintended manipulator operation may result in injury.

• Confirm that no person is present in the P-point maximum envelope

of the manipulator and that you are in a safe location before:

– Turning ON the power for the DX100.

– Moving the manipulator with the programming pendant.

– Running the system in the check mode.

– Performing automatic operations.

Injury may result if anyone enters the P-point maximum envelope of the

manipulator during operation. Always press an emergency stop button

immediately if there is a problem.

The emergency stop buttons are located on the right of front door of the

DX100 and the programming pendant.

vi

HW1481050

Page 7

163471-1CD

CAUTION

7 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

Definition of Terms Used In this Manual

• Perform the following inspection procedures prior to conducting

manipulator teaching. If problems are found, repair them

immediately, and be sure that all other necessary processing has

been performed.

– Check for problems in manipulator movement.

– Check for damage to insulation and sheathing of external wires.

• Always return the programming pendant to the hook on the cabinet

of the DX100 after use.

The programming pendant can be damaged if it is left in the

manipulator's work area, on the floor, or near fixtures.

• Read and understand the Explanation of Warning Labels in the

DX100 Instructions before operating the manipulator:

Definition of Terms Used In this Manual

The MOTOMAN is the YASKAWA industrial robot product.

The MOTOMAN usually consists of the manipulator, the controller, the

programming pendant, and the manipulator cables.

In this manual, the equipment is designated as follows:

Equipment Manual Designation

DX100 controller DX100

DX100 programming pendant Programming pendant

Cable between the manipulator and the

DX100

Description of the Operation Procedure

In the explanation of the operation procedure, the expression “Select • • •”

means that the cursor is moved to the object item and the SELECT key is

pressed, or that the item is directly selected by touching the screen.

Registered Trademark

In this manual, names of companies, corporations, or products are

trademarks, registered trademarks, or brand names for each company or

corporation. The indications of (R) and TM are omitted.

Manipulator cable

vii

HW1481050

Page 8

MH50/MH50-35/MH80/

WARNING

Do not enter

robot

work area.

WARNING

Moving parts

may cause

injury

Nameplate:

WARNING Label B:

WARNING Label A:

Nameplate

WARNING label A

WARNING label B

8 of 51

MS80 Zeroing

Explanation of Warning Labels

Explanation of Warning Labels

The following warning labels are attached to the manipulator.

Always follow the warnings on the labels.

Also, an identification label with important information is placed on the

body of the manipulator. Prior to operating the manipulator, confirm the

contents.

Figure 3: Warning Label Locations

163471-1CD

viii

HW1481050

Page 9

163471-1CD

9 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

Safeguarding Tips

Safeguarding Tips

All operators, programmers, maintenance personnel, supervisors, and

anyone working near the system must become familiar with the operation

of this equipment. All personnel involved with the operation of the

equipment must understand potential dangers of operation. General

safeguarding tips are as follows:

• Improper operation can result in personal injury and/or damage to

the equipment. Only trained personnel familiar with the operation of

this equipment, the operator's manuals, the system equipment, and

options and accessories should be permitted to operate this

equipment.

• Improper connections can damage the equipment. All connections

must be made within the standard voltage and current ratings of the

equipment.

• The system must be placed in Emergency Stop (E-Stop) mode

whenever it is not in use.

• In accordance with ANSI/RIA R15.06-2012, section 4.2.5, Sources of

Energy, use lockout/tagout procedures during equipment

maintenance. Refer also to Section 1910.147 (29CFR, Part 1910),

Occupational Safety and Health Standards for General Industry

(OSHA).

Mechanical Safety Devices

The safe operation of this equipment is ultimately the users responsibility.

The conditions under which the equipment will be operated safely should

be reviewed by the user. The user must be aware of the various national

codes, ANSI/RIA R15.06-2012 safety standards, and other local codes

that may pertain to the installation and use of this equipment.

Additional safety measures for personnel and equipment may be required

depending on system installation, operation, and/or location. The following

safety equipment is provided as standard:

• Safety barriers

• Door interlocks

• Emergency stop palm buttons located on operator station

Check all safety equipment frequently for proper operation. Repair or

replace any non-functioning safety equipment immediately.

ix

HW1481050

Page 10

MH50/MH50-35/MH80/

10 of 51

MS80 Zeroing

Programming, Operation, and Maintenance Safety

Programming, Operation, and Maintenance Safety

All operators, programmers, maintenance personnel, supervisors, and

anyone working near the system must become familiar with the operation

of this equipment. Improper operation can result in personal injury and/or

damage to the equipment. Only trained personnel familiar with the

operation, manuals, electrical design, and equipment interconnections of

this equipment should be permitted to program, or maintain the system.

All personnel involved with the operation of the equipment must

understand potential dangers of operation.

• Inspect the equipment to be sure no potentially hazardous conditions

exist. Be sure the area is clean and free of water, oil, debris, etc.

• Be sure that all safeguards are in place. Check all safety equipment

for proper operation. Repair or replace any non-functioning safety

equipment immediately.

• Check the E-Stop button on the operator station for proper operation

before programming. The equipment must be placed in Emergency

Stop (E-Stop) mode whenever it is not in use.

163471-1CD

• Back up all programs and jobs onto suitable media before program

changes are made. To avoid loss of information, programs, or jobs, a

backup must always be made before any service procedures are

done and before any changes are made to options, accessories, or

equipment.

• Any modifications to the controller unit can cause severe personal

injury or death, as well as damage to the robot! Do not make any

modifications to the controller unit. Making any changes without the

written permission from YASKAWA will void the warranty.

• Some operations require standard passwords and some require

special passwords.

• The equipment allows modifications of the software for maximum

performance. Care must be taken when making these modifications.

All modifications made to the software will change the way the

equipment operates and can cause severe personal injury or death,

as well as damage parts of the system. Double check all

modifications under every mode of operation to ensure that the

changes have not created hazards or dangerous situations.

• This equipment has multiple sources of electrical supply. Electrical

interconnections are made between the controller and other

equipment. Disconnect and lockout/tagout all electrical circuits

before making any modifications or connections.

• Do not perform any maintenance procedures before reading and

understanding the proper procedures in the appropriate manual.

• Use proper replacement parts.

• Improper connections can damage the equipment. All connections

must be made within the standard voltage and current ratings of the

equipment.

x

HW1481050

Page 11

163471-1CD

11 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

Maintenance Safety

Maintenance Safety

Turn the power OFF and disconnect and lockout/tagout all electrical

circuits before making any modifications or connections.

Perform only the maintenance described in this manual. Maintenance

other than specified in this manual should be performed only by

YASKAWA-trained, qualified personnel.

Summary of Warning Information

This manual is provided to help users establish safe conditions for

operating the equipment. Specific considerations and precautions are also

described in the manual, but appear in the form of Dangers, Warnings,

Cautions, and Notes.

It is important that users operate the equipment in accordance with this

instruction manual and any additional information which may be provided

by YASKAWA. Address any questions regarding the safe and proper

operation of the equipment to YASKAWA Customer Support.

xi

HW1481050

Page 12

MH50/MH50-35/MH80/

NOTE

(937) 847-3200

12 of 51

MS80 Zeroing

Customer Support Information

Customer Support Information

If you need assistance with any aspect of your MH50/MH50-35/MH80/

MS80 Zeroing system, please contact YASKAWA Customer Support at

the following 24-hour telephone number:

For routine technical inquiries, you can also contact YASKAWA Customer

Support at the following e-mail address:

When using e-mail to contact YASKAWA Customer Support, please

provide a detailed description of your issue, along with complete contact

information. Please allow approximately 24 to 36 hours for a response to

your inquiry.

163471-1CD

techsupport@motoman.com

Please use e-mail for routine inquiries only. If you have an

urgent or emergency need for service, replacement parts,

or information, you must contact YASKAWA Customer

Support at the telephone number shown above.

Please have the following information ready before you call Customer

Support:

• System MH50/MH50-35/MH80/MS80

Zeroing

• Robots ___________________________

• Primary Application ___________________________

• Controller DX100

• Software Version Access this information on the

Programming Pendant’s LCD

display screen by selecting {MAIN

MENU} - {SYSTEM INFO} {VERSION}

• Robot Serial Number Located on the robot data plate

• Robot Sales Order Number Located on the DX100 controller

data plate

xii

HW1481050

Page 13

163471-1CD

13 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

Table of Contents

Table of Contents

1 Zeroing Function ............................................................................................................................. 1-1

1.1 Outline ............................................................................................................................... 1-1

1.2 Details on Zeroing Function...............................................................................................1-2

1.2.1 System Configuration ........................................................................................... 1-2

1.2.1.1 System Configuration of the Zeroing Device Using the CF Card ............ 1-2

1.2.1.2 System Configuration of the Zeroing Device Using the USB Connector. 1-3

1.2.2 Operational Procedure and Cautions ................................................................... 1-4

1.2.2.1 Before the Zeroing Operation.................................................................. 1-4

1.2.2.2 Connection of the Zeroing Devices ......................................................... 1-4

1.2.2.3 Zeroing Procedure for S-Axis .................................................................. 1-6

1.2.2.4 Zeroing Procedure for L-Axis ................................................................ 1-11

1.2.2.5 Zeroing Procedure for U-Axis................................................................ 1-16

1.2.2.6 Zeroing Procedure for R-Axis................................................................ 1-21

1.2.2.7 Zeroing Procedure for B-Axis ................................................................ 1-26

1.2.2.8 Zeroing Procedure for T-Axis ................................................................ 1-31

1.3 Errors in the Zeroing Operation and Solutions ................................................................ 1-36

xiii

HW1481050

Page 14

MH50/MH50-35/MH80/

NOTE

NOTE

14 of 51

MS80 Zeroing

1 Zeroing Function

1.1 Outline

1 Zeroing Function

Zeroing function automatically allows for the restoration of the home

position data when the manipulator’s home position data disappear.

(Optional function)

This function only applies to the manipulator which was ordered to be

equipped with the zeroing function and shipped.

1.1 Outline

The DX100 stores the manipulator home position based on the pulse

value of each axis encoder. Since the home position is already set and

registered before shipment, zeroing operation does not need to be

performed at the normal operation. However, zeroing operation needs to

be performed to restore the home position since the home position data

disappear when you perform the following operations, or the followings

occur.

163471-1CD

• Replacement of Motors

• Replacement of Encoders

• Backup Battery Exhaustion in the Manipulator

The home position data is stored by the backup battery. If

the battery is exhausted, the home position data disappear

again when turning OFF the DX100 power even when the

zeroing operation is performed.

Be sure to replace the battery periodically. For the battery

replacement, refer to “Maintenance and Inspection” of

“MOTOMAN-MH50 INSTRUCTIONS”.

The home positioning cannot be performed accurately by

the zeroing operation if changing the combination of the

manipulator and the DX100.

1-1

HW1481050

Page 15

163471-1CD

NOTE

Zeroing device

PP

1

2

3

Communication interface

5

Amplifier

Lead wire

Communication cable

4

Manipulator

Controller (DX100)

Sensor

15 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1.2.1 System Configuration

1.2.1.1 System Configuration of the Zeroing Device Using the CF Card

1 Zeroing Function

1.2 Details on Zeroing Function

1.2 Details on Zeroing Function

The system configuration of the zeroing function is described in the

following.

Fig. 1-1: Zeroing System Configuration Using CF Card Slot

Table 1-1: Components for Zeroing Device Using CF Card Slot

Component Type

1

Sensor HW0381863-A 1

2

Amplifier HW0381864-A 1

3

Lead wire HW0470652-A 1

4

Communication cable C232N-915 1

5

Communication interface

The communication interface REX-CF60 has been discontinued.

Qty.

Manufacturer

YASKAWA Electric Corporation

YASKAWA Electric Corporation

YASKAWA Electric Corporation

YASKAWA Electric Corporation

1

REX-CF60

YASKAWA Electric Corporation

The sensor, amplifier, and communication interface are

precision instruments.

Handle and store them with due care.

1-2

HW1481050

Page 16

MH50/MH50-35/MH80/

NOTE

1

2

3

4

5

16 of 51

MS80 Zeroing

1.2.1.2 System Configuration of the Zeroing Device Using the USB Connector

1 Zeroing Function

1.2 Details on Zeroing Function

Fig. 1-2: Zeroing System Configuration Using USB Slot

Communication cable

Amplifier

2

4

Communication interface

5

163471-1CD

Lead wire

3

Zeroing device

Manipulator

PP

1 Sensor

Controller (DX100)

Table 1-2: Components for Zeroing Device Using USB Slot

Component Type

Sensor HW0381863-A 1

Amplifier HW0381864-A 1

Lead wire HW0470652-A 1

Communication cable C232N-915 1

Communication interface REX-USB60F 1

Qty.

Manufacturer

YASKAWA Electric Corporation

YASKAWA Electric Corporation

YASKAWA Electric Corporation

YASKAWA Electric Corporation

YASKAWA Electric Corporation

The sensor, amplifier, and communication interface are

precision instruments.

Handle and store them with due care.

1-3

HW1481050

Page 17

163471-1CD

WARNING

NOTE

Using the CF card slot Using the USB slot

17 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1.2.2 Operational Procedure and Cautions

1 Zeroing Function

1.2 Details on Zeroing Function

• False zeroing operation may lead to the manipulator’s operation

error.

Be sure to follow the set procedures and perform the zeroing

operation upon ensuring the safety.

Injury may result from unintentional or unexpected manipulator motion,

or operation error.

The zeroing function is only valid when the security mode is

set to the management mode.

For the security mode, refer to chapter 7 “Security System”

of the “DX100 INSTRUCTIONS”.

1.2.2.1 Before the Zeroing Operation

Remove the tool attached to the manipulator and perform the zeroing

operation for accurate home positioning by the zeroing function. If the

zeroing operation is performed with the tool attached to the manipulator,

the tool’s weight may affect positioning accuracy.

1.2.2.2 Connection of the Zeroing Devices

1. When using the CF card slot: Insert the communication interface

(REX-CF60) into the CF card slot of the

programming pendant.

When using the USB slot : Insert the communication interface

(REX-USB60F) into the USB slot of the

programming pendant.

Fig. 1-3: Insertion of the Communication Interface

1-4

HW1481050

Page 18

MH50/MH50-35/MH80/

18 of 51

MS80 Zeroing

163471-1CD

1 Zeroing Function

1.2 Details on Zeroing Function

2. When using the CF card slot: Connect the communication interface

(REX-CF60) with the amplifier by using

the communication cable (C232N-915).

When using the USB slot : Connect the communication interface

(REX-USB60F) with the amplifier by

using the communication cable

(C232N-915).

3. Connect the lead wire to the amplifier.

(Do not connect the sensor yet.)

The installation locations of the zeroing sensors for each axis are shown in

Fig. 1-4 “Installation Locations of the Zeroing Sensors”.

Perform the zeroing operation for every axis by referring to the procedures

described in the following pages.

The appearance of parts and installation locations may vary for each

model. In this manual, details are described by using the figures of MH50.

Fig. 1-4: Installation Locations of the Zeroing Sensors

T-axis

B-axis

R-axis

U-axis

L-axis

S-axis

1-5

HW1481050

Page 19

163471-1CD

S-axis

NOTE

NOTE

NOTE

NOTE

NOTE

19 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1.2.2.3 Zeroing Procedure for S-Axis

1 Zeroing Function

1.2 Details on Zeroing Function

Perform the zeroing operation for S-axis with the following procedure.

1. Remove the plug and cover from the attaching portion for the sensor.

Be sure to remove the cover. If the zeroing operation is

performed with the cover on, the sensor may be damaged.

The plug, cover, and cover mounting screws are small

parts.

Be sure not to lose them during the operation.

Be sure that the servo power is OFF and no safety hazard

is around the manipulator when approaching the

manipulator.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

2. Perform the home position alignment by adjusting the alignment marks

on the S-axis of the manipulator in the “TEACH” mode.

Be sure to adjust the home position alignment marks and

perform the zeroing operation.

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

3. Check that no spatter, fume or rust is attached in/on the sensor

mounting hole, or sensor detecting element after removing the plug

and cover.

– Remove the spatter, fume, and rust if they are found.

1-6

HW1481050

Page 20

MH50/MH50-35/MH80/

NOTE

NOTE

20 of 51

MS80 Zeroing

163471-1CD

1 Zeroing Function

1.2 Details on Zeroing Function

4. Install the sensor onto the mounting holes.

Never use tools, or avoid excessive force on the sensor.

Failure to observe this instruction may result in damage to

the sensor.

5. Connect the lead wire to the sensor.

6. Turn ON the amplifier power.

– If the amplifier power has been turned ON for prolonged periods of

time, tu

7. Set the mode selector switch on the programming pendant to

“TEACH”.

8. Select {Robot} → {Zeroing} from [Main Menu].

Then, select “S: S-axis” on the touch panel.

rn OFF the power once and turn ON the power again.

9. Turn ON the servo power by the [SERVO ON READY] button and

able switch on the programming pendant.

En

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

1-7

HW1481050

Page 21

163471-1CD

NOTE

NOTE

21 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

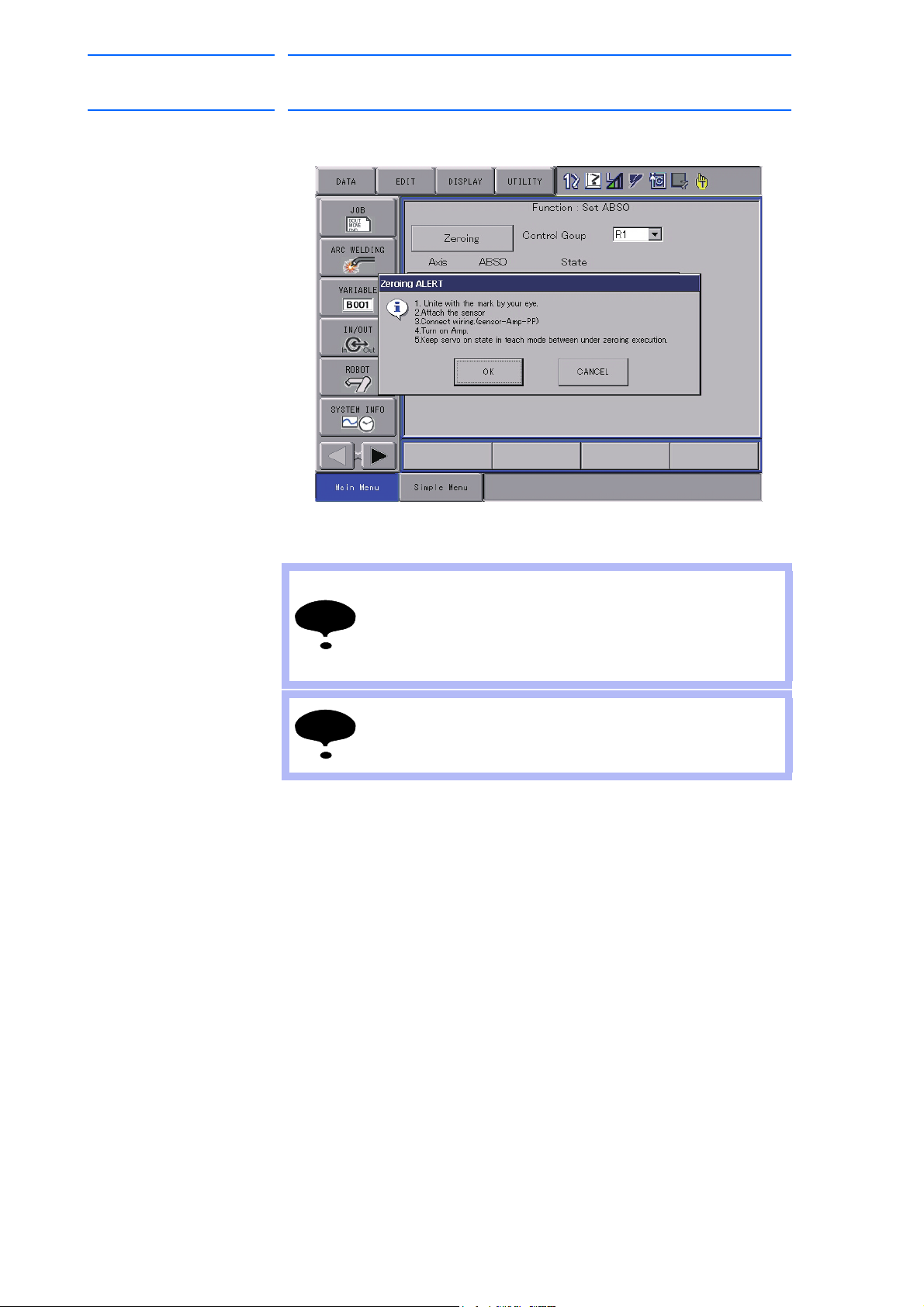

10. Press {Zeroing} on the touch panel, and pop-up window appears

displaying the CAUTION message.

11. Press {OK} by following the message in the pop-up window, and the

manipulator st

arts automatically.

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

The manipulator motion is hard to be detected due to its

slight motion.

Confirm that no person approach the manipulator.

1-8

HW1481050

Page 22

MH50/MH50-35/MH80/

NOTE

NOTE

NOTE

22 of 51

MS80 Zeroing

163471-1CD

1 Zeroing Function

1.2 Details on Zeroing Function

12. The programming pendant screen shows the message to confirm the

completion of the zeroing operation, then indicates the calculated

absolute data.

13. Turn OFF the servo power.

Be sure to turn OFF the servo power to approach the

manipulator.

Injury may result from unintentional or unexpected

manipulator motion.

14. Turn OFF the amplifier power.

15. Disconnect the lead wire from the sensor.

16. Remove the sensor from the manipulator.

After the zeroing operation, be sure to remove the sensor

from the manipulator before starting the manipulator.

If the manipulator is operated with the sensor attached to

the manipulator, the sensor may be damaged.

17. Reinstall the plug and cover onto the manipulator.

Be sure to install the plug and cover to prevent any dirt on

the sensor mounting holes or sensor detecting element.

The zeroing operation cannot be performed if any dirt is

attached on them.

1-9

HW1481050

Page 23

163471-1CD

NOTE

23 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

18. Remove dust on the sensor for the sensor dust.

19. Confirm the manipulator position as follows:

Select {Robot} from [Main Menu] → {Second Home Position}.

– The Second Home Position window appears.

–

For safety reasons, automatic operations by playback cannot be

performed unless the position is confirmed.

20. Turn ON the servo power by the [SER

Enable switch on the programming pendant.

Then, press [FWD] to move TCP to the second home position.

– Check for any position deviation of the manipulator’s second home

position.

21. Select {Data} from [Main Menu] → {Confirm Position}.

– The message “Home position checked” appears.

22. Confirm the operation in the “TEACH” mode before restarting

au

tomatic operation by playback.

– Check the followings to confirm the operation.

• Any deviation at each taught point by FWD operation in the

“TEACH” mode

• Test runs

Be sure to confirm the home position before starting

automatic operation.

If false home position is input by the zeroing function, it may

lead to errors in the manipulator performance.

VO ON READY] button and

1-10

HW1481050

Page 24

MH50/MH50-35/MH80/

L-axis

NOTE

NOTE

NOTE

NOTE

NOTE

24 of 51

MS80 Zeroing

1.2.2.4 Zeroing Procedure for L-Axis

163471-1CD

1 Zeroing Function

1.2 Details on Zeroing Function

Perform the zeroing operation for L-axis with the following procedure.

1. Remove the plug and cover from the attaching portion for the sensor.

Be sure to remove the cover. If the zeroing operation is

performed with the cover on, the sensor may be damaged.

The plug, cover, and cover mounting screws are small

parts.

Be sure not to lose them during the operation.

Be sure that the servo power is OFF and no safety hazard

is around the manipulator when approaching the

manipulator.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

2. Perform the home position alignment by adjusting the alignment marks

on the L-axis of the manipulator in the “TEACH” mode.

Be sure to adjust the home position alignment marks and

perform the zeroing operation.

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

3. Check that no spatter, fume or rust is attached in/on the sensor

mounting hole, or sensor detecting element after removing the plug

and cover.

– Remove the spatter, fume, and rust if they are found.

1-11

HW1481050

Page 25

163471-1CD

NOTE

NOTE

25 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

4. Install the sensor onto the mounting holes.

Never use tools, or avoid excessive force on the sensor.

Failure to observe this instruction may result in damage to

the sensor.

5. Connect the lead wire to the sensor.

6. Turn ON the amplifier power.

– If the amplifier power has been turned ON for prolonged periods of

tim

e, turn OFF the power once and turn ON the power again.

7. Set the mode selector switch on the programming pendant to

“TEA

CH”.

8. Select {Robot} → {Zeroing} from [Main Menu].

Then, select “L: L-axis” on the touch panel.

9. Turn ON the servo power by the [SER

Enable switch on the programming pendant.

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

1-12

VO ON READY] button and

HW1481050

Page 26

MH50/MH50-35/MH80/

NOTE

NOTE

26 of 51

MS80 Zeroing

163471-1CD

1 Zeroing Function

1.2 Details on Zeroing Function

10. Press {Zeroing} on the touch panel, and pop-up window appears

displaying the CAUTION message.

11. Press {OK} by following the message in the pop-up window, and the

anipulator starts automatically.

m

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

The manipulator motion is hard to be detected due to its

slight motion.

Confirm that no persons approach the manipulator.

1-13

HW1481050

Page 27

163471-1CD

NOTE

NOTE

NOTE

27 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

12. The programming pendant screen shows the message to confirm the

completion of the zeroing operation, then indicates the calculated

absolute data.

13. Turn OFF the servo power.

Be sure to turn OFF the servo power to approach the

manipulator.

Injury may result from unintentional or unexpected

manipulator motion.

14. Turn OFF the amplifier power.

15. Disconnect the lead wire from the sensor.

16. Remove the sensor from the manipulator.

After the zeroing operation, be sure to remove the sensor

from the manipulator before starting the manipulator.

If the manipulator is operated with the sensor attached to

the manipulator, the sensor may be damaged.

17. Reinstall the plug and cover onto the manipulator.

Be sure to install the plug and cover to prevent any dirt on

the sensor mounting holes or sensor detecting element.

The zeroing operation cannot be performed if any dirt is

attached on them.

1-14

HW1481050

Page 28

MH50/MH50-35/MH80/

NOTE

28 of 51

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

18. Remove dust on the sensor for the sensor dust.

19. Confirm the manipulator position as follows:

Select {Robot} from [Main Menu] → {Second Home Position}.

– The Second Home Position window appears.

–

For safety reasons, automatic operations by playback cannot be

performed unless the position is confirmed.

163471-1CD

20. Turn ON the servo power by the [SER

Enable switch on the programming pendant.

Then, press [FWD] to move TCP to the second home position.

– Check for any position deviation of th

position.

21. Select {Data} from [Main Menu] → {Confirm Position}.

– The message “Home position checked” appears.

22. Confirm the operation in the “TEACH” mode before restarting

a

utomatic operation by playback.

– Check the followings to confirm the operation.

• Any deviation at each taught point by FWD operation in the

“TEACH” mode

• Test runs

Be sure to confirm the home position before starting

automatic operation.

If false home position is input by the zeroing function, it may

lead to errors in the manipulator performance.

VO ON READY] button and

e manipulator’s second home

1-15

HW1481050

Page 29

163471-1CD

U-axis

NOTE

NOTE

NOTE

NOTE

NOTE

29 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1.2.2.5 Zeroing Procedure for U-Axis

1 Zeroing Function

1.2 Details on Zeroing Function

Perform the zeroing operation for U-axis with the following procedure.

1. Remove the plug and cover from the attaching portion for the sensor.

Be sure to remove the cover. If the zeroing operation is

performed with the cover on, the sensor may be damaged.

The plug, cover, and cover mounting screws are small

parts, be sure not to lose them during the operation.

Be sure that the servo power is OFF and no safety hazard

is around the manipulator when approaching the

manipulator.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

2. Perform the home position alignment by adjusting the alignment marks

on the U-axis of the manipulator in the “TEACH” mode.

Be sure to adjust the home position alignment marks and

perform the zeroing operation.

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

3. Check that no spatter, fume or rust is attached in/on the sensor

mounting hole, or indentation after removing the plug and cover.

– Remove the spatter, fume, and rust if they are found.

1-16

HW1481050

Page 30

MH50/MH50-35/MH80/

NOTE

NOTE

30 of 51

MS80 Zeroing

163471-1CD

1 Zeroing Function

1.2 Details on Zeroing Function

4. Install the sensor onto the mounting holes.

Never use tools, or avoid excessive force on the sensor.

Failure to observe this instruction may result in damage to

the sensor.

5. Connect the lead wire to the sensor.

6. Turn ON the amplifier power.

– If the amplifier power has been turned ON for prolonged periods of

time, tu

7. Set the mode selector switch on the programming pendant to

“TEACH”.

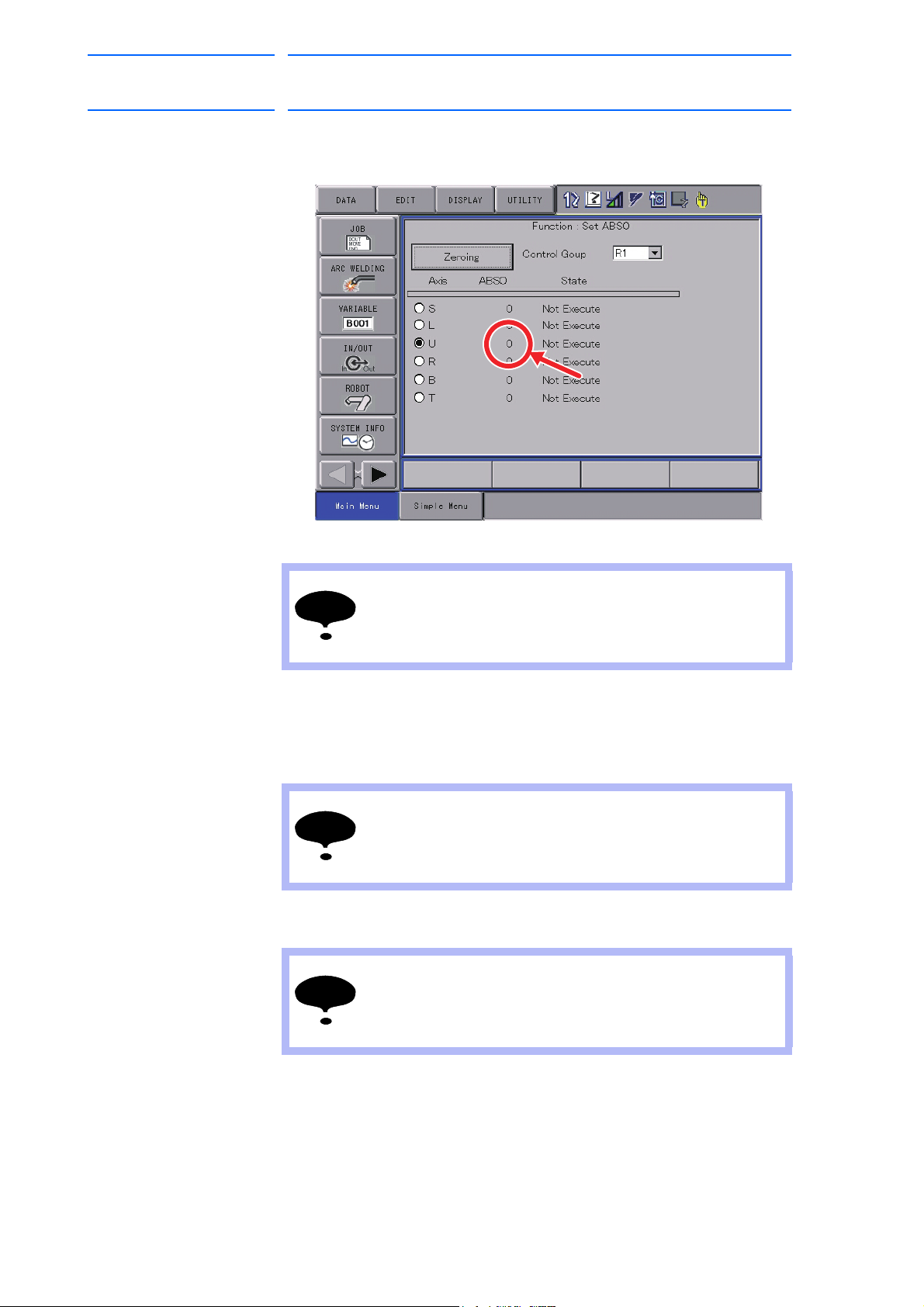

8. Select {Robot}

Then, select “U: U-axis” on the touch panel.

rn OFF the power once and turn ON the power again.

→ {Zeroing} from [Main Menu].

9. Turn ON the servo power by the [SERVO ON READY] button and

able switch on the programming pendant.

En

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

1-17

HW1481050

Page 31

163471-1CD

NOTE

NOTE

31 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

10. Press {Zeroing} on the touch panel, and pop-up window appears

displaying the CAUTION message.

11. Press {OK} by following the message in the pop-up window, and the

manipulator st

arts automatically.

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

The manipulator motion is hard to be detected due to its

slight motion.

Confirm that no persons approach the manipulator.

1-18

HW1481050

Page 32

MH50/MH50-35/MH80/

NOTE

NOTE

NOTE

32 of 51

MS80 Zeroing

163471-1CD

1 Zeroing Function

1.2 Details on Zeroing Function

12. The programming pendant screen shows the message to confirm the

completion of the zeroing operation, then indicates the calculated

absolute data.

13. Turn OFF the servo power.

Be sure to turn OFF the servo power to approach the

manipulator.

Injury may result from unintentional or unexpected

manipulator motion.

14. Turn OFF the amplifier power.

15. Disconnect the lead wire from the sensor.

16. Remove the sensor from the manipulator.

After the zeroing operation, be sure to remove the sensor

from the manipulator before starting the manipulator.

If the manipulator is operated with the sensor attached to

the manipulator, the sensor may be damaged.

17. Reinstall the plug and cover onto the manipulator.

Be sure to install the plug and cover to prevent any dirt on

the sensor mounting holes or sensor detecting element.

The zeroing operation cannot be performed if any dirt is

attached on them.

1-19

HW1481050

Page 33

163471-1CD

NOTE

33 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

18. Remove dust on the sensor for the sensor dust.

19. Confirm the manipulator position as follows:

Select {Robot} from [Main Menu]

– The Second Home Position window appears.

–

For safety reasons, automatic operations by playback cannot be

performed unless the position is confirmed.

→ {Second Home Position}.

20. Turn ON the servo power by the [SER

Enable switch on the programming pendant.

Then, press [FWD] to move TCP to the second home position.

– Check for any position deviation of the manipulator’s second home

position.

21. Select {Data} from [Main Menu]

– The message “Home position checked” appears.

22. Confirm the operation in the “TEACH” mode before restarting

au

tomatic operation by playback.

– Check the followings to confirm the operation.

• Any deviation at each taught point by FWD operation in the

“TEACH” mode

• Test runs

Be sure to confirm the home position before starting

automatic operation.

If false home position is input by the zeroing function, it may

lead to errors in the manipulator performance.

VO ON READY] button and

→ {Confirm Position}.

1-20

HW1481050

Page 34

MH50/MH50-35/MH80/

NOTE

NOTE

NOTE

NOTE

NOTE

R-axis

34 of 51

MS80 Zeroing

1.2.2.6 Zeroing Procedure for R-Axis

163471-1CD

1 Zeroing Function

1.2 Details on Zeroing Function

Perform the zeroing operation for R-axis with the following procedure.

1. Remove the plug and cover from the attaching portion for the sensor.

Be sure to remove the cover. If the zeroing operation is

performed with the cover on, the sensor may be damaged.

The plug, cover, and cover mounting screws are small

parts.

Be sure not to lose them during the operation.

Be sure that the servo power is OFF and no safety hazard

is around the manipulator when approaching the

manipulator.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

2. Perform the home position alignment by adjusting the alignment marks

on the R-axis of the manipulator in the “TEACH” mode.

Be sure to adjust the home position alignment marks and

perform the zeroing operation.

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator in a

safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

1-21

HW1481050

Page 35

163471-1CD

NOTE

35 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

3. Check that no spatter, fume or rust is attached in/on the sensor

mounting hole, or sensor detecting element after removing the plug

and cover.

– Remove the spatter, fume, and rust if they are found.

4. Install the sensor onto the mounting holes.

Never use tools, or avoid excessive force on the sensor.

Failure to observe this instruction may result in damage to

the sensor.

5. Connect the lead wire to the sensor.

6. Turn ON the amplifier power.

– If the amplifier power has been turned ON for prolonged periods of

tim

e, turn OFF the power once and turn ON the power again.

7. Set the mode selector switch on the programming pendant to

“TEA

CH”.

8. Select {Robot}

Then, select “R: R-axis” on the touch panel.

→ {Zeroing} from [Main Menu].

1-22

HW1481050

Page 36

MH50/MH50-35/MH80/

NOTE

NOTE

NOTE

36 of 51

MS80 Zeroing

163471-1CD

1 Zeroing Function

1.2 Details on Zeroing Function

9. Turn ON the servo power by the [SERVO ON READY] button and

Enable switch on the programming pendant.

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

10. Press {Zeroing} on the touch panel, and pop-up window appears

displaying the CAUTION message.

11. Press {OK} by following the message in the pop-up window, and the

manipulator starts automatically.

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

The manipulator motion is hard to be detected due to its

slight motion.

Confirm that no persons approach the manipulator.

1-23

HW1481050

Page 37

163471-1CD

NOTE

NOTE

NOTE

37 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

12. The programming pendant screen shows the message to confirm the

completion of the zeroing operation, then indicates the calculated

absolute data.

13. Turn OFF the servo power.

Be sure to turn OFF the servo power to approach the

manipulator.

Injury may result from unintentional or unexpected

manipulator motion.

14. Turn OFF the amplifier power.

15. Disconnect the lead wire from the sensor.

16. Remove the sensor from the manipulator.

After the zeroing operation, be sure to remove the sensor

from the manipulator before starting the manipulator.

If the manipulator is operated with the sensor attached to

the manipulator, the sensor may be damaged.

17. Reinstall the plug and cover onto the manipulator.

Be sure to install the plug and cover to prevent any dirt on

the sensor mounting holes or sensor detecting element.

The zeroing operation cannot be performed if any dirt is

attached on them.

1-24

HW1481050

Page 38

MH50/MH50-35/MH80/

NOTE

38 of 51

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

18. Remove dust on the sensor for the sensor dust.

19. Confirm the manipulator position as follows:

Select {Robot} from [Main Menu]

– The Second Home Position window appears.

–

For safety reasons, automatic operations by playback cannot be

performed unless the position is confirmed.

→ {Second Home Position}.

163471-1CD

20. Turn ON the servo power by the [SER

Enable switch on the programming pendant.

Then, press [FWD] to move TCP to the second home position.

– Check for any position deviation of th

position.

21. Select {Data} from [Main Menu]

– The message “Home position checked” appears.

22. Confirm the operation in the “TEACH” mode before restarting

a

utomatic operation by playback.

– Check the followings to confirm the operation.

• Any deviation at each taught point by FWD operation in the

“TEACH” mode

• Test runs

Be sure to confirm the home position before starting

automatic operation.

If false home position is input by the zeroing function, it may

lead to errors in the manipulator performance.

VO ON READY] button and

e manipulator’s second home

→ {Confirm Position}.

1-25

HW1481050

Page 39

163471-1CD

B-axis

NOTE

NOTE

NOTE

NOTE

NOTE

39 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1.2.2.7 Zeroing Procedure for B-Axis

1 Zeroing Function

1.2 Details on Zeroing Function

Perform the zeroing operation for B-axis with the following procedure.

1. Remove the plug and cover from the attaching portion for the sensor.

Be sure to remove the cover. If the zeroing operation is

performed with the cover on, the sensor may be damaged.

The plug, cover, and cover mounting screws are small

parts.

Be sure not to lose them during the operation.

Be sure that the servo power is OFF and no safety hazard

is around the manipulator when approaching the

manipulator.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

2. Perform the home position alignment by adjusting the alignment marks

on the B-axis of the manipulator in the “TEACH” mode.

Be sure to adjust the home position alignment marks and

perform the zeroing operation.

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

3. Check that no spatter, fume or rust is attached in/on the sensor

mounting hole, or sensor detecting element after removing the plug

and cover.

– Remove the spatter, fume, and rust if they are found.

1-26

HW1481050

Page 40

MH50/MH50-35/MH80/

NOTE

NOTE

40 of 51

MS80 Zeroing

163471-1CD

1 Zeroing Function

1.2 Details on Zeroing Function

4. Install the sensor onto the mounting holes.

Never use tools, or avoid excessive force on the sensor.

Failure to observe this instruction may result in damage to

the sensor.

5. Connect the lead wire to the sensor.

6. Turn ON the amplifier power.

– If the amplifier power has been turned ON for prolonged periods of

time, tu

7. Set the mode selector switch on the programming pendant to

“TEACH”.

8. Select {Robot}

Then, select “B: B-axis” on the touch panel.

rn OFF the power once and turn ON the power again.

→ {Zeroing} from [Main Menu].

9. Turn ON the servo power by the [SERVO ON READY] button and

able switch on the programming pendant.

En

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

1-27

HW1481050

Page 41

163471-1CD

NOTE

NOTE

41 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

10. Press {Zeroing} on the touch panel, and pop-up window appears

displaying the CAUTION message.

11. Press {OK} by following the message in the pop-up window, and the

manipulator st

arts automatically.

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

The manipulator motion is hard to be detected due to its

slight motion.

Confirm that no persons approach the manipulator.

1-28

HW1481050

Page 42

MH50/MH50-35/MH80/

NOTE

NOTE

NOTE

42 of 51

MS80 Zeroing

163471-1CD

1 Zeroing Function

1.2 Details on Zeroing Function

12. The programming pendant screen shows the message to confirm the

completion of the zeroing operation, then indicates the calculated

absolute data.

13. Turn OFF the servo power.

Be sure to turn OFF the servo power to approach the

manipulator.

Injury may result from unintentional or unexpected

manipulator motion.

14. Turn OFF the amplifier power.

15. Disconnect the lead wire from the sensor.

16. Remove the sensor from the manipulator.

After the zeroing operation, be sure to remove the sensor

from the manipulator before starting the manipulator.

If the manipulator is operated with the sensor attached to

the manipulator, the sensor may be damaged.

17. Reinstall the plug and cover onto the manipulator.

Be sure to install the plug and cover to prevent any dirt on

the sensor mounting holes or sensor detecting element.

The zeroing operation cannot be performed if any dirt is

attached on them.

1-29

HW1481050

Page 43

163471-1CD

NOTE

43 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

18. Remove dust on the sensor for the sensor dust.

19. Confirm the manipulator position as follows:

Select {Robot} from [Main Menu]

– The Second Home Position window appears.

–

For safety reasons, automatic operations by playback cannot be

performed unless the position is confirmed.

→ {Second Home Position}.

20. Turn ON the servo power by the [SER

Enable switch on the programming pendant.

Then, press [FWD] to move TCP to the second home position.

21. Check for any position deviation of the manipulator’s second home

sition.

po

22. Select {Data} from [Main Menu]

– The message “Home position checked” appears.

23. Confirm the operation in the “TEACH” mode before restarting

au

tomatic operation by playback.

– Check the followings to confirm the operation.

• Any deviation at each taught point by FWD operation in the

“TEACH” mode

• Test runs

Be sure to confirm the home position before starting

automatic operation.

If false home position is input by the zeroing function, it may

lead to errors in the manipulator performance.

VO ON READY] button and

→ {Confirm Position}.

1-30

HW1481050

Page 44

MH50/MH50-35/MH80/

NOTE

NOTE

NOTE

NOTE

NOTE

T-axis

44 of 51

MS80 Zeroing

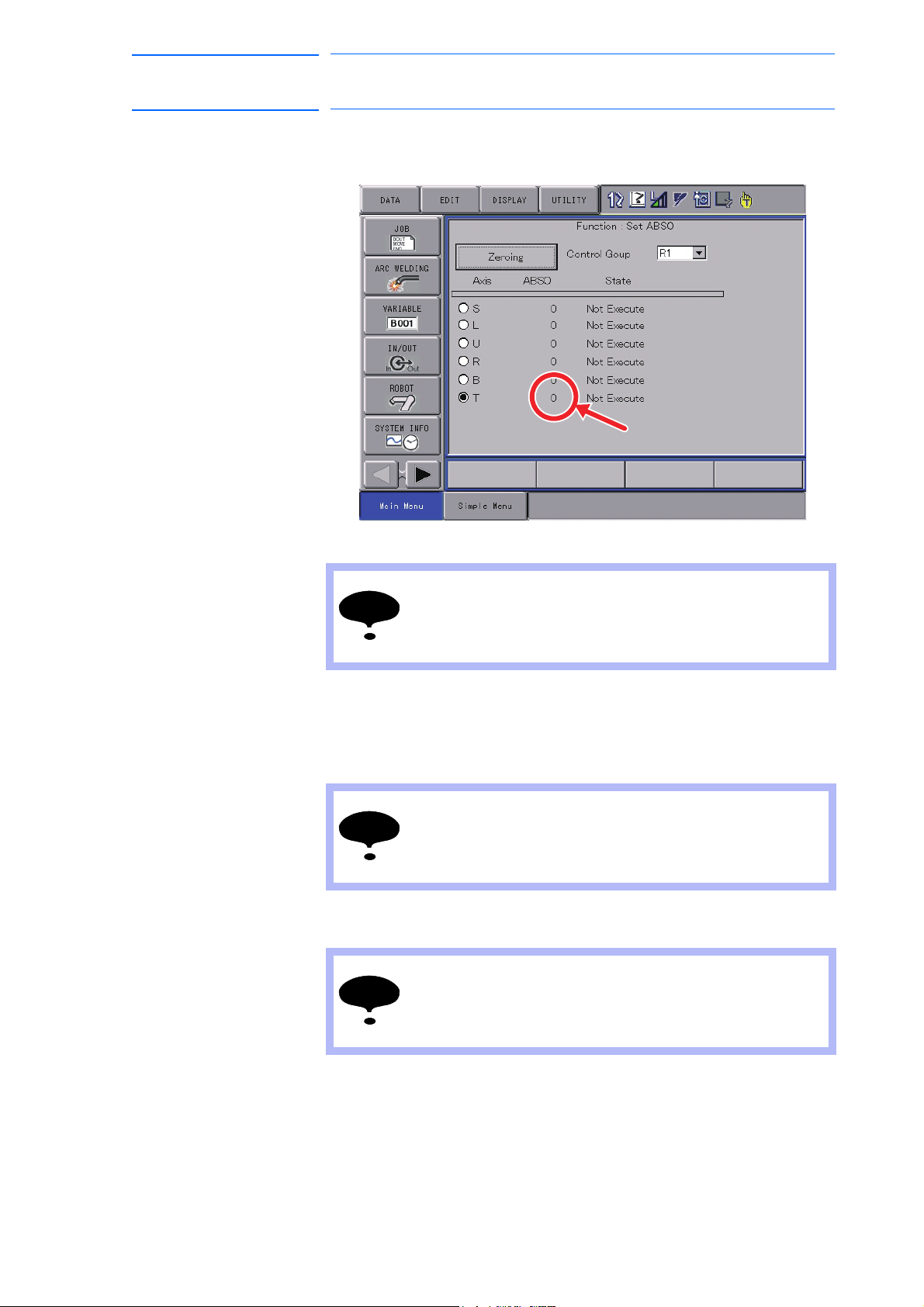

1.2.2.8 Zeroing Procedure for T-Axis

163471-1CD

1 Zeroing Function

1.2 Details on Zeroing Function

Perform the zeroing operation for T-axis with the following procedure.

1. Remove the plug and cover from the attaching portion for the sensor.

Be sure to remove the cover. If the zeroing operation is

performed with the cover on, the sensor may be damaged.

The plug, cover, and cover mounting screws are small

parts.

Be sure not to lose them during the operation.

Be sure that the servo power is OFF and no safety hazard

is around the manipulator when approaching the

manipulator.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

2. Perform the home position alignment by adjusting the alignment marks

on the T-axis of the manipulator in the “TEACH” mode.

Be sure to adjust the home position alignment marks and

perform the zeroing operation.

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

3. Check that no spatter, fume or rust is attached in/on the sensor

mounting hole, or sensor detecting element after removing the plug

and cover.

– Remove the spatter, fume, and rust if they are found.

1-31

HW1481050

Page 45

163471-1CD

NOTE

NOTE

45 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

4. Install the sensor onto the mounting holes.

Never use tools, or avoid excessive force on the sensor.

Failure to observe this instruction may result in damage to

the sensor.

5. Connect the lead wire to the sensor.

6. Turn ON the amplifier power.

– If the amplifier power has been turned ON for prolonged periods of

tim

e, turn OFF the power once and turn ON the power again.

7. Set the mode selector switch on the programming pendant to

“TEA

CH”.

8. Select {Robot}

Then, select “T: T-axis” on the touch panel.

→ {Zeroing} from [Main Menu].

9. Turn ON the servo power by the [SER

Enable switch on the programming pendant.

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

1-32

VO ON READY] button and

HW1481050

Page 46

MH50/MH50-35/MH80/

NOTE

NOTE

46 of 51

MS80 Zeroing

163471-1CD

1 Zeroing Function

1.2 Details on Zeroing Function

10. Press {Zeroing} on the touch panel, and pop-up window appears

displaying the CAUTION message.

11. Press {OK} by following the message in the pop-up window, and the

anipulator starts automatically.

m

Confirm that no persons are present in the P-point

maximum envelope of the manipulator and the operator is

in a safe place.

Injury may result from unintentional or unexpected

manipulator motion, or operation error.

The manipulator motion is hard to be detected due to its

slight motion.

Confirm that no persons approach the manipulator.

1-33

HW1481050

Page 47

163471-1CD

NOTE

NOTE

NOTE

47 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

12. The programming pendant screen shows the message to confirm the

completion of the zeroing operation, then indicates the calculated

absolute data.

13. Turn OFF the servo power.

Be sure to turn OFF the servo power to approach the

manipulator.

Injury may result from unintentional or unexpected

manipulator motion.

14. Turn OFF the amplifier power.

15. Disconnect the lead wire from the sensor.

16. Remove the sensor from the manipulator.

After the zeroing operation, be sure to remove the sensor

from the manipulator before starting the manipulator.

If the manipulator is operated with the sensor attached to

the manipulator, the sensor may be damaged.

17. Reinstall the plug and cover onto the manipulator.

Be sure to install the plug and cover to prevent any dirt on

the sensor mounting hoes or sensor detecting element.

The zeroing operation cannot be performed if any dirt is

attached on them.

1-34

HW1481050

Page 48

MH50/MH50-35/MH80/

NOTE

48 of 51

MS80 Zeroing

1 Zeroing Function

1.2 Details on Zeroing Function

18. Remove dust on the sensor for the sensor dust.

19. Confirm the manipulator position as follows:

Select {Robot} from [Main Menu]

– The Second Home Position window appears.

–

For safety reasons, automatic operations by playback cannot be

performed unless the position is confirmed.

→ {Second Home Position}.

163471-1CD

20. Turn ON the servo power by the [SER

Enable switch on the programming pendant.

Then, press [FWD] to move TCP to the second home position.

– Check for any position deviation of th

position.

21. Select {Data} from [Main Menu] → {Confirm Position}.

– The message “Home position checked” appears.

22. Confirm the operation in the “TEACH” mode before restarting

a

utomatic operation by playback.

– Check the followings to confirm the operation.

• Any

deviation at each taught point by FWD operation in the

“TEACH” mode

• Test runs

Be sure to confirm the home position before starting

automatic operation.

If false home position is input by the zeroing function, it may

lead to errors in the manipulator performance.

VO ON READY] button and

e manipulator’s second home

1-35

HW1481050

Page 49

163471-1CD

49 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

1 Zeroing Function

1.3 Errors in the Zeroing Operation and Solutions

1.3 Errors in the Zeroing Operation and Solutions

If errors occur during the zeroing operation, confirm the error contents and

perform the following operations.

Message Contents Operation

There is little depth of the hole or it

is large.

Investigate the hole.

ErrorCode:55550004

Switch mode to teach.

Again, Execute zeroing.

Keep servo on state in teach mode

between under zeroing execution.

Again, Execute zeroing

Loop Error [The maximum

measurement point were

exceeded.]

ErrorCode:55550005

Loop Error [Acquiring a pulse went

wrong.]

ErrorCode:55550006

Loop Error [The processing which

starts robot operation went wrong.]

ErrorCode:55550008

Loop Error [The processing which

stops robot operation went wrong.]

ErrorCode:55550009

Loop Error [Acquiring the value of

the sensor went wrong.]

ErrorCode:55550010

Error [Sensor Amp (Read():D1)]

ErrorCode:55550044

Information

* Check the amp power supply of

the sensor.

* Check connection of the RS232C cable.

* Check Battery.

Alarm : Sensor Amp (Battery) Amplifier battery exhaustion Replace the battery with the new

Alarm : Sensor Amp (Write Error

EEPROM)

Error in the data on the hole depth

caught by the sensor

The mode selector switch on the

programming pendant is set to “PLAY”

mode at the start of the zeroing

operation.

The servo power is not turned ON at

the start of the zeroing operation.

Error in the zeroing processing Possible causes: False parameter

Error in communication Possible causes: Inconsistency in

Error in communication Contact your nearest YASKAWA

Error in communication Check if the alarm lamp is lit,

Amplifier EEPROM writing error Contact your nearest YASKAWA

Check if dust or spatter is

present on the hole.

Check for damage or cracks

on the sensor exterior, or

deformation of the sensor

end.

Perform the zeroing

operation again upon

confirming the procedures.

Set the mode selector switch to

“TEACH” to perform the zeroing

operation.

Turn ON the servo power by the

operations as gripping the Enable

switch of the programming

pendant, etc.

settings for zeroing speed,

distance, radius, and etc., false

starting point of the zeroing

operation and etc.

Contact the nearest YASKAWA

representative.

software version.

Contact your nearest YASKAWA

representative.

representative for perceiving the

details on the current state by the

particular numbers.

Contact your nearest YASKAWA

representative.

or cables and etc. are

connected properly.

Turn OFF the power to the

amplifier, and turn ON again.

Then perform the zeroing

operation.

battery.

representative.

1-36

HW1481050

Page 50

163471-1CD

50 of 51

MH50/MH50-35/MH80/

MS80 Zeroing

Message Contents Operation

Alarm : Sensor Amp (AD Over) AD Over Alarm of the amplifier Contact your nearest YASKAWA

Error [Sensor Amp (Auto

Zero:OK)]

ErrorCode:55550046

Error [No CtrlGroup]

ErrorCode:55550052

Error [No Axis]

ErrorCode:55550056

Not Found : RS-232C CF-Card

ErrorCode:55550001

Error [RS-232C Communication]

ErrorCode:55550017

Error [RS-232C Communication]

ErrorCode:55550018

Error RS-232C Communication]

ErrorCode:55550019

Error [RS-232C Communication]

ErrorCode:55550020

Error Occur The zeroing operation is terminated

Finish! (Error Occur)

Operator Stop The zeroing operation is terminated

Finish! (Operator Stop)

The operator pushed the stop.

Error [Any axis don't set ABSO.]

ErrorCode:55550088

Loop Error [The maximum moving

pulse over.]

ErrorCode:55550097

1 Zeroing Function

1.3 Errors in the Zeroing Operation and Solutions

representative.

Error in zeroing of the amplifier Contact your nearest YASKAWA

representative.

Zeroing was performed with the DX100

which has no manipulator control

group.

Zeroing was performed with the

manipulator control group which has no

operable axes.

CF-Card for the RS-232C is not

inserted into the slot of the

programming pendant.

Errors occur during the amplifier

communication

due to error occurrence.

with the stop button.

Error in the zeroing processing Contact your nearest YASKAWA

Error in the zeroing processing Contact your nearest YASKAWA

Perform the zeroing operation by

the DX100 with the manipulator

control group.

Specify the manipulator control

group with operable axes.

Insert the CF-Card for the RS232C into the slot.

Contact your nearest YASKAWA

representative.

Confirm the error content and

remove the error cause. Then,

perform the zeroing operation

again from the start.

Perform the zeroing operation

again from the start.

representative.

representative.

1-37

HW1481050

Page 51

HEAD OFFICE

2-1 Kurosakishiroishi, Yahatanishi-ku, Kitakyushu 806-0004, Japan

Phone +81-93-645-7703 Fax +81-93-645-7802

100 Automation Way, Miamisburg, OH 45342, U.S.A.

Phone +1-937-847-6200 Fax +1-937-847-6277

YASKAWA America Inc. (Motoman Robotics Division)

Yaskawastrasse 1, 85391 Allershausen, Germany

Phone +49-8166-90-100 Fax +49-8166-90-103

YASKAWA Europe GmbHRobotics Divsion )

Phone +82-2-784-7844 Fax +82-2-784-8495

151 Lorong Chuan, #04-02A, New Tech Park, Singapore 556741

Phone +65-6282-3003 Fax +65-6289-3003

YASKAWA Electric (Singapore) PTE Ltd.

No7 Yongchang North Road, Beijing E&T Development AreaChina 100176

Phone +86-10-6788-2858 Fax +86-10-6788-2878

YASKAWA SHOUGANG ROBOT Co. Ltd.

#426, Udyog Vihar, Phase- IV,Gurgaon, Haryana, India

Fax +91-124-475-8542Phone +91-124-475-8500

YASKAWA India Private Ltd. (Robotics Division)

YASKAWA Electric (China) Co., Ltd.

22F, One Corporate Avenue, No.222, Hubin Road, Huangpu District, Shanghai 200021, China

Phone +86-21-5385-2200 Fax 㸩86-21-5385-3299

YASKAWA Electric (Thailand) Co., Ltd.

59,1st-5th Floor, Flourish Building, Soi Ratchadapisek 18,Ratchadapisek Road,

Huaykwang, Bangkok 10310, THAILAND

Phone +66-2-017-0099 Fax +66-2-017-0199

12F, No.207, Sec. 3, Beishin Rd., Shindian District, New Taipei City 23143, Taiwan

Fax +886-2-8913-1513Phone +886-2-8913-1333

YASKAWA Electric Taiwan Corporation

Secure Building-Gedung B Lantai Dasar & Lantai 1 JI. Raya Protokol Halim Perdanakusuma,

Jakarta 13610, Indonesia

Fax +62-21-2982-6741Phone +62-21-2982-6470

PT. YASKAWA Electric Indonesia

Phone +46-480-417-800 Fax +46-486-414-10

YASKAWA Nordic AB

Verkstadsgatan 2, Box 504 ,SE-385 25 Torsas, Sweden

35F, Three IFC, 10 Gukjegeumyung-ro, Yeongdeungpo-gu, Seoul, Korea 07326

YASKAWA Electric Korea Corporation

MOTOMAN-MH50/ MH50-35/ MH80/ MS80

51 of 51

OPTIONS

INSTRUCTIONS

FOR ZEROING FUNCTION

Specifications are subject to change without notice

for ongoing product modifications and improvements.

MANUAL NO.

HW1481050

3

Loading...

Loading...