Page 1

YASNAC

LX

3

FOR

TURNING

APPLICATIONS

COMPACT

PROGRAMMING

FUNCTION

OPERATOR’S

MANUAL

Sci\

1

?f?i

fei

tea

r

.

a

1

r;r

3*8

rf;

I]

,V

$

%

1

gf

K

•SSI

K

:•

Wi

i<

a

b

Before

initial

operation,

read

these

instructions

thoroughly,

and

retain

for

future

reference.

YASKAWA

Page 2

This

manual

describes

the

operator

procedures

for

“Compact

Programming

Function”

which

is

an

option¬

al

function

for

YASNAC

LX3.

For

the

operator

procedures

for

the

basic

con¬

trol,

refer

to

the

manual

“YASNAC

LX3

Operation

Manual”.

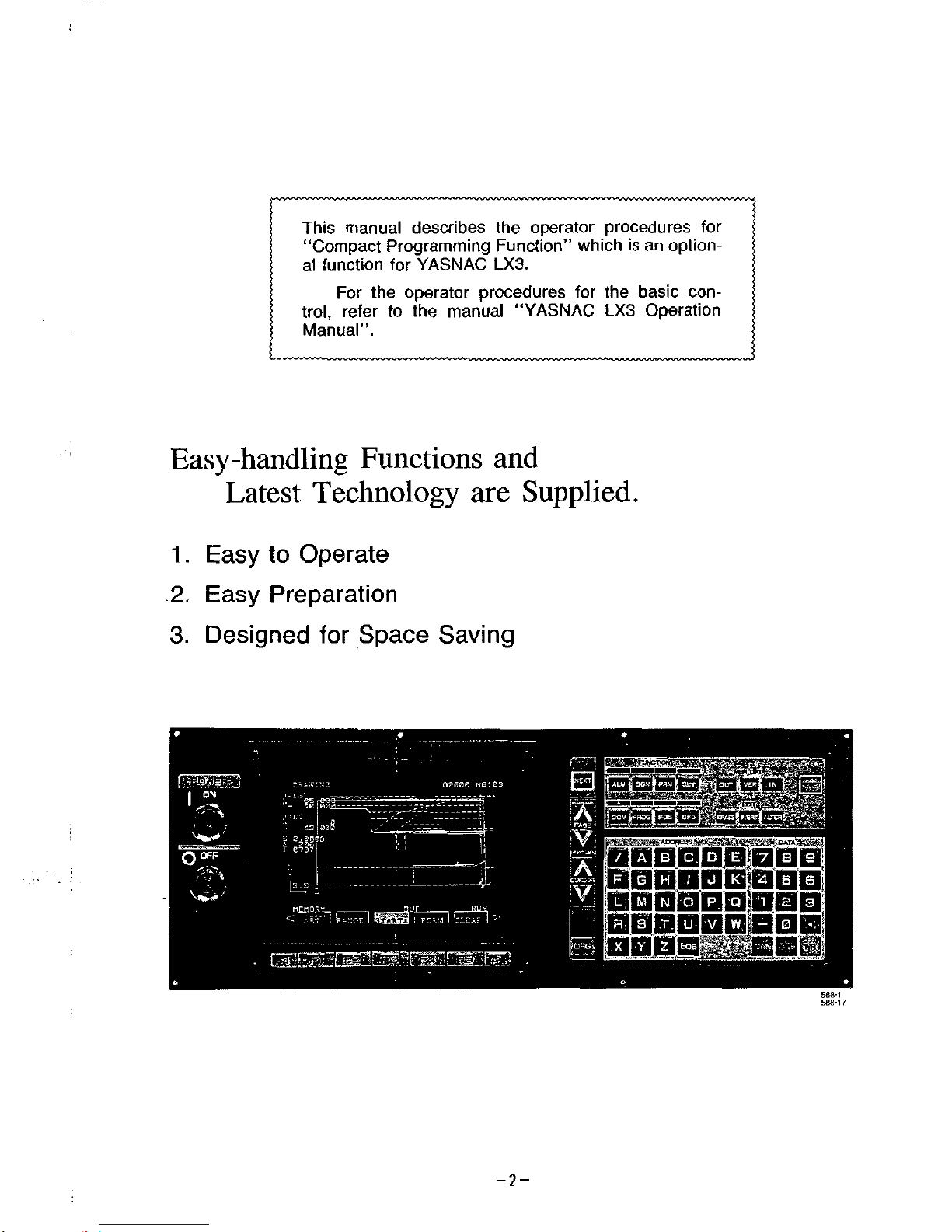

Easy-handling

Functions

and

Latest

Technology

are

Supplied.

1

.

Easy

to

Operate

2.

Easy

Preparation

3.

Designed

for

Space

Saving

r_.

EU

&

mm

m

02000

N6103

|

ON

5;

00°

i

mr

m

utiamM

0°FF

4

IA

_

JL

m

IL8:'

iOOQQQllOOj

n

"?Wr\

s£?1

m

588*1

586*1

i

-2-

Page 3

CONTENTS

1.

FUNCTION

OUTLINES

AND

FEATURES

2.

NC

OPERATOR

PANEL

AND

DISPLAY

2.1

NC

OPERATOR

PANEL

FUNCTION

OUTLINES

2.2

DISPLAY

IMMEDIATELY

AFTER

TURNING

POWER

ON

2.3

CONSTANT

DISPLAY

MESSAGES

2.4

FUNCTION

DISPLAY

7

8

8

14

15

18

3.

INTERACTIVE

PROGRAMMING

3.1

NC

UNIT

INTERNAL

CONFIGURATION

AND

FLOW

OF

INTERACTIVE

PROCESSES

3.2

CALL

UP

OF

INTERACTIVE

MODE

3.3

PROGRAM

NO.

SETTING

(FOR

NEW

DATA)

3.4

SETTING

BLANK

SHAPE

3.5

SETTING

BY

VARIABLE

TURNING

MENU

3.6

SETTING

WITH

DETAILED

TURNING

MENU

(ROUGHING,

FINISHING)

3.7

SETTING

OF

APPROACH

3.8

SETTING

OF

BASIC

DATA

3.9

SETTING

FINISH

SHAPE

3.10

PROGRAM

INSERTION

'

3.11

ESCAPE

SETTING

3.12

ESCAPE

FROM

INTERACTIVE

MODE

3.13

PRECAUTIONS

3.14

MESSAGES

IN

INTERACTIVE

MODE

3.15

FINISH

TURNING

EXECUTED

WITH

NC

COMPACT

PROGRAMMING

FUNCTIONS

4

CALCULATION

FUNCTION

4.1

INTERSECTION

POINT

OF

LINE

AND

LINE

4.2

INTERSECTION

POINTS

OF

LINE

AND

CIRCLE

4.3

CONTACT

POINTS

OF

LINE

INTERSECTING

ONE

POINT

AND

A

CIRCLE

4.4

CONTACT

POINTS

OF

LINE

OF

THE

SPECIFIED

ANGLE

AND

CIRCLE

4.5

CONTACT

POINTS

OF

A

LINE

THAT

CONTACTS

TWO

CIRCLE

4.6

INTERSECTION

POINTS

OF

CIRCLE

AND

CIRCLE

4.7

CONTACT

POINTS

OF

CIRCLE

THAT

INTERSECTS

ONE

POINT

AND

CONTACTS

A

LINE

—

129

4.8

CONTACT

POINTS

OF

CIRCLE

CONTACTING

A

LINE

AND

CIRCLE

4.9

CONTACT

POINTS

OF

CIRCLE

CONTACTING

TWO

LINES

4.10

CONTACT

POINTS

OF

CIRCLE

THAT

INTERSECTS

ONE

POINT

AND

CONTACTS

CIRCLE-

-

132

4.11

CONTACT

POINTS

OF

CIRCLE

CONTACTING

WITH

TWO

CIRCLES

4.12

CENTER

POINT

AND

RADIUS

OF

A

CIRCLE

THAT

INTERSECTS

POINTS

5.

PROGRAM

MODIFICATION

5.1

PREPARATIONS

FOR

MODIFICATION

5.2

MODIFICATION

PROCEDURE

5.3

ENDING

THE

PROGRAM

MODIFICATION

6.

DRAWING

OF

PROGRAMMING

6.1

SETTING

1

6.2

SETTING

OF

DRAWING

PROGRAM

6.3

HOW

TO

ENTER

THE

DRAWING

MODE

6.4

MATERIAL

SETTING

6.5

CLEARING

THE

DRAWING

6.6

SHAPE

..

6.7

START

OF

DRAWING

6.8

SETTING

THE

DRAWING

AREA

6.9

SETTING

2(DRAWING

END

OPERATION)

7.

OPERATION

OF

A

GENERATED

PROGRAM

8.

OPERATION

OF

INTERACTIVE

PARAMETERS

8.1

HOW

TO

ENTER

THE

INTERACTIVE

PARAMETERS

DISPLAY

8.2

SETTING

THE

INTERACTIVE

PARAMETERS

9.

INTERACTIVE

PARAMETER

LIST

39

39

41

41

43

45

46

51

55

57

81

82

84

84

87

89

118

119

123

124

125

126

128

130

131

133

135

136

136

136

142

143

144

144

146

-•

148

150

151

151

153

155

156

157

157

157

160

-3-

Page 4

:

:

INDEX

Chapter

Section

No.

Subject

C

CALCULATION

FUNCTION

CALL

UP

OF

INTERACTIVE

MODE

.

CENTER

POINT

AND

RADIUS

OF

A

CIRCLE

THAT

INTERSECTS

POINTS

CLEARING

THE

DRAWING

Common

mode

display

CONSTANT

DISPLAY

MESSAGES

CONTACT

POINTS

OF

A

LINE

THAT

CONTACTS

TWO

CIRCLES

-

CONTACT

POINTS

OF

CIRCLE

CONTACTING

A

LINE

AND

CIRCLE

CONTACT

POINTS

OF

CIRCLE

CONTACTING

TWO

LINES

CONTACT

POINTS

OF

CIRCLE

CONTACTING

WITH

TWO

CIRCLES

CONTACT

POINTS

OF

CIRCLE

THAT

INTERSECTS

ONE

POINT

AND

CONTACTS

A

LINE

4

CONTACT

POINTS

OF

CIRCLE

THAT

INTERSECTS

ONE

POINT

AND

CONTACTS

CIRCLE

CONTACT

POINTS

OF

LINE

INTERSECTING

ONE

POINT

AND

A

CIRCLE

4

CONTACT

POINTS

OF

LINE

OF

THE

SPECIFIED

ANGLE

AND

CIRCLE

4

D

Deleting

Process

Display

by

CDGN

)

(DIAGNOSIS)

FUNCTION

Key

Display

by

means

of

(PRM

)

FUNCTION

Key

Display

by

the

use

of

[SET

)

FUNCTION

Key

Display

for

Interactive

Parameters

#30

to

#39

Display

for

Interactive

Parameters

#40

to

tt

49

Display

for

Interactive

Parameters

#50

to

#59

Display

for

Interactive

Parameters

#60

to

#69

DISPLAY

IMMEDIATELY

AFTER

TURNING

POWER

ON

Display

with

(ALM

)

FUNCTION

Key

Display

with

(COM

)

(COMMAND)

FUNCTION

Key

Display

with

(OFS

)

FUNCTION

Key

Display

with

(POS

)

FUNCTION

Key

Display

by

(PROG)

(PROGRAM)

FUNCTION

Key

Drawing

DRAWING

OF

PROGRAMMING

Drilling

Drilling

Setting

E

EDIT

mode

ENDING

THE

PROGRAM

MODIFICATION

ESCAPE

FROM

INTERACTIVE

MODE

Page

118

4

3

3.2

4

......

4.12

6

6.5

2

......

2.4.6.

1

41

;

135

150

27

2

2.3

15

126

4

4.5

130

4

4.8

4.9

131

4

4

4.11

133

4.7

129

4.10

132

4

4.3

124

4.4

14

5

......

5.

2.2.

3

2

......

2.4.2

2

......

2.4.3

•

2

......

2.4.4

8

......

8.2.2

•

140

19

20

23

158

8

8

2

3

8.2.4

8.2.5

158

159

8

8

159

2

2.2

14

2.4.1

18

2

2

......

24.5

2

......

2.4.8

2

......

2.4.7

2

......

2.4.6

3

......

3.15.2

25

38

37

26

117

6

143

3

3.15.2

3.9.3

89

3

77

2

2.

4.

6.

2

29

5

5.3

142

3

......

3.12

84

3

......

3.12.2

84

Escape

from

Interactive

Mode

during

Program

Creation

ESCAPE

SETTING

3.11

3

82

3

......

3.15.6

3

......

3.9

2 2

3

......

3

15.3

3

......

3.15

107

F

Face

Finish

Turning

Face

Groove

Turning

Face

Rough

Turning

FINISH

TURNING

EXECUTED

WITH

NC

COMPACT

PROGRAMMING

FUNCTION

73

91

88

2

2.4

18

FUNCTION

DISPLAY

FUNCTION

OUTLINES

AND

FEATURES

1

/

3

......

3.13.5

3

......

3.15.10

3

......

3.15

9

G

Generated

NC

Statements

Groove

Finish

Turning

Groove

Rough

Turning

H

HOW

TO

ENTER

THE

DRAWING

MODE

HOW

TO

ENTER

THE

INTERACTIVE

PARAMETERS

DISPLAY

86

114

111

6

6.3

8

8.1

146

157

-4-

Page 5

INDEX

(Cont'd)

Subject

I/O

signal

selective

display

function

Initialization

Inner

Diameter

O.D.

Grooving

inner

Diameter

(I.D.)

Finish

Turmg

inner

Diameter

(I.D.)

Rough

Turnig

Inserting

a

Process

(mod

ify/i

risert

mode

is

used.)

Interactive

Data

Search

Timing

INTERACTIVE

PARAMETER

LIST

Interactive

Parameters

#20

to

#29

INTERACTIVE

PROGRAMMING

•ÿÿÿ

Chapter

Section

No.

2

......

2.4.2.

1

3

......

3.15.1

•

3

......

3.

9.2.3

3

......

3.15.8

3

......

3.15.5

Page

I

19

89

73

110

102

5

......

5.

2.2.2

3

......

3.13

2

139

85

160

9

8.2.1

157

8

3

39

3

......

3.13.1

3

......

3.13.3

84

Interactive

Programming

Data

Transfer

Interference

Check

INTERSECTION

POINTS

OF

CIRCLE

AND

CIRCLE

INTERSECTION

POINTS

OF

LINE

AND

CIRCLE

INTERSECTION

POINTS

OF

LINE

AND

LINE

85

4.6

128

4

123

4

4.2

119

4

4.1

M

MATERIAL

SETTING

MESSAGES

IN

INTERACTIVE

MODE

MODIFICATION

PROCEDURE

Modifying

a

Process

(modify

mode

is

used)

Modifying

the

Blank

Data

N

NC

OPERATOR

PANEL

AND

DISPLAY

NC

OPERATOR

PANEL

FUNCTION

OUTLINES

NC

UNIT

INTERNAL

CONFIGURATION

AND

FLOW

OF

INTERACTIVE

PROCESSES

......

3

......

3.1

39

Notes

on

Editing

Interactive

Program

Using

the

EDIT

key

O

O.D.

grooving

OPERATION

OF

A

GENERATED

PROGRAM

OPERATION

OF

INTERACTIVE

PARAMETERS

Outer

Diameter(O.D.)

Finish

Turning

Outer

Diameter

(O.D.)

Rough

Turning

P

PRECAUTIONS

PREPARATIONS

FOR

MODIFICATION

PROGRAM

INSERTION

PROGRAM

MODIFICATION

PROGRAM

NO.

SETTING

(FOR

NEW

DATA)

S

Selecting

the

Variable

Turning

Menu(End

Facing

O.D.

Turning,

etc.)

SETTING

1

SETTING

2(DRAWING

END

OPERATION)

Setting

Approach

for

Drilling

Setting

Approach

for

Facing,

O.D.

and

I.D.

Machining

Setting

Approach

for

Grooving

Setting

Approach

for

Threading

SETTING

BLANK

SHAPE

SETTING

BY

VARIABLE

TURNING

MENU

SETTING

FINISH

SHAPE

6

6.4

148

3

......

3.14

87

5

5.2

136

5.2.2.

1

137

5

5

5.2.1

136

2

8

2

2.1

8

3

3.1

3.4

86

.......

3

......

3.9.2.

1

71

7

157

8

157

3

......

3.15.7

3

......

3.15.4

109

94

3

......

3.13

84

136

5 5

1

3.10

81

3

5

136

3

3.3

41

5

......

5.2.2

6

......

6.1

136

144

6.9

6

155

3

......

3.7.3

3

......

3.7.1

54

51

3

......

3.7.2

3

......

3.7.4

54

55

3

3.4

43

3

3.5

45

3

3.9

57

Setting

interna!

toggle

switch

SETTING

OF

APPROACH

SETTING

OF

BASIC

DATA

Setting

of

COMMON

macro

variables

SETTING

OF

DRAWING

PROGRAM

2

2.4.4.

1

23

3

3.7

51

3.8

3

55

2

......

2.

4.

4.

3

6

6.2

25

144

-5-

Page 6

INDEX

(Corn'd)

Chapter

Section

No.

-

2

......

2.4.4

2

•••

2

......

2.

4.

3.

2

-

2

......

2

4.3.3

•

2

......

2.4.

3.1

6

......

6.8

••••

Page

Subject

Setting

of

LOCAL

macro

variable

Setting

RS-232C

input

parameters

Setting

RS-232C

output

parameters

Setting

RS-232C

parameters

SETTING

THE

DRAWING

AREA

24

S

21

22

21

153

8

......

8.2

•

3

......

3.9.4

3

......

3.6

•

6

......

6.6

•

6

......

6.7

•

157

SETTING

THE

INTERACTIVE

PARAMETERS

Setting

Threading

SETTING

WITH

MINOR

TURNING

MENU

(ROUGHING.

FINISHING)

SHAPE

START

OF

DRAWING

T

Threading

Turning

Program

Created

W

When

Drilling

is

set

When

Face,

O.D.

and

I.D.

Roughing

has

been

Set

When

Face,

O.D.

and

I.D.

Roughing

has

been

Set

When

Face,

O.D.

and

I.D.

have

been

Set

When

Facing

is

Set

When

Grooving

has

been

Set

When

Grooving

has

been

Set

When

Grooving

is

Set

When

I.D.

Turning

is

Set

When

O.D.

Turning

is

Set

When

Threading

is

Set

When

Programming

not

Possible

by

Interaction

79

46

151

151

3

......

3.15.11

3

......

3.12.1

115

84

3

......

3.6.5

3

......

3.8.1

3

......

3.8.2

3

......

3.9.1

3

......

3.6.1

49

55

56

57

46

3

......

3.8.3

3

......

3.9.2

3

......

3.6.4

3

......

3.6.3

3

......

3.6.2

56

71

48

48

47

3

......

3.6.6

3

......

3.9.5

50

80

-6-

Page 7

1.

FUNCTION

OUTLINES

AND

FEATURES

The

compact

interactive

function

has

been'

designed

to

.

enable

NC

machining

part

programs

to

be

automatically

generated

through

simple

interactive

opera¬

tions

conducted

in

accordance

with

the

displayed

process

menu

on

the

CRT.

Since

the

generated

programs

mainly

use

"canned

cycles

G70

through

G76",

they

are

short,

and

process

comments

are

also

automatically

attached

to

them.

For

this

reason,

the

generated

programs

are

easy

to

understand

and

easy

to

modify

.

This

interactive

automatic

programming

function

allows

the

utilization

of

almost

all

types

of

turning

operations

including

end

facing,

O.D.

turning,

l.D.

turning,

grooving,

drilling,

and

threading,

despite

its

easy

operation.

(1)

"Compact

interactive"

automatic

programming

can

be

executed

even

while

the

NC

is

engaged

in

turning

operations.

(2)

When

finished

state

data

is

input,

the

finished

work

piece

shape

is

auto¬

matically

displayed

on

the

CRT

for

visual

check

convenience.

(3)

Because

the

automatically

generated

programs

mainly

consist

of

canned

cycles,

they

occupy

only

small

part

program

memory

capacity,

allowing

easy

modifications

and

changes.

(4)

Where

canned

cycles

are

undesirable

(for

rough

surface

removing,

etc.)

or

short

cycle

time

is

important,

turning

menus

for

free

shapes

is

available.

(5)

During

the

interactive

mode

program

generation,

any

programs

can

be

manually

added

or

change.

(6)

The

generated

programs

tion".

can

be

checked

by

means

of

the

"Drawing

func-

During

the

drawing

process,

the

material

shape

is

also

displayed.

•

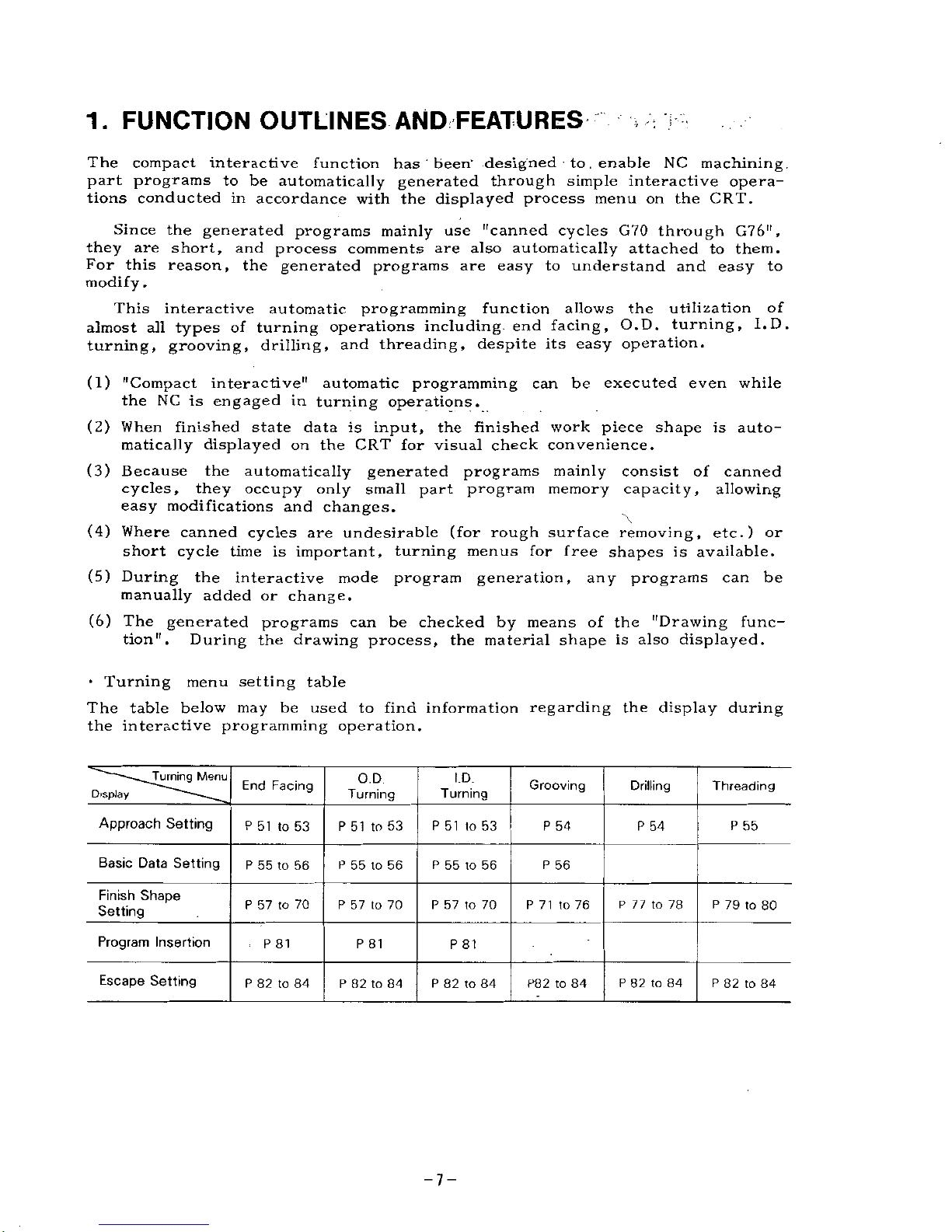

Turning

menu

setting

table

The

table

below

may

be

used

to

find

information

regarding

the

display

during

the

interactive

programming

operation.

Turning

Menu

O.D

Turning

l.D.

Grooving

End

Facing

Threading

Drilling

Turning

Display

Approach

Setting

P

51

to

53

P

51

to

53

P

51

to

53

P

54

P

54

P

55

Basic

Data

Setting

P

55

to

56

P

56

P

55

to

56

P

55

to

56

Finish

Shape

Setting

P

71

to

76

P

57

to

70

P

57

to

70

P

77

to

78

P

79

to

80

P

57

to

70

Program

Insertion

P

81

P

81

P

81

Escape

Setting

P

82

to

84

P

82to84

P

82

to

84

P

82to84

P

82

to

84

P82to84

-7-

Page 8

2.

NC

OPERATOR

PANEL

AND

DISPLAY

2.

1

NC

OPERATOR

PANEL

FUNCTION

OUTLINES

The

operator

panel

of

YASNAC

LX3

incorporating

the

compact

interactive

func¬

tion

is

shown

in

Fig.

2.1.

follows:

The

names

and

functions

of

the

elements

are

as

®

PAGE

KEYS

©

MEMORY

DATA

KEYS

(D

NEXT

KEY

<D

9

INCH

CRT

GRAPHIC

DISPLAY

©

EDITING

KEYS

<D

FUNCTION

KEYS

©

POWER

ON-OFF

BUTTON

©

RESET

KEY

±_

©

YASNAC

©

FUNCTION

MEM

DATA

[NEXT

|

|

POWER"!

|RESET|

|ALM|[PGN||PRM|["SET|

|

OUT

1

1

VER||

IN

[

I

ON

EDIT

|COM[|PROO|ÿPOSJ|OF5[

|lMSRT||ALTEj—

PAGE

B

DATA

ADDRESS

000

000

000

000000

000

0000

o

OFF

|CAN|

HI

WR

|

[ORG]

3

0101

01

B

3

B

©

®

o-

0

©

DATA

KEYS

©ORIGIN

KEY

©

SOFTWARE

FUNCTION

KEYS

®

CURSOR

KEYS

©

ADDRESS

KEYS

Fig.

2.

1

YASNAC

LX3

Operator

Panel

©

Power

ON-OFF

Button

(1)

POWER

ON

button

The

button

for

turning

on

Power

to

the

NC

unit.

Pushing

it

once

energizes

the

control

circuit

only,

and

pushing

it

once

more

energizes

also

the

servo

power

system.

This

button

is

also

pushed

after

an

emergency

stop,

etc.

to

re-energize

the

servo

power

system.

(2)

POWER

OFF

button

The

button

for

turning

off

power

to

the

NC

unit.

Depressing

this

button

de-energizes

both

the

control

circuit

and

the

servo

power

system

of

the

NC

unit.

-8-

Page 9

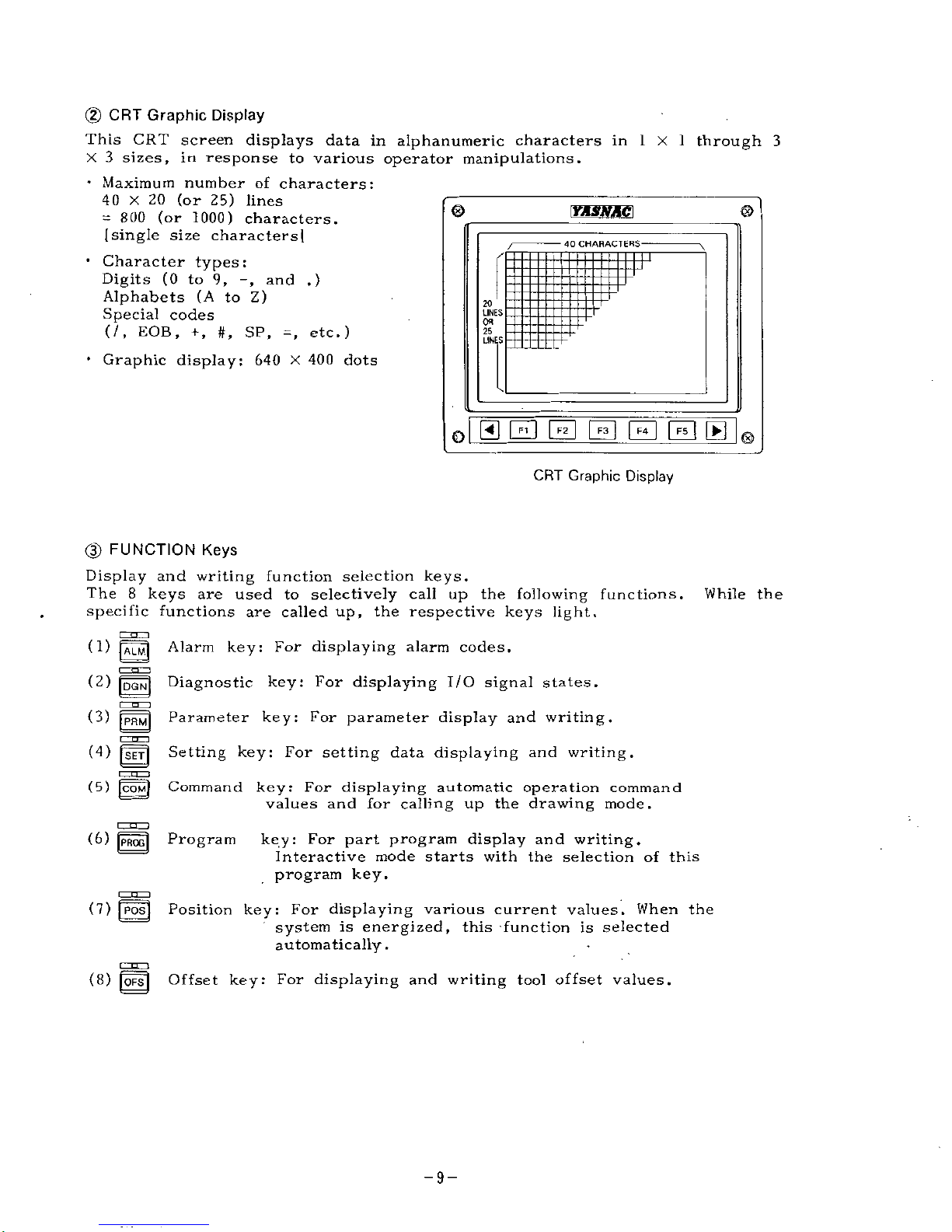

(2)

CRT

Graphic

Display

This

CRT

screen

displays

data

in

alphanumeric

characters

in

1

X

1

through

3

X

3

sizes,

in

response

to

various

operator

manipulations.

•

Maximum

number

of

characters:

40

X

20

(or

25)

lines

=

800

(or

1000)

characters.

(single

size

characters]

•

Character

types:

Digits

(0

to

9,

and

.)

Alphabets

(A

to

Z)

Special

codes

(/,

EOB,

+

,

#,

SP,

=

,

etc.)

•

Graphic

display:

640

X

400

dots

0

©

YASNAC\

40

CHAHACTEHS-

T

20

LINES

Ofl

25

LINES

©

CRT

Graphic

Display

(D

FUNCTION

Keys

Display

and

writing

function

selection

keys.

The

8

keys

are

used

to

selectively

call

up

the

following

functions.

specific

functions

are

called

up,

the

respective

keys

light.

While

the

(

1)

|ALM|

(2)

m

(3)

m

cznzp

(4)

(23

(5)

[COM)

Alarm

key:

For

displaying

alarm

codes.

Diagnostic

key:

For

displaying

I/O

signal

states.

Parameter

key:

For

parameter

display

and

writing.

Setting

key:

For

setting

data

displaying

and

writing.

Command

key:

For

displaying

automatic

operation

command

values

and

for

calling

up

the

drawing

mode.

(8)

|

PRQG

j

Program

key:

For

part

program

display

and

writing.

Interactive

mode

starts

with

the

selection

of

this

program

key.

(7)

[POS|

Position

key:

For

displaying

various

current

values.

When

the

system

is

energized,

this

function

is

selected

automatically.

(8)

|QFS|

Offset

key:

For

displaying

and

writing

tool

offset

values.

-9-

Page 10

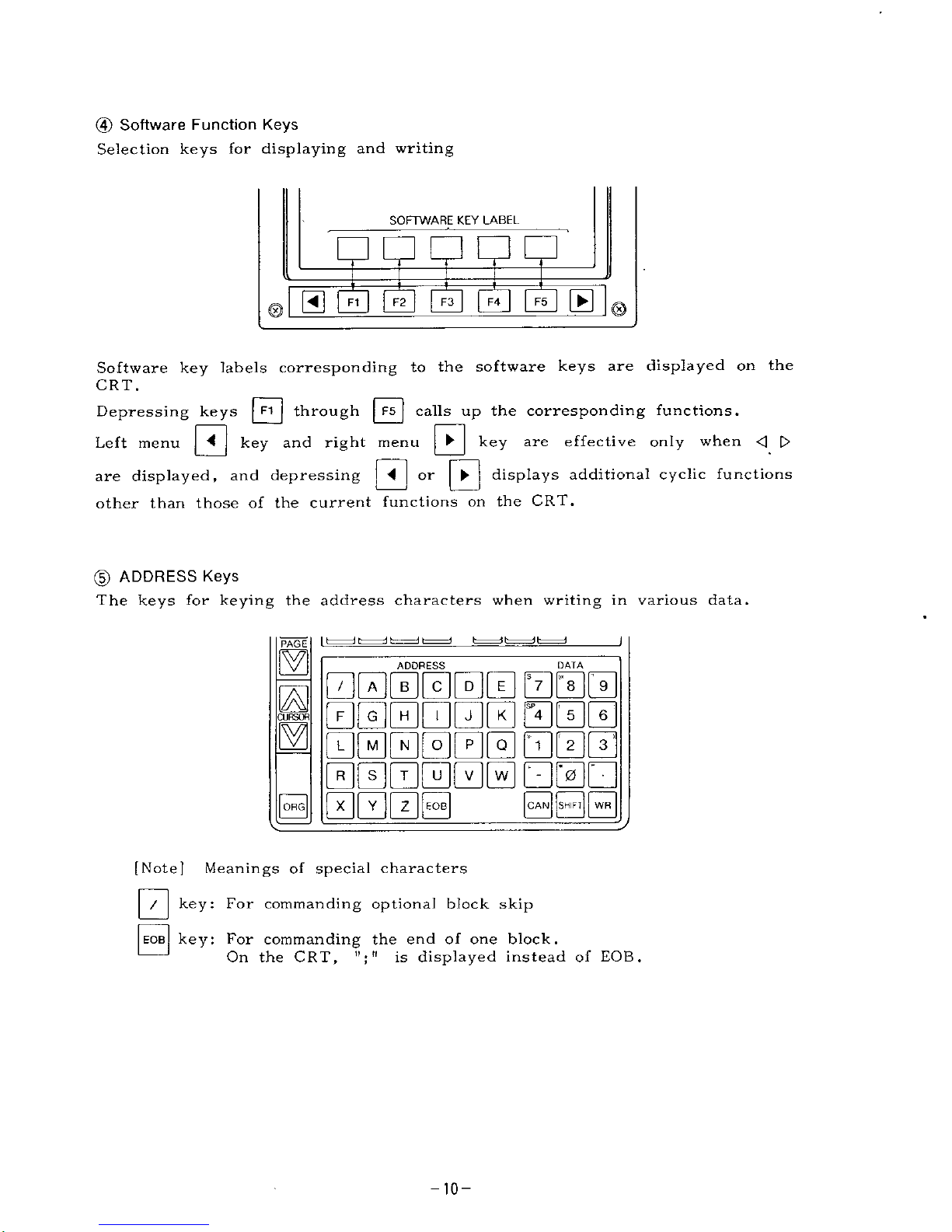

(4)

Software

Function

Keys

Selection

keys

for

displaying

and

writing

SOFTWARE

KEY

LABEL

F4~]

|F5|

[ÿ)

0

CD

CS

F3

Software

key

labels

corresponding

to

the

software

keys

are

displayed

on

the

CRT.

Depressing

keys

|

F1

j

through

|F5|

calls

up

the

corresponding

functions.

key

are

effective

only

when

<

[>

0

0

Left

menu

key

and

right

menu

S

°r

H

displays

additional

cyclic

functions

are

displayed,

and

depressing

other

than

those

of

the

current

functions

on

the

CRT.

(D

ADDRESS

Keys

The

keys

for

keying

the

address

characters

when

writing

in

various

data.

PAGE

ADDRESS

DATA

000000

000

000000

000

000000

000

000000

000

0000

CURSOR

[CAN]

jsKIFl]

|WR|

|QHG|

[Note]

Meanings

of

special

characters

key:

For

commanding

optional

block

skip

/

key:

For

commanding

the

end

of

one

block.

On

the

CRT,

"

;

"

is

displayed

instead

of

EOB.

EOB

-10-

Page 11

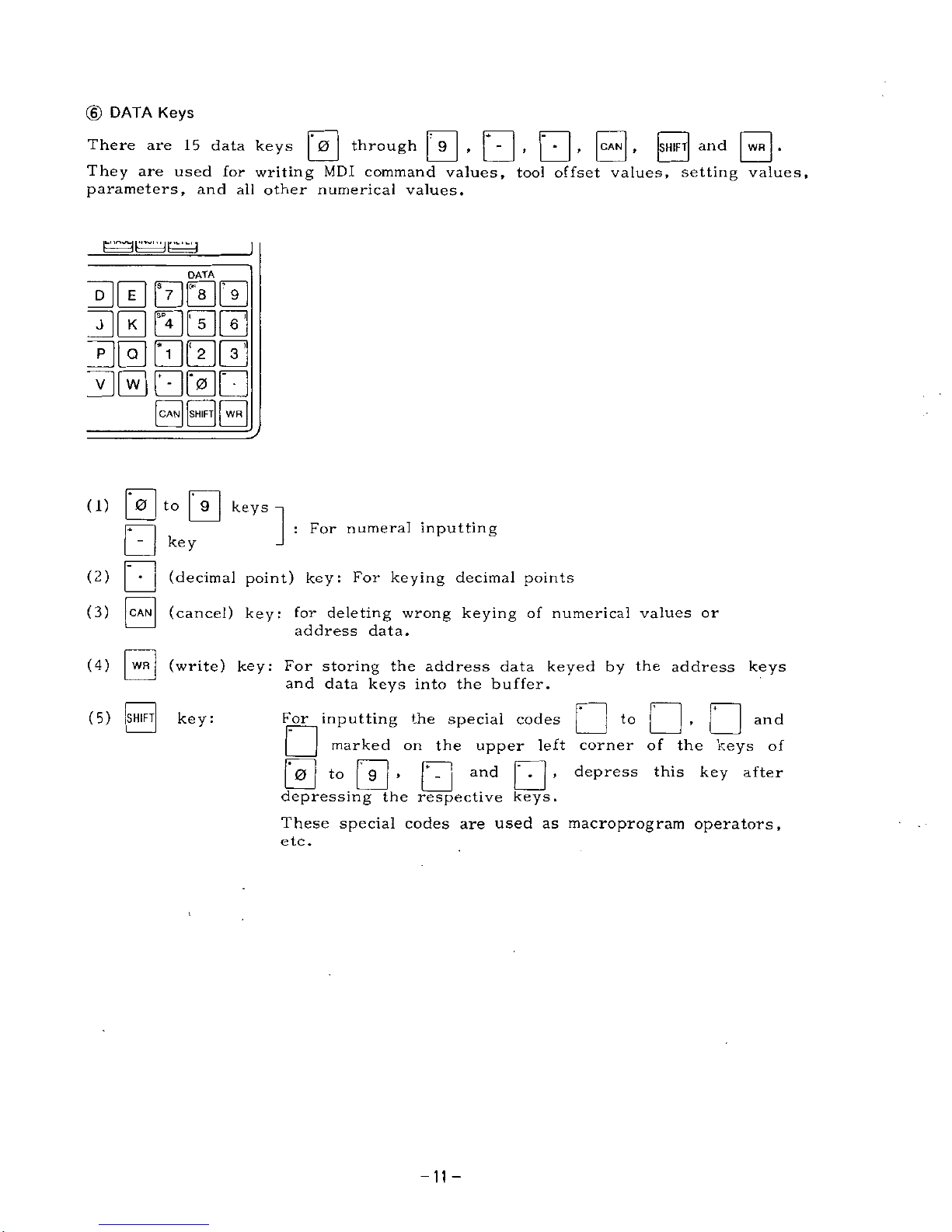

©

DATA

Keys

|0|

through

|

9

|

,

[

-

|

,

|-|

,

|CAN[

,

|SH1FT|

0-

There

are

15

data

keys

They

are

used

for

writing

MDI

command

values,

tool

offset

values,

setting

values,

parameters,

and

all

other

numerical

values.

and

DATA

30

BBS

30000

B0000

B0B0B

|CAN||SHIFT||

WR

|

|

9

|

keys

(1)

0

to

:

For

numeral

inputting

key

(2)

(decimal

point)

key:

For

keying

decimal

points

(cancel)

key:

for

deleting

wrong

keying

of

numerical

values

or

address

data.

(3)

CAN

|

WR

|

(write)

key:

For

storing

the

address

data

keyed

by

the

address

keys

and

data

keys

into

the

buffer.

(4)

|SHIFT|

key:

•

(5)

For

inputting

the

special

codes

~

|

marked

on

the

upper

left

corner

of

the

keys

of

depress

this

key

after

and

to

3

*ÿ>

0-

depressing

the

respective

keys.

These

special

codes

are

used

as

macroprogram

operators,

etc.

and

-11-

Page 12

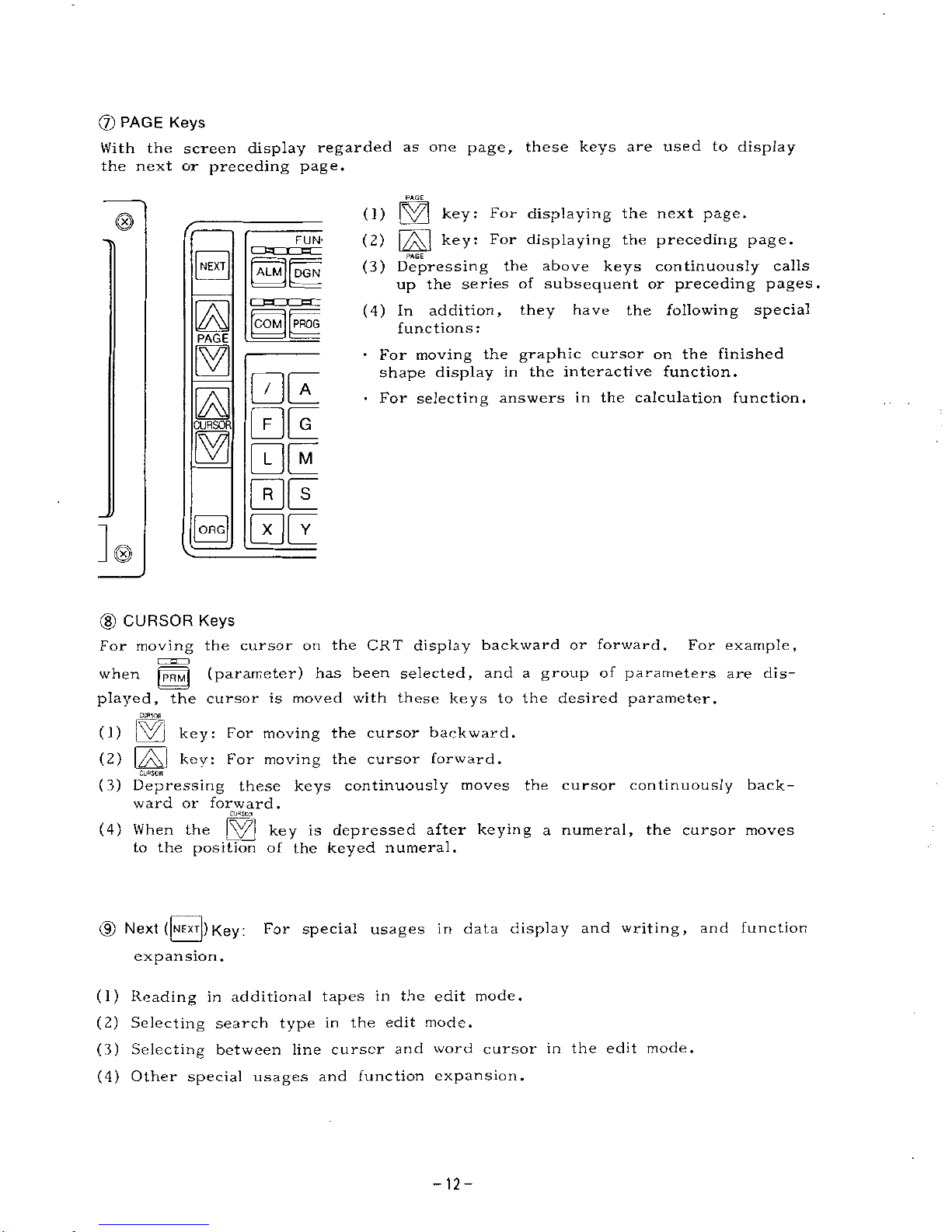

(7)

PAGE

Keys

With

the

screen

display

regarded

as

one

page,

these

keys

are

used

to

display

the

next

or

preceding

page.

PAGE

(1)

key:

For

displaying

the

next

page.

(2)

|/ÿ\j

key:

For

displaying

the

preceding

page.

PAGE

(3)

Depressing

the

above

keys

continuously

calls

up

the

series

of

subsequent

or

preceding

pages.

(4)

In

addition,

they

have

the

following

special

functions:

•

For

moving

the

graphic

cursor

on

the

finished

shape

display

in

the

interactive

function.

For

selecting

answers

in

the

calculation

function.

FUN'

NEXT

ALM

DGN

COM

PROG

PAGE

BE

F

G

CURSOR

BE

|ORG|

(8)

CURSOR

Keys

For

moving

the

cursor

on

the

CRT

display

backward

or

forward.

has

been

selected

For

example,

and

a

group

of

parameters

are

dis¬

played,

the

cursor

is

moved

with

these

keys

to

the

desired

parameter.

jp||ij

(parameter)

when

Cl/PSOP

(1)

iVl

key:

For

moving

the

cursor

backward.

(2)

|/A\|

key:

For

moving

the

cursor

forward.

CURSOR

(3)

Depressing

these

keys

continuously

moves

the

cursor

continuously

back¬

ward

or

forward.

CURSOR

(4)

When

the

[\yÿ[

key

is

depressed

after

keying

a

numeral,

the

cursor

moves

to

the

position

of

the

keyed

numeral.

(9)

Next

(|NEXT[)

Key:

For

special

usages

in

data

display

and

writing,

and

function

expansion.

(1)

Reading

in

additional

tapes

in

the

edit

mode.

(2)

Selecting

search

type

in

the

edit

mode.

(3)

Selecting

between

line

cursor

and

word

cursor

in

the

edit

mode.

(4)

Other

special

usages

and

function

expansion.

-12-

Page 13

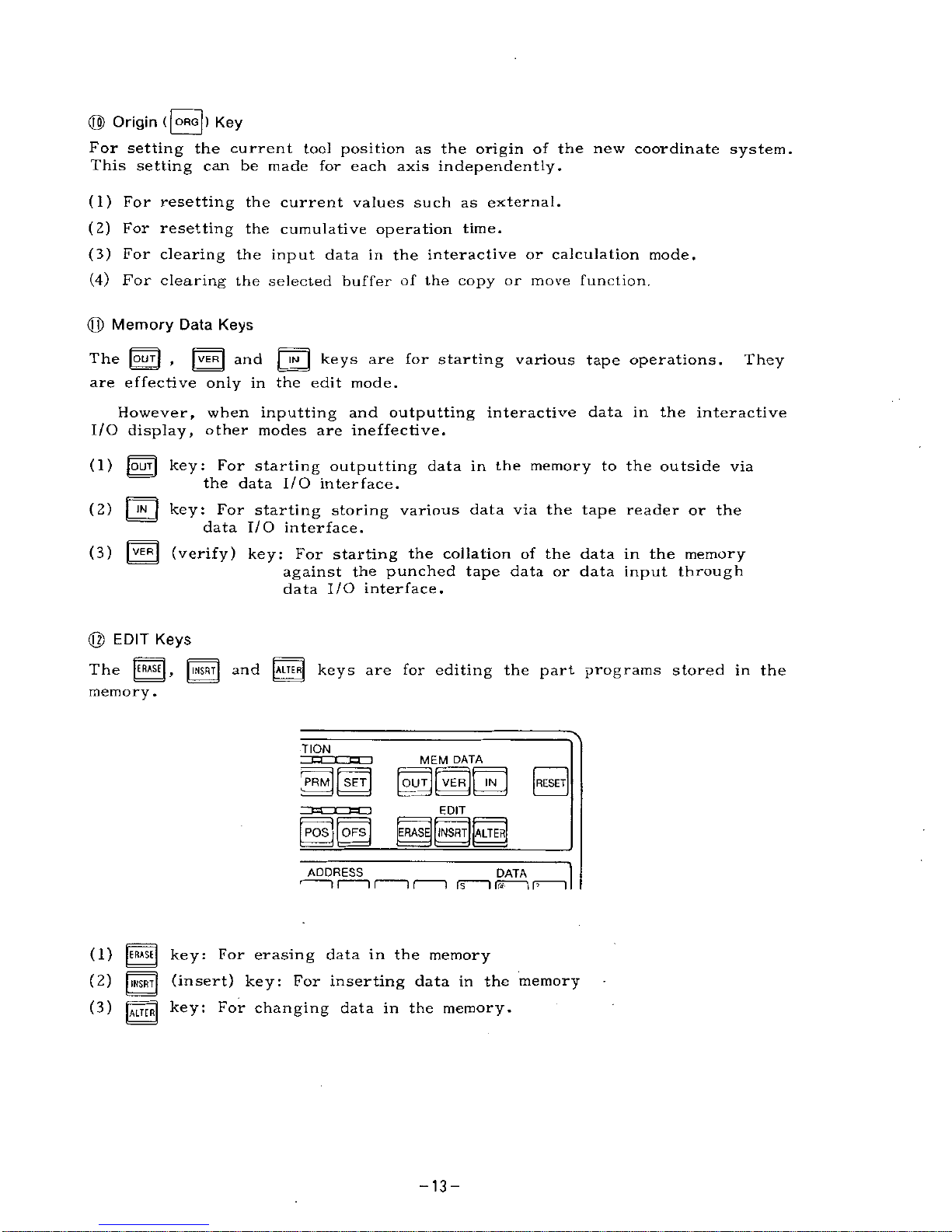

(J§>

Origin

(|ORG[)

Key

For

setting

the

current

tool

position

as

the

origin

of

the

new

coordinate

system.

This

setting

can

be

made

for

each

axis

independently.

(1)

For

resetting

the

current

values

such

as

external.

(2)

For

resetting

the

cumulative

operation

time.

(3)

For

clearing

the

input

data

in

the

interactive

or

calculation

mode.

(4)

For

clearing

the

selected

buffer

of

the

copy

or

move

function.

(Q)

Memory

Data

Keys

and

|~

IN

j

keys

are

effective

only

in

the

edit

mode.

However,

when

inputting

and

outputting

interactive

data

in

the

interactive

I/O

display,

other

modes

are

ineffective.

(1)

[ourj

key:

For

starting

outputting

data

in

the

memory

to

the

outside

via

the

data

I/O

interface.

(2)

[

IN

j

key:

For

starting

storing

various

data

via

the

tape

reader

or

the

data

I/O

interface.

(3)

|

VER|

(verify)

key:

For

starting

the

collation

of

the

data

in

the

memory

against

the

punched

tape

data

or

data

input

through

data

I/O

interface.

four)

,

|VER|

The

for

starting

various

tape

operations.

They

are

@

EDIT

Keys

[ERASE

|

r

|

INSRT|

[ALTER!

keys

are

for

editing

the

part

programs

stored

in

the

The

and

memory

.

TION

MEM

DATA

'PRM||

SET]

|

OUTJ

[VER]

[

IN

|

[RESET]

EDIT

[

POS

j

|

OFS|

|ERASE[[INSRT|[ALTER[

ADDRESS

DATA

is

"i

ns

i

r>

i

T

r

(1)

[ERASE

|

key:

For

erasing

data

in

the

memory

(2)

|

IMSRT|

(insert)

key:

For

inserting

data

in

the

memory

|MT[R|

key:

For

changing

data

in

the

memory.

(3)

-13-

Page 14

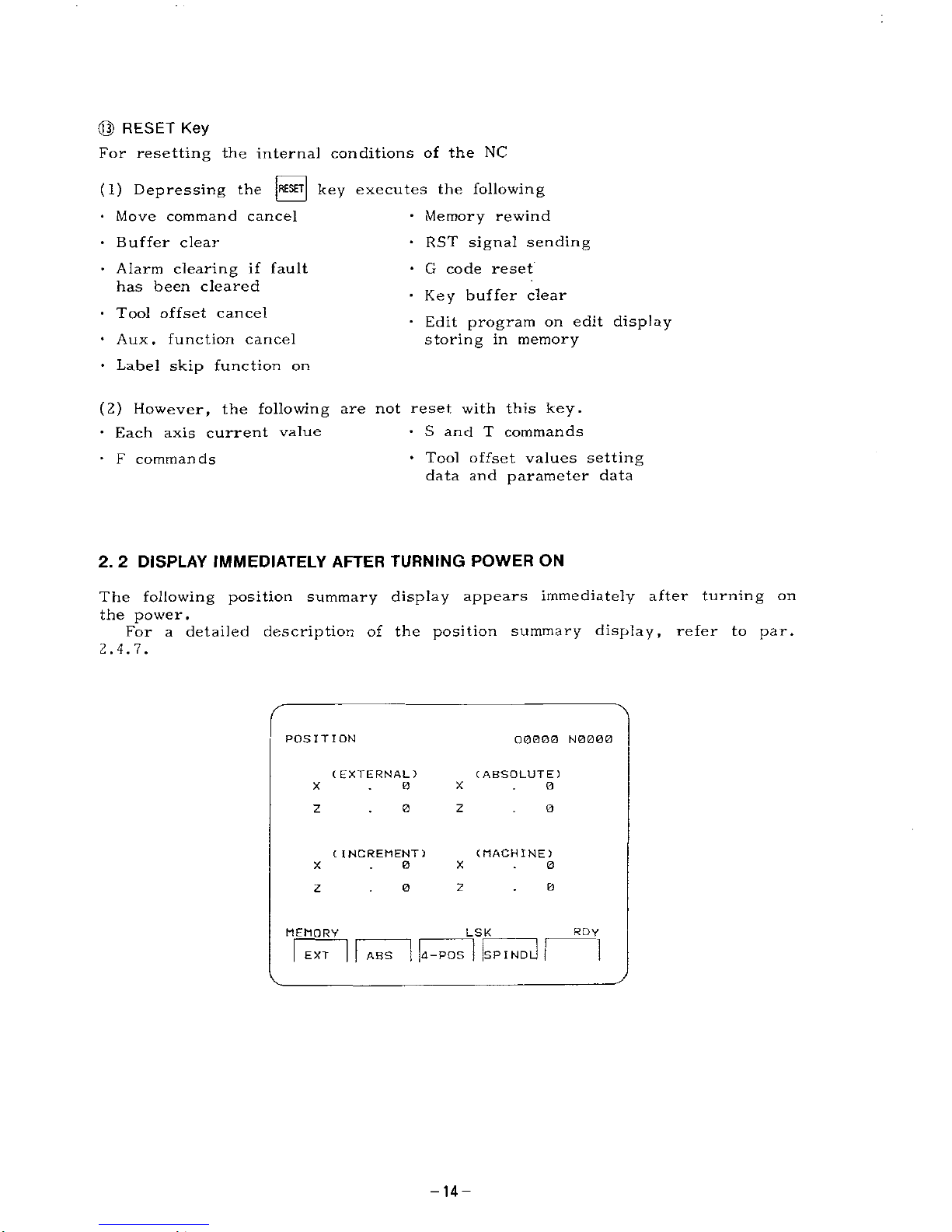

©

RESET

Key

For

resetting

the

internal

conditions

of

the

NC

(1)

Depressing

the

|RESET|

key

executes

the

following

•

Memory

rewind

•

RST

signal

sending

*

G

code

reset

•

Key

buffer

clear

*

Edit

program

on

edit

display

storing

in

memory

•

Move

command

cancel

•

Buffer

clear

•

Alarm

clearing

if

fault

has

been

cleared

•

Tool

offset

cancel

•

Aux

.

function

cancel

•

Label

skip

function

on

(2)

However,

the

following

are

not

reset

with

this

key.

•

S

and

T

commands

•

Tool

offset

values

setting

data

and

parameter

data

•

Each

axis

current

value

•

F

commands

2.

2

DISPLAY

IMMEDIATELY

AFTER

TURNING

POWER

ON

The

following

position

summary

display

appears

immediately

after

turning

on

the

power.

For

a

detailed

description

of

the

position

summary

display,

refer

to

par.

2.4.7.

POSITION

Q0BO0

N0000

(

EXTERNAL)

(

ABSOLUTE)

X

X

0

0

0

0

z

z

(MACHINE)

C

INCREMENT)

0

0

X

X

z

0

0

z

RDY

MEMORY

LSK

!

SPIND

ABS

d-POS

EXT

-14-

Page 15

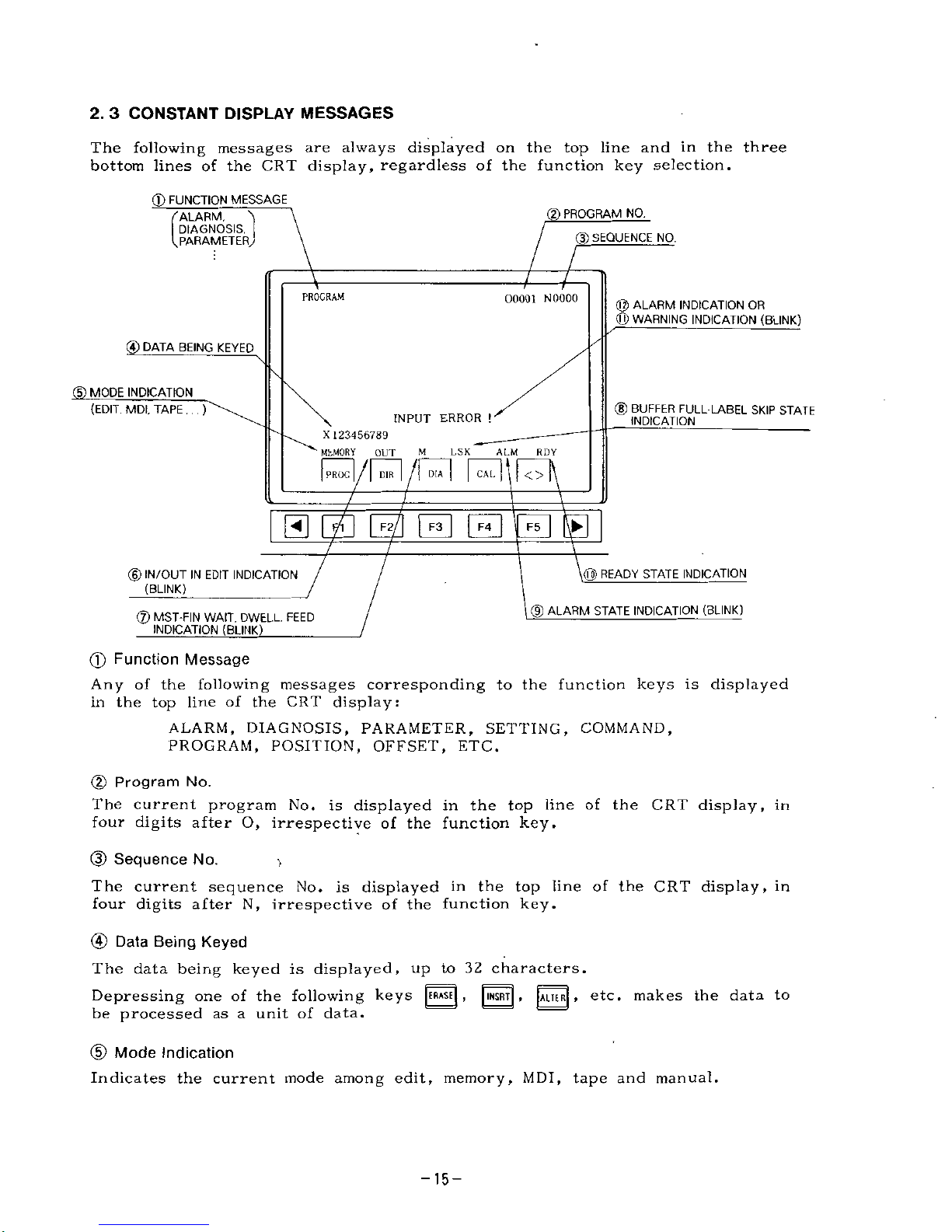

2.

3

CONSTANT

DISPLAY

MESSAGES

The

following

messages

are

always

displayed

on

the

top

line

and

in

the

three

bottom

lines

of

the

CRT

display,

regardless

of

the

function

key

selection.

(D

FUNCTION

MESSAGE

(2)

PROGRAM

NO.

'ALARM,

DIAGNOSIS,

PARAMETER,

(p

SEQUENCE

NO.

PROGRAM

00001

NOOOO

@

ALARM

INDICATION

OR

<Q)

WARNING

INDICATION

(BLINK)

©

DATA

BEING

KEYED

(5)

MODE

INDICATION

©

BUFFER

FULL

LABEL

SKIP

STATE

INDICATION

(EDIT,

MDI,

TAPE

.

. .

)

INPUT

ERROR

!

X

123456789

MhMORY

OUT

Ml

|

PROG

|

/|

DIR

|

f\

DIA

|

l.S

K

ALM

RDY

CAL

<>

5

0

B

E

a

M

READY

STATE

INDICATION

©

IN/OUT

IN

EDIT

INDICATION

(BLINK)

®

ALARM

STATE

INDICATION

(BLINK)

®

MST-FIN

WAIT,

DWELL,

FEED

INDICATION

(BLINK)

_

(f)

Function

Message

Any

of

the

following

messages

corresponding

to

the

function

keys

is

displayed

in

the

top

line

of

the

CRT

display:

ALARM,

DIAGNOSIS,

PARAMETER,

SETTING,

COMMAND,

PROGRAM,

POSITION,

OFFSET,

ETC.

(2)

Program

No.

The

current

program

No.

is

displayed

in

the

top

line

of

the

CRT

display,

in

four

digits

after

O,

irrespective

of

the

function

key.

(3)

Sequence

No.

The

current

sequence

No.

is

displayed

in

the

top

line

of

the

CRT

display,

in

four

digits

after

N,

irrespective

of

the

function

key.

@

Data

Being

Keyed

The

data

being

keyed

is

displayed,

up

to

32

characters.

Depressing

one

of

the

following

keys

[ERASE

[

,

|INSRT|

,

[ALTE

R|

»

etc.

makes

the

data

to

be

processed

as

a

unit

of

data.

(D

Mode

Indication

Indicates

the

current

mode

among

edit,

memory,

MDI,

tape

and

manual.

-15-

Page 16

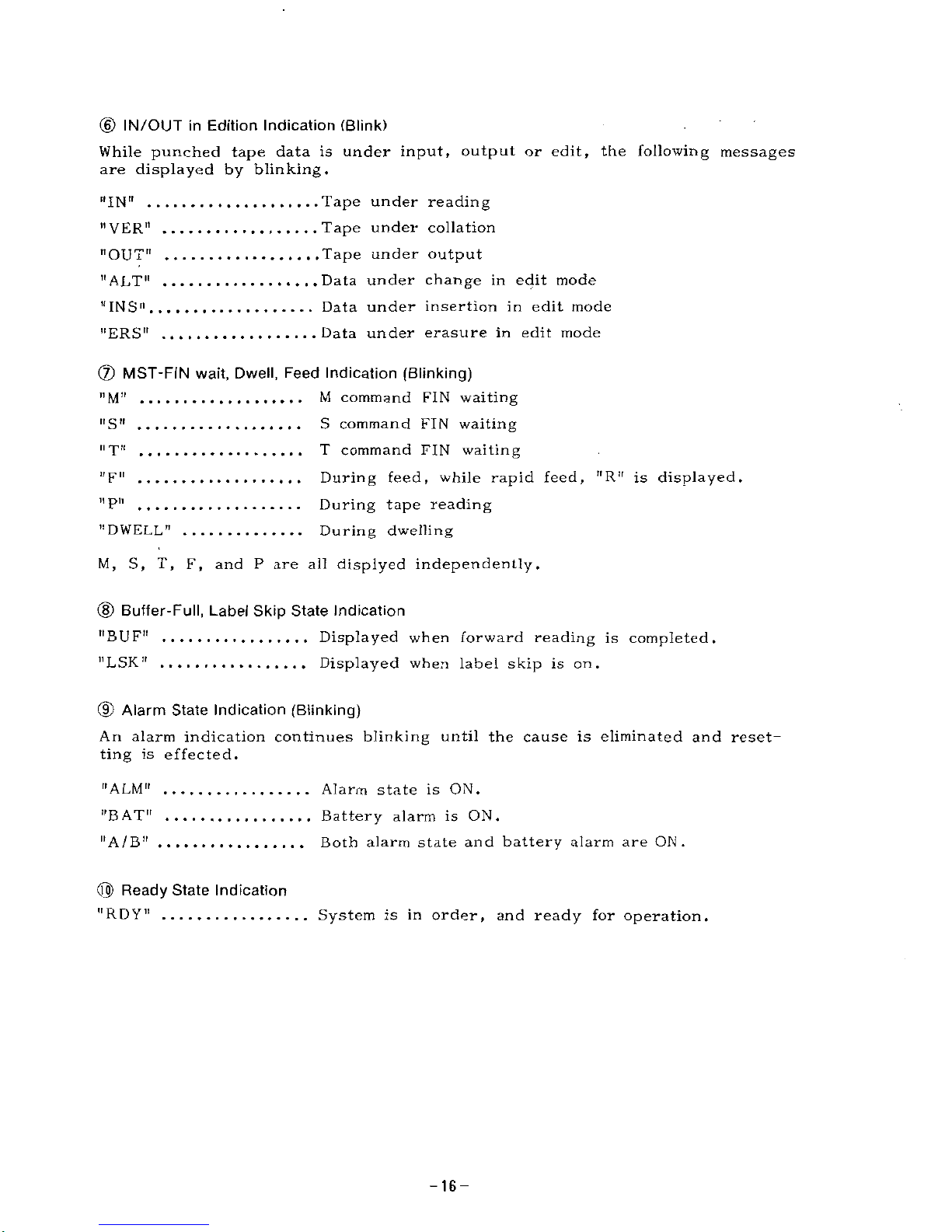

(6)

IN/OUT

in

Edition

Indication

(Blink)

While

punched

tape

data

is

under

input,

output

or

edit,

the

following

messages

are

displayed

by

blinking.

Tape

under

reading

Tape

under

collation

Tape

under

output

Data

under

change

in

edit

mode

Data

under

insertion

in

edit

mode

Data

under

erasure

in

edit

mode

"IN"

"VER"

"OUT"

"ALT"

"INS"

"ERS"

®

MST-FIN

wait,

Dwell,

Feed

Indication

(Blinking)

M

command

FIN

waiting

S

command

FIN

waiting

T

command

FIN

waiting

During

feed,

while

rapid

feed,

"R"

is

displayed.

During

tape

reading

During

dwelling

"M"

11

S"

n

'pii

ti

pn

ii

pn

"DWELL"

M,

S,

T,

F,

and

P

are

all

displyed

independently.

(D

Buffer-Full,

Label

Skip

State

Indication

"BUF"

Displayed

when

forward

reading

is

completed.

Displayed

when

label

skip

is

on.

"LSK"

(9)

Alarm

State

Indication

(Blinking)

An

alarm

indication

continues

blinking

until

the

cause

is

eliminated

and

reset¬

ting

is

effected.

"ALM"

Alarm

state

is

ON.

Battery

alarm

is

ON.

Both

alarm

state

and

battery

alarm

are

ON.

"BAT"

"A/B"

@)

Ready

State

Indication

-IRDY"

System

is

in

order,

and

ready

for

operation.

-16-

Page 17

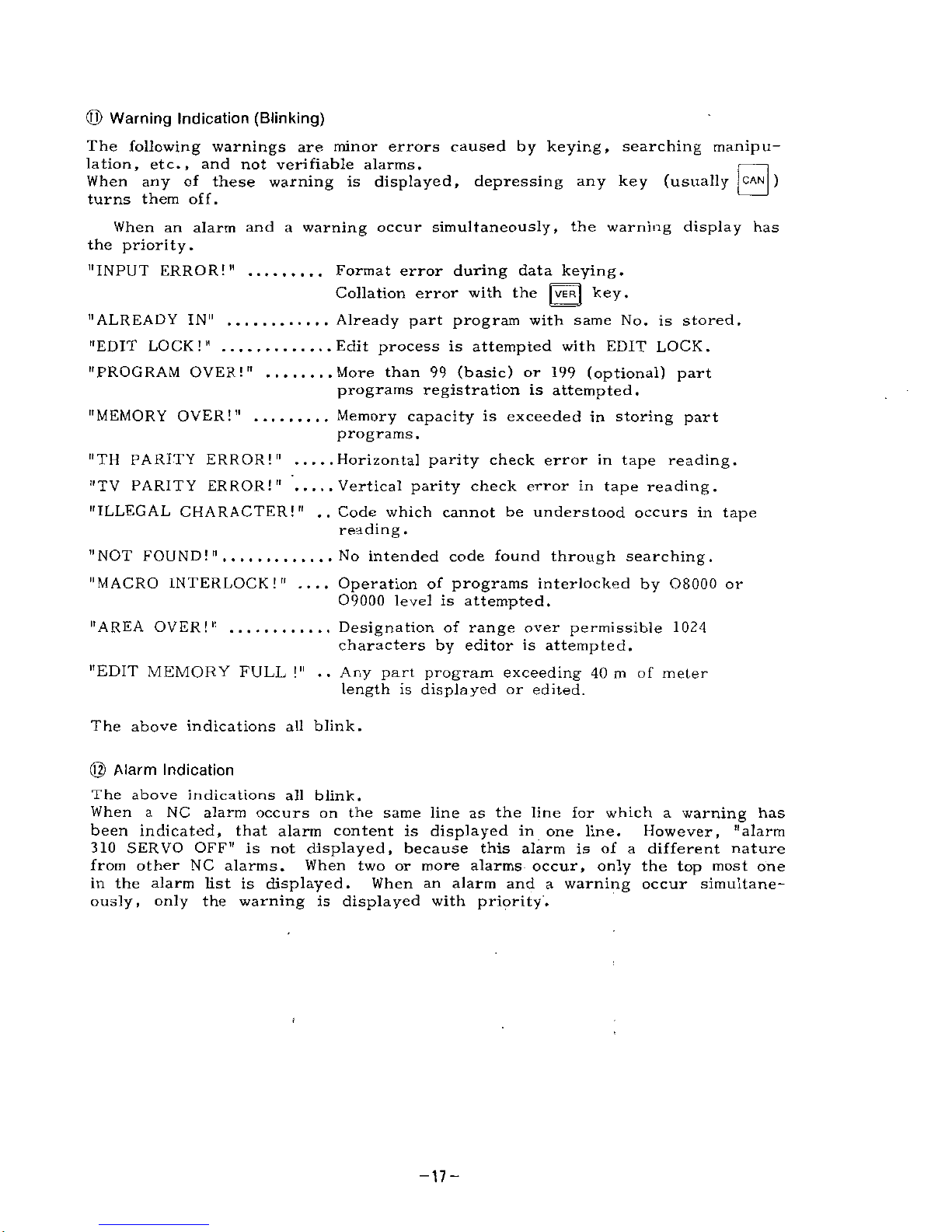

(Q)

Warning

Indication

(Blinking)

The

following

warnings

are

minor

errors

caused

by

keying,

searching

manipu¬

lation,

etc.,

and

not

verifiable

alarms.

When

any

of

these

warning

is

displayed,

depressing

any

key

turns

them

off.

(usually

|

CAN

|

)

When

an

alarm

and

a

warning

occur

simultaneously,

the

warning

display

has

the

priority.

"INPUT

ERROR!"

Format

error

during

data

keying.

Collation

error

with

the

|

VER|

key.

Already

part

program

with

same

No.

is

stored.

Edit

process

is

attempted

with

EDIT

LOCK.

More

than

99

(basic)

or

199

(optional)

part

programs

registration

is

attempted.

Memory

capacity

is

exceeded

in

storing

part

programs

.

Horizontal

parity

check

error

in

tape

reading.

Vertical

parity

check

error

in

tape

reading.

"ILLEGAL

CHARACTER!"

..

Code

which

cannot

be

understood

occurs

in

tape

reading

.

No

intended

code

found

through

searching.

"MACRO

INTERLOCK!"

....

Operation

of

programs

interlocked

by

08000

or

09000

level

is

attempted.

Designation

of

range

over

permissible

1024

characters

by

editor

is

attempted.

"EDIT

MEMORY

FULL

!"

..

Any

part

program

exceeding

40

m

of

meter

length

is

displayed

or

edited.

"ALREADY

IN"

"EDIT

LOCK!"

"PROGRAM

OVER!"

"MEMORY

OVER!"

"TH

PARITY

ERROR!"

"TV

PARITY

ERROR!"

"NOT

FOUND!"

"AREA

OVER!"

The

above

indications

all

blink.

©

Alarm

Indication

The

above

indications

all

blink.

When

a

NC

alarm

occurs

on

the

same

line

as

the

line

for

which

a

warning

has

been

indicated,

that

alarm

content

is

displayed

in

one

line.

However,

"alarm

310

SERVO

OFF"

is

not

displayed,

because

this

alarm

is

of

a

different

nature

from

other

NC

alarms.

When

two

or

more

alarms

occur,

only

the

top

most

one

in

the

alarm

list

is

displayed.

When

an

alarm

and

a

warning

occur

simultane¬

ously,

only

the

warning

is

displayed

with

priprity.

-17-

Page 18

2.

4

FUNCTION

DISPLAY

With

a

unit

equipped

with

the

Compact

Interactive

Function,

the

operation

and

display

for

the

FUNCTION

keys

are

partly

different

from

those

described

in

YASNAC

LX3

Manual

(TOE-C843-9.

20)

,

as

described

below:

c~nm

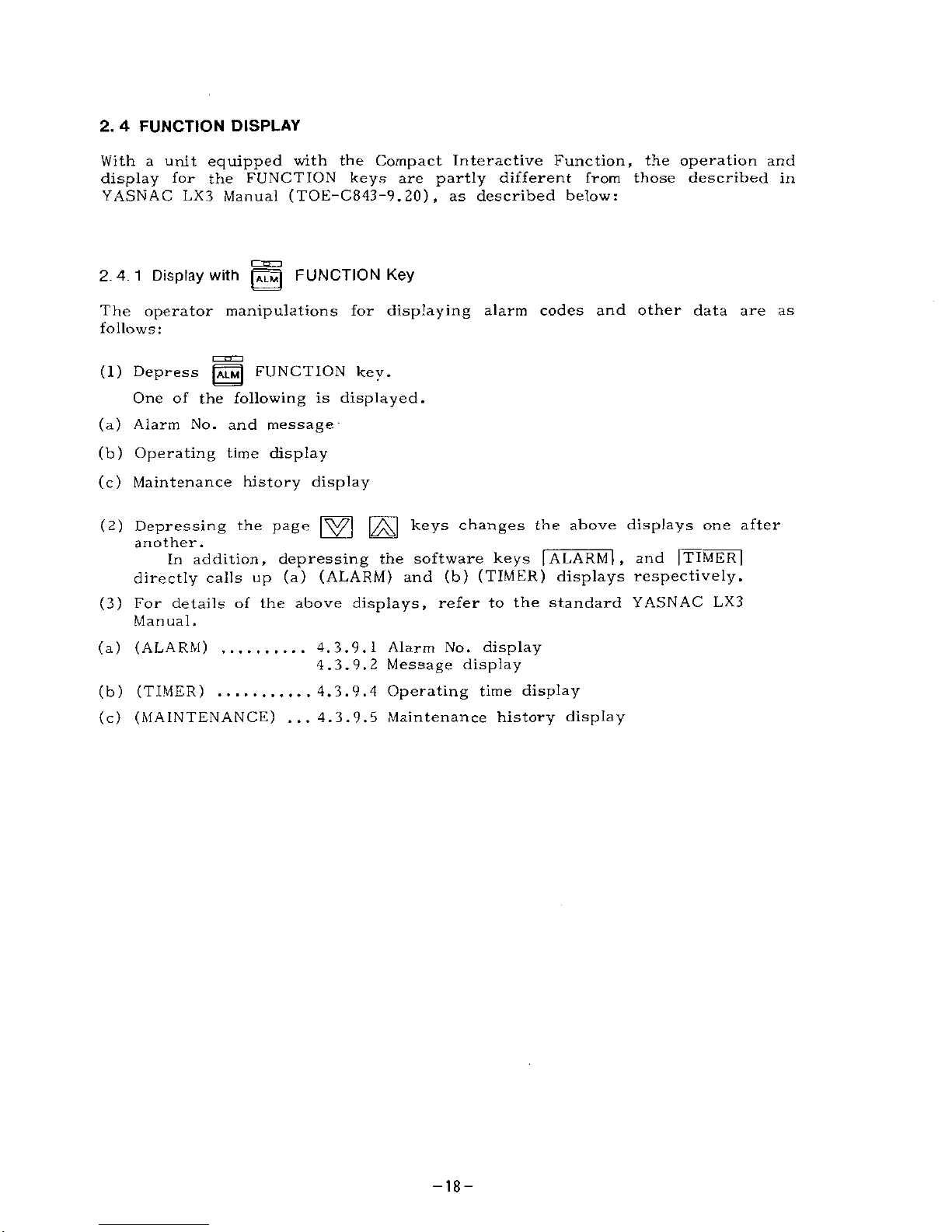

2.4.1

Display

with

pÿjj

FUNCTION

Key

The

operator

manipulations

for

displaying

alarm

codes

and

other

data

are

as

follows:

(1)

Depress

gD

FUNCTION

key.

One

of

the

following

is

displayed.

(a)

Alarm

No.

and

message

(b)

Operating

time

display

(c)

Maintenance

history

display

(2)

Depressing

the

page

|ÿ7|

|2ÿ|

keys

changes

the

above

displays

one

after

another.

In

addition,

depressing

the

software

keys

|

ALARM

[

,

and

|TIMER

|

directly

calls

up

(a)

(ALARM)

and

(b)

(TIMER)

displays

respectively.

(3)

For

details

of

the

above

displays,

refer

to

the

standard

YASNAC

LX3

Manual.

(a)

(ALARM)

..........

4.

3.9.1

Alarm

No.

display

4.

3.

9.

2

Message

display

(b)

(TIMER)

...........

4.

3.

9.

4

Operating

time

display

(c)

(MAINTENANCE)

...4.

3.

9.

5

Maintenance

history

display

-18-

Page 19

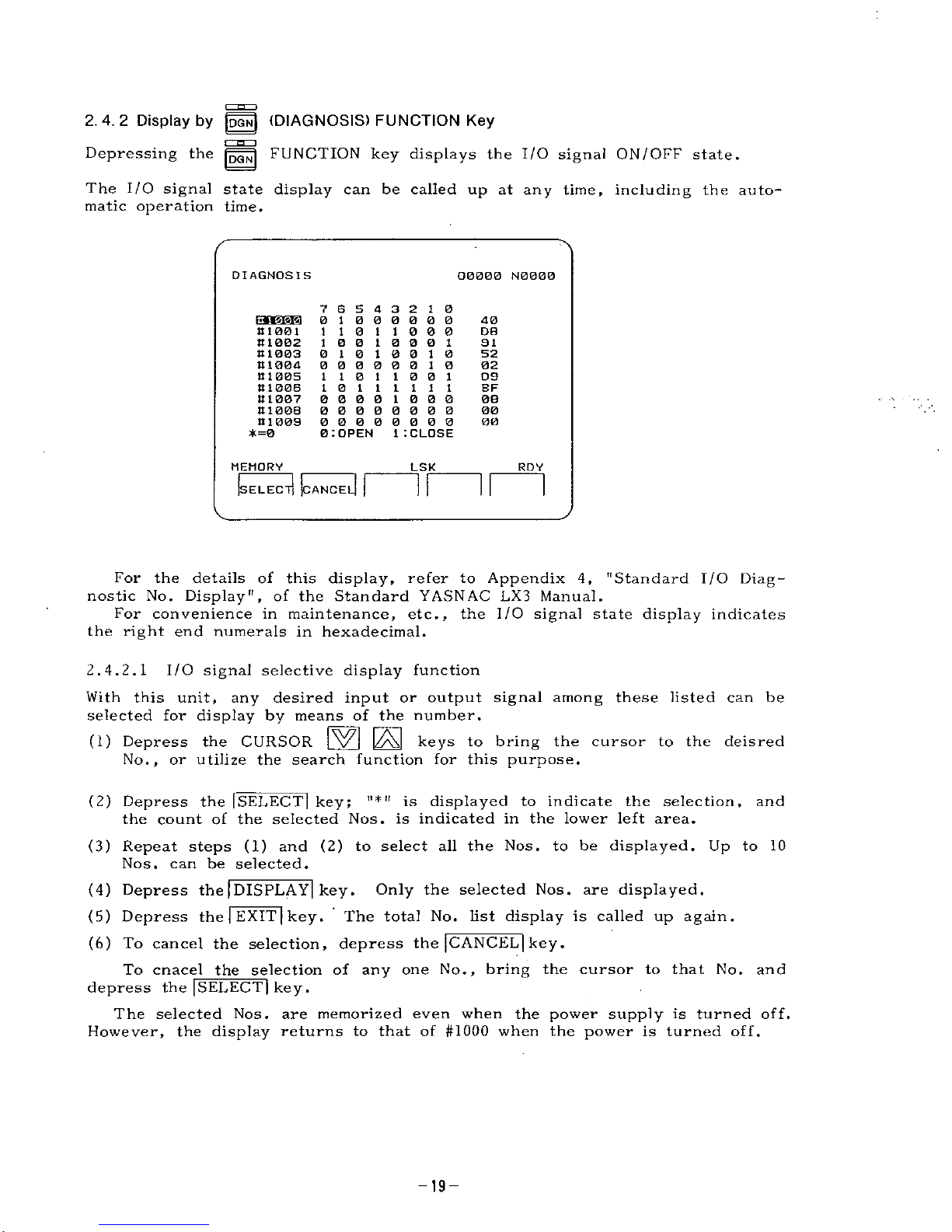

2.4.2

Display

by

||N|

(DIAGNOSIS)

FUNCTION

Key

Depressing

the

FUNCTION

key

displays

the

I/O

signal

ON/OFF

state.

The

I/O

signal

state

display

can

be

called

up

at

any

time,

including

the

auto¬

matic

operation

time.

DIAGNOSIS

O000B

N0000

7

6

5

4

3

2

1

0

01

000000

110

110

0 0

1

0 0

1

0

0

0

1

0

10

10

0

10

00000010

110

110

0

1

10

111111

0000

1

000

00000000

00000000

0

:

OPEN

40

81001

111002

It

1

003

111004

81005

81006

81007

81006

81009

*=0

D8

91

52

02

09

BF

08

00

00

1

I

CLOSE

MEMORY

LSK

RDY

(SELECT]

(

dl

]

CANCE

For

the

details

of

this

display,

refer

to

Appendix

4,

"Standard

I/O

Diag¬

nostic

No.

Display",

of

the

Standard

YASNAC

LX3

Manual.

For

convenience

in

maintenance,

etc.,

the

I/O

signal

state

display

indicates

the

right

end

numerals

in

hexadecimal.

2.4.2.1

I/O

signal

selective

display

function

With

this

unit,

any

desired

input

or

output

signal

among

these

listed

can

be

selected

for

display

by

means

of

the

number.

(1)

Depress

the

CURSOR

(zAJ

keys

to

bring

the

cursor

to

the

deisred

No.,

or

utilize

the

search

function

for

this

purpose.

(2)

Depress

the

|SELECT|

key;

ii

*

it

is

displayed

to

indicate

the

selection,

and

the

count

of

the

selected

Nos.

is

indicated

in

the

lower

left

area.

(3)

Repeat

steps

(1)

and

(2)

to

select

all

the

Nos.

to

be

displayed.

Up

to

10

Nos.

can

be

selected.

(4)

Depress

the

|

DISPLAY|

key.

Only

the

selected

Nos.

are

displayed.

(5)

Depress

the

|

EXIT

|

key.

The

total

No.

list

display

is

called

up

again.

(6)

To

cancel

the

selection,

depress

the

[CANCEL]

key

.

To

cnacel

the

selection

of

any

one

No.,

bring

the

cursor

to

that

No.

and

depress

the

|SELECT|

key.

The

selected

Nos.

are

memorized

even

when

the

power

supply

is

turned

off.

However,

the

display

returns

to

that

of

#1000

when

the

power

is

turned

off.

-19-

Page 20

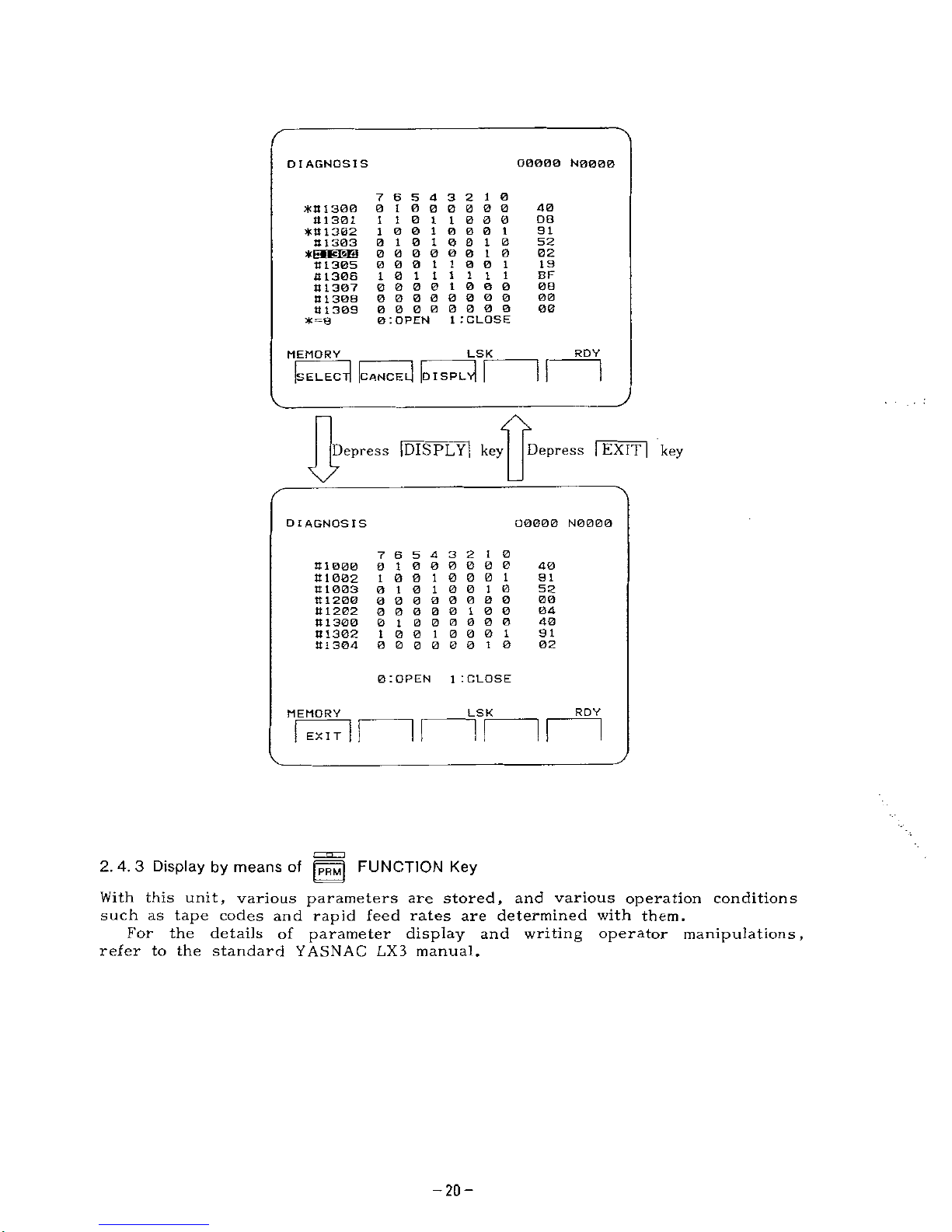

O0000

N0000

DIAGNOSIS

7

6

5

4

3

2

1

0

0

1

000000

110

110

0

0

10010001

01010010

00000010

0

0 0

1

1

0

0

1

10

111111

0000

1000

00000000

00000000

0

:OPEN

40

*tt

1

300

4

1301

*111302

111303

DB

9

I

52

*p«»cisri

02

19

11

1305

111306

It

1307

8

1308

8

1309

*=8

BF

00

00

00

1

.'CLOSE

RDY

LSK

MEMORY

v|

I

d

d

Is

DISPL

CANCE

ELEC

Depress

|DISPLY|

key

Depress

|

EXIT

|

key

\7

O0000

N0000

DIAGNOSIS

7

6

5

4

3

2

10

01000000

1

0

0

1

0

0

0

1

0

10

10

0

10

00000000

00000

1

00

01

000000

1

0

0

1

0

0

0

1

0

0

0

0 0

0

10

40

81000

81002

8

1003

81200

8

1202

81300

81302

81304

91

52

00

04

40

91

02

0

:OPEN

1

ICLOSE

RDY

LSK

MEMORY

ir

EXIT

2.4.3

Display

by

means

of

FUNCTION

Key

With

this

unit,

various

parameters

are

stored,

and

various

operation

conditions

such

as

tape

codes

and

rapid

feed

rates

are

determined

with

them.

For

the

details

of

parameter

display

and

writing

operator

manipulations,

refer

to

the

standard

YASNAC

LX3

manual.

-20-

Page 21

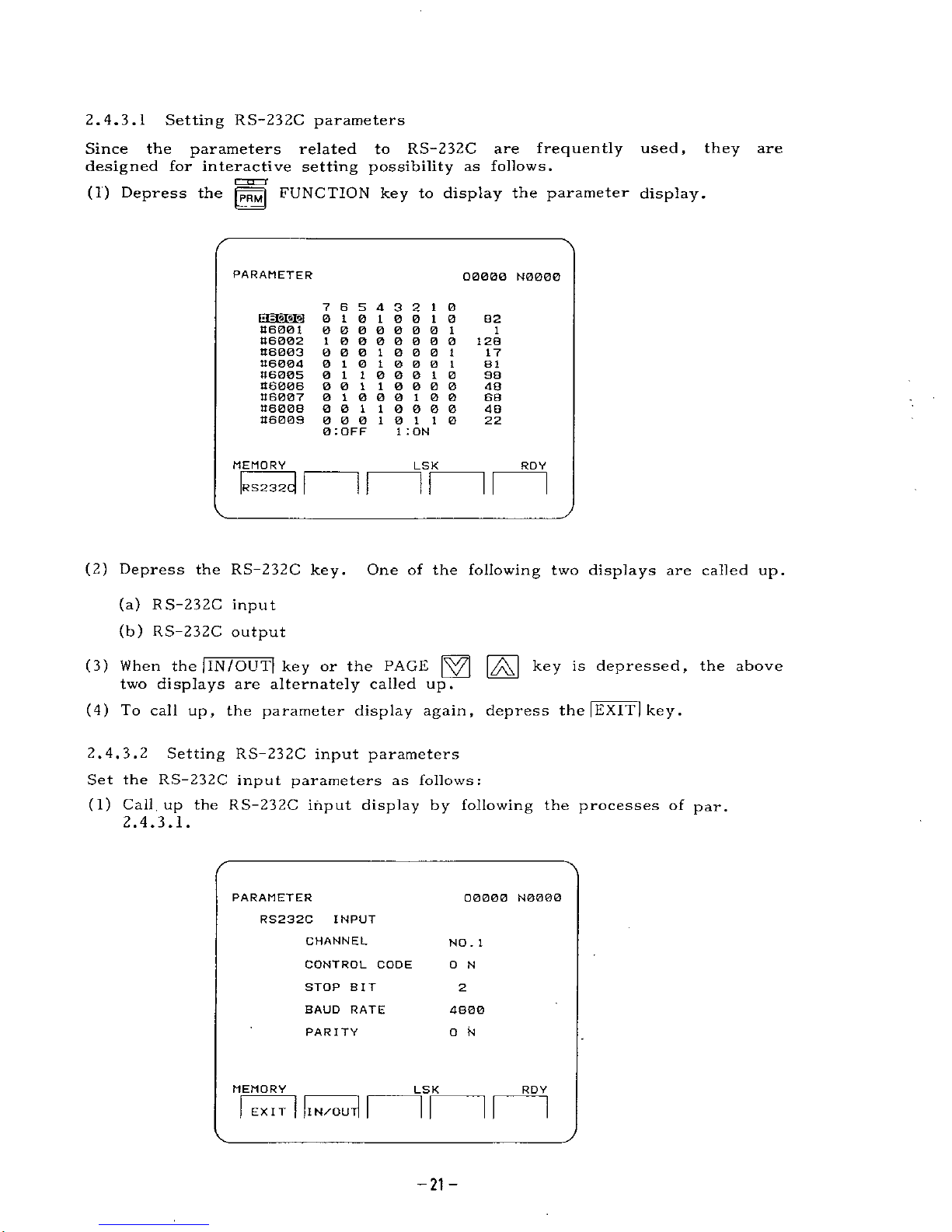

2.

4.

3.1

Setting

RS-232C

parameters

Since

the

parameters

related

to

RS-232C

are

frequently

used,

they

are

designed

for

interactive

setting

possibility

as

follows.

(1)

Depress

the

jpRM|

FUNCTION

key

to

display

the

parameter

display.

PARAMETER

00000

N0000

7

6

5

4

3

2

1

0

0

10

10

0

10

0 0 0 000 0

1

1

0000000

0 0

010

0

0

1

0

1

0

1

0 0

0

1

0

1

1

0 0

0

1

0

001

10000

01000100

001

10000

00010

1

1

0

0

:

OFF

B2

t-iil'WA

46001

46002

46003

46004

46005

46006

46007

46008

46009

1

128

17

81

98

48

68

48

22

1

:

ON

MEMORY

LSK

ROY

31

If

RS232

(2)

Depress

the

RS-232C

key.

(a)

RS-232C

input

(b)

RS-232C

output

(3)

When

the

jlN/OUT|

key

or

the

PAGE

|ÿ7[

|ÿJ

key

is

depressed,

the

above

two

displays

are

alternately

called

up.

(4)

To

call

up,

the

parameter

display

again,

depress

the

|

EXIT

|

key

.

One

of

the

following

two

displays

are

called

up.

2.4.

3.2

Setting

RS-232C

input

parameters

Set

the

RS-232C

input

parameters

as

follows:

(1)

Call

up

the

RS-232C

input

display

by

following

the

processes

of

par.

2.

4.

3.1.

PARAMETER

00000

N0000

RS232C

INPUT

CHANNEL

NO

.

1

CONTROL

CODE

0

N

STOP

BIT

2

BAUD

RATE

4800

O

N

PARITY

MEMORY

LSK

RDY

EXIT

I

N/QU

-21-

Page 22

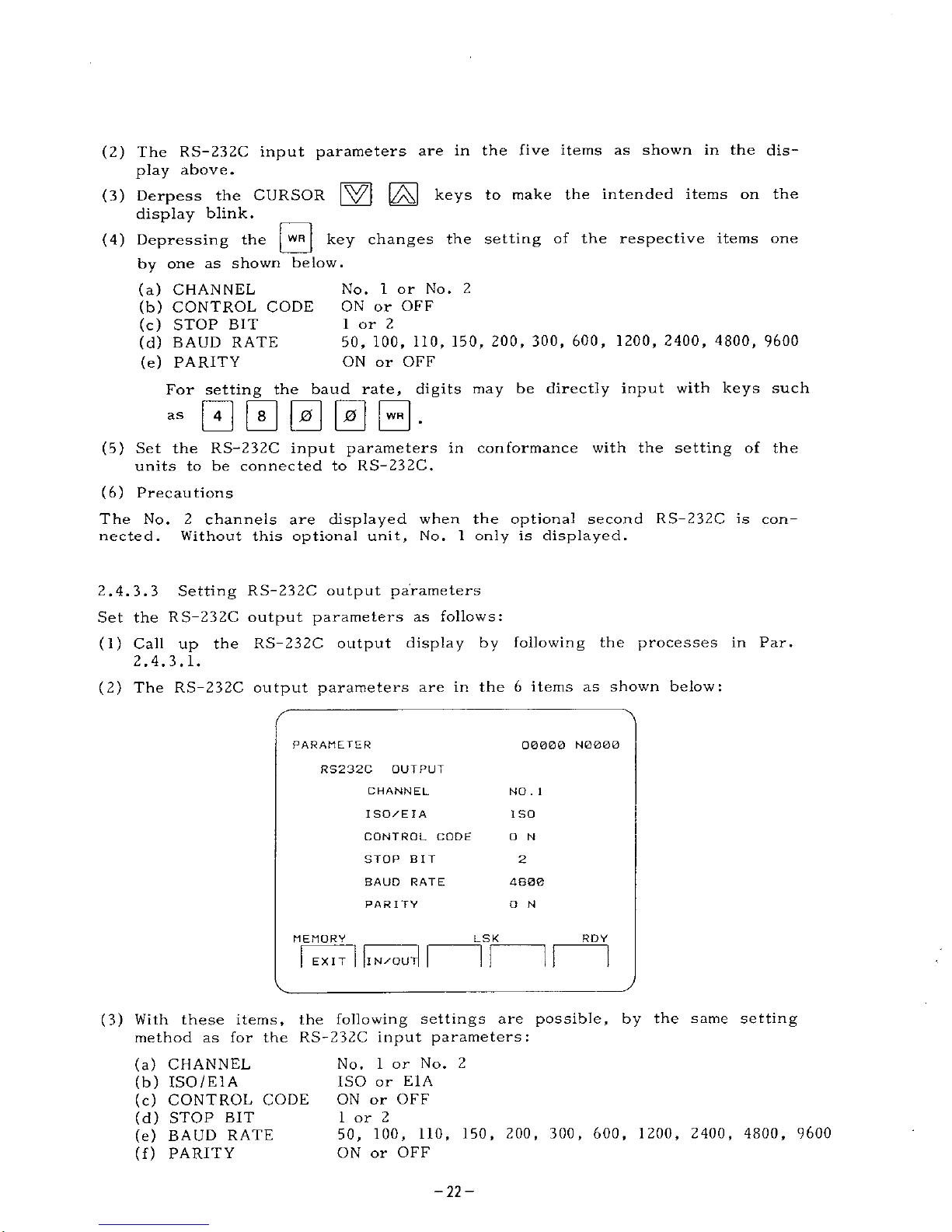

(2)

The

RS-232C

input

parameters

are

in

the

five

items

as

shown

in

the

dis¬

play

above.

(3)

Derpess

the

CURSOR

|\ÿj

keys

to

make

the

intended

items

on

the

display

blink.

(4)

Depressing

the

by

one

as

shown

below.

(a)

CHANNEL

(b)

CONTROL

CODE

(c)

STOP

BIT

(d)

BAUD

RATE

(e)

PARITY

For

setting

the

baud

rate,

digits

may

be

directly

input

with

keys

such

0

key

changes

the

setting

of

the

respective

items

one

No.

1

or

No.

2

ON

or

OFF

1

or

2

50,

100,

110,

150,

200,

300,

600,

1200,

2400,

4800,

9600

ON

or

OFF

00000.

as

(5)

Set

the

RS-232C

input

parameters

in

conformance

with

the

setting

of

the

units

to

be

connected

to

RS-232C.

(6)

Precautions

The

No.

2

channels

are

displayed

when

the

optional

second

RS-232C

is

con¬

nected.

Without

this

optional

unit,

No.

1

only

is

displayed.

Setting

RS-232C

output

parameters

Set

the

RS-232C

output

parameters

as

follows:

(1)

Call

up

the

RS-232C

output

display

by

following

the

processes

in

Par.

2.

4.

3.1.

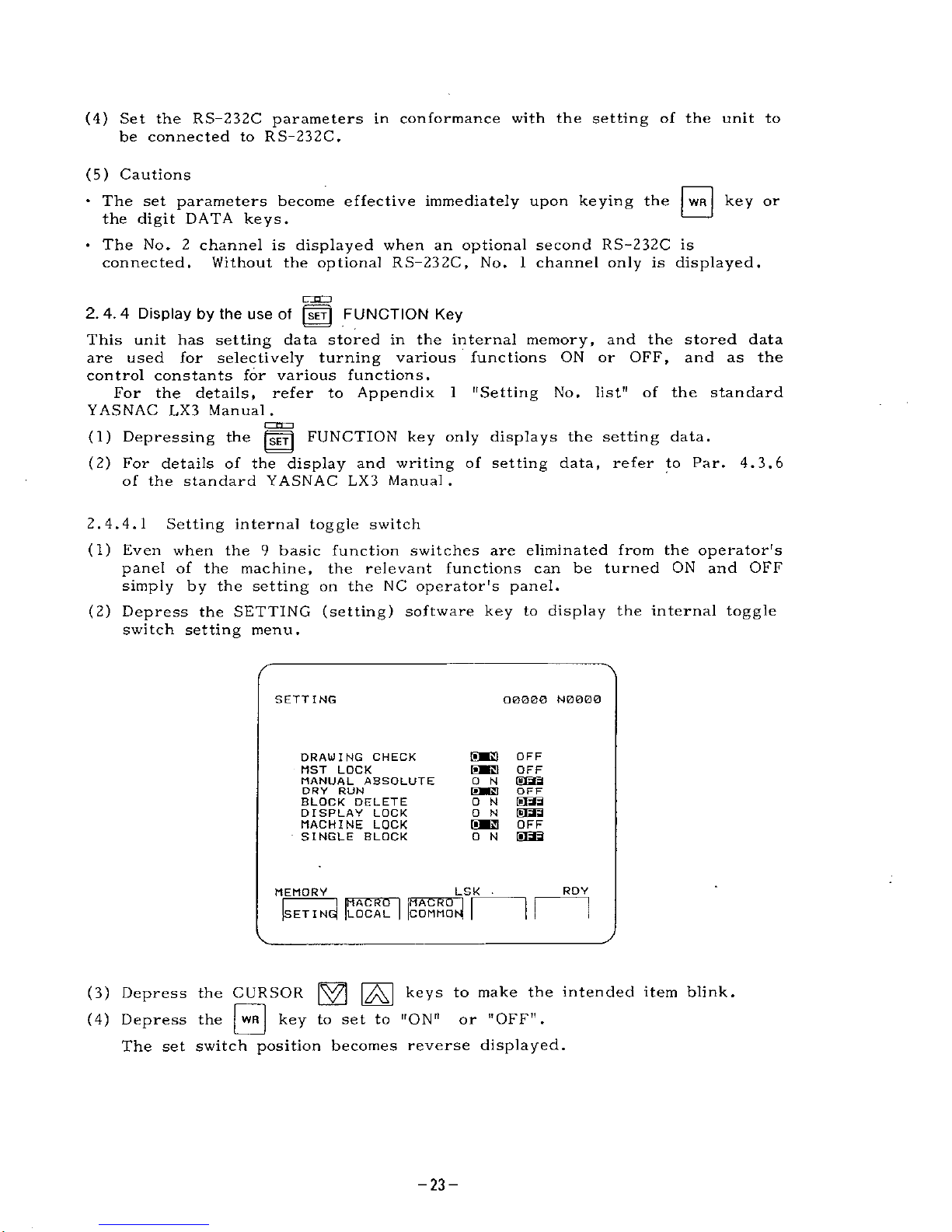

(2)

The

RS-232C

output

parameters

are

in

the6items

as

shown

below:

2.

4.

3.

3

PARAMETER

00000

N0000

RS232C

OUTPUT

CHANNEL

NO

.

1

I

SO/E

I

A

ISO

CONTROL

CODE

O

N

STOP

BIT

2

BAUD

RATE

4800

PARITY

O

N

MEMORY

LSK

RDY

HI

II

IN/OU

EXIT

(3)

With

these

items,

the

following

settings

are

possible,

by

the

same

setting

method

as

for

the

RS-232C

input

parameters:

(a)

CHANNEL

(b)

ISO

/El

A

(c)

CONTROL

CODE

(d)

STOP

BIT

(e)

BAUD

RATE

(f)

PARITY

No.

1

or

No.

2

ISO

or

E1A

ON

or

OFF

1

or

2

50,

100,

110,

150,

200,

300,

600,

1200

ON

or

OFF

2400,

4800,

9600

-22-

Page 23

(4)

Set

the

RS-232C

parameters

in

conformance

with

the

setting

of

the

unit

to

be

connected

to

RS-232C.

(5)

Cautions

*

The

set

parameters

become

effective

immediately

upon

keying

the

WR

key

or

the

digit

DATA

keys.

-

•

The

No.

2

channel

is

displayed

when

an

optional

second

RS-232C

is

connected.

Without

the

optional

RS-232C,

No.

1

channel

only

is

displayed.

L.-TX-J

2.4.4

Display

by

the

use

of

[

SET

j

FUNCTION

Key

This

unit

has

setting

data

stored

in

the

internal

memory,

and

the

stored

data

are

used

for

selectively

turning

various

functions

ON

or

OFF,

and

as

the

control

constants

for

various

functions.

For

the

details,

refer

to

Appendix

1

"Setting

No.

list"

of

the

standard

YASNAC

LX3

Manual.

r~n

i

(1)

Depressing

the

jÿTfj

FUNCTION

key

only

displays

the

setting

data.

(2)

For

details

of

the

display

and

writing

of

setting

data,

refer

to

Par.

4.3.6

of

the

standard

YASNAC

LX3

Manual

.

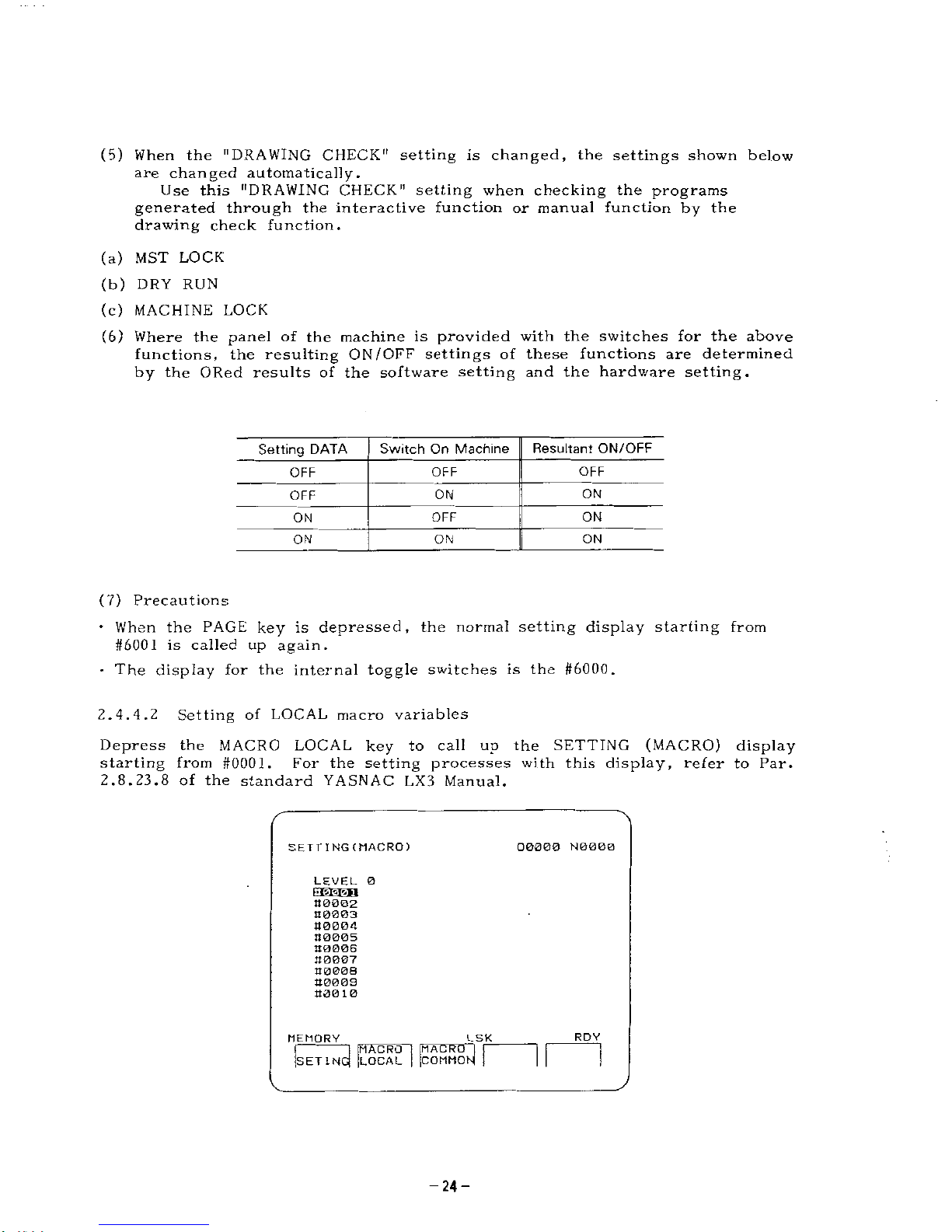

2.4.4.1

Setting

internal

toggle

switch

(1)

Even

when

the

9

basic

function

switches

are

eliminated

from

the

operator's

panel

of

the

machine,

the

relevant

functions

can

be

turned

ON

and

OFF

simply

by

the

setting

on

the

NC

operator's

panel.

(2)

Depress

the

SETTING

(setting)

software

key

to

display

the

internal

toggle

switch

setting

menu.

SETTING

O0Q00

N0000

SK3

[iMBl

0

N

[ÿMl

O

N

ON

[ÿM3

O

N

OFF

OFF

[8iaa

OFF

EBB

OFF

1SBB

DRAUING

CHECK

MST

LOCK

MANUAL

ABSOLUTE

DRY

RUN

BLOCK

DELETE

DISPLAY

LOCK

MACHINE

LOCK

SINGLE

BLOCK

RDY

LSK

.

MEMORY

MACRO

LOCAL

3!

COMMOI

SETIN

(3)

Depress

the

CURSOR

|ÿ7]

|ÿJ

keys

(4)

Depress

the

|

WR

j

to

make

the

intended

item

blink.

key

to

set

to

"ON"

or

"OFF".

The

set

switch

position

becomes

reverse

displayed.

-23-

Page 24

(5)

When

the

"DRAWING

CHECK"

setting

is

changed,

the

settings

shown

below

are

changed

automatically.

Use

this

"DRAWING

CHECK"

setting

when

checking

the

programs

generated

through

the

interactive

function

or

manual

function

by

the

drawing

check

function.

(a)

MST

LOCK

(b)

DRY

RUN

(c)

MACHINE

LOCK

(6)

Where

the

panel

of

the

machine

is

provided

with

the

switches

for

the

above

functions,

the

resulting

ON

/OFF

settings

of

these

functions

are

determined

by

the

ORed

results

of

the

software

setting

and

the

hardware

setting.

Resultant

ON/OFF

Switch

On

Machine

Setting

DATA

OFF

OFF

OFF

ON

ON

OFF

ON

OFF

ON

ON

ON

ON

(7)

Precautions

•

When

the

PAGE

key

is

depressed,

the

normal

setting

display

starting

from

#6001

is

called

up

again.

•

The

display

for

the

internal

toggle

switches

is

the

#6000.

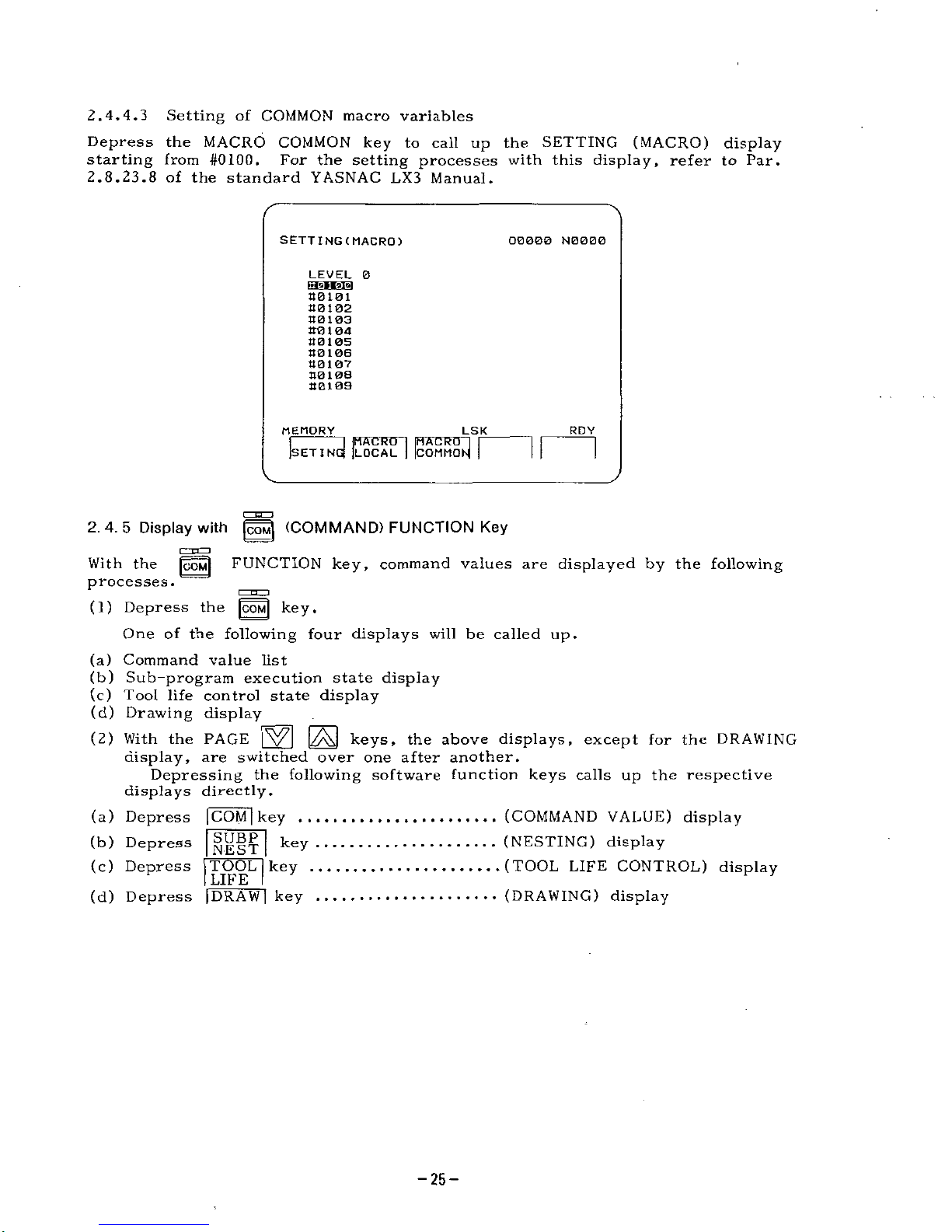

2.

4.4.

2

Setting

of

LOCAL

macro

variables

Depress

the

MACRO

LOCAL

key

to

call

up

the

SETTING

(MACRO)

display

starting

from

#0001.

For

the

setting

processes

with

this

display,

refer

to

Par.

2.8.23.8

of

the

standard

YASNAC

LX3

Manual.

SETT

ING(MACRO)

00000

N0000

LEVEL

0

00002

00003

00004

00005

00006

00007

00008

00008

O00

10

RDY

LSK

MEMORY

I

a

MACRO

COMMO

MACRO

LOCAL

SETIN

-24-

Page 25

2.

4.

4.

3

Setting

of

COMMON

macro

variables

Depress

the

MACRO

COMMON

key

to

call

up

the

SETTING

(MACRO)

display

starting

from

#0100.

For

the

setting

processes

with

this

display,

refer

to

Par.

2.8.23.8

of

the

standard

YASNAC

LX3

Manual.

SETTING(MACRQ)

O0000

N0000

LEVEL

0

EHEEB

801

02

80103

80104

801

05

80106

80107

80108

80109

LSK

]

MACRO

]

|

POMMOM

]

MEMORY

RDY

MACRO

G)

[LOCAL

SET

I

N

2.

4.

5

Display

with

|U

(COMMAND)

FUNCTION

Key

c=n=

D

With

the

|COM|

FUNCTION

key,

command

values

are

displayed

by

the

following

processes.

_

p

n,..J

(1)

Depress

the

|COM|

key.

One

of

the

following

four

displays

will

be

called

up.

(a)

Command

value

list

(b)

Sub-program

execution

state

display

(c)

Tool

life

control

state

display

(d)

Drawing

display

(2)

With

the

PAGE

keys,

the

above

displays,

except

for

the

DRAWING

display,

are

switched

over

one

after

another,

Depressing

the

following

software

function

keys

calls

up

the

respective

displays

directly.

(a)

Depress

|COM

|

key

(b)

Depress

(c)

Depress

TOOL

key

LIFE

(d)

Depress

[DRAW

|

key

(COMMAND

VALUE)

display

(NESTING)

display

(TOOL

LIFE

CONTROL)

display

(DRAWING)

display

SUBP

NEST

key

-25-

Page 26

(3)

For

a

detailed

description

of

these

displays,

refer

to

the

following

sec¬

tions:

(a)

(COMMAND

VALUE)

Standard

YASNAC

LX3

Manual

Par.

4.

3.

2.1

Standard

YASNAC

LX3

Manual

Par.

4.

3.2.2

(b)

(NESTING)

(c)

(TOOL

LIFE

CONTROL)

Standard

YASNAC

LX3

Manual

Par,

4.

3.2.3

Par.

6

of

this

manual

(d)

(DRAWING)

2.

4.

6

Display

with

(PROGRAM)

FUNCTION

Key

(1)

Depress

the

|PR0G|

FUNCTION

key

to

call

up

the

PROGRAM

display.

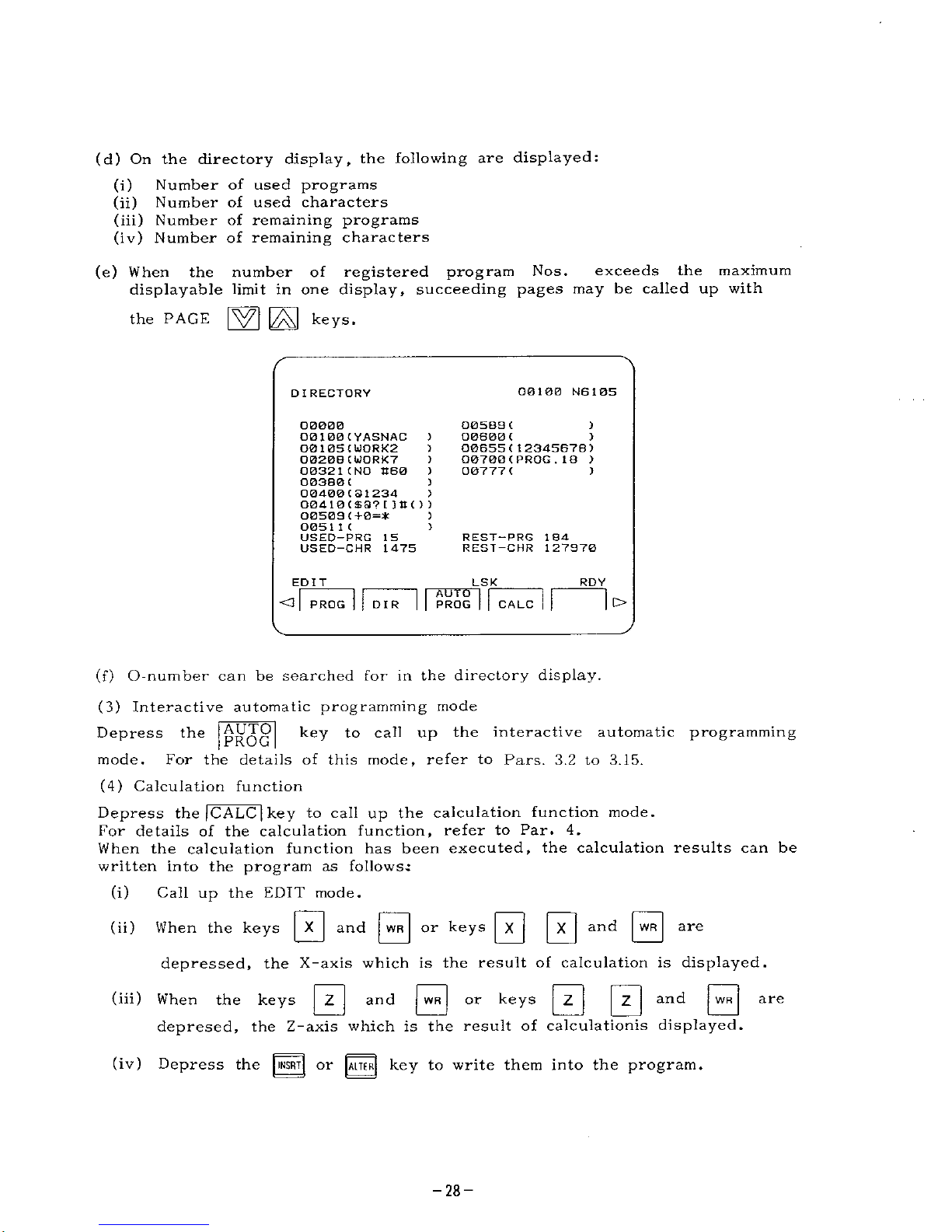

(2)

The

program

functions

are

in

the

following

6

modes,

each

differing

in

function

and

operator

manipulation.

(a)

JOG

mode

Mode

for

manual

continuous

feeding

of

the

machine

(b)

HANDLE/STEP

mode

Mode

for

using

manual

pulse

generator

(c)

TAPE

mode

Mode

for

NC

tape

operation

(d)

MDI

mode

Mode

for

writing

command

values

with

MDI

(manual

data

input)

and

their

execution

(e)

MEMORY

mode

Mode

for

automatic

operation

of

stored

programs

(f)

EDIT

mode

Mode

for

program

storing,

reading

in

and

from

the

memory,

and

for

editing

(3)

For

the

details

of

the

above

6

modes,

refer

to

Par.

4.3.3

of

the

Standard

YASNAC

LX3

Manual.

-26-

Page 27

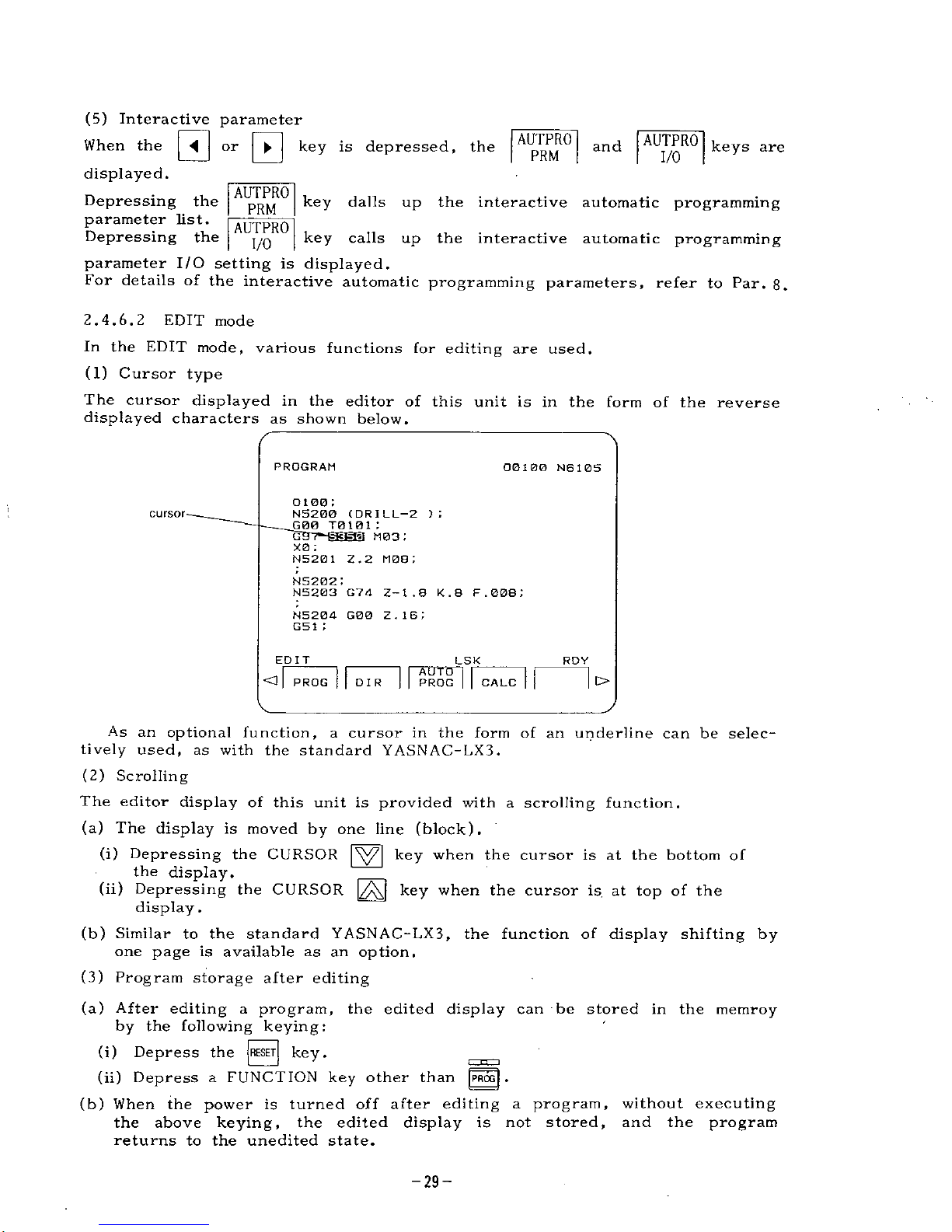

2.

4.

6.1

Common

mode

display

With

the

program

function,

there

are

displays

which

are

common

to

all

the

modes

.

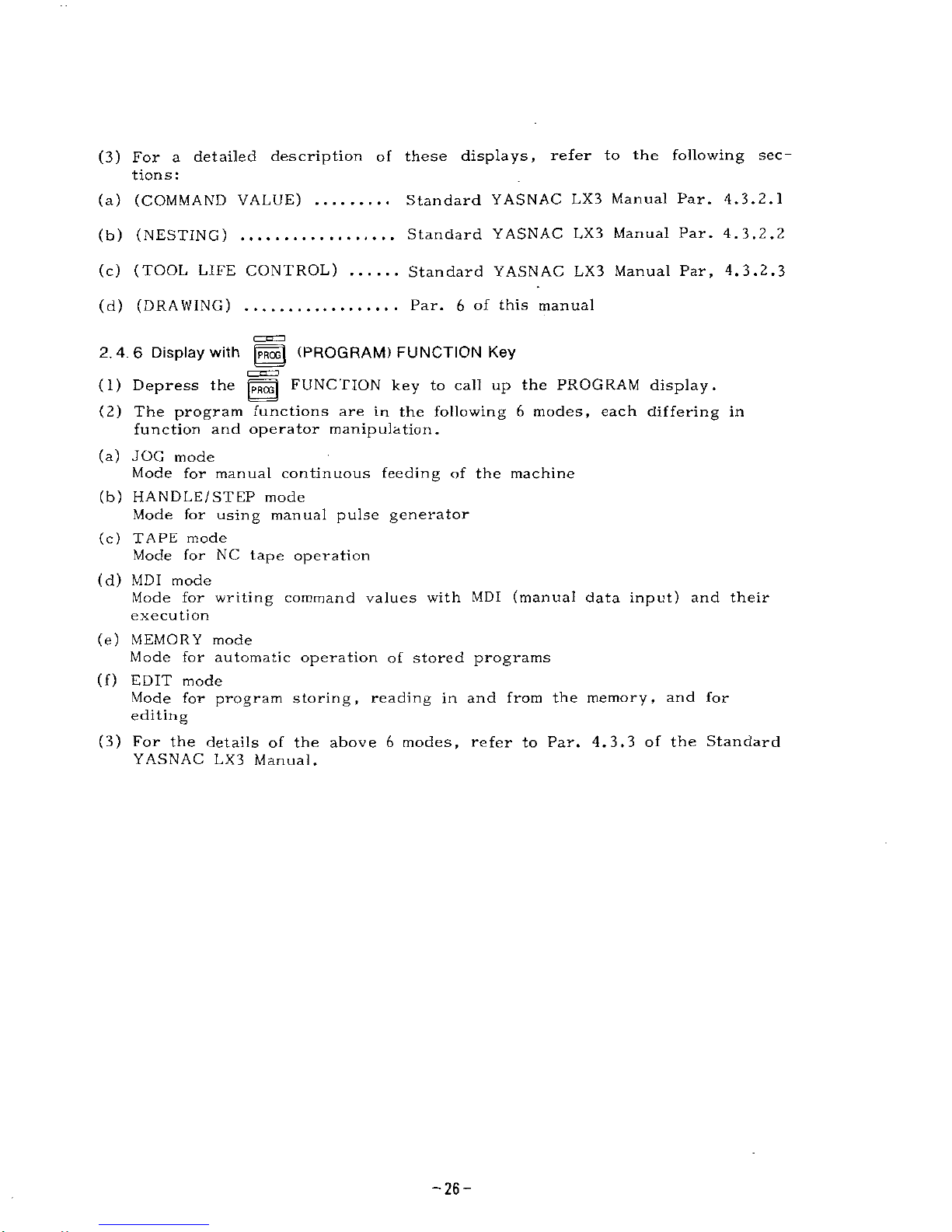

(1)

Program

display

(a)

Depress

the

|PROG|

key

to

call

up

the

program

display.

On

the

program

display,

NC

programs

and

operation

data

are

displayed,

except

that

in

the

EDIT

mode,

no

operation

data

is

displayed.

PROGRAM

00100

N6105

N5200

(DRILL-2)

;

G00

T0101

;

/

(ABS)

(MODAL

-G)

T—

NO

:

T0

1

00

22.0000

G01

G69

2.0000

G97

G

1

23

G99

G40

0

G37

0

G39

G67

X

Z

FEED

:

E

.

80000

(

i

n

c

h/r

e

v)

(INC)

X

ACTUAL

:

S

LIMIT

:

S

4

000

COMMAND

:S

300

0

Z

MEMORY

LSK

RDY

<1

<>

|

t>

PROG

DIR

PROG

CALC

(b)

The

NC

programs

are

displayed

only

in

the

MDI,

MEMORY

and

EDIT

modes.

(c)

Depressing

the

|~<

>

|

key

switches

the

operation

data

display

and

cancels

one

after

another.

(d)

The

operation

data

includes

the

following

displays:

(i)

POSITION

(ABS),

(INC)

(iii)

T-NO

(tool

No.)

(v)

Spindle

speed

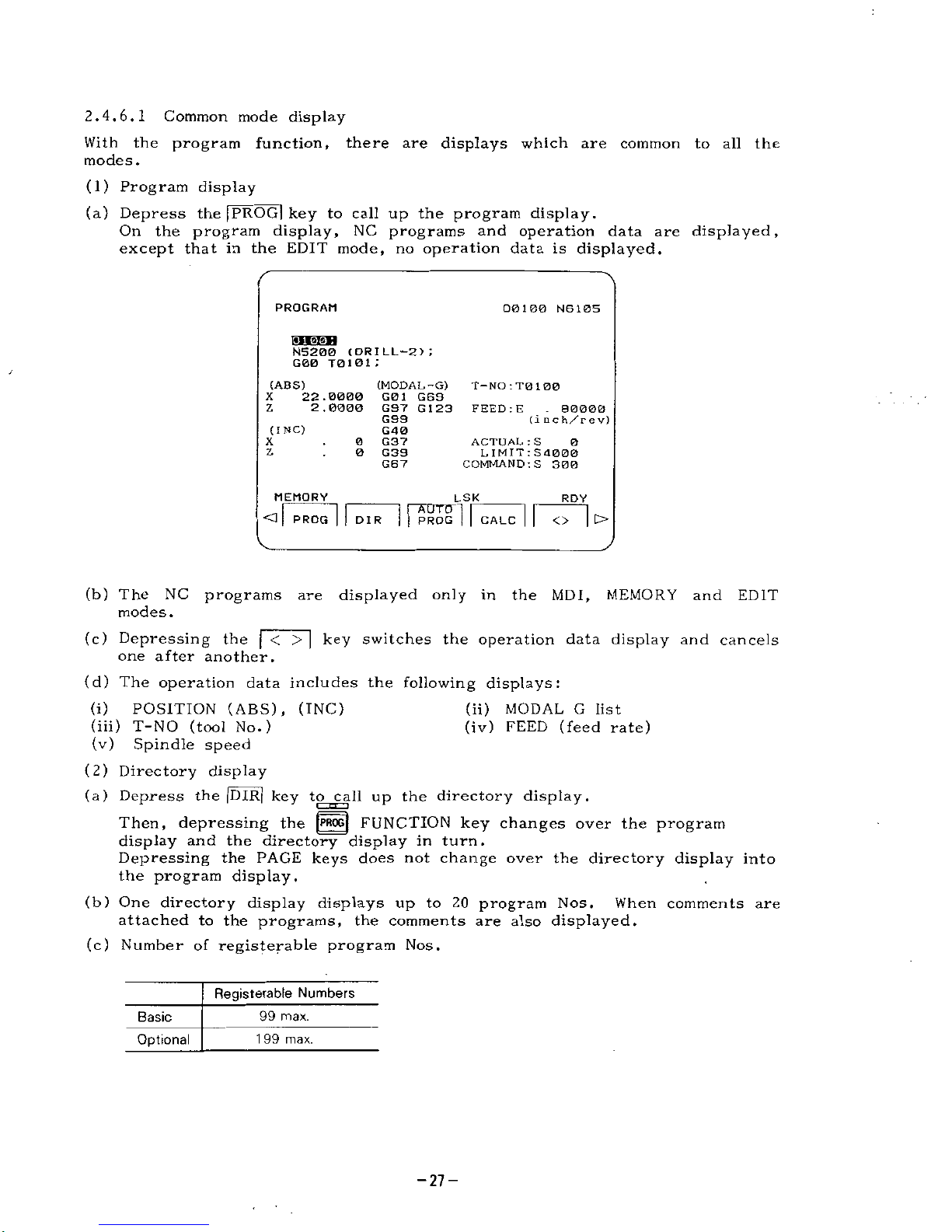

(2)

Directory

display

(a)

Depress

the

|DIR|

key

to

call

up

the

directory

display.

Then,

depressing

the

|P»OG(

FUNCTION

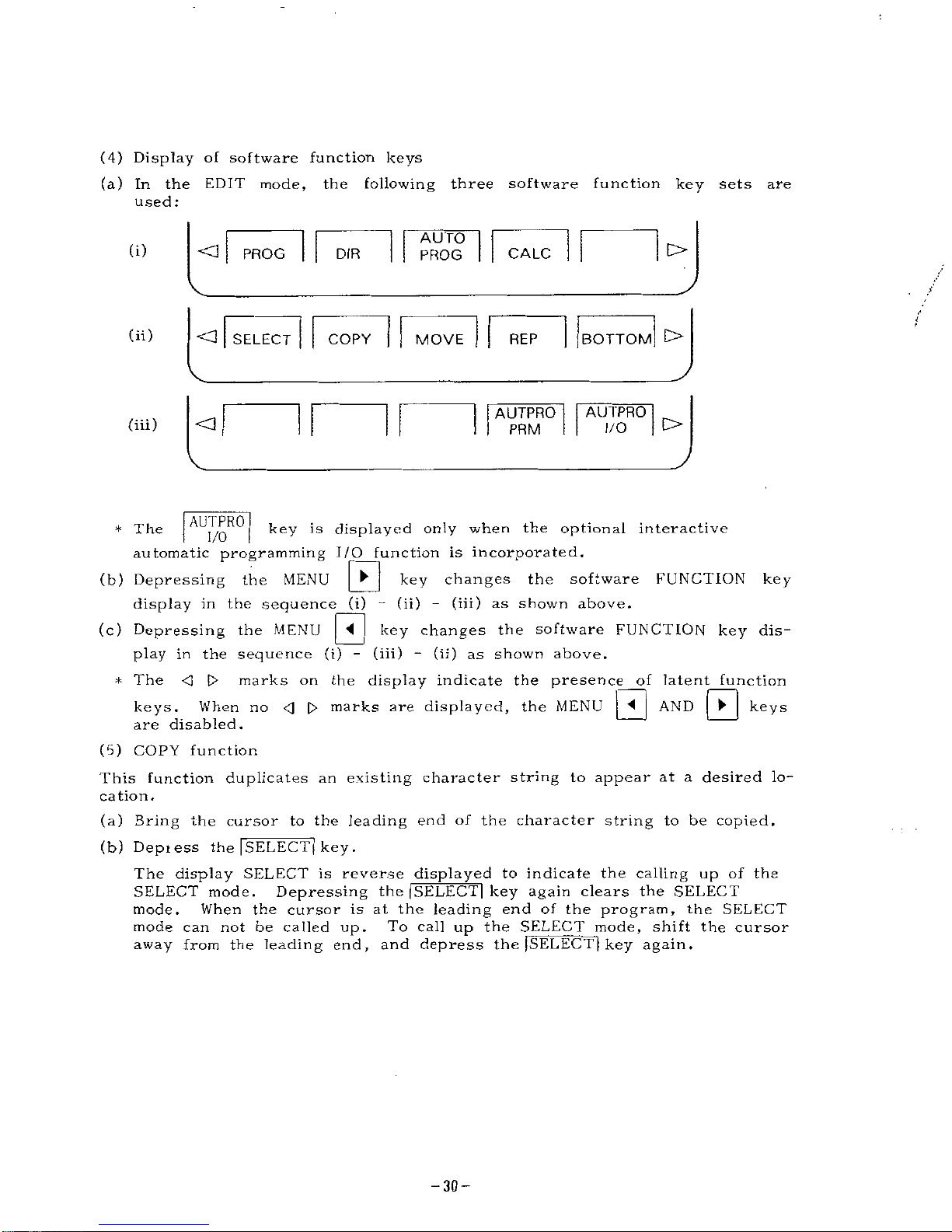

key

changes