YASKAWA VS MINI J7 series, VS mini CIMR-J7AC20P4, VS mini CIMR-J7AC20P1, VS mini CIMR-J7AC20P2, VS mini CIMR-J7AC20P7 Instruction Manual

...Page 1

VS mini J7 Series

INSTRUCTION MANUAL

COMPACT GENERAL-PURPOSE INVERTER

Upon receipt of the product and prior to initial operation, read

these instructions thoroughly, and retain for future reference.

YASKAWA

MANUAL NO. TOE-S606-12G

Page 2

PREFACE

YASKAWA’s VS mini J7 (hereinafter, called VS mini).

is a small and simple inverter; as easy as using a

contactor. This instruction manual describes

installation, maintenance and inspection,

troubleshooting, and specifications of the VS mini.

Read this instruction manual thoroughly before

operation.

YASKAWA ELECTRIC CORPORATION

General Precautions

• Some drawings in this manual are shown with the protective cover or

shields removed, in order to describe detail with more clarity. Make

sure all covers and shields are replaced before operating this product.

• This manual may be modified when necessary because of improvement

of the product, modification, or changes in specifications.

Such modifications are denoted by a revised manual No.

• To order a copy of this manual, if your copy has been damaged or lost,

contact your YASKAWA representative.

• YASKAWA is not responsible for any modification of the product

made by the user, since that will void your guarantee.

2

Page 3

NOTES FOR SAFE OPERATION

NOTE

CAUTION

WARNING

CAUTION

Read this instruction manual thoroughly before installation, operation,

maintenance or inspection of the VS mini. In this manual, NOTES FOR

SAFE OPERATION are classified as “WARNING” or “CAUTION.”

Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury to personnel.

Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury to personnel and damage to equipment.

It may also be used to alert against unsafe practices.

Even items described in may result in a vital accident in some

situations. In either case, follow these important notes.

: These are steps to be taken to insure proper operation.

3

Page 4

WARNINGS FOR UL/cUL MARKING

CAUTION

Use 75°C copper wires or equivalent.

Low voltage wires shall be wired with Class I Wiring.

• Do not connect or disconnect wiring, or perform signal checks while the

power supply is turned ON.

• The Inverter internal capacitor is still charged even after the power supply

is turnd OFF. To prevent electric shock, disconnect all power before

servicing the Inverter. Then wait at least one minute after the power

supply is disconnected and all indecators are OFF.

• Do not perform a withstand voltage test on any part of the Inverter. This

electronic equipment uses semiconductors and is vulnerable to high

voltage.

• Do not remove the Digital Operator or the blank cover unless the power

supply is turned OFF. Never touch the printed control board (PCB) while

the power supply is turned ON.

• This Inverter is not suitable for use on a circuit capable of delivering more

than 18,000 RMS symmetrical amperes, 250volts maximum (200V class

units) or 18,000 RMS symmetrical amperes, 480volts maximum (400V

class units).

WARNINGS FOR CE MARKINGS

• Only basic insulation to meet the requirements of protection class 1 and

overvoltage category II is provided with control circuit terminals.

Additional insulation may be necessary in the end product to conform to

CE requirements.

• For 400 V class Inverters, make sure to ground the supply neutral to

conform to CE requirements.

• For conformance to EMC directives, refer to the relevant manuals for the

requirements.

Document No. EZZ008389 for Japanese version,

Document No. EZZ008390 for English version

4

Page 5

RECEIVING

CAUTION

• Do not install or operate any inverter which is damaged or

has missing parts.

Failure to observe this caution may result in personal injury or

equipment damage.

MOUNTING

CAUTION

• Lift the cabinet by the heatsink. When moving the

unit, never lift by the plastic case or the terminal covers.

Otherwise, the main unit may be dropped causing damage

to the unit.

• Mount the inverter on nonflammable material (i.e. metal).

Failure to observe this caution can result in a fire.

• When mounting units in an enclosure, install a fan or

other cooling device (open chasis to keep the intake air

temperature below 50: (122<).

Overheating may cause a fire or damage to the unit.

• The VS mini generates heat. For effective cooling,

mount it vertically.

Refer to the figure in “Mounting Dimensions” on page 18.

(Ref. page)

15

(Ref. page)

17

17

18

5

Page 6

WIRING

WARNING

(Ref. page)

• Only commence wiring after verifying that the power

supply is turned OFF.

Failure to observe this warning can result in an electric shock

or a fire.

• Wiring should be performed only by qualified personnel.

Failure to observe this warning can result in an electric shock

or a fire.

• When wiring the emergency stop circuit, check the wiring

thoroughly before operation.

Failure to observe this warning can result in personal injury.

• For 400V class, make sure to ground the supply neutral.

Failure to observe this warning can result in an electric shock

or a fire. 24

• Make sure to ground the ground terminal according to the

local grounding code.

Failure to observe this warning can result in an electric shock

or a fire. 24

20

20

20

6

Page 7

CAUTION

• Verify that the inverter rated voltage coincides with the

AC power supply voltage.

Failure to observe this caution can result in personal injury

or a fire.

• Do not perform a withstand voltage test of the inverter.

It may cause semi-conductor elements to be damaged.

• Make sure to tighten terminal screws of the main circuit

and the control circuit.

Failure to observe this caution can result in a malfunction,

damage or

• Never connect the AC main circuit power supply to

output terminals U/T1, V/T2, and W/T3.

The inverter will be damaged and invalidate the guarantee.

• Do not connect or disconnect wires or connectors

while power is applied to the circuit.

Failure to observe this caution can result in personal injury.

• Do not change signals during operation.

The machine or the inverter may be damaged.

a fire.

(Ref. page)

20

20

7

Page 8

OPERATION

WARNING

• Only turn ON the input power supply after replacing

the front cover.

Do not remove the covers while current is flowing.

Failure to observe this warning can result in an electric shock.

• Never operate the digital operator or dip the switches

when your hand is wet.

Failure to observe this warning can result in an electric shock.

• Never touch the terminals while current is flowing, even

during inverter stopping.

Failure to observe this warning can result in an electric shock.

• When the fault retry function is selected, stand clear of

the inverter or the load, since it may restart suddenly

after being stopped.

(Construct machine system, so as to assure safety for personnel,

even if the inverter should restart.)

warning can result in personal injury.

• When continuous operation after power recovery is

selected, stand clear of the inverter or the load, since

it may restart suddenly after being stopped.

(Construct machine system, so as to assure safety for personnel,

even if the inverter should restart.)

warning can result in personal injury.

• Since the digital operator stop button can be disabled

by a function setting, install a separate emergency

stop switch.

Failure to observe this warning can result in personal injury.

• If an alarm is reset with the operation signal ON, the inverter

restarts automatically. Only reset the alarm after verifying

that the operation signal is OFF.

Failure to observe this warning can result in personal injury.

Failure to observe this

Failure to observe this

(Ref. page)

53

48

26

8

Page 9

CAUTION

(Ref. page)

• Never touch the heatsink since the temperature is very high.

Failure to observe this caution can result in harmful burns

to the body.

• Since it is easy to change operation speed from low to

high speed, verify the safe working range of the motor

and machine before operation.

Failure to observe this caution can result in personal injury

and machine damage.

• Install a holding brake separately if necessary.

Failure to observe this caution can result in personal injury.

• If using an Inverter with an elevator, take safety measures on the

elevator to prevent the elevator from dropping.

Failure to observe this caution can result in personal injury.

• Do not change signals during operation.

The machine or the inverter may be damaged.

• All the constants of the inverter have been preset

at the factory. Do not change the settings unnecessarily.

The inverter may be damaged.

27

MAINTENANCE AND INSPECTION

WARNING

• Never touch high-voltage terminals in the inverter.

Failure to observe this warning can result in an electric shock.

•

Disconnect all power before performing maintenance or inspection.

Then wait at least one minute after the power supply is disconnected

and all LEDs and CHARGE LED are extinguished.

The capacitors are still charged and can be dangerous.

9

Page 10

WARNING

(Ref. page)

• Do not perform withstand voltage test on any part

of the VS mini.

This electronic equipment uses semiconductors and is

vulnerable to high voltage.

• Only authorized personnel should be permitted to perform

maintenance, inspections or parts replacement.

[Remove all metal objects (watches, bracelets, etc.)

before operation.]

(Use tools which are insulated against electric shock.)

Failure to observe this warning can result in an electric shock.

CAUTION

(Ref. page)

• The control PC board employs CMOS ICs.

Do not touch the CMOS elements.

They are easily damaged by static electricity.

• Do not connect or disconnect wires, cooling fan or connentors

while power is applied to the circuit.

Failure to observe this caution can result in personal injury.

Others

WARNING

• Never modify the product.

Failure to observe this warning can result in an electric shock or personal

injury and will invalidate the guarantee.

84

84

10

Page 11

11

WARNING DISPLAY

A warning label is displayed on the front cover of the inverter, as shown

below. Follow these instructions when handling the inverter.

Example of 200V class, 3-phase, 1.5 kW inverter

Warning Display (Back of this manual)

Warning Display

ź

English

Żų

ź

French

Żų

ź

Japanese

Żų

WARNING

– Risk of electric shock.

Read manual before installing.

Wait 1 minute for capacitor discharge after

disconnecting power supply.

To conform to requirements, make sure

to ground the supply neutral for 400V class.

•

•

•

үųᨖų

Ყ

ƚƕȷᩓƷƓƦǕƕƋǓLJƢŵų

Ƒ˄ƚŴᢃ᠃ƷЭƴƸ࣏ƣӕৢᛟଢǛƓᛠLjɦƞƍŵų

ᡫᩓɶӏƼᩓเᢚૺࢸᲫЎˌϋƸȕȭȳȈǫȐȸǛų

ٳƞƳƍưɦƞƍŵų

ᲮᲪᲪ᳐ኢǤȳȐȸǿƷئӳƸŴᩓเƷɶࣱໜƕעƞǕƯų

ƍǔƜƱǛᄩᛐƠƯɦƞƍŵᲢųųݣࣖᲣų

•

•

•

WARNING

– Risk of electric shock.

Read manual before installing.

Wait 1 minute for capacitor discharge after

disconnecting power supply.

To conform to requirements, make sure

to ground the supply neutral for 400V class.

•

•

•

AVERTISSEMENT

–

Risque de décharge

électrique.

Lire le manuel avant I’installation.

Attendre 1 minute après la coupure de I’alimentation,

pour permettre la décharge des condensateurs.

Pour répondre aux exigences , s’assurer que le

neutre soit reli

é à la terre, pour la série

400V.

•

•

•

䡲

Japanese/French Warning Display

An English warning display is on

the front panel of the inverter.

If you need Japanese or French

warning display, use the stickers at

the back of this manual. Place it

over the English warning display.

NAMEPLATE

PLASTIC CASE

QUALIFICATION

MARK

STATUS

INDICATOR

LAMP

WARNING

DISPLAY

Page 12

CONTENTS

NOTES FOR SAFE OPERATION••••••••••••••••••••••••••••••3

1. RECEIVING•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••15

Checking the Name Plate ••••••••••••••••••••••••••••••••••••••••••••••15

2. IDENTIFYING THE PARTS••••••••••••••••••••••••••••••••••16

3. MOUNTING•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••17

Choosing a Location to Mount the Inverter•••••••••••••••••••••••••17

Mounting Dimensions••••••••••••••••••••••••••••••••••••••••••••••••••••18

Mounting/Removing Components ••••••••••••••••••••••••••••••••••••19

4. WIRING••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••20

Wiring Instructions••••••••••••••••••••••••••••••••••••••••••••••••••••••••20

Wire and Terminal Screw Sizes•••••••••••••••••••••••••••••••••••••••21

Wiring the Main Circuit ••••••••••••••••••••••••••••••••••••••••••••••••••24

Wiring the Control Circuit •••••••••••••••••••••••••••••••••••••••••••••••25

Wiring Inspection••••••••••••••••••••••••••••••••••••••••••••••••••••••••••26

5. OPERATING THE INVERTER ••••••••••••••••••••••••••••27

Test Run ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••27

Operating the Digital Operator ••••••••••••••••••••••••••••••••••••••••29

LED Description•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••31

Simple Data Setting ••••••••••••••••••••••••••••••••••••••••••••••••••••••35

6. PROGRAMMING FEATURES•••••••••••••••••••••••••••••36

Constant Set-up and Initialization ••••••••••••••••••••••••••••••••••••36

Selecting V/f pattern •••••••••••••••••••••••••••••••••••••••••••••••••••••37

Switching LOCAL/REMOTE Modes••••••••••••••••••••••••••••••••••40

Selecting Run/Stop Commands••••••••••••••••••••••••••••••••••••••••41

Selecting Frequency Reference•••••••••••••••••••••••••••••••••••••••42

Setting Operation Conditions ••••••••••••••••••••••••••••••••••••••••••43

Reverse run prohibit •••••••••••••••••••••••••••••••••••••••••••••••••••••43

Multi-step speed selection••••••••••••••••••••••••••••••••••••••••••••••43

Operating at low speed••••••••••••••••••••••••••••••••••••••••••••••••••44

Adjusting speed setting signal•••••••••••••••••••••••••••••••••••••••••45

Adjusting frequency upper and lower limits ••••••••••••••••••••••••47

Using two accel/decel times •••••••••••••••••••••••••••••••••••••••••••47

12

Page 13

Automatic restart after momentary power loss ••••••••••••••••••••48

Soft-start characteristics ••••••••••••••••••••••••••••••••••••••••••••••••49

Torque detection ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••50

Frequency detection •••••••••••••••••••••••••••••••••••••••••••••••••••••52

Jump frequencies•••••••••••••••••••••••••••••••••••••••••••••••••••••••••53

Continuing operation by automatic fault reset •••••••••••••••••••••53

Operating coasting motor without trip •••••••••••••••••••••••••••••••54

Holding accel/decel temporarily•••••••••••••••••••••••••••••••••••••••55

Using frequency meter or ammeter ••••••••••••••••••••••••••••••••••56

Calibrating frequency meter or ammeter •••••••••••••••••••••••••••56

Reducing motor noise or leakage current ••••••••••••••••••••••••••57

Operator stop key selection ••••••••••••••••••••••••••••••••••••••••••••59

Selecting Stopping Method•••••••••••••••••••••••••••••••••••••••••••••60

Selecting stopping method •••••••••••••••••••••••••••••••••••••••••••••60

Applying DC injection braking •••••••••••••••••••••••••••••••••••••••••61

Building Interface Circuits with External Devices •••••••••••••••••62

Using input signals •••••••••••••••••••••••••••••••••••••••••••••••••••••••62

Using output signals •••••••••••••••••••••••••••••••••••••••••••••••••••••65

Setting Frequency by Current Reference Input •••••••••••••••••••67

Preventing motor from stalling (Current limit)••••••••••••••••••••••69

Decreasing Motor Speed Fluctuation••••••••••••••••••••••••••••••••71

Slip compensation ••••••••••••••••••••••••••••••••••••••••••••••••••••••••71

Motor Protection ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••72

Motor overload detection •••••••••••••••••••••••••••••••••••••••••••••••72

Selecting Cooling Fan Operation ••••••••••••••••••••••••••••••••••••73

Using MEMOBUS (MODBUS) Communications (Optional)

••••••••74

MEMOBUS (MODBUS) communications ••••••••••••••••••••••••••74

Communication specifications•••••••••••••••••••••••••••••••••••••••••74

Using Constant Copy Function••••••••••••••••••••••••••••••••••••••••75

Constant Copy function •••••••••••••••••••••••••••••••••••••••••••••••••75

READ function•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••77

COPY function•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••78

VERIFY function ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••80

Inverter capacity display ••••••••••••••••••••••••••••••••••••••••••••••••81

Software No. display •••••••••••••••••••••••••••••••••••••••••••••••••••••82

13

Page 14

7. MAINTENANCE AND INSPECTION ••••••••••••••••••84

Periodical Inspection ••••••••••••••••••••••••••••••••••••••••••••••••••••84

Part Replacement ••••••••••••••••••••••••••••••••••••••••••••••••••••••••84

8. FAULT DIAGNOSIS •••••••••••••••••••••••••••••••••••••••••••••87

Protective and Diagnostic Function ••••••••••••••••••••••••••••••••••87

Troubleshooting •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••95

9. SPECIFICATIONS •••••••••••••••••••••••••••••••••••••••••••••••••98

Standard Specifications (200V Class)•••••••••••••••••••••••••••••••98

Standard Specifications (400V Class) •••••••••••••••••••••••••••••101

Standard Wiring •••••••••••••••••••••••••••••••••••••••••••••••••••••••••104

Sequence Input Connection with NPN/PNP Transistor •••••••106

Dimensions/Heat Loss•••••••••••••••••••••••••••••••••••••••••••••••••109

Recommended Peripheral Devices ••••••••••••••••••••••••••••••••111

Constants List••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••113

14

Page 15

1. RECEIVING

C I M R — J 7 A C 2 0 P 1

Inverter

VS mini J7 Series

MODEL

No.

A

B

C

Type

Digital operator provided (with potentiometer)

Digital operator not provided

Digital operator provided (without potentiometer)

0P1

0P2

0P4

0P7

1P5

2P2

3P0

4P0

Applicable maximum motor output

No.

No.

B

2

4

Voltage Class

Single-phase 200VAC

Three-phase 200VAC

Three-phase 400VAC

No.CSpecifications

European standards

Note: Contact your YASKAWA representatives

for the type without heatsink.

2 0 P 1 0

SPEC

B

2

4

Single-phase 200VAC

Three-phase 200VAC

Three-phase 400VAC

No. Protective structure

Open chassis

(IP20)

0

INVERTER MODEL

MASS

INPUT SPEC.

OUTPUT SPEC.

LOT NO.

SERIAL NO.

SOFTWARE NO.

0.1kW

0.25kW

0.55kW

1.1kW

1.5kW

2.2kW

–

4.0kW

200V class

–

0.37kW

0.55kW

1.1kW

1.5kW

2.2kW

3.0kW

4.0kW

400V class

0P1

0P2

0P4

0P7

1P5

2P2

3P0

4P0

Applicable maximum motor output

No.

0.1kW

0.25kW

0.55kW

1.1kW

1.5kW

2.2kW

–

4.0kW

200V class

–

0.37kW

0.55kW

1.1kW

1.5kW

2.2kW

3.0kW

4.0kW

400V class

After unpacking the VS mini, check the following :

▫ Verify that the part numbers match your purchase order or packing slip.

▫ Check the unit for physical damage that may have occurred during

If any part of VS mini is missing or damaged, call for service immediately.

Checking the Name Plate

shipping.

Example of 3-phase, 200VAC, 0.1kW (0.13HP)

15

Page 16

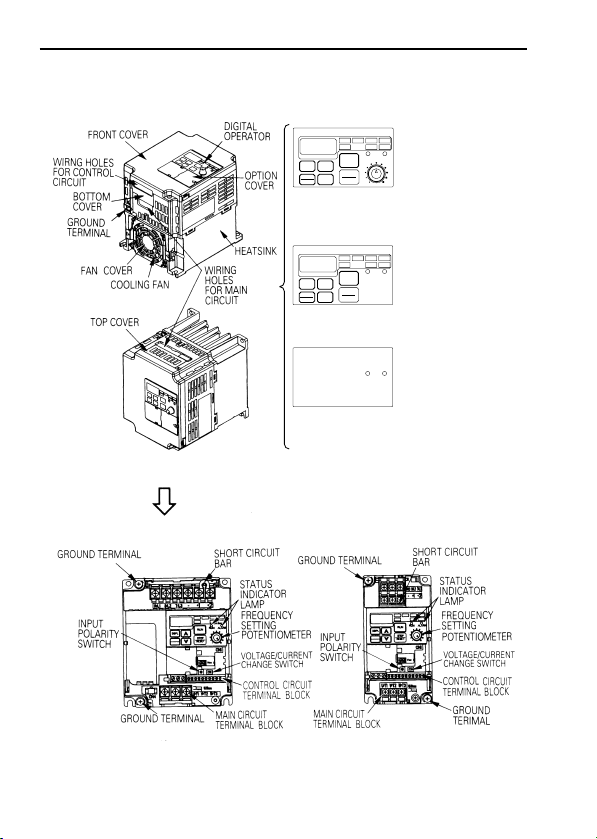

2. IDENTIFYING THE PARTS

FREF

DSPL

RUN

RUN

MIN MAX

DATA

ENTER

<>

FOUT IOUT MNTR

F/R LO/RE PRGM

STOP

RESET

ALARM

FREF

DSPL

RUN

RUN

DATA

ENTER

<>

FOUT IOUT MNTR

F/R LO/RE PRGM

STOP

RESET

ALARM

RUN ALARM

Digital operator (with potentiometer)

Used for setting or changing constants.

Frequency can be set using potentiometer.

Digital operator (without potentiometer)

Used for setting or changing constants.

Without digital operator

In models without digital operator,

only status can be displayed.

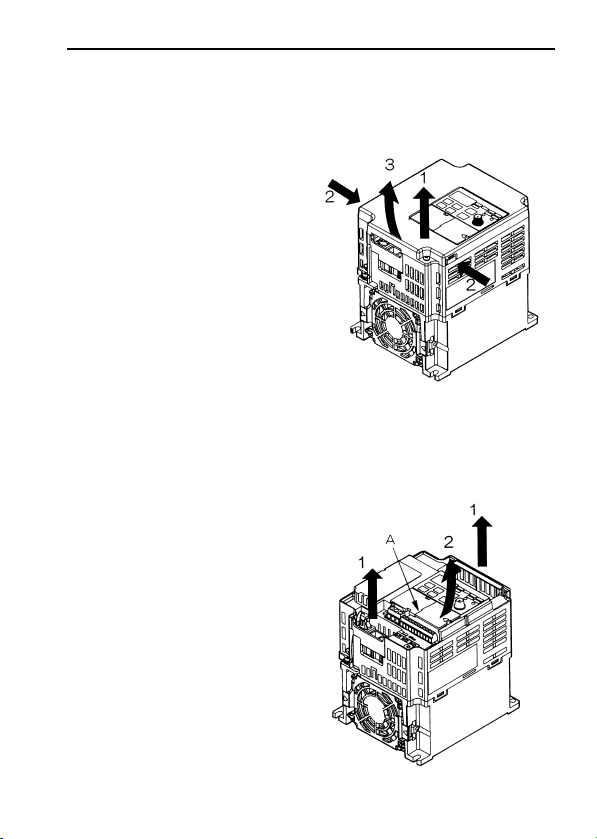

Opening the covers

CIMR-J7**21P5, 22P2, 24P0

B0P7, B1P5

40P2, 40P4, 40P7, 41P5

42P2, 43P0, 44P0

16

CIMR-J7

20P1, 20P2, 20P4, 20P7,

**

B0P1, B0P2, B0P4

Page 17

3. MOUNTING

Choosing a Location to Mount the Inverter

Be sure the inverter is protected from the following conditions :

▫ Extreme cold and heat. Use only within the ambient temperature range :

-10 to +50ºC (14 to 122ºF)

▫ Rain, moisture

▫ Oil sprays, splashes

▫ Salt spray

▫ Direct sunlight. (Avoid using outdoors)

▫ Corrosive gases (e.g. sulfurized gas) or liquids

▫ Dust or metallic particles in the air.

▫ Physical shock, vibration.

▫ Magnetic noise. (Example : welding machines, power devices, etc.)

▫ High humidity.

▫ Radioactive substances.

▫ Combustibles : thinner, solvents, etc.

17

Page 18

30mm

(1.18 in.)

OR MORE

30mm

(1.18 in.)

OR MORE

100mm (3.94 in.)

OR MORE

100mm (3.94 in.)

OR MORE

Mounting Dimensions

To mount the VS mini, dimensions as shown below are required.

18

Page 19

Mounting / Removing Components

Removing and Mounting Digital Operator and Covers

• Removing front cover

Use a driver to loosen the screw

on the front cover surface to

direction 1 to remove it. Then

press the right and left sides to

direction 2 and lift the front cover

to direction 3.

• Mounting front cover

Insert the tab of the upper part of

the front cover into the groove of

the inverter, and press the lower

part of the front cover onto the

plastic case until the cover snaps

shut. Then, tighten the screws.

• Removing option cover

After removing front cover,

remove the option cover to

direction 2 with section A as a

supporting point.

• Mounting option cover

Mount the terminal cover in the

descending order of the above

procedure for removal.

• Removing upper/bottom covers

After removing front cover, lift

the covers to direction 1.

• Mounting upper/bottom covers

Mount the front cover in the

descending order of the above

procedure for removal.

19

Page 20

4. WIRING

200V 3-phase Input

Power Supply

Specification Product

CIMR-J7??2???

Connect to R/L1,

S/L2, T/L3

Connect to R/L1, S/L2

200V Single Input Power Supply Specification

Product

CIMR-J7??B???

Connect to R/L1, S/L2, T/L3

400V 3-phase Input

Power Supply Specification

Product

CIMR-J7??4???

Wiring Instructions

(1) Always connect the power input terminals R/L1, S/L2, and T/L3 (R/L1,

S/L2 for single-phase) and power supply via a molded-case circuit

braker (MCCB) or a fuse. Never connect them to terminals

U/T1,V/T2,W/T3, –, +1 or +2.

Refer to page 108 for recommended peripheral devices. For singlephase inverters, always use terminals R/L1 and S/L2. Never connect to

terminal T/L3.

(2) Connect the motor wiring to terminals U/T1, V/T2 and W/T3 on the

main circuit output side (bottom of the inverter).

(3) If the wiring distance between inverter and motor is long, reduce the

inverter carrier frequency. For details, refer to “Reducing motor noise

or leakage current (n46)” on page 57.

(4) Control wiring must be less than 50m (164ft) in length and separate from

the power wiring. Use twisted-pair shielded wire when inputting the

frequency signal externally.

(5) Tighten the screws on the main circuit and control circuit terminals.

(6) Do not connect or disconnect wiring, or perform signal check while the

power supply is turned ON.

(7) For 400V class inverters, make sure to ground the supply neutral to con-

form to CE requirements.

(8) Only basic insulation to meet the requirements of protection class 1 and

overvoltage category II is provided with control circuit terminals.

Additional insulation may be necessary in the end product to conform to

CE requirements.

(9) A closed-loop connector should be used when wiring to the main circuit

terminal.

(10) Voltage drop should be considered when determining wire size.

Voltage drop can be calculated using the following equation:

Select a wire size so that voltage drop will be less than 2% of the normal

rated voltage.

20

Inverter Power Supply Connection Terminals

Phase-to phase voltage drop (V)

= √3 × wire resistance (Ω/km) × wiring distance (m) × current (A) × 10

-3

Page 21

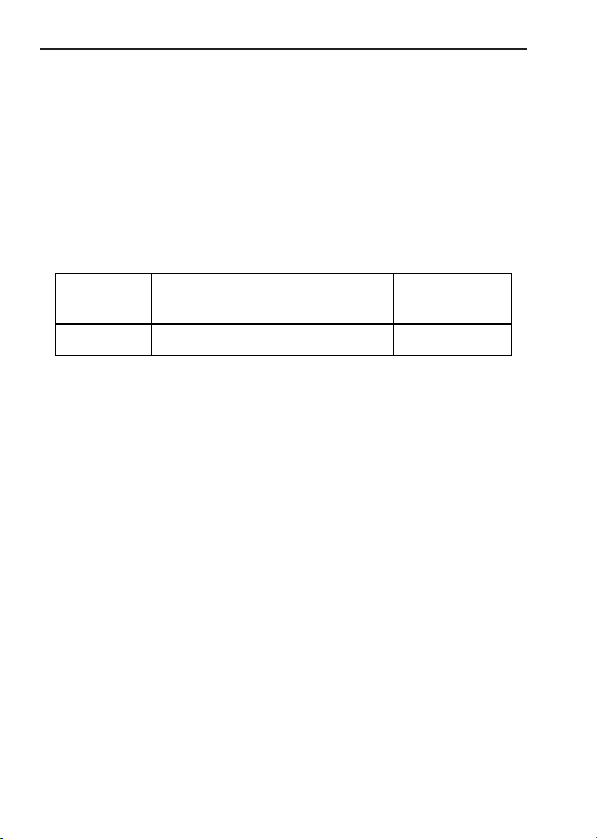

Wire and Terminal Screw Sizes

Applicable size

Recommended size

Model

Terminal

Symbol

Screw

2. Main Circuit

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

0.8 to 1.0

(7.1 to 8.88)

0.8 to 1.0

(7.1 to 8.88)

0.8 to 1.0

(7.1 to 8.88)

0.8 to 1.0

(7.1 to 8.88)

1.2 to 1.5

(10.7 to 13.3)

0.75 to 2

0.75 to 2

0.75 to 2

0.75 to 2

2 to 5.5

18 to 14

18 to 14

18 to 14

18 to 14

14 to 10

2

2

2

2

14

14

14

14

600V

vinyl-

sheathed

wire or

equivalent

200V Class 3-phase Input Series

Note : The wire size is set for copper wires at 75°C (160°F).

Tightening

Torque

N

•

m (Ib

•

in

)

mm

2

Wire

AWG

mm

2

AWG

Type

5.5

10

CIMRJ7AC

20P1

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

20P2

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

20P4

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

20P7

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

24P0

M3.5

M3.5

M3.5

M3.5

M4

0.8 to 1.0

(7.1 to 8.88)

2 to 5.5 14 to 10

3.5

14

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

22P2

M3.5

0.8 to 1.0

(7.1 to 8.88)

2 to 5.5 14 to 10

2

14

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

21P5

M3.5

Model

Common to

all models

Terminal Symbol

MA, MB, MC

S1 to S5,SC,FS,

FR,FC,AM,AC

Screw

twisted wire

single

mm

2

mm

2

Wire

Recommended size

Applicable size

AWGAWG

0.5 to 1.25

0.5 to 1.25

twisted wire

single

0.5 to 0.75

0.5 to 1.25

20 to 16

20 to 16

20 to 18

20 to 16

Shielded

wire or

equivalent

1. Control Circuit

Tighte Torque

N • m (Ib • in)

M3

M2

Type

0.5 to 0.6

(4.44 to 5.33)

0.22 to 0.25

(1.94 to 2.21)

0.75

0.75

18

18

21

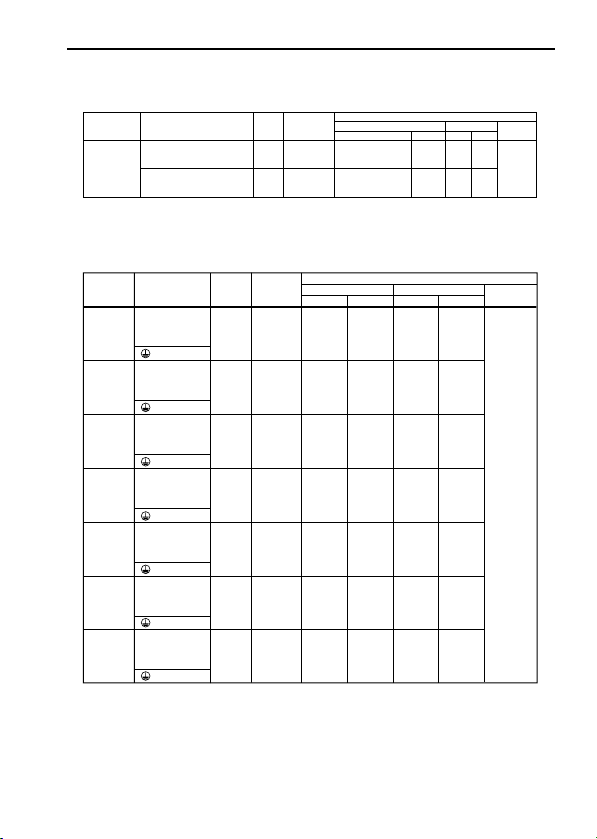

Page 22

Applicable size

Recommended size

Model

Terminal

Symbol

Screw

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

0.8 to 1.0

(7.1 to 8.88)

0.8 to 1.0

(7.1 to 8.88)

0.8 to 1.0

(7.1 to 8.88)

0.8 to 1.0

(7.1 to 8.88)

0.75 to 2

0.75 to 2

0.75 to 2

2 to 5.5

18 to 14

18 to 14

18 to 14

14 to 10

2

2

2

14

14

14

600V

vinyl-

sheathed

wire or

equivalent

200V Class Single-phase Input Series

Tightening

Torque

N

•

m (lb

•

in

)

mm

2

Wire

AWG

mm

2

AWG

Type

CIMRJ7AC

B0P1

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

B0P2

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

B0P4

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

B0P7

M3.5

M3.5

M3.5

M3.5

0.8 to 1.0

(7.1 to 8.88)

2 to 5.5 14 to 10

5.5

10

2

14

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

B1P5

M3.5

3.5

12

2

14

Notes : 1. The wire size is set for copper wires at 75°C (160°F).

2. Three-phase input is also available for single-phase input series.

22

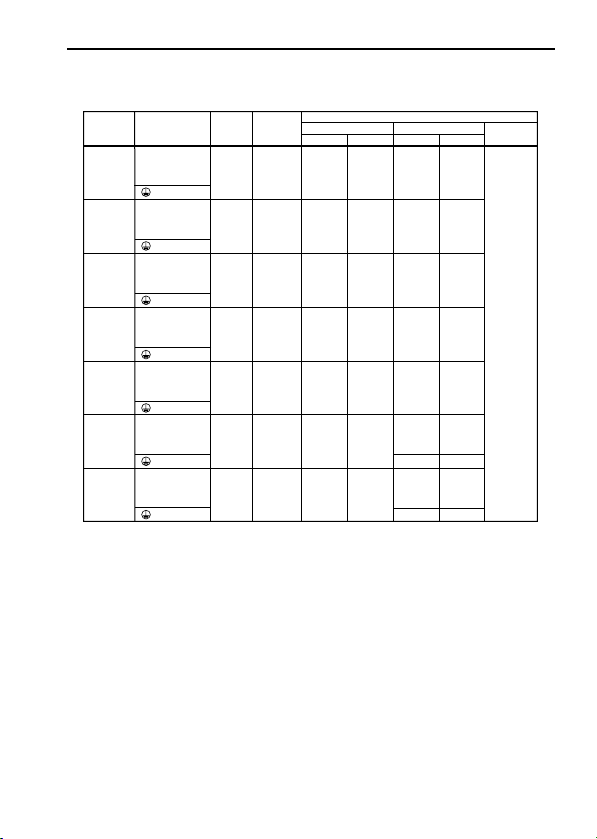

Page 23

Applicable size

Recommended size

Model

Terminal

Symbol

Screw

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

0.8 to 1.0

(7.1 to 8.88)

0.8 to 1.0

(7.1 to 8.88)

0.8 to 1.0

(7.1 to 8.88)

0.8 to 1.0

(7.1 to 8.88)

1.2 to 1.5

(10.65 to 13.31)

2 to 5.5

2 to 5.5

2 to 5.5

2 to 5.5

2 to 5.5

14 to 10

14 to 10

14 to 10

14 to 10

14 to 10

2

2

2

2

14

14

14

14

600V

vinyl-

sheathed

wire or

equivalent

400V Class 3-phase Input Series

Note : The wire size is set for copper wires at 75°C (160°F).

Tightening

Torque

N

•

m (Ib

•

in

)

mm

2

Wire

AWG

mm

2

AWG

Type

2

3.51412

CIMRJ7AC

40P2

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

40P4

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

40P7

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

41P5

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

44P0

M3.5

M3.5

M3.5

M3.5

M4

1.2 to 1.5

(10.65 to 13.31)

2 to 5.5 14 to 10

2

3.5

14

12

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

43P0

M4

1.2 to 1.5

(10.65 to 13.31)

2 to 5.5 14 to 10

214

R/L1,S/L2,T/L3,

–,+1,+2,

U/T1,V/T2,W/T3

CIMRJ7AC

42P2

M4

23

Page 24

L1L2L

3

Wiring the Main Circuit

NOTE

• Main circuit input power supply

Always connect the power supply

input terminals R/L1, S/L2,

R/L1, S/L2

[

Never connect them to terminal

U/T1,V/T2,W/T3, B1, B2, –, +1, or +2.

Otherwise the inverter may be damaged.

•

Make sure to ground the ground terminal

according to the local grounding code.

Never ground the VS mini in common

with welding machines, motors, or other

electrical equipment.

When several VS mini units are used

side by side, ground each unit as shown

in examples. Do not loop the ground

wires.

for single-phase inverters].

For single-phase inverters, always

use terminals R/L1 and S/L2. Never

connect to terminal T/L3.

Grounding (Use ground terminal .)

line to

and T/L3

[Example of 3-phase,

200V class, 1.5kW

inverters]

•

Braking resistor connection (optional)

To connect the braking resistor, cut the

protector on terminals B1 and B2.

To protect the braking resistor from

overheating, install a thermal overload

relay between the braking resistor and

the inverter. This provides a sequence

which shuts off the power supply, by a

thermal relay trip contact.

Use this same procedure when

connecting a braking resistor unit.

• Inverter output

Connect the motor terminals to U/T1,

V/T2, W/T3.

Wiring the main circuit terminals

Pass the cables through wiring hole and

connect. Be sure to mount the cover in

its original position.

GOOD GOOD POOR

24

Connect with a Phillips (plus) screwdriver.

Page 25

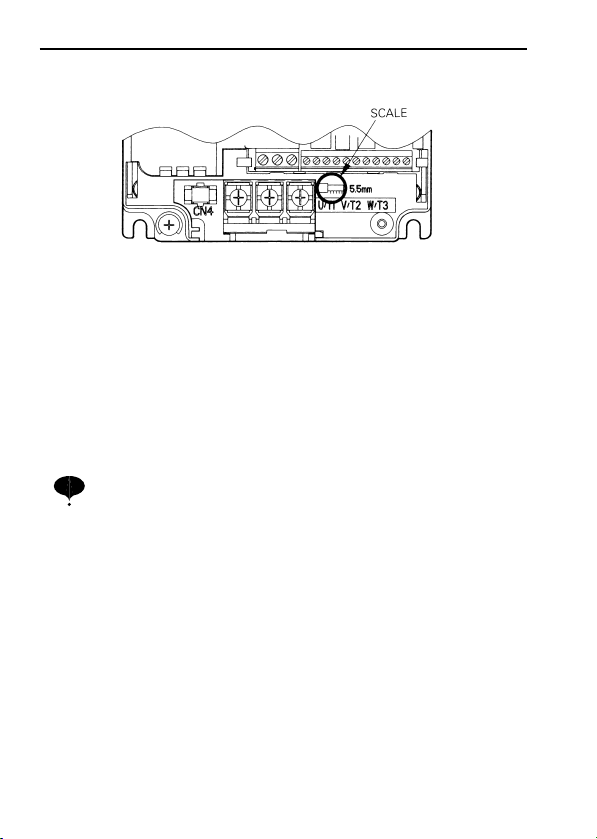

Wiring the Control Circuit

MC

SW7

SW8

S1 S2 S3 S4 S5 SC

NPN

FS FR FC AM AC

MA MB

PNP

5.5 mm

(0.22 in.)

0.4 mm max

(0.016 in.)

2.5 mm max

(0.098 in.)

Only basic insulation is provided for the control circuit terminals.

Additional insulation may be necessary in the end product.

• Control circuit terminals

Pass the cable through wiring hole and connect. Be sure to mount the

covers on its original position.

* SW7 can be changed according to sequence input signal (S1 to

S5) polarity.

0V common: NPN side (factory setting)

+24 common: PNP side

Refer to page 103 for SW7.

Refer to page 67 for SW8.

Wiring the control circuit terminals

Screwdriver blade width

Insert the wire into the lower part of the terminal block and connect it tightly

with a screwdriver.

Wire sheath strip length must be 5.5mm (0.22in.).

25

Page 26

NOTE

Open the front cover and verify that the strip length is 5.5mm. (0.22in.)

Wiring Inspection

After completing wiring, check the following :

▫ Wiring is proper.

▫ Wire clippings or screws are not left in the unit.

▫ Screws are securely tightened.

▫ Bare wire in the terminal does not contact other terminals.

If the FWD (REV) run command is given during the operation reference

selection (n02=1) from the control circuit terminal, the motor will start

automatically after the main circuit input power supply is turned ON.

26

Page 27

5. OPERATING THE INVERTER

Name

Run

Command

Selection

Frequency

Reference

Selection

Constant

n02 = 0 --- Enables operator RUN, STOP/RESET

= 1 --- Enables control circuit terminal run/stop

= 2 --- Enables communications (MEMOBUS communications)

n03 = 0 --- Enables operator volume

= 1 --- Enables frequency reference 1 (constant n21)

= 2 --- Enables voltage reference (0 to 10V) of control circuit

terminal

= 3 --- Enables current reference (4 to 20mA) of control circuit

terminal

= 4 --- Enables current reference (0 to 20mA) of control circuit

terminal

= 6 --- Enables communications (MEMOBUS communications)

Test Run

The inverter operates by setting the frequency (speed).

There are three types of operation modes for the VS mini :

1 Run command from the digital operator (potentiometer/digital setting).

2 Run command from the control circuit terminal.

3 Run command from communications (MEMOBUS communications)

Prior to shipping, the drive is set up to receive run command and frequency

reference from the operator. Below are instructions for running the VS mini

using the digital operator (with potentiometer). For instructions on

operation, refer to page 35.

Operation reference or frequency reference constants can be selected

separately as shown below.

27

Page 28

Operation Steps

Operator

Display

12-LED

Display

Status

Indicator

LED

RUN ALARM

RUN ALARM

RUN ALARM

Status indicator lamp

: ON

: Blinking : OFF

1. Turn the potentiometer fully to the left before

turning the power ON.

2. F/R blinks.

Select FWD/REV run using keys.

Never select REV when reverse run is

prohibited.

3. Press DSPL to blink FREF. Then press RUN.

4.

Operates the motor by turning the

potentiometer to the right. (Frequency

reference corresponds to the potentiometer

0.0

(Forward)

or

(Reverse)

0.0 to 60.0

Minimum

output

frequency is

1.5Hz

FREF

NOTE

0.0

RUN ALARM

F/R

FREF

FREF

NOTE

If the potentiometer is switched rapidly,

the motor also accelerates or decelerate

rapidly corresponding to the potentiometer

movement. Pay attention to load status

and switch the potentiometer with the

speed not to affect motor movement.

Operation Check Points

▫ Motor rotates smoothly.

▫ Motor rotates in the correct direction.

▫ Motor does not have abnormal vibration or noise.

▫ Acceleration or deceleration is smooth.

▫ Current matching the load flows.

▫ Status indicator LEDs and digital operator display are correct.

28

Page 29

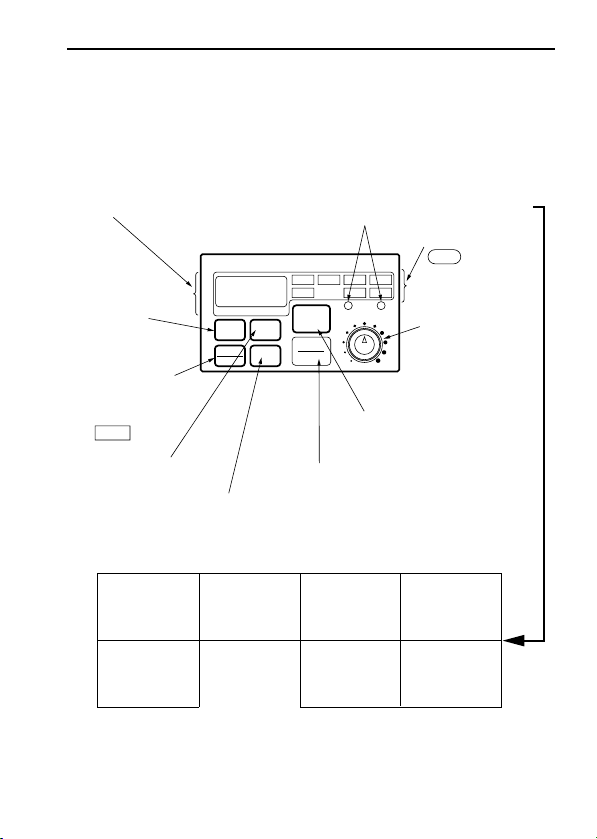

Operating the Digital Operator

Press to switch

between

function LEDs.

Press to increase

constant no./data

value.

Press to decrease

constant no./data

value.

Function display LEDs (Color in parenthesis indicates the color of LED.

)

Press to stop the motor.

(Press to reset at faults.)

Press to run

the motor.

Frequency setting

potentiometer

Changes frequency

setting according to

potentiometer.

Data display section Status indicator

FREF

Frequency reference

setting/monitoring

(GREEN)

FOUT

Output frequency

monitor

(GREEN)

IOUT

Output current

monitor

(GREEN)

F/R

Operator RUN

command FWD/REV

selection

(GREEN)

PRGM

Constant no./data

(RED)

MNTR

Multi-function

monitor

(GREEN)

LO/RE

LOCAL/REMOTE

Selection

(RED)

Function display LEDs

LED switches to another

function each time

DSPL is pressed.

The displayed data can

be changed.

Press to enter the

constant data.

(Displays the constant

data when

selecting constant no.

by PRGM LED.)

FREF

NPJT31250-1

DSPL

RUN

RUN

MIN MAX

DATA

ENTER

<>

FOUT IOUT MNTR

F/R LO/RE PRGM

STOP

RESET

ALARM

All functions of the VS mini are set by the digital operator. Below are

descriptions of the display and keypad sections.

DIGITAL OPERATOR

29

Page 30

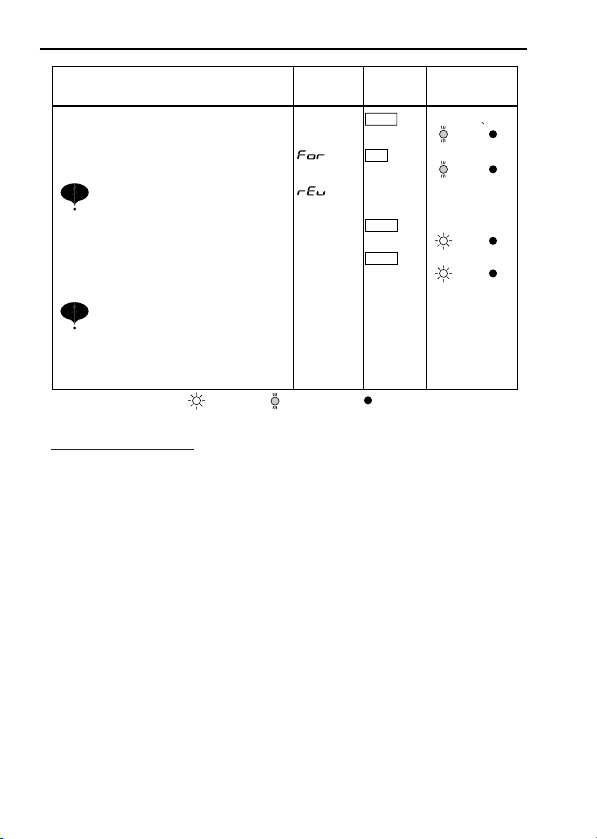

Description of Status Indicator LEDs

STOP

RESET

There are two LEDs on the middle right section of the face of the VS mini.

The inverter status is indicated by various combinations of ON, BLINKING

and OFF LEDs. RUN indicator and status indicator on the button

RUN

have the same function.

: ON

RUN ALARM

(Green)

(Red)

Operation Ready

(During Stop)

RUN ALARM

Ramp to Stop

RUN ALARM RUN ALARM

: BLINKING : OFF: BLINKING (Long Blinking)

Normal Operation

For details on how the status indicator LEDs function at inverter faults, refer

to Section 8 “FAULT DIAGNOSIS AND CORRECTIVE ACTIONS” on

page 87. If a fault occurs, the ALARM LED lights.

The fault can be reset by turning ON the fault reset signal (or pressing

NOTE

key on the digital operator) with the operation signal OFF or

by turning OFF the power supply. If the operation signal is ON, the

fault cannot be reset by the fault reset signal.

30

Page 31

LED Description

Power ON

FREF

FOUT

IOUT

MNTR

F/R

DSPL

DSPL

DSPL

DSPL

DSPL

Frequency reference setting/monitor (Hz)

Sets VS mini operation speed.

Output frequency monitor (Hz)

Displays frequency that VS mini is currently

outputting.

Setting disabled.

Output current monitor (A)

Displays current that VS mini is currently

outputting.

Setting disabled.

Multi-function monitor

Description of the selected monitor is

displayed.

(Refer to pages 32 and 33 for details.)

FWD/REV run selection

Sets the motor rotation direction when

run command is given by the digital operator.

Setting can be changed by or key.

FO (forward run) EV (reverse run)

<

<

By pressing on the digital operator, each of the function LEDs can be

selected.

The following flowchart describes each function LED.

DSPL

If the VS mini loses

power while in one

of these modes, it

will return to this

mode once power is

restored.

Monitor No.

U01: Frequency reference (FREF)

U02: Output frequency (FOUT)

U03: Output current (IOUT)

U04: Output voltage reference (Unit: 1V)

U05: DC voltage (Unit: 1V)

U06: Input terminal status

U07: Output terminal status

U09: Fault history

U10: Software No.

U15: Data reception error

31

Page 32

LO/RE

PRGM

DSPL

DSPL

LOCAL / REMOTE Selection

Constant No. / data

Sets and changes data using

constant No. (Refer to page 34.)

FREF

Return to

This function switches the operation; operation

using the digital operator including frequency

setting with potentiometer, or that using the input

terminals or through communications

Setting can be changed by or key.

(Local) (Remote)

<

<

Multi-Function monitor

Press key. When is ON, data

can be displayed by selecting monitor No.

[Example] Monitoring Output Voltage Reference

DSPL MNTR

MNTR

U04

ENTER

MNTR

DSPL

ENTER

or

Select U04 by

pressing

or key.

^

^

Output voltage reference

is displayed.

MNTR

• Selecting monitor

DSPL

IOUT

DSPL

F/R

200

32

Page 33

Constant

No.

Name Description

U01

U02

U03

U04

U05

U06

U07

U09

U10

Frequency reference

(FREF)

Output frequency

(FOUT)

Output current

(IOUT)

Output voltage

DC voltage

Input terminal status

Output terminal status

Fault history

Software No.

Frequency reference can be monitored.

(Same as FREF)

Output frequency can be monitored.

(Same as FOUT)

Output current can be monitored.

(Same as IOUT)

Output voltage can be monitored.

Main circuit DC voltage can be monitored.

Input terminal status of control circuit terminals

can be monitored.

Output terminal status of control circuit

terminals can be monitored.

Last four fault history is displayed.

Software No. can be checked.

Hz

Hz

A

V

V

---

---

---

---

U15 Data reception error

Contents of MEMOBUS communication data

reception error can be checked.

(contents of transmission register No. 003DH

are the same)

---

• Monitoring

1: Terminal S1 is “closed.”

Input terminal status

1: Terminal S2 is “closed.”

1: Terminal S3 is “closed.”

1: Terminal S4 is “closed.”

1: Terminal S5 is “closed.”

1: Terminal MA-MC is “closed.”

Output terminal status

Not used

Not used

Following items can be monitored by U- constants.

Input/Output terminal status

33

Page 34

34

Setting and referring constants

Following shows how to select and change constants.

LO/RE

PRGM

DSPL

DSPL

PRGM

ENTER

PRGM PRGM

ENTER

PRGM

PRGM

FREF

REMOTE/LOCAL

selection

Constant

No./

data

n02

Run command

selection

After

1 sec

Initial setting:0

operator reference

Set to 1

Control circuit

terminal reference

(blinking at changing)

• Setting n02 (Run command selection)

Data setReturn to

constant No.

display

600

N01

LO

N02 0

N02

1

1

Clearing fault history

Set constant n01 to 6 to clear fault history. Set data returns to its

initial value after completion of 6 setting.

Note: Constant initialize (n01=12, 13) clears the fault history.

Fault history display method

Fault description is displayed when U09 is selected.

(Example)

??? : Fault description

"---" is displayed if there is no fault.

(Refer to page 87 for details.)

Page 35

NOTE

Simple Data Setting

Operation Steps

1. Turn ON the power supply.

7. Press to stop.

STOP

Operator

Display

LED

Display

Status Indicator

LED

2. Set constant n03 to 1.

3. Set the following constants.

4. Select forward or reverse run by

pressing q or w key.

5.

Set the reference by pressing q or w

key.

6. Press .

15.0

5.0

0.0

1

60.0

0.0 to 60.0

FREF

PRGM

FOUT

PRGM

n16 : 15.0 (acceleration time)

n17 : 5.0 (deceleration time)

Examine the application.

(Never select REV when

reverse run is prohibited.)

RUN

FOUT

FREF

F/R

60.0 to 0.0

(Forward)

(Reverse)

or

Status indicator lamp : BLINKING (Long Blinking) : BLINKING : OFF

RUN ALARM

RUN ALARM

RUN ALARM

RUN ALARM

RUN ALARM

RUN ALARM

RUN ALARM

Potentiometer setting (Refer to 5. OPERATING THE INVERTER) and

digital setting are both available for simple accel/decel operation of the VS

mini.

Frequency reference by potentiometer signal is set with initial setting

(n03=0).

Factory setting of the model with operator (without potentiometer) is set by

digital operator (n03=1).

Following is an example in which the function LEDs are used to set

frequency reference, acceleration time, deceleration time, and motor

direction.

35

Page 36

6. PROGRAMMING FEATURES

Factory settings of the constants are shown as in the tables.

Constant Set-up and Initialization

Constant selection/initialization (n01)

The following table describes the data which can be set or read when n01 is

set.

Unused constants among n01 to n79 are not displayed.

n01 Setting

0 n01

1

6

7

12

13

* Excluding setting disabled constants.

†

Refer to page 63.

NOTE

(1) The set values of input terminal function selection 2 to 5 (n36 to n39) are the same.

(2) If the following conditions are not satisfied in the V/f pattern setting :

(3) If the following conditions are not satisfied in the Jump frequency setting :

(4) If Frequency reference lower limit (n31) Frequency reference upper limit (n30)

(5) If motor rated current (n32) 150% of inverter rated current

Constant that can be set Constant that can be referred

n01 to n79*

Fault history cleared

Not used

Initialize

Initialize (3-wire sequence)

“EMM” appears on the LED display for one second and the set data returns to its initial

values in the following cases :

Max. output frequency (n09) Max. voltage output frequency (n11)

For details, refer to “Adjusting torque according to application” (V/f pattern setting) on page 37.

Jump frequency 2 (n50) Jump frequency 1 (n49)

> Mid. output frequency (n12)

Min. output frequency (n14)

n01 to n79

n01 to n79

†

36

Page 37

Selecting V/f pattern

Adjusting torque according to application

Adjust motor torque by using “V/f pattern” and “full-range automatic torque

boost”.

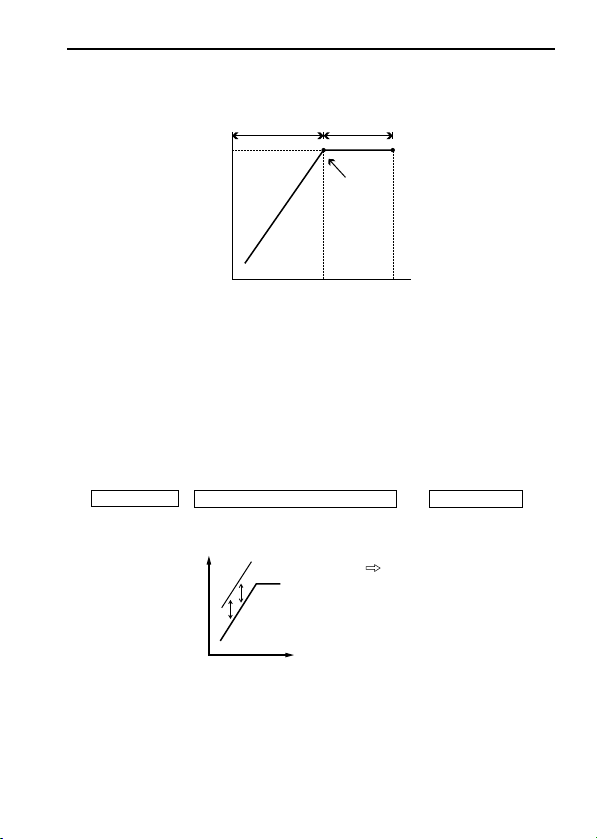

• V/f pattern setting

Set V/f pattern by n09 to n15 as described below. Set each pattern when

using a special motor (high-speed motor, etc.) or when requiring special

torque adjustment of machine.

V: (VOLTAGE)

n10

n13

n15

0

n14 n12 n11 n09

Constants

No.

n09

n10

n11

n12

n13

n14

n15

Be sure to satisfy the following

conditions for the setting of n09 to

n15.

n14 n12 < n11 n09

If n14 = n12 is set, the set value of n13

f

(FREQUENCY)

Name Unit Setting range

Max. output frequency

Max. voltage

Max. voltage output

frequency (base frequency)

Mid. output frequency

Mid. output

frequency voltage

Min. output frequency

Min. output

frequency voltage

is disabled.

0.1Hz

1V

0.1Hz

0.1Hz

1V

0.1Hz

1V

Initial

50.0 to 400.0Hz 50.0Hz

1 to 255V

(1 to 510V)

0.2 to 400.0Hz

1 to 399Hz

1 to 255V

(1 to 510V)

0.1 to 10.0Hz

1 to 50V

(1 to 100V)

Setting

200V

(400V)

50.0Hz

1.3Hz

12V

(24V)

1.3Hz

12V

(24V)

37

Page 38

• Typical setting of V/f pattern

Constant

n09

n10

n11

n12

n13

n14

n15

Setting

60.0

200

60.0

1.5

12

1.5

12

Constant Setting

50.0

200

50.0

1.3

12

1.3

12

n09

n10

n11

n12

n13

n14

n15

Constant Setting

60.0

200

60.0

30.0

50

1.5

10

n09

n10

n11

n12

n13

n14

n15

Constant Setting

50.0

200

50.0

25

50.0

1.3

10

n09

n10

n11

n12

n13

n14

n15

Constant Setting

60.0

200

60.0

3.0

24

1.5

18

n09

n10

n11

n12

n13

n14

n15

Constant Setting

50.0

200

50.0

2.5

24

1.3

18

n09

n10

n11

n12

n13

n14

n15

V

200

12

1.5 60 f

V

200

12

1.3 50 f

V

200

50

10

1.5 30 60 f

V

200

50

10

1.3 25 50 f

V

200

24

18

1.5 3 60 f

V

200

24

18

1.3 2.5 50 f

Set the V/f pattern according to the application as described below. For

400V class, the voltage values (n10, n13, and n15) should be doubled.

When running at a frequency exceeding 50Hz/60Hz, change the maximum

output frequency (n09).

Note: Be sure to set the maximum output frequency according to the motor characteristics.

(1) For general-purpose applications

Motor Specification : 60Hz

Motor Specification : 50Hz

(Factory setting)

(2) For fans/pumps

Motor Specification : 60Hz Motor Specification : 50Hz

(3) For applications requiring high starting torque

Motor Specification : 60Hz Motor Specification : 50Hz

Increasing voltage of V/f pattern increases motor torque, but an excessive

increase may cause motor overexcitation, motor overheat or vibration.

Note : n012 is to be set to motor rated voltage.

38

Page 39

Output voltage Torque compensation gain (n63)

Required torque

n11

=60Hz

n10

=200V

n09

=90Hz

BASE POINT

CONSTANT TORQUE

CONSTANT OUTPUT OR

VARIABLE OUTPUT

When operating with frequency larger than 60Hz/50Hz, change only max.

f (FREQUENCY)

Required torque Increase voltage

V

(VOLTAGE)

output frequency (n09).

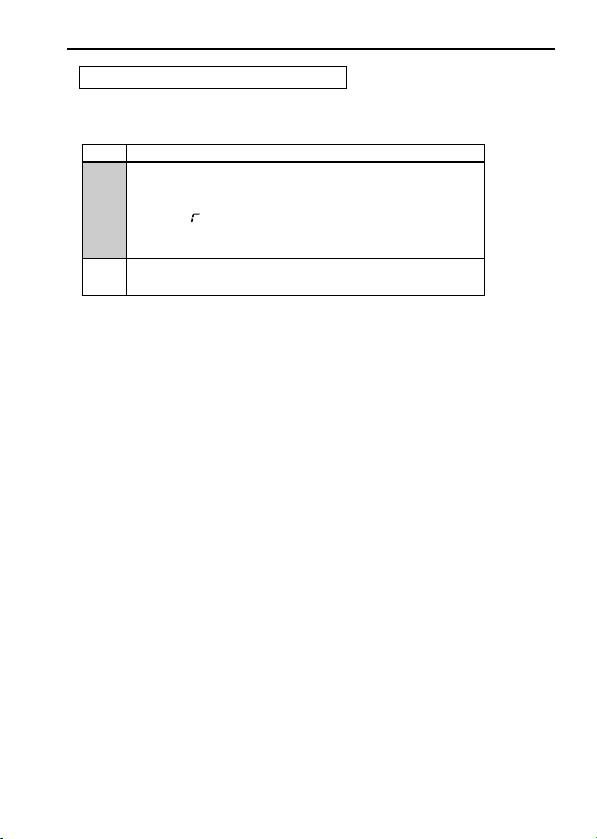

• Full-range automatic torque boost

Motor torque requirement changes according to load conditions. Fullrange automatic torque boost adjusts voltage of V/f pattern according to

the requirement. The VS mini automatically adjusts the voltage during

constant-speed operation as well as during acceleration.

The required torque is calculated by the inverter.

This ensures tripless operation and energy-saving effects.

Operation

Normally, no adjustment is necessary for torque compensation gain (n63

factory setting : 1.0). When the wiring distance between the inverter and the

motor is long, or when the motor generates vibration, change the automatic

torque compensation gain. In these cases, set the V/f pattern (n09 to n15).

39

Page 40

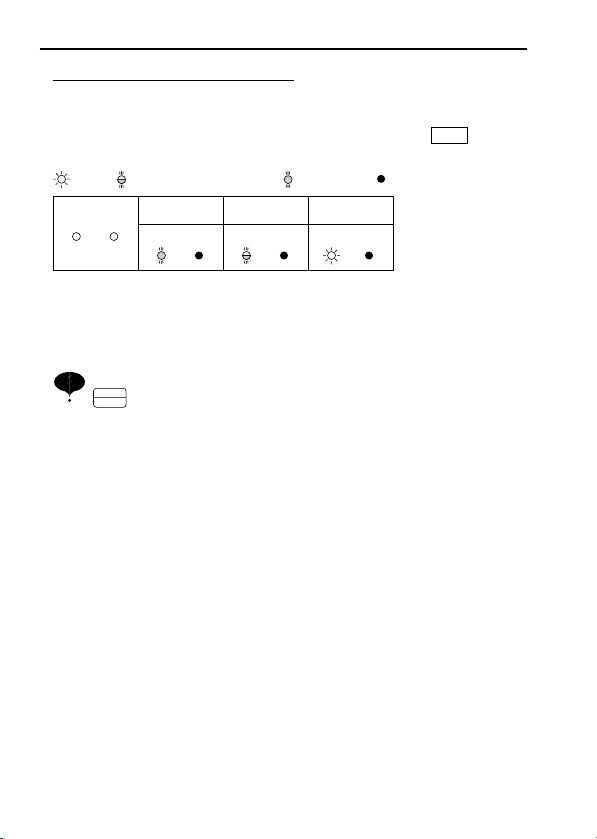

Switching LOCAL/REMOTE Modes

The following functions can be selected by switching the LOCAL or

REMOTE mode. To select RUN/STOP commands or frequency

reference, change the mode in advance depending on the following

applications.

• LOCAL mode : Enables the digital operator for RUN/STOP

•

REMOTE mode

How to select LOCAL/REMOTE modes

When LOCAL/REMOTE

switching function is not set

for multi-function input

selection

commands and FWD/REV run commands.

Frequency reference can be set by volume or .

: Run by the n02 setting (run command selection).

Frequency reference can be set by n03 (frequency

reference selection) setting.

When LOCAL/REMOTE

switching function is set at

multi-function input selection

(When 17 is not set

to any of constants

n36 to n39)

(When 17 is set to

any of constants

n36 to n39)

FREF

Select Lo for operator

selection.

LO/RE LO/RE

LOCAL mode REMOTE mode

40

Select rE for operator

selection.

Set multi-function

input terminal is turned

ON.

Set multi-function

input terminal is turned

OFF.

Page 41

Selecting Run/Stop Commands

IM

S1

S2

SC

FWD RUN/STOP

REV RUN/STOP

Refer to Switching LOCAL / REMOTE Modes (page 40) to select

either the LOCAL mode or REMOTE mode.

Operation method (RUN / STOP commands, FWD / REV run

commands) can be selected by the following method.

LOCAL mode

When Lo (local mode) is selected for digital operator ON mode,

or when LOCAL / REMOTE switching function is set and the input

terminals are turned ON, run operation is enabled by the or of

the digital operator, and FWD/REV run is enabled by ON mode

<

(using or key).

LO / RE

selected for multi-function input selection.

<

is not effective when local / remote switching function is

REMOTE mode

• Select remote mode.

There are following two methods to select remote mode.

1. Select rE (remote mode) for selection.

LO / RE

2. When the local / remote switching function is selected for multi-

function input selection, turn OFF the input terminal to select remote

mode.

• Select operation method by setting the constant n02.

n02=0: Enables the digital operator (same with local mode)

=1: Enables the multi-function input terminal (see fig. below)

=2: Enables communications (refer to page 74) (When option card

is installed)

• Example for using the multi-function input terminal as operation

reference (two-wire sequence)

LO / RE

STP

F / R

RUN

For example of three-wire sequence, refer to page 63.

n02 : 1 (Initial setting : 0)

n36 : 2

Operating (RUN / STOP commands) by communications

(When option card is installed)

Setting constant n02 to 2 in REMOTE mode can give RUN/STOP

commands by communication (MEMOBUS communications).

For details, refer to page 74.

41

Page 42

Selecting Frequency Reference

IM

FS

FREQUENCY

SETTING POWER

+12V, 20mA

FR

FC(0V)

2KΩ

MASTER SPEED

FREQUENCY

REFERENECE

(0 TO +10V)

Frequency reference can be selected by the following methods.

Setting by operator

Select REMOTE or LOCAL mode in advance. For the method for

selecting the mode, refer to page 40.

LOCAL mode

Select command method by constant n07.

n07=0 :

Enables the setting by potentiometer on digital operator (initial setting).

Factory setting of the model with digital operator (without

potentiometer) is n07=1.

=1 : Enables the digital setting by digital operator, setting value is

stored in constant n21 (frequency reference 1).

• Digital setting by digital operator

Input frequency while FREF is lit (press ENTER after setting the numeric

value).

Frequency reference setting is effective when 1 is set to constant n08

instead of pressing ENTER key.

n08=0 :

Enables frequency reference setting by ENTER key (initial setting).

=1 : Disable frequency reference setting by ENTER key.

REMOTE mode

Select command method by constant n03.

n03=0 :

Enables frequency reference setting by potentiometer on digital

operator (initial setting). Initial setting of the model with digital

operator (without potentiometer) is n03=1.

=1 : Frequency reference 1 effective. (constant n21)

=2 : Voltage reference (0 to 10V) (See the figure below)

=3 : Current reference (4 to 20mA) (Refer to page 67)

=4 : Current reference (0 to 20mA) (Refer to page 67)

=6 : communication (Refer to page 74)

Example of frequency reference by voltage signal

n03 = 2 (Factory setting : 0)

42

Page 43

Setting Operation Conditions

NOTE

FWD

RUN/STOP

REV RUN/STOP

MULTI-STEP

SPEED REF 1

MULTI-STEP

SPEED REF 2

MULTI-STEP

SPEED REF 3

S1

S2

S3

S4

S5

SC

Reverse run prohibit (n05)

“Reverse run disabled” setting does not accept a reverse run command from

the control circuit terminal or digital operator. This setting is used for

applications where a reverse run command can cause problems.

Setting

0

1

By combining frequency reference and input terminal function selections,

up to 16 steps of speed can be set.

8-step speed change

n02=1 (operation mode selection )

n03=1 (

n21=25.0Hz (

n22=30.0Hz (

n23=35.0Hz (

n24=40.0Hz (

n25=45.0Hz (

n26=50.0Hz (

n27=55.0Hz (

n28=60.0Hz (

Description

Reverse run enabled.

Reverse run disabled.

Multi-step speed selection

Frequency reference

Frequency reference 1)n38=7 (Multi-function contact input terminal 4)

Frequency reference 2)

Frequency reference 3

Frequency reference 4

Frequency reference 5

Frequency reference 6

Frequency reference 7

Frequency reference 8

When all multi-function

reference inputs are OFF,

frequency reference selected

by constant n03 (frequency

reference selection) becomes

effective.

selection )

n36=1

n37=6 (Multi-function contact input terminal 3)

n39=8 (Multi-function contact input terminal 5)

)

)

)

)

)

)

n36=2 (Input terminal S2) Initial Setting

n37=6 (Input terminal S3) Change the setting to 6.

n38=7 (Input terminal S4) Change the setting to 7.

n39=8 (Input terminal S5) Change the setting to 8.

43

Page 44

ON

ONON ON ON

ONON

ON

TIME

(n28) 60.0 Hz

(n27) 55.0 Hz

(n26) 50.0 Hz

(n25) 45.0 Hz

(n24) 40.0 Hz

(n23) 35.0 Hz

(n22) 30.0 Hz

(n21) 25.0 Hz

FREQUENCY

REFERENCE

FWD (REV) RUN/STOP

MULTI-STEP SPEED REF. 1

(TERMINAL S3)

MULTI-STEP SPEED REF. 2

(TERMINAL S4)

MULTI-STEP SPEED REF. 3

(TERMINAL S5)

Operating at low speed

By inputting a jog command and then a forward (reverse) run command,

operation is enabled at the jog frequency set in n29. When multi-step speed

references 1, 2, 3 or 4 are input simultaneously with the jog command, the

jog command has priority.

Name

Jog frequency

Jog command

44

Constant No.

n29

n36 to n39

Factory setting : 6.0Hz

Set to “10” for any constant.

Setting

Page 45

FREQURNCY REFERNCE

0V

(4mA)

(0mA)

10V

(20mA)

(20mA)

MAX. OUTPUT FREQUENCY

GAIN

100

MAX. OUTPUT FREQUENCY

BIAS

100

MAX. FREQUENCY (100%)

0%

0V 5V 10V

Adjusting speed setting signal

To provide frequency reference by analog input of control circuit terminal FR or

FC, the relationship between analog input and frequency reference can be set.

( ) indicates the value when current

reference input is selected.

• Frequency reference gain (n41)

The analog input voltage value for the max. output frequency (n09) can be

set in units of 1% (max. output frequency n09=100%)

Factory setting : 100%

*

• Frequency reference bias (n42)

The frequency reference provided when analog input is 0V (4mA or 0mA)

can be set in units of 1%. (max. output frequency n09=100%)

Factory setting : 0%

*

Typical Setting

• To operate the inverter with frequency reference of 50% to 100% at 0 to

5V input

Gain n41 = 200

Bia s n42 = 0

45

Page 46

• To operate the inverter with frequency reference of 50% to 100% at 0 to

MAX. FREQUENCY (100%)

50%

0V 10V

10V input

Gain n41 = 100

Bia s n42 = 50

46

Page 47

Adjusting frequency upper and lower limits

INTERNAL

FREQUENCY

REFERENCE

FREQUENCY

UPPER LIMIT

(n30)

SET FREQUENCY REFERENCE

FREQUENCY

LOWER LIMIT

(n31)

Using two accel/decel times

FORWARD (REVERSE)

RUN COMMAND

MULTI-STEP

SPEED REFERENCE

ACCEL/DECEL

TIME SELECTION

(TERMINAL S2 TO S5)

* When “deceleration to a stop” is selected (n04 = 0).

By setting input terminal function selection (either of n36 to n39) to “11

(accel/decel time select)”, accel/decel time is selected by turning ON/OFF the

accel/decel time select (terminal S2 to S5).

At OFF : n16 (accel time 1)

At ON : n18 (accel time 2)

OUTPUT

FREQUENCY

n17 (decel time 1)

n19 (decel time 2)

• Frequency reference upper limit (n30)

Sets the upper limit of the frequency reference

in units of 1%.

(n09: Max. output frequency = 100%)

Factory setting: 100%

• Frequency reference lower limit (n31)

Sets the lower limit of the frequency reference

in units of 1%.

(n09: Max. output frequency = 100%)

When operating at frequency reference 0,

operation is continued at the frequency

reference lower limit.

However, when frequency reference lower

limit is set to less than the min. output

frequency (n14), operation is not performed.

Factory setting: 0%

ACCEL

TIME 1

(n16)

DECEL

TIME 1

(n17)

ACCEL

TIME 2

(n18)

DECEL

TIME 2*

(n19)

DECEL

TIME 1*

(n17)

TIME

ON

ON

ON

47

Page 48

• Accel time

Set the time needed for output frequency to reach 100% from 0%.

• Decel time

Set the time needed for output frequency to reach 0% from 100%.

(Maximum output frequency n09=100%)

Automatic restart after momentary power loss (n47)

When momentary power loss occurs, operation restarts automatically.

Description

Setting

Setting

Continuous operation after momentary power loss

Continuous operation after momentary power loss

0

0

not provided.

not provided.

Continuous operation after power recovery within

Continuous operation after power recovery within

1*

momentary power loss ridethru time

Continuous operation after power recovery (Fault

Continuous operation after power recovery (Fault

2*†

2*†

output not provided)

output not provided)

* Hold the operation command to continue the operation after recovery from a momentary

power loss.

† When 2 is selected, operation restarts if power supply voltage reaches its normal level while

control power supply is held. No fault signal is output.

Description

48

Page 49

Soft-start characteristics (n20)

DC INJECTION BRAKING

TIME AT STOP

n53

MIN. OUTPUT FREQUENCY

MIN. OUTPUT

FREQUENCY n14

DECELERATION

DECELERATION

ACCELERATION

FORWARD RUN COMMAND

REVERSE RUN COMMAND

OUTPUT FREQUENCY

ACCELERATION

n14

S-curve characteristics in

FREQUENCY

REFERENCE

OUTPUT

FREQUENCY

S-CURVE CHARACTERISTIC TIME (Tsc)

OUTPUT

FREQUENCY

TIME

To prevent shock at machine start/stop, accel/decel can be performed in Scurve pattern.

Setting

0

1

2

3

Note : S-curve characteristic time is the time from accel/decel rate 0 to a regular accel/decel rate

determined by the set accel/decel time.

S-curve characteristic time

S-curve characteristic not provided

0.2 second

0.5 second

1.0 second

The following time chart shows FWD/REV run switching at deceleration to

a stop.

49

Page 50

Torque detection

If an excessive load is applied to the machine, output current increase can be

detected to output alarm signals to multi-function output terminals MA and

MB.

To output an overtorque detection signal, set output terminal function

selection n40 to “overtorque detection” [Setting:6 (NO contact) or 7 (NC

contact)].

MOTOR CURRENT

n60

MULTI-FUNCTION OUTPUT SIGNAL

(OVERTORQUE DETECTION SIGNAL)

TERMINAL MA, MB

Overtorque detection release width (hysterisis) is set at approx. 5% of inverter

*

rated current.

* *

TIME

ONON

n61n61

50

Page 51

• Overtorque detection function selection (n59)

Overtorque detection not provided

Detected during constant-speed running,

and operation continues after detection.

Setting

0

1

2

3

4

Description

Detected during constant-speed running,

and operation stops during detection.

Detected during running,

and operation continues after detection.

Detected during running,

and operation stops during detection.

(1) To detect overtorque at accel/decel, set to 3 or 4.

(2) To continue the operation after overtorque detection, set to 1 or 3.

During detection, the operator displays “OL3” alarm (blinking).

(3) To halt the inverter by a fault at overtorque detection, set to 2 or 4. At

detection, the operator displays “OL3” fault (ON).

• Overtorque detection level (n60)

Sets the overtorque detection current level in units of 1%. (Inverter rated

current = 100%)

Factory setting: 160%

• Overtorque detection time (n61)

If the time when motor current exceeds the overtorque detection level (n60)

is longer than overtorque detection time (n61), the overtorque detection

function operates.

Factory setting : 0.1sec.

51

Page 52

Frequency detection (n58)

Effective when either of output terminal function selection n40 is set to

“frequency detection” (setting: 4 or 5). “Frequency detection” turns ON

when output frequency is higher or lower than the frequency detection level

(n58).

Frequency detection 1

•

(Output frequency Frequency detection level n58)

(Set n40 to “4.”)

FREQUENCY DETECTION

LEVEL [Hz] (n58)

•

Frequency detection 2

OUTPUT

FREQUENCY

FREQUENCY

DETECTION

SIGNAL

ON

RELEASE

WIDTH

–2Hz

(Output frequency Frequency detection level n58)

(Set n40 to “5.”)

RELEASE

OUTPUT

FREQUENCY

FREQUENCY

DETECTION

SIGNAL

WIDTH

+2Hz

FREQUENCY

DETECTION

LEVEL (Hz)

(n58)

ONON

52

Page 53

Jump frequencies (n49 to n51)

OUTPUT FREQUENCY

FREQUENCY REFERENCE

n51

n49

n50

n51

This function allows the prohibition or “jumping” of critical frequencies so

that the motor can operate without resonance caused by machine systems.

This function is also used for dead band control. Setting the value to 0.00Hz

disables this function.

Set prohibited frequency 1 or 2 as follows :

n49 n50

If this condition is not satisfied

the inverter displays

one second and restores the

data to original settings.

EMM

Operation is prohibited within jump frequency range.

However, motor operates without jumping during accel/decel.

Continuing operation by automatic fault reset (n48)

Sets the inverter to restart and reset fault detection after a fault occurs.

The number of self-diagnosis and retry attempts can be set at n48 up to 10.

The inverter automatically restarts after the following faults occur :

OC (overcurrent)

GF (ground fault)

OV (overvoltage)

The number of retry attempts are cleared to 0 in the following cases :

(1) If no other fault occurs within 10 minutes after retry

(2) When the fault reset signal is ON after the fault is detected

(3) Power supply is turned OFF

for

53

Page 54

Operating coasting motor without trip

To operate coasting motor without trip, use the speed search command or

DC injection braking at start.

• Speed search command

Restarts a coasting motor without stopping it. This function enables

smooth switching between motor commercial power supply operation and

inverter operation.

Set input terminal function selection (n36 to n39) to “14” (search

command from maximum output frequency) or “15” (search command

from set frequency).

Build a sequence so that FWD (REV) run command is input at the same

time as the search command or after the search command. If the run

command is input before the search command, the search command

becomes disabled.

• Time chart at search command input

FWD (REV) RUN COMMAND

SEARCH COMMAND

MAX. OUTPUT FREQUENCY OR

FREQUENCY REFERENCE AT

RUN COMMAND INPUT

OUTPUT FREQUENCY

MIN. BASEBLOCK

TIME (0.5s)

ON

SPEED SEARCH OPERATION

ON

AGREED SPEED

DETECTION

• DC injection braking at start (n52, n54)

Restarts a coasting motor after stopping it. Set the DC injection braking

time at start in n54 in units of 0.1 second. Set DC injection braking current

in n52 in units of 1% (inverter rated current =100%). When the setting of

n54 is “0”, DC injection braking is not performed and acceleration starts

from the minimum output frequency.

When n52 is set to 0, acceleration starts from

the minimum output frequency after the

baseblocking for n54 setting time.

MIN. OUTPUT

FREQUENCY

n14

n54

DC INJECTION BRAKING

54

TIME AT START

Page 55

Holding accel/decel temporarily

To hold acceleration or deceleration, input accel/decel hold command. The

output frequency is maintained when the accel/decel hold command is input

during acceleration or deceleration.

When the stop command is input during accel/decel prohibition command

input, accel/decel hold is released and operation ramps to stop.

Set multi-function input terminal selection (n36 to n39) to 16 (accel/decel

hold command).

Time chart at accel/decel hold command input

FWD (REV)

RUN COMMAND

ACCEL/DECEL

HOLD COMMAND

FREQUENCY

REFERENCE

OUTPUT

FREQUENCY

FREQUENCY

AGREED

SIGNAL

Note : When the FWD (REV) run command is input along with the accel/decel hold command,

the motor does not operate. However, when frequency reference lower limit (n31) is set

greater than or equal to min. output frequency (n14), the motor operates at frequency

reference lower limit (n31).

ON

ON

ONONON

ON

55

Page 56

Using frequency meter or ammeter (n44)

SettingSetting

Description

Output frequency

Output current

0

1

AM

AC

0 TO 10VDC

FREQUENCY METER

FM

OUTPUT FREQUENCY

(OUTPUT CURRENT)

Analog monitor gain

can be set by n45

100 %

03V

ANALOG OUTPUT

10V

FM

OUTPUT FREQUENCY

(OUTPUT CURRENT)

100 %

n45=0.30

FACTORY SETTING

n45=1.00

ANALOG OUTPUT

3V 10V

AM

AC

FREQUENCY METER/AMMETER

(3V 1mA FULL-SCALE)

n45

FM

Selects to output either output frequency or output current to analog output

terminals AM-AC for monitoring.

In initial setting, analog voltage of approx. 10V is output when output frequency

(output current) is 100%.

Calibrating frequency meter or ammeter (n45)

Used to adjust analog output gain.

Set the analog output voltage at 100% of output frequency (output current).

Frequency meter displays 0 to 60Hz at 0 to 3V.

n45 Setting

10V = 3V

0.30

56

·

·

·

Output frequency becomes

100% at this value.

Page 57

Reducing motor noise or leakage current (n46)

fc=CARRIER FREQUENCY

2.5kHz

1.0kHz

83.3Hz 208.3Hz

fout=OUTPUT

FREQUENCY

fout=OUTPUT

FREQUENCY

fout=OUTPUT

FREQUENCY

fc=12 fout

fc=CARRIER FREQUENCY

2.5kHz

1.0kHz

41.6Hz 104.1Hz

fc=24 fout

fc=CARRIER FREQUENCY

2.5kHz

1.0kHz

27.7Hz 69.4Hz

fc=36 fout

n46=7

n46=8

n46=9

Set inverter output transistor switching frequency (carrier frequency).

Setting

7

8

9

1

2

3

4

Carrier Frequency

12 fout

24 fout

36 fout

2.5

5.0

7.5

10.0

(Hz)

(Hz)

(Hz)

(kHz)

(kHz)

(kHz)

(kHz)

Metallic Noise

from Motor

Higher

Not

audible

Noise and Current

Leakage

Smaller

Larger

Setting values 7, 8, or 9 multiplies output frequency according to output

frequency value.

57

Page 58

Factory setting varies according to inverter capacity (kVA).

NOTE

Wiring Distance between