Page 1

Varispeed-626MTIII Drives

AC ADJUSTABLE SPEED DRIVES FOR MACHINE TOOL SPINDLES

3.7 TO 30 kW (5 TO 40 HP), 30-MINUTE OPERATION RATING

2.2 TO 22 kW (3 TO 60 HP), CONTINUOUS OPERATION RATING

Page 2

Page 3

Varispeed-626MTlll Drives (VS-626MTIU ) are highly reliable adjustable speed

AC spindle motor drives for NC machine tools. VS-626MTIII drives combine a compact, high speed AC spindle drive motor with a digital vectorcontrolled, high performance transistor inverter (controller).

The VS-626MTIU drives achieve high speed operation and heavy

duty machining even while operating under adverse environmental conditions. The VS-626MTIII is an ideal spindle drive for machining centers,

lathes, milling machines, etc.

The features of the VS-626MTIU are as follows:

● 8000 r/rein max and constant power range (1 : 5.3) (for 7.5kW or below)

● Constant power (1

● Enhanced performance through digital vector control

● Compact and lightweight

● Low vibration/low noise operation

● Improved machining due to unique motor cooling system

● Reliable functions for improved maintenability

: 12) with winding selection

AC Spindle Motor

F’lange-mounted Model UAASKA-08CAI

68742

VS-626MTIII Controller

Model CIMR-MTIU-7.5K

Page 4

CONTENTS

1. RATINGS AND SPECIFICATIONS . .......... 1

1.1 STAN DA RD SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 STAT US MONITOR IN G FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 PROTECTION FUNCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. CHARACTERISTICS ““””””””..... ‘“”’”....’”””””””” 5

2.1 OUTPUT POW ER–SPEED CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . 5

22 TO RQUE–SPEED CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 MOTOR MECHANICAL CHARACTERISTICS . . . . . . . . . . . . . . . 7

3. BLOCKDIAGRAM””””....... 8

4. WIRING . . . . ... . . . . . .. . . . . . . . .. . . .. ........... . . .. .... .... ~~~~~~ 9

4.1 INTERCONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 CO NNECTOR SIG NAL LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1;

4.3 LEAD SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4 WI RI NG IN STRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5. CONTROL SIGNAL . . . . . . . . ... . .. . . 16

5.1 SEQUENCE IN PUT SIGNAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 SPEED REFER EN CE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 SEQUENCE OUT PUT SIGNAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.40 PTICAL EN CO DE R(PG) PULSE OUTPUT CIRCLJIT . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.5 ANALOGOUTPUT Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6. DIMENSIONS AND INSTALLATION ... . . . . . . 28

6.1 AC SPIN DLE MOTOR DIMENSIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2 VS-626MTIII CONTROLLER DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.31 NSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7. CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . 32

7.1 CON STRUCTION OF VS-626MTIDC ON TROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.2 PRINTED CIRCUIT BOARD LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8. PREPARATION FOR OPERATION .................. . . 34

8.1 CHECKS BEFORE TEST RUN..... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.2 CHECKING POWER UN IT AND PRINTED CIRCUIT BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.3 CHECKING POTENTIOMETER SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.4 CHECKING POWER SUPPLY VOLTAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.5 CHECKING SPEED COMMAND IN PUT SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.6 FAULT DETECTION IN ISOLATION AM PLIFIER IN BASE DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9. OPERATION ON THE SETTiNG PANEL . .. . . . . . . . . . . . . . . 37

9.1 FUNCTIONS OF THE SETTING PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.2 LED DISPLAY AN D OPERATION KEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.3 KEY OPERATION AN D LED DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.4 ALARM DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.5 CO NTROL SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10. TEST RUN .. . . . . . . . . . . . . . . . . . . . . 42

10,1 CHECKING AFTER POWERON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10.2 STATE DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

10.3 CONTROL CONSTANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

10.4 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

I1. SETTING AND ADJUSTMENT . . . .. . . . . ~~~~~~~~~~~~~~~~~~~~46

11.1 SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

11.2 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

12. VS-626MTIII CHECK TERMINALS AND THEIR SIGNALS””’””’”””””””” 51

13. MAINTENANCE . . . . . . . . . . . . . . . . .. . . 52

13.1 DAILY INSPECTION ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

13.2 PER IODIC CLEANING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

13.3 PER IODIC INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

13.4 CHECKING SEMICONDUCTOR ELEMENTS FOR MAIN CIRCUIT. . . . . . . . . . . . . . . . . . 54

13.5 REPLACEM EN T OF PRINTED CIRCUIT BOARDS . . . . . . . . . . . . . . . . . . . . . . . 56

14. TROUBLESHOOTING”””” ““” 60

15. sPAREPARTs ””””””””””””””””””””””’”’””””””” ““”””””””’””””””’””’””’”””’’’”””””””””””””’” 66

1—

20

Page 5

CONTENTS (Cent’d)

[lFeatures of Winding Selection l . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .

.. . . .. . . . . . . . . . . . . .

.. . . . . . . . . . . . ..

67

“16. SPECIFICATIONS """""-""" . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . 68

“17. CHARACTERISTICS """".""" . . .. . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . 69

1:7.1 OUT PUT POW ER, TORQUE VS MOTOR SPEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

1:7, 2 MOTOR MECHANICAL SPEcl FlcATlo Ns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

’18. MOTOR DIM ENSIONS AND MOUNTING CONDITIONS in mm.””................. 72

“1;3,1 MO TORDIMENSIONS mm..... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

“1~3.2AC SPl NDLEMOTORMOUNTl NG CON DITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

-19. wlRING" """"""""' """"""""""'"" """"""""""'"""" """"` `. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

INTERCONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

‘!3.1

~!3.2coNNEcToRs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

:~o. CONTROLSIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

76

21. OPERATION """""""""""""""""""". . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . .. 78

MOTOR CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

2!-1.1

Z!”I.2 WI ND IN G SELECTION OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

2“I.3WINDING SELECTION PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

:?”l.4N0TEs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

22. MAGNETIC CONTACTOR FOR WINDING SELECTION ““”””.. . . . . . 83

RATING AN D SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

22.1

;!:?. 2D1MENs10Ns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

~!:?.30pE.RAT10N . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

:?3. TROUBLESHOOTING””””””””””””””. 84

[-Magnetic Sensor Type Spindle Orientati~n] . . . . . . . . . . . . .. . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 85

24. SPECIFICATIONS ”-”””””””””””””...... 85

SPIN DLE ORIENTATION SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

24.1

24.2 DETECTOR SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

25. SYSTEM CONFIGURATION ““””””... 87

Xi.OUTLINEOFOPE RATION ““””””-”””.... 88

OR IENTATION CONTROL. ..”..””..””,’.........,. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

2!6.1

L!6.20RIENTATION OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

:?7. wlRINGsPEclFlcATloNs """"""""-"""" """"""""""""""""""""""""""""""""""""""""""""..9o

2!:7.1 INTERCONNECTIONS BETWEEN DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

z!;7,2DEscR1pT10 NoFcoNTRoLstGNALs . . . . . . . . . . . . . . . 91

Dimensions ANDINSTALLATION -""" """""""""".. . . . . . . . . . 93

:!{3.

DIM EN SIG NO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

2!8.1

Z!8.21NSTALLINGMA GNETOANDMAGNETIC SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Z!8.3 PRECAUTION SIN MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

;!’9. COMPONENTS OF ORIENTATION CARD ““”””. . . . . . . . .. . . 97

:)10.ADJLJSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

FUNCTION OF POTENTIOMETERS AN D SHUNT CONNECTOR . . . . . . . . . . . . . . . . . . . . . . . . . 98

30.1

30.2ADJUSTINGP ROCEDURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...100

30,3 AD JUST MEN TO FPOTENTIOMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...103

31. LED DISPLAY ““”””--”-””””””””.106

{):2. CHECK TERMINALS AND THEIR SIGNALS ““”””””....107

3:3. REPLACEMENT OF ORIENTATION BOARD ““........107

3,4. TROUBLESHOOTING FOR SPINDLE ORIENTATION SYSTEM ~~ ~~ ~ . . ~ . 108

[-Encoder Typespindle orientatio~] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..1o9

:l:5. sPEclFlcATloNs """""""""""""""""`'""" """"""""""""""'""" `"""" """"" """""""""""""""""`...lo9

35.1 SPIN DLE ORIENTATION SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

352EN CO DE RSPECIF1CATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

—li —

Page 6

CONTEb(TS (Cent’d)

36. CONFIGURATION . . . . .. . . . . . . . . . ...111

37. ORIENTATION OUTLINE . . . . . . . . . . . . . . . . . . . ...112

37.1 ORIENTATION CO NTROL OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

37.20 RI ENTATION OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

38. WIRING DIAGRAM .. . . . . . . . . . . . . . . . . . . . . . . 116

38.1 INTERCON NECTION DIAGRAM.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

38.2 CON NECTORPIN AR RANGMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

38.3 PRECAUTIONS ON WIRING.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

40. DIMENSIONS AND INSTALLATION . . . . . . . . . ...123

40,1 ORIENTATION CAR D(JPAC-C346) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

40.2 EN CO DE R(PC-1024LH[:: K-68) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

41. ADJUSTMENT . . . . .. . . . . . . . . . . . . . . . . . . . . . . ..l24

41.1 FUNCTION SO FDIP SW ITCH ES AND SE LECT CON NECTARS ..,.... . . . . . . . . . . . . . . . . . 124

41.2 SETTING OF CONTROL CONSTANTS MONITORING CONTROL SIGNALS . . . . . . . . . . . . . . . . . . . 125

41.3 ADJUSTING PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

41.4 SETTING EACH PART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

APPENDIX A HOW TO CALCULATE ACCELERATION AND DECELERATION TIME ~““~ “ 136

APPENDIX B HOWTOCALCULATEGDZ . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...138

- Ill

Page 7

Subject

/4 Absolute Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...37.2.2 . . . . . . ...113

AC Spindle Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1o11 . . . . . . . . . 42

AC SPIN DLE MOTOR Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6.1 . . . . . . . . . . . . 28

AC SPINDLE MOTOR MOUNTING CONDITIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...18.2 . . . . . . . . . . . 73

Adjustable Potentiometers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...30.1.1

ADJUSTING PROCEDURE . . . . . ..-. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41. 3 . . . . . . . . . ...1.

Section No.

Page

. . . . . . . .

ADJUSTING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...11.2. . . . . . . . . . . . 48

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...30... . . . . . . . . . . . 98

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...41 . . . . . . . . . . ...124

Adjustment of Load Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1123 . . . . . . . . . 49

Adjustment of Loop Gain of Speed Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . ...11 .2.4 . . . . . . . . . 511

Adjustment of Motor Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...11.2.1

ADJUSTMENT OF POTENTIOMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...30.3 . . . . . . . . ...1.

Adjustment of Speedometer

ALARM DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9.4 . . . . . . . . . . . . 40

Allowable Radial Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.3.1 . . . . . . . . . .

ANALOG OUTPUT SIGNAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5.5 . . . . . . . . . . . . 2;

Auto Winding Change Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...21.3.2 . . . . . . . . . 81

El BCD Command Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...41.43 . . . . . . ...132

BIAS Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...30. 3,2 . . . . . . . ..lo3

BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3 . . . . . . . . . . . . . . 8

c

CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2 . . . . . . . . . . . . . . 5

CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 . . . . . . . . . . . . . . 69

CHECK TERM INALSAND THE IR SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 . . . . . . . . . . . . ..lo7

CHECKING AFTER POWERON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10. 1 . . . . . . . . . . . . 42

CHECKING POTENTIOMETER SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..8.3 . . . . . . . . . . . . 34

CHECKING POWER SUPPLY VOLTAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8.4 . . . . . . . . . . . . 34

CHECKING POWER UN IT AN DPRINTED CIRCUIT BOARDS . . . . . . . . . . . . . . . . . ..8.2 . . . . . . . . . ..- 34

CHECKING SEMICONDUCTOR ELEMENTS FOR MAIN CIRCUIT . . . . . . . . . . .13.4 . . . . . . . . . . . 54

CHECKING SPEED COMMAND INPUT SELECTION . . . . . . . . . . . . . . . . . . . . . . . . ...8.5 . . . . . . . . . . . . 35

CHECKS BEFORE TEST RUN . . . . . ..- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..8.l . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . .. . . . ..30. 2 .. . . . . . . . . ..1cIo

. . . . . . . . .

..11 .2.2 . . . . . . 49

COMPONENTS OF ORIENTATION CARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..29 . . . . . . . . . . . . . . 97

CO NFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...7 . . . . . . . . . . . . . . 32

CON FIG URATION . . . . . . . . . . . . ..-. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...36..............111

CONNECTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...19.2 . . . . . . . . . . . 75

CON NECTOR PIN ARRANGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...38.2

CON NECTOR SIG NAL LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4.2 . . . . . . . . . . . 10

CON STRUCTION OF VS-626MT~ CONTROLLER . . . . . . . . . . . . . . . . . . . . . . . . . ...7.1 . . . . . . . . . . . . 32

CO NTROL CO NSTANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..lo. 3.... . . . . . . . . 43

CO NTROL SIGNAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5 . . . . . . . . . . . . . . 16

Control Signal Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..g.32 . . . . . . . . . . 38

CO NT ROL SIG NABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9.5 . . . . . . . . . . . . 41

CONTROL SIG NABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 . . . . . . . . . . . . . . 76

Control Signals and Control Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...41.2.2

DAILY INSPECTION ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13. 1 . . . . . . . . . . . . 52

D

DESCRIPTION OF CO NTROL SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27. 2 . . . . . . . . . . . . 91

DESCRIPTION OF CON TROL SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...39..............119

DETECTOR SPECIFICATION S.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.2 . . . . . . . . . . . . 86

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...22.2 . . . . . . . . . . . . 83

—lv —

. . . . . . . . . .

. . . . . . . . .

117

127

Page 8

INDEX (Cent’d)

D

Encoder Type Spindle Orientation . . . . . ...””’”’’””””””””’”””””””” ““” ”””””””’”””””””””’””””””””””” 109

E

ENCODER . . . . . . . . . . . ...” ““””””””” “40. 2””” ”””123

ENCODER SPECIFICATIONS . . . . . ...”””””””””” ““””””35.2”..”””””” 110

External Torque Limit Level Setting . . . . . . . . . .”””””.”” “11 .1.2 ““” 46

F

FAULT DETECTION IN ISOLATION AMPLIFIER IN BASE DRIVE ””. ”””- .””. ””””’ 8.6”””””””””””” 36

Features of Winding Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...””” ~~ 67

For Type FS-1378C . . . . . . . . . . . . . . . . . . . . . . . . ...27.1.1 .“. 90

For Type FS-200A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ., ...27.1.2 .“. 91

FUNCTION OF POTENTIOMETERS AN D SHUNT CONNECTOR . . . . ...30.1 . . . . . . . 98

FUNCTIONS OF DIP SWITCH ES AND SELECT CONNECTORS . . . . . . . . . ..41.1........124

FUNCTION SO FTHE SETTING PANEL . . . . . . . . . . . . . . . . . . . . ...9.1 . . . . . . . . 37

G

H-G, M-G, L-G Adjustment.. . . . . . . . . . . . . . . . . . . . . . . ...30.3.3 “.. ”. 103

H

H-SPD, L-S PD Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..”’ 30.3.6 ““. .”. ”105

H-T Adjustment . . . . . . . . . ““”””’’’”’”’’”””30. 3.4 ““”’”’’”104

Home Mode Display . . . . . “....,...”””””” “9. 3.1 ““”””””” 38

HOW TO CALCULATE ACCELERATION AND DECELERATION TIME . . APPENDIX A. 136

HOW TO CALCULATEGD2 . . . . . . . . . . . ...” ........””AppENDIXB” “138

I

K

L

Load Meter Full Scale Setting .“” ””””” “11 .1.1 ‘“”””””” 46

LVLAdlustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..30,31 . . . . . . ...103

M

v–

Page 9

INDEX (Cent’d)

Subject

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.3.2 . . . . . . . . . . 7

IM

MOTOR CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-..........21.1 . . . . . . . . . . . 78

MOTOR DIM ENSIONS AND MOUNTING C0NDIT10N5 ””””” ”””. ””--” ””””””--” ““18”.”””””” 72

MOTOR DIM ENS IONS mm....””” ““”- ””-” ” ”” ”””” ” ”” ” ” ” ”” .””” ””””--- ““”” .””- ”””” 18.1””””””””.””’ 72

MOTOR MECHANICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . .2. 3 . . . . . . . . . . . . 7

MO1-OR ME CHANICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...17.2 . . . . . . . . . . . . 71

M-SPD Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...30.3. 7 . . . . . ...105

M Normal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..26. 2.1 . . . . . . . . . 89

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21. 4 . . . . . . . . . . . . 82

13

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10. 4. . . . . . . . . . . 45

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...21 . . . . . . . . . . . . . . 78

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...22.3 . . . . . . . . . . . 83

Operation of Switches and Displays . . . . . . . . . . . . . . . . . . . . . . . . . ...41.2.1 . . . . . . ...125

OPERATION ON THE SETTING PANEL . . . . . . . . . . . . . . . . . . . . . . . . 9. . . . . . . . . . . . . 37

OPERATION OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 37. . . . . . . . . . . .112

OPTICAL ENCODE R(PG) PULSE OUTPUT CIRCUIT . . . . . . . . . . . . . . .5.4 . . . . . . . . . . . . 26

orientationC ard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...281.1 . . . . . . . . . 93

ORIENTATION CARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.1 . . . . . . . . . . . .123

ORIENTATION CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...26.1 . . . . . . . . . . 88

OR IENTATION CONTROL OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . ...37.1...........112

ORIENTATION OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26. 2. . . . . . . . . 89

ORIE:NTATION OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . ...37.2..........113

Orientation Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...41. 4.5 . . . . . . ...132

OUTLINE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . .. 26...... 88

Section No.

Page

OUT PUT POWER–SPEED CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . ...2.1 . . . . . . . . . . . . 5

OUT PUT POWER, TO RQUEVS MOTOR SPEED . . . . . . . . . . . . . . ...17. 1 . . . . . . . . . . . 69

p

PERIODIC CLEAN ING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.2 . . . . . . . . . . . 52

PERIODIC INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13. 3 . . . . . . . . . . . . 53

Position Control Proportional Gain

Positioning End Detection Width and Cancellation Width . . . . . . . . . . . . . . . . . . . . . . . ...41.4.2 . . . . . . ...131

Potentiometers Adjusted before Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...30.1.2 . . . . . . 98

PRINTED CIRCUIT BOAR DLAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7. 2 . . . . . . . . . . . 33

PRECAUTIONS IN MOUNTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.3....”” 96

PRECAUTIONS ON WI RI NG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..38 .3 . . ..”” ”118

PREPARATION FOR OPERATION . . . . . . . . . . . . . . . . . . . . . . . . ...8....” 34

Prolonged Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...13.3.1

PROTECTION FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . ...1.3 . . ...””” 4

1? Rated Speed Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...11.1.4 ..””” 46

RATINGS AN D SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . ...1 . . . . . . ...”” 1

RATINGS AN D SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 .1.....”” 83

Replacement of Base Drive Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...13.5.2 ..””” 58

Replacement of Control Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . ...13.5.1 . . ...”.” 56

REPLACEM ENT OF ORIENTATION BOARD . . . . . . . . . . . . ...33.........107

REPLACEM ENTOF PRINTED CIRCUIT BOARDS . . . . . . . . . . . . . . . ...13. 5 . . . . . . . . . . 56

Return tothe Home Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9.3.5 . . . ...” 39

!; Selection of Connector Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301. 3........ 99

SEQUENCE IN PUT SIGNAL.. . . . . . . . . . . . . . . . . . . . . . . . . . . ...5.1 . . . . . . . . . . . 16

SEQUENCE OUTPUT SIG NAL . . . . . . . . . . . . . ...5.3 . . . . . . 23

SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ,, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1 1 ,1 . . . . . . . . . . . . 46

SET’rl NGANDADJLJSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ., . . . . . . ...11 . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ,,

—vl —

..41 .4.4 . . . ...132

. . . . . . . .

54

Page 10

INDEX (Cent’d)

Subject

s SETTING EACH PART . . . . . . . . . . . . . . . . . . . . . ...41.4 . . . . ...131

SETTING OF CONTROL CONSTANTS MONITORING OF CONTROL SIGNALS ..41.2 . . . . . . ...125

Soft Start Time Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...11.1.3

SPARE PAPTS . . . . . . . . . . . . . . . . ..”” .” ..15.... . . . . . . . . . 66

SPECIFICATIONS . . . . . . . . . . . . . . . ..”” ” . 16.””...... 68

SPECIFICATION S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.. . . . . . . . . . . 85

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..35 . . . . . . . ..l O9

Speed Coincidence Range Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . ...11.1.7 . . . . . . 47

SPEED REFERENCE . . . . . . . . . . . . . . . . . . . . . . . ...5.2 . . . . . . . . . 20

Speed Detection Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...11.1.5 . . . . . . . . . 47

Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...26.2.2 . . . . . 90

T

Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...37.2.1 . . . . ...113

TEST RUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10. . . . . . . . . . 42

Thyristor Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...13.4.2 . . . . . . . . 55

Torque Detection Level Setting. . . . . . . . . . . . . . . . . . . . . . . . . . ...11.1.6 . . . . . . . . 47

Section No.

. . . . . . . .

Page

46

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . ..42..... . . . ...134

TROUBLESHOOTING FOR SPINDLE ORIENTATION SYSTEM . . . . . . . ...34 . . . . . . . . . . . ...108

VS-626MTIII CHECK TERM INALS AND THE IR SIG NABS . . . . . . . . . . . . . 12. . . . . . . . . 51

v

VS-626MTllI Controller . . . . . . . . . . . . . . . .,........,......10.1.2 . . . . . . 42

VS-626MTIDC ON TROLL ERDIMENSIONS . . . . . . . . . . . . . . . . . . 6. 2. . . . . . . . . . 29

vu —

Page 11

II.

RATINGS AND SPECIFICATIONS

1.1

STANDARD SPECIFICATIONS

Table 1 1 Standard Speclflcatlons of AC Spindle Motor

Type), UAASKA-E]CA3 (Foot-mounted Type)

08 ~ 11 1 15

7.5

[461

(7.5)

[371

(Q)

i [62]

(lo)

[461

(;:)

[901

(;:)

[71]

‘ 22

19

18.5

(25)

[961

(4:)

[821 i [991

(::)

[1121 [1661

18.5

(25)

1150(40tol 150

r/rein constant

.—

f{atedt

output Power

kW (HP)

Rated Speed

rlmin

Model

30-minute Rating 3.7 5.5

[50% ED]

(HP)

[Current]

Continuous 2.2

Rating (HP)

[Current]

Base Speed 1500 (40 to 1500 r/mln : constant to-sue)

Maximum Speed

UAASKA-[~CAl (Flange-mounted

04%

(5)

[321

(3)

[231 I [!?1

06

(7.5) i (lo)

[391

37 5.5 7.5

I

8000 (1500 r/rein or more : 6000 (1 500 r/rein or more constant

constant torque)

1“ ,

—

14.0 23,5

10.4 17.4

0021

—.

(;;)

(15:1)

g

O to +40’C, 32 to 104” F, 950/. RH or below

75 dB (A) or below

I f~, !ti~r

:@q&

120%, 60 s of 30-minute rating (50%ED)

Class F –

v-5

‘1

Munsell notation NI 5

Magnetic encoder

;~~

80 dB (A) or below

ClutputTorqueat Base Speed

(ContinuousI{atedCurrent)

Fiotor Inertia (J)

overload Capacity

Cooling Method Single-phase, 200VAC, 50 or 60 Hz, 220VAC, 50 or 60 Hz; 230VAC, 60 Hz

Insulation

Ambient l“emperature, Humidity

\/ibration

Noise Level

Faint Colo;Speed Detector

Approx. Mass kg (lb)

.-—

‘ IJAASKJ-L.

‘ Rated output power is guaranteed when input voltage is 200V 50/60 Hz, 220V 50/60 Hz, or 230V 60Hz

If input voltage is lower than 200 V, rated output power IS not guaranteed

i I 5.minute rating (5070 ED)/contmuous rating for 3.7/2 2 kW

‘--;CA1 (Flange-mounted type), UAASKJ-[~~CA3 (Foot-mounted type)

Nm

kgf.m 1 43 2.40

..~.

kg.mz 0.0095

Ib.ftz 090 1 99

-- .

30

30

(40)

22

(30)

[1311

v-lo

*

MODEL DESIGNATION

~ AC SPINDLE MOTOR

UAAS KA-L;CA3

AC Spindle Motor

Cooling Method

E: Self-cooled type, K: Externally fan-cooled type,

W: Liquid-cooled type

(

Output Power A: Standerd, B: Wide range constant powe;,

H: High speed, J: Base speed 1150 r/rein

(

T T

[[~T~

)

)

–l-

Detector A: Without home position,

MTIH Series

Capacity

04: 3.;/2,2 kW

30: 30/22 kW

Mounting Method 1: Flange-mounted,

(3: FooMnounted )

Z: With home position

(

)

Page 12

1.1 STANDARD SPECIFICATIONS (Cent’d)

Table 1.2 Standard Speclf]cations of VS-626MTIJI Controller

Type CIMR-MT~-~~~

Power Supply

—-

Max Required

Power Supply

(at 30-minute Rating)

Dlsslpated Power

(Continuous Rating/30 -mmute

Rating)

Circuit

Control Method

Braking Method

Speed Adjustable

Ranae

kVA 7

3.7 K 5.5 K

Three-phase, 200VAC, 50 or 60 Hz, 220VAC, 50 or 60 Hz, 230VAC, 60Hz

9

230/330 320/400 400/520 530/750 780/1030 1 9CXY1080 1120/1320 1440/1970

w _ , id~

40 to 8000 r/rein

(1

O 2% maximum speed or below (load variation

$~ ‘.. ‘–

Speed

Command

Input

Ambient

Temperature

—

Humidity

Allowable Vibration

Finish in Munsell Notation

Installation

Standards

Approx

Mass

kg

(lb)

*JIS Ja~anese Industrial Standard

The Standard of Japan Electrical Manufacturers’ Assoclatlon

‘JEM

tJEC Standard of Japanese Electrotechn!cal Committee

Temperature during shlppmg

#

u.

~ Dlgltal

I At Operation o to t 55°c

At Storage $

[

Indoor-use, tree from dirt, dust, hquld, trarmful gases,etc

Self-cooled

Type for

Totally-enclosed

Panel

Panel-installed

Type

- ‘~

(3P3 )

(4’lg9)

75K

(Voltage tloctuation + 10 to – 1 5%)

12

T

-—

— —

—

200)

120%, 1 mnute of 30-minute ratlrg (50?4 ED)

~ 10VDC (+ forward and — reverse) or

+ 10VDC (forward and reverse .sIgnals)

Bnary 12-bit, BCD 2-dlglt or 3-dlglt

95?4 RH or below (non-condensing)

IG at 20Hz or below. O 2G at 20 to 50Hz

llK

I

19 24 ~ 30 ~ 36 48

I

PWM transistor Inverter control

Vector control

Regenerative braking

7

–20 to 4-60”C (–4 tO 140°F)

COMply wth JIS*, JEM’, JECt

(775)

(7T4)

15K

~ 185K I 22K

I

40 to 6000 r/rein

‘(32 to 131 ‘F]

5Y 7/1

(7T4) (17;5) (1::3) (1764)

(8&2!

(1

150)

10 to 1

~

(1::7) (1:45)

00%)

30 K

401245:0rmn

112,

[1

80

87

(191 8)

MODEL DESIGNATION

● CONTROLLER

Inverter

VS-626MTIII

Series Name

Max Applicable Motor Output

3.7: 3.7 kW

30: 30 kW

–2–

Page 13

1.2 STATUS MONITORING FUNCTIONS

The VS--626 MTIII has many status monitoring functions to

status of the spindle drive (Table 1. 3) . Each operation

the LEDs on the setting pane] of the control

pr;nted

circuit board by operation

ci” the key switches on the setting panel.

Table 1.3 Status Monitoring Functions

LED Display

Code

NFB

NREF

TREF

MTEMP

STATUS

ALM

DIDSP

DODSP

NFBS

FLUX

Interface output state Bit

Magnetic

Name

Meter speed

Speed command

LQ ‘--

Torque command

Motor temperature

77 ~::;a~bent -

Internal state

Alarm state

~

Interface input state ~

Spindle speed

4Q ‘-

flux command

Unit

I r/rnin I

%

1

~Hexadecimal i

1Hexadecimal

Bit

%

monitor the operation

status is displayed by

Display

~

Varies depending on

Varies depending on

in~ut sianal state

+

1

at Power ON

I(III!

l_!,l.1l_t

n

luJ_l

internal state

11n ,-1l–l

1.I1.1l_l IL)

1:1l–l1–I,-81-1

LICui 100

---

,11I:,jl;

,1

Note: (;,.-H ; to -fl~ are trace-back data. (Refer to Par. 9.3.3 “Trace-back Display.”)

-3-

Page 14

1.3 PROTECTION FUNCTIONS

In case a malfunction occurs during operation,

the malfunction state is displayed by

the LEDs of the setting panel according to the malfunction], as shown in Table 1.4,

and operation puts on hold. In case multiple malfunctions occur, Lhe malfunctions

are recorded in the order they occurred. This will be useful for analysis of the

cause of malfunction.

Table 1, 4 Protection Functions

NO.

10

11

LED *

Display

---

:*...

~:,/.,

, ,-,l—

,L, L

---

,,, ,

!,LL

,- ,-,,-

LL, L’

,-,i ,

!J!J

fl~

;,;,

L,L,

1

2

3

4

5

6

7

Code

EYIGSTP Emergency stop error

(x

YICCB

RGOC

Ov

0s

LIV

8

~- ~ OverlO:—–—–

9

~,~:~:

DEV

I +---“-‘--

:: ‘%-&:::-”-”----0110

Name

—.

Ckercurrent 1110

.-

IvICCB trip 1101

Regenerative overcurrent

‘-1

———— ——

Overvoltage

Overspend

Undervoltage 1001

Excessive speed deviation

Thermo detector disconnection

Alarm Cord

~C3 AC2 AC1 AC(I

1111

—

1100

1011

1010

1 0 0 0

0111

13

===~~~EE~:I’l 1-:

14

15

16

17

18

19

20

21

22

23

“1’rouble indication, “-” , 1s shown as the first mall’unction.

‘W’hon motor does not move dur]ng operat]on ‘e.&. motor rock. cl:sconncctlng of motor side, fuse

blown Inside base dI-l\er)

*If control function failure (CPF) occurs, shut off the po\ver, and tk,en t~rn on the power again.

If CF’1” still cont~r.ues. replace control board.

+‘~hls functi(jn is only winding selection

;~~~

;: ~;~-

/:(:;

,2,- ,-

{ LJL

;&cl

/~-.~; (

/~-/;~:

, ,- ,:,,-,

(L!,!,

. . . . .

!:~ ,~

Al) 16-bit ,11) defective

CF’WAI)

P(3

PGC PG counter defective

CPU :~D defective

-

.-.

PG disconnection’

ROM PRO\I error

RAI’v-I Internal RAM error

RMv-E

RAN1-N

CPF

CHE

,n~ Indication ~PC, dlsconnectl on) appears.

!ixternal Ri\M error

N-\~-R:ilvI error

Control function failure

IVinding selection error*

SYStC~l.

—

——-[

I

-~o 1

0 0

+

--;00 1 1

~

o 0 1

o 001

0000

—

1111

c)

–4-

Page 15

2!. CHARACTERISTICS (COMBINATION WITH STANDARD MOTOR)

18kW(24Hp)

(I-MINUTE RATING)

2.1 OUTPUT POWER–SPEED CHARACTERISTICS

4.4kW (6 HP)

(1-MINuTE RATING)

OUTPUT

POWER

(kW) 2

4

3.7 kW (5

(15-MINU% RATING, 50%ED)

2,2 kW (3 Hp)

(CONTINUOUS RATING)

)

OUTPUT

POWER

(kW)

I

16

12

8

15kW (20 Hp)

(30-MINUTE RATING, 50%ED)

llkW(15Hp)

(CONTINUOUS RATING)

r

[r

CJUTPUT

POWER

(kW)

cIuTPUT

POWER

(kW)

OUTPUT 8

POWER

(kW)

o

1 I I

1000 200030004000 50006000 70008000

MOTOR SPEED lrmln)

(a) 3.7/ 2.2 kW (5/3 HP)

6.6kW (9

HP)

(1-MINUTE RATING)

5.5kW (7 5 Hp)

(30-MINUTE RATING, 50%ED)

i

4

1

o

1/

8 ~“)

6

4

/r

12

1

3.7kW(5Hp)

(CONTINUOUS RATING)

1

1000 2000 30004000 50006000 7000 8000

MOTOR SPEED (rm.)

I

(b) 5.5/3.7kW (7.5/5 HP)

9.0kW(12Hp)

(1-MINUTE RATING)

I

7.5kW(10Hp)

5.5kW (7.5 HP)

(CONTINUOUS RATING)

—..—

10002000300040005000600070008000

MOTOR SPEED (rmln)

7.5/5.5kW (10/7 .5 HP)

(c)

13.2kW (18 Hp)

(1-MINUTE RATING)

llkW(15Hp)

(30-MINUTE RATING, 50%ED)

75kW(10Hp)

(CONTINUOUS RATING)

I I

I

4

~

..L...—.. —

o

100020003000400050006000

MOTOR SPEED lr;mln)

(e) 15/l lkW(20/15HP)

22.2 kW (30 HP)

(1-MINUTE RATINGI

18.5 kW (25 Hp)

(30-MINUTE RATING, 50 °/OED)

15kW (20 HP)

(CONTINUOUS RATING I

2000 4000 6000

MOTOR SPEED

(r~mm)

OUTPUT

POWER

(kW)

24 -

16

8

[7

oL—

(f) 18.5/15 kW (25/20 HP)

26.4 kW (35 HP)

(1-NINUTE RATING)

22 kW (30 HP)

(30-MINUTE RATING, 50%ED)

18.5 kW (25 Hp)

h

LI

(CONTINUOUS RATING)

2000

MOTOR SPEED tr~mln)

4000

22/18.5 kW (30/25 HP)

36 kW (48 HP)

[1-MINUTE RATING)

30 kW (40 HP)

(30-MINUTE RATING, 50 °/oED)

w

22 kW (30 HP)

[CON-FINUOUS RATING)

t

6000

OUTPUT 16

POWER

(kW)

OUTPUT

POWER

(kW)

24

8

0

(g)

32 r

24

16

8

4 I

o

1

1000

2000 30004000 50006000

MOTOR SPEED (r:rnln)

(d) 11/7.5 kW(15/10HP)

E

0

1

J

–F–

.

(h) 30/22 kW (40/30 HP)

2.1 Output Power–Speed

Fig.

2000

MOTOR SPEED [r,mln)

40004500

Characteristics

Page 16

2.2 TORQUE–SPEED CHARACTERISTICS

-CCJIN=L

ogf. )[\. m)

w -

‘~

(a) 3.7/2.2kW (5/3 HP)

m)

{L~l.m’lh

,,

‘IL o

(b) 5.5/3.7kW (7.5/5 HP)

.hJlh!JTERATIF, G

~~5-P,l INUTE RATING 150%b D)

2000 4000 6000 8000

P,IOTOO SPEED ir@mnl

30-MINUTE RATING (50?4 ED!

2000

4000

VOTOR SPEEO

ir,mul

6000

1

80uC)

:kgm) (k m)

io –

:OP,oLIE 6 –

ljgf m) (Nm)

16 –

[2RWE 8

l-----=

8–

4 –

2 –

12 –

4 –

lca -

80 –

60 -

:~2,JgJow

40 -

20 ~

I

(e) 15/llkW(20/15HP)

120 -

80 -

40 –

1 ‘,!INUTE ?ATING

30 MINUTE RATING (50%E3

moo

I,11JT08 SPEEC <r,m n“]

.lOco

1hllNLTE PATi NG

33 Mlh UTE RATING (50 °/OEOJ

6,0>

1

0“1’-

OL 01

(C)

7.5/5.5kW (10/7 .5 HP)

‘T++

60 –

40 –

W;l:oods

20 –

(d) 11/7.5 kW(15/10HP)

2000

.vOT!2R SPEE3 (r; v,r,

4000 6000

MOTOR SPEEO

l-~; NUTE HATING

30 MlNJTE RATING (50 °/oED)

rlm,nl

1 1

8000

(j.

120

12

‘OROUL 80

8

4

‘~

OLob~

(kgfm)(Nm)

“r I

:;0

Zj 250

~. 2C0

T~RQuE

~~ 150

o~u,

y~goous

40

(9) 22/18.5 kW (30/25 HP)

3ca

-.

P,IOTOP SPEECI ;r’rmm

(f) 18.5/15 kW (25/20 HP)

VJ!b,LTE %iTING

30-M INdTE RATING 150 °/.kD;

MOTOR SPEEO (r,m.)

b.ll NJ7E RATING

30 MINUTE RATING

:50%ED)

60011

(h) 30/22 kW (40/30 HP)

Fig, 2.2 Torque-Speed Characteristics

–6–

lo I(I3

~

5

01 o~

&lClfl~LOUS

50

f.40TOR SPEED ;,,.,,, ,

20c1<1

J90045LIU

Page 17

2.3 MOTOR MECHANICAL CHARACTERISTICS

2 3.1

Allowable Radial Load

Table 2.1 shows allowable radial load according to AC spindle motor types .

Allowable radial load means maximum values of the load applying to the shaft

extension.

Table 2, 1 Allowable Radial Load

1 1/7.5 (15/10)

15/11 (20/10)

(Rated Output)

003 mm (Less than 7 5/5.5 kW)

I

I 0.033 mm (11/7 5 to 22/185k W)

270 (595)

I 0042 mm (30/22kW)

I 002 mm (Less than 7.5/5.5 kW)

I 0.022 mm (1 1/75 to 22/185 kw)

I 0028 mm (30/22kW)

2. 3.2

11

15

* The model of 30 is UAASKJ.

Mechanical Specifications

Table 2.2 Foot-Mounted Type

Accuracy (T. I.R)*

Parallel to Shaft

Shaft Run Out

*T, I R (Total Indicator Reading)

Table 2.3 Flange-Mounted Type

Accuracy (T.I.R) *

Flange Surface

Perpendicular to Shaft

Flange Diameter

Concentric to Shaft

* T.I,R (Total Indicator Reading)

(Rated Output)

0.04 mrr (Less than 22/18.5 kW)

0.06 mm (30/22

004 mm (Less than 7 5/5.5 kW)

0046 mm (11/7.5 to 22/18.5 kW)

i=

I 0028 mm (30/22 kW)

kW)

-7-

Page 18

THREE-PHASE

AC POWER —

SUPPLY

—

vS-626MTM CONTROLLER

,--------

I 1 1

T

t

—

—.

._.

—-1

—

I

AC SPINDLE MOTOR

II

IL

COOLING FAN

9

MOTOR

)

—

L J

w

Y Y

I

I

J

7Y’--

w

I

m

I

ANALOG

SPEED

REFERENCE

OPERATION

SEQUENCE

DIGITAL

SPEED

REFERENCE

—

u

—

v

—

L.d ‘

r

7

H II

A L.—

L

==&=L-!

1-

I

-%r

—A

I

rE!---

I CONTROL ~

CPU

--i

I

CURRENT

REFERENCE

----Em&

I

L--

SPEEDOMETER,

SIGNALS (AO)

4

I

LOAD METER

ALARM

CODE

(DO)

7 .

PG

4TER.

‘ACE

, -4

-1-

3CN

F==

1-

–-

TS

I

I

PG

PULSE

OUTPUT

STAT US

SIGNAL

OUTPUT

ALARM CODE

I

SPEEDOMETER

LOAD METER

OUTPUT

Fig. 3.1 Blcck Diagram of VS-626MTIII

Page 19

4.

WIRING

4.1

INTERCONNECTIONS

3-PHASE

POWER SUPPLY ‘200/220 VAC a50/60 HZ a230 VAC 60 Hz

EMERGENCY STOP

FORWARD RUN _&

REVERSE RUN

TORQUE LIMIT (H) ~~%

TORQUE LIMIT (L) —~

SOFT START CANCEL

ALARM RESET ~

SPEED REFERENCE ~—

SELECTION

L GEAR SELECTION ~

M GEAR SELECTION

P/Pi SELECTION

MOTOR WINDING

READY

ORIENTATION

(OPTIONAL)

SELECTION

(OPTIONAL)

MCCB

~“

a

=5

u

e;g

L

d

7!90V

❑

a

_. $ ::w

y

VS-626MTUI CONTROLLER

r“” ; ‘“’”’ ‘--

‘<t

;j

,,,

+Ov

3 ::G

&8 FOR

+9 REV

?Ov

x

. .

#i R5T

490V

&5 ~A5

82 :;:

45

pp,

~oov

u,

v,

u

$.

3CN E’

%

*:::g P

pp~ 1A ‘ I

%

AC SPINDLE MOTOR

,$-- f~

v *

.

WA!

E

/:

~,

-!

++..

—

t

il.

‘3 ,

4 (~’

J

.5

s pG’

“7

.81’

9

=. -

-1

ANALOG

SPEED

REFERENCE .

4

INPUT

ZERO SPEED SIGNAL

ZERO SPEED SIGNAL

SPEED COINCIDENCE SIGNAL

SPEED DETECTING SIGNAL

TORQUE DETECTING SIGNAL

TORQUE LIMIT SIGNAL

SPINDLE ROTATING SIGNAL

MOTOR\VINDINGSELECTIONCOMPLETIONSIGNAL

ORIENTATIONCOMPLETIONSIGNAL

COMMON GROUND (33 TO 40)

f,,

;1

*J

a

3

-3 NCOM

‘lOv

2 Ss

}ICN

95

’46

i

~3 ZSPD

$ ~;T

&6 TDET

&7 TLE

4$X 1P

~9 ORE

~o CHWE

&l COM1

1CN 4A

:;&

A&;; :;::

COM2 2!&

SM

LM + 4 +

ORIENTATION

CARD

(OPTIONAL) Ov

➤ _– __________

N-CREEP ~ —

I

I

I

I

o vl~

Pos[: 151

IP[:+ ;$

+15&

Ov 7..

19,20 ~

m

‘i----

-1=

Ov:$

47.[

3

I=

ALARM SIGNAL

ALARM COOE

“0”

“3”

COMMON

(23, 24, 26, 27)

v

v

GROUND

+

VFS SPEEDOMETER

10

10 VFS LOAD METER

FS-1378C

—–1

~

‘&

~

~

1

ph

MAGNETO

,&jNGSNOE~lc SPINDLE

I

1- ‘----3’~@T:::::5ea

Fig. 4.1

Wiring Diagram of VS-626MTllI Drive

x PCA, x PCB and x PCC are the reverse

signals c)f PCA, ,PCB and PCC respectively

–9–

Page 20

4.2 CONNECTOR SIGNAL LIST

Table 4.1 1 CN Signal List

Pin No. ]

1 I+15V

Signal

Pin No, Signal

2 1ss

3 I Analog speed reference (N COM)

5 I Speed reference selection

6

7

8

9

10

Ready ( RDY)

I

Emergency stop (EMG)

Forward run ( FOR)

i Reverse run (REV)

Torque limit signal H (TLH)

I

(DAS)

w%%%%%=--

13 I Alarm reset (RST)

Motor winding selection (CHW) 39 ~ Orientation completion (ORE)

: --i=xxozG-–-––

16

17 L gear selection (LGR)

18

~-...+..

20

21

22 “

23

24

25

Orientation command (ORT)

M gear selection (MGR)

I

Ov

Alarm code output bit O

Alarm code output bit 1

Alarm code output common

‘- - “-+——

—— -

—

26 Alarm code output bit 2

27

Alarm code output bit 3

+

29

30 Ov

4

31

I

32

I

33 I Zero speed (ZSPD)

34 I Speed coincidence (AGR)

35

36

37 I Torque limit (TLE)

38

40 Motor winding selection completion (CHWE)

41

42

43

44

45

46

47 Speedometer signal

48

49

50

Speed detecting (NDET)

Torque detecting (TDET)

1

Spindle rotating signal

I

Common ground Pin No(33 to 40)

Alarm signal contact output

2

Zero speed contact output

Ov

Ov

Load meter signal

—

–lo–

Page 21

Table 4.2 2 CN Signal List

Pin No. I Signal

1 I Diryfal speed reference (Dl)

Digital speed reference (D2)

~ -

4 ~ Digital speed reference (D4) l-generator output ( PCC)

5

6 I Digital speed reference (D6] I 16

7 I Digital speed reference (D7)

8 I Digital speed reference (D8)

9 I Digital speed reference (D9)

10 I Digital speed reference (Dl O) I 20 I Shield sheath (SS)

Pin No. Signal

—

1

2

3

41

5

6

7

8 ‘ Thermo detector input (THSA)

Digital speed reference (D3)

Digital speed reference (D5)

Ov

i

+5V

1

Shield sheath (SS)

I

Table 4, 3 3 CN Signal List

-+*’Orinput’’’sB)-

x Shows the reverse signals

I Pin No. I

I 11 I Digital speed reference (DI 1)

Digital speed reference (DI 2)

+: =

15 Pulse generator output ( * PCC)

~ Pulse generator output (PCA)

I 17

18 Pulse generator output (PCB)

19 Pulse generator output ( *

-+

Pin No.

Pulse generator output ( * PCA)

I

I

11 ; Motor winding selection (optional) (CC)

Motor winding selection (optional) (CA I )

++- -

14 I Pulse generator input ( PCC)

15 I Pulse generator input ( * PCC)

16

Motor winding selection (optional) (CA2)

Pulse generator input (PCA)

–+-

+:-=:::::=: “--

19 ~ Pulse generator input (* PCB)

20 Frame ground (FG)

Signal

PCB)

Signal

–11–

Page 22

4.3 LEAD SPECIFICATIONS

Power lead type, size and terminal screw are listed in Table 4.4.

motor power leads are shown in Table 4.5.

Control signal lead and connectors are

—

listed ;n Table 4.6.

Table 4.4 Power Lead Specifications

Type

600 V

cabtyre

cable

Lead

(:;: )

l“””-”----

VS-626MTIII

Type

CIMR-MTIll[z;

3.7 K

5.5 K

7.5 K

IIK

15K

18.5 K

+

22 K

30 K

Application

Cooling fan power lead I 600 V vinyl-insulated lead ~ 2(14)

*

I

i

I

I

i

I

i

I

Table 4, 5 Cooling Fan Motor Power Lead Specifications

Size

5.5

(lo)

(15%

I VS-626MTIII Controller

Terminal

I

I

(:)

;:

22

(4)

30

(2)

38

(1)

Input

R, S, T, E

output

U, V, W, E

i

+

1

Lead

“;y~”—”

Terminal

Screw

M5

M8

Size

mm2(AWG)

Terminal

Input

u, v,

bV, E

Terminal

u, v

Cooling fan

Motor

Terminal

Screw

I

I M4

M5

I

M8

M8

I

M8

M8

M8

~

Terminal

Screw

M4

Table 4.6 Control Signal Lead and Connector Specifications

Connector

Code

*Except for analog signal lines, signal line ICN may also be in conventional vinyl lead [0 5 mmz (20 AWG)]

for electric appliances, provided the following are observed

. To minimize adverse effects of noise, the signal lead and the power lead should be separately run through as

short a passage as possible. The signal lead should be 20 meters or below

. The outer diameter of the cable bundle must be smaller than the size of the connector outlet opening

given below

t Use the composite cables KQVV-SW (22 AWG x 3 cores, 26 AWG x 6 pairs) made by Fujikura Cable

Works, Ltd

Application

Type MR-50LF. 16 mm (O 636 inches) diameter

Type MR-20LF 11 mm (O 433 Inches) diameter

Connector

Type M R- ~Manufacturer

F

Lead

Size

–12–

Page 23

4.4 WIRING INSTRUCTIONS

Complete VS-626MTIII interconnections, follo~ving the instructions given below.

(1) Control signal leads ( lCN to 3CN) must be separated from main circuit leads

(.R, S, T, U, V, W) and other power lines and power supply lines to prevent erro-

neous operation caused by noise interference .

(2) Use the twisted shielded lead for the control signal line, and connect the shield

s heath to any of the controller terminals .

the wiring distance of the signal leads be 20 meters or below.

See Fig. 4.2.

It is recommended that

SHIELD

SHEATH

TO

SH

Fig. 4.2 Shielded Lead Termination

(3) Make a positive grounding using ground terminal E on the casing of VS-626MTIE.

. Ground resistance should be 1000 or less .

. Never ground VS-626MTIII in common with welding machines , motors , and other

large-current electrical equipment , or

separate conduit from leads for large–current electrical equipment.

0 Use ground lead listed in Table 4.4 and make the length as short as possible.

. Even when VS-626MTIII is grounded through its mountings such as channel base

or steel plate, be sure to ground VS-626MTJII using the ground terminal E.

. Where several VS-626MTIII units are used side by side, all the units should pre-

ferably be grounded directly to the grouncl poles . However, connecting all the

ground terminals of VS-626MTID in parallel,

to the ground pole is also permissible (Fig, 4. 3) . However, do not form a lC)OP

with the ground leads ,

ARMOR

/

Insulate these parts

with insulating tape

ground pole. RurL the ground lead in a

and ground only one of VS- 626 MTID

Good

E

E

E

Poor

w

W

Fig, 4.3 Grounding

Good

Fig. 4.4 Grounding of Motor and VS-626MTIII

of Three VS-626MTlU Units

Poor

E

b

-13-

E

—

Page 24

4.4 WIRING INSTRUCTIONS (Cent’d)

(4) Phase rotation of input terminals (R,

S , T ) is available to each direction,

clockwise and counterclockwise.

(5)

Never connect power supply to output terminals (U, V, W) .

(6)

Connect VS-626MTIII controller output terminals (U, V, W’) to motor terminals

v, w).

(u,

Care should be taken to prevent contact of wiring leads with VS-626MTlIt

(7)

cabinet,

for short-circuit may result.

(8) Never connect power factor correction capacitor between the vS-626MTIII con-

troller and motor.

u

v

L._

VS-626M”TIU

CONTROLLER

-.---.J

w

/

\

\

\

\

—---

Never connect power factor

correction capacitor

1

Fig, 4.5 Removal of Power Factor Correction Capacitor

(9) When applying a ground fault interrupter or relay, it should have good balance

characteristics and be connected on the power supply side as shown in Fig. 4.6.

Since the output from the VS-626MTlIl controller contains higher-level harmonic

components , a zero–phase current flows through the stray capacitor (Cl) of the

cable between VS–626,MTIII controller and motor or through the stray capacitor

( c2) of the motor, sometimes resulting in erroneous operation of the ground fault

interrupter.

ing:

Make the cable bet~reen the VS-626MTIIt controller and motor as short as possible

and reduce the steady state zero-phase current.

- Set the ground fault interrupter to a value larger than the rated current.

Use a ground fault interrupter which is designed for inverter or is not operated

by impulse waves .

Because of this, they must be installed in accordance with the follow-

GROUND

FAULT

-W*C2

Fig. 4.6 Installation of Ground Fault Interrupter

–14-

Page 25

( 10) If both the VS-626MTIU controller and magnetic contactor are placed in the

same control panel,

noise generated from the coil of the magnetic contactor.

in parallel with the coil of the magnetic contactor.

th; energy stored

suited to the coil.

the controller may sometimes operate erroneously due to the

Connect a surge absorber

The surge absorberewill absorb

in the coil of magnetic contactor

Yaskawa’s magnetic contractors

and thus must have a capacity

and surge absorbers are shown

in Table 4.7.

CAUTION

Never connect surge absorbers to the output terminals (0, @), @) of the controller,

Table 4, 7 Surge Absorbers

Magnetic Contactor

Surge Absorber*

and Control Relay

Type

Magnetic-contactort

HI-1OE, -20E, -25E,

~ ‘CR2-’”A22E I 05/uF+200Q

200V I Control Relav

Class

*Made by MARCON Electronics. Co., Ltd.

For contractors other than those listed above, use the following surge absorbers.

. For 200V class’ Type DCR 2–50A22E

t Made by Yaskawa Controls Co., Ltd.

f Made by Omron Corporation.

4 Made by Fuji Electric Co., Ltd.

RA-6E,, RL-33E*

Control Relay

LY-2, -3*

HH-22, -23~

MM-2, -4f

I

Type ~

i--

DCR2-10A25C

Specifications

1

250 VAC

I

250 VAC

~ O.l,u F+ 200(2

Code No,

CO02417

CO02482

T

–15–

Page 26

5. CONTROL SIGNAL

5.1 SEQUENCE INPUT SIGNAL

hen designing input signals, take the following conditions into consideration.

\Vhen relay contacts, etc. are used, the contact capacity

(15 m.4 or above)

‘1’he filter in the le~el shifter circuit in the input section causes approximately

3 rns delay in the signals.

Since a pull-up resistor is incorporated in the circuit,

also be inputted.

and 2 TT

or beloti for I,OJV level.

In this case,

input sig-nals 20 V or above for the HIGI1 level,

must be 30 V or abol:e

contactless signals can

E’ig. 5.1 shows the input interface circuit,

Fig. 5.1 Input Interface Circuit

The ON/OFF state of the input signal can be checked by the LED display on the

setting panel (L-se mode l_l,–,–l_l1

.See par. 9 for operation.

- ) . See Fig. 5,2 for the display

IZ’I E!.- n-, 12: lc7(-

/LL /—L -L ~~_L /_/

-.

ET

FiDY

TLL

ORT

Note. ON status-input s!gnal hghts.

Fig. 5.2 Display of Input State

and ‘l’able 5.1 gives the slgmal functions

~-24V

~~

-EMG FOR

SSC RST

LGR

REV TLH

CHW PPI

MGR DAS

signal

Ready

m

Zonnector

No.

1

CN

Table 5.1 Functions of Sequence Input Signals

Pin

1-0,

6

Signal

CL(X5E

I

,

On

Function

‘l’he main circuit is established lvi~h [R~ closed,

so the base block reset conditions are satisfied

approximately -. .

tVhen II?LII- IS opened during run, base is blocked

instant l>, and the motor current is interrupted.

started if ~OR or [RE1~! is not opened once.

to pin LTo. 20 (0 V).

svstem becomes ready for operation.

, —.—J

\trhen 1RD~ ~1s opened,

\l’here RD\y is not used, connect lCN-pin .XO.6

In z j seconds after ~~- , 1~~~ are Closecl, the

_— —.,

–16-

~ 5 seconds after RI)~ is closed.

the motor cannot be re-

Page 27

—

—

Signal

Table 5.1 Functions of Sequence Input Signals (Cent’d)

Zonnector

No.

Pin

No.

On

Signal

l+nct.ion

[’or-ward

Run

I-FOF

Reverse

Run

[~~q

l~rnergenc~

stop

[~~~1

L—J.–—l

1 CN

1 CN

8

CI.OSE

I

I

9

CLOSE

~With ~lYl and ~~ closed and the speed refer-

ence

positive,

when ~]R is closed, the motor

runs CCJV as viewed from drive end; and when

~~l&~lOsed ‘he motor ,

Therefore, when

speed reference and run

signals are combined, the

motor runs in the directions shown below.

I

Speed reference

1==1==

C

386-78

, When the signal is opened during run, the motor

is stopped by the regenerati~e braking and

when the motor s~eed reaches to zero, the motor

current is interrupted b>’ base blocking.

, The acceleration and deceleration time is set

with the accel/decel constants ( L - IO

TSFS) .

The time between halt and 100 96 rated speed can

be set be~ween 0.1 and 30 seconds. However,

for some load GD ‘ values, the set accel/decel

time may be exceeded.

~Q~”’ and 1~~] shou~d be closed at least 15 ms

after ~~1 and ~Yl are closed. 1FOR and ~~~

should not be closed ahead of ml and WY–I.

. When both ~. and IIWV are =

closed, the motor stops. In this

case, if whichever of them becomes open, the moLor re-

~~_

FoR70r~ pm)

sumes running, so that care

must be taken to avoid accident.

When FOl~or~~~ is closed,

the motor runs at the speed }’”r” c“’’’’’’+”)

specified by a speed reference.

!jZjil Mlm

15

CLOSED

CMWED

— .—

ms and above

+=

__--3-L

-.

Be sure to first set a speed

when running the motor,

When a trouble occurs during run, base is blocked

OPEN

immediately to inter~-upt the motor current.

When ~1(1 is opened during run, the motor is

—.—

quickly stopped by regenerative braking, and

then, the current is interrupted. Even when the

motor is not stopped, the current is automatically

interrupted within the pl-eset time ( :1

r, – 1 :

).

When ~~ is depressed, the motor cannot be

restarted if [FOR , ~\71 or m with orientation

-—

card is not open once.

When ;ELl~ is not to be used connect pin No. 7

to pin N-o. 21 (O V).

-17-

Page 28

5.1 SEQUENCE INPUT SIGNAL (Cent’d)

Table 5.1 Functions of Sequence Input Signals (Cent’d)

Signal

Torque

Limit

~

Soft-starl

Cancel

r=

;onnector ~Pin ~ On

No. No. Signal

1 CN

10

11

CLOSE

I

12

1 c>”

CLOSE

Function

I

This signal is for temporarily limiting the motor

torque with a mechanically oriented spindle or

gear shift.

W~hen ~] or ml is closed, the torque

is limited and the torque limit signal is output.

Even if ~~] and ~~ are simultaneously

closed,

The torque limit level, m is preset by

lorque limit constant ( ~I-I-:]’;:

5 and 100 % of 30-minute rating.

TLL level is a half of ~L~l.

Vt’hen ~LHl or ~ is not be used, leave

pin Nos. 10 and 11 open.

This signal is for canceling the soft start function so that speed reference is changed by speed

command ~.vithout delay, for inching or other

special control modes.

‘1’L~ will close before ~.

w

m “r

—

121!%

CLO$F

roRQIE ,.,W, -~

l.Fvkl

EXTLIM) between

(0%

Soft-star

Cancel

$s.5

. ervo

s

Mode

Signal

[)

Speed

Regulato

P/PI

Selection

m

1 CN

I

1 chT 15 CLOSE

(P)

‘1~--

OPE’PJ

(P 1)

When ~ is closed, the accel/decel set time is

neglected, and the motor is accelerated or

decelerated in short time by the current limit

accel/decel function.

\Vhen ~ is not to be used, leave pin No. 12

open.

Selecting “1” on bit 10 of SELCD 1 ( /L--~:=)

permits change to servo mode.

II~ II

: Soft start cancel at

1CI+12 “close”

[

~

This signal is for selecting P/F’1 control of speed

regulator.

I \\’hen ~ is closed, the speed controller swithes

to P control, regardless of the operation state.

~Iyhen not performing P control, leave pin TXo.13

open.

: Changes to Servo mode at

“ 1“

lCN-12 “close”

The gain of speed loop, etc,

changes to servo mode

[

1

–18–

Page 29

Table 5.1 Functions of Sequence Input Signals (Cent’d)

Signal

;Speed

Referen

;Selectio

:Signal

Im

.41arm

Reset

[m

Connector

No.

1 CN

1 CN

Pin

No.

13

5

On

Signal

OPEN

(analog)

CLOSE

(digital)

CLOSE

1

OPEN

Function

.

The type of speed reference input [ analog

input (10 V/100

YO ) or digital input ] is selected

with this signal.

.

When ml is opened, it is analog speed refer-

ence, and when it is closed, it is digital speed

input during base blocking.

.

The following four can be selected for digital

speed input (preset at the factory before

dehvery).

“ 12-bit binary

. 3-digit BCD

. 2-digit BCD

o Internal speed setting

These selections are determined by SELCD 1

( [,-,.~: ~

—

J

‘ This signal is for restoring the run ready state

after eliminating the cause of the tripping of the

protective circuit, as the result of overload.

~m is effective only after the tripping of a

protecting circuit.

I While ~] or ml is c’[osed, or ~] is closed,

with orientation card resetting is not possible.

I The ~~ switch incorporated in the controller

is equivalent to this signal in function.

~Resetting is effected at the edge of ~].

Therefore, open ~] if closed.

In the protective circuit sequence, malfunction

has priority. An example of the timing chart

for resetting is given below.

OVERLOAD

,ROTECT,O,,,.,, ~~

CLOSE

m

m

““~

I

m

0’ ~~

&L&!mm ~~

CIRCUIT TRIF>

In addition, there are orientation command, LTgear selection and M-gear selection as

sequence input signals. For detads, see “Magnetic Sensor Type Spindle Orientation” on

page 83.

–19-

RESET END

Page 30

5.2 SPEED REFERENCE

~jA*

T

-1

Table 5.2 Speed Reference Input

Signal

Analog

Reference

[Xml

Digital

Speed

Input

(Dlto D12

;onnector Pin

Lo. No.

1 Cx

2 CN

Function

I “ Rated input voltage is +10 VDC,

3

I

o

‘l’he allowable input voltage is *12 VDC.

However, since the controller limits it at 105

value, the maximum speed of the motor is limited at 105 %

of the rated speed.

The input impedance of - is 50 k 0-.

\

10:%

x

RA:!E (‘,I>EF-l)

,,,R,*ARDF,,v ;

H6.\

—r m

‘1 “v :’0’2”

<EVFP’,1Hl\

j.......... ;

R.lT~!l \!Ef.[,

With various combinations of 1“5% . ..... ......

NCOM’ and run signals,

speeds and directions of

rotation shown below are

–,m~o R

obtained.

m

is effective and the motor runs when run signal

ml or ~ is closed.

While ml or REV: is on,

sometimes the motor will not

stop completely even when [NCOM is set to O V. To

stop the motor completely, open ~0~ or -l whichever

is closed. (While either is closed, current flows. )

To improve noise resistance, use shielded lead for the

~NCOM~ circuit.

When setting =~1 manually,

the reference ~oltage of the

controller can be used,

provided the current is

kept up to 10 m.A.

~~’~;R-:(: I

.

1

‘I’wo types of speed settings (Internal speed setting

to

12

T

Lo

and external digital speed setting) can selected.

The follo~ving three can be selected for digital speed inputs

(preset at th~ factory before delivery). - -

. 12-bit binary “ 3-digit BCD

. 2-digit 13CD

—

Speed setting method is changed by the control constants

( E-- ?Z ) SELCD 1 bit,

8

SEI.CII 1 Bitl!) 141312111098765 43210

YO of rated

)05’%

FOR] ;

105%

vS-626MT ~

~,;l~

L-1

SELCD 1 is selected in hexadecimal.

- Selecting method of’ speed settinglCN-5, 19=CD 1 ( ‘.-75 )

OFF:- –I-O

ON

ON ,0 0 0

ONIO~~O,O

ON~l

‘--”-::~b~d=:=

lBlt3~Blt2 Bitl Bit O~

.——. ——

..–––— ——–- ----- —————

-——

1 0 [nlernal speed setting

—~ +

o ~ o 1,0

–20-

Analog speed setting

2-digit BCD

Binary

I

3-dig-it BCD

Page 31

Table 5.2 Speed Reference Input (Cent’d)

Signal

Digital

Speed

Input

(Dlto D12

Connector

No.

2 CN

Pin

No.

to

12

Function

For digital speed (binary BCD) and internal speed

1

setting, forward and reverse run are selected by

contact signal of FOR “REV from outside.

.

Internal speed setting

Speed setting number : 8 steps

Setting value : % setting for N 100 (rated speed)

is input in !:4-1-’-:I to ‘-!:

,5$?-’+3

E,-,-’W

,5#.,- q ~

When the plural speed selecting contacts turn ON

simultaneously, lower speed setting No. is available.

When all speed selecting contacts turn OFF, speed

setting is O.

During operation setting constanw ( [,- -’-:: to ‘-:!2 )

cannot be selected.

This function is not applicable to PROM for winding

selection.

SPD 3 3

I SF’D4

SPD 5

I

I

I

4

5

(0.00 to 100.00)

D3

I

D4

I

D5

I

12-bit binary, 2-digit BCD or 3-digit 13CD can be selected

1

to

12

for the ‘digital speed input (preset at the factory before

delivery).

External digital speed setting,

D3

D4

D5

D6

D7 7i

D8

D9

D 10

D 11

D

12

“ 12-bit Binary becomes the rated speed input when all

signals are closed.

. 3-digit BCD becomes the rated speed input at 999.

0 2-digit BCD becomes the reted speed input at 99.

3: 4 4

41

5: 16

6;

81 128

9! 256

8 8

10

11

12 ~

–21-

i

:! ‘A

10 1

Page 32

5.2 SPEED REFERENCE (Cont’d)

Table 5.2 Speed Reference Input (Cent’d)

Signal

Base Bloc]

Signal

m

~Winding \

Selection

Signal )

\

Connector

No.

lCN

Pin

No.

14

On

Signal

CLOSED

Function

Base block signal activates by selecting 1 for

bit 11 of SELCD1 ( [,-,-/~I ).

Bit 15141312111098765 43210

mr3scmlIm

I

,,0 : CHW, (lGN- 14) signal is unavailable

k

“1” : Baseblock at lCN-14 “closed”

(Motor coasting to a stop)

This signal is originally used for winding

selection .

is not used for base block.

—

There fore winding selection PRO M

-22-

Page 33

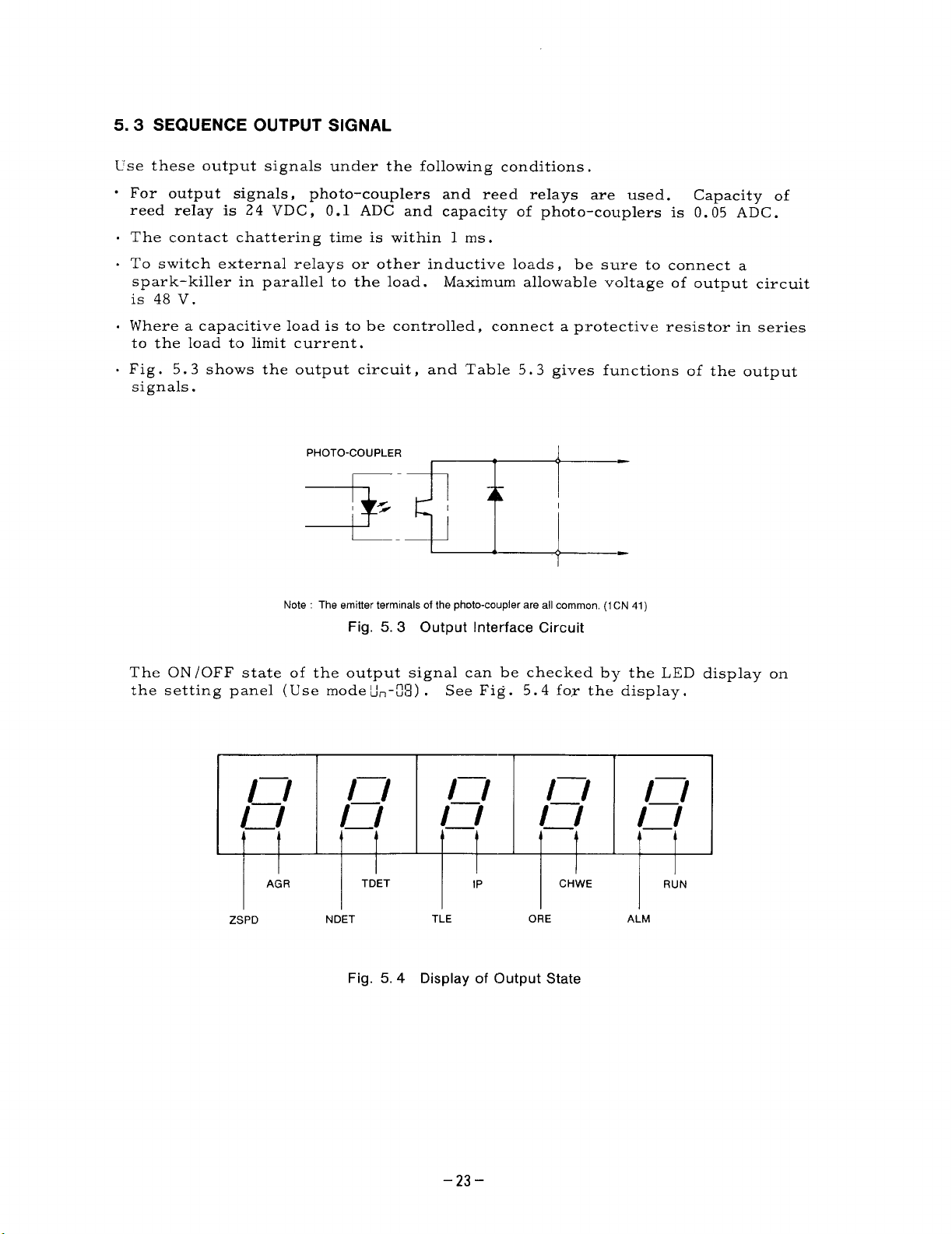

5.3 SEQUENCE OUTPUT SIGNAL

Use these output signals under the following conditions.

o For output signals, photo-couplers and reed relays are used.

reed reIay is