Page 1

Page 2

Preface

How to Change the Digital Operator Display from Japanese to English

The VARISPEED-626MC5Series of general-purposeInvertersprovidesV/f control and vector control as standard features along with user-friendly operation.

This manual is designed to ensure correct and suitable application of VARISPEED-626MC5-series

Inverters.Readthis manual beforeattemptingto install,operate,maintain, orinspectan Inverter and

keep it in asafe, convenient locationfor futurereference. Beforeyou understandall precautionsand

safety information before attempting application.

i

Page 3

Safety Information

The following conventionsare used to indicateprecautions in this manual. Failure to heed precautions provided

in this manual canresult in seriousor possibly even fatalinjury ordamageto theproducts orto relatedequipment

and systems.

!

WARNING Indicates precautions that, if not heeded, could possibly result in loss of life or

CAUTION Indicates precautions that, if not heeded, could result inrelatively serious orminor

!

The warning symbolsfor ISO and JIS standards are different, as shown below.

The ISO symbol is used in this manual.

Bothofthesesymbols appearon warninglabelson Yaskawaproducts.Pleaseabide by thesewarninglabelsregard-

lessof whichsymbol isused.

serious injury.

injury, damage to the product, or faulty operation.

ISO JIS

Yaskawa, 2000

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted,

in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

writtenpermissionof Yaskawa. Nopatentliability isassumedwith respectto theuse of theinformation contained

herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information

contained in this manual is subject to change without notice. Every precaution hasbeen taken in the preparation

of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is any liability

assumed for damages resulting from the use of the information contained in this publication.

ii

Page 4

Visual Aids

How to Change the Digital Operator Display from Japanese to English

The following aids are used to indicate certain types of information for easier reference.

AEXAMPLE"

INFO

IMPORTANT

Indicates application examples.

Indicates supplemental information.

Indicates importantinformation that should be memorized.

iii

Page 5

General Precautions

D The diagrams in this manual may be indicated without covers or safety shields to show de-

tails. Be sure to restore covers or shields before operating the Units and run the Units according to the instructions described in this manual.

D Any illustrations, photographs, or examples used in thismanual are provided as examples

only and may not apply to all products to which this manual is applicable.

D The products and specifications described in this manual or the content and presentation

of the manual may be changed without notice to improve the product and/or the manual.

D When ordering a newcopy of the manual due to damage orloss, contact your Yaskawarep-

resentatives or the nearest Yaskawa sales office and provide the manual number shownon

the front cover.

D If nameplates become warn or damaged, order new ones from your Yaskawa representa-

tives or the nearest Yaskawa sales office.

iv

Page 6

Safety Precautions

J Confirmations upon Delivery

D Never installan Inverter that is damaged or missing components.

Doing so can result in injury.

J Installation

D Always hold the case when carryingthe Inverter.

If the Inverter is held by the front cover, the main body oftheInvertermay fall,possiblyresultingininjury.

D Attach the Inverterto a metal or othernoncombustible material.

Fire can result if the Inverter is attached to a combustible material.

D Install a cooling fan or other cooling device when installing more thanone Inverter in

thesame enclosureso thatthe temperatureof the airentering theInvertersis below

45_C.

Overheating can result in fires or other accidents.

J Wiring

D Always turn OFF the input power supply before wiring terminals.

Otherwise, an electric shock or fire can occur.

D Wiring mustbe performed by an authorized person qualified in electricalwork.

Otherwise, an electric shock or fire can occur.

D Be sure to ground the ground terminal.

(200 V class:Ground to 100 : or less,400 V class:Ground to 10 : or less)

Otherwise, an electric shock or fire can occur.

D Always check the operationof any emergency stop circuits after they are wired.

Otherwise, there is the possibility of injury. (Wiring is the responsibility of the user.)

D Never touch the outputterminalsdirectlywith yourhands orallow theoutput lines to

come into contact with the Invertercase. Never short the outputcircuits.

Otherwise, electrical shock or grounding can occur.

How to Change the Digital Operator Display from Japanese to English

CAUTION

Page

NO TAG

CAUTION

Page

NO TAG

NO TAG

NO TAG

WARNING

Page

NO TAG

NO TAG

NO TAG

NO TAG

NO TAG

CAUTION

D Check to be sure that the voltage of the main AC power supply satisfies the rated

voltage of the Inverter.

Injuryor firecan occurif the voltageis not correct.

D Do not perform voltage withstand tests on the Inverter.

Otherwise, semiconductor elementsand other devices can be damaged.

D Connectbrakingresistors,BrakingResistor Units, and BrakingUnits as shownin the

I/O wiring examples.

Otherwise, a fire can occur.

D Tighten allterminal screws to the specified tightening torque.

Otherwise, a fire may occur.

D Do not connect AC power to output terminals U, V,and W.

Theinteriorparts of theInverterwill bedamagedif voltage is applied tothe output terminals.

v

Page

NO TAG

NO TAG

NO TAG

NO TAG

NO TAG

Page 7

CAUTION

D Do notconnect phase-advancingcapacitors orLC/RC noisefilters to the outputcir-

cuits.

The Inverter can be damaged or internal parts burntif thesedevicesare connected.

D Do not connect electromagneticswitches or contactorsto the output circuits.

Ifa loadis connectedwhile the Inverter isoperating,surgecurrentwill cause the overcurrent

protection circuit inside the Inverter to operate.

J Setting User Constants

CAUTION

D Disconnect the load (machine, device) from the motor before autotuning.

The motor may turn, possibly resulting in injury or damage to equipment. Also, motor

constantscannot be correctly set withthe motorattachedto a load.

J Trial Operation

WARNING

D Check to besure thatthefrontcover is attached beforeturning ON the powersupply.

Do not remove the front cover during operation.

An electric shock may occur.

D Donot come closetothemachinewhen thefault reset functionis used.Ifthealarmed

is cleared,the machine may start movingsuddenly.

Also, design the machine so that human safety is ensured even when it is restarted.

Injury may occur.

D Provide a separateemergency stop switch;the Digital OperatorSTOP Key is valid

only when its function is set.

Injury may occur.

D ResetalarmsonlyafterconfirmingthattheRUN signalis OFF. If an alarmis resetwith

the RUN signal turned ON, the machine may suddenly start.

Injury may occur.

CAUTION

D Don’t touch the radiation fins (heat sink), braking resistor,or Braking Resistor Unit.

These can become very hot.

Otherwise, a burn injury mayoccur.

D Be sure that the motor and machine is within the applicable ranges before starting

operation.

Otherwise, an injury may occur.

D Provide a separate holding brake if necessary.

Otherwise, an injury may occur.

D Don’t check signals whilethe Inverter is running.

Otherwise, the equipment may be damaged.

D Becarefulwhen changing Invertersettings.The Inverteris factory set to suitableset-

tings.

Otherwise, the equipmentmay be damaged.Youmust,however,you must set the powersupply voltage jumperfor 400 V classInvertersof 18.5 kW or higher(see NO TAG).

NO TAG

NO TAG

Page

NO TAG

Page

NO TAG

NO TAG

NO TAG

NO TAG

Page

NO TAG

NO TAG

NO TAG

NO TAG

NO TAG

vi

Page 8

How to Change the Digital Operator Display from Japanese to English

J Maintenance and Inspection

WARNING

D Do not touch the Inverterterminals. Some of the terminals carry high voltages and

are extremelydangerous.

Doing so can result in electric shock.

D Alwayshave the protectivecoverin place whenpowerisbeing suppliedto theInvert-

er. When attaching the cover, always turn OFF power to the Inverter through the

MCCB.

Doing so can result in electric shock.

D AfterturningOFFthemain circuitpower supply,waituntil the CHARGEindicatorlight

goes out before performance maintenance or inspections.

The capacitor will remain chargedand is dangerous.

D Maintenance, inspection,and replacement of parts must be performed only by au-

thorized personnel.

Remove allmetal objects,such as watches and rings, beforestarting work.Always

use grounded tools.

Failure to heed these warning can result in electric shock.

CAUTION

D ACMOS IC is used inthecontrolboard.Handlethe controlboardand CMOS ICcare-

fully. The CMOS IC can be destroyed by staticelectricity if touched directly.

The CMOS IC can be destroyed by static electricity if touched directly.

D Do not change the wiring,or remove connectorsor the DigitalOperator,during op-

eration.

Doing so can result in personalinjury.

J Other

WARNING

D Do not attempt to modify or alter the Inverter.

Doing so can result in electrical shock or injury.

Page

NO TAG

NO TAG

NO TAG

NO TAG

Page

NO TAG

NO TAG

vii

Page 9

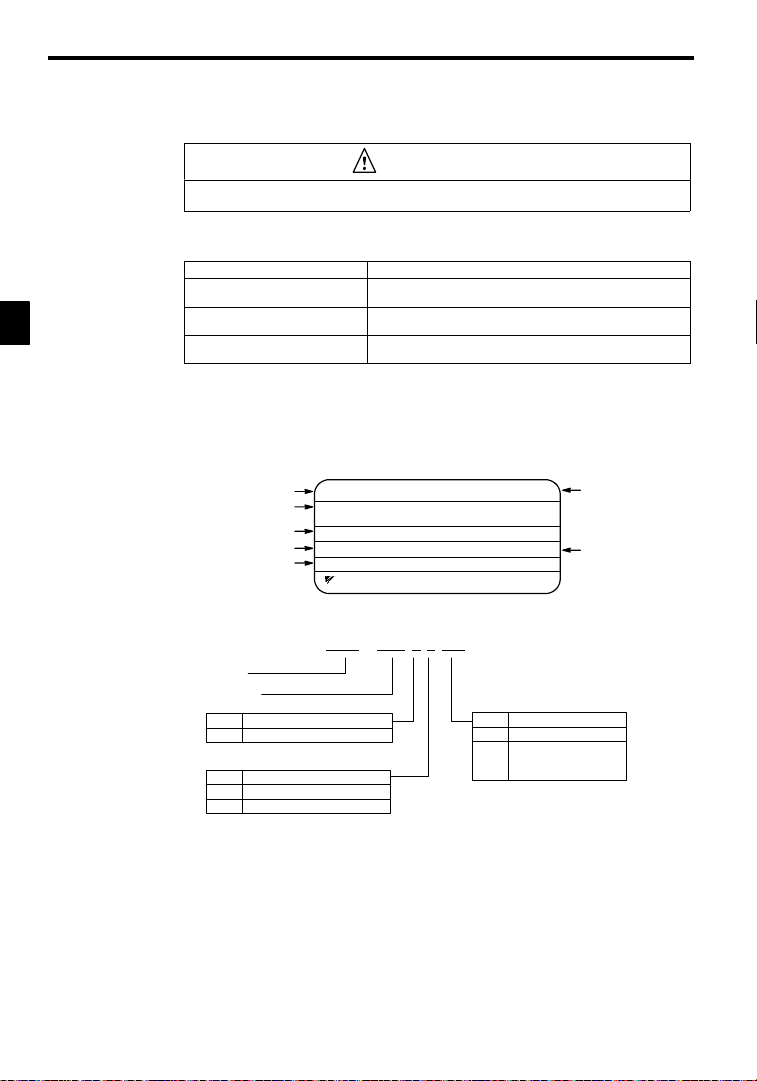

Warning Label Contents and Position

There is a warning label on the Inverter in the position shown in the following illustration. Always heed the warnings given on thislabel.

6

2

6

M

C

5

Warning label

position

Illustration shows the CIMR-MC5A23P7

Warning Label Contents

WARNING

S

S 1

S

May cause injury or electric

shock.

S Please follow the instructions in

the manual before installation or

operation.

S Disconnect all power before opening

front cover of unit. Wait 1 minute

until DC Bus capacitors discharge.

S Use proper grounding techniques.

viii

Page 10

How to Change the Digital Operator Display from Japanese to English

How to Change the Digital Operator Display from Japanese to English

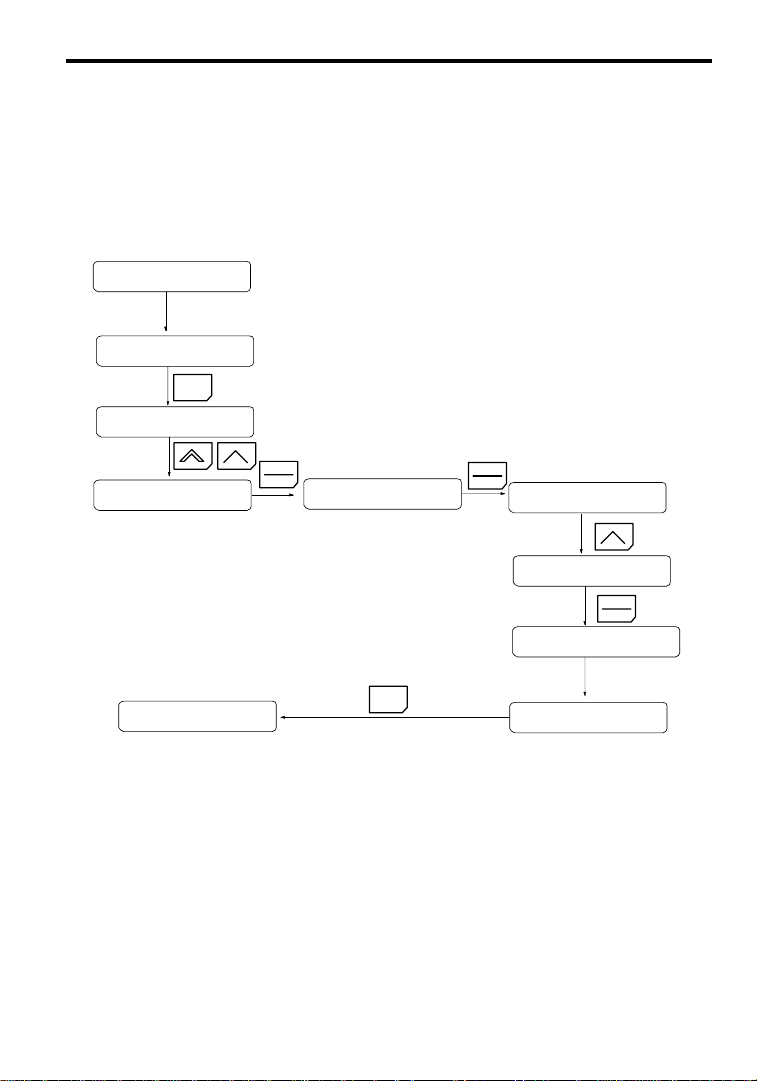

Ifthe DigitalOperator displaysmessagesin Japanese,change to the English mode using thefollowing steps.

(This manual provides descriptions for the English mode.)

Power ON

U1--01=0.00 HZ

MENU

MC5

MC5

Main Menu

Operation

DATA

ENTER

(Language)

(Japanese)

MENU

ix

DATA

ENTER

A1--00=1

(Japanese)

A1--00=0

English

ENTER

Entry Accepted

Select language

English

DATA

Page 11

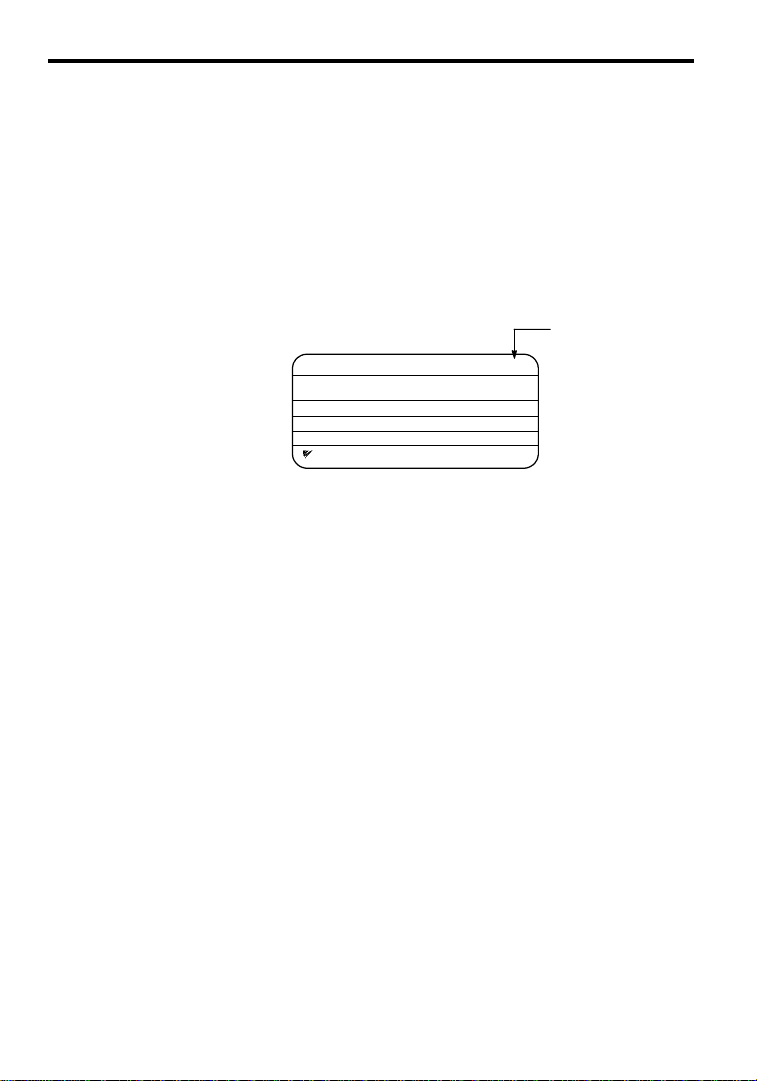

Before Reading This Manual

V

This manual explains both the conventional VS--626MC5 Inverters and the MC5--series Inverters

for SPEC: F.

The shaded sections or those specified as being for SPEC: F apply only to MC5--series Inverters for

SPEC: F (Inverters with revised version letters of F or later.)

Be certain to check the specification on the Inverter nameplate.

Example of Inverter Nameplate

MODEL : CIMR--MC5A20P4 SPEC: 20P41F

INPUT : AC 3PH 200-220 V 50Hz

OUTPUT: AC 3PH 0-230 V 1.2kVA 3.2 A

LOT NO : MASS : 3.0kg

SER NO :

YASKAWA ELECTRIC COR PORATION

200-230 V 60Hz

JAPAN

ersion code

x

Page 12

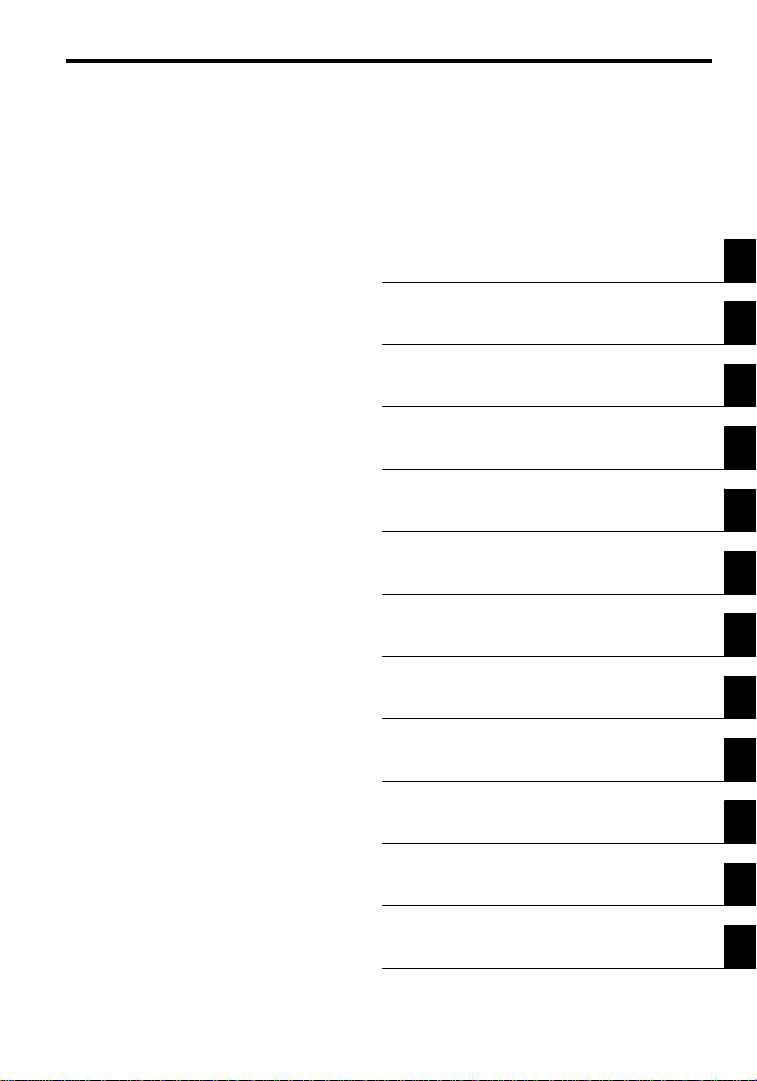

CONTENTS

11 Introduction

12 Handling Inverters

13 Wiring

14 Setting User Constants

15 Trial Operation

16 Basic Operation

17 Advanced Operation

18 User Constants

19 Troubleshooting

10 Maintenance and Inspection

1

2

3

4

5

6

7

8

9

10

11 Specifications

12 Appendix

xi

11

12

Page 13

Table of Contents

1 Introduction 1 - 1.........................................

1.1 Outline and Functions 1 - 2........................................

1.1.1 VS-626MC5 InverterModels 1 -2.............................................

1.1.2 Outline of Control Methods 1 -4...............................................

1.1.3 Functions 1 - 4.............................................................

1.2 Nomenclature 1 - 7...............................................

1.2.1 VS-626MC5 Components 1- 7................................................

1.2.2 Digital Operator Components 1- 8.............................................

2 Handling Inverters 2 - 1...................................

2.1 Confirmations upon Delivery 2 - 2..................................

2.1.1 Nameplate Information 2 - 2..................................................

2.2 Exterior and Mounting Dimensions 2 - 4.............................

2.3 Checking and Controlling the Installation Site 2 - 6.....................

2.3.1 Installation Site 2 - 6........................................................

2.3.2 Controlling the Ambient Temperature 2 - 6.......................................

2.3.3 Protectingthe Inverter from Foreign Matter 2 -6..................................

2.4 Installation Orientation and Space 2 - 7...............................

2.5 Removing/Attaching the Digital Operator and

Front Cover 2 - 8

2.5.1 Invertersof 15 kW or Less 2 -8...............................................

2.5.2 Invertersof 18.5 kW or Higher 2 -9............................................

3 Wiring 3 - 1..............................................

3.1 Connections to Peripheral Devices 3 - 3..............................

3.2 Connection Diagram 3 - 4.........................................

3.3 Terminal Block Configuration 3 - 5..................................

3.4 Wiring Main Circuit Terminals 3 - 6.................................

3.4.1 ApplicableWire Sizes and Closed-loopConnectors 3 -6............................

3.4.2 Main Circuit Terminal Functions 3 -9...........................................

3.4.3 Main Circuit Configurations 3 -10..............................................

3.4.4 Standard Connection Diagrams 3 -12............................................

3.4.5 Wiring the Main Circuits 3 - 13.................................................

3.5 Wiring Control Circuit Terminals 3 - 20...............................

3.5.1 Wire Sizes and Closed-loop Connectors 3 - 20.....................................

3.5.2 Control Circuit Terminal Functions 3- 21.........................................

3.5.3 Control Circuit Terminal Connections(All Models) 3 -22............................

3.5.4 Control Circuit Wiring Precautions 3 - 23.........................................

3.6 Wiring Check 3 - 23...............................................

3.7 Installing and Wiring PG Speed Control Cards 3 - 24.....................

3.7.1 Installing a PG Speed Control Card 3- 24.........................................

3.7.2 PG Speed Control Card Terminal Blocks 3 - 25....................................

3.7.3 Wiring a PG Speed Control Card 3 -26...........................................

3.7.4 Wiring PG Speed ControlCard TerminalBlocks 3 -28...............................

3.7.5 Selectingthe Numberof PG (Encoder) Pulses 3 -30.................................

4 Setting User Constants 4 - 1................................

4.1 Using the Digital Operator 4 - 2.....................................

xii

Page 14

Tableof Contents

4.2 Modes 4 - 4....................................................

4.2.1 InverterModes 4 - 4........................................................

4.2.2 Switching Modes 4 -5.......................................................

4.2.3 User Constant Access Levels 4 - 6..............................................

4.2.4 OperationMode 4 - 11.......................................................

4.2.5 Initialize Mode 4 - 18........................................................

4.2.6 Programming Mode 4 -26....................................................

4.2.7 Autotuning Mode 4 -29......................................................

4.2.8 Modified Constants Mode 4 -31................................................

5 TrialOperation 5 - 1......................................

5.1 Procedure 5 - 3..................................................

5.2 Trial Operation Procedures 5 - 4....................................

5.2.1 Power ON 5 - 4............................................................

5.2.2 Checking the Display Status 5- 4..............................................

5.2.3 Initializing Constants 5 - 4....................................................

5.2.4 Setting Input Voltage 5 - 5....................................................

5.2.5 Autotuning 5 - 6...........................................................

5.2.6 No-load Operation 5 - 8......................................................

5.2.7 Loaded Operation 5 - 9......................................................

6 Basic Operation 6 - 1......................................

6.1 Common Settings 6 - 2...........................................

6.1.1 Setting the Access Level and Control Method: A1-01, A1-02 6 -2.....................

6.1.2 Frequency ReferenceSettings:b1-01, H3-01, H3-08, H3-09 6 -4.....................

6.1.3 Frequency Referencefrom Digital Operator: b1-01, o1-03, d1-01 to d1-09 6 - 7..........

6.1.4 Run Source and SequenceInput Responsiveness: b1-02, b1-06, b1-07 6 -9..............

6.1.5 Acceleration/Deceleration Times: C1-01 through C1-08, C1-09,C1-10, C1-11 6 -10.......

6.1.6 Prohibiting Reverse Operation: b1-04 6 - 11.......................................

6.1.7 Selectingthe StoppingMethod: b1-03 6 -12......................................

6.1.8 Multi-function Input Settings: H1-01 throughH1-06 6 -12...........................

6.2 Open-loop Vector Control 6 - 17.....................................

6.2.1 Autotuning for general-purpose motors 6 -17......................................

6.2.2 Autotuning for machine tool spindlemotors 6 -18..................................

6.2.3 Autotuning Faults 6 -21......................................................

6.3 Flux VectorControl 6- 22..........................................

6.3.1 PG Speed Control Card Settings 6 - 22...........................................

6.3.2 Setting the Zero-speed Operation Constants 6 - 25..................................

6.3.3 Autotuning for general-purpose motors 6 -27......................................

6.3.4 Autotuning for machine tool spindlemotors 6 -29..................................

6.3.5 Autotuning Faults 6 -31......................................................

6.3.6 Speed Control(ASR) Structure 6 - 32............................................

6.3.7 Speed Control (ASR) Gain 6 -34...............................................

7 Advanced Operation 7 - 1..................................

7.1 Open-loop Vector Control 7 - 2.....................................

7.1.1 TorqueLimit Function 7 -3...................................................

7.1.2 Adjusting Speed Feedback 7- 5...............................................

7.1.3 Setting/Adjusting Motor Constants 7 - 5.........................................

7.1.4 Operation Selectionwhen Output Voltage Saturated 7 - 8............................

7.1.5 Starting Torque Compensation Function (forSPEC: F) 7 -9..........................

7.2 Flux VectorControl 7- 10..........................................

7.2.1 TorqueLimit Function 7 - 11...................................................

7.2.2 Setting/Adjusting Motor Constants 7 -12.........................................

7.2.3 Operation Selectionwhen Output Voltage Saturated 7 - 16............................

7.3 Common Functions 7 - 17..........................................

7.3.1 ApplicationConstants:b 7 -18.................................................

7.3.2 Tuning Constants: C 7 -21....................................................

7.3.3 ReferenceConstants: d 7 - 24..................................................

7.3.4 Option Constants: F 7 - 26.....................................................

xiii

Page 15

7.3.5 External Terminal Functions:H 7 - 31............................................

7.3.6 ProtectiveFunctions:L 7 - 48..................................................

7.3.7 OperatorConstants:o 7 - 60...................................................

7.4 Optional Functions 7 - 64..........................................

7.4.1 Winding Change Function 7 - 64................................................

7.4.2 Wiring for WindingChange 7 - 66..............................................

7.4.3 Setting/Adjusting the WindingChange Constants 7 -69..............................

8 User Constants 8 - 1.......................................

8.1 Initialize Mode Constants 8 - 3.....................................

8.2 Programming Mode Constants 8 - 4.................................

8.2.1 ApplicationConstants:b 8 - 4.................................................

8.2.2 Autotuning Constants: C 8- 7.................................................

8.2.3 ReferenceConstants: d 8 - 12..................................................

8.2.4 Motor ConstantConstants: E 8 - 14..............................................

8.2.5 Options Constants: F 8- 18....................................................

8.2.6 Terminal Constants:H 8 - 21...................................................

8.2.7 ProtectionConstants:L 8 - 26..................................................

8.2.8 OperatorConstants:o 8 - 32...................................................

8.2.9 Winding Change Constants:P 8- 34.............................................

8.2.10 Factory Settings that Change with the Control Method (A1-02) 8 -35..................

8.2.11 Factory Settings that Change with the Inverter Capacity (o2-04) 8 -36..................

9 Troubleshooting 9 - 1......................................

9.1 Protective and Diagnostic Functions 9 - 2.............................

9.1.1 Fault Detection 9 - 2........................................................

9.1.2 Minor FaultDetection 9 - 6...................................................

9.1.3 Operation Errors 9 - 8.......................................................

9.2 Troubleshooting 9 - 9.............................................

9.2.1 If ConstantConstantsCannot Be Set 9- 9........................................

9.2.2 If the Motor DoesNot Operate 9 - 9............................................

9.2.3 If the Directionof the Motor Rotationis Reversed 9- 11.............................

9.2.4 If the Motor Does Not Put Out Torque or If Acceleration is Slow 9 - 11..................

9.2.5 If the Motor Does Not Operate According to Reference 9 - 11.........................

9.2.6 If the Slip Compensation Function HasLow Speed Precision 9 -11.....................

9.2.7 If Thereis Low Speed Control Accuracy at High-speed Rotation in Open-loop

Vector Control Mode 9 - 11....................................................

9.2.8 If Motor Deceleration is Slow 9 - 12.............................................

9.2.9 If the Motor Overheats 9 - 12...................................................

9.2.10 If Thereis NoiseWhen the Inverteris Started or From an AM Radio 9 -12..............

9.2.11 If the Ground FaultInterrupterOperates When the Inverter is Run 9 -13................

9.2.12 If There is Mechanical Oscillation 9 - 13.........................................

9.2.13 If the Motor Rotates Even When Inverter Output is Stopped 9 - 13.....................

9.2.14 If 0 V is Detected When the Fan is Started, or Fan Stalls 9 - 13........................

9.2.15 If Output Frequency Does Not Riseto Frequency Reference 9 -14.....................

9.2.16 Winding change errorhas occurred 9 - 14........................................

10 Maintenance and Inspection 10 - 1...........................

10.1 Maintenance and Inspection 10 - 3...................................

10.1.1 Daily Inspection 10 - 3......................................................

10.1.2 Periodic Inspection 10 - 3....................................................

10.1.3 Periodic Maintenanceof Parts 10 - 3............................................

11 Specifications 11 - 1........................................

11.1 Standard Inverter Specifications 11 - 2................................

11.2 Specifications of Options and Peripheral Devices 11 - 6...................

12 Appendix 12 - 1...........................................

12.1 Inverter Application Precautions 12 - 2................................

xiv

Page 16

Tableof Contents

12.1.1 Selection 12 -2...........................................................

12.1.2 Installation 12 - 2.........................................................

12.1.3 Settings 12 -3...........................................................

12.1.4 Handling 12 - 3..........................................................

12.2 Motor Application Precautions 12 - 4.................................

12.2.1 Usingthe Inverter for an Existing StandardMotor 12 - 4...........................

12.2.2 Usingthe Inverter for SpecialMotors 12 - 5.....................................

12.2.3 Power Transmission Mechanism (Speed Reducers,

Belts,and Chains) 12 -5...................................................

12.3 Peripheral Device Application Precautions 12 - 6........................

12.4 Wiring Examples 12 - 8.............................................

12.4.1 Using a Braking Resistor Unit 12 - 8............................................

12.4.2 Using a Braking Unit and Braking ResistorUnit 12 - 8..............................

12.4.3 Using TwoBraking Units in Parallel 12 -11....................................

12.4.4 Using Three Braking Resistor Units in Parallel 12 - 12..............................

12.4.5 Using a JVOP-95-j,-96-j VS Operator 12 - 13...................................

12.4.6 Using an Open-collector Transistorfor Operation

Signals 12 - 14............................................................

12.4.7 Using Open-collector,Contact Outputs 12 - 14.....................................

12.5 UserConstants 12 - 15..............................................

xv

Page 17

1

Introduction

This chapter provides an overview of the VS-626MC5 Inverter and describes its functions and components.

1.1 Outline and Functions 1 - 2....................

1.1.1 VS-626MC5 Inverter Models 1 - 2....................

1.1.2 Outline of Control Methods 1 - 4.....................

1.1.3 Functions 1 - 4....................................

1.2 Nomenclature 1 - 7..........................

1.2.1 VS-626MC5 Components 1 - 7......................

1.2.2 Digital Operator Components 1 - 8....................

1

-1

Page 18

Introduction

Maximum

p

listedattherigh

t

200

Vcl

p

listedattherigh

t

00Vcl

1.1.1 VS-626MC5 Inverter Models

1.1 Outline and Functions

1

Voltage

Class

4

The VS-626 MC5 Inverter is a compact spindle drive specially designed for machine tool application. MC5

Inverter has features such as winding change during operation, and autotuning function fordual winding motors.

TheVS-626MC5Invertersprovidesfull-currentvectorcontrolbased on advanced controllogic. Anautotuning

function is included for easy vector control.

The Digital Operatorprovides aliquid crystaldisplay that is 2 lines by 16 charactersin size. Userconstant settingsand monitoritems are easilyread in interactiveoperations in eitherJapaneseor English. (The display language can be changed by setting a user constant.)

1.1.1 VS-626MC5 Inverter Models

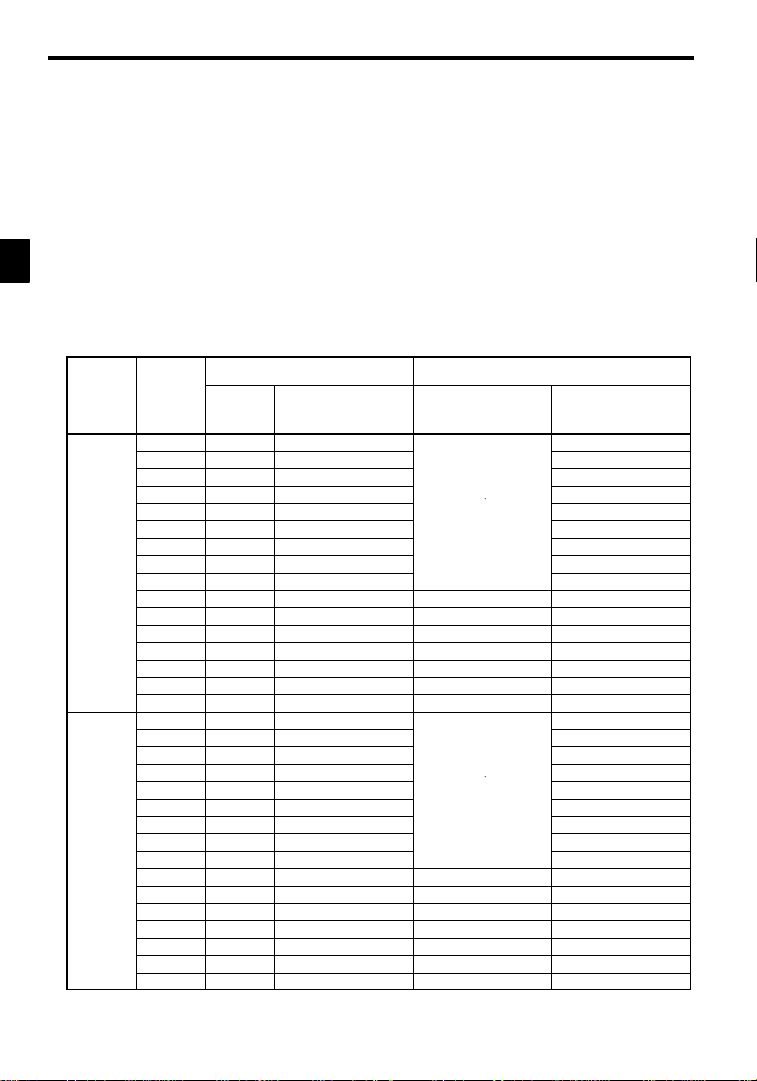

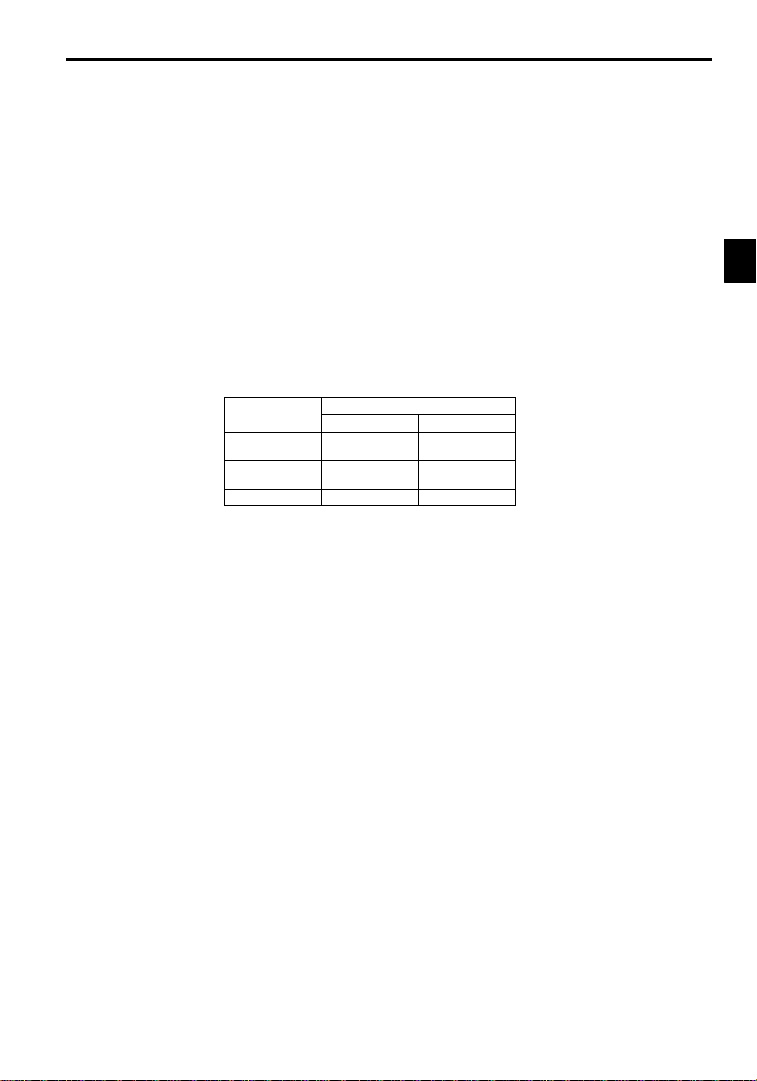

VS-626MC5Inverters are available in200 and 400V class models.These are listedin the followingtable.

A total of 32 models is available for motor capacities of 0.4 to 75 kW.

Table 1.1 VS-626MC5Inverter Models

Maximum

Applicable

ass

ass

Motor Out-

put [kW]

Output Ca-

pacity [kVA]

0.4 1.2 CIMR-MC5A20P4 20P41*

0.75 2.3 CIMR-MC5A20P7 20P71*

1.5 3.0 CIMR-MC5A21P5 21P51*

2.2 4.2 CIMR-MC5A22P2

3.7 6.7 CIMR-MC5A23P7

5.5 9.5 CIMR-MC5A25P5

7.5 13 CIMR-MC5A27P5 27P51 *

11 19 CIMR-MC5A2011 20111 *

15 24 CIMR-MC5A2015 20151 *

18.5 30 CIMR-MC5A2018 20180 * 20181 ‡

22 37 CIMR-MC5A2022 20220 * 20221‡

30 50 CIMR-MC5A2030 20300 † 20301‡

37 61 CIMR-MC5A2037 20370 † 20371‡

45 70 CIMR-MC5A2045 20450 † 20451‡

55 85 CIMR-MC5A2055 20550 † 20551‡

75 110 CIMR-MC5A2075 20750 ‡ 20751 ‡

0.4 1.4 CIMR-MC5A40P4 40P41*

0.75 2.6 CIMR-MC5A40P7 40P71*

1.5 3.7 CIMR-MC5A41P5 41P51*

2.2 4.7 CIMR-MC5A42P2

3.7 6.1 CIMR-MC5A43P7

5.5 11 CIMR-MC5A45P5

7.5 14 CIMR-MC5A47P5 47P51 *

11 21 CIMR-MC5A4011 40111 *

15 26 CIMR-MC5A4015 40151 *

18.5 31 CIMR-MC5A4018 40180 * 40181 ‡

22 37 CIMR-MC5A4022 40220 * 40221 ‡

30 50 CIMR-MC5A4030 40300 * 40301 ‡

37 61 CIMR-MC5A4037 40370 * 40371 ‡

45 73 CIMR-MC5A4045 40450 * 40451 ‡

55 98 CIMR-MC5A4055 40550 † 40551 ‡

75 130 CIMR-MC5A4075 40750† 40751‡

VS-626MC5

Model Number

Open Chassis Type

CIMR-MC5A

Remove the top and bottom

covers from the models

listed at the right.

Remove the top and bottom

covers from the models

listed at the right.

*: Immediatedelivery †: Available from factory ‡: Manufactured upon order

Inverter Specifications

(Specify all required standards when ordering.)

(IEC IP 00)

.

*

.

*

Enclosed Wall-mounted

Type

(IEC IP 20, NEMA 1)

CIMR-MC5A

22P21 *

23P71 *

25P51 *

42P21 *

43P71 *

45P51 *

-2

Page 19

1.1.2 Outline of Control Methods

The VS-626MC5 uses two control methods.

D Open-loop vector control (factory setting)

D Flux vector control

PG stands for pulse generator (encoder).

Vector control isa method for removinginterferencewithmagnetic flux and torque,andcontrolling torque

according to references.

Currentvectorcontrol independently controlsmagneticflux current and torquecurrent by simultaneously

controlling the motorprimary current and phases. Thisensures smooth rotation,high torque,and accurate

speed/torque control at low speeds.

If the motorconstants required forvector control arenot known, the motor constantscan be automatically

set with autotuning.

The control methods are effective for the following applications:

D Open-loop vector control: General variable-speed drive.

D Flux vector control: Simple servodrive, high-precision speed control/torque control.

The control characteristics for each mode are shown in Table 1.2.

Table 1.2 ControlMethod Characteristics

Characteristic

Speed Control

Range

Speed Control

Precision

Initial Drive 150% at 1 Hz 150% at 0 r/min

Open-loop Flux Vector

1.1.3 Functions

J Autotuning

Autotuning is effectivefor vectorcontrol. It solves problems in applicable motorrestrictions and difficult

constant settings. The motor constants are automatically set by entering a value from the motor’s rating

nameplate.

Autotuning allows fluxvector control tooperate accurately withvirtually any normalAC induction motor,

regardless of the supplier.

Always perform autotuning for motor unit separately before vector control operation.

J Frequency References

Thefollowing five typesoffrequency references can beused to controlthe output frequencyof the Inverter.

D Numeric input from the Digital Operator

D Voltage input within a range from 0 to 10 V

D Voltageinput within arange from 0 to r10 V (with negative voltages,rotation is in the oppositedirec-

tion from the run command.)

D Current input within a range from 4 to 20 mA

D Input from Option Card

Any of the above frequency references can be used by setting a constant.

Amaximumof nine frequency references can beregisteredwith the Inverter.Withremote multi-step speed

reference inputs, the Inverter can operate in multi-step speed operation with a maximum of nine speed

steps.

J Low Noise

Theoutput transistorof the Inverteris an IGBT (insulated gatebipolar transistor).Using sine-wave PWM

with a high-frequency carrier, the motor does not generate metallic noise.

1.1Outlineand Functions

1

Vector Control

1:100 1:1000

0.2 % 0.02 %

-3

Page 20

1

Introduction

1.1.3 Functions

J Monitor Function

The following items can be monitored with the DigitalOperator: Frequencyreference, outputfrequency,

output current, motor speed, outputvoltage reference,main-circuit DC voltage, output power,torque reference,statusof input terminals,status of outputterminals, operating status,totaloperating time,software

number, speed deviation value, PID feedback value, fault status, fault history,etc.

All types of data can be monitored even with multi-function analog output.

J Bilingual Digital Operator

The Digital Operatorcan displayeither Englishor Japanese.The Digital Operator’s liquid crystal display

provides a 16-character x 2-line display area.

Easy-to-read displays allow the advanced functions of the Inverter to be set in interactive operations to

input constants, monitoring items, etc. Change the constant setting to select the English display.

J Harmonic Countermeasures (0.4 to 160 kW Models)

The VS-626MC5 Inverters support DC reactors to easily handle high-frequency control guidelines.

D DC reactors (optional) can be connected to 0.4 to 15 kW models.

D Models from 18.5 to 75 kW have a built-in DC reactor.

J User Constant Structure and Three Access Levels

The VS-626MC5 has a number of user constants for setting various functions. These user constants are

classified into a hierarchy to make them easier to use.

Thelevels areas followsfrom topto bottom:Modes, Groups,Functions, andConstants. The access levels

for the user constants are shown in Table 1.3.

Table 1.3 AccessLevels for User Constants

Level Contents

Mode Classified according to operation

Groups Classified by application.

Functions Classified by function. See user constants.

Constants Individualuser constant settings.

TheVS-626MC5 allowsthe following three access levelsto be set in order to further simplify setting user

constants. (An access level is a range of user constants that can be referenced or set.)

Quick-Start Reads/sets user constants required for trial operation. [Factory setting]

Basic Reads/setsuser constants that are commonly used.

Advanced Reads/sets all the user constants that can be used.

Operation: For operating the Inverter. (All kinds of monitoring are possible.)

Initialize: For selecting the language displayed at the Digital Operator,set-

Programming: For setting user constants for operation.

Autotuning: Forautomatic calculation or setting motor constants. (Only under

Modified constants: For referencing or changing user constants after shipping.

ting access levels, initialization, and the control modes.

the vector control mode.)

-4

Page 21

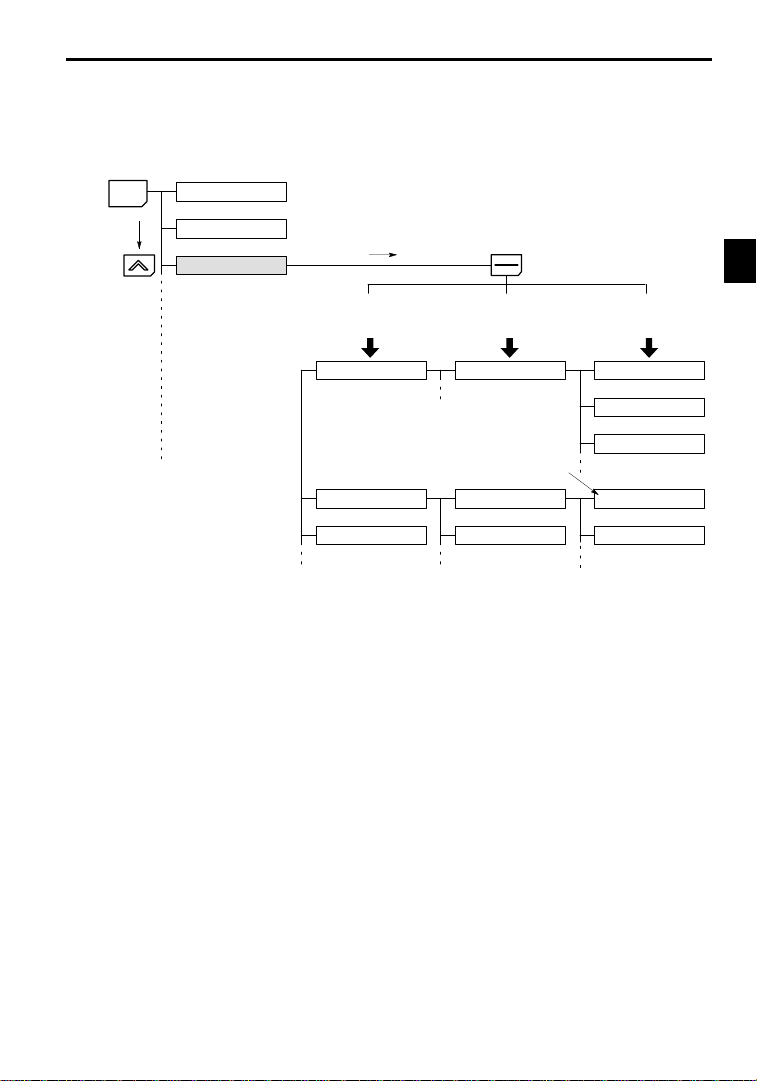

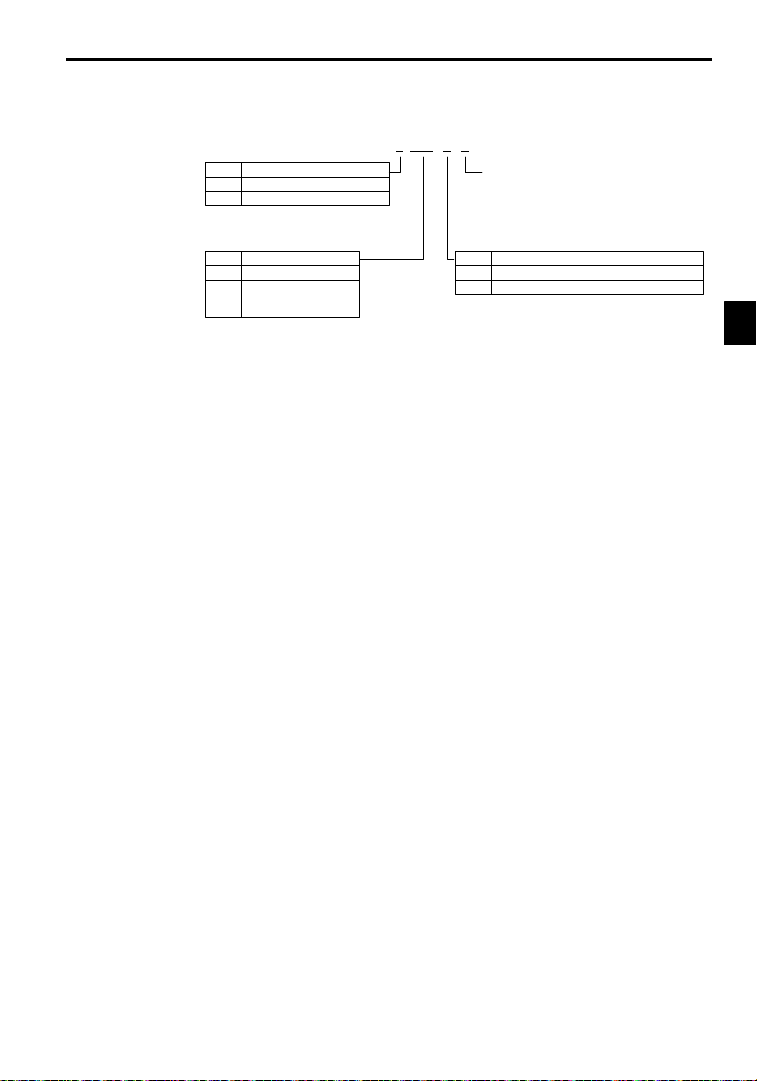

MENU

1.1Outlineand Functions

In general, press the DATA/ENTER Key to move from an upper to a lower level. This varies somewhat,

however, according to the access level, as shown in Fig. 1.1. For the Quick-Start access level, which has

fewuser constants that canbe set,pressingthe DATA/ENTERKey jumpsdirectlyto theuser constant level; whereas for the Advanced access level, which has many user constants, pressing the DATA/ENTER

Key first leads to the Group level.

Operation mode

Initialize mode

Programming mode

AdvancedBasicQuick-Start

Displays group level.

DAT

A

ENTER

Displays function level.

Displays constant level.

1

Mode

Fig 1.1 Access Level Structure

Application

Tuning

Reference

Groups

b1 Sequence

Constant to be changed

C1 Accel/Decel

C2 S-curve Acc/Dec

Functions

b1-01 Reference source

b1-02 Run source

b1-03 Stopping method

C1-01 Accel Time 1

C1-02 Decel Time 1

Constants

-5

Page 22

Introduction

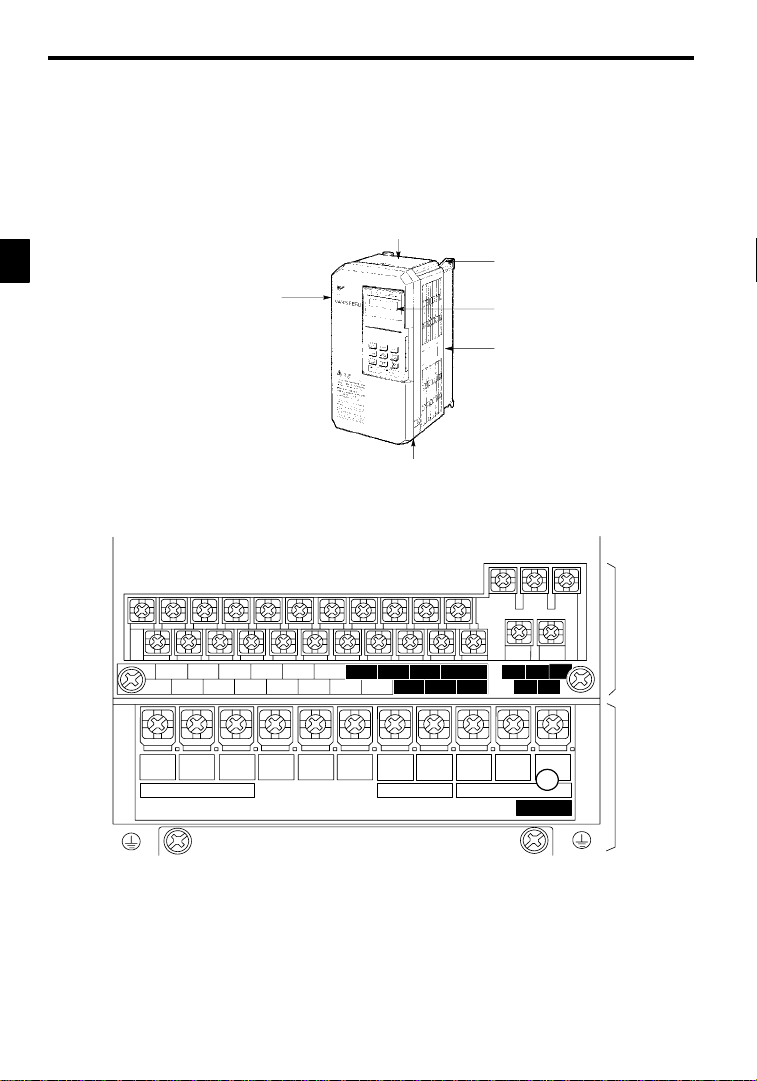

1.2.1 VS-626MC5 Components

1

1.2 Nomenclature

Thissection provides thenames of VS-626MC5 components, andthe components andfunctions of the Digital

Operator.

1.2.1 VS-626MC5 Components

The appearanceof Inverter and the names of its components are shown in Figure 1.2.

Protective cover (top)

Mounting hole

Front cover

6

2

6

M

C

5

Protective cover (bottom)

Digital Operator

JVOP-130

Die-cast case

Fig 1.2 Appearance of VS-626MC5, Model CIMR-MC5A20P4 (200 V,0.4 kW)

A 200 V Class Inverter with 0.4 kW Output is shown below with the front cover removed.

11 12(G) 13 14 15 16 17 25 26 27 33 18 19 20

1234567821 22 23 9

R

L1

S

L2

Power input

T

©

L3

¨1

¨2B1

Braking Resistor Motor output

U

B2

T1

V

T2

10

W/T3

CHARGE

Fig 1.3 TerminalArrangement

Control circuit

terminals

Main circuit

terminals

-6

Page 23

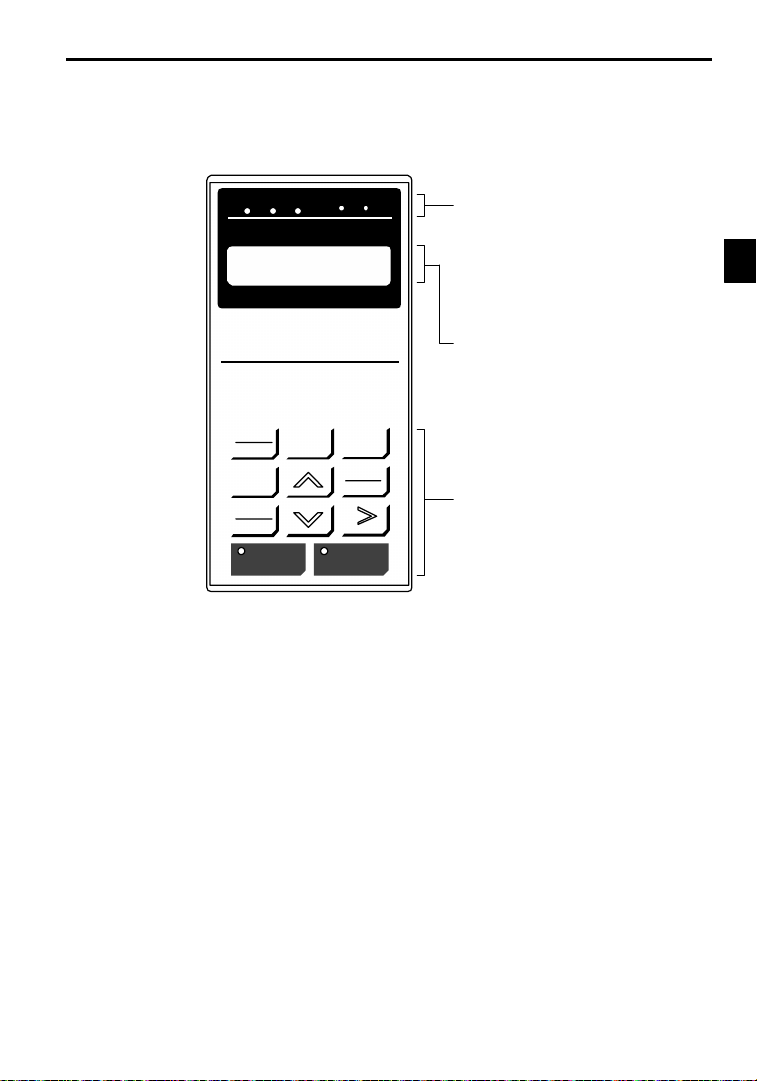

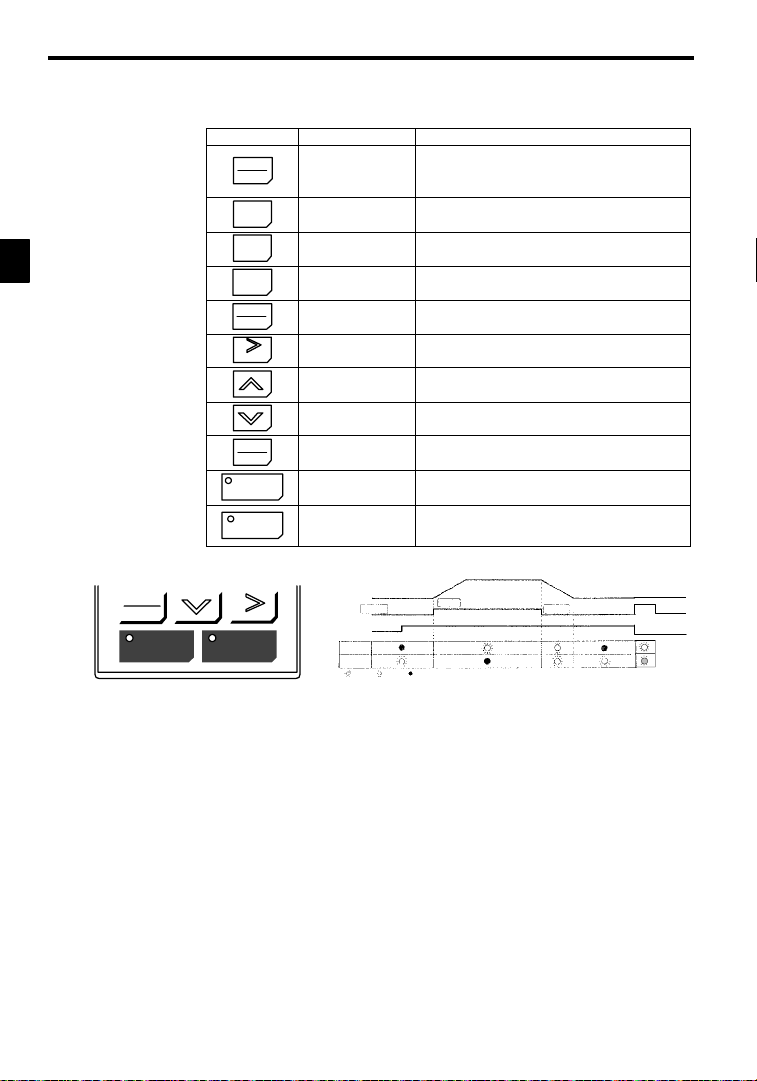

1.2.2 Digital Operator Components

Thissection describes thecomponent names and functions of theDigital Operator. The componentnames

and functions are shown in Figure 1.4 and key functions are described in Table1.4.

1.2Nomenclature

DRIVE FWD REV REMOTE

DIGITAL OPERATOR

JVOP-130

LOCAL

REMOTE

JOG

FWD

REV

SEQ REF

Frequency Ref

U1--01 = 00.00 HZ

MENU

RUN STOP

ESC

DATA

ENTER

RESET

Operation Mode Indicators

DRIVE: Lit when in operation mode.

FWD: Lit when there is a forward reference input.

REV: Lit when there is a reverse reference input.

SEQ: Lit when an operation reference from the

REF: Lit when the frequency reference from con-

Data Display

Two-line LCD that displays data for monitoring,

user constants, and set values with 16 characters

per line.

Keys

Execute operations such as setting user constants,

monitoring, jogging, and autotuning.

Fig 1.4 Digital Operator Component Names and Functions

control circuit terminal is enabled.

trol circuit terminals 13 and 14 is enabled.

1

-7

Page 24

Introduction

1.2.2 Digital Operator Components

1

Note Except in diagrams, keys are referred to using the key names listed in the above table.

FWD

REV

RUN STOP

Table 1.4 KeyFunctions

Key Name Function

LOCAL

REMOTE

MENU

FWD

RESET

LOCAL/REMOTE Key

MENU Key Displaysmenus.

ESC Key

ESC

JOG

JOG Key

FWD/REV Key

REV

RESET Key

Increment Key

Decrement Key

DAT

DATA/ENTER Key

A

ENTER

RUN

RUN Key

STOP

RESET

STOP Key

Inverter output frequency

Frequency setting

STOP

RUN

LitBlinkingNot lit

The RUN and STOP indicators light and blink to indicate operating status.

Switches between (LOCAL) operation via the Digital Operator

and control circuit terminal (REMOTE) operation.

This key can be enabled or disabled by setting a user constant

(o2-01).

Returns to the status before the DATA/ENTER Key was

pressed.

Enables jog operation when the VS-626MC5 is being operated

from the Digital Operator.

Selects the rotation direction of the motor when the

VS-626MC5 is being operated from the Digital Operator.

Sets the number of digits for user constant settings.

Also acts as the reset key when a fault has occurred.

Selects menu items, groups, functions, and user constant

names, and increments set values.

Selects menu items, groups, functions, and user constant

names, and decrements set values.

Enters menu items, functions, constants, and set values after

they are set.

Starts the VS-626MC5 operation when the VS-626MC5 is in

operation with the Digital Operator.

Stops VS-626MC5 operation.

This key can be enabled or disabled by setting a user constant

(o2-02) when operating from the control circuit terminal.

STOP

RUN

Fig 1.5 RUN and STOP Indicators

STOP

-8

Page 25

2

Handling Inverters

This chapter describes the checks required upon receiving a VS-626MC5

Inverter and describes installation methods.

2.1 Confirmations upon Delivery 2- 2..............

2.1.1 Nameplate Information 2 - 2.........................

2.2 Exterior and Mounting Dimensions 2 - 4.........

2.3 Checking and Controlling the Installation

Site 2 - 6..................................

2.3.1 Installation Site 2 - 6...............................

2.3.2 Controlling the Ambient Temperature 2 - 6..............

2.3.3 Protecting the Inverter from Foreign Matter 2 - 6.........

2.4 Installation Orientation and Space 2 - 7..........

2.5 Removing/Attaching the Digital Operator and

Front Cover 2 - 8............................

2.5.1 Inverters of 15 kW or Less 2 - 8......................

2.5.2 Inverters of 18.5 kW or Higher 2 - 9...................

2

-1

Page 26

Handling Inverters

2.1.1 Nameplate Information

2

2.1 Confirmations upon Delivery

CAUTION

D Never install an Inverter that is damaged or missing components.

Doing so can result in injury.

Check the following items as soon as the Inverter is delivered.

Table 2.1 Checks

Has the correct model of Inverter been

delivered?

Is the Inverter damaged in any way? Inspect the entire exterior of the Inverter to see if there are any scratches or

Are any screws or other components

loose?

If you find any irregularitiesin the aboveitems, contact the agency from which you purchasedthe Inverter or

your Yaskawa representative immediately.

2.1.1 Nameplate Information

J Example Nameplate

Input specifications

Output specifications

J Inverter Model Numbers

Inverter

VS-626MC5

Item Method

Check the model number o n the nameplate on the side of the Inverter (See

2.1.1).

other damage resulting from shipping.

Use a screwdriver or other tools to check for tightness.

Standard domestic (Japan) Inverter: 3-phase, 200 VAC,0.4 kW,IEC IP20 and NEMA 1 standards

Model number

Lot number

Serial number

MODEL : CIMR-MC5A20P4 SPEC: 20P41F

INPUT : AC 3PH 200-220 V 50Hz

OUTPUT: AC 3PH 0-230 V 1.2kVA 3.2 A

LOT NO : MASS : 3.0kg

SER NO :

YASKAWA ELECTRIC CORPORATION

CIMR -MC5A 2 0P4

No. Specification

A Standard domestic model

No. Voltage Class

2 AC input, 3-phase, 200 V

4 AC input, 3-phase, 400 V

200-230 V 60Hz

JAPAN

No. Max. Motor Capacity

0P4

0P7

to

075

“P” indicates the decimal point.

Inverter specifications

Mass

0.4 kW

0.75 kW

to

75kW

-2

Page 27

J Inverter Specifications

No. Voltage Class

2 AC input, 3-phase, 200 V

4 AC input, 3-phase, 400 V

2 0P4 1 F

2.1Confirmations upon Delivery

Version(Enter the specifications

form number when special specifications are required.)

No. Max. Motor Capacity

0P4

0P7

to

075

“P” indicates the decimal point.

0.4 kW

0.75 kW

to

75kW

D Open Chassis Type(IEC IP00)

Protected so that parts of the human body cannot reach electrically charged parts from the front when

the Inverter is mounted in a control panel.

D Enclosed Wall-mountedType (IEC IP20, NEMA 1)

The Inverter is structured so that the Inverter is shielded from the exterior,and can thus be mounted

to the interior wall of astandard building (not necessarily enclosed in a control panel). The protective

structure conforms to the standards of NEMA 1 in the USA.

No. Protective Structure

0

1

Open chassis (IEC IP00)

Enclosed wall-mounted (IEC IP20, NEMA 1)

2

-3

Page 28

Handling Inverters

2.2 Exterior and Mounting Dimensions

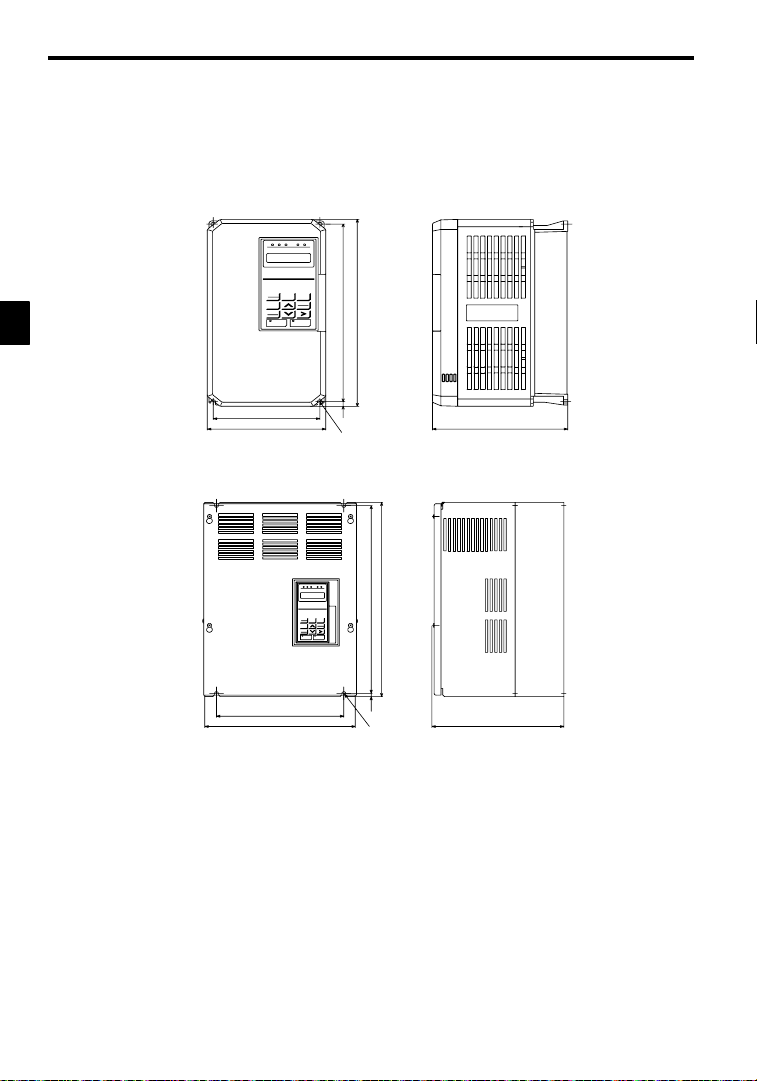

J 200 V/400 V Class Inverters of 15 kW and Lower

The following diagram shows a 200 V class, 1.5 kW Inverter.

Remove the top and bottom covers when mounting 200 V/400 V class Inverters of 15 kW or lower in a

control panel.

2

W1

W

H1

H

H2

4-d

D

J 200 V/400 V Class Inverters of 18.5 kW and Higher

The following diagram shows a 200 V class, 18.5 kW Inverter.

H 1

H

W1

W

H2

4-d

D

-4

Page 29

2.2Exterior and Mounting Dimensions

Vol

l

icab

l

D

C

5

tio

n

200

V

5

5

5

5

i

n

5

54.5

tio

n

400

V

5

5

5

5

i

n

5

5

5

5

Max. Ap-

t-

p

Motor Out-

put

[kW]

e

age

class

0.4

0.75

1.5

2.2

3.7

5.5

7.5

11

200 V

class

15

18.5

22

30

37

45

55

75 575 925 400 445 895 15.0 135 580 1290 400 445 895 270 145 M12

0.4

0.75

1.5 4 4

2.2

3.7

5.5

7.5

11

400 V

class

15

18.5

22

30

37

45 850 152.5

55

75

* 1. Same for open chsassis and enclosed wall-mounted types.

* 2. See page - 4 for mounting dimensions.

Note An attachment is required to mount the cooling fins (finsection) on the outside of the control panel for200 V/400 V class

Invertersof 15 kWor less. Please ask yourYaskawarepresentative for details. Dimensionaldrawings for models with externally mounted cooling fins and other special requirements are also available from your Yaskawa representative.

Open Chassis (IP00) Enclosed Wall-mounted (NEMA1)

W H D W1 H1 H2

Approx.

W H D W1 H1 H2

Mass

Approx.

Mass

140 280 160 126 266 7.0 3 140 280 160 126 266 7.0 3 M5

140 280 180 126 266 7.0 4.5140 280 180 126 266 7.0 4.5M

200 300 205186 2858.0

5.5

6

250 380 225236 3657.511 250

325450 2852754357.528 330

425675350 320 650 12.

61

62

200 300 205186 2858.0

380

225236 36

400

610

28527543

675

430 985350 320 650 212.

5.5

7.5

27.5

87.5

152.5

475800 350 370 77512.580 480 1110 350 370 775212.587 M10

140 280 160 126 266 7.0 3 140 280 160 126 266 7.0 3 M

140 280 180 126 266 7.0

140 280 180 126 266 7.0

4.

200 300 205186 2858.0 6 200 300 205186 2858.0 6 M6

250 380 225236 3657.511 250 380 225236 3657.511 M6

325450 2852754357.

325 625 285 275 610 7.5 44 330

4

820 350 350 79512.

29

330 610 28527543587.

31

78

285 275 610

81

460 1130 350 350 795212.

82

87.

Table 2.2 VS-626MC5External Dimensions (mm) and Approx. Masses (kg)

Mounting

Holes

6

11 M6

32 M6

67

M10

68

32

34

48 M6

87

M10

88

d*1

M6

M5

M6

Reac-

tor

Option

Built-

in

Option

Built-

in

*1

2

-5

Page 30

2

Handling Inverters

2.3.1 Installation Site

2.3 Checking and Controlling the Installation Site

CAUTION

D Always hold the case when carrying the Inverter.

IftheInverteris held by the front cover,the main body oftheInvertermayfall, possibly resulting in injury.

D Attach the Inverter to a metal or other noncombustible material.

Fire can result if the Inverter is attached to a combustible material.

D Install a cooling fan or othercooling device when installing more than oneInverter in the same

enclosure so that the temperature of the air entering the Inverters is below 45_C.

Overheating can result in fires or other accidents.

Install the VS-626MC5 in the installation site described below and maintain optimum conditions.

2.3.1 Installation Site

Install the Inverter under the following conditions.

Type Ambient Operating Temperature Humidity

Enclosed wallmounted

Open chassis

Protectioncoversareattachedto the topandbottom of the Inverter.Be sure to removethe protectioncovers

before installing a 200 or 400 V Class Inverter with an output of 15 kW or less in a panel.

D Install theInverter in aclean location freefrom oil mist anddust. It canbe installed ina totally enclosed

panel that is completely shielded from floating dust.

D When installing or operating theInverter, always take special careso that metal powder,oil, water,or

other foreign matter does not get into the Inverter.

D Do not install the Inverter on combustible material, such as wood.

D Install the Inverter in a location free from radioactive materials and combustible materials.

D Install the Inverter in a location free from harmful gasses and liquids.

D Install the Inverter in a location without excessive oscillation.

D Install the Inverter in a location free from chlorides.

D Install the Inverter in a location not in direct sunlight.

2.3.2 Controlling the Ambient Temperature

To enhance the reliability of operation, the Inverter should be installed in an environment free from extreme temperature increases. If the Inverter is installed in an enclosed environment, such as a box, use a

cooling fan or air conditioner to maintain the internal air temperature below 45qC.

2.3.3 Protecting the Inverter from Foreign Matter

Place a cover over the Inverter during installation to shield it from metal power produced by drilling.

Always remove the cover from the Inverter after completing installation. Otherwise, ventilation will be

reduced, causing the Inverter to overheat.

--10 to 40_C

--10 to 45_C

90% RH or less (no condensation)

90% RH or less (no condensation)

-6

Page 31

2.4 Installation Orientation and Space

Install the Inverter on a vertical surfaceso as not to reduce the cooling effect. When installingthe Inverter,always provide the following installation space to allow normal heat dissipation.

2.4Installation Orientation and Space

IMPORTANT

50 mm min.

120 mm min.

30 mm min. 30 mm min.

50 mm min.

(a) Horizontal Space

Fig 2.1 VS-626MC5 Installation Orientation and Space

S The same space is required horizontally and vertically for both open chassis (IP00) and enclosed

wall-mounted (IP20, NEMA 1) Inverters.

S Always removethe protection covers before installing a 200 or 400 V Class Inverter with an output

of 15 kW or less in a panel.

S Always provide enough space for suspension eye bolts and the main circuit lines when installing a

200 or 400 V Class Inverter with an output of 30 kW or more in a panel.

120 mm min.

(b) Vertical Space

Air

Air

2

-7

Page 32

Handling Inverters

2.5.1 Inverters of 15 kW or Less

2

2.5 Removing/Attaching the Digital Operator and

Front Cover

Remove the front cover to wire the terminals.

For models of 15 kW or less (both 200 V and 400 V class), do not remove or mount the front cover without

first removing theDigital Operator; otherwise,the Digital Operatormay malfunctiondue to imperfect contact.

Use the following procedures to remove or attach the front cover.

2.5.1 Inverters of 15 kW or Less

J Removing the Digital Operator

Pressthe lever onthe sideof the DigitalOperatorin thedirection of arrow1 to unlockthe DigitalOperator

and lift theDigital Operator in the directionof arrow2 toremove the Digital Operator asshown inthe following illustration.

Front cover

Digital

Operator

Fig 2.2 Removing the Digital Operator

J Removing the Front Cover

Pressthe left and right sidesof thefront cover in the directionsof arrows 1 and liftthe bottomof thecover

in the direction of arrow 2 to remove the front cover as shown in the following illustration.

2

1

Front cover

1

2

1

Fig 2.3 Removing the Front Cover

-8

Page 33

2.5Removing/Attaching the Digital Operator and

J Mounting the Front Cover

Afterwiring the terminals,mount thefront cover to theInverter by performinginreverse order to the steps

to remove the front cover.

1. Do not mount the front cover with the Digital Operator attached to the front cover; otherwise,Digital

Operator may malfunction due to imperfect contact.

2. Insert the tab of the upper part of the front cover into the groove of the Inverter and press the lower

part of the front cover onto the Inverteruntil the front cover snaps shut.

J Mounting the Digital Operator

1. Hook the Digital Operatorat A (two locations)on the front cover in the direction of arrow 1 as shown

in the following illustration.

2. Press the Digital Operator in the direction of arrow 2 until it snaps in place at B (two locations).

Digital

Operator

Front cover

Fig 2.4 Mounting the Digital Operator

Donot remove or attachthe DigitalOperatorormount or removethe frontcoverusingmethods other than

NOTE

1.

those described above, otherwise the Inverter may break or malfunction due to imperfect contact.

2. Neverattach the frontcoverto the Inverterwith the DigitalOperator attachedto the front cover.Imperfect

contact can result.

Alwaysattachthe front cover totheInverter by itselffirst,and then attach theDigitalOperatorto the front

cover.

2.5.2 Inverters of 18.5 kW or Higher

The front cover can be removed without removing the Digital Operator from the Inverter provided that

the Inverter has an output of 18.5 kW or higher.

Loosen the four screws of the front cover and move the front cover slightly upwards to remove the front

cover.

2

2

1

A

B

2

-9

Page 34

3

Wiring

This chapter describes wiringterminals, main circuit terminal connections,

main circuit terminal wiring specifications, control circuit terminals, and

control circuit wiring specifications.

3.1 Connections to Peripheral Devices 3 - 3..........

3.2 Connection Diagram 3 - 4.....................

3.3 Terminal Block Configuration 3 - 5..............

3.4 WiringMain Circuit Terminals 3 - 6.............

3.4.1 Applicable Wire Sizes and Closed Loop

Connectors 3 - 6...................................

3.4.2 Main Circuit Terminal Functions 3 - 9.................

3.4.3 Main Circuit Configurations 3 - 10.....................

3.4.4 Standard Connection Diagrams 3 - 12...................

3.4.5 Wiring the Main Circuits 3 - 13........................

3.5 WiringControl Circuit Terminals 3 -20...........

3.5.1 Wire Sizes and Closed-loop Connectors 3 -20............

3.5.2 Control Circuit Terminal Functions 3 - 21................

3.5.3 Control Circuit Terminal Connections (All Models) 3 - 22...

3.5.4 Control Circuit Wiring Precautions 3 - 23................

3.6 WiringCheck 3 - 23...........................

3.7 Installing and Wiring PG Speed Control

Cards 3 - 24.................................

3.7.1 Installing a PG Speed Control Card 3 - 24...............

3.7.2 PG Speed Control Card TerminalBlocks 3 - 25...........

3.7.3 Wiring a PG Speed Control Card 3 - 26.................

3.7.4 Wiring PG Speed Control Card TerminalBlocks 3 -28.....

3.7.5 Selecting the Number of PG (Encoder) Pulses 3 - 30.......

3

-1

Page 35

Wiring

WARNING

D Always turn OFF the input power supply before wiring terminals.

Otherwise, an electric shock or fire can occur.

D Wiring must be performed by an authorized person qualified in electrical work.

Otherwise, an electric shock or fire can occur.

D Be sure to ground the ground terminal.

(200 V class: Ground to 100 : or less, 400 V class: Ground to 10 : or less)

Otherwise, an electric shock or fire can occur.

D Always check the operation of any emergency stop circuits after they are wired.

Otherwise, there is the possibility of injury.(Wiring is the responsibility of the user.)

D Never touch the output terminals directly with your hands or allow the output lines to come into

contact with the Inverter case. Never short the output circuits.

Otherwise, electrical shock or grounding can occur.

CAUTION

3

D Check tobe surethat thevoltage of the main AC power supply satisfies therated voltage ofthe

Inverter.

Injury or fire can occur if the voltage is not correct.

D Do not perform voltage withstand tests on the Inverter.

Otherwise, semiconductor elements and other devices can be damaged.

D Connect braking resistors, BrakingResistor Units, and Braking Units as shown in the I/O wiring

examples.

Otherwise, a fire can occur.

D Tighten all terminal screws to the specified tightening torque.

Otherwise, a fire may occur.

D Do not connect AC power to output terminals U, V, and W.

The interior parts of the Inverter will be damaged if voltage is applied to the output terminals.

D Do not connect phase-advancing capacitors or LC/RC noise filters to the output circuits.

The Inverter can be damaged or internal parts burnt if these devices are connected.

D Do not connect electromagnetic switches or contactors to the output circuits.

If a load isconnected whilethe Inverter is operating, surge current will cause the overcurrent protection

circuit inside the Inverter to operate.

-2

Page 36

3.1 Connections to Peripheral Devices

Examplesofconnectionsbetween the VS-626MC5 andtypicalperipheraldevices are shown inFigure3.1.Use

this illustration to gain an understanding of the overall equipment configuration.

Power supply

Molded-case circuit

breaker or ground

fault interrupter

Magnetic contactor

AC reactor for power

factor improvement

3.1Connections to Peripheral Devices

3

Input noise filter

VS-626MC5

Ground

6

2

6

M

C

5

Output noise filter

Magnetic contactor

Ground

Fig 3.1 Example Connections to Peripheral Devices

-3

DC reactor for power

factor improvement

Motor

Page 37

Wiring

3.2 Connection Diagram

The connection diagram of the VS-626MC5 is shown in Figure 3.2.

When using the Digital Operator, the motor can be operated by wiring only the main circuits.

DC reactor to improve input

power factor (optional)

Short-circuit bar

¨ 2

¨ 1B1B2

P

©

R (L1)

S (L2)

T (L3)

VS-626MC5

Forward run command

(forward when closed)

Reverse run command

(reverse when closed)

3

4

5

Multi-function contact

inputs

6

7

8

Sequence common

11

(Insulated from 0V

terminal)

12 Shield terminal

15 Frequency setting power

15 V, 20 mA

13 Master speed reference

-- 1 0 to 10 V (20 k

(Default:0to 10 V/100%)

14 Master speed reference

4 to 20 mA (250

16 Multi-function analog input

(-- 1 0 to 10 V (20 k

(Default: Auxiliary frequency

17

0V

33

Frequency setting

power:

--15 V,20 mA

MCCB

3-phase power

200 to 230 V

50/60 Hz

3

Factorypreset

functions

External

frequency

references

R

S

T

Forward Run/Stop

Reverse Run/Stop

External fault

Fault reset

Multi-step speed setting 1

(Master/auxiliary switch)

Multi-step speed setting 2

Jog frequency reference

External baseblock command

0 to 10 V

2k

4 to 20 mA

0 to 10 V

0V

2k

P

P

Analog

monitor 2

Analog

monitor 1

reference

0 to 10 V/100%)

Braking Resistor Unit (Optional)

U (T1)

V (T2)

W (T3)

23

21

22

(12)

18

19

20

9

10

25

26

27

Motor

Ground to 100 : max.)

-FM

Fault contact output

250 VAC, 1Amax.

30 VDC, 1Amax.

Multi-function contact output

250 VAC, 1Amax.

30 VDC, 1Amax.

Default: Running signal)

Open collector 1

Default: Zero speed

signal)

Open collector 2

Default: Speed

agree signal

Multi-function output

common

I

M

+

Multi-function analog output

-- 1 0 to 10 V

AM

Default: Output current

5V/Inverter rated current)

--

Multi-function analog output

-- 1 0 to10 V

Default: Output frequency

+

0 to 10 V/100% frequency

Multi-function

open-collector

output

48 V , 50 mA

max.

*Shield

P

* Twisted-pair wires

Fig 3.2 Connection Diagram (Model CIMR-MC5A27P5 Shown Above)

-4

Page 38

3.3Terminal Block Configuration

Controlcircuit terminals 1 to33 are not arrangedinorder of terminalnumbers; they arearrangedasshown

NOTE

1.

below.Be sure to wire them correctly.

13 14 15 16 17

12345678

2. Do not use control circuit terminals 13 and 14 at the same time.

(The two signals will be added inside the Inverter if they are input at the same time.)

3. The maximum output current capacity of the +15 V/--15 V output from control circuit terminals 15 and

33 is 20 mA.

4. The multi-function analogoutput is a dedicated meteroutput for a frequency meter, ammeter, etc. Do not

use this output for feedback control or for any other control purpose.

Useone of the optional AnalogMonitor Cards (AO-08or AO-012) foranalog outputs to the control system.

5. Disable the stall prevention during deceleration (set constant L3-04 to 0) when using a Braking Resistor

Unit.If this userconstant isnot changed to disablestall prevention, the systemmaynot stop duringdeceleration.

6. Set constant L8--01 to 1, 2 or 3 to enable protectionfor the internal DBresistor (modelERF) whenusing

an internal braking resistor.The braking resistor will not be protected unless this setting is changed to

enable protection.

7. DC reactors to improvethe inputpower factorcan be connected as an option only to Inverters for 15 kW

or less. Remove the short bar from between ¨1and¨2whenconnectingaDCreactor.

8. There is no DC power supply input terminals for 200 V class Inverters of 30 to 75 kW and 400 V class

Inverters of 55 to 75 kW,and DC power cannot be input to these Inverters.

25 26 27 33 18 19 2011 12(G)

3.3 Terminal Block Configuration

The terminal block for a 200 V class Inverter with an output of 0.4 kW is shown in Figure 3.3.

11 12(G) 13 14 15 16 17 25 26 27 33 18 19 20

1234567821 22 23 9

21 22 23 9 10

10

Control circuit

terminals

3

R

L1

T

S

L2

Power input Braking resistor Motor output

©

L3

¨1

¨2B1

U

B2

T1

Fig 3.3 TerminalArrangement

-5

V

T2

W/T3

CHARGE

Main circuit

terminals

Page 39

Wiring

M

C5A20

P

5

M

C5A20

P

5

M

C5A21

P

M

C5A22P2

5

M

C5A23

P

5.5

M

C5A

25P

5

M

C5A

27P

5

M

C5A2011

M

C5A20

1

MC5A201

8

Mai

n

Powercables,e.g.,600Vvinyl

Circuit

s

MC5A202

2

powercables

M

C5A2030

M

C5A20

3

M

C5A20

M

C5A20

M

C5A20

3.4.1 Applicable Wire Sizes and Closed-loop Connectors

3.4 Wiring Main Circuit Terminals

3.4.1 Applicable Wire Sizes and Closed-loop Connectors

VS-626MC5 Model

Circuit

3

Circuits

Control

Circuits

Note The wire thickness is set for copper wires at 75qC.

CIMR-

4 M4 2to5.

7 M4 2to5.

5 M4

7 M4

5 M

5 M

5

MC5A2018

MC5A2022

7

45

55

75

All models 1to33 M3.5 0.5to2 Shielded twisted-pair wires

Select the appropriate wires and crimp terminals from Table 3.1 to Table3.3. Referto instruction manual

TOE-C726-2j for wire sizes for Braking Resistor Units and Braking Units.

Table 3.1 200 V Class Wire Sizes

WireThickness

Termi-

(see note)

TerminalSymbol

R, S, T, © , ¨ 1,¨ 2,B1,B2,U,V,W

R, S, T, © , ¨ 1,¨ 2,B1,B2,U,V,W

R, S, T, © , ¨ 1,¨ 2,B1,B2,U,V,W

R, S, T, © , ¨ 1,¨ 2,B1,B2,U,V,W

R, S, T, © , ¨ 1,¨ 2,B1,B2,U,V,W

R, S, T, © , ¨ 1,¨ 2,B1,B2,U,V,W

R, S, T, © , ¨ 1,¨ 2,B1,B2,U,V,W

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W M8 30

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W

r, M4 0.5to5.5

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W

r, M4 0.5to5.5

R, S, T, U, V,W M10 38 to 100

© , ¨ 3 M8

r, M4 0.5to5.5

R, S, T, U, V,W M10 38 to 100

© , ¨ 3 M8

r, M4 0.5to5.5

R, S, T, U, V,W M10 60 to 100

© , ¨ 3 M8

r, M4 0.5to5.5

R, S, T, U, V,W M10 100

© , ¨ 3 M8

r, M4 0.5to5.5

R, S, T, U, V,W M12 100 to 200

© , ¨ 3 M8

r, M4 0.5to5.5

nal

Screws

M4 3.5to5.

M6

M6 8

M8

M8

M8 22

M8 22

M8 22

M8 30

M8 50

2

mm

2to5.5

3.5to5.5

8

5.5to8

8

5.5to8

22

8

30

14

38

14

Wire Type

power cables

-6

Page 40

3.4Wiring Main Circuit Terminals

M

C5A40

P

5

M

C5A40

P

5

M

C5A41

P

5

M

C5A42P2

5

M

C5A43

P

M

C5A45P

5

M

C5A47P

5

5.5

M

C5A4011

M

C5A40

1

MC5A401

8

,g,

y

MC5A402

2

MC5A403

0

MC5A403

7

MC5A404

5

M

C5A40

M

C5A40

VS-626MC5 Model

Circuit

Circuits

Control

Circuits

Note The wire thickness is set for copper wires at 75qC.

CIMR-

4 M4 2to5.

7 M4 2to5.

5 M4 2to5.

7 M4

5 M4 3.5to5.

5 M

5

MC5A4018

Main

MC5A4022

MC5A4030

MC5A4037

MC5A4045

55

75

All models 1to33 M3.5 0.5to2 Shielded twisted-pair wires

Table 3.2 400 V Class Wire Sizes

TerminalSymbol

R, S, T, © , ¨ 1,¨ 2,B1,B2,U,V,W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V,W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V,W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V,W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V,W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V,W

R, S, T, © , ¨ 1,¨ 2,B1,B2,U,V,W

R, S, T, © , ¨ 1,¨ 2,B1,B2,U,V,W M5 8to14

R, S, T, © , ¨ 1,¨ 2,B1,B2,U,V,W M5 8to14

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W M6 14

r, M4 0.5to5.5

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W M6 22

r, M4 0.5to5.5

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W

r, M4 0.5to5.5

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W

r, M4 0.5to5.5

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W

r, M4 0.5to5.5

R, S, T, U, V,W M10 38 to 100

© , ¨ 3 M8

r , 200, 400 M4 0.5to5.5

R, S, T, U, V,W M10 38 to 100

© , ¨ 3 M8

r , 200, 400 M4 0.5to5.5

Termi-

Wire Thickness

nal

(see note)

Screws

M4 2to5.

M6 8

M6 8

M8 8

M8 8

M8

M8

M8

M8 22

M8 22

mm

2to5.5

3.5to5.5

22

8

30

14

50

14

2

Power cables, e.g., 600 V vinyl

power cables

Wire Type

3

-7

Page 41

Wiring

5

5

5

5/5.5

50/

3.4.1 Applicable Wire Sizes and Closed-loop Connectors

Table 3.3 Closed-loop Connector Sizes (JIS C 2805) (For 200 V/400 V Classes)

Wire Thicknessmm

3

NOTE

Determine the wire size for the main circuit so that line voltage drop is within 2% of the rated voltage.

Line voltage drop is calculated as follows:

(If there is the possibility of excessive voltage drop, use a larger wire suitable to the required length.)

Line voltage drop

2

TerminalScrews Size

0.

0.7

1.2

2

3.

8

14

22

30/38 M8 38to 8

60

80

100

100 100 to 12

150

200 200 to 12

¯

(V) 3

x wire resistance (:/km) x wire length (m) x current (A) x 10

M3.5 1.25to 3.5

M4 1.25 to 4

M3.5 1.25to 3.5

M4 1.25 to 4

M3.5 1.25to 3.5

M4 1.25 to 4

M3.5 2to3.5

M4 2to4

M5 2to5

M6 2to6

M8 2to8

M4 5.5to4

M5 5.5to5

M6 5.5to6

M8 5.5to8

M5 8to5

M6 8to6

M8 8to8

M6 14 to 6

M8 14 to 8

M6 22 to 6

M8 22 to 8

M8 60 to 8

M10 60 to 10

M10

M12

80 to 10

100 to 10

150 to 12

-- 3

-8

Page 42

3.4.2 Main Circuit Terminal Functions

Main circuit terminal functions are summarized according to terminal symbols in Table3.4 and Table3.5.

Wire the terminals correctly for the desired purposes.

Table 3.4 200 V Class Main Circuit Terminal Functions

Purpose TerminalSymbol Model:CIMR-MC5A

Main circuit power input R (L1), S (L2), T (L3) 20P4 to 2075

Inverter outputs U(T1), V(T2),W(T3) 20P4 to 2075 (all models)

DC power input ¨ 1--© 20P4 to 2022

Braking Resistor Unit connec-

tion

DC reactor connection ¨ 1--¨ 2 20P4to 2015

Braking Unit connection ¨ 3--© 2011 to 2075

Cooling fan power input r, 2018 to 2022

Cooling fan power input

control power input)

Ground 20P4 to 2075 (all models)

Note Models CIMR-MC5A2030 to 2075 do not support standard DC power input.

Table 3.5 400 V Class Main Circuit Terminal Functions

Purpose TerminalSymbol Model:CIMR-MC5A

Main circuit power input R (L1), S (L2), T (L3) 40P4 to 4075

Inverter outputs U(T1), V(T2),W(T3) 40P4 to 4075 (all models)

DC power input ¨ 1--© 40P4 to 4045

Braking Resistor Unit connec-

tion

DC reactor connection ¨ 1--¨ 2 40P4to 4015

Braking Unit connection ¨ 3--© 4018 to 4075

Cooling fan power input r, 4018 to 4045

Cooling fan power input

(control power input)

Ground 40P4 to 4075 (all models)

Note Models CIMR-MC5A4055 to 4075 do not support standard DC power input.

r -- 200: 200 to 230 VACinput

r -- 400: 380 to 460 VAC input

3.4Wiring Main Circuit Terminals

B1, B2 20P4 to 27P5

r,

B1, B2 40P4 to 4015

2030 to 2075

4055 to 4075

3

-9

Page 43

Wiring

3.4.3 Main Circuit Configurations

3

3.4.3 Main Circuit Configurations

The main circuit configurations are shown in Figure 3.4 and Figure 3.5.

J 200 V Class

CIMR-MC5A20P4 to 21P5 (0.4 to 1.5 kW

¨3

Fincoolingfan

B2B1

Control

circuits

Control

circuits

U(T1)

V(T2)

W(T3)

U(T1)

V(T2)

W(T3)

*1

¨1

¨2

(DCL

R(L1)

option)

S(L2)

*2

T(L3)

©

Power

supply

(RCC)

CIMR-MC5A2011to 2015 (11, 15 kW)

*1

¨1

¨2

(DCL

R(L1)

option)

S(L2)

*2

T(L3)

©

Power

supply

(RCC)

CIMR-MC5A22P2 to 27P5 (2.2 to 7.5 kW)

(DCL

option)

*1

¨1

¨2

R(L1)

S(L2)

*2

T(L3)

©

Power

supply

(RCC)

Fin cooling fan

B2B1

U(T1)

V(T2)

W(T3)

Control

circuits

CIMR-MC5A2018 to 2022 (18.5, 22 kW)

¨1

¨2

*1

R

S

*3

T

©

r

Fin cooling fan

Power

supply

(RCC)

¨3

Internal

cooling fan

Control

circuits

U

V

W

CIMR-MC5A2030 to 2075 (30 to 75 kW)

¨3

R

S

*1

T

©

r

Fincoolingfan

Power

supply

(RCC)

Internal

cooling fan

U

V

W

Control

circuits

* 1 Prewired at the factory.

* 2 Remove theshort-circuit barfrom between¨1 and ¨2whenconnecting aDC

reactor to Inverters of 15 kW or less.

* 3 Prewired atthe factory.Whensupplying power tothe main circuitsfrom theDC

power supply, remove the wiring from R-r and S- .

Fig 3.4 200 V Class Inverter Main Circuit Configurations

-10

Page 44

J 400 V Class

CIMR-MC5A40P4 to 41P50.4 to 1.5 kW

B2B1

Control

circuits

U(T1)

V(T2)

W(T3)

(DCL

option)

*1

¨1

¨2

R(L1)

S(L2)

*2

T(L3)

©

Power

supply

(RCC)

3.4Wiring Main Circuit Terminals

CIMR-MC5A42P2 to 43P72.2 3.7 kW

(DCL

option)

*1

¨1

¨2

R(L1)

S(L2)

*2

T(L3)

©

Power

supply

(RCC)

Fin cooling fan

B2B1

U(T1)

V(T2)

W(T3)

Control

circuits

CIMR-MC5A45P5 to 40155.5to15kW

(DCL

option)

*1

¨1

¨2

R(L1)

S(L2)

*2

T(L3)

©

Power

supply

(RCC)

Fin cooling fan

B2B1

U(T1)

V(T2)

W(T3)

Control

circuits

CIMR-MC5A4018 to 404518.5to45kW

*1

*3

CIMR-MC5A4055 to 40755575 kW

¨3

R

S

*1

T

©

r

200

400

Fincoolingfan

Power

supply

(RCC)

Internal

cooling fan

U

V

W

Control

circuits

* 1 Prewired at the factory.