Page 1

VS-616PS5 Series

Programming Manual

Brushless Motor Drive

Page 2

2 VS-616PS5 Programming Manual

Page 3

WARNING

YASKAWA manufactures component parts that can be used in a wide variety of industrial applications.

The selection and application of YASKAWA products remains the responsibility of the equipment

designer or end user. YASKAWA accepts no responsibility for the way its products are incorporated

into the final system design.

Under no circumstances should any YASKAWA product be incorporated into any product or design as

the exclusive or sole safety control. Without exception, all controls should be designed to detect faults

dynamically and fail safely under all circumstances. All products designed to incorporate a component

part manufactured by YASKAWA must be supplied to the end user with appropriate warnings and

instructions as to that part’s safe use and operation. Any warnings provided by YASKAWA must be

promptly provided to the end user.

YASKAWA offers an express warranty only as to the quality of its products in conforming to standards

and specifications published in YASKAWA’s manual. NO OTHER WARRANTY, EXPRESS OR

IMPLIED, IS OFFERED. YASKAWA assumes no liability for any personal injury, property damage,

losses, or claims arising from misapplication of its products.

VS-616PS5 Programming Manual 3

Page 4

READ THIS ENTIRE MANUAL BEFORE INSTALLING OR OPERATING THE VS-616PS5!

WARNING!

The PS5 motor uses permanent magnets. HIGH VOLTAGE is generated by the

motor whenever the rotor is turning, with or without a power supply. Make sure

the motor is not turning before performing ANY service on the motor or on the

inverter.

If there is a possibility that the motor can be turned by the load while inverter

power is off, install a contactor or a manual disconnect to open the motor leads

while servicing the inverter. Interlock the disconnect with the control circuits of

the drive.

ONLY PERSONNEL WHO ARE EXPERIENCED IN WORKING WITH HIGH VOLTAGE, HIGH

POWER EQUIPMENT SHOULD INSTALL OR SERVICE THIS EQUIPMENT.

Turn off the supply power to the VS-616PS5 AND make sure the motor is stopped AND the internal

capacitors are discharged before connecting or disconnecting wires or touching any internal parts.

The VS-616PS5 internal capacitors remain charged even after the power supply is turned off. Wait

at least five minutes after removing power. Make sure all LED’s are off before servicing the inverter.

Do not use a Megger or other type of high withstand voltage tester on the VS-616PS5. Higher volt-

ages can damage the semiconductors used in the inverter.

Do not connect or disconnect the operator or a computer while the VS-616PS5 is running.

FAILURE TO OBSERVE THE WARNINGS AND PRECAUTIONS IN THIS MANUAL CAN EXPOSE THE USER TO HIGH

VOLTAGES, RESULTING IN DAMAGE TO EQUIPMENT, SERIOUS PERSONAL INJURY, OR EVEN DEATH.

POWER SUPPLY LIMITATIONS

The VS-616PS5 is suitable for use on a circuit capable of delivering not

more than 65,000 RMS symmetrical amperes at 480 VAC maximum (for

460 VAC class units) or 240 VAC maximum (for 230 VAC class units).

NOTICENOTICE

The information contained within this document is the proprietary property of Yaskawa Electric America,

Inc. This information may not be copied, reproduced, or transmitted to other parties without the expressed

written authorization of Yaskawa Electric America, Inc.

No patent liability is assumed with respect to the use of the information contained herein.

Yaskawa is constantly improving its high-quality products. The information contained in this manual is sub-

ject to change without notice.

Every precaution has been taken in the preparation of this manual. Nevertheless, Yaskawa assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of

the information contained in this publication.

4 VS-616PS5 Programming Manual

Page 5

Contents

Section Description Page

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

VS-616PS5 PARAMETER TREE . . . . . . . . . . . . . . . . . . . . . . . . .8

A INITIALIZATION PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . .9

A1 Initialization Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

B APPLICATION PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . .10

B1 Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

B2 Zero Speed Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

B3 Magnetic Pull-in Current. . . . . . . . . . . . . . . . . . . . . . . . . .15

B4 Delay Timers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

B5 PID Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

B6 Reference Hold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

B7 Droop Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

C TUNING PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

C1 Accel/Decel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

C2 PG Origin Pulse Compensation . . . . . . . . . . . . . . . . . . . .27

C3 Voltage Limitation Control. . . . . . . . . . . . . . . . . . . . . . . . .28

C5 ASR Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

C6 Carrier Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

D REFERENCE PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

D1 Preset References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

D2 Reference Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

D3 Jump Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

D4 Hold Reference Memory. . . . . . . . . . . . . . . . . . . . . . . . . .39

D5 Torque Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

E MOTOR PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

E1 Motor Constant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

F OPTION PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

F1 PG Option Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

F2 AI-14 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

F3 DI-08/DI-16H Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

F4 AO-08/AO-12 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

F5 DO-02 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

F6 DO-08 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

F9 CP-916 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

H CONTROL CIRCUIT TERMINAL PARAMETERS . . . . . . . . . . . . . . .61

H1 Digital Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

H2 Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

H3 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

H4 Analog Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

L PROTECTION PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . .82

L2 Power Loss Ridethrough . . . . . . . . . . . . . . . . . . . . . . . . .82

L3 Stall Prevention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

L4 Reference Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

L5 Fault Restart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

L6 Torque Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

L7 Torque Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

VS-616PS5 Programming Manual 5

Page 6

Section Description Page

L8 Hardware Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

O OPERATOR PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

O1 Monitor Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

O2 Key Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

T TUNING PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

T1 Auto-tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Appendix VS-616PS5 PARAMETER LIST. . . . . . . . . . . . . . . . . . . . . . . . 101

6 VS-616PS5 Programming Manual

Page 7

Introduction

Introduction

The Model VS-616PS5 is a series of high quality, general purpose, inverters designed to

control the current in a permanent magnet (PM) brushless motor. In the PM motor, current is

directly related to torque.

With power outputs ranging from 0.5 to 500 horsepower (HP), the VS-616PS5 series is suitable for any application. The inverters provide full start-up torque, smooth low speed operation, and precise speed control from zero to full speed. The proprietary auto-tuning function

allows the inverters to get the best performance from PM motors manufactured worldwide.

Some of Yaskawa’s proprietary features of the VS-616PS5 inverter include torque control,

automatic tuning to the motor characteristics, UL recognized electronic thermal motor overload, energy saving operation, PID loop control, and low noise operation. Also available is a

digital operator for simple programming. The design team has used the latest in microprocessor technology to produce the ultimate drive for any application.

Use the Parameter Tree on the following page to determine which control mode and access

level each parameter is available in.

The VS-616PS585 ships preset to the Quick-start access level. This publication describes

all Quick-Start, Basic and Advanced parameters. For installation and simplified Quick-Start

parameters, please refer to YEA-TOA-S616-10.22.

VS-616PS5 Programming Manual 7

Page 8

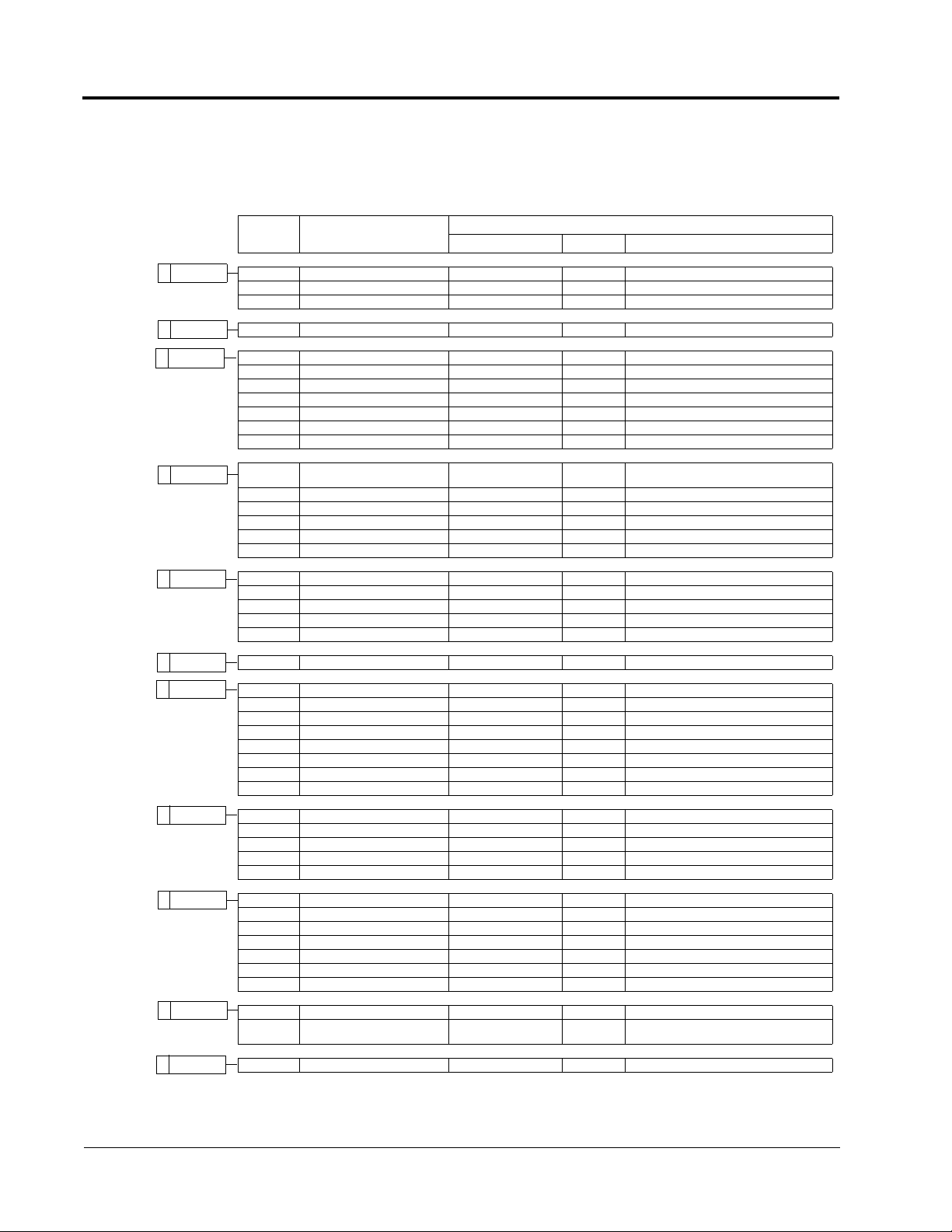

VS-616PS5 Parameter Tree

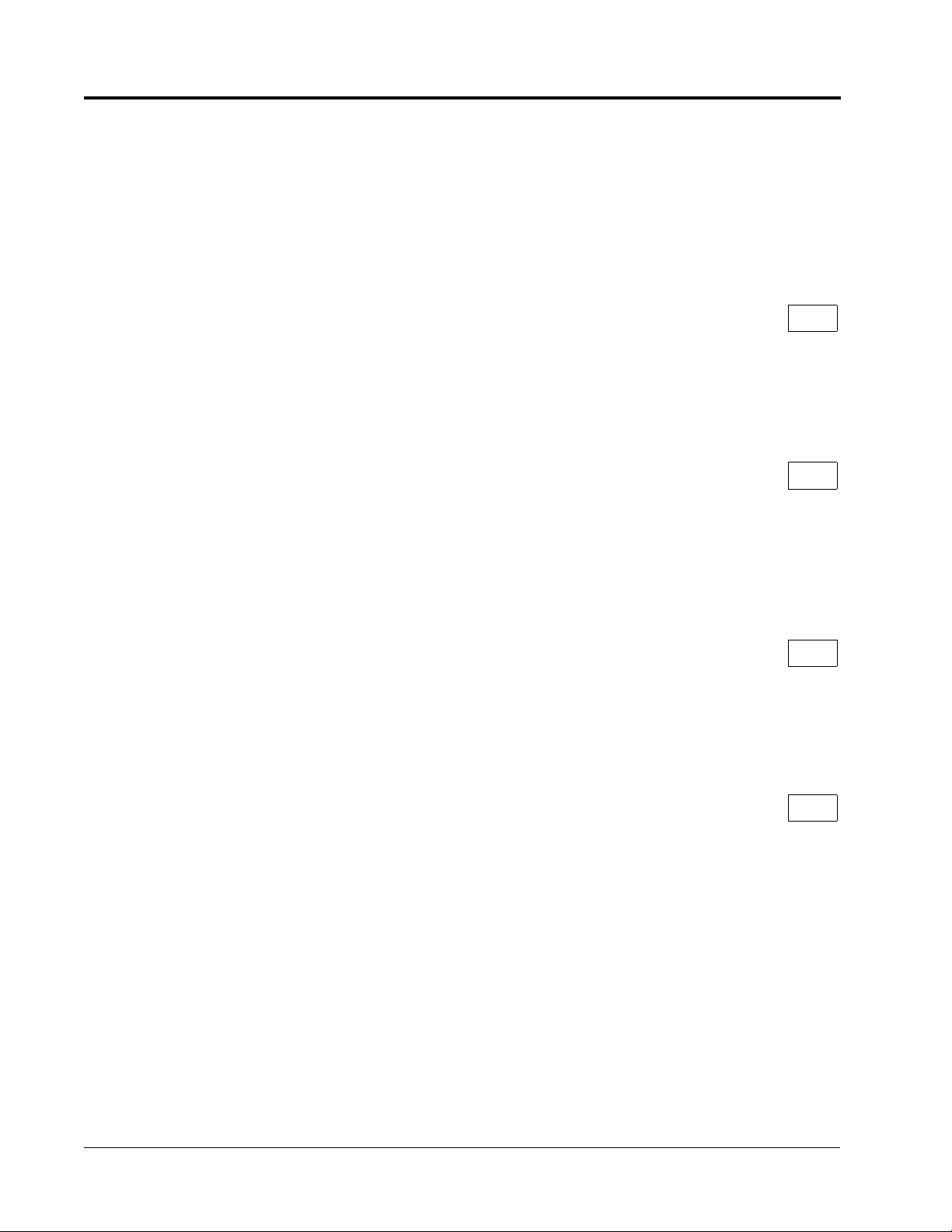

VS-616PS5 Parameter Overview

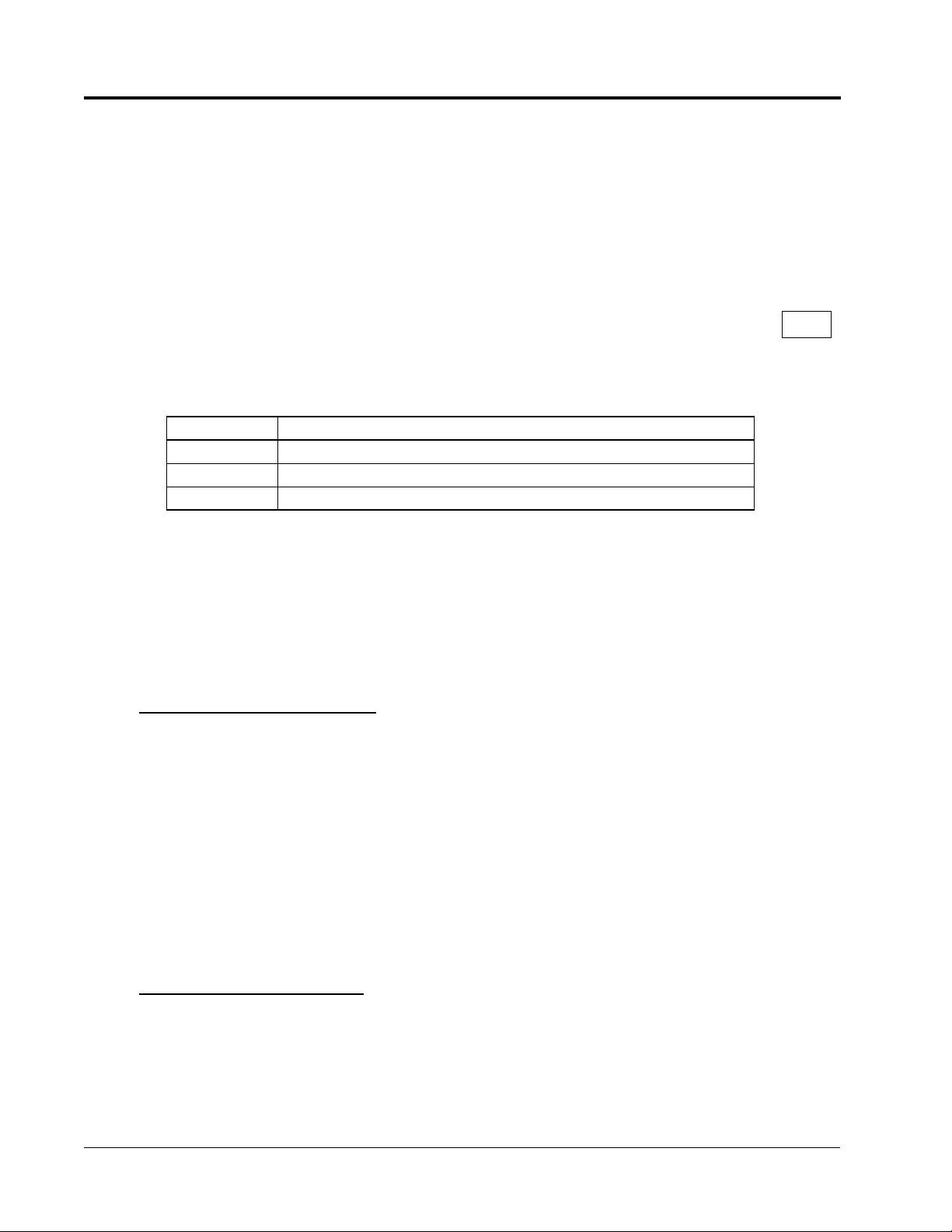

Group Function Parameter No.

Quick-start Basic Advanced

MonitorU

A Initialize

ApplicationB

TuningC

ReferenceD

MotorE

OptionF

U1 Monitor 01-03, 05-14 15-19 20-22,27-33,41-47, 49,50,53,54,55

U2 Fault Trace 01-14 15,16 17-22

U3 Fault History 01-08

A1 Initialize 01, 03, 04

B1 Sequence 01-03 04 05-06

B2 Zero Speed Level 01

B3 Magnetic Pull-in 02, 04, 05

B4 Delay Timers 01, 02

B5 Pid Control 01-08

B6 Reference Hold 01-04

B7 Droop Control 01, 02

C1 Accel/decel 01, 02

C2 PG Origin Pulse Comp. 13

C3 Voltage Limit Control 05

C5 Asr Tuning 01-04 05-07

C6 Carrier Frequency 02

C7 S-Curve Characteristics 01-04

D1 Preset Reference 01-04, 09 05-08

D2 Reference Limit 01, 02

D3 Jump Speed 01-04

D4 Hold Reference Memory 01

D5 Torque Control 01-06

E1 Motor Constant 01-13, 17 15,16

F1 PG Option Set-up 01,05 02-04 08-11, 13

F2 AI-14 Set-up 01

F3 DI-08, 16 Set-up 01

F4 AO-08, 12 Set-up 01-06

F5 DO-02 Set-up 01, 02

F6 DO-08 Set-up 01

F8 Speed Feedback Selection 01 02

F9 CP-916 Set-up 01-06

03, 04,

09

05-08, 10, 11

TerminalH

ProtectionL

OperatorO

TuningT

H1 Digital Inputs 01-06

H2 Digital Outputs 01-03

H3 Analog Inputs 01-03 04-12

H4 Analog Outputs 01-07

H5 Serial Communications 01-05

L2 Power Loss Ridethrough 01, 02 05

L3 Stall Prevention 01

L4 Reference Detection 01, 02 03-05

L5 Fault Restart 01, 02

L6 Torque Detection 01-03 04-06

L7 Torque Limit 01-04

L8 Hardware Protection 01, 02, 03, 05, 07, 10

O1 Monitor Select 01-03

O2 Key Select

T1 Auto-tuning 02,03

01, 02,

04

05-08

* User Selectable

8 VS-616PS5 Programming Manual

Page 9

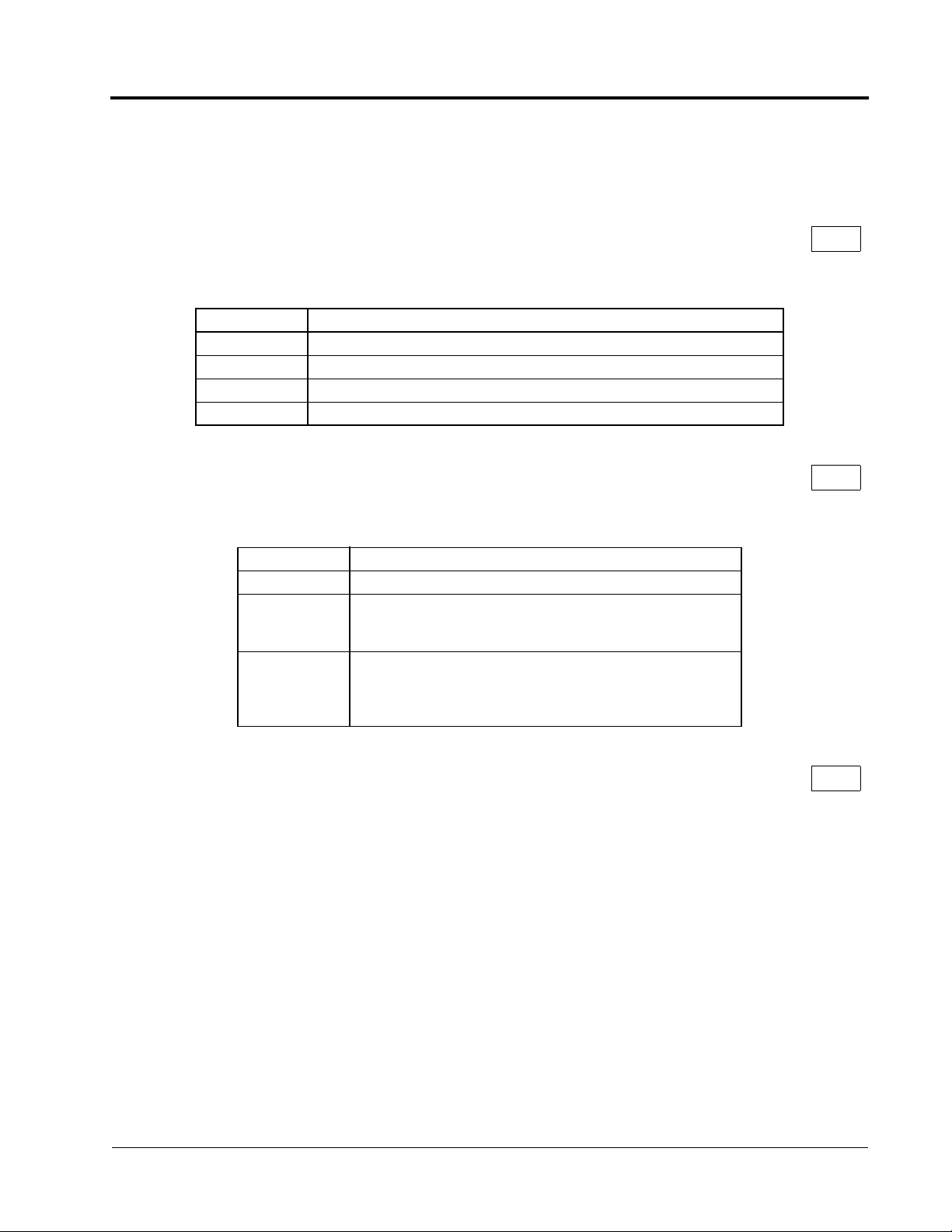

Section A: Initialization Parameters

A1 Initialization Set-up

Main Menu:Initialize <ENTER>

A Initialization Parameters

A1 Initialization Set-up

A1-01 Parameter Access Level Q

This parameter allows the “masking” of parameters according to user level. See the

following table:

Setting Description

0 Operation Only

2 Quick Start Level (factory default) - For maintenance-level programming.

3 Basic Level - For basic programming in most applications.

4 Advanced Level - For advanced programming in special applications.

A1-03 Operator Status Q

Use this parameter to reset the inverter to its factory default settings. Initialize the

inverter after changing the control PCB, or after selecting inverter capacity (O2-04).

Setting Description

0 No Initialization (factory default).

2220 2-Wire Initialization - terminal 1 becomes FWD run command and

terminal 2 becomes REV run command. All other parameters are

reset to their original factory default settings.

3330 3-Wire Initialization - terminal 1 becomes run command, terminal 2

becomes stop command and terminal 3 becomes FWD/REV run

selection. All other parameters are reset to their original factory

default settings.

A1-04 Password Entry Q

This parameter allows password entry to view masked parameters.

VS-616PS5 Programming Manual 9

Page 10

Section B: Application Parameters

B1 Initialization Sequence

Main Menu: Programming <ENTER>

B Application Parameters

B1 Sequence

B1-01 Frequency Reference Selection Q

B1-02 Operation Method Selection Q

Setting Range: 0 to 4

Factory Default: 1

Frequency reference and run command can be set independently as shown below:

Setting Description

0 Run by digital operator reference

1 Run by external terminal reference (factory default).

2 Run by serial communication

3 Option card (run by CP-916 B/G, 216 I/F references

4 Run by personal computer (CP-717) reference

6 Pulse Train reference (valid for B1-01 only, used with PG-P2)

By depressing the LOCAL/REMOTE key on the digital operator, the operation mode

can be selected as shown below:

Local: Frequency reference and run command from digital operator. (Remote

SEQ and REF LEDs off)

Remote:Operation according to frequency reference and run command set by B1-

01 & B1-02, respectively.

The Control Method is reset to remote operation when power is cycled.

B1-03 Stopping Method Selection Q

Setting Range: 0 to 3

Factory Default: 0

This function selects the stopping method suitable for the application.

Setting Description

0 Ramp to stop (factory default).

1 Coast to stop.

3 Coast to stop with timer.

10 VS-616PS5 Programming Manual

Page 11

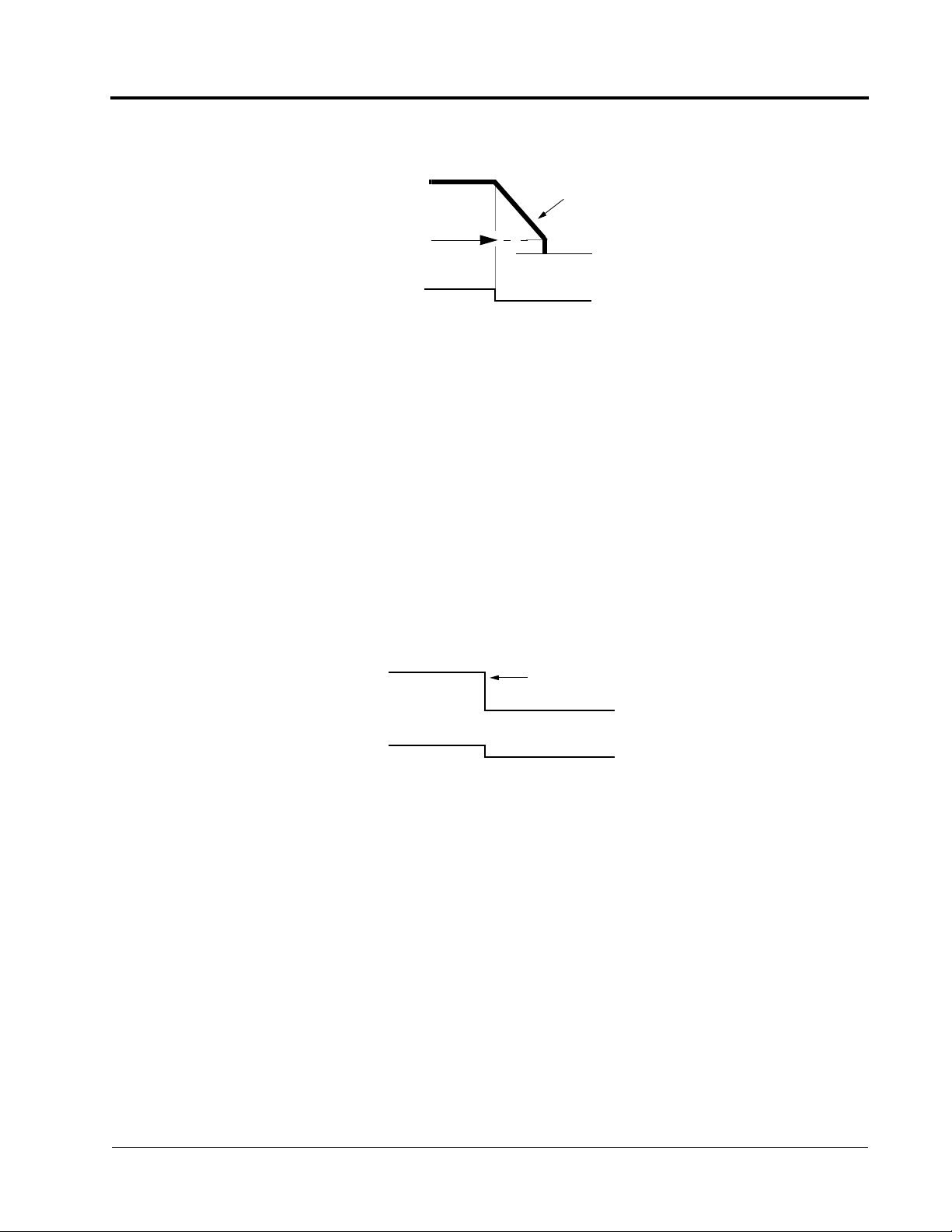

• Ramp to Stop (B1-03 = “0”)

Section B: Application Parameters

B1 Sequence

Output Frequency

Zero Speed Level

Factory Default 0.5Hz

Run Command

ON

OFF

Decel time 1 (C1-02)

Figure 1 Stopping Method - Ramp to Stop

Upon removal of the FWD (REV) run command, the motor decelerates at a rate

determined by the time set in deceleration time 1 (C1-02) and baseblocks upon

reaching the zero speed level (B2-01) or minimum speed (E1-08), whichever is

higher. If the deceleration time setting is too short or the load inertia is large, an overvoltage fault (OV) may occur during deceleration. In this case, increase the deceleration time or install an optional braking transistor and/or braking resistor (braking

transistors are provided as standard for units 230V 7.5kW and smaller, 460V 15kW

and smaller).

Braking torque: without braking resistor, approximately 5% of motor rated torque

with braking option, approximately 150% of motor rated torque

• Coast to Stop (B1-03 = “1”)

Output frequency

Run command

ON

Inverter output is shut OFF

when stop command is given.

OFF

Figure 2 Stopping Method - Coast to Stop

Upon removal of the FWD (REV) run command, the motor starts to coast. Upon reapplying the run command operation will resume after the minimum baseblock time

(L2-03) elapses.

Coast to Stop with Timer 1 (B1-03 = “3”) should be used to prohibit the inverter from

starting into a rotating motor. When setting B1-03=3, the deceleration time (C1-02) is

used as the timer during which operation is prohibited.

VS-616PS5 Programming Manual 11

Page 12

Section B: Application Parameters

B1 Sequence

• Coast to Stop with Timer 1 (B1-03 = “3”)

Output Frequency

Coasting

FWD (REV)

Run Command

Run Command Disabled

Decel Time 1

(C1-02)

Accel Time 1

(C1-01)

Time

ONONON

Figure 4 Stopping Method - Coast to Stop w/Timer

Upon removal of the run command, a new run command is blocked until the coast to

stop timer has elapsed (same as Decel 1). After the timer elapses, the user must

enter another run command for the inverter to begin acceleration. This stopping

method is disabled during flux vector control.

B1-04 Reverse Operation Enable/Disable B

Setting Range: 0 to 1

Factory Default: 0

A “reverse run disabled” setting does not allow a reverse run command from the control circuit terminal or the digital operator. This setting is used in applications where a

reverse run command is undesirable.

Setting Description

0 Reverse run is enabled (factory default).

1 Reverse run is disabled.

B1-05 Operation Selection at Zero Speed A

Select an operation mode to be used when the speed reference (analog input) drops

below the minimum speed setting (El -08).

Setting Description

0 E1-08 is ignored, run according to speed reference.

12 VS-616PS5 Programming Manual

Page 13

Section B: Application Parameters

B1 Sequence

Setting Description

1 Baseblock (factory default)- No output to motor

2 Run at minimum output speed (E1-08).

3 Zero-speed operation (internal speed reference is set to “0”)

B1-06 LOCAL/REMOTE Run Select A

This parameter determines how the inverter will function when switching from local to

remote operation when the external run command is applied.

Selection Description

0 Operation is disabled if the external run command is applied

prior to switching from local to remote. The run command

must be removed and re-applied to start operation.

1 Operation is enabled if the external run command is applied

prior to switching from local to remote.(factory default).

VS-616PS5 Programming Manual 13

Page 14

Section B: Application Parameters

B2 Servo Speed Level

B2 Zero Speed Level

.

B2-01 Zero-speed Level (Baseblock level) B

Setting Range: 0.0 to 20.0%

Factory Default: 0.5%

Sets the speed at which the inverter baseblocks upon deceleration. 20% equals 20%

of the maximum speed setting as entered in parameter E1-06.

The initial value is 0.5%. The units can be changed by O1-03.

14 VS-616PS5 Programming Manual

Page 15

Section B: Application Parameters

B3 Magnetic Pull-in

B3 Magnetic Pull-in

The magnetic pull-in (Synchronization) feature is used only during the PG orientation

auto-tuning process. During normal operation this function is not performed.

During PG Orientation Auto-Tuning, the following parameters are used to gradually

ramp up the motor current to a desired level to allow a “soft” rotor pole alignment.

Once the magnetic pull-in is completed, the PG Orientation feature is performed.

B3-02 Magnetic Pull-in Current A

Setting Range: 0 to 150%

Factory Default: 50%

The current level during initial magnetic pull-in is set in units of 1%.

A setting of 100% generates Motor rated current (E1-04). Increasing this value

increases the motor torque during the pull-in process.

B3-04 Current Ramp-up Time A

Setting Range: 0.0 to 5.0s

Factory Default: 1.0s.

Sets the rate at which the current is increased during the magnetic pull-in process.

Too short a setting will result in abrupt rotor movement.

VS-616PS5 Programming Manual 15

Page 16

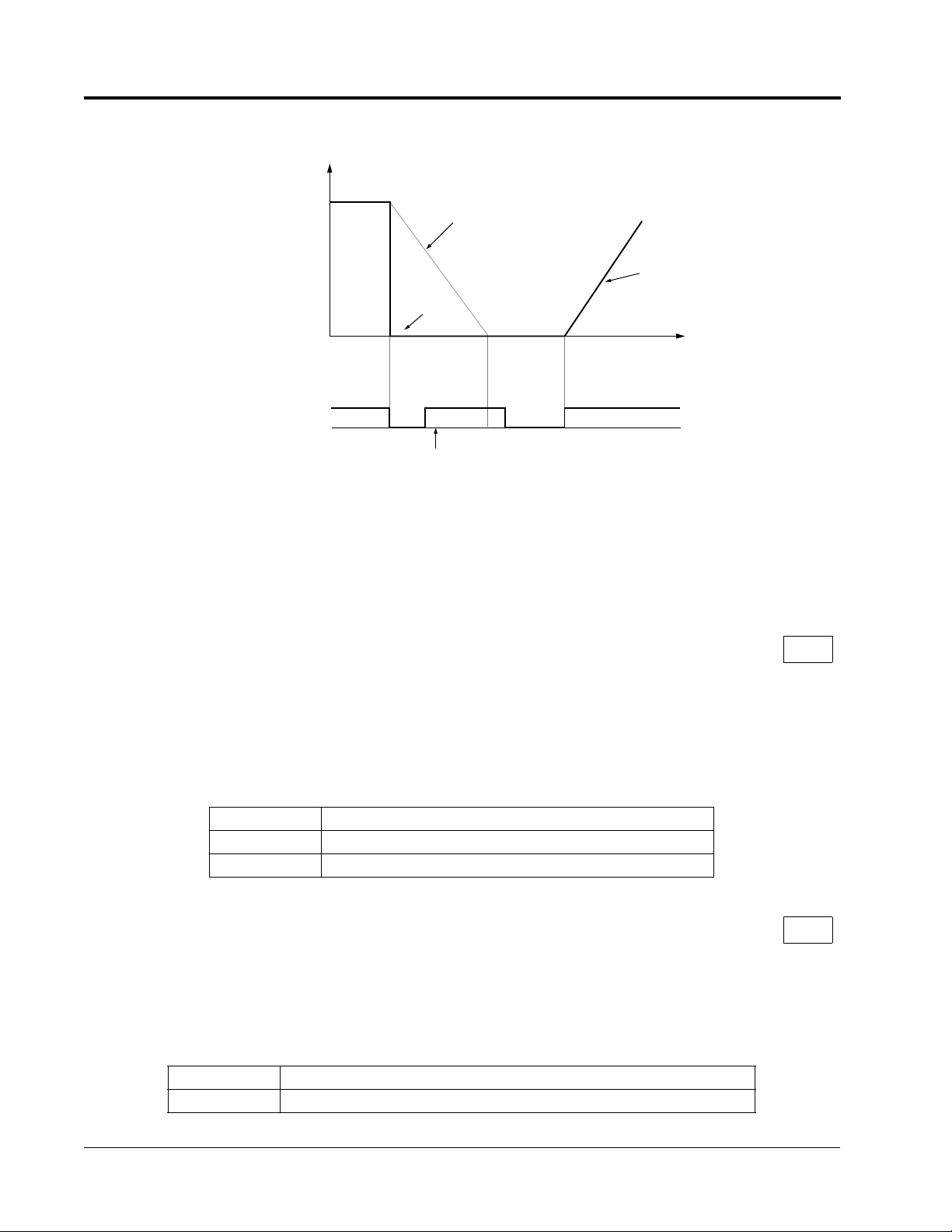

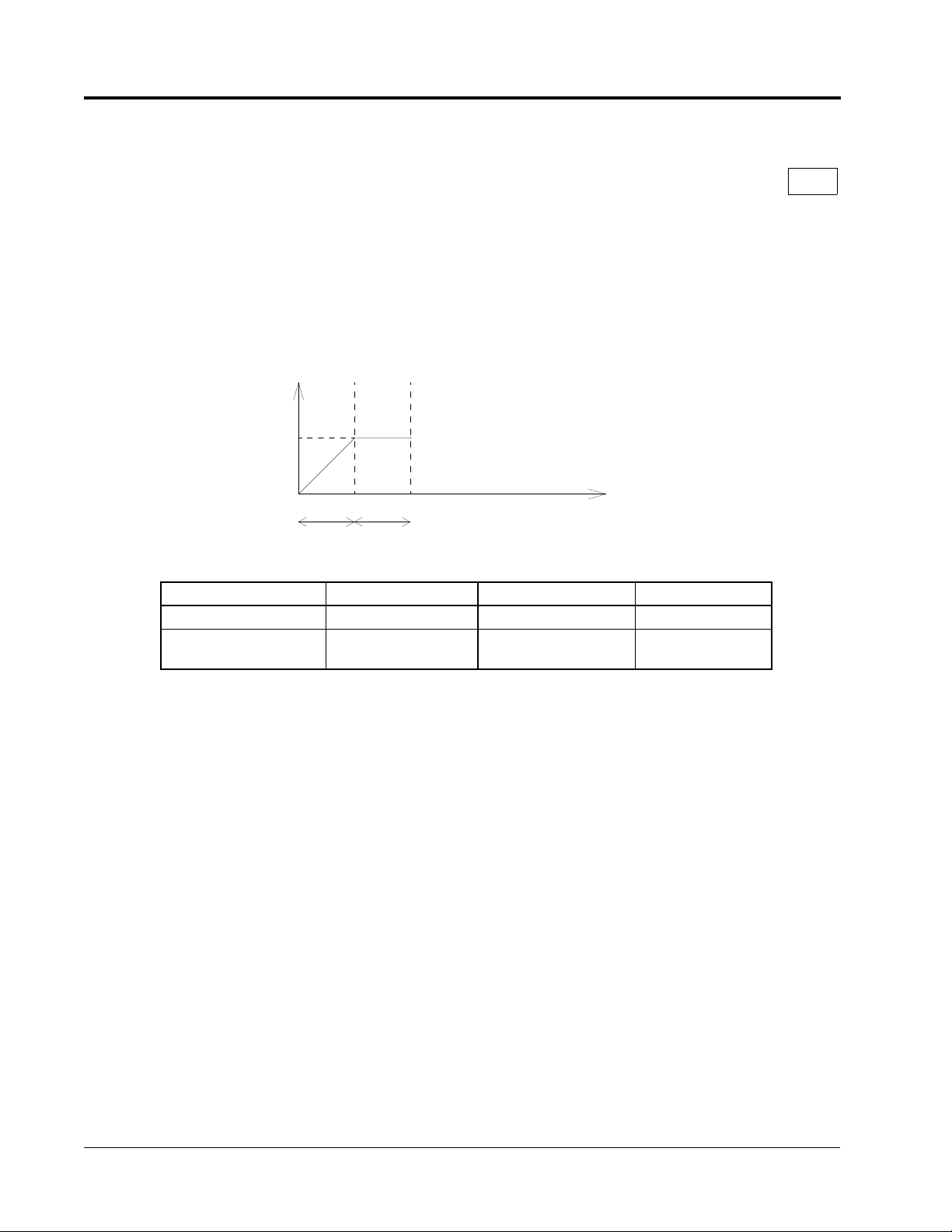

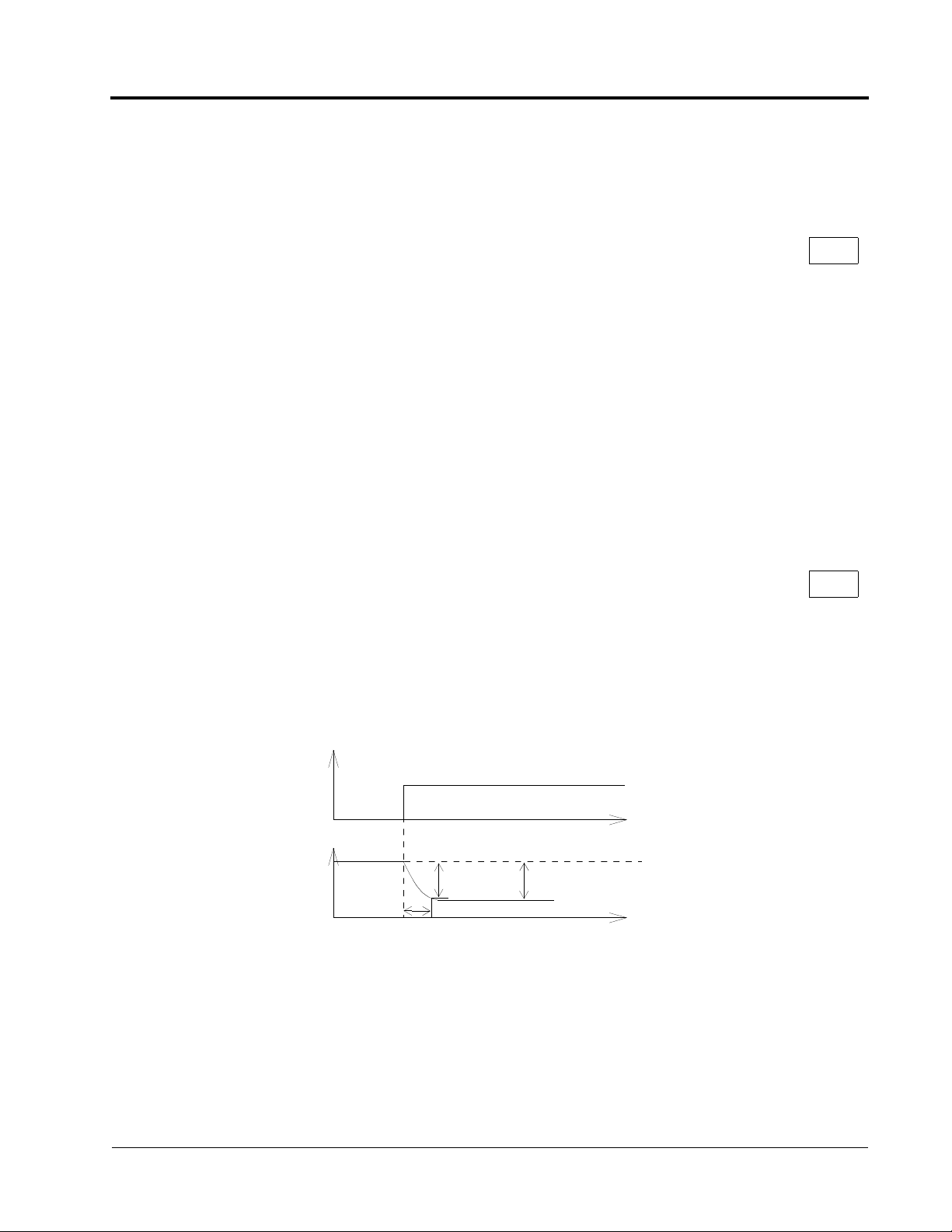

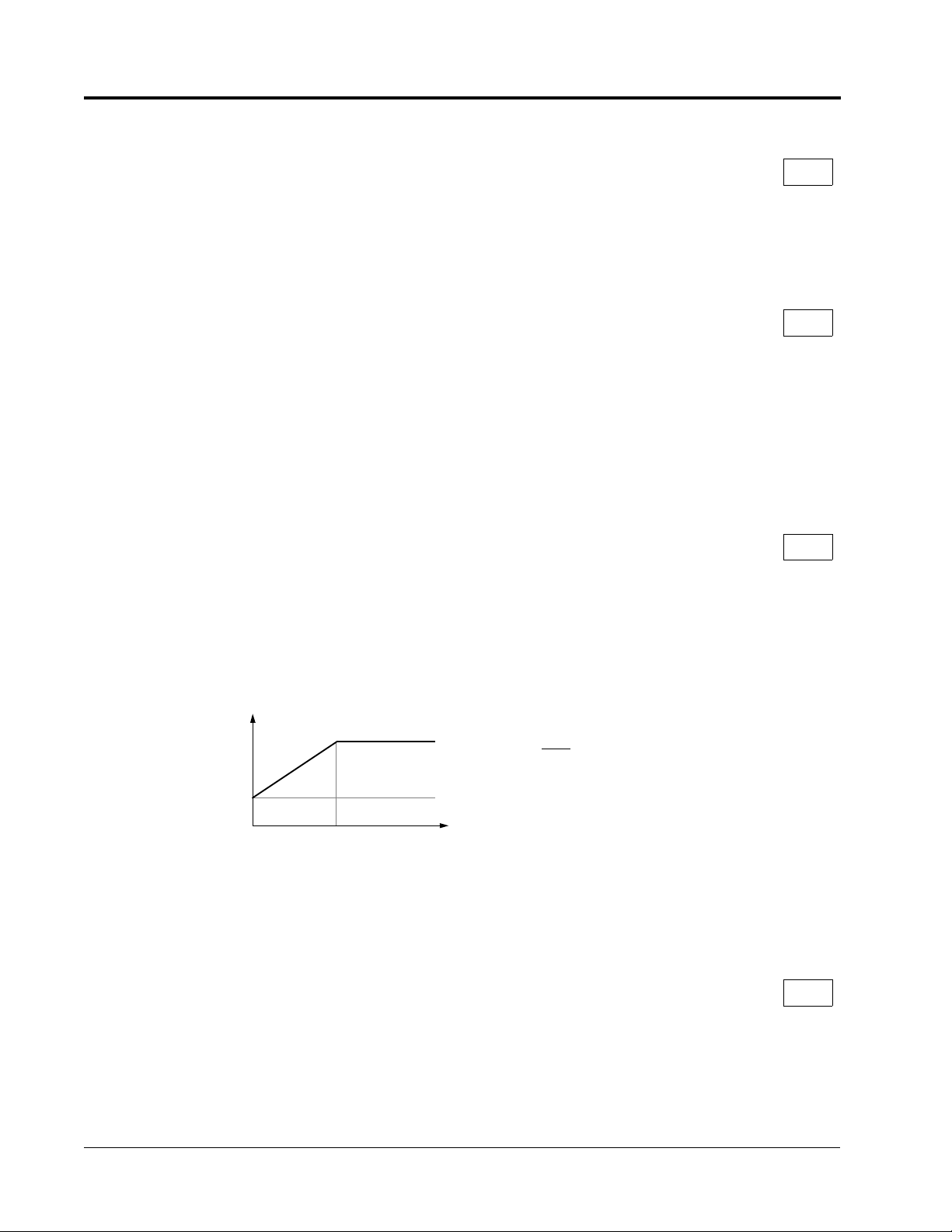

Current Value

B3-04

B3-05

Section B: Application Parameters

B3 Magnetic Pull-in

B3-05 Magnetic Pull-in Time A

Setting Range: 0.0 to 5.0s

Factory Default: 1.0s

This parameter sets the time to allow the rotor to pull in (align) with the magnetic field

at initial excitation. Pull-in waiting time is set in units of 0.1s.

The current vs. time plot during the magnetic pull-in process is as follows:

B3-02

0 1 2

Operation Status B3-02 Adjustment B3-04 Adjustment B3-05Adjustment

Slow Start - Decrease set value Decrease set value

Insufficient torque, and

“STO” is output

Increase set value. - -

Time

16 VS-616PS5 Programming Manual

Page 17

Section B: Application Parameters

B4 Delay Timers

B4 Delay Timers

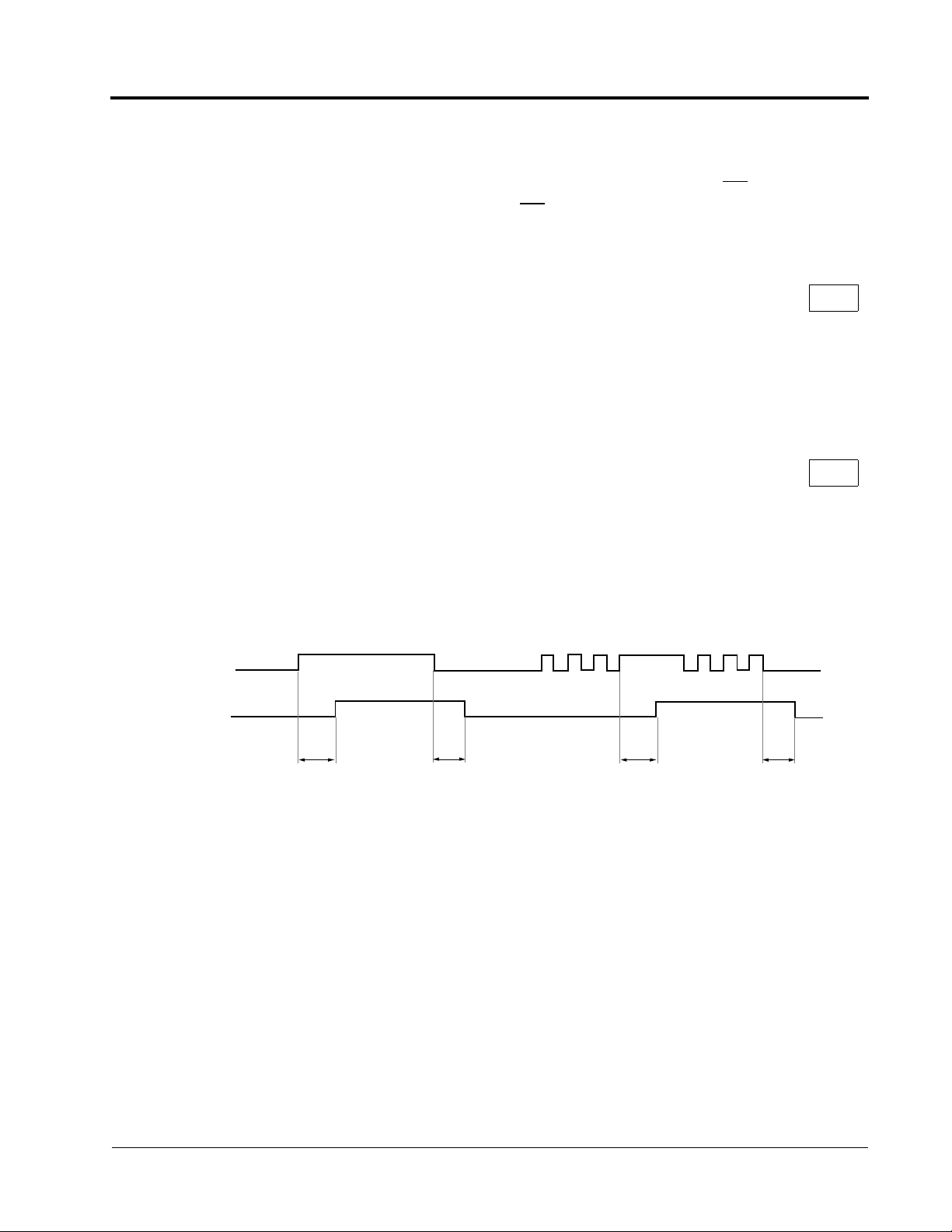

Use the inverter input (multifunction inputs) and output (multifunction outputs) in

place of an external timer. When a multi-function contact input (H1-XX = “18”) is

closed, a multi-function contact output (H2-XX = “12”) can be set to close after the

On-delay time (B4-01) has expired. This function operates independently of any concurrent inverter activity.

B4-01 On-delay Timer A

Setting Range: 0.0 to 300.0s

Factory Default: 0.0s

Sets the ON-delay time in units of 0.1 second. The multi-function input must be

“closed” for longer than the ON-delay timer for the multi-function output to close.

B4-02 Off-delay Timer A

Setting Range: 0.0 to 300.0s

Factory Default: 0.0s

Sets the OFF-delay time in units of 0.1 second. The multi-function input must be

“open” longer than the OFF-delay timer for the multi-function output to open.

Multi-function Contact

Input: Timer Function

Multi-function Contact

Output: Timer Function

B4-01

ON

ON

B4-02

ON ON ON

B4-01

ON

ON ON ON

ON

B4-02

Figure 8 Timing Diagram of Timer Function

VS-616PS5 Programming Manual 17

Page 18

Section B: Application Parameters

B5 PID Control

B5 PID Control

The Proportional, Integral, and Derivative (PID) control function provides closed-loop

control and regulation of a system variable such as temperature or pressure. A control signal based on the difference (or error) between a feedback signal and a desired

setpoint is produced. Integration and derivative calculations are then performed on

this signal, based upon the PID parameter settings (B5-01 to B5-08), to minimize

deviation, for precise control.

B5-01 PID Control Mode Selection A

To enable PID control, set PID control mode selection to “1” or “2”, according to the

description below. Also be sure to set terminal 16 function selection (H3-05) to PID

feedback (Set Value: “B”).

Setting Description

0 PID is disabled (factory default).

1 PID is enabled (deviation signal is put through derivative control).

2 PID operates with feed forward (feedback signal is put through derivative control).

Notes:

1. PID with feed forward applies control much quicker than normal PID, without waiting for the

deviation signal to build up.

2. A PID inverse feedback signal can be selected by inverting the settings for terminal 16 gain

and bias.

Then select the PID control intended value (setpoint) and detected value (feedback)

setpoint as follows:

Detected Value (Feedback)

Set the PID feedback value with the control circuit terminal 16 voltage signal (0 to

10V, -10 to 10V) or multi-step speed parameters H1-03 to H1-06.

Control circuit terminal 16 voltage signal:

Set reference selection (B1-01) to “1” and set H3-05 = “B”.

Multi-step speed parameters via multifunction inputs (H1-01 to H1-06):

Set reference selection (B1-01) to “0.”

Set multifunction inputs to (H1-01 to H1-06) set value 3,4 and/or 5.

(allows combination of multi-step speed references and jog frequency reference

as entered in parameter D1-01 thru D1-09)

Intended Value (Setpoint)

The control circuit terminal 14 current signal (4 to 20mA) or voltage signals (0 to 10V,

-10 to +10V) can be used to set the PID setpoint value.

Control circuit terminal 14 accepts 4-20 MA current signal:

Set terminal 14 signal selection (H3-08) to “2.”

18 VS-616PS5 Programming Manual

Page 19

Section B: Application Parameters

B5 PID Control

Control circuit terminal 14 accepts voltage signal:

Set terminal 14 signal selection (H3-08) to “0” for 0-10 VDC input signal or “1” for 10 to 10 VDC input signal. The J1 jumper must also be cut to set-up terminal 14

to accept a voltage signal.

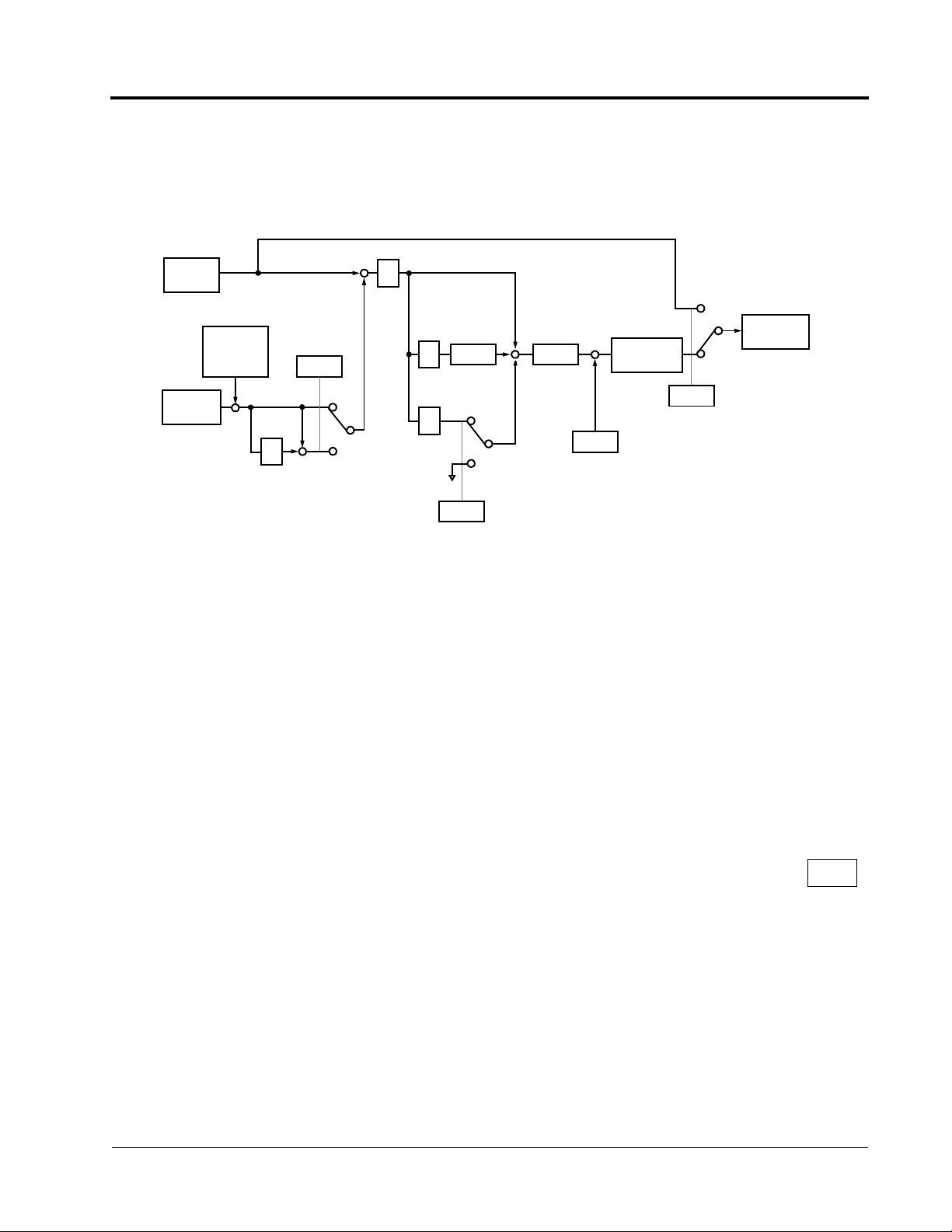

B5-02

B5-01

1

+

2

+

P

0

Frequency

Reference

I

B5-03

D

B5-05

Limit

B5-04

1

2

B5-06

++

Limit

+

Offset

B5-07

B5-08

Output

Delay Time

1 or 2

B5-01

Intended

Value

Detected

Value

H3-06

Feedback

Calibration

Gain

D

B5-05

(Deviation) -

+

B5-01

Figure 9 PID Control Block Diagram

Notes:

1. I value is reset to ”0” when operation stops.

2. The upper limit of the I value can be set by parameter B5-04.

Increase the value of parameter B5-04 to upgrade control capability by

integration. If the control system is unstable and it cannot be stopped by

adjusting the integral time, output delay time, etc., decrease the set value

of parameter B5-04.

3. PID control can be canceled by a multi-function contact input signal.

By setting any of parameters H1-01 to H1-06 to “19” and by closing the

contact during running PID control is disabled and the intended value signal itself is used as a frequency reference signal.

B5-02 PID Control Proportional Gain A

Setting Range: 0.00 to 25.00

Factory Default: 1.00

The proportional gain is the value by which the deviation signal is multiplied to generate a new frequency reference. Too high a setting will result in oscillations (instability).

Too low a setting will result in a sluggish response.

VS-616PS5 Programming Manual 19

Page 20

Section B: Application Parameters

B5 PID Control

B5-03 PID Control Integral Time A

Setting Range: 0.00 to 360.0s

Factory Default: 1.00s

The integral calculation sums the deviation over time which forces the deviation to

become zero. Thus, the feedback will match the desired setpoint. The integral time

determines how quickly the integral gain increase is added to the control loop. Too

high a setting will result in slow response. Too low a setting may result in rapid oscillations (instability).

B5-04 PID Control Integral Limit A

Setting Range: 0.0 to 100.0%

Factory Default: 100.0%

The integral limit is used to limit the range of the integral term. In some applications it

may be desirable to limit the integral term to improve system response. Otherwise,

the integral value may become large and overshoots may result when the integral

value takes a long time to integrate in the opposite direction. This value is set as a

percentage of maximum motor speed (E1-06).

B5-05 PID Control Derivative Time A

Setting Range: 0.00 to 10.00s

Factory Default: 0.00s

The derivative calculation attempts to control the remaining overshoot left over after

the proportion and integral calculations. If the system is approaching the intended

value very rapidly, the derivative control produces a strong braking action to prevent

overshoot. If the system is already stable with very little deviation change, derivative

control has very little effect. The derivative time is used to dampen oscillations and

reduce overshoot, thus improving stability. Setting the derivative time to a larger

number produces more braking action in the control system.

B5-06 PID Control Limit A

Setting Range: 0.0 to 100.0%

Factory Default: 100.0%

The PID limit places a limit on the PID signal output, limiting the output frequency reference. Normally this is set to 100% to allow unrestrained operation of the PID function. This value is set as a percentage of maximum motor speed (E1-06).

20 VS-616PS5 Programming Manual

Page 21

Section B: Application Parameters

B5 PID Control

B5-07 PID Control Offset A

Setting Range: ±100.0%

Factory Default: 0.0%

The PID offset adds a bias to the calculated PID value.

B5-08 PID Control Output Primary Delay Time A

Setting Range: 0.00 to 10.00s

Factory Default: 0.00s

The output delay time builds in a delay to changes in the calculated PID value, which

can prevent oscillations and improve stability. Use the PID Delay Time when transients occur in the system and it is undesirable to have the PID respond.

Parameters B5-04 thru B5-08 are preset at the factory to optimum values for most

applications, and hence, do not need to be changed.

When tuning a system, first increase the proportional gain until oscillations occur.

Then, reduce the proportional gain slightly until the oscillations stop. Next, reduce the

integral time slowly until oscillations begin. Then, increase the integral time slowly so

that the oscillations cease. Test the system under all conditions, observe the stability

and verify that the desired operation is generated. Fine tune the proportional and integral times, along with any other PID parameter as needed.

VS-616PS5 Programming Manual 21

Page 22

Section B: Application Parameters

B6 Reference Hold

B6 Reference Hold

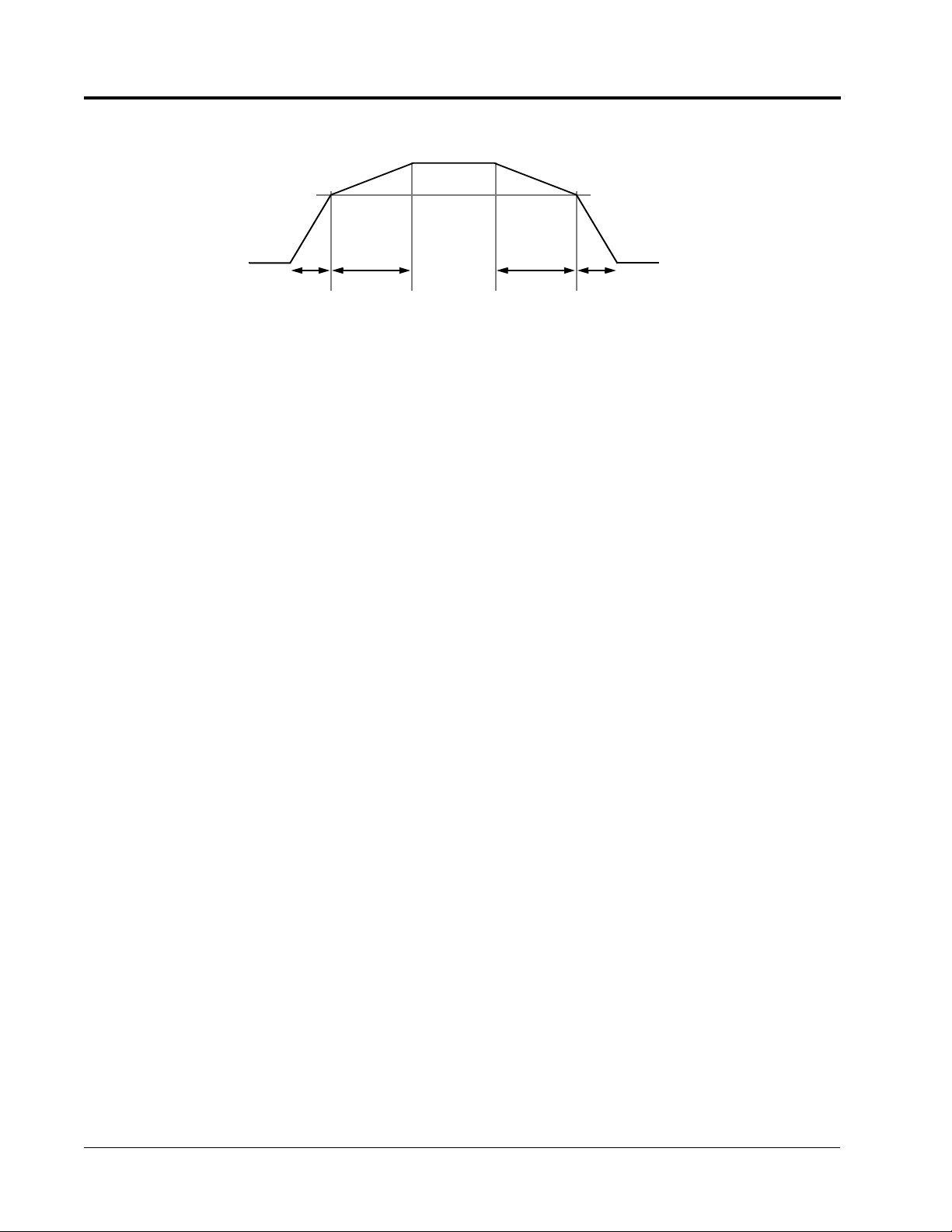

The reference hold or dwell function is used to temporarily hold the output frequency

at a set reference, for a set time, during the acceleration and deceleration process.

Use this function when driving a permanent magnet motor, or a motor with a heavy

starting load. The pause in acceleration allows the magnets in a permanent magnet

motor to synchronize with the stator field of the motor, thus reducing traditionally high

starting current.

B6-01 Dwell Reference at Start A

Setting Range: 0.00 to 100.00%

Factory Default: 0.00%

Sets the dwell frequency reference during acceleration in units of 0.01%.

B6-02 Dwell Time at Start A

Setting Range: 0.0 to 10.0s

Factory Default: 0.0s

Sets the amount of time that the frequency reference “dwells” during acceleration in

units of 0.1s.

B6-03 Dwell Reference at Stop A

Setting Range: 0.00 to 100.00%

Factory Default: 0.00%

Sets the dwell frequency reference during deceleration in units of 0.01%.

B6-04 Dwell Time at Stop A

Setting Range: 0.0 to 10.0s

Factory Default: 0.0s

Sets the amount of time that the frequency reference “dwells” during deceleration in

units of 0.1s.

22 VS-616PS5 Programming Manual

Page 23

Section B: Application Parameters

B7 DROOP Control

B7 Droop Control

Droop Control is a function that allows the speed of a motor to decrease in proportion

to load torque. This can be used to insure load sharing between drives on multiple

drive systems.

B7-01 Droop Capacity A

Range:0.0 to 100.0%

Factory Default: 0.0%

Droop amount (%)

=

B701–()

------------------------- %

100

x 100

A setting of 100% allows the speed to drop 100% of the maximum speed value

(when the torque is 100%).

Droop response time is set with parameter B7-02.

B7-02 Droop Delay Time A

Setting Range: 0.00 to 1.00s

Factory Default: 0.10s

When B7-02 is decreased, drooping response becomes quicker, but the motor

hunts more easily.

Torque

Load

Motor

Speed

63%

B7-02

Droop Amount (B7-01)

= Torque (%) x B7-01

VS-616PS5 Programming Manual 23

Page 24

Section C: Tuning Parameters

C1 Accel/Decel

C Tuning Parameters

C1 Accel/Decel

C1-01 Acceleration Time 1 Q

C1-02 Deceleration Time 1 Q

C1-03 Acceleration Time 2 B

C1-04 Deceleration Time 2 B

C1-05 Acceleration Time 3 A

C1-06 Deceleration Time 3 A

C1-07 Acceleration Time 4 A

C1-08 Deceleration Time 4 A

Setting Range: 0.00 to 6000.0s

Factory Default: 10.0s

The acceleration parameters set the time necessary for the output speed to accelerate from 0 to the maximum Speed (E1-06). Deceleration parameters set the time

needed for the output Speed to decelerate from the maximum speed to 0. .

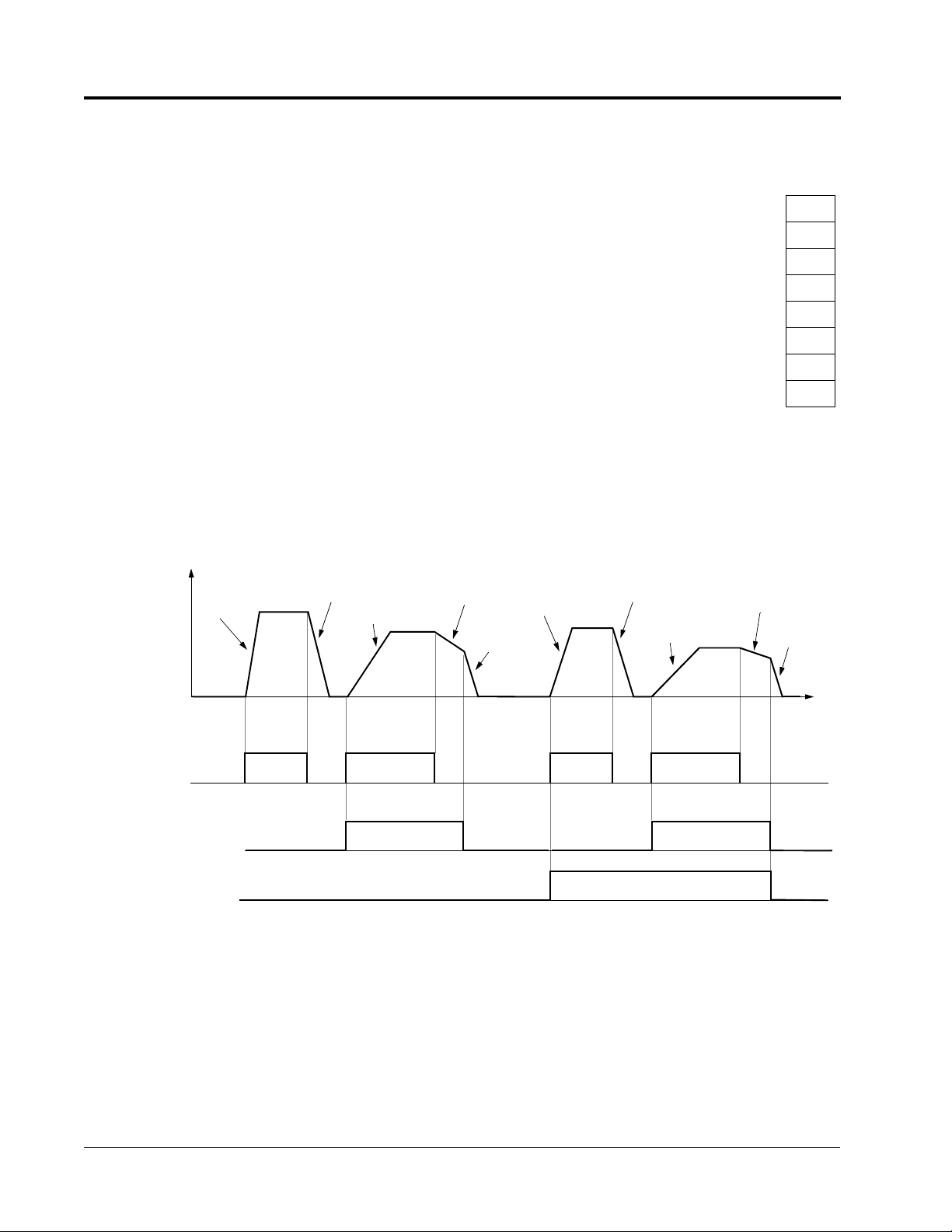

Accel Time 1

(C1-01)

Output

Frequency

FWD (REV) Run Command

Accel/Decel Time Selection 1

(Terminals 3 to 8, Setting = “7”)

Accel/Decel Time Selection 2

(Terminals 3 to 8, Setting = “1A”)

* When “ramp to stop” is selected (B1-03 = “0”)

Decel Time 1* (C1-02)

ON OFF ON

Figure 13 Timing Diagram of Accel/Decel Time Adjustment

Accel Time 2 (C1-03)

ON

Decel Time 2*

(C1-04)

Decel Time 1*

(C1-02)

Accel Time 3

(C1-05)

ON OFF ON

OFF

Decel Time 3* (C1-06)

Accel Time 4 (C1-07)

ON

ON

Decel Time 4*

(C1-08)

Decel Time 1*

(C1-02)

Time

Use the multifunction inputs to select up to four accel/decel times. When any of the

multi-function contact input selections (H1-01 to H1-06) are set to “7”and “1A”, up to

four accel/decel times can then be selected by opening or closing the appropriate

accel/decel time selection commands (terminals 3 to 8).

24 VS-616PS5 Programming Manual

Page 25

Section C: Tuning Parameters

C1 Accel/Decel

.

Accel/decel Time Selection 1

Multi-function Input

Setting = “7”

Open or not set Open or not set C1-01 C1-02

Closed Open or not set C1-03 C1-04

Open or not set Closed C1-05 C1-06

Closed Closed C1-07 C1-08

Accel/decel Time Selection 2

Multi-function Input

Setting = “1A”

Accel Time Decel Time

C1-09 Fast-stop Time B

Setting Range: 0.00 to 6000.0s

Factory Default: 10.0s

When a Multi-function contact input is set to fast-stop command (setting = “15”), and

the contact closes the fast stop feature is executed.

It may be necessary to install a braking unit to achieve the desired stopping rate and

eliminate over-voltage from occurring.

C1-10 Accel/Decel Time Setting Units A

Setting Description

0 Accel/decel time (C1-01 to C1-09) setting range is in units of 0.01s.

Accel/decel time setting range: 0.00 to 600.00s

1 Accel/decel time (C1-01 to C1-09) setting range is in units of 0.1 second.

Accel/decel time setting range: 0.0 to 6000.0s (factory default).

If any of the parameters C1-01 to C1-09 is set to 600.1 seconds or more, C1-10 cannot be set to “0.”

C1-11 Automatic Accel/Decel Time Switching Speed Level A

Setting Range: 0.0 to 100.0%

Factory Default: 0.0%

Accel/decel times can be changed automatically, without using the multi-function contact inputs. This feature is active anytime C1-11 is not equal to 0.

Use accel/decel times set in parameters C1-01 and C1-02 when output frequency ≥

C1-11.

Use accel/decel times set in parameters C1-07 and C1-08 when output frequency <

C1-11.

Multi-function contact inputs which are set for accel/decel selection have priority over

VS-616PS5 Programming Manual 25

Page 26

Section C: Tuning Parameters

C1 Accel/Decel

the automatic change of accel/decel.

Output Frequency

Accel/Decel Switching Level

(C1-11)

C1-07

C1-01 C1-02 C1-08

Figure 14 Accel/Decel Switching Level Adjustment

26 VS-616PS5 Programming Manual

Page 27

Section C: Tuning Parameters

C2 PG Origin Pulse Compensation

C2 PG Origin Pulse Compensation

C2-13 PG Origin Pulse Compensation Value Q

Setting Range: ±180°

Indicates the angular displacement between the magnetic pole and the marker pulse

from the hall sensor or encoder feedback devices. This value is used to control the

commutation to insure optimum performance.

This value is automatically set when performing PG origin auto-tuning.

Do not change after setting.

This value is not initialized at initialization.

VS-616PS5 Programming Manual 27

Page 28

Section C: Tuning Parameters

C3 Voltage Limit Control

C3 Voltage Limit Control

C3-05 Voltage Limit Control Selection A

This parameter sets the voltage limit control.

Set Value Description

0 •Voltage limitation control is not performed (fac-

tory default).

1 •Voltage limitation control is performed limits the

output voltage to 230 (460) by reducing the d-axis

current level.

28 VS-616PS5 Programming Manual

Page 29

C5 ASR Tuning

Proportional Gain According to Motor Speed

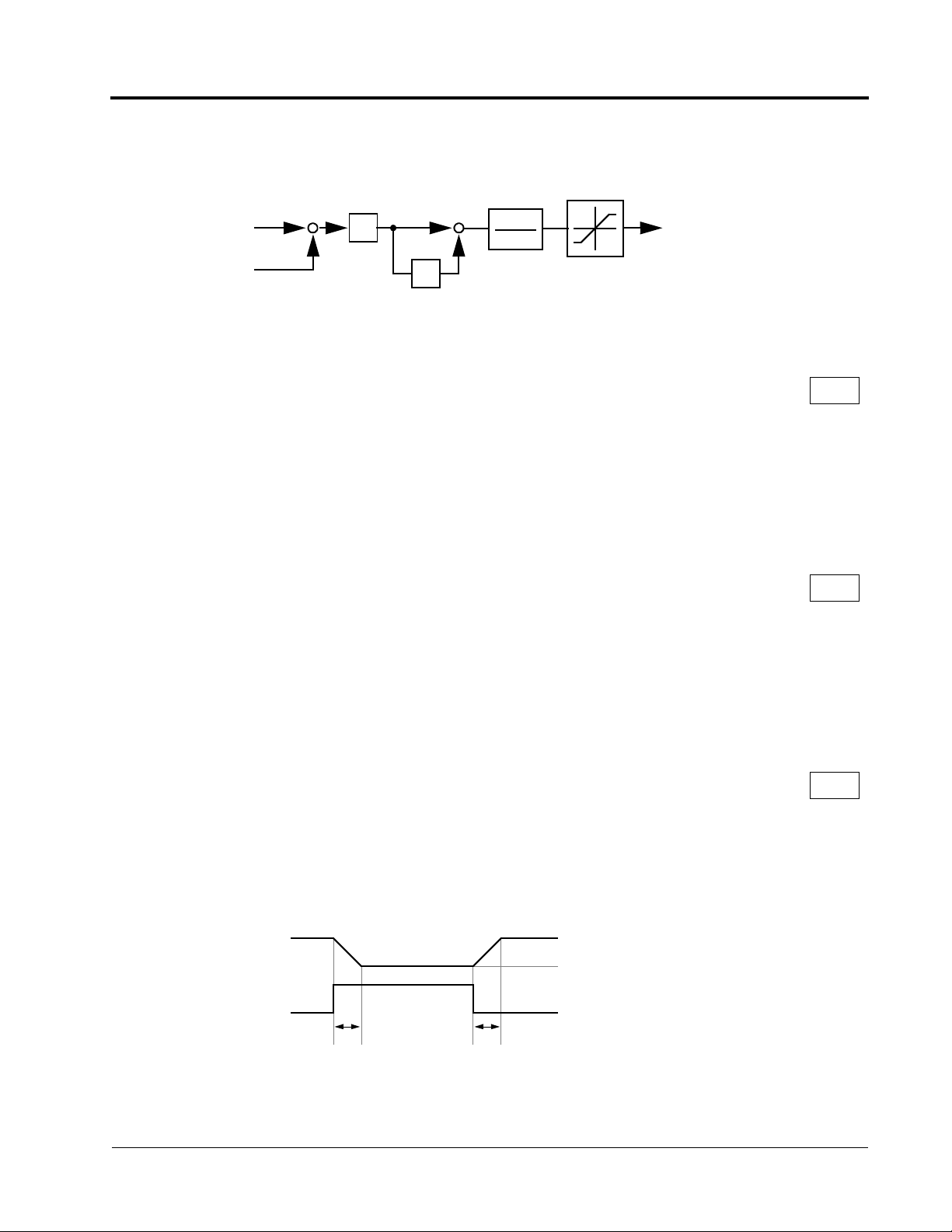

The Automatic Speed Regulator (ASR) provides closed loop motor speed control so

that optimum performance during changes in motor speed or load can be achieved.

Section C: Tuning Parameters

C5 ASR Tuning

Torque Limit

Secondary Current Reference

L7-01 ~ L7-04

Speed Reference

Speed Feedback

+

C5-01, C5-03

-

P

I

C5-02, C5-04

+

+

1

1 + ST

C5-05

Figure 20 ASR Block Diagram (Flux Vector Control)

C5-01 ASR Proportional Gain 1 B

Setting Range: 0.00 to 300.00

Factory Default: 5.00

The ASR proportional gain 1 adjusts the speed in response to the speed deviation

signal. Speed response increases as the proportional gain is increased. However,

the load may become unstable if the ASR proportional gain is set too high.

C5-02 ASR Integral Time 1 B

Setting Range: 0.000 to 10.000s

Factory Default: 0.500s

The ASR integral time 1 adjusts the inverter’s response time to changes in load.

Response increases as the integral time is decreased. However, the load may

become unstable if the ASR integral time is set too low.

C5-03 ASR Proportional Gain 2 B

Setting Range: 0.00 to 300.00

Factory Default: 5.00

The ASR proportional gain 2 is an additional proportional gain adjustment that can be

enabled by a multi-function contact input (H1-XX = “77”).

(see Figure 22)

C5-03 Proportional Gain

Multi-function Input

(H1-XX = “77”)

ON

OFF

C5-02

OFF

ON

C5-02

Figure 21 ASR Multi-function Input Timing Diagram

VS-616PS5 Programming Manual 29

Page 30

Section C: Tuning Parameters

C5 ASR Tuning

C5-04 ASR Integral Time 2 B

Setting Range: 0.000 to 10.000s

Factory Default: 0.500s

The ASR integral time 2 is an additional integral time adjustment.

C5-05 ASR Output Primary Delay Time A

Setting Range: 0.000 to 0.500s

Factory Default: 0.004s

Mechanical backlash in an application causes secondary current (I2) reference variations in the motor’s rotor. This condition can undesirably limit the adjustment of ASR

parameters. The output delay time constant is used to control these secondary current (I2) reference variations.

C5-06 ASR Switching Speed Level A

Setting Range: 0.00 to 100.00%

Factory Default: 0.00%

Sets speed at which C5-01 and C5-02 are achieved. When C5-06 is set to any setting other than 0, both sets of proportional and integral values are used (See Figure

22).

C5-01

C5-02

C5-03

P gain · I time

0

C5-06

C5-04

f

FB

Motor Speed

P · N

fFB =

120

where . . .

P = Number of Motor Poles

N = Motor RPM

* When C5-06 =”0”, proportional gain 1 (C5-01)

and integral time 1 (C5-02) are selected.

Figure 22 ASR Switching Speed Level

Notes:

1. When C5-06 =” 0”, proportional gain 1 (C5-01) and integral time 1 (C5-02) are selected.

C5-07 ASR P Gain at Start A

Setting Range: 0.00 to 300.00

Factory Default: 5.00

This parameter sets the ASR P gain applied at magnetic pole pull-in. It is set to a

unit of 0.01.

30 VS-616PS5 Programming Manual

Page 31

Section C: Tuning Parameters

C6 Carrier Frequency

C6 Carrier Frequency

This function sets the inverter output transistor switching frequency (carrier frequency). Increase the carrier frequency to reduce motor noise and decrease it to

reduce leakage current. When increasing the carrier frequency above the factory

default values, current derating is necessary.

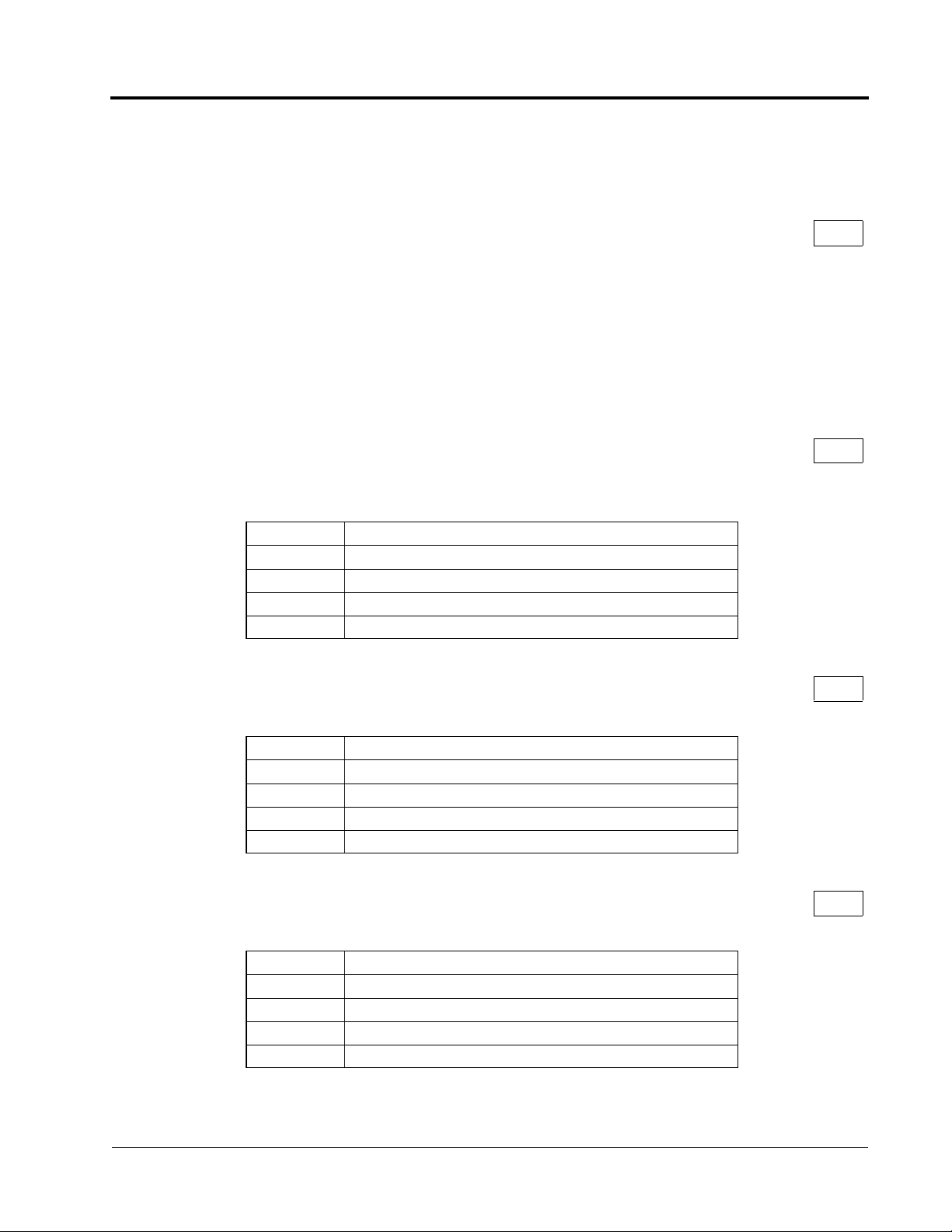

C6-02 Carrier Frequency Upper Limit A

Factory Settings:

230 Volt Models

Model Number Carrier Frequency

PS5U20P4

PS5U20P7

PS5U21P5

PS5U22P2

PS5U23P7

PS5U25P5

PS5U27P5

PS5U2011

PS5U2015

8kHz

460 Volt Models

Model Number Carrier Frequency

PS5U40P4

PS5U40P7

PS5U41P5

PS5U42P2

PS5U43P7

PS5U45P5

PS5U47P5

PS5U4011

PS5U4015

PS5U4018

PS5U4022

PS5U4030

PS5U4037

PS5U4045

PS5U4055

PS5U4075

PS5U4110

PS5U4160

8kHz

4kHz

VS-616PS5 Programming Manual 31

Page 32

Section C: Tuning Parameters

C6 Carrier Frequency

460 Volt Models

Model Number Carrier Frequency

PS5U4185

2kHzPS5U4220

PS5U4300

Pulse

Reference

1/100

C6-14

Speed Reference

C6-13

32 VS-616PS5 Programming Manual

Page 33

Section C: Tuning Parameters

C6 Carrier Frequency

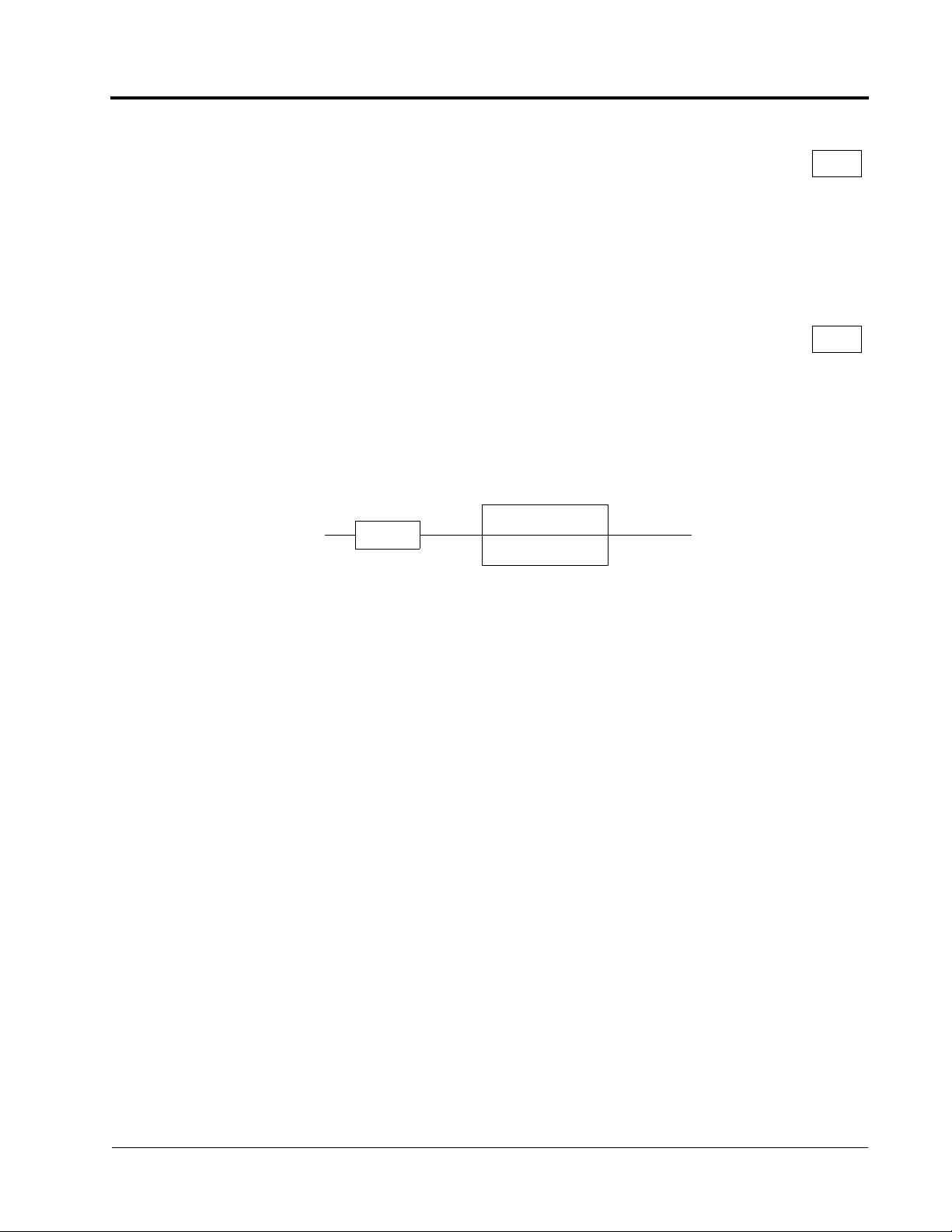

C6-13 Pulse Reference Ratio Denominator Value A

Setting Range: 0 - 1000

Factory Default: 0

Sets the denominator portion of the pulse reference multiplication block. Used when

B1-02=6 (Pulse Train reference mode).

C6-14 Pulse Reference Ratio Numerator Value A

Setting Range: 0 - 1000

Factory Default: 0

Sets the numerator portion of the pulse reference multiplication block. Used when

B1-02=6 (Pulse Train reference mode).

Pulse

Reference

1/100

C6-14

Speed Reference

C6-13

VS-616PS5 Programming Manual 33

Page 34

Section C: Tuning Parameters

C7 S-Curve Accel/Decel

C7 S-Curve Accel/Decel

An S-curve pattern is used to reduce shock and provide smooth transitions during machine

acceleration and deceleration. S-curve characteristic time is the time it takes to reach the set

accel/decel rate during a speed change.

C7-01 S-Curve Time at Acceleration Start A

C7-02 S-Curve Time at Acceleration End A

C7-03 S-Curve Time at Deceleration Start A

C7-04 S-Curve Time at Deceleration End A

Setting Range: 0.00 to 2.50s

Factory Default: 0.00s

.

Frequency Reference

Output Frequency

S-curve Characteristic

Time (Tsc)

Output Frequency

Time

Figure 15 S-curve Characteristic Timing Diagram

The following figure shows FWD/REV run switching with deceleration to stop.

FWD Run Command

REV Run Command

C7-02

Output Frequency

C7-01

C7-03

C7-04

DC Injection Braking

Time at Stop

B2-04

C7-01

C7-02 C7-03

C7-04

Figure 16 S-curve Characteristics - FWD/REV Operation

Time to accelerate from the minimum frequency

to the maximum frequency (total acceleration)

= C1-XX + (C7-01 + C7-02)/2

34 VS-616PS5 Programming Manual

Page 35

Section D: Reference Parameters

D1 Preset References

D Reference Parameters

D1 Preset References

D1-01 Preset Reference 1 Q

D1-02 Preset Reference 2 Q

D1-03 Preset Reference 3 Q

D1-04 Preset Reference 4 Q

D1-05 Preset Reference 5 B

D1-06 Preset Reference 6 B

D1-07 Preset Reference 7 B

D1-08 Preset Reference 8 B

Setting Range: 0.00 to 100.00%

Factory Default: 0.00%

Up to 9 preset speed references (including jog) with the multi-function contact input

function selections. When using the multi-step speed references, set the reference

selection (B1-01) to “0,” and set terminal 16 selection (H3-05) to “1F.” See the following table for programming preset speed references.

Terminal 5

H1-03 = “3”

Open Open Open Open Speed Reference 1 - Set Reference Source

Closed Open Open Open Speed Reference 2 - Set Terminal 16 Selection

Open Closed Open Open Speed Reference 3

Closed Closed Open Open Speed Reference 4

Open Open Closed Open Speed Reference 5

Closed Open Closed Open Speed Reference 6

Open Closed Closed Open Speed Reference 7

Closed Closed Closed Open Speed Reference 8

Closed Closed Closed Closed Jog Speed Reference

Terminal 6

H1-04 = “4”

Terminal 7

H1-05 = “5”

Terminal 8

H1-06 = “6”

Speed Reference

(B1-01) to “0.”

(H3-05) to “1F.”

D1-09 Jog Frequency Reference B

Setting Range: 0.00 to 100.00%

Factory Default: 10.00%

The jog frequency reference can be set in this parameter. Depress the JOG key on

the digital operator, or close terminal 7 to use this function. The jog command always

has priority over other reference commands. When using the multi-step speed references as indicated in the table above, change the jog command from terminal 7 to

terminal 8 (H1-06 = “6”). Selecting the jog frequency reference via a multifunction

input selects the jog frequency reference only. A separate run command also needs

to be applied to start the unit.

VS-616PS5 Programming Manual 35

Page 36

Section D: Reference Parameters

D1 Reference Limits

Frequency

Reference

D1-01

10.0Hz

FWD (REV) Run/Stop

D1-02

20.0Hz

D1-03

30.0Hz

D1-04

40.0Hz

D1-05

45.0Hz

ON

D1-06

50.0Hz

D1-08

60.0Hz

D1-07

55.0Hz

D1-09

6.0Hz

Time

Multi-step Speed Ref. 1

(Terminal 5)

Multi-step Speed Ref. 2

(Terminal 6)

Multi-step Speed Ref. 3

(Terminal 7)

Jog Ref.

(Terminal 8)

ON

ON

ON

ON ON

ON

ON

ON

Figure 24 Multi-step Speed Operation - Timing Diagram

Note: Setting units for D1-01 to D1-09 are dependent upon the setting of digital operator display mode

(O1-03). Possible setting units include Hz, percentage, RPM, or engineering units. See section

O1, Monitor Selection, for more details.

36 VS-616PS5 Programming Manual

Page 37

Section D: Reference Parameters

D2 Reference Limits

D2 Reference Limits

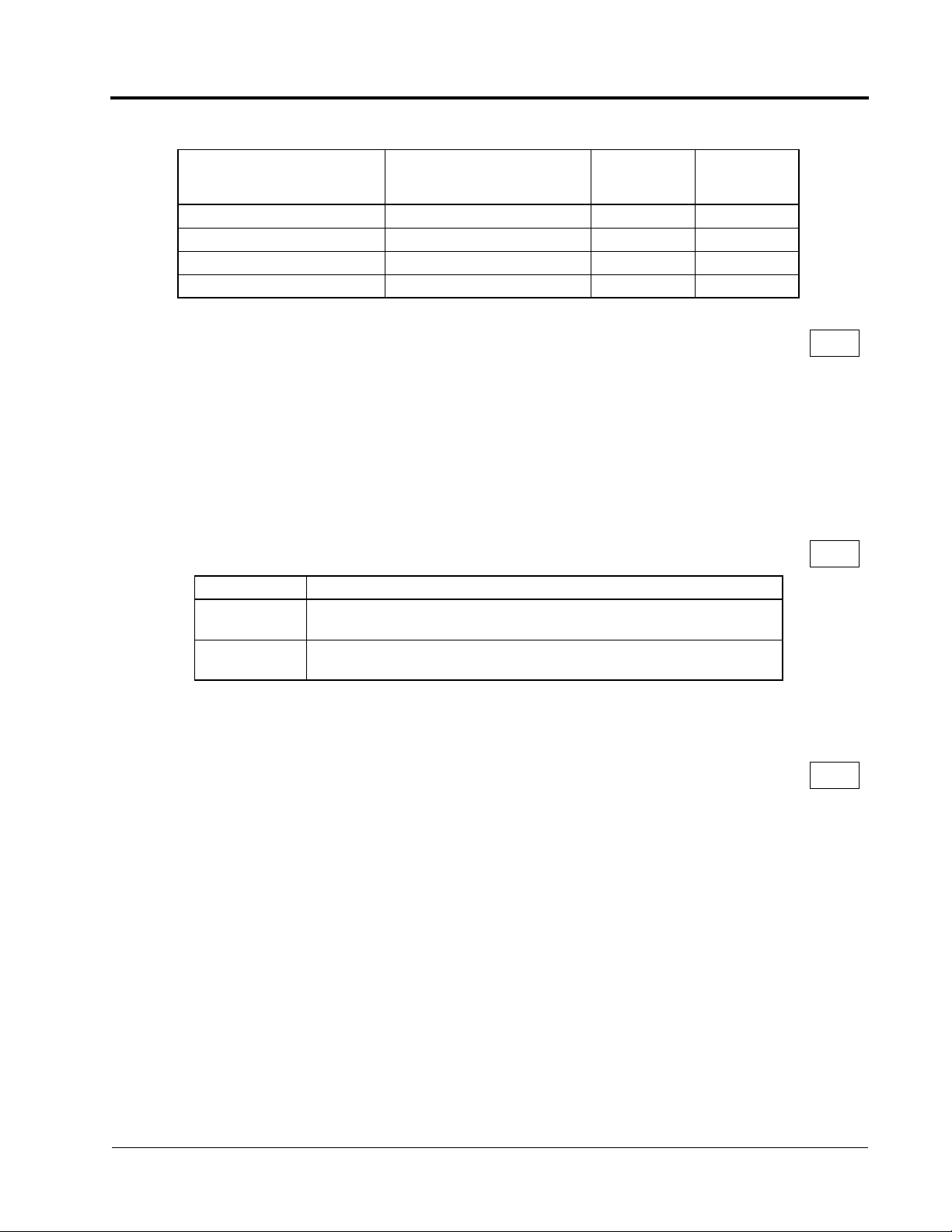

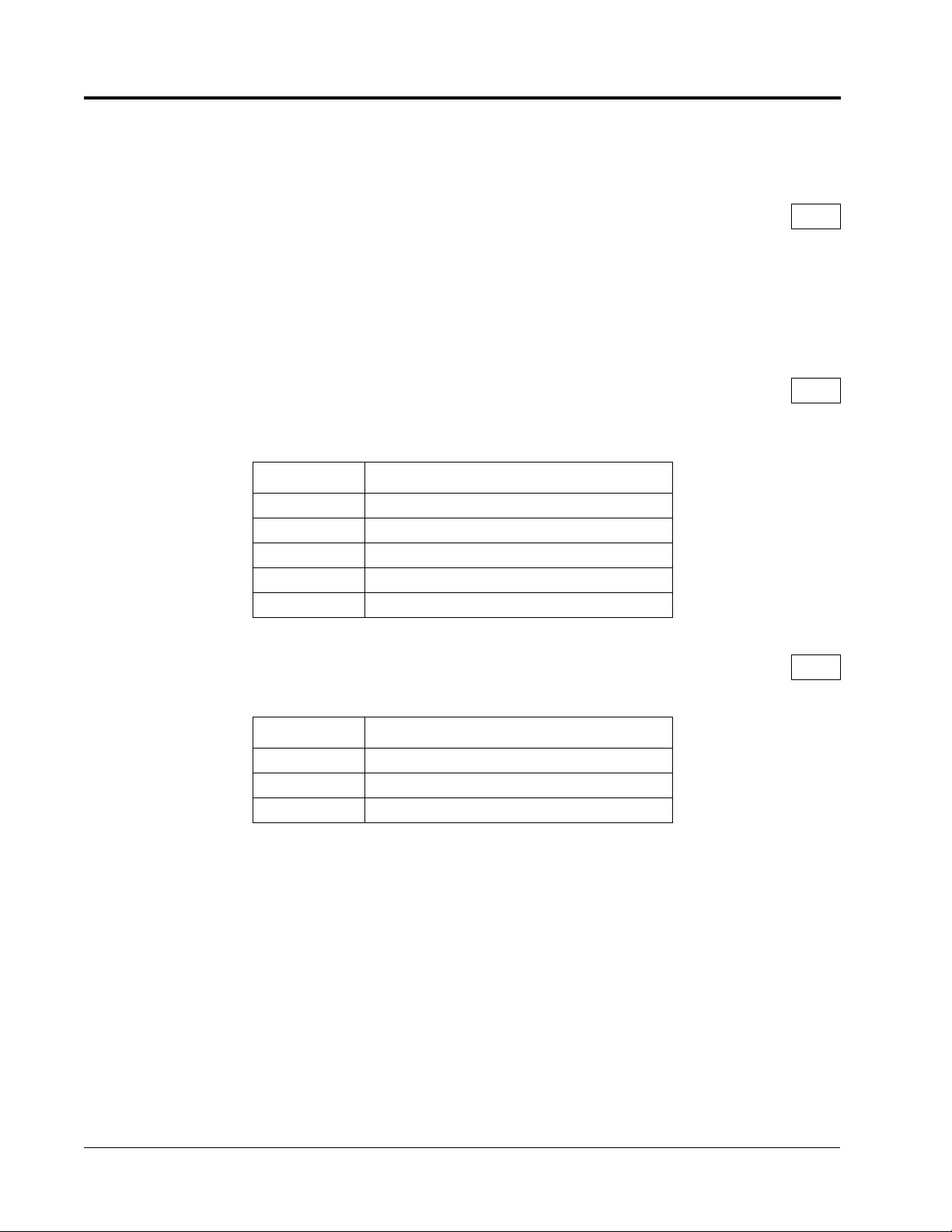

D2-01 Speed Reference Upper Limit B

Setting Range: 0.0 to 110.0%

Factory Default: 100.0%

The speed reference upper limit is set as a percentage of the maximum output speed

(E1-06). Limits the maximum output speed of the motor.

D2-02 Speed Reference Lower Limit B

Setting Range: 0.0 to 100.0%

Factory Default: 0.0%

The speed reference lower limit is set as a percentage of the maximum output speed

(E1-06). When a run command is input and the speed reference is less than the

lower limit, operation continues at the speed reference lower limit. However, when

the lower limit is set to less than the minimum output speed (E1-08), operation discontinues.

%

100

Internal

Speed

Reference

D2-02

0

Set Frequency Reference

E1-06

D2-01

Hz

Figure 25 Setting Frequency Upper and Lower Limits

VS-616PS5 Programming Manual 37

Page 38

Section D: Reference Parameters

D3 Jump Frequencies

D3 Jump Frequencies

D3-01 Jump Speed Reference 1 A

D3-02 Jump Speed Reference 2 A

D3-03 Jump Speed Reference 3 A

Setting Range: 0.0 to 200.0%

Factory Default: 0.0%

D3-04 Jump Speed Reference Bandwidth A

Setting Range: 0.0 to 200.0%

Factory Default: 1.0%

These functions allow the prohibition or “jumping” of critical Speeds so that the motor

can operate without resonant vibrations caused by some machine systems. They are

also used for dead band controls. Setting the value to 0.0% disables each function.

Output

Frequency

%

D3-02

D3-01

Set Frequency Reference

D3-03

D3-04

D3-04

Figure 26 Jump Frequencies

D3-04

%

38 VS-616PS5 Programming Manual

Page 39

D4 Reference Memory (Memorize Last Reference)

D4 Reference Memory (Memorize Last Reference)

Section D: Reference Parameters

D4-01 Reference Memory Selection - (Up/Down or Accel/

Decel Hold Feature)

Selects whether the reference memorization feature during, Up/Down or Accel/Decel

Hold operation is stored when operation is stopped (when power is removed or when

the run command is cancelled or overridden).

Setting Description

0 Reference memorization during Up/Down or Accel/Decel Hold operation not retained. If a

stop command is given or if power is removed, the frequency reference is reset to 0Hz. If

the inverter is decelerating when the run command is restored, operation resumes at the

frequency reference which the inverter has ramped down to (factory default).

1 Reference memorization during an Up/Down or Accel/Decel hold operation is retained. If a

stop command is given, or if power is removed, operation resumes at the held frequency

reference when run command is restored.

Note: Up/Down operation is set using the multi-function contact input function selections (H1-01 to H1-

06, setting = “10” and “11”). Accel/Decel Hold operation is set using multi-function contact input

function selections (H1-01 to H1-06, setting = “A”). See section H1, Digital Inputs, for more

information.

A

VS-616PS5 Programming Manual 39

Page 40

Section D: Reference Parameters

D5 Torque Control

D5 Torque Control

D5-01 Torque Control Selection A

Select either speed and torque control.

Setting Description

0 Speed control enabled with torque limit (factory default)

1 Torque control enabled with speed limit

Speed/torque control selection can also be made by using a multi-function contact

input function selection (H1-XX = “71”). When using a multifunction contact input to

switch between speed and torque control, set D5-01 = “0”.

D5-02 Torque Limit Primary Delay Time A

Setting Range: 0 to 1000ms

Factory Default: 0ms

Sets delay time constant for torque reference input in the torque control mode, in

units of 1ms. This can be used to filter (smooth) a noisy/rapidly fluctuating torque reference signal so that abrupt torque changes do not occur.

D5-03 Speed Limit Input Selection A

Select speed limit location in the torque control mode.

Setting Description

1 Speed limit is the analog speed reference set by

terminal 13 or 14 (factory default).

2 Speed limit is the digital value set by D5-04.

D5-04 Speed Limit Value A

Setting Range: ±120%

Factory Default: 0%

Sets the speed limit value in the torque control mode as a percentage of the maximum output frequency. Used when D5-03 = “2.”

D5-05 Speed Limit Bias A

Setting Range: 0 to 120%

Factory Default: 5%

Sets the speed limit bias value in the torque control mode as a percentage of the

maximum output frequency. See “Torque Control Operation” description on following

page.

40 VS-616PS5 Programming Manual

Page 41

Section D: Reference Parameters

D5 Torque Control

D5-06 Speed/Torque Control Changeover Delay Timer A

Setting Range: 0 to 1000ms

Factory Default: 50ms

When using a multifunction input to switch between speed and torque mode, D5-06

can be used to allow the analog signals to be modified in preparation for the newly

selected mode.

Upon a change in command (Speed/Torque) the analog input values are retained for

the time set in D5-06 so the analog signals can be changed to accommodate the new

mode. After the D5-06 time elapses the new analog signals are accepted.

Torque Control Operation

To select torque control, set torque selection (D5-01) to “1,” or close the multi-function contact input set to speed/torque control (H1-XX = “71”) and set terminal 16 function selection to torque reference (H3-05 = “13”).

Torque

Compensation

Torque

Reference

Speed Limit

*2

Torque Limit

+

1

1 + ST

T = D5-02

*1

SFS

Motor Speed

(D5-05)

Speed

Limiting

Circuit

+

+

Iq

Figure 27 Torque Control Block Diagram

*1: When speed limit selection (D5-03) is set to “1,” the master frequency reference input from ter-

minal 13 or 14 becomes the speed limit; when speed limit selection (D5-03) is set to “2,” the set

value of D5-04 becomes the speed limit.

*2: When terminal 14 function selection is set to torque compensation (H3-09 = “14”), the terminal l4

set value can be used as the torque compensation value.

When torque reference > 0 and speed limit > 0 (winder application sequence), the following sequence is activated:

• When [-1 × speed limit bias (D5-05)] < motor speed (%) < [speed limit + D5-05],

torque control is activated using the set torque reference.

• When motor speed > [speed limit + D5-05], speed limiting circuit outputs a negative torque reference to prevent the motor speed from increasing.

• When motor speed < [-l × D5-05], the speed limiting circuit outputs a positive

torque reference to prevent the motor speed from increasing in the reverse direction.

VS-616PS5 Programming Manual 41

Page 42

Torque

Torque

Torque

Section D: Reference Parameters

D5 Torque Control

Therefore, when torque reference > 0 and speed limit (%) > 0, the torque control

range is:

[-l × D5-05] < motor speed < [speed limit + D5-05]

Refer to the following table for more details on the relationship between torque reference, speed limit, and motor speed.

Configuration

Winder Control Unwinder Control

Line Direction

TN

T

N

Line Direction

Direction of Motor

Rotation

Refer-

ence

Polarity

Torque

Refer-

ence

(TREF)

Speed

Limit

(NLIM)

Torque Profile

M

Motor

M

Motor

Forward Reverse Forward Reverse

+ - - +

+ - + -

Torque

Torque

Limit

D5-05

TREF

0

NLIM

Speed

Limit

Torque

Limit

NLIM

TREF

Torque

D5-05

0

Speed

Torque

Limit

D5-05

Torque

0

NLIM

Speed

Limit

Torque

Limit

Torque

TREF

NLIM

D5-05

0

Speed

Limit

Speed/Torque Control Switching

• Speed control or torque control can be selected “on the fly” by using the multifunction input speed/torque control selection command (H1-XX = “71”).

Terminal No. Parameter No. Setting Description

8 H1-06 71 Speed/torque control selection

13 B1-01

D5-03

1

1

Frequency reference selection (terminals 13, 14)

Speed limit selection (terminals 13, 14)

16 H3-05 13 Torque reference

42 VS-616PS5 Programming Manual

Page 43

Section D: Reference Parameters

D5 Torque Control

Speed/Torque

Selection Command

(Terminal 8 Input)

Run Command

Control Method

Terminal 13 Input

Terminal 16 Input

Sequence

STOP

OFF ON OFF ON

RUN

Speed Control Torque Control

Speed Reference Speed Limit

Torque Limit Torque Reference

Speed Control Torque Control Speed Control (decel to stop)

Speed Reference Speed Limit

Torque Limit Torque Reference

• ‚ • ‚ ƒ

Figure 28 Speed/Torque Control Selection Timing Diagram

Sequence Description

• When the speed/torque control selection contact is OPEN, speed control is activated:

• Speed reference during speed control depends on the frequency reference

selection (B1-01) setting. To use terminal 13 or 14 as the master frequency reference, set Bl-0l to “l.”

• Torque limit during speed control is the smaller of the absolute value of terminal

16 torque limit (H3-05 = 13), or the values set in the torque limit parameters (L7-

01 to L7-04).

• When a stop command is given during speed control, speed control is maintained and the smaller of the absolute value of terminal l6 torque limit, or the values set in the torque limit parameters (L7-01 to L7-04), is used as the torque

limit. Then the motor decelerates to stop.

‚ When the speed/torque control selection contact is CLOSED, torque control is

activated:

• Speed limit during torque control is:

• the master frequency reference at terminal 13 or 14 when speed limit selection

(D5-03) is set to “1”

• the speed limit value (D5-04) when D5-03 = “2,” regardless of the frequency reference selection (B1-01) setting.

• During torque control, the terminal 16 analog input value becomes the torque

reference.

ƒ By giving a stop command during torque control, operation changes to speed control automatically, and the motor decelerates to stop. The torque limit during deceleration to stop becomes the values set in the torque limit parameters (L7-01 to L7-04).

Note:The control mode actually changes after the speed/torque control selection command changes and

after the reference delay timer (D5-06) elapses. The terminal 13 speed reference/speed limit and the

terminal 16 torque limit/torque reference are stored in the inverter until the time set to D5-06 passes.

VS-616PS5 Programming Manual 43

Page 44

Section E: Motor Parameters

E1 V/f Pattern

E Motor Parameters

E1 Motor Constant

E1-01 Inverter Input Voltage Setting Q

Setting Range: 180 to 230V (360 to 460V)

Factory Default: 230V (460V)

Set E1-01 to the nominal expected line voltage (exact setting is not required)

This setting adjusts the overvoltage level, the braking transistor turn on level, and the

stall prevention level during deceleration.

Inverter

Voltage

230 150 - 255 400V 380V 380V 375V 380V

460 >400 800V 760V 760V 750V 760V

460 <400 720V 680V 660V 650V 670V

E1-01

Setting

Overvoltage Trip Braking Transistor Stall

Trip Reset ON OFF

Level

Only built-in type braking transistors will be affected, not CDBR units.

E1-02 Motor Capacity Selection Q

Setting Range: 1000 to 1239

Factory Default: 0

Used in conjunction with the motor connection selection (E1-17) to automatically load

the motor parameter (E1-03 thru E1-13) from a pre-programmed look-up table. When

setting E1-02 to any setting other than 1000, be sure to set E1-17 to the proper connection setting first. Then, set E1-03 to the proper motor winding type. When set to

1000, manual entry of parameter E1-03 - E1-13 is required.

Do not change the value after it has been set as the motor parameters will be modified.

E1-03 Motor Rated Voltage Q

Setting Range: 0.0 to 255.0V (0-510.0 V)

Factory Default: 230.0 (460.0)

Sets the motor rated voltage. Set to 230.0 for 320VDC nameplated motors and 460.0

for 640VDC nameplated motors.

44 VS-616PS5 Programming Manual

Page 45

Section E: Motor Parameters

E1 V/f Pattern

E1-04 Motor Rated Current Q

Setting Range: 0.0 to 605.0

Factory Default: 0.00 (E1-02=1000)

Set to the motor rated current as indicated on the motor nameplate for motor capacity

7.5kW or less is set in units of 0.01A, and for motor capacity 11kW or greater, in units

of 0.1A.

E1-05 Number of Motor Poles Q

Setting Range: 2, 4, 6, or 8

Factory Default: 4 (E1-02=1000)

Use this parameter to set the number of motor poles.

E1-06 Maximum Motor Speed Q

Setting Range: 0 to 6000rpm

Factory Default: 1 (E1-02=1000)

Set the maximum motor speed with this parameter in units of 1rpm. Avoid the constant horsepower range due to lack of field weakening control in the brushless DC

machine.

E1-07 Base Motor Speed Q

Setting Range: 0 to 6000rpm

Factory Default: 1 (E1-02=1000)

Base motor speed is set in units of 1rpm.

.

E1-08 Minimum Motor Speed Q

Setting Range: 0 to 6000rpm

Factory Default: 30 (E1-02=1000)

The minimum motor operating speed is set in units of 1rpm.

VS-616PS5 Programming Manual 45

Page 46

Section E: Motor Parameters

E1 V/f Pattern

E1-09 Motor Terminal to Terminal Resistance Q

Setting Range: 0 to 65.535Ω

Factory Default: 0.000 (E1-02=1000)

Set the terminal to terminal resistance of the motor in units of 0.001Ω.

E1-10 Motor d Axis Inductance Q

Setting Range: 0.00 to 600.00mH

Factory Default: 0.00 (E1-02=1000)

The d Axis inductance is set in units of 0.01mH.

E1-11 Motor q Axis Inductance Q

Setting Range: 0.00 to 600.00mΗ

Factory Default: 0.00 (E1-02=1000)

This parameter sets the q Axis inductance in units of 0.01mH at the time the motorrated load is established. Set this value equal to the setting in parameter E1-10 for

surface magnet PM motors.

E1-13 Induced Voltage Constant Q

Setting Range: 20.0 to 500.0 V/1000 RPM

Factory Default: 0.0 (E1-02=1000)

This parameter sets the induced voltage RMS value for the motor in units of 0.1V/

1000 RPM. Enter the induced voltage generated at 1000 RPM motor speed. Make

sure the induced voltage at the maximum speed (E1-06 does not exceed the voltage

rating of the inverter.

Do not change the value after it has been set.

E1-15 Motor Mechanical Loss A

Setting Range: 0.0 to 10.0%

Factory Default: 0.0

The motor’s mechanical loss is set in units of 0.1%. Used to improve torque linearity

The motor’s rated output is 100%.

46 VS-616PS5 Programming Manual

Page 47

RfI

×

T

Section E: Motor Parameters

E1 V/f Pattern

E1-16 Motor Feeder Resistance A

Setting Range: 0.0 to 10.0%

Factory Default: 1.0

Wiring resistance between the inverter and the motor is set by a percentage value of

the inverter’s rated voltage.

R

feed

m

------------------100×=

V

b

------3

Where:

R

=Percent wiring resistance between inverter and motor

feed

Rf= Feeder resistance (Ω)

Im= Rated current (E1-04) (A)

Vb= Inverter rated voltage (E1-03) (V)

E1-17 Motor Connection Selection A

Setting Range: 0 to 3

Factory Default: 0

Sets the winding connection configuration for the connected motor. Used only when

using the winding data look-up tables, E1-02 is not equal to 1000 (see Installation &

Quick Start Manual). Set E1-17 to the proper configuration first, then set E1-02 to the

proper winding code. This parameter is not used if E1-02=1000.

0: 1∆ Connection:

·

1

T

·

·

2

T

3

VS-616PS5 Programming Manual 47

Page 48

T

·

·

T

Section E: Motor Parameters

E1 V/f Pattern

1: 2∆ Connection:

1

2: 1Y Connection:

3: 2Y Connection:

·

·

·

·

·

·

T

2

T

3

1

·

T

2

T

3

T

·

·

·

·

·

1

T

2

T

3

48 VS-616PS5 Programming Manual

Page 49

Section F: Option Parameters

F1 PG Option Set-up

F Option Parameters

F1 PG Option Set-up

These parameters set up the Speed feedback pulse generator (PG).

F1-01 PG Pulses per Revolution Q

Setting Range: 0 to 10000

Factory Default: 30

This parameter sets the number of PG pulses per motor revolution (pulses/rev). Enter

the PPR of the hall sensor signals HS4 & HS5 for Hall sensor only feedback (F8-

01=1). Use the encoder PPR for motors using encoders (F8-01=0). Consult the factory when using encoders with greater than 4096 PPR.

F1-02 PG Disconnection Detection Stopping Method B

Selects the stopping method when a disconnected PG is detected.

Setting Description

0 Ramp to stop - according to C1-02. (Declaration time 1).

1 Coast to stop (factory default).

2 Fast-stop - according to C1-09.

3 Alarm flashes, operation continues.

F1-03 Overspeed Detection Stopping Method B

Selects the stopping method when an overspeed condition is detected.

Setting Description

0 Ramp to stop - according to C1-02 (Declaration time 1).

1 Coast to stop (factory default).

2 Fast-stop - according to C1-09.

3 Alarm flashes, operation continues.

F1-04 PG Deviation Detection Stopping Method B

Selects the stopping method when excessive speed deviation is detected.

Setting Description

0 Ramp to stop - according to C1-02 (Declaration time 1).

1 Coast to stop.

2 Fast-stop - according to C1-09.

3 Alarm flashes, operation continues (factory default).

VS-616PS5 Programming Manual 49

Page 50

Section F: Option Parameters

F1 PG Option Set-up

F1-05 PG Rotation Selection Q

Sets the relationship between the motor rotation direction and PG polarity. (Hall sensor HS4 & HS5 or encoder channel A & B).

Setting Description

0 HS5 leads HS4 (channel B leads A) in FWD direction.

1 HS4 leads HS5 (A leads B) in FWD direction (factory default).

The motor’s rotation direction applies when viewing the motor shaft from the load

side.

F1-08 Overspeed Detection Level A

Setting Range: 0 to 120%

Factory Default: 115%

This parameter sets the motor overspeed detection level as a percentage of maximum output speed (E1-06). Used in conjunction with parameter F1-09 to sense an

overspeed condition.

F1-09 Overspeed Detection Time A

Setting Range: 0.0 to 2.0s

Factory Default: 0.0s

Sets the elapsed time from when an overspeed condition is detected to when a fault

(or alarm) occurs.

Overspeed Level (F1-08)

|Motor Speed|

0

Overspeed Fault Signal

OFF

F1-09

ON

Figure 29 Overspeed Detection Timing Diagram

A fault signal is output to stop operation after the absolute value of the motor speed

exceeds the set value of F1-08 for the time set to F1-09. The stopping method is set

by F1-03.

50 VS-616PS5 Programming Manual

Page 51

Section F: Option Parameters

F1 PG Option Set-up

F1-10 PG Deviation Detection Level A

Setting Range: 0 to 50%

Factory Default: 10%

This sets the excessive speed deviation detection level as a percentage of maximum

output speed (E1-06). Used in conjunction with parameter F1-11 to sense a speed

deviation condition.

F1-11 PG Deviation Detection Time A

Setting Range: 0.0 to 10.0s

Factory Default: 0.5s

This parameter sets the elapsed time for which a speed deviation condition must

exist, before a fault (or alarm) is generated.

Speed Reference

Motor Speed

Speed Deviation

Fault Signal

OFF ON

F1-11

OFF

F1-10

Figure 30 Overspeed Detection Timing Diagram

A fault (or alarm) signal is output after the deviation between speed reference and the

actual motor speed exceeds the set value of F1-10 and after the time set to F1-11

elapses. The stopping method is set with F1-04. Also, detection is not activated

while accelerating/decelerating or during torque control.

F1-13 PG Open Detection Delay Time A

Setting Range: 0.0 to 10.0s

Factory Default: 3.0s

This sets the time for which a PG open condition must exist, before a fault (or alarm)

is generated.

• The stopping method, when a “PGO” condition is detected, is selected by parameter F1-02.

VS-616PS5 Programming Manual 51

Page 52

Section F: Option Parameters

F2 AI-14B Set-up

F2 AI-14B Set-up

F2-01 AI-14B Function Selection A

Sets CH1 to CH3 input functions when AI-14B option is connected.

Setting Function CH1 (TC1 to TC4) CH2 (TC2 to TC4) CH3 (TC3 to TC4)

0 3-channel individual

input (factory default)

1 3-channel additional

input

Substitute for

terminals 13 & 17

Sum of CH1 to CH3 input values is used as the speed

reference value. (Reference the AI-14B instruction manual for

details).

Substitute for

terminals 14 & 17

Substitute for

terminals 16 & 17

When the 3CH individual input selection is used, set parameter B1-01 to “1” (frequency reference from control circuit terminal). The option/inverter reference selection, which is selected by a multi-function contact input (H1-XX = “2”), is disabled

when using the AI-14B option.

52 VS-616PS5 Programming Manual

Page 53

Section F: Option Parameters

F3 DI-08/DI-16H Set-up

F3 DI-08/DI-16H Set-up

F3-01 Digital Input Option A

This parameter selects the setting mode of the frequency reference input from the DI-

08 and DI-16H options.

Setting Frequency Reference Setting Mode

0 BCD 1% unit (factory default)

1 BCD 0.1% unit

2 BCD 0.01% unit

3 Not used

4 Not used

5 Not used

6 Not used

7 Binary

DI-08: 255/100%

DI-16H, 12-bit selection: 4096/100%

DI-16H, 16-bit selection: 30000/100%

VS-616PS5 Programming Manual 53

Page 54

Section F: Option Parameters

F4 AO-08/AO-12 Set-up

F4 AO-08/AO-12 Set-up

F4-01 Analog Output Channel 1 Selection A

Setting Range: 1 to 53

Factory Default: 5

Selects the analog output monitors for channel 1 of the AO-08 and AO-12 options.

Possible settings are as follows:

Setting Description

1 Speed reference

2 Output frequency

3 Inverter output current

5 Motor speed (factory default)

6 Output voltage

7 DC bus voltage

8 Output power

9 Torque reference (internal)

15 External terminal 13 input voltage

16 External terminal 14 input voltage

17 External terminal 16 input voltage

18 Motor secondary current (Iq)

19 Motor excitation current (Id)

20 Primary frequency after SFS

21 Speed controller ASR input

22 Speed controller ASR output

27 qAxis current control reference

28 dAxis current control reference

29 Voltage limit control output

30 qAxis current control output

31 dAxis current control output

32 Output voltage reference (Vq)

33 Output voltage reference (Vd)

45 External torque reference

46 Torque compensation value

49 Control section software number

50 Speed detection PG counter value

53 PID feedback

54 VS-616PS5 Programming Manual

Page 55

Section F: Option Parameters

F4 AO-08/AO-12 Set-up

F4-02 Analog Output Channel 1 Gain A

Setting Range: ±300.0

Factory Default: 1.0

Sets the channel 1 output gain for the analog output monitors. To obtain the output

level, multiply the monitor output level by the gain value set in this parameter (F4-02).

F4-03 Analog Output Channel 1Bias A

Setting Range: ±109.2%

Factory Default: 0.0%

Sets the channel 1 output bias for the analog output monitors. To determine the output level, add the bias value set in F4-03 to the monitor output level.

F4-04 Analog Output Channel 2 Selection A

Setting Range: Same as F4-01

Factory Default: Inverter output current (setting = “3”)

Select the analog output monitors for channel 2 of the AO-08 and AO-12 options.

Select from the table included in parameter F4-01.

F4-05 Analog Output Channel 2 Gain A

Setting Range: ±300.0

Factory Default: 1.0

This parameter sets the channel 2 output gain for the analog output monitors. To

determine the output level, multiply the monitor output level by the gain value set in

this parameter F4-05.

F4-06 Analog Output Channel 2 Bias A

Setting Range: ±109.2%

Factory Default: 0.0%

Sets the channel 2 output bias for the analog output monitors. To determine the output level, add the bias value set in F4-06 to the monitor output level.

VS-616PS5 Programming Manual 55

Page 56

Section F: Option Parameters

F5 DO-02 Set-up

F5 DO-02 Set-up

F5-01 DO-02C Digital Output Channel 1 Selection A

Setting Range: 0 to 37

Factory Default: During run 1 (setting = “0”)

Selects the multi-function output selections for channel 1 of the DO-02C option.

Setting Description Setting Description

0 During run 1 (factory default) 12 Timer output

1 Zero speed 13 Agree 2

2 Sref/Sout agree 1 14 Agree 2

3 Sref/Sset agree 1 15 Speed detection 3

4 Speed detection 1 16 Speed detection 4

5 Speed detection 2 17 Torque detection 1(N.C.)

6 Inverter ready 18 Torque detection 2 (N.O.)

7 DC bus undervoltage 19 Torque detection 2 (N.C)

8 Baseblock 1 1A Reverse direction

9 Option reference 1B Baseblock 2

A Remote operation 1D Regenerating

B Torque detection 1 (N.O.) 1E Restart enabled

C Loss of reference 1F Overload (OL1)

D DB overheat 20 OH prealarm

E Fault 30 Current/torque limit

F Not used 31 Speed limit

10 Minor fault 37 During run 2

11 Reset command active 37

For detailed information on these settings, refer to section H2, Digital Outputs.

F5-02 DO-02C Digital Output Channel 2 Selection A

Setting Range: Same as F5-01

Factory Default: Zero speed (setting = “1”)

Use this function to select the multi-function output selections for channel 2 of the

DO-02C option.

56 VS-616PS5 Programming Manual

Page 57

Section F: Option Parameters

F6 DO-08 Set-up

F6 DO-08 Set-up

F6-01 DO-08 Digital Output Selection A

Selects the multi-function output selections for the DO-08 option.

Setting Terminal No. Description

TD5/TD11 Overcurrent (SC, OC, GF)

TD6/TD11 Overvoltage (OV)

0

8-channel

individual

(factory default)

1

binary output

TD7/TD11 Inverter overload (OL2)

TD8/TD11 Fuse blown (PUF)

TD9/TD11 Not used

TD10/TD11 Inverter overheat (OH1)

TD1/TD2 During zero-speed detection

TD3/TD4 During speed agree

TD5/TD11

TD6/TD11

TD7/TD11

TD8/TD11

TD9/TD11 During zero-speed detection

TD10/TD11 During speed agree

TD1/TD2 During run

TD3/TD4 Minor fault

Binary output *

* When F6-01 is set to binary output (setting = “1”), use the table below to read the DO-08 terminal 5,6,7 and 8 output.

TD8/TD11

(bit 3)

0 0 0 0 No fault

0 0 0 1 Overcurrent (SC, OC, GF)

0 0 1 0 Overvoltage (OV)

0 0 1 1 Inverter overload (OL2)

0 1 0 0 Inverter overheat (OH)

0 1 0 1 Overspeed (OS)

0 1 1 0 Fuse blown (FU)

0 1 1 1 Not used

1 0 0 0 External fault (EF3 ~ EF8)

1 0 0 1 Controller fault (CPF)

1 0 1 0 Motor overload (OL1)

1 0 1 1 Not used

1 1 0 0 Power loss (UV1, UV2, UV3)

1 1 0 1 Excessive speed deviation (DEV)

1 1 1 0 PG disconnection (PGO)

1 1 1 1 Not used

TD7/TD11

(bit 2)

TD6/TD11

(bit 1)

TD5/TD11

(bit 0)

Description

Note: When the terminal is open, the bit setting is “0”; when the terminal is closed, the bit setting is “1”.

VS-616PS5 Programming Manual 57

Page 58

Section F: Option Parameters

F8-01 Speed Feedback Detection Method

F8 PG Option Set-up 2

F8-01 Speed Feedback Detection Method Q

Setting Range: 0,1

Factory Default: 1