Page 1

http://www.chinakong.com 中国工控网站收集整理

VS-616PC5/P5 Series

User’s Manual

Variable Torque Inverter

(with software version 5110/5120 and newer)

Page 2

!

WARNING

PRECAUTIONS

1) Read this manual in its entirety before installing or operating the VS616PC5/P5 inverter. This manual applies to inverters with software

versions 5110 and 5120 only and is not intended to be used in conjunction with any other software.

2) Do not connect or disconnect wiring, or perform signal checks while

the power supply is turned ON.

3) The VS-616PC5/P5 internal capacitor may be charged even after the

power supply is turned OFF. To prevent electric al shock, disconn ect all

power before servi cing the inverter . Then wait at least five minutes

after the power supply is disconnected and all LEDs are ext inguished.

4) Do not perf o rm a withstand volt a ge t e st or a megger test on any part

of the VS-616PC5/P5. This electronic equipment uses semiconductors and is vulnerable to high voltage.

5) Do not remove the operator unless the power supply is turned OFF .

Never touch the printed control board while the power supply is

turned ON.

6) The VS-616PC5/P5 is suitable for use on a circuit capable of delivering

not more than 65,000 RMS symmetrical amperes, 480 Volts maximum

(460V class units), 240 Volts maximum (230V cla ss units ).

Failure to observe these and other precautions highlighted in this manual

will expose the user to high voltages, resulting in equipment damage,

serious injury or death.

NOTICE

Printed April, 1999. The information contained within this document is

the proprietary property of Yaskawa Electric America, Inc., and may not

be copied, reproduced or transmitted to other parties without the

expressed written authorization of Yaskawa Electric America, Inc.

No patent liability is assumed with respect to the use of the information

contained herein. Moreover, because Yaskawa is constantly improving its

high-quality products, the information contained in this manual is subject

to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, Yaskawa assumes no responsibility for

errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

2 VS-616PC5/P5 User’s Manual

Page 3

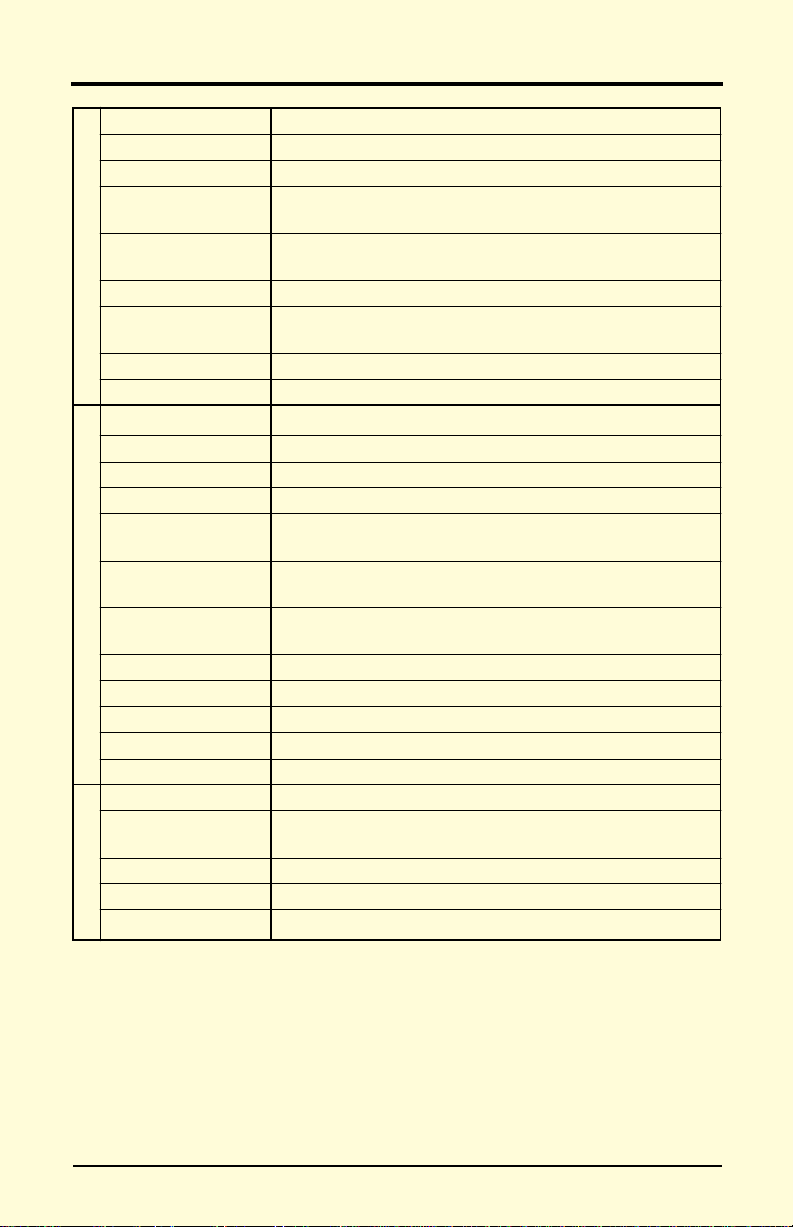

Contents

CONTENTS

Section Description Page

1 RECEIVING & INSTALLATION

1.1 I

1.2 S

VS-616PC5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

VS-616P5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3 P

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Checking the Nameplate. . . . . . . . . . . . . . . . . . . . . . . . . 11

Identifying the Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 M

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Dimensions/Heat Loss. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.5 W

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Main Circuit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2 OPERATION

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.1 T

2.2 D

2.3 LED D

2.4 O

3 PROGRAMMING F E ATURES

3.1 VS-616PC5/P5 P

3.2 P

3.3 VS-616PC5/P5 O

Accel/decel time adjustment. . . . . . . . . . . . . . . . . . . . . . 50

Automatic fault retry . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Automatic restart after momentary power loss . . . . . . . 51

Carrier frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

NTRODUCTION

PECIFICATIONS

RELIMINARY INSPECTION

OUNTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Choosing a Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Removing and Replacing the Digital Operator . . . . . . . 14

Removing and Replacing the Front Cover. . . . . . . . . . . 14

IRING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

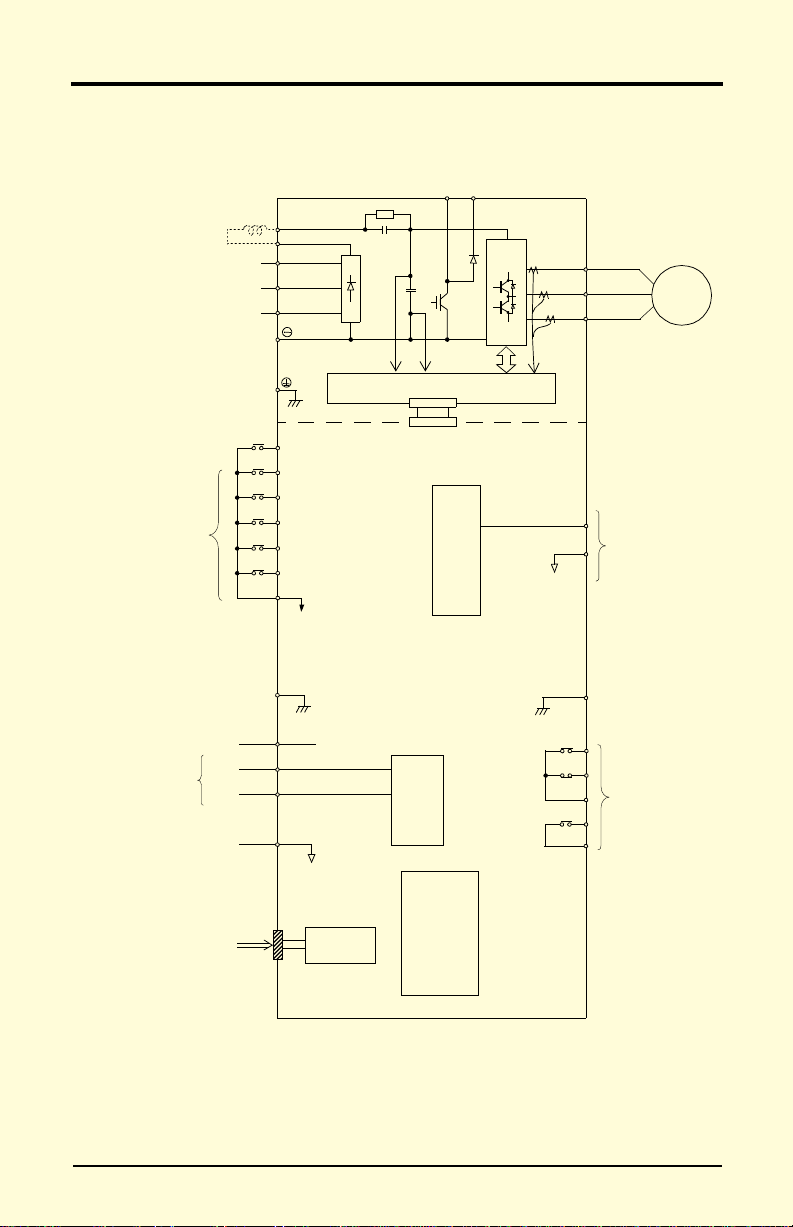

VS-616PC5 Connection Diagram . . . . . . . . . . . . . . . . . 19

VS-616P5 Connection Diagram. . . . . . . . . . . . . . . . . . . 20

T erminal Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Wire and Terminal Screw Sizes . . . . . . . . . . . . . . . . . . . 25

Control Circuit Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . 28

RIAL OPERATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Display at Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Operation Checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

IGITAL OPERATOR DISPLAY

ESCRIPTION

PERATION MODE SELECTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . 37

ARAMETERS

ARAMETER SET-UP

PERATION

& I

(n001~n1 16) . . . . . . . . . . . 41

NITIALIZ ATION

. . . . . . . . . . . . . . . 49

. . . . . . . . . . . . . . . . . . . . . . . . 50

VS-616PC5/P5 User’s M anual 3

Page 4

Contents

Current limit (Stall prevention). . . . . . . . . . . . . . . . . . . . 52

DC injection braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Energy savings control . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Frequency agree set point . . . . . . . . . . . . . . . . . . . . . . . . 57

Frequency meter or ammeter . . . . . . . . . . . . . . . . . . . . . 58

Frequency meter or ammeter calibration . . . . . . . . . . . . 58

Frequency signal adjustment. . . . . . . . . . . . . . . . . . . . . . 58

Jog operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Jump frequencies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

MODBUS communication. . . . . . . . . . . . . . . . . . . . . . . 61

Motor overload detection . . . . . . . . . . . . . . . . . . . . . . . . 62

Multi-step speed selection. . . . . . . . . . . . . . . . . . . . . . . . 64

Phase loss detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

PID Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Reverse run prohibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Soft-start characteristics . . . . . . . . . . . . . . . . . . . . . . . . . 68

Speed limit adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Stopping method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

T orque adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

T orque detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Tripless operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

V/f pattern adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Slip compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.4 I

NPUTS

& O

UTPUTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Multi-function input signals . . . . . . . . . . . . . . . . . . . . . . 78

Analog input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Multi-function output signals . . . . . . . . . . . . . . . . . . . . . 83

4DIAGNOSTICS

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

4.1 M

AINTENANCE

NSPECTION

& I

. . . . . . . . . . . . . . . . . . . . . . 87

Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Parts Replacement Schedule. . . . . . . . . . . . . . . . . . . . . . 87

4.2 A

LARM

AULT DISPLAY

& F

. . . . . . . . . . . . . . . . . . . . . . . . . 88

Alarm Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Fault Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Motor Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

A APPENDIX

A-1 B

A-2 D

A-3 CE C

RAKING CONNECTION DIAGRAMS

IGITAL OPERATOR MONITOR DISPLAY

ONFORMANCE

. . . . . . . . . . . . . . . . . . 94

. . . . . . . . . . . . . . 95

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4 VS-616PC5/P5 User’s Manual

Page 5

Chapter 1 - Receiving & Installation

- CHAPTER 1 -

RECEIVING &

INSTALLATION

Section Description Page

1 RECEIVING & INSTALLATION

1.1 I

1.2 S

VS-616PC5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

VS-616P5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3 P

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Checking the Nameplate. . . . . . . . . . . . . . . . . . . . . . . . . 11

Identifying the Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 M

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Dimensions/Heat Loss. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.5 W

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Main Circuit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

NTRODUCTION

PECIFICATIONS

RELIMINARY INSPECTION

OUNTING

Choosing a Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Removing and Replacing the Digital Operator . . . . . . . 14

Removing and Replacing the Front Cover. . . . . . . . . . . 14

IRING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

VS-616PC5 Connection Diagram . . . . . . . . . . . . . . . . . 19

VS-616P5 Connection Diagram. . . . . . . . . . . . . . . . . . . 20

T erminal Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Wire and Terminal Screw Sizes . . . . . . . . . . . . . . . . . . . 25

Control Circuit Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

VS-616PC5/P5 User’s M anual 5

Page 6

Chapter 1 - Receiving & Installation

Introduction

1.1 INTRODUCTION

The VS-616PC5/P5 is a series of

high quality,

variable torque inve rters.

With a power range of 5 to 500 HP, it provides all the functionality of

prior series, in a compact, low cost package. This functionality includes

Yaskawa proprietary features like full-range automatic torque boost, electronic thermal motor overload, energy savings and PID operation, lownoise operation and various other features. It also features a new digital

operator for simple programming. Utilizing the latest microprocessor

technology, members of Yaskawa’s design team have collaborated to

make the VS-616PC5/P5 the world’s first optimized inverter specifically

designed for variable torque applications.

This manual details installation, start-up and operating procedures for the

VS-616PC5/P5 series adjustable frequency drive controller . Descriptions

of diagnostic and troubleshooting procedures are also included herein.

6 VS-616PC5/P5 User’s Manual

Page 7

#

#

Chapter 1 - Receiving & Installation

Specifications

1.2 SPECIFICATIONS

VS-616PC5

Inverter Model

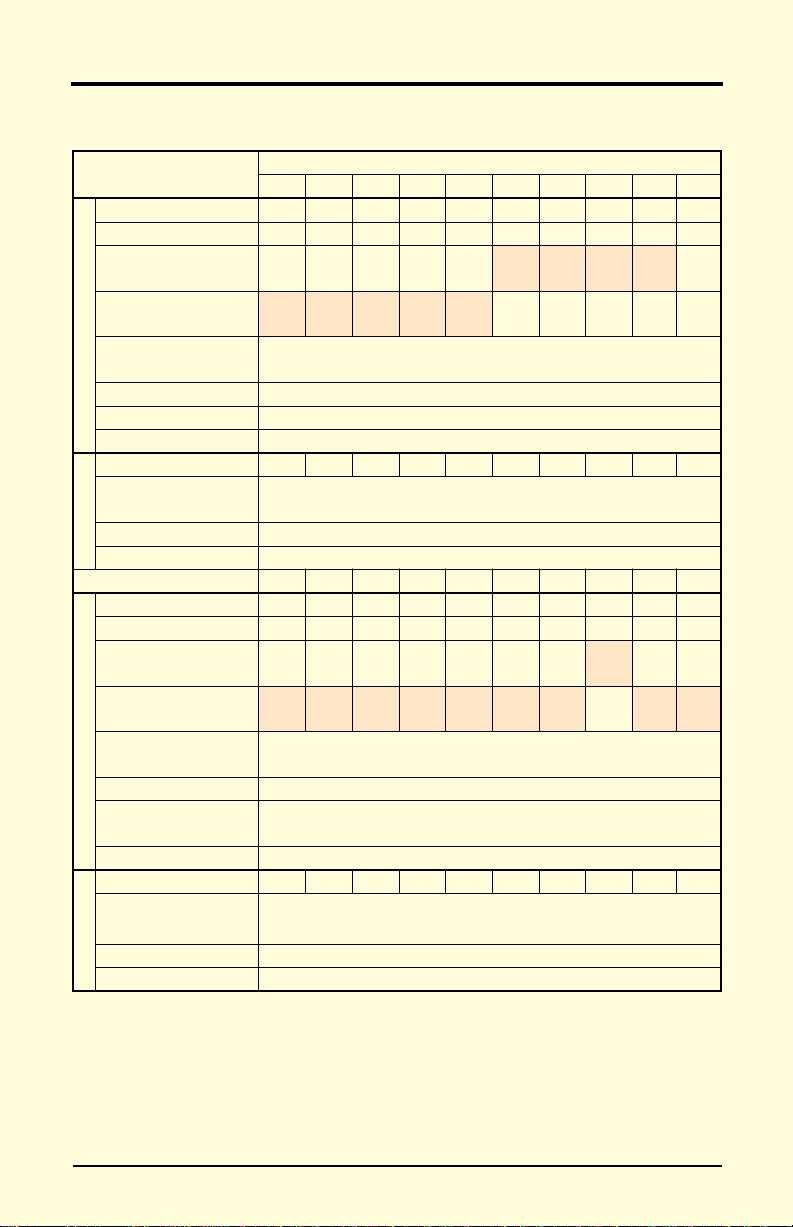

Motor Output (HP) * 0.5 1 2 3 5 7.5 10 20 25 Capacity (kVA) 1.2 2.3 3.0 4.2 6.7 9.5 13 19 24 Rated Output

Current (A)-V T * *

Rated Output

Current (A)-CT**

Max. Voltage

Output Characteristics

Rated Output Fre quency 0.1 to 400 Hz

Overload Capacity - VT 120% Rate d Output Cu rrent for 1 minute

Overload Capacity - CT 150% Rated Out p ut Curren t f o r 1 minute

Input Cu rrent (A ) 3.9 7.2 9.6 13.2 21 33 44 65 82 Rated V oltage &

Frequency

Voltage Fluctuation +10%, -15%

Power Su pply

Frequency Fluctuation ±5%

Motor Output (HP) * 0.5 1 2 3 5 7.5 10 15 20 25

Capacity (kVA) 1.4 2.6 3.7 4.7 6.1 8.6 11 14 21 26

Rated Output

Current (A)-V T * *

Rated Output

Current (A)-CT**

Max. Voltage

Rated Output Fre quency 0.1 to 400 Hz

Output Character i st ics

Overload Capaci ty-VT**

Overload Capacity-CT** 150% Rated Outpu t Current f o r 1 minute

Inp u t C u r rent (A ) 2.3 4. 3 6.1 8.0 10.2 14.0 17.8 26.0 35.0 40.0

Rated V oltage &

Frequency

Voltage Fluctuation +10%, -15%

Power Supply

Frequency Fluctuation ±5%

VS-616PC5

CIMR-P5U

CIMR-P5U 40P4 40P7 41P5 42P2 43P7 44P0 45P5 47P5 4011 4015

20P4 20P7 21P5 22P2 23P7 25P5 27P5 2011 2015 -

3.2 6 8 11 17.5 27 36 54 68 -

3.2 6 8 11 17.5 25 33 49 64 3-Phase, 200/208/22 0/230V

(Proportional to input voltage)

3-Phase

220 - 230V, 50/60Hz

1.9 3.6 5.1 6.6 8.5 11.7 14.8 21.0 28.6 34.0

1.9 3.6 5.1 6.6 8.5 11.7 14.8 18 28.6 34.0

3-Phase, 380/400/415/440/460V

(Proportional to input voltage)

120% Rated Output Current for 1 minute

(Model 47P5 is rated 150% / 1 minute)

3-Phase

380 -440 - 460V, 50/60Hz

* HP ratings based on standard NEMA 4-pole motor data.

#

For 380V operation, the motor rated current must be less than or equal to the inverter

rated current.

** VT: Variable Torque rating (n116=1), CT: Constant Torque rating (n116=0)

Note: Shaded areas indicate factory settings.

VS-616PC5/P5 User’s M anual 7

Page 8

Chapter 1 - Receiving & Installation

Specifications

Control Method Sine wave PWM with full-range, automatic torque boost

Frequency Control

Range

Fre quency Ac curacy Digital command: 0.0 1%, Ana l og comm and: 0.1%

Frequency Setting Res olution

Output Frequency Resolution

Frequency Se tti ng 0 to +10VDC (20kΩ), 4-20mA (250Ω)

Control Charac teris tic s

Accel/De cel T im e

Braking Torq ue Approx. 20%

No. of V-f Patter ns 1 preset V/f pattern and 1 custom pattern

Motor Overl oad Protection

Instantaneous Ove rcurrent

Fus e Pro tection Motor coasts to stop at blown fuse.

Overload Motor coasts to stop after 1 min. at rated overload capacity.

Overvoltage

Undervoltage

Momentary P ower Loss

Protective Functions

Heatsink Overheat Thermi s tor - OH1, OH2

Stall Preven tion

Ground Fault Provided by electronic circuit

Power Charge Indication Charge LED stays on until v oltage drops below 50VDC

Inp u t P h a s e Lo s s Single-phase protection

Loc ation Indoor (protected from corrosive gases and dust)

Ambient

Temperature

Storage

Temperature

Humidity 95% RH (non-condens i ng)

Vibration

Environmental Conditions

Motor coasts to stop at approx. 200% rated output current.

Motor coasts to a stop if converter output voltage exceeds 410VDC

Motor coasts to stop if conv ert er output voltage drops below user

Immediat e s t op after 15 ms or longer power loss. (Continuous system ope ra-

tion dur ing power loss les s than 2 sec is eq uipped as standa r d.)

Stall prevention at acce leration/deceleration and const ant speed

+14 to 104°F (-10 to 40°C) for NEMA 1 type (not frozen)

9.8m/s2 (1G) less than 20Hz, up to 1.96m/s2 (0.2G) at 20 to 50Hz

Digital Operator Ref erence: 0.1Hz,

Analog Reference: 0.06Hz (@60Hz)

(Accel/Decel time setting independently: 0.1 sec )

Electronic thermal overload relay (I2T)

+14 to 113°F (-10 to 45°C) for open chassis type

0.1 to 400 Hz

0.01 Hz

0.0 to 3600.0 sec.

(820VDC at 460V input)

adjustable value

operation

-4 to 140°F (-20 to 60°C)

8 VS-616PC5/P5 User’s Manual

Page 9

Chapter 1 - Receiving & Installation

Specifications

VS-616P5

Motor Output (HP) * 30 40 50 60 75 100 125

Capacity (kVA) 303750617085110

Rated Output

Current (A) - VT **

Rated Output

Current (A) - CT **

Max. Voltage

Output Characteristics

Rated Output Frequenc y 0.1 to 400 Hz

Overload Capacity - VT ** 120% Rated Output Cur rent / 1 minute

Overload Capacity - CT ** 150% Rated Output Current / 1 minute

Input Cu r rent (A) 88 119 143 176 212 270 344

Rated Vo lta ge &

Frequen cy

Voltage Fluctuatio n +10%, -15%

Power Supply

Frequency Fluctuation ±5%

Motor Ou tput (HP) * 30 40 50 60 75 100 150 200 250 300 400 500

Cap a c i ty ( kVA) 31 40 50 61 73 98 130 170 230 260 340 460

Rated Output

Current (A) - VT **

Rated Output

Current (A) - CT **

Max. Voltage

Output Chara cter isti cs

Rated Output Frequenc y 0.1 to 400 Hz

Overload Capacity - VT * * 120% Rated Current / 1 minute

Overload Capacity - CT * * 150% Rated Current / 1 minute

Inp ut Current (A ) 46 58 72 88 106 141 198 264 330 456 608 810

Rated Vo lta ge &

Frequen cy

Voltage Fluctuatio n +10%, -15%

Power Supply

Frequency Fluctuation ±5%

Inverter M odel

CIMR-P5U

CIMR-P5U 4018 4022 4030 4037 4045 4055 4075 4110 4160 4185 4220 4300

#

#

2018 2022 2030 2037 2045 2055 2075

80 104 130 160 192 248 312

64 83 104 128 154 198 250

41 52 65 80 96 128 180 240 302 380 506 675

32 42 52 64 77 102 144 182 242 304 404 540

3-Phase, 380/400/415/440/460V

VS-616P 5

—

3-Phase, 200/208/220/230V

(Proportional to input voltage)

—

3-Phase

220 - 230V, 50/60Hz

(Proportional to input voltage)

3-Phase

380 -440 - 460V, 50/60Hz

* HP ratings based on standard NEMA 4-pole motor data.

#

For 380V operation, the motor rated current must be less than or equal to the inverter

rated current.

** VT: Variable Torque rating (n116=1), CT: Constant Torque rating (n116=0)

Note: Shaded areas indicate factory settings.

VS-616PC5/P5 User’s M anual 9

Page 10

Chapter 1 - Receiving & Installation

Specifications

Control Method Sine wave PWM with full-range, automatic torque boost

Frequency C o nt rol Range 0.1 to 400 Hz

Frequency Accuracy D igital comma nd: 0.01%, Analog command: 0.1%

Frequency Setting

Resolution

Output Frequency

Resolution

Frequen cy Setting 0 to +10VDC (20kΩ), 4-20mA (250Ω)

Control Characteristics

Accel/Decel Time

Braking Torque Approx. 20%

No. of V-f Patterns 1 preset V/f pattern and 1 custom pattern

Motor Ov erload Protection

Instantaneous Overcurrent Motor coasts to stop at approx. 180% rated output current.

Fuse Pro tection Motor coasts to stop at blown fuse.

Overload Motor coasts to stop after 1 min. at rated overload capacity.

Overvol tag e

Undervoltage

Momenta ry Power Loss

Protective Functions

Heatsink Overheat Thermistor - OH1, OH2

Stall Pre ve ntion Stall prevention at accele r ation/decelerat io n a nd constant speed operation

Ground Fault Provided by electronic circuit

Power Charge Indication Charge LED stays on until voltage drops below 50VDC

Input Ph as e L oss Single-phase protection

Location I ndoor (protected from corrosive gases an d dus t )

Ambient Temperature

Storage Temperature -4 to 140°F (-20 to 60°C)

Humidi ty 95% RH (non- co ndensing)

Vibrat ion

Environmental Conditions

Motor coasts to stop if converter output voltage exceeds 410VDC

Motor coas ts to st o p if co nv er ter output voltag e dr op s below user

Immediat ely stop after 1 5 m s or lo nger power loss . (C o nt i nuous system

operation during power loss less than 2 sec is equipped as standard.)

+14 to 104°F (-10 to 40°C) for NEMA 1 type (not frozen)

9.8m/s

Digital Operator Reference: 0.1Hz,

Analog Reference: 0.06Hz (@60Hz)

0.01 Hz

0.0 to 3600.0 sec.

(Accel/Decel time setting independently: 0.1 sec )

2

Electronic thermal overload relay (I

(820VDC at 460V input )

adjustable value

+14 to 113°F (-10 to 4 5°C ) for open cha ssis type

2

(1G) less than 20Hz, up to 1.96 m/s2 (0.2G) at 20 to 50Hz

T)

10 VS-616PC5/ P5 U s er’s Ma nual

Page 11

Figure 1 Nameplate Example of American Model CIMR-P5U43P7

Figure 2 Nameplate Description

Chapter 1 - Receiving & Installation

Preliminary Inspection

1.3 PRELIMINARY INSPECTION

Receiving

After unpacking the VS-616PC5/P5:

· Verify that the part numbers on the drive nameplate match the numbers on yo ur purchase order or packing sli p.

· Check the unit for physical damage which may have occurred durin g

shipping. If any part of the drive is missing or damaged, notify the

carrier and your Yaskawa representative immediately.

· Verify that all internal hardware (i.e. components, screws, etc.) is

seated properly and fastened securely.

· Verify that the instruction manual is included (YEA-TOA-S616-12).

· If the drive will be stored after receiving, place it in its original packaging and store according to temperature specifications on page 8.

Checking the Nameplate

Inverter

Model

Input Spec.

Output Spec.

Lot No.

Serial No.

UL File No.

MODEL :

INPUT :

OUTPUT :

LOT NO : MASS : 4.5 kg

SER NO :

UL FILE NO

:

CIMR - P5 U 4 3P7 1 F

Inverter

VS-616PC5/P5 Series

Specifications

A: Japanese specifications

E: European specifications

U: American specifications

Voltage Class

2: 3-phase, 230V

4: 3-phase, 460V

CIMR-P5U43P7

AC 3PH

AC 3PH 0-460V 6.1kVA 8.5A

E131457

380-440V 50Hz

380-460V 60Hz

SPEC :

10.2A

Enclosure

Model Designation

See Specifications, pp 7-10

43P71F_

Inverter

Spec.

Mass

Mg

Revision symbol

0: Open chassis

1: NEMA 1 (IP20)

3P7 to 300

VS-616PC5/P5 User’s M anual 11

Page 12

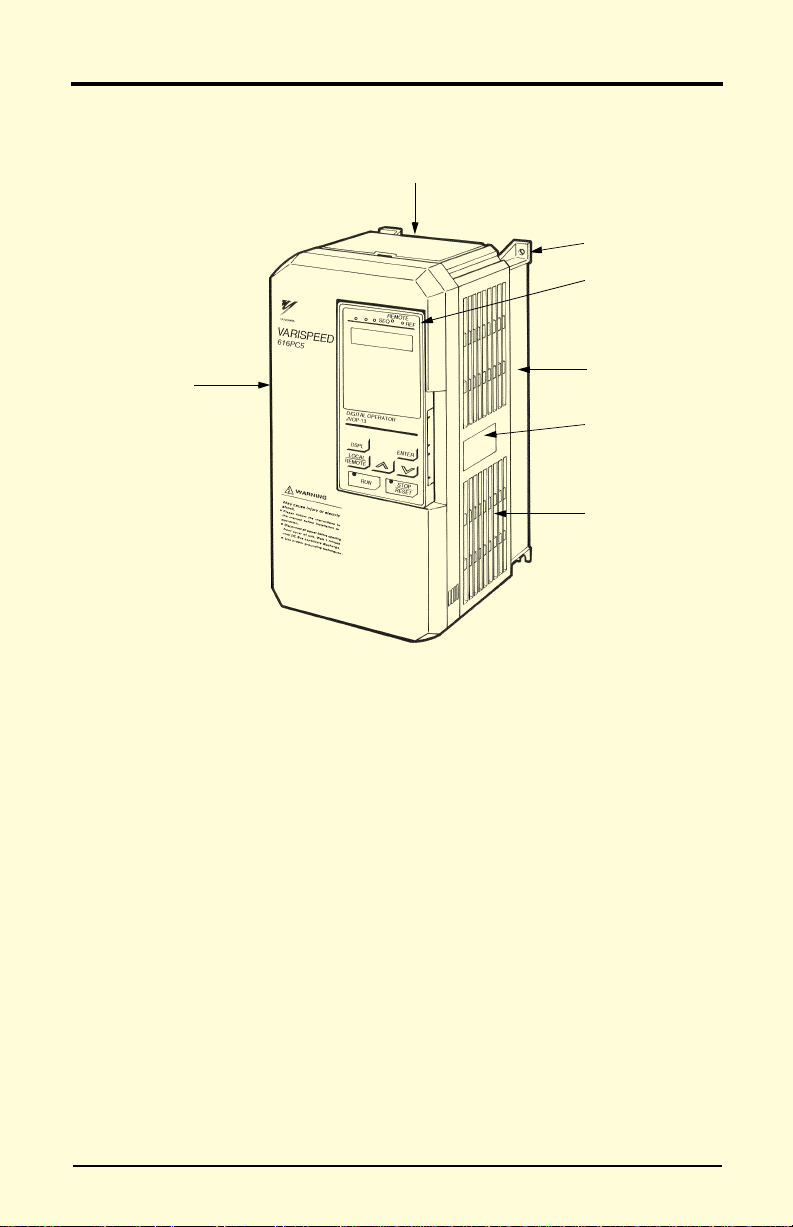

Figure 3 Parts Identification - Model CIMR-P5U43P7

Chapter 1 - Receiving & Installation

Preliminary Inspection

Identifying the Parts

Front Cover

Protective Cover (top/bottom)

4 Mounting Holes

Digital Operator

D

R

I

V

E

F

W

D

R

E

V

0

P

JVOP-130P

Heatsink

Nameplate

Ventilation Slots

12 VS-616PC5/ P5 U s er’s Ma nual

Page 13

Chapter 1 - Receiving & Installation

Mounting

1.4 MOUNTING

!

CAUTION

PRECAUTIONS

1) When preparing to mount the VS-616PC5/P5, lift it by its base. Never

lift it by the front cover.

2) Mount the inverter onto nonflammable material.

3) The VS-616PC5/P5 generates heat. For the most effective cooling

possible, mount it vertically. For more details, refer to “Dimensions/

Heat Loss” on pages 15 & 16 and “Clearances” on page 17.

4) When mounting units in an enclosure, install a fan or other cooling

device to keep the intake air temperature below 113°F (45°C).

Failure to observe these precautions may result in equipment damage.

Choosing a Location

Be sure that the inverter is mounted in a location protected against the following conditions:

· Extreme cold and heat. Use only within the ambient temperature range:

14 to 104°F (-10 to 40°C).

· Direct sunlight (not for use outd oo rs )

· Rain, moisture

· High humidity

· Oil sprays, splash es

· Salt spray

· Dust or metallic particles in the air

· Corro sive gases (e.g. sulfurized gas) or liqu i ds

· Radioactive substances

· Combustibles (e.g. thinner, solvents, etc.)

· Physical shock, vibration

· Magnetic noise (e.g. welding machines, power devices, etc.)

VS-616PC5/P5 User’s M anual 13

Page 14

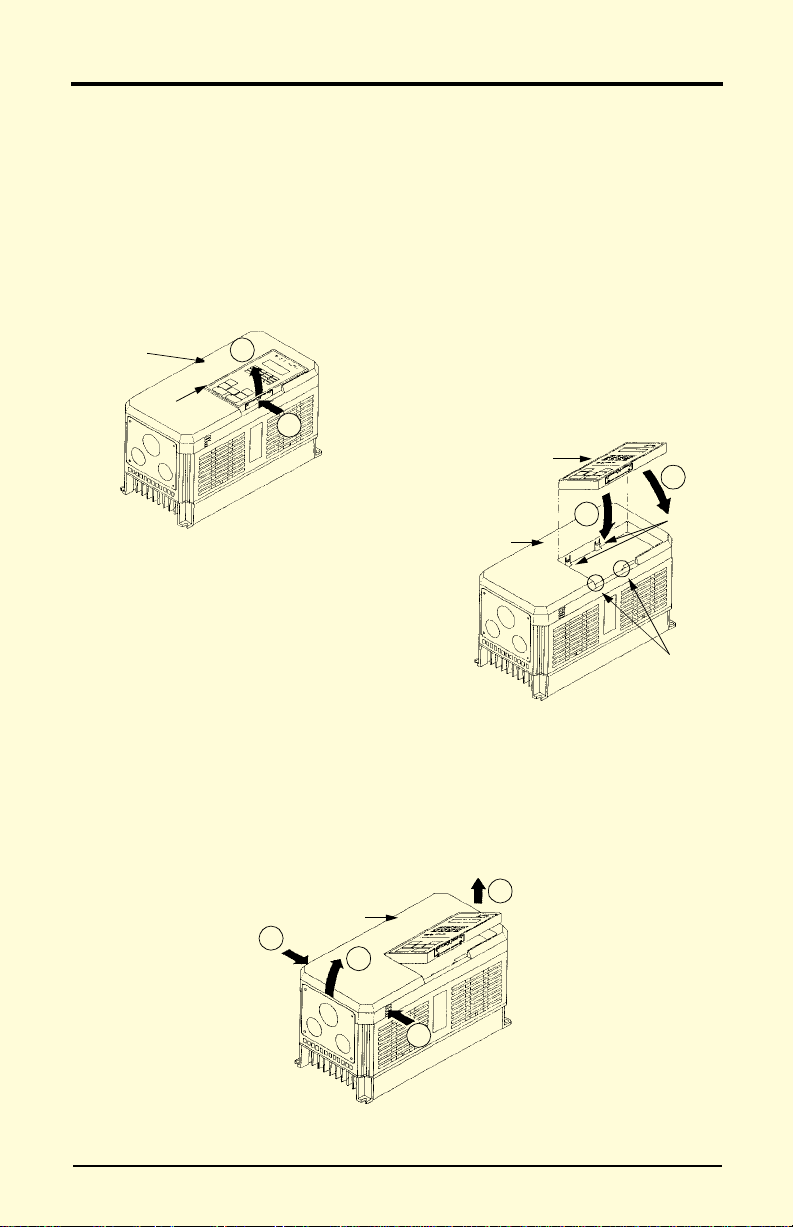

Figure 4 Removing the Digital Operator

Figure 5 Replacing the Digital Operator

Figure 6 Removing and Replacing the Front Cover

Chapter 1 - Receiving & Installation

Mounting

Removing and Replacing the Digital Operator

To remove the digital operator from the front cover, push the operator

lever in the direction shown by arrow 1 and lift the digital operator in the

direction shown by arrow 2 (see Figure 4).

To replace the digital operator, engage the operator onto retaining tabs A

in the direction shown by arrow 1 and then onto retaining tabs B in the

direction shown by arrow 2, locking the digital operator into place (see

Figure 5).

Front Cover

Digital Operator

2

1

Digital Operator

2

1

Front Cover

Retaining

Ta bs A

Retaining

Tabs B

Removing and Replacing the Front Cover

To remove the front cover, first remove the digital operator (see previous

section). Then squeeze the cover on both sides in the direction shown by

arrows 2 and lift the cover in the direction shown by arrow 3.

1

Front Cover

2

3

14 VS-616PC5/ P5 U s er’s Ma nual

2

Page 15

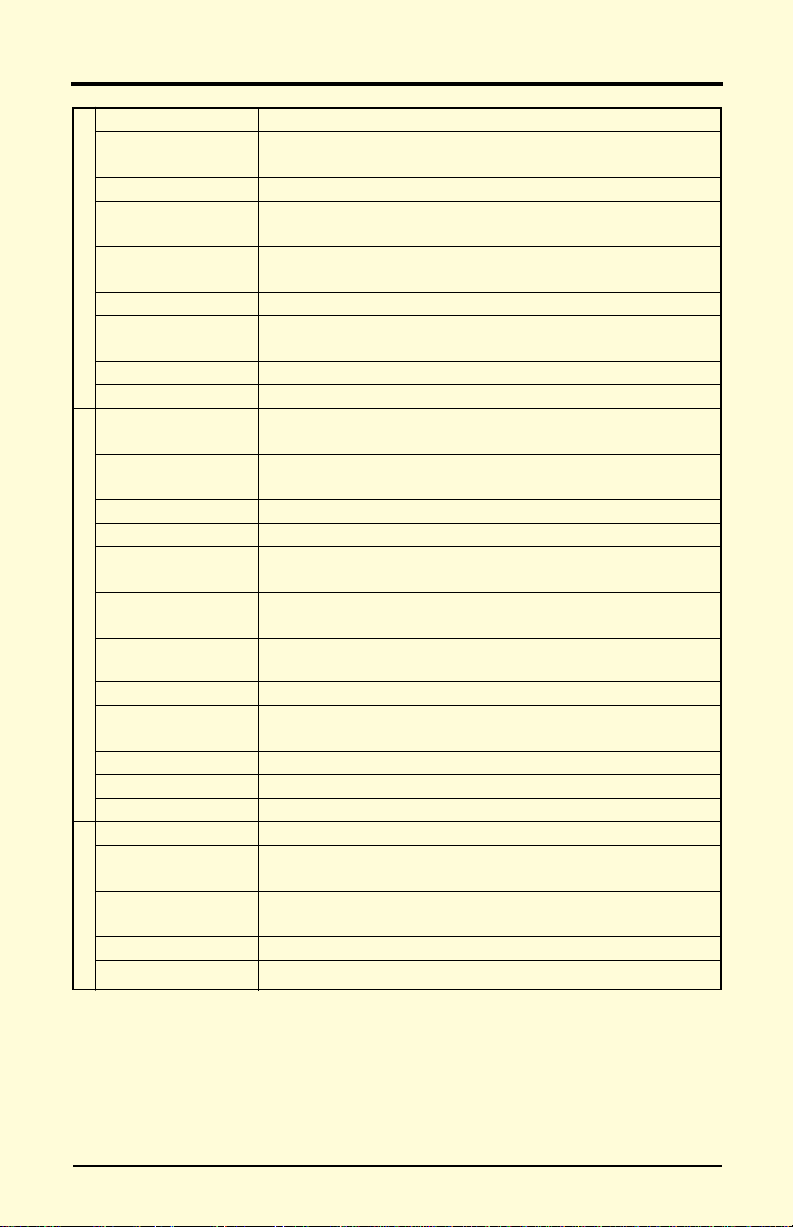

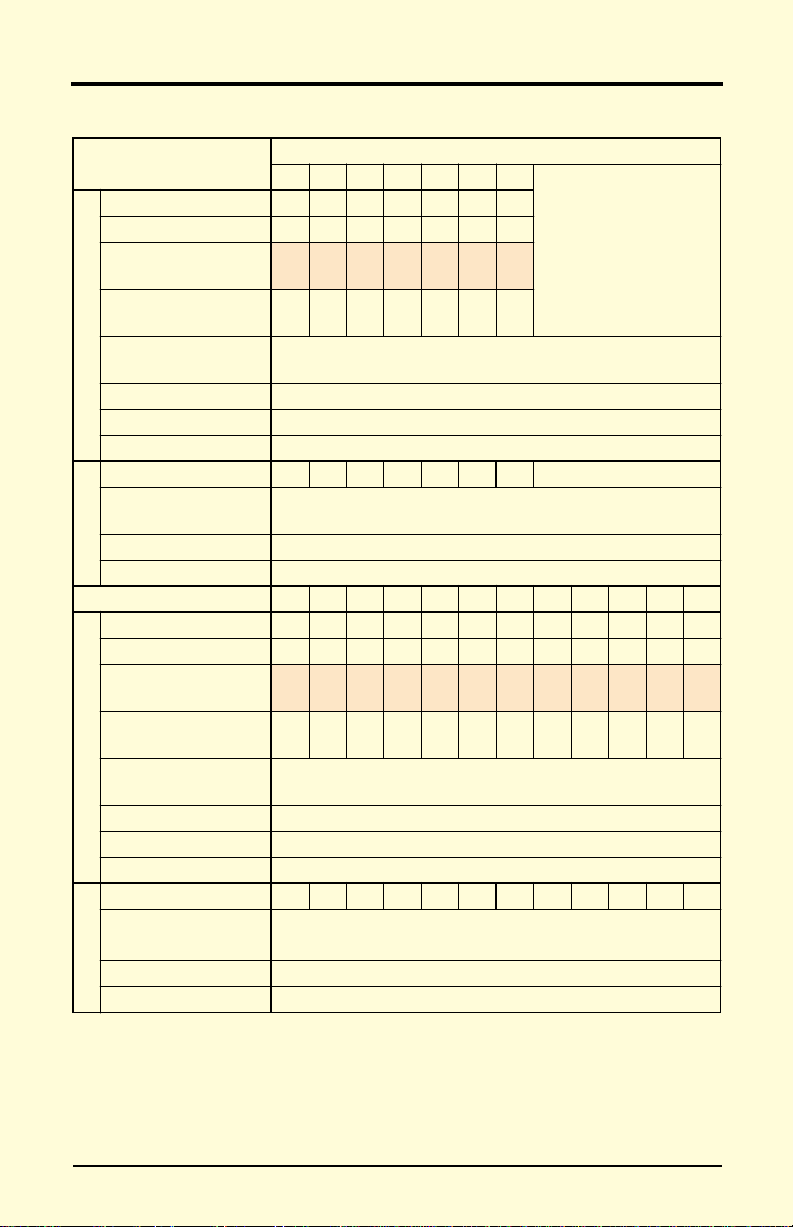

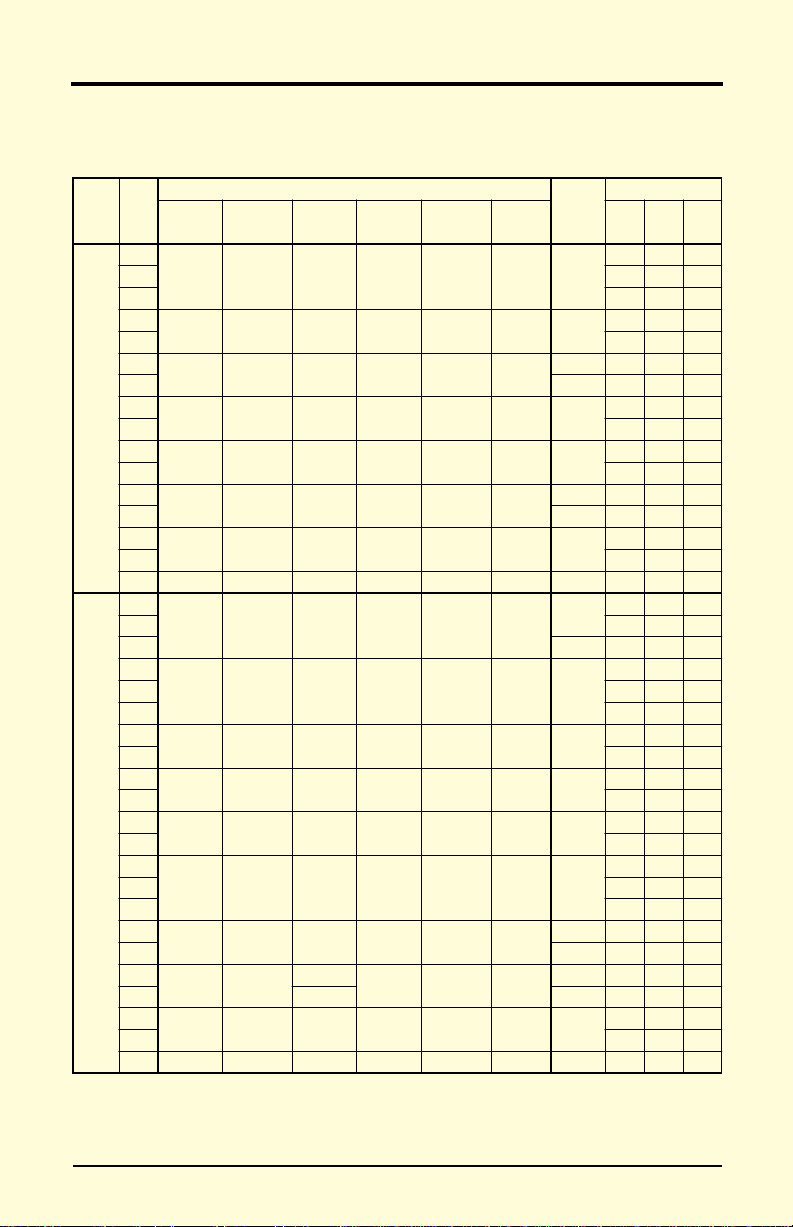

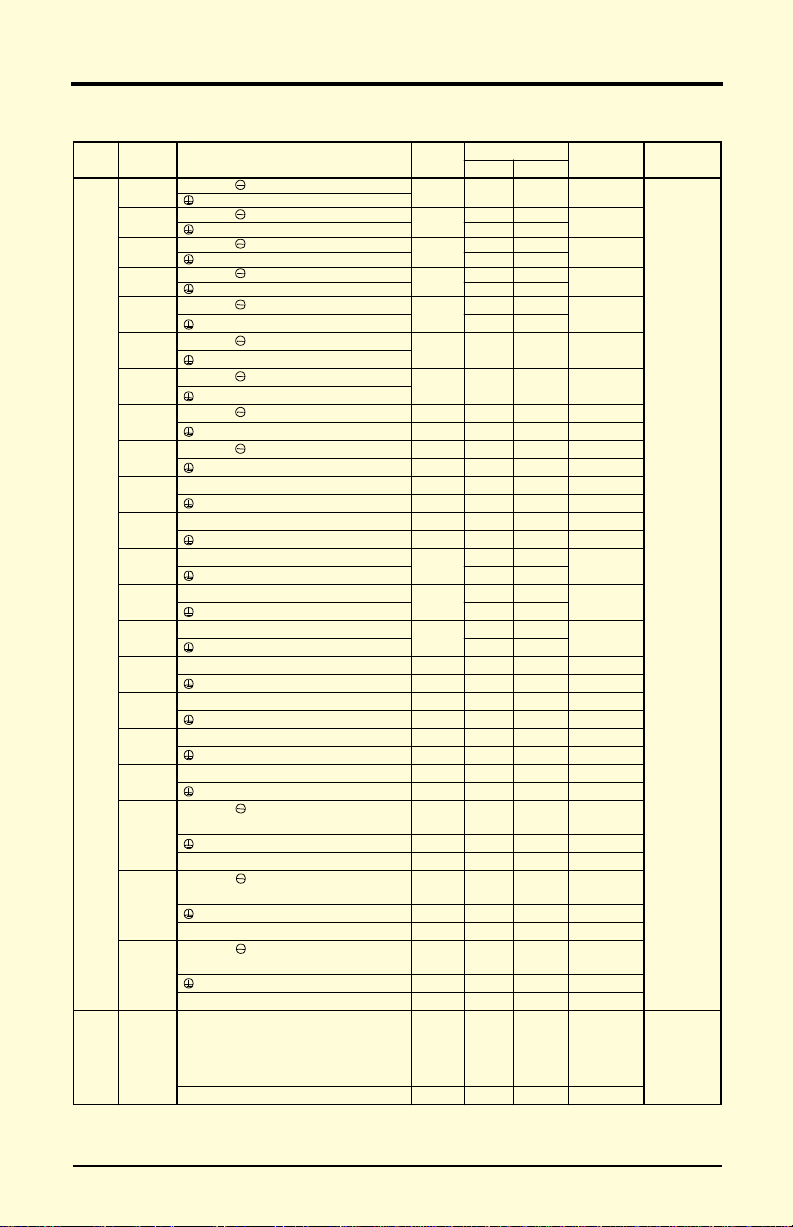

Dimensions/Heat Loss

Chapter 1 - Receiving & Installation

Mounting

Open Chassis Type (IP00)

Model

Voltage

CIMR

230V

460V

WHDW1H1H2

-P5U

20P4

5.51 (140) 11.02 (280) 6.30 (160) 4.96 (126) 10.47 (266) 0.28 (7) 6.5 (3)

20P7 25 65 90

21P5 40 80 120

22P2

5.51 (140) 11.02 (280) 7.09 (180) 4.96 (126) 10.47 (266) 0.28 (7) 10 (4.5)

23P7 135 80 215

25P5

7.87 (200) 11.81 (300) 8.07 (205) 7.32 (186) 11.22 (285) 0.31 (8)

27P5

2011

9.84 (250) 14.96 (380) 8.86 (225) 9.29 (236) 14.37 (365) 0.30 (7.5) 24 (11)

2015

2018

12.80 (325) 17.72 (450) 11 .2 2 (285) 10.83 (275) 17.13 (435) 0.30 (7.5) 62 (28)

2022

2030

16.73 (425) 26.57 (675) 13.78 (350) 12.60 (320) 25.59 (650) 0.49 (12.5)

2037

2045

18.70 (475) 31.50 (800) 13.78 (350) 14.57 (370) 30.51 (775) 0.49 (12.5) 176 (80)

2055

2075 22. 64 (5 75) 36.42 (925) 15.75 (400) 17.52 (445) 35.24 (895) 0.59 (15) 298 (135) 2300 1300 3600

40P4

40P7

5.51 (140) 11.02 (280) 6.30 (160) 4.96 (126) 10.47 (266) 0.28 (7)

41P5

42P2

43P7

5.51 (140) 11.02 (280) 7.09 (180) 4.96 (126) 10.47 (266) 0.28 (7) 10 (4.5)

44P0

45P5

7.87 (200) 11.81 (300) 8.07 (205) 7.32 (186) 11.22 (285) 0.31 (8) 13 (6)

47P5

4011

9.84 (250) 14.96 (380) 8.86 (225) 9.29 (236) 14.37 (365) 0.30 (7.5) 24 (11)

4015

4018

12.80 (325) 17.72 (450) 11 .2 2 (285) 10.83 (275) 17.13 (435) 0.30 (7.5) 60 (27)

4022

4030

4037

12.80 (325) 24.61 (625) 11 .2 2 (285) 10.83 (275) 24.02 (610) 0.30 (7.5) 97 (44)

4045

4055

17.91 (455) 32.28 (820) 13.78 (350) 13.78 (350) 31.30 (795) 0.49 (12.5)

4075

4110

22.64 (575) 36.42 (925)

4160 15.75 (400) 320 (145) 2670 1520 4190

4185

37.40 (950) 57.09 (1450) 17.13 (435) 29.53 (750) 55.12 (1400) 0.98 (25) 794 (360)

4220

37.80 (960) 62.99 (1600) 17.91 (455) 29.53 (750) 61.02 (1550) 0.98 (25) 926 (420) 6820 2910 9730

4300

Open Chassis Dimensions in inches (mm)

14.76 (375)

17.52 (445) 35.24 (895) 0.59 (15)

Mass

lbs (kg)

12 (5.5) 210 90 300

13 (6) 235 110 345

134 (61) 1050 500 1550

137 (62) 1250 700 1950

6.5 (3)

8.8 (4) 30 80 110

174 (79) 1110 710 1820

176 (80) 1430 890 2320

298 (135) 1870 1160 3030

Heat Loss (W)

Heat

Inside

unit

Total

sink

15 50 65

80 60 140

425 160 585

525 200 725

655 230 885

830 280 1110

1550 750 2300

1950 1000 2950

10 50 60

20 65 85

65 60 125

80 65 145

120 80 200

135 85 220

240 120 360

305 150 455

390 180 570

465 195 660

620 260 880

705 315 1020

875 370 1245

970 415 1385

3400 1510 4910

4740 2110 6850

VS-616PC5/P5 User’s M anual 15

Page 16

Chapter 1 - Receiving & Installation

Mounting

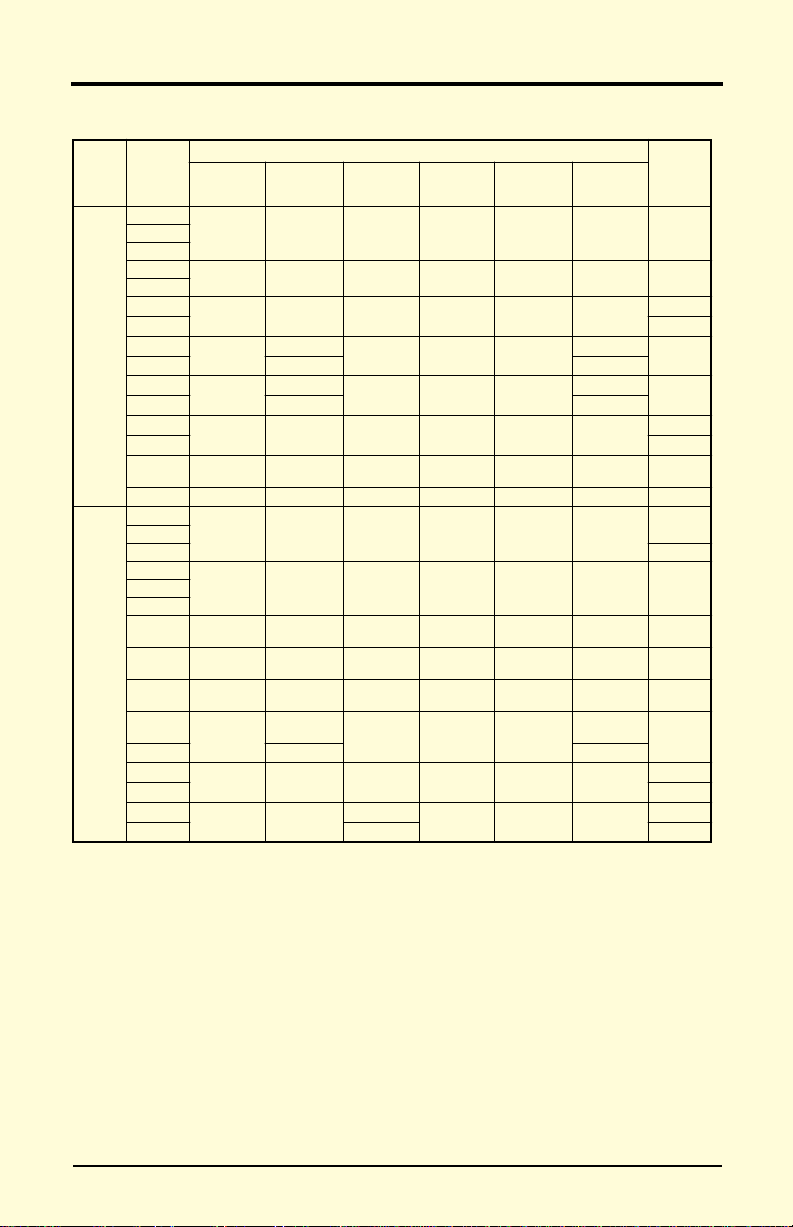

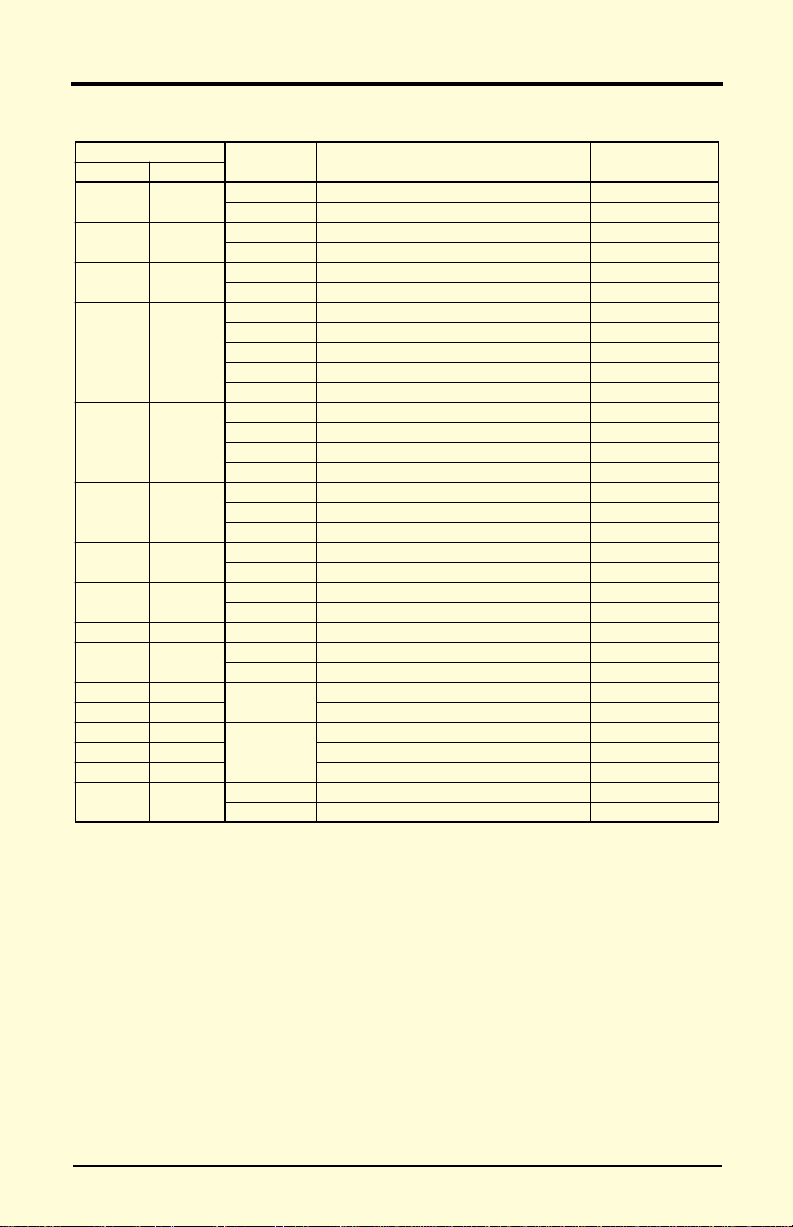

Enclosed Type (NEMA 1, IP20)

Model

Voltage

(CIMR-

P5U)

20P4

5.51 (140) 11.02 (280) 6.30 (160) 4.96 (126) 10.47 (266) 0.28 (7) 6.5 (3)20P7

21P5

22P2

5.51 (140) 11.02 (280) 7.09 (180) 4.96 (126) 10.47 (266) 0.28 (7) 10 (4.5)

23P7

25P5

7.87 (200) 11.81 (300) 8.07 (205) 7.32 (186) 11.22 (285) 0.31 (8)

27P5

2011

230V

460V

9.84 (250)

2015

2018

12.99 (330)

2022

2030

16.93 (430) 38.78 (985) 13.78 (350) 12.60 (320) 25.59 (650) 8.37 (212.5)

2037

2045

18.90 (480) 43.70 (1110) 13.78 (350) 14.57 (370) 30.51 (775) 8.37 (212.5) 192 (87)

2055

2075 22.83 (580) 50.79 (1290) 15.75 (400) 17.52 (445) 35.24 (895) 10.63 (270) 320 (145)

40P4

5.51 (140) 11.02 (280) 6.30 (160) 4.96 (126) 10.47 (266) 0.28 (7)

40P7

41P5 8.8 (4)

42P2

5.51 (140) 11.02 (280) 7.09 (180) 4.96 (126) 10.47 (266) 0.28 (7) 10 (4.5)43P7

44P0

45P5

7.87 (200) 11.81 (300) 8.07 (205) 7.32 (186) 11.22 (285) 0.31 (8) 13 (6)

47P5

4011

9.84 (250) 14.96 (380) 8.86 (225) 9.29 (236) 14.37 (365) 0.30 (7.5) 24 (11)

4015

4018

12.99 (330) 24.02 (610) 11.22 (285) 10.83 (275) 17.13 (435) 3.44 (87.5) 68 (31)

4022

4030

4037

12.99 (330)

4045

4055

18.11 (460) 44.49 (1130) 13.78 (350) 13.78 (350) 31.30 (795) 8.37 (212.5)

4075

4110

22.83 (580) 50.79 (1290)

4160 15.75 (400) 342 (155)

14.96 (380)

15.75 (400) 1.08 (27.5)

24.02 (610)

26.57 (675) 6.00 (152.5)

30.91 (785)

33.46 (850) 6.00 (152.5)

NEMA 1 Dimensions in inches (mm)

8.86 (225) 9.29 (236) 14.37 (365)

11.22 (285) 10.83 (275) 17.13 (435)

11.22 (285) 10.83 (275) 24.02 (610)

14.76 (375)

17.52 (445) 35.24 (895) 10.63 (270)

0.30 (7.5)

3.44 (87.5)

3.44 (87.5)

Mass

lbs (kg)WHDW1H1H2

12 (5.5)

13 (6)

24 (11)

71 (32)

148 (67)

150 (68)

6.5 (3)

106 (48)

187 (85)

190 (86)

320 (145)

16 VS-616PC5/ P5 U s er’s Ma nual

Page 17

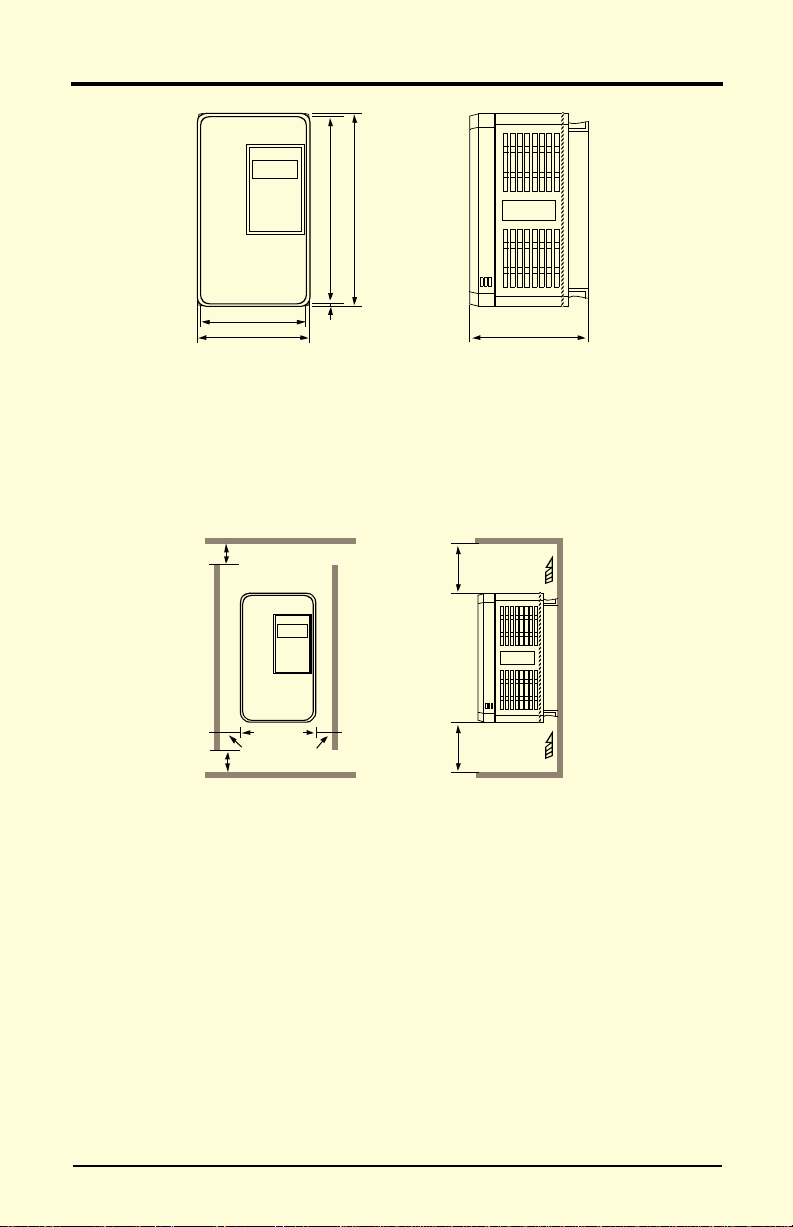

Front View

Side View

Figure 7 VS-616PC5/P5 Dimension Diagram

Front View

Side View

Figure 8 VS-616PC5/P5 Clearances

Chapter 1 - Receiving & Installation

Mounting

H

H1

W1

W

H2

D

Clearances

When mounting the VS-616PC5/P5, allow sufficient clearances for effective cooling as shown below:

1.97in (50mm)

1.18in (30mm)

1.97in (50mm)

4.72in (120mm)

4.72in (120mm)

Air

Air

Notes:

1) The required clearances at the top, bottom, and both sides of the inverter are the same

for both open chassis and NEMA 1 enclosures.

2) For inverter models 25HP and less (230V & 460V), remove the top and bottom covers

to convert NEMA 1 units to open chassis

3) Allowable intake air temperature:

Open chassis: 14°F to 113°F (-10°C to +45°C)

NEMA 1: 14°F to 104°F (-10°C to 40°C)

4) Whe n mounting units in an enclosure, install a fan or other cooling device to limit the

air temperature within the inverter to below 113°F (45°C).

VS-616PC5/P5 User’s M anual 17

Page 18

Chapter 1 - Receiving & Installation

Wiring

1.5 WIRING

!

CAUTION

PRECAUTIONS

1) Do not connect or disconnect wiring, or perform signal checks while

the power supply is turned ON.

2) Connect the power supply wiring to terminals L1, L2 and L3 on the

main circuit input section. DO NOT connect the power supply wiring

to output terminals T1, T2 and T3.

3) Connect the motor wiring to terminals T1, T2 and T3 on the main circuit output section.

4) Never touch the output circuit directly or place the output line in contact with the inverter enclosure.

5) Do not connect a phase-advancing capacitor or an LC/RC noise filter

to the output circuit.

6) The motor wiring must be less than 328ft (100m) in length and in a

separate conduit from the input power wiring.

7) Control wiring must be less than 164ft (50m) in length and in a separate conduit from both the motor wiring and the power wiring.

8) T ighten the screws on the main circuit and control circuit terminals.

9) Low voltage wires shall be wired with Class 1 wiring.

10)Please observe national electrical code (NEC) when wiring electrical

devices.

Failure to observe these precautions may result in equipment damage.

Inspection

After wiring is complete, verify that:

All wiring is correctly installed.

Excess screws and wire clippings are removed from inside of the unit.

Screws are securely tightened.

Exposed wire has no contact with other wiring or terminals.

18 VS-616PC5/ P5 U s er’s Ma nual

Page 19

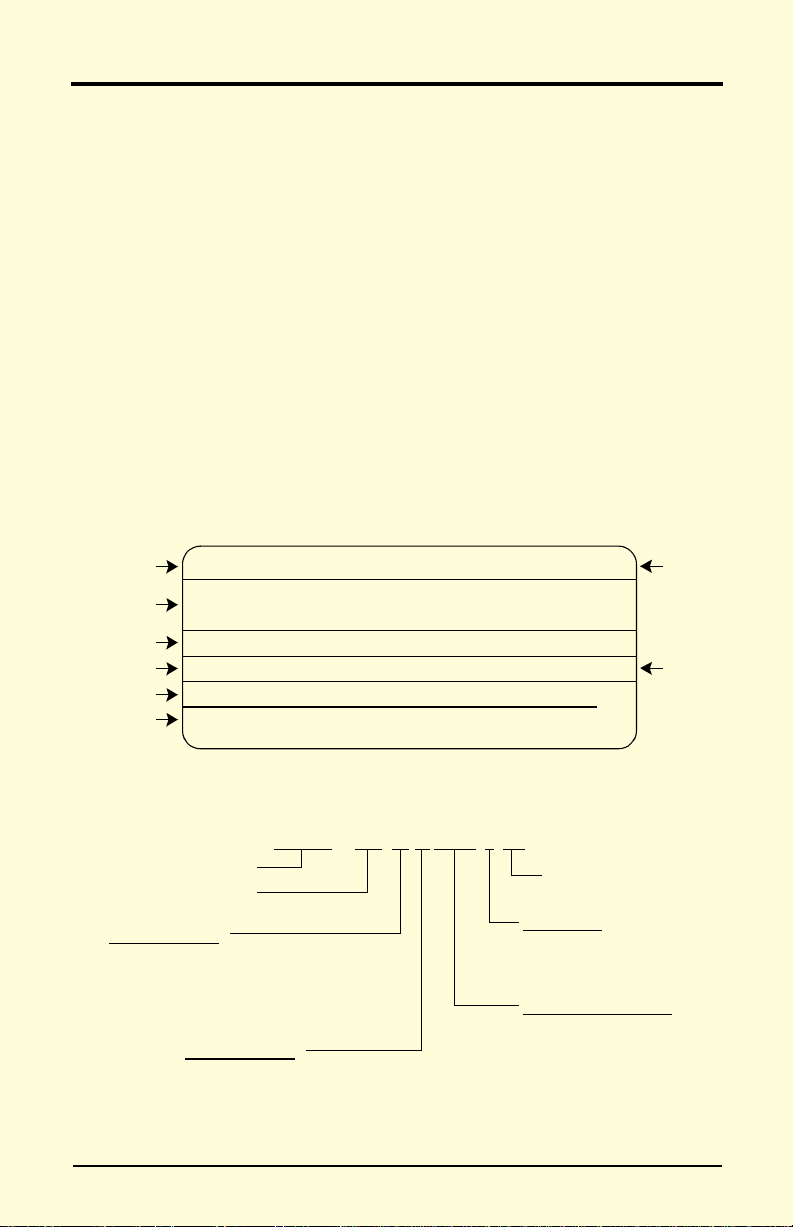

Figure 9 VS-616PC5 Terminal Diagram

230V: Models 20P4 through 27P5

460V: Models 40P4 through 4015

Chapter 1 - Receiving & Installation

Wiring

VS-616PC5 Standard Connection Diagram

DC Link Reactor (option)

Ground

230V units: 100Ω or less

460V units: 10Ω or less

Multi-Function

Contact Inputs

1

⊕

2

⊕

L1

L2

L3

S1 - Fixed

S2

S3

S4

S5

S6

SC (Com)

G

Gate Drive

PWM

8 bit

B1 B2

0~10V

(Com) AC

G

AM

T1

T2

T3

IM

Multi-Function

Analog Outputs

FS

Analog Inputs

Input FI selectable

4~20mA

or

0~10V

Serial Port

0~+10V

4~20mA

(+15V)

FV

(20kΩ)

FI

(250Ω)

(0V)

FC

RS-232

(10-pin)

A/D

10 bit

Operator

Digital

MA

MB

MC

M1

M2

VS-616PC5/P5 User’s M anual 19

Multi -Function

Contact Outputs

250VAC, 1A or less

30VDC, 1A or less

Page 20

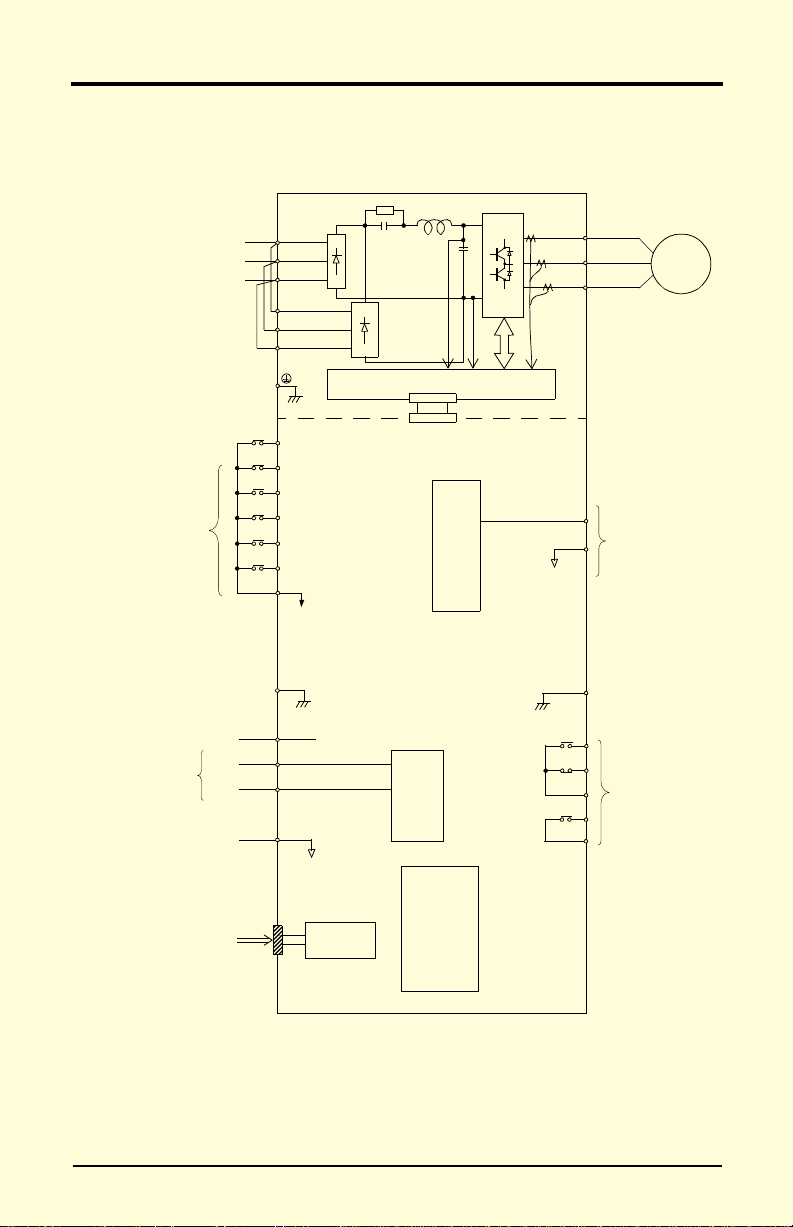

Figure 10 VS-616P5 Terminal Diagram

230V: Models 2018 through 2075

460V: Models 4018 through 4160

Chapter 1 - Receiving & Installation

Wiring

VS-616P5 Standard Connection Diagram

L1

L2

L3

L11

L21

L31

Ground

230V units: 100Ω or less

460V units: 10Ω or less

Multi-Function

Inputs

S1 - Fixed

S2

S3

S4

S5

S6

SC (Com)

G

Gate Drive

PWM

8 bit

0~10V

(Com) AC

G

AM

T1

T2

T3

IM

Multi-Function

Analog Outputs

FS

Analog Inputs

Input FI selectable

4~20mA

or

0~10V

Serial Port

0~+10V

4~20mA

(+15V)

FV

(20kΩ)

FI

(250Ω)

(0V)

FC

RS-232

(10-pin)

A/D

10 bit

Operator

Digital

MA

MB

MC

M1

M2

20 VS-616PC5/ P5 U s er’s Ma nual

Multi -Function

Relay Outputs

250VAC, 1A or less

30VDC, 1A or les s

Page 21

Chapter 1 - Receiving & Installation

Wiring

Main Circuit Wiring

Input Wiring

· Molde d-Case Circuit Breaker ( MCCB)

Be sure to connect MCCBs or fuses between the AC main circuit power

supply and VS-616PC5/P5 input terminals L1, L2 and L3, to protect the

power supp l y wi ri ng .

· Ground Fault Interrupter

When connecting a ground fault interrupter to input terminals L1, L2

and L3, select one that is not affected by high frequency.

Examples: NV series by Mitsubishi Electric Co., Ltd. (manufactured

in or after 1988), EGSG series by Fuji Electric Co., Ltd.

(manufactured in or after 1984).

· Magnetic Contactor (MC)

Inverters can be used without an MC installed on the power supply side.

An MC can be used instead of an MCCB to apply the main circuit

power supply. However, when an MC is switched OFF on the primary

side, dynamic braking does not function and the motor coasts to stop.

The load can be operated/stopped by closing/opening the MC on the

primary side. However, frequent switching may cause the inverter to

malfunction.

When using a braking resistor unit, use an MC to break the power supply

side of the inverter in the event of a dynamic braking overload relay trip.

Otherwise, if the inverter malfunctions, the braking resistor unit may be

burned out.

· Terminal Block Connect i on Sequence

Input power supply phases can be connected to any terminal regardless

of the order of L1, L2 and L3 on the terminal block.

· AC Reactor

When conn ecti n g an i nver te r (2 30 V/4 60 V, 25HP or les s) to a large capacity power supply transformer (600kVA or more), or when switching a

phase-advancing capacitor, excessive peak current flows through the input

power supply circuit, which may damage the converter section. In such

cases, install a DC reactor (optional) between inverter ⊕1 and ⊕2 terminals, or an AC reactor (optional) on the input side. Installation of a reactor

is also effective for improving power factor on the power supply side.

VS-616PC5/P5 User’s M anual 21

Page 22

n054

Chapter 1 - Receiving & Installation

Wiring

· Surge Suppressor

For inductive loads (i.e. magnetic contactors, magnetic relays, magnetic

valves, solenoids, magnetic brakes, etc.) connected near the inverter,

use a surge suppressor across the coils to limit the transients on the supply lines.

Output Wiring

· Motor Connec ti on

Connect motor lead wires to output terminals T1, T2 and T3. Verify that

the motor rotates in the forward direction (CCW: counterclockwise

when viewed from the motor load side) with the forward run command.

If the motor rotation is incorrect, exchange any two of the motor leads.

· Magnetic Starter

Do not connect a magnetic starter or a magne tic contactor to the output

circuit. If the motor load is connected or di sconnected while the inverter

is running, the inverter overcurrent protective circuitry may trip.

· Thermal Overload Relay

An electronic overload protective function (I

2

t) is incorporated into the

inverter. However, when driving several motors with one inverter, or

when switching between multiple windings of a multiple winding

motor, use an external thermal overload relay(s). In this case, set parameter n034 to “Disabled”.

· Wiring Distance Between Inverter and Motor

If the total wiring distance between inverter and motor is excessively

long and the inverter carrier frequency (IGBT switching frequency) is

high, harmonic leakage current from the wiring will adversely affect the

inverter and peripheral devices. If the wiring distance is long, reduce

the inverter carrier frequency as described below. C arrier frequency can

be set by param et er n054.

Wiring Distance Between Inverter and Motor

Wiring Distance between

Inverter and Motor

Carrier Frequency *

(Set value of parameter

)

Up to 164 ft.

(50m)

15kHz or less

(6)

Up to 328 ft.

(100m)

10kHz or l ess

More than 328 ft.

(4)

* Increasing the carrier frequency above the factory default value requires

current derating. Contact your Yaskawa representative for details.

22 VS-616PC5/ P5 U s er’s Ma nual

(100m)

5kHz or less

(2)

Page 23

Chapter 1 - Receiving & Installation

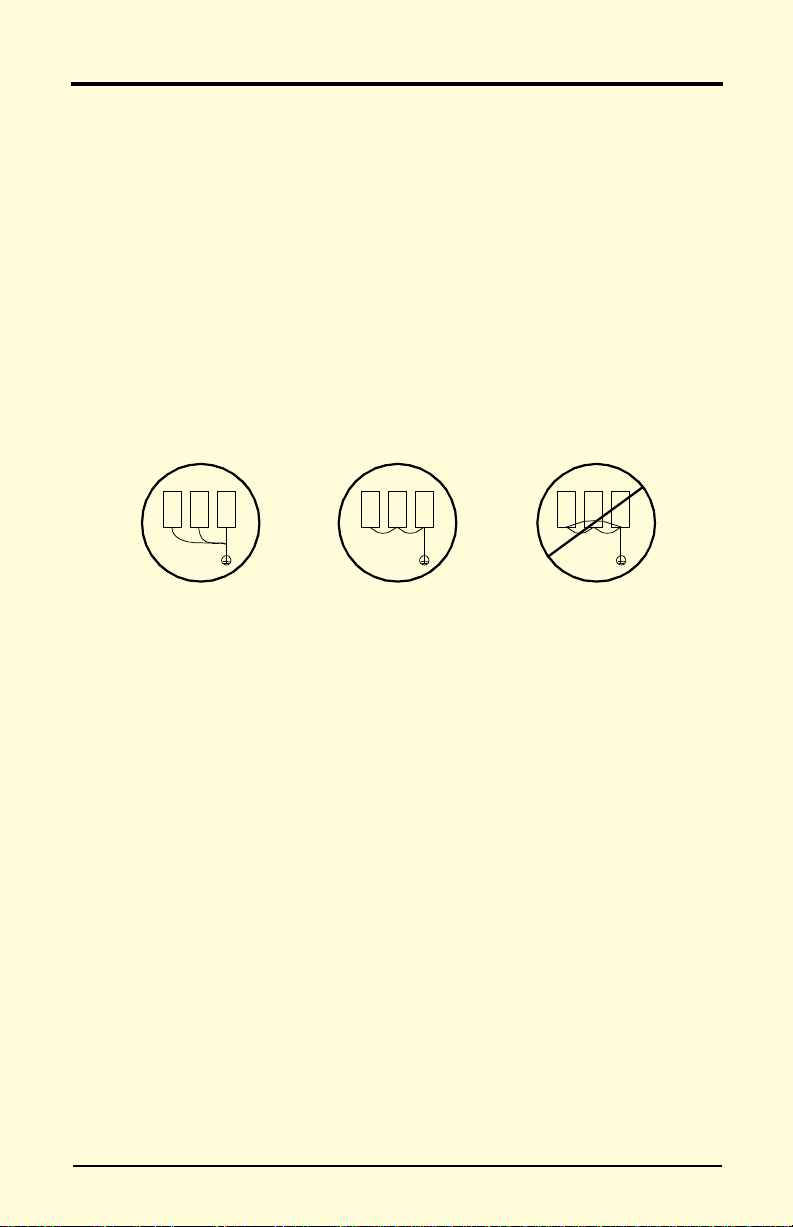

Figure 11 Grounding Example of 3 VS-616P5 Inverters

(a) Acceptable

(b) Acceptable

(c) Not Acceptable

Wiring

Grounding

· Ground Resistance

230V clas s: 10 0Ω or less, 460V class: 10Ω or less.

· Never ground the VS-616PC5/P5 in common with welding machines,

motors, or other high-current electrical equipment. Run all ground wiring in a separate conduit.

· Use ground wiring as specified in “Wire and Terminal Screw Sizes” on

page 25, and keep the length as short as possible.

· Whe n using severa l VS-616PC5/P5 units side by side, groun d the units

as shown in Figure 10, (a) or (b). Do not loop the wires as shown in (c).

VS-616PC5/P5 User’s M anual 23

Page 24

Chapter 1 - Receiving & Installation

Wiring

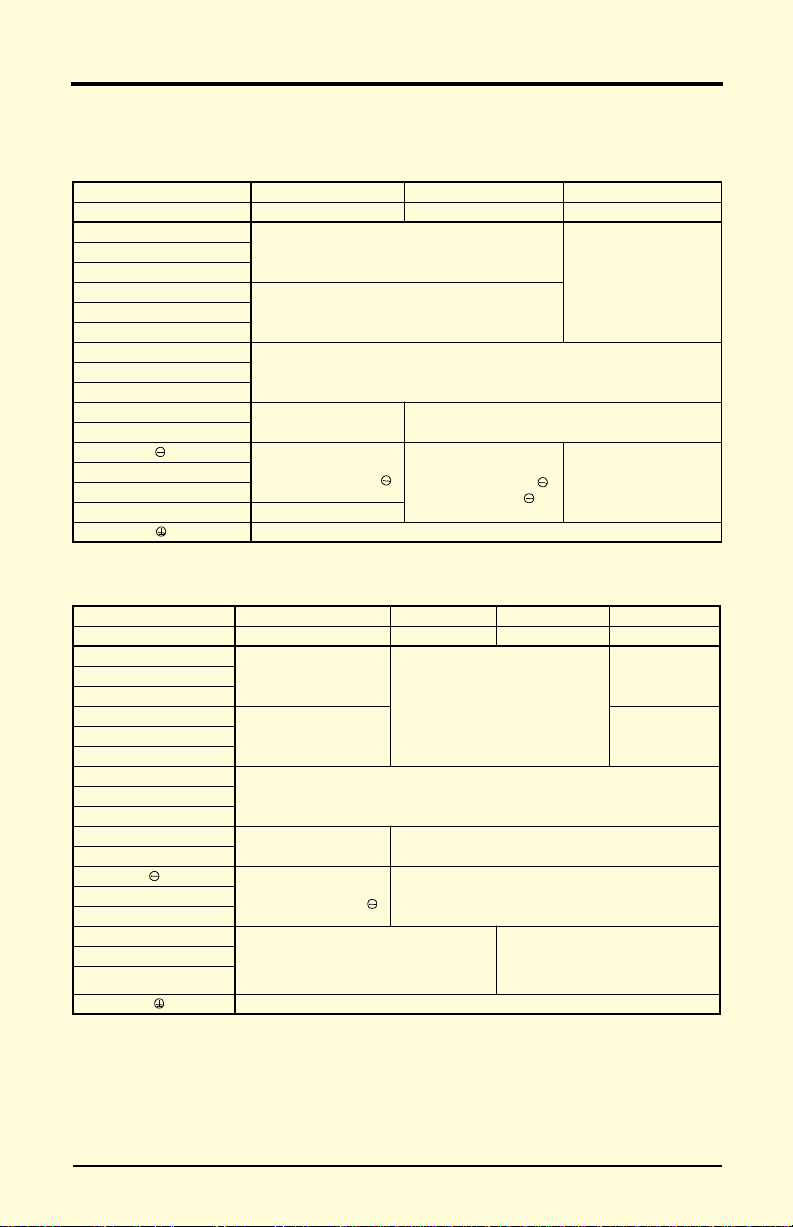

Terminal Functions

230V Class Terminal Functions

Model CIMR-P5U 20P4 to 27P5 2011 to 2015 2018 to 2075

Nominal Motor Output 0.5 to 10HP 20 to 25HP 30 to 125HP

L1

L2

L3

L11

L31

T1

T3

B1

B2

1

⊕

2

⊕

3 ---

⊕

DC power supply (⊕1 -

460V Class Terminal Functions

Model CIMR-P5U 40P4 to 4015 4018 to 4045 4055 to 4160 4185 to 4300

Nominal Motor Output 0.5 to 25HP 30 to 75HP 100 to 250HP 300 to 500HP

L1

L2

L3

L11

L31

T1

T3

s

s

B1

B2

⊕

⊕

200

400

1

2

r

Brakin g resistor unit ---

DC reactor (⊕1 - ⊕2)

DC power supply (⊕1 -

Main circuit input power supply

---L21

Inverter outputT2

Braking resistor unit ---

DC reactor (⊕1 - ⊕2)

Ground terminal (Ground resistance: 100Ω or less)

DC reactor (⊕1 - ⊕2)

)

DC power supply (⊕1 -

Braking unit (⊕3 -

)

Main circuit input

power supply

Main circuit input power supply

--- ---L21

Inverter outputT2

)

---

Ground terminal (Ground resistance: 10Ω or less)

r - s 200: 200 to 230 VAC input

r - s 400: 380 to 460 VAC input

Main circuit input

power supply

)

Main circuit input

power supply

---

Cooling fan power supply

(Control power supply)

---

24 VS-616PC5/ P5 U s er’s Ma nual

Page 25

Wire and Terminal Screw Sizes

-3

Chapter 1 - Receiving & Installation

Wiring

230V Class Wire Size

Model

Circuit

CIMR-

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U20P4

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U20P7

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U21P5

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U22P2

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U23P7

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U25P5

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U27P5

L1, L2, L3, , ⊕1, ⊕2, ⊕3, T1, T2, T3

P5U2011

Main

Control

* Wire sizes are based on 75°C copper wire.

L1, L2, L3, , ⊕1, ⊕2, ⊕3, T1, T2, T3 M8 3 30 90.3 (10.2)

P5U2015

L1, L2, L3, L11, L21, L31, T1, T2, T3

P5U2018

L1, L2, L3, L11, L21, L31, T1, T2, T3

P5U2022

L1, L2, L3, L11, L21, L31, T1, T2, T3 M10 4/0 100 203.6 (23.0)

P5U2030

L1, L2, L3, L11, L21, L31, T1, T2, T3 M10 1/0 x 2P 60 x 2P 203.6 (23.0)

P5U2037

L1, L2, L3, L11, L21, L31, T1, T2, T3 M10 1/0 x 2P 60 x 2P 203.6 (23.0)

P5U2045

L1, L2, L3, L11, L21, L31, T1, T2, T3 M10 1/0 x 2P 60 x 2P 203.6 (23.0)

P5U2055

L1, L2, L3, L11, L21, L31, T1, T2, T3 M12 4/0 x 2P 100 x 2P 349.6 (39.5)

P5U2075

S1, S2, S3, S4, S5, S6, SC

Common

FV, FI, FS, FC

to all

AM, AC, M1, M2, MA, MB, MC

models

G M3.5 20 - 14 0.5 - 2 8.9 (1.0)

Terminal Symbol

Terminal

Screw

M4 14 - 10 2 - 5.5 12.4 (1.4)

M4 14 - 10 2 - 5.5 12.4 (1.4)

M4

M4 12 - 10 3.5 - 5.5 12.4 (1.4)

M4 10 5.5 12.4 (1.4)

M5

M5

M6

M6 8 8 45.1 (5.1)

M8

M8

M8 4 22 90.3 (10.2)

M8 4 22 90.3 (10.2)

M8 4 22 90.3 (10.2)

M8 3 30 90.3 (10.2)

M8 1 50 90.3 (10.2)

Wire Size *

AWG mm

14 - 10 2 - 5.5

12 - 10 3.5 - 5.5

88

10 - 8 5.5 - 8

88

10 - 8 5.5 - 8

422

88

330

614

238

614

- 20 - 16

Stranded

0.5 - 1.25

Solid

0.5 - 1.25

2

Max. Torque

lb-in (N·m)

12.4 (1.4)

22.1 (2.5)

22.1 (2.5)

45.1 (5.1)

90.3 (10.2)

90.3 (10.2)

-

Wire Type

Power cable:

600V vinyl

sheathed wire

or equivalent

Twisted

shielded wire

with Class 1

wiring

Note:

Voltage drop should be considered when determining wire size. Voltage drop can be

calculated using the following equation:

Phase-to phase voltage dr op (V )

wire resistance (Ω/km) x wiring distance (m) x current (A) x 10

3=

Select a wire size so that voltage drop will be less than 2% of the normal rated voltage.

VS-616PC5/P5 User’s M anual 25

Page 26

Chapter 1 - Receiving & Installation

Wiring

460V Class Wire Size

Model

Circuit

CIMR-

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U40P4

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U40P7

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U41P5

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U42P2

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U43P7

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U45P5

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3

P5U47P5

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3 M5 8 - 6 8 - 14 22.1 (2.5)

P5U4011

L1, L2, L3, , ⊕1, ⊕2, B1, B2, T1, T2, T3 M5 8 - 6 8 - 14 22.1 (2.5)

P5U4015

L1, L2, L3, L11, L21, L31, T1, T2, T3 M6 6 14 45.1 (5.1)

P5U4018

L1, L2, L3, L11, L21, L31, T1, T2, T3 M6 4 22 45.1 (5.1)

P5U4022

L1, L2, L3, L11, L21, L31, T1, T2, T3

P5U4030

Main

Control

* Wire sizes are based on 75°C copper wire.

L1, L2, L3, L11, L21, L31, T1, T2, T3

P5U4037

L1, L2, L3, L11, L21, L31, T1, T2, T3

P5U4045

L1, L2, L3, L11, L21, L31, T1, T2, T3 M10 4/0 100 203.6 (23.0)

P5U4055

L1, L2, L3, L11, L21, L31, T1, T2, T3 M10 1/0 x 2P 60 x 2P 203.6 (23.0)

P5U4075

L1, L2, L3, L11, L21, L31, T1, T2, T3 M10 1/0 x 2P 60 x 2P 203.6 (23.0)

P5U4110

L1, L2, L3, L11, L21, L31, T1, T2, T3 M12 4/0 x 2P 100 x 2P 349.6 (39.5)

P5U4160

L1, L2, L3, , ⊕1, ⊕3, T1, T2, T3

P5U4185

r, s200, s400 M4 20 - 10 0.5 - 5.5 12.4 (1.4)

L1, L2, L3, , ⊕1, ⊕3, T1, T2, T3

P5U4220

r, s200, s400 M4 20 - 10 0.5 - 5.5 12.4 (1.4)

L1, L2, L3, , ⊕1, ⊕3, T1, T2, T3

P5U4300

r, s200, s400 M4 20 - 10 0.5 - 5.5 12.4 (1.4)

S1, S2, S3, S4, S5, S6, SC

Common

FV, FI, FS, FC

to all

AM, AC, M1, M2, MA, MB, MC

models

G M3.5 20 - 14 0.5 - 2 8.9 (1.0)

Terminal Symb ol

Terminal

Screw

M16

M16

M16

Wire Size *

AWG mm

M4 14 - 10 2 - 5.5 12.4 (1.4)

14 - 10 2 - 5.5

M4

12 - 10 3.5 - 5.5

14 - 10 2 - 5.5

M4

12 - 10 3.5 - 5.5

14 - 10 2 - 5.5

M4

12 - 10 3.5 - 5.5

14 - 10 2 - 5.5

M4

12 - 10 3.5 - 5.5

M4 12 - 10 3.5 - 5.5 12.4 (1.4)

M5 8 - 6 8 - 14 22.1 (2.5)

M6 8 - 6 8 - 14 45.1 (5.1)

M6 8 - 6 8 - 14 45.1 (5.1)

M8 8 - 6 8 - 14 90.3 (10.2)

M8 4 22 90.3 (10.2)

422

M8

422

330

M8

422

150

M8

330

M8 1 50 90.3 (10.2)

M8 1/0 60 90.3 (10.2)

M8 1/0 60 90.3 (10.2)

M8 4/0 100 90.3 (10.2)

650MCM

x 2P

M8 650MCM 325 90.3 (10.2)

650MCM

x 2P

M8 650MCM 325 90.3 (10.2)

650MCM

x 2P

M8 650MCM 325 90.3 (10.2)

- 20 - 16

Max. Torque

2

lb-in (N·m)

12.4 (1.4)

12.4 (1.4)

12.4 (1.4)

12.4 (1.4)

90.3 (10.2)

90.3 (10.2)

90.3 (10.2)

325 x 2P 867.4 (98.0)

325 x 2P 867.4 (98.0)

325 x 2P 867.4 (98.0)

Stranded

0.5 - 1.25

Solid

0.5 - 1.25

-

Wire Type

Power cable:

600V vinyl

sheathed wire

or equivalent

Twisted

shielded wire

with Class 1

wiring

26 VS-616PC5/ P5 U s er’s Ma nual

Page 27

Chapter 1 - Receiving & Installation

Wiring

JST Closed Loop Connectors

Wire Size *

AWG mm

20 0.5

18 0.75

16 1.25

14 2

12 - 10 3.5 - 5.5

88

614

422

3 - 2 30 - 38 M8 38 - 8 90.3 (10.2)

1 - 1/0 50 - 60

3/0 80

4/0 100 100 - 10 203.6 (23.0)

4/0 100

300MCM 150 150 - 12 349.6 (39.5)

400MCM 200 200 - 12 349.6 (39.5)

650MCM 325

Terminal Screw JST Closed-Loop Connectors (Lugs)

2

Max. Torque

lb-in (N·m)

M3.5 1.25 - 3.5 8.9 (1.0)

M4 1.25 - 4 12.4 (1.4)

M3.5 1.25 - 3.5 8.9 (1.0)

M4 1.25 - 4 12.4 (1.4)

M3.5 1.25 - 3.5 8.9 (1.0)

M4 1.25 - 4 12.4 (1.4)

M3.5 2 - 3.5 8.9 (1.0)

M4 2 - 4 12.4 (1.4)

M5 2 - 5 22.1 (2.5)

M6 2 - 6 45.1 (5.1)

M8 2 - 8 90.3 (10.2)

M4 5.5 - 4 12.4 (1.4)

M5 5.5 - 5 22.1 (2.5)

M6 5.5 - 6 45.1 (5.1)

M8 5.5 - 8 90.3 (10.2)

M5 8 - 5 22.1 (2.5)

M6 8 - 6 45.1 (5.1)

M8 8 - 8 90.3 (10.2)

M6 14 - 6 45.1 (5.1)

M8 14 - 8 90.3 (10.2)

M6 22 - 6 45.1 (5.1)

M8 22 - 8 90.3 (10.2)

M8 60 - 8 90.3 (10.2)

M10 60 - 10 203.6 (23.0)

M10

M12

M12 x 2 325 - 12 349.6 (39.5)

M16 325 - 16 867.4 (98.0)

80 - 10 203.6 (23.0)

100 - 12 349.6 (39.5)

Note:

The use of a JST closed-loop connector (lug) is recommended to maintain proper

clearances. Please contact your Yaskawa representative for more information.

VS-616PC5/P5 User’s M anual 27

Page 28

Chapter 1 - Receiving & Installation

n036

n040

n043

n043

(n042)

(n041)

(n052)

Figure 12 Control Circuit Terminal Arrangement

Figure 13 Wiring the Control Circuit Terminal

Wiring

Control Circuit Wiring

The following table outlines the functions of the control circuit terminals.

Contr ol Circuit Terminals

Classifi-

Terminal Function Description Signal Level

cation

S1 Forward run/stop Forward run when closed, stop when open

S2 Reverse run/stop

S3 External fault input

S4 Fault reset input Reset when closed

S5 Multi-step speed reference 1 Enabled when closed

S6 Multi-step speed reference 2 Enabled when closed

Multi-function Input Signal

SC Sequence input common terminal —

FS +15V Power supply output For analog command +15V power supply

FV Frequency referen c e i nput (voltage) 0 to +10V/100%

FI Frequency reference input (curr ent ) 4 to 20mA/100% 4 to 20m A (250Ω)

FC Common terminal 0V —

Analog Input Signal

Multi-function

Output Signal

Signal

Output

Analog

Connection to shield sheath of

G

signal lead

M1

During running (N.O. contact) Closed when running

M2

MA

Fault contact output

MB

(N.O./N.C. contact)

MC

AM Frequency meter output

AC Common

Reverse run when closed,

stop when open

Fault when closed, normal

state when open

Fault when closed between

terminals MA and MC

Fault when open between

terminals MB and MC

0 to +10V/100% frequency

Multi-function contact

to

inputs (

= “FV=MSTR”:

FV enabled

= “FI=MSTR”:

FI enabled

——

Multi-function contact

output

Multi-function contact

output

Multi-function analog

monitor 1

Photo-coupler

insulation

)

Input: +24VDC 8mA

+15V (allowable cur-

rent 20mA max.)

0 to +10V (20kΩ)

Dry contact

Contact capacity:

250VAC 1A or less

30VDC 1A or less

0 to +10V

2mA or less

G

S1 S2 S3 S4 S5 S6SC SC FV FI FS FC AM AC M1 M2 MA MB MC

Insert the wire into the lower part of the terminal

block and connect tightly with a screwdriver.

0.02in (0.6mm)

max

0.14in (3.5mm)

max

28 VS-616PC5/ P5 U s er’s Ma nual

0.28in (7mm) max

Page 29

- CHAPTER 2 -

OPERATION

Section DescriptionPage

2 OPERATION

Precautions30

2.1 T

2.2 D

2.3 LED D

2.4 O

RIAL OPERATION

Digital Operator Display at Po wer-up 31

Operation Checkpoints32

Basic Operation32

IGITAL OPERATOR DISPLAY

ESCRIPTION

PERATION MODE SELECTION

31

36

35

37

Page 30

!

WARNING

PRECAUTIONS

1) Only turn ON the input power supply after replacing the front cover.

Do not remove the cover while the inverter is powered up.

2) When the retry function (n060) is selected, do not approach the

inverter or the load, since it may restart suddenly after being stopped.

3) Since the Stop key can be disabled by a function setting, install a se parate emergency stop swi tch to disconnect power or fault the inve rter.

4) Do not touch the heatsink or braking resistor, due to very high temperatures.

5) Since it is very easy to change operation speed from low to high

speed, verify the safe working range of the motor and machine before

operation.

6) Install a separate holdi ng brake, if necessary.

7) Do not check signals during operation.

8) All inverter parameters have been preset at the factory . Do not change

the settings without thorough review of the possible consequences.

Failure to observe these precautions may result in equipment damage,

serious personal injury, or death.

30 VS-616PC5/ P5 U s er’s Ma nual

Page 31

2.1 TRIAL OPERATION

Figure 14 Digital Operator Display at Power-up

(JVOP-130P)

SEQ

REF

DRIVE

FWD

REV

To ensure safety, prior to initial operation, disconnect the machine coupling so that the motor is isolated from the machine. If initial operation

must be performed while the motor is still coupled to the machine, use

great care to avoid potentially hazardous conditions. Check the following

items before a trial run:

· Wiring and terminal connections are proper.

· Wire clippings and other debris removed from the unit.

· Screws are securely tightened.

· Motor is securely mounted.

· All items are correctly grounded.

Digital Operator Display at Power-Up (JVOP-130P)

When the system is ready for operation, turn ON the power supply . Verify

that the inverter powers up properly. If any problems are detected, turn

OFF the power supply immediately. The digital operator display illuminates as shown below when the power supply is turned ON.

REMOTE

F

requency Ref

0.0 HZ

ENTERDSPL

STOP

RESET

kWoutFref Fout Iout

FbiasVmtr V/F Fgain

PRGM

F/R Montr Accel Decel

FLA PID kWsav

DIGITAL OPERATOR

JVOP-130P

LOCAL

REMOTE

RUN

VS-616PC5/P5 User’s M anual 31

Operation Mode Indicators:

DRIVE: Lit when in operation mode.

FWD: Lit when there is a forward run command input.

REV: Lit when there is a reverse run command input.

SEQ: Lit when the run command from the control circuit

terminal is enabled.

REF: Lit when the frequency reference from control cir-

cuit terminals 13 and 14 is enabled.

Display Section:

2 line

16 character alphanumeric LCD that displays

×

data for monitoring, user parameters, and set values.

Keys:

Execute operations such as setting user parameters,

monitoring, and auto-tuning.

Page 32

Operation Checkpoints:

Figure 15 Operation Sequence by Digital Operator

· Motor rotates smoothly.

· Motor rotates in the correct direction.

· Motor has no abnormal vibratio n and is not noisy.

· Acceleration and deceleration are smooth.

· Unit is not overloaded.

· Status indicator LEDs and digital operator display are correct.

Basic Operation

The inverter will operate after receiving a frequency reference. There are

two operation modes for the VS-616PC5/P5:

· Run command from the digital operator.

· Run command from the control circuit terminals.

Operation by Digital Operator

The diagram below shows a typical operation pattern using the digital

operator. Pressing the LOCAL/REMOTE key once while the inverter is

stopped places the inverter in the LOCAL mode. The digital operator,

JVOP-130P, can then be used to start and stop and change the reference.

1

Power

ON

23

Forward

Forward Run

Frequency Setting

4

15Hz

Frequenc y Refer en ce Chang e

56

Stop

Reverse Run

Reverse

60Hz

32 VS-616PC5/ P5 U s er’s Ma nual

Page 33

Typical Operation Example by Digital Operator (JVOP-130P)

Description Key Sequence Digital Operator Display

(1) Power ON

· Displays frequency reference value.

Operation Condition Setting

· Select LOCAL mode.

LOCAL

REMOTE

REMOTE LED (SEQ, REF) ON

Frequenc y Ref

REMOTE LED (SEQ, REF) OFF

0.0 Hz

(2) Frequency Se tt i ng

· Change frequency reference value.

· Write-in set value.

· Select output frequency monitor display.

(3) Forward Run

· Forward run (15Hz)

(4) Frequency Re ferenc e Valu e Change ( 15~60Hz )

· Select frequency reference value display.

· Change set value.

· Write-in set value.

· Select output frequency monitor display.

(5) Reverse Run

· Select revers e run.

Change the value

by depressing

ENTER

DSPL

RUN

DSPL

Depress 15 times

Change the value

by depressing

ENTER

DSPL

DSPL

Depress 3 times.

Switch to “rev”

by depressing

Frequency R ef

15.0 Hz

Frequency R ef

15.0 Hz

Output Freq

0.0 Hz

Output Freq

15.0 Hz

RUN LED ON

Frequenc y Ref

15.0 Hz

Frequency Ref

60.0 Hz

Frequency Ref

60.0 Hz

Output Freq

60.0 Hz

Forward/Reverse

For

Forward/Reverse

rev

REVERSE LED (REV) ON

· Write-in set value.

· Select output frequency monitor display.

ENTER

DSPL

Forward/Reverse

rev

Output Freq

60.0 Hz

Depress 13 times.

(6) Stop

· Decelerates to stop.

STOP

RESET

Output Freq

0.0 Hz

RUN LED OFF STOP LED ON

VS-616PC5/P5 User’s M anual 33

Page 34

Operatio n by Control Circuit Terminal Signa l

Figure 16 Operation Sequence by Control Circuit Terminal Signal

The diagram below shows a typical operation pattern using the control

circuit terminal signals.

4

Stop

1

Power ON

2

Operatio n

Frequency Setting

Forward

60Hz

3

Typical Operation Example by Control Circuit Terminal Signal

Description Key Sequence Digital Operator Display

(1) Power ON

· Displays frequency reference value.

REMOTE mode is preset at the factory.

(2) Frequency Se tt i ng

· Input fr equenc y ref erence volt age ( curr ent)

by control circuit terminal FV or FI and verify the input value by the digital operator.

Frequency R ef

REMOTE LED (SEQ, REF) ON

Frequency R ef

For reference voltage 10V

0.0 Hz

60.0 Hz

Output Frequency Display

· Write-in set value.

(3) Forward Run

· Close between control circuit terminals S1

and SC to perform forward run.

(4) Stop

· Open between control circuit terminals S1

and SC to stop operation.

DSPL

Output Freq

0.0 Hz

Output Freq

60.0 Hz

RUN LED ON

Output Freq

0.0 Hz

STOP LED ON

(RUN LED blinking

during deceleration)

34 VS-616PC5/ P5 U s er’s Ma nual

Page 35

2.2 DIGITAL OPERATOR DISPLAY

SEQ

REF

Figure 17 Digital Operator Display at Power-up

DRIVE

FWD

REV

All functions of the VS-616PC5/P5 are accessed usin g the JVOP -130P Digital Operator. Below are descriptions of the display and keypad sections.

REMOTE

F

requency Ref

0.0 HZ

F/R Montr Accel Decel

FLA PID kWsav

DIGITAL OPERATOR

JVOP-130P

ENTERDSPL

LOCAL

REMOTE

RUN

STOP

RESET

kWoutFref Fout Iout

FbiasVmtr V/F Fgain

PRGM

Operation Mode Indicators:

DRIVE: Lit when in operation mode.

FWD: Lit when there is a forward run command input.

REV: Lit when there is a reverse run command input.

SEQ: Lit when the run command from the control circuit

terminal or serial communication is enabled.

REF: Lit when the frequency reference from control cir-

cuit terminals FV or FI, or serial communication is

enabled.

Display (L CD)

Displays set values of each function or monitoring values such

as output frequency and current (2 line × 16 characte r al ph anumeric) .

Enter Key

Displays the current value of each parameter and allows new

values to be entered.

Increase/Decrea se K eys

Changes set values or parameter numbers.

: Increment key

∧

:Decrement key

∨

Operation Comma nd Ke ys

Operation command keys operate the inverter.

STOP/RESET: Red LED lights after depressing STOP key.

RUN: Red LED lights after depressing RUN key.

Inverter op erat ion is s topped. (rese ts oper ati on

after faults; reset is disabled while run command is ON)

Inverter ope rat ion begins

Display Key

Scrolls through display monitors and QuickStart parameters, and allows access to all

parameters.

VS-616PC5/P5 User’s M anual 35

Operation Mode Selection Key

Alternate between REMOTE and LOCAL (digital operator)

operation.

Page 36

2.3 LED DESCRIPTION

Simple operation of the VS-616PC5/P5 is possible, by using the quick-start displays.

Quick-Start Displays (Example of CIMR-P5U23P7)

Description Key Sequence Digital Operator Display Remarks

Power ON

Frequency reference

setting/monitoring

Output frequency monitor

Output current monitor

Output power monitor

FWD/REV run command

selection

Monitor selection

Acceleration time

Deceleration time

Input voltage

DSPL

DSPL

DSPL

DSPL

DSPL

DSPL

DSPL

DSPL

DSPL

Frequency R ef

Output Freq

Output Amps

Output Po w er

Forward/Reverse

Monitor U-01

Frequency Ref

Accel Time 1

10.0 Sec

Decel Time 1

10.0 Sec

Input Voltage

230.0 VAC

0.0 Hz

0.0 Hz

0.0 A

0.0 kW

For

Depress

[ENTER] key

to display the

monitor value.

V/f pattern selection

Frequency reference gain

Frequency reference bias

Motor rated current

PID selection

Energy saving selection

Parameter Number/data

DSPL

DSPL

DSPL

DSPL

DSPL

DSPL

DSPL

V/f Selection

60Hz Preset

Term inal FV Gain

100%

Terminal FV Bias

0%

Mo to r rated FL A

19.6A

PID Mode

Disabled

Energy Sav Sel

Disabled

Parameter n00 2

Oper Mode Select

Set/read is

enabled only

during stop.

Depress

[ENTER] key

to display data.

36 VS-616PC5/ P5 U s er’s Ma nual

Page 37

2.4 OPERATION MODE SELECTION

(n002, Oper Mo de Select)

The VS-616PC5/P5 has two operation modes: LOCAL and REMOTE

(see table below for description). These two modes can be selected by the

digital operator “LOCAL/REMOTE” key only when operation is stopped.

The operation mode selected can be verified by observing the SEQ and

REF LEDs on the digital operator (as shown below). The operation mode

is set to REMOTE (run by control circuit terminals FV and FI frequency

reference and run command from control circuit terminals) prior to shipment. Multi-function contact inputs from control circuit terminals S3 to

S6 are enabled in both operation modes.

· LOCAL: Both frequency reference and run command are set

by the digital operato r. Remote SEQ and R EF LEDs

go OFF.

· REMOTE: Master frequency reference and run command can

be selected as described in the table below.

Parameter n11 1, LOC/REM Change, will determine if the inverter will

acknowledge a previously closed run input during a switchover from

LOCAL to REMOTE mode.

· When n111 is set to “Cycle Extern Run”, the inverter will not start

if the run input is closed during the transition from LOCAL to

REMOTE.

· When n111 is set to “Acept Extern Run”, the inverter will immediately start if the run input is closed during the transition from

LOCAL to REMOTE.

Operation Mode Selection

LED

Display

0 SEQ=OPR REF=OPR Operation by run command

1 SEQ=TRM REF=OPR Operation by run command

2 SEQ=OPR REF=TRM Operation by run command

3 SEQ=TRM REF=TRM Operation by run command

4 SEQ=OPR REF=COM Operation by run command

5 SEQ=TRM REF=COM Operation by run command

6 SEQ=COM REF=COM Operation by run command

7 SEQ=COM REF=OPR Operation by run command

LCD

Display

Operation Method Selection

from digital operator

from control circuit terminal

from digital operator

from control circuit terminal

from digital operator

from control circuit terminal

from serial communication

from serial communication

SEQ

LED

OFF Master frequency reference

ON Master frequency reference

OFF Master frequency reference

ON Master frequency reference

OFF Master frequency reference

ON Master frequency reference

ON Master frequency reference

ON Master frequency reference

Reference Selection

from digital operator

from digital operator

from control circuit terminals

FV and FI

from control circuit terminals

FV and FI

set by serial communication

set by serial communication

set by serial communication

from digital operator

REF

LED

OFF

OFF

ON

ON

ON

ON

ON

OFF

VS-616PC5/P5 User’s M anual 37

Page 38

LED

Display

8 SEQ=COM REF=TRM Operation by run command

LCD

Display

Operation Method Selection

from serial communication

SEQ

LED

ON Master frequency reference

Reference Selection

from control circuit terminals

FV and FI

REF

LED

ON

- CHAPTER 3 -

PROGRAMMING

FEATURES

Section Description Page

3 PROGRAMMING F E ATURES

3.1 VS-616PC5/P5 P

3.2 P

3.3 VS-616PC5/P5 O

Accel/decel time adjustment. . . . . . . . . . . . . . . . . . . . . . 50

Automatic fault retry . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Automatic restart after momentary power loss . . . . . . . 51

Carrier frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Current limit (Stall prevention). . . . . . . . . . . . . . . . . . . . 52

DC injection braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Frequency meter or ammeter . . . . . . . . . . . . . . . . . . . . . 58

Frequency meter or ammeter calibration . . . . . . . . . . . . 58

Frequency signal adjustment. . . . . . . . . . . . . . . . . . . . . . 58

Jog operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

ARAMETER SET-UP

Energy savings control . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Frequency agree set point . . . . . . . . . . . . . . . . . . . . . . . . 57

ARAMETERS

NITIALIZ ATION

& I

PERATION

(n001~n1 16) . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . 49

38 VS-616PC5/ P5 U s er’s Ma nual

Page 39

Jump frequencies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

MODBUS communication. . . . . . . . . . . . . . . . . . . . . . . 61

Motor overload detection . . . . . . . . . . . . . . . . . . . . . . . . 62

Multi-step speed selection. . . . . . . . . . . . . . . . . . . . . . . . 64

Phase loss detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

PID Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Reverse run prohibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Soft-start characteristics . . . . . . . . . . . . . . . . . . . . . . . . . 68

Speed limit adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Stopping method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

T orque adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

T orque detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Tripless operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

V/f pattern adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Slip compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.4 I

NPUTS

& O

UTPUTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Multi-function input signals . . . . . . . . . . . . . . . . . . . . . . 78

Analog input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Multi-function output signals . . . . . . . . . . . . . . . . . . . . . 83

VS-616PC5/P5 User’s M anual 39

Page 40

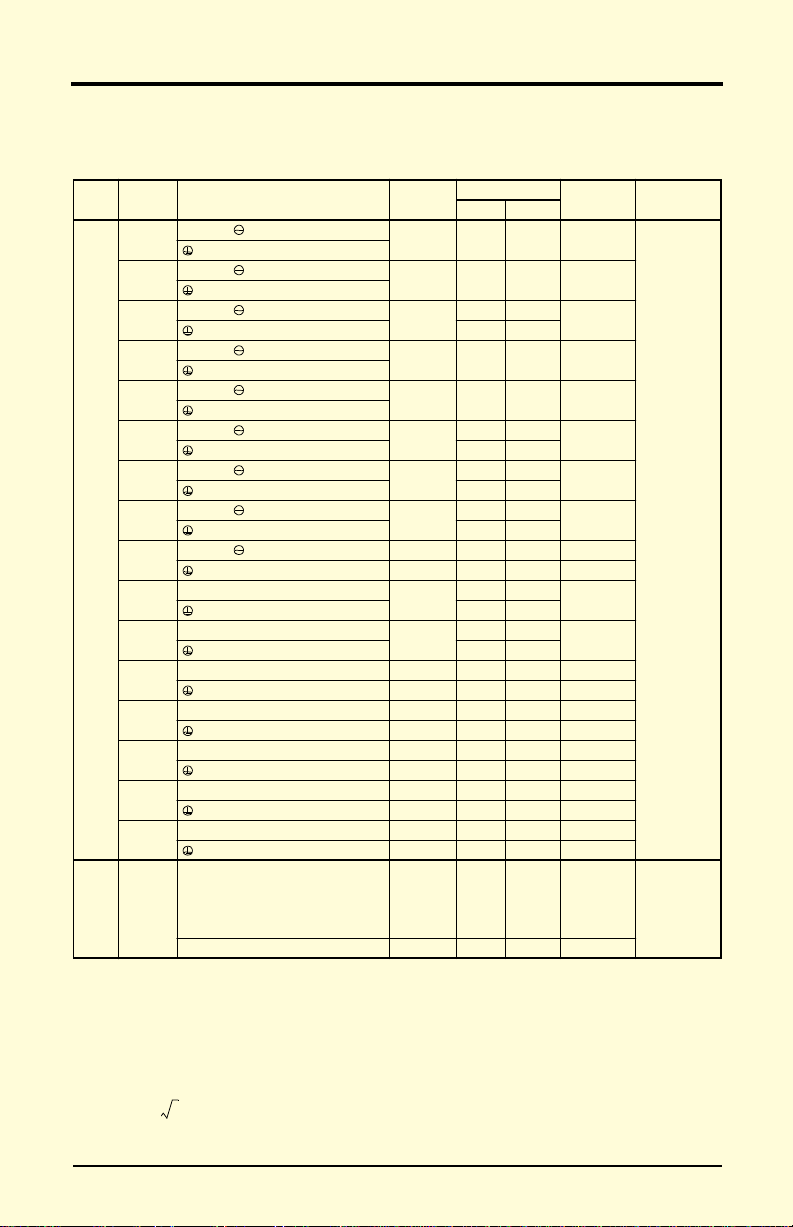

3.1 VS-616PC5/P5 Par ame te rs

No. Function Name

(LCD Operator Display)

n001

Parameter selection/

initialization

(Password)

n002

Operation mode selection

(Oper Mode Select)

Input voltage

n003

(Input Voltage)

Stopping method

n004

(Stopping Method)

n005

Motor rotation

(Motor Rotation)

Prohibit reverse operation

n006

(Reverse Oper)

Local/remote key function

n007

(Local/Remote Key)

n008

Stop key function

(Oper STOP Key)

n009

Frequency reference setting method from operator

(Operator MOP)

V/f pattern selection

n010

(V/f Selection)

Maximum frequency

n011

(Max Frequency)

Maximum voltage

n012

(Max Voltage)

Base frequency

n013

(Base Frequency)

0:

read and set,

n001

1:

n001~n035

2:

n001~n053

3:

n001~n116

read and set,

read & set,

read and set

4, 5: Not used

6: 2-wire initialization (Japanese specifications)

7: 3-wire initialization (Japanese specifications)

8: 2-wire initialization (American specifications)

9: 3-wire initialization (American specifications)

LED Setting LCD Setting Operation Reference

0 SEQ=OPR REF=OPR Operator Operator

1 SEQ=TRM REF=OPR Terminal Operator

2 SEQ=OPR REF=TRM Operator Terminal

3 SEQ=TRM REF=TRM Terminal Termin al

4 SEQ=OPR REF=COM Operator Serial com

5 SEQ=TRM REF=COM Termi n a l Serial com

6 SEQ=COM REF=COM Serial com Serial com

7 SEQ=COM REF=OPR Serial com Operator

8 SEQ=COM REF=TRM Serial com Terminal

Unit: 0.1V

Setting range: 150.0~255.0V (510V for 460V units)

LED Setting LCD Setting Description

0 Ramp to stop Ramp to stop

1 Coast to stop Coast to stop

2 Coa st w/Timer1 Coast to stop with timer

3 Coast w/Timer2 Coast to stop with timer

LED Setting LCD Setting Description

0 Rotate C.C.W. CCW shaft rotation

1 Rotate C.W. CW shaft rotation

LED Setting LCD Setting Description

0 R ev Allo wed Reverse operation enabled

1 Rev Prohibited Re v erse operatio n disabled

LED Setting LCD Setting

0 Disabled

1 Enabled

LED Setting LCD Setting Description

0 Disabled Stop key is disabled when

1 Enabled Stop key is always enabled

LED Setting LCD Setting

0 Enter not used

1 Enter key used

LED Setting LCD Setting Description

0 User Defined V/f Custom V/f pattern

1 60 Hz Preset Fixed V/f pattern

Unit: 0.1Hz

Setting range: 50.0~400.0Hz

Unit: 0.1V

Setting range: 0.1~255.0V (510V for 460V units)

Unit: 0.1Hz

Setting range: 0.2~400.0Hz

(n001~n116)

Description Factory

Default

n002~n116

n036~n116

n054~n116

read only

read only

read only

149

SEQ=TRM

REF=TRM

230.0V

(460.0V)

Ramp to

Stop

(Run command cycle)

(auto-start after time out)

Rotate

C.C.W.

Rev

Allowed

Enabled 37

Enabled -

operated from terminals

Enter

key

used

(n011 ~ n017 can be set)

60 Hz

Preset

60.0Hz 76

230.0V 76

60.0Hz 76

User

Setting

Ref.

Page

37

-

70

-

68

-

75,96

40 VS-616PC5/ P5 U s er’s Ma nual

Page 41

No. Function Name

(LCD Operator Display)

n014

Mid. output frequency

(Mid Frequency)

n015

Mid. frequency voltage

(Mid Voltage)

n016

Minimum output

frequency

(Min Frequency)

n017

Minimum output voltage

(Min Voltage)

n018

Acceleration time 1

(Accel Time 1)

n019

Deceleration time 1

(Decel Time 1)

Acceleration time 2

n020

(Accel Time 2)

Deceleration time 2

n021

(Decel Time 2)

S-curve selection

n022

(S-Curve Select)

Display mode

n023

(Display Units)

n024

Frequency reference 1

(Reference 1)

n025

Frequency reference 2

(Reference 2)

n026

Frequency reference 3

(Reference 3)

Frequency reference 4

n027

(Reference 4)

Not used - - - -

n028

Not used - - - -

n029

n030

Jog frequency

(Jog Reference)

n031

Frequency upper limit

(Ref Upper Limit)

Frequency lower limit

n032

(Ref Lower Limit)

Motor rated current

n033

(Motor Rated FLA)

Unit: 0.1Hz

Setting range: 0.1~399.9Hz

Unit: 0.1V

Setting range: 0.1~255.0V (510V for 460V units)

Unit: 0.1Hz

Setting range: 0.1~10.0Hz

Unit: 0.1V