Page 1

VS-616G5 Series (Revision F)

Programming Manual

Constant Torque Inverter with Adaptive Vector Control (AVC™)

Page 2

PRECAUTIONS

WARNING

1) Only turn ON the input power supply after replacing the front cover. Do not remove the cover

while the inverter is powered up.

2) When the retry function (parameter L5-02) is selected, do not approach the inverter or the load,

since it may restart suddenly after being stopped.

3) Since the Stop key can be disabled by a function setting, install a separate emergency stop switch.

4) Do not touch the heatsink or braking resistor, due to very high temperatures.

5) Since it is very easy to change operation speed from low to high speed, verify the safe working

range of the motor and machine before operation.

6) Install a separate holding brake, if necessary.

7) Do not check signals during operation.

8) All inverter parameters have been preset at the factory. Do not change the settings unless required.

Failure to observe these precautions may result in equipment damage, serious personal injury or death.

NOTICE

Printed April 1999. The information contained within this document is the proprietary property of

Yaskawa Electric America, Inc., and may not be copied, reproduced or transmitted to other parties

without the expressed written authorization of Yaskawa Electric America, Inc.

!

No patent liability is assumed with respect to the use of the information contained herein. Moreover,

because Yaskawa is constantly improving its high-quality products, the information contained in this

manual is subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

2 VS-616G5 Programming Manual

Page 3

Contents

Contents

Section Description Page

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

VS-616G5 PARAMETER TREE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

A INITIALIZATION PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

A1 Initialization Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

A2 User’s Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

B APPLICATION PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

B1 Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

B2 DC Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

B3 Speed Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

B4 Delay Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

B5 PID Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

B6 Reference Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

B8 Energy Saving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

B9 Zero Servo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

C TUNING PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

C1 Accel/Decel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

C2 S-Curve Accel/Decel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

C3 Motor Slip Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

C4 Torque Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

C5 ASR Tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

C6 Carrier Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

C7 Hunting Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

C8 Factory Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

D REFERENCE PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

D1 Preset References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

D2 Reference Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

D3 Jump Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

D4 Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

D5 Torque Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

E MOTOR PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

E1 V/f Pattern 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

E2 Motor 1 Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

E3 Motor 2 Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

E4 Motor 2 V/F Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

E5 Motor 2 Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

F OPTION PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

F1 PG Option Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

F2 AI-14 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

F3 DI-08, 16 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

F4 AO-08 Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

F5 DO-02 Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

F6 DO-08 Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

F7 PO-36F Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

F8 SI-F/G Option Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

F9 CP-916 Option Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

H CONTROL CIRCUIT TERMINAL PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

VS-616G5 Programming Manual 3

Page 4

Contents

Section Description Page

H1 Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

H2 Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

H3 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

H4 Analog Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

H5 Serial Communication Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

L PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

L1 Motor Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

L2 Power Loss Ridethrough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

L3 Current Limit/Stall Prevention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

L4 Reference Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

L5 Fault Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

L6 Torque Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

L7 Torque Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

L8 Hardware Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

O OPERATOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

O1 Monitor Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

O2 Key Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

AUTO-TUNING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Appendix VS-616G5 PARAMETER LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

4 VS-616G5 Programming Manual

Page 5

Introduction

Quick-Start Access Level Structure

Introduction

Thank you for purchasing Yaskawa’s VS-616G5 high performance vector inverter. The G5 employs

the latest hardware and software technology to provide unmatched performance, reliability and application flexibility.

The G5 flexible control mode architecture allows four choices of motor control technology for your

application:

· Open Loop Vector is best for most applications, as it offers Adaptive Vector Control technology

(AVC™) for precise speed regulation, quick response and high starting torque.

· Closed Loop Flux Vector is the choice for applications requiring torque control, very precise speed

regulation and full torque control at zero speed.

· V/f (Volts per Hertz) mode with Yaskawa’s proprietary full range auto-torque boost provides ideal

control for multi-motor applications.

· Closed Loop V/f allows encoder feedback for use with the Volts/hertz mode.

Use the following key to determine which control mode and access level are available for each parameter.

No. Parameter Name LCD Display

A1-00 Language Selection Select Language

Q: Quick-Start Level, selected parameters for maintenance-level programming

B: Basic Level, selected parameters for basic programming in most applications

A: Advanced Level, all parameters for advanced programming in special applications

The menu structure for all access levels are the same for the Operation, Initialize, Auto-tuning and

Modified constants sections. The Programming section menu structure for each access level is as follows:

MENU

Basic Access Level Structure

MENU

Programming

Programming

Function Level

Data Name Data Entry

Data Name Data Entry

V/f V/f w/PG

Q Q Q Q

Open Loop

Vector

Flux

Vector

VS-616G5 Programming Manual 5

Advanced Access Level Structure

MENU

Programming

Group Level Function Level Data Name Data Entry

Page 6

Introduction

Software Version Explanation

Yaskawa recognizes the need to continuously improve product quality. This product may receive feature enhancements in the form of software or hardware changes. New programming parameters will be

added to the latest programming manual. When a new parameter is added a software version note will

be placed next to the parameter.

Software Version Example:

A1-00 Language Selection Select Language

Select the language displayed on the digital operator according to the following table:

Setting Description

0 English (factory default)

1 Japanese

2 Deutsche <1110>

3 Francais <1110>

4 Italiano <1110>

5 Espanol <1110>

6 Portugues <1110>

This version note <1110> indicates that five additional languages have been added with software version 1110.

The part number of the main control printed circuit board on the drive reflects the software version.

The software version normally increases to a higher number with newer versions. Please consult the

factory for details.

PCB Part Number Example: ETC615991-S1110 Software version 1110

Q Q Q Q

The VS-616G5 ships preset to open loop vector control, quick-start access level. This publication

describes all Quick-Start, Basic and Advanced parameters. For installation and simplified Quick-Start

parameters, please refer to YEA-TOA-S616-10.12C.

6 VS-616G5 Programming Manual

Page 7

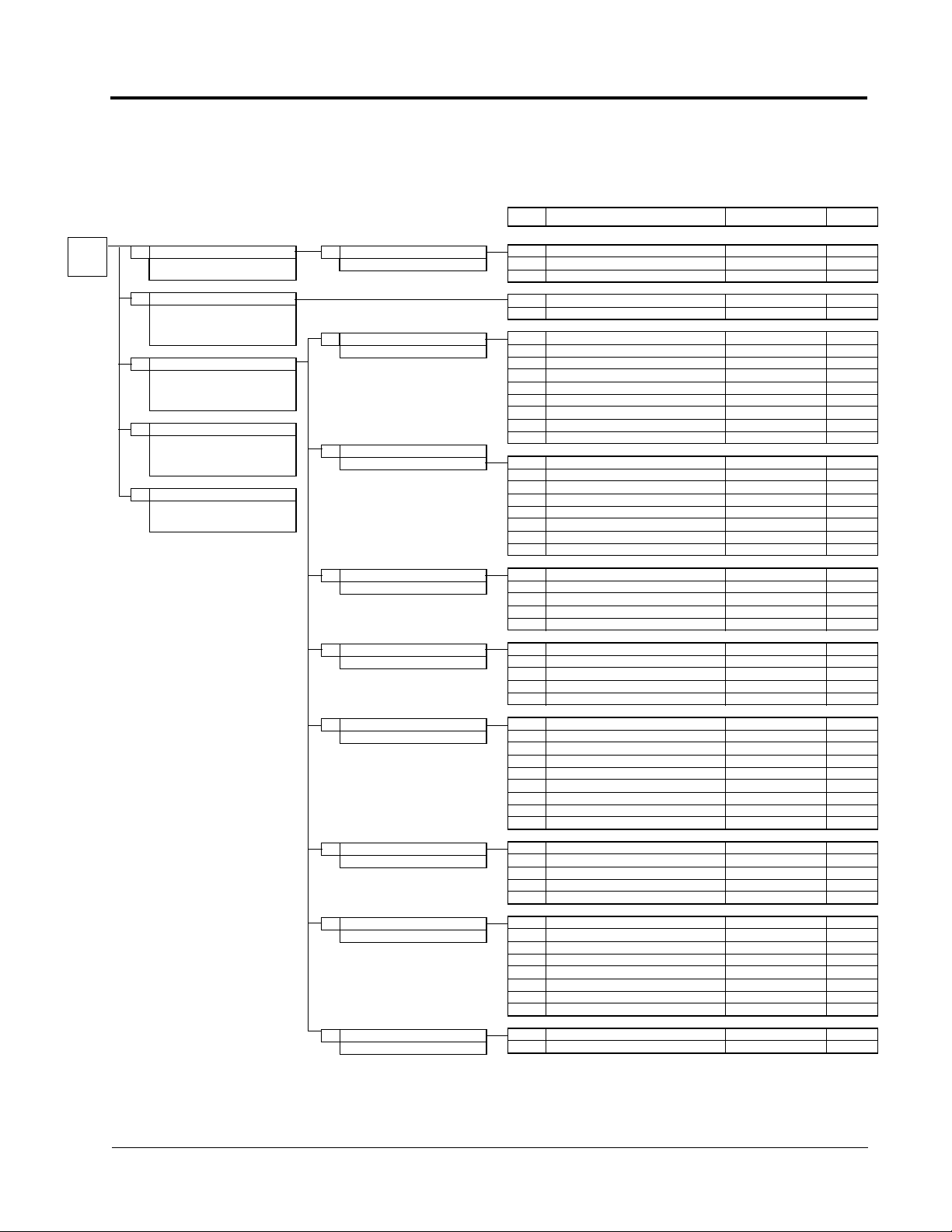

VS-616G5 Parameter Tree

VS-616G5 Parameter Tree

Group Function Display Access Level

Menu

Inverter operation is enabled.

Inverter status is displayed.

A Initialize

Language selection in LCD display.

Constant access levels, control method

selection and initializing passwords.

Parameters are set/read. Items to be set/

read vary depending on the access level

setting.

Motor parameters are automatically set

by inputting turning data (motor nameplate values) when performing vector.

Only parameters that have been changed

from the factory setting are set/read.

Operation

Programming

Auto-tuning

Modified Constants

U Monitoring Items

B Application

C Tuning

D Reference

E Motor Parameters

F Option

H Control Circuit Terminals

L Protection

O Digital Operator

Monitor

Application

Tuning

Reference

Motor

Option

Terminal

Protection

Operator

U1 Status monitoring Monitor Q, B, A

U2 Fault trace Fault Trace Q

U3 Fault history Fault History Q

A1 Initialization Initialize Q

A2 User setting parameter User Parameters A

B1 Operation method selection Sequence Q, B, A

B2 DC injection braking DC Braking B

B3 Speed search Speed Search A

B4 Timer function Delay Timers A

B5 PID control PID Control A

B6 DWELL function Reference Hold A

B7 Droop control Droop control A

B8 Energy-saving control Energy Saving A

B9 Zero Servo Zero Servo A

C1 Accel/decel time Accel/Decel Q, B, A

C2 S-curve characteristics S-curve Acc/Dec A

C3 Motor slip compensation Motor-slip Comp B. A

C4 Torque compensation Torque Comp B, A

C5 ASR ASR Tuning B, A

C6 Carrier frequency Carrier Freq BA

C7 Hunting prevention Hunting Prev A

C8 Factory-tuning constant Factory Tuning A

D1 Frequency reference value Preset Reference Q, A

D2 Upper/lower limits Reference Limits B

D3 Jump frequency Jump Frequencies B

D4 Sequence Sequence A

D5 Torque reference Torque Control A

E1 V/f pattern V/F Pattern Q

E2 Motor parameters Motor Setup Q, A

E3 Motor 2 control method Motor 2 Ctl Meth A

E4 V/f pattern/2 V/f Pattern 2 A

E5 Motor 2 constants Motor 2 Setup A

F1 PG speed control card PG Option setup Q, B, A

F2 Analog reference card A1-14 Setup B

F3 Digital input card DI-08, 16 Setup B

F4 Analog monitor card AO-08, 16 Setup B

F5 Digital output card DO-02 Setup B

F6 Digital output card DO-08 Setup B

F7 Pulse monitor card PO-36F Setup B

F8 SI-F/G card SI-F/G B

F9 DDS-B/SI-B card DDSS/SI-B B

H1 Sequence input Digital Inputs B

H2 Sequence output Digital Outputs B

H3 Analog input Analog Inputs B, A

H4 Analog output Analog Outputs B

H5 MODBUS communication (RS-485) Serial Com Setup A

L1 Motor electric thermal overload relay Motor Overload B

L2 Momentary power loss ride-through PwrLoss Ridethru B, A

L3 Stall prevention Stall Prevention B, A, F

L4 Frequency Detection Ref Detection B, A

L5 Fault retry Fault Restart B

L6 Overtorque detection Torque Detection B, A

L7 Torque limit Torque Limit B

L8 Hardware protection Hdwe Protection B, A

O1 Display selection Monitor Select B, A

O2 Key selection Key Selections B, A

VS-616G5 Programming Manual 7

Page 8

This page intentionally left blank.

8 VS-616G5 Programming Manual

Page 9

Main Menu: Initialize <ENTER>

A Initialization Parameters

A1 Initialization Set-up

Section A: Initialization Parameters

A1 Initialization Set-up

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

A1-00 Language Selection Select Language

Select the language displayed on the digital operator according to the following table:

Setting Description

0 English (factory default)

1 Japanese

2 Deutsch <1110>

3 Francais <1110>

4 Italiano <1110>

5 Espanol <1110>

6 Portugues <1110>

A1-01 Parameter Access Level Access Level

This parameter allows the “masking” of parameters according to user level. See the following table:

Setting Description

0 Operation Only

1 User Program - Accesses parameters selected by OEM (A2-01 to A2-32).

2 Quick Start Level (factory default) - For maintenance-level programming.

3 Basic Level - For basic programming in most applications.

4 Advanced Level - For advanced programming in special applications.

Q Q Q Q

Q Q Q Q

A1-02 Control Method Selection Control Method

Q Q Q Q

Select the control method best suited for your application.

Setting Description

0 V/f Control - For general-purpose and multiple motor applications.

1 V/f with PG Feedback - For general-purpose applications requiring closed

loop speed control.

2 Open Loop Vector (factory default) - For applications requiring precise

speed control, quick response and higher torque at low speeds (150%

torque below 1Hz).

3 Flux Vector - For applications requiring very precise speed and torque con-

trol at a wide speed range including 0 speed. Uses encoder feedback.

VS-616G5 Programming Manual 9

Page 10

Section A: Initialization Parameters

A1 Initialization Set-up

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

A1-03 Operator Status Init Parameters

Use this parameter to reset the inverter to its factory default settings. Initialize the inverter after changing the control PCB, or after selecting language (A1-00), control method (A1-02), or inverter capacity

(O2-04).

Setting Description

0 No Initialization (factory default)

1110 User Initialization - resets the inverter to user-specified initial

values. To set user-specified initial values, make all required

changes to parameter settings, then set O2-03 to “1”. The

inverter will memorize all current settings as the user-specified

initial values. Up to 50 changed parameters can be stored.

2220 2-Wire Initialization - terminal 1 becomes FWD run command

and terminal 2 becomes REV run command. All other parameters are reset to their original factory default settings.

3330 3-Wire Initialization - terminal 1 becomes run command, termi-

nal 2 becomes stop command and terminal 3 becomes FWD/

REV run selection. All other parameters are reset to their original factory default settings.

Q Q Q Q

A1-04 Password Entry Enter Password

Q Q Q Q

Parameter A1-04 is used to enter a password into the inverter, to be able to make adjustments to locked param-

eters.

Password protection is provided for:

A1-01 Access Level

A1-02 Control Method

A1-03 Initialization

A2-01 to A2-32 User Parameters (If selected)

10 VS-616G5 Programming Manual

Page 11

A2 User’s Parameters

The user can select up to 32 parameters for quick-access programming. By setting the user access level

(A1-01) to “User Program”, only the parameters selected in function A2 can be accessed by the user.

Parameter A1-01 must be set to 4 (advanced access level) to input parameter numbers into A2-01

through A2-32, and then A1-01 must be set to 1 (User Level) for only the user selected parameters to

be viewed.

Main Menu: Programming <ENTER>

B Application Parameters

B1 Sequence

Section B: Application Parameters

A2 User Parameters and B1 Sequence

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B1-01 Frequency Reference Selection Reference Source

B1-02 Operation Method Selection Run Source

Frequency reference and run command can be set independently as shown below:

Setting Description

0 Command from digital operator

1 Command from control circuit terminal (factory default)

2 Command from serial communication

3 Command from option card

4 EWS (Reference from CP-717)* <1110>

This setting will be used with the CP-717 to run and change

the reference through DP-RAM.

* Setting parameter B1-01 or B1-02 to 4 allows reference and/or run source from CP-717 when

either CP-916 or CP-216 option cards are installed.

By depressing the LOCAL/REMOTE key on the digital operator, the operation mode can be

selected as shown below:

Local: Operation according to frequency reference and run command from digital operator.

Remote: Operation according to frequency reference and run command set by B1-01 and B1-

02.

Q Q Q Q

Q Q Q Q

The digital operator is reset to remote operation when power is cycled.

VS-616G5 Programming Manual 11

Page 12

Section B: Application Parameters

B1 Sequence

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B1-03 Stopping Method Selection Stopping Method

This function selects the stopping method suitable for the particular application.

Setting Description

0 Ramp to stop (factory default)

1 Coast to stop

2 DC injection to stop

3 Coast to stop with timer

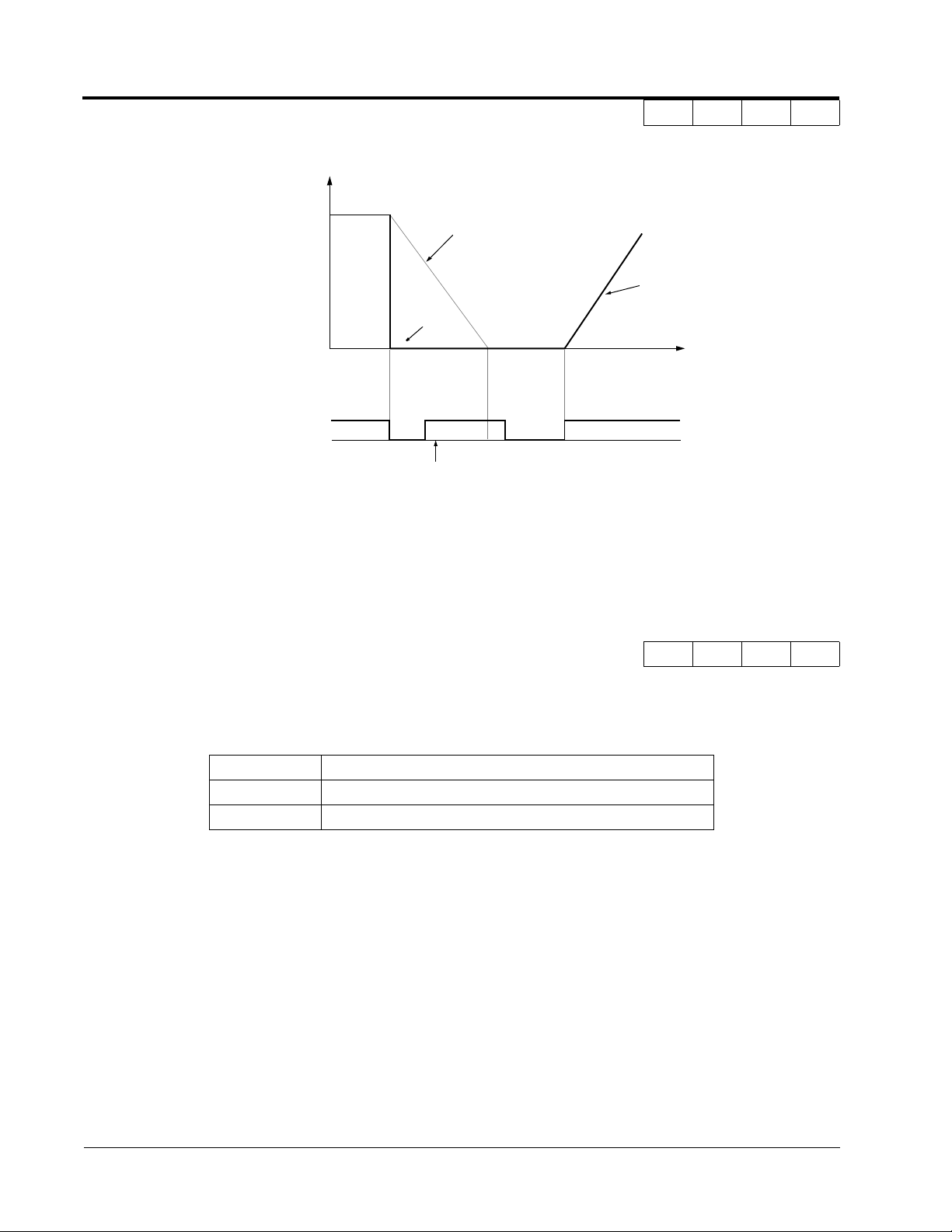

· Ramp to Stop (B1-03 = “0”)

Output Frequency

Decel time 1 (C1-02)

Zero Speed Level (Frequency at

DC Injection Braking Start - B2-01)

Factory Default: 0.5Hz

DC injection Braking Time

at Stop (B2-04)

Factory Default: 0.5 s

Run Command

ON

OFF

Q Q Q Q

Figure 1 Stopping Method - Ramp to Stop

Upon removal of the FWD (REV) run command, the motor decelerates at a rate determined by the

time set in deceleration time 1 (C1-02) and DC injection braking is applied after the minimum output

frequency (E1-09) has been reached. If the deceleration time is set too short or the load inertia is large,

an overvoltage fault (OV) may occur during deceleration. In this case, increase the deceleration time or

install an optional braking transistor and/or braking resistor (braking transistors are provided as standard for units 230V 7.5kW and smaller, 460V 15kW and smaller).

Braking torque: without braking resistor, approx. 20% of motor rated torque

with braking option, approx. 150% of motor rated torque

12 VS-616G5 Programming Manual

Page 13

· Coast to Stop (B1-03 = “1”)

Section B: Application Parameters

B1 Sequence

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

Output frequency

Run command

ON

Inverter output is shut OFF

when stop command is given.

OFF

Figure 2 Stopping Method - Coast to Stop

Upon removal of the FWD (REV) run command, the motor starts to coast. After a stop command is

given, a run command is accepted and operation will start after the minimum baseblock time (L2-03)

elapses. If there is a possibility that a run command might be entered before the motor has come to a

stop, the speed search function (B3) or Coast to Stop with Timer 1 (B1-03 = “3”) should be employed.

· DC Injection Braking to Stop (B1-03 = “2”)

Output Frequency

Inverter Output OFF during

Minimum Baseblock Time (L2-03)

Factory Default: 0.5s

Run Command

ON

DC injection Braking Time

at Stop (B2-04)

Factory Default: 0.0s

OFF

DC injection

Braking Time

DC injection Braking Time

at Stop (B2-04)

B2-04 x 10

Figure 3 Stopping Method - DC Injection Braking to Stop

Upon removal of the FWD (REV) run command, the motor brakes to stop, according to the DC injection braking time at stop set in B2-04. If this value is set to “0” (factory default), DC injection braking

is disabled, and the motor coasts to stop. When choosing this function, note that the actual stop time is

the time set in B2-04 multiplied by 10 (see Figure 3 above). This stopping method is disabled during

flux vector control. Braking duty cycle should allow excess motor heat to dissipate.

VS-616G5 Programming Manual 13

Page 14

Section B: Application Parameters

B1 Sequence

· Coast to Stop with Timer 1 (B1-03 = “3 ”)

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

Output Frequency

Coasting

FWD (REV)

Run Command

Run Command Disabled

Decel Time 1

(C1-02)

Figure 4 Stopping Method - Coast to Stop w/ Timer

After a stop command is given, a run command is not accepted while the coast to stop timer elapses

(same as Decel 1). After the timer runs out, another run command must be given for the inverter to

begin acceleration. This stopping method is disabled during flux vector control.

B1-04 Prohibition of Reverse Operation Reverse Oper

Accel Time 1

(C1-01)

Time

ONONON

B B B B

A “reverse run disabled” setting does not allow a reverse run command from the control circuit terminal or the digital operator. This setting is used in applications where a reverse run command is undesirable.

Setting Description

0 Reverse run enabled (factory default)

1 Reverse run disabled

14 VS-616G5 Programming Manual

Page 15

Section B: Application Parameters

B1 Sequence

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B1-05 Operation Selection at Zero Speed Zero Speed Oper

During flux vector control, select an operation mode to be employed when the frequency reference (analog input) drops below the minimum output frequency (El -09). During V/f or open loop vector control,

baseblock is applied when the output frequency drops below the minimum output frequency (El -09).

Setting Description

0 E1 -09 disabled, run according to frequency reference (factory default)

1 Baseblock

2 Run at minimum output frequency (E1-09)

3 Zero-speed operation (internal speed reference is set to “0”)

B1-06 Input Scan Time Cntl Input Scans

This parameter selects the microprocessor scan time for reading sequence input data from the control

circuit terminals.

Setting Description

0 2ms scan time for 2 scans

1 5ms scan time for 2 scans (factory default)

- - - A

B B B B

Set to “0” when a quicker response is needed from the control circuit terminals.

B1-07 Operation Selection After Switch to Remote Mode LOC/REM RUN Sel

Parameter b1-07 determines how the inverter will function when switching between local and remote

operation. This function prevents the motor from running when switching between local/remote and

the inverter is controlled from the digital operator.

Setting Description

0 (Cycle Extrn RUN) - If the run command is closed when switching from local control to remote control,

the inverter will not run. The run command must be cycled for the inverter to run. (factory default)

1 (Accept Extrn RUN) - If the run command is closed, when switching from local control to remote con-

trol, the inverter will run.

A A A A

VS-616G5 Programming Manual 15

Page 16

Section B: Application Parameters

B2 DC Braking

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B1-08 Run Command Acceptance During Programming RUN CMD at PRG

As a safety precaution the drive will not respond to a change in the run command when the digital

operator is being used to set or adjust parameters.This parameter will allow the drive to accept or

reject a change in the run command when the digital operator is being used to change or adjust parameters. <1110>

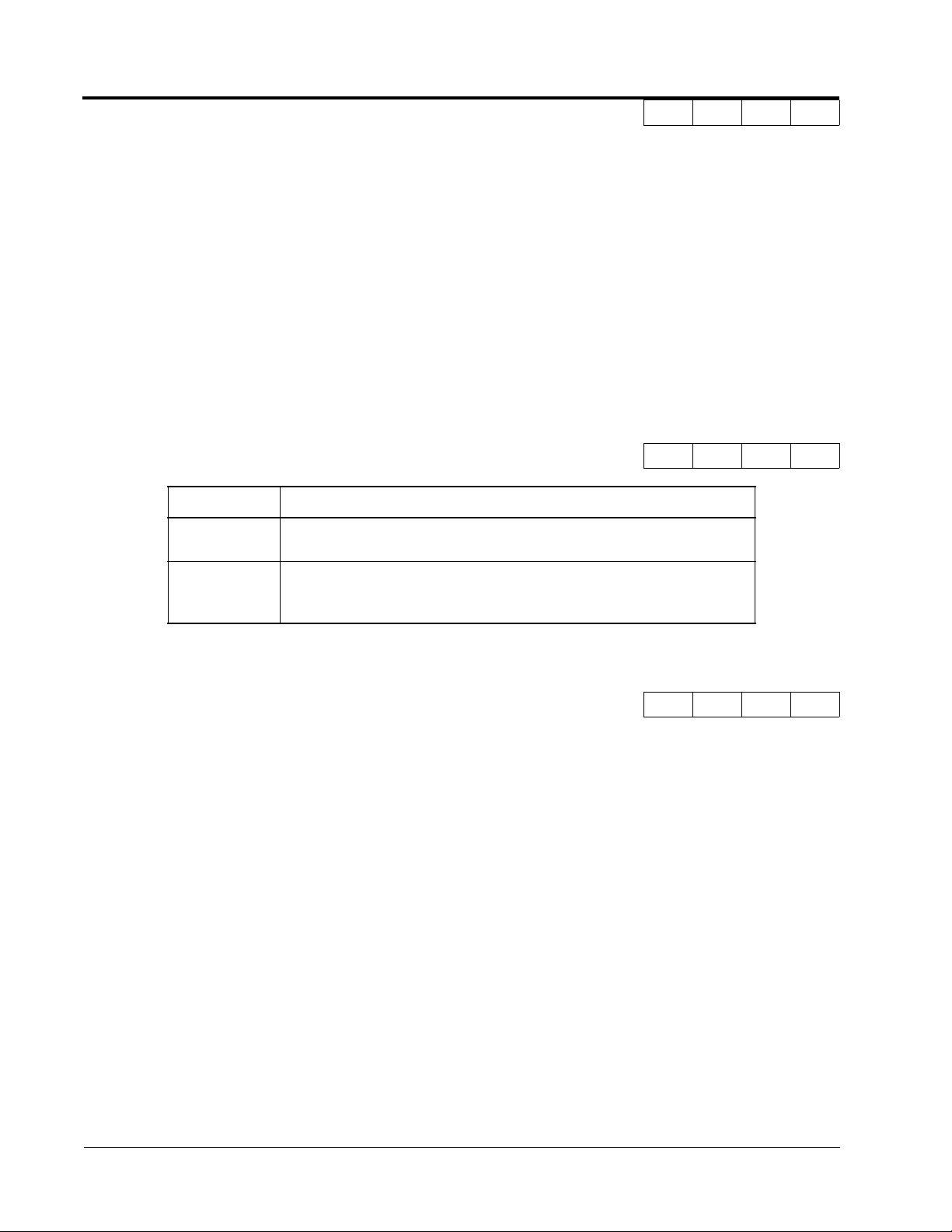

Table 1:

Setting Description

0 Run command is disabled when drive is in the programming mode. (factory default)

1 Run command is enabled when the drive is in the program mode

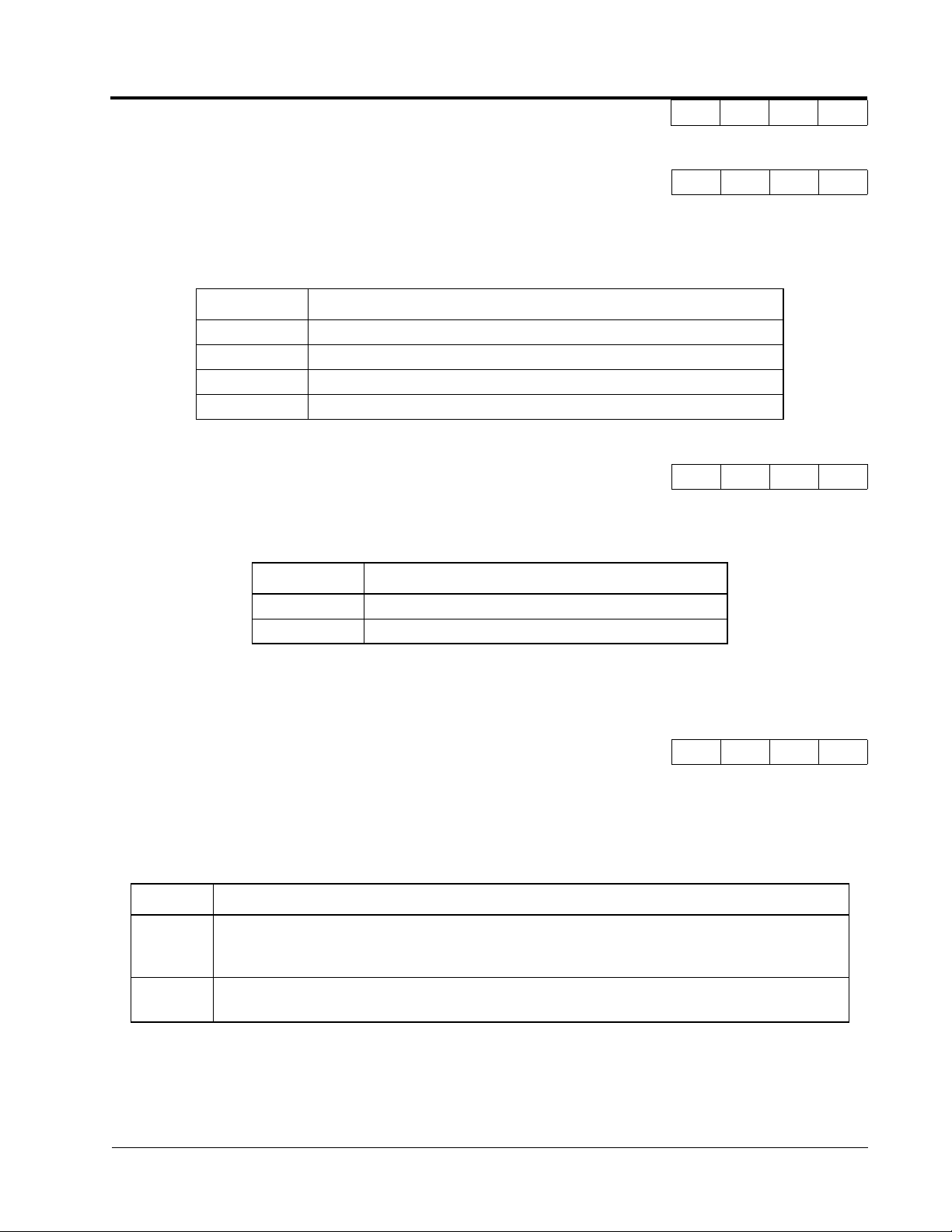

B2 DC Braking

B2-01 DC Braking Frequency (Zero Speed Level) DCInj Start Freq

Setting Range: 0.0 to 10.0Hz

Factory Default: 0.5Hz

Sets the frequency at which DC injection braking (or initial excitation for flux vector control) starts, in

units of 0.1 Hz. When B2-01 < E1-09, DC injection braking starts from the minimum frequency reference (E1-09).

A A A A

B B B B

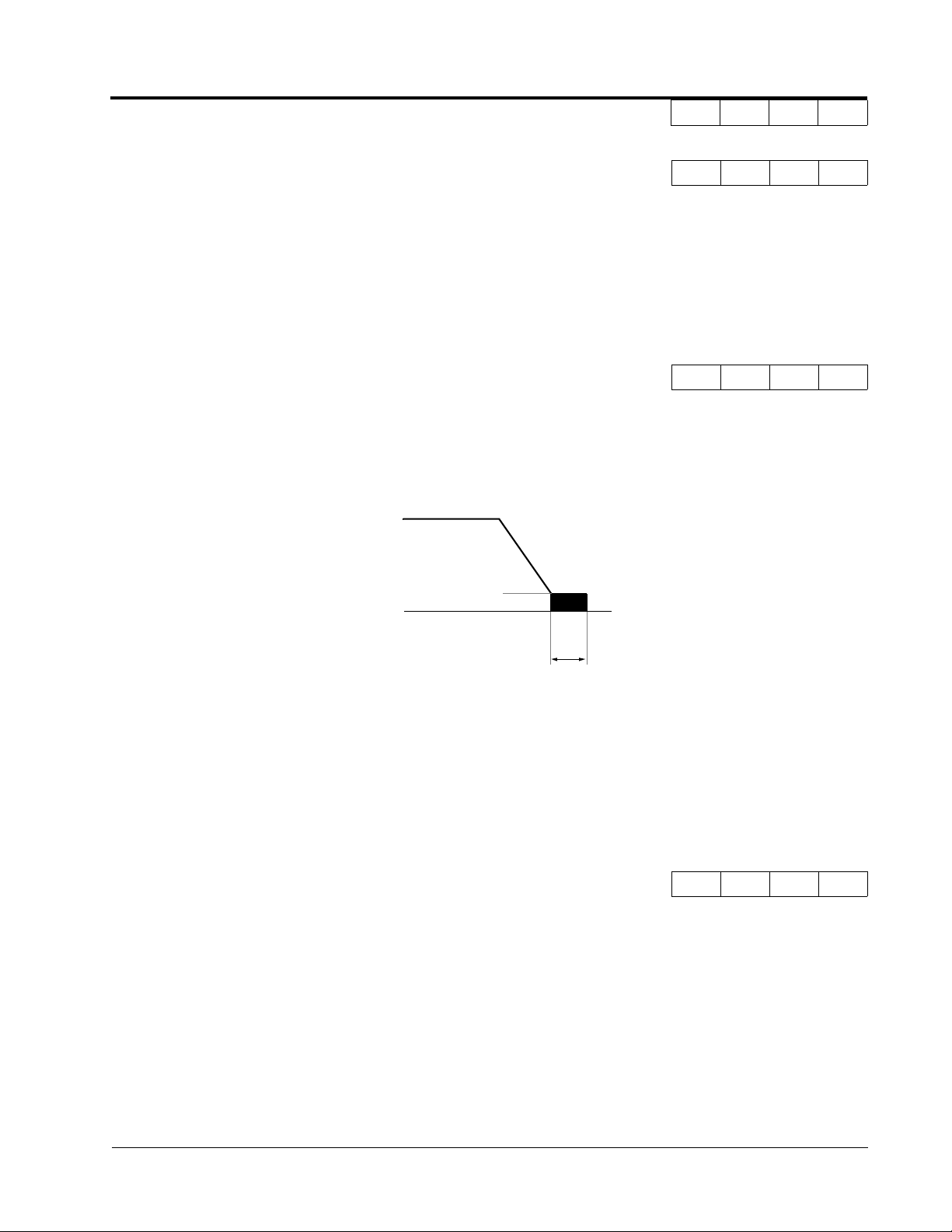

B2-01

DC Injection

Braking Frequency

B2-03

DC Injection Braking

Time at Start

Figure 5 DC Injection Braking at Starting

B2-02 DC Braking Current DCInj Current

Setting Range: 0 to 100%

Factory Default: 50%

DC injection braking current is set as a percentage of inverter rated current. In flux vector control

mode, initial excitation is performed according to the motor no-load current set in E2-03. This param-

eter should not be set unnecessarily high or motor overexcitation may occur.

B B B -

16 VS-616G5 Programming Manual

Page 17

Section B: Application Parameters

B2 DC Braking

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B2-03 DC Braking Time at Start DCInj Time@Start

Setting Range: 0.00 to 10.00s

Factory Default: 0.00s

DC injection braking at start can be used to stop a spinning motor (or when motor rotation direction is

unknown) prior to running. DC injection braking time at start (or initial excitation for flux vector control) is set in units of 0.1 second. When B2-03 is set to “0”, DC injection braking is disabled and acceleration starts from the minimum output frequency.

B2-04 DC Braking Time at Stop DCInj Time@Stop

Setting Range: 0.00 to 10.00s

Factory Default: 0.00s

DC injection braking time at stop (or initial excitation for flux vector control) is set in units of 0.1 second. When B2-04 is set to “0”, DC injection braking is disabled, and the inverter output shuts OFF.

E1-09

Min. Output Frequency

B B B B

B B B B

B2-04

DC injection Braking

Time at Stop

Figure 6 DC Injection Braking Time at Stop

When coast to stop is selected as the stopping method (B1-03), DC injection braking at stop is disabled.

B2-08 Magnetic Flux Compensation Level <1110> FieldComp

Setting Range: 0 to 500%

Factory Default: 0%

This parameter allows the magnetizing motor flux to be boosted when starting the motor. This parameter

will facilitate a quick ramp-up of the torque reference and magnetizing current reference to reduce motor

slip during start. A setting of 100% equals motor no-load current E1-09. This flux level will be applied

below Minimum Output Frequency (E1-09) until the DC Injection Time at Start (B2-03) expires. This

parameter is useful when starting motors that are relatively larger than the inverter, due to the requirement

for increased magnetizing current. This parameter may also compensate for reduced starting torque due to

motor circuit inefficiencies.

- - A A

VS-616G5 Programming Manual 17

Page 18

Section B: Application Parameters

B3 Speed Search

B3 Speed Search

When starting into a coasting motor, use the speed search command or DC injection braking at start, to

prevent a drive trip and motor burnout.

This function allows the restart into a coasting motor without the necessity to stop. It is useful during

inverter bypass operation, when switching between the motor receiving power directly from the line

and from the inverter. Two interlocking contactors must be employed for commercial power switchover to prevent line power from being applied to the inverter output terminals.

Set the multi-function contact input selection (H1-01 to H1-06) to “61” (start search command from

maximum output frequency), “62” (start search command from the set frequency), or “64” (start

search command from the SFS frequency when baseblock is applied).

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B3-01 Speed Search after Run Command SpdSrch at Start

A - A -

Setting Description

0 Speed search disabled, the motor accelerates to the set frequency from the

min. frequency reference after run command is given (factory default).

1 Speed search enabled after run command is given, according to multi-func-

tion contact input selection. When using an encoder, the motor accelerates/

decelerates to the set frequency from the motor speed.

Note: This parameter is disabled except when (A1-02=1) (V/F w/PG Fdbk) or 3 (Flux Vector)

B3-02 Speed Search Detection Current Level SpdSrch Current

Setting Range: 0 to 200%

Factory Default: 150%

After power loss and recovery, speed search begins to ramp the frequency down from a specified point in

order to locate the frequency of the spinning motor. During initial speed search the inverter’s output current exceeds the speed search detection current level. This level is set as a percentage of inverter rated

current. When the inverter’s output current is less than the speed search detection level, the frequency is

interpreted as the speed agree level, and the inverter accelerates/decelerates to the specified frequency.

A - A -

Note: Factory setting defaults to 150 when A1-02=0 (V/F Control). When A1-02=2 (Open Loop Vec-

tor), the default is 100.

18 VS-616G5 Programming Manual

Page 19

Section B: Application Parameters

B4 Delay Timers

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B3-03 Speed Search Deceleration Time SpdSrch Dec Time

Setting Range: 0.1 to 10.0s

Factory Default: 2.0s

Sets deceleration time during speed search in units of 0.1 second. When speed search deceleration time

is set to 0.0 second, speed search is disabled. The speed search deceleration time should be set to be

somewhat faster than the decel rate of coasting motor. Build an input sequence so that the speed search

command is input at the same time or prior to the FWD (REV) run command. If the run command is

input before the search command, the search command is not effective. Below is a timing diagram of

the search command input:

FWD (REV) Run Command

Speed Search Command

Max. Output Frequency,

Frequency Reference at

Run Command Input,

or SFS Output Frequency

Output Frequency

Motor Speed

ON

Min. Baseblock

Time (L2-03)

Speed Search

Decel Time (B3-03)

Speed Search

Operation

Coasting Accelerating

ON

A - A -

B3-02

Figure 7 Search Command Input Timing Diagram

B4 Delay Timers

The inverter input and output contacts can be used in place of an external timer. When multi-function

contact input (H1-__ = “18”) is closed, a multi-function contact output (H2-__ = “12”) can be set to

close after the On-delay time (B4-01) has expired. When multi-function contact input (H1-__ = “18”)

is opened, a multi-function contact output (H2-__ = “12”) can be set to open after the Off-delay time

(B4-01) has expired. This function operates independently of any action the inverter is performing.

B4-01 On-delay Timer Delay-ON Timer

Setting Range: 0.0 to 100.0s

Factory Default: 0.0s

Sets the ON-delay time in units of 0.1 second. The multi-function input must be “closed” for longer

than the ON-delay timer for the multi-function output to close.

Speed Agree Detected

Output Current

A A A A

VS-616G5 Programming Manual 19

Page 20

Section B: Application Parameters

B5 PID Control

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B4-02 Off-delay Timer Delay-OFF Timer

Setting Range: 0.0 to 100.0s

Factory Default: 0.0s

Sets the OFF-delay time in units of 0.1 second. The multi-function input must be “open” for longer

than the OFF-delay timer for the multi-function output to open.

Multi-function Contact

Input: Timer Function

Multi-function Contact

Output: Timer Function

B4-01

ON

ON

B4-02

ON ON ON

B4-01 B4-02

Figure 8 Timing Diagram of Timer Function

B5 PID Control

The Proportional, Integral and Derivative (PID) control function provides closed-loop control and regulation of a system variable such as temperature or pressure. A control signal based on the difference

(or proportion) between a feedback signal and a desired setpoint is produced. Integration and derivative calculations are then performed on this signal, based upon the PID parameter settings (B5-01 to

B5-08), to minimize deviation, for more precise control.

A A A A

ON

ON ON ON

ON

Proportional - P

PID refers to the type of action used to control modulating equipment such as valves or dampers. With

proportional control, a control signal based on the difference between an actual condition and a

desired condition is produced. The difference, such as that between an actual temperature and setpoint

is the “error”. The inverter adjusts its output signal related directly to the error magnitude.

Integral - I

The integral action is designed to minimize offset. An integrating term is used to observe how long the

error condition has existed, summing the error over time. Once the system has stabilized, the offset

would be minimized.

Derivative - D

Overshoot refers to a control loop tendency to overcompensate for an error condition, causing a new

error in the opposite direction. Derivative action provides an anticipatory function that exerts a “braking” action on the control loop. When combined, the proportional integral, and derivative actions provide quick response to error, close adherence to the setpoint, and control stability.

20 VS-616G5 Programming Manual

Page 21

Section B: Application Parameters

Figure 9 PID Block Diagram

VS-616G5 Programming Manual 21

Figure 9 PID Block Diagram

Page 22

Section B: Application Parameters

B5 PID Control

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B5-01 PID Control Mode Selection PID Mode

To enable PID control, set PID control mode selection to “1” or “4”, according to the description

below. Also be sure to set terminal 16 function selection (H3-05) to PID feedback (setting: “B”).

Setting Description

0 PID disabled (factory default)

1 PID enabled (deviation signal is put through derivative control)

2 PID with feed forward (feedback signal is put through derivative control)

3 <1110> Reference= Frequency reference + PID output, D is Fdbk

4 <1110> Reference= Frequency reference + PID output, D is feed-forward

Notes:

1. PID with feed forward applies control much quicker than normal PID, without waiting for

the deviation signal to build up.

2. A PID inverse feedback signal can be selected by inverting the settings for terminal 16

gain and bias.

Then select the PID control intended value setpoint or detected feedback value setpoint as follows:

Intended Value Setting

The control circuit terminal 16 voltage signal (0 to 10V, -10 to 10V) or multi-step speed parameters H103 to H1-06 can be used to set the PID intended value.

A A A A

Control circuit terminal 16 voltage signal:

Set reference selection (B1-01) to “1”.

Multi-step speed parameters (H1-03 to H1-06):

Set reference selection (B1-01) to “0”.

(combination of multi-step speed references and jog frequency reference)

Detected Value Setting (Feedback)

The control circuit terminal 14 current signal (4 to 20mA) or voltage signals (0 to 10V, -10 to 10V) can

be used to set the PID detected value.

Control circuit terminal 14 current signal:

Set terminal 14 signal selection (H3-08) to “2”.

Control circuit terminal 14 voltage signal:

Set terminal 14 signal selection (H3-08) to “0”or “1”.

22 VS-616G5 Programming Manual

Page 23

Notes:

1. I value is reset to ”0” when operation stops.

2. The upper limit of the I value can be set by parameter B5-04.

Increase the value of parameter B5-04 to upgrade control capability by integration. If the control

system vibrates and it cannot be stopped by adjusting the integral time, output delay time, etc.,

decrease the set value of parameter B5-04.

3. PID control can be canceled by a multi-function contact input signal.

By setting any of parameters H1-01 to H1-06 to “19” and by closing the contact during running,

PID control is disabled and the intended value signal itself is used as a frequency reference signal.

Section B: Application Parameters

B5 PID Control

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B5-02 PID Control Proportional Gain PID Gain

Setting Range: 0.00 to 25.00

Factory Default: 1.00

The proportional gain is the value by which the deviation signal is multiplied to generate a new frequency reference.

B5-03 PID Control Integral Time PID I Time

Setting Range: 0.00 to 360.0 seconds

Factory Default: 1.00 seconds

The integral calculation sums the deviation over time, which eliminates the offset, thus achieving the

intended value. The integral time determines how quickly the integral gain increase is added to the

control loop.

B5-04 PID Control Integral Limit PID I Limit

Setting Range: 0.0 to 100.0%

Factory Default: 100.0%

The integral limit value eliminates oscillations and improves stability. This value is set as a percentage

of maximum output frequency (E1-04).

A A A A

A A A A

A A A A

B5-05 PID Control Derivative Time PID D Time

A A A A

Setting Range: 0.00 to 10.00 seconds

Factory Default: 0.00 seconds

The derivative calculation attempts to control the remaining overshoot left over after the proportion

and integral calculations. If the system is approaching the intended value very rapidly, the derivative

control produces a strong braking action to prevent overshoot. If the system is already stable with very

little deviation change, derivative control has very little effect. The derivative time is used to dampen

oscillations and reduce overshoot, thus improving stability. Setting the derivative time to a larger number produces more braking action in the control system.

VS-616G5 Programming Manual 23

Page 24

Section B: Application Parameters

B5 PID Control

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B5-06 PID Control Limit PID Limit

Setting Range: 0.0 to 100.0%

Factory Default: 100.0%

The PID limit value further eliminates oscillations and improves stability. This value is set as a percentage of maximum output frequency (E1-04).

B5-07 PID Control Offset PID Offset

Setting Range: -100.0% to +100.0%

Factory Default: 0.0%

The PID offset adds a bias to the calculated PID value, in order to reduce any offset.

B5-08 PID Control Output Primary Delay Time PID Delay Time

Setting Range: 0.00 to 100.0 seconds

Factory Default: 0.00 seconds

The output delay time is used to delay changes in the calculated PID value, which can prevent oscillations and improve stability.

A A A A

A A A A

A A A A

Parameters B5-04 and B5-06 to B5-08 are preset at the factory to optimum values for most applications, hence, do not need to be changed. When tuning a system, first adjust the proportional gain until

oscillations are reduced. Then adjust the integral time so that minimal deviation is achieved as quickly

as possible, without oscillations. Finally, adjust the derivative time to reduce any overshoot at start-up.

B5-09 PID Output Selection <1110> Output Level Sel

The PID output term for the inverter control can be either negative or positive output.

Setting Description

0 PID Normal or Forward Output (factory default)

Increase in the manipulated variable when the process variable is larger than

the setpoint and decrease the manipulated variable when the process variable is smaller.

1 PID Reverse or Inverse Output

Increase the manipulated variable when the process variable is smaller than

the setpoint and decrease the manipulated variable when the process variable is larger than the setpoint.

A A A A

24 VS-616G5 Programming Manual

Page 25

Section B: Application Parameters

B5 PID Control

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B5-10 PID Output Gain <1110> Output Gain

Setting Range: 0.0 to 25.0

Factory Default: 1.0

This parameter sets the gain of the PID output. The PID output can be monitored by parameter U1-37

PID Output Monitor. Refer to PID Block Diagram Figure 9.

B5-11 PID Output Reverse <1110> Output Rev Sel

This parameter is used when the motor is required to change direction during PID operation in

response to a negative PID output signal. The PID output can be monitored using parameter U1-37

PID Output Monitor.

Setting Description

0 Zero limit (factory default)

When PID output is negative, motor direction is not changed. The PID output

is limited to 0.

1 Reverse

When PID output is negative the motor will reverse direction.

A A A A

A A A A

Note: When Reverse Prohibit B1-04 is selected, reverse will not operate.

B5-12 Loss of Feedback Action <1110> Fb Los Det Sel

This parameter is used to select what action the inverter will take on a loss of PID feedback. A loss of

PID feedback occurs when the feedback signal falls below the B5-13 Feedback Loss Detection Level

for the time set by B5-14 Feedback Loss Detection Time.

Setting Description

0 Disabled (factory default)

PID feedback missing detection is disabled.

1 Alarm

PID feedback missing detection is enabled. Operation continues after loss of

feedback. The text “Fbl” will be displayed on the digital operator.

2 Fault

PID feedback missing detection is enabled. The inverter output to the motor

is shut off (the motor is stopped) and “Fbl” is displayed on the digital operator.

A A A A

VS-616G5 Programming Manual 25

Page 26

Section B: Application Parameters

B6 Reference Hold

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B5-13 PID Feedback Loss Detection Level <1110> Fb los Det Lvl

Setting Range: 0 to 100%

Factory Default: 1%

This parameter sets the level at which a loss of PID feedback is detected. The PID feedback must be at

or below this level for the time defined by B5-14 before a loss of feedback can be detected. A setting

of 100% represents 100% of the feedback signal.

B5-14 PID Output Gain <1110> Output Gain

Setting Range: 0.0 to 25.0

Factory Default: 1.0

This parameter sets the gain of the PID output. The PID output can be monitored by parameter U1-37

PID Output Monitor. Refer to PID Block Diagram Figure 9.

B6 Reference Hold

The reference hold or dwell function is used to temporarily hold the output frequency at a set reference, for a set time, and then start it again. This function can be used when driving a permanent magnet

motor, or a motor with a heavy starting load. This pause in acceleration allows the magnets in a permanent magnet motor to synchronize with the stator field of the motor, thus reducing traditionally high

starting current.

A A A A

A A A A

B6-01 Dwell Frequency Reference at Start Dwell Ref @Start

Setting Range: 0.0 to 400.0Hz

Factory Default: 0.0Hz

Sets the dwell frequency reference during acceleration in units of 0.1Hz.

B6-02 Dwell Time at Start Dwell Time@Start

Setting Range: 0.0 to 10.0s

Factory Default: 0.0s

Sets the amount of time that the frequency reference “dwells” during acceleration in units of 0.1s.

B6-03 Dwell Frequency Reference at Stop Dwell Ref @Stop

Setting Range: 0.0 to 400.0Hz

Factory Default: 0.0Hz

Sets the dwell frequency reference during deceleration in units of 0.1Hz.

A A A A

A A A A

A A A A

26 VS-616G5 Programming Manual

Page 27

Section B: Application Parameters

B7 Droop Control and B8 Energy Saving

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B6-04 Dwell Time at Stop Dwell Time @Stop

Setting Range: 0.0 to 10.0s

Factory Default: 0.0s

Sets the amount of time that the frequency reference “dwells” during deceleration in units of 0.1s.

B7 Droop Control

The Drooping function reduces the motor speed based on the load torque of the motor.

B7-01 Droop Control Gain Droop Quantity

Setting Range: 0.0 to 100.0

Factory Default: 0.0

Parameter b7-01 sets the amount of motor speed reduction when the motor is producing 100% of rated

torque. The actual amount of motor speed reduction is based on the ratio of the amount of motor

torque and the maximum output frequency (E1-04).

B7-02 Droop Control Delay Time Droop Delay Time

Setting Range: 0.03 to 2.00

Factory Default: 0.05

A A A A

- - - A

- - - A

Parameter b7-02 sets the response time for the drooping function. Decreasing the droop delay time,

will cause the response to become quicker; however, instability may occur.

B8 Energy Saving

This feature can save energy during operation under lightly loaded conditions, by decreasing output

voltage, energy-saving operation is made available. Energy saving control is enabled by a multi-func-

tion contact input, when control mode selection (A1-02) is set to “0” (V/f Control) or “1” (V/f w/PG

Fdbk).

Parameters B8-03, B8-04 and B8-05 are for energy savings in the vector modes. B8-01 and B8-02 are

only functional in the V/f modes via a multi-function input command. Parameters B8-03, B8-04 and

B8-05 are for automatic energy savings in the vector modes.

B8-01 Energy Saving Gain Energy Save Gain

Setting Range: 0 to 100%

Factory Default: 80%

The output voltage during energy-saving operation is the product of the normal V/f settings (El-03 to

E1-10) and the energy saving gain. The output voltage decreases and recovers in the voltage recovery

time (L2-04). As the energy saving gain increases, the output voltage increases also. This feature is

only enabled by a multi-function contact input.

A A - -

VS-616G5 Programming Manual 27

Page 28

Section B: Application Parameters

B8 Energy Savings

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

B8-02 Energy Saving Starting Frequency Energy Save Freq

Setting Range: 0.0 to 400.0Hz

Factory Default: 0.0Hz

After the multi-function contact input for energy-saving operation closes (H1-__, setting: “63”), the

output voltage is decreased when the output frequency reaches the energy-saving starting frequency.

This feature is only enable by multi-function contact input.

.

B8-03 Automatic Energy Saving <1110> Energy Save Sel

This parameter is used to select if Automatic Energy Saving Mode is to be on or off. A multi-function

contact input is not required to activate Automatic Energy Saving Mode. This mode of operation automatically searches for the optimum motor voltage required to save energy. This function is separate

and not to be confused with parameters B8-01 and B8-02. The energy saving mode that utilizes B8-01

and B8-02 requires a multi-function input to be activated for operation. This Automatic Energy Saving Mode selection does not require a multi-function input to activate operation.

Setting Description

0 Disabled (factory default)

Energy saving mode will not be activated under light loads.

1 Enabled

The energy saving mode will be activated under light loads.

A A - -

- - A A

B8-04 Energy Saving Control Gain Energy Save Gain

Setting Range: 0 to 10.0

Factory Default: 0.7

The output voltage during energy-saving operation is the product of the normal V/f settings (El-03 to

E1-10) and the energy saving gain. The output voltage decreases and recovers according to the EnergySaving Control Time Constant B8-05. As the energy saving gain increases, the output voltage

increases also.

Note: When the control mode A1-02=3, the default factory setting becomes 1.0

B8-05 Energy Control Time-Constant Energy Save F. T

Setting Range: 0.00 to 10.00

Factory Default: 0.50

Parameter B8-05 sets the response time for the Automatic Energy Saving function.

Decreasing the Energy Control Time-Constant, will cause the response to become quicker; however,

instability may occur if this is decreased too much.

Note: When control mode A1-02=3, the default factory setting becomes 0.01.

- - A A

- - A A

28 VS-616G5 Programming Manual

Page 29

FWD

Energy

Saving

Command

(Multi-function input

setting = “63”)

Fout

Section B: Application Parameters

B9 Zero Servo

V/f V/f w/PG

Fref ≥ B8-02

Open Loop

Vector

Flux

Vector

Vout

L2-04

V/f Pattern × Energy Saving Gain (B8-01)

Figure 10 Timing Diagram of Energy Saving Function

B9 Zero Servo

The zero servo function is enabled when the multi-function contact input is set to zero servo command

(H1-__ = “72”). The motor position is then memorized when motor speed feedback is less than the

zero speed level (B2-01).

B9-01 Zero Servo Gain Zero Servo Gain

Setting Range: 0 to 100

Factory Default: 5

Sets the zero-servo position loop gain. When adjusting the gain, the higher the setting, the quicker the

response. However, if the gain is set too high, it can cause overshoot and a possible runaway condition.

B9-01

Kp

∫

Deviation

Counter

Speed Reference

Motor Speed Feedback

0

(Position Ref.)

+

-

Motor

Position

- - - A

Figure 11 Zero Servo Position Loop

B9-02 Zero Servo Bandwidth Zero Servo Count

- - - A

Setting Range: 0 to 16383 pulses

Factory Default: 10 pulses

Sets zero servo bandwidth in units of one pulse. During zero servo control, the multi-function contact

output (H2-__ = “33”) is closed until the number of pulses (or bandwidth) is completed. Then the contact output opens.

VS-616G5 Programming Manual 29

Page 30

Section C: Tuning Parameters

C1 Accel/Decel

.

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

Zero Servo Function

(Multi-function Input

H1-__ setting = “72”)

Zero Servo Completion

(Multi-function Output

H2-__ setting = “33”)

Notes:

1. For multi-function contact input function selection, refer to parameters H1-01 to H1-06.

2. For multi-function contact output function selection, refer to parameters H2-01 to H2-03.

3. This function is only available during flux vector control (Al-02 = “3”).

C Tuning Parameters

C1 Accel/Decel

OFF

(Factory Default: 0.5Hz)

Zero Servo Loop

ON

Motor Speed

Zero Servo Bandwidth

Position Deviation

ON

Zero Speed Level

(B2-01)

Speed Loop

(B9-02)

OFF

Figure 12 Timing Diagram of Zero Servo Function

C1-01 Acceleration time 1 Accel Time 1

C1-02 Deceleration time 1 Decel Time 1

C1-03 Acceleration time 2 Accel Time 2

C1-04 Deceleration time 2 Decel Time 2

C1-05 Acceleration time 3 Accel Time 3

C1-06 Deceleration time 3 Decel Time 3

C1-07 Acceleration time 4 Accel Time 4

C1-08 Deceleration time 4 Decel Time 4

Setting Range: 0.00 to 6000.0s

Note: Setting range may be 0.00-600.0 or 0.0-6000.0 depending on the setting of parameter C1-10.

Factory Default: 10.0s

Acceleration time sets the time necessary for the output frequency to accelerate from 0Hz to maximum

output frequency. Deceleration time sets the time necessary for the output frequency to decelerate from

the maximum output frequency to 0Hz.

Q Q Q Q

Q Q Q Q

B B B B

B B B B

A A A A

A A A A

A A A A

A A A A

30 VS-616G5 Programming Manual

Page 31

Section C: Tuning Parameters

C1 Accel/Decel

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

Accel Time 1

(C1-01)

Output

Frequency

FWD (REV) Run Command

Accel/Decel Time Selection 1

(Terminals 3 to 8, Setting = “7”)

Accel/Decel Time Selection 2

(Terminals 3 to 8, Setting = “1A”)

* When “deceleration to stop” is selected (B1-03 = “0”)

Decel Time 1* (C1-02)

Accel Time 2 (C1-03)

ON OFF ON

Figure 13 Timing Diagram of Accel/Decel Time Adjustment

ON

Decel Time 2*

(C1-04)

Decel Time 1*

(C1-02)

Accel Time 3

(C1-05)

ON OFF ON

OFF

Decel Time 3* (C1-06)

Accel Time 4 (C1-07)

ON

ON

Decel Time 4*

(C1-08)

Decel Time 1*

(C1-02)

Time

When any of the multi-function contact input selections (H1-01 to H1-06) are set to “7”and “1A”, up to

four accel/decel times can then be selected by opening or closing the appropriate accel/decel time selection

commands (terminals 3 to 8).

.

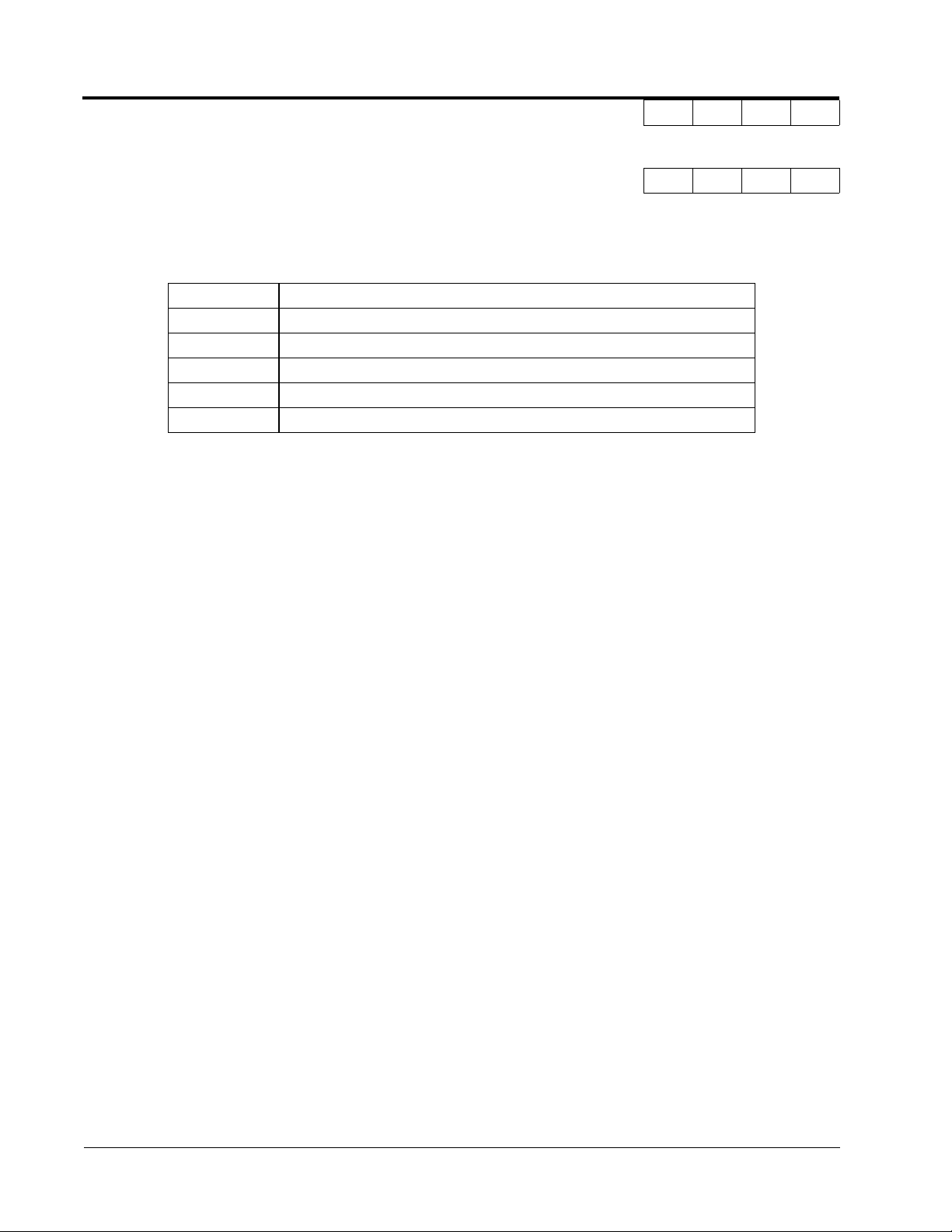

Accel/decel Time

Selection 1

Multi-function Input

Setting = “7”

Accel/decel Time

Selection 2

Multi-function Input

Setting = “1A”

Accel Time Decel Time

Open or not set Open or not set C1-01 C1-02

Closed Open or not set C1-03 C1-04

Open or not set Closed C1-05 C1-06

Closed Closed C1-07 C1-08

C1-09 Fast-Stop Time Fast Stop Time

Setting Range: 0.00 to 6000.0s

Factory Default: 10.0s

Fast-stop time is enabled when:

Multi-function contact input is set to fast-stop command (setting = “15”), and the contact closes.

The default stopping method when a fault is detected is fast-stop.

B B B B

VS-616G5 Programming Manual 31

Page 32

Section C: Tuning Parameters

C2 S-Curve Accel/Decel

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

C1-10 Accel/Decel Time Setting Unit Acc/Dec Units

Setting Description

0 Accel/decel time (C1-01 to C1-09) setting range is in units of 0.01 second.

Accel/decel time setting range: 0.00 to 600.00s

1 Accel/decel time (C1-01 to C1-09) setting range is in units of 0.1 second.

Accel/decel time setting range: 0.0 to 6000.0s (factory default)

If any of the parameters C1-01 to C1-09 is set to 600.1 seconds or more, C1-10 cannot be set to “0”.

C1-11 Accel/Decel Time Switching Frequency Level Acc/Dec SW Freq

Setting Range: 0.0 to 400.0Hz

Factory Default: 0.0Hz

Accel/decel times can be changed automatically, without using the multi-function contact inputs.

Use accel/decel times set in parameters C1-01 and C1-02 when output frequency ≥ C1-11.

Use accel/decel times set in parameters C1-07 and C1-08 when output frequency < C1-11.

When multi-function contact inputs are set for accel/decel selection, this command has priority over

automatic change of accel/decel.

Accel/Decel Switching Level

(C1-11)

A A A A

A A A A

Output Frequency

C1-07

C1-01 C1-02 C1-08

Figure 14 Accel/Decel Switching Level Adjustment

C2 S-Curve Accel/Decel

An S-curve pattern is used to reduce shock and provide smooth transitions during machine acceleration and deceleration. S-curve characteristic time is the time from the output frequency to the set accel/

decel time.

C2-01 S-Curve Time at Acceleration Start SCrv Acc @ Start

C2-02 S-Curve Time at Acceleration End SCrv Acc @ End

C2-03 S-Curve Time at Deceleration Start SCrv Dec @ Start

C2-04 S-Curve Time at Deceleration End SCrv Dec @ End

Setting Range: 0.00 to 2.50s

Factory Default: 0.20s

A A A A

A A A A

A A A A

A A A A

32 VS-616G5 Programming Manual

Page 33

Section C: Tuning Parameters

C2 S-Curve Accel/Decel

V/f V/f w/PG

.

Open Loop

Vector

Flux

Vector

Frequency Reference

Output Frequency

S-curve Characteristic

Time (Tsc)

Output Frequency

Time

Figure 15 S-curve Characteristic Timing Diagram

The following figure shows FWD/REV run switching during deceleration to stop.

FWD Run Command

REV Run Command

C2-02 C2-03

C2-04

Output Frequency

C2-01

DC Injection Braking

Time at Stop

B2-04

Figure 16 S-curve Characteristics - FWD/REV Operation

Time to accelerate from the minimum frequency

to the maximum frequency (total acceleration)

C2-01

C2-04

C2-02 C2-03

= C1-__ + (C2-01 + C2-02)/2

VS-616G5 Programming Manual 33

Page 34

Section C: Tuning Parameters

C3 Motor Slip Compensation

C3 Motor Slip Compensation

As the load becomes larger, the motor speed is reduced and motor slip increases. The slip compensation function keeps the motor speed constant even under varying load conditions.

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

C3-01 Slip Compensation Gain Slip Comp Gain

Setting Range: 0.0 to 2.50

Factory Default: 1.0

This function controls the output frequency in response to the load’s torque demand. Increase the set

value in one tenth (0.1) increments when operating at low speeds; decrease the set value as the motor

speed increases.

During flux vector control, this gain compensates for motor slip causes by changes in temperature.

Normally, this setting does not have to be modified.

Note: Default factory setting will be 0.0 when parameter A1-02=0 [V/F mode]. When parameter A102=2 [Open Loop Vector] or 3 [Flux Vector] the default factory setting will be 1.0.

C3-02 Slip Compensation Primary Delay Time Slip Comp Time

Setting Range: 0 to 10000ms

Factory Default: 200ms

Adjust the slip compensation delay time when motor speed is unstable or speed response is slow.

Increase the set value in 10ms increments when operating at low speeds; decrease the set value as the

motor speed increases.

B - B B

A - A -

C3-03 Slip Compensation Limit Slip Comp Limit

A - A -

Sets the slip compensation limit as a percentage of motor rated slip (E2-02).

E1-04

× C3-03

E1-06

C3-03

Output Frequency

Base

Frequency

E1-04E1-06

Maximum

Frequency

Figure 17 Slip Compensation Limit Adjustment

34 VS-616G5 Programming Manual

Page 35

Section C: Tuning Parameters

C3 Motor Slip Compensation

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

C3-04 Slip Compensation During Regeneration Slip Comp Regen

Setting Description

0 Slip compensation disabled during regeneration (factory default)

1 Slip compensation enabled during regeneration

C3-05 Flux Calculation Method Flux Select

Parameter C3-05 determines if the motor torque characteristic is based on output frequency or motor

speed.

Setting Description

0 Slip Included

Motor torque characteristic is based on frequency. (factory default)

1 Slip Excluded

Motor torque characteristic is based on motor speed.

A - A -

- - A -

Torque

100%

=0

=1=0

0%

=1

60Hz 1800 rpm 120Hz 3600 rpm

When running the motor only in the constant torque region, leave parameter C3-05 set to 0 for the

best performance.

When running the motor in the constant horsepower region, set parameter C3-05 to 1 because the

larger flux will result in better motor stability.

VS-616G5 Programming Manual 35

Page 36

Section C: Tuning Parameters

C4 Torque Compensation

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

C3-06 Output Voltage Limit Operation Selection <1110> Output V Limit

Setting Description

0 Disabled (factory default)

When this parameter is “0” slip compensation will be disabled when the motor

is operating above its base speed. The motor voltage will not be reduced

above base speed.

1 Enabled

Open Loop Vector Mode: When this parameter is set to “1” the motor voltage will be reduced slightly when the motor is operating above 90% base

speed. Slip Compensation is enabled. Speed control accuracy is improved.

This may prevent speed instabilities due to motor voltage saturation. This setting may improve speed regulation however motor torque/amp will be

reduced by up to 10% due to motor voltage reduction above base speed.

Flux Vector Mode: Torque linearity is improved.

C4 Torque Compensation

Motor torque can be adjusted by changing the V/f pattern (E1-03) or by adjusting the torque compensation gain. For details on setting the V/f pattern, see section E1, V/f Pattern Adjustment,.

Parameters C4-03, C4-04 and C4-05 are added for the OLV mode to help improve starting/breakaway

response. Individual torque compensation settings are possible for forward (C4-03) and reverse (C4-

04). The delay time (C4-05) is the time for which the internal torque reference will be increased. This

torque compensation is much like inputting an analog torque reference via an analog input.

- - A A

C4-01 Torque Compensation Gain Torq Comp Gain

B B B -

The motor torque requirement changes according to load conditions. Full-range automatic torque boost

adjusts the voltage of the V/f pattern according to the required torque. The VS-616G5 automatically

adjusts the voltage during constant-speed operation as well as during acceleration.

The required torque is calculated by the inverter. This ensures tripless operation and power savings.

36 VS-616G5 Programming Manual

Page 37

Section C: Tuning Parameters

C4 Torque Compensation

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

Output voltage ∝ Torque compensation gain × Required torque

Voltage

Required torque ⇒ Increase voltage

Frequency

Figure 18 Torque Characteristics

Normally, no adjustment is necessary for torque compensation gain. When more torque is needed,

increase the torque compensation gain in one tenth (0.1) increments. When the wiring distance

between the inverter and the motor is long, or when the motor generates excessive vibration, decrease

the torque compensation gain.

Increasing torque compensation gain increases motor torque, but an excessive increase may cause the

following:

· Inverter fault trips due to motor overexcitation

· Motor overheat or excessive vibration

C4-02 Torque Compensation Time Constant Torq Comp Time

Setting Range: 0 to 10000ms

Factory Default: 20ms

Increase the torque compensation time constant in 10ms increments when the motor output current is

unstable, and decrease this value when speed response is slow.

Note: When A1-02=2 [Open Loop Vector] the factory default setting is 20 ms. When A1-02=1or 3

[V/F or V/F w/PG] factory default setting is 200 ms.

C4-03 Forward Torque Compensation Value at Start<1110> F TorqCmp @ start

Setting Range: 0.0 to 200.0%

Factory Default: 0.0

This parameter may improve the motor performance during start. This feature functions only when

starting a motor. Torque reference and motor flux can be ramped up quickly to improve speed

response during start. A setting of 0.0 disables this feature.

A A A -

- - A -

VS-616G5 Programming Manual 37

Page 38

Section C: Tuning Parameters

C5 ASR Tuning

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

C4-04 Reverse Torque Compensation Value at Start<1110> R TorqCmp @ start

Setting Range: 0.0 to 200.0%

Factory Default: 0.0

This parameter may improve the motor performance during start. This feature functions only when

starting a motor. Torque reference and motor flux can be ramped up quickly to improve speed

response during start. A setting of 0.0 disables this feature.

C4-05 Torque Compensation Time Constant@Start<1110> TorqCmp Delay T

Setting Range: 0 to 200 ms

Factory Default: 1 ms

This parameter functions with C4-03 and C4-04. This parameter is the time delay that will be applied

to the Torque Compensation parameters C4-03 and C4-04. A setting of less than 4 milliseconds (ms)

causes this filter to be disabled.

C5 ASR Tuning

The automatic speed regulator (ASR) provides optimum performance during changes in motor speed

or load, when speed feedback is provided.

Frequency Reference

- - A -

- - A -

+

+

Output Frequency

Speed Feedback

Speed Reference

Speed Feedback

+

-

Variation

Ratio Limit

C5-01, C5-03

P

I

C5-02, C5-04

+

Limit

+

C5-05

Figure 19 ASR Block Diagram (V/f Control with PG Feedback)

Torque Limit

Secondary Current Reference

L7-01 ~ L7-04

+

-

C5-01, C5-03

P

I

C5-02, C5-04

+

+

1

1 + ST

C5-06

Figure 20 ASR Block Diagram (Flux Vector Control)

38 VS-616G5 Programming Manual

Page 39

Proportional Gain According to Motor Speed

Section C: Tuning Parameters

C5 ASR Tuning

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

C5-01 ASR Proportional Gain 1 ASR P Gain 1

- B - B

Setting Range: 0.00 to 300.00

Factory Default: 20.00

The ASR proportional gain 1 adjusts the speed in response to speed deviation, and softens the effect of

changes in load. Speed response increases as the proportional gain is increased. However, the load may

become unstable if the ASR proportional gain is set too high.

Note: When parameter A1-02=1 [V/f w/PG] the factory default setting is 0.20. When parameter

A1-02=3 the factory default setting is 20.00.

C5-02 ASR Integral Time 1 ASR I Time 1

- B - B

Setting Range: 0.000 to 10.000s

Factory Default: 0.500s

The ASR integral time 1 adjusts the inverter’s response time to changes in load. Speed response

increases as the integral time is decreased. However, the load may become unstable if the ASR integral

time is set too low.

Note: When A1-02=1 [V/f w/PG] the factory default setting is .200. When A1-02=3 factory default setting is 0.500

When A1-02=1 [V/f w/PG] factory default setting is 0.20. When A1-02=3 factory default setting is 20.00.

When A1-02=1 [V/f w/PG] factory default setting is 0.200. When A1-02=3 factory default setting is 0.500

When A1-02=1 [V/f w/PG] factory default setting is 0.02 When A1-02=3 factory default setting is 20.00.

C5-03 ASR Proportional Gain 2 ASR P Gain 2

- B - B

Setting Range: 0.00 to 300.00

Factory Default: 20.00

The ASR proportional gain 2 is an additional proportional gain adjustment that can be enabled by a

multi-function contact input (H1-__ = “77”).

(see Figure 22)

C5-03 Proportional Gain

Multi-function Input

(H1-__ = “77”)

ON

OFF

C5-02

OFF

ON

C5-02

Figure 21 ASR Multi-function Input Timing Diagram

Note: When parameter A1-02=1 [V/f w/PG] factory default setting is .02 When A1-02=3 the factory

default setting is 20.00.

VS-616G5 Programming Manual 39

Page 40

Section C: Tuning Parameters

C5 ASR Tuning

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

C5-04 ASR Integral Time 2 ASR I Time 2

Setting Range: 0.000 to 10.000s

Factory Default: 0.500s

The ASR integral time 2 is an additional integral time adjustment.

C5-05 ASR Limit ASR Limit

Sets ASR frequency compensation limit as a percentage of maximum output frequency (El -04). This

function is enabled when V/f control with PG feedback is selected as the control method (A1-02).

C5-06 ASR Output Primary Delay Time ASR Delay Time

Setting Range: 0.000 to 0.500s

Factory Default: 0.004s

Mechanical backlash in an application causes secondary current (I2) reference variations in the motor’s

rotor. This condition can prevent the adjustment of ASR parameters.The output delay time constant is

used to control these secondary current (I2) reference variations.

C5-07 ASR Switching Frequency Level ASR Gain SW Freq

Setting Range: 0.0 to 400.0Hz

Factory Default: 0.0Hz

- B - B

- A - -

- - - A

- - - A

Sets frequency to change ASR proportional gain and integral time constant in units of 0.1Hz when flux

vector control is selected.

C5-01

C5-02

C5-03

P gain · I time

0

C5-07

or

E1-04

C5-04

f

FB

Motor Speed

P · N

fFB =

120

where:

P = Number of Motor Poles

N = Motor RPM

* When C5-07 =”0”, proportional gain 1 (C5-01)

and integral time 1 (C5-02) are selected.

Figure 22 ASR Switching Frequency Level

Notes:

1.When C5-07 =”0”, proportional gain 1 (C5-01) and integral time 1 (C5-02) are selected.

2.During V/f control with PG feedback (A1-02 = “1”), the frequency switching level becomes

the maximum output frequency (E1-04).

40 VS-616G5 Programming Manual

Page 41

Section C: Tuning Parameters

C6 Carrier Frequency

V/f V/f w/PG

Open Loop

Vector

Flux

Vector

C5-08 ASR Integral Limit ASR I Limit

Setting Range: 0 to 400%

Factory Default: 400%

.Parameter C5-08 adjusts the amount of Integral control of the automatic speed regulator in the Closed

Loop Flux Vector control mode. Setting parameter C5-08 to zero will make the ASR control propor tional. Setting C5-08 to 400% will make the ASR control proportional and integral.

C5-08=0

P Control