Page 1

MagneTek

VCD 723

Product Guide

Page 2

Manual Contents

Revision

History

Related

Documents List

The following table shows all pages that have been revised since the f irst issue of

this manual.

Revision Affected Pages

Date

9/15/93 Initial

The following publications provide additional information on the VCD 723

drives. Each is a vailable from MagneTek. Please use the form provided at the

back of this manual to place your order.

● Maintenance Guide TM 6723-10

● PCDU Guide TM 6723-20

● MicroTrac® LAN Network Guide TM 6723-30

Additional copies of this manual can also be ordered by specifying the VCD 723

Product Guide (TM 6723).

9/15/93

Revision History

i

Page 3

Warranty

ii

9/15/93

Page 4

Warranty

Warranty

Standard products manufactured by MagneTek are warranted to be free from

defects in workmanship and material for a period of one year from date of

shipment and any products which are defectiv e in w orkmanship or material will

be repaired or replaced, at MagneTek's option, at no charge to the Buyer. Final

determination as to whether a product is actually defective rests with MagneTek.

The obligation of MagneTek hereunder shall be limited solely to repair or

replace, at MagneTek's discretion, products that fall within the foregoing

limitations, and shall be conditioned upon receipt by MagneTek or written notice

of any alleged defects or deficiency promptly after discovery and within the

warranty period, and in the case of components or units purchased by

MagneTek, the obligations of MagneTek shall not exceed the settlement that

MagneTek is able to obtain from the supplier thereof. No products shall be

returned to MagneTek without its prior consent. Products which MagneTek

consents to have returned shall be shipped prepaid f.o.b. MagneTek's factory.

MagneTek cannot assume responsibility or accept inv oices for unauthorized

repairs to its components, even though defective. The life of the products of

MagneTek depends, to a large extent, upon the usage thereof, and MAGNETEK

MAKES NO WARRANTY AS TO FITNESS OF ITS PRODUCTS FOR THE

SPECIFIC APPLICATIONS BY THE BUYER NOR AS TO PERIOD OF

SERVICE UNLESS MAGNETEK SPECIFICALLY AGREES OTHERWISE

IN WRITING AFTER THE PROPOSED USAGE HAS BEEN MADE

KNOWN TO IT.

Limitation

Of Liability

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT

NOT LIMITED T O, ANY WARRANTY OF MERCHANTABILITY OR OF

FITNESS FOR A PARTICULAR PURPOSE AND BUYER HEREBY

WAIVES ANY AND ALL CLAIMS THEREFORE.

IN NO EVENT SHALL MAGNETEK BE LIABLE FOR LOSS OF PROFIT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL DAMAGES WHETHER

ARISING OUT OF WARRANTY, BREACH OF CONTRACT OR TORT.

9/15/93

Warranty

iii

Page 5

Manual Contents

Table of

Contents

Page

Introduction........................................................................................................1

How To Use This Manual .............................................................................1

Controls and Indicators .................................................................................1

Safety Statements ..........................................................................................2

How To Contact MagneTek ..........................................................................2

Drive Description ..........................................................................................3

Ratings and Specifications.............................................................................5

System Considerations ................................................................................12

Installation and Start-up................................................................................15

Pre-Installation Considerations ...................................................................15

Physical Installation ....................................................................................15

Electrical Connection ..................................................................................19

Pre-Power Check .........................................................................................25

Drive Start-up .............................................................................................27

Operation..........................................................................................................31

Controls and Indicators ...............................................................................31

Start-up Operation ......................................................................................32

General Operation .......................................................................................34

Parameter Functions ....................................................................................35

Monitor Functions .......................................................................................36

Error Handling/Reporting ...........................................................................36

Non-Volatile RAM-Access .........................................................................40

Load Defaults Function ...............................................................................42

Upload/Download of Program or Parameters ............................................43

Hex Monitor ................................................................................................49

iv

Table of Contents

Troubleshooting/Maintenance.......................................................................51

Fault and Error Conditions ..........................................................................51

Troubleshooting Flowcharts.........................................................................59

Diode and Transistor Module Resistance Test ...........................................73

Spare Parts List ............................................................................................75

Appendices ........................................................................................................78

VCM Motor/PG (Digital Tachometer) Connection ...................................78

Motor Parameters ........................................................................................81

Node, Channel and Subchannel Assignments ............................................84

Glossary...........................................................................................................103

9/15/93

Page 6

Manual Contents

List of

Illustrations

List of Tables

Figure

Number Title Page

1 Typical MicroTrac System Diagram.............................................. 14

2 VCD 723 Dimensions .................................................................... 16

3 VCD 723 Basic Interconnection Diagram..................................... 20

4 VCD 723 External Connections Diagram...................................... 21

5 Proper Grounding of Three VCD 723 Drives................................ 25

6 Voltage Selection in 460V VCD 723, 15HP and Above............... 26

7 Local Control Display Unit (LCDU)............................................. 31

8 VCD 723 to IBM PC Compatible Computer Interconnect

Diagram .......................................................................................... 43

Table

Number Title Page

1 Motor Control Specifications.......................................................... 5

2 Terminal I/O Specifications ............................................................ 9

3 Digital Feedback Tachometer Connector CA1 Terminal

Specifications.................................................................................. 11

4 Summary of Option Cards.............................................................. 11

5 Closed Loop Connectors and Wire Sizes for Terminal

Screws ............................................................................................. 23

6 Wire Sizing for Main Circuit.......................................................... 23

7 Function Number Assignments...................................................... 34

8 Standard Error and Fault Descriptions........................................... 51

9 AC MicroTrac Circuit Card Test Points ........................................ 72

10 Diode Module Resistances ............................................................. 73

11 Transistor Module Resistances....................................................... 74

12 Spare Parts List - 230 Volt Drives................................................... 75

13 Spare Parts List - 460 Volt Drives................................................... 76

14 Connection of VCM........................................................................ 78

15 TB1 - PG (Digital Tachometer) Connection.................................. 79

16 Connections on PG (Digital Tachometer) Card ............................. 79

9/15/93

List of Illustrations

v

Page 7

Introduction

1

How To Use

This Manual

Controls and

Indicators

Status LEDs

MagneTek has made this product guide an easy to use reference. To help you use

this manual, we have provided the following guides:

● The top of each page has an identification of the section. For example, notice

that at the top of this page appears. This identifies

the page as part of Section 1, Introduction. There are four sections in this

manual: Introduction, Installation and Start-Up, Operation and

Troubleshooting/ Maintenance.

● Each section is organized into one or more major subject headings. These are

the main topics covered in that section. You will recognize major subject

headings by their distinctive appearances. The next line illustrates an example:

This is an example of a major subject heading from Section 3.

Each major subject heading may have one or more minor topics that are

covered. The next line illustrates an e xample:

This is a minor topic covered under “Controls and Indicators.”

Each minor topic may have one or more descripti v e headings. These identify

items covered within the minor topic. The next line illustrates an e xample:

Introduction

1

Ready

This is a descriptive heading covered under “Status LEDs.”

At the bottom of each page is the name of the first major subject heading

covered on that page. The page number and re vision date are also included.

For example, at the bottom of this page, the information indicates that “How

to Use This Manual” is the first major subject heading. It was last revised

September 15, 1993.

Using the information on the top of the page to find the section, the bottom of

the page to find the major subject heading and the left margin to f ind the

minor topics and descriptive headings, you can easily page through the

manual to find the information you need.

A table of contents is also included. The Table of Contents can be used to

locate section and major topics. A glossary is provided to define terms which

may be unfamiliar .

9/15/93

How To Use This Manual

1

Page 8

1

Introduction

Safety

Statements

How To Contact

MagneTek

In addition to notes, the following types of precautionary statements appear in

this manual.

IMPORTANT

A statement of conditions which should be observed during driv e

setup or operation to ensure dependable service.

CAUTION

A statement of conditions which must be observed to prev ent

undesired equipment faults or degraded drive system

performance.

W ARNING

A statement of conditions which MUST BE OBSER VED to

prevent personal injury or serious equipment damage.

For additional information, contact any MagneTek Representative, Authorized

Distributor , or our Technical Support Staff at:

MagneTek

16555 West Ryerson Road

New Berlin, WI 53151

(800) 541-0939 (414) 782-0200

FAX: (414) 782-1283

2

Safety Statements

9/15/93

Page 9

Introduction

1

Drive

Description

P erformance

Flexibility

The MicroTrac name is used to describe MagneTek's family of digital system

drives and the compatible products used to create systems. This manual

describes the MicroTrac compatible VCD 723 AC motor drive.

The VCD 723 is a high performance, sine-coded, Pulse Width Modulated

(PWM) AC motor drive which genera tes an adjustable three phase output for

complete speed or torque control of a compatible AC induction motor. The

VCD 723 can maintain a 150% current overload for 60 seconds with automatic

stall prevention and v oltage boost to prevent nuisance tripping during load or line

side transient conditions. The VCD 723 will not induce any voltage line

notching distortion to the utility line and maintains a displacement power factor

of approximately 0.98 throughout its speed range.

The VCD 723 drive is totally software configurable to the application through a

high level graphical language, called Programmable Application Control (PAC).

PA C provides complete flexibility without having to make hardware

adjustments. Interface to other equipment is provided with local Input/Output

(I/O) or a high speed Local Area Network (LAN). Use of the LAN means that a

single coaxial cable eliminates multiple conductor cables and provides high

noise immunity. Extensive diagnostic and setup capability are provided thr ough

two control/display units. The Local Control/Display Unit (LCDU) is mounted

flush with the drive co v er and consists of a Liquid Crystal Displa y (LCD) with

two lines of sixteen alphanumeric characters, fi v e pushbuttons, and fiv e status

Light Emitting Diodes (LED’ s). The LCDU can be used for all setup functions

and many diagnostics. The Portable Control/Display Unit (PCDU) is an optional

hand-held device that can be plugged into any MicroTrac compatible drive and

used for all the same functions as the LCDU plus some advanced diagnostics.

The PCDU has two lines of sixteen alphanumeric characters and a thirty-key

keypad.

9/15/93

Accuracy

The distributed control architecture of the MicroT rac system means that each

drive performs its o wn regulation calculations synchronized to a common high

accuracy crystal master. Thus, even minute crystal drift will not affect multiple

drive tracking. This allo ws a MicroTrac system to maintain the drift between

sections to 0.00% at steady state. The fully digital nature of the regulation

means that an individual drive can maintain a 0.00% average dif ference between

set and actual speed from no-load to full-load when using digital tachometer

speed feedback. Digital setup and performance assure exact process line and

finished product duplication shift to shift and month to month. Speeds, tensions,

ratios, draws, limits, ranges, alarms, and other control parameters can be set as

percentages or exact numerical values via keypad or thumbwheel switches with

up to six digits of resolution. Parameters are entered and displayed in plain and

understandable English. The drive can be completely set up prior to actual

running and changes can be made during operation. Keypad entry of changed

parameters, protected memory, and factory default values allow the operator to

modify data with minimum risk to the process.

Drive Description

3

Page 10

1

Introduction

Useability

Versatility

The VCD 723 drive is composed of several major components. The base

component is the MagneTek VCD 703 drive, with special software. To this is

added the MicroTrac circuit card, which provides gr aphical PAC programming

environment, LAN communications and e xtra local I/O. The other components

are the Local and Portable Control/Display Units, which allow user friendly

interface for drive setup and provides extensive diagnostic capabilities. In

addition, optional circuit cards can be added for expanded local I/O capabilities

and added functionality.

The VCD 723 can be set up to operate in one of two major modes based on the

level of regulation ena bled. The first mode allows the driv e to run as if it were a

VCD 703 drive, b ut the input for the constants come from the PAC environment

instead of from the Digital Operator . In addition to utilizing the speed control

logic of the VCD 703 drive to control the motor, this mode adds the extra I/O

capabilities that are present on the MicroTrac circuit card. This also allo ws f or

all of the advantages and flexibility of utilizing the PAC programming language.

In this mode, the inputs and outputs on the VCD 723 behave in the same way

that they would hav e had this been a VCD 703 drive, however , the An, Bn, Cn,

Dn, On, Sn, and Un constants are entered via the PA C environment.

The second major operating mode of the VCD 723 has the VCD 703 drive

operate as a slave to the MicroTrac circuit card. In this mode, the PAC

programmer has complete freedom in how the motor should be controlled,

including which inputs/outputs should perform a specific function.

Characteristics

The VCD 723 is mounted in a NEMA 1 wall mount enclosure, with other

power/control components required for VCD/VCM interconnection.

When properly installed, operated and maintained, the VCD 723 can provide

years of troublefree service. It is important that the person who operates,

inspects, or maintains this equipment thoroughly read and understand this

manual before proceeding.

4

Drive Description

9/15/93

Page 11

Ratings and Specifications

Control Specifications

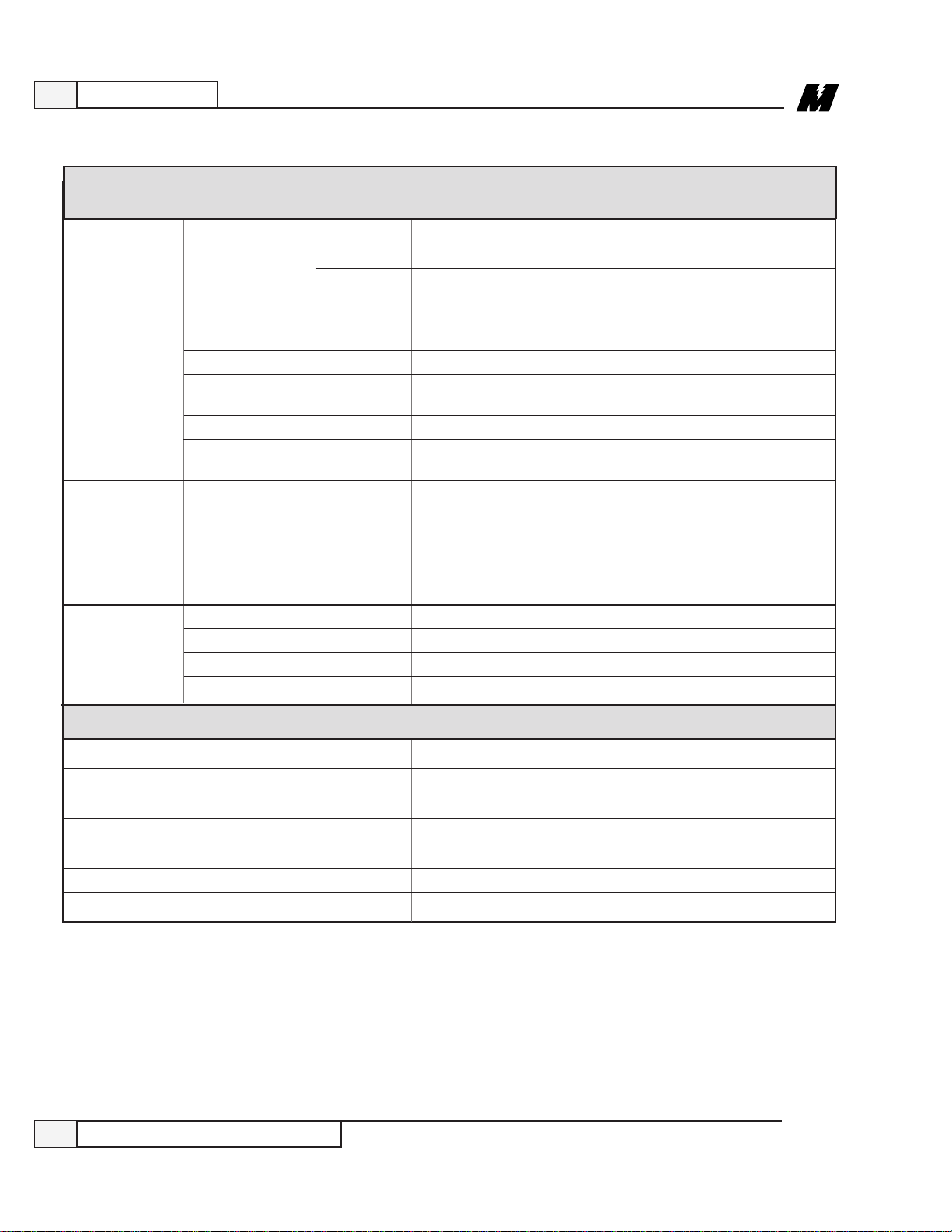

Table 1. Motor Control Specifications

SECTION A. 208/230V

Drive

Introduction

1

Model

General

Use Capacity HP 3 5 7.5 10 15 20 30 50

Circuit Breaker (MCCB)

Rating A

Low

Noise

Opera-

(1)

tion

Rated Output Voltage 180V

Overload Current

Rating

Voltage/Frequency 3-Phase 208V, 50Hz 208/230V, 60Hz

Allowable

Input

Power

Fluctuation

VCD 723-

Input

Current A 11 18 26 35 53 70 97 106 140 211

Continuous Rated

Current A

Capacity HP 3 5 7.5 10 15 20 30

Continuous Rated

Current A

Motor HP 3 5 7.5 10 15 20 25 30 40 50

Model

VCD 723-

V ±10%

F ± 5%

A003 A005 A7P5 A010 A015 A020 A030 A050

9.6 16 24 32 48 64 96 160

20 30 50 60 100 100 150 300

A003 A005 A7P5 A010 A015 A020 A030 N/A

7.68 12.8 19.2 25.6 38.4 51.2 76.8

150% for one minute

(2)

Motor (VCM)

Capacity

Model VMA___ 003 005 7P5 010 015 020 025 030 040 050

Rated Speed rpm 1750 rpm (4-pole, 60Hz)

Rated Voltage 3-phase 190 VAC

Rated Current A 9.6 16.0 22.8 29.4 44.0 57.0 69.0 82.0 120 148

Rated

Torque

2

WK

Frame No. 182T 184T 213T 215T 254T 256T 284T 286T 324T 326T

HP 3 5 7.5 10 15 20 25 30 40 50

(KW) (2.2) (3.7) (5.5) (7.5) (11) (15) (18.5) (22) (30) (37)

lb-ft 9 15 22.5 30 45 60 75 90 120 150

2

lb-ft

0.183 0.264 0.543 0.680 1.253 1.617 3.260 4.050 5.96 7.5

See notes on page 8.

9/15/93

Ratings and Specifications

5

Page 12

1

Introduction

Table 1. Motor Control Specifications - Continued

SECTION B1. 380/415/460V; 3-60 HP

Drive

Model

General

Use Capacity HP 1 3 5 10 15 20 30 40 60

Circuit Breaker (MCCB) 5

Rating A

Low

Noise

Opera-

(1)

tion

Rated Output Voltage 360V

Overload Current

Rating

Voltage/Frequency 3-Phase 380/415/460V, 50/60Hz

Allowable

Input

Power

Fluctuation

VCD 723-

Input

Current A 2.82 5 9 14 18 26 35 42 53 70 97 106

Continuous Rated

Current A

Capacity HP 1 3 5 10 15 20 30 40 60

Continuous Rated

Current A

Motor HP 1 3 5 7.5 10 15 20 25 30 40 50 60

Model

VCD 723-

B001 B003 B005 B010 B015 B020 B030 B040 B060

2.56 4.8 8 16 24 32 48 64 96

10 20 30 50 60 100 100 150

B001 B003 B005 B010 B015 B020 B030 B040 B060

2.05 3.84 6.4 12.8 19.2 25.6 38.4 51.2 76.8

150% for one minute

V ±10%

F ± 5%

(2)

Motor (VCM)

Capacity

Model VMB___ 001 003 005 7P5 010 015 020 025 030 040 050 060

Rated Speed rpm 1750 rpm (4-pole, 60Hz)

Rated Voltage 3-phase 380 VAC

Rated Current A 1.63 4.8 8 11.4 14.7 22 28.5 34.5 41 60 74 82

Rated

Torque

2

WK

Frame No. 143T 182T 184T 213T 215T 254T 256T 284T 286T 324T 326T 364T

HP 1 3 5 7.5 10 15 20 25 30 40 50 60

(KW) (0.7) (2.2) (3.7) (5.5) (7.5) (11) (15) (18.5) (22) (30) (37) (45)

lb-ft 3 9 15 22.5 30 45 60 75 90 120 150 180

2

lb-ft

0.074 0.183 0.264 0.543 0.680 1.253 1.617 3.260 4.050 5.960 7.500 9.340

See notes on page 8.

6

Ratings and Specifications

9/15/93

Page 13

Introduction

Table 1. Motor Control Specifications - Continued

SECTION B2. 380/415/460V; 75-400 HP

Drive

Model

General

Use Capacity HP 75 100 150 200 250 300 400

VCD 723-

Input

Current A 141 211 246 330 374 496 663

Motor HP

B075 B100 B150 B200 B250 B300 B400

75 100 150 200 250 300 400

1

Continuous Rated

Current A

Circuit Breaker (MCCB)

Rating A

Rated Output Voltage 360V

Overload Current

Rating

Voltage/Frequency 3-Phase 380/415/460V, 50/60Hz

Allowable

Input

Power

Fluctuation

Capacity

Model VMB___ 075 100 150 200 250 300 400

Rated Speed rpm 1750 rpm (4-pole, 60Hz)

Rated Voltage 3-phase 380 VAC

Rated Current A 103 142 206 272 338 398 525

Rated

Torque

2

WK

V ± 10%

F ± 5%

HP 75 100 150 200 250 300 400

(KW) (55) (75) (110) (160) (185) (220) (300)

lb-ft 225 300 450 600 750 900 1200

2

lb-ft

128 165 224 300 340 450 600

225 300 400 600 600 800 1000

150% for one minute

Motor (VCM)

11.77 17.6 37.0 69.58 74.22 88.14 97.42

(2)

Frame No. 365T 404T 444T 445T 447T 449T 449T

See notes on page 8.

9/15/93

Ratings and Specifications

7

Page 14

1

Introduction

Table 1. Motor Control Specifications - Continued

SECTION C. All VCD 723’s

SECTION C. ALL GPD 503s (CONTINUED)

Control Method Digital flux vector, Sine-coded PWM

Speed Control

Control Speed Reference Digital Operator reference: 0.01 Hz (12 bits)

Characteristics Setting Resolution Analog reference: 0.06 Hz/60Hz (10 bits)

Auto Speed Reference Signal 0 to +10 VDC (20k Ω), or 4 to 20 mA (250 Ω)

Range 1:1000 operation possible even at stall

Precision Digital ref.: ± 0.01% (–10 to +40°C, +14 to +140°F)

Analog ref.: ± 0.1% (25 ± 10°C, 77 ± 50°F)

Accel / Decel Time 0 to 3000 sec (resolution: 0.1 sec.)

Torque Limit Setting range: 0 to 300%. Forward/Reverse set independently

Selectable Functions Multi-step speed operation (9 steps max.), S-curve accel/decel,

Inverter Overcurrent, overvoltage, cooling fin overheat, undervoltage,

Protective Motor Overload, overheat, overspeed

Functions

Environmental

Conditions Storage Temperature

Rated speed 1750 rpm (4 poles)

Pulse Generator 1024 ppr (standard) Higher rates are available.

Thermistor Standard

Load Connection Direct coupling or belt drive

Insulation Type Class F

Ambient Temperature –20 to +40°C (–4 to +104°F)

Location Indoor

System Excessive speed deviation, open-phase detection, continuous

Ambient Temperature –10 to +45°C (+14 to +113°F)

(See Note 4)

Humidity 90% RH (no condensation)

Vibration 1 G at less than 20 Hz, up to 0.2 G at 20 to 50 Hz.

SECTION D. All VCM’s

(Accel / Decel times set independently)

zero speed control, servo lock, arbitrary torque detection, etc.

cooling fan failure, grounding, etc.

operation during momentary power loss (immediate stop at end

of programmed ride-thru time, 2 sec. max.)

–20 to +60°C (–4 to +140°F)

SECTION D

(See Note 3)

NOTES:

(1) Low noise operation can be selected by setting of Sn-09 : 0XXX = General Use (low carrier frequency – 2.08 kHz);

1XXX = Low Noise Operation (high carrier frequency - 12.5 kHz). Rated current is 80% of General Use rated current.

(2) 100% reference current is Continuous Rated Current for Low Noise Operation or General Use.

(3) For a drive rated 230V 5HP or less, or 460V 3HP or less, standard max. ride-thru time is 1 sec (1000 msec). The

max. ride-thru time can be extended to 2 sec (2000 msec) by adding an optional external mounting capacitor unit.

(4) Temperature during shipping. Storing in this temperature for a long period may deteriorate main circuit capacitor.

8

Ratings and Specifications

9/15/93

Page 15

Introduction

1

Terminal

Functions and

Control Signal

Specifications

There are various types of I/O available in the VCD 723. The terminal I/O

specifications are listed in Table 2. The digital feedback tachometer connector

specifications are listed in Table 3. A diagram of these connections can be found

in Figure 4.

Table 2. Terminal I/O Specifications

TERMINAL FUNCTION DESCRIPTION

1,2,4,5,6,7,8

3

9,10

11

12

13

14

15

16

17

18,19,20

21,22

23,24

25,26

27

Logic inputs

Logic inputs

Logic output,

normally open

relay contact

Logic input

common

Shield tie point

Analog input

Analog input

Analog input

power supply

Analog input

Analog input

common

Logic output,

form C relay

contact

Analog output

Current monitor

analog output

Logic outputs,

open collector

Open collector

output common

The input is off (logic 0) when the input is open, and on

(logic 1) when the input is connected to Logic Input

Common (0V). If input is from a relay contact, the

contact rating must be: 30 VDC min

100 mA min

If input is from an open collector, the rating must be:

35 VDC min

100 mA min

This is always used for external fault generation. This

input cannot be reassigned. The SN12 constant can be

used to set this input to Normally Open or Normally

Closed. If Normally Open is selected, a fault is indicated

when the contact closes and if Normally Closed is

selected an open contact indicates the fault.

Normally open relay contact.

Contact capacity: 250 VAC at 1A or below.

30 VDC at 1A or below.

Common (0V) for use in wiring Logic Inputs.

Shield sheath tie point which is connected to Chassis

Common.

Non-isolated 0 to 10 VDC analog input. Input has 20K

ohms of impedance. Resolution is 10 bits.

Non-isolated 4 to 20 mA analog input. Input has 250

ohms of impedance. Resolution is 10 bits.

Control power supply for analog input: +15 VDC at 20

mA max.

Non-isolated 0 to 10 VDC analog input. Input has 20K

ohms of impedance. Resolution is 10 bits.

Common (0V) for use in wiring analog inputs.

18 is Normally Open, 19 is Normally Closed, and 20 is

Common. Contact Capacity: 250 VAC at 1A or below.

30 VDC at 1A or below.

Non-isolated 0 to 11 VDC analog output. Maximum

sourcing current is 2 mA. 21 is positive with respect to

22. Resolution is 8 bits.

Non-isolated analog output. Approximately 5 VDC at

rated output current.

Photocoupler isolated output. Capacity of +48 VDC

max at 50 mA max.

Common (0V) for use in wiring multi-function open

collector outputs.

9/15/93

Ratings and Specifications

9

Page 16

1

Introduction

Table 2. Terminal I/O Specifications - Continued

TERMINAL FUNCTION DESCRIPTION

28,29

30

31

32

51

52

53

54

55,56

57

58

59,60,61,62

63

64

65,66,67,68

69

70

71,72,73,74

Connector

CA1

Logic outputs,

open collector

Motor

thermistor input

Motor

thermistor input

common

Shield tie point

+10VREF

output

-10VREF

output

I/O common

Shield tie point

Analog outputs

I/O common

Shield tie point

Analog input

I/O common

Shield tie point

Analog input

I/O common

Shield tie point

Digital

Tachometer

inputs

Digital

Tachometer

Connector

Photocoupler isolated output. Capacity of +48 VDC

max at 50 mA max.

Motor temperature feedback.

Common (0V) for use in wiring motor thermistor input.

Shield sheath tie point which is connected to Chassis

Common.

Reference voltage output for use with MicroTrac card

analog inputs. 10 mA max capacity.

Reference voltage output for use with MicroTrac card

analog inputs. 10 mA max capacity.

Common (0V) for use with MicroTrac card I/O.

Shield sheath tie point which is connected to Chassis

Common.

Non-isolated -10 to +10 VDC analog outputs.

Maximum sourcing current is 2 mA. Resolution is

12 bits.

Common (0V) for use with MicroTrac card I/O.

Shield sheath tie point which is connected to Chassis

Common.

Non-isolated differential analog input. Input has over

100K ohms of impedance. Resolution is 12 bits. Input

voltage range is -600 to +600 mV when terminals 60 (+)

and 61 (-) are used. Input voltage range is -10 to +10

VDC when terminals 59 (+) and 62 (-) are used.

Common (0V) for use with MicroTrac card I/O.

Shield sheath tie point which is connected to Chassis

Common.

Non-isolated differential analog input. Input has over

100K ohms of impedance. Resolution is 12 bits. Input

voltage range is -600 to +600 mV when terminals 66 (+)

and 67 (-) are used. Input voltage range is -10 to +10

VDC when terminals 65 (+) and 68 (-) are used.

Common (0V) for use with MicroTrac card I/O.

Shield sheath tie point which is connected to Chassis

Common.

The quadrature encoder A (terminal 71), /A (terminal

72), B (terminal 73), and /B (terminal 74) signals are

connected here. There is 100 ohms of impedance

between each pair of encoder input signals. Input

differential voltage of 5 VDC max. The maximum

input frequency is 300KHz.

Isolated +12 VDC power supply to quadrature encoder

and quadrature encoder signal inputs.

10

Ratings and Specifications

9/15/93

Page 17

Introduction

Table 3. Digital Feedback Tachometer Connector

CA1 Terminal Specifications

TERMINAL FUNCTION DESCRIPTION

1

Option Cards

1

2

3,4,5,6

7

Isolated power

supply

Isolated power

supply

common

Digital

Tachometer

inputs

Shield tie point

Isolated power supply for digital tachometer: +12 VDC

at 200 mA max.

Common (0V) for digital tachometer isolated power

supply.

The quadrature encoder A (terminal 3), /A (terminal 4),

B (terminal 5), and /B (terminal 6) signals are connected

here. There is 560 ohms of impedance between each

signal pair, pair A and /A and pair B and /B. Input

differential voltage of 5 VDC max. The maximum input

frequency is 300KHz.

Shield sheath tie point which is connected to Chassis

Common.

There are various option cards a vailable to provide additional capability. The

option cards are each described in detail in a separate User Reference Sheet. A

summary of available option cards is contained in Table 4.

Table 4. Summary of Option Cards

9/15/93

OPTION CARD FUNCTION

Analog Monitor, AO-8 Has two analog output channels with 8 bit resolution. Each output

voltage is from 0 to +10 VDC and is non-isolated.

Analog Monitor, AO-12 Has two analog output channels with 12 bit resolution. Each output

voltage is from 0 to +10 VDC and is non-isolated.

Digital Output, DO-8 Has six photocoupler output channels with a single common. Also

has two independent relay contact output channels.

Torque Control, TRQ-A Closes the torque control loop for higher accuracy torque control.

Ratings and Specifications

11

Page 18

1

Introduction

System

Considerations

When operating in a system application, the VCD 723 can be used with other

MagneTek devices with which it will communicate by means of the MicroT rac

Local Area Network (LAN). Refer to Figure 1 for a typical MicroTrac System.

Each of the following remote devices (board or assembly) is descr ibed in detail

in a separate User Reference Sheet.

● Remote Display Controller LAN Node PCB (RDC) – This board provides

a means for the MicroTrac system to have system operating parameters

displayed at locations remote from the MicroTrac drive. The RDC

communicates with the drive through the LAN. A single RDC can support

up to 31 Remote Display Units (RDUs). By means of a Portable

Display/Control Unit (PCDU), the RDC allows the selected display for each

RDU to be changed at anytime.

● Remote Display Unit (RDU) – Designed for mounting in a panel cutout, the

RDU provides a two-line LED display (16 character alphanumeric, and 5-1/2

digit numeric). Consisting of a terminal, the information on its display is

transmitted by a Remote Display Controller LAN Node PCB.

● Remote Keyboard Assembly – Designed for mounting on a panel with or

near a Remote Display Unit, the Remote Keyboard allows initiation of RDU

display changes without the need for a Portable Display/Control Unit.

● Remote I/O [Input/Output] Controller LAN Node PCB (RIO) – This

board provides a means for the MicroTrac system to have inputs or outputs at

locations remote from the drive. The RIO communicates with the drive

through the LAN. A single RIO can support up to 6 Remote I/O boards,

using any combination of the following:

1. Remote Logic I/O PCB (LOGI/O) – This board provides remote logic

signal input/output capability for the MicroTrac system. It is connected

to a Remote I/O Controller LAN Node PCB for communication with the

drive.

2. Remote Analog I/O PCB (ANI/O) – This board provides remote analog

signal input/output capability for the MicroTrac system. It is connected

to a Remote I/O Controller LAN Node PCB for communication with the

drive.

3. Remote Thumbwheel Switch I/O PCB (TWIO) – This board provides

remote thumbwheel switch input/output capability for the MicroTrac

system. It can support up to 9 Thumbwheel Switch Assemblies. This

board is connected to a Remote I/O Controller LAN Node PCB for

communication with the drive.

12

System Considerations

9/15/93

Page 19

Introduction

● Remote Programmable Logic Controller (PLC) Interface – Available for

a variety of PLCs. These devices allow bi-directional communication via the

MicroTrac LAN between dri ves and the PLC. Both logic and numeric data

can be transferred.

● Remote Power Supply – The Remote Power Supply produces control level

voltages for use by a Remote LAN Node PCB or a Remote Display Unit.

● Remote Serial Communication Controller LAN Node PCB (RSC) – This

board provides a means for the MicroTrac system to have input from or

output to other equipment that uses RS-232 serial communication. The RSC

communicates with the drive through the LAN.

1

9/15/93

System Considerations

13

Page 20

1

MicroTrac

Drive

DRIVE

CONTROL

UNIT

REMOTE

INPUT/OUTPUT

CONTROLLER

PCB (RI/O)

REMOTE

PLC INTER-

FACE

REMOTE

COMMUNICATIONS

CONTROLLER

PCB (RSC)

REMOTE

DISPLAY

CONTROLLER

PCB (RDC)

DISPLAY #1

REMOTE

DISPLAY

UNIT (RDU)

DISPLAY #2

PERSONAL

COMPUTER

PROGRAMMABLE

LOGIC

CONTROLLER (PLC)

RS-232 OR

RS-422

RS-485

DISPLAY #3

DISPLAY #4

UP TO 9 BANKS OF

6 DIGITS

PCDU

MESSAGE

SELECT

+1 8 8 8 8 8

8 8 8 8 8 8

+1 8 8 8 8 8

THUMB

WHEELS

8 ISOLATED LOGIC

I/O MODULES

7 NON-ISOLATED

LOGIC OUTPUTS

16 NON-ISOLATED

LOGIC INPUTS

4 ISOLATED ANALOG

I/O MODULES

7 NON-ISOLATED

ANALOG OUTPUTS

4 NON-ISOLATED

ANALOG OUTPUTS

4 NON-ISOLATED

ANALOG INPUTS

REMOTE

THUMBWHEEL

INPUT/OUTPUT

PCB

(TWI/O)

REMOTE

ANALOG

INPUT/OUTPUT

PCB

(ANI/O)

UP TO 6 REMOTE INPUT/OUTPUT PCBS

UP TO 31 REMOTE

DISPLAY UNITS

KEYBOARD

REMOTE

LOGIC

INPUT/OUTPUT

PCB

(LOGI/O)

KEYBOARD

ENABLE

2.5 million bits/second

93 Ohm

Terminator

93 Ohm

Terminator

LOCAL

I/O

RG 62/U Coaxial Cable

1 2 3 D C

4 5 6 D N

7

8 9

0

N E

•

LA-8

LOCAL

I/O

LOCAL

I/O

MicroTrac

Drive

DRIVE

CONTROL

UNIT

MicroTrac

Drive

DRIVE

CONTROL

UNIT

+

-

Introduction

14

System Considerations

Figure 1. Typical MicroTrac System Diagram

9/15/93

Page 21

Installation and Start-up

2

Pre-installation

Considerations

Receipt of

Shipment

Unpacking

Repacking

Location of the VCD 723 is important to achieve proper performance and

normal operating life. The unit should be installed in an area where it will be

protected from the following:

● Direct sunlight, rain or extreme (condensing) moisture.

● Corrosive gases or liquids.

● Vibration, airborne dust or metallic particles.

All equipment is tested against defect at the factory. Any damages or shortages

evident when the equipment is receiv ed must be reported immediately to the

commercial carrier who transported the equipment. Assistance, if required, is

available from your MagneTek representative. Always refer to the order number ,

equipment description, and serial number when contacting MagneTek.

Remove the protective shipping material from around the equipment. Remove

all packing material. Inspect for loose wiring. Make sure all contact wedges and

other shipping devices hav e been remo ved.

For long periods of storage, equipment should be covered to prevent corrosion,

and should be placed in a clean, dry , location. If possible, equipment should be

stored in its original crating. Periodic inspection should be made to ensure that

the equipment is dry and that no condensation has accumulated. The equipment

warranty does not cover damage due to improper storage. Assistance, if

required, is available from your MagneTek representative.

Physical

Installation

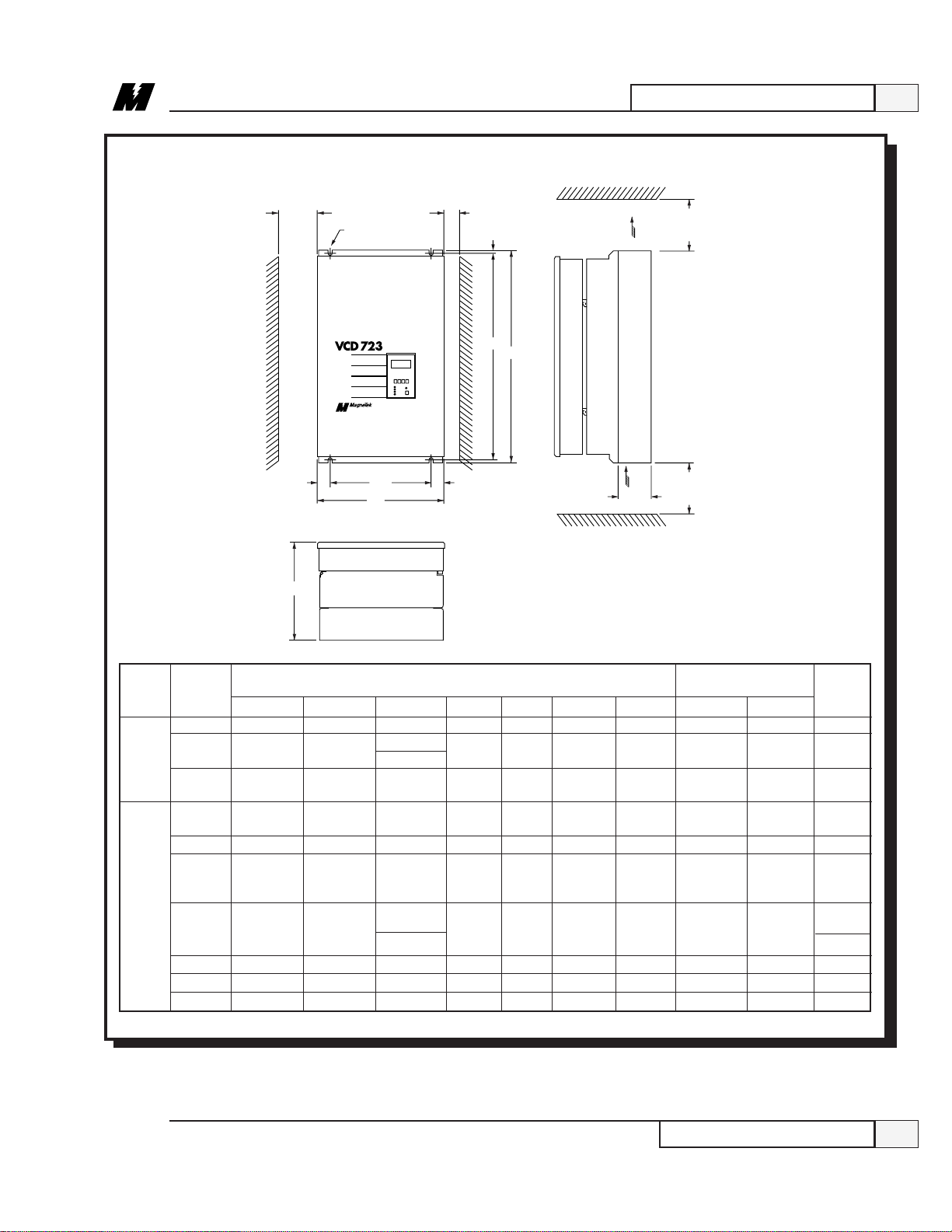

For effecti ve cooling as well as proper maintenance, the VCD 723 must be

installed vertically. Use the holes provided on the back of the driv e for

installation. There MUST be a MINIMUM 6 inch clearance above and below

the VCD 723 enclosure. A MINIMUM 3 inch clearance is required on the left

side of the VCD 723 enclosure. See Figure 2 for physical dimensions.

9/15/93

Pre-installation Considerations

15

Page 22

2

D

BOTTOM VIEW

W1

A

W

A

3.15

MAX. SCREW SIZE

SEE COLUMN “C”

MIN. 1.2

H

B

H1

FRONT VIEW

6.00 MIN.

AIR

6.00 MIN.

K

SIDE VIEW

COVER

AIR

LA-12

VCD 723 Standard Protected Chassis

Installation and Startup

ENCLOSURE DIMENSIONS MTG HOLE DIMENSIONS

INPUT HP (kW)

H W D A B C K H1 W1

208 / 5 (3.7)

3 (2.2)

230V

7.5 (5.5)

10 (7.5)

380 / 3 (2.2) 13.94 (354) 8.05 (204) 8.66 (220) .48 (12) .39 (10)

415 /

460V 5 (3.7)

10 (7.5)

11.97 (304) 8.05 (204) 8.86 (225) .48 (12) .39 (10)

13.94 (354) 8.05 (204) 10.04 (255) .48 (12) .39 (10)

13.94 (354) 8.05 (204) 10.04 (255) .48 (12) .39 (10)

IN INCHES (mm) IN INCHES (mm)

1/4

-20 (M6) 1.57 (40) 11.22 (285) 7.09 (180) 21 (10)

1/4

-20 (M6) 1.57 (40) 13.19 (335) 7.09 (180) 27 (12)

1/4

-20 (M6) 1.57 (40) 13.19 (335) 7.09 (180) 27 (12)

1/4

-20 (M6) 1.57 (40) 13.19 (335) 7.09 (180) 27 (12)

WEIGHT

LBS. (KG)

16

Figure 2. VCD 723 Dimensions (Sheet 1 of 3)

Physical Installation

Note: Consult Factory for Shipping Weights.

9/15/93

Page 23

D

BOTTOM VIEW

W1

A

W

A

MIN.

4.00

(100)

MAX. SCREW SIZE

SEE COLUMN “C”

MIN.

1.20

(30)

H

B

H1

FRONT VIEW

MIN.

6.00

(152)

AIR

MIN.

6.00

(152)

K

SIDE VIEW

AIR

VCD 723 Standard Protected Chassis

LA-13

Installation and Start-up

2

INPUT HP (kW)

15 (11) 19.69 (500) 9.84 (250) 10.04 (255) .96 (25) .30 (7.5)

208 / 20 (15)

230V 30 (22) 10.04 (255)

40 (30)

50 (37)

15 (11)

20 (15)

380 / 30 (22) 21.65 (550) 12.80 (325) 10.04 (255) 1.19 (30) .30 (7.5)

415 / 40 (30)

460V 50 (37) 28.54 (725) 13.78 (350) 11.02 (280) 1.97 (50) .30 (7.5)

60 (45)

75 (55)

100 (75) 36.42 (925) 22.64 (575)

150 (110) 12.99 (330) 234 (106)

200 (160) 53.54 (1360) 23.62 (600) 17.72 (450)

300 (220) 57.09 (1450) 37.40 (950) 17.12 (435)

400 (300) 63.00 (1600) 37.80 (960) 17.72 (450)

H W D A B C K H1 W1

21.65 (550) 12.80 (325)

31.50 (800) 18.70 (475) 11.02 (280) 1.97 (50) .39 (10)

19.69 (500) 9.84 (250) 10.04 (255) .96 (25) .30 (7.5)

ENCLOSURE DIMENSIONS MTG HOLE DIMENSIONS

IN INCHES (mm) IN INCHES (mm)

9.65 (245)

11.02 (280)

.96 (25) .30 (7.5)

1.97 (50) .49 (12.5) 7/16

1.97 (50)

3.94 (100)

4.13 (105)

.69 (17.5)

.98 (25)

.98 (25)

Note: Consult Factory for Shipping Weights.

Figure 2. VCD 723 Dimensions (Sheet 2 of 3)

1/4

(M6) 4.11 (104) 19.09 (485) 7.87 (200) 52 (24)

1/4

(M6)

3.37 (86) 21.06 (535) 10.83 (275) 76 (35)

7/16

(M10) 4.30 (109) 30.71 (780) 14.76 (375) 105 (48)

1/4

(M6) 2.58 (66) 19.09 (485) 7.87 (200) 54 (25)

1/4

(M6)

3.37 (86) 21.06 (535) 10.43 (265) 76 (35)

3/8

(M8)

4.14 (105) 27.76 (705) 9.84 (250) 105 (48)

(M10)

4.30 (109) 35.43 (900) 18.70 (475)

1/2

(M12) 5.90 (150) 52.16 (1325) 21.65 (550) 379 (172)

1/2

(M12) 4.05 (103) 55.12 (1400) 29.53 (750) 797 (362)

1/2

(M12) 4.05 (103) 61.02 (1550) 29.53 (750) 905 (411)

WEIGHT

LBS. (KG)

199 (90)

9/15/93

Physical Installation

17

Page 24

2

U

KEYWAY

U

N–W

C

2F

BA

V MIN.

TERMINAL BOX FOR

TACHOMETER AND

THERMISTOR

TERMINAL BOX FOR

MOTOR AND

BLOWER

VCM Motor - Foot Mount

LA-14

D

EE

4 HOLES

"H" DIA.

Installation and Start-up

ALL DIMENSIONS IN INCHES

HP FRAME

182T

3

184T

5

213T

7.5

215T

10

254T

15

256T

20

284T

25

286T

30

324T

40

326T

50

364T

60

365T

75

405T

100

444T

150

445T

200

447T

300

449T

400

* DIMENSION TOLERANCES

DIM. D TOL. DIM. U TOL.

UP TO + .00 UP TO + .0000

8.00 – .03 1.5000 – .0005

OVER + .00 OVER + .000

8.00 – .06 1.5000 – .001

BA C D * E 2F H

4.50

20.50

2.75

4.50

21.50

2.75

5.25

24.26

3.50

5.25

25.76

3.50

6.25

29.25

4.25

6.25

31.00

4.25

7.00

32.50

4.75

7.00

34.00

4.75

8.00

34.63

5.25

8.00

36.13

5.25

9.00

41.94

5.88

9.00

42.94

5.88

10.00

45.62

6.63

11.00

48.25

7.50

11.00

50.25

7.50

11.00

54.00

7.50

11.00

67.75

7.50

3.75

3.75

4.25

4.25

5.00

5.00

5.50

5.50

6.25

6.25

7.00

7.00

8.00

9.00

9.00

9.00

9.00

4.50

5.50

5.50

7.00

8.25

10.00

9.50

11.00

10.50

12.00

11.25

12.25

13.75

14.50

16.50

20.00

22.00

.406

.406

.406

.406

.531

.531

.531

.531

.656

.656

.657

.657

.828

.828

.828

.828

.828

FRAME

180

210

250

280

320

360

400

440

U *

1.1250

1.3750

1.625

1.875

2.125

2.375

2.875

3.375

V

2.50

3.12

3.75

4.38

5.00

5.75

7.00

8.25

N-W

2.75

3.38

4.00

4.62

5.25

5.88

7.25

8.50

U

Keyway

.250 x .125

.312 x .156

.375 x .188

.500 x .250

.500 x .250

.625 x .312

.750 x .375

.875 x .438

18

Physical Installation

Figure 2. VCD 723 Dimensions (Sheet 3 of 3)

9/15/93

Page 25

Installation and Start-up

2

Electrical

Connection

All basic connections are shown in Figure 3 and the drive’s external connection

locations are shown in Figure 4. Most of the control I/O are shown in a gener al

fashion for an example of proper wiring. Because of the flexibility of the VCD

723, many of the control functions (i.e., R UN, Speed Reference, etc.) are not

permanently assigned to a specific I/O point. The function that many of the I/O

points serve is dependent upon the designer. See schematic and interconnection

diagrams for specific connections.

It is very important that voltage isolation be maintained with all the I/O points

which are not already isolated. For example, the analog outputs are not isolated.

Therefore, if an analog output is driving a meter movement, then the movement

must be in reference to the VCD 723 I/O common and not to any other common

(i.e., earth common). On the other hand, if the analog output is connected to a

non-isolated analog input of some test equipment, then analog isolation is

necessary. The analog isolation must be performed with components not

supplied with the VCD 723.

9/15/93

Electrical Connection

19

Page 26

2

Installation and Start-up

LCDU

Pulse Generator Connection

20

Electrical Connection

Ground Connection

MicroTrac/Inverter Connection

LA-15

Figure 3. VCD 723 Basic Interconnection Diagram

9/15/93

Page 27

Installation and Start-up

Pulse Generator

(CA1)

PCDU

MicroTrac LAN

I/O Terminals 1-32

(See figure below

for numbering order)

I/O Terminals 50-74

LA-16

11 12 13 14 15 16 17

1 2 3 4 5 6 7 8

18 19 20

32 9 10

25 26 27 28 29 30

21 22 23 24 31

The connection of control circuit terminals 1 to 32 do not follow the terminal numbering

order. See the following figure for correct wiring (printed on the PC board).

2

9/15/93

Figure 4. VCD 723 External Connections Diagram

Electrical Connection

21

Page 28

2

Installation and Start-up

Wire Sizes and

Connections

Ensure that wire size and disconnect devices conform to the installation

contractor’ s dra wings and to all applicable codes. Refer to Tables 5 and 6 for

proper wire sizes and interconnecting information.

CAUTION

● Use only factory supplied installation instructions to install

dynamic braking resistors. Failure to do so may cause

equipment damage or personnel injury.

● Use 600 volt vinyl-sheathed wire or equi valent. Wire size

should be determined considering ampacity and codes.

● Never connect A C main power to output terminals T1(U),

T2(V), and T3(W).

● NEVER allow wire leads to contact the VCD 723

enclosure. Short-circuit may result.

● NEVER connect power factor correction capacitors or

noise filter to VCD 723 output.

● Size of control wire must be suitable for Class I circuits.

● Use only closed loop (ring lug) connectors sized for the

selected wire gauge. The connectors are to be installed

using the correct crimp tool recommended by the connector

manufacturer .

Observe the following precautions when making wiring connections:

● Separate the leads used for control I/O (i.e., the signals on terminals 1

through 32, terminals 51 through 76, connector CA1, etc.) from those used

for the power signals (i.e., L1(R), L2(S), L3(T), T1(U), T2(V), T3(W)). Do

not run these two groups in the same conduit or wire trough.

● Provide shielded and twisted leads as indicated on the schematic and

interconnection diagrams. Connect shield sheath AT THE VCD 723 END

ONLY. The far end should be dressed neatly and left unconnected. Twisted

shielded pair wire should be used for long runs.

● Lead length should NOT EXCEED 164 feet (50 meters).

● The contact output control leads from terminals 9, 10, 18, 19, and 20 must be

separated from the other control leads.

● If the drive is being used in a LAN, use a BNC “T” connector to connect the

LAN coaxial cable to the drive.

22

Electrical Connection

9/15/93

Page 29

Installation and Start-up

Table 5. Closed Loop Connectors and Wire SIzes for Terminal Screws

2

WIRE SIZE TERMINAL CLOSED LOOP

AWG mm

20 0.5

18 0.75

16 1.25

14 2

12 3.5

10 5.5

8 8

2

SCREW SIZE CONNECTOR

M3.5 1.25 - 3.5

M4 1.25 - 4

M4 2 - 4

M5 2 - 5

M4 3.5 - 4

M5 3.5 - 5

M4 5.5 - 4

M5 5.5 - 5

M5 8 - 5

M6 8 - 6

6 14 M6 14 - 6

4 22 M8 22 - 8

1 38 M8 38 - 8

1 38 38 - 10

2/0 60 60 - 10

3/0 80 80 - 10

M10

4/0 100 100 - 10

4/0 100 100 - 10

MCM300 150 150 - 12

M12

MCM400 200 200 - 12

Table 6. Wire Sizing for Main Circuit

DRIVE WIRE SIZE

MODEL TERMINAL

VCD 723- TERMINAL SYMBOL SCREW SIZE AWG MM

SECTION A. 208/230 V

A003, L1(R), L2(S), L3(T), N, B1/P, B2, T1(U), T2(V), T3(W) M4 12 - 10 3.5 - 5.5

A005

A7P5, L1(R), L2(S),L3(T), N, B1/P, B2,T1(U),T2(V),T3(W) M5 10 - 8 5.5 - 8

A010

A015 L1(R), L2(S), L3(T), P1, P3, T1(U), T2(V), T3(W), N M6 8 - 6 8 - 14

A020 L1(R), L2(S), L3(T), P1, P3, T1(U), T2(V), T3(W), N M8 8 - 4 8 - 22

9/15/93

G(E) M4 14 - 10 2 - 5.5

G(E) M5 14 - 10 2 - 5.5

G(E) M8 14 - 10 2 - 5.5

l1(r), l2(s) M4 20 - 14 0.5 - 2

G(E) M8 14 - 10 2 - 5.5

Electrical Connection

2

23

Page 30

2

Installation and Start-up

Table 6. Wire Sizing for Main Circuit - Continued

DRIVE WIRE SIZE

MODEL TERMINAL

VCD 723- TERMINAL SYMBOL SCREW SIZE AWG MM

SECTION A. 208/230 V (Continued)

A025, L1(R), L2(S), L3(T), P1, P3, T1(U), T2(V), T3(W), N M8 4 - 2 22 - 38

A030

A040, L1(R), L2(S), L3(T), P1, P3, T1(U), T2(V), T3(W), N M10 1 - 4/0 38 - 100

A050

B001, L1(R), L2(S), L3(T), N, B1/P, B2, T1(U), T2(V), T3(W) M4 12 - 10 3.5 - 5.5

B003

B005, L1(R), L2(S), L3(T), N, B1/P, B2, T1(U), T2(V), T3(W) M4 12 - 10 3.5 - 5.5

B010

B015, L1(R), L2(S), L3(T), N, B1/P, B2, T1(U), T2(V), T3(W), P3 M5 10 - 8 5.5 - 8

B020

B030 L1(R), L2(S), L3(T), N, P1,P3, T1(U), T2(V), T3(W) M6 8 - 6 8 - 14

B040, L1(R), L2(S), L3(T), N, P1, P3, T1(U), T2(V), T3(W) M8 4 - 3 22 - 38

B060

B075, L1(R), L2(S), L3(T), N, P1, P3, T1(U), T2(V), T3(W) M10 1 - 4/0 38 - 100

B100,

B150

B200, L1(R), L2(S), L3(T), N, P1, P3, T1(U), T2(V), T3(W) M12 4/0 - MCM400 100 - 200

B250

B300, L1(R), L2(S), L3(T), N, P1, P3, T1(U), T2(V), T3(W) M12 MCM650 x 2P 325 x 2P

B400

G(E) M8 14 - 10 2 - 5.5

l1(r), l2(s) M4 20 - 14 0.5 - 2

G(E) M8 14 - 10 2 - 5.5

l1(r), l2(s) M4 20 - 14 0.5 - 2

SECTION B. 380/415/460V

G(E) M4 14 - 10 2 - 5.5

G(E) M5 14 - 10 2 - 5.5

G(E) M8 14 - 10 2 - 5.5

l1(r), l2200(s200), l2 400(s400), x, y M4 20 - 14 0.5 - 2

G(E) M8 14 - 10 2 - 5.5

l1(r), l2200(s200), l2 400(s400), x, y M4 20 - 14 0.5 - 2

G(E) M8 14 - 10 2 - 5.5

l1(r), l2200(s200), l2 400(s400), x, y M4 20 - 14 0.5 - 2

G(E) M8 14 - 10 2 - 5.5

l

1(r), l2 200(s200), l2 400(s400), x, y M4 20 - 14 0.5 - 2

G(E) M8 14 - 10 2 - 5.5

l1(r), l2200(s200), l2 400(s400), x, y M4 20 - 14 0.5 - 2

G(E) M8 14 - 10 2 - 5.5

1(r), l2 200(s200), l2 400(s400), x, y M4 20 - 14 0.5 - 2

l

2

24

Electrical Connection

9/15/93

Page 31

Installation and Start-up

CORRECT CORRECT NOT

ACCEPTABLE

GROUND

POLE

GROUND

POLE

GROUND

POLE

LA-10

2

Grounding

The VCD 723 must be solidly grounded using the main circuit ground terminal

G (E).

● Ground wire resistance should be 100 ohms or less.

● NEVER ground the VCD 723 in common with welding machines, motors,

or other large current electrical equipment. Run the ground lead in a separate

conduit from leads for large current electrical equipment.

● Use ground lead size listed in table 6, and make the length as short as

possible.

● Where several VCD 723 dri v es are used side b y side, all should be grounded

directly, or daisy chained to earth ground (see Figure 5). DO NOT FORM A

LOOP WITH THE GROUND LEADS.

Pre-Po wer

Check

Figure 5. Proper Grounding of Three VCD 723 Drives

CAUTION

To prevent damage to the drive, the following checks must be

performed before applying input power.

❏ Make sure wires are properly connected.

❏ Verify ground connections to the drive.

❏ Disconnect motor from its load. To ensure safety, prior to test operation,

disconnect the coupling or belt which connects the motor with the machine

so that motor operation is isolated. If an operation must be performed while

the motor is directly connected to the machine, use great care to avoid an y

possible hazardous condition.

❏ For 460V, 15HP and above verify that the power voltage select connector in

the VCD 723 is positioned correctly for the input power line voltage (see

Figure 6). Voltage is preset to 460V at the factory . Reposition if required.

❏ Check that all mechanical connections inside VCD 723 are tight.

9/15/93

Pre-Power Check

25

Page 32

2

Installation and Start-up

200V 380V 440V

220/ 400/ 460V

230V 415V

FUSE

•

•

•

•

Figure 6. Voltage Selection in 460V VCD 723, 15HP and Abo ve

❏ Remove any excess packing material.

❏ Check that all shipping devices and relay wedges ha v e been r emo ved.

Manually operate all contactors and relays to ensure that they move freely.

❏ Verify that all electrical connections are secure.

❏ Verify that all transformers are connected for proper voltage, according to the

drive system schematic diagram.

❏ Verify that the PG-X tachometer card is installed.

❏ Verify the EPROM inserted in the VCD 703 control board is labeled

according to the drawings supplied.

❏ Verify that all connections are made per the schematic.

❏ Verify that the three phase power connections are secure.

CAUTION

Verify that incoming power IS NOT connected to the drive's

output terminals. (Terminals T1, T2, and T3). Improper

connection will cause severe damage to the drive when

energized.

26

Pre-Power Check

9/15/93

Page 33

Drive Start-up

Installation and Start-up

❏Verify the motor, blower, thermistor, and PG (Digital Tachometer) wiring for

proper voltage and phase sequence. If the motor is a MagneTek Vector

Control Motor (VCM), then see the appendix for proper wiring. If the motor

is not a MagneTek VCM, then see the manufacturer supplied drawings.

❏Apply three phase input power to the drive.

❏Verify that the “CHARGE” lamp inside the drive is lit.

❏The first message that will be displayed on the Local Control Display Unit is

the following:

Verifying the

CRC-16. Wait . . .

This is an indication that the CPU is verifying the program loaded in its

memory is valid. The check takes approximately 5 seconds. After the check,

one of a number of messages will be displayed.

❏When the program and non-volatile memory is valid, the following message

will be displayed on the Local Control Display Unit:

2

Powered Up

and Ready

In addition, the Ready LED will be lit.

❏The following is a list of abnormal display conditions that may occur, and

the actions necessary to correct the situation:

● If there is an invalid program in memory, then the following message

will be displayed on the Local Control Display Unit:

Select BAUD rate

19200 UP,DWN,ENT

If this occurs, a new program must be uploaded into memory. See Section 3

for the proper program upload procedure.

● Check that no faults are indicated on the drive’s display. A fault is

indicated by the Fault LED being lit and a fault message appearing on the

Local Control Display Unit. See Section 3 for more detailed information

regarding fault reporting and clearing.

9/15/93

Drive Start-up

27

Page 34

2

Installation and Start-up

●As part of the program’s start-up procedure, the validity of the nonvolatile

parameters are checked. If the values are invalid, the following message is

displayed on the Local Control display Unit:

BAD NVRAM CRC

ENT FOR DEFAULTS

If this occurs, press the ENT key. The factory programmed default values

will then be loaded into non-volatile memory.

❏The parameter values should be checked for proper settings. The settings

will be shown on the Function list supplied with the order documentation.

Refer to Section 3 to find the operating procedure necessary to view and

change parameter values. These parameter values include the following:

●Speed Reference Setting Constants (i.e., Main Speed Reference, Jog

Speed Reference).

●Application Constants (i.e., Accel Time, Decel Time, Forward Side

Torque Limit).

●Control Constants (i.e., Speed Reference Input Limit, Pulse Generator

Pulses Per Motor Revolution, Motor Overload Detection starting Current).

●Motor Constants (i.e., Base Speed, Number of Motor Poles, Motor Rated

Current, Rated Slip Frequency).

●Order Constants (i.e., Select Control with or without Pulse Generator

Feedback, Select Control with or without motor thermistor).

●System Constants (i.e., MagneTek Vector Control Motor Selection,

Input/Output Function Assignments, Control Behavior Selections, Carrier

Frequency Selection).

●Any other values that may be job specific (i.e., Empty Roll Diameter for

winder applications, Follower Pulse Generator Pulses Per Revolution).

❏Check the Pulse Generator’s (PG) rotation.

●Select the parameter to view the PG Feedback (function number 604).

●Manually rotate the shaft counter clockwise, as viewed from the shaft end.

Verify that the displayed PG feedback is positive.

If the display does not change from “0”, check the PG cable connections.

If the problem persists, check for pulses at test points “PA” and “PB” on

the right-hand side of the PG-X card, with an oscilloscope.

If the PG feedback shows a negative sign (“-”), reverse the polarity by

reversing the wiring between the A and B channels. This is accomplished

by switching the wire labeled A+ with wire labeled B+, then switching

wire labeled A- with wire labeled B-.

28

Drive Start-up

9/15/93

Page 35

Installation and Start-up

●Manually rotate the shaft clockwise, as viewed from the shaft end. Verify

that the displayed PG feedback is negative (“-”).

❏Check the motor rotation.

●Check that the drive is in the forward rotation mode.

●Start the motor at a slow speed by using the JOG input if one is present.

Check that the motor accelerates smoothly and that the speed feedback is

the same as the speed reference.

●If the motor does not accelerate smoothly or oscillates, check or perform

the following:

❶Reverse any two motor leads.

IMPORTANT

If leads are reversed, re-identify and record the fact that the leads

were reversed.

2

❷If the speed feedback does not read the same as the speed reference,

verify that the pulse generator’s Pulse Per Revolution constant

(function number 46) is set to the proper value for your pulse

generator.

❸Again start the motor at a slow speed by using the JOG input if one is

present. If instability is still present, check for a noise related

problem:

Program the drive for open loop mode by disabling the Pulse

Generator input.

Start the motor at low speed again by using the JOG input if one is

present. If instability disappears, the problem is noise related.

Program the drive for closed loop mode by enabling the Pulse

Generator input.

❹To verify that noise is the source of the problem, perform the

following:

Change the drive constant, which changes the carrier frequency, from

2.08 KHz to 12.5 KHz.

9/15/93

● Using the LCDU change the appropriate constants.

● Using the LCDU save the changes to NVRAM.

Drive Start-up

29

Page 36

2

Installation and Start-up

● Power the drive down long enough for the charge light to go out.

● Power up the drive.

Run the drive at low speed by using the JOG input if one is present. If

instability increases, the problem is noise related.

Return the carrier frequency to its original setting.

❺If it has been determined that noise is the source of the problem, check

for grounding problems:

Motor must be grounded.

Drive must be grounded.

Check shield connections.

Power leads from the line and to the motor should be isolated from the

pulse generator signals.

Par ameter

Verification

External power supply connections for tachometer common should be

isolated from the earth ground.

External signals, if used, should be isolated from earth ground.

❻If noise is not the problem (instability is not related to carrier

frequency), contact MagneTek Service about adjusting regulator

constants.

❏Perform a motor test run. The test run should be in both the forward and

reverse direction.

❏Connect the motor coupling, or belt, to the load.

❏Verify once again that the VCD 723 parameter values are set to their proper

values. Refer to section 3 to find the operating procedure necessary to view

and change parameter values.

❏Record any parameter values that were changed from their factory default

values.

❏Operate the drive using external control signal inputs shown on the system

schematic and verify proper operation.

30

Drive Start-up

9/15/93

Page 37

Operation

2 Line - 16 Character LCD Display

LA-17

ESC ENT

READY

RUN

TORQUE LIMIT

OVERLOAD

FAULT

RST

3

Controls and

Indicators

Accessible through the front cover of the VCD 723 are local controls and

indicators. Figure 7 shows the Local Control Display Unit.

9/15/93

Status LEDs

Ready

Run

Torque Limit

Overload

Figure 7. Local Control Display Unit (LCDU)

At the top of the LCDU is a liquid crystal display . Two lines of sixteen

alphanumeric characters can be displayed. This allows for English language

legends and units while entering or viewing data.

There are fiv e light emitting diodes on the LCDU. These are used as a quick

indication of the drive’s status.

Indicates that the drive is ready to operate.

Drive is controlling motor speed.

Drive is demanding more torque than is a vailable.

Motor current is in the overload region.

Controls and Indicators

31

Page 38

3

Operation

Fault

Local Control

Display Unit

(LCDU)

ESC

Up Arrow

Indicates that a drive fault exists. The Fault/Error Code List (see Table 8 located

in the Troubleshooting/Maintenance section) defines what conditions the drive

will recognize as faults.

IMPORTANT

Clearing a Fault from the Fault List is NOT THE SAME as

resetting the fault. Some faults are transient in nature and require

no further action after clearing the fault from the Fault List.

Others require additional action to allow the drive to continue to

run. See the Fault/Error Code List for further details.

All status lights are under the control of the application specific software. The

PAC program for this drive must be consulted to determine the actual meaning

for each light.

There are five keypad keys on the LCDU. These allow for the entry and viewing

of data. They can also be used for operating the drive.

Allows you to “back out” of an operation. For example, if a mistake is made

while entering numerical data, the ESC key can be pressed before the data is

entered, allowing the operator to start over.

Scrolls to the next higher number. The number may be a specific function

number or the modification of the value of a parameter.

Down Arrow

ENT

RST

Start-up

Operation

Scrolls to the next lower number. The number may be a specific function

number or the modification of the value of a parameter.

Completes an operation. It may be pressed to enter a modified parameter’s

value, or to go “deeper into” a function.

Used to clear the fault list. There are other methods that can be used to clear the

fault list, but this key provides a shortcut. Any time this key is pressed, the fault

list will be cleared. Depending on the nature of the fault and the PAC program

loaded, this button can also clear the fault condition as well as the record of the

fault.

An optional Portable Control Display Unit (PCDU) can be plugged into a

telephone style jack at the side of the VCD 723 drive (reference figure 4). If

your drive is equipped with this option, refer to the PCDU guide provided with

the unit for operating procedures.

❏After applying power, the first message displayed on the Local Control

Display Unit is the following:

Verifying the

CRC-16. Wait...

32

Start-up Operation

9/15/93

Page 39

Operation

This is an indication that the CPU is verifying the program loaded in

memory is valid. The check takes approximately 5 seconds. After the

check, one of a number of messages will be displayed.

❏When the program and non-volatile memory are valid, the following

message will be displayed on the Local Control Display Unit:

Powered Up

and Ready

In addition, the Ready LED will be lit.

❏The following is a list of abnormal display conditions that may occur, and the

actions necessary to correct the situation:

If there is an invalid program in memory, then the following message will

•

be displayed on the Local Control Display Unit:

Select BAUD rate

19200 UP,DWN,ENT

3

If this occurs, a new program must be uploaded into memory. The

program upload procedure is explained later in this section.

A fault condition may have occurred, in which case a fault message will

•

be displayed. An example of a fault message would be as follows:

Divide by Zero

F103 Blk:00170

A fault message is always displayed in this fashion. The top line of the

LCDU display contains a description of the fault. The bottom line of the

LCDU display contains the Fault assigned number and other information

that will help determine the cause of the fault. In the example given

above, the extra information shows which PAC block was being executed.

If the block number is 0000 the fault occurred in the kernel code. When

the fault is related to the MicroTrac LAN, instead of the PAC block

number, a Local Area Network Node number will appear (i.e., Node:002),

which will identify the device on the MicroTrac LAN with which the fault

is associated.

9/15/93

Start-up Operation

33

Page 40

3

Operation

When a fault message is displayed, the source of the fault should be

corrected. After the fault source is corrected, the fault may be cleared by

pressing the RST key on the LCDU.

As part of the program’ s startup procedure, it checks the validity of the

•

parameters that are stored in non-volatile memory. If the values are

inv alid, then the following message is displayed on the Local Control

Display Unit:

BAD NVRAM CRC

ENT FOR DEFA ULTS

If this occurs, press the ENT key. The factory programmed default values

will then be loaded into non-volatile memory.

General

Operation

After the drive has powered up and the display is showing “Powered Up and

Ready”, or a fault number, the LCDU can be used to enter new values for

parameters, monitor drive functions, and perform certain drive diagnostics. Every

operation that the LCDU performs is called a “function”. Each function is

assigned a unique number . Function numbers and descriptions are listed in Table 7.

Table 7. Function Number Assignments

Function

Number Description

000 Fault Display/Clear

1 to 599 PAC Dependent Parameter Values

600-799 PAC Dependent Monitor Only Values

800 Error Display

801 Modify Fault and Error Declarations

802-899 Reserved for Advanced Fault and Error Control

900-979 Reserved for Diagnostics and Tests

980 (P) PAC Block Trace Monitor

981-991 Reserved for Diagnostics and Tests

992 (L) Upload/Download of Program or Parameters

993 (P) Reset All Non-Volatile RAM

994 Save/Restore Non-Volatile RAM Parameters

995 Load Defaults

996-998 Reserved for Diagnostics and Tests

999 Hex Monitor

34

General Operation

(P) These functions are only available through use of the optional Portable Control Display

Unit (PCDU).

(L) These functions are only available through use of the Local Control Display Unit (LCDU).

9/15/93

Page 41

Operation

3

Parameter

Functions

The functions numbered 1 through 599 are reserved for settable parameters. The

function numbers for these settable parameters depend on the PAC program,

although some function numbers may be standardized. Examples of settable

parameters are Accel Times, Regulator Gains, and Rated Speed.

The following steps explain how to modify a given parameter v alue via the

LCDU display:

❏ Press the Up or Down Arro w k eys to select the desired function number.

The display shows a description of the function on the top line, and the

present value, units, and function number on the bottom line.

TA CH COUNTS

1024. PPR P068

❏ Press the ENT key to allo w the currently displayed parameter to be modified.

After the ENT key is pressed, a prompt will be given to indicate that the

modify mode is active.

TA CH COUNTS

1024. PPR EDIT

❏ Press the Up or Down ke ys to change the value of the parameter . The least

significant digit of the parameter will be changed by 1 for ev ery k eypress.

Holding the key down will result in an auto repeat of the k eypress. If a

minimum or maximum limit is exceeded for the parameter value, then the

message “vLIMv” or “^LIM^” will be displayed, respectively.

❏ At this point, the ENT key or the ESC key may be pressed.

Press the ENT key to accept the currently entered value for the displa yed

parameter . If the value is within the minimum and maximum limits for the

parameter, it is accepted and the modify prompt disappears. If the value has

exceeded a limit when the ENT key is pressed, the limit is accepted and the

modify prompt disappears.

A modified parameter is retained only as long as power is applied. Function

#994 is used to save the ne w value in nonvolatile memory .

Press the ESC key to exit the modify mode without changing the parameter

value. The modify prompt will disappear and the original value will return.

9/15/93

Parameter Functions

35

Page 42

3

Operation

Monitor

Functions

Error Handling/

Reporting

Functions numbered 600 through 799 are reserved for parameters that may be

viewed, but not modif ied. The function n umbers for these displayable

parameters depend on the PA C program, although some function n umbers may

be standardized. Examples of displayable parameters are Speed Feedback,

Actual Motor RPM, and Inv erter Output Current.

The following steps explain how to display a given parameter via the LCDU

display:

❏ Press the Up or Down Arro w k eys to select the desired function number .

The display shows a description of the function on the top line, and the

present value, units, and function number on the bottom line.

SPEED

0.000 PU M600

The drive has two methods for reporting errors and f aults. Each condition may

utilize one, both, or neither of the reporting methods.

1. The most conventional method is called f ault reporting. Each occurrence of a

fault is recorded in an area of memory called the Fault List. At the moment a

fault condition occurs, the red FAULT light will light and a unique fault

number will appear on the LCDU. The Fault List stores the 16 oldest faults

and stops recording faults as soon as the list is filled. This list is erased when

the drive is powered down or reset. Whether or not the driv e stops or

continues to run is dependent on the way the particular fault is implemented

within the PA C diagram. Most standard f aults are set so tha t the drive will

stop if a fault occurs.

36

Monitor Functions

2. The second method is called error reporting. Each occurrence of an error is

recorded in an area of memory called the Error List. Error reporting differs

from fault reporting in several respects. First, at the moment an err or