Page 1

YASKAWA

Varispeed L7

INSTRUCTION MANUAL

INVERTERS FOR ELEVATOR DRIVES

MODEL: CIMR-L7B

200V CLASS 3.7 to 55kW (7 to 93kVA)

400V CLASS 3.7 to 55kW (7 to 106kVA)

Upon receipt of the product and prior to initial operation, read these instructions

thoroughly, and retain for future reference.

YASKAWA

MANUAL NO. TOEP C710676 08B

Page 2

Copyright © 2008 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this

publication.

Page 3

Preface

This manual is designed to ensure correct and suitable

application of Varispeed L7-Series Inverters. Read this

manual before attempting to install, operate, maintain,

or inspect an Inverter and keep it in a safe, convenient

location for future reference. Be sure you understand

all precautions and safety information before attempting application.

General Precautions

• The diagrams in this manual may be indicated without covers or safety shields to show details.

Be sure to restore covers or shields before operating the Units and run the Units according to the

instructions described in this manual.

• Any illustrations, photographs, or examples used in this manual are provided as examples only

and may not apply to all products to which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of the

manual may be changed without notice to improve the product and/or the manual.

• When ordering a new copy of the manual due to damage or loss, contact your Yaskawa representatives or the nearest Yaskawa sales office and provide the manual number shown on the front

cover.

• If nameplates become warn or damaged, order new ones from your Yaskawa representatives or

the nearest Yaskawa sales office.

I

Page 4

Safety Information

IMPORTANT

WARNING

CAUTION

The following conventions are used to indicate precautions in this manual. Failure to heed precautions provided in this manual can result in serious or possibly even fatal injury or damage to

the products or to related equipment and systems.

Indicates precautions that, if not heeded, could possibly result in loss of life or serious injury.

Indicates precautions that, if not heeded, could result in relatively serious or minor injury, damage

to the product, or faulty operation.

Failure to heed a precaution classified as a caution can result in serious consequences depending

on the situation.

Indicates important information that should be memorized.

II

Page 5

Safety Precautions

WARNING

CAUTION

CAUTION

WARNING

Motor Selection

• Use only a Yaskawa permanent magnet motor in combination with this Inverter, specifically

SSE4-F21. Running any other permanent magnet motor with this Inverter may cause the

Inverter to operate abnormally. Consult with Yaskawa before attempting to use a motor other than

the model specified.

Confirmations upon Delivery

• Never install an Inverter that is damaged or missing components.

Doing so can result in injury.

Installation

Wiring

• Always hold the case when carrying the Inverter.

If the Inverter is held by the front cover, the main body of the Inverter may fall, possibly resulting in injury.

• Attach the Inverter to a metal or other noncombustible material.

Fire can result if the Inverter is attached to a combustible material.

• Install a cooling fan or other cooling device when installing more than one Inverter in the same

enclosure so that the temperature of the air entering the Inverters is below 45×C.

Overheating can result in fires or other accidents.

• Always turn OFF the input power supply before wiring terminals.

Otherwise, an electric shock or fire can occur.

• Wiring must be performed by an authorized person qualified in electrical work.

Otherwise, an electric shock or fire can occur.

• Be sure to ground the ground terminal. (200 V Class: Ground to 100 Ω or less, 400 V Class:

Ground to 10 Ω or less)

Otherwise, an electric shock or fire can occur.

• Always check the operation of any fast stop circuits after they are wired.

Otherwise, there is the possibility of injury. (Wiring is the responsibility of the user.)

• Never touch the output terminals directly with your hands or allow the output lines to come into contact with the Inverter case. Never short the output circuits.

Otherwise, an electric shock or ground short can occur.

• Do not use the Inverter for any load other than a three-phase AC motor.

• A permanent magnet motor is a type of permanent magnet motor with a rotor in which a magnet is

integrated. Unlike an induction motor, the permanent magnet motor terminal generates high voltage when the motor is running, even when the Inverter power is shut off. Be sure to completely

stop the motor before wiring, maintenance and inspection.

Failure to do so may result in electric shock.

III

Page 6

• Wire the Inverter so that the Run command switches off when a Stop command (or Fast stop com-

CAUTION

WARNING

WARNING

mand) is input to terminal BB or terminal BB1.

If the Run command is not removed, then the motor will begin running as soon as the Stop command (or Fast stop command) is cleared.

This can result in personal injury.

• Check to be sure that the voltage of the main AC power supply satisfies the rated voltage of the

Inverter.

Injury or fire can occur if the voltage is not correct.

• Do not perform voltage withstand tests on the Inverter.

Otherwise, semiconductor elements and other devices can be damaged.

• Connect braking resistors, Braking Resistor Units, and Braking Units as shown in the I/O wiring

examples.

Otherwise, a fire can occur and the Inverter, braking resistors, Braking Resistor Units, and Braking Units can be damaged.

• Tighten all terminal screws to the specified tightening torque.

Otherwise, a fire may occur.

• Do not connect AC power to output terminals U, V, and W.

The interior parts of the Inverter will be damaged if voltage is applied to the output terminals.

• Do not connect phase-advancing capacitors or LC/RC noise filters to the output circuits.

The Inverter can be damaged or interior parts burnt if these devices are connected.

• When a magnetic contactor is connected to the output circuits, do not switch it ON and OFF while

the Inverter is running.

Surge current will cause the overcurrent protection circuit inside the Inverter to operate.

• This Inverter can drive an induction motor or a permanent magnet motor. Select a suitable control

method (parameter A1-02) for the motor you drive.

Failure to do so will cause damage to the motor.

Setting User Parameters

• Do not change the factory setting (0) in b1-03 (Run Command source selection).

Doing so can cause the elevator to drop.

• Do not change the factory setting (1) in L8-05 (Input open-phase protection selection).

You can change it to 0, but only after confirming that there are no factors that cause input open

phase.

Doing so may damage the Inverter main circuits.

IV

Page 7

CAUTION

• Disconnect the load (machine, device) from the motor before performing rotational autotuning or

WARNING

pole tuning.

The motor may turn, possibly resulting in injury or damage to equipment. Also, motor parameters cannot be correctly set

with the motor attached to a load.

• Stay clear of the motor until rotational autotuning or pole tuning has been successfully completed.

The motor could stop and then start again unexpectedly and this could result in injury.

• Always confirm the following before rotational autotuning or pole tuning:

• The lock key has been removed from the motor shaft.

• There are neither people nor objects around the motor shaft.

• The motor is at a complete stop.

Failure to do so may result in injury.

• Be careful when handling the shaft and coupling.

Failure to do so may result in injury.

• Be careful not to injure yourself with the key groove when turning the motor shaft by hand.

Failure to do so may result in injury.

• When operating a permanent magnet motor for the first time, or after exchanging a permanent

magnet motor or an Inverter, set a correct motor parameter to the Inverter before the operation,

and be sure to check the motor speed detection.

Shortage of torque may be the cause when the motor is pulled in the load direction or when the motor does not run as

directed, such as reverses, doesn't work, or over-accelerates.

Refer to Chapter 4 Trial Operation for details.

• Do not change the parameter settings unnecessarily.

Doing so may impede motor operation.

• When running a permanent magnet motor, be sure to set the following parameters.

• Motor related parameters (E1-, E5-)

• Parameters for PG open-circuit detection function (F1-)

• Parameters for excessive speed deviation detection function (F1-)

• Parameters for over-acceleration detection function (S3-)

Failure to do so will cause damage to the equipment.

• If running a permanent magnet motor with any option cards other than the PG-F2 card, and not

using the braking sequence recommended by this Inverter, set the following braking sequences

externally.

• After inputting the operational order, or closing the pole detection complete signal, release the braking.

A basket will be pulled by a counter weight. Be careful of this, as it can cause injury.

• If running a permanent magnet motor with any option cards other than the PG-F2 card, note that

the Inverter has not been adapted for use with batteries. If so, do not select the battery as the

power source for an operation.

Shortage of torque may be the cause when the motor is pulled in the load direction or when the motor does not run as

directed, such as reverses, doesn't work, or over-accelerates.

Trial Operation

• Check to be sure that the front cover is attached before turning ON the power supply.

An electric shock may occur.

• Provide a separate fast stop switch; the Digital Operator STOP Key is valid only when its function is

set.

Injury may occur.

• Reset alarms only after confirming that the RUN signal is OFF.

Injury may occur.

V

Page 8

CAUTION

• Do not touch the radiation fins (heatsink), braking resistor, or Braking Resistor Unit. These can

WARNING

CAUTION

become very hot.

Otherwise, a burn injury may occur.

• Be sure that the motor and machine is within the applicable ranges before starting operation.

Otherwise, an injury may occur.

• Provide a separate holding brake if necessary.

Always construct the external sequence to confirm that the holding brake is activated in the event

of an emergency, a power failure, or an abnormality in the Inverter.

Failure to observe this caution can result in injury.

• If using an Inverter with a elevator, take safety measures on the elevator to prevent the elevator

from dropping.

Failure to observe this caution can result in injury.

• Do not check signals while the Inverter is running.

Otherwise, the equipment may be damaged.

• Be careful when changing Inverter settings. The Inverter is factory set to suitable settings.

Otherwise, the equipment may be damaged.

Maintenance and Inspection

• Do not touch the Inverter terminals. Some of the terminals carry high voltages and are extremely

dangerous.

Doing so can result in electric shock.

• Always have the protective cover in place when power is being supplied to the Inverter. When

attaching the cover, always turn OFF power to the Inverter through the MCCB.

Doing so can result in electric shock.

• After turning OFF the main circuit power supply, wait for the time indicated on the front cover, and

make sure the CHARGE indicator light has gone out, and then perform maintenance and inspection.

The capacitor will remain charged and is dangerous.

• Maintenance, inspection, and replacement of parts must be performed only by authorized personnel.

Remove all metal objects, such as watches and rings, before starting work. Always use grounded

tools.

Failure to heed these warning can result in electric shock.

VI

• Be sure to completely stop the permanent magnet motor before maintenance and inspection.

Failure to do so may result in electric shock.

• A CMOS IC is used in the control board. Handle the control board and CMOS IC carefully.

The CMOS IC can be destroyed by static electricity if touched directly.

• Do not change the wiring, or remove connectors or the Digital Operator, during operation.

Doing so can result in personal injury.

Page 9

Other

WARNING

CAUTION

• Do not attempt to modify or alter the Inverter.

Doing so can result in electrical shock or injury.

• Do not subject the Inverter to halogen gases, such as fluorine, chlorine, bromine, and iodine, at any

time even during transportation or installation.

Otherwise, the Inverter can be damaged or interior parts burnt.

VII

Page 10

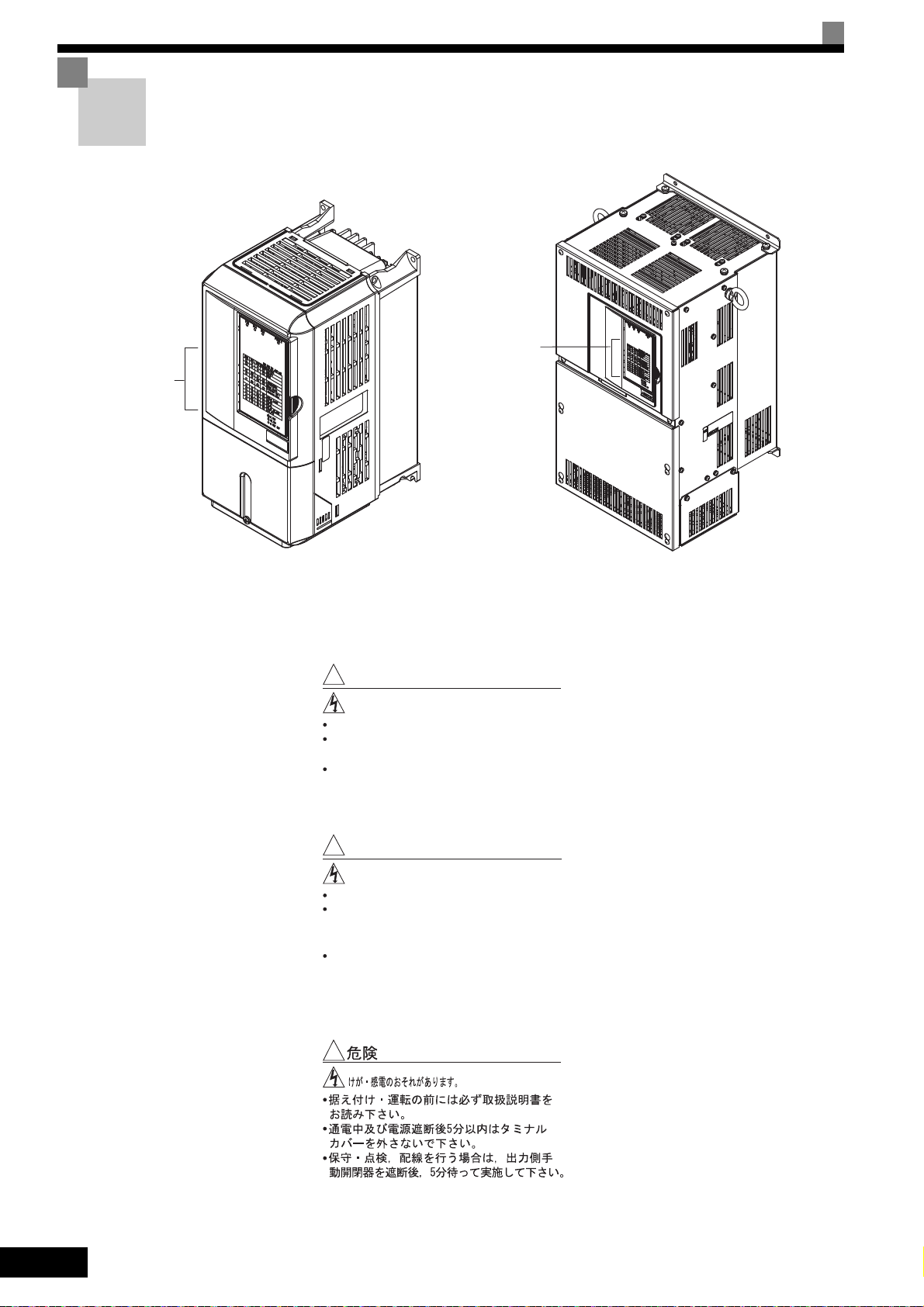

Warning Labels on the Inverter

Warnings

listed

here

CIMR-L7B23P7 (example)

CIMR-L7B2022 (example)

!

WARNING

Risk of electric shock.

Read manual before installing.

Wait 5 minutes for capacitor discharge

after disconnecting power supply.

After opening the manual switch between

the drive and motor, please wait 5 minutes

before inspecting, performing maintenance

or wiring the drive.

!

AVERTISSEMENT

Risque de décharge électrique.

Lire le manuel avant l' installation.

Attendre 5 minutes aprés la coupure de

l' allmentation. Pour permettre la

décharge des condensateurs.

Après avoir déconnécte la protection

entra le drive et le moteur, veuillez

patienter 5 minutes avant d' inspecter,

d' eff

ectuer une opération de montage

ou de câblage du variateur.

!

Be sure to read and follow all warning labels on the Inverter before installation.

Warnings

listed

here

Text on Warning Labels

VIII

Page 11

Warranty Information

Free Warranty Period and Scope

Warranty Period

This product is warranted for twelve months after being delivered to Yaskawa’s customer or if

applicable eighteen months from the date of shipment from Yaskawa’s factory whichever comes

first.

Scope of Warranty

Inspections

Periodic inspections must be conducted by the customer. However, upon request, Yaskawa or

one of Yaskawa’s Service Centers can inspect the product for a fee. In this case, if after conferring with the customer, a Yaskawa product is found to be defective due to Yaskawa workmanship or materials and the defect occurs during the warranty period, then this fee will be waived

and the problem remedied free of charge.

Repairs

If a Yaskawa product is found to be defective due to Yaskawa workmanship or materials and the

defect occurs during the warranty period, Yaskawa will provide a replacement, repair the defective product, and provide shipping to and from the site free of charge.

However, if the Yaskawa Authorized Service Center determines that the problem with a

Yaskawa product is not due to defects in Yaskawa’s workmanship or materials, then the customer will be responsible for the cost of any necessary repairs. Some problems that are outside

the scope of this warranty are:

• Problems due to improper maintenance or handling, carelessness, or other reasons where the

customer is determined to be responsible.

• Problems due to additions or modifications made to a Yaskawa product without Yaskawa’s

understanding.

• Problems due to the use of a Yaskawa product under conditions that do not meet the recommended specifications.

• Problems caused by natural disaster or fire.

• Or other problems not due to defects in Yaskawa workmanship or materials.

Exceptions

Restrictions

Warranty service is only applicable within Japan.

However, after-sales service is available for customers outside of Japan for a reasonable fee.

Contact your local Yaskawa representative for more information.

Any inconvenience to the customer or damage to non-Yaskawa products due to Yaskawa's

defective products whether within or outside the warranty period are NOT covered by this warranty.

• This Inverter does not guarantee performance of the entire elevator system.

• Proper safety measure must be taken on the upper controller side of the hoist application.

• The swing suppression and noise preventative features in this Inverter do not guarantee passenger comfort.

• The Varispeed L7 was not designed or manufactured for use in devices or systems that may

directly affect or threaten human lives or health.

• Customers who intend to use the product described in this manual for devices or systems relating to transportation, health care, space aviation, atomic or electric power, or underwater use

must contact their Yaskawa representatives or the nearest Yaskawa sales office beforehand.

• This product has been manufactured under strict quality-control guidelines. However, if this

product is to be installed in any location where failure of this product could involve or result

in a life-and-death situation or loss of human life or in a facility where failure may cause a

serious accident or physical injury, safety devices must be installed to minimize the likelihood

of any accident.

IX

Page 12

Registered Trademarks

The following registered trademarks are used in this manual.

• DeviceNet is a registered trademark of the ODVA (Open DeviceNet Vendors Association, Inc.).

• InterBus is a registered trademark of Phoenix Contact Co.

• Profibus is a registered trademark of Siemens AG.

• HIPERFACE

®

is a registered trademark of STEGMANN Incorporated.

X

Page 13

Contents

Safety Information ..........................................................................................II

Safety Precautions ........................................................................................III

Warning Labels on the Inverter ................................................................... VIII

Warranty Information .................................................................................... IX

Registered Trademarks ................................................................................. X

1 Handling Inverters ................................................................. 1-1

Varispeed L7 Models ...................................................................................1-2

Permanent magnet motor Application Example ..........................................1-3

Permanent magnet motor Application Example ............................................................1-3

Confirmations upon Delivery .......................................................................1-4

Checks ...........................................................................................................................1-4

Nameplate Information ..................................................................................................1-4

Component Names ........................................................................................................1-6

Exterior and Mounting Dimensions ..............................................................1-8

Open Chassis Inverters (IP00) ......................................................................................1-8

Enclosed Wall-mounted Inverters (NEMA1 / IP20) ........................................................1-8

Checking and Controlling the Installation Site ...........................................1-10

Installation Site ............................................................................................................1-10

Controlling the Ambient Temperature ..........................................................................1-10

Protecting the Inverter from Foreign Matter .................................................................1-10

Installation Orientation and Space ............................................................. 1-11

Removing and Attaching the Terminal Cover ............................................1-12

Removing the Terminal Cover .....................................................................................1-12

Attaching the Terminal Cover .......................................................................................1-12

Removing/Attaching the Digital Operator/LED Monitor and Front Cover ..1-13

Inverters of 18.5 kW or Less ........................................................................................1-13

Inverters of 22 kW or More ..........................................................................................1-15

2 Wiring ...................................................................................... 2-1

Connections to Peripheral Devices .............................................................2-2

Connection Diagram ....................................................................................2-3

Terminal Block Configuration .......................................................................2-5

Wiring Main Circuit Terminals ......................................................................2-6

Applicable Wire Sizes and Closed-loop Connectors .....................................................2-6

Main Circuit Terminal Functions ..................................................................................2-10

Main Circuit Configurations ..........................................................................................2-11

Standard Connection Diagrams ...................................................................................2-12

Wiring the Main Circuits ...............................................................................................2-13

XI

Page 14

Wiring Control Circuit Terminals ................................................................ 2-18

Wire Sizes ................................................................................................................... 2-18

Control Circuit Terminal Functions .............................................................................. 2-20

Control Circuit Terminal Connections .......................................................................... 2-23

Control Circuit Wiring Precautions .............................................................................. 2-24

Wiring Check .............................................................................................2-25

Checks ........................................................................................................................ 2-25

Installing and Wiring Option Cards ............................................................ 2-26

Option Card Models and Specifications ...................................................................... 2-26

Installation ...................................................................................................................2-26

PG Speed Control Board Terminals and Specifications .............................................. 2-28

Wiring .......................................................................................................................... 2-30

Wiring the Terminal Blocks .......................................................................................... 2-34

Selecting the Number of PG (Encoder) Pulses ........................................................... 2-35

3 LED Monitor/Digital Operator and Modes ............................3-1

LED Monitor JVOP-163 ............................................................................... 3-2

LED Monitor .................................................................................................................. 3-2

LED Display Examples .................................................................................................. 3-2

Digital Operator JVOP-160 ..........................................................................3-3

Digital Operator Display ................................................................................................ 3-3

Digital Operator Keys .................................................................................................... 3-3

Inverter Modes .............................................................................................................. 3-6

Switching Modes ........................................................................................................... 3-7

Drive Mode ....................................................................................................................3-8

Quick Programming Mode ............................................................................................. 3-9

Advanced Programming Mode .................................................................................... 3-10

Example Operations .................................................................................................... 3-10

Verify Mode ................................................................................................................. 3-12

Autotuning Mode ......................................................................................................... 3-13

4 Trial Operation ........................................................................4-1

Overview of Trial Operation Procedure ....................................................... 4-2

Performing a Trial Operation ......................................................................4-3

Turning on the Power .................................................................................................... 4-3

Display at Power Up ...................................................................................................... 4-3

Basic Settings ................................................................................................................ 4-4

Setting Motor Related Parameters ................................................................................ 4-6

Application Settings ..................................................................................................... 4-20

No-load Operation ....................................................................................................... 4-21

Loaded Operation ........................................................................................................ 4-21

Check and Recording User Parameters ...................................................................... 4-22

XII

Performance Optimization ......................................................................... 4-23

Page 15

5 Parameters ............................................................................. 5-1

Parameter Descriptions ...............................................................................5-2

Description of Parameter Tables ....................................................................................5-2

Digital Operation Display Functions and Levels ..........................................5-3

Parameters Available in Quick Programming Mode ......................................................5-4

Parameter Tables ......................................................................................5-10

A: Setup Settings .........................................................................................................5-10

Application Parameters: b ............................................................................................5-12

Tuning Parameters: C ..................................................................................................5-15

Reference Parameters: d .............................................................................................5-21

Motor Parameters: E ....................................................................................................5-23

Option Parameters: F ..................................................................................................5-26

Terminal Function Parameters: H ................................................................................5-31

Protection Function Parameters: L ..............................................................................5-38

N: Special Adjustments ................................................................................................5-45

Digital Operator/LED Monitor Parameters: o ...............................................................5-47

Elevator Function Parameters: S .................................................................................5-51

U: Monitor Parameters .................................................................................................5-58

Factory Settings that Change with the Control Method (A1-02) .................................. 5-66

Parameters that change with V/f patterns ....................................................................5-68

Factory Settings that Change with the Inverter Capacity (o2-04) ................................5-73

6 Parameter Settings by Function ........................................... 6-1

Carrier Frequency Derating and Current Limitation .....................................6-2

Carrier Frequency Setting ..............................................................................................6-2

Current limitation level at low speeds ............................................................................6-3

EN81-1 Compliance ....................................................................................6-4

Control/Brake Sequence .............................................................................6-6

Up and Down Commands ..............................................................................................6-6

Speed Reference Source Selection ...............................................................................6-7

Speed Selection Sequence Using Multi-function Contact Inputs ...................................6-8

Fast Stop ......................................................................................................................6-13

Inspection RUN ............................................................................................................6-14

Brake Sequence ..........................................................................................................6-15

Short Floor Operation ..................................................................................................6-21

Acceleration and Deceleration Characteristics ..........................................6-23

Setting Acceleration and Deceleration Times ..............................................................6-23

Acceleration and S-curve Settings ...............................................................................6-26

Output Speed Hold (Dwell Function) ...........................................................................6-27

Stall Prevention During Acceleration ...........................................................................6-28

Adjusting Analog Input Signals ..................................................................6-30

Adjusting Analog Frequency References ....................................................................6-30

XIII

Page 16

Speed Detection and Speed Limitation .....................................................6-32

Speed Agreement Function ......................................................................................... 6-32

Limiting the Elevator Speed ......................................................................................... 6-34

Improving the Operation Performance ...................................................... 6-35

Droop Control Function ............................................................................................... 6-35

Reducing the Motor Speed Fluctuation (Slip Compensation Function) ....................... 6-36

Torque Compensation Function Adjustments .............................................................. 6-39

Automatic Speed Regulator (ASR) (Closed-loop Vector only) .................................... 6-41

A/D Conversion Delay Time Tuning ............................................................................ 6-43

Torque Compensation Reduction at Stop .................................................................... 6-44

Stabilizing Speed (Automatic Frequency Regulator) (Open-loop Vector) .................... 6-45

Inertia Compensation (Closed-loop Vector only) ......................................................... 6-47

Improving the Leveling Accuracy by Slip Compensation ............................................ 6-48

Field Forcing ................................................................................................................ 6-49

Adjusting the DC Injection Current .............................................................................. 6-50

Motor Rotation Direction Change ................................................................................ 6-51

Protective Functions .................................................................................. 6-52

Preventing Motor Stalling During Operation ................................................................ 6-52

Operation Selection at Frequency Reference Loss ..................................................... 6-53

Motor Torque Detection/Car Stuck Detection .............................................................. 6-53

Limiting the Motor Torque (Torque Limit Function) ...................................................... 6-57

Internal Cooling Fan Failure OH1 Detection ............................................................... 6-58

Motor Overload Protection .......................................................................................... 6-60

Output Current Observation ........................................................................................ 6-62

Inverter Protection .....................................................................................6-64

Inverter Overheat Protection ....................................................................................... 6-64

Output Open Phase Protection ................................................................................... 6-64

Ground Fault Protection .............................................................................................. 6-65

Cooling Fan Control .................................................................................................... 6-66

Setting the Ambient Temperature ............................................................................... 6-67

Over Acceleration Detection (DV6 Fault Detection) .................................................... 6-67

Selection of Conditions for Detection of Excessive Speed Deviation .......................... 6-68

Input Terminal Functions ........................................................................... 6-69

Closing the Inverter Output (Baseblock) ..................................................................... 6-69

Stopping the Inverter on External Device Errors (External Fault Function) ................. 6-70

Using the Timer Function ............................................................................................ 6-71

Magnetic Contactor Answer Back Detection ............................................................... 6-72

Output Terminal Functions ........................................................................ 6-73

Magnetic Position Detection Status Signal .................................................................. 6-76

Motor and V/f Pattern Setup ...................................................................... 6-77

Setting Motor Parameters ........................................................................................... 6-77

Autotuning ................................................................................................................... 6-79

Setting the V/f Pattern ................................................................................................. 6-83

XIV

Page 17

Digital Operator/LED Monitor Functions ....................................................6-85

Setting Digital Operator/LED Monitor Functions ..........................................................6-85

Copying Parameters (JVOP-160 only) ........................................................................6-89

Prohibiting Overwriting of Parameters .........................................................................6-93

Setting a Password ......................................................................................................6-94

Displaying User-set Parameters Only ..........................................................................6-95

Machine Data Copy Function ......................................................................................6-95

PG Option Cards .......................................................................................6-97

Setting the Absolute Encoder Resolution (F1-21) .....................................................6-100

Emergency Operation ..............................................................................6-101

Automatic Fault Reset .............................................................................6-105

UV1 Fault Reset Operation Selection Function ........................................................6-106

MEMOBUS Communications ..................................................................6-107

RS-422/485 Interface .................................................................................................6-107

7 Troubleshooting .................................................................... 7-1

Protective and Diagnostic Functions ...........................................................7-2

Fault Detection ...............................................................................................................7-2

Alarm Detection .............................................................................................................7-9

Operator Programming Errors .....................................................................................7-12

Autotuning Faults ........................................................................................................7-13

Digital Operator Copy Function Faults .........................................................................7-15

Machine Data Copy Function Faults ......................................... 7-16

Troubleshooting .........................................................................................7-17

If A Parameter Cannot Be Set .....................................................................................7-17

If the Motor Does Not Operate Properly ......................................................................7-18

If the Direction of the Motor Rotation is Reversed .......................................................7-18

If the Motor Stalls or Acceleration is Slow ....................................................................7-18

If Motor Deceleration is Slow .......................................................................................7-19

Motor torque is insufficient. ..........................................................................................7-19

If the Motor Overheats .................................................................................................7-19

If Peripheral Devices are Influenced by the Starting or Running Inverter ....................7-20

If the Earth Leakage Breaker Operates When the Inverter is Running .......................7-20

If There is Mechanical Oscillation ................................................................................7-20

8 Maintenance and Inspection ................................................. 8-1

Maintenance and Inspection ........................................................................8-2

Periodic Inspection ........................................................................................................8-2

Periodic Maintenance of Parts .......................................................................................8-3

Types and Number of Cooling Fans Used in the Inverter ..............................................8-4

Cooling Fan Replacement Outline .................................................................................8-5

Circulation Fan Replacement Outline ..........................................................................8-10

Removing and Mounting the Control Circuit Terminal Board .......................................8-12

XV

Page 18

9 Specifications .........................................................................9-1

Inverter Specifications ................................................................................. 9-2

Specifications by Model ................................................................................................. 9-2

Common Specifications ................................................................................................. 9-4

10 Appendix ...............................................................................10-1

Inverter Application Precautions ...............................................................10-2

Selection ...................................................................................................................... 10-2

Installation ................................................................................................................... 10-2

Settings ....................................................................................................................... 10-2

Handling ...................................................................................................................... 10-3

Motor Application Precautions ..................................................................10-4

Using the Inverter for an Existing Standard Motor ....................................................... 10-4

Using the Inverter for Special Motors .......................................................................... 10-4

Power Transmission Mechanism (Speed Reducers, Belts, and Chains) .................... 10-4

EMC Compatibility ..................................................................................... 10-5

Line Filters .................................................................................................10-7

User Parameters .......................................................................................10-9

Revision History

XVI

Page 19

1

Handling Inverters

This chapter describes the checks required upon receiving or installing an Inverter.

Varispeed L7 Models ..........................................................1-2

Permanent magnet motor Application Example..................1-3

Confirmations upon Delivery...............................................1-4

Exterior and Mounting Dimensions .....................................1-8

Checking and Controlling the Installation Site ..................1-10

Installation Orientation and Space ....................................1-11

Removing and Attaching the Terminal Cover ...................1-12

Removing/Attaching the Digital Operator/ LED Monitor and

Front Cover .......................................................................1-13

Page 20

1

Varispeed L7 Models

The Varispeed L7 Series includes Inverters in two voltage classes: 200 V and 400 V. The maximum motor capacities

vary from 3.7 to 55 kW (23 models).

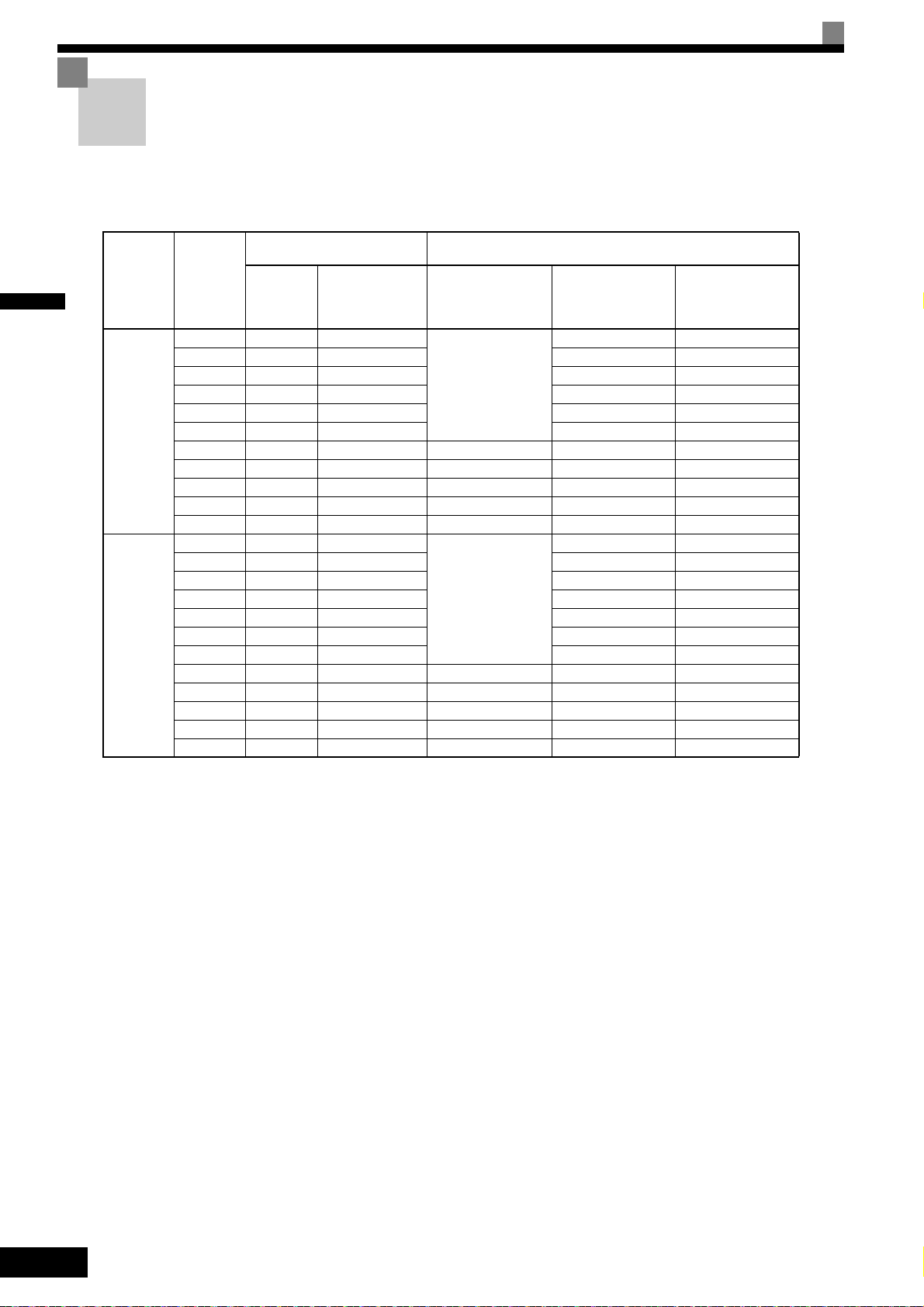

Table 1.1 Varispeed L7 Models

Maximum

Voltage

Class

200 V class

400 V class

* 200 V/400 V class 30KW-55KW model is developing.

Motor

Capacity

kW

3.7 7 CIMR-L7B23P7

5.5 10 CIMR-L7B25P5 25P51 25P57

7.5 14 CIMR-L7B27P5 27P51 27P57

11 20 CIMR-L7B2011 20111 20117

15 27 CIMR-L7B2015

18.5 33 CIMR-L7B2018 20181 20187

22 40 CIMR-L7B2022 20220 20221 20227

30 54 CIMR-L7B2030 20300 20301 20307

37 67 CIMR-L7B2037 20370 20371 20377

45 76 CIMR-L7B2045 20450 20451 20457

55 93 CIMR-L7B2055 20550 20551 20557

3.7 7 CIMR-L7B43P7

4.0 9 CIMR-L7B44P0 44P01 43P77

5.5 12 CIMR-L7B45P5 45P51 45P57

5 15 CIMR-L7B47P5 47P51 47

7.

11 22 CIMR-L7B4011 40111 40117

15 28 CIMR-L7B4015 40151 40157

18.5 34 CIMR-L7B4018 40181 40187

22 40 CIMR-L7B4022 40220 40221 40227

30 54 CIMR-L7B4030 40300 40301 40307

37 67 CIMR-L7B4037 40370 40371 40377

45 80 CIMR-L7B4045 40450 40451 40457

55 106 CIMR-L7B4055 40550 40551 40557

Varispeed L7

Output

Capacity

kVA

Basic Model

Number

(Always specify through the protective structure when ordering.)

Open Chassis

(IEC IP00)

CIMR-L7B

Remove the top and

bottom covers from the

Enclosed Wall-mounted

model.

Remove the top and bot-

tom covers from the

Enclosed Wall-mount

model.

Specifications

Enclosed Wall-

mounted

(NEMA 1)

CIMR-L7B

23P71 23P77

20151

43P71 43P77

Enclosed Wall-

mounted

(IEC IP20)

CIMR-L7B

20157

P57

1-2

Page 21

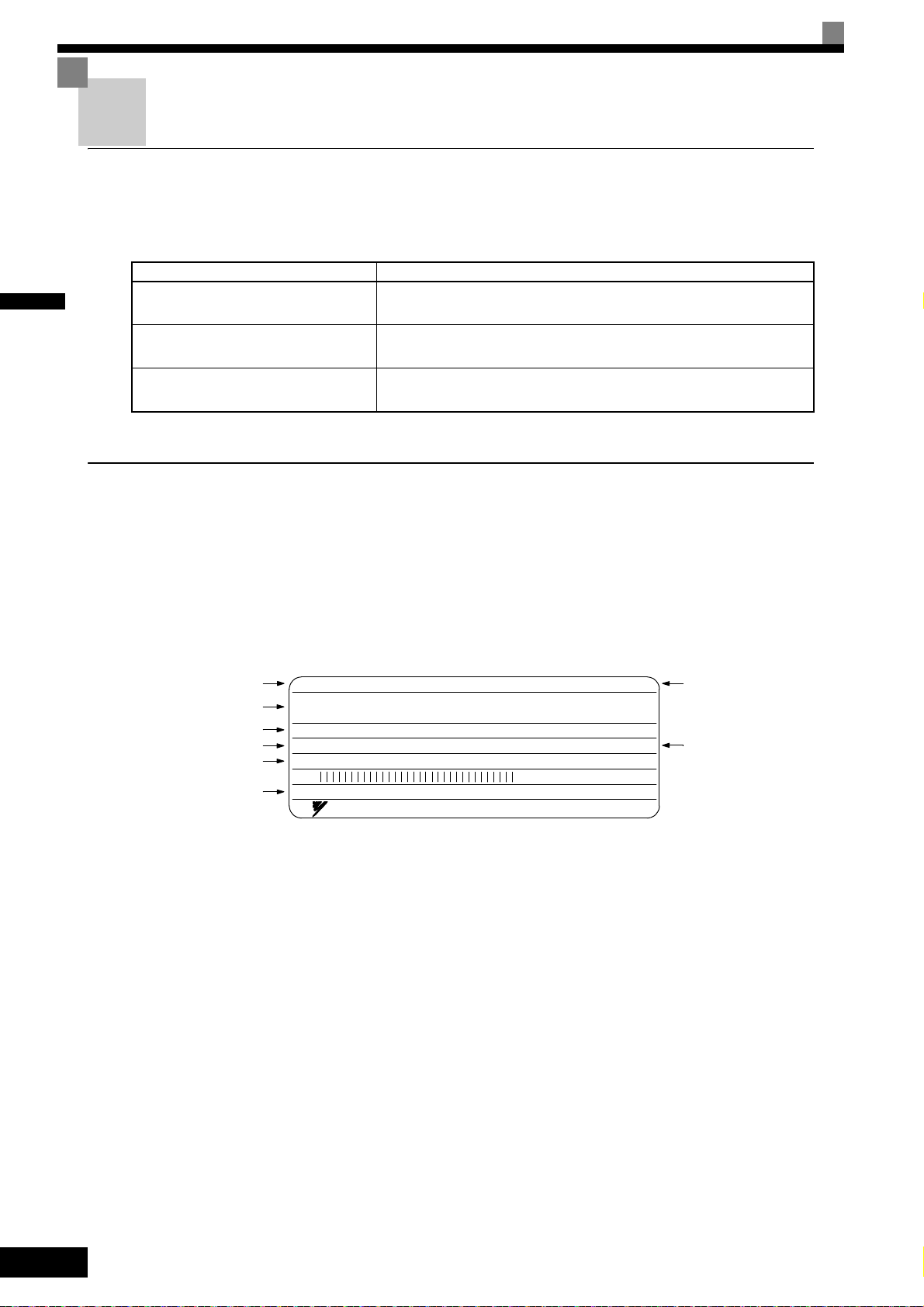

Permanent magnet motor Application Example

Permanent magnet motor Application Example

Permanent magnet motor Application Example

The table below lists which models of Yaskawa’s standard SPM motors correspond with which models of

EnDat encoders.

Application Examples: Yaskawa SPM Motors and EnDat Encoders

Load Capacity

kg

200 V Class

450

600

750

900

1000

400 V Class

450

600

750

900

1000

Elevator Speed

m/min

45 2.1 72 22P1072

60 2.8 96 22P8096

90 4.2 144 24P2144

45 2.8 72 22P8072

60 3.7 96 23P7096

90 5.6 144 25P6144

105 6.5 168 26P5168

45 3.5 72 23P5072

60 4.6 96 24P6096

90 6.9 144 26P9144

105 8.1 168 28P1168

45 4.2 72 24P2072

60 5.6 96 25P6096

90 8.3 144 28P3144

105 9.7 168 29P7168

45 4.6 72 24P6072

60 6.2 96 26P2096

90 9.2 144 29P2144

105 11 168 2011168

45 2.1 72 42P1072

60 2.8 96 42P8096

90 4.2 144 44P2144 47P5

45 2.8 72 42P8072

60 3.7 96 43P7096

90 5.6 144 45P6144

105 6.5 168 46P5168

45 3.5 72 43P5072

60 4.6 96 44P6096

90 6.9 144 46P9144

105 8.1 168 48P1168

45 4.2 72 44P2072

60 5.6 96 45P6096

90 8.3 144 48P3144

105 9.7 168 49P7168

45 4.6 72 44P6072

60 6.2 96 46P2096

90 9.2 144 49P2144

105 11 168 4011168

Motor Output *1

kW

Revolutions per

Minute *2

-1

min

Motor Model

SSE4--F21

Inverter Model

CIMR-L7B

25P5

27P5

2011

27P5

2015

2011

2015

2011

2018

45P5

45P5

4011

47P5

4011

4015

4011

4015

1

* 1. 105 m/min up to 1000 kg.

* 2. Sheave diameter of 400 m with a roping ratio of 2:1.

1-3

Page 22

1

Inverter model

Inverter

specifications

Mass

Input s pecification

Output specification

Serial number

UL file numbe r

Lot number

MADE IN JA PAN

YASKAWA ELECTRIC CORPORARION

SPEC: 43P77A

PRG:

M

s

MASS: 4.0 kg

CIMR-L7B43P7

AC3PH 380-480V 50/60Hz 10.2A

AC3PH 0-480V 0-120Hz 8.5A 3min. 50%ED 8.5kVA

FILE NO E131457

INPUT

OUTPUT

O/N

S/N

MODEL

Confirmations upon Delivery

Checks

Check the following items as soon as the Inverter is delivered.

Table 1.2 Checks

Item Method

Has the correct model of Inverter been

delivered?

Is the Inverter damaged in any way?

Check the model number on the nameplate on the side of the Inverter.

Inspect the entire exterior of the Inverter to see if there are any scratches or

other damage resulting from shipping.

Are any screws or other components

loose?

Use a screwdriver or other tools to check for tightness.

If you find any irregularities in the above items, contact the agency from which you purchased the Inverter.

Nameplate Information

There is a nameplate attached to the side of each Inverter. The nameplate shows the model number, specifications, lot number, serial number, and other information about the Inverter.

Example Nameplate

The following nameplate is an example for a standard domestic European Inverter: 3-phase, 400 VAC,

3.7 kW, IEC IP20 standards

1-4

Fig 1.1 Nameplate

Page 23

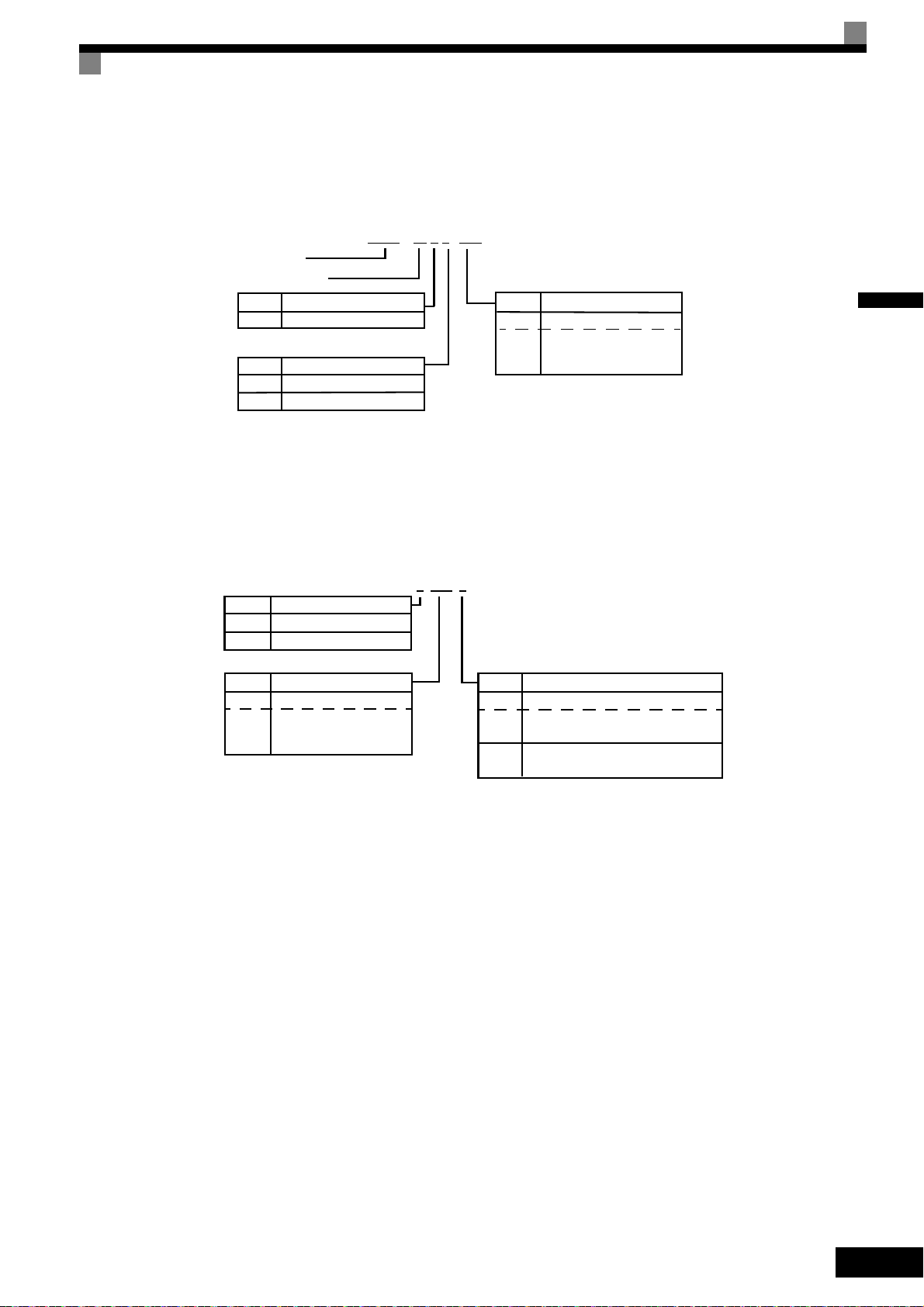

Confirmations upon Delivery

CIMR – L7 B 2 3P7

Inverter

Varispeed L7

No.

B

Specification

IM Motor (PG optional)

No.

Voltage Class

2

4

AC Input, 3-phase, 200 V

AC Input, 3-phase, 400 V

No.

Max. Motor Capacity

3P7

3.7 kW

5P5

5.5 kW

to

to

55

55 kW

“P” Indicates the decimal point.

2 3P7 1

No.

2

4

Voltage Class

AC Input, 3-phase, 200 V

AC Input, 3-phase, 400 V

No.

Max. Motor Capacity

3P7

3.7 kW

5P5

5.5 kW

to

to

55

55 kW

No.

Protective Structure

0

Open chassis (IEC IP00)

1

Enclosed wall-mounted

(NEMA Type 1)

“P” Indicates the decimal point

7

(IEC IP20)

Enclosed wall-mounted

Inverter Model Numbers

The model number of the Inverter on the nameplate indicates the specification, voltage class, and maximum

motor capacity of the Inverter in alphanumeric codes.

Fig 1.2 Inverter Model Numbers

1

Inverter Specifications

The Inverter specifications (“SPEC: A”) on the nameplate indicate the voltage class, maximum motor capacity, the protective structure, and the revision of the Inverter in alphanumeric codes.

Fig 1.3 Inverter Specifications

1-5

Page 24

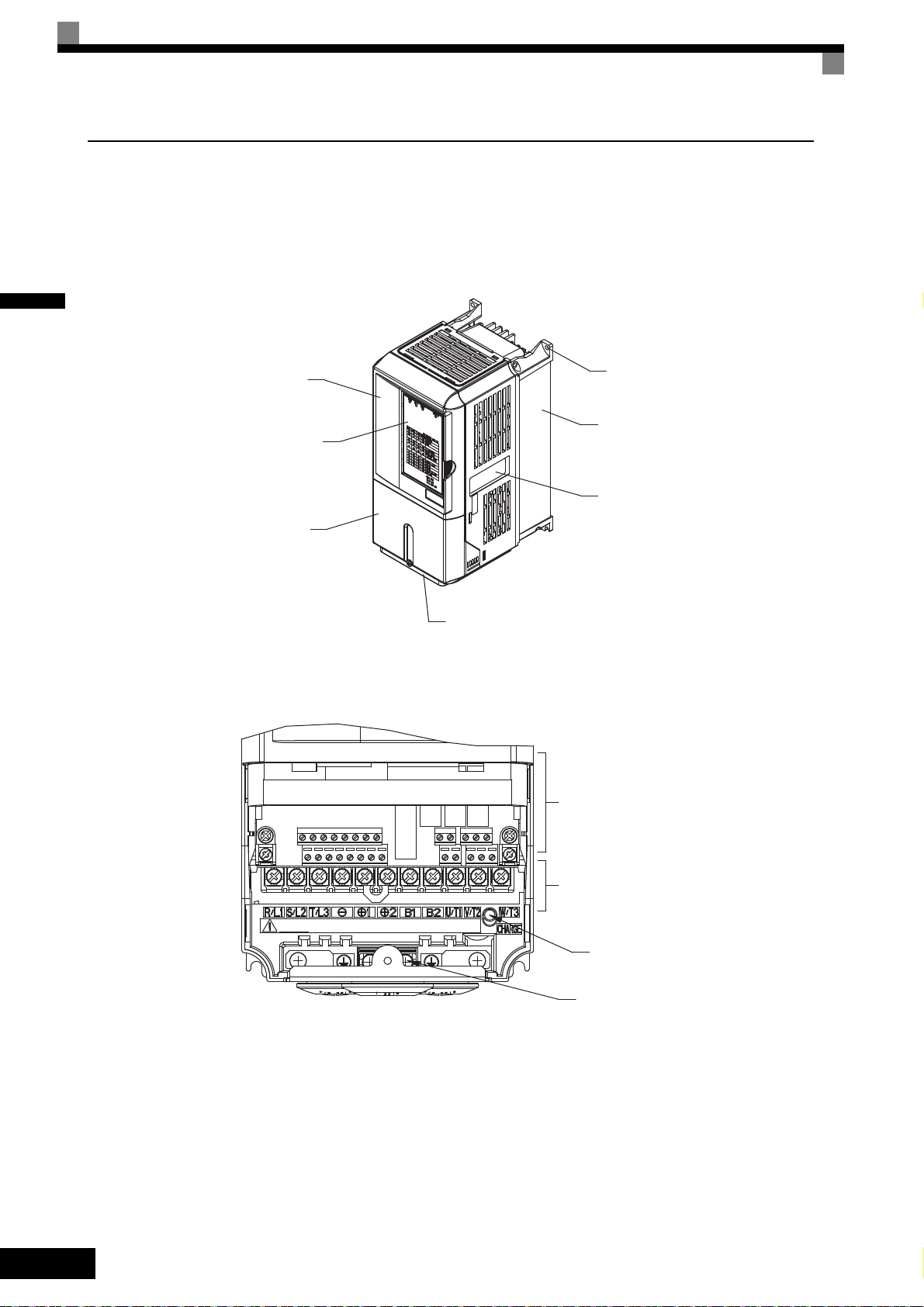

1

Front cover

Digital Operator

Terminal cover

Bottom protective cover

Nameplate

Diecast cover

Mounting

Control circuit terminals

Main circuit terminals

Ground terminal

Charge indicator

Component Names

Inverters of 18.5 kW or Less

The external appearance and component names of the Inverter are shown in Fig 1.4. The Inverter with the terminal cover removed is shown in Fig 1.5.

Fig 1.4 Inverter Appearance (18.5 kW or Less)

Fig 1.5 Terminal Arrangement (18.5 kW or Less)

1-6

Page 25

Confirmations upon Delivery

Front cover

Inveter cover

Digital Operator

Terminal cover

Nameplate

Cooling fan

Mounting holes

Control

circuit

terminals

Charge indicator

Ground terminals

Main

circuit

terminals

Inverters of 22 kW or More

The external appearance and component names of the Inverter are shown in Fig 1.6. The Inverter with the terminal cover removed is shown in Fig 1.7.

1

Fig 1.6 Inverter Appearance (22 kW or More)

Fig 1.7 Terminal Arrangement (22 kW or More)

1-7

Page 26

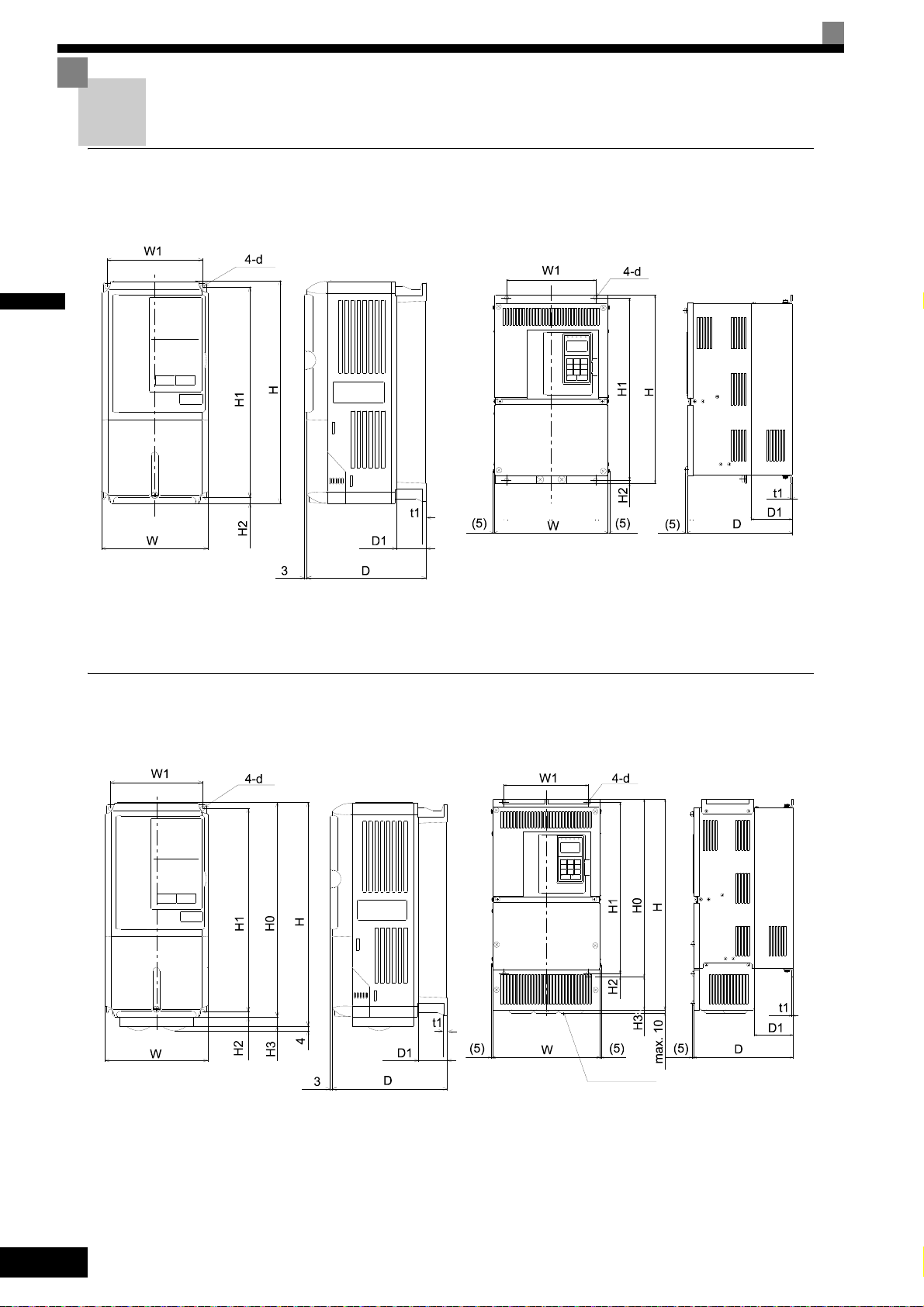

1

200 V Class Inverters of 22 or 55 kW

400 V Class Inverters of 22 to 55 kW

200 V/400 V Class Inverters of 3.7 to 18.5 kW

200 V Class Inverters of 22 or 55 kW

400 V Class Inverters of 22 to 55 kW

200 V/400 V Class Inverters of 3.7 to 18.5 kW

Grommet

Exterior and Mounting Dimensions

Open Chassis Inverters (IP00)

Exterior diagrams of the Open Chassis Inverters are shown below.

Fig 1.8 Exterior Diagrams of Open Chassis Inverters

Enclosed Wall-mounted Inverters (NEMA1 / IP20)

Exterior diagrams of the Enclosed Wall-mounted Inverters (NEMA1 / IP20) are shown below.

1-8

Fig 1.9 Exterior Diagrams of Enclosed Wall-mounted Inverters

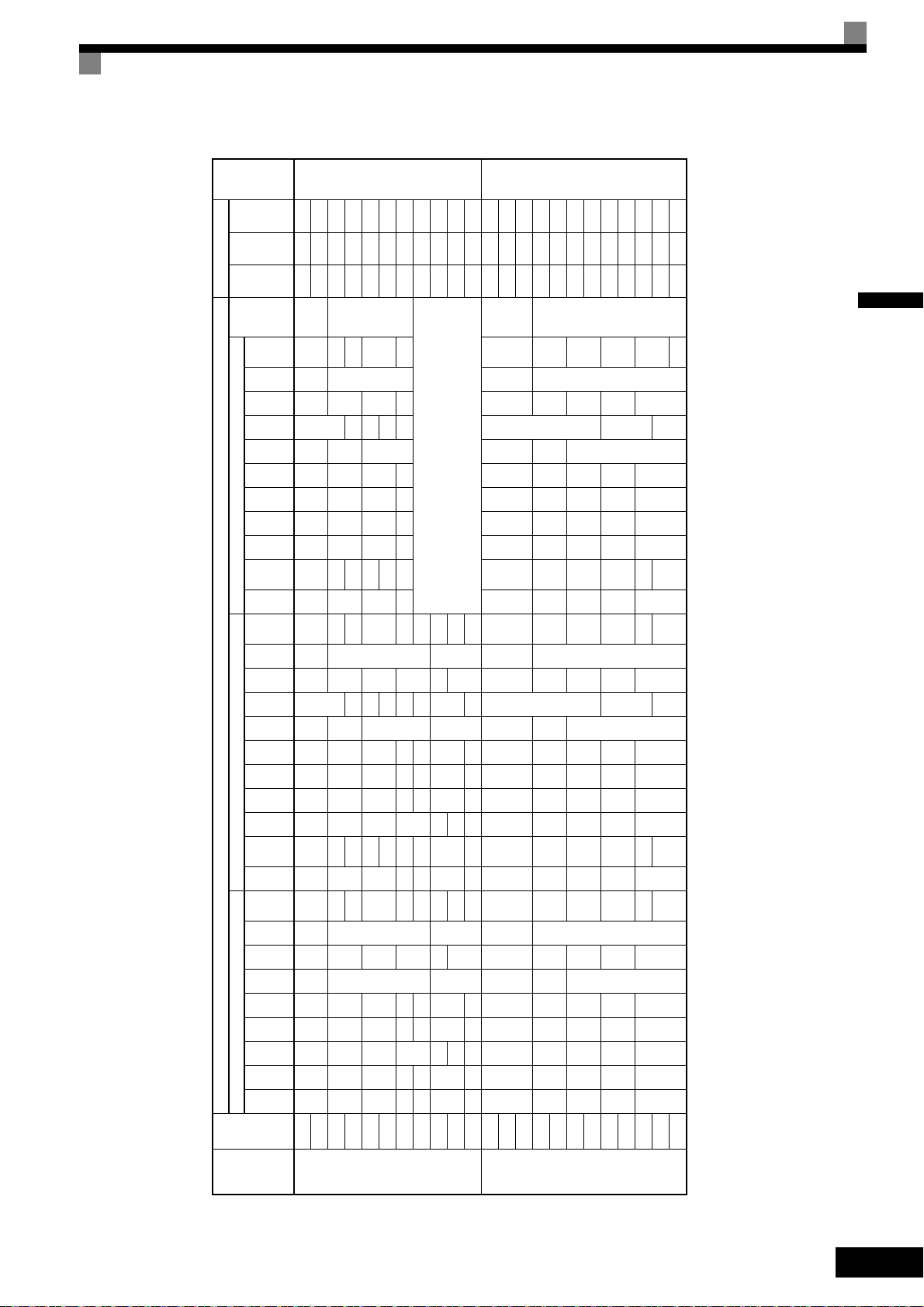

Page 27

Exterior and Mounting Dimensions

Voltage

Class

Max.

Appli-

cable

Motor

Output

[kW]

Dimensions (mm) Caloric Value (W)

Cool-

ing

Method

Open Chassis (IP00) Enclosed Wall-mounted (NEMA1) Enclosed Wall-mounted (IP20)

Mount-

ing

Holes

d*

Exter-

nal

Inter-

nal

To ta l

Heat

Gen-

era-

tion

W H D W1H1H2D1 t1

App-

rox.

Mass

W H D W1H0H1H2H3D1 t1

App-

rox.

Mass

W H D W1H0H1H2H3D1 t1

App-

rox.

Mass

200 V

(3-phase)

3.7

140 280 177 126 266 7 59 5 4 140 280 177 126 280 266 7

0

59 5 4 140 280 177 126 280 266 7

0

59 5 4 M5

112 74 186

Fan

5.5 164 84 248

7.5

200 300 197 186 285

7.5

65.5

2.3

6

200

300

197 186 300 285 8 65.5

2.3

6

200

300

197 186 300 285 8 65.5

2.3

6

M6

219 113 332

11 7 310 10 7 310 10 7 374 170 544

15

240 350 207 216 335 78 11 240

350

207 216 350 335

7.5

0

78 11 240

350

207 216 350 335

7.5

0

78 11

429 183 612

18.5 380 30 380 30 501 211 712

22 250 400

258

195 385

100

17 254 535

258

195 400 385 135

100

20 254 464 258 195 400 385 64 100 19 586 274 860

30 275 450 220 435 20 279 615 220 450 435 165 23 865 352 1217

37

375 600

298

250 575

12.5

100

3.2

52

380 809

298

250

600 575

12.5

209

100

3.2

57 1015

411 1426

45 328

130

57 328

130

62 1266 505 1771

55 450 725 348 325 700 78 453 1027 350 325 725 700 302 86 1588 619 2207

400 V

(3-phase)

3.7

140 280 177 126 266 7 59 5 4 140 280 177 126 280 266 7

0

59 5 4 140 280 177 126 280 266 7

0

59 5 4 M5

80 68 148

Fan

4.0 91 70 161

5.5 127 82 209

7.5

200 300 197 186 285 8 65.5

2.3

6 200 300 197 186 300 285 8 65.5

2.3

6 200 300 197 186 300 285 8 65.5

2.3

6

M6

193 114 307

11 252 158 410

15

240 350 207 216 335

7.5

78 10 240 350 207 216 350 335

7.5

78 10 240 350 207 216 350 335

7.5

78 10

326 172 498

18.5 426 208 634

22

275 450 258 220 435 100 17 279 535 258 220 450 435

85

100 20 279 514.5 258 220 450 435

64

100 19

466 259 725

30 678 317 995

37

325 550 283 260 535 105

31

329

635

283 260 550 535 105

35

329

614

283 260 550 535 105

34

784 360 1144

45

30 715 165 34 629.5 79.5

901 415 1316

55 33 1203 495 1698

Table 1.3 Inverter Dimensions (mm) and Masses (kg)

1

1-9

Page 28

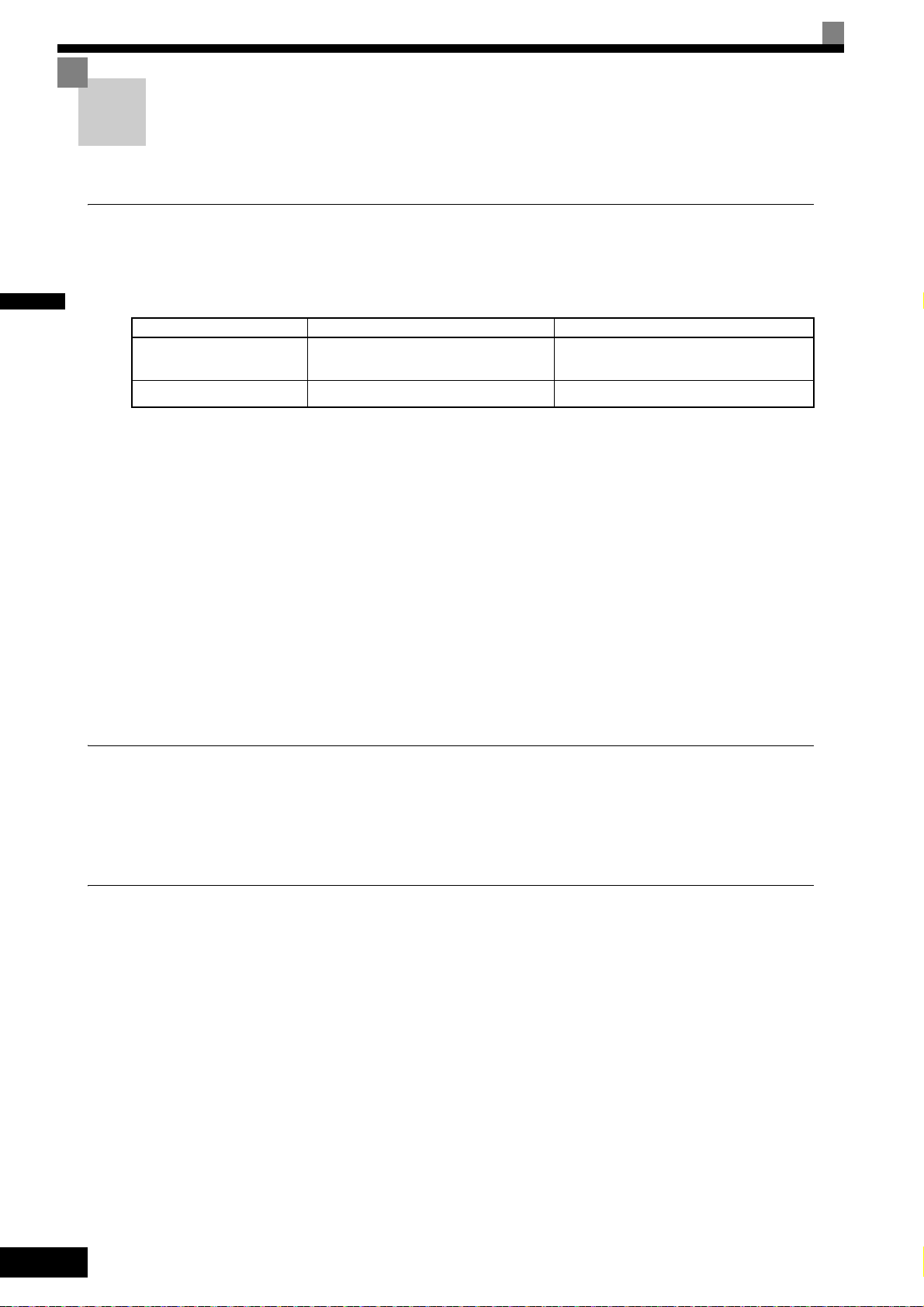

Checking and Controlling the Installation Site

Install the Inverter in the installation site described below and maintain optimum conditions.

Installation Site

1

Install the Inverter under the following conditions in a pollution degree 2 environment.

Table 1.4 Installation Site

Type Ambient Operating Temperature Humidity

Enclosed wall-mounted

(NEMA1)

Open chassis and IEC IP20 -10 to + 45 °C 95% RH or less (no condensation)

Protection covers are attached to the top and bottom of the Inverter. Be sure to remove the protection covers

before installing a 200 or 400 V Class Inverter with an output of 18.5 kW or less in a panel.

Observe the following precautions when mounting the Inverter.

• Install the Inverter in a clean location which is free from oil mist and dust. It can be installed in a totally

enclosed panel that is completely shielded from floating dust.

• When installing or operating the Inverter, always take special care so that metal powder, oil, water, or other

foreign matter does not get into the Inverter.

• Do not install the Inverter on combustible material, such as wood.

• Install the Inverter in a location free from radioactive materials and combustible materials.

• Install the Inverter in a location free from harmful gasses and liquids.

• Install the Inverter in a location without excessive oscillation.

• Install the Inverter in a location free from chlorides.

• Install the Inverter in a location not in direct sunlight.

-10 to + 40 °C 95% RH or less (no condensation)

Controlling the Ambient Temperature

To enhance the reliability of operation, the Inverter should be installed in an environment free from extreme

temperature increases. If the Inverter is installed in an enclosed environment, such as a cabinet, use a cooling

fan or air conditioner to maintain the internal air temperature below 45°C.

Protecting the Inverter from Foreign Matter

Place a cover over the Inverter during installation to shield it from metal power produced by drilling.

Always remove the cover from the Inverter after the completion of the installation. Otherwise, ventilation will

be reduced, causing the Inverter to overheat.

1-10

Page 29

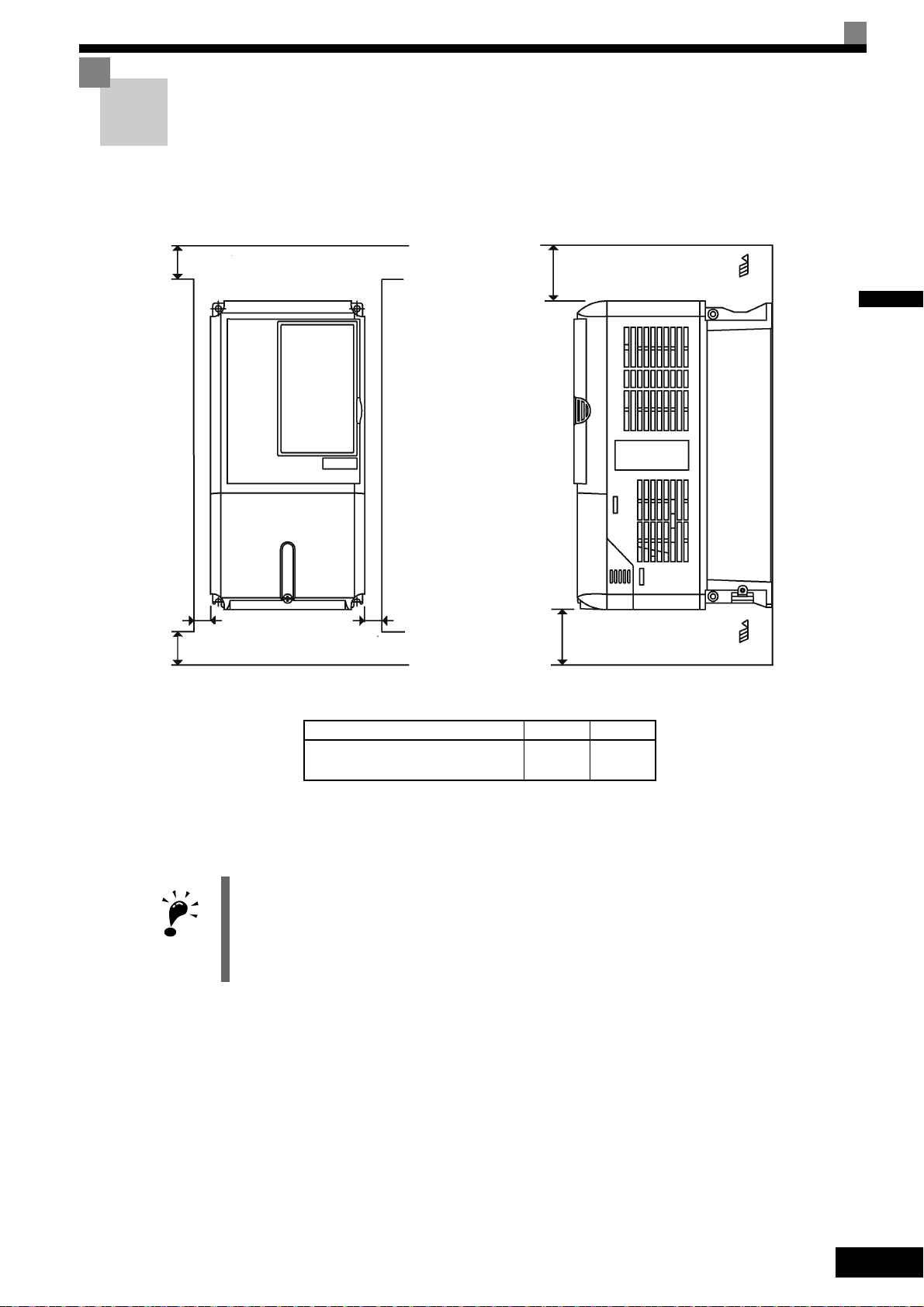

Installation Orientation and Space

IMPORTANT

A

50 mm min.

30 mm min.

30 mm min.

B

120 mm min.

Air

Air

Vertical Space

Horizontal Space

AB

200 V Class Inverter, 3.7 to 55 kW

400 V Class Inverter, 3.7 to 55 kW

50 mm 120 mm

Installation Orientation and Space

Install the Inverter vertically so as not to reduce the cooling effect. When installing the Inverter, always provide the following installation space to allow normal heat dissipation.

1

Fig 1.10 Inverter Installation Orientation and Space

1. The same space is required horizontally and vertically for both Open Chassis (IP00) and Enclosed Wallmounted (IP20, NEMA 1) Inverters.

2. Always remove the protection covers before installing a 200 or 400 V Class Inverter with an output of

18.5 kW or less in a panel.

Always provide enough space for suspension eye bolts and the main circuit lines when installing a 200 or

400 V Class Inverter with an output of 22 kW or more in a panel.

1-11

Page 30

Removing and Attaching the Terminal Cover

1

1

2

2

1

Remove the terminal cover to wire cables to the control circuit and main circuit terminals.

Removing the Terminal Cover

1

Inverters of 18.5 kW or Less

Loosen the screw at the bottom of the terminal cover, press in on the sides of the terminal cover in the directions of arrows 1, and then lift up on the terminal in the direction of arrow 2.

Fig 1.11 Removing the Terminal Cover (Model CIMR-L7B43P7 Shown Above)

Inverters of 22 kW or More

Loosen the screws on the left and right at the top of the terminal cover, pull out the terminal cover in the direction of arrow 1 and then lift up on the terminal in the direction of arrow 2.

1-12

Fig 1.12 Removing the Terminal Cover (Model CIMR-L7B4022 Shown Above)

Attaching the Terminal Cover

When the terminal block wiring has been completed, attach the terminal cover by reversing the removal procedure.

For Inverters with an output of 18.5 kW or less, insert the tab on the top of the terminal cover into the groove

on the Inverter and press in on the bottom of the terminal cover until it clicks into place.

Page 31

Removing/Attaching the Digital Operator/ LED Monitor and Front Cover

2

1

Removing/Attaching the Digital Operator/

LED Monitor and Front Cover

Inverters of 18.5 kW or Less

To attach optional boards or change the control circuit terminal board connector, remove the Digital Operator/

LED Monitor and front cover in addition to the terminal cover. Always remove the Digital Operator/LED

Monitor from the front cover before removing the front cover.

The removal and attachment procedures are described below.

Removing the Digital Operator/LED Monitor

Press the lever on the side of the Digital Operator/LED Monitor in the direction of arrow 1 to unlock the Digital Operator/LED Monitor and lift the Digital Operator/LED Monitor in the direction of arrow 2 to remove

the Digital Operator/LED Monitor as shown in the following illustration.

1

Fig 1.13 Removing the Digital Operator/LED Monitor (Model CIMR-L7B43P7 Shown Above)

1-13

Page 32

1

1

1

2

A

B

Removing the Front Cover

Press the left and right sides of the front cover in the directions of arrows 1 and lift the bottom of the cover in

the direction of arrow 2 to remove the front cover as shown in the following illustration.

Fig 1.14 Removing the Front Cover (Model CIMR-L7B43P7 Shown Above)

Mounting the Front Cover

After wiring the terminals, mount the front cover to the Inverter by performing the steps to remove the front

cover in reverse order.

1. Do not mount the front cover with the Digital Operator/LED Monitor attached to the front cover; otherwise, Digital Operator/LED Monitor may malfunction due to imperfect contact.

2. Insert the tab of the upper part of the front cover into the groove of the Inverter and press the lower part of

the front cover onto the Inverter until the front cover snaps shut.

Mounting the Digital Operator/LED Monitor

After attaching the terminal cover, mount the Digital Operator/LED Monitor onto the Inverter using the following procedure.

1. Hook the Digital Operator/LED Monitor at A (two locations) on the front cover in the direction of arrow 1

as shown in the following illustration.

2. Press the Digital Operator/LED Monitor in the direction of arrow 2 until it snaps in place at B (two locations).

Fig 1.15 Mounting the Digital Operator/LED Monitor

1-14

Page 33

Removing/Attaching the Digital Operator/ LED Monitor and Front Cover

IMPORTANT

1

2

1. Do not remove or attach the Digital Operator/LED Monitor or mount or remove the front cover using methods other than those described above, otherwise the Inverter may break or malfunction due to imperfect

contact.

2. Never attach the front cover to the Inverter with the Digital Operator/LED Monitor attached to the front

cover. Imperfect contact can result.

Always attach the front cover to the Inverter by itself first, and then attach the Digital Operator/LED Monitor to the front cover.

Inverters of 22 kW or More

For Inverters with an output of 22 kW or more, remove the terminal cover and then use the following procedures to remove the Digital Operator/LED Monitor and front cover.

Removing the Digital Operator/LED Monitor

Use the same procedure as for Inverters with an output of 18.5 kW or less.

1

Removing the Front Cover

Lift up at the location label 1 at the top of the control circuit terminal board in the direction of arrow 2.

Fig 1.16 Removing the Front Cover (Model CIMR-L7B4022 Shown Above)

Attaching the Front Cover

After completing the required work, such as mounting an optional board or setting the control circuit terminal

board, attach the front cover by reversing the procedure to remove it.

1. Confirm that the Digital Operator/LED Monitor is not mounted on the front cover. Contact faults can occur

if the cover is attached while the Digital Operator/LED Monitor is mounted to it.

2. Insert the tab on the top of the front cover into the slot on the Inverter and press in on the cover until it

clicks into place on the Inverter.

Attaching the Digital Operator/LED Monitor

Use the same procedure as for Inverters with an output of 18.5 kW or less.

1-15

Page 34

2

Wiring

This chapter describes the terminals, main circuit terminal connections, main circuit terminal wiring specifications, control circuit terminals, and control circuit wiring specifications.

Connections to Peripheral Devices.....................................2-2

Connection Diagram ...........................................................2-3

Terminal Block Configuration..............................................2-5

Wiring Main Circuit Terminals .............................................2-6

Wiring Control Circuit Terminals .......................................2-18

Wiring Check.....................................................................2-25

Installing and Wiring Option Cards ...................................2-26

Page 35

2

Power supply

Molded-case

circuit breaker

or ground fault

interrupter

Magnetic contactor (MC)

Zero phase reactor

Zero phase reactor

Motor

Ground

Input noise filter

Output noise filter

Inverter

Ground

Braking resistor

DC reactor for power

factor improvement

AC reactor for power

factor improvement

Varispeed F7

ᧂⓂ

Connections to Peripheral Devices

Examples of connections between the Inverter and typical peripheral devices are shown in Fig 2.1.

Fig 2.1 Example Connections to Peripheral Devices

2-2

Page 36

Connection Diagram

Communication

and

Control Cards

(For Option)

S1

S2

S3

S4

S5

S6

S7

BB

BB1

SC

E(G)

0㨪+10V

1

2

3

+V

A1

AC

R+

R-

S+

S-

IG

0V

M5

M6

Multi-function contact output 3

M3

M4

Multi-function contact output 2

M1

M2

Multi-function contact output 1

MA

MB

MC

TA3

TA1

TA2

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

A pulse

B pulse

Z pulse

SG

2CN

PG-X2

(Option)

Fault contact output

MA

MC

(20kΩ )

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

1 2

B1 B2

UX

P0

N0

Input voltage for control power

200 V Class: 250 to 300VDC

400 V Class: 500 to 600VDC0V

Factory setting:

Brake release command

Factory setting:

Magnetic contactor control

Factory setting:

Inverter operation ready

Min. load

5 VDC,10 mA

IM/PM

U

V

W

Motor

12V

0V

A+

AB+

BZ+

Z-

PG

R

S

T

MCCB MC

(Ground to

10 Ω max.)

Inverter

CIMR-L7B43P7

*1

*1

*1

*1

*2

*3

*4

*5

*9

*5

*6

*7

*8

+24V 8mA

+24V

2kΩ

2kΩ

3-phase power

380 to 480 V

50/60 Hz

DC reactor to

improve input power

factor (Optional)

Short-circuit Bar

Braking Resistor

unit (Optional)

Forward run/stop

Reverse run/stop

Nominal speed

Inspection Run

Intermediate speed

Leveling speed

Not used

Hardware

baseblock 1

Hardware

baseblock 2

Multi-function

contact inputs

(Factory setting)

External

frequency

reference

Frequency

setter

Frequency setting

adjustment

Shield wire

connection terminal

Frequency setting

power +15 V 20 mA

Master speed

reference 0 to 10 V

MEMOBUS

communications

RS-485/422

Terminating

resistance

Pulse monitor

output

RS-422 Level

Wiring distance:d:

30 m max.

250 VAC, 10 mA min. 1 A max.

30 VAC, 10 mA min. 1 A max.

Multi-function contact output

250 VAC, 10 mA min. 1 A max.

30 VAC, 10 mA min. 1 A max.

Min. load

5 VDC,10 mA

CN5 (NPN setting)

Example: 400 V 3.7 kW (CIMR-L7B43P7)

Connection Diagram

2

* 1. indicates shield wire and indicates twisted-pair shield wire.

* 2. Main circuit terminals are indicated with double circles and control circuit terminals are indicated with single circle.

* 3. The output current capacity of the +V and −V terminals is 20 mA. Do not short-circuit between the +V and AC terminals. Doing so may result in a mal-

* 4. The wiring for a motor with a cooling fan is not required for self-cooling motors.

* 5. Sequence input signals S1 to S7, BB, and BB1 are labeled for sequence connections (0 V common and sinking mode) for no-voltage contacts or NPN

function or a breakdown of the Inverter.

transistors. These are the factory settings.

For PNP transistor sequence connections (+24V common and sourcing mode) or to provide a 24-V external power supply, refer to page 2-22.

Fig 2.2 Connection Diagram (Model CIMR-L7B43P7 Shown Above)

2-3

Page 37

* 6. Do not ground nor connect the AC terminal on the control circuit to the unit. Doing so may result in a malfunction or a breakdown of the Inverter.

IMPORTANT

* 7. Disable the stall prevention during deceleration (set parameter L3-04 to 0) when using a Braking Resistor Unit or a Braking Unit. If this user parameter

is not changed to disable stall prevention, the system may not stop during deceleration.

* 8. During battery operation, input voltage for control power from the PO and NO terminals. The PO and NO terminals are set to the B1 (or 3) and

terminals when shipping.

* 9. To enable the Inverter, the BB and BB1 terminals must be closed. If one of the terminals is closed, "BB" will be displayed on the Digital Operator and

the Inverter will not start.

1. Control circuit terminals are arranged as shown below.

2

E(G)

2. The output current capability of the +V terminal is 20 mA.

3. Main circuit terminals are indicated with double circles and control circuit terminals are indicated with single

circles.

4. The wiring of the multi-function contact inputs S1 to S7, BB, and BB1 are shown for the connection of contacts or NPN transistors (0V common and sinking mode). This is the factory setting.

5. A DC reactor is an option only for Inverters of 18.5 kW or less. Remove the short circuit bar when connecting

a DC reactor.

6. The minimum permissible load of a multi-function contact output and an error contact output is 10 mA.

7. The master frequency reference is set to a voltage input reference as the factory setting.

R+ R-

IG S+ S-

S1 S2 S3 S4 S5 S6 S7 BB1

+V A1 ACSC SC SC BB

M5 M6 MAM1MB MCM2E(G)

M3 M4

2-4

Page 38

Terminal Block Configuration

Control circuit terminals

Main circuit terminals

Ground terminal

Charge indicator

Control

circuit

terminals

Charge indicator

Ground terminals

Main

circuit

terminals

The terminal arrangements are shown in Fig 2.3 and Fig 2.4.

Terminal Block Configuration

2

Fig 2.3 Terminal Arrangement (200 V/400 V Class Inverter of 3.7 kW)

Fig 2.4 Terminal Arrangement (200 V/400 V Class Inverter of 22 kW or more)

2-5

Page 39

2

Wiring Main Circuit Terminals

Applicable Wire Sizes and Closed-loop Connectors

Select the appropriate wires and crimp terminals from Table 2.1 to Table 2.3. Refer to instruction manual

TOBPC72060000 for wire sizes for Braking Resistor Units and Braking Units.

Table 2.1 200 V Class Wire Sizes

Inverter

Model

CIMR-

L7B23P7

Terminal Symbol

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3, PO, NO

Termi-

Screws

Tightening

nal

M4 1.2 to 1.5

Torque

(N•m)

Possible

Wire Sizes

2

(AWG)

mm

4

(12 to 10)

Recommended

Wire Size

2

(AWG)

mm

4

(12)

Wire Type

L7B25P5

L7B27P5

L7B2011

L7B2015

L7B2018

L7B2022

L7B2030

L7

B2037

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3, PO, NO

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3, PO, NO

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3, PO, NO

R/L1, S/L2, T/L3, , 1, 2, U/T1, V/T2,

W/T3, NO

B1, B2, PO M5 2.5

R/L1, S/L2, T/L3, , 1, 2, U/T1, V/T2,

W/T3, NO

B1, B2, PO M5 2.5

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31, NO

3, PO

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31, NO

3, PO

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31, NO

3, PO

r/l1, Δ/l2 M4 1.3 to 1.4

M4 1.2 to 1.5

M5 2.5

M5 2.5

M6 4.0 to 5.0

M6 4.0 to 5.0

M8 9.0 to 10.0

M6 4.0 to 5.0

M8 9.0 to 10.0

M6 4.0 to 5.0

M8 9.0 to 10.0

M8 9.0 to 10.0

M6 4.0 to 5.0

M8 9.0 to 10.0

M10 17.6 to 22.5

M8 8.8 to 10.8

M10 17.6 to 22.5

6

(10)

10

(8 to 6)

16

(6 to 4)

25

(4 to 2)

10

(8 to 6)

25

(4)

25 to 35

(3 to 2)

10 to 16

(8 to 6)

25

(4)

25 to 35

(3 to 1)

10 to 16

(8 to 4)

25 to 35

(4 to 2)

50

(1 to 1/0)

10 to 16

(8 to 4)

to 35

25

(4 to 2)

70 to 95

(2/0 to 4/0)70(2/0)

6 to 16

(10 to 4)

35 to 70

(2 to 2/0)

0.5 to 4

(20 to 10)

6

(10)

10

(8)

16

(6)

25

(4)

-

25

(4)

25

(3)

-

25

(4)

25

(3)

-

25

(4)

50

(1)

-

25

(4)

–

35

(2)

1.5

(16)

Power cables,

e.g., 600 V vinyl

power cables

2-6

Page 40

Table 2.1 200 V Class Wire Sizes (Continued)

Inverter

Model

CIMR-

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31, NO

L7B2045

3, PO

r/l1,

Δ/l2 M4 1.3 to 1.4

R/L1, S/L2, T/L3, , 1, NO

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M10 17.6 to 22.5

L7B2055

* The wire thickness is given for copper wires at 75°C

3, PO

r/l1,

Δ/l2 M4 1.3 to 1.4

Inverter

Model

CIMR-

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

L7B43P7

U/T1, V/T2, W/T3, NO, PO

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

L7B44P0

U/T1, V/T2, W/T3, NO, PO

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

L7B45P5

U/T1, V/T2, W/T3, NO, PO

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

L7B47P5