YASKAWA Varispeed G7 Series, CIMR-G7A20P7, CIMR-G7A Series, CIMR-G7A20P4, CIMR-G7A21P5 Instruction Manual

...Page 1

YASKAWA

Varispeed G7

INSTRUCTION MANUAL

GENERAL PURPOSE INVERTER (ADVANCED VECTOR CONTROL)

MODEL: CIMR-G7A

200V CLASS 0.4 to 110kW (1.2 to 160kVA)

400V CLASS 0.4 to 300kW (1.4 to 460kVA)

Upon receipt of the product and prior to initial operation, read these instructions

thoroughly, and retain for future reference.

YA S K A WA

MANUAL NO. TOE-S616-60.1E

Page 2

Preface

This manual is designed to ensure correct and suitable

application of Varispeed G7-Series Inverters. Read

this manual before attempting to install, operate, maintain, or inspect an Inverter and keep it in a safe, convenient location for future reference. Be sure you

understand all precautions and safety information

before attempting application.

General Precautions

• The diagrams in this manual may be indicated without covers or safety shields to show details.

Be sure to restore covers or shields before operating the Units and run the Units according to the

instructions described in this manual.

• Any illustrations, photographs, or examples used in this manual are provided as examples only

and may not apply to all products to which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of the

manual may be changed without notice to improve the product and/or the manual.

• When ordering a new copy of the manual due to damage or loss, contact your Yaskawa representatives or the nearest Yaskawa sales office and provide the manual number shown on the front

cover.

• If nameplates become warn or damaged, order new ones from your Yaskawa representatives or

the nearest Yaskawa sales office.

i

Page 3

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed precautions provided in this manual can result in serious or possibly even fatal injury or damage to

the products or to related equipment and systems.

WARNING

CAUTION

IMPORTANT

Indicates precautions that, if not heeded, could possibly result in loss of life or serious injury.

Indicates precautions that, if not heeded, could result in relatively serious or minor injury, damage

to the product, or faulty operation.

Failure to heed a precaution classified as a caution can result in serious consequences depending

on the situation.

Indicates important information that should be memorized.

ii

Page 4

Safety Precautions

Confirmations upon Delivery

• Never install an Inverter that is damaged or missing components.

Doing so can result in injury.

Installation

• Always hold the case when carrying the Inverter.

If the Inverter is held by the front cover, the main body of the Inverter may fall, possibly resulting in injury.

• Attach the Inverter to a metal or other noncombustible material.

Fire can result if the Inverter is attached to a combustible material.

• Install a cooling fan or other cooling device when installing more than one Inverter in the same

enclosure so that the temperature of the air entering the Inverters is below 45°C.

Overheating can result in fires or other accidents.

CAUTION

CAUTION

Wiring

• Always turn OFF the input power supply before wiring terminals.

• Wiring must be performed by an authorized person qualified in electrical work.

• Be sure to ground the ground terminal. (200 V Class: Ground to 100 Ω or less, 400 V Class:

• Always check the operation of any emergency stop circuits after they are wired.

• Never touch the output terminals directly with your hands or allow the output lines to come into con-

• If the power supply is turned ON during the FWD (or REV) Run Command is given, the motor will

• When the 3-wire sequence is set, do not make the wiring for the control circuit unless the multi-

WARNING

Otherwise, an electric shock or fire can occur.

Otherwise, an electric shock or fire can occur.

Ground to 10 Ω or less)

Otherwise, an electric shock or fire can occur.

Otherwise, there is the possibility of injury. (Wiring is the responsibility of the user.)

tact with the Inverter case. Never short the output circuits.

Otherwise, an electric shock or ground short can occur.

start automatically.

Turn the power supply ON after verifying that the RUN signal is OFF.

Failure to observe this warning may result in injury.

function input terminal constant is set.

Failure to observe this warning may result in injury.

CAUTION

• Check to be sure that the voltage of the main AC power supply satisfies the rated voltage of the

Inverter.

Injury or fire can occur if the voltage is not correct.

• Do not perform voltage withstand tests on the Inverter.

Otherwise, semiconductor elements and other devices can be damaged.

• Connect braking resistors, Braking Resistor Units, and Braking Units as shown in the I/O wiring

examples.

Otherwise, a fire can occur and the Inverter, braking resistors, Braking Resistor Units, and Braking Units can be damaged.

iii

Page 5

• Tighten all terminal screws to the specified tightening torque.

Otherwise, a fire may occur.

• Do not connect AC power to output terminals U, V, and W.

The interior parts of the Inverter will be damaged if voltage is applied to the output terminals.

• Do not connect phase-advancing capacitors or LC/RC noise filters to the output circuits.

The Inverter can be damaged or interior parts burnt if these devices are connected.

• Do not connect magnetic contactors to the output circuits.

If a load is connected while the Inverter is operating, surge current will cause the overcurrent protection circuit inside the

Inverter to operate.

Setting User Constants

• Disconnect the load (machine, device) from the motor before performing rotational autotuning.

The motor may turn, possibly resulting in injury or damage to equipment. Also, motor constants cannot be correctly set

with the motor attached to a load.

• Stay clear of the motor during rotational autotuning.

The motor repeats running and stopping until autotuning has been completed, possibly resulting in injury.

• In stationary autotuning 1, when the motor is first operated in the drive mode after tuning, the

remaining motor constants E2-02 (Motor rated slip) and E2-03 (Motor no-load current) are set automatically. To perform an operation immediately after stationary autotuning 1, use the following procedure under the recommended conditions.

(1) Check the values of E2-02 and E2-03 in verify mode or advanced programming mode.

(2) Run the motor once in drive mode under the following conditions.

• The Inverter and the motor are connected.

• The motor shaft is not locked with a mechanical brake or other stopping mechanism (or function).

• A motor-load ratio of 30% or less is maintained.

• A speed of 30% or more of the base frequency set at E1-06 (default = highest frequency) is maintained at

a constant speed for one second or more.

(3) After stopping the motor, check the values of E2-02 and E2-03 again in verify mode or advanced program-

ming mode. If the values of E2-02 and E2-03 differ from the ones before the first operation was carried out,

the settings have been successfully completed. Next, check if the values are suitable or not.

If the values of E2-02 and E2-03 differed greatly from the reference data of the motor in the test report or the instruction

manual (TOE-S616-60.1), hunting, motor vibrations, insufficient motor torque, or an overcurrent may occur because the

motor is operated although the aforementioned conditions have not been fulfilled after stationary autotuning 1. For elevators, failure to observe this caution may result in the cage falling or injury. If so, perform stationary autotuning 1 again and

run the motor using the aforementioned procedure under the recommended conditions or perform stationary autotuning 2

or rotational autotuning.

Usually the standard setting for E2-02 is 1 Hz to 3 Hz, and that for E2-03 is 30% to 65% of the rated current for a generalpurpose motor. Generally, the larger the motor capacity is, the smaller the rated slip and the ratio of the no-load current to

the rated current become. Use the data given in Factory Settings that Change with the Inverter Capacity (o2-04) of Chap-

ter 5 User Constants as a reference.

CAUTION

CAUTION

iv

Trial Operation

WARNING

• Check to be sure that the front cover is attached before turning ON the power supply.

An electric shock may occur.

• Do not come close to the machine when the fault reset function is used. If the alarmed is cleared,

the machine may start moving suddenly.

Also, design the machine so that human safety is ensured even when it is restarted.

Injury may occur.

• Provide a separate emergency stop switch; the Digital Operator STOP Key is valid only when its

function is set.

Injury may occur.

Page 6

WARNING

• Reset alarms only after confirming that the RUN signal is OFF.

Injury may occur.

CAUTION

• Don't touch the radiation fins (heatsink), braking resistor, or Braking Resistor Unit. These can

become very hot.

Otherwise, a burn injury may occur.

• Be sure that the motor and machine is within the applicable ranges before starting operation.

Otherwise, an injury may occur.

• Provide a separate holding brake if necessary.

Always construct the external sequence to confirm that the holding brake is activated in the event

of an emergency, a power failure, or an abnormality in the Inverter.

Failure to observe this caution can result in injury.

• If using an Inverter with an elevator, take safety measures on the elevator to prevent the elevator

from dropping.

Failure to observe this caution can result in injury.

• Don't check signals while the Inverter is running.

Otherwise, the equipment may be damaged.

• Be careful when changing Inverter settings. The Inverter is factory set to suitable settings. For the

Inverters in the 400 V class of 55 kW or more, however, select the correct power supply voltage

jumper according to the input voltage.

Otherwise, the equipment may be damaged.

Maintenance and Inspection

• Do not touch the Inverter terminals. Some of the terminals carry high voltages and are extremely

dangerous.

Doing so can result in electric shock.

• Always have the protective cover in place when power is being supplied to the Inverter. When

attaching the cover, always turn OFF power to the Inverter through the MCCB.

Doing so can result in electric shock.

• After turning OFF the main circuit power supply, wait until the CHARGE indicator light goes out

before performing maintenance or inspections.

The capacitor will remain charged and is dangerous.

• Maintenance, inspection, and replacement of parts must be performed only by authorized personnel.

Remove all metal objects, such as watches and rings, before starting work. Always use grounded tools.

Failure to heed these warning can result in electric shock.

• For 400-V class Inverters of 55 kW to 300 kW with SPEC: E or later, take safety measures such as

the installation of an emergency-stop switch before adjusting constants.

Failure to do so may result in injury caused by the motor accidentally rotating during stationary autotuning performed by

the Inverter when the constants are adjusted.

• Provide a separate holding brake if necessary.

Always make any adjustments other than those involving the operation of the Inverter with the holding brake released.

Failure to observe this caution may result in injury.

• If using an Inverter with an elevator, take safety measures on the elevator to prevent the elevator

from dropping.

Failure to observe this caution can result in injury.

WARNING

v

Page 7

Other

CAUTION

• A CMOS IC is used in the control board. Handle the control board and CMOS IC carefully.

The CMOS IC can be destroyed by static electricity if touched directly.

• Do not change the wiring, or remove connectors or the Digital Operator, during operation.

Doing so can result in personal injury.

WARNING

• Do not attempt to modify or alter the Inverter.

Doing so can result in electrical shock or injury.

CAUTION

• Do not subject the Inverter to halogen gases, such as fluorine, chlorine, bromine, and iodine, at any

time even during transportation or installation.

Otherwise, the Inverter can be damaged or interior parts burnt.

vi

Page 8

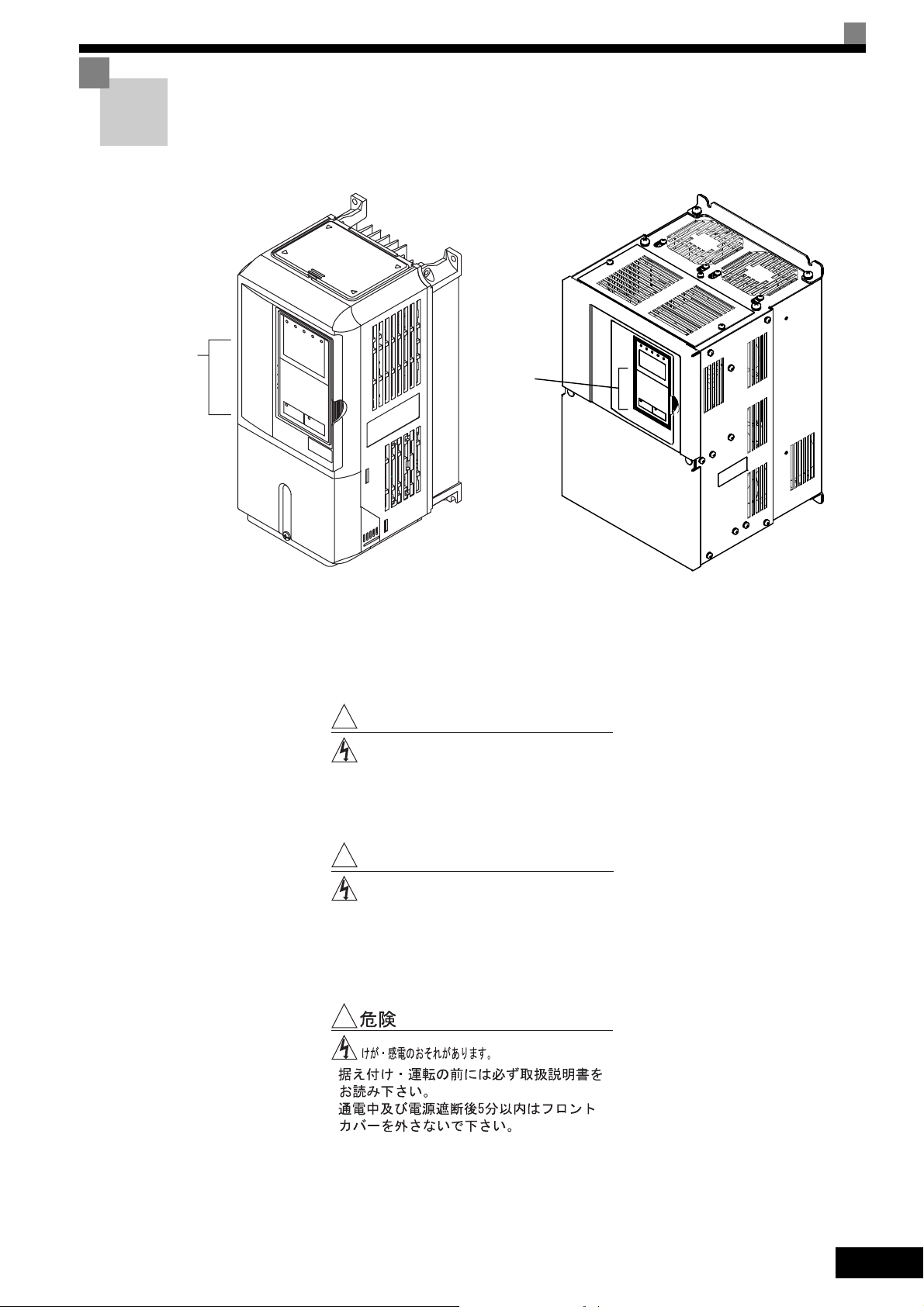

Warning Information and Position

There is warning information on the Inverter in the position shown in the following illustration.

Always heed the warnings.

Warning

information

position

Warning

information

position

Illustration shows the CIMR-G7A20P4

Warning Information

!

WARNING

Risk of electric shock.

yRead manual before installing.

yWait 5 minutes for capacitor discharge

after disconnecting power supply.

!

AVERTISSEMENT

Risque de décharge électrique.

yLire le manuel avant l' installation.

yAttendre 5 minutes aprés la coupure de

l' allmentation. Pour permettre la

décharge des condensateurs.

!

Illustration shows the CIMR-G7A2018

y

y

vii

Page 9

Warranty Information

Free Warranty Period and Scope

Warranty Period

This product is warranted for twelve months after being delivered to Yaskawa’s customer or if

applicable eighteen months from the date of shipment from Yaskawa’s factory whichever comes

first.

Scope of Warranty

Inspections

Periodic inspections must be conducted by the customer. However, upon request, Yaskawa or

one of Yaskawa’s Service Centers can inspect the product for a fee. In this case, if after conferring with the customer, a Yaskawa product is found to be defective due to Yaskawa workmanship or materials and the defect occurs during the warranty period, then this fee will be waived

and the problem remedied free of charge.

Repairs

If a Yaskawa product is found to be defective due to Yaskawa workmanship or materials and the

defect occurs during the warranty period, Yaskawa will provide a replacement, repair the defective product, and provide shipping to and from the site free of charge.

However, if the Yaskawa Authorized Service Center determines that the problem with a

Yaskawa product is not due to defects in Yaskawa’s workmanship or materials, then the customer will be responsible for the cost of any necessary repairs. Some problems that are outside

the scope of this warranty are:

• Problems due to improper maintenance or handling, carelessness, or other reasons where the

customer is determined to be responsible.

• Problems due to additions or modifications made to a Yaskawa product without Yaskawa’s

understanding.

• Problems due to the use of a Yaskawa product under conditions that do not meet the recom-

mended specifications.

• Problems caused by natural disaster or fire.

• Or other problems not due to defects in Yaskawa workmanship or materials.

Warranty service is only applicable within Japan.

However, after-sales service is available for customers outside of Japan for a reasonable fee.

Contact your local Yaskawa representative for more information.

Exceptions

Any inconvenience to the customer or damage to non-Yaskawa products due to Yaskawa's

defective products whether within or outside the warranty period are NOT covered by this warranty.

Restrictions

• The Varispeed G7 was not designed or manufactured for use in devices or systems that may

directly affect or threaten human lives or health.

• Customers who intend to use the product described in this manual for devices or systems

relating to transportation, health care, space aviation, atomic or electric power, or underwater

use must contact their Yaskawa representatives or the nearest Yaskawa sales office beforehand.

• This product has been manufactured under strict quality-control guidelines. However, if this

product is to be installed in any location where failure of this product could involve or result

in a life-and-death situation or loss of human life or in a facility where failure may cause a

serious accident or physical injury, safety devices must be installed to minimize the likelihood

of any accident.

viii

Page 10

Registered Trademarks

The following registered trademarks are used in this manual.

• DeviceNet is a registered trademark of the ODVA (Open DeviceNet Vendors Association,

Inc.).

• InterBus is a registered trademark of Phoenix Contact Co.

• ControlNet is a registered trademark of ControlNet International, Ltd.

• LONWORKS is a registered trademark of the Echelon.

Before Reading This Manual

There are places in this manual where the constants and explanations depend on the software

version. Explanations for both old and new versions are provided. Parts that are shaded and

parts where “PRG: 102 only” appears apply to G7-series Inverters with software version

PRG: 102 and later. Parts where “PRG: 103 only” appears apply only to G7-series Inverters

with software version PRG: 103.

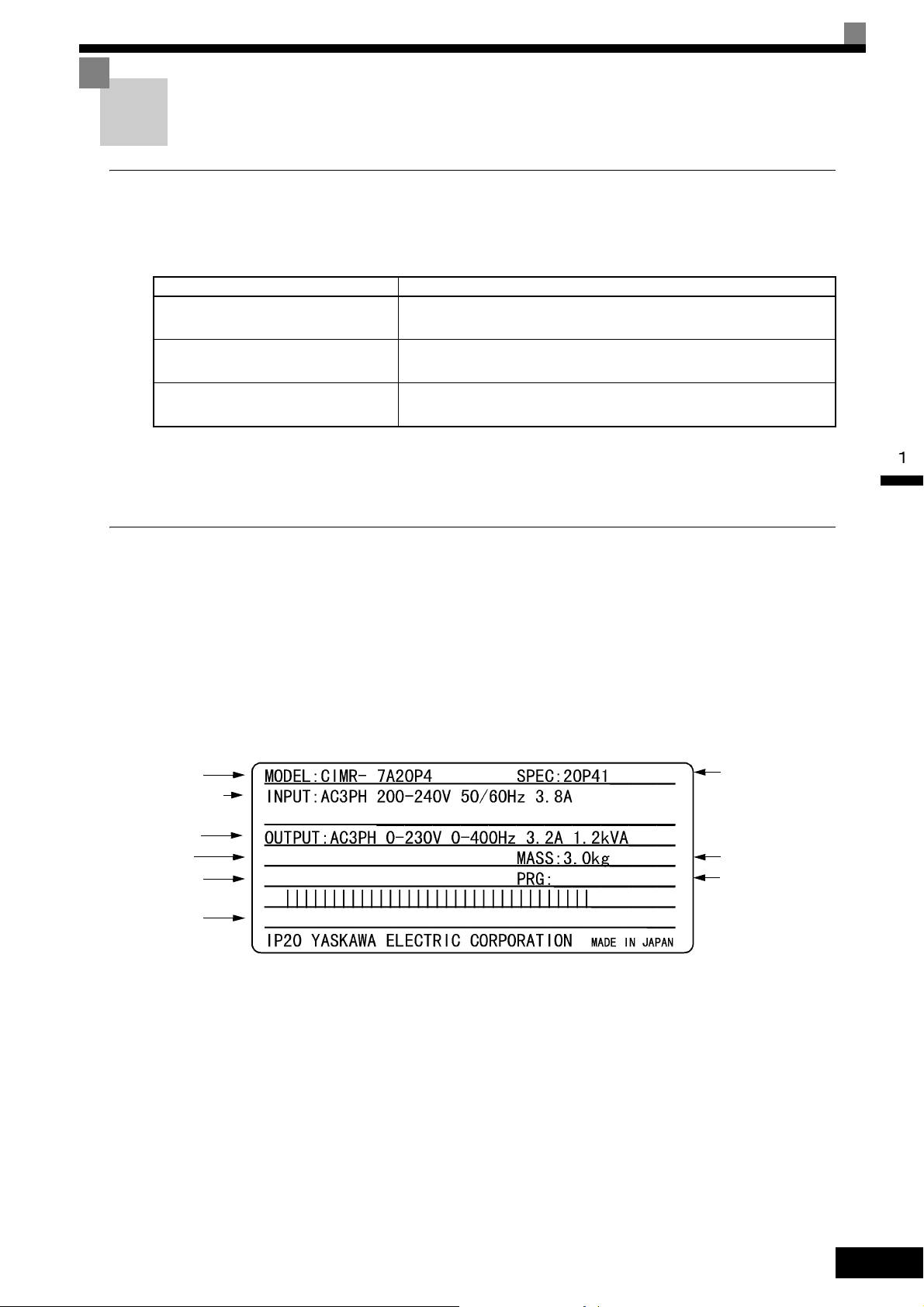

Be sure to confirm the PRG number on the Inverter’s nameplate. An example is given below.

Inverter model

Input specifications

Input specifications

Output

specifications

Lot number

Serial number

UL file number

G

O/N :

S/N :

FILE NO.: E131457

1020

Inverter

specifications

Mass

Version of software

ix

Page 11

Contents

Safety Information ............................................................................................ii

Safety Precautions ..........................................................................................iii

Warning Information and Position..................................................................vii

Warranty Information..................................................................................... viii

Registered Trademarks...................................................................................ix

Before Reading This Manual...........................................................................ix

1 Handling Inverters ...................................................................1-1

Varispeed G7 Introduction............................................................................ 1-2

Varispeed G7 Models..................................................................................................... 1-2

Confirmations upon Delivery........................................................................1-3

Checks ........................................................................................................................... 1-3

Nameplate Information................................................................................................... 1-3

Component Names ........................................................................................................ 1-5

Exterior and Mounting Dimensions ..............................................................1-6

Open Chassis Inverters (IP00) ....................................................................................... 1-6

Enclosed Wall-mounted Inverters [NEMA1 (Type 1)] ..................................................... 1-7

Checking and Controlling the Installation Site..............................................1-9

Installation Site...............................................................................................................1-9

Controlling the Ambient Temperature ............................................................................. 1-9

Protecting the Inverter from Foreign Matter ................................................................... 1-9

Installation Orientation and Space..............................................................1-10

Removing and Attaching the Terminal Cover ............................................. 1-11

Removing the Terminal Cover ...................................................................................... 1-11

Attaching the Terminal Cover ....................................................................................... 1-12

Removing/Attaching the Digital Operator and Front Cover ........................1-13

Inverters of 15 kW or Less ........................................................................................... 1-13

Inverters of 18.5 kW or More........................................................................................ 1-16

Removing and Attaching the Protection Cover .......................................... 1-17

Removing the Protection Cover ................................................................................... 1-17

Attaching the Protection Cover..................................................................................... 1-18

x

2 Wiring .......................................................................................2-1

Connections to Peripheral Devices.............................................................. 2-2

Connection Diagram .................................................................................... 2-3

Terminal Block Configuration ....................................................................... 2-5

Page 12

Wiring Main Circuit Terminals .......................................................................2-6

Applicable Wire Sizes and Closed-loop Connectors ......................................................2-6

Main Circuit Terminal Functions...................................................................................2-13

Main Circuit Configurations...........................................................................................2-14

Standard Connection Diagrams....................................................................................2-15

Wiring the Main Circuits................................................................................................2-16

Wiring Control Circuit Terminals .................................................................2-22

Wire Sizes and Closed-loop Connectors......................................................................2-22

Control Circuit Terminal Functions ...............................................................................2-24

Control Circuit Terminal Connections ...........................................................................2-28

Control Circuit Wiring Precautions................................................................................2-29

Wiring Check ..............................................................................................2-30

Checks..........................................................................................................................2-30

Installing and Wiring Option Boards ...........................................................2-31

Option Board Models and Specifications......................................................................2-31

Installation.....................................................................................................................2-32

PG Speed Control Board Terminals and Specifications................................................2-33

Wiring............................................................................................................................2-35

Wiring Terminal Blocks .................................................................................................2-38

Selecting the Number of PG (Encoder) Pulses ............................................................2-39

3 Digital Operator and Modes................................................... 3-1

Digital Operator ............................................................................................3-2

Digital Operator Display..................................................................................................3-2

Digital Operator Keys......................................................................................................3-2

Modes ...........................................................................................................3-5

Inverter Modes................................................................................................................3-5

Switching Modes.............................................................................................................3-6

Drive Mode .....................................................................................................................3-7

Quick Programming Mode ..............................................................................................3-8

Advanced Programming Mode .....................................................................................3-10

Verify Mode...................................................................................................................3-13

Autotuning Mode...........................................................................................................3-14

4 Trial Operation ........................................................................ 4-1

Overview of Trial Operation Procedure ........................................................4-2

Trial Operation Procedures...........................................................................4-3

Setting the Power Supply Voltage Jumper (400 V Class Inverters of 55 kW or Higher). 4-3

Power ON .......................................................................................................................4-3

Checking the Display Status...........................................................................................4-4

Basic Settings.................................................................................................................4-5

Settings for the Control Methods ....................................................................................4-7

Autotuning.......................................................................................................................4-9

Application Settings ......................................................................................................4-16

xi

Page 13

No-load Operation........................................................................................................ 4-16

Loaded Operation......................................................................................................... 4-16

Check and Recording User Constants ......................................................................... 4-17

Adjustment Suggestions ............................................................................ 4-18

5 User Constants ........................................................................5-1

User Constant Descriptions.......................................................................... 5-2

Description of User Constant Tables .............................................................................. 5-2

Digital Operation Display Functions and Levels........................................... 5-3

User Constants Settable in Quick Programming Mode.................................................. 5-4

User Constant Tables................................................................................... 5-8

A: Setup Settings............................................................................................................ 5-8

b: Application Constants............................................................................................... 5-10

C: Autotuning Constants .............................................................................................. 5-21

d: Reference Constants................................................................................................ 5-27

E: Motor Constant Constants ....................................................................................... 5-33

F: Option Constants ..................................................................................................... 5-39

H: Terminal Function Constants................................................................................... 5-46

L: Protection Function Constants ................................................................................. 5-58

N: Special Adjustments ................................................................................................ 5-69

o: Digital Operator Constants ....................................................................................... 5-73

T: Motor Autotuning...................................................................................................... 5-77

U: Monitor Constants.................................................................................................... 5-78

Factory Settings that Change with the Control Method (A1-02)................................... 5-87

Factory Settings that Change with the Inverter Capacity (o2-04)................................. 5-90

6 Constant Settings by Function...............................................6-1

Frequency Reference...................................................................................6-2

Selecting the Frequency Reference Source................................................................... 6-2

Using Multi-Step Speed Operation................................................................................. 6-5

Varispeed G7 Function Block......................................................................................... 6-8

Run Command ........................................................................................... 6-10

Selecting the Run Command Source ........................................................................... 6-10

Stopping Methods ...................................................................................... 6-12

Selecting the Stopping Method when a Stop Command is Sent .................................. 6-12

Using the DC Injection Brake ....................................................................................... 6-16

Using an Emergency Stop............................................................................................ 6-17

Acceleration and Deceleration Characteristics ..........................................6-18

Setting Acceleration and Deceleration Times............................................................... 6-18

Accelerating and Decelerating Heavy Loads (Dwell Function) .................................... 6-22

Preventing the Motor from Stalling During Acceleration

(Stall Prevention During Acceleration Function)........................................................... 6-23

Preventing Overvoltage During Deceleration

(Stall Prevention During Deceleration Function) ..........................................................6-25

xii

Page 14

Preventing Overvoltage by Automatically Reducing the Regenerative Torque Limit

(Overvoltage Inhibit Function, PRG: 102 only) ..........................................................6-26

Adjusting Frequency References ...............................................................6-28

Adjusting Analog Frequency References .....................................................................6-28

Operation Avoiding Resonance (Jump Frequency Function).......................................6-31

Adjusting Frequency Reference Using Pulse Train Inputs ...........................................6-33

Speed Limit (Frequency Reference Limit Function) ...................................6-34

Limiting Maximum Output Frequency...........................................................................6-34

Limiting Minimum Frequency........................................................................................6-34

Improved Operating Efficiency ...................................................................6-36

Reducing Motor Speed Fluctuation (Slip Compensation Function) ..............................6-36

Compensating for Insufficient Torque at Startup and Low-speed Operation

(Torque Compensation) ................................................................................................6-38

Hunting-prevention Function.........................................................................................6-40

Stabilizing Speed (Speed Feedback Detection Function) ............................................6-41

Machine Protection .....................................................................................6-42

Reducing Noise and Leakage Current..........................................................................6-42

Limiting Motor Torque (Torque Limit Function).............................................................6-46

Preventing Motor Stalling During Operation .................................................................6-49

Changing Stall Prevention Level during Operation Using an Analog Input ..................6-50

Using Frequency Detection: L4-01 to L4-05.................................................................6-50

Detecting Motor Torque ................................................................................................6-53

Changing Overtorque and Undertorque Detection Levels Using an Analog Input .......6-56

Motor Overload Protection............................................................................................6-57

Setting Motor Protection Operation Time......................................................................6-59

Motor Overheating Protection Using PTC Thermistor Inputs........................................6-60

Limiting Motor Rotation Direction..................................................................................6-62

Continuing Operation..................................................................................6-63

Restarting Automatically After Power Is Restored........................................................6-63

Speed Search ...............................................................................................................6-64

Continuing Operation at Constant Speed When Frequency Reference Is Lost............6-71

Restarting Operation After Transient Fault (Auto Restart Function).............................6-72

Operation Selection After Cooling Fan Fault ................................................................6-73

Inverter Protection ......................................................................................6-74

Performing Overheating Protection on Mounted Braking Resistors .............................6-74

Reducing Inverter Overheating Pre-Alarm Warning Levels..........................................6-75

Input Terminal Functions ............................................................................6-76

Temporarily Switching Operation between Digital Operator and

Control Circuit Terminals...............................................................................................6-76

Blocking Inverter Outputs (Baseblock Commands)......................................................6-77

Stopping Acceleration and Deceleration (Acceleration/Deceleration Ramp Hold) .......6-78

Raising and Lowering Frequency References Using Contact Signals (UP/DOWN).....6-79

Accelerating and Decelerating Constant Frequencies in the Analog References

(+/- Speed)....................................................................................................................6-82

Hold Analog Frequency Using User-set Timing............................................................6-83

xiii

Page 15

Switching Operations between a Communications Option Board and

Control Circuit Terminals .............................................................................................. 6-83

Jog Frequency Operation without Forward and Reverse Commands (FJOG/RJOG) . 6-84

Stopping the Inverter by Notifying Programming Device Errors to the Inverter

(External Fault Function) .............................................................................................. 6-85

Output Terminal Functions ......................................................................... 6-86

Monitor Constants ...................................................................................... 6-88

Using the Analog Monitor Constants............................................................................ 6-88

Using Pulse Train Monitor Contents............................................................................. 6-90

Individual Functions ................................................................................... 6-92

Using MEMOBUS Communications............................................................................. 6-92

Using the Timer Function ........................................................................................... 6-105

Using PID Control....................................................................................................... 6-106

Energy-saving ............................................................................................................ 6-115

Setting Motor Constants............................................................................................. 6-117

Setting the V/f Pattern ................................................................................................6-120

Torque Control ........................................................................................................... 6-127

Speed Control (ASR) Structure .................................................................................. 6-136

Increasing the Speed Reference Response (Feed Forward Control) ........................ 6-142

Droop Control Function .............................................................................................. 6-143

Zero-servo Function ................................................................................................... 6-145

Digital Operator Functions........................................................................ 6-148

Setting Digital Operator Functions ............................................................................. 6-148

Copying Constants..................................................................................................... 6-151

Prohibiting Writing Constants from the Digital Operator.............................................6-156

Setting a Password .................................................................................................... 6-156

Displaying User-set Constants Only........................................................................... 6-157

Options ..................................................................................................... 6-158

Performing Speed Control with PG ............................................................................ 6-158

Using Digital Output Boards ....................................................................................... 6-162

Using an Analog Reference Board............................................................................. 6-164

Using a Digital Reference Board ................................................................................ 6-165

Using Inverters for Elevating Machines.................................................... 6-170

Brake ON/OFF Sequence .......................................................................................... 6-170

Stall Prevention during Deceleration .......................................................................... 6-172

Autotuning .................................................................................................................. 6-172

Braking Resistor Overheating Protection ................................................................... 6-172

Momentary Power Loss Restart ................................................................................. 6-172

Torque Limit................................................................................................................ 6-172

I/O Open-phase Protection and Overtorque Detection .............................................. 6-173

External Baseblock Signal.......................................................................................... 6-173

Acceleration/Deceleration Time.................................................................................. 6-173

Magnetic Contactor on the Inverter’s Output-side...................................................... 6-173

Control-related Adjustments....................................................................................... 6-174

xiv

Page 16

Reducing Shock during Elevating Machine Start, Stop, Acceleration,

and Deceleration.........................................................................................................6-176

Confirming Startup Current and Reducing Carrier Frequency....................................6-179

Overvoltage Inhibit Function.......................................................................................6-180

Current Alarm Function ............................................................................6-181

Peak Hold Current Monitoring Function ...................................................6-182

Maintenance Timer Display Function .......................................................6-183

Settings Required to Use Maintenance Timer Display Function.................................6-183

Settings Required After Replacement of Cooling Fan or Electrolytic Capacitor .........6-184

7 Troubleshooting ..................................................................... 7-1

Protective and Diagnostic Functions ............................................................7-2

Fault Detection................................................................................................................7-2

Alarm Detection ............................................................................................................7-15

Operation Errors ...........................................................................................................7-20

Errors During Autotuning .............................................................................................7-22

Errors when Using the Digital Operator Copy Function................................................7-23

Troubleshooting ..........................................................................................7-25

If Constant Constants Cannot Be Set...........................................................................7-25

If the Motor Does Not Operate......................................................................................7-26

If the Direction of the Motor Rotation is Reversed........................................................7-29

If the Motor Does Not Put Out Torque or If Acceleration is Slow..................................7-29

If the Motor Operates Higher Than the Reference .......................................................7-29

If the Slip Compensation Function Has Low Speed Precision......................................7-30

If There is Low Speed Control Accuracy at High-speed Rotation in

Open-loop Vector Control Method................................................................................7-30

If Motor Deceleration is Slow ........................................................................................7-30

If the Motor Overheats..................................................................................................7-31

If There is Noise When the Inverter is Started or From an AM Radio ..........................7-32

If the Ground Fault Interrupter Operates When the Inverter is Run..............................7-32

If There is Mechanical Oscillation.................................................................................7-32

If the Torque Generated for the Motor is Insufficient (Insufficient Power).....................7-34

If the Torque Reference (U1-09) at Low Speeds in Open-loop Vector 2 Control is

Large Compared to That at Medium and High Speeds ................................................7-34

If Shock Occurs Near the Speed Estimator Switching Frequency in

Open-loop Vector 2 Control (PRG: 102 only) ............................................................7-34

If Torque Ripple Occurs at Very Low Speeds in Open-loop Vector 2 Control

(PRG: 102 only).........................................................................................................7-35

If the Motor Rotates Even When Inverter Output is Stopped........................................7-35

If OV is Detected When the Fan is Started, or Fan Stalls .............................................7-35

If Output Frequency Does Not Rise to Frequency Reference ......................................7-35

Acoustic Noise From the Motor ....................................................................................7-36

xv

Page 17

8 Maintenance and Inspection ..................................................8-1

Maintenance and Inspection ........................................................................8-2

Outline of Warranty......................................................................................................... 8-2

Daily Inspection.............................................................................................................. 8-2

Periodic Inspection......................................................................................................... 8-2

Periodic Maintenance of Parts ....................................................................................... 8-3

Procedure for Adjusting Constants after Replacement of Control Board ....................... 8-3

Types and Number of Cooling Fans Used in the Drive ..................................................8-5

Cooling Fan Replacement Outline ................................................................................. 8-6

Circulation Fan Replacement Outline........................................................................... 8-16

Removing and Mounting the Control Circuit Terminal Board ....................................... 8-21

9 Specifications ..........................................................................9-1

Standard Inverter Specifications................................................................... 9-2

Specifications by Model.................................................................................................. 9-2

Common Specifications.................................................................................................. 9-4

Specifications of Options and Peripheral Devices........................................ 9-6

10 Appendix ................................................................................10-1

Varispeed G7 Control Methods .................................................................. 10-2

Control Methods and Features..................................................................................... 10-2

Control Methods and Applications................................................................................ 10-4

Inverter Application Precautions ................................................................ 10-6

Selection.......................................................................................................................10-6

Installation ....................................................................................................................10-7

Settings ........................................................................................................................10-7

Handling .......................................................................................................................10-8

Motor Application Precautions ................................................................... 10-9

Using the Inverter for an Existing Standard Motor........................................................ 10-9

Using the Inverter for Special Motors ......................................................................... 10-10

Power Transmission Mechanism (Speed Reducers, Belts, and Chains) ................... 10-10

Conformance to UL Standard................................................................... 10-11

Conformance to CE Markings .................................................................. 10-13

CE Markings............................................................................................................... 10-13

Requirements for Conformance to CE Markings........................................................ 10-13

xvi

Wiring Examples ...................................................................................... 10-20

Using a Braking Resistor Unit .................................................................................... 10-20

Using a Braking Unit and Braking Resistor Unit......................................................... 10-21

Using Braking Units in Parallel ................................................................................... 10-22

Using a Braking Unit and Three Braking Resistor Units in Parallel............................ 10-23

Using a VS Operator .................................................................................................. 10-24

Using Transistors for Input Signals and a 0-V Common in Sinking Mode with an

Internal Power Supply ................................................................................................ 10-25

Page 18

Using Transistors for Input Signals and a +24-V Common in Sourcing Mode............10-26

Using Transistors for Input Signals and a 0-V Common in Sinking Mode with an

External Power Supply ...............................................................................................10-27

Using Contact and Open Collector Outputs................................................................10-28

User Constants.........................................................................................10-29

INDEX

Revision History

xvii

Page 19

1

Handling Inverters

This chapter describes the checks required upon receiving or installing an Inverter.

Varispeed G7 Introduction ...........................................1-2

Confirmations upon Delivery........................................1-3

Exterior and Mounting Dimensions..............................1-6

Checking and Controlling the Installation Site .............1-9

Installation Orientation and Space .............................1-10

Removing and Attaching the Terminal Cover ............ 1-11

Removing/Attaching the Digital Operator and Front

Cover .........................................................................1-13

Removing and Attaching the Protection Cover.......... 1-17

Page 20

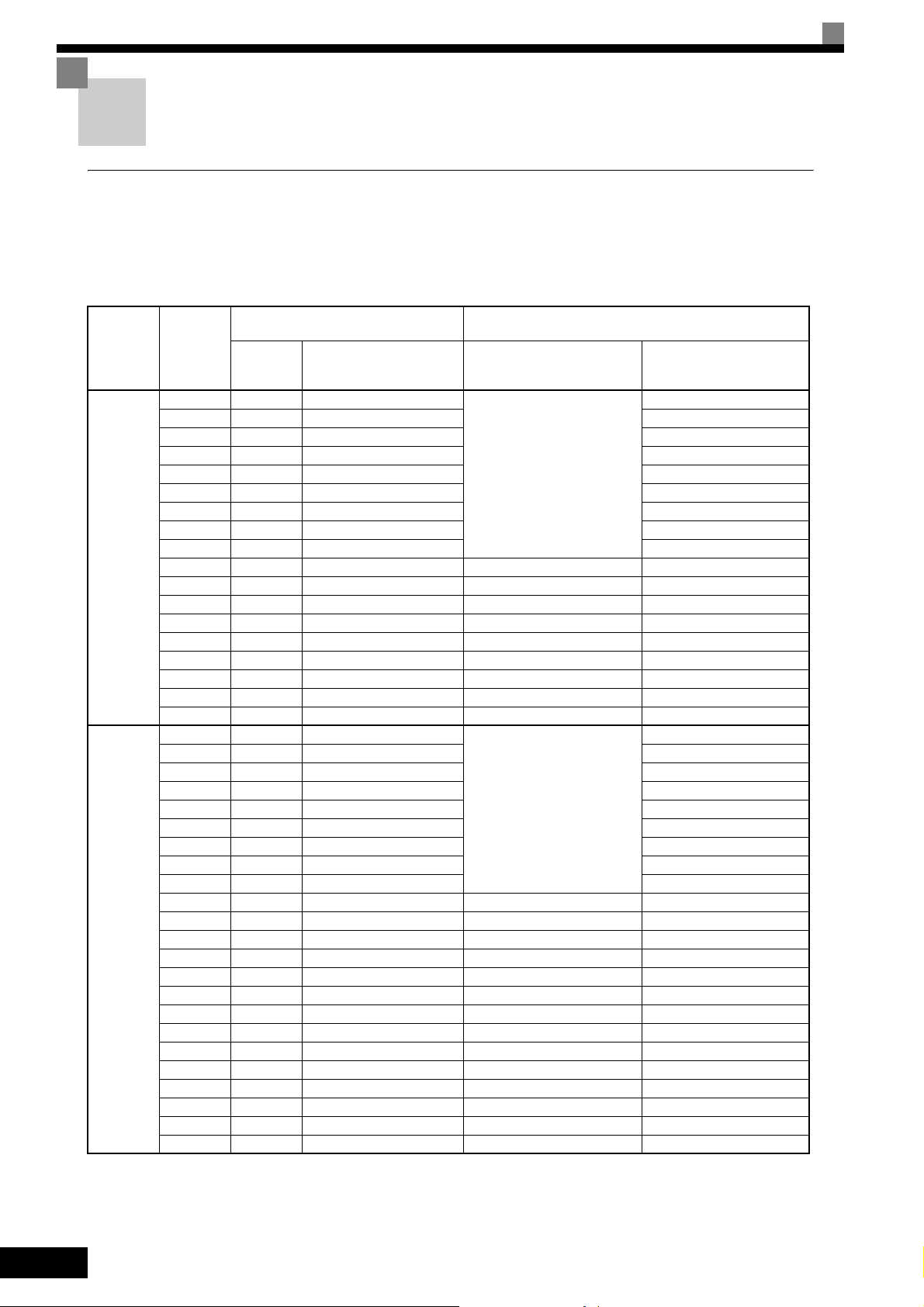

Varispeed G7 Introduction

Varispeed G7 Models

The Varispeed-G7 Series of Inverters included two Inverters in two voltage classes: 200 V and 400 V. Maximum

motor capacities vary from 0.4 to 300 kW (41 models).

Table 1.1 Varispeed G7 Models

Voltage

Class

200 V Class

400 V Class

Maximum

Motor

Capacity

kW

0.4 1.2 CIMR-G7A20P4

0.75 2.3 CIMR-G7A20P7 20P71

1.5 3.0 CIMR-G7A21P5 21P51

2.2 4.6 CIMR-G7A22P2 22P21

3.7 6.9 CIMR-G7A23P7 23P71

5.5 10 CIMR-G7A25P5 25P51

7.5 13 CIMR-G7A27P5 27P51

11 19 CIMR-G7A2011 2011

15 25 CIMR-G7A2015 20151

18.5 30 CIMR-G7A2018 20180 20181

22 37 CIMR-G7A2022 20220 20221

30 50 CIMR-G7A2030 20300 20301

37 61 CIMR-G7A2037 20370 20371

45 70 CIMR-G7A2045 20450 20451

55 85 CIMR-G7A2055 20550 20551

75 110 CIMR-G7A2075 20750 20751

90 140 CIMR-G7A2090 20900 -

110 160 CIMR-G7A2110 21100 -

0.4 1.4 CIMR-G7A40P4

0.75 2.6 CIMR-G7A40P7 40P71

1.5 3.7 CIMR-G7A41P5 41P51

2.2 4.7 CIMR-G7A42P2 42P21

3.7 6.9 CIMR-G7A43P7 43P71

5.5 11 CIMR-G7A45P5 45P51

7.5 16 CIMR-G7A47P5 47P51

11 21 CIMR-G7A4011 40111

15 26 CIMR-G7A4015 40151

18.5 32 CIMR-G7A4018 40180 40181

22 40 CIMR-G7A4022 40220 40221

30 50 CIMR-G7A4030 40300 40301

37 61 CIMR-G7A4037 40370 40371

45 74 CIMR-G7A4045 40450 40451

55 98 CIMR-G7A4055 40550 40551

75 130 CIMR-G7A4075 40750 40751

90 150 CIMR-G7A4090 40900 40901

110 180 CIMR-G7A4110 41100 41101

132 210 CIMR-G7A4132 41320 41321

160 250 CIMR-G7A4160 41600 41601

185 280 CIMR-G7A4185 41850 -

220 340 CIMR-G7A4220 42200 -

300 460 CIMR-G7A4300 43000 -

Output

Capacity

kVA

Va r i sp ee d G7

Basic Model Number

(Always specify through the protective structure when ordering.)

Open Chassis

(IEC IP00)

CIMR-G7

Remove the top and bottom cov-

ers from the Enclosed Wall-

mounted model.

Remove the top and bottom cov-

ers from the Enclosed Wall-

mount model.

Specifications

Enclosed Wall-mounted

[IEC IP20, NEMA 1 (Type 1)]

CIMR-G7A

20P41

40P41

1-2

Page 21

Confirmations upon Delivery

Checks

Check the following items as soon as the Inverter is delivered.

Table 1.2 Checks

Item Method

Has the correct model of Inverter been

delivered?

Check the model number on the nameplate on the side of the Inverter.

Confirmations upon Delivery

Is the Inverter damaged in any way?

Are any screws or other components

loose?

Inspect the entire exterior of the Inverter to see if there are any scratches or

other damage resulting from shipping.

Use a screwdriver or other tools to check for tightness.

If you find any irregularities in the above items, contact the agency from which you purchased the Inverter or

your Yaskawa representative immediately.

Nameplate Information

There is a nameplate attached to the side of each Inverter. The nameplate shows the model number, specifications, lot number, serial number, and other information on the Inverter.

Example Nameplate

The following nameplate is an example for a standard domestic (Japan) Inverter: 3-phase, 200 VAC, 0.4 kW,

IEC IP20 and NEMA 1 (Type 1) standards

Inverter model

Input specifications

Input specifications

Output

specifications

Lot number

Serial number

O/N :

S/N :

G

1020

Inverter

specifications

Mass

Version of software

UL file number

FILE NO.: E131457

Fig 1.1 Nameplate

1-3

Page 22

Inverter Model Numbers

The model number of the Inverter on the nameplate indicates the specification, voltage class, and maximum

motor capacity of the Inverter in alphanumeric codes.

CIMR - G7 A 2 0P4

Inverter

Varispeed G7

No.

A

No.

2

4

Specification

Standard domestic model

Voltage Class

AC input, 3-phase, 200 V

AC input, 3-phase, 400 V

Fig 1.2 Inverter Model Numbers

No.

Max. Motor Capacity

0P4

0P7

to

300

"P" indicates the decimal point.

0.4 kW

0.75 kW

to

300 kW

*

Inverter Specifications

The Inverter specifications (“SPEC”) on the nameplate indicate the voltage class, maximum motor capacity,

the protective structure, and the revision of the Inverter in alphanumeric codes.

2 0P4 1 A

No.

2

4

Voltage Class

AC input, 3-phase, 200 V

AC input, 3-phase, 400 V

Design revision order

TERMS

No.

0P4

0P7

300

"P" indicates the decimal point.

Max. Motor Capacity

to

0.4 kW

0.75 kW

to

300 kW

*

No.

0

1

Protective Structure

Open chassis (IEC IP00)

Enclosed wall-mounted [IEC IP20,

NEMA 1 (Type 1)]

Fig 1.3 Inverter Specifications

Open Chassis Type (IEC IP00)

Protected so that parts of the human body cannot reach electrically charged parts from the front when the

Inverter is mounted in a control panel.

Enclosed Wall-mounted Type [IEC IP20, NEMA 1 (Type 1)]

The Inverter is structured so that the Inverter is shielded from the exterior, and can thus be mounted to the

interior wall of a standard building (not necessarily enclosed in a control panel). The protective structure conforms to the standards of NEMA 1 (Type 1) in the USA. The protective covers (see Fig. 1.4) are required for

an IEC IP20 or NEMA 1 (Type 1) protective structure.

1-4

Page 23

Confirmations upon Delivery

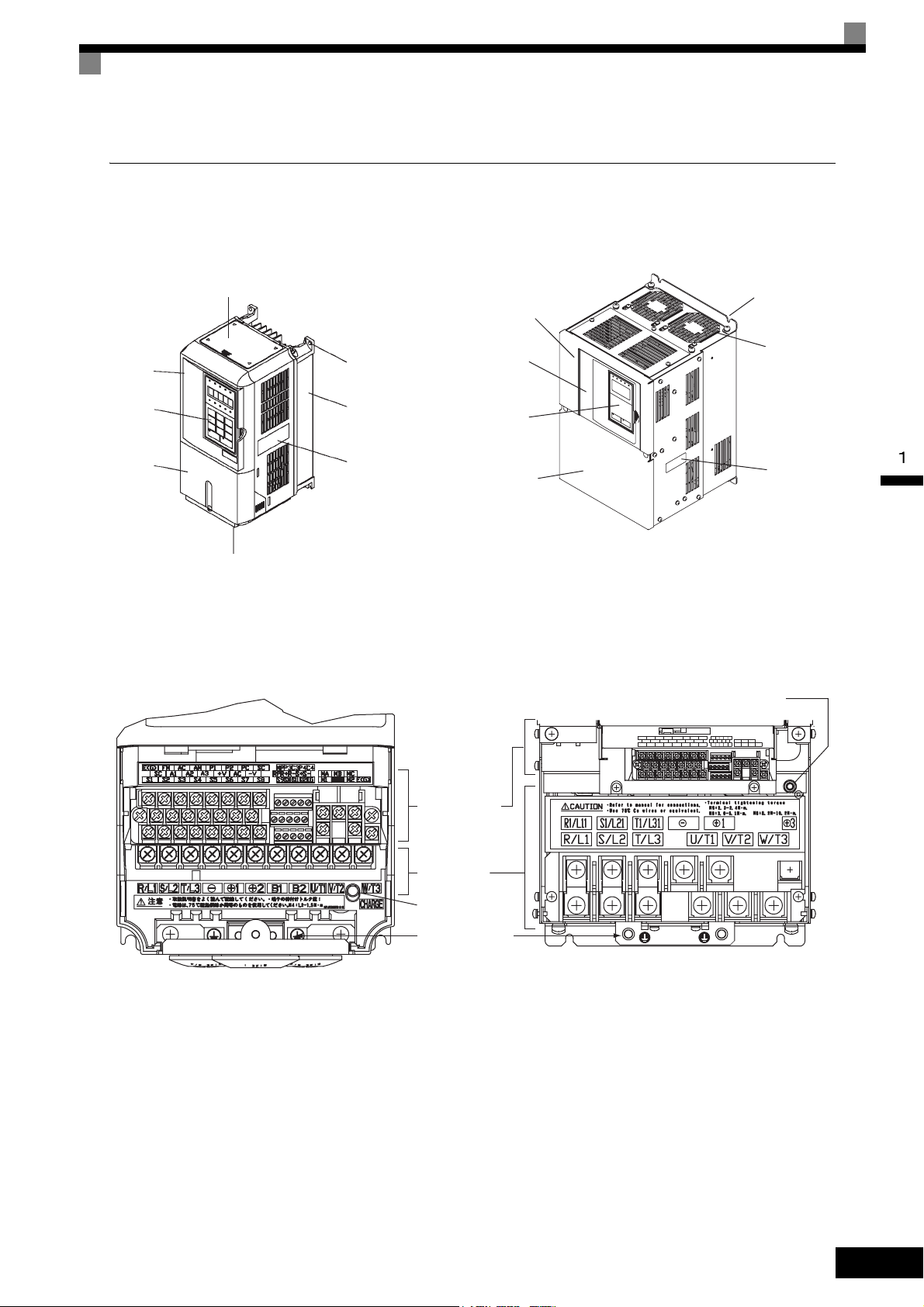

Component Names

The external appearance and component names of the Inverter are shown in Fig 1.4. The Inverter with the terminal cover removed is shown in Fig 1.5.

Front

cover

Digital

Operator

Terminal

cover

Top protective cover

Inverter cover

Mounting hole

Diecast case

Nameplate

Bottom protective cover

15 kW or Less 18.5 kW or More

Front cover

Digital

Operator

Terminal

cover

Fig 1.4 Inverter Appearance

Mounting

hole

Cooling

fan

Nameplate

Charge indicator

15 kW or Less

Control circuit

terminals

Main circuit

terminals

Charge indicator

Ground terminal

18.5 kW or More

Fig 1.5 Terminal Arrangement

1-5

Page 24

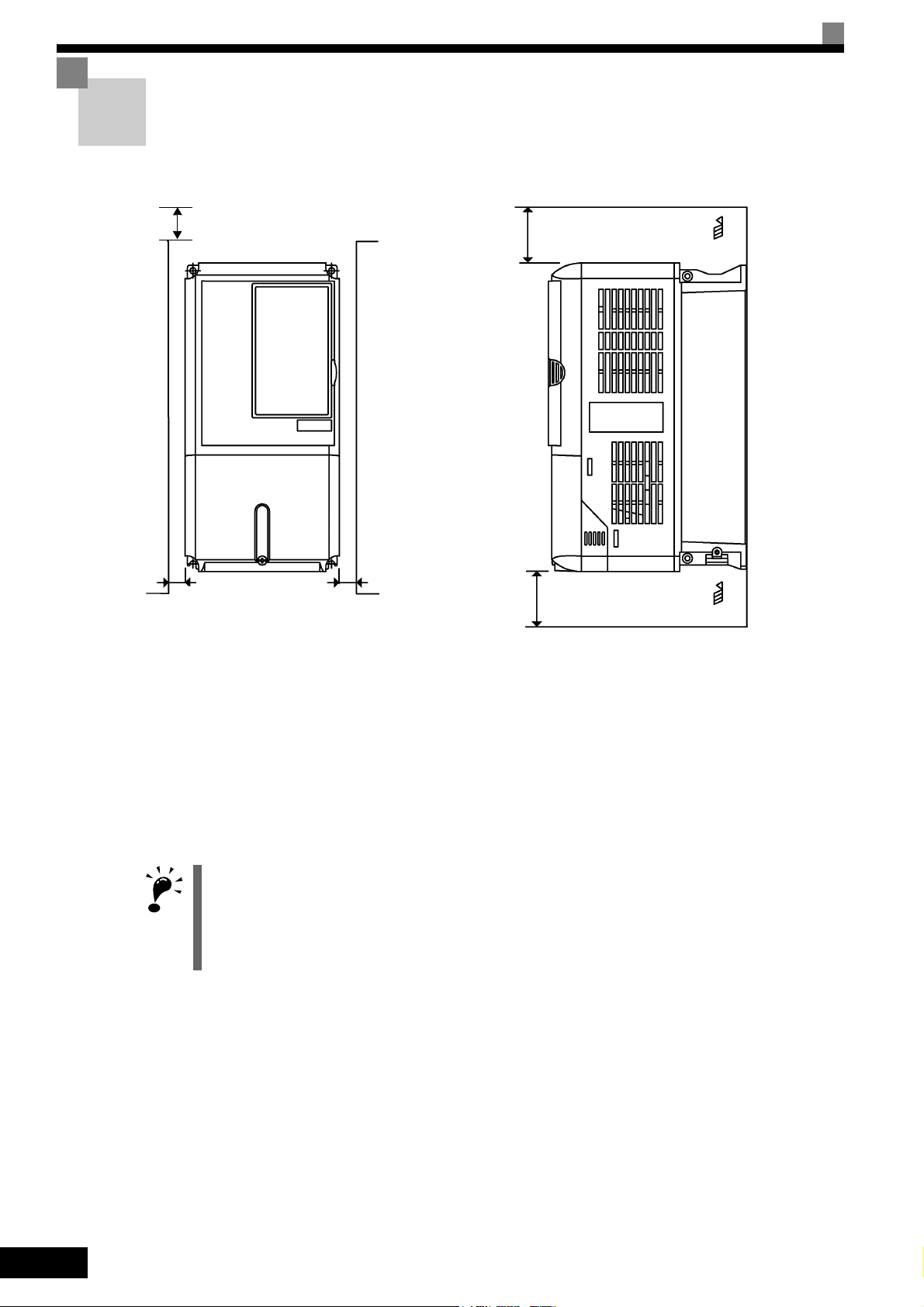

Exterior and Mounting Dimensions

Open Chassis Inverters (IP00)

Exterior diagrams of the Open Chassis Inverters are shown below.

W1

W

200 V/400 V Class Inverters of 0.4 to 15 kW

4-d

H1H2DH

3

W2

D1

W1

6-d

W1

t1

(5)*

* (10) for 200 V Class Inverters of 30 to 110 kW or

400 V Class Inverters of 55 to 160 kW.

200 V Class Inverters of 18.5 to 110 kW

400 V Class Inverters of 18.5 to 160 kW

W

4-d

(5)*

H1

H2

H

t1

(5)

D1

D

1-6

H

W3

W1

W

400 V Class Inverters of 185 to 300 kW

H2 H1

D

Fig 1.6 Exterior Diagrams of Open Chassis Inverters

t1

D1

Page 25

Exterior and Mounting Dimensions

Enclosed Wall-mounted Inverters [NEMA1 (Type 1)]

Exterior diagrams of the Enclosed Wall-mounted Inverters [NEMA1 (Type 1)] are shown below.

W1

W

200 V/400 V Class Inverters of 0.4 to 15 kW

4-d

H1H2DH0

H3

4 H

3

Fig 1.7 Exterior Diagrams of Enclosed Wall-mounted Inverters

D1

W1

t1

W

* (7.5) for 200 V Class Inverters of 30 to 75 kW or 400 V

Class Inverters of 55 to 160 kW.

200 V Class Inverters of 18.5 to 75 kW

400 V Class Inverters of 18.5 to 160 kW

4-d

H1

H2

(5)*(5)*

Grommet

H0

H3

H

Max.10

t1

D1

D(5)

1-7

Page 26

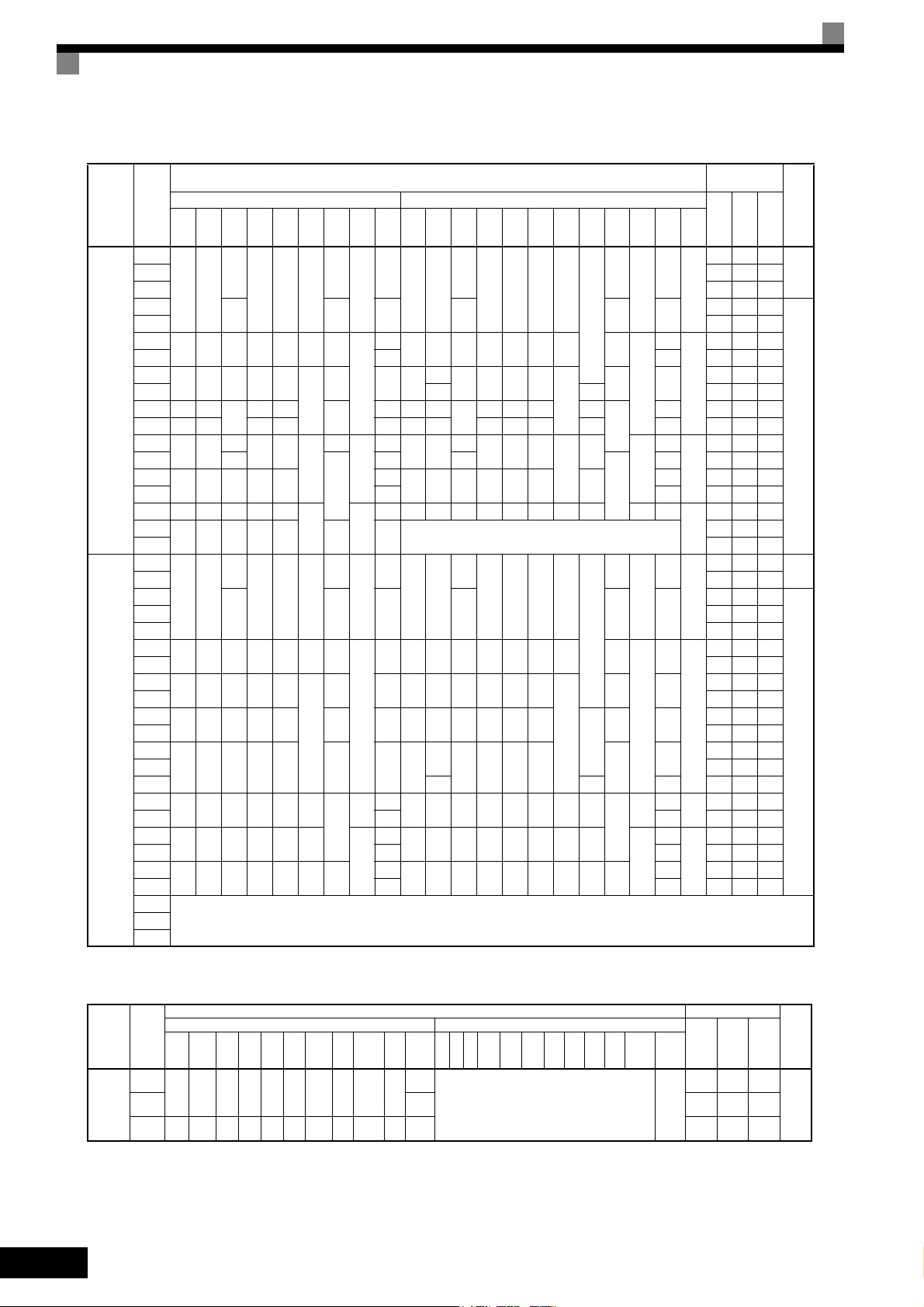

Table 1.3 200 VAC and 400 VAC (0.4 kW to 300 kW) Inverter Dimensions (mm) and Masses (kg)

Max.

Appli-

Voltage

cable

Class

Motor

Output

W H D W1H1H2D1 t1

[kW]

0.4

0.75 43 42 85

140 280

1.5 58 47 105

2.2

3.7 122 64 186

5.5

200 300 197 186 285 8 65.5

7.5 7 7 263 112 375

11

240 350 207 216 335

200 V

(3-phase)

15 380 30 473 174 647

18.5 250 400

22 275 450 220 435 24 279 615 220 450 435 165 27 679 257 936

30

375 600

37 328

45

450 725 348 325 700

55 87 95 1474 607 2081

75 500 850 358 370 820

90

575 885 378 445 855 140 150 ---

110 2389 1194 3583

0.4

0.75 21 44 65

1.5

140 280

2.2 41 49 90

3.7 76 64 140

5.5

200 300 197 186 285 8 65.5

7.5 198 106 304

11

240 350 207 216 335

15 311 135 446

18.5

275 450 258 220 435 100 26 279 535 258 220 450 435

400 V

(3-phase)

22 516 210 726

30

325 550 283 260 535 105 37 329

37 737 285 1022

45 715 165 40 929 340 1269

55

450 725 348 325 700 12.5

75 91 99 1554 596 2150

90

500 850 358 370 820 15

110 127 137 2299 928 3227

132

575 916 378 445 855 46 140

160 175 185 3614 1501 5115

185

300

* Same for Open Chassis and Enclosed Wall-mounted Inverters.

Open Chassis (IP00) Enclosed Wall-mounted [NEMA1 (Type 1)]

157

126 266 7

39

5

177 59 4 177 59 4

78 11 240

2.3

7.5

12.5

100

100

3.2

258

298

195 385

250 575

130

15 4.5

157

126 266 7

39

5

177 59 4.5 177 59 4.5

78 10 240 350 207 216 350 335

2.3

7.5

3.2

130

4.5

Dimensions (mm)

Approx.

W H D W1H0H1H2H3D1 t1

Mass

3

140 280

157

126 280 266 7

Approx.

Mass

39

5

0

6

200 300 197 186 300 285 8 65.5

350

207 216 350 335

21 254 535

57

380 809

63 328

86

453 1027 348 325 725 700 302

195 400 385 135

258

298

250 600 575

7.5

12.5

209

78 11

2.3

100

3.2

130

108 504 1243 358 370 850 820 15 393 4.5 114

3.5

140 280

157

126 280 266 7

39

5

0

7 200 300 197 186 300 285 8 65.5

78 10

2.3

7.5

635

283 260 550 535 105

90

453 1027 348 325 725 700 12.5 302

109

504 1243 358 370 850 820 15 393

165

579 1324 378 445 916 855 46 408 140

100 29

85

130

3.2

127

4.5

175 2612 1105 3717

See Table 1.4220

Heat Genera-

tion (W)

Tot a l

Mount-

ing

Holes

d*

Exter

nal

Inter-

nal

Heat

Gen-

eration

21 36 57

3

M5

83 53 136

6

187 87 274

357 136 493

M6

24 599 242 839

62

68 1080 434 1514

94 1291 510 1801

878 362 1240

M10

2009 823 2832

M12

1660 871 2531

3.5

7

10 39 49

M5

33 46 79

132 79 211

246 116 362

354 174 528

M6

39

98

633 246 879

1239 488 1727

M10

1928 762 2690

M12

Cooling

Method

Natu-

ral

Fan

Natu-

ral

Fan

1-8

Voltage

Class

400 V

(3-phase)

Table 1.4 400 VAC (185 to 300 kW) Inverter Dimensions (mm) and Masses (kg)

Max.

Appli-

cable

Motor

W H D W1W2W3 H1 H2 D1 t1

Output

[kW]

185

710 1305 413 540 240 270 1270 15 125.5 4.5

300 916 1475 413 730 365 365 1440 15 125.5 4.5 415 6749 2941 9690

Open Chassis (IP00) Enclosed Wall-mounted [NEMA (Type1)]

Dimensions (mm) Heat Generation (W )

Mount-

Exter-

Approx.

WHDW1W2W3H1H2D1 t1

Mass

260

--- M12

Approx.

Mass

ing

Holes

d*

Inter-

nal

nal

4436 1994 6430

Tot a l

Heat

Gener-

ation

Cooling

Method

Fan220 280 5329 2205 7534

Page 27

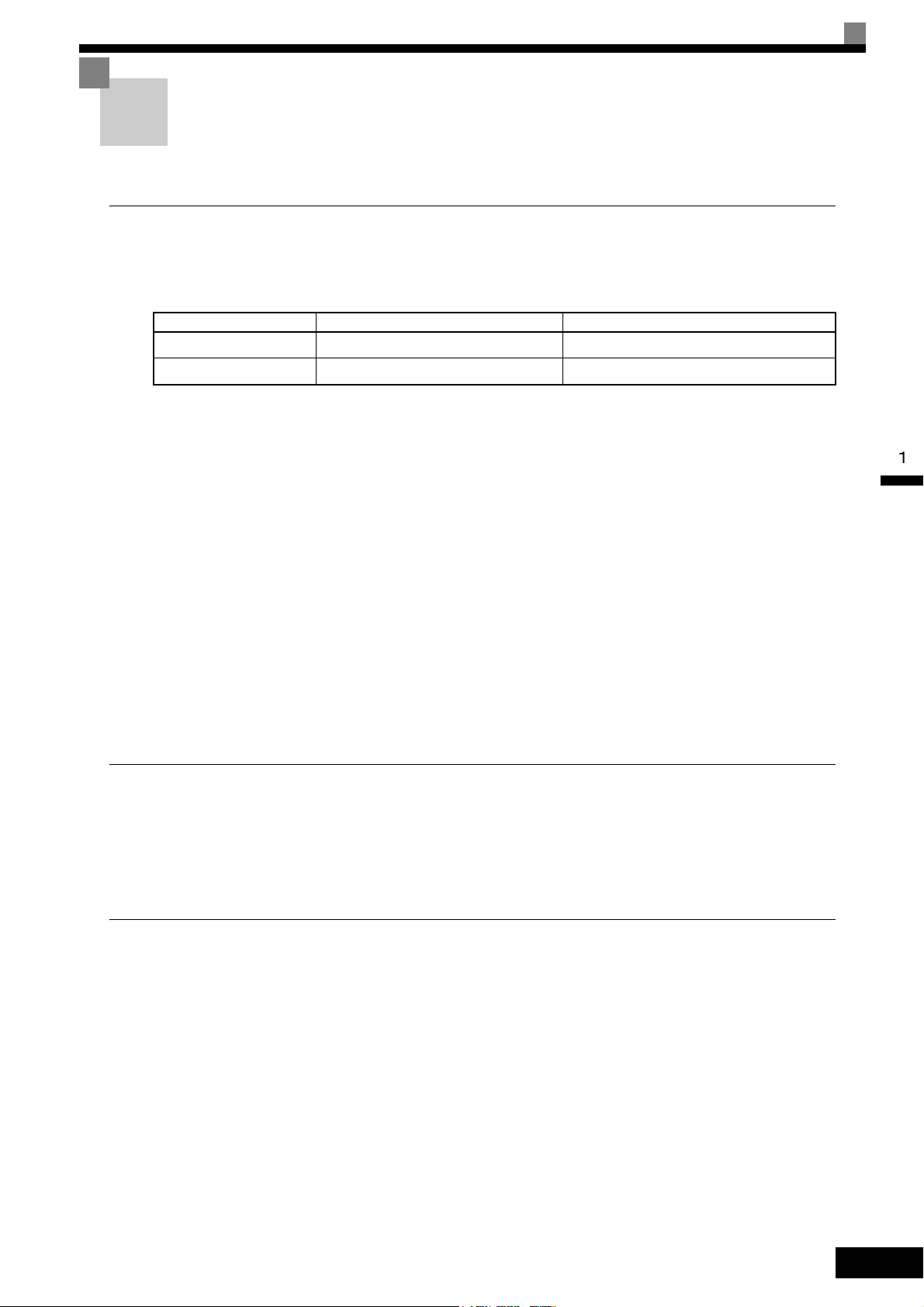

Checking and Controlling the Installation Site

Checking and Controlling the Installation Site

Install the Inverter in the installation site described below and maintain optimum conditions.

Installation Site

Install the Inverter under the following conditions and a pollution level of 2 or less (UL standard).

Table 1.5 Installation Site

Type Ambient Operating Temperature Humidity

Enclosed wall-mounted -10 to + 40 °C 95% RH or less (no condensation)

Open chassis -10 to + 45 °C 95% RH or less (no condensation)

Protection covers are attached to the top and bottom of the Inverter. Be sure to remove the protection covers

before installing a 200 or 400 V Class Inverter with an output of 15 kW or less in a panel. Refer to Page 1-17

on how to remove the protection covers.

Observe the following precautions when mounting the Inverter.

• Install the Inverter in a clean location free from oil mist and dust. It can be installed in a totally enclosed

panel that is completely shielded from floating dust.

• When installing or operating the Inverter, always take special care so that metal powder, oil, water, or other

foreign matter does not get into the Inverter.

• Do not install the Inverter on combustible material, such as wood.

• Install the Inverter in a location free from radioactive materials and combustible materials.

• Install the Inverter in a location free from harmful gasses and liquids.

• Install the Inverter in a location without excessive oscillation.

• Install the Inverter in a location free from chlorides.

• Install the Inverter in a location not in direct sunlight.

Controlling the Ambient Temperature

To enhance the reliability of operation, the Inverter should be installed in an environment free from extreme

temperature increases. If the Inverter is installed in an enclosed environment, such as a box, use a cooling fan

or air conditioner to maintain the internal air temperature below 45°C.

Protecting the Inverter from Foreign Matter

Place a cover over the Inverter during installation to shield it from metal powder produced by drilling.

Always remove the cover from the Inverter after completing installation. Otherwise, ventilation will be

reduced, causing the Inverter to overheat.

1-9

Page 28

Installation Orientation and Space

Install the Inverter vertically so as not to reduce the cooling effect. When installing the Inverter, always

provide the following installation space to allow normal heat dissipation.

A mm min.

30 mm min.

30 mm min.

B mm min.

Air

120 mm min.

Air

Vertical SpaceHorizontal Space

200 V Class Inverters of 110 kW or 400 V Class Inverters of 160 to 220 kW*: A = 120, B = 120

400 V Class Inverters of 300 kW*: A = 300, B = 300

All other Inverters*: A = 50, B = 120

*If, however, there is a fan in the top of the control panel with sufficient exhaust capacity, the following

dimensions may be used: A = 50, B = 120.

Fig 1.8 Inverter Installation Orientation and Space

1. The same space is required horizontally and vertically for both Open Chassis (IP00) and Enclosed Wallmounted [IP20, NEMA 1 (Type 1)] Inverters.

IMPORTANT

2. Always remove the protection covers before installing a 200 or 400 V Class Inverter with an output of

15 kW or less in a panel. Refer to Page 1-17 on how to remove the protection covers.

Always provide enough space for suspension eye bolts and the main circuit lines when installing a 200 or

400 V Class Inverter with an output of 18.5 kW or more in a panel.

1-10

Page 29

Removing and Attaching the Terminal Cover

Removing and Attaching the Terminal Cover

Remove the terminal cover to wire cables to the control circuit and main circuit terminals.

Removing the Terminal Cover

Inverters of 15 kW or Less

Loosen the screws at the bottom of the terminal cover, press in on the sides of the terminal cover in the direction indicated by arrow 1, and then lift the terminal cover up to an angle of about 30 degrees in the direction

indicated by arrow 2.

Remove the terminal cover in the direction indicated by arrow 3.

1

2

1

3

Fig 1.9 Removing the Terminal Cover (Model CIMR-G7A23P7 Shown Above)

Approx. 30

°

Inverters of 18.5 kW or More

Loosen the screws on the left and right at the top of the terminal cover, pull out the terminal cover in the direction of arrow 1 and then lift up on the terminal in the direction of arrow 2.

1

2

Fig 1.10 Removing the Terminal Cover (Model CIMR-G7A2018 Shown Above)

1-11

Page 30

Attaching the Terminal Cover

When wiring the terminal block has been completed, attach the terminal cover by reversing the removal procedure.

For Inverters with an output of 15 kW or less, insert the tab on the top of the terminal cover into the grove on

the Inverter and press in on the bottom of the terminal cover until it clicks into place.

1-12

Page 31

Removing/Attaching the Digital Operator and Front Cover

Removing/Attaching the Digital Operator and

Front Cover

The methods of removing and attaching the Digital Operator and Front Cover are described in this section.

Inverters of 15 kW or Less

To attach optional boards or change the terminal board connector, remove the Digital Operator and front cover

in addition to the terminal cover. Always remove the Digital Operator from the front cover before removing

the terminal cover.

The removal and attachment procedures are given below.

Removing the Digital Operator

Press the lever on the side of the Digital Operator in the direction of arrow 1 to unlock the Digital Operator

and lift the Digital Operator in the direction of arrow 2 to remove the Digital Operator as shown in the following illustration.

2

Fig 1.11 Removing the Digital Operator (Model CIMR-G7A43P7 Shown Above)

1

1-13

Page 32

Removing the Front Cover

Press the left and right sides of the front cover in the directions of arrows 1 and lift the bottom of the cover in

the direction of arrow 2 to remove the front cover as shown in the following illustration.

1

1

2

Fig 1.12 Removing the Front Cover (Model CIMR-G7A43P7 Shown Above)

Mounting the Front Cover

After wiring the terminals, mount the front cover to the Inverter by performing in reverse order to the steps to

remove the front cover.

1. Do not mount the front cover with the Digital Operator attached to the front cover; otherwise, Digital

Operator may malfunction due to imperfect contact.

2. Insert the tab of the upper part of the front cover into the groove of the Inverter and press the lower part of

the front cover onto the Inverter until the front cover snaps shut.

Mounting the Digital Operator

After attaching the front cover, mount the Digital Operator onto the Inverting using the following procedure.

1. Hook the Digital Operator at A (two locations) on the front cover in the direction of arrow 1 as shown in

the following illustration.

2. Press the Digital Operator in the direction of arrow 2 until it snaps in place at B (two locations).

1-14

Page 33

Removing/Attaching the Digital Operator and Front Cover

A

1

2

B

Fig 1.13 Mounting the Digital Operator

IMPORTANT

1. Do not remove or attach the Digital Operator or mount or remove the front cover using methods other than

those described above, otherwise the Inverter may break or malfunction due to imperfect contact.

2. Never attach the front cover to the Inverter with the Digital Operator attached to the front cover. Imperfect

contact can result.

Always attach the front cover to the Inverter by itself first, and then attach the Digital Operator to the front

cover.

1-15

Page 34

Inverters of 18.5 kW or More

For Inverter with an output of 18.5 kW or more, remove the terminal cover and then use the following procedures to remove the Digital Operator and front cover.

Removing the Digital Operator

Use the same procedure as for Inverters with an output of 18.5 kW or less.

Removing the Front Cover

Lift up at the location label 1 at the top of the control circuit terminal board in the direction of arrow 2.

2

1

Fig 1.14 Removing the Front Cover (Model CIMR-G7A2018 Shown Above)

Attaching the Front Cover

After completing required work, such as mounting an optional board or setting the control circuit terminal

board, attach the front cover by reversing the procedure to remove it.

1. Confirm that the Digital Operator is not mounted on the front cover. Contact faults can occur if the cover is

attached while the Digital Operator is mounted to it.

2. Insert the tab on the top of the front cover into the slot on the Inverter and press in on the cover until it

clicks into place on the Inverter.

Attaching the Digital Operator

Use the same procedure as for Inverters with an output of 15 kW or less.

1-16

Page 35

Removing and Attaching the Protection Cover

Removing and Attaching the Protection Cover

Inverters of 15 kW or less have protection covers on the top and bottom as shown in Fig. 1.4.Always

remove the protection covers before installing an Inverter of 15 kW or less in a panel. Use the following

procedure to remove and attach a protection cover.

Removing the Protection Cover

Top Protection Cover

Insert the tip of the straightedge screwdriver in the slot. Then, lift the cover up in the direction shown by the

arrow to remove it.

Slot

Fig 1.15 Removing the Top Protection Cover (Model CIMR-G7A43P7 Shown Above)

Bottom Protection Cover

1. Remove the terminal cover as described on Page 1-11.

2. Loosen the two screws, and remove the protection cover.

3. Return the screws to their original position and tighten (them).

4. Reattach the terminal cover as described on Page 1-12.

Screws

Bottom Protection

Cover

Terminal Cover

Fig 1.16 Removing the Bottom Protection Cover (Model CIMR-G7A43P7 Shown Above)

1-17

Page 36

Attaching the Protection Cover

Top Protection Cover

The protection cover has four hooks: two hooks on the bottom and two on the sides. Fit the bottom hooks into

the holes, bend the cover slightly, and press the cover down until the hooks on the side snap.

Holes for bottom hooks

Fig 1.17 Attaching the Top Protection Cover (Model CIMR-G7A43P7 Shown Above)

Bottom Protection Cover

To attach the bottom protection cover, reverse the procedure used to remove it.

1-18

Page 37

2

Wiring

This chapter describes wiring terminals, main circuit terminal connections, main circuit termi-

nal wiring specifications, control circuit terminals, and control circuit wiring specifications.

Connections to Peripheral Devices..............................2-2

Connection Diagram ....................................................2-3

Terminal Block Configuration.......................................2-5

Wiring Main Circuit Terminals ......................................2-6

Wiring Control Circuit Terminals ................................2-22

Wiring Check .............................................................2-30

Installing and Wiring Option Boards ..........................2-31

Page 38

Connections to Peripheral Devices

Examples of connections between the Inverter and typical peripheral devices are shown in Fig 2.1.

Power supply

Molded-case

circuit breaker

or ground fault

interrupter

Magnetic contactor (MC)

AC reactor for power

factor improvement

Zero phase reactor

Input noise filter

Inverter

Ground

Output noise filter

Braking resistor

Varispeed F7

DC reactor for power

factor improvement

Zero phase reactor

2-2

Motor

Ground

Fig 2.1 Example Connections to Peripheral Devices

Page 39

Connection Diagram

00

)

+1

+ 3