Page 1

Varispeed-501)W11

INDUSTRIAL

USE

THYRISTOR

CONVERTER

UNITS

Before

initial

operation,

read

these

instructions

thoroughly,

and

retain

for

future

reference

.

Page 2

When

properly

installed,

operated

and

maintained,

this

unit

will

providealifetimeofoptimum

operation.It

is

mandatory

that

the

person

who

operates, inspects,

and

maintains

this

equipment

thoroughly

reads

and

understands

this

manual

andhasinhis possession

at

all

time

.

IMPORTANT

.

Make

no

withstand

voltage

testonthe

VS-505WII

because

it

incorporates

semi-conductor

electronic

circuits

.

.Ifinsulation resistance

tests

are

neccessary,

make

them

onlyinaccordance

with the

instructions

given

in

this

manual

.

682-215

Type

CDMR-W11

Type

CDMR-WIL

(Type

S)

(Type

L)

460

V,

105

A

460

V,

420

A

CONTENTS

682-234

.

Do

not

tamper

with

potentiometersofthe

power

units

since

they

were

preset

at the

factory

before

shipment

.

Varispeed-505W11

(VS-505WII)isa

thyristor

converter

unit

for

varispeed

reversible

operation

of

industrial

DC

motors

.

For

correct

operationofVS-505WII,

users

must

thoroughly read these

instructions

.

This

manualisalso

necessary

for

maintenance

and

troubleshooting,

and

threfore

should

be kept

filed

for

ready

reference

.

For

detailsonDC

motors,

referto"Instructions

for

IndustrialDCMotors"

(TOE-C435-3B)

.

Type

CDMR-W11

(Type

M)

230

V,

260

A

682-227

RECEIVING........

. . . .

3

Interconnections...........4

MAINTENANCE

. . . . . . . .

10

STORAGE............ . .

3

Cautions

when

Wiring

. . . . . .

4

Periodic

Inspection

. . . . . .

.

10

LOCATION

. . ...........

3

TEST

RUN..............

5

Parts

Replacement

. ......10

INSTALLATION.........3

Check

before

Test

CautionsinReplacing

WIRING

. . . . ............3

Run

.

. . . . . ... . . . . . ..... .

5

Control

Board

. . . . . . . . ...

14

Component

Arrangement

No-Load

Operation........

6

Troubleshooting

Guide

.

...

14

in

VS-505WH.... . . . . . . . .

3

Full-Load Operation

. . . . -

6

SPAREPARTS

. ..... . . . .

15

Terminal

Sizes

and

Carrying

Currents

. . ... . ...

4

Adjustment

.

. . .......

.

. . .

6

REFERENCE..........

. .

16

Page 3

RECEIVING

or

missing

.

STORAGE

If

the

equipment

is

temporarily

stored

or

ma-

chine stops

foranextended

length

of

time,

the

following

precautions

should

be

taken

.

LOCATION

Store

the

equipment

under

the

following

condi-

tions

.

"

Free

from

rainfall

and

drops

of

water

"

Clean

and dry

(a)

Control

Circuit

"

Free from

corrosive

gas

and

liquid

"

Ambient

temperature:OOC

to400

C

WIRII4G

Make

wiring

in

reference

to

the

interconnection

diagram

furnished

on your

order

and

the

follow-

ing

.

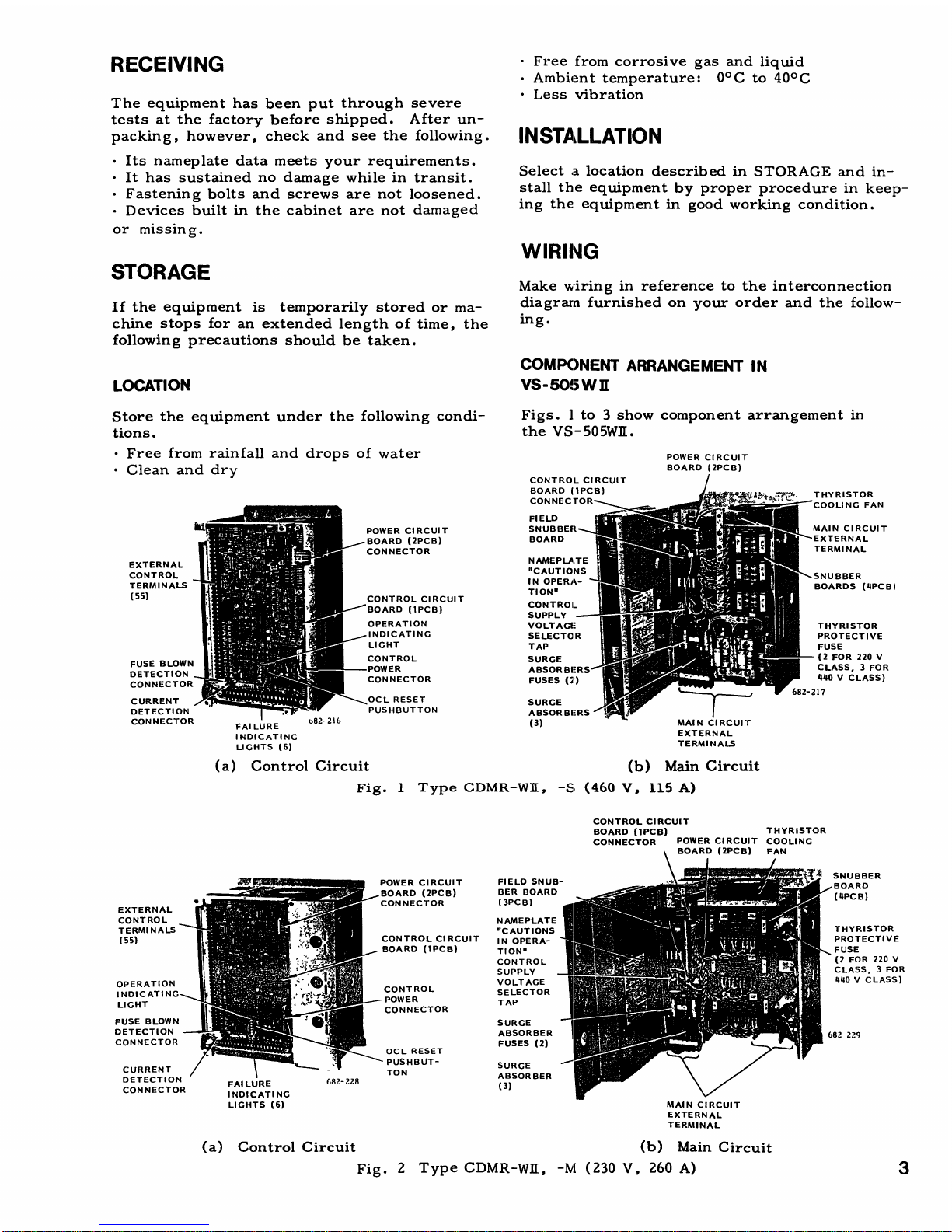

COMPONENT

ARRANGEMENT

IN

VS-505

W

II

Figs.1to3

show

component

arrangement

in

the

VS-505WII

.

NAMEPLATE

"CAUTIONS

I

NOPERA-

TION"

CONTROL

SUPPLY

VOLTAGE

SELECTOR

TAP

POWER

CIRCUIT

BOARD

(2PCB)

(a)

Control

Circuit

Fig.1

Type

CDMR-WI[,

-S,

(460V,115

A)

(b)

Main

Circuit

CONTROL

CIRCUIT

BOARD

(1PCB)

THYRISTOR

CONNECTOR

POWER

CIRCUIT

COOLING

BOARD

(2PCB)FAN

MAIN

CIRCUIT

EXTERNAL

TERMINAL

(b)

Main

Circuit

Fig

.

2

Type

CDMR-WII,

-1V[

(230

V,

260 A)

THYRISTOR

PROTECTIVE

FUSE

(2

FOR

220

V

CLASS,3FOR

440

V

CLASS)

THYRISTOR

PROTECTIVE

FUSE

(2

FOR

220

V

CLASS,3FOR

440VCLASS)

The

equipment

has

been

put

through

severe

testsatthe

factory

before

shipped.After

un-

packing,

however,

check

and

see the

following

.

"

Less

vibration

INSTALLATION

"

Its

nameplate

data

meets

your

requirements

.

"Ithas

sustained

no

damage

whileintransit

.

Select.alocation

described

in

STORAGE

and

in-

"

Fastening

bolts

and

screws are

not

loosened

.

stall

the

equipment

by proper

procedure

in

keep-

"

Devices

builtinthe cabinet are not

damaged

ing the

equipment

in

good

working

condition

.

Page 4

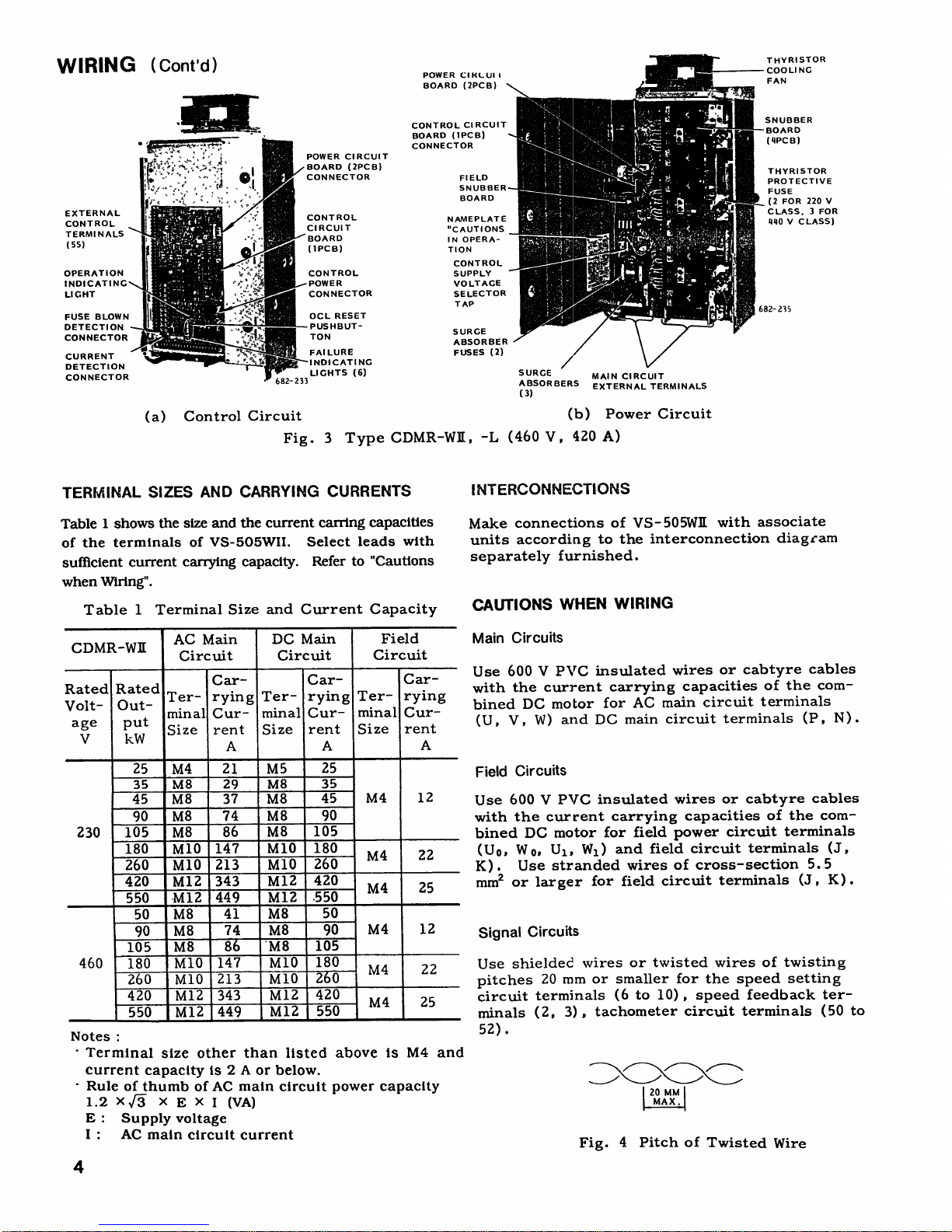

WIRING

(Cont'd)

4

TERMINAL

SIZES

AND

CARRYING

CURRENTS

Table1shows

the

size

and

the current

earring

capacities

of

the

terminals

of

VS-505WII

.

Select

leads

with

sufficient

current

carrying capacity.Referto"Cautions

when

Wiring"

.

Table

1

Terminal

Size

and

Current

Capacity

Notes

-

Terminal

size

other

than

listed

above

is

M4

and

current

capacityis2Aor

below

.

Ruleofthumb

ofACmain

circuit

power

capacity

1

.2XF

XEXI

(VA)

E

:Supply

voltage

I

:AC

main

circuit

current

SURGE

ABSORBERS

Control

Circuit

(b)

Power

Circuit

Fig.3

Type

CDMR-WII

:,

-L

(460

V,

420

A)

INTERCONNECTIONS

Make

connections

of

VS-505WII

with

associate

units

according

to

the

interconnection

diagram

separately

furnished

.

CAUTIONS

WHEN

WIRING

Main

Circuits

Use

600VPVC

insulated

wires

or

cabtyre

cables

with

the

current

carrying

capacities

of

the

com-

bined

DC

motor

for

AC

main

circuit

terminals

(U,

V, W)

and

DC

main

circuit

terminals

(P,

N)

.

Field

Circuits

Signal

Circuits

MAIN

CIRCUIT

EXTERNAL

TERMINALS

Use

600VPVC

insulated

wires

or

cabtyre

cables

with

the

current

carrying

capacities

of

the

com-

bined

DC

motor

for

field

power

circuit

terminals

(Uo,

Wo,U1,

Wl)

and

field

circuit

terminals

(J,

K)

.Use

stranded

wires

of

cross-section

5.5

mm2or larger

for

field

circuit

terminals

(J,K).

Use

shielded

wires

or

twisted

wires

of

twisting

pitches

20

mm

or

smaller

for

the

speed

setting

circuit

terminals

(6 to 10),speed

feedback

ter-

minals

(2,

3),

tachometer

circuit

terminals

(50

to

52)

.

Fig.4

Pitch

of

Twisted

Wire

AC

Main

DC

Main

Field

CDMR-W11

Circuit Circuit

Circuit

Car- Car- Car-

RatedRated

Ter

-

ryingTer- ryingTer-

rying

Volt-

Out-

minal

Cur-

minal

Cur-

minal

Cur-

age

e

put

rent

Size rent

Size

rent

V

kW

A A

A

25

M4

21

M

5 25

35

M8

29

M8

35

45

M8

37

M8

45

M4

12

90

M8

74

M8

90

230

105

M8

86

M8

105

180

M10

147

M10

180

M4

22

260

M10

213

M10

260

420

M12

343

M12

420

M4

25

550

-M12

449

M12

.550

50

M8

41

M8

50

90

M8

74

M8

90

M4

12

105

M8

8

'M8

105

460 180

M10

147

M10

180

M4

22

260

M10

213

M10

2&0

420

M12

343

M12

420

M4

25

550

M12

449

M12

550

Page 5

Separation

of

Signal

Cables

from Main

Circuit

Cables

To

avoid

inductive

interference

from

other

cables,

run

the

shieldedor

twisted

wires

(1to55)

separatefrommain

circuit

cables(U,V,W;

Uo,

WO

;

U1,

W1;P,N;J,

K)

inabundle

or

thruaduct

.

CAUTION

After

wiring,

check

interconnections

.

Make

in-

sulation

resistance

tests

usinga500Vmegger

.

Connect

VS-505WIE

main

circuit

terminals

(U,

V,

W

;

Uo,W

o

;

U1,

W

1

;

P,

N;J,

K)

with

common

lead.Measure

the

insulation

resistance

between

common

lead

and

the

ground

.

When

the

test

result

is

2

MSZ

or

more,

it

means

that wiring

is

good

.

TEST

RUN

When

the

VS-505WIL

has

been

correctly

installed

and

wired,

the

unit shall

be

tested

through

a

test

run

as

follows

.

If

trouble

is

foundduring

the

test

run,

re-

ferto"Check

Before

Test

Run"

and

"Trouble-

shooting

Guide"

for

necessary

measures

.

If

the

cause

of

the

trouble

cannot

be

located,

or

repair

is

impossible,

notify

our

service

station,

giving

the

detailsoftrouble

conditions

.

CHECK

BEFORE

TEST

RUN

Make

the

following

checks

prior

to

the

test

run

.

Table

2

Check

before

Test

Run

*

VS-

505WEoflarger

capacity

than

230V,45Aor

460V,

90

A

are

provided

withathyristor

cooling

fan

.

Fig

.5Inspection

Window

of

DC

Motor

D

Fig.6

Tap

Selection

of

Control

Supply

Voltage

Table

3

Supply

Voltage

Allowable

Range

50H

z

60Hz

For

50

Hz,

slide

the

switch

keyup.

For60Hz,

slide

the switch

key

down

.

Fig.7

Power

Frequency

Selector

Switch

Check

Pomts Check

Items

Interconnec-

"

Correct

wiring

tions

between"Tightening

of

terminal

screws

v

s-

505WE

and

Associ-

ate

Units

DC

Motor

"

Disconnection

from

the

driven

machine

"

Removalofthrust

block

"

Remove

inspection

covers

and

blow

out

with

air to

clean

commutator.(Fig.5)

VS-505WII

"

Adhesion

of

dirtordustonthe

enclosure

"

Smooth

hand

rotation

of

thyristor

cooling

fan

"

Check

items

in

"Cautions

in

Operation"

on

the

backofthe

control

board

door

"

Correct

connectionofthe

shunt

connector

to

the

voltage

selecting

tap

(Fig

.

6)

"

Correct

settingofthe

frequency

selector

switch

(Fig.7)

"

Correct

adjustmentofpotentiometers

on

the

control

board

(1PCB)

Refertored

paint

Supply

Volt-"Voltagesofanytwoofphases

U, V,Ware

age

at

Input

within

the

valuesonTable3.

Check

with

a

Terminals

of

tester

.

VS-505WR

"

Terminals

Uo

and

U1,

and

Woand

W,

are

connected

.

"

Rotating

directionofthe

motor

blower

meets

with

the

arrow

marked

on

the

blower

.

Nominal

Supply

Permissible

Voltage

Supply

Frequency

Voltage

Selector

Voltage

Variation

Tap

200

V

50/60

Hz

170-220

V

200

V

220

V

50/60

Hz

187-242

V

220

V

400

V

50/60

Hz

340-440

V

400

V

440

V

50/60

Hz

374-484

V

440

V

Page 6

TEST

RUN

(Cont'd

)

NO-LOAD

OPERATION

After

making

the

checks

specified

before

test

run,

thoroughly

check

the

environment

of the

system

for

safety

.

Check

the

polarityofDC

tachometer

generator

feedback

voltage.When

the

motorisrunning

forward,

the

polarity of

VS-505WIl

signal

terminal2(3

:0V)is

minus

and

it

is

plus during

reverse

runningofthe

motor

.

Then,

run

the

motor

without

load

according

to

Table4.

FULL-LOAD

OPERATION

Before

starting

full-load

operation,

stop

the

power

supply,

couple

theDCmotortothe

driven

machine,

and

check

the

motor

and

the

driven

machine

for

safe

and

obstruction-free

conditions.Table5gives

full-load

operation

procedure

.

Table

4

No-load

Operation

*

VS-505W11.rated

220

V.45Aand

above

and460V.90A

and

above

are

provided

with a

thyrlstor

cooling

fan

.

6

ADJUSTMENT

Do

not

tamper

unnecessarily

with the

potentiometers

on

the

control

circuit

board

since

they

have been

adjusted

at

the

factory

before

shipped

.

Adjuster

Locations

and

Functions

Adjuster

locations

on

the control

circuit

board

and

functions

are

shown

in

rig.8

and

Table6.

The

characteristicsofcontrol

circuit

board

check

terminals

are

shownin:Fig.9

and

Table7.

0

sx

V

~

0

Fig.8

Adjuster

Locations

on

Control

Circuit

Board

'fable 5

Full-load

Operation

Order

Operation

Check

Items

9

1

Set

the

speed

reference

at

zero

.

2

Turn

on main

circuit

Smooth

rotationofthe

powersuppy

.

thyristor

cooling

fan

.

Smooth

rotationofthe

blower

forDCmotor

.

Rotating

directionofthe

blower

meets

with

the

mark-

ingonthe

blower

.

3

Make

an

operationalse-

Indication

light

"PREP"

on

quence

and

checktobe

the

control

board(1PCB)

sure

that

operation

is

turnson.

ready.(Turn

on

ready

signal,

motor

cooling

fan

ON

/OFF

signal

.)

4

Turn-on

the

operation

signal

.

5

Gradually,

increasethe

Smooth

accelerationofDC

speed

setting

value

.

motor

.

No

abnormalodor,

smoke,

vibration

and

noiseonDC

motor

.

6

Remove

the

hand-hole

No

brush

chattering

and

cover

and

check

the

I

sparkingatthebrushes

.

commutator

.

To

avoid

excessive

temperature

riseofDC

motor

windinginframe

112, 132,

reclose

the

window

within5minutes

.

7

Gradually,turn

the

Smooth

acceleration

of

DC

speed

setting

potentiom-

motor

.

eter

clockwise

.

8

'

Increase

the

speed

set-

DC

motor

rotatesatthe

ting

valuetothe

maxi-

maximum

speed

.

Check

mum

.

withaspeedometer

.

9 Change

the

speed

to

DC

motorspeed

corre-

various

values

.

sponds

with

the

set

values

.

10

Turn

off

the

operation

DC

motor

suddenly

stops

.

signal

.

11

Turn

off

the

main

cir-

cult

power

supply

.

Order

Operation

1

Setthe

speed

at

zero

.

2

Turnonthe

main

circ

uitpower

supply

.

3

Turn

on

operation

signal

and

gradually

increase

the

speed

.

Check

to

be

sure

that

the

motor

and

driven

machine

are

correctly

r

u

nning

.

4

Tu

rn

off

the

operationsig

n

al

.

5

Tu

rnoffmaincircuit

power

supply

.

Page 7

Table6Control

Circuit

Board

Adjuster

Locations

and

Functions

Type:o

Adjuster

Adjuster

Adjuster

Function

Adjusting

Method

Specifications

Adjusters

Location

Name

1

~+

RATE

Accel

time

adjustmentatfwdrun

.

Clockwise

rotation

increases

3-75

sec

(Decel

time

adjustmentatrvs

run

.)

accel

time

.

2

(D

RATE

Decel

time

adjustment

at

fwd run

Clockwise

rotation

increases

decel

time

.

3

-

75

sec

(Accel

time

adjus

tment

at

rvs

run

.)

3

NGAIN

ASR

Gain

adjustment

.

Clockwise

rotation

increases

GAIN

4

Speed

feedback

adjustment

.

Clockwise

rotation

decreases

±6V/10046 specA

NMAX

s"geed

.

5

IGAIN

ACR

Gain adjustment

.

Clockwise

rotation

increases

gain

.

6

Main

circuit

current

feedback

Clockwise

rotation

decreases

+3

V/100%

current

IFB

adjustment

.

current

.

7

F

LIMIT

Speed and

current

limit

value

at

Clockwise

rotation

increases

150%

(Standard)

forward

run

.

limit

value

.

8

R

LIMIT

Speed

and

current

limit

value

at

Clockwise

rotation

increases

150%

(Standard)

reverse

run

.

li

mitvalue

.

9

CEMF

Counter

electromotive

force

Clockwise

rotation

increases

0.17 -0.84

times

Potenti-

compensation

.

gain

.

ometers

10

SM

Speedometer

adjustment

.

Clockwise

rotation

increases

1

mADC

max

.pointer

swin:.

Ammeter

adjustment

.

Clockwise

rotation

increases pointer

1

mADC

max

11

AM

swing

.

12

NOFS

ASR

offset

adjustment

.

evolt.iz- e

13

IOFS

ACR

offset

adjustment

.

t-volta

,",

.-e

14

KIPP

Phase

shift

lag

limit

adjust-

Clockwise

rotation

advances

shift

lag

155oek

Standard

ment

limit

Adjustment

of

phase

shifter

Clockwise

rotation

advances

90'-k

-

li_T1i°eZ

15

PSB

operation

point

.

:,hase

.

(Adjustable)

Setting

overload

detection

Clockwise

rotation

increases

110%

Standard

16

OL%

start

point

.

overload

detection

start

.,oint.

17

OLT

Setting

overload

detection

Clockwise

rotation

increases

150%,6.0

sec

(Standard)

time

.

o

.eration

time

.

18

ZCD

Setting

zero

current

detec-

Clockwise

rotation

increases

0% -

10n

(Adjustable)

tion

level

.

detection

level

.

7%

(Standard)

19

IREF

Setting

field

current

.

Clockwise

rotation

increases

field

current

.

Resistor

20

14FBR

1FBR

-

Rough

adjustment

of

field

cur-

Selection

rent

detection

voltage

level

.

Open

the

resistor

according

Refertomotor

specifi-

(Open)

21

5FBR

-

Rough

adjustmentofmain

circuit

to

specifications

.

cations

.

9FBR

current

detection

voltage

level

.

Slide

22

1SW

Control

Method

selector

(Speed

N-1

Current

Switch

control)

control)

~

M®

50

Hz-

"0Hz

Rough

adjustment

of

speed

Selectionothe

voltage

level

24

A

-

D

detection

voltage

level

.

accordingtotype

of

tack-gen

and

motor

rateds.

,

eed

.

25

E

Selection

of soft start

El

operation

E2

Soft

start

Selection

ofPI orPcontrolby©

PI

control

26

F

ACR

control

method

"A

P

contr

ol

Selection

ofPI orPcontrolby©

Pc

mntrol

Plug

27

H

ASR

control

method

©

P1

control

control

Selection

Selectionofzero-speed

condi-

J 1

block

after

motor

28

tion at

motor

overheat

.

reached

zero

speed

by

J

stopo.eration

.

~~

ime(giate

gate

block

.

29

K

Selectionofstart

interlock

©Wit

zero-speed

condition

.

~~

Without

Selectionofzero-speed

cord-

Field

half-reduced

after

tion at

motor

blower

stop

.

ttiotor

zero-speed

by

stop

30

L

_operation.(Gate

block)

Field

half-reduced

immediately

.

-

(Gate

block)

Selectionofexciter

according

I©Exciter

used

.

31

M

to

typeof

motor

field

.

©

Exciter

not

used

.

Open

"

Speed

control

by

voltage

detection

.

"

Speed

control

by

AC

Short-

32

OPN

tach-gen

.

circuit

Short

-

Jumper

circuited

other

than the

above

.

Open

-

Special

application

.

33

OPS

--

Short-

Other

than

the

above

.

circuited

Page 8

TEST

RUN

(Cont'd)

Adjustment

Procedure

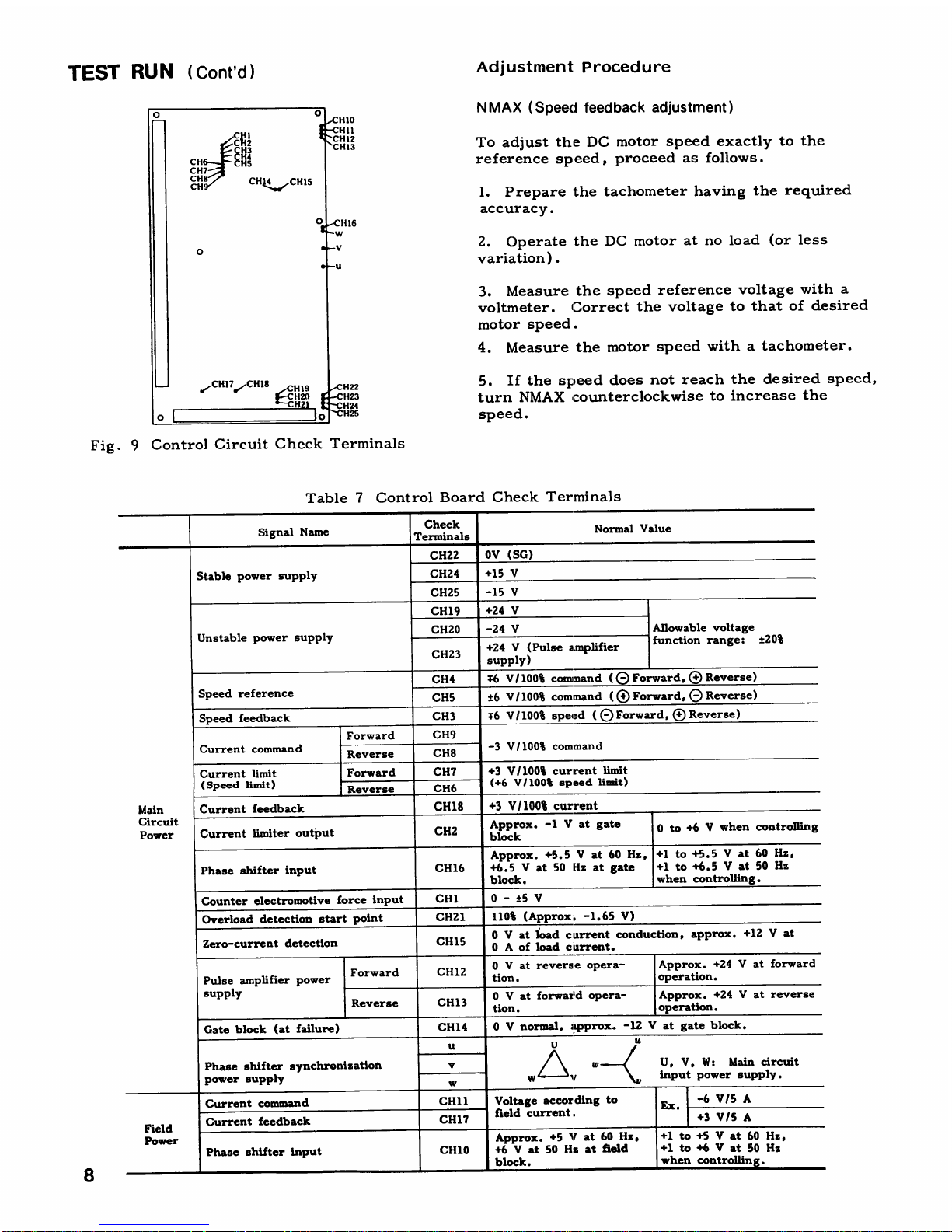

Fig.9

Control

Circuit

Check

Terminals

N

MAX

(Speed

feedback adjustment)

Table7Control

Board

Check

Terminals

To

adjust

the

DC

motor

speed

exactlytothe

reference

speed,

proceedasfollows

.

1.Prepare

the

tachometer

having

the

required

accuracy

.

2.Operate

the

DC

motoratno

load

(or

less

variation)

.

3.Measure

the

speed

reference

voltage

with

a

voltmeter.Correct

the

voltagetothat of

desired

motor

speed

.

4.Measure

the

motor

speed

withatachometer

.

5

.

If

the

speed

does

not

reach

the

desired

speed,

turn

NMAX

counterclockwise

to

increase

the

speed

.

Signal

Name

Check

Terminals

Normal

Value

CH22

OV

(SG

)

Stable

power

supply

CH24

+15

V

CH25

-15

V

CH19

+24

V

CH20

-24

V

Allowable

voltage

Unstable

power

supply

CH23

+24

V

(Pulse

amplifier

supply)

function

range

:

±20%

CH4

:6

V/100%

com

mand

(8

Forward,

(+

Reverse)

Speed

reference

CH5

±6

V/100%

com

mand

((D

Forward,

(DReverse)

Speed

feedback

CH3

;6V/

100%

spe

ed

(0

Forward,

+

Reverse)

Forward

CH9

Current

command

Reverse

CH8

-3

V/100%

command

Current

limit

Forward

CH7

+3

V/100%

current

limit

(Speed

limit)

Reverse

CH6

(+6

V/100%

speed

limit)

Main

Current

feedback

CH18

+3 VI100%

current

Circuit

Power

Current

limiter

output

CH2

.-1Vatgate

ock

bl

Approx

0 t

o

+6Vwhen

controlling

Phase

shifter

input

CH16

Approx.+5.5Vat60

Hz,

+6

.5Vat50Hzatgate

block

.

+1to+5

.5Vat 60

Hz,

+1to+6

.5Vat 50

Hz

when

controlling

.

Counter

electromotive

force

input

CH1

0 - ±5

V

Overload

detection

start

point

CH21

110%

(Approx:-1

.65

V)

Zero-current

detection

CH15

0

V

at

load

current

conduction,

approx

.

+12Vat

0Aof

load

current

.

Pulse

amplifier

power

Forward

C1112

0

Vatreverse

opera-

tion

.

Approx.+24Vat

forward

operation

.

supply

Reverse

CH13

0Vat

fozwaz~d

opera-

tion

.

Approx.+24Vat

reverse

operation

.

Gate

block

(at failure)

CH14

0

V

normal,:!pprox.-12Vat

gate

bloc

k

.

u

U

u

Phase

shifter

synchronization

v

4/_~s

ar

U, V,W:

Main

circuit

power

supply

w

w

11

y

input

power

supply

.

Current

command

CH11

Voltage

according

to

~

-6

V/5

A

Field

Current

feedback

CH17

field

current

.

+3

V/5

A

Power

Phase

shifter

input

CH10

Approx.+5

Vat60

Hz,

+6Vat

50

Hzatfield

block

.

+1

to +5Vat60Hz,

+1 to

+6Vat 50

Hz

when

controlling

.

Page 9

6.If

the

speed

exceeds

the

desired

speed,

turn

NMAX

clockwise

to

decrease

the

speed

.

FLIMIT

(Forward

limit

value

adjustment)

RLIMIT

(Reverse

limit

value

adjustment)

1.Current

limitation

(Speed

control)

Slide

the

control

method

selector

switch

(1SW)

on

the

control

circuit

board

toN.

When

the

voltages

at

CH7

(forward)

and

CH6

(reverse) are+3V,

100%

current

limit

valueisobtained

.

Current

limit

value

can

be

set

within

the

range

of0%to

250%

by

F

LIMIT

andRLIMIT

.

2.Speed

limitation

(Current

control)

Slide

the

control

method

selector

switch

(1SW)

on

the

control

circuit

board

toI.

When

the

voltages

atCH7

(forward)

and

CH6(reverse)

are

+6

V,

100%

speed

limit

valueisobtained.Speed

limit

value

can

be

set

within the

range

of0%to

250%

by

F

LIMIT

andRLIMIT

.

PSB

(Phase

shifter

operating point

adjustment)

PSB

sets

the

phase

shifter

operating

point

.

1.When

the

current

controller

(ACR)

is

inte-

gral-controlled

Connect

the

plug

selectorFon

the

control

circuit

board

atFl.

Turn

PSB

fully

counterclockwise

.

2.When

the

current

controller

(ACR)

is

ratio-

controlled

Connect

the

plug

selectorFon

the

control

circuit

board

atF2.

Turn

PSB

clockwise gradually

with

reference

current

at 0V(0VatCH2),and

set

at

the

position

where

main

circuit

current

is

ready

to

start

.

CEMF

(Counter

electromotive force

compensation)

Current

loopisvulnerable

to

counter

electro-

motive

force.In

order

to

obtain

optimum

per-

formance,acompensating

electromotive

force

has

to

be

biased

on

the

phase

shifter,

depending

on

the control

mode

.

1

.

When

the

current

controller

(ACR)

is

ratio-

controlled

Adjust

CEMF,

observing

the

motor

acceleration

current withasynchroscope

.

Turn

CEMF

fully

counterclockwise,

and

turn

CEMF

clockwise

gradually

until

optimum

value

shown

in

Fig.10

is

obtained

.

2.When

the

current

controller

(ACR)

is

inte-

gral-controlled

MOTOR

ACCELERATION

CUR

1tENT

Field

Current

Adjustment

Fig

.

10

CEMF

Adjustment

CEMF

compensation

reduces

the

loss

time

due

to

Forward/Reverse

selectiontoas the

same

level

as

the

integral

control

of

ACR

.

Turn

CEMF

fully

counterclockwise,

and

during

motor

acceleration

by

current

limit

gradually

turnitclockwise

until

the voltageatCH2

on

the

control

circuit

board

stabilizes

.

Field

current

adjustment

is

required

for

checking

the

setting

at

the factory or

for

fine

adjustment

.

To

change

the

setting,

selection

of

resistors

(1FBRto

4FBR)on

the

control

circuit

board

is

required

.

1.For

constant

field

current

a

.

ConnectaDC

ammeter

to

the

field

circuit

.

b.Adjust

so

that

the

ammeter

indicates

the

rated

field

current with

IREF

on

the

control

circuit

board.(Refertothe

test

report

or

nameplate

data

.)

2.For

field

weakening

control

SYNCHROSCOPESCREEN

ADJUST

THE

SWEEP

SPEED

ADAPTED

TO

THE

MOTOR

ACCELERAITON

TIME

TO

BRING

THE

CURVES

TO

A

CONVENIENT

POSITION

.

Field

weakening

controlismade

for

the

VS-505WII

combined

with

field

weakening

control unit

type

JGSM-51-

D

.

a.Connect

DC

ammeter

to

the

field

circuit

and

DC

voltmetertooutput

terminals

P,N.

b.Turn

IREF

on

the

control

circuit

board

and

FORCE

FLD

andV

LIMIT

of

field

controller

fully

counterclockwise

.

c.Seat

the

minimum

field

weakening

current

by

IREF.In

this

case, set the

current

at

80%

field

weakening

current

at

maximum

speed

.

(See the

test

report

.)

d.Set the

rated

field

current

(field

intensifying

by

FORCE

FLD

.(See the

test

report

or

name-

plate

data

.)

e.Alter

the

motor

starts,

gradual

increasing

the

speed

reference

increases

the

voltage

across

P

andNand

governs

itatsome

value

.Turn

V

LIMIT

clockwise gradually

so

that

the

governed

valueisthe rated voltage

.

Page 10

MAINTENANCE

VS-505WIl

requires

almost

no

daily

inspection

.

To

keep

the

correct

and

successful

operation,

periodic

maintenance

operations

should

be

per-

formed.The

users

should

prepare

their

own

maintenance

programs

based

on

the

following

guidelines

.

PERIODICINSPECTION

Table8shows

the

minimum

inspection items

and

the

procedures

.

Table

8

Periodic Inspection

PARTS

REPLACEMENT

.

Replace

the

parts

required

after

checking

the

trouble

and

correcting

it

according

to

TROUBLE-

SHOOTING

GUIDE

.

.

Turn

off

the

power

before

part removal

or

mounting

.

10

Fig.11

Field

Thyrsitor

Assembly

Field

Thyristor

Replacement

With

all

the

Models,

thyristor

modules

consisting

of

a thyristor

andadiode

are

used

as the

field

thyristor.Replace

them

as

follows

.

1.Remove

the

four

mounting

screws

of

field

snubber

board

(3PCB),

lead

clamping screws,

control

power

connector

.

Then,

remove

snubber

board.See

Fig.11

.

2.Remove

lead

clamping

screws

connecting

to

thyristor,

and

remove

the leads

from

thyristor

.

In

this

case,

mark

all

terminals

for

identification

.

See

Fig.12

.

3.Remove

thyristor

mounting

screws

(2)

and

remove

thyristor

module

.

4

.

ChecktY;Ie

type

and

capacity of

new

thyristor

module

against the

requirements.Installitby

reversing

the

removal

procedure,

making

con-

nections

to

the

terminals

identifiedbythe

marks

made

before

removing

the

old

thyristor

module

.

Coat

the thyristor

mounting

surface

with

joint

compound,

JOINTAL

Z

madeby

Nippon

Light

MetalCo. ,

Ltd

.

Main

Circuit

Thyristor

Replacement

VS-505W

1,

230Vat25A

The

unit

uses

a thyristor

module

consisting

of

two

thyristors.Replace

itasfollows

.

1.Remove

snubber

board

(4PCB)

mounting

screws

(5)

and

lead

clamping

screws.Remove

snubber

board.(Fig

.

13)

2

.

Remove

bus

bar

mounting

screws

and

lead

clamping

screws

connected

to

thyristor.Remove

bus

bar

and

leads.(Fig

.

14)

In

this

case,

mark

the terminals

for

identification

.

3

.

Remove

two

thyristor

clamping

screws

and

thyristor

.

4.Check

the

replacement

module

for

type

and

capacity,

and

reinstallitby

reversing

the

dis-

assembly

procedure,

identifying the terminals

by

means

of the

marks

made

prior

to

disassembling

.

THYRISTOR

MTGSCREWS

Fig.12

With

SnubberBoard

Removed

Inspection

Part

Inspection

Item

Inspection

Procedure

Whattodo

Remarks

Thyristor

"

Noise

"

Check

for

Replace

.

Ruleofthumb

cooling

any

inter-

for

cooling

fan

fan

mittent

or

replacement

:

unusual

15,000

hours

noise

.

of

operation

.

"

Vibration"Feel

by

hand

.

-

General

"

Dust

or

.

Check

for

Clean

with

dirt

dust

clogging

an

electri-

or

dirt

cal

cleaner

"

Loose

ter-

adhesion

.

,

Tighten

.

minal

"

Check

for

screws

or

loose

screws

nuts

or nuts

.

Page 11

Main

Circuit

Thyristor

Replacement

VS-505W

1,

230Vat

35

to

105A,460Vat50to

105

A

The

unit

usesathyristor

module

consisting

of

two

thyristors.Replace

it

as

follows

.

1.Remove

snubber

board

(4PCB)

mounting

screws

(5)

and

remove

snubber

board

.

(Fig.15)

2

.

Remove

busbar

mountingscrews

and

lead

clamping

screwsconnected

to

thyristor.Remove

bus

bar

and

leads

.

(Fig

.

16).In

this

case,

mark

the

terminals

for

identification

.

3

.

Remove

two

thyristor

clamping

screws

and

thyristor

.

4.Check

the

replacement

module

for

type

and

capacity,

and

reinstallitby

reversing

the

dis-

assembly

procedure,

identifying

the

terminals

by

means

of

the

marks

made

prior

to

disassembling

.

Coat

the

thyristor

mounting

surface

with

joint

compound,

JOINTAL

Z

made

by

Nippon

Light

Metal

Co.,

Ltd

.

SNUBBER

BOARD

.TG

SCREWS

(5)

Fig

.

13

Field

Thyristor

Assembly

(230

V,

25

A)

Fig

.

14

With

Snubber

Board

Removed

Main

Circuit

Thyristor

Replacement

VS-505

W1,230Vat

180to550A,460Vat

180

to

550

A

The

VS-505WIE

usesaflat

thyristor

module

as

a

power

module

.For 180Aand

260

A,

one

power

module

is

employed,

and

for

420

A,

and

550

A,

three

power

modules

are

employed

.

Proceed

as

follows

.

1.Remove

the

clamping

screws

for

thyristor

gate

(C)

and

cathode

(K)

terminals

(24 for 260

A

or

below,

and8for

420

A

or

more),

and

free

the

leads.Remove

fuse

mounting

bolt(s)

(3 for

260

A

or

below

and1for

420

A

or

more)

.(Fig

.

17)

2.Loosen

power

module

mounting

bolts

(7

for

260Aor below,8for

420

A

or

more),and

remove

the

power

module

.

THYRISTOR

CLAMPING

-

SCREWS

S14UBBER

BOARD

MTG

SCREWS

(5)

Fig.15

Main

Circuit

Thyristor

Assembly

(460

V,

105

A)

BUSBAR-

Fig

.

16

With

Snubber

Board

Removed

Page 12

MAINTENANCE

(Cont'd

)

3.Place

the

main

circuit

thyristor

moduleon

a

work

bench

.

Remove

the

snubber

board

(4PCB-

U,

V, W) mountingscrews

(3

for

260Aor below,

4 for

420Aor

more),

and

take

out

the

snubber

board.(Fig.18)

4.Loosen

the

fin

mounting

nuts

alternately,

turning

1/4

turn

at a

time.Then,

remove

the

leaf

spring

.

5

.

Remove

the

fin

and

take

out

the

leaf

spring

.

6.Clean

the

contact

surfaces

of

the

new

thy-

ristor

and

the

fin,

and

thinly

coat

these

surfaces

with

joint

compound,

JOINTAL

Z

madeby

Nippon

Light

Metal

Co.,Ltd

.

7.Align

the

fin

locating

pin

and

the

thyristor

locating

hole, after

making

sure

that

the

polarity

of

the

thyristor

is

correct

.

8.Keeping

the

leaf

spring

and

the

fininparal-

lel,

finger-tighten

the

clamping

nuts

.

Then,

tighten

them

alternately

through

1/4

turn

at

a

time,

three

times

each

withasocket

wrench

.

Now,

the

thyristor

fin

has

been

installed

.

12

Thyristor

Protective

Fuse

Replacement

2.Remove

the

two

fuse

mounting

bolts

.

VS-505W

11,

230Vat25to

105A,460Vat50to

105

A

1.Pull

up

the

fuse

blown

indicating

microswitch

with

the

leads

connected

.(Fig

.

19)

3.Mount

the

replacement

fuse

by

reversing

the

removing

procedure,

after

checking

it

for

model

and

capacity

.

9.Tighten

the

snubber

board

mountingscrews

.

Then,

mount

the

thyristor

module

by

reversing

thedisassembling

procedure,

tightening

the

screws

firmly

.

THYRISTOR

GATE

(G)

CATHODE

(K)

TERMINALS

FUSE

K

(RED)

G

(WHITE)

THYRISTOR

681-193

(a)

With

Thyristor

Removed

Fig.18

Thyristor

Replacement

(b)

Thyristor

Fig.17

Main

Circuit

Thyristor

(460

V,

420

A)

Fig.19

Main

Circuit

Fuse

Assembly

(460

V,

105

A)

Page 13

Thyristor

Protective

Fuse

Replacement

VS

-505W

1,

230Vat

180

to

550A,460Vat

180

to

550

A

1 .

Remove

the

two

lead

clamping

screws

of

the

fuse-blown

indicating

mocroswitch

and

free

the

leads

.

(Fig

.

20)

2.Remove

the

two

fuse

mounting

bolts,

and

remove

the fuse

together

with

the

fuse-blown

indicating

microswitch

.

3.Check

the

replacement

fuse

for

model

and

capacity,

and

installitby

reversing

the

disas-

sembling

procedure

.

Surge

Absorber

Fuse

Replacement

Surge

Absorber

Replacement

Fig.20

Main

Circuit

FuseAssembly

(460

V,

420 A)

1.Pull

the

fuse

element

and

removeit.

(Fig.21)

2.Mount

the

replacement

fuse,

after

checking

its

model

and

capacity

.

Fig.21

Surge

Absorber

Fuse

1.Remove

three

surge

absorber

mounting

screws

and

remove

surge

absorber

.

2.Check

the

replacement

surge

absorber

for

model

and

capacity.Mount

three

surge

ab-

sorbers

after

connecting

M4

pressure

termi-

nalstotheir leads

as

shown

in

Fig.22

.

IL

)k,

Thyristor

Cooling

Fan

Replacement

Fig.22

Surge

Absorber

with

Pres-

sure

Terminals

Connected

to

Leads

To

replace a thyristor

cooling

fan

withanew

one,

proceed

as

follows

.(Fig.23)

The

VS-505WIL

unitsrated

230

V,

25A;

460

V,

50Aare

self-

cooled

type

.

1

.Remove

the

cooling

fan

power

lead

.

2.Unscrew

the

two

fan

mountingscrews

and

dismount

the fan

.

3.Remove

the fan

by

reversing the

disassembl-

ing

procedure

.

(a)

230

V,

45to105

A;460

V,

90/105

A

FAN

POWER

SUPPLY

LEADS

(2)

r

.

.

(b)

230

V,

180/260A;

460

V,

180/260

A

(c)

230

V, 420/550A;

460

V,

420/550

A

Fig

.

23

Thyristor

Cooling

Fan

1

3

Page 14

MAINTENANCE

(Cont'd

)

Control

Circuit

Board

Replacement

Disconnect

all

the

leads

from

the

terminals

.

Then,

unplug

the

connectors

shown

in

Fig

.

24,

and

remove

the

6

control

circuit

board

mounting

screws

.

Mount

the

new

board

by

reversing the

disassembling

procedure

.

Plug-in

the

connectors

firmly

.

CAUTIONS

IN

REPLACING

CONTROL

CIRCUIT

BOARD

TROUBLESHOOTING

GUIDE

1

4

EXTERNAL

CONTROL

TERMINALS

FUSE-BLOWN

DETECTION

CONNECTOR

CURRENT

DETECTION

CONNECTOR

Make

sure

that

the

typeofthe

new

control

circuit

board

agrees

with

the

nameplate

and

potentiometer

settings of

new

control

circuit

board

are the

same

as the old

one.Refertothe

nameplate

"CautionsinOperation"

postedonthe

inside of

the

control

circuit

board

doorofVS-505WII.See

Table6"Adjuster

Locationsonthe Control

Circuit

Board

and

Functions"

.

Fig.24

Control

Board

Table

9

Troubleshooting

Guide

Note:If

the

readingisnot

m

.

accurate

measurement

with a

500Vmeggerisrequired

.Reading

must

be3megohms

or

above

.

Trouble

Possible

cause

Check

method

Whattodo

PREP

lamp

Control

Failure

indicating

OFF

printed

lampON.

board

Operation

sequence

Check

the

external

operation

sequence

._Replace

the

control

board.See

Replace-

failure

.

mentofControl

Board

.

OCL

lamp

Control

Too

low

setting

of Is setting

dial at

the positions

indicated

Set the setting

dialtothe

ON

printed

"OL%,"

"OLT"

.

b

lock

"

dint?

position of lock

dint

.

board

Too

high

setting of

"FLIMIT,"

"RLIMIT"

RefertoTables

6and 7

.

Incorrect

setting of

Readjust

.

"IFB'

:

Thyristor

Defective

deterto-

Check

thyristor

(Fig.25)

.

Replace

thyrtstor.(See

Main

rated)

.

CircuitThrtstoronpage

9.)

Motor

and

Overloaded

.

Check

load

current

.

A

iust loa

.

Reset

.

driven

Locking

.

Run

motor

without

load,

and seeifit

locks

Repair

motor

.

machine

Check

load for

locking

.

Layer

shorting

in

Run

motor

with

terminalsPandNdis-

Repair

motor

.

motor

.

connected.If

OCL

lamp

does

not

light,

the

motor

and

its

circuit

are

defective

.

Grounding

of

motor

Measure

resistance

between

terminal

P)

"

Repair

motor

.

circuit

.

(or N)

and

ground

(E)

with

a multitester."

Correct

wiring

.

If

the

reading

is

nearly-on

the

largest

scale of the tester,

the

circuitisnormal

.

U

lamp

Thyristor Defective

deterto-

Check

thyrtstor

(Fig.25)

Replace

thyrtstor.(See

Main

Circuit

ON

r

ated)

.

Th

rtstoronpage9.

Motor Layer

shorting

in

Operate

only

board

with

(P)

and

(NT

-1-

s-

Repair

motor

.

motor

.

connected.If

fuseisnot

blown,

motor

circuit

is

defective

.

Groundingofmotor

Measure

resistance

across

terminal

I'

or"repair

motor

.

To

replace

circuit

.

N)

and

ground

(E)

with

a multitester,

and"Correct

wiring

.

fuses (1FU,

if

the

readingisnearly

m

on

the

largest

ZFU.5FU),

scaleofthe

tester, the

circuit

is

normal

.

refer

to

o

(See

Note

.)

Replacement

t

;

Control

Defective

phase

Ifthemotor

isnormal.replace

of

Thyristor

circuit

control

circuit)

.

control circsut

board.Refer

Protection

"

O

board

to

ReplacementofControl

Fuse

.

c

Circuit

Board

on page13.

c

Fuse

Defective

deterio-

rated)

.

_

FL

lamp

Motor Layer

shorting

in

Measure

resistance

across

terminal J

and

"

Repair

motor

.

ON

field

winding

.

K

with

converter

terminal J

andKdis-

"

Replace

fuse.(3FUor4FU)

.

connected

withatester.If

it

indicates

m,

it

means-

field

circuitisdisconnected

.

Groundingoffield

Measure

resistance

across

terminal

(.Ior

K

circuit

.

andground

(E)

with

a multitester,

and

if

the

readingisnearlymon

the

largest

scale of the tester,

the

circuitisnormal

.

Control

Defective

.

If

the

motorisnormal,

replace control

[board

circuit

board.See

ReplacementofControl

Boardonpa_e 13

.

THG

lamp

Motor

Over

Main

circuit

Check

load

current.'

Ad

ust load

.

ON

loading.Field

circuit

Check

field

current

.

Head

ust.See

Adjustment

on

page

7 .

Locking

.

Run

motor

without

load,

and see

if it

locks.Reitmotor

.

Check

load for lockmf-

.-,

.

A

.'

_'J

.

Blocked

air filter

.

Refer

to the

instructions

for Industrial

DC

Motors

(TOE-C435-3)

.

Insufficient

cooling

Check

the

blower

for

correct

running

Correct

wiring

.

with

blower

.

direction

.

MCF

lamp

Motor

Cooling

blower

stop.Check

fan

for

lockingoroverloadinE

; .

Repairor

replace

fan

.

ON

_Check

thermal

relay

for

tri..in

TCF

lamp

Thyristor

cooling

an stop

.

Check

fan for

locking

or

overloading

.

Replace

the

thyristor

cooling

fan.See

ON

Where

the

fanisprovided

with

Replacement

of

Thyristor

Cooling

Fan,

failure

sensor

on page12.

Surge

Main

CKT

Excessive

surge

.

Check

fuses

3FU,

4FU

.

Eliminate

causeofsurge.Replace

surge

absorber

and

fuse.See

ReplacementofSurge

of

fuse

blown

Absorber

Fuse

and

Replacement

of

Sure

Absorber

.

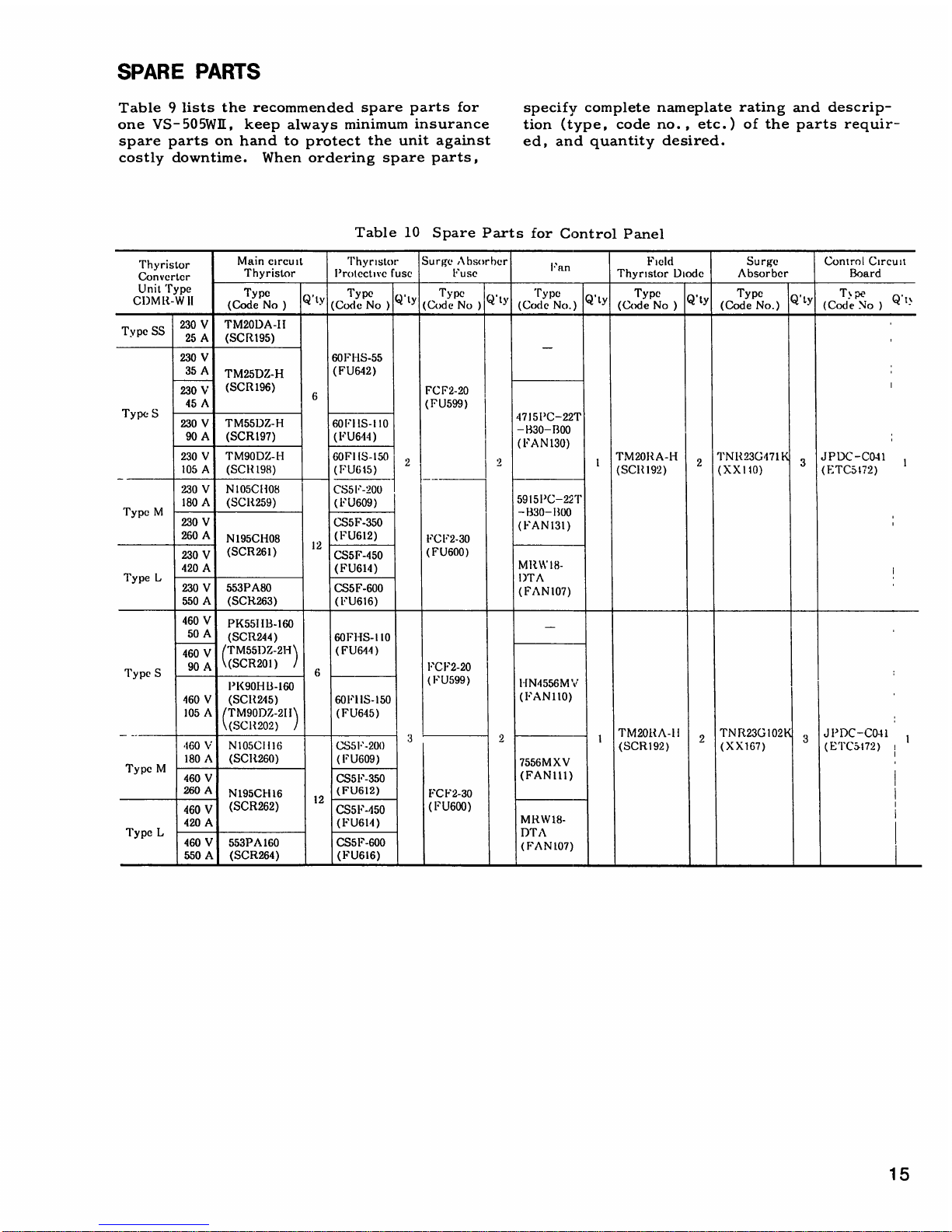

Page 15

SPARE

PARTS

Table9lists

the

recommended

spare

parts

for

one

VS-505WII,

keep

always

minimum

insurance

spare

parts

on

hand

to

protect

the

unit

against

costly

downtime

.

When

ordering

spare

parts,

Table

10

Spare

Parts

for

Control

Panel

specify

complete

nameplate

rating

and

descrip-

tion

(type,

code

no

. ,

etc.)of

the

parts

requir-

ed,

and

quantitydesired

.

Thyristor

Main

circuit

Thyristor

Surge

Absorber

Fan

Field

Surge

Control

Circuit

Converter

Thyristor

Protective

fuse

Fuse

Thyristor

Diode

Absorber

Board

CI)MlTWII

Type

(~'tyType

Q,ty

Type

I

Q~ty

Type

Q.ty

Type

Q,ty

Type

Q.tY

T%pe

Q

'

t -

`

(CodeNo)

(CodeNo)

(Code

No

)

(CodeNo.)

(Code

No)

(CodeNo.)

(Code

No)

TypeSS

230VTM20DA-II

25A(SCR195)

230

V

60FHS-55

35

A

TM25DZ-H

(FU642)

230

V

(SCR196)

6

FCI"2-20

45

A

(FU599)

Type

S

230

V

TM55D7,-H

60FIIS-110

I

4715I'C-22T

90A(SCR197)

(FU644)

-1330-1300

'

(FAN130)

'

230VTM90D/

.-1-1

60FIIS-150I2

.~

1

TM20RA-Ii

2

'I'NR23G471'3

JPDC_

C041

I

105A(SC1?198)

(FU615)

(SC

IZ192)

(XX110)

(FTCa1

;2)

230VN105CH08

CS5F-200

-~

M

180A(SCR259)

(FU609)

I

59151'C-22T

Type

230

V

CS5F-350

-1330-13tH)

(FAN

131)

,

260

A

N195CH08

(FU612)

FCF2-30

230

V

(SCR261)

12

CS5F-450

(FU600)

L

420

A

(FU614)

MlI

.W18-

Type

230

V

553PA80

CS5F-600

(FAN107)

550A(SCR263)

(FU616)

460

V

PK55IIB-160

-

50

A

(SCR244)

60FIiS-110

460

V

rI'M55DZ-21i

(FU644

)

90

A

1(SCR201)

PCF2-20

Type

S

6

PK90HB-160

(FU599)

HN4556MV

460V(SCII245)

60FHS-150

(FAN110)

'

105A(TM90Dl,-211

(FU645)

\(SCH202)

'

TM20IZA-l1

TNR23GIO2

'

J1'DC-CO-11

3

1

2

3

1

.160VN105CI116

CS5F-200

(SCR192) (X

X167)

(ETCa172)

;

M

180A(SCR260)

(FU609)

7556MXV

Type

460

V

CS5

F-350

(FANI

11)

2(i0

A

N195CII16

12

(FU612)

FCF2-30

j

460

V

(SCR262)

CS5F-450

(FU600)

i

L

420

A

(

FU614

)

MRW18-

Type

460V553PA160

CS5F-600

(fTAN107)

550A(SCR264)

(FU616)

i

Page 16

(REFERENCE)

ROUGH

CHECK

OF

THYRISTORS

Where

thyristors

normally

function,

the

following

values

are

obtained

.

More

than

several

hundreds

of

kiloohms

across

Several

ohms

to

several

hundreds

of

ohms

across

(A)

and

(K)

.

(G)

and

(K)

.

IPA

RPA

1

6

FS

FT

(a)

Resistance

across

thyristor

(b)

Resistance

across

thyristor

terminals

(A)

and

(K)

terminals

(G)

and

(K)

ELEMENTARY

DIAGRAM

OF

THYRISTOR

CONVERTER

UNIT

(TYPE

CDMR-W

II,

230V,

90A)

P15

RT=4-p

18

P19,

P20

1PCB

G1

K1

K2

G2

G1

K1

N3,4

Y

1,

Y5

I

R1

Il

R

.)

JPDC-P05()

FPA~

,

RPA

i

G1

Thyristor

fails

i

f 0or-isin-

dicated

on the

even

either

tester

(x

1

0

range)

Fig

.

25

Rough

Check

of

Thyristors

AC

POWER

SUPPLY

200/220V 50/60Hz

-----------

~----------

Fig.26

Main

Circuit

500W1500

Thyristor

fails

if

0 or-is

in-

dicated

on

the

even

either

tester(x1

S2

range)

CONTROLLER

JPDC-CO41

R

1PCB

Page 17

HALT

._27

PREPARATION

O

STOP0RUN

9

FLD

ROCK

Flu

(MCF)

FuH

TCFH

DCTG

20

-

3+0

nv/

I(X)%

uw/

I(X)%

15v/

I(X)%

SPFEO

REFERENCE

FROM

CONTROL

TRANSFORMER

6

-P.0V

-

+48V

LOGIC

CIRCUIT

+15VOV

-15V

(P)

23

CONTACT

RATING

220VAC2A

24

VDC

2A

RUN

M-ON

COM

'FLD

CONT

PREPARATION

:

i{----------

_

L

4

JGSM-519}T~-

6131415

__l-i

_i

pno

20,NAOU

LT

CUM

NC

4 51 52 49

©I2

3a

s

©

FBR

OCL

IREF

-

-24V

Fig

.

27

Control

Circuit

ESE

CHIT

CH17

ACR

7,

FK

50Hz4y60Hz,

NH1

REVERSING

CONTROL

LER

ZC

0

CH15

PS

llms

llms

A

S

FBR

aoaa

10

SELECTOR

SWITCH

nnn

!ij4dj

I

IFLDIFB

CH12

CH13

1Q

v

TYPE

:JPDC-CO41

Z

~TF

FPA

RPA

RT

QRFI

FROM

POWER

PCB

H

FROM

POWER

PCB

H

Page 18

(REFERENCE)

(Cont'd)

FUNCTIONS

OF

EXTERNAL

CONTROL

TERMINALS

1

8

Table

11

Functions

of

External

Control

Terminals

for

Input

Notes

1.Use

highly

reliable

contact

for

input

interface

signal

considering

that the

load

is 48

VDC,

10

mA

.

2.Provideanoise

killer at

both endsofcoil

when

relays,

contactors,

etc.are

used

.

Signal

Name

Terminal

Function

1

Ready

signal

-

-°

0-

30

"Close" --- Field

intensifying

.

"O"men"

---

Gateblock+Field

half-reduced

.

2

Operation

signal

29

"Close"

---

Speed

reference

"ON"-;

Accelerationtospeed

--0

reference

value

.

"Open"

---

Speed

reference

"OFF"-Stop

by

regenerative

braking+Gate

block

.

29

"RUN"

---

Speed

reference

"ON"-}Accelerationtospee,

"

reference

value

.

j j

28

"STOP"

---

Speed

reference

"OFF"-"

Stop

by

regenerative

~

braking-Gate

block

.

3

Quick

stop

27

Quick

stopat'

Close'incaseofsoft

start

operation

.

signal

-o

o-

"Close"

---

Speed

reference

"OFF"-}Stop

by

regenerative

braking-rGate

block

.

4

Main

circuit

M

2 "Close" ---

Gate

block

Terminals

26

and

35

(or

36)

input

answer

back

~

0-

released

.

short-circuited

unless

used

.

signal

5

Motor

overheat

33

"Open"

---

Gate

block

.

si

nal

- -

"Close" ---

Normally

.

"

Field

block

signal

3 "Close"

---

Fie143

block.(Field

circuit

clipped

at

PP

-°

°-

phase

.)

7

Motor

blower

31

"Close"

---

Field intensifying

.

ON

/OFF

signal °-

"Open"

---

Gate

block-~Field

currenthalf-reduced

.

8

External gate

_

4-47

"Close"

---

Gate

block

.

block

signal

9

External

(OCL)

45 -

46

"Close"

---

Normally

.

Terminals

45

and4"

short-

failure

reset

~~-

"Open"

---

Reset

.

circuited

when

reset

button

in

the

unitisused

.

10

Fuse

blown

R1-R2

"Open"

---

Normally

.

detection

signal

"Close"

---

Gate

block

.

(inside)

11

Thyristor

cooling

R3-R4

With

failure

detection

cooling

fan

(option)

.

fan

stop

signal

__0

"Open"

---

Normally

.

(inside)

"Close" ---

Gate

block

12

Speed

reference

t&

V

/100$N

"

Soft

start

commnw

"

-"zei~~z:e

.

(0+Forward,

(D

7

-4

V

'100

""

"3to 75

(Variable)

Reverse)

8 ±10V/100%N

sec

.

9

f15

7100%N

Accel.time, decel.time

ad-

10

0

V

(SG)

justable

independently

.

12

*6V/

100$N

Terminals

11

an,.1

short-

circuited

.

13

±6V/100

0

/6N

13

External

current

reference

(

(D

14 ±3

V/100%

Ia

Forward

torque,

0

Reverse

15 0

V

(SG)

torque)

14

Speed

feedback

-

DCTG

2 3

(+)

signal

15

CEMF

compensation

48

Forward

:4V/1U0%

Va

Reverse:+6

V/100%Va

1

"

Automatic

field

1

Output

received from

field

controller

TypeJGSM-51

.

weakening

current

command

17

Speed

feedback

5

"

Output

from

TypeJGSM-

5

(Voltage

feedback)

When

reversible

operation

by

ACTG.(OPN:Open)

"

Output

fromtype

JGSM-53

When

speed

controlled

by

voltage

detection

.

(OPN:OP

,

en)

Page 19

Table

12

Functions

of

External

Control

Terminals

for

Output

*Allowable

rating 24

VDC,

50mA.(24

VDC

power

supply

required

externally

.)

Signal

Name

Terminal

Function

1

Ready

signal 24 - 25

Contact

signal

closed

when

.

.-0

operationisready

.

Allowable

contact

(PREP

lightON.)

capacity

2

Operation

signal

zz

3

21-22-23

NO

contact

----

For

input

220

VAC,2A

o- c

ommand

.

24

3 Failure signal

19~~

18-19-20

Contact

signalcose"or

VDC,

2

A

0-1

-

°

opened)

when

failure

occurs

.

4

Zero-speed

44

"ON"

at

motor

speed

1% or

below

(±6

V/100%

NPB)

.

detectionsin

al

5

Main

circuit

current

detec-

49

-

V

100

Ia

tion

signal

(Allowable load

impedance:3

k9Z)

±12VMax

6

Speed

reference

signal

11

-6

V/100%

N

Terminals

11an(A

12

short-circuited

.

7

Speed

feedback

signal

4

Input

from

Type

JGSM-

when

revers1peoperation

b

ACTG

. (

OPN:Open)

8

Indi-

Thyristor

cooling

39

"ON"