Page 1

Models: MV and CIMR-V7* Document Number: IG.V7.01

V7 and V74X Drives

Installation Guide

Page 2

WARNINGS, CAUTIONS, INSTRUCTIONS

WARNING

WARNING

YASKAWA manufactures component parts that can be used in a wide variety of industrial applications. The selection and

application of YASKAWA products remain the responsibility of the equipment designer or end user. YASKAWA accepts no

responsibility for the way its products are incorporated into the final system design. Under no circumstances should any

YASKAWA product be incorporated into any product or design as the exclusive or sole safety control. Without exception, all

controls should be designed to detect faults dynamically and fail safely under all circumstances. All products designed to

incorporate a component part manufactured by YASKAWA must be supplied to the end user with appropriate warnings and

instructions as to that part’s safe use and operation. Any warnings provided by YASKAWA must be promptly provided to the

end user. YASKAWA offers an express warranty only as to the quality of its products in conforming to standards and specifications published in the YASKAWA manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS OFFERED. YASKAWA

assumes no liability for any personal injury, property damage, losses, or claims arising from misapplication of its products.

• Do not connect or disconnect wiring while the power is on. Do not remove covers or touch circuit boards while

the power is on.

• Before servicing, disconnect all power to the equipment. The internal capacitor remains charged even after the

power supply is turned OFF. Status indicator LEDs and Digital Operator display will be extinguished when the DC

bus voltage is below 50 VDC. To prevent electric shock, wait at least 5 minutes after all indicators are OFF.

• Do not perform a withstand voltage test on any part of the unit. This equipment uses sensitive devices and may

be damaged by high voltage.

• The drive is not suitable for circuits capable of delivering more than 18,000 RMS symmetrical amperes at 250V

maximum or 480V maximum. Install adequate branch short circuit protection. Refer to page 13. Failure to do so

may result in equipment damage and/or personal injury.

• Input Fuses are required for proper branch short circuit protection for all NEMA type 4X/12 drives. Failure to use

recommended fuses (See Appendix 4) may result in damage to the drive and/or personal injury.

2

Page 3

WARNINGS, CAUTIONS, INSTRUCTIONS

For Enclosed wall-mounted type (NEMA type 1)

When mounting units in an enclosure, remove the top, bottom and terminal covers. Install a cooling fan or

some other means to maintain the air entering the enclosure below 113°F (45°C).

For Water and dust tight type (NEMA type 4X/12)

Never submerge this model in water. For the cable lead-in section, use a waterproof cable gland. After

completion of wiring, mount the front cover and bottom cover with care so as not to damage the gasket.

The front cover mounting screws and bottom cover mounting screws are made of stainless. Replacements

must be of stainless steel and the same length.

IMPORTANT

• Wiring should be performed only by qualified personnel.

• Verify that the rated voltage of the Drive matches the voltage of the incoming power.

• Some drawings in this manual are shown with the protective covers and shields removed, in order to describe

detail with more clarity. Make sure all covers and shields are replaced before operating this product.

• This manual may be modified when necessary because of product improvement, modification, or changes in

specifications.

• YASKAWA is not responsible for any modification of the product made by the user, doing so will void the warranty.

3

Page 4

Intentionally left blank

4

Page 5

CONTENTS

SECTION DESCRIPTION PAG E

1 Drive Specifications.................................................................................................... 6

2 Preliminary Inspection ............................................................................................... 11

Introduction................................................................................................................. 11

Receiving .................................................................................................................. 11

Nameplate Structure ................................................................................................. 12

Model Number Structure ........................................................................................... 13

Drive Spec Structure ................................................................................................. 15

3 Mounting Precautions ............................................................................................... 16

4 Wiring: Main and Control Circuit ................................................................................ 18

Main Circuit Input/Output Wiring ................................................................................ 18

Control Circuit ........................................................................................................... 18

Wiring: Grounding ..................................................................................................... 20

Wiring: Wire and Terminal Screw Sizes .................................................................... 21

Wiring: Terminal Functions and Voltages .................................................................. 22

5 Peripheral Devices ..................................................................................................... 24

Recommended Short Circuit Protection..................................................................... 24

Auxiliary Input/Output Power Option Devices ............................................................ 26

6 Conformance to European EMC Directive ................................................................ 28

7 Interconnection Precautions and Diagrams .............................................................. 30

Interconnection Diagram: 2-Wire Control .................................................................. 32

Interconnection Diagram: 3-Wire Control .................................................................. 34

8 Drive Parameter Listing ............................................................................................. 36

9 Monitor Displays ........................................................................................................ 50

10 Drive Dimensions ...................................................................................................... 52

5

Page 6

Drive Specifications Section 1

230V Class

Model CIMR-V7* 20P1 20P2 20P4 20P7 21P5 22P2 23P7 25P5 27P5

Max. applicable motor output

HP

(1)

Drive capacity (kVA) 0.3 0.6 1.1 1.9 3.0 4.2 6.7 9.5 13

Rated Output Current (A) 0.8 1.6 3.0 5.0 8.0 11.0 17.5 25 33

Output

Rated Input Current (A) 1.1 1.8 3.9 6.4 11.0 15.1 24.0 33.0 39.6

Max. Output Voltage (V) 200 to 230V (proportional to input voltage)

Characteristics

Max. Output Frequency (Hz) 400 Hz (programmable)

Rated Input Voltage and

Frequency

Allowable voltage fluctuation -15% to +10%

Power

Supply

Allowable frequency fluctuation ±5%

Cooling Method

istics

(QTY) NEMA 4 self self self self fan fan fan self self

Physical

Character-

460V Class

SECTION A.

MV A001 A002 A003 A005 A008 A011 A017 A025 A033

NEMA 1 self self self fan fan fan fan fan(2) fan(2)

Model No. Related Specifications

1/8 1/4 1/2

3/4

2357.510

and 1

3-phase. 200 to 230 V, 50/60 Hz

(5)

Model CIMR-V7* - - 40P2 40P4 40P7 41P5 42P2 43P7 45P5 47P5

Max. applicable motor

output HP

Drive capacity (kVA) - - 0.9 1.4 2.6 3.7 4.2 7 11 16

Rated Output Current (A) - - 1.2 1.8 3.4 4.8 5.5 8.6 14.8 21

Output

Rated Input Current (A) - - 1.6 2.4 4.7 7.0 8.1 12.0 19.6 27.8

Characteristics

Max. Output Voltage (V) 380 to 460V (proportional to input voltage)

Max. Output Frequency (Hz) 400 Hz (programmable)

Rated Input Voltage and

Frequency

Allowable voltage fluctuation -15% to +10%

Power

Supply

Allowable frequency fluctuation ±5%

Cooling Method

istics

Physical

(QTY) NEMA 4 - - self self self fan - - fan self self

Character-

MV - - B001 B002 B003 B005 - - B009 B015 - -

(1)

- - 1/2 3/4 1&2 3 3 5

3-phase. 380 to 460 V, 50/60 Hz

NEMA 1 - - self self self fan - - fan fan(2) fan(2)

7.5 &

10

(6)

15

(6

(6

(6

6

Page 7

SpecificationsSection 1

Drive

Control method Sine wave PWM (V/ f Control or Open Loop Vector)

SECTION B.

Frequency control range 0.1 to 400 Hz

Frequency accuracy Digital command: ±0.01% (14 to 122°F, -10 to +50°C)

(temperature change) Analog command: ±0.5% (77°F ± 18°F, 25°C ± 10°C)

Speed Regulation

Frequency setting resolution 0.1 Hz (100Hz or more)

Output frequency resolution

Overload capacity 150% of rated output current for 1 minute

Frequency Reference Signal

Accel/Decel Time

Control Characteristics

Braking Torque

V/f characteristics Custom V/f pattern

0 to 10VDC (20kΩ), 4 to 20mA (250Ω), 0 to 20mA (250Ω) pulse train input,

All Drives

Open Loop Vector: ±0.2%

V/Hz Mode: ±0.5% – 1% with Slip Compensation

Digital Operator reference: 0.01 Hz (< 100Hz)

Analog

reference: 0.06Hz/60Hz (1/1000)

0.01 Hz

Digital Operator Pot

(accel/decel time are independently programmed)

Continuous regenerative torque: Approx. 20% (150% with

optional braking resistor, braking transistor built-in)

0.01 to 6000 sec.

Short-term average deceleration torque (2)

0.2kW: 150%

0.75kW: 100%

1.5kW: 50%

2.2kW or more: 20%

See notes at end of table

(table continued on next page)

7

Page 8

Drive

Specifications Section 1

Motor overload protection Electronic thermal overload relay

Instantaneous overcurrent

Overload

Overvoltage

Undervoltage

Momentary Power Loss

Heatsink overheat Protected by electronic circuit

Protective Functions

Stall prevention level

Ground fault Protected by electronic circuit (overcurrent level)

Power charge indication RUN lamp says ON or digital operator LED stays ON.

Cooling Fan Fault Protected by electronic circuit

Run/stop input 2-Wire or 3-Wire

Multi-function input

Input signalsOutput signals

Other Functions

Multi-function output (output frequency or set value), during overtorque detection,

8

Analog monitor 0 to +10VDC output, programmable for output frequency or output current

SECTION B.

All Drives (Continued)

Motor coasts to stop at approx. 250%

Motor coasts to stop after 1 min. at 150% of

Motor coasts to stop if DC bus voltage exceeds

Motor coasts to stop when DC bus voltage is

210VDC or less (230V), 400VDC or less (460V)

• Not provided (stops if power loss is 15 ms or longer)

• Automatic restart at recovery from 0.5 sec. power loss

Independently programmable during accel and

constant-speed running. Selectable during decel.

ON until the DC bus voltage becomes 50V or less.

Seven of the following input signals are selectable:

Forward/reverse run (3-Wire sequence), fault reset,

external fault (NO/NC contact input), multi-step speed operation,

external baseblock (NO/NC contact input, speed search command,

accel/decel hold command, LOCAL/REMOTE selection,

communication/control circuit terminal selection,

emergency stop fault emergency stop alarm

(1 NO/NC contact output, 2 photo-coupler outputs):

Fault, running, zero speed, at frequency, frequency detection

during undervoltage detection, minor error, during baseblock, operation mode,

inverter run ready, during fault retry, during UV, during speed search,

of drive current

drive rated current (7)

410VDC (230V), 820VDC (460V)

The following operations are selectable:

• Automatic restart

(Charge LED is Provided for 400V)

Jog command, accel/decel time select,

Following output signals are selectable

data output through communication

Page 9

SpecificationsSection 1

Drive

SECTION B.

Standard functions

Status indicator LEDs RUN and ALARM LEDs provided as standard

Digital Operator

Display

Other Functions

Terminals Screw terminals for both main circuit and control circuit

Wiring distance between

drive and motor

Enclosure Open Type/NEMA type 1/NEMA type 4X/12

Cooling method Self-cooling/cooling fan

Ambient temperature 14 to 104°F (-10 to 40°C)

Humidity 95% RH or less (non-condensing)

Storage temperature

Location Indoor (free from corrosive gases or dust)

Elevation 3,280 feet (1,000 m) or less

conditions

Environmental

Vibration

NOTES:

(1)

Based on an N.E.C. standard 4-pole motor for max.applicable motor output.

(2)

Shows deceleration torque for an uncoupled motor decelerating from 60 Hz in 0.1 seconds.

(3)

Contact Yaskawa for wiring distances greater than 328 ft. (100 m).

(4)

Temperature during shipping (for short periods of time).

(5)

On NEMA type 4X/12 model only, maximum continuous rating of 30.8 A is 40 degrees C maximum ambient. For 33.0 A maximum

continuous rating, maximum ambient is 32 degrees C.

(6)

Applies to NEMA type 4X/12 model only.

(7)

On Model 47P5 NEMA type 4X/12 (21A), overload is 120% for 1 minute.

(4)

All Drives (Continued)

Open Loop Vector Control, full-range automatic torque boost, auto restart,

upper/lower frequency limit, DC injection braking current/time at start/stop,

frequency reference gain/bias, prohibited frequencies,

analog meter calibrating gain, S-curve accel/decel, slip compensation,

MODBUS communications (RS485/422, Max. 19.2K bps),

frequency reference from digital operator pot

Monitors frequency reference, output frequency,

output current, FWD/REF selection

328 ft (100 m) or less

-4 to 140°F (-20 to 60°C)

Up to 1G, at less than 20 Hz;

up to 0.2G, at 20 to 50 Hz

(3)

9

Page 10

Intentionally left blank

10

Page 11

Preliminary

InspectionSection 2

Introduction

This document pertains to the V7 ac drive. This document is equally applicable to drives identified as GPD315, GPD315/V7,

GPD315/V74X, and V74X. Additionally, in this document, the word “drive”, “ac drive”, and “inverter” may be used interchangeably. The V7 (NEMA type1) and V74X (NEMA type 4X/12), hereafter referred to as the "Drive," are general purpose sinecoded pulse width modulated AC motor drives which generate an adjustable voltage/frequency three phase output for complete speed control of most conventional squirrel cage induction motors. Automatic stall prevention and voltage boost prevent

nuisance tripping during load or line side transient conditions. The Drive will not induce any voltage line notching distortion

back to the utility line, and it maintains a displacement power factor of not less than 0.98 throughout its speed range.

When properly installed, operated and maintained, the Drive will provide a lifetime of service. It is mandatory that the person

who operates, inspects, or maintains this equipment thoroughly read and understand this manual before proceeding.

This installation guide details installation procedures and parameter setting ranges. For programming, refer to the Technical

Manual TM.V7.01 on the CD-ROM included with the Drive.

Receiving

Check nameplate - Be certain your input voltage source, motor and Drive nameplates are all marked either 230V or 460V.

Other voltages can be used, but require additional programming; see TM.V7.01.

11

Page 12

Preliminary

Y

Y

Inspection Section 2

Nameplate Structure

MODEL NO.

REFERENCE

INPUT SPEC

OUTPUT SPEC

LOT NO.

SERIAL NO.

MODEL:

CIMR-V7AU23P7

MVA017

REF:

3PH 200-230VAC 50/60Hz 24A

INPUT:

3PH 0-230VAC MAX. 0-400Hz 17.5A

OUTPUT:

LOT NO.:

SER NO.: N8W0593-8-043/V9905

E131457FILE NO.:

INSTALLATION CATEGORY: II

SPEC:

MASS: 2.4kg

PRG: 8021

IP20

23P71

INVERTER SPEC

MASS

SOFTWARE NO.

INSTALLATION CATEGOR

V7 [NEMA type 1]

MODEL NO.

REFERENCE

INPUT SPEC

OUTPUT SPEC

LOT NO.

SERIAL NO.

MODEL:

CIMR-V7AU23P7

MVA017

REF:

3PH 200-230VAC 50/60Hz 24A

INPUT:

3PH 0-230VAC MAX. 0-400Hz 17.5A

OUTPUT:

LOT NO.:

SER NO.: N8W0593-8-043/V9905

E131457FILE NO.:

INSTALLATION CATEGORY: II

SPEC:

MASS: 2.4kg

PRG: 8021

IP20

23P71

INVERTER SPEC

MASS

SOFTWARE NO.

INSTALLATION CATEGOR

V74X [NEMA type 4X/12]

12

Page 13

Model Number Structure

Preliminary

InspectionSection 2

C I M R - V 7 A M 2 3 P 7

DRIVE

V7 SERIES

No. Type

A With digital operator

B Without digital operator

C With digital operator

R Finless

Note: Contact your YASKAWA representative

for finless type drives.

No. Applicable maximum motor output

230V 460V

0P1 1/8 HP ---

0P2 1/4 HP 1/2 HP

0P4 1/2 HP 3/4 HP

0P7 3/4 & 1 HP 1 & 2 HP

1P5 2 HP 3 HP

2P2 3 HP 3 HP

3P7 5 HP 5 HP

5P5 7.5 HP 7.5 & 10 HP

7P5 10 HP 15

No. Voltage Class

B Single-phase 230VAC

2 Three-phase 230VAC

4 Three-phase 460VAC

No. Specifications

U UL Specification (U.S.)

or M Specification)

(1)

Applies to NEMA type 4X12 model only

(1)

13

Page 14

Intentionally left blank

14

Page 15

Drive Spec Structure

Preliminary

InspectionSection 2

2 3 P 7 1

B Single-phase 230VAC

2 Three-phase 230VAC

4

Three-phase 460VAC

Note: Model Number and Drive Spec Number are required to fully define a drive.

(1)

Applies to NEMA type 4X/12 model only.

No. Applicable maximum motor output

0P1 1/8 HP ---

0P2 1/4 HP 1/2 HP

0P4 1/2 HP 3/4 HP

0P7 3/4 & 1 HP 1 & 2 HP

1P5 2 HP 3 HP

2P2 3 HP 3 HP

3P7 5 HP 5 HP

5P5 7.5 7.5 & 10 HP

7P5 10 HP 10/15

230 V 460 V

(1)

HP

No. Protective structure

0 Open chassis

(IP20, IP00)

1 Enclosed wall-mounted

(NEMA 1)

4 Water and dust tight

(NEMA 4/IP66)

7 Open chassis (IP20)

Top-closed type

15

Page 16

Mounting Precautions Section 3

Location of the Drive is important to achieve proper performance and normal operating life. The unit should be installed in an

area where it will be protected from:

• Extreme cold and heat. Use only within the ambient temperature range (for open chassis

type): 14 to 122°F (-10 to +50°C) (for enclosed wall mount type): 14 to 104°F (10 to +40°C)

• Rain, moisture

• Oil sprays, splashes

• Salt spray

• Direct sunlight. (Avoid using outdoors)

• Corrosive gases (e.g. sulfurized gas) or liquids

• Dust or metallic particles in the air

• Physical shock, vibration

• Magnetic noise (Example: welding machines, power devices, etc.)

• High humidity

• Radioactive substances

• Combustibles: thinner, solvents, etc.

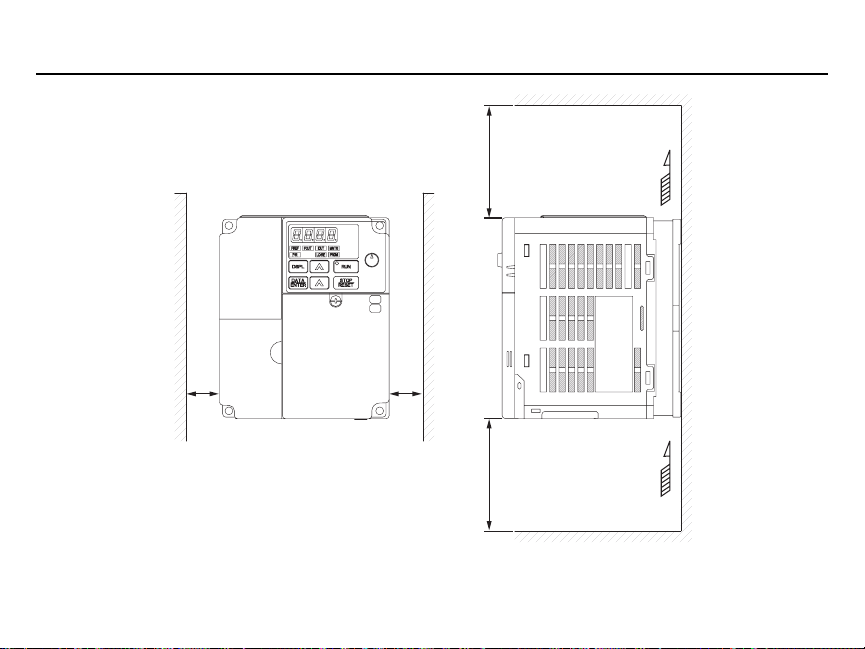

When preparing to mount the Drive, lift it by its base, never by the front cover. For effective cooling, as well as proper maintenance, the Drive must be installed on a flat, non-flammable vertical surface (wall or panel) using recommended mounting

screws. There MUST be a MINIMUM 3.94 in. clearance above and below the Drive to allow air flow over the heat sink fins.

A minimum 1.18 in. clearance is required on each side of the Drive.

16

Page 17

Mounting

PrecautionsSection 3

3.94 in.

(100mm)

1.18 in.

(30mm)

1.18 in.

(30mm)

3.94 in.

(100mm)

Important: To use the CIMR-V7*U25P5, 27P5, 45P5, and 47P5 Drives

as an open chassis, remove top and bottom covers and allow 1.97 in. (50mm)

clearance on each side of the drive.

AIR

AIR

17

Page 18

Wiring Main and Control Circuit Section 4

Main Circuit Input /Output Wiring

• Use 600V vinyl-sheathed wire or equivalent. Wire size and type should be determined by local electrical codes.

• Avoid routing power wiring near equipment sensitive to electrical noise.

• Avoid running input and output wiring in the same conduit.

• NEVER connect AC main power to output terminals T1(U), T2(V), and T3(W).

• NEVER allow wire leads to contact metal surfaces. Short-circuit may result.

• NEVER connect power factor correction capacitors to the Drive output. Consult Yaskawa when connecting noise

filters to the Drive output.

• WIRE SIZING MUST BE SUITABLE FOR CLASS I CIRCUITS.

• When connecting motor to Drive’s output terminals, include a separate ground wire. Attach ground wire solidly to

motor frame and to Drive’s ground terminal .

• When using armored or shielded cable for connection between Drive and motor, solidly connect armor or shield

to motor frame, and to Drive’s ground terminal .

• Motor lead length should NOT EXCEED 164 feet (50 meters), and motor wiring should be run in a separate conduit from the power wiring. If lead length must exceed this distance, reduce carrier frequency (see TM.V7.01,

paragraph 5.8) and consult factory for proper installation procedures.

• Use UL listed closed loop connectors or CSA certified ring connectors sized for the selected wire gauge. Install

connectors using the correct crimp tool recommended by the connector manufacturer.

Control Circuit

All basic control circuit (signal) interconnections are shown in the appropriate diagram:

• Interconnections for external two-wire control in combination with the Digital Operator are shown in Figure 1-5.

• Interconnections for external three-wire control in combination with the Digital Operator are shown in Figure 1-6.

Make wire connections according to Figures 1-5 and 1-6 and Table 1-2; observe the following:

• Signal Leads: Terminals S1-S7 & SC; RP, FS, FR & FC; R+, R-, S+, S-; & AM & AC.

• Control Leads: Terminals P1, P2 & PC; MA, MB & MC.

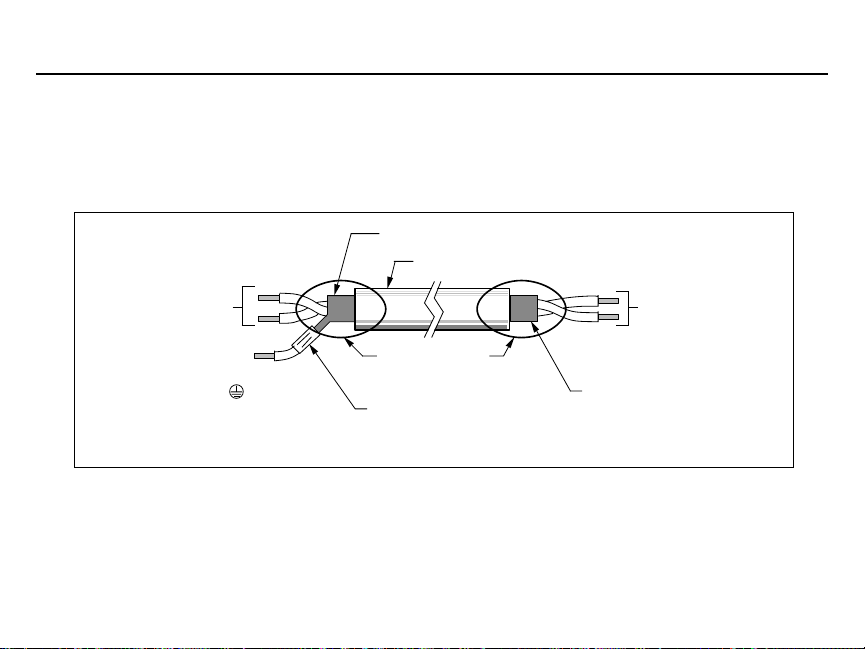

• Use twisted shielded or twisted-pair shielded wire (20-16 AWG [0.5 – 1.25mm2]) for control and signal circuit

leads. The shield sheath MUST be connected at the drive end ONLY (terminal ). The other end should be

dressed neatly and left unconnected (floating). See Figure 1-1.

18

Page 19

Main and Control CircuitSection 4

• Signal leads and feedback leads (PG) must be separated from control leads main circuit leads, and any other

power cables, to prevent erroneous operation caused by electrical noise.

• Lead length should NOT EXCEED 164 feet (50 meters). Wire sizes should be determined considering the voltage drop.

• All AC relays, contactors and solenoids should have RC surge supressors installed across their coils.

• All DC relays, contactors and solenoids should have diodes installed across their coils.

SHIELD SHEATH

OUTER JACKET

Wiring

TO DRIVE

SIGNAL

TERMINALS

TO SHIELD

SHEATH

TERMINAL

(TERM. )

WRAP BOTH ENDS

OF SHEATH WITH

INSULATING TAPE

CRIMP

CONNECTION

Figure 1-1. Shielded Sheath Termination

DO NOT

CONNECT

TO

EXTERNAL

CIRCUIT

19

Page 20

Wiring Grounding Section 4

• The Drive must be solidly grounded using the main circuit ground terminal .

• If Drive is installed in a cabinet with other equipment, ground leads for all equipment should be connected to a

common low-impedance ground point within the cabinet.

• The supply neutral should be connected to the ground point within the cabinet.

• Select appropriate ground wire size from Table 1-1.

• Make all ground wires as short as practical.

• NEVER ground the Drive in common with welding machines, or other high power electrical equipment.

• Where several Drives are used, ground each directly to the ground point (see Figure 1-2). DO NOT FORM A

LOOP WITH THE GROUND LEADS.

• When connecting a motor to the Drive’s output terminals, include a separate ground wire. Attach ground wire

solidly to motor frame and to Drive’s ground terminal .

• When using armored or shielded cable for connection between Drive and motor, solidly connect armor or shield

to motor frame, and to the Drive’s ground terminal .

CORRECT CORRECT NOT

ACCEPTABLE

Figure 1-2. Correct Ground Connection

20

Page 21

Wire and Terminal Screw SizesSection 4

Wiring

230V 3-phase Input

Model

CIMR- lb • in size size Type

V7* MV (N • m) mm

20P1 A001 M3.5

20P2 A002 M3.5

20P4 A003

20P7 A005

21P5 A008 M4

22P2 A011 M4

23P7 A017 M4

25P5 A025 M5

27P5 A033 M5

Table 1.1 Wire and Terminal Screw Sizes

Terminal Symbol Screw Torque Applicable Recommended

R/L1, S/L2, T/L3

B1, B2 (0.8 to 1.0) 10

U/T1, V/T2, W/T3

-, +1,+2 (0.8 to 1.0) 14 600V

Tightening Wire

2

7.1 to 8.88

(0.8 to 1.0) 14

7.1 to 8.88

(0.8 to 1.0) 14

7.1 to 8.88

M3.5

7.1 to 8.88

M3.5

10.65 to 13.31

(1.2 to 1.5) 10 sheathed

10.65 to 13.31

(1.2 to 1.5) 10 equivalent

10.65 to 13.31

(1.2 to 1.5) 10

22.19

(2.5)

22.19

(2.5)

AWG mm2AWG

18 to

0.75 to 2

0.75 to 2

0.75 to 2

0.75 to 2

2 to 5.5

2 to 5.5

2 to 5.5

5.5 to 8 10 to 8 8 8

5.5 to 8 10 to 8 8 8

18 to

18 to

18 to

14 to

14 to

14 to

214

214

214

214

214

3.5 12

5.5 10

460V 3-phase Input

Model

CIMR- lb • in size size Type

V7* MV (N • m) mm2AWG mm2AWG

40P2 B001 M4

40P4 B002 M4

40P7 B003

41P5 B005

42P2 —

43P7 B009 M4

45P5 B015 M4

47P5 —

Terminal Symbol Screw Torque Applicable Recommended

R/L1, S/L2, T/L3

B1, B2 (1.2 to 1.5) 10 sheathed

U/T1, V/T2, W/T3

-, +1,+2

x 1

Tightening Wire

10.65 to 13.31

(1.2 to 1.5) 10

10.65 to 13.31

(1.2 to 1.5) 10 600V

10.65 to 13.31

M4

10.65 to 13.31

M4

(1.2 to 1.5) 10

10.65 to 13.31

(1.2 to 1.5) 10 3.5 x 1 12 x 1

12.43

(1.4) 10

22.19

M5

(2.5) 10

2 to 5.5

2 to 5.5

2 to 5.5

2 to 5.5

2 to 5.5

3.5 to 5.5

5.5 to 8

14 to

214

14 to

214

14 to

214

14 to

214

14 to 2 14

12 to

5.5 10

12 to

5.5 10

Note: The wire size is set for copper wires at 160°F (75°C)

vinyl-

wire or

vinyl-

wire or

equivalent

21

Page 22

Wiring Terminal Functions and Voltages Section 4

Control Circuit

Model Terminal Symbol Screw

S1 to S7, P1, P2, SC,

to

PC, R+, R-, S+, S-,

FS, FR, FC, AM, AC, RP

MA, MB, MC M3

Common

all models

Tightening Wire

Torque

lb • in (N • m) size

4.44 to 5.33 twisted wire 0.5 to 1.25 20 to 16 0.75 18

(0.5 to 0.6) single 0.5 to 1.25 20 to 16

1.94 to 2.21 twisted wire 0.5 to 0.75 20 to 18

M2

(0.22 to 0.25) single 0.5 to 1.25 20 to 16

Applicable size

2

mm

AW G m m2AW G

Recommended

0.75 18

Type

Shielded

wire or

equivalent

Table 1-2. Terminal Functions and Voltages

Table 1-1. Wire and Terminal Screw Sizes - continued

TERMINAL FUNCTION VOLTAGE / SIGNAL LEVEL

L1 (R) 230V Drive: 200 / 208 / 220 / 230V at 50/60 Hz

L2 (S) Main circuit input power supply 460V Drive: 380 / 400 / 440 / 460 / 480V

L3 (T) at 50/60 Hz

T1 (U)

T2 (V) Main circuit output

T3 (W)

B1 For connection of braking resistor (option)

B2

+1

DC Reactor terminals

+2

– DC Bus terminals (+1 & –)

Ground terminal (100 ohms or less) – – – –

S1 Multi-Function-Input 1 Factor y setting is " Forward Run/Stop " (1).

S2 Multi-Function-Input 2 Factory setting is " Reverse Run/Stop " (1).

S3 Multi-Function-Input 3 Factory setting is " External Fault (NO contact)

S4 Multi-Function-Input 4 Factory setting is " Fault Reset " (1)

230V Drive: 0 - 200 / 208 / 220 / 2 30V

460V Drive: 0 - 400 / 440 / 460 / 4 80V

(Forward run when closed, stop when open)

(Reverse Run when closed, stop when open)

input " (1)

(table continued on next page)

22

Page 23

Terminal Functions and VoltagesSection 4

Table 1-2. Terminal Functions and Voltages - continued

TERMINAL FUNCTION VOLTAGE / SIGNAL LEVEL

S5 Multi-Function-Input 5 Factory setting is " Multi-step Speed

S6 Multi-Function-Input 6 Factory setting is " Multi-step Speed

S7 Multi-Function-Input 7 Factory setting is " Jog Reference" (1)

SC Sequence common for terminals S1-S7. Common terminal for sequence inputs

FS Frequency reference power supply +12 VDC

FR Frequency reference input 0 to +10V/100% (20K ohms) or 4-20 mA (250 Ω

RP Frequency reference –Pulse Train input 30 KHz maximum pulse input

FC Frequency reference input common 0 V

MA Multi-function contact output – NO contact Factory Contact capacity:

MB Multi-function contact output – NC contact Setting 250 Vac at 1A or below

MC Multi-function contact output – Common is " Fault " 30 Vdc at 1A or below

AM Multi-function analog monitor (+) Factory setting is

AC Analog monitor common 0 V

P1 Multi-Function Open Factory setting is

Collector Output 1 " Drive Running "

P2 Multi-Function Open Factory setting is

Collector Output 2 " Speed Agree "

PC Multi-Function Open 0V

Collector Output common

R+ Receive input (+) MODBUS

R– Receive input (–) communication RS-485/422 MODBUS protocol,

S+ Send output (+) RS-485 or RS-422. 19.2 kps max.

S– Send output (–)

NOTES:

(1)

These inputs have factory settings based on 2-wire reset. For 3-wire reset definitions, see Figure 1-6.

" Output frequency "

0-10V = 0-100%

Reference 1 " (1)

Reference 2 " (1)

Monitor output: 0 to +10V; 2 mA maximum.

Photocoupler output:

48 VDC; 50 mA or less.

Wiring

)

23

Page 24

Peripheral Devices Section 5

The following peripheral devices may be required to be mounted between the AC main circuit power supply and the Drive

input terminals L1 (R), L2 (S) and L3 (T).

CAUTION

Never connect a general LC/RC noise filter to the Drive output circuit.

Never connect a phase-advancing capacitor to the input/output sides or a surge

suppressor to the output side of the Drive.

When a magnetic contactor is installed between the Drive and the motor, never turn it

on or off during operation.

Note: For more details on peripheral devices, contact your manufacturer.

Recommended Branch Short Circuit Protection Peripheral Devices

All models have UL evaluated motor overload protection built in. Motor overload protection is also provided in accordance with

the NEC and CEC. Additional branch circuit overload protection is not required.

230V 3-Phase

Model CIMR-V7* 20P1 20P2 20P4 20P7 21P5 22P2 23P7 25P5 27P5

Capacity (kVA) 0.3 0.6 1.1 1.9 3.0 4.2 6.7 9.5 13.0

Rated output current (A) 0.8 1.6 3.0 5.0 8.0 11.0 17.5 25.0 33.0

Rated input current (A) 1.1 1.8 3.9 6.4 11.0 15.1 24.0 33.0 39.6

Max. Time Delay Fuse Rating (A)

Max. Non-Time Delay Fuse Rating (A)

Max. MCCB Rating (A) 15 15 15 15 2030 405060

24

MV A001 A002 A003 A005 A008 A011 A017 A025 A033

(1)

1.8 3.2 6.25 10 17.5 20 25 45 60

(2)

3 5 10 20 30 45 45 70 80

Page 25

Peripheral

q

DevicesSection 5

460V 3-Phase

Model CIMR-V7* 40P2 40P4 40P7 41P5 42P2 43P7 45P5 47P5

Capacity (kVA) 0.9 1.4 2.6 3.7 4.2 7.0 11.0 14.0

Rated output current (A) 1.2 1.8 3.4 4.8 5.5 9.2 14.8 18/21

Rated input current (A) 1.6 2.4 4.7 7.0 8.1 12.0 19.6 23.8 / 27.8

Max. Time Delay Fuse Rating (A)

Max. Non-Time Delay Fuse Rating (A)

Max. MCCB Rating (A) 15 15 15 15 20 20 30 40

Notes:

(1)

Apply UL designated Class RK5 fuses.

(2)

Apply UL designated Class CC or T non-time delay fuses.

(3)

Model 47P5 rated 21A is only applicable to the NEMA type 4X/12 version.

Input fuse sizes are determined by NEC guidelines, and should not exceed the ratings shown in the table.

Fuse Ratings are based upon 250V fuses for 230V Drives, and 600V for 460V Drives

Fuse Manufacturer’s Designators: Class CC: KTK, FNQ or equivalent

MV B001 B002 B003 B005 --- B009 B015 B018

(1)

2.8 4 8 12 15 20 35 45

(2)

5 7 12 20 25 35 60 70

Class RK5: FRN, FRS or equivalent

Class T: JJS, JJN or e

uivalent

(3)

Magnetic Contactor

Mount a surge protector on the coil. When using a magnetic contactor to start and stop the Drive, do not exceed one start per

hour.

Ground Fault Interrupter

Select a ground fault interrupter not affected by high frequencies. To prevent malfunctions, the current should be 200mA or

more and the operating time 0.1 second or more.

AC and DC Reactor

Install a reactor to connect to a power supply transformer of large capacity (600 kVA or more) or to improve the power factor

on the power supply side.

Noise Filter

Use a noise filter exclusively for the Drive if radio noise generated from the Drive causes other control devices to malfunction.

25

Page 26

Peripheral

Devices Section 5

Auxiliary Input and Output Power Option Devices

A disconnect device (circuit breaker, contactor, disconnect switch, etc.) should NOT be used as a means of starting and stopping the Drive or motor.

A disconnect device can be installed for emergency stop purposes, but when that disconnect device is opened, there may be

loss of electrical braking.

Figure 1-3 is a factory guideline for proper wiring practices and relative locations within the electrical path from the line to the

load. It does not imply what devices are needed for a particular application, nor does it show what devices were shipped with

a particular order. Therefore, disregard those items in the diagram which are not being used in your installation. However, it is

recommended that an input or DC reactor be used with all Drive ratings when wired to a source of 600 kVA or greater. Mount

all optional power devices close to the Drive, and keep electrical connections as short as possible.

Note: DO NOT run input and output wiring in the same conduit.

26

Page 27

CUSTOMER’S

3fl A.C. LINE

POWER

SUPPLY

NOTES

1. Connect Drive ground terminal or panel to

earth ground. Always use low impedance

paths and connections.

2. Mount input and output RFI filters

as close to the Drive as possible (on the

same panel, if possible). Filters should have

a solid connection from filter case or ground

terminal to Drive panel or ground terminal

(conduit with good bare metal to bare metal

connections may serve as the path). If

multiple input or output RFI filters are used,

they must be wired in parallel.

3. Shield conductors with metallic conduit.

4. Connect output conduit in a manner that

allows it to act as an unbroken shield from the

Drive panel to the motor casing.

5. RF noise filter (different from RFI filter) part

no. 05P00325-0023 is a delta wye capacitor

network which is wired in parallel with the

Drive input terminals. On the smaller Drives

with die cast chassis, it must be mounted

externally. On the larger Drives with sheet

metal chassis, it may be mounted inside the

area where the input power wiring enters the

Drive. On units equipped with bypass, it may

be wired to the primary side of the circuit

breaker and mounted to the bypass panel or

sidewall.

6. Connection points:

Drive w/o Bypass Drive w/ Bypass

L1, L2, L3

Input

Output

T1, T2, T3

physically

Ckt BrkrL1,L2,L3

Unwired side of

Overload relay

L3

L2

L1

ISOLATION

TRANSFORMER

H3

H2

H1

X3

X2

X1

RF NOISE

FILTER

EARTH GROUND

SEE NOTE 2

EARTH GROUND

SEE NOTE 1

RFI FILTER

C1(L3)

B1(L2)

A1(L1)

INPUT

L

L

O

I

A

N

D

E

(G)

SEE NOTE 5

OUTPUT

RFI FILTER

OUTPUT

REACTOR

A.C. MOTOR

(L3)C2

(L2)B2

(L1)A2

EARTH GROUND

SEE NOTE 2

INPUT

AC DRIVE

SEE NOTE 6

INPUT

REACTOR

C1

B1

A1

L3L2L1

OUTPUT

123

IN

OUT

456

SEE NOTE 3

T3T2T1

SEE NOTES 3, 4

SEE NOTES 3, 4

C1B1A1

C2B2A2

SEE NOTES 3, 4

T3T2T1

Peripheral

DevicesSection 5

C2

B2

A2

L31L21L11

DC

REACTOR

+ 1

+ 2

TO CASE

EARTH

GROUND

SEE NOTE 2

Figure 1-3. Customer Connection Diagram For Isolation Transformers, Input Reactors, Input RFI Filters,

DC Reactors, Output Reactors and Output RFI Filters

27

Page 28

Conformance to European EMC Directive Section 6

In order to conform to EMC standards, the following methods are required for line filter application, cable shielding and Drive

installation.

The line filter and Drive must be mounted on the same metal plate. The filter should be mounted as close to the Drive as

practical. The cable must be kept as short as possible and the metal plate should be securely grounded. The ground of the

line filter and the Drive must be bonded to the metal plate with as much bare-metal contact as possible.

For main circuit input cables, a screened cable is recommended within the panel and is also suggested for external connections. The screen of the cable should be connected to a solid ground. For the motor cables, a screened cable (max. 20 m)

must be used and the screen of the motor cable should be connected to ground at both ends by a short connection, again

using as much bare-metal contact as practical.

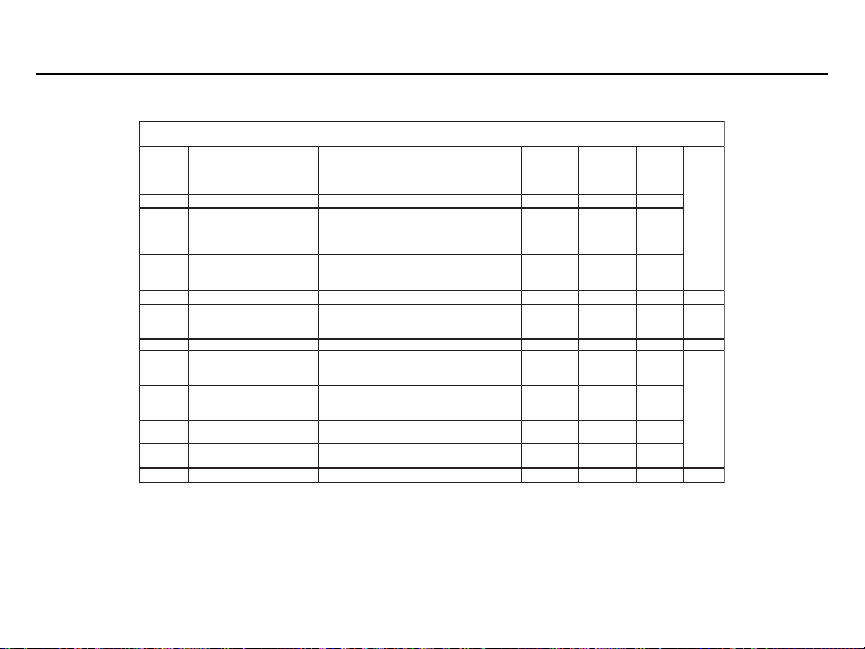

Table 1-4 and Figure 1-4 show the line filter list for EMC standards and the installation/wiring of the Drive and line filter. For a

more detailed explanation, refer to document “Installation Guidelines for EMC Directive Using AC Drive Products.”

Table 1-4. Line Filters for EMC Standards

Model

CIMR- Part Number Rated Weight Dimensions in in.(mm)

V7* MV FIL00 Current (A) lbs. (kg) H x W x D

20P1 A001

20P2 A002

20P4 A003

20P7 A005

21P5 A008

22P2 A011

23P7 A017 1085 26 2.4 (1.1) 6.9 x 5.7 x 2.0 (174 x 144 x 50) 6.3 x 4.7 (161 x 120) M5

25P5 A025

27P5 A033

40P2 B001

40P4 B002

40P7 B003

41P5 B005

42P2 —

43P7 B009 1088 15 2.4 (1.1) 6.9 x 5.7 x 2.0 (174 x 144 x 50) 6.3 x 4.7 (161 x 120) M5

45P5 B015

47P5 —

28

1083 10 1.8 (0.8) 7.6 x 3.2 x 2.0 (194 x 82 x 50) 7.1 x 2.4 (181 x 62) M5

1084 16 2.2 (1.0) 6.7 x 4.4 x 2.0 (169 x 111 x 50) 6.1 x 3.6 (156 x 91) M5

1100 50 5.1 (2.3) 12.0 x 7.2 x 2.2 (304 x 184 x 56) 11.3 x 5.9 (288 x 150) M6

1086 5 2.2 (1.0) 6.7 x 4.4 x 1.8 (169 x 111 x 45) 6.1 x 3.6 (156 x 91) M5

1087 10 2.2 (1.0) 6.7 x 4.4 x 1.8 (169 x 111 x 45) 6.1 x 3.6 (156 x 91) M5

1101 30 5.1 (2.3) 12.0 x 7.2 x 2.2 (304 x 184 x 56) 11.3 x 5.9 (288 x 150) M6

(1)

D is the distance the filter will extend outward from the surface of the metal plate.

Line Filter

Mounting Dim. in in. (mm) Screw

(1)

H1 x W1 Size

Page 29

European EMC DirectiveSection 6

Conformance to

Cable Length

max. 40cm

L2 PEL1 L3

MAINS

FILTER

LOAD

Ground Bands (remove any paint)

DRIVE

V7

L2L1 L3L1 L3L2

4-d

H

H1

Metal Plate

Motor Cable

max. 20m

W1

D

W

Ground Bands (remove any paint)

IM

3~

Figure 1-4. Installation of Line Filter and V7N Drive

29

Page 30

Interconnection Precautions and Diagrams Section 7

Notes for Figure 1-5 (2-Wire Control) and Figure 1-6 (3-Wire Control)

, – Indicates components not supplied.

– Main circuit terminal.

– Indicates control circuit terminal.

( ) – Indicates alternate terminal marking, i.e., (R) and L1.

L – Function labels shown for these terminals are determined by factory settings of

through

n056

. (see TM.V7N.01)

G – Function labels shown for these terminals are determined by factory settings of

(see TM.V7N.01)

1. Insulated twisted shielded wire is required.

2-conductor #18 GA. (Belden #8760 or equivalent).

3-conductor #18 GA. (Belden #8770 of equivalent).

Connect shield ONLY AT the Drive END (ground terminal ). Stub and isolate other end.

2. +12V voltage output current capacity of control terminal FS is 20mA max.

3. The Drive’s Electronic Thermal Overload function (n036, n037) meets standards set by UL and CUL for motor

thermal overload protection. If local code requires a separate mechanical overload protection, an overload relay

should be installed, interlocked with the Drive as shown. It should be the manual reset type to prevent automatic

restart following a motor fault and subsequent contact reclosure after cool down.

4. Customer to connect terminal to earth ground.

5. If the Digital Operator is used, remote operators, which duplicate functions of its command keys may not be

required. See Figure 4-1.

6. For installation of Braking Resistor or Braking Resistor unit, refer to Appendix 6, “Dynamic Braking Option.”

30

n050

n057

through

n059

.

Page 31

Interconnection Precautions

CAUTION

WARNING

and DiagramsSection 7

7. An optional DC reactor may be added for harmonic attenuation, if needed. See separate instruction sheet for wiring.

8. If application does not allow reverse operation, parameter n006, Reverse Run Prohibit Selection, should be set to

“ 1 ” (Reverse Run Disabled), and the Reverse Run/Stop input can be eliminated.

9. Input fuses are required for proper branch circuit short circuit protection for all NEMA Type 4 drives. Failure

to use recommended fuses (see appendix 4) may result in damage to the drive and/or personal injury.

The Drive leaves the factory with parameters initialized for 2-Wire control (when using external Run/Stop

signals). Before using the initialization function of constant n001, know your control wiring configuration:

10 = Factory 2-Wire Control Initialization (Maintained RUN Contact)

11 = Factory 3-Wire Control Initialization (Momentary START/STOP Contact)

Entering either Initialization code resets all parameters to factory settings, and automatically returns parameter

n001 setting to “ 1 ”. If the Drive is connected for 3-Wire control and this parameter is set to “ 10 ” (2-Wire

Control Initialization), the motor may run in reverse direction WITHOUT A RUN COMMAND APPLIED.

Equipment damage or personal injury may result.

Parameter n012 must be set to proper motor voltage.

Always ground the Drive using the ground terminal provided.

Never connect main circuit output terminals T1 (U), T2 (V) & T3 (W) to AC main circuit power supply.

When programmed for auto-restart ( n082 = “ 1 ” thru “ 10 ”), the motor may restart unexpectedly — personal

injury may result.

For Enclosed wall-mounted type (NEMA type 1)

When mounting units in an enclosure, remove the top, bottom and terminal covers. Install a cooling fan or some

other means to maintain the air entering the enclosure below 113°F (45°C).

31

Page 32

Interconnection Diagram 2-Wire Control Section 7

S3

S4

Figure 1-5. Standard Connections (2-Wire Control)

32

(Parameter n001 set to “10”)

Page 33

Interconnection Diagram

CAUTION

2-Wire ControlSection 7

• After wiring is complete, verify that all wiring is correctly installed, excess screws and wire clippings are removed from inside of unit, screws are securely tightened, and exposed wire does not

contact other wiring or terminals.

• The Drive leaves the factory with all parameters set for 2-wire external control/ reference control.

To use the Drive in a 3-wire application, Drive parameters n001, n003 and n004 must be reprogrammed and Figure 1-6 used for all external connections.

• If a FWD or REV run command is given from the control circuit terminal when the operation

method selection function ( n003 ) is set to “ 1 ” and the “LO/RE” selection is set to “RE”, the

motor will start automatically as soon as power is applied to the main circuit.

33

Page 34

Interconnection Diagram 3-Wire Control Section 7

Figure 1-6. Standard Connections (3-Wire Control)

34

(Parameter n001 set to “11”)

Page 35

Interconnection Diagram

CAUTION

3-Wire ControlSection 7

• After wiring is complete, verify that all wiring is correctly installed, excess screws and wire clippings are removed from inside of unit, screws are securely tightened, and exposed wire does not

contact other wiring or terminals.

• The Drive leaves the factory with all parameters set for 2-wire external control/ reference control.

To use the Drive in a 3-wire application, Drive parameters n001, n003 and n004 must be reprogrammed and Figure 1-6 used for all external connections.

• If a FWD or REV run command is given from the control circuit terminal when the operation

method selection function ( n003 ) is set to “ 1 ” and the “LO/RE” selection is set to “RE”, the

motor will start automatically as soon as power is applied to the main circuit.

35

Page 36

Drive Parameter Listing (n001-n004) Section 8

The Drive control circuits use various parameters to select functions and characteristics of the Drive. Changing of parameter

settings must be done in the Program mode, or by use of the Function LEDs, if available (see TM.V7.01, Section 4).

The following table lists all parameters in numerical order. For each parameter, reference paragraph(s) in TM.V7.01, Section

5 are listed (if applicable) where the features of the Drive affected by that parameter are described.

V7 Parameters

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

n001 Parameter Selection / 4: n001 - n179 can be read and set

Initialization 5: n001 - n179 can be read and set 1 1 5.21

n002 Control Method Selection

n003 Operation Method Selection 1: Terminal 1 1 5.13

n004 Reference Selection

36

0: n001 can be read and set;

n002 - n179 read only

1: n001 - n039 can be read and set

2: n001 - n079 can be read and set

3: n001 - n119 can be read and set

Run command accepted during Program mode

6: Clear Fault History Only

7: Not Used

8: 2-wire Initialization (Japan Spec.)

9: 3-wire Initialization (Japan Spec.)

10: 2 wire initialization (USA Spec)

11: 3 wire initialization (USA Spec.)

0: V/f Control

1: Open Loop Vector

0: Digital Operator

2: Serial Communication (Modbus)

3: Option Card

0: Digital Operator Pot

1: Digital Operator

2: Voltage Reference (0 to 10V)

3: Current Reference (4 to 20 mA)

4: Current Reference (0 to 20 mA) 5.11,

5: Pulse Train Reference 1 2 5.13

6: Serial Communications (Modbus)

7: Multi-Function Analog Input (0 to 10V)

8: Multi-Function Analog Input (4 to 20 mA)

9: Option Card

10 2.2

Page 37

Drive Parameter Listing

V7 Parameters - Continued

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

n005 Stop Method

n006 Reverse Prohibit

n007 STOP Key Function

Reference Selection -

n008

Digital Operator

Frequency Reference Setting new value

n009

Method From Digital Operator 1: ENTER key does not have to be pressed

Operation Selection 0: Disabled (operation continues)

n010 When Digital Operator is 1: Enabled (motor coasts to a stop and fault 1 0 5.15

Disconnected is displayed)

n011 Frequency - Max. 50.0 to 400.0 0.1 (Hz) 60.0

Voltage - Max.

n012

Frequency - Max.

n013

Voltage Point

n014 Frequency - Midpoint 0.1 to 399.9 0.1 (Hz) (Note 2) 5.27

Voltage - Midpoint

n015

n016 Frequency - Min. 0.1 to 10.0 0.1 (Hz) (Note 2)

Voltage - Min.

n017

0: Ramp to stop

1: Coast to stop

0: Reverse Run enabled

1: Reverse Run disabled

0: STOP key is effective regardless of

programming of n003

1: STOP key is effective only when sequence

command (per n003) is from Digital Operator

0: Frequency Reference from digital

operator pot 1 0 5.13

1: Frequency Reference from n024

0: ENTER key must be pressed to write-in

to write-in new value

0.1 to 255.0 (230V drive)

0.2 to 510.0 (460V drive) 460.0

0.2 to 400.0 0.1 (Hz) 60.0

0.1 to 255.0 (230V drive)

0.2 to 510.0 (460V drive)

0.1 to 50.0 (230V drive)

0.2 to 100.0 (460V drive)

10 5.24

10

10 5.13

10 5.13

0.1 (V)

0.1 (V) (Note 2)

0.1 (V) (Note 2)

230.0

(n005-n017)Section 8

37

Page 38

Drive Parameter Listing (n018-n035) Section 8

Drive Parameters - Continued

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

Accel/Decel Time 0: 0.1

n018

Setting Unit 1: 0.01

n019 Acceleration Time 1 (Note 4) 0.00 to 600.0

n020 Deceleration Time 1 (Note 4) or or

n021 Acceleration Time 2 (Note 4) 0.0 to 6000 0.1 (sec)

n022 Deceleration Time 2 (Note 4) (Dependent on n018 setting)

n023 S-curve Selection

n024 Frequency Reference 1 (Note 4) 6.00

n025 Frequency Reference 2 (Note 4) 0.00

n026 Frequency Reference 3 (Note 4) 0. 01 (Hz) 0.00

n027 Frequency Reference 4 (Note 4) 0 .00 to 400.00 (< 100 Hz) 0.00

n028 Frequency Reference 5 (Note 4) o r 0.00 5.1 1

n029 Frequency Reference 6 (Note 4) 0.1 (Hz) 0.00

n030 Frequency Reference 7 (Note 4) (>= 100 Hz) 0.00

n031 Frequency Reference 8 (Note 4) 0.00

n032 Jog Frequency Reference (Note 4) 6.0 0 5.12

Frequency Reference Upper

n033

Limit

Frequency Reference Lower

n034

Limit

Digital Operator 1: 0.1%

n035

Display Mode 2 - 39: rpm

0: No S-cur ve

1: 0.2 second

2: 0.5 second

3: 1.0 second

0. to 110

0. to 110

0: 0.01 Hz (less than 100 Hz) / 0.1 Hz

40 - 3999: custom

38

0

1 (sec) .2

0.01 sec

1(%) 100

1(%) 0

10.0

10

1 0 5.30

5.2

5.3

5.9

Page 39

Drive Parameter Listing

Drive Parameters - Continued

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

n036 Motor Rated Current (Up to 150% of drive rated current) 0.1 (A) (Note 1) 5.25

Electronic Thermal Overload

n037

Protection (for OL1 fault)

Electronic Thermal Overload

n038

Protection Time Constant

Cooling Fan Operation (continues operation for 1 minute after

n039

Selection drive is stopped)

n040 Motor Rotation

Acceleration Time 3

n041

(Note 4)

Deceleration Time 3

n042

(Note 4)

Acceleration Time 4

n043

(Note 4)

Deceleration Time 4

n044

(Note 4)

n050 Multi-function Input [can only be set in n052] 11

Selection 1 (Terminal S1) 1: Forward run (2 wire control) (1)

Multi-function Input

n051

Selection 2 (Terminal S2)

Multi-function Input

n052

Selection 3 (Terminal S3)

0.1 to 49.5

0: Shor t term rating

1: Standard rating 01

2: Disabled 5.25

1 to 60

0: Operates only when drive is running

1: Operates with power applied to drive

0: Rotate C.C.W.

1: Rotate C.W. (or opposite direction)

0.00 to 600.00

or

0.0 to 6000.0

(Dependent on n018 setting)

0: Fwd / Rev command (3 wire control)

2: Reverse run (2 wire control)

3: Exter nal Fault (N.O.)

4: Exter nal Fault (N.C.)

5: Fault Reset

6: Multi-step speed ref. cmd. A

7: Multi-step speed ref. cmd. B

8: Multi-step speed ref. cmd. C

1 (min) 8

10

10

0.01 (sec)

or 5.2

10.0

0.1 (sec)

1 2 5.18

(2)

13

(0)

(n036-n052)Section 8

39

Page 40

Drive Parameter Listing (n053-n058) Section 8

Drive Parameters - Continued

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

Multi-function Input

n053

Selection 4 (Terminal S4)

Multi-function Input

n054

Selection 5 (Terminal S5)

Multi-function Input

n055

Selection 6 (Terminal S6)

n056 Multi-function Input

Selection 7 (Terminal S7)

Multi-Function Output

n057 Selection 1

(Terminals MA, MB & MC)

Multi-Function Output

n058 Selection 2

(Terminals P1 & PC)

40

9: Multi-step speed ref. cmd. D

10: JOG Selection

11: Accel/Decel time change cmd.

12: External Base Block (N.O.)

13: External Base Block (N.C.)

14: Speed search from max. freq.

15: Speed search from set freq.

16: Accel/Decel hold command

17: Remote/Local selection

18: Serial Communication / control ckt.

selection

19: Fast Stop - Fault (N.O.)

20: Fast Stop - Alarm (N.O.)

21: Fast Stop - Fault (N.C.) 1 10

22: Fast Stop - Alarm (N.C.) (10)

23: PID control off

24: I value reset (PID)

25: I value hold (PID)

26: Over Heat Pre-alarm OH3

27: Accel/Decel Time Select 2

34: Up

0: Fault

1: During running

2: Speed Agree

3: Zero Speed

4: Frequency detection 1

5: Frequency detection 2

6: Overtorque detection (N.O.)

7: Overtorque detection (N.C.)

8: Undertorque Detection (N.O.)

9: Undertorque Detection (N.C.) 1 1

10: Minor Fault

11: During Base Block

12: Local / Remote

13: Ready

15

16

17

10

(5)

(6)

(7)

5.18

5.19

Page 41

Drive Parameter Listing

Drive Parameters - Continued

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

Multi-Function Output

n059 Selection 3

(Terminals P2 & PC)

``

Analog Frequency Reference

n060

Gain (term. FR to FC) (Note 4)

Analog Frequency Reference

n061

Bias (term. FR to FC) (Note 4)

Analog frequency reference

n062

filter time constant 0.00 to 2.00 0.01 (sec) 0.10

(term. FR to FC) (Note 4)

Frequency Reference Loss 0: No Detection

n064

Detection 1: Continue to run at 80% of max. frequency

Monitor Output 0: Analog monitor output

n065

Selection 1: Pulse monitor output

Multi-function Analog Output (10V = 400 VDC [800 VDC])

n066

(Terminals AM & AC) 3: Motor Torque 1 0 5.17

n067 Analog Monitor Gain (Note 4) 0.00 to 2.00 0.01 1.00

Analog Frequency Reference

n068

Gain (CN2, Voltage Ref Input)

Analog Frequency Reference

n069

Bias (CN2, Voltage Ref Input)

14: During auto restart

15: During undervoltage

16: During reverse run

17: During speed search 1 2

18: Serial Comm. Controlled

19: PID feedback loss

20: Frequency Reference Loss Detect (N.O.)

21: Overheat Pre-alarm OH3 (N.O.)

0 to 255 1 (%) 100

-100 to 100 1 (%) 0

1 0 5.33

1 0 5.17

0: Output frequency (10V = 100% Fmax)

1: Output Current (10V = 100% drive

rated current)

2: DC Bus Voltage

(10V = Motor rated torque)

4: Output Power

(10V = Drive Capacity kW)

5: Output Voltage 10V = n012 (voltage max)

6: Frequency Reference

-255 to 255 1% 100

-100 to 100 1% 0

5.32

(n059-n069)Section 8

5.8

41

Page 42

Drive Parameter Listing (n070-n079) Section 8

Drive Parameters - Continued

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

Analog Frequency Reference

Filter Time Constant 0.00 to 2.00 0.01 s 0.10

n070

(CN2, Voltage Ref Input)

Analog Frequency Reference

n071

Gain (CN2, Current Ref Input)

Analog Frequency Reference

n072

Bias (CN2, Current Ref Input)

Analog Frequency Reference

Filter Time Constant 0.00 to 2.00 0.01 s 0.10

n073

(CN2, Current Ref Input)

Pulse Train Frequency

n074

Reference Gain

Pulse Train Frequency

n075

Reference Bias

Pulse Train Frequency Ref-

n076

erence Filter Time Constant

n077 Multi-Function Analog

Input Selection

Multi-Function Analog Input 0: 0 - 10V

n078

Signal Selection 1: 4 - 20 mA

Multi-Function Analog Input

n079

Bias Setting

42

-255 to 255 1% 100

-100 to 100 1% 0

-255 to 255 1% 100

-100 to 100 1% 0 5.11

0.00 to 2.00 0.01 s 0.10

0: Multi-Function analog input disabled

1: Aux. Frequency reference

2: Frequency gain 01

3: Frequency bias

4: Voltage bias

10

0 to 50 1% 10

5.32

5.32

Page 43

Drive Parameter Listing

Drive Parameters - Continued

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

n080 Carrier Frequency

Momentary Power Loss recovery within 2 sec.

n081

Ride-through Method 2: Continuous operation after power 1 0 5.16

Number of auto restarts

n082

attempts

n083 Prohibit Frequency 1 0.00 to 400.0

n084 Prohibit Frequency 2 0.00 to 400.0

n085 Prohibit Frequency 3 0.00 to 400.0

n086 Prohibit Frequency Deadband 0.00 to 25.50 0.01 (Hz) 0.00

n089 DC Injection Current 0 to 100 1 (%) 50

n090 DC Injection Time at stop 0.0 to 25.5 0.1 (sec) 0.0 5.7

n091 DC Injection Time at start 0.0 to 25.5 0.1 (sec) 0.0

Stall Prevention During 0: Enabled

n092

Deceleration 1: Disabled

Stall Prevention During

n093

Acceleration

Stall Prevention Level During

n094

Running

n095 Frequency Detection Level 0.00 to 400.0

1 to 4 (x 2.5 kHz)

7 to 9 (synchronous)

0: Not Provided

1: Continuous operation after power

recovery within control logic time

(no fault output)

0 to 10 1 0 5.4

30 to 200 1 (%) 170 5.23

30 to 200 1 (%) 160

13 5.5

0.01 (Hz)

or 0.1 (Hz)

0.01 (Hz)

or 0.1 (Hz)

0.01 (Hz)

or 0.1 (Hz)

0.01 (Hz)

0.00

0.00 5.6

0.00

10

0.00 5.19

(n080-n095)Section 8

43

Page 44

Drive Parameter Listing (n096-n109) Section 8

Drive Parameters - Continued

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

n096 Overtorque Detection (OL3) coast to stop 1 0

Overtorque Detection

n097 Selection (OL3)

(Note 5)

Overtorque Detection

n098

Level (OL3)

Overtorque Detection

n099

Delay Time (OL3)

Up/Down Hold 0: Disabled

n100

Memory 1: Enabled

Speed Search

n101

Deceleration Time

Speed Search Operation

n102

Level

Torque Compensation Gain

n103

(Note 4)

Torque Compensation

n104

Time Constant

Torque Compensation 0.1 (W) or

n105

Iron Loss

n106 Motor Rated Slip (Note 4) 0.0 to 20.0 0.1 (Hz) (Note 1) 2.2, 5.22

Motor Line-to-line

n107

Resistance

Motor Leakage 0.01 (mH)

n108

Inductance (Note 1)

Torque Compensation

n109

Limit (Note 5)

44

0: Detection Disabled

1: Detect only at set frequency;

operation continues

2: Detect only at set frequency;

3: Detect during all frequency conditions;

operation continues

4: Detect during all frequency conditions;

coast to stop 5.20

0: Detected by output torque

1: Detected by output current

30 to 200 1 (%) 160

0.1 to 10.0 0.1 (sec)

0.0 to 10.0 2 5.18

0 to 200% 1 (%) 150 5.18

0.0 to 2.5 0.1 1.0

0.0 to 25.5 (Note 2)

0.0 to 6550

0.000 to 65.50 (Note 1)

0.00 to 655.0

0 to 250 150 5.26

10

0.1

1 0 5.10

0.1 (sec)

0.1 (sec)

(Note 1)

1 (W)

0.001 (ohm)

or 0.1 (mH)

(Note 1)

1 (%)

5.26

Page 45

Drive Parameter Listing

Drive Parameters - Continued

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

n110 Motor No-load Current 0 to 99 1 (%) (Note 1) 2.2

n111 Slip Compensation Gain (Note 4) 0. 0 to 2. 5 (No te 2)

Slip Compensation Primary

n112

Delay Time

Slip Compensation Selection 0: Disabled

n113

During Regeneration 1: Enabled

Stall Prevention Above Base (level is based on setting of n094)

n115

Speed During Run 1: Enabled

Stall Prevention During Run,

n116

Accel/Decel Time Select

n117 Under torque Detection

Select (UL3)

Undertorque Detection Inverter rated current = 100%; if n097 = 0

n118

Level (UL3) (detection by torque); motor rated torque

Undertorque Detection

n119

Time (UL3)

n120 Frequency Reference 9 (Note 4) 0.00

n121 Frequency Reference 10 (Note 4) 0. 01 (Hz ) 0.0 0

n122 Frequency Reference 11 (Note 4) (< 100 Hz) 0.00

n123 Frequency Reference 12 (Note 4) 0.0 0 to 400.00 or 0.00 5.11

n124 Frequency Reference 13 (Note 4) 0.1 (Hz) 0. 00

n125 Frequency Reference 14 (Note 4) (>= 100 Hz) 0.00

n126 Frequency Reference 15 (Note 4) 0.00

n127 Frequency Reference 16 (Note 4) 0.00

0.0 to 25.5 (Note 2)

0: Disabled

(level at Fmax is n094 x 0.4)

0: Follows acc/dec #1 (n019, n020)

or acc/dec #2 (n021, n022)

Note: Multi-Function input selectable 1 0

1: Follows acc/dec #2 (n021, n022)

always

0: Undertorque detection disabled

1: Detected during constant speed running.

Operation continues after detection

2: Detected during constant speed running.

Operation stops during detection

3: Detected during all frequency conditions.

Operation continues

4: Detected during all frequency conditions.

coast to stop

0 to 200%

becomes 100%

0.1 to 10.0 .1

0.1

0.1 (sec)

10

10

10

1(%) 0

0.1 (sec)

(n110-n127)Section 8

5.22

5.23

5.34

45

Page 46

Drive Parameter Listing (n128-n140) Section 8

Drive Parameters - Continued

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

n128 PID Control Selection 5: Inverse PID - D = Feed Forward

n129 PID Feedback Gain (Note 4) 0.00 to 10.00 0.01 1.00

n130 PID Proportional Gain (Note 4) 0.00 to 25.00 0.1 1.0

n131 PID Integral Time (Note 4) 0.00 to 360.00 0.1 s 1.0 5.28

n132 PID Derivative Time (Note 4) 0.00 to 2.50 0.01 0.00

n133 PID Offset Adjustment (Note 4) - 100 to 100 1% 0

n134 Integral Value Limit (Note 4) -100 to 100 1% 100

n135 PID Output Lag Filter Time (Note 4) 0.0 to 10.0

Feedback Loss

n136 1: Enabled - Alarm (operation continues) 1 0

Detection Selection

Feedback Loss

n137

Detection Level

Feedback Loss

n138

Detection Time

Energy Saving Selection

n139

(Energy Saving)

Energy Saving Gain

n140

K2 (Energy Saving)

46

0: PID control disabled

1: D = Feed Forward

2: D = Feedback

3: Reference + PID (D = Feed Forward)

4: Reference + PID (D = Feedback) 1 0

6: Inverse PID - D = Feedback

7: Inverse PID - Reference + PID

(D = Feed Forward)

8: Inverse PID - Reference + PID

(D = Feedback)

0: Disabled

2: Enabled Fault (coast to stop)

0 to 100 1% 0

0.0 to 25.5

0: Energy saving disabled

1: Energy saving enabled

Note: Energy saving becomes enabled by

V/f control mode

0.00 to 6550 0.1 or 1 (Note 1)

0.1 s 1.0

10(Note 2)

5.31

Page 47

Drive Parameter Listing

Drive Parameters - Continued

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

Energy Saving Voltage

n141 Lower Limit at 60 Hz

(Energy Saving)

Energy Saving Voltage

n142 Lower Limit at 6 Hz

(Energy Saving)

Time of Average kW

n143

(Energy Saving) (x 24 ms) (24 ms)

Voltage Limit of Tuning

n144

(Energy Saving)

Step Voltage of Tuning to

n145

100% Output Voltage 0.1 to 10.0 0.1% 0.5

(Energy Saving)

Step Voltage of Tuning to

n146

5% Output Voltage 0.1 to 10.0 0.1% 0.2

(Energy Saving)

n149 Pulse Train Input Scaling 100 to 3300 1 (x 10 Hz)

Pulse Monitor Output 36: 36f output 24, 36, 40,

n150

Frequency Selection Frequency Reference Monitor: 41, 42, 43,

Modbus Time Out

n151

Detection

0 to 120 1% 50

0 to 25 1% 12

1 to 200

1 to 100 1% 0

Output Frequency Monitor:

0: 1440 Hz / Max. output frequency

1: 1f output

6: 6f output

12: 12f output

24: 24f output 0, 1, 6, 12,

40: 1440Hz / Max. output frequency 44, 45

41: Frequency reference * 1

42: Frequency reference * 6

43: Frequency reference * 12

44: Frequency reference * 24

45: Frequency reference * 36

0: Fault - Coast to stop

1: Fault - Ramp to stop (n020)

2: Fault - Ramp to stop (n022) 1 0 5.14

3: Alarm - operation continues

4: Disabled

11

3072

(30,720 Hz)

0 5.17

5.31

5.11

(n141-n151)Section 8

47

Page 48

Drive Parameter Listing (n152-n163) Section 8

Drive Parameters - Continued

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

Modbus Frequency 1: 0.01 Hz

n152

Reference Unit 2: 30000/100%

n153 Modbus Slave Address 0 to 32 1 0

n154 Modbus Baud Rate

n155 Modbus Parity Selection 1: odd parity 1 2

n156 Modbus Send Waiting Time 10 to 65 1 (msec) 10

n157 Modbus RTS control 1: RTS control disabled 1 0

n158 Motor Code 0 to 70 1 (Note 1)

Energy Saving Voltage

n159

Upper Limit At 60 Hz 0 to 120 1% 120

(Energy Saving)

Energy Saving Voltage

n160

Upper Limit At 6 Hz 0 to 25 1% 16

(Energy Saving) 5.31

Power Supply Detection

n161

Hold Width (Energy Saving)

Power Supply Detection

n162

Filter Time Constant (x 4 ms) (20 ms)

n163 PID Output Gain 0.0 to 25.0 0.1 1.0

48

0: 0.1 Hz

3: 0.1 %

0: 2400 bps

1: 4800 bps 5.14

2: 9600 bps

3: 19200 bps

0: even parity

2: no parity

0: RTS control enabled

(RS-422A 1 to 1 communication)

0 to 100 1% 10

0 to 255

10

12

15

5.28

Page 49

Drive Parameter Listing

Drive Parameters - Continued

PARA- SETTING RANGE SETTING FACTORY USER PARA.

METER NAME (AND UNITS) INCREMENT SETTING SETTING REF.

n164 PID Feedback Selection

Input Phase Loss

n166

Detection Level

Input Phase Loss

n167

Detection Time

Output Phase Loss

n168

Detection Level

Output Phase Loss

n169

Detection Time

n173 DC Injection P Gain 1 to 999 1 (0.001) 83 (0.083)

n174 DC Injection I Time 1 to 250 1 (4ms)

n175 Reduce Carrier

at low speed selection

Digital Operator Parameter Cpy: COPY executes Cpy

n176

Copy Function Selection vFy: VERIFY executes vFy

Digital Operator

n177

Parameter copy

Access Selection

n178 Fault History (Note 3) N/A N/A 6.2

n179 Software Number (Note 3) N/A N/A 4.4

Note 1: Factory setting differs depending on V7 capacity. See Appendix 3-1.

Note 2: Factory setting differs depending on control method selected (n002). See Appendix 3-1.

Note 3: n178 and n179 are display only parameters

Note 4: Parameter can be changed while V7 is operating.

0: Terminal FR (Voltage 0 - 10V)

1: Terminal FR (Current 4 - 20mA)

2: Terminal FR (Current 0 - 20mA)

3: Multi-Function Analog Input

(Voltage 0 - 10V)

4: Multi-Function Analog Input

(Current 4 - 20mA)

5: Pulse input

0 to 100 (%) 1% 0

0 to 255 (sec) 1 sec 0

0 to 100 (%)

0.0 to 2.0 (sec) 0.1 sec 0

0: Disabled

1: Carrier Frequency reduced to 2.5kHz 1 0 5.5

when Fout <= 5Hz & Iout >= 110%

rdy : READY status rdy

rEd: READ executes rEd

vA: Inverter capacity display vA

Sno: Software No. display

0: Read disabled

1: Read allowed

1 0 5.28

1% 0

25

(100ms)

rdy 5.29

Sno

1 0 5.29

(n164-n179)Section 8

49

Page 50

Monitor Displays Section 9

When using the Monitor Function, a variety of information will appear on the Digital Operator display when each of the U-XX

(display only) parameters is selected.

PARAMETER DISPLAY

U - MONITORED ITEM EXAMPLE

01 Frequency reference (Hz) 60.0

02 Output frequency (Hz) 60.0

03 Output current (A) 12.5

04 AC output voltage (V) 230

05 DC Bus voltage (VPN ) 325

06 Input terminal status

07 Output Terminal status IIIIIIII

08 Motor Torque (%) 72

(Open loop vector only)

09 Fault record (last 4 faults)

10 Software number 0024

XXXX

(3)

11 Output Power (KW) 99.9

15 Data reception error

16 PID Feedback (%) 35.0

17 PID Input (%) 100

18 PID Output (%) 75.5

50

IIIIIIII

oC

IIIIIIII

(1)

(2)

(4)

Page 51

Monitor DisplaysSection 9

(1)

Actual display appearance:

Term.S1 input OPEN

Term.S2 input CLOSED

Term.S3 input OPEN

Term.S4 input CLOSED

Term. S6 input CLOSED

Term.S7 input OPEN

Not used

Term.S5 input OPEN

(3)

See TM.V7.01, Section 6 for viewing

of fault log contents.

(4)

Actual display appearance:

CRC error

Data length OK

Not used

Parity error

Over run error

Framing OK

Timeout error

Not used

(2)

Actual display appearance:

MA-MC CLOSED

P1 - PC OPEN

P2 - PC CLOSED

{

Not used

51

Page 52

Drive Dimensions Section 10

Fig. 1

2-d

H2

W W

W

52

0.06

(1.5)

H3H1

H

H4

0.16

(4.0)

0.33

(8.5)

D

Page 53

Drive DimensionsSection 10

V7 Enclosed wall mounted type (NEMA type 1)

Volta ge

3-phase 20P4 A003 1/2 2.68 5.83 4.25 2.20 4.65 0.20 0.24 5.04 0.79 M4 2.20 15.8 12.3 28.1 1

Model Si ze Di mensions in inches (mm) Weight Heat Loss (W)

CIMR- Lbs. Heat-

Class

V7* MV

20P1 A001 1/8 2.68 5.83 2.99 2.20 4.65 0.20 0.24 5.04 0.79 M4 1.55 3.7 9.3 13.0 1

20P2 A002 1/4 2.68 5.83 2.99 2.20 4.65 0.20 0.24 5.04 0.79 M4 1.55 7.7 10.3 18.0 1

230V (68) (148) (76) (56) (118) (5) (6) (128) (20) (0.7)

20P7 A005 3/4 & 1 2.68 5.83 5.04 2.20 4.65 0.20 0.24 5.04 0.79 M4 2.65 28.4 16.7 45.1 1

(1)

When drives include network communications option board, add 1.5" to drive depth.

HP W H DW1H1H2W2H3H4d

(68) (148) (76) (56) (118) (5) (6) (128) (20) (0.7)

(68) (148) (108) (56) (118) (5) (6) (128) (20) (1.0)

(68) (148) (128) (56) (118) (5) (6) (128) (20) (1.2)

(kg) sink Internal Total

Fig.

53

Page 54

Drive Dimensions Section 10

Fig. 2

4-d

H2

W1

W

W

54

0.06

(1.5)

H

H3H1

H4

0.16

(4.0)

0.33

(8.5)

D

Page 55

Drive DimensionsSection 10

V7 Enclosed wall mounted type (NEMA type 1)

Volta ge

3-phase (108) (148) (140) (96) (118) (5) (6) (128) (20) (1.7)

3-phase (108) (148) (140) (96) (118) (5) (6) (128) (20) (1.7)

(1)

Model Si z e Dimensions in inches (mm) Weight Heat Loss (W )

CIMR- Lbs. Heat -

Class

V7* MV

21P5 A008 2 4.25 5.83 5.16 3.78 4.65 0.20 0.24 5.04 0.79 M4 3.53 53.7 19.1 72.8 2

230V 22P2 A011 3 4.25 5.83 5.51 3.78 4.65 0.20 0.24 5.04 0.79 M4 3.75 60.4 34.4 94.8 2

23P7 A017 5 5.51 5.83 5.63 5.04 4.65 0.20 0.24 5.04 0.79 M4 5.30 96.7 52.4 149.1 2

40P2 B001 1/2 4.25 5.83 3.62 3.78 4.65 0.20 0.24 5.04 0.79 M4 2.65 9.4 13.7 23.1 2

40P4 B002 3/4 4.25 5.83 4.43 3.78 4.65 0.20 0.24 5.04 0.79 M4 2.65 15.1 15.0 30.1 2

460V 40P7 B003 1& 2 4.25 5.83 5.51 3.78 4.65 0.20 0.24 5.04 0.79 M4 3.75 30.3 24.6 54.9 2

41P5 B005 3 4.25 5.83 6.14 3.78 4.65 0.20 0.24 5.04 0.79 M4 3.75 45.8 29.9 75.7 2

42P2 — 3 4.25 5.83 6.14 3.78 4.65 0.20 0.24 5.04 0.79 M4 3.75 50.5 32.5 83.0 2

43P7 B009 5 5.51 5.83 5.63 5.04 4.65 0.20 0.24 5.04 0.79 M4 5.30 73.4 44.5 117.9 2

HP W H DW1H1H2W2H3H4d

(108) (148) (131) (96) (118) (5) (6) (128) (20) (1.6)

(140) (148) (143) (128) (118) (5) (6) (128) (20) (2.4)

(108) (148) (92) (96) (118) (5) (6) (128) (20) (1.2)

(108) (148) (110) (96) (118) (5) (6) (128) (20) (1.2)

(108) (148) (156) (96) (118) (5) (6) (128) (20) (1.7)

(108) (148) (156) (96) (118) (5) (6) (128) (20) (1.7)

(140) (148) (143) (128) (118) (5) (6) (128) (20) (2.4)

(kg) sin k Internal Total

When drives include network communications option board, add 1.5" to drive depth.

Fig.

55

Page 56

Drive Dimensions Section 10

Fig. 3

4-d

0.06

(1.5)

H

H1

H2

0.09

(2.20)

W1

W

56

W2

0.33

(8.5)

D

Page 57

Drive DimensionsSection 10

V7 Enclosed wall mounted type (NEMA type 1)

Volta ge

3-phase 27P5 A033 10 7.09 10.24 6.70 6.46 9.61 0.31 0.31 – – M5 11.89 219.2 98.9 318.1 3

3-phase 47P5 – 15

(1)

(2)

(3)

Model Si z e Dimensions in inches (mm) Weight Heat Loss (W )

CIMR- Lbs. Heat -

Class

V7* MV

25P5 A025 7.5 7.09 10.24 6.70 6.46 9.61 0.31 0.31 – – M5 11.45 170.4 79.4 249.8 3

230V (180) (260) (170) (164) (244) (8) (8) (5.2)

45P5 B015 10 7.09 10.24 6.70 6.46 9.61 0.31 0.31 – – M5 10.14 168.8 87.7 256.5 3

460V (180) (260) (170) (164) (244) (8) (8) (4.6)

HP W H DW1H1H2W2H3H4d