Page 1

V7 PROFIBUS-DP

Technical Manual

®

Option

Models: CIMR-V7* Document Number TM.V7.12

Page 2

Page 3

Warnings and Cautions

This Section provides warnings and cautions pertinent to this product, that if not heeded, may

result in personal injury, fatality, or equipment damage. Yaskawa is not responsible for

consequences of ignoring these instructions.

WARNING

YASKAWA manufactures component parts that can be used in a wide variety of industrial applications. The selection and application of

YASKAWA products remain the responsibility of the equipment designer or end user. YASKAWA accepts no responsibility for the way its

products are incorporated into the final system design. Under no circumstances should any YASKAWA product be incorporated into any

product or design as the exclusive or sole safety control. Without exception, all controls should be designed to detect faults dynamically

and to fail safely under all circumstances. All products designed to incorporate a component part manufactured by YASKAWA must be

supplied to the end user with appropriate warnings and instructions as to that part’s safe use and operation. Any warnings provided by

YASKAWA must be promptly provided to the end user. YASKAWA offers an express warranty only as to the quality of its products in

conforming to standards and specifications published in the YASKAWA manual. NO OTHER WA RRANTY, EXPRESS OR IMPLIED, IS

OFFERED. YASKAWA assumes no liability for any personal injury, property damage, losses, or claims arising from misapplication of its

products.

WARNING

Read and understand this manual before installing, operating, or servicing this drive. All warnings, cautions, and instructions must be

followed. All activity must be performed by qualified personnel. The drive must be installed according to this manual and local codes.

Do not connect or disconnect wiring while the power is on. Do not remove covers or touch circuit boards while the power is on. Do

not remove or insert the digital operator while power is on.

Before servicing, disconnect all power to the equipment. The internal capacitor remains charged even after the power supply is turned

off. Status indicator LEDs and Digital Operator display will be extinguished when the DC bus voltage is below 50 VDC. To prevent

electric shock, wait at least 5 minutes after all indicators are OFF and measure DC bus voltage and verify that it is at a safe level.

Do not perform a withstand voltage test on any part of the unit. This equipment uses sensitive devices and may be damaged by high

voltage.

The drive is not suitable for circuits capable of delivering more than the specified RMS symmetrical amperes. Install adequate branch

short circuit protection per applicable codes. Refer to the specification. Failure to do so may result in equipment damage and/or

personal injury.

Do not connect unapproved LC or RC interference suppression filters, capacitors, or over voltage protection devices to the output of

the drive. Capacitors may generate peak currents that exceed drive specifications.

To avoid unnecessary fault displays, caused by contactors or output switches placed between drive and motor, auxiliary contacts must

be properly integrated into the control logic circuit.

YASKAWA is not responsible for any modification of the product made by the user, doing so will void the warranty. This product

must not be modified.

Verify that the rated voltage of the drive matches the voltage of the incoming power supply before applying power.

To meet CE directives, proper line filters and proper installation are required.

Some drawings in this manual may be shown with protective covers or shields removed, to describe details. These must be replaced

before operation.

Observe Electrostatic Discharge Procedures when handling the drive and drive components to prevent ESD damage.

The attached equipment may start unexpectedly upon application of power to the drive. Clear all personnel from the drive, motor and

machine area prior to applying power. Secure covers, couplings, shaft keys, machine beds and all safety equipment before energizing

the drive.

Do not attempt to disassemble this unit. There are no user serviceable parts. Disassembling this unit will void any and all

warranties.

i

Page 4

Introduction

This manual explains the specifications and handling of the Yaskawa V7 PROFIBUS-DP Option for the Yaskawa model V7 drive. The V7

PROFIBUS-DP Option connects the drive to a PROFIBUS-DP network and facilitates the exchange of data.

This document pertains to the V7 drive. However, this document is equally applicable to drives identified as GPD 315, GPD 315/V7, GPD

315/V74X, and V74X. Additionally, in this document, the word “inverter”, “ac drive” and “drive” may be used interchangeably.

To ensure proper operation of this product, read and understand this manual. For details on installation and operation of the V7 drive, refer

to the V7 Technical Manual. For details on specific V7 parameters, refer to the V7 MODBUS

and support files are available on the CD that came with the drive, CD.4005, and are available for download at www.drives.com

For information on PROFIBUS-DP contact the PROFIBUS Organization at www.profibus.org.

V7 T echnical Manual document reference TM.V7.01

V7 MODBUS

V7 PROFIBUS-DP Technical Manual document reference TM.V7.12

GPD is a trademark of Yaskawa, Inc.

MODBUS

PROFIBUS

All trademarks are the property of their respective owners.

®

T echnical Manual document reference TM.V7.11

®

is a registered trademark of Schneider Automation, Inc.

®

and PROFIBUS-DP® are registered trademarks of PROFIBUS Nutzerorganisation e.V.

®

T echnical Manual. All technical manuals

.

ii

Page 5

Table of Contents

Chapter 1 Installation...........................................................................1-1

Installation Check Sheet.....................................................................................1-3

Unpack and Inspect............................................................................................1-5

Installation and Wiring........................................................................................1-6

Option LEDs.....................................................................................................1-11

Drive Faults ......................................................................................................1-13

Parameter Settings...........................................................................................1-14

Chapter 2 Network Configuration....................................................... 2-1

Configuration......................................................................................................2-3

GSD File.............................................................................................................2-6

Chapter 3 Network Communications.................................................3-1

16 Word Input/Output Message..........................................................................3-3

6 Word Input/Output Message............................................................................3-7

3 Word I/Os Message.......................................................................................3-10

Parameter Access Error Messages..................................................................3-12

Handshaking..................................................................................................... 3-13

Appendix A Product Specification........................................................ 1

Appendix B Parameter Access.............................................................. 1

Parameter Access Overview .................................................................................3

Read Drive Data Example.....................................................................................5

Read Drive Data Error Example............................................................................6

Write Drive Data Example.....................................................................................7

Write Drive Data Error Example............................................................................8

Appendix C Troubleshooting................................................................. 1

Troubleshooting Check List...................................................................................3

Installation Troubleshoo ting...................................................................................5

Wiring And Cabling................................................................................................8

PROFIBUS-DP Configuration..............................................................................11

V7 PROFIBUS-DP Option Diagnostics................................................................12

iii

Page 6

This page intentionally left blank.

iv

Page 7

Chapter 1 Installation

This chapter describes how to install and setup the V7 PROFIBUS-DP Option

Installation Check Sheet................................................... 1 - 3

Unpack & Inspect .............................................................. 1 - 5

Installation And Wiring...................................................... 1 - 6

Option LEDs...................................................................... 1 - 11

Drive Faults...................................................................... 1 – 13

Parameter Settings.......................................................... 1 - 14

Installation 1-1

Page 8

This page intentionally left blank

Installation 1-2

Page 9

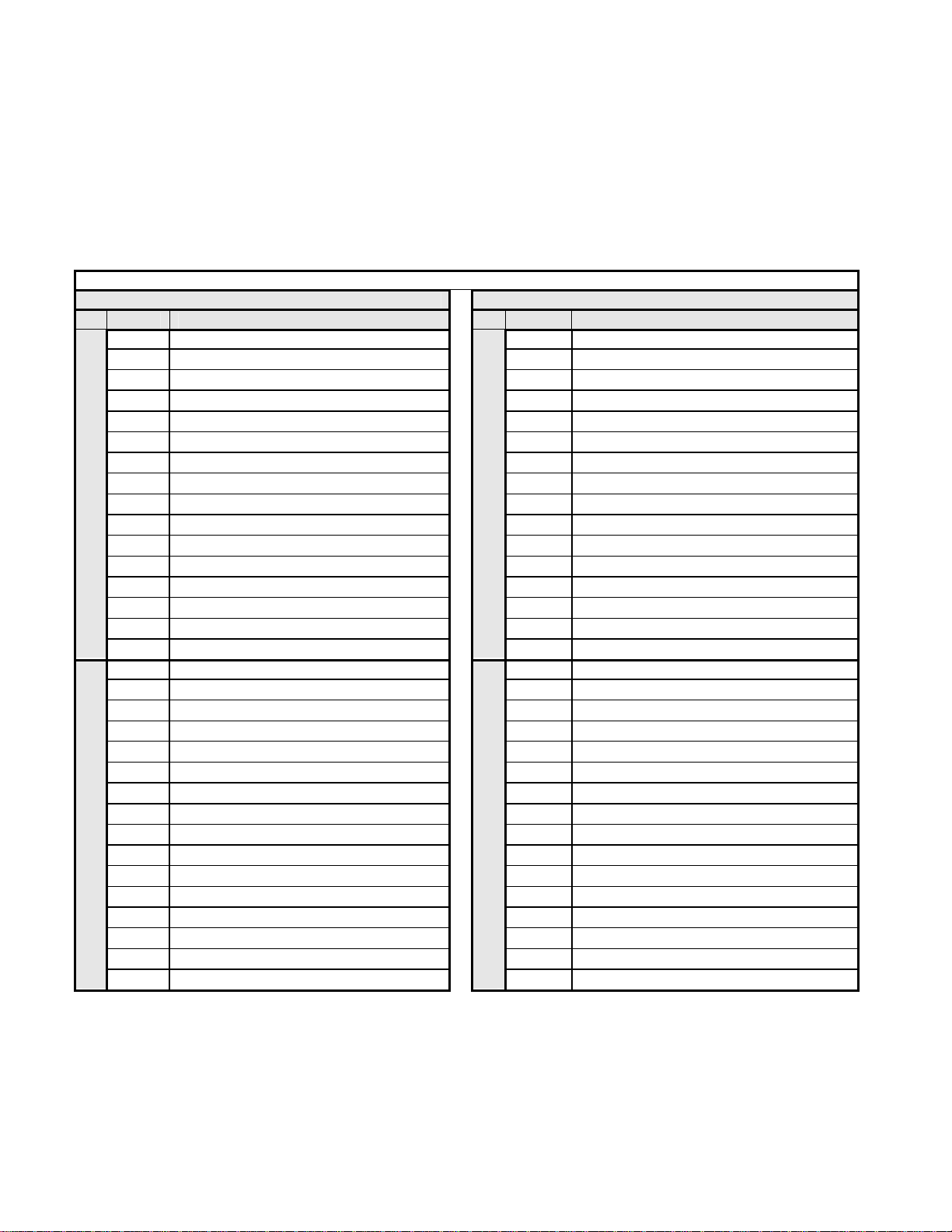

Installation Check Sheet

The following is a quick reference guide to install and configure the V7 PROFIBUS-DP Option. Make a copy of this page and check-off

each item as it is completed. For detailed information please refer to the detailed sections that follow.

1: Unpack the V7 PROFIBUS-DP Option and verify that all components are present and undamaged. Refer to Figure 1.1 –

V7PROFIBUS-DP Option, Table 1.1 – Product Parts List .

2:

3:

4:

Connect power to the drive and verify that the drive functions correctly. This includes running the drive from the operator

keypad. Refer to the V7 Technical Manual for information on connecting and operating the drive.

Remove power from the drive and wait for the charge lamp to be completely extinguished. Wait at least five additional

minutes for the drive to be completely discharged. Measure the DC bus voltage and verify that it is at a safe level.

Install the V7 PROFIBUS-DP Option on the drive.

4.1:

4.2:

4.3:

4.4:

4.5:

5:

6:

Connect the V7 to the PROFIBUS-DP communication network. Refer to Figure 1.4 – V7 PROFIBUS-DP Option

Connections and Table 1.3 - PROFIBUS-DP Cable Connections

Set the node address for the drive. Refer to Figure 1.5 – Setting the V7 PROFIBUS-DP Option Node Address.

Remove the V7 operator keypad and terminal cover.

Remove the plastic protective cover from over the CN2 connector. Refer to Figure 1.2 –Remove CN2 Cover and

Install Option Mounting Bracket.

Install the option mounting bracket provided on to the drive. Refer to Figure 1.2 – Remove CN2 Cover and

Install Option Mounting Bracket.

Connect the ground wire provided to the ground connector on the back of the V7 PROFIBUS-DP Option. Refer to

Table 1.2 – Ground Cables & Drive Models and to Figure 1.3 – Mount the V7 Option.

Mount the V7 PROFIBUS-DP Option onto the drive. Refer to Figure 1.3 – Mount the V7 Option.

7:

8:

9:

10:

11:

12:

13:

If this unit is either the first or the last device on the network, including PLCs and PROFIBUS-DP Masters, and active

termination is not used, set the termination resistor switch to ON. If this device is not the first or last device on the network

or active termination is used, set the termination resistor switch to OFF. Refer to Figure 1.6 – Termination Switch.

Secure the V7 PROFIBUS-DP Option to the drive.

Configure the PROFIBUS network for the drive. Refer to the documentation included with the PROFIBUS configuration

utility supplied with the PROFIBUS-DP Master controller.

Apply power to the drive. And verify that the diagnostic LEDs on the front of the V7 PROFIBUS-DP Option are in their

correct state. Refer to Table 1.4 –Diagnostic LED Status.

Remove power from the drive and wait for the charge lamp to be completely extinguished. Wait at least five additional

minutes for the drive to be completely discharged. Measure the DC bus voltage level to confirm that it is at a safe level.

Reinstall the operator keypad and terminal cover.

Set parameters n003, n004 and n035 to their appropriate values. Refer to Table 1.5 – Option Specific Parameter Settings.

Installation 1-3

Page 10

This page intentionally left blank.

Installation 1-4

Page 11

Unpack and Inspect

Prior to unpacking, check the package label and verify that the product received matches the product ordered. Unpack the option and verify

that the following items are included in the product package and are undamaged.

Locking Screw

Indicator

LEDs

ERR

COMM

PWR

WD

Front

Profibus Cable

Connector

S2 S1

Termination Switch

Mounting Bracket

M3x8 Screw

Figure 1.1 – V7 PROFIBUS-DP Option

CN1 - Modular Plug

RJ45 Female

Node Address

Switches

Ground Wires

E

E

E

6" (150mm)

8.5" (220mm)

12.5" (320mm)

CN3 - Modular Plug

RJ45 Male

CN1

Connector

Back

Ground Wire Connec t i o n

E

E

E

Table 1.1 – Product Parts List

Part Qty.

V7 PROFIBUS-DP Option 1

Mounting Bracket 1

M3×8 Screw 1

6” Ground Wire (150mm) 1

8.5” Ground Wire (220mm) 1

12.5” Ground Wire (320mm) 1

Quick Start Installation Guide 1

Installation 1-5

Page 12

Installation and Wiring

The following describes the installation and configuration of the V7 PROFIBUS-DP Option. For detailed information please refer to the

appropriate sections of this manual or the V7 Technical Manual.

Verify Drive Operation

Connect power to the drive and verify that the drive functions properly. This includes running the drive from the operator

keypad. Refer to the V7 Technical Manual, for information on connecting and operating the drive.

Remove power from the drive and wait for the charge lamp to be com pletely extinguished. Wait at least five additional minutes

for the drive to be completely discharged. Measure DC bus voltage and verify that it is at a safe level.

Remove the operator keypad and terminal cover.

Remove CN2 Protective Cover and Install Mounting Bracket

Remove the plastic protective cover from the CN2 connector on the drive by cutting the three tabs as shown below. Install the option

mounting bracket and secure it to the drive with the M3x8 screw provided.

Remove the CN2

protective cover

by carefully

clipping the

three tabs

CN2 Cover

Option kit mounting

bracket

Align hole in

mounting bracket

with nib on front of

the V7 drive

Secure mounting

bracket to V7 drive

with M3x8 screw

provided

Figure 1.2 – Remove CN2 Cover and Install Option Mounting Bracket

Installation 1-6

Page 13

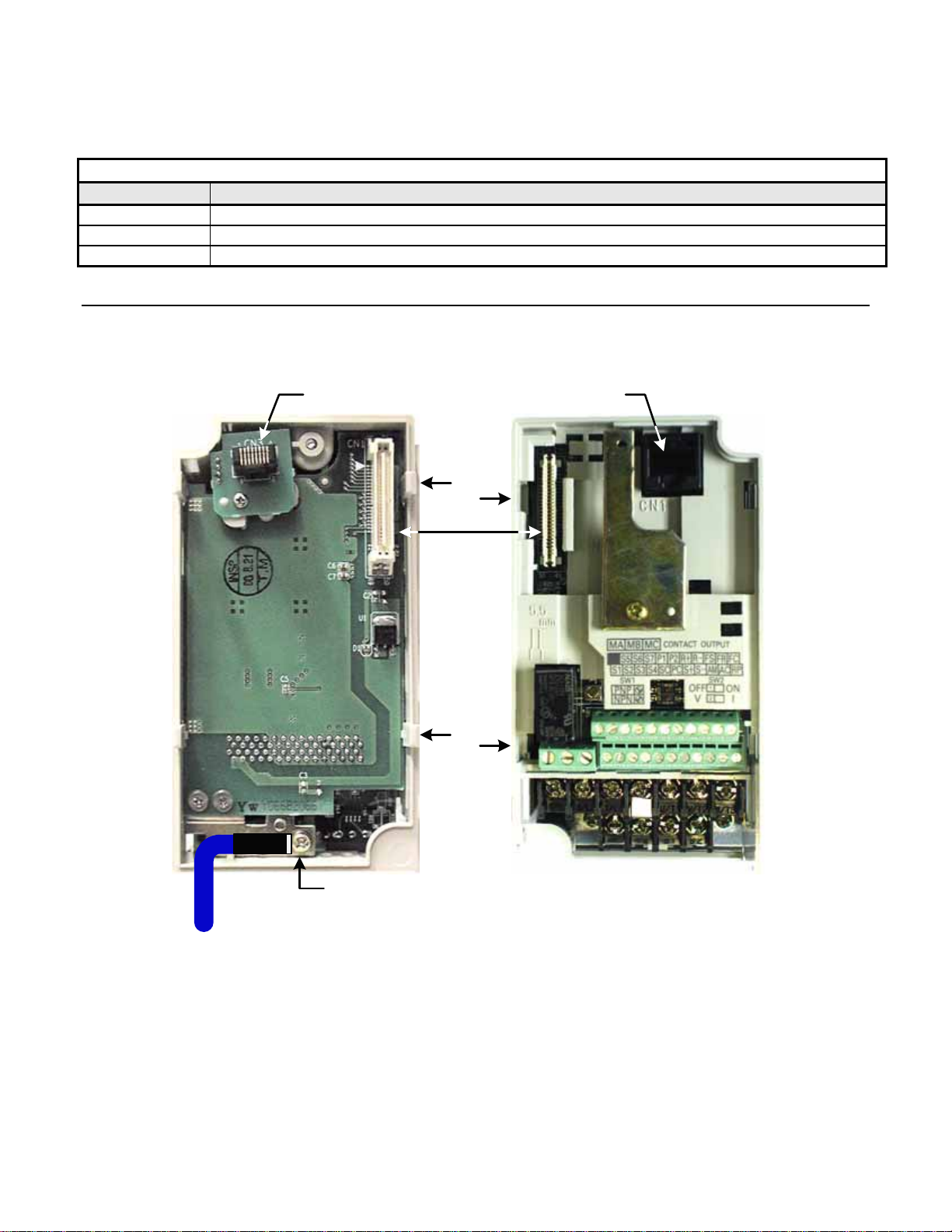

Connect Ground Wire

Connect the ground wire to the ground connector on the back of the V7 PROFIBUS-DP Option. Select the wire of the appropriate length

based on drive model.

Table 1.2 – Ground Cable & Drive Models

Cable Length Drive Models

6” (150mm) 20P1, 20P2, 40P2

8.5” (220mm) 20P4, 20P7, 21P5, 22P2, 23P7, 40P4, 40P7, 43P7, 41P5, 42P2

12.5” (320mm) 25P5, 27P5, 47P5

Mount the V7 PROFIBUS-DP Option

Mount the V7 PROFIBUS-DP Option onto the drive by following the instructions below.

Align the CN1 connector on the back of the option with its mating CN2 connector on the front of the drive.

Simultaneously align the CN3 connector, the male RJ45 connector, on the back of the option with the CN1 connector, the female

RJ45 connector, on the front of the drive.

Align the tabs on the option with their corresponding slots on the front of the drive.

Press the option and the drive together until the tabs lock into their associated slots.

Secure the option to the V7 drive by tightening the locking screw at the top-center on the front of the option.

Connect the ground wire from the V7 PROFIBUS-DP Option to the ground terminal on the V7 drive.

E

Ground Wire

CN3 - Male RJ45

Connector

Tab

CN1 - CN2

Tab

Ground Terminal

Figure 1.3 – Mount the V7 Option

CN1 - Female

RJ45 Connector

Slot

Slot

Installation 1-7

Page 14

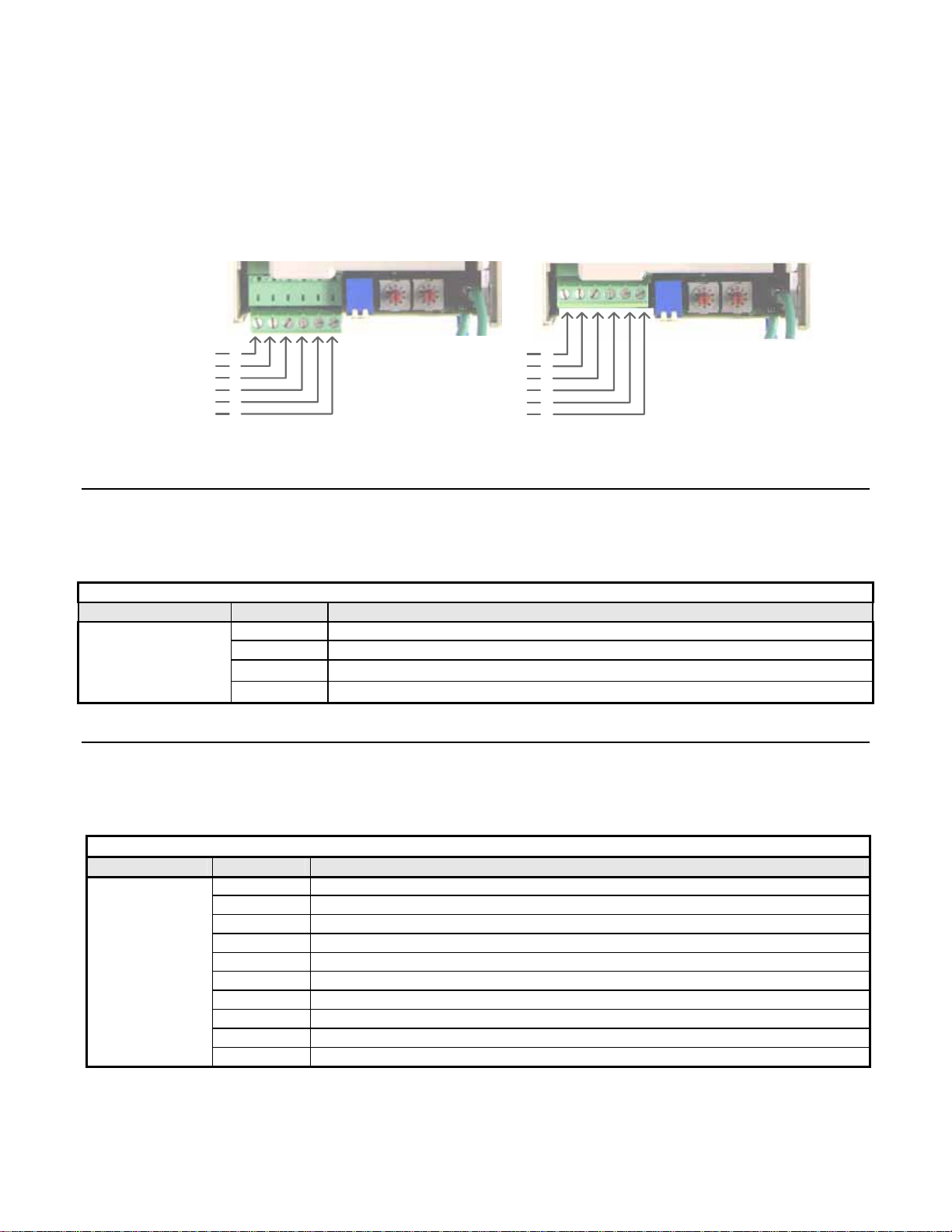

Connect The V7 To The PROFIBUS-DP Communications Network.

Determine the type of connector on the V7 PROFIBUS-DP Option. Connector Style A is a modified Phoenix pluggable

connector. The modification can be seen on the back of the connector as a small circuit board. Connector Style B is a standard

Phoenix pluggable connector without modification.

Connect the PROFIBUS-DP network cable to the V7 PROFIBUS-DP Option. Refer to the appropriate connection drawing in

Figure 1.4 below for your connector style.

Use standard PROFIBUS-DP cable as specified by the PROFIBUS Organization

Troubleshooting for more information on network cabling.

Connector Style A Connector Style B

www.profibus.org. Refer to Appendix C

A In (Green)

B In (Red)

A Out (Green)

B Out (Red)

Shield

Reserved

1

2

3

4

5

6

Reserved

Reserved

A In/Out (Green)

B In/Out (Red)

Shield

Reserved

1

2

3

4

5

6

Figure 1.4 – V7 PROFIBUS-DP Option Connections

Table 1.3 – PROFIBUS-DP Cable Connections

Connector Style A

Pin Name Function

1 A In-(Green) Negative Input RxD/TxD (Connected from the previous device)

2 B-In (Red) Positive Input RxD/TxD (Connected from the previous device)

3 A Out-(Green) Negative Output RxD/TxD (Connect to the next device)

4 B-Out (Red) Positive Output RxD/TxD (Connect to the next device)

5 Shield BUS cable shield (Connected to PE internally on the communication option)

6 Reserved

Connector Style B

Pin Name Function

1 Reserved

2 Reserved

3 A In/ Out-(Green) Negative Input/Output RxD/TxD

4 B-In/Out (Red) Positive Input/Output RxD/TxD

5 Shield BUS cable shield (Connected to PE internally on the communication option)

6 Reserved

Installation 1-8

Page 15

Set Node Address

Set the node address for the drive setting the 10‘s digit with S2 and the 1’s digit with S1. All devices on the network must have unique node

addresses. Check the network layout to verify that the node address selected is unique, matches the master configuration for that device and

falls between 3 – 9 9.

Address = (Switch 2 x 10) + (Switch 1 x 1)

Example: Set node address to 15

Set address switch 2 to "1 Set address switch 1 to "5"

0

1

9

6

S2

2

3

4

5

8

7

Figure 1.5 – Setting the V7 PROFIBUS-DP Option Node Address

0

1

9

6

S1

2

3

4

5

8

7

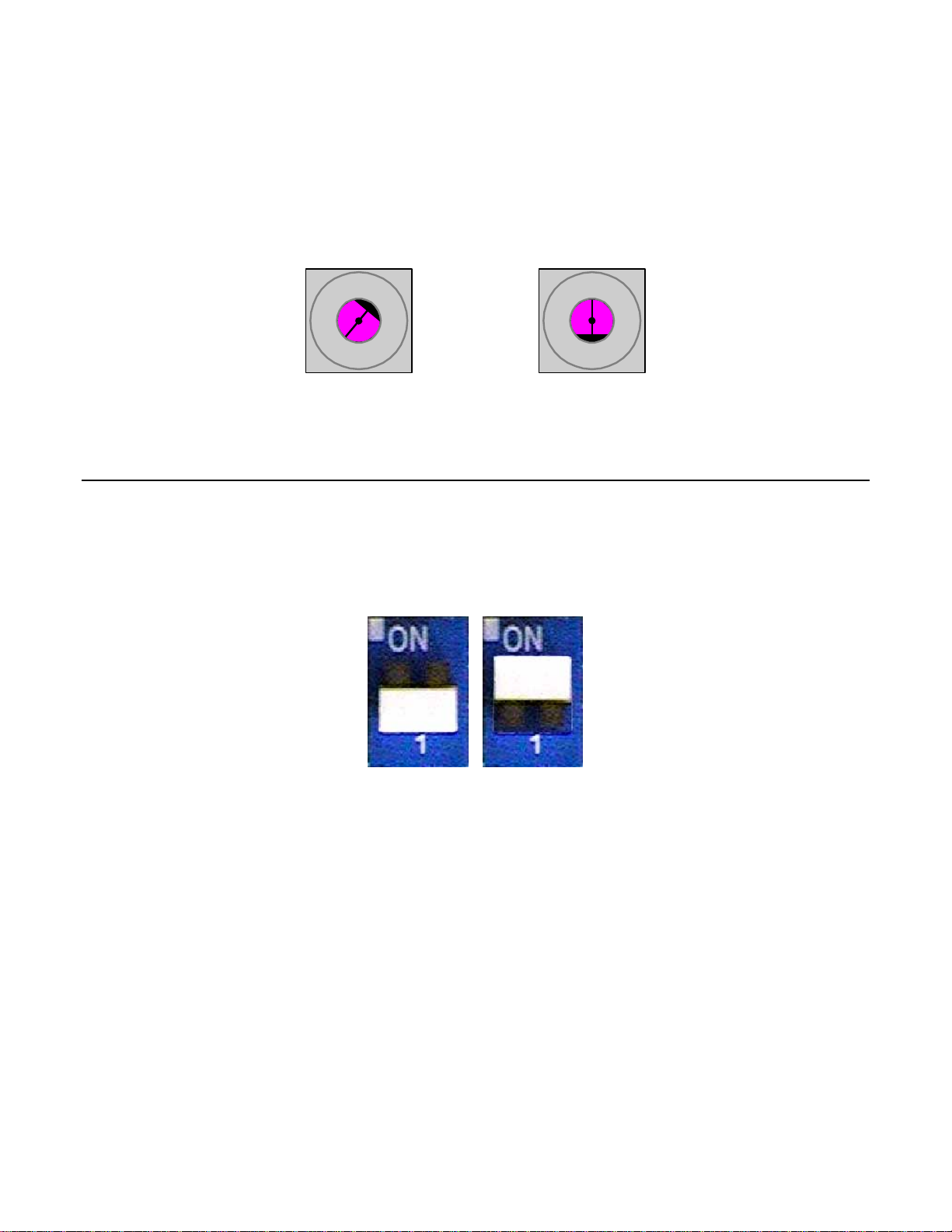

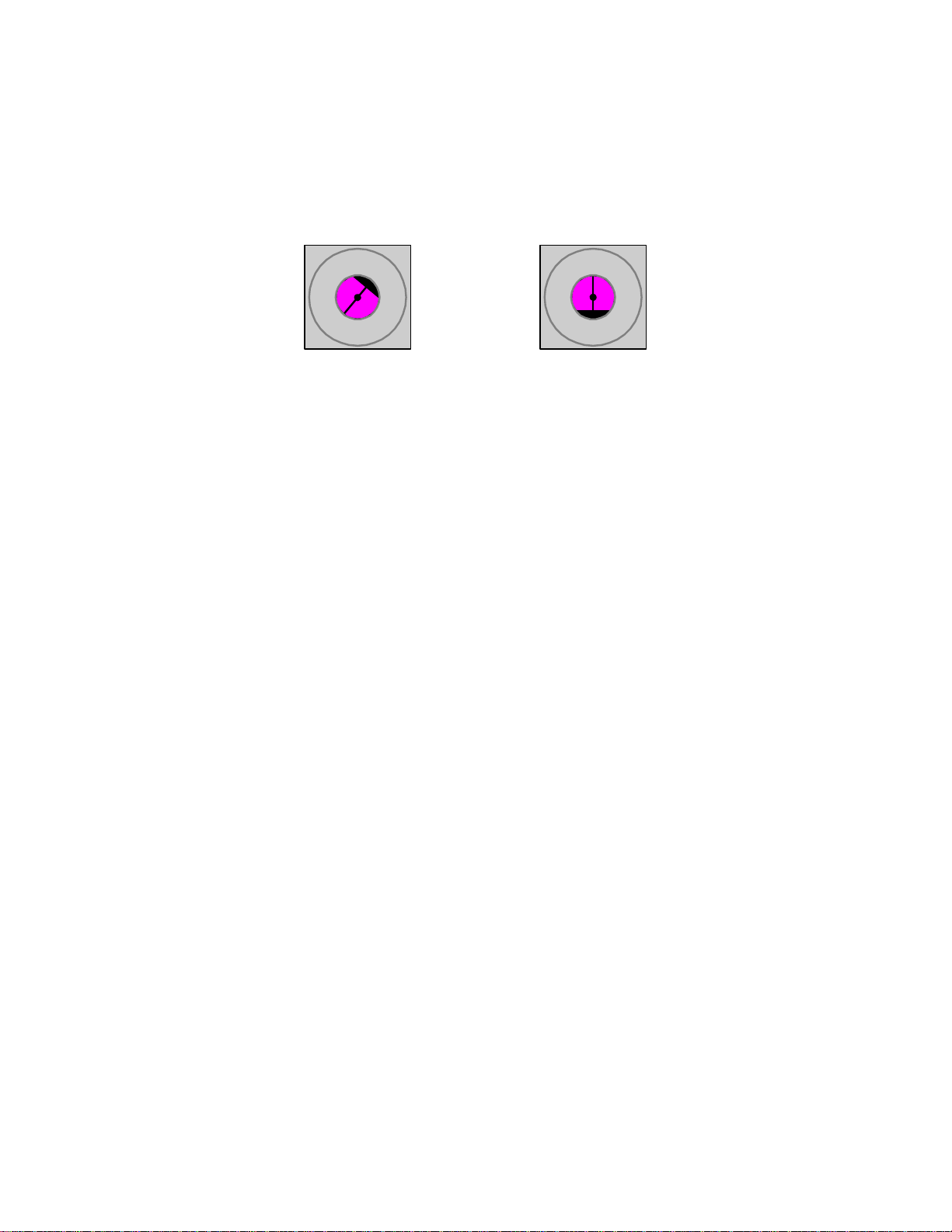

Set Network Termination

If this unit is either the first or the last device on the network, including any PLC and/or PROFIBUS-DP Master, and active termination is

not used, set the termination resistor switch to ON. If this device is not the first or last device on the network or active termination is used,

set the termination resistor switch to OFF. Active termination is the recommended termination method and is required for networks

operating above 1.5Mbps. Active termination will eliminate the possibility of network failure due to the removal of a terminated device.

The Siemens Active terminator Module part number is 6ES7 972-0DA00-0AA0.

OFF

Figure 1.6 – Termination Switch

ON

Installation 1-9

Page 16

Verify V7 PROFIBUS-DP Option Operation

Apply power to the drive.

Verify that the diagnostic LEDs on the front of the V7 PROFIBUS-DP Option are in their correct state.

Table 1.4 – Correct Diagnostic LED States

LED Display

PWR COM ERR WD

Solid Green Solid Green OFF Flashing Green Normal Normal communication possible.

Remove power from the drive and wait for the charge lamp to be com pletely extinguished. Wait at least five additional minutes

for the drive to be completely discharged. Measure the DC bus voltage and verify that it is at a safe level.

Secure the communication option to the drive, aligning the recessed screw at the top-center of the option with the threaded hole

in the mounting bracket.

Install the operator keypad and terminal cover.

Set drive parameters n003, n004 and n035 to appropriate values.

Table 1.5 – Option Specific Parameter Settings

Addr Param Function Data +/- Limits - Description Default

103h n003 Operation Method Selection

104h n004 Reference Selection

123h n035 Frequency Reference Unit Selection

Content Cause

0 Operator keypad

1 Terminal

2 Serial Communication

3

Option Card (PROFIBUS-DP Option)

0 Operator keypad Pot

1 Operator keypad

2 Voltage Reference (0-10v)

3 Current Reference (4-20 Ma)

4 Current Reference (0-20 Ma)

5 Pulse Train Reference

6 Serial Communication

7 Multi-Function Analog Input (0-10vdc)

8 Multi-Function Analog Input(4-20ma)

9

Option Card (PROFIBUS-DP Option)

0 0.01 Hz (< 100hz), 0.1hz (100 Hz >=100hz)

1 0.1%

2-39 Rpm

40-3999 User Setting

1

2

0

Installation 1-10

Page 17

Option LEDs

The PROFIBUS-DP Option Unit is equipped with four indication LEDs for module and PROFIBUS-DP status indication. The LEDs are

located on the unit according to the figure’s below.

Indicator LEDs

ERR

COMM

PWR

WD

Figure 1.8 – V7 PROFIBUS-DP LED Locations

LED Indicators

The following LEDs indicates the PROFIBUS-DP status.

Table 1.6 – Communication LEDs

LED Color Indication/Function

COMM Green Lit during data exchange with the PROFIBUS-DP Master .

ERR Red Lit when no data exchange is taken place.

Module Status Indicators

The following LEDs indicates the status of the V7 PROFIBUS-DP Option.

Table 1.7 – Diagnostic LEDs

LED Color Indication/Function

PWR Green Lit when the +5V power to the electronics is OK. Turned off if the +5V is below +4.5V (min)

WD Red/Green

Indicates the module status

OFF Communication Option CPU not running.

Solid Green: Initialization.

Flashing green: Normal operation.

Solid Red: Internal Communication Option error.

Flashing red: V7 error detected.

Other indication Unspecified, Communication Option error

Installation 1-11

Page 18

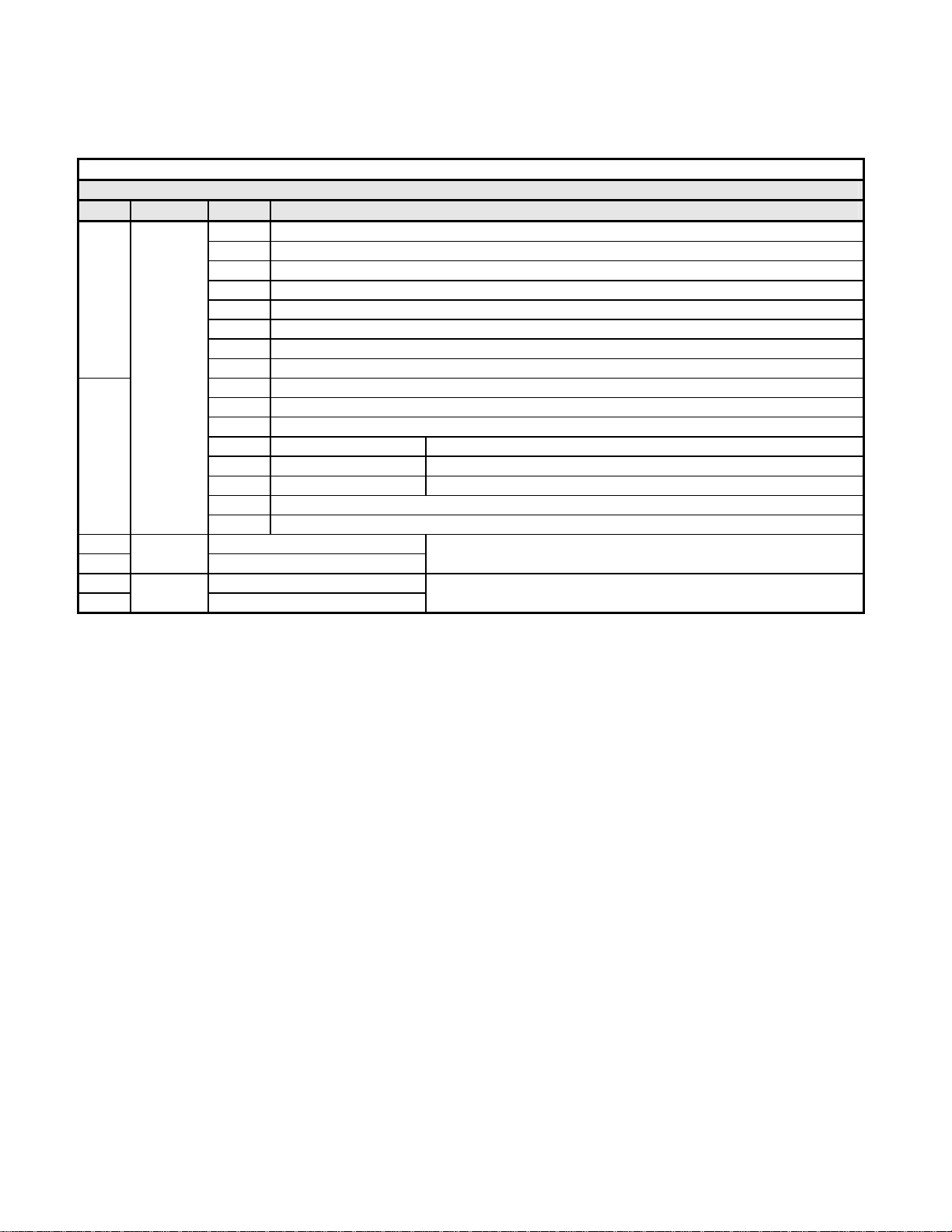

LED Diagnostics

The following table presents the faults displayed by the LEDs on the communication option, their causes, and solutions.

Table 1.8 – LED Diagnostics

LED Display

PWR COM ERR WD

OFF OFF OFF OFF

Solid

Green

Solid

Green

Solid

Green

Solid

Green

Solid

Green

Solid

Green

OFF

OFF

OFF

Solid

Green

Solid

Green

Solid

Green

Solid

Red

Solid

Red

Flashing

Red

Flashing

Red

OFF

OFF

Solid

Red

Flashing

Red

Solid

Green

Solid

Green

Solid

Green

Flashing

Green

Content Cause Solutions

Power

OFF

CPU

Error

Drive

Error

Com

Error

Com

Error

CPU

Init

Normal

Power is not being supplied

from the drive.

Power is not being supplied to

the option unit due to poor

option unit connection.

Option unit CPU error.

Error in Drive unit.

A fault has occurred rendering

communication impossible.

A fault has occurred rendering

communication impossible.

Option unit under initialization

Normal communication

possible.

• Check the main circuit wiring on the drive.

• Cycle drive power.

• Turn of the drive power .

• Check the option unit connection to the

drive.

• Cycle drive power.

• Cycle drive power.

• Replace option unit if fault persists.

• Cycle drive power.

• Replace V7 PROFIBUS-DP Option if fault

persists

• Replace drive if fault persists.

• Check whether the address set in the

PROFIBUS-DP Master differs from the

address of the option unit.

• Check that the master is functioning

properly.

• Check that the termination resistor is

correctly connected to the communication

line.

• Check whether the communication line is

correctly connected (disconnected or poor

connection).

• Check that the communication line is

separated from the main power line.

• Check whether the address is duplicated

with any other devices within the

PROFIBUS-DP network.

• Wait until WD LED is flashing

Installation 1-12

Page 19

Drive Faults

The following is a table of faults caused by the communication option that will be displayed on the V7 Operator Keypad, their causes, and

possible solutions. For any fault displayed on the operator that is not listed in the following table, please see the V7 Technical Manual.

Table 1.9 – Drive Faults

Fault Content Cause Solution

BUS Option Com Error

EF0 External Fault from Option

F06 Option Connection Fault

F21

F22

F23

Communication Option Selfdiagnostic Fault

Com Option Model Code No.

Fault

Com Option Mutual Diagnostic

Fault

Communication is not established

between PROFIBUS-DP Master and

the drive.

External fault is active from

PROFIBUS-DP option.

The drive and communication are not

correctly connected.

Communication option is not working.

• Check PROFIBUS-DP communication LED display.

• Turn OFF external fault input.

• Turn OFF the drive power supply and check the connection

of the option unit and drive, and then, turn ON the drive

power supply. If the fault persists, change the option unit.

• Turn the drive power supply back ON. If the fault persists,

replace the option unit.

Installation 1-13

Page 20

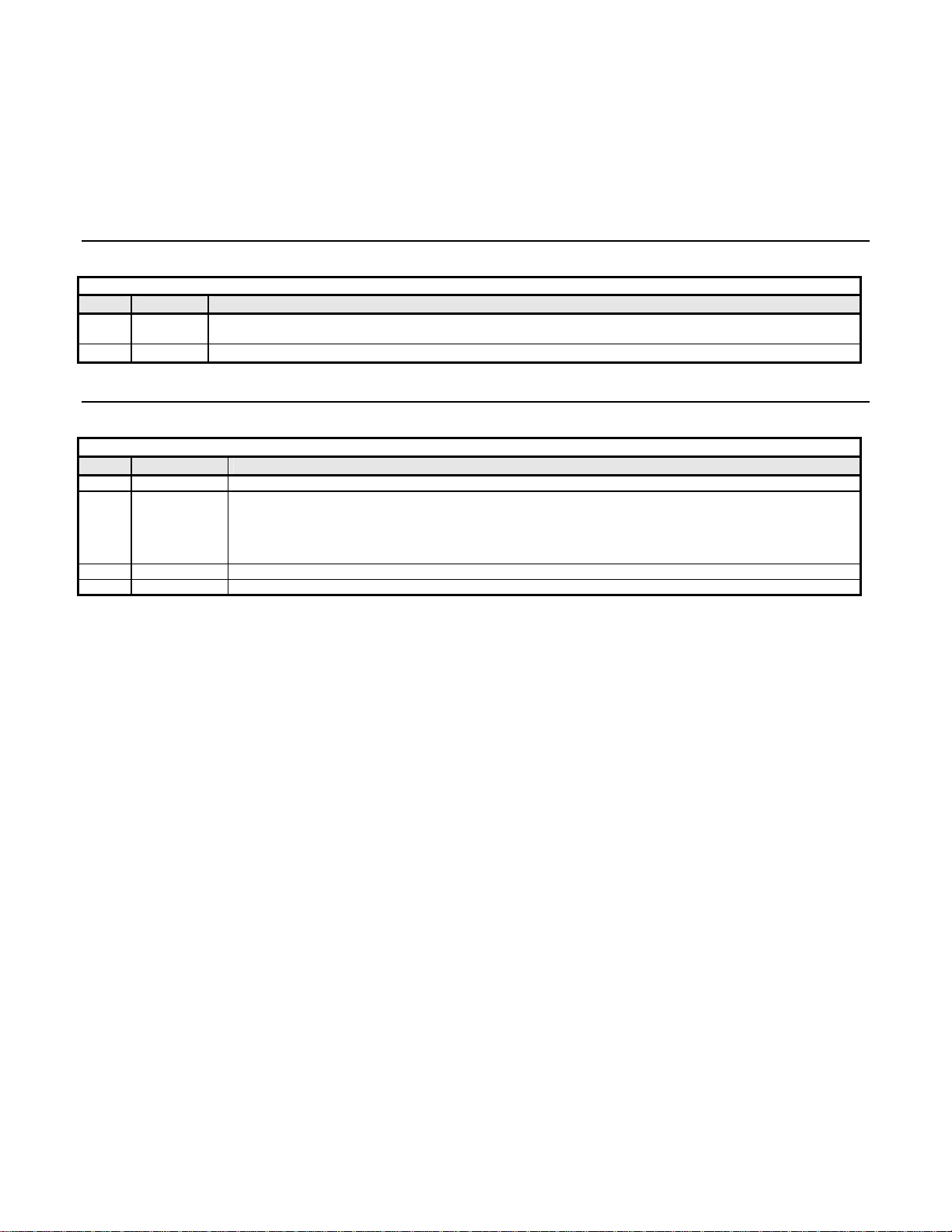

Parameter Settings

The following sections describe the parameters in the V7 that affect communications through the PROFIBUS-DP Communication Option.

For complete information on V7 drive parameters refer to the V7 MODBUS

®

T echnical Manual.

Run/Stop and Frequency Selection

The run/stop and frequency reference commands can originate from serial communication, the operator keypad, external terminals, or the

PROFIBUS-DP Option. Parameter n003 (Operation Method Selection) allows the selection of the origin of the run/stop commands.

Parameter n004 (Reference Selection) allows the selection of the origin of the frequency reference. The run/stop and frequency reference

commands may have different origins. The run/stop command may be set to External Terminals (n003 = 1) while the Frequency Reference

may be set to Option Card (PROFIBUS-DP Option) (n004 = 9).

Table 1.10 – Operation Method Selection

n003 Operation Method Selection (Run/Stop)

0 Operator keypad

1 External Terminals (Default setting is 1)

2 Serial Communication

3 Option Card (PROFIBUS-DP Option)

Table 1.11 – Frequency Reference Source Selection

n004 Frequency Reference Selection

0 Operator keypad Pot

1 Operator keypad

2 Voltage Reference (0-10V) (Default setting is 2)

3 Current Reference (4 to 20 mA)

4 Current Reference (0 to 20 mA)

5 Pulse Train Reference

6 Serial Communications (Parameter Access)

7 Multi- Function Analog Input (0 to 10V)

8 Multi-Function Analog Input (4 to 20mA)

9 Option Card (PROFIBUS-DP Option)

Installation 1-14

Page 21

Operator Display Mode

Parameter n035 sets the scaling and units of the frequency reference and output frequency on the operator keypad.. It also determines the

scaling and units of the Speed Command, Speed Reference, and Output Frequency used by the PROFIBUS-DP Option

Table 1.12 – Operator keypad Display Mode

n035 Description

0 0.1hz

1 0.1%

2 – 39 RPM (number of motor poles)

40 - 3999 User setting

Frequency Reference Units

Parameter n152 sets the resolution of the frequency reference and output frequency monitor. The output frequency resolution of the

operator keypad is settable via n035, Frequency Reference Unit Selection. If the operator keypad resolution is set to 0.1 Hz (n035=0), and

the resolution is changed to 0.01 Hz in n152, the value in the hundredths digit rounded off when displayed on the operator keypad.

Table 1.13 – Frequency Reference Unit Selection

n152 Frequency Reference Unit Selection

0 0.1 Hz (Default setting is 0)

1 0.01 Hz

2 100% / 30,000

3 0.1%

Installation 1-15

Page 22

This page intentionally left blank.

Installation 1-16

Page 23

Chapter 2 Network Configuration

This chapter provides an example configuration using the COM PROFIBUS

configuration utility from Siemens. It also explains the differences between the

three station configurations.

Configuration..................................................................... 2 - 3

GSD File ............................................................................. 2 - 6

Network Configuration 2-1

Page 24

This page intentionally left blank

Network Configuration 2-2

Page 25

Configuration

Once the V7 PROFIBUS-DP Option has been installed and the drive parameters set appropriately, it is necessary to add the drive to the

PROFIBUS-DP network through the use of a configuration tool. This tool is usually supplied by the vendor that supplied the PROFIBUSDP Master controller. This section provides a general overview of how to select the appropriate drive configuration. The Siemens COM

PROFIBUS configuration tool is used in the examples. The examples and descriptions below assume familiarity with both PROFIBUS-DP

network and setting up a PROFIBUS-DP Master for the devices on that network.

The PROFIBUS-DP Communication Option can be configured as one of three possible I/O configurations, 16 word input/output, 6 word

input/output and 3 word I/Os, combined input/output, messages. The structure of each message is described in Chapter 3 – Network

Communications.

Configure Master Device

Copy the GSD file from the CD that came with the V7 PROFIBUS-DP Option to the GSD sub-directory under the COM

PROFIBUS directory. The GSD file may also be downloaded from

Open COM PROFIBUS and configure the Master device. A Siemens 545-1104 is used in this example.

Select the DRIVES block from the list of available devices. The cursor should change to Move the cursor to below

the icon representing the Master device and press the left mouse button.

http://www.drives.com

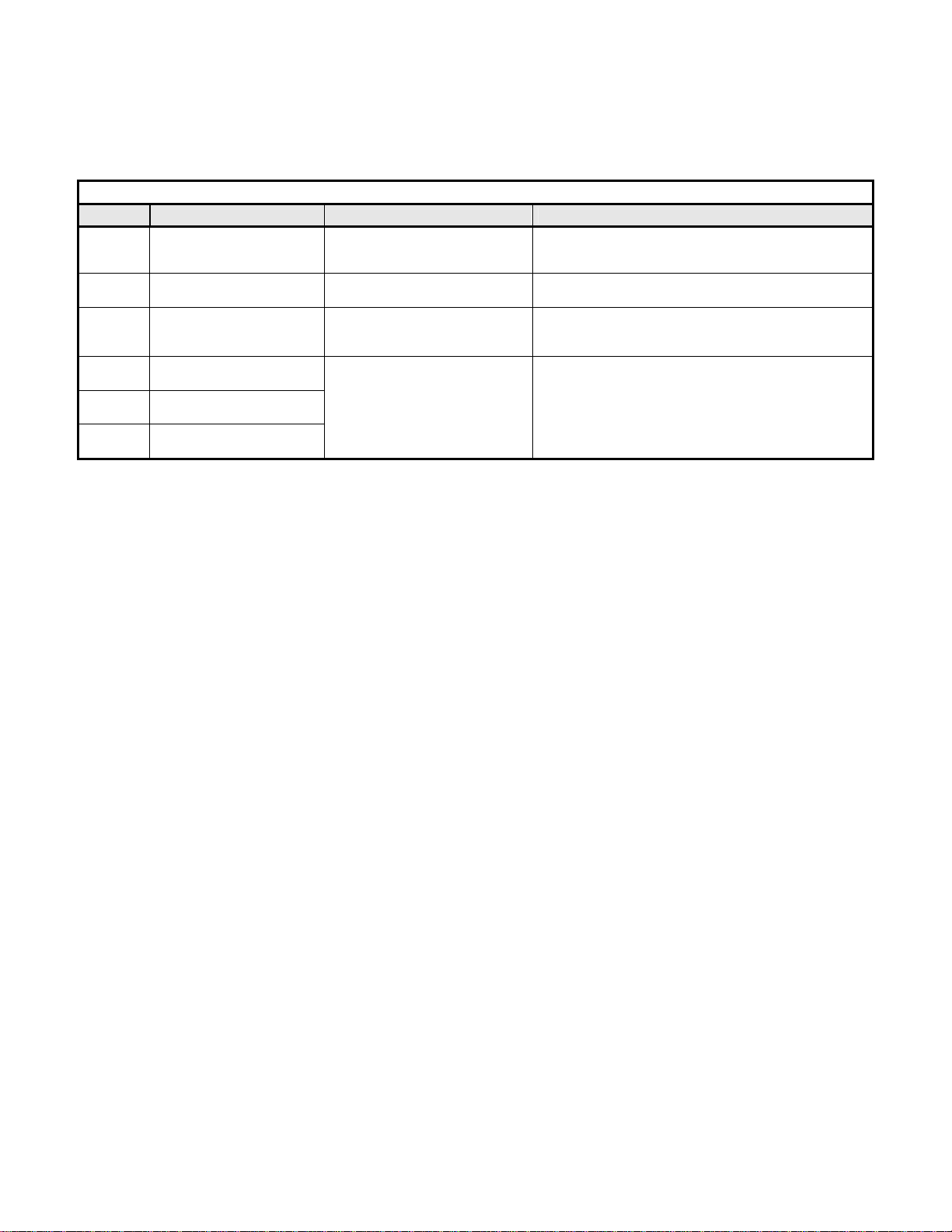

Figure 2.1 – Select Drive

Select Drive Address

A list box will appear displaying the available addresses for the drive. Select an address for the drive and click on the OK button. The

address selected must match the address switch setting on the V7 PROFIBUS-DP Option for the drive selected. Refer to the engineering

documentation or network schematic to determine which address is applicable for the drive selected.

Figure 2.2 – Select Address

Network Configuration 2-3

Page 26

Select Station Type

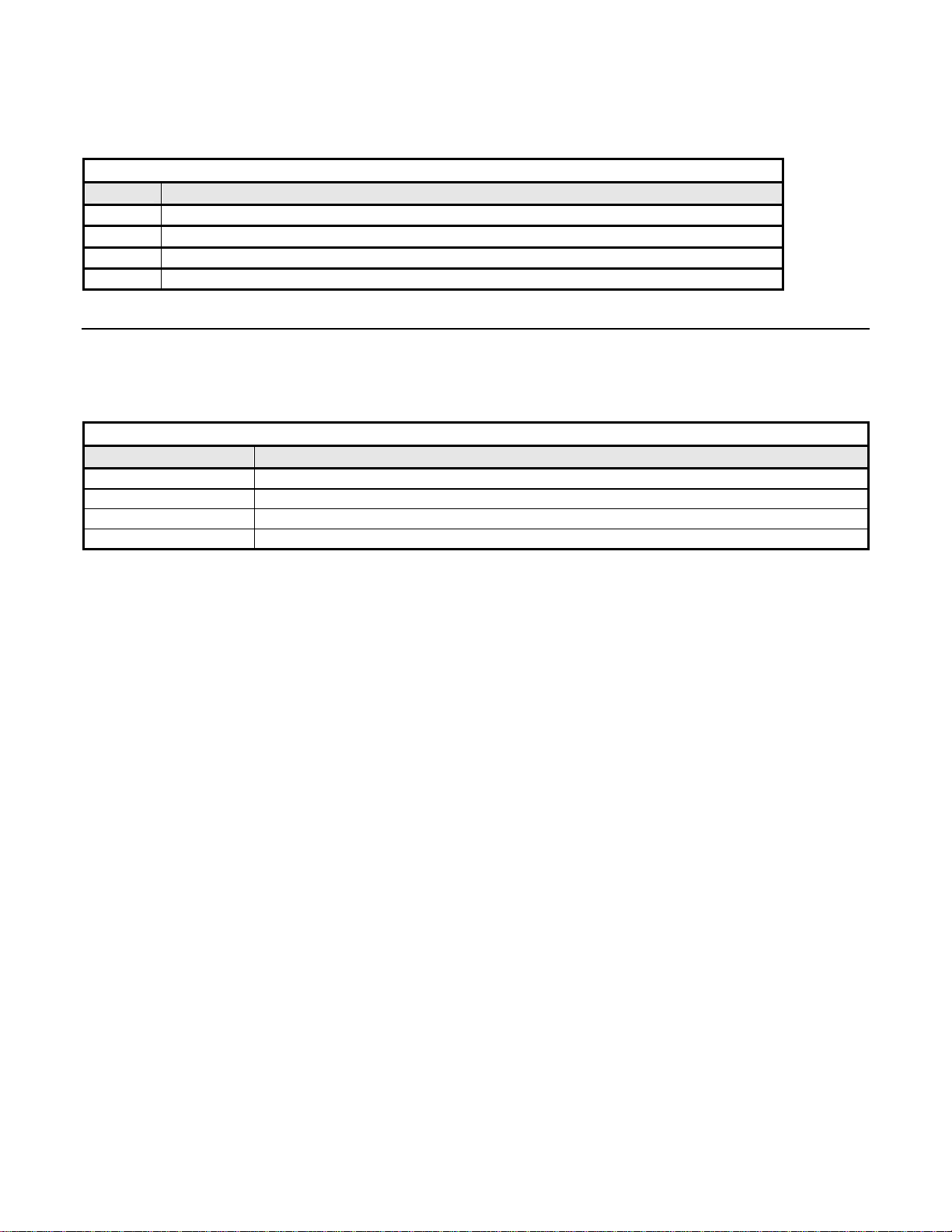

Select the appropriate station type from the list displayed. The V7 PROFIBUS-DP Option is listed as PROFIBUS-DP INTER. Highlight

the selection and click on the Configure button.

Figure 2.3 – Select Station Type

Station Configuration

Select the configuration desired. Basic Data consists of 3 word I/Os, combined input/output. Extended Data 1 consists of 16 input words

and 16 output words. Extended Data 2 consists of 6 input words and 6 output words.

Figure 2.4 – Select Configuration

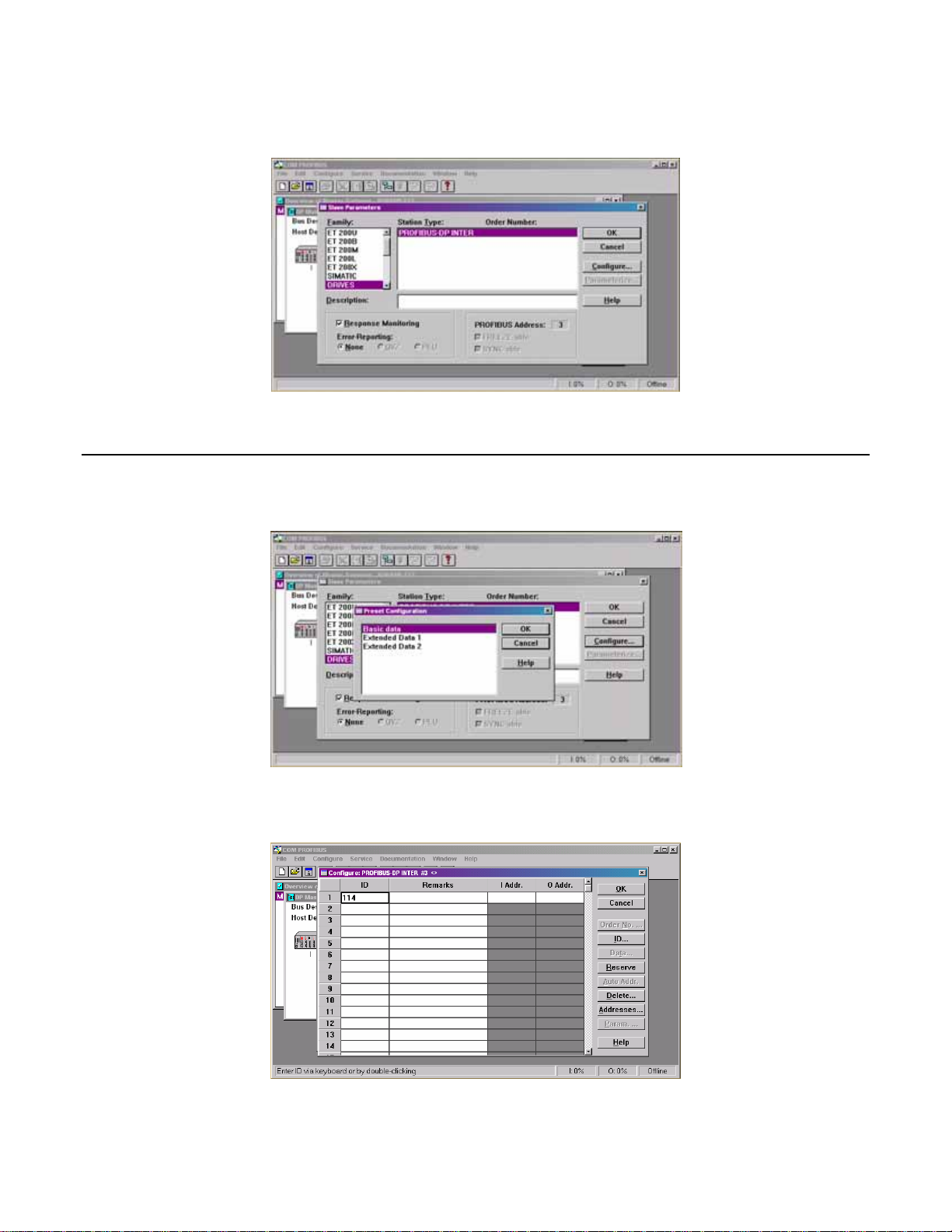

The Basic Data configuration consists of 6 words of combined I/O. 3 input words and 3 output words. Refer to 3 Word I/O

Message section of Chapter 3 for a detailed description of the Basic Data configuration .

Figure 2.5 – Basic Data Configuration

Network Configuration 2-4

Page 27

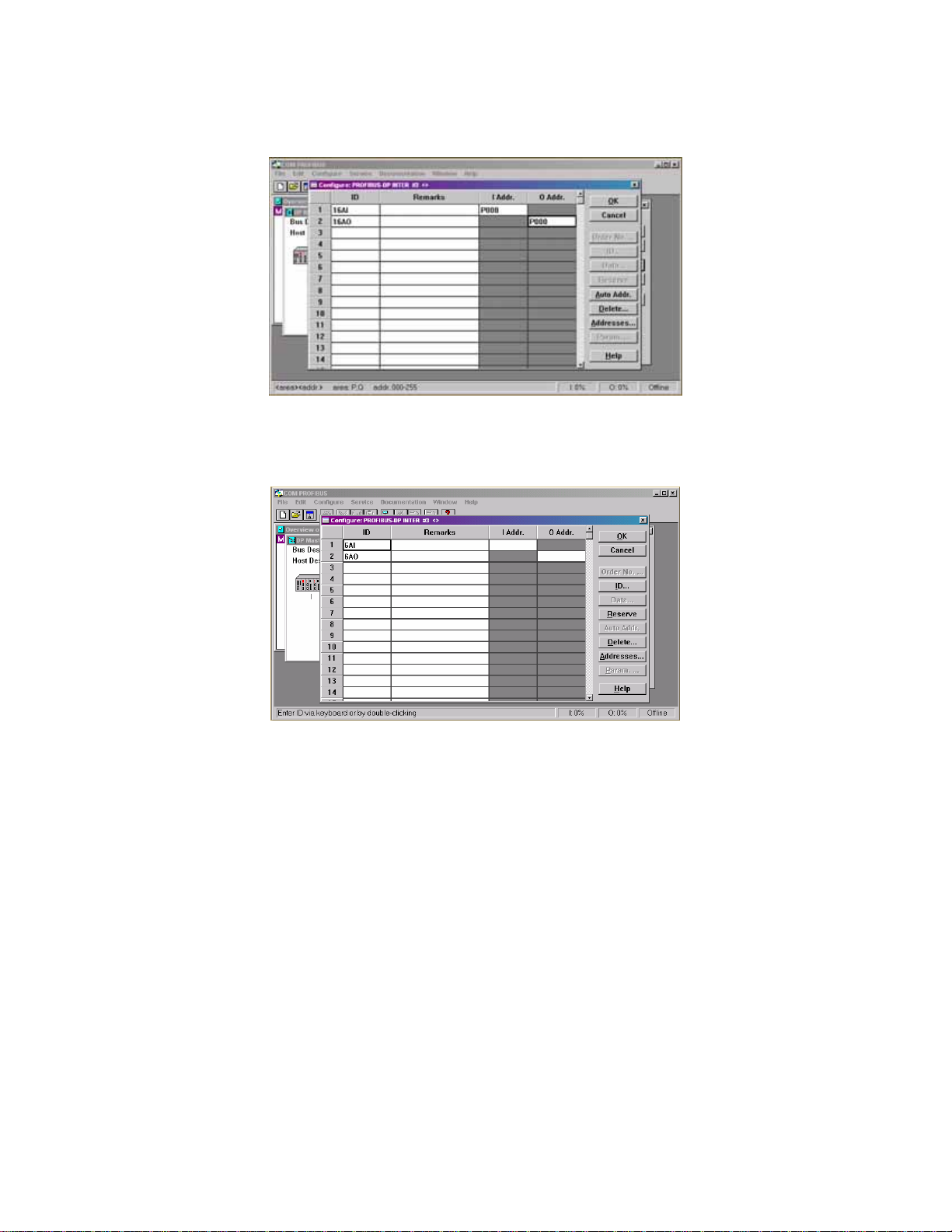

The Extended Data 1 configuration consists of 16 input words and 16 output words. Refer to 16 Word Input/Output Message

section of Chapter 3 for a detailed description of the Extended Data 1 configuration. This configuration is also used on those V7

PROFIBUS-DP Options that have an Option Name SI-P/V7 or Code Numbers prior to 73606-7110. The Option Name and Code

Number are located on the right side of the option.

Figure 2.6 – Extended Data 1 Configuration

The Extended Data 2 configuration consists of 6 input words and 6 output words. Refer to 6 W ord Input/Output Message section

of Chapter 3 for a detailed description of the Extended Data 2 configuration. This configuration is also used on those V7

PROFIBUS-DP Options previously released as Profibus II.

Figure 2.6 – Extended Data 2 Configuration

Network Configuration 2-5

Page 28

GSD File

The listing of the current GSD file is shown below. The GSD file name is YASK00CA.GSD. The file is listed for information purposes only. Do not attempt to

modify the GSD file in any way.

;=====================================================================

; Device description file according to DIN 19245 Part 3 (PROFIBUS-DP)

;=====================================================================

;; FILENAME : YASK00CA_Rev1YEA.GSD

;--------------------------------------------------------------------; DEVICENAME : PROFIBUS-DP INTERFACE CARD SI-P1

;--------------------------------------------------------------------; PROTOCOL : PROFIBUS-DP slave

;--------------------------------------------------------------------; VENDOR : Yaskawa Electric

;--------------------------------------------------------------------; DATE : 06 June 2001

;--------------------------------------------------------------------; MODIFICATIONS : 06 June 2001, rev. 3.0 Created

; 08 April 2002, TW,rev 3.3 Revised for customer compatibility

;;=====================================================================

#PROFIBUS_DP

GSD_Revision = 1

Vendor_Name = "YASKAWA ELECTRIC"

Model_Name = "PROFIBUS-DP INTERFACE CARD SI-P1"

Revision = "Version 3.3"

Ident_Number = 0x00CA

Protocol_Ident = 0

Station_Type = 0

FMS_supp = 0

Hardware_Release = "Version 1.3"

Software_Release = "Version 3.3"

9.6_supp = 1

19.2_supp = 1

45.45_supp = 1

93.75_supp = 1

187.5_supp = 1

500_supp = 1

1.5M_supp = 1

3M_supp = 1

6M_supp = 1

12M_supp = 1

MaxTsdr_9.6 = 60

MaxTsdr_19.2 = 60

MaxTsdr_45.45 = 250

MaxTsdr_93.75 = 60

MaxTsdr_187.5 = 60

MaxTsdr_500 = 100

MaxTsdr_1.5M = 150

MaxTsdr_3M = 250

MaxTsdr_6M = 450

MaxTsdr_12M = 800

Redundancy = 0

Repeater_Ctrl_Sig = 2

24V_Pins = 0

Implementation_Type = "SPC3"

Freeze_Mode_supp = 1

Sync_Mode_supp = 1

Auto_Baud_supp = 1

Set_Slave_Add_supp = 0

Min_Slave_Intervall = 1

Modular_Station = 1

Max_Module = 1

Max_Input_Len = 32

Max_Output_Len = 32

Max_Data_Len = 64

Modul_Offset = 1

Fail_Safe = 0

Slave_Family = 1

Max_Diag_Data_Len = 6

Module = "Basic data" 0x72

EndModule

Module = "Extended Data 1" 0x5F, 0x6F

EndModule

Module = "Extended Data 2" 0x55, 0x65

EndModule

Network Configuration 2-6

Page 29

Chapter 3 Network Communications

This chapter describes in detail the composition of the three station types.

16 Word Input/Output Messages...................................... 3 - 3

6 Word Input/Output Messages........................................ 3 - 7

3 Word I/Os Messages .................................................... 3 - 10

Parameter Access Error Messages................................ 3 - 12

Handshaking.................................................................... 3 - 13

Network Communications 3-1

Page 30

This page intentionally left blank.

Network Communications 3-2

Page 31

16 Word Input/Output Message

The V7 PROFIBUS-DP Option can be configured as one of three possible I/O configurations; 16 word input/output message, 6 word

input/output message and 3 word I/Os, combined input/output, messages. The 16 word input/output message structure is described in this

section.

The 16 word input and output messages are divided into two areas. The first 16 bytes of each message is fixed. This is the most frequently

used data and is referred to as the fast I/O data. The remaining 16 bytes of each message are used for reading from and writing to all other

drive parameters and is referred to as parameter data. All command, monitor, and parameter data in the drive is accessible via the

Parameter Access portion of the message.

Table 3.1 – V7 PROFIBUS-DP 16 Word Input/Output Message Table

Output Data (PROFIBUS-DP Master-> V7) Input Data (V7 -> PROFIBUS-DP Master )

Byte Function Byte Function

0 RUN Operation Command MSB 0 Drive Status MSB

1 RUN Operation Command LSB 1 Drive Status LSB

2 Frequency Reference MSB 2 Reserved

3 Frequency Reference LSB 3 Reserved

4 Reserved 4 Reserved

5 Reserved 5 Reserved

6 Reserved 6 Reserved

7 Reserved 7 Reserved

8 Reserved 8 Frequency Reference MSB

9 Reserved 9 Frequency Reference LSB

Fast I/O Area

10 Reserved 10 Output Frequency MSB

11 Reserved 11 Output Frequency LSB

12 Reserved 12 Output Current MSB

13 Reserved 13 Output Current LSB

14 Multifunction Digital Output MSB 14 Main Speed Pulse Train Command MSB

15 Multifunction Digital Output LSB

Function Code

16

17 Starting Address MSB 17 Starting Address MSB

18 Starting Address LSB 18 Starting Address LSB

19 Data Length (2, 4, 6 or 8 bytes of data) 19 Data Length (2, 4, 6 or 8 bytes of data)

20 Data 1 MSB 20 Data 1 MSB

21 Data 1 LSB 21 Data 1 LSB

22 Data 2 MSB 22 Data 2 MSB

23 Data 2 LSB 23 Data 2 LSB

24 Data 3 MSB 24 Data 3 MSB

25 Data 3 LSB 25 Data 3 LSB

26 Data 4 MSB 26 Data 4 MSB

Parameter Access Area

27 Data 4 LSB 27 Data 4 LSB

28 Reserved 28 Reserved

29 Reserved 29 Reserved

30 Reserved 30 Reserved

31 Handshake Register

Fast I/O Area

15 Main Speed Pulse Train Command LSB

16

Function Code

Parameter Access Area

31 Handshake Register

Network Communications 3-3

Page 32

Fast I/O Output Data

The fast I/O output data area is used to transfer parameter data directly to the drive via a dual port RAM interface. The following table

details the functions of the fast I/O output data (Bytes 0 to 15) For detailed explanation of the terminal and multi-function inputs and

outputs, refer to the V7 Technical Manual.

Table 3.2 – 16 Word Input/Output Message Fast I/O Output Data

Fast I/O Output Data (PROFIBUS-DP Master -> V7)

Byte Function Bit Note

0 Fwd Run/Stop 1 = RUN Forward (Enabled when n003 is set to 3)

1 Rev Run/Stop 1 = RUN Reverse (Enabled when n003 is set to 3)

2 Terminal S3 1 = Close (terminal function dependent on setting of parameter n052)

0

Command

Reference

1

2 Frequency Reference MSB

Frequency

Reference

3

4 - 13 Reserved Must be set 0

Multi-Function

14

Output

Reserved

15

3 Terminal S4 1 = Close (terminal function dependent on setting of parameter n053)

4 Terminal S5 1 = Close (terminal function dependent on setting of parameter n054)

5 Terminal S6 1 = Close (terminal function dependent on setting of parameter n055)

6 Terminal S7 1 = Close (terminal function dependent on setting of parameter n056)

7 Reserved

8 External Fault 1 = External Error

9 Fault Reset 1 = Reset Fault

Ah - Fh Reserved

0.01Hz

Frequency Reference LS

0

Terminal MA MB MC 1 = Close (terminal function dependent on setting of parameter n057)

1

Terminal P1-PC 1 = Close (terminal function dependent on setting of parameter n058)

2

Terminal P2-PC 1 = Close (terminal function dependent on setting of parameter n059)

3 - Fh

Reserved

scaling is dependent on the setting of parameter n035

Network Communications 3-4

Page 33

Fast I/O Input Data

The fast I/O input data area is used to transfer parameter data directly from the drive via a dual port RAM interface. The following table

details the functions of the fast I/O input data (Bytes 0 to 15). For detailed explanation of the terminal and multi-function inputs and

outputs, refer to the V7 Technical Manual.

Table 3.3 – 16 Word Input/Output Message Fast I/O Input Data

Fast I/O Input Data (V7 -> PROFIBUS-DP Master )

Byte Function Bit Note

0 Running

1 @ Zero Speed

2 @ Reverse

0

Drive

Status

1

2 - 7 Reserved Always 0

8 Frequency Reference MSB

Frequency

Reference

9

10 Output Frequency MSB

Output

Frequency

11

12 Output Current MSB

Output

Current

13

Frequency

14 Pulse Train MSB

Reference

Pulse Train

15

Terminal PR

3 Reset Signal

4 @ Frequency Agree

5 Drive Ready (Rdy)

6 Minor Fault

7 Major Fault

8 OPE Error

9 Fault Restart

10 Local/Remote

11 Multi-function Output 1 1 = Close (terminal function dependent on setting of parameter n057)

12 Multi-function Output 2 1 = Close (terminal function dependent on setting of parameter n058)

13 Multi-function Output 3 1 = Close (terminal function dependent on setting of parameter n059)

14 Reserved

15 Reserved

0.01Hz

Frequency Reference LSB

Output Frequency LSB

Output Current LSB

Pulse train LSB

scaling is dependent on the setting of parameter n035

0.01Hz

scaling is dependent on the setting of parameter n035

0.1A

Parameter Access Area

This area is used to read and write parameter data from and to the drive. The PROFIBUS-DP Master completes the Parameter Access

command (output) message and waits for and then processes the data returned in the Parameter Access response (input) message. These

messages may contain 1 - 4 words of data. The handshaking byte is used to synchronize the communications between the PROFIBUS-DP

Master and the drive. This is necessary due to the additional time required for the drive to process the message. Refer to the Handshaking

section of this chapter for more information on handshaking. Note: Care must be taken when writing certain parameters to the V7 drive as

other parameters may be dependant on them. Control method, n002, maximum Frequency, n011, and Acc/Dec Scale Time, n018, are just a

few parameters whose setting will affect other parameter’s settings or ranges.. Refer to V7 MODBUS

information.

Network Communications 3-5

®

T echnical Manual for more

Page 34

Parameter Access Command Message Structure

Two command, output, functions are available, read parameter data, 03h, and write parameter data, 10h. If no parameter access

communications is desired, use 00h as the function code. These function codes are programmed in byte 16 of the 16 word input/output

message. Bytes 17 and 18 contain the parameter access address of the parameter to be accessed. Byte 19 contains the number of data bytes

to be read from or written to the drive. Since each parameter consists of two bytes, this value is incremented by two for each parameter

accessed. Bytes 19 through 27 contain the data to be written to the selected parameter. If the command is to read parameter data, bytes 19

through 27 must be set to 0.

Table 3.4 – 16 Word Input/Output Message Parameter Access Command Structure

Output Data – Parameter Access Command Message (PROFIBUS-DP Master -> V7)

Byte Name Function

16 Function Code

17 Starting Address MSB

18 Starting Address LSB

19 Data Quantity Bytes of data (2 x Number of parameters to be read or written)

20 Data 1 MSB

21 Data 1 LSB

22 Data 2 MSB

23 Data 2 LSB

24 Data 3 MSB

25 Data 3 LSB

26 Data 4 MSB

27 Data 4 LSB

28 Reserved

29 Reserved

30 Reserved

31 Handshaking Register Synchronizes drive communication with PROFIBUS-DP Master

Parameter Access Command Code (Read data = 03h, Write data = 10h)

The first register to be read or written

Value of data to write to the drive parameter Starting Address

Value of data to write to the drive parameter Starting Address + 1

Value of data to write to the drive parameter Starting Address + 2

Value of data to write to the drive parameter Starting Address + 3

Parameter Access Response Message Structure

The standard Parameter Access response structure is described below. In a non-erroneous response, the Function Code, Starting Register

and Data Quantity are identical to the command messa ge. If the command function code is 03h, read data, the data bytes will contain the

values of the requested parameters. If the command function code is 10h, write data, the data bytes will contain 0 and should be ignored.

Table 3.5 – 16 Word Input/Output Message Parameter Access Response Structure

Input Data – Parameter Access Response Message (V7 -> PROFIBUS-DP Master )

Byte Name Function

16 Function Code

17 Starting Address MSB

18 Starting Address LSB

19 Data Quantity Bytes of data (2 x Number of parameters to be read or written)

20 Data 1 MSB

21 Data 1 LSB

22 Data 2 MSB

23 Data 2 LSB

24 Data 3 MSB

25 Data 3 LSB

26 Data 4 MSB

27 Data 4 LSB

28 Reserved

29 Reserved

30 Reserved

31 Handshaking Register Synchronizes drive communication with PROFIBUS-DP Master

Parameter Access Response Code (Command code or command code & 80h for error)

The first register to be read or written

Value of data read from the drive parameter Starting Address

Value of data read from the drive parameter Starting Address + 1

Value of data read from the drive parameter Starting Address + 2

Value of data read from the drive parameter Starting Address + 3

Network Communications 3-6

Page 35

6 Word Input/Output Message

The 6 word input and output messages are divided into two areas. The first 4 bytes of each message is fixed. This is the most frequently

used data and is referred to as the fast I/O data. The remaining 8 bytes of each message are used for reading from and writing to all other

drive registers and is referred to as parameter data. All command, monitor, and parameter data in the drive is accessible via the Parameter

Access portion of the message. . Note: Care must be taken when writing certain parameters to the V7 drive as other parameters may be

dependant on them. Control method, n002, maximum Frequency, n011, and Acc/Dec Scale Time, n018, are just a few. Refer to V7

MODBUS

The 6 word input and output messages was designed for situations where processor memory may be a factor in the number of PROFIBUSDP devices resident on the network.

Byte Function Byte Function

Fast I/O

Parameter Access

®

T echnical Manual for more information.

Table 3.7 – V7 PROFIBUS-DP 6 Word Input/Output Message I/O Table

Output Data (PROFIBUS-DP Master -> V7) Input Data (V7 -> PROFIBUS-DP Master )

0 RUN Operation Command MSB 0 Drive Status MSB

1 RUN Operation Command LSB 1 Drive Status LSB

2 Frequency Reference MSB 2 Frequency Feedback MSB

3 Frequency Reference LSB

Function Code

4

5 Starting Address MSB 5 Starting Address MSB

6 Starting Address LSB 6 Starting Address LSB

7 Data Length (always 2) 7 Data Length (always 2)

8 Data 1 MSB 8 Data 1 MSB

9 Data 1 LSB 9 Data 1 LSB

10 Reserved 10 Reserved

11 Reserved 11 Reserved

12 Handshake Register

Fast I/O

3 Frequency Feedback LSB

4

Function Code

Parameter Access

12 Handshake Register

Fast I/O Output Data

The fast I/O output data area is used to transfer parameter data directly to the drive via a dual port RAM interface. The following table

details the functions of the fast I/O output data (Bytes 0 to 3) For detailed explanation of the terminal and multi-function inputs and

outputs, refer to the V7 Technical Manual.

Table 3.8 – 6 Word Input/Output Message Fast I/O Output Data

Fast I/O Output Data (PROFIBUS-DP Master -> V7)

Byte Function Bit Note

0 Fwd Run/Stop 1 = RUN Forward (Enabled when n003 is set to 3)

1 Rev Run/Stop 1 = RUN reverse (Enabled when n003 is set to 3)

2 Terminal S3 1 = Close (terminal function dependent on setting of parameter n052)

0

Command

Reference

1

2 Frequency Reference MSB

Frequency

Reference

3

3 Terminal S4 1 = Close (terminal function dependent on setting of parameter n053)

4 Terminal S5 1 = Close (terminal function dependent on setting of parameter n054)

5 Terminal S6 1 = Close (terminal function dependent on setting of parameter n055)

6 Terminal S7 1 = Close (terminal function dependent on setting of parameter n056)

7 Reserved

8 External Fault 1 = External Error

9 Fault Reset 1 = Reset Fault

Ah – Fh Reserved

0.01Hz

Frequency Reference LSB

scaling is dependent on the setting of parameter n035

Network Communications 3-7

Page 36

Fast I/O Input Data

The fast I/O input data area is used to transfer parameter data directly from the drive via a dual port RAM interface. The following table

details the functions of the fast I/O input data (Bytes 0 to 3) For detailed explanation of the terminal and multi-function inputs and outputs,

refer to the V7 Technical Manual.

Table 3.9 – 6 Word input/Output Message Fast I/O Input Data

Fast I/O Input Data (V7 -> PROFIBUS-DP Master )

Byte Function Bit Note

0 Running

1 @ Zero Speed

2 @ Reverse

0

Drive

Status

1

2 Frequency Reference MSB

Frequency

Reference

3

3 Reset Signal

4 @ Frequency Agree

5 Drive Ready (Rdy)

6 Minor Fault

7 Major Fault

8 OPE Error

9 Fault Restart

10 Local/Remote

11 Multi-function Output 1 1 = Close (terminal function dependent on setting of parameter n057)

12 Multi-function Output 2 1 = Close (terminal function dependent on setting of parameter n058)

13 Multi-function Output 3 1 = Close (terminal function dependent on setting of parameter n059)

14 Reserved

15 Reserved

0.01Hz

Frequency Reference LSB

scaling is dependent on the setting of parameter n035

Parameter Access Area

This area is used to read and write parameter data from and to the drive. The PROFIBUS-DP Master completes the Parameter Access

command (output) message and waits for and then processes the data returned in the response (input) message. These messages may

contain 1 - 4 words of data. The handshaking byte is used to synchronize the communications between the PROFIBUS-DP Master and the

drive. This is necessary due to the additional time required for the drive to process the message.

Network Communications 3-8

Page 37

Parameter Access Command Message Structure

Two command, output, functions are available, read parameter data, 03h, and write parameter data, 10h. If no Parameter Access

communications is desired, use 00h as the function code. These function codes are programmed in byte 4 of the 6 word input/output

message. Bytes 5 and 6 contain the address of the parameter to be accessed. Byte 7 contains the number of data bytes to be read from or

written to the drive. Since only one parameter may be accessed at a time, this value must always be set to 2. Bytes 8 and 9 contain the data

to be written to the selected parameter. If the command is to read parameter data, bytes 8 and 9 must be set to 0.

Table 3.10 – 6 Word Input/Output Message Parameter Access Command Messages

Output Data – Parameter Access Command Message (PROFIBUS-DP Master -> V7)

Byte Name Function

4 Function Code

5 Starting Address MSB

6 Starting Address LSB

7 Data Quantity (Bytes of data (2 x Number of parameters to be read or written)

8 Data 1 MSB

9 Data 1 LSB

10 Reserved

11 Reserved

12 Handshaking Register Synchronizes drive communication with PROFIBUS-DP Master

Parameter Access Command Code (Read data = 03h, Write data = 10h)

The first register to be read or written

Value of data to write to the drive parameter Starting Address

Parameter Access Response Message Structure

The standard Parameter Access response structure is described below. In a non-erroneous response, the Function Code, Starting Address

and Data Quantity are identical to the command messa ge. If the command function code is 03h, read data, the data bytes will contain the

values of the requested registers. If the command function code is 10h, write data, the data bytes will contain 0 and should be ignored.

Table 3.11 – 6 Word Input/Output Message Parameter Access Response Structure

Input Data – Parameter Access Response Message (V7 -> PROFIBUS-DP Master )

Byte Name Function

4 Function Code

5 Starting Address MSB

6 Starting Address LSB

7 Data Quantity Bytes of data (2 x Number of parameters to be read or written) (always 2)

8 Data 1 MSB

9 Data 1 LSB

10 Reserved

11 Reserved

12 Handshaking Register Synchronizes drive communication with PROFIBUS-DP Master

Parameter Access Response Code (Command code or command code & 80h for error)

The first register to be read or written

Value of data read from the drive parameter Starting Address

Network Communications 3-9

Page 38

3 Word I/Os Message

The 3 word I/Os messages have only one fixed area. This is the most frequently used data and is referred to as the fast I/O data. 6 Byte

messages are used when processor memory is a critical factor in the network design. As shown below the 3 word I/Os message contains

only the minimum drive data.

Table 3.12 – V7 PROFIBUS-DP 3 Word Message I/O Table

OUTPUT DATA PROFIBUS-DP Master -> V7 INPUT DATA V7 -> PROFIBUS-DP Master

Byte Function Byte Function

0 RUN Operation Command MSB 0 Drive Status MSB

1 RUN Operation Command LSB 1 Drive Status LSB

2 Frequency Reference MSB 2 Frequency Reference MSB

3 Frequency Reference LSB 3 Frequency Reference LSB

Fast I/O

4 Torque Reference MSB 4 Torque Reference MSB

5 Torque Reference LSB

Fast I/O Output Data

The fast I/O output data area is used to transfer parameter data directly to the drive via a dual port RAM interface. The following table

details the functions of the fast I/O output data (Bytes 0 to 5) For detailed explanation of the terminal and multi-function inputs and outputs,

refer to the V7 Technical Manual.

Fast I/O

5 Torque Reference LSB

Table 3.13 – 3 Word Message Fast I/O Output Data

Fast I/O Output Data (PROFIBUS-DP Master -> V7)

Byte Function Bit Note

0 Fwd Run/Stop 1 = RUN Forward (Enabled when n003 is set to 3)

1 Rev Run/Stop 1 = RUN reverse (Enabled when n003 is set to 3)

2 Terminal S3 1 = Close (terminal function dependent on setting of parameter n052)

0

Command

Reference

1

2 Frequency Reference MSB

Frequency

Reference

3

4 Torque Reference MSB

Torque

Reference

5

3 Terminal S4 1 = Close (terminal function dependent on setting of parameter n053)

4 Terminal S5 1 = Close (terminal function dependent on setting of parameter n054)

5 Terminal S6 1 = Close (terminal function dependent on setting of parameter n055)

6 Terminal S7 1 = Close (terminal function dependent on setting of parameter n056)

7 Reserved

8 External Fault 1 = External Error

9 Fault Reset 1 = Reset Fault

Ah - Fh Reserved

1 = 0.01Hz or 1 = 1 RPM

Frequency Reference LSB

Torque Reference LSB

scaling is dependent on the setting of parameter n035

0 – 100%

Network Communications 3-10

Page 39

Fast I/O Input Data

This area is used to transfer parameter data directly from the drive dual port RAM interface. The following tables detail the functions of

the fast I/O input data (Bytes 0 to 5)

Table 3.14 – 3 Word Message Fast I/O Input Data

Fast I/O Input Data (V7 -> PROFIBUS-DP Master )

Byte Function Bit Note

0 Running

1 @ Zero Speed

2 @ Reverse

0

Drive

Status

1

2 Frequency Reference MSB

Frequency

Reference

3

4 Torque Reference MSB

Torque

Reference

5

3 Reset Signal

4 @ Frequency Agree

5 Drive Ready (Rdy)

6 Minor Fault

7 Major Fault

8 OPE Error

9 Fault Restart

10 Local/Remote

11 Multi-function Out put 1 1 = Close (terminal function dependent on setting of parameter n057)

12 Multi-function Output 2 1 = Close (terminal function dependent on setting of parameter n058)

13 Multi-function Output 3 1 = Close (terminal function dependent on setting of parameter n059)

14 Reserved

15 Reserved

0.01Hz

Frequency Reference LSB

Torque Reference LSB

scaling is dependent on the setting of parameter n035

0 – 100%

Network Communications 3-11

Page 40

Parameter Access Error Messages

Whenever there is an invalid parameter access message, the drive will respond with an error message containing the fault code for that

particular error. Parameter access pertains only to16 Word and 6 word messages.

16 Word Input/Output Message

If an erroneous Parameter Access message is sent to the drive, the drive will respond with a fault message. The MSB of byte 16 of the fault

response will be set. If the fault is a read parameter data fault, byte 16 of the response message will contain 83h, read parameter function

code 03h with the MSB set. If the fault is a write parameter data fault, byte 16 of the response message will contain 90h, write parameter

function code 10h with the MSB set. Byte 19 will contain 2 and byte 21 will contain the specific error code. Refer to Table 3.15 below for

description of the possible error codes.

6 Word Input/Output Message

If an erroneous Parameter Access message is sent to the drive, the drive will respond with a fault message. The MSB of byte 4 of the fault

response will be set. If the fault is a read parameter data fault, byte 4 of the response message will contain 83h, read parameter function

code 03h with the MSB set. If the fault is a write parameter data fault, byte 4 of the response message will contain 90h, write parameter

function code 10h with the MSB set. Byte 7 will contain 2 and byte 9 will contain the specific error code. Refer to Table 3.15 below for

description of the possible error codes.

Table 3.15 – Parameter Access Fault Message Response

Error Code Error Name Details

01h Function Error Invalid function code

02h Address Error Parameter starting address greater than 600h

03h Amount of Data Fault Read or Write less than 2 words or more than 4 words

21h Data Content Fault Parameter exceeds upper and lower limits

• Parameter change during running or under-voltage

22h Write Fault

• ENTER command was written during running

• Write attempted to read–only data or during under-voltage

• Write attempted during parameter data storage

Network Communications 3-12

Page 41

Handshaking

The handshaking register is necessary to synchronize the send/receive timing of parameter access message data between the PROFIBUSDP Master and the V7 PROFIBUS-DP Option. One register (byte 32 of the 16 word input/output message or byte 12 of the 6 word

input/output message) in the input and output parameter access message areas is dedicated to handshaking. The data set in the output area

of the master becomes enabled in the V7 PROFIBUS-DP Option when the status of the HS bit, bit 7, is changed.

Command Handshaking Register PROFIBUS-DP Master To V7

Table 3.16 – Handshaking Output Register Bit Definitions

Bit Name Function

7 HS

6 - 0

Response Handshake Register V7 To PROFIBUS-DP Master

Bit Name Function

7 HS Handshaking bit. Used to synchronize the data exchange. Toggled when a new response is transmitted

6 - 5 STATUS

4 - 1 WD Watch Dog Counter, incremented approximately every 64 ms.

0 Not used

Handshaking bit. Used to synchronize the data exchange. Toggled when a new command is transmitted. This bit must be

cleared after power-up or re-initialization by the Master program.

Not used.

Table 3.17 – Handshaking Input Register Bit Definitions

Status of data exchanged between Communication Option and drive.

00H: Idle

01H: Sending parameter access message to drive

10H: Waiting for parameter access response from drive

11H: Response received from drive

Network Communications 3-13

Page 42

This page intentionally left blank.

Network Communications 3-14

Page 43

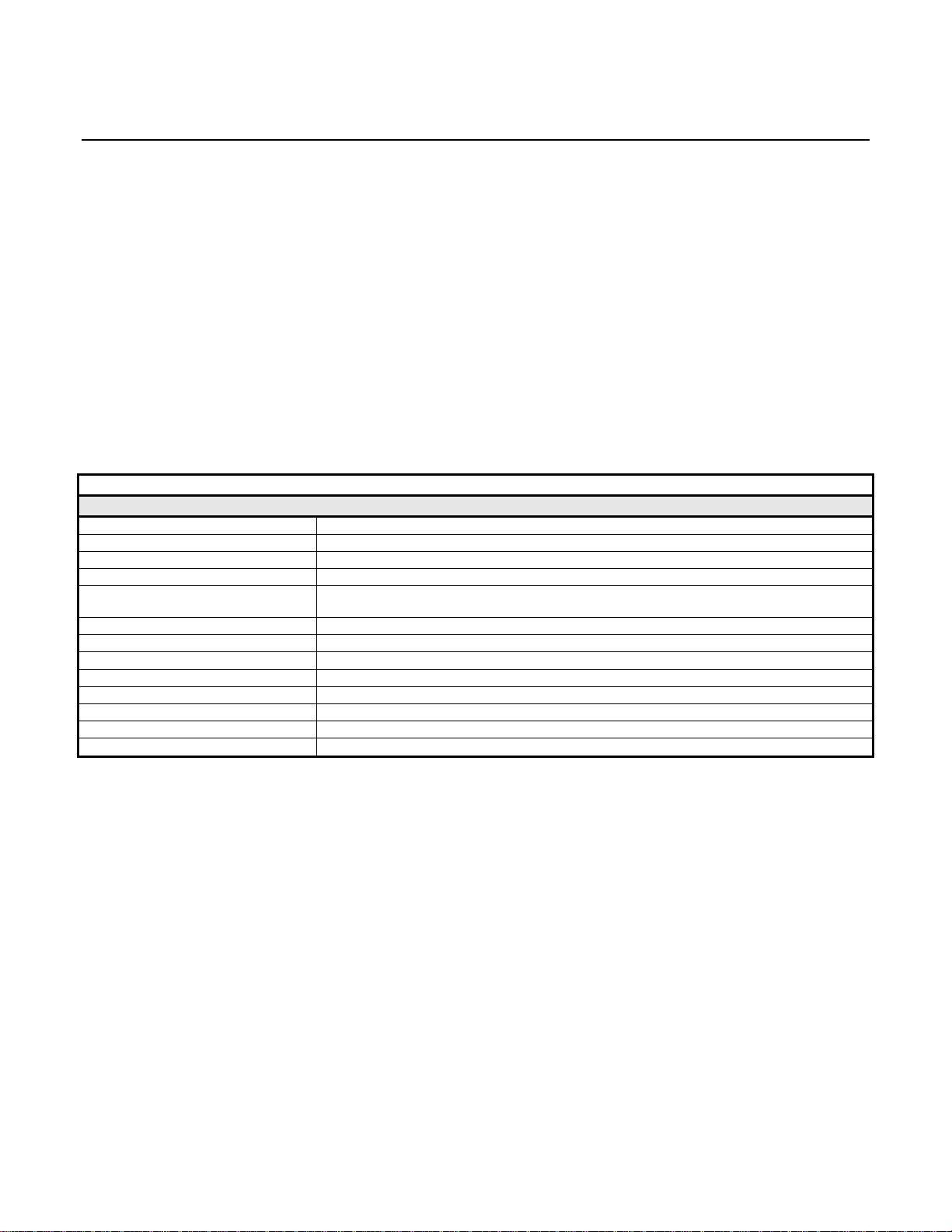

Appendix A Product Specification

This appendix describes the specification for the PROFIBUS-DP Option interface

car.

Table A.1 – Product Specific ation

V7 PROFIBUS-DP Option

Ambient Temperature -10 to +45OC (14 to 113OF)

Storage Temperature -20 to +60OC (-4 to 140OF)

Relative Humidity Not to exceed 90% RH (non-condensing)

Altitude Not to exceed 1000m (3280ft)

Vibration

PROFIBUS-DP Specification PROFIBUS-DP Slave- EN 50170

PROFIBUS-DP Profile Vendor-Specific, PNO-approved

Connector Type 6-pin open-style screw connector

Physical Layer Type Isolated Physical Layer (RS485 transceiver + photo-coupler)

Node Address Setting 2 Decimal Rotary Switches: address 1 to 99

Baud Rate Auto-configure: 9600 bps to 12 Mbps

ASIC Implementation SPC 3

Feature Support Freeze Mode, Sync Mode, Auto Baud

1G (9.8m/s

0.2G (2m/s

2

) at 10 to 20Hz.

2

) at 20 to 50Hz.

Product Specification A-1

Page 44

This page intentionally left blank.

Product Specification A-2

Page 45

Appendix B Parameter Access

This appendix describes in detail how to read and write parameter data to and

from the V7 drive.

Parameter Access Overview............................................. B - 3

Read Drive Data Example................................................. B - 5

Read Drive Data Error Example........................................ B - 6

Write Drive Data Example................................................. B - 7

Write Drive Data Error Example ....................................... B - 8

Parameter Access B-1

Page 46

This page intentionally left blank.

Parameter Access B-2

Page 47

Parameter Access Overview

Parameter access allows the reading and writing of drive parameters. For a detailed description of the V7 drive parameters refer to the V7

MODBUS

®

T echnical Manual.

Initialize Data Structures

Prior to setting the command message, insure that the command message handshake byte HS, bit 7, bit matches the HS bit, bit 7, of the

response message.

Set PROFIBUS-DP Master Command Message

Function Code: Enter 03h (0000 0011) to read data from the drive or 10h (1010 0000) to write data to the drive. If no

parameter access messaging is required, enter 00h as the function code.

Addressing: All register addresses consist of two (2) bytes. The most significant byte, the upper half, is entered as the Starting

Address MSB. The least significant byte, the lower half, is entered as the S tarting Address LSB. If more than one V7 register is

to be accessed, only valid with 16 word input/output messages, the registers must be consecutive beginning with the register at

the starting address.

z Starting Address MSB: Enter the upper half of the starting address. For address 1234h, enter 12h.

z Starting Address LSB: Enter the lower half of the starting address. For address 1234h, enter 34h.

Data Quantity: Enter the quantity of data to either read or write. Each register contains 2 data bytes. To read or write 1

register, enter 2. To read or write 2 registers, enter 4. For 6 word input/output messages, 2 is the only valid entry.

Data: All drive register data consists of 2 bytes. The most significant byte, the upper half, of the value is contained in Data #

MSB. The least significant byte, the lower half, is contained in Data # LSB. For reading data from the drive, these registers must

be set to 0. For writing data to the drive, enter the data in the order that it is to be written to the drive at consecutive addresses

starting with the address entered as the Starting Address. For 16 word input/output messages, if data is to be written to 2 registers,

enter the appropriate values into Data 1 and Data 2. Data 3 and Data 4 must contain 0.

z Data # MSB: To read drive data, set this value to 0. To write data, enter the most significant byte, the upper half, of the data

to be written. To write data 5678h, enter 56h. To write more than one register, valid for 16 word input/output messages only,

the registers must be consecutive starting with the address entered as the Starting Address.

z Data # LSB: To read drive data, set this value to 0. To write data, enter the least significant byte, the lower half, of the data

to be written. To write data 5678h, enter 78h. To write more than one register, valid for 16 word input/output messages only,

the registers must be consecutive starting with the address entered as the Starting Address.

Handshaking: Set the HS bit, the MSB, bit 7, of the command message handshaking byte to the same state as the HS bit ,

the MSB, bit 7, of the response message handshaking byte.

Toggle the PROFIBUS-DP Master Handshake Bit

Toggle the command message Handshake MSB, the most significant bit, bit 7, to signal the drive that the command message contains a

valid parameter access section. Make sure that all data has been entered into the command message before setting this bit. It is advisable to

insert at least one processor scan between setting the command message and setting the handshake bit. Maintain the state of the HS bit until

another command is to be sent to the drive.

Message Received By PROFIBUS-DP Option - Ignore All Response Data

To signify the receipt of the command message, the PROFIBUS-DP Option will set the response message handshaking HS bit to match the

state of the command message handshaking HS bit. Depending on the scan time of the PROFIBUS-DP Master and the interval between

reviewing response messages, the PROFIBUS-DP Master may not see this response.

Parameter Access B-3

Page 48

Message Sent To Drive - Ignore All Response Data

The PROFIBUS-DP Option formats the Parameter Access command message and transmits it to the drive, setting bit 5 of the response

message handshake. Depending on the scan time of the PROFIBUS-DP Master and the interval between reviewing response messages, the

PROFIBUS-DP Master may not see this response.

Wait For Drive Response - Ignore All Response Data.

Upon receiving the Parameter Access message from the PROFIBUS-DP Option, the drive processes the message, setting bit 6 and resetting

bit 5 of the response message handshake. This processing typically takes 10ms to 15ms dependant on the state of the drive at the time of

receiving the message. Depending on the scan time of the PROFIBUS-DP Master and the interval between reviewing response messages,

the PROFIBUS-DP Master may not see this response.

Process Response – Store And Process Data

The response message handshake byte bits 5 and 6 are set to signal that the drive has completed processing the Parameter Access message.

If the command message was to read drive data, the data bytes will now contain valid data. If the command message was to write drive

data, the data has been successfully written.

Parameter Access B-4

Page 49

Read Drive Data Example

Table B.2 – Read Drive Data Example

PROFIBUS-DP Master Command Initialize Data Structures Drive Response

Function Code 00h Function Code 03h

Starting Address MSB 00h Starting Address MSB 01h

Starting Address LSB 00h Starting Address LSB 00h

Data Quantity 00h Data Quantity 02h

Data 1 MSB 00h Data 1 MSB 00h

Data 1 LSB 00h Data 1 LSB 00h

Handshaking (1000 0000) 80h

PROFIBUS-DP Master Command Set PROFIBUS-DP Master Command Message Drive Response

Function Code 03h Function Code 03h

Starting Address MSB 00h Starting Address MSB 01h

Starting Address LSB 37h Starting Address LSB 00h

Data Quantity 02h Data Quantity 02h

Data 1 MSB 00h Data 1 MSB 00h

Data 1 LSB 00h Data 1 LSB 00h

Handshaking (1000 0000) 80h

PROFIBUS-DP Master Command Toggle the PROFIBUS-DP Master Handshake Bit Drive Response

Function Code 03h Function Code

Starting Address MSB 00h Starting Address MSB

Starting Address LSB 37h Starting Address LSB

Data Quantity 02h Data Quantity

Data 1 MSB 00h Data 1 MSB

Data 1 LSB 00h Data 1 LSB

Handshaking (0000 0000) 00h

PROFIBUS-DP Master Command Wait for Response Drive Response

Function Code 03h Function Code

Starting Address MSB 00h Starting Address MSB

Starting Address LSB 37h Starting Address LSB

Data Quantity 02h Data Quantity

Data 1 MSB 00h Data 1 MSB

Data 1 LSB 00h Data 1 LSB

Handshaking (0000 0000) 00h

PROFIBUS-DP Master Command Wait for Response Drive Response

Function Code 03h Function Code

Starting Address MSB 00h Starting Address MSB

Starting Address LSB 37h Starting Address LSB

Data Quantity 02h Data Quantity

Data 1 MSB 00h Data 1 MSB

Data 1 LSB 00h Data 1 LSB

Handshaking (0000 0000) 00h

PROFIBUS-DP Master Command Process Response Drive Response

Function Code 03h Function Code 03h

Starting Address MSB 00h Starting Address MSB 00h

Starting Address LSB 37h Starting Address LSB 37h

Data Quantity 02h Data Quantity 02h

Data 1 MSB 00h Data 1 MSB 00h

Data 1 LSB 00h Data 1 LSB 15h

Handshaking (0000 0000) 00h

Set the command message handshake byte HS bit to the same state as the

response message handshake HS bit.

Set the Function Code, Starting Address, and Data Quantity. This

example configures the command message to retrieve data from drive

register at address 0037h, Output Power . For detailed information of

drive registers refer to the V7 Technical Manual and the V7 MODBUS

Technical Manual.

After the data bits have been set, toggle the HS bit, bit 7, of the command

handshake byte to signal the drive that the command message contains a

Parameter Access command. On receipt of the command message, the

HS bit, bit 7, of the response message handshake byte is set to the same

state as the HS bit of the command message handshake byte. As the

response message may contain invalid data, ignore all response message

data.

The PROFIBUS-DP Option formats the command message and transmits

it to the drive, setting bit 5 of the response handshake byte. As the

response message may contain invalid data, ignore all response message

data.

Bit 5 is reset and bit 6 set of the response handshake byte when the

message has been received by the drive and that the drive has begun

processing the message. As the response message may contain invalid

data, ignore all response message data.

Bits 5 and 6 of the response byte handshake are both set when the

processing has been completed and the response message contains valid

data.

®

Handshaking (1110 0000) E0h

Handshaking (1110 0000) E0h

Handshaking (0000 0000) 00h

Handshaking (0010 0000) 20h

Handshaking (0100 0000) 40h

Handshaking (0110 0000) 60h

Parameter Access B-5

Page 50

Read Drive Data Error Example

Table B.3 – Read Drive Data Error Example

PROFIBUS-DP Master Command Initialize Data Structures Drive Response

Function Code 00h Function Code 03h

Starting Address MSB 00h Starting Address MSB 01h

Starting Address LSB 00h Starting Address LSB 00h

Data Quantity 00h Data Quantity 02h

Data 1 MSB 00h Data 1 MSB 00h

Data 1 LSB 00h Data 1 LSB 00h

Handshaking (0000 0000) 00h

PROFIBUS-DP Master Command Set PROFIBUS-DP Master Command Message Drive Response

Function Code 03h Function Code 03h

Starting Address MSB 10h Starting Address MSB 01h

Starting Address LSB 00h Starting Address LSB 00h

Data Quantity 02h Data Quantity 02h

Data 1 MSB 00h Data 1 MSB 00h

Data 1 LSB 00h Data 1 LSB 00h

Handshaking (0000 0000) 00h

PROFIBUS-DP Master Command Toggle the PROFIBUS-DP Master Handshake Bit Drive Response

Function Code 03h Function Code

Starting Address MSB 10h Starting Address MSB

Starting Address LSB 00h Starting Address LSB

Data Quantity 02h Data Quantity

Data 1 MSB 00h Data 1 MSB

Data 1 LSB 00h Data 1 LSB

Handshaking (1000 0000) 80h

PROFIBUS-DP Master Command Wait for Response Drive Response

Function Code 03h Function Code

Starting Address MSB 10h Starting Address MSB

Starting Address LSB 00h Starting Address LSB

Data Quantity 02h Data Quantity

Data 1 MSB 00h Data 1 MSB

Data 1 LSB 00h Data 1 LSB

Handshaking (1000 0000) 80h

PROFIBUS-DP Master Command Wait for Response Drive Response

Function Code 03h Function Code

Starting Address MSB 10h Starting Address MSB

Starting Address LSB 00h Starting Address LSB

Data Quantity 02h Data Quantity

Data 1 MSB 00h Data 1 MSB

Data 1 LSB 00h Data 1 LSB

Handshaking (1000 0000) 80h

PROFIBUS-DP Master Command Process Response Drive Response

Function Code 03h Function Code 83h

Starting Address MSB 10h Starting Address MSB 00h

Starting Address LSB 00h Starting Address LSB 00h

Data Quantity 02h Data Quantity 02h

Data 1 MSB 00h Data 1 MSB 00h

Data 1 LSB 00h Data 1 LSB 02h

Handshaking (1000 0000) 80h

Set the command message handshake byte HS bit to the same state as the

response message handshake HS bit.

Set the Function Code, Starting Address, and Data Quantity. This

example configures the command message to retrieve data from drive

register at address 0037h, Output Power . For detailed information of

drive registers refer to the V7 Technical Manual and the V7 MODBUS

Technical Manual.. For the purposes of this example, an invalid Starting

Address was entered.

After the data bits have been set, toggle the HS bit, bit 7, of the command

handshake byte to signal the drive that the command message contains a

Parameter Access command. On receipt of the command message, the