SGMCS

Features Application Examples

1Directly coupled to a load without a mechanical

1Semiconductor equipment

transmission such as a gear.

1LCD manufacturing equipment

1Powerful and smooth operation throughout the speed

range from low to high.

(Instantaneous peak torque: 6 to 600 N·m

maximum speed: 250 to 500 min

-1

)

1High-resolution, 20-bit encoder for highly precise

indexing.

1Units for inspection and testing

1Electronic parts assembling

machines

1IC handlers

1Inspection units for integrated

1Easy wiring and piping with the hollow structure.

circuits

1Automated machines

1Robots

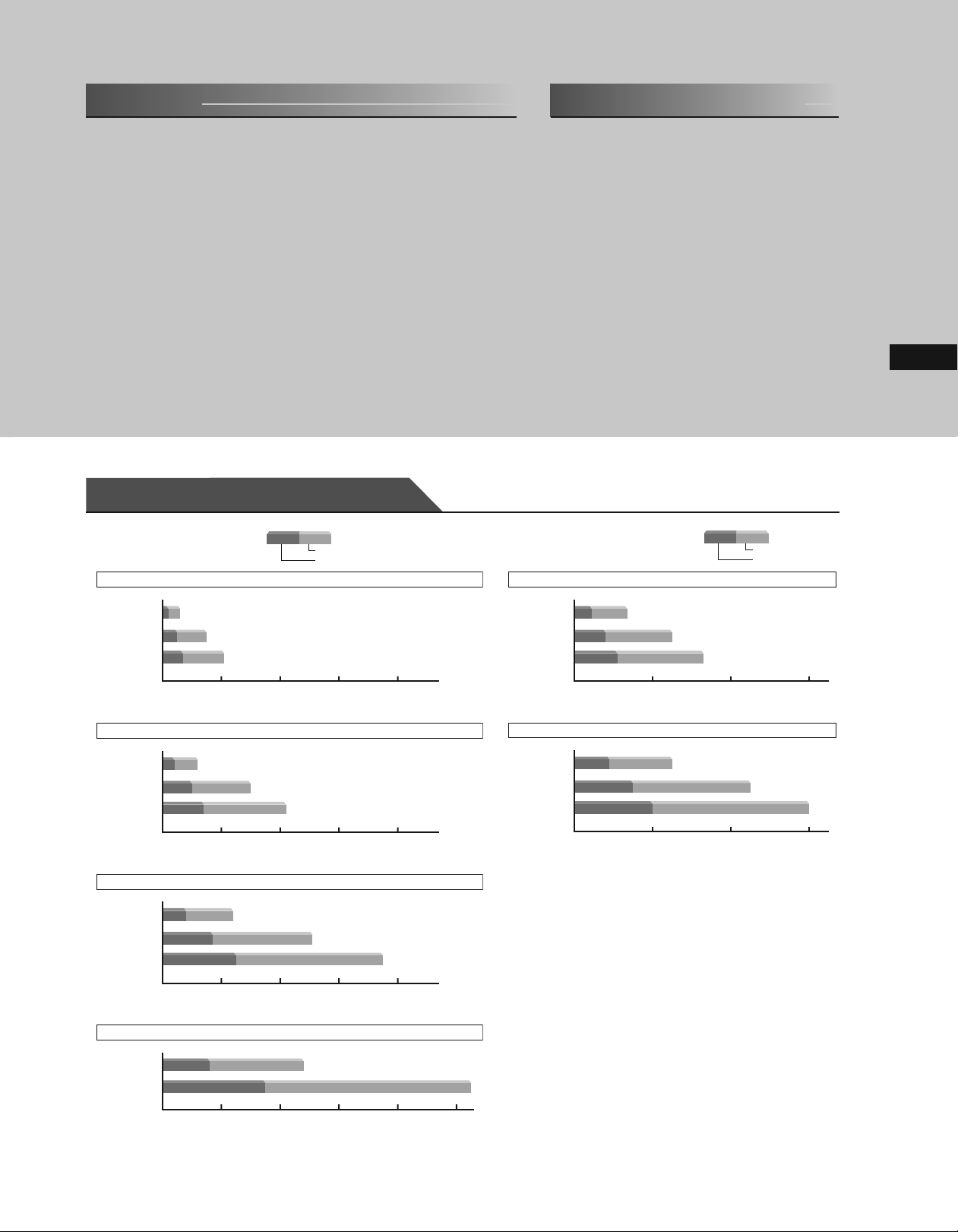

Rated Torque / Peak Torque

1Small-capacity 1Medium-capacity

Outer Diameter

135

mm, Inner Diameter 20 mm

Inst. Peak Torque

Rated Torque

Outer Diameter

280

mm, Inner Diameter 75 mm

Inst. Peak Torque

Rated Torque

Direct Drive Servomotors

SGMCS-02B

05

B

SGMCS-

07

B

SGMCS-

Outer Diameter

SGMCS-04C

10

SGMCS-

C

14

SGMCS-

C

Outer Diameter

SGMCS-08D

17

D

SGMCS-

25

D

SGMCS-

Outer Diameter

(

Rated Torque 2.0 / Inst. Peak Torque 6.0 N・m

)

(

5.0/15.0

)

(

7.0/21.0

20 40 60 80

175

mm, Inner Diameter 35 mm

(

)

4.0/12.0

)

(

10.0/30.0

(

14.0/42.0

20 40 60 80

230

mm, Inner Diameter 60 mm

(

)

8.0/24.0

(

20 40 60 80

290

mm, Inner Diameter 75 mm

)

17.0/51.0

)

SGMCS-45M

80

SGMCS-

1

AM

SGMCS-

M

N・m

Outer Diameter

SGMCS-80N

1

SGMCS-

EN

2

SGMCS-

ZN

N・m

)

(

)

25.0/75.0

(

Rated Torque

45

/ Inst. Peak Torque

(

)

80/240

(

110/330

200 400 600

360

mm, Inner Diameter

(

)

80/240

200 400 600

)

118

135

mm

(

150/450

N・m

(

200/600

)

N・m

)

)

N・m

N・m

SGMCS-16E

35

SGMCS-

(

)

16.0/48.0

E

20 40 60 80 100

(

35.0/105.0

)

N・m

102

103

Ratings and Specifications

1Small-capacity Series

Time Rating: Continuous

Vibration Class: V15

Insulation Resistance: 500 VDC, 10 M

Ω min.

Ambient Temperature: 0 to 40˚C

Excitation: Permanent magnet

Mounting: Flange method

Thermal Class: A

Voltage 200 V VV

Servomotor Model SGMCS-¡¡¡¡¡

Rated Output

Rated Torque

*1

*1, *2

W 42 105 147 84 209 293 168 356 393 335 550

N·m 2.0 5.0 7.0 4.0 10.0 14.0 8.0 17.0 25.0 16.0 35.0

02B¡C 05B¡C 07B¡C 04C¡C 10C¡C 14C¡C 08D¡C 17D¡C 25D¡C 16E¡B 35E¡B

Instantaneous Peak Torque*1N·m 6.0 15.0 21.0 12.0 30.0 42.0 24.0 51.0 75.0 48.0 105

Stall Torque

Rated Current

Instantaneous Max. Current*1A

Rated Speed

Max. Speed

Torque Constant N·m/A

Rotor Moment of Inertia

*1

*1

*1

*1

N·m 2.05 5.15 7.32 4.09 10.1 14.2 8.23 17.4 25.4 16.5 35.6

A

rms

rms

-1

min

-1

min

rms

×10-4 kg·m

1.8 1.7 1.4 2.2 2.2 2.8 1.9 2.5 2.6 3.3 3.5

5.4 5.1 4.1 7.0 7.0 8.3 5.6 7.5 8.0 9.4 10.0

200 200 200 150 200 150

500 500 400 300 500 350 250 500 250

1.18 3.17 5.44 2.04 5.05 5.39 5.1 7.8 10.8 5.58 11.1

2

28 51 77 77 140 220 285 510 750 930 1430

Rated Power Rate*1kW/s 1.4 4.9 6.4 2.1 7.1 8.9 2.2 5.7 8.3 2.75 8.57

Rated Angular Acceleration*1rad/s

Absolute Accuracy second

Repeatability second

Applicable SERVOPACK

*1: These items and torque-motor speed characteristics quoted in combination with an SGDV SERVOPACK are at an armature winding temperature of 100˚C. Other values

quoted at 20˚C.

*2: Rated torques are continuous allowable torque values at 40˚C with a steel heat sink attached.

Heat sink: SGMCS-¡¡B : 350 mm

SGMCS-¡¡D : 550 mm

Notes: 1 SGMCS servomotor with holding brake is not available.

2 For the bearings used in SGMCS servomotors, loss varies according to the bearing temperature. At low temperatures, the amount of heat loss will be large.

1

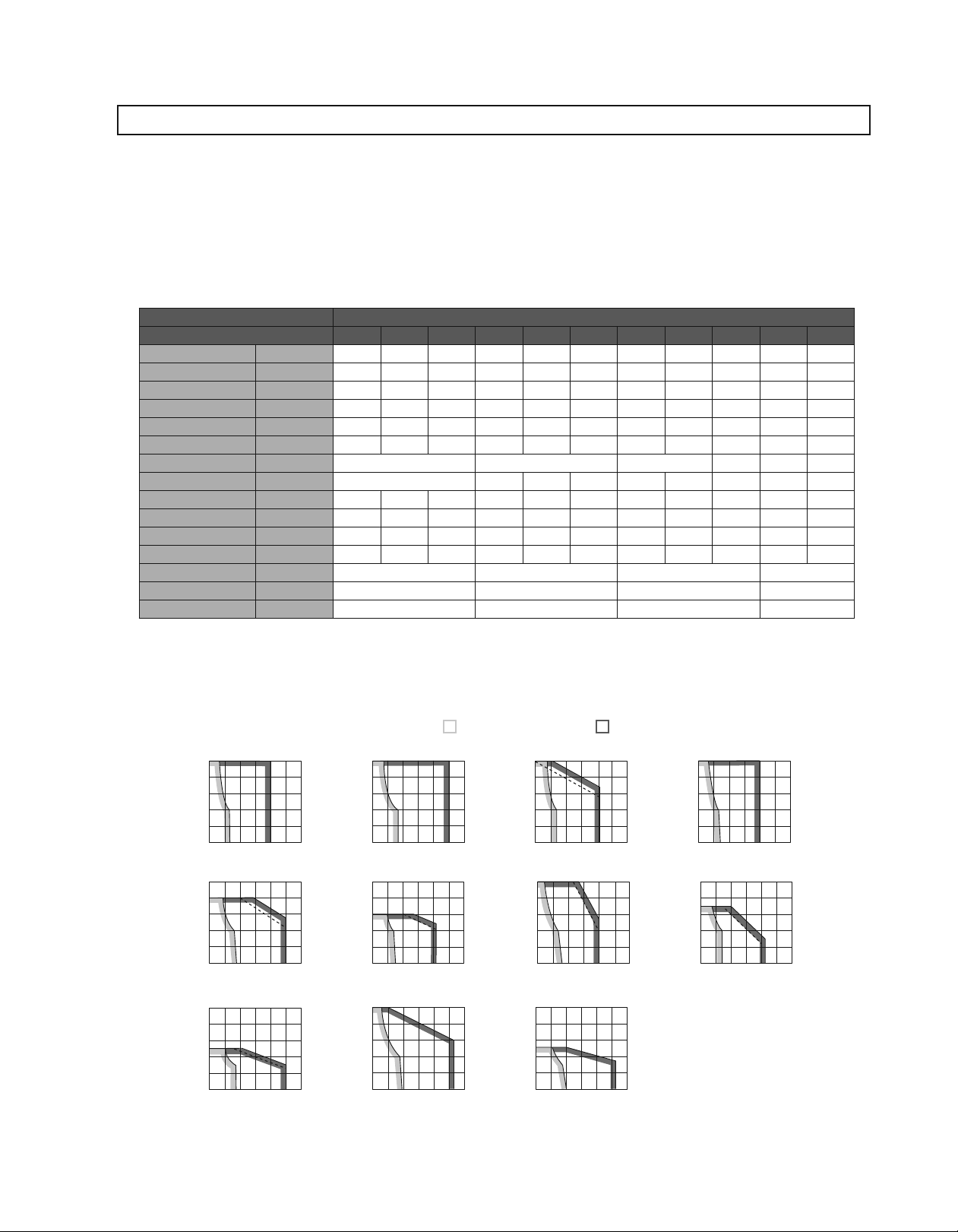

Small-capacity Series: Torque-Motor Speed Characteristics

SGMCS-02B

)

500

-1

min

400

(

300

200

A

100

Motor Speed

0

1

0

.53.04.56.07.

Torque (N・m

SGMCS-

)

500

-1

400

min

(

300

200

A

100

Motor Speed

0

0

612182430

Torque (N・m

SGMCS-

)

500

-1

400

min

(

300

200

A

100

Motor Speed

0

15 30 45 60 75

0

Torque (N・m

Notes: 1 The solid, dotted lines of the intermittent duty zone indicate the characteristics when a servomotor runs with the following combinations:

· The solid line: With a three-phase 200 V SERVOPACK

· The dotted line: With a single-phase 100 V SERVOPACK

2 When the effective torque during intermittent duty is within the rated torque, the servomotor can be used within the intermittent duty zone.

3 When the main circuit cable length exceeds 20 m, note that the intermittent duty zone of the Torque-Motor Speed Characteristics will shrink as the line-to-line voltage drops.

2

710 980 910 520 710 640 280 330 330 170 240

±15 ±15 ±15 ±15

±1.3 ±1.3 ±1.3 ±1.3

SGDV-¡¡¡¡

2R8A 2R8A 2R8A 5R5A

× 350 mm × 12 mm SGMCS-¡¡C : 450 mm × 450 mm × 12 mm

× 550 mm × 12 mm SGMCS-¡¡E : 650 mm × 650 mm × 12 mm

)

-1

min

(

B

5

)

10

C SGMCS-14C SGMCS-08D SGMCS-17D

B

)

25

D SGMCS-16E SGMCS-35E

B

)

Motor Speed

)

-1

min

(

Motor Speed

)

-1

min

(

Motor Speed

SGMCS-

500

400

300

200

A

100

0

0

3691215

500

400

300

200

A

100

0

0

10 20 30 40 50

500

400

300

200

A

100

0

0

918273645

Torque (N・m

B

Torque (N・m

Torque (N・m

Withstand Voltage: 1500 VAC for one minute

Enclosure: Totally enclosed, self-cooled, IP42 (except for gaps on the rotating

section of the shaft)

Ambient Humidity: 20% to 80% (no condensation)

Drive Method: Direct drive

Rotation Direction: Counterclockwise (CCW) with forward run reference when

viewed from the load side

A

: Continuous Duty Zone B: Intermittent Duty Zone

05

B

B

)

)

B

)

)

500

-1

400

min

(

300

200

A

100

Motor Speed

0

0

)

500

-1

400

min

(

300

200

A

100

Motor Speed

0

0

)

500

-1

400

min

(

300

200

A

100

Motor Speed

0020 40 60 80 100

07

SGMCS-

510152025

612182430

B

Torque (N・m

B

Torque (N・m

B

Torque (N・m

B

)

)

)

)

500

-1

400

min

(

300

200

100

Motor Speed

0

)

500

-1

400

min

(

300

200

100

Motor Speed

(Note2)

04

SGMCS-

A

3691215

0

Torque (N・m

A

0012 24 36 48 60

C

B

B

Torque (N・m

)

)

Direct Drive Servomotors

SGMCS

Ratings and Specifications

1Medium-capacity Series

Time Rating: Continuous

Vibration Class: V15

Insulation Resistance: 500 VDC, 10 M

Ω min.

Ambient Temperature: 0 to 40˚C

Excitation: Permanent magnet

Mounting: Flange method

Thermal Class: F

Voltage 200 V

Servomotor Model SGMCS-¡¡¡¡¡

Rated Output

Rated Torque

*1

*1, *2

W 707 1260 1730 1260 2360 3140

N·m 45 80 110 80 150 200

45M¡ 80M¡ 1AM¡ 80N¡ 1EN¡ 2ZN¡

Instantaneous Peak Torque*1N·m 135 240 330 240 450 600

Stall Torque

Rated Current

Instantaneous Max. Current*1A

Rated Speed

Max. Speed

Torque Constant N·m/A

Rotor Moment of Inertia

*1

*1

*1

*1

N·m 45 80 110 80 150 200

A

rms

rms

-1

min

-1

min

×

10-4 kg·m

rms

5.80 9.74 13.4 9.35 17.4 18.9

17 28 42 28 56 56

8.39 8.91 8.45 9.08 9.05 11.5

2

388 627 865 1360 2470 3060

Rated Power Rate*1kW/s 52.2 102 140 47.1 91.1 131

Rated Angular Acceleration*1rad/s

Applicable SERVOPACK

*1: These items and torque-motor speed characteristics quoted in combination with an SGDV SERVOPACK are at an armature winding temperature of 20˚C.

*2: Rated torques are continuous allowable torque values at 40˚C with a steel heat sink attached.

Heat sink: 750 mm

Notes: 1 SGMCS servomotor with holding brake is not available.

2 For the bearings used in SGMCS servomotors, loss varies according to the bearing temperature. At low temperatures, the amount of heat loss will be large.

2

SGDV-¡¡¡¡

× 750 mm × 45 mm

1160 1280 1270 588 607 654

7R6A 120A 180A 120A 200A 200A

Withstand Voltage: 1500 VAC for one minute

Enclosure: Totally enclosed, self-cooled, IP44

(except for shaft opening)

Ambient Humidity: 20% to 80% (no condensation)

Drive Method: Direct drive

Rotation Direction: Counterclockwise (CCW) with forward run reference when

viewed from the load side

150

300 250

Rotary Motors

Direct Drive Servomotors

1

Medium-capacity Series: Torque-Motor Speed Characteristics

SGMCS-45M SGMCS-80M

300

)

-1

min

(

200

100

A

Motor Speed

0

0 50 100 150

Torque (N・m

SGMCS-1EN SGMCS-2ZN

300

)

-1

min

200

(

100

A

0

Motor Speed

0 100 200 300 400 500

Notes: 1 When the effective torque during intermittent duty is within the rated torque, the servomotor can be used within the intermittent duty zone.

2 When the main circuit cable length exceeds 20 m, note that the intermittent duty zone of the Torque-Motor Speed Characteristics will shrink as the line-to-line voltage drops.

Torque (N・m

B

)

B

)

300

)

-1

min

(

200

100

A

Motor Speed

0

0 100 200 300

Torque (N・m

300

)

-1

min

200

(

100

A

0

Motor Speed

0 200 400 600 800

Torque (N・m

A

: Continuous Duty Zone B: Intermittent Duty Zone

SGMCS-1AM SGMCS-80N

300

)

-1

min

200

(

B

)

B

)

100

A

0

Motor Speed

0 100 200 300 400

Torque (N・m

B

)

(Note1)

300

)

-1

min

200

(

100

A

0

Motor Speed

0 100 200 300

Torque (N・m

B

)

104

Ratings and Specifications

1Allowable Load Moment of Inertia at the Motor Shaft

Allowable Load Moment of Inertia

(Rotor Moment of Inertia Ratio)

SGMCS-

Servomotor Model

02B¡C, 05B¡C, 07B¡C, 04C¡C 2.0, 5.0, 7.0, 4.0 10 times

10C¡C 10.0 5 times

14C¡C, 08D¡C, 17D¡C, 25D¡C, 16E¡B, 35E¡B 14.0, 8.0, 17.0, 25.0, 16.0, 35.0 3 times

45M¡A, 80M¡A, 1AM¡A, 80N¡A, 1EN¡A, 2ZN¡A 45, 80, 110, 150, 200 3 times

Rated Torque

N·m

1Load Moment of Inertia

The larger the load moment of inertia, the worse the movement response.

The allowable load moment of inertia (

moment of inertia of each servomotor (

on servomotor drive conditions.

Use the AC servo drive capacity selection program SigmaJunmaSize+ to check the operation conditions. The program

can be downloaded for free from our web site (http://www.e-mechatronics.com/).

An overvoltage alarm (A.400) is likely to occur during deceleration if the load moment of inertia exceeds the allowable load

moment of inertia. SERVOPACKs with a built-in regenerative resistor may generate a regenerative overload alarm

(A.320). Take one of the following steps if this occurs.

· Reduce the torque limit.

· Reduce the deceleration rate.

· Reduce the maximum speed.

· Install an external regenerative resistor if the alarm cannot be cleared using the steps above. Refer to Regenerative

Resistors on page 293.

JL) depends on motor capacity and is limited to within 5 to 30 times the rotor

JM). This value is provided strictly as a guideline and results may vary depending

105

Direct Drive Servomotors

k

SGMCS

Mechanical Specifications

1Allowable Loads

The loads applied while a servomotor is running are roughly classified in the following patterns. Design the machine so that the

thrust load and moment load will not exceed the values in the table.

F

Where F is external force,

Thrust load: Fa

Moment load: M

Servomotor Model

SGMCS-

Dimension A mm 0 0 0 0 33 37.5

Allowable Thrust Load (Fa)

Allowable Moment Load (M)

Note: SGMCS-02B to -35E servomotors, set dimensions A to 0 (zero).

=F+

Load mass

=

0

¡

02B 05B 07B 04C 10C 14C 08D 17D 25D 16E 35E 45M 80M

N 1500 3300 4000 11000 9000 16000

N·m 40 50 64 70 75 90 93 103 135 250 320 180 350

L

F

Where F is external force,

Thrust load: Fa

Moment load: M

=F+

Load mass

=F×

L

F

Where F is external force,

Thrust load: Fa

Moment load: M

=

Load mass

(

=F×

L

L

(

See the table below

A

for the dimension A of

each servomotor model.

)

+

A

1AM

80N 1EN 2ZN

Rotary Motors

)

1Mechanical Tolerance

The following table shows tolerances for the servomotor’s output shaft and installation area.

See the dimensional drawing of the individual servomotor for more details on tolerances.

(1) Small-capacity Series

Dia.

¡

Dia.

¡

Drive End

Opposite

Drive End

④

Dia.

A

②

A

(2) Medium-capacity Series

¡

④

Dia.

Drive End

Opposite

Drive End

A

B

A

②

¡

¡

Dia.

Dia.

Dia.

②

B

1Direction of Rotation

Positive rotation of the servomotor

is counterclockwise when viewed

from the load.

①

B

Run-out of the Surface of the Shaft

Run

Perpendicularity between the Flange Face and Output Shaft

③

B

Coaxiality of Output Axis and Mounting Socket Joint

①

Run

Run

B

A

⑤

Perpendicularity between the Flange Face and Output Shaft

Coaxiality of Output Axis and Mounting Socket Joint 0.08 0.08

Right angle between Flange Face and Output Shaft 0.08 0.08

Tolerance T.I.R.

(Total Indicator Reading) Units: mm

-

out at the End of the Shaft 0.04 0.04 0.04 0.04

Tolerance T.I.R.

(Total Indicator Reading) Units: mm

-

out of the Surface of the Shaft 0.02 0.02

-

out at the End of the Shaft 0.04 0.04

02B 05B 07B 04C 10C 14C 08D 17D 25D 16E 35E

0.02 0.02 0.02 0.02

0.07 0.07 0.08 0.08

0.07 0.07 0.08 0.08

1Impact Resistance

Mount the servomotor with the axis

horizontal. The servomotor will withstand the following vertical impacts:

· Impact Acceleration: 490 m/s

· Number of Impacts: 2

Servomotor Model SGMCS-

Servomotor Model SGMCS-

45M 80M 1AM 80N 1EN 2ZN

−−

2

Impact applied

to the servomotor

Direct Drive Servomotors

Vertical

1Vibration Resistance

Mount the servomotor with the axis horizontal. The servomotor will withstand the following vibration acceleration in three directions: Vertical, side to side, and front to

back.

Front to bac

Servomotor Type

Small-capacity Series

Medium-capacity Series

Vibration Acceleration at

Flange

49 m/s

24.5 m/s

2

2

Vertical

Side to Side

Vibration applied to

the servomotor

1Vibration Class

The vibration class at rated motor speed is V15. (A vibration

class of V15 indicates a total vibration amplitude of 15

maximum on the servomotor during rated rotation.)

1Enclosure

Servomotor Type Enclosure

Small-capacity Series

Medium-capacity Series

IP42 (except for gaps on the rotating section of the shaft)

IP44

μ

m

106

Loading...

Loading...