100/200V Single-phase Sigma II Servo Systems

Selecting Your SGMAH Sigma II Servo System

First, select the Sigma II servomotor suited for your application using SigmaSize: the Yaskawa

servomotor sizing software, available at no charge. (Request SigmaSize software via e-mail, at:

literature@yaskawa.com).

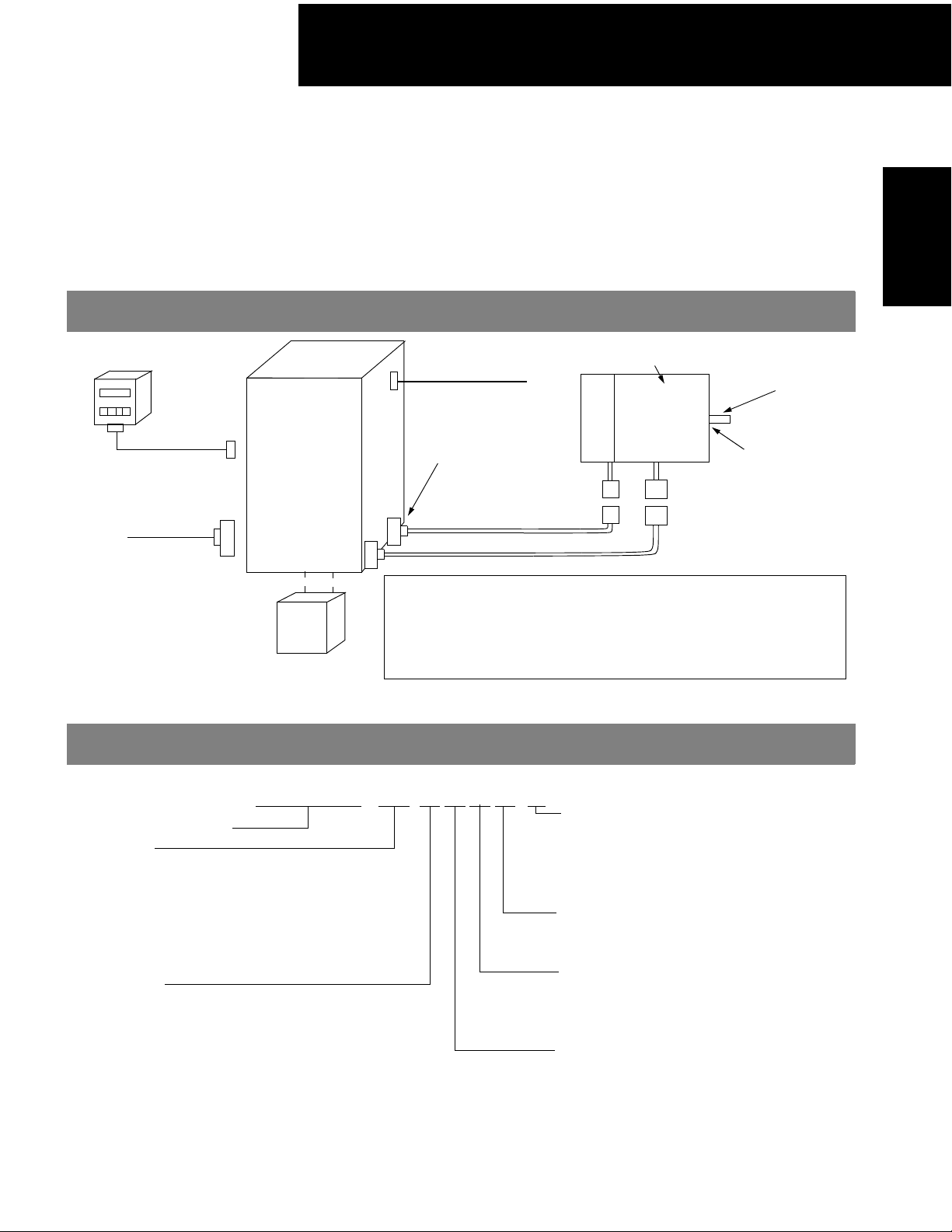

Use the diagram below to locate and identify the components of your system. Each item is lettercoded and cross-referenced in the option tables on the following pages.

System Configuration

SGMAH

Servomotors

Digital Operator (E)

3CN

Peripheral

Signal

Cable (E)

1CN

I/O Signal

Connector

(D)

Regenerative Unit (E)

SGDH Servo

Amplifier

(B)

Model Number Designation

SGMAH - 01 A A F 4 1

Sigma II Servomotor Type

Rated Output

A3: 30W (0.04hp)

A5: 50W (0.07hp)

01: 100W (0.13hp)

02: 200W (0.25hp)

04: 400W (0.5hp)

08: 750W (1hp)

Power Supply

A: 200V

B: 100V

5CN

For Monitor (D)

Connector

Encoder (D)

Encoder side

Connector (D)

2CN

Encoder Cable (C)

Motor Cable (C)

Optional Holding Brake

Shaft Keyway

SGMAH

Servomotor

(A)

Shaft Seal

Motor side

Connector (D)

Specify a technical manual, if it is needed, on your

servo system purchase order:

Sigma II Series Servo System User’s Manual: YEA-SIA-S800-32.2

(Manual is provided at no charge with a purchase order,

but it must be requested).

Accessories

1: Standard

C: Standard with 24V

S: Standard with Shaft Seal*

E: Standard with Brake & Shaft Seal*

Shaft Specifications

4: Straight Shaft with Keyway*

2: Straight Shaft without Keyway

Revision Level

F: Standard

N: NEMA flange (200W, 400W & 800W

only without holding brake)

Encoder Specifications

A: 13-bit (2048 x 4) Incremental Encoder

1: 16-bit (16384 x 4) Absolute Encoder

Brake*

DC

* Keyways, shaft seals, and holding brakes not available on motors with NEMA flanges (revision level = N).

21

Loading...

Loading...