Page 1

External Dimensions Units: mm

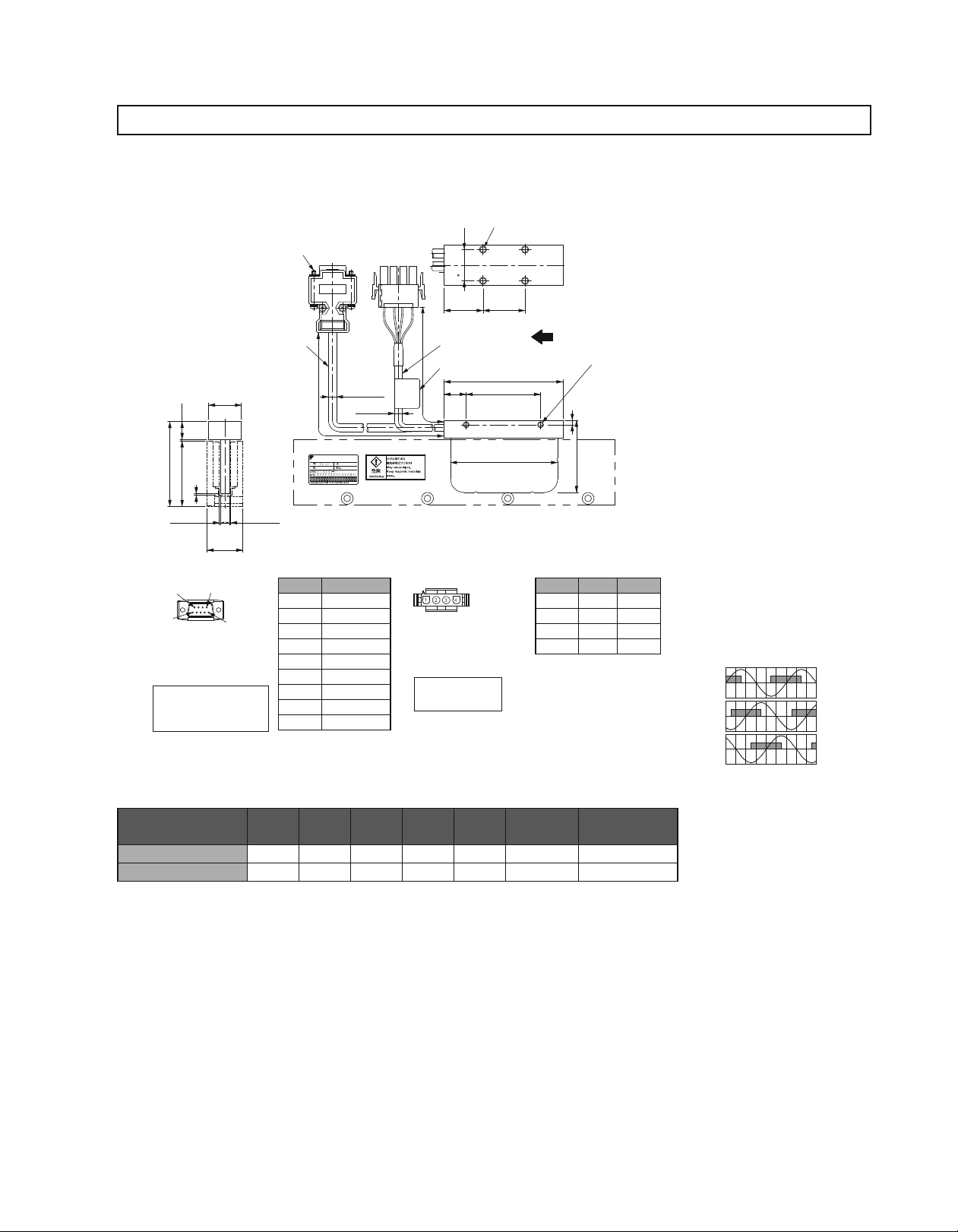

(1) SGLGW-30SGLGW-30

3Moving Coil: SGLGW-30A¡¡¡C¡ (With a connector by Tyco Electronics AMP K.K.)

22

12

1

)

44

57

(

)

1

(

)

G (Gap

G (Gap

24

Hall Sensor

Connector Specifications

Pin Connector:

17

JE-

by DDK Ltd.

The Mating Connector

Socket Connector

:

Stud :

9

5

23090-02

17

17L-002

17L-002C1

JE-

6

1

(D8C

13090-02

C or

)

(D8C

2

-Screws

4-40

UNC

#

Cable

20276

,

UL

26

AWG

)

Pin No. Signal

1

2 Phase U

3 Phase V

4 Phase W

5

6 Not used

7 Not used

)

8 Not used

9 Not used

50

±

(

500

5.3

Dia.

(

5

+

5V (Power supply)

0V (Power supply)

Dia.

50

±

Cable

500

2517

UL

Nameplate

)

15

)

Linear Servomotor

Connector Specifications

Plug : 350779-1

Pin : 350924-1 or

770672-1

by Tyco Electronics AMP K.K.

The Mating Connector

350780-1

Cap :

350925-1

Socket :

770673-1

4-M4

Mounting Screws, Depth

5

17

5

L

4

L

The moving coil moves in the direction indicated by the arrow

, AWG

25

when current flows in the order of phase U, V, and W.

2×2-M4

1

L

3

L

Mounting Screws, Depth 5 on Both Sides

3

5

2

L

.

48

Hall Sensor Output Signals

Pin No. Signal

1

2

3

4 FG Green

or

Phase U

Phase V

Phase W

Wire Color

Red

White

Blue

When the moving coil moves in the

direction indicated by the arrow in

the figure, the relationship between

the hall sensor output signals Su,

Sv, Sw and the inverse power of

each motor phase Vu, Vv, Vw

becomes as shown in the figure

below.

Vu

Su

Inverse

Vv

Power

(V)

Sv

Vw

0 180 360 540

Sw

Electrical Angle ( ˚

)

125

Moving Coil Model

SGLGW-

30A050C¡ 50 48 30 20

L1 L2 L3 L4 L5 G (Gap)

20 0.85 0.14

30A080C¡ 80 72 50 30 25 0.95 0.19

*: The values indicate the mass of moving coil with a hall sensor unit.

Approx. Mass*

kg

Page 2

External Dimensions Units: mm

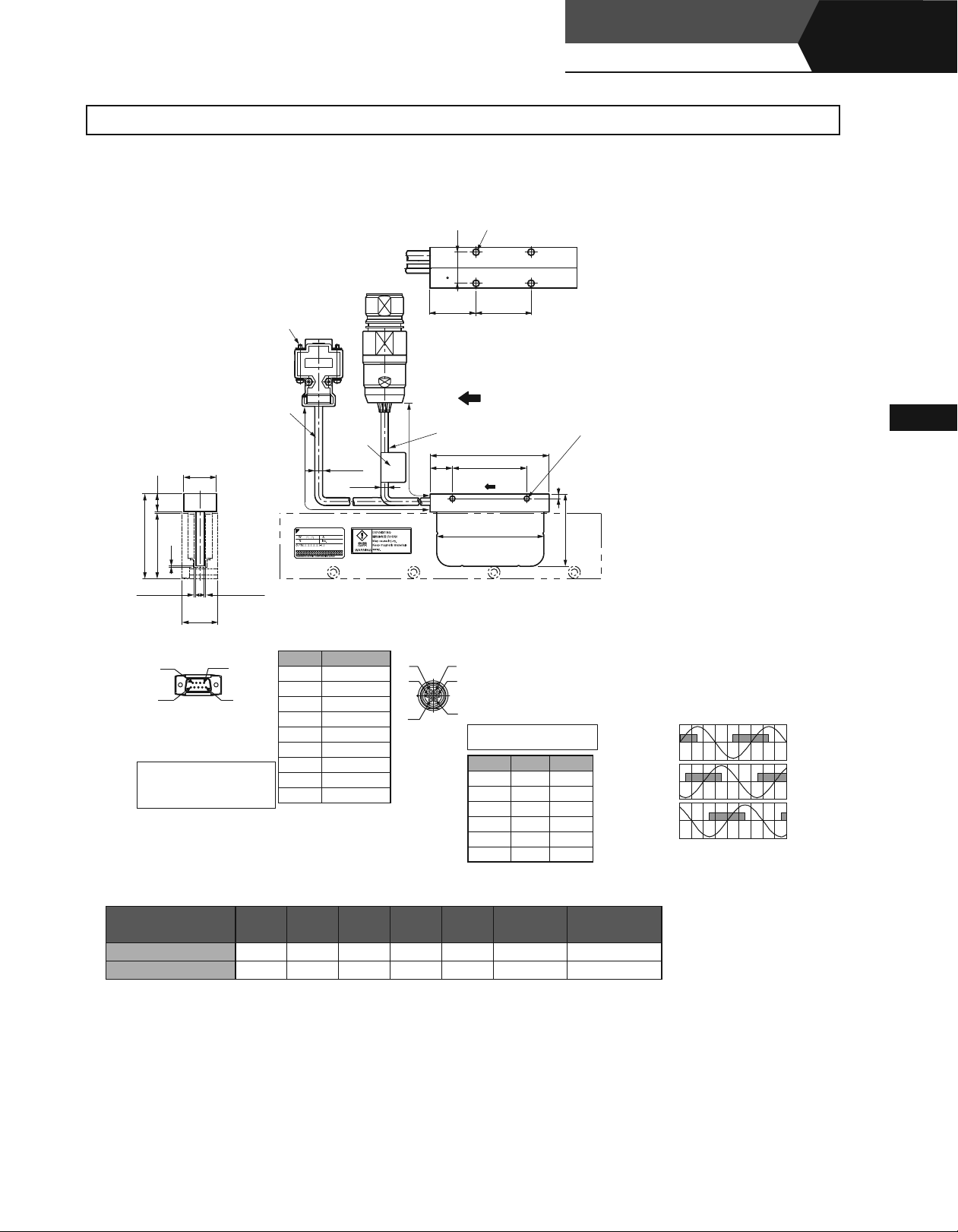

3Moving Coil: SGLGW-30A¡¡¡C¡D (With a connector by Interconnectron GmbH)

M

4

4

-

Mounting Screws, Depth

17

5

50

±

500

Cable

UL

15

L

2517

2

-Screws

4-40

#

UNC

Cable

UL

20276

, AWG

26

Name

plate

50

±

(

)

5.3

22

12

500

Dia

(

5

Dia

)

1

)

44

57

)

(

1

(

4

L

The moving coil moves in the direction

indicated by the arrow when current flows

in the order of phase U, V, and W.

25

,AWG

1

L

3

L

3

5

2

L

.

48

Linear Servomotors

SGLGW

5

×

2-M4

2

Mounting Screws, Depth 5 on Both Sides

(Coreless Type)

Linear

Linear Servomotors

G (Gap

)

G (Gap

)

24

Hall Sensor

Connector Specifications

9

5

Pin Connector :

17

23090-02

JE-

by DDK Ltd.

The Mating Connector

Socket Connector :

17

JE-

Stud :

13090-02

17L-002

C or

17L-002C1

(D8C

Moving Coil Model

SGLGW-

30A050C¡D

)

)

Pin No. Signal

+

1

5V (Power supply)

2 Phase U

3 Phase V

4 Phase W

0V (Power supply)

5

6 Not used

7 Not used

8 Not used

9 Not used

6

1

(D8C

L1 L2 L3 L4 L5

50 48 30

Linear Servomotor

Connector Specifications

2

1

6

Extension: SROC06JMSCN

3

Pin :

021.423.1020

by Interconnectron GmbH

4

5

The Mating Connector

: SPUC06KFSDN

Plug

020.030.1020

Socket:

Pin No. Signal

1

Phase U

Phase V

2

Phase W

3

Not used

4

Not used

5

6 FG Green

G

(Gap)

20 20 0.85 0.14

30A080C¡D 80 72 50 30 25 0.95 0.19

*: The values indicate the mass of moving coil with a hall sensor unit.

236

Wire Color

Red

White

Blue

–

–

Approx. Mass*

169

Hall Sensor Output Signals

When the moving coil moves in the direction indicated by the arrow in the figure, the

relationship between the hall sensor output

signals Su, Sv, Sw and the inverse power of

each motor phase Vu, Vv, Vw becomes as

shown in the figure below.

Vu

Su

Inverse

Power

(V)

Vv

Sv

Vw

0 180 360 540

Electrical Angle

kg

Sw

(

)

°

126

Page 3

External Dimensions Units: mm

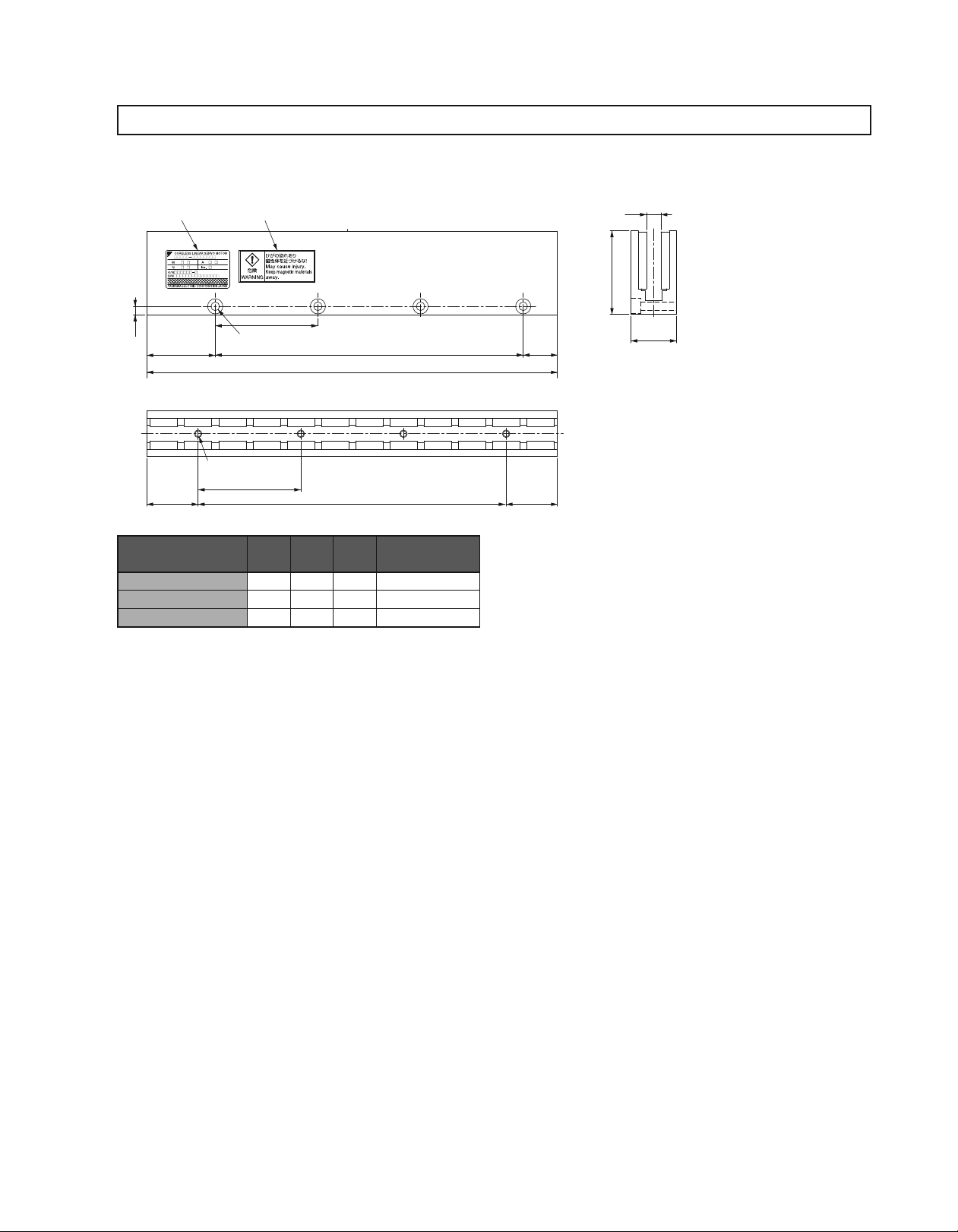

3Magnetic Way: SGLGM-30: SGLGM-30 SGLGM-30SGLGM-30¡¡¡A

5

.

4

Nameplate

36

Warning Label

45

Pitch

N-4.5 Dia. Mounting Holes (Per unit

8

Dia. Counter Boring, Depth 5 on Both Sides.

L1 (Unit

7.6

44

)

(18)

2

1

-0.

)

3

-0.

L

24

N-M4 Mounting Screws, Depth

Pitch

27

Magnetic Way Model

SGLGM-

6

54

L1 L2 N

2

L

(27)

Approx. Mass

kg

30108A 108 54 2 0.6

30216A

30432A 432

Note: If you have a pacemaker or any other electronic medical device, do not go near the magnetic way of the linear servomotor.

216 162 4 1.1

378 8 2.3

127

Page 4

Linear Servomotors

SGLGW

External Dimensions Units: mm

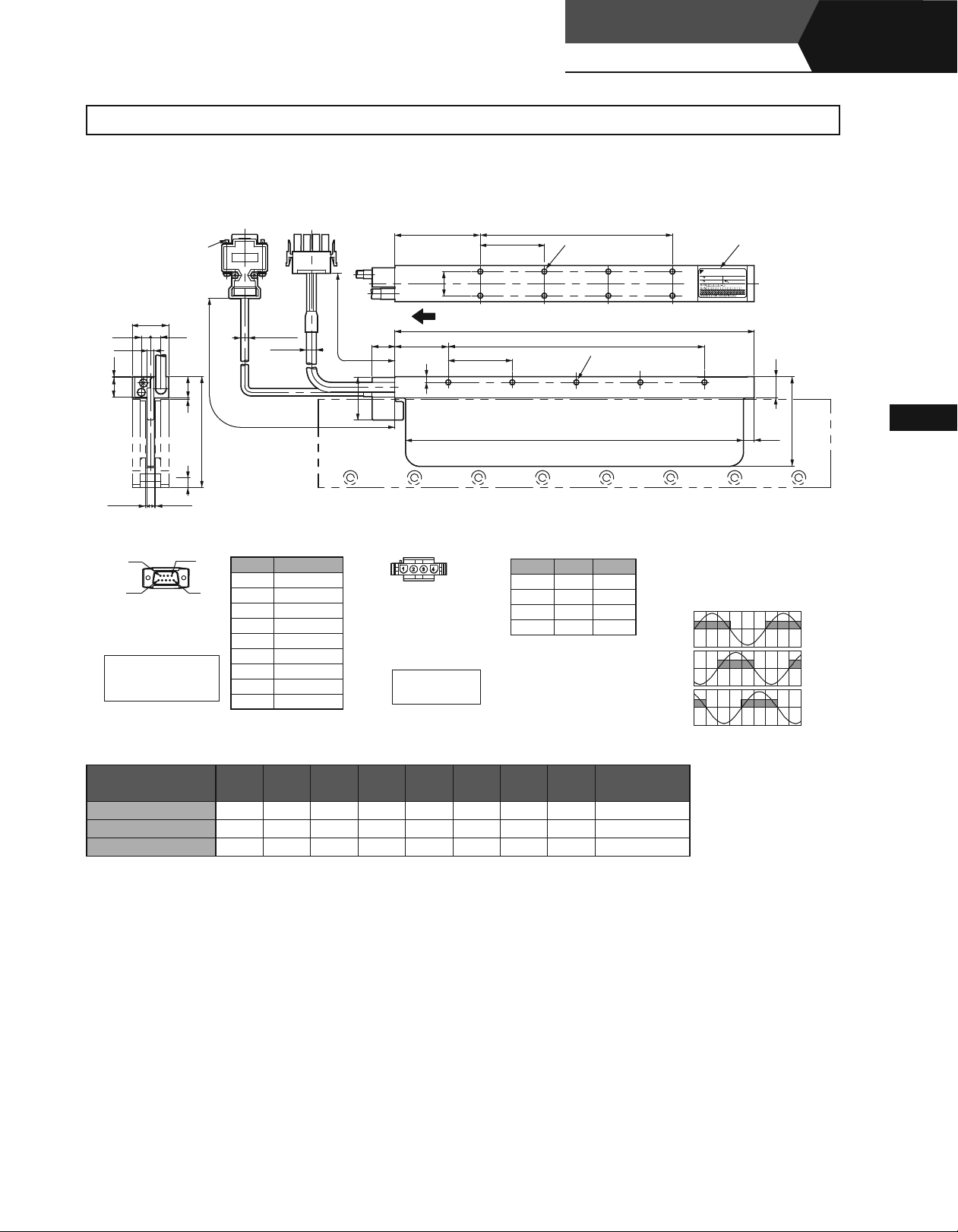

(2) SGLGW-402) SGLGW-40) SGLGW-40SGLGW-40

3Moving Coil: SGLGW-40A¡¡¡C¡ (With a connector by Tyco Electronics AMP K.K.)

6

2

-Screws

#4-40 UNC

5

L

45

L

Mounting Holes

N2-M4 Tapped Holes, Depth

(Coreless Type)

Linear

Nameplate

6

25.4

7

2

5

6

.

4

8

.

5

.

0

14

.

15

1

7

8

Gap 0.

8

Gap 0.

Hall Sensor

Connector Specifications

9

5

Pin Connector :

17

23090-02

JE-

by DDK Ltd.

The Mating Connector

Socket Connector :

17

JE-

17L-002

Stud :

17L-002C1

(D8C

13090-02

C or

6

1

)

(D8C

50

±

500

78

)

(

)

5.3

Dia.

(

)

7

Dia.

Pin No. Signal

+

1

5V (Power supply)

2 Phase U

3 Phase V

4 Phase W

0V (Power supply)

5

6 Not used

7 Not used

8 Not used

9 Not used

50

±

500

16

4

L

4

30

Linear Servomotor

Connector Specifications

Plug : 350779-1

Pin : 350561-3 or

350690-3 (No.1 to 3)

350654-1

350669-1 (No.4)

by Tyco Electronics AMP K.K.

The Mating Connector

Cap :

Socket :

17

The moving coil moves in the direction indicated by the arrow when current flows in the order of phase U, V, and W.

45

Pin No. Signal

350780-1

350570-3

or

350689-3

1

L

3

L

Mounting Holes on Both Sides

1-M4

N

2

L

Wire Color

1

Phase U

Red

Phase V

Phase W

White

Blue

2

3

4 FG Green

Tapped Holes, Depth

Inverse

Power

(V)

6

Hall Sensor Output Signals

When the moving coil moves in the direction indicated by the arrow in the figure, the

relationship between the hall sensor output

signals Su, Sv, Sw and the inverse power of

each motor phase Vu, Vv, Vw becomes as

shown in the figure below.

Vu

Su

Vv

Vw

0 180 360 540

15

(

)

7.5

Sv

Sw

Electrical Angle

63

(

°

Linear Servomotors

)

Moving Coil Model

SGLGW-

40A140C¡ 140 125 90 30

L1 L2 L3 L4 L5 L6 N1 N2

52.5 45 3 4 0.40

40A253C¡ 252.5 237.5 180 37.5 60 135 5 8 0.66

40A365C¡ 365 350 315 30 52.5 270 8 14 0.93

*: The values indicate the mass of moving coil with a hall sensor unit.

Approx. Mass*

kg

128

Page 5

External Dimensions Units: mm

3Moving Coil: SGLGW-40A¡¡¡C¡D (With a connector by Interconnectron GmbH)

2

-Screws

#4-40 UNC

5

L

45

L

Mounting Screws,

N

6

2-M4

Tapped Holes, Depth

Name plate

6

25.4

5

6

.

8

4

.

5

.

0

7

14

Gap 0.

8

Gap 0.

Hall Sensor

Connector Specifications

9

5

Pin Connector :

17

23090-02

JE-

by DDK Ltd.

The Mating Connector

Socket Connector :

17

13090-02

JE-

17L-002

Stud :

17L-002C1

50

±

50

±

2

.

500

(

5.3

Dia.

(

7

Dia.

500

)

)

16

17

The moving coil moves in the direction indicated by the arrow when current flows in the order of phase U, V, and W.

4

L

4

45

1

L

3

L

Mounting Holes on Both Sides

1-M4

Tapped Holes, Depth

N

6

15

15

1

78

30

2

L

(

7.5

63

)

7

8

Hall Sensor Output Signals

When the moving coil moves in the direction indicated by the arrow in the figure, the

relationship between the hall sensor output

signals Su, Sv, Sw and the inverse power of

each motor phase Vu, Vv, Vw becomes as

shown in the figure below.

Vu

Su

Vv

Inverse

Power

(V)

Vw

Sv

Sw

0 180 360 540

(

Electrical Angle

°

)

(D8C

(D8C

C or

Linear Servomotor

Connector Specifications

2

1

6

Extension: SROC06JMSCN

3

Pin :

by Interconnectron GmbH

4

5

The Mating Connector

: SPUC06KFSDN

Plug

Socket:

Pin No. Signal

1

2

3

4

5

6 FG Green

021.423.1020

020.030.1020

Wire Color

Phase U

Phase V

White

Phase W

Not used

Not used

169

236

Red

Blue

–

–

)

)

Pin No. Signal

+

1

5V (Power supply)

2 Phase U

3 Phase V

4 Phase W

0V (Power supply)

5

6 Not used

7 Not used

8 Not used

9 Not used

6

1

129

Moving Coil Model

SGLGW-

40A140C¡D

L1 L2 L3 L4 L5 L6 N1 N2

140 125 90

30 52.5 45 3 4 0.40

40A253C¡D 252.5 237.5 180 37.5 60 135 5 8 0.66

40A365C¡D 365 350 315 30 52.5 270 8 14 0.93

*: The values indicate the mass of moving coil with a hall sensor unit.

Approx. Mass*

kg

Page 6

External Dimensions Units: mm

3Magnetic Way : SGLGM-40¡¡¡C (Without mounting holes on the bottom)(Without mounting holes on the bottom)

SGLGM-40¡¡¡CT (With mounting holes on the bottom)(With mounting holes on the bottom)

1

-0.

(

)

1

Unit

1

L

3

-0.

Linear Servomotors

SGLGW

25.4

±

0.2

7.4

4-C1

(Coreless Type)

±

0.2

9

7.4

4

Linear

25.4

±

0.2

±

0.2

1

-C

9

Nameplate

Warning Label

X

7

X

22.5

22.5

X

X

Type

Standard

Force

45

Pitch

N-5.5 Dia. Mounting Holes (Per unit

45

Pitch

N-M5 Mounting Screws, Depth 13 (Per unit

(

Only for SGLGM- CT

2

L

)

2

L

)

Standard-force Magnetic Way

Model SGLGM-

40090C or 40090CT

40225C or 40225CT 225

40360C or 40360CT 360 315 8 3.1

40405C or 40405CT 405 360 9 3.5

(

)

22.5

(

)

22.5

)

L1 L2 N Approx. Mass kg

90 45 2 0.8

180 5 2.0

5.4

SGLGM-

¡¡¡

40

40450C or 40450CT 450 405 10 3.9

3High-force Magnetic Way : SGLGM-40 : SGLGM-40: SGLGM-40¡¡¡C-M (Without mounting holes on the bottom)(Without mounting holes on the bottom)

SGLGM-40¡¡¡CT-M (With mounting holes on the bottom)(With mounting holes on the bottom)

1(1

L

1

-0.

)

Unit

3

-0.

±

0.2

4-C1

31.8

62

12.7

Dia.

5

.

5

Dia.

10

)

13

(

5.4

SGLGM-

40

31.8

X-X

¡¡¡

12.2

CT

±

0.2

X-X

C

Note: If you have a pacemaker or any other

electronic medical device, do not go

near the magnetic way of the linear

servomotor.

12.27.4

±

0.2

7.4

4-C1

±

0.2

62

Dia.

5

.

5

Dia.

10

Linear Servomotors

7

22

Type

High

Force

Nameplate

X

Pitch

X

N-5.5 Dia. Mounting Holes (Per unit

5

.

X

45

Pitch

N-M5 Mounting Screws, Depth 13 (Per unit

Warning Label

45

High-force Magnetic Way

Model SGLGM-

40090C-M or 40090CT

40225C-M or 40225CT-M 225 180 5 2.6

40360C-M or 40360CT-M 360 315 8 4.1

40405C-M or 40405CT-M 405 360 9 4.6

40450C-M or 40450CT-M 450 405 10 5.1

222.5

L

)

2

L

)

L1 L2 N Approx. Mass kg

-M 90 45

(

)

22.5

(

)

22.5

2 1.0

5.4

X-X

SGLGM-

¡¡¡

40

62

15.9

Dia.

Dia.

5

.

10

5

)

5.4

13

(

X-X

SGLGM-

¡¡¡

C-M

40

CT-M

Note: If you have a pacemaker or any other

electronic medical device, do not go

near the magnetic way of the linear

servomotor.

62

Dia.

5

.

5

Dia.

10

130

Page 7

External Dimensions Units: mm

(3) SGLGW-603) SGLGW-60) SGLGW-60SGLGW-60

3Moving Coil: SGLGW-60A¡¡¡C¡ (With a connector by Tyco Electronics AMP K.K.)

5

6.5

4.8

5

.

0

14

Gap 0.

8

25.4

2

-Screws

#

4-40

7.2

Gap 0.

UNC

15

1

7

8

L

45

17

50

50

±

500

(

5.3

Dia.

(

7

Dia.

±

500

)

)

16

The moving coil moves in the direction indicated by the arrow when current flows in the order of phase U, V, and W.

4

L

4

45

30

98

L

Mounting Holes

N2-M4 Tapped Holes, Depth

L

L

L

6

6

1

3

Mounting Holes on Both Sides

1-M4

Tapped Holes, Depth

N

2

6

Nameplate

15

(

)

7.5

83

Hall Sensor

Connector Specifications

9

5

Pin Connector :

17

23090-02

JE-

by DDK Ltd.

The Mating Connector

Socket Connector :

17

JE-

17L-002

Stud :

17L-002C1

Moving Coil Model

SGLGW-

(D8C

13090-02

C or

6

)

(D8C

1

)

Pin No. Signal

+

1

5V (Power supply)

2 Phase U

3 Phase V

4 Phase W

0V (Power supply)

5

6 Not used

7 Not used

8 Not used

9 Not used

L1 L2 L3 L4 L5 L6 N1 N2

60A140C¡ 140 125 90 30

Linear Servomotor

Connector Specifications

Plug : 350779-1

Pin : 350561-3 or

350690-3 (No.1 to 3)

350654-1

350669-1 (No.4)

by Tyco Electronics AMP K.K.

The Mating Connector

350780-1

Cap :

350570-3

Socket :

350689-3

or

Hall Sensor Output Signals

Pin No. Signal

1

Phase U

Phase V

2

Phase W

3

4 FG Green

Wire Color

Red

White

Blue

When the moving coil moves in the

direction indicated by the arrow in the

figure, the relationship between the hall

sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu, Vv,

Vw becomes as shown in the figure below.

Vu

Inverse

Vv

Power

(V)

Vw

0 180 360 540

52.5 45 3 4 0.48

60A253C¡ 252.5 237.5 180 37.5 60 135 5 8 0.82

60A365C¡ 365 350 315 30 52.5 270 8 14 1.16

*: The values indicate the mass of moving coil with a hall sensor unit.

Su

Sv

Sw

Electrical Angle(°

Approx. Mass

)

*

kg

131

Page 8

External Dimensions Units: mm

3Moving Coil: SGLGW-60A¡¡¡C¡D (With a connector by Interconnectron GmbH)

5

6

4.8

5

.

0

14

2

-Screws

#

4-40

UNC

L

45

17

50

25.4

5

.

7.2

(

5.3

50

±

Dia.

(

7

Dia.

500

±

500

)

)

16

The moving coil moves in the direction indicated by the arrow when current flows in the order of phase U, V, and W.

4

L

4

45

15

1

30

98

L

Mounting Screws, Depth

2-M4

N

L

L

L

Linear Servomotors

SGLGW

6

Tapped Holes, Depth

1

3

Mounting Holes on Both Sides

1-M4

Tapped Holes, Depth

N

2

(Coreless Type)

6

6

Name plate

(

7.5

)

Linear

15

83

7

8

Gap 0.

8

Gap 0.

Hall Sensor

Connector Specifications

9

5

Pin Connector :

17

23090-02

JE-

by DDK Ltd.

The Mating Connector

Socket Connector :

17

13090-02

JE-

17L-002

Stud :

17L-002C1

(D8C

(D8C

C or

6

1

Moving Coil Model

SGLGW-

60A140C¡D

Pin No. Signal

+

1

5V (Power supply)

2 Phase U

3 Phase V

)

)

4 Phase W

0V (Power supply)

5

6 Not used

7 Not used

8 Not used

9 Not used

L1 L2 L3 L4 L5 L6 N1 N2

140 125 90

60A253C¡D 252.5 237.5 180 37.5 60 135 5 8 0.82

60A365C¡D 365 350 315 30 52.5 270 8 14 1.16

*: The values indicate the mass of moving coil with a hall sensor unit.

Linear Servomotor

Connector Specifications

2

1

6

5

Extension: SROC06JMSCN

3

Pin :

by Interconnectron GmbH

4

The Mating Connector

: SPUC06KFSDN

Plug

Socket:

Pin No. Signal

1

Phase U

Phase V

2

Phase W

3

Not used

4

Not used

5

6 FG Green

30 52.5 45 3 4 0.48

021.423.1020

020.030.1020

Wire Color

Red

White

Blue

–

–

236

169

Hall Sensor Output Signals

When the moving coil moves in the direction indicated by the arrow in the figure, the

relationship between the hall sensor output

signals Su, Sv, Sw and the inverse power of

each motor phase Vu, Vv, Vw becomes as

shown in the figure below.

Vu

Su

Inverse

Vv

Power

(V)

Vw

Sv

0 180 360 540

Electrical Angle

Sw

(

)

°

Approx. Mass*

kg

Linear Servomotors

132

Page 9

External Dimensions Units: mm

3Magnetic Way : SGLGM-60¡¡¡C (Without mounting holes on the bottom)(Without mounting holes on the bottom)

SGLGM-60¡¡¡CT (With mounting holes on the bottom)(With mounting holes on the bottom)

1

-0.

(

)

1

Unit

1

L

3

-0.

7.4

4-C1

25.4

±

0.2

±

0.2

9

7.4

4-C1

25.4

±

0.2

±

0.2

9

Nameplate

X

Warning Label

82

7

22.5

22.5

X

5.5

Dia. Mounting Holes (Per unit

N-

45

Pitch

X

2

L

)

2

L

(

(

22.5

22.5

)

)

Dia.

5

.

5

45

Pitch

5.4

X-X

SGLGM-

¡¡¡

60

C

Type

Standard

Force

N-M5 Mounting Screws, Depth 13 (Per unit

X

(

Only for SGLGM- CT

Standard-force Magnetic Way

Model SGLGM-

60090C or 60090CT

60225C or 60225CT 225

60360C or 60360CT 360 315 8 4.1

60405C or 60405CT 405 360 9 4.6

)

)

L1 L2 N Approx. Mass kg

90 45 2 1.1

180 5 2.6

60450C or 60450CT 450 405 10 5.1

3High-force Magnetic Way : SGLGM-60 : SGLGM-60: SGLGM-60¡¡¡C-M (Without mounting holes on the bottom)(Without mounting holes on the bottom)

SGLGM-60¡¡¡CT-M (With mounting holes on the bottom)(With mounting holes on the bottom)

1(1

L

1

-0.

)

Unit

3

-0.

±

0.2

4-C1

31.8

82

12.7

Dia.

5

.

5

Dia.

10

Dia.

10

)

13

(

5.4

X-X

SGLGM-

¡¡¡

60

CT

Note: If you have a pacemaker or any other

electronic medical device, do not go

near the magnetic way of the linear

servomotor.

31.8

±

12.27.4

0.2

7.4

±

0.2

4-C1

12.2

±

0.2

133

7

Type

High

Force

22.5

Nameplate

X

Pitch

X

N-5.5 Dia. Mounting Holes (Per unit

Pitch

X

N-M5 Mounting Screws, Depth 13 (Per unit

X

(

Only for SGLGM- CT-M

Warning Label

45

45

High-force Magnetic Way

Model SGLGM-

60090C-M or 60090CT

60225C-M or 60225CT-M 225 180 5 3.3

60360C-M or 60360CT-M 360 315 8 5.2

60405C-M or 60405CT-M 405 360 9 5.9

60450C-M or 60450CT-M 450 405 10 6.6

222.5

L

)

2

L

)

)

L1 L2 N Approx. Mass kg

-M 90 45

(

)

22.5

)

(

22.5

2 1.3

5.4

X-X

SGLGM-

¡¡¡

60

82

82

15.9

Dia.

Dia.

5

.

5

10

)

13

(

SGLGM-

¡¡¡

C-M

Note: If you have a pacemaker or any other

60

electronic medical device, do not go

near the magnetic way of the linear

servomotor.

5.4

X-X

CT-M

Dia.

5

.

5

Dia.

10

Page 10

Linear Servomotors

SGLGW

External Dimensions Units: mm

(4) SGLGW-90

3Moving Coil: SGLGW-90A¡¡¡C¡ (With a connector by Tyco Electronics AMP K.K.)(With a connector by Tyco Electronics AMP K.K.)

(Coreless Type)

Linear

49

26

110

1

Gap

11

Gap

.

8

50.8

Hall Sensor

Connector Specifications

9

5

Pin Connector :

17

23090-02

JE-

by DDK Ltd.

The Mating Connector

Socket Connector :

17

JE-

Stud :

13090-02

17L-002

C or

17L-002C1

(D8C

(D8C

2

-Screws

4-40

#

Cable

20276

UL

2

1

6

1

138

)

UNC

26

,AWG

(

Pin No. Signal

1

2 Phase U

3 Phase V

4 Phase W

5

6 Not used

7 Not used

)

8 Not used

9 Not used

)

5.3

Cable

+

5V (Power supply)

0V (Power supply)

UL

50

±

500

2517

50

Nameplate

±

500

15

,AWG

Linear Servomotor

Connector Specifications

Plug

Pin :

by Tyco Electronics AMP K.K.

The Mating Connector

Cap

Socket :

)

5

.

10

(

:

350779-1

350218-3

350547-3

350654-1

350669-1

:

350780-1

350536-3

350550-3

L

5

L

4

or

(No.1 or

(No.

)

4

or

95

65

Pin No. Signal

1

2

3

)

3

4 FG Green

6

L

N2-M6Mounting Screws, Depth

9

32

×

2

N1-M6

1

L

3

L

The moving coil moves in the direction indicated by the arrow

when current flows in the order of phase U, V, and W.

(

Mounting Screws, Depth

on Both Sides

)

9

8

121

2

L

Hall Sensor Output Signals

When the moving coil moves in the direction indicated by the arrow in the figure, the

Wire Color

relationship between the hall sensor output

Phase U

Phase V

Phase W

signals Su, Sv, Sw and the inverse power of

Red

each motor phase Vu, Vv, Vw becomes as

White

shown in the figure below.

Blue

Vu

Su

Inverse

Power

(V)

Vv

Vw

Sv

0 180 360 540

Electrical Angle

Sw

(

)

°

Linear Servomotors

Moving Coil Model

SGLGW-

90A200C¡ 199

L1 L2 L3 L4 L5 L6 N1 N2

189 130 40

60 95 3 4 2.2

90A370C¡ 367 357 260 40 55 285 5 8 3.65

90A535C¡ 535 525 455 40 60 380 8 10 4.95

*: The values indicate the mass of moving coil with a hall sensor unit.

Approx. Mass*

kg

134

Page 11

External Dimensions Units: mm

3Magnetic Way: SGLGM-90¡¡¡A

Warning Label

63

N-Mounting Holes (Per unit

5

.

8

19

Neameplate

X

X

Pitch

31.5

63

Pitch

N-M6 Mounting Screws, Depth 14.

1

-0.

(

)

1

Unit

1

L

3

-0.

(

)

2

L

31.5

13.8

5

.

95

110

18

5

.

50.8

)

2

L

(44)

Dia.

12

Dia.

6

.

6

6.5

X-X

5

Magnetic Way

SGLGM-

90252A 252 189 4 7.3

90504A

Note: If you have a pacemaker or any other electronic medical device, do not go near the magnetic way of the linear servomotor.

L1 L2 N

504 441 8 14.7

Approx. Mass

kg

135

Loading...

Loading...