YASKAWA SGDV-***A**A Series, SGDV-180A, SGDV-***F**A Series, SGDV-***D**A Series, SGDV-200A Safety Precautions

...

Σ-V

シリーズACサーボパック

SGDV

安全上のご注意

形式 SGDV-FA

SGDV-AA

SGDV-DA

製品を安全にお使い頂くために,本書を必ずお読みください。

また,本書をお手元に保管していただくとともに,最終的に

本製品をご使用になるユーザー様のお手元に確実に届けられるよう,

お取り計らい願います。

Σ-V

SERIES AC SERVOPACK SGDV

SAFETY PRECAUTIONS

Type SGDV-FA

SGDV-AA

SGDV-DA

To properly use the product, read this manual thoroughly

and retain for easy reference, inspection, and maintenance.

Ensure the end user receives this manual.

MANUAL NO. TOBP C710800 10E

Copyright © 2007 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission

of Yaskawa. No patent liability is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to

improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation

of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of

the information contained in this publication.

General Precautions

• The drawings presented in this manual are sometimes shown

without covers or protective guards. Always replace the cover or

protective guard as specified first, and then operate the products

in accordance with the manual.

• The drawings presented in this manual are typical examples and

may not match the product you received.

• This manual is subject to change due to product improvement,

specification modification, and manual improvement. When this

manual is revised, the manual code is updated and the new manual is published as a next edition. The edition number appears on

the front and back covers.

• Yaskawa will not take responsibility for the results of unauthorized modifications of this product. Yaskawa shall not be liable for

any damages or troubles resulting from unauthorized modification.

Safety Information

The following conventions are used to indicate precautions in this manual.

Failure to heed precautions provided in this manual can result in serious or

possibly even fatal injury or damage to the products or to related equipment

and systems.

WARNING

CAUTION

PROHIBITED

MANDATORY

Indicates precautions that, if not heeded, could possibly result in loss of life or serious injury.

Indicates precautions that, if not heeded, could result

in relatively serious or minor injury, damage to the

product, or faulty operation.

In some situations, the precautions indicated could

have series consequences if not heeded.

Indicates prohibited actions that must not be performed. For example, this symbol would be used to in-

dicate that fire is prohibited as follows: .

Indicates compulsory actions that must be performed.

For example, this symbol would be used as follows to

indicate that grounding is compulsory: .

E-1

Notes for Safe Operation

WARNING

• Never touch any rotating motor parts while the motor is running.

Failure to observe this warning may result in injury.

• Before starting operation with a machine connected, make

sure that an emergency stop can be applied at any time.

Failure to observe this warning may result in injury or damage to

the product.

• Never touch the inside of the SERVOPACKs.

Failure to observe this warning may result in electric shock.

• Do not remove the cover of power supply terminal while the

power is ON.

Failure to observe this warning may result in electric shock.

• Do not touch terminals for five minutes after the power is

turned OFF.

Residual voltage may cause electric shock.

• Do not touch terminals while the charge indicator is lit.

Residual voltage may cause electric shock.

• Do not touch terminals for five minutes after voltage resistance test.

Residual voltage may cause electric shock.

• Follow the procedures and instructions for the trial operation

as noted in the applicable manual for that product.

Malfunctions that occur after the servomotor is connected to the

equipment not only damage the equipment, but may also cause an

accident resulting in death or injury.

• The output range of multi-turn data for Σ-V series absolute

detection system differs from that for conventional systems

(15-bit encoder and 12-bit encoder). Especially when “Infi-

nite length positioning system” of Σ series is to be configured with Σ-V series, be sure to make the system

modification.

E-2

WARNING

• The multi-turn limit value must be changed only for special

applications.

Changing it inappropriately or unintentionally can be dangerous.

• If the Multi-turn Limit Disagreement alarm occurs, check the

setting of parameter Pn205 in the SERVOPACK to be sure

that it is correct.

If Fn013 is executed when an incorrect value is set in Pn205, an

incorrect value will be set in the encoder. The alarm will disappear

even if an incorrect value is set, but incorrect positions will be

detected, resulting in a dangerous situation where the machine will

move to unexpected positions.

• Do not remove the front cover, cables, connectors, or

optional items on the foreside while the power is ON.

Failure to observe this warning may result in electric shock.

• Do not damage, press, exert excessive force or place heavy

objects on the cables.

Failure to observe this warning may result in electric shock, stopping operation of the product, or fire.

• Do not modify the product.

Failure to observe this warning may result in injury, damage to the

product, or fire.

• Provide an appropriate stopping device on the machine side

to ensure safety. A holding brake for a servomotor with

brake is not a stopping device for ensuring safety.

Failure to observe this warning may result in injury.

• Do not come close to the machine immediately after resetting momentary power loss to avoid an unexpected restart.

Take appropriate measures to ensure safety against an

unexpected restart.

Failure to observe this warning may result in injury.

• Connect the ground terminal to electrical codes (ground

resistance: 100 Ω or less for a SERVOPACK with a 200 V/

100 V power supply. 10 Ω or less for a SERVOPACK with a

400 V power supply).

Improper grounding may result in electric shock or fire.

E-3

WARNING

• Installation, disassembly, or repair must be performed only

by authorized personnel.

Failure to observe this warning may result in electric shock or

injury.

• The person who designs a system using the safety function

(Hard Wire Baseblock function) must have full knowledge of

the related safety standards and full understanding of the

instructions in Σ-V series User’s Manual Design and Maintenance.

Failure to observe this warning may result in injury or damage to

the product.

E-4

Storage and Transportation

CAUTION

• Do not store or install the product in the following places.

• Locations subject to direct sunlight.

• Locations subject to temperatures outside the range specified in the

storage/installation temperature conditions.

• Locations subject to humidity outside the range specified in the storage/installation humidity conditions.

• Locations subject to condensation as the result of extreme changes in

temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust, salts, or iron dust.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Failure to observe this caution may result in fire, electric shock, or damage to the product.

• Do not hold the product by the cables, motor shaft, or detector

while transporting it.

Failure to observe this caution may result in injury or malfunction.

• Do not place any load exceeding the limit specified on the packing box.

Failure to observe this caution may result in injury or malfunction.

• If disinfectants or insecticides must be used to treat packing

materials such as wooden frames, pallets, or plywood, the packing materials must be treated before the product is packaged,

and methods other than fumigation must be used.

Example: Heat treatment, where materials are kiln-dried to a

core temperature of 56°C for 30 minutes or more.

If the electronic products, which include stand-alone products and products installed in machines, are packed with fumigated wooden materials, the electrical components may be greatly damaged by the gases or

fumes resulting from the fumigation process. In particular, disinfectants

containing halogen, which includes chlorine, fluorine, bromine, or

iodine can contribute to the erosion of the capacitors.

E-5

Installation

CAUTION

• Never use the products in an environment subject to water, corrosive gases, inflammable gases, or combustibles.

Failure to observe this caution may result in electric shock or fire.

• Do not step on or place a heavy object on the product.

Failure to observe this caution may result in injury or malfunction.

• Do not cover the inlet or outlet ports and prevent any foreign

objects from entering the product.

Failure to observe this caution may cause internal elements to deteriorate resulting in malfunction or fire.

• Be sure to install the product in the correct direction.

Failure to observe this caution may result in malfunction.

• Provide the specified clearances between the SERVOPACK and

the control panel or with other devices.

Failure to observe this caution may result in fire or malfunction.

• Do not apply any strong impact.

Failure to observe this caution may result in malfunction.

E-6

Wiring

CAUTION

• Be sure to wire correctly and securely.

Failure to observe this caution may result in motor overrun, injury, or

malfunction.

• Do not connect a commercial power supply to the U, V, or W servomotor connection terminals.

Failure to observe this caution may result in injury or fire.

• Securely connect the power supply terminal screws and servomotor connection terminal screws.

Failure to observe this caution may result in fire.

• Do not bundle or run the main circuit cables and input/output signal lines or the encoder cables together in the same duct. Keep

power and signal lines separated by at least 30 cm.

• Use twisted-pair shielded wires or multi-core twisted pair

shielded wires for input/output signal lines and the encoder

cables.

The maximum length is 3 m for input/output signal lines and 20 m for

encoder cables.

• Do not touch the power terminals for 5 minutes after turning

power OFF because high voltage may still remain in the SERVOPAC K.

Make sure the charge indicator is out first before wiring or starting an

inspection.

• Observe the following precautions when wiring main circuit terminal blocks.

• If the main circuit terminal is the connector, remove the connector

from the SERVOPACK prior to wiring.

• Insert only one wire per insertion slot on the terminal block and the

connector.

• Make sure that the core wire is not electrically shorted to adjacent core

wires.

E-7

CAUTION

• Install the battery at either the host controller and the battery unit

of the encoder.

It is dangerous to install batteries at both simultaneously, because that

sets up a loop circuit between the batteries.

• Always use the specified power supply voltage.

An incorrect voltage may result in fire.

• Take appropriate measures to ensure that the input power supply

is supplied within the specified voltage fluctuation range. Be particularly careful in places where the power supply is unstable.

An incorrect power supply may result in damage to the product.

• Install external breakers or other safety devices against short-circuiting in external wiring.

Failure to observe this caution may result in fire.

• Take appropriate and sufficient countermeasures for each when

installing systems in the following locations.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic

fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

Failure to observe this caution may result in damage to the product.

• Do not reverse the polarity of the battery when connecting it.

Failure to observe this caution may damage the battery, SERVOPACK,

and servomotor or cause it to explode.

• Wiring or inspection must be performed by a technical expert.

E-8

Operation

CAUTION

• Conduct trial operation on the servomotor alone with the motor

shaft disconnected from machine to avoid any unexpected accidents.

Failure to observe this caution may result in injury.

• Before starting operation with a machine connected, change the

settings to match the parameters of the machine.

Starting operation without matching the proper settings may cause the

machine to run out of control or malfunction.

• Avoid frequently turning power ON and OFF.

Since the SERVOPACK has a capacitor in the power supply, a high

charging current flows when power is turned ON. Frequently turning

power ON and OFF causes main power devices like capacitors and

fuses to deteriorate, resulting in unexpected problems.

• Forced stop function with forward/reverse overtravel is not effective during JOG mode operation using utility function Fn002 and

zero point search using Fn003.

• When using the servomotor for a vertical axis, install the safety

devices to prevent workpieces to fall off due to occurrence of

alarm or overtravel. Set the servomotor so that it will stop in the

zero clamp state at occurrence of overtravel.

Failure to observe this caution may cause workpieces to fall off due to

overtravel.

• When not using the tuning-less function, set to the correct

moment of inertia ratio Pn103.

Setting to an incorrect moment of inertia ratio may cause vibration.

• Do not touch the SERVOPACK heatsinks, regenerative resistor,

or servomotor while power is ON or soon after the power is

turned OFF.

Failure to observe this caution may result in burns due to high temperatures.

• Do not make any extreme adjustments or setting changes of

parameters.

Failure to observe this caution may result in injury or damage to the

product due to unstable operation.

E-9

CAUTION

• When an alarm occurs, remove the cause, reset the alarm after

confirming safety, and then resume operation.

Failure to observe this caution may result in damage to the product, fire,

or injury.

• Do not use the holding brake of the servomotor for braking.

Failure to observe this caution may result in malfunction.

• Always use the servomotor and SERVOPACK in one of the specified combinations.

Failure to observe this caution so may result in fire or malfunction.

• The servomotor stopping method of turning the main-circuit or

control-circuit power OFF without turning the servo OFF during

operation can not be set in Parameter Pn001.

• When turning the main-circuit power OFF without turning the servo

OFF:

The servomotor will be stopped by dynamic braking (DB).

• When turning the control-circuit power OFF without turning the servo

OFF:

The stopping method will vary depending on the SERVOPACK

model.

Refer to the Σ-V Series User's Manual Design and Maintenance for

details.

Maintenance and Inspection

CAUTION

• Do not disassemble the SERVOPACK.

Failure to observe this caution may result in electric shock or injury.

• Do not attempt to change wiring while the power is ON.

Failure to observe this caution may result in electric shock or injury.

• When replacing the SERVOPACK, resume operation only after

transferring the previous SERVOPACK parameters to the new

SERVOPACK.

Failure to observe this caution may result in damage to the product.

E-10

Disposal

CAUTION

• When disposing of the products, treat them as ordinary industrial

waste.

Warranty Information

Free Warranty Period

This product is warranted for twelve months after being delivered to Yaskawa’s

customer or if applicable eighteen months from the date of shipment from

Yaskawa’s factory whichever comes first.

Scope of Warranty

If a Yaskawa product is found to be defective due to Yaskawa workmanship or

materials and the defect occurs during the warranty period, Yaskawa will provide a replacement, repair the defective product, and provide shipping to and

from the site free of charge.

However, if the Yaskawa Authorized Service Center determines that the problem

with a Yaskawa product is not due to defects in Yaskawa’s workmanship or

materials, then the customer will be responsible for the cost of any necessary

repairs.

E-11

1 Checking Products on Delivery

MODEL SGDV-1R6A01A

Use proper grounding techniques.

A

Check the following items when the Σ-V Series SERVOPACK is delivered.

Is the delivered SERVOPACK the one

that was ordered?

Is there any damage? Check the overall appearance, and check for

Are there any loose screws? Check screws for looseness using a screw-

If any of the above items are faulty or incorrect, contact your Yaskawa sales

representative or the dealer from whom you purchased the products.

1.1 Nameplate

Items Check Method

Check the model numbers marked on the

nameplates of the SERVOPACK. Check the

accessories as well.

damage or scratches that may have occurred

during shipping.

driver.

pplicable

power supply

Serial number

SERVOPACK type

Rated output current

SERVOPACK nameplate

E-12

2 Installation

2 Installation

Observe the Installation instructions in Σ-V series User’s Manual Setup

Rotational Motor (SIEPS80000043) or Σ-V series User’s Manual Setup Linear Motor (SIEPS80000044).

For installation sites, use proper care with the following notes.

Situation Notes on Installation

When installed in a control

panel

When installed near a heating unit

When installed near a

source of vibration

When installed in a place receiving corrosive gases

Others • Avoid installation in a hot and humid place or where

• Design the control panel size, unit layout, and cooling method so that the surrounding air temperature

of the SERVOPACK does not exceed 55°C.

• When installing multiple SERVOPACKs side by

side in a control panel, install cooling fans and provide sufficient space around each SERVOPACK to

allow cooling by fan and natural convection. Provide a space of 5 mm or more between each of the

SGDV-R70A, R90A, 1R6A, or 2R8A SERVOPACKs and 10 mm or more for any other SERVOPAC K s.

Suppress radiation heat from the heating unit and a

temperature rise caused by convection so that the surrounding air temperature of the SERVOPACK does

not exceed 55°C.

Install a vibration isolator underneath the SERVOPACK to prevent it from receiving vibration.

Corrosive gases do not immediately affect the SERVOPACK but will eventually cause SERVOPACK or

contactor-related devices to malfunction. Take appropriate action to protect against corrosive gases.

excessive dust or iron powder is present in the air.

• Be sure there is no condensation or freezing.

• Keep the surrounding air temperature 45 °C or less

to ensure long-term reliability.

E-13

3 Wiring

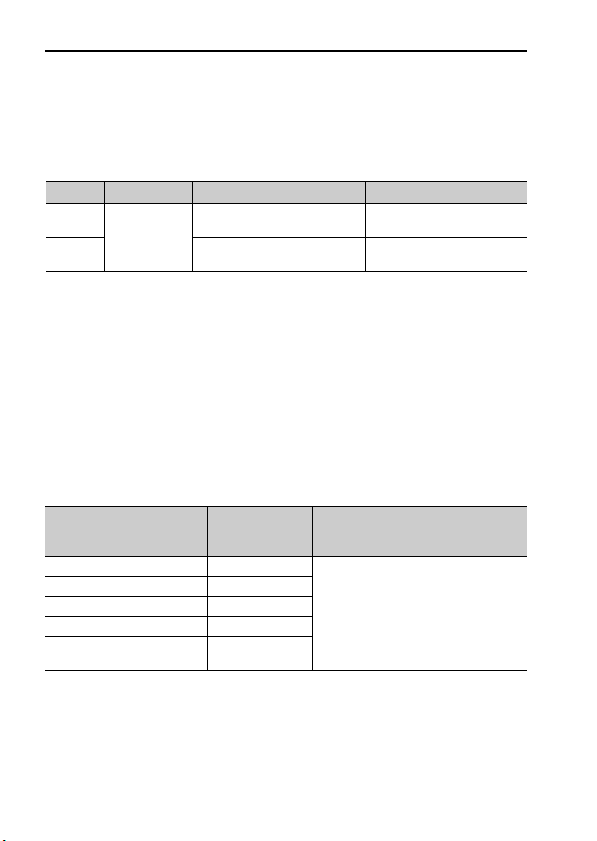

3.1 Molded-case Circuit Breaker and Fuse

When choosing a molded-case circuit breaker and a fuse capacity, refer to

this table. The rated input current of the SERVOPACK is the nominal value

at the rated load.

Select the appropriate capacity in accordance with the specified derating.

Cutoff characteristics (25°C): 300% five seconds min.

SERVOPACK

Model SGDV-

R70F 0.2 1.5 0.38 250 V 240 V

R90F 0.3 2.5

2R1F 0.7 5

2R8F 1.4 10

R70A 0.2 1.0 0.2

R90A 0.3 1.0

1R6A 0.6 2.0

2R8A 1 3.0

3R8A 1.4 3.0

5R5A 1.6 6.0

7R6A 2.3 6.0

120A 3.2 7.5 0.25

180A 4 10

200A 5.9 15

330A 7.5 25 0.3

470A 10.7 29

550A 14.6 37

590A 21.7 54 0.45 600 V 480 V

780A 29.6 73

1R9D 1.1 1.4 1.2

3R5D 2.3 2.9

5R4D 3.5 4.3

8R4D 4.5 5.8 1.4

120D 7.1 8.6

170D 11.7 14.5

210D 12.4 17.4 1.5

260D 14.4 21.7

280D 21.9 31.8 1.7

370D 30.6 43.4

Power Supply

Capacity per

SERVOPACK

(kVA)

Rated Input Current of

SERVOPACK

(A

Main circuit

power supply

rms

E-14

)

Control circuit

power supply

Rated Voltage

Fuse MCCB

3.2 Main Circuit Wiring

Do not use SGDV SERVOPACKs in a power-supply environment where a

short-circuit current of 5000 A or more flows after a short circuit occurs.

The maximum available voltage is

• With 100V class: 115 Vrms

• With 200V class: 230 Vrms

• With 400V class: 480 Vrms (neutral grounding)

SERVOPACKs must be used with UL-listed fuses or circuit breakers, in

accordance with the guidelines of the National Electrical Code (NEC).

Use 75 °C heat-resistant copper wires or an equivalent.

Use a flexible cable for moving parts when the SERVOPACK is used with a

linear servomotor.

3.3 Wire Size and Tightening Torque

Cable Types

• Wire sizes are selected for three cables per bundle at 40°C surrounding air

temperature with the rated current.

• Use cable with a minimum withstand voltage of 600 V for main circuits.

• If cables are bundled in PVC or metal ducts, consider the reduction ratio

of the allowable current.

• Use heat-resistant cables under high surrounding air or panel temperatures where normal vinyl cables will rapidly deteriorate.

• Use cables within the allowable moment of inertia.

• Do not use cables under continuous regenerative state.

The following table shows the wire size and allowable current for three

cables. Use a cable whose specifications meet or are less than the values in

the table.

3 Wiring

E-15

600-V Heat-resistant Vinyl Cables (HIV)

Nominal

Cross

AWG S ize

20 0.5 19/0.18 39.5 6.6 5.6 4.5

- 0.75 30/0.18 26.0 8.8 7.0 5.5

18 0.9 37/0.18 24.4 9.0 7.7 6.0

16 1.25 50/0.18 15.6 12.0 11.0 8.5

14 2.0 7/0.6 9.53 23 20 16

12 3.5 7/0.8 5.41 33 29 24

10 5.5 7/1.0 3.47 43 38 31

8 8.0 7/1.2 2.41 55 49 40

6 14.0 7/1.6 1.35 79 70 57

4 22.0 7/2.0 0.85 91 81 66

Note: The values in the table are only for reference.

Section

Diameter

mm

2

Configuration

Number of

wires/mm

2

Conductive

Resistance

Ω/km

Allowable Current

at Surrounding Air

Temperature A

30°C 40°C 50°C

Wire Size

The following table shows the markings for the power-supply terminals,

the wire sizes, the screw sizes and torque for the ground terminals of the

SERVOPACK.

L1, L2, L3: Main circuit power-supply input terminals

U, V, W: Servomotor connection terminals

L1C, L2C / 24 V, 0 V: Control power input terminals

B1, B2: External regenerative resistor terminals

: Ground terminal

E-16

Wire Size and Tightening Torque for Connectors

SERVOPACK

Model SGDV-

R70F HIV

R90F

2R1F HIV

2R8F

R70A HIV

R90A

1R6A

2R8A HIV

3R8A HIV

5R5A

7R6A

120A

1R9D HIV

3R5D

5R4D

Terminal Symbol and Wire Size(mm2)

L1, L2, L3

/L1, L2

1.25

2.0

1.25

2.0

1.25

U, V, W

HIV

1.25

HIV

1.25

2.0

HIV

1.25

L1C, L2C

/24V, 0V

HIV

1.25

HIV

1.25

HIV

1.25

B1/+, B2

HIV

1.25

HIV

1.25

HIV

1.25

HIV2.0

or more

HIV2.0

or more

HIV2.0

or more

3 Wiring

Ground Terminal

Te rm i na l

Tightening

Screw

Size

M4 1.2 to 1.4

M4 1.2 to 1.4

M4 1.2 to 1.4

Torque

(Nxm)

E-17

Wire Size and Tightening Torque for Terminal Screws

SERVOPACK

Model SGDV-

180A HIV

200A HIV

330A HIV

470A HIV

550A HIV

590A HIV

780A

8R4D HIV

120D

170D HIV

210D HIV

260D HIV

280D HIV

370D HIV

* 1. The tightening torque is 1.8 Nxm for the following terminal on the SGDV-330A

SERVOPACK.

Terminal Symbol and Wire Size(mm2)

HIV

3.5

5.5

HIV

8.0

HIV

14.0

HIV

22.0

HIV

2.0

HIV

3.5

HIV

5.5

HIV

8.0

HIV

14.0

L1C, L2C

/24V, 0V

HIV

1.25

HIV

1.25

L1, L2, L3 U, V, W

3.5

5.5

8.0

14.0

22.0

2.0

3.5

3.5

5.5

8.0

14.0

B1/+, B2

HIV

2.0

HIV

3.5

HIV

5.5

HIV

8.0

HIV

22.0

HIV

1.25

HIV

2.0

HIV

3.5

HIV

5.5

HIV

8.0

・Servomotor connection terminals (U, V, W)

* 2. The tightening torque is 2.5 to 3.8 N

SGDV-470A, -550A, -590A, and -780A SERVOPACKs.

xm for the following terminal on the

・Ground terminal ( )

* 3. The tightening torque is 1.4 N

xm for all terminals other than the ground terminal

( ) on the SGDV-8R4D and -120D SERVOPACKs.

* 4. The screw size is M5 and the tightening torque is 2.4 N

minals on the SGDV-170D SERVOPACK.

・Main circuit power-supply input terminals (L1, L2, L3)

・Servomotor connection terminals (U, V, W)

The screw size is M4 and the tightening torque is 1.8 N

minals on the SGDV-170D SERVOPACK.

・Control power input terminals (24 V, 0 V)

E-18

Te rm i na l

Screw

Size

HIV2.0

or more

HIV2.0

or more

M4

M6

M4*31.2 to 1.4*

M5*41.6 to 2.4*

M6*54.5 to 5.5*

xm for the following ter-

xm for the following ter-

Tightening

Torque

(Nxm)

1.2 to 1.4*

4.5 to 5.5*

1

2

3

4

5

3 Wiring

・External regenerative resistor terminals (B1/+, B2)

* 5. The tightening torque is 2.5 to 3.8 N

SGDV-210D, -260D, -280D, and -370D SERVOPACKs.

xm for the following terminals on the

・Ground terminal ( )

The screw size is M4 and the tightening torque is 1.4 N

xm for the following ter-

minals on the SGDV-210D, -260D, -280D, and -370D SERVOPACKs.

・Control power input terminals (24 V, 0 V)

E-19

4 Inspection

4.1 SERVOPACK Inspection

For inspections and maintenance of the SERVOPACK, follow the inspection

procedures in the table below at least once every year.

Item Frequency Procedure Remedy

Exterior At least once

a year

Loose

screws

4.2 SERVOPACK’s Parts Replacement Schedule

The following electric or electronic parts are subject to mechanical wear or

deterioration over time. To avoid failure, replace these parts at the frequency

indicated.

Refer to the standard replacement period in the following table, contact your

Yaskawa representative. After an examination of the part in question, we

will determine whether the parts should be replaced or not.

The parameters of any SERVOPACKs overhauled by Yaskawa are reset to

the factory settings before shipping. Be sure to confirm that the parameters

are properly set before starting operation.

Part

Cooling Fan 4 to 5 years • Surrounding Air Temperature:

Smoothing Capacitor 7 to 8 years

Relays -

Fuses 10 years

Aluminum Electrolytic

Capacitor on Circuit Board

Check for dust, dirt, and oil

on surfaces.

Check for loose terminal

block and connector screws.

Standard

Replacement

Period

Annual average of 30°C

• Load Factor: 80% max.

• Operation Rate: 20 hours/day

max.

5 years

Clean with compressed air

or cloth.

Tighten any loose screws.

Operating Conditions

E-20

5 Compliance with CE Marking

5 Compliance with CE Marking

5.1 Installation Conditions of EMC Directive

To adapt the EMC directives (EN55011 group1 classA, EN61800-3) for a

combination test using servomotors and SERVOPACKs from the Σ-V

series, a ferritic core, a noise filter, or a surge absorber must be used. For

details, read the Installation instructions in Σ-V series User’s Manual Setup

Rotational Motor (SIEPS80000043) or Σ-V series User’s Manual Setup Linear Motor (SIEPS80000044).

However, because this product is built-in, check that the following conditions are still met after being installed in the final product.

5.2 Conditions Corresponding to Low Voltage Directive

To adapt SERVOPACKs to the Low Voltage Directive, make sure that the

following environmental conditions are met.

• Installation category: III

• Pollution degree: 2

• Protection class: 10

• Altitude: 1000 m max.

Be sure to install a fuse for the main circuit power-supply as well as meeting

these environmental conditions. To choose the fuse capacity, refer to 3.1

Model-case Circuit Breaker and Fuse Capacity.

E-21

6 Installation Conditions of UL Standards

To adapt SERVOPACKs to the UL standards, make sure that the following

conditions are met.

• Pollution degree: 2

• Protection class: 10

• Altitude: 1000 m max.

• Tightening torque: Varies*

• The end user must use a transient suppressive device on the 24 VDC control power input of the 400 V main power input type SERVOPACKs to

limit transient overvoltages to 500 V maximum.

(Example: surge absorber, etc.)

• Current capacity: Varies*

* 1. Use the maximum tightening torque listed in the table of Wire Size and

Tightening Torque for Connectors and for Terminal Screw.

* 2. Install the fuse or circuit breakers listed in the 3.1 Molded-case Circuit

Breaker and Fuse in accordance with the guidelines of NEC.

* 3. The following restrictions apply, depending on the SERVOPACKs used.

SERVOPACK

Model SGDV-

180A, 200A Available rated current for modeled-case circuit breaker: 40 A or

330A • Available rated current for non-time delay fuse: 70 A or less

470A, 550A • Available rated current for molded-case circuit breaker: 60 A or

590A, 780A • Available rated current for molded-case circuit breaker: 100 A or

210D, 260D • Available rated current for molded-case circuit breaker: 60 A or

280D, 370D • Available rated current for molded-case circuit breaker: 80 A or

less

• Available rated current for time delay fuse: 40 A or less

• Do not use single wires.

less

• Available rated current for non-time delay fuse or time delay

fuse: 60 A or less

less

• Available rated current for non-time delay fuse or time delay

fuse: 100 A or less

(Available rated current for class J non-time delay or faster fuse:

125 A or less)

less

• Available rated current for non-time delay fuse: 60 A or less

• Available rated current for time delay fuse: 35 A or less

less

• Available rated current for non-time delay fuse: 125 A or less

• Available rated current for time delay fuse: 75 A or less

1

2, *3

Restrictions

E-22

6 Installation Conditions of UL Standards

For the SGDV-330A, -590A, -780A, -280D and -370D SERVOPACKs, connect cables using following terminal kits.

Terminal Kit

Model

(Quantity of

Crimp Terminal

and Sleeve

Required per

SERVOPACK)

JZSP-CVT9330A-E: 1 set

JZSP-CVT9780A-E: 1 set

JZSP-CVT9280D-E: 1 set

JZSP-CVT9370D-E: 1 set

*12

*12

*12

*12

SERVOPACK

Model SGDV-

330A L1C, L2C

590A, 780A L1, L2, L3

280D U,V,W

370D U,V,W

Connection

Ter m in a ls

(Control Power

Input)

-1, -2

(DC Reactor)

B1/+, -2

(DC Power Input)

U, V, W

(Motor Main Circuit)

(Input Power

and Motor Main

Circuit)

(Main Power Input)

U, V, W

(Motor Main Circuit)

(Input Power

and Motor Main

Circuit)

(Motor Main Circuit)

(Input Power

and Motor Main

Circuit)

(Motor Main Circuit)

(Input Power

and Motor Main

Circuit)

Crimp

Terminal

Model

(By J.S.T.Mfg.

Co.,Ltd.)

*1

R1.25-4

5.5-4NS TP-006

8-4NS TP-014

*2

R2-4

*3

R22-6

*4

R2-6

*5

R8-6

*4

R2-6

*6

R14-6

*4

R2-6

Sleeve

(By Tokyo

Dip Co.,Ltd.)

TP-003

(Black)

(White)

(Black)

TP-038

(Black)

TP-014

(Black)

TP-022

(Black)

Model

*7

*8

*9

*10

*9

*11

* 1. The 170721-1 crimp terminal manufactured by Tyco Electronics AMP K.K. can

E-23

be used as an alternative.

* 2. The 170722-1 crimp terminal manufactured by Tyco Electronics AMP K.K. can

be used as an alternative.

* 3. The 170733-1 crimp terminal manufactured by Tyco Electronics AMP K.K. can

be used as an alternative.

* 4. The 170724-1 crimp terminal manufactured by Tyco Electronics AMP K.K. can

be used as an alternative.

* 5. The 170728-2 crimp terminal manufactured by Tyco Electronics AMP K.K. can

be used as an alternative.

* 6. The 170730-2 crimp terminal manufactured by Tyco Electronics AMP K.K. can

be used as an alternative.

* 7. The TCM-21-14 sleeve manufactured by Shinagawa Shoko CO., LTD. can be

used as an alternative.

* 8. The TCM-53-12 sleeve manufactured by Shinagawa Shoko CO., LTD. can be

used as an alternative.

* 9. The TCM-141-14 sleeve manufactured by Shinagawa Shoko CO., LTD. can be

used as an alternative.

* 10. The TCM-381-14 sleeve manufactured by Shinagawa Shoko CO., LTD. can be

used as an alternative.

* 11. The TCM-221-14 sleeve manufactured by Shinagawa Shoko CO., LTD. can be

used as an alternative.

* 12. Since it is packed up together with SERVOPACK, it is not necessary to order the

terminal kit.

E-24

6 Installation Conditions of UL Standards

For the SERVOPACKs without special terminal kit other than those in the

table on the previous page, connect the cable to the ground terminal using

following terminal kits.

Terminal Kit

Model

(Quantity of

Terminal Kit

Required per

SERVOPACK)

JZSP-CVT9FGM4-E: 1 set

SERVOPACK

Model SGDV-

F, R70A,

R90A, 1R6A,

2R8A, 3R8A,

5R5A, 7R6A,

120A, 180A,

200A, 1R9D,

3R5D, 5R4D,

8R4D, 120D

Connection

Terminals

(Input Power

and Motor

Main Circuit)

Terminal

Screw

SIze

M4

Crimp Termi-

nal Model

(By J.S.T.Mfg.

Co.,Ltd.)

*1

R2-4

*4

170D M5

470A, 550A

210D, 260D

* 1. The 170722-1 crimp terminal manufactured by Tyco Electronics AMP K.K. can

be used as an alternative.

* 2. The 170723-1 crimp terminal manufactured by Tyco Electronics AMP K.K. can

be used as an alternative.

* 3. The 170724-1 crimp terminal manufactured by Tyco Electronics AMP K.K. can

be used as an alternative.

* 4. Since it is not attached to SERVOPACK, it is necessary to order. Please place an

M6

R2-5

R2-6

*2

*3

JZSP-CVT9FGM5-E: 1 set

JZSP-CVT9FGM6-E: 1 set

*4

*4

order to the Yaskawa Control.

E-25

Dimensional Drawing for Crimp Terminals

19.1

8.3 6.8

φ4.3

8.0

φ3.4

φ5.6

1.0

(mm)

Model: R1.25-4 Model: 5.5-4NS

φ4.3

8.0

0.8

7.0

15.8

4.8

φ1.7

(mm)

φ3.4

Model: 8-4NS Model: R22-6

φ4.3

8.0

1.2

9.3

21.8

8.5

φ4.5

(mm)

7.1

φ

φ6.4

16.5

1.8

Model: R8-6 Model: R14-6

φ6.4

12.0

1.2

9.3

23.8

8.5

φ4.5

(mm)

7.1

φ

φ6.4

12.0

1.5

E-26

13.5

33.7

13.3

29.8

12.0

10.5

φ7.7

(mm)

φ5.8

(mm)

11. 5

φ

φ9.0

6 Installation Conditions of UL Standards

21.8

11

4.8

(mm)

φ6.4

12

φ2.3

φ4.1

0.8

Model: R2-4 Model: R2-5

φ4.3

φ5.3

8.5

0.8

Model: R2-6

7.8

16.8

4.8

φ2.3

(mm)

φ4.1

0.8

9.5

16.8

7.3

4.8

φ2.3

(mm)

φ4.1

E-27

7 Overload Characteristics

The overload detection level is set under hot start* conditions at a servomotor surrounding air temperature of 40°C.

10000.0

1000.0

Detecting time (s)

100.0

B

C

A

10.0

1.0

100%

Rated torque

(Rated current)

* A hot start indicates that both the SERVOPACK and the servomotor have

run long enough at the rated load to be thermally saturated.

Note: The overload protection characteristics of A, B, and C in the figure are

applicable when the SERVOPACK is combined with one of the follow-

Rated torque + Maximum torque

Approx.

2

Maximum torque

Rated torque

Maximum torque

(Maximum current)

ing servomotors.

E-28

Motor Type

SGMSV

-A

SGMSV

-D

SGMGV

-A

Graph

Type

SGMAV SGMJV SGMPS

–-A5 to -08–––––

A

– – – -10 to -70 -10 to -50 -03 to -1E -03 to -1E

B

-A5 to 10 – -01 to -15 – – – –

C

× 100%

SGMGV

-D

Revision History

54321

The revision dates and numbers of the revised manuals are given on the bottom

of the back cover.

MANUAL NO. TOBP C710800 10B

Published in Japan December 2007 07-3

1

Date of

publication

Revision number

Date of original

publication

Date of

Publication

September

2010

June 2009 7 Revision: Graph of overload characteris-

August 2008 All

June 2008 Back cover Revision: Address

December 2007 All

March 2007 – – First edition

Rev.

Section Revised Content

No.

3.1 Addition: Rated voltage

7 Addition: Current description

Back cover Revision: Address

Addition: Original instructions

tics

chapters

chapters

6 Revision: Installation conditions of UL

Completely revised

Addition: 100-V class SERVOPACKs

(model: SGDV-FA)

200-V class SERVOPACKs

(model: SGDV-120A, -180A, -200A, and

-330A)

standards

Σ-V

SERIES AC SERVOPACK SGDV

SAFETY PRECAUTIONS

IRUMA BUSINESS CENTER (SOLUTION CENTER)

480, Kamifujisawa, Iruma, Saitama 358-8555, Japan

Phone 81-4-2962-5151 Fax 81-4-2962-6138

YASKAWA AMERICA, INC.

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone (800) YASKAWA (800-927-5292) or 1-847-887-7000 Fax 1-847-887-7310

YASKAWA ELETRICO DO BRASIL LTDA.

Avenida Fagundes Filho, 620 Sao Paulo-SP CEP 04304-000, Brazil

Phone 55-11-3585-1100 Fax 55-11-5581-8795

YASKAWA EUROPE GmbH

Hauptstraβe 185, Eschborn 65760, Germany

Phone 49-6196-569-300 Fax 49-6196-569-398

YASKAWA ELECTRIC UK LTD.

1 Hunt Hill Orchardton Woods Cumbernauld, G68 9LF, United Kingdom

Phone 44-1236-735000 Fax 44-1236-458182

YASKAWA ELECTRIC KOREA CORPORATION

7F, Doore Bldg. 24, Yeoido-dong, Yeoungdungpo-gu, Seoul 150-877, Korea

Phone 82-2-784-7844 Fax 82-2-784-8495

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

151 Lorong Chuan, #04-01, New Tech Park 556741, Singapore

Phone 65-6282-3003 Fax 65-6289-3003

YASKAWA ELECTRIC (SHANGHAI) CO., LTD.

No.18 Xizang Zhong Road. 17F, Harbour Ring Plaza Shanghai 200001, China

Phone 86-21-5385-2200 Fax 86-21-5385-3299

YASKAWA ELECTRIC (SHANGHAI) CO., LTD. BEIJING OFFICE

Room 1011, Tower W3 Oriental Plaza, No.1 East Chang An Ave.,

Dong Cheng District, Beijing 100738, China

Phone 86-10-8518-4086 Fax 86-10-8518-4082

YASKAWA ELECTRIC TAIWAN CORPORATION

9F, 16, Nanking E. Rd., Sec. 3, Taipei 104, Taiwan

Phone 886-2-2502-5003 Fax 886-2-2505-1280

YASKAWA ELECTRIC CORPORATION

YASKAWA

In the event t hat the end us er of this pro duct is to be the military and said prod uct is to be e mployed in any wea pons systems o r the manufactur e

thereof, the export will fal l under the re levant regulation s as stipulat ed in the Foreig n Exchange and Foreign Trade Regulatio ns. Therefore, be sure

to follow all procedures and submit all re levant documenta tion according to any and all rules, regula tions and laws that may apply.

Specificatio ns are subject to change wi thout notice for ongoing produ ct modificatio ns and improveme nts.

© 2007-2010 YASKAWA ELECTRIC CORPORATION. All rig hts reserved.

MANUAL NO. TOBP C710800 10E

Published in Japan September 2010 07-3

10-6-3

Original instructions

5 -0

Loading...

Loading...