259

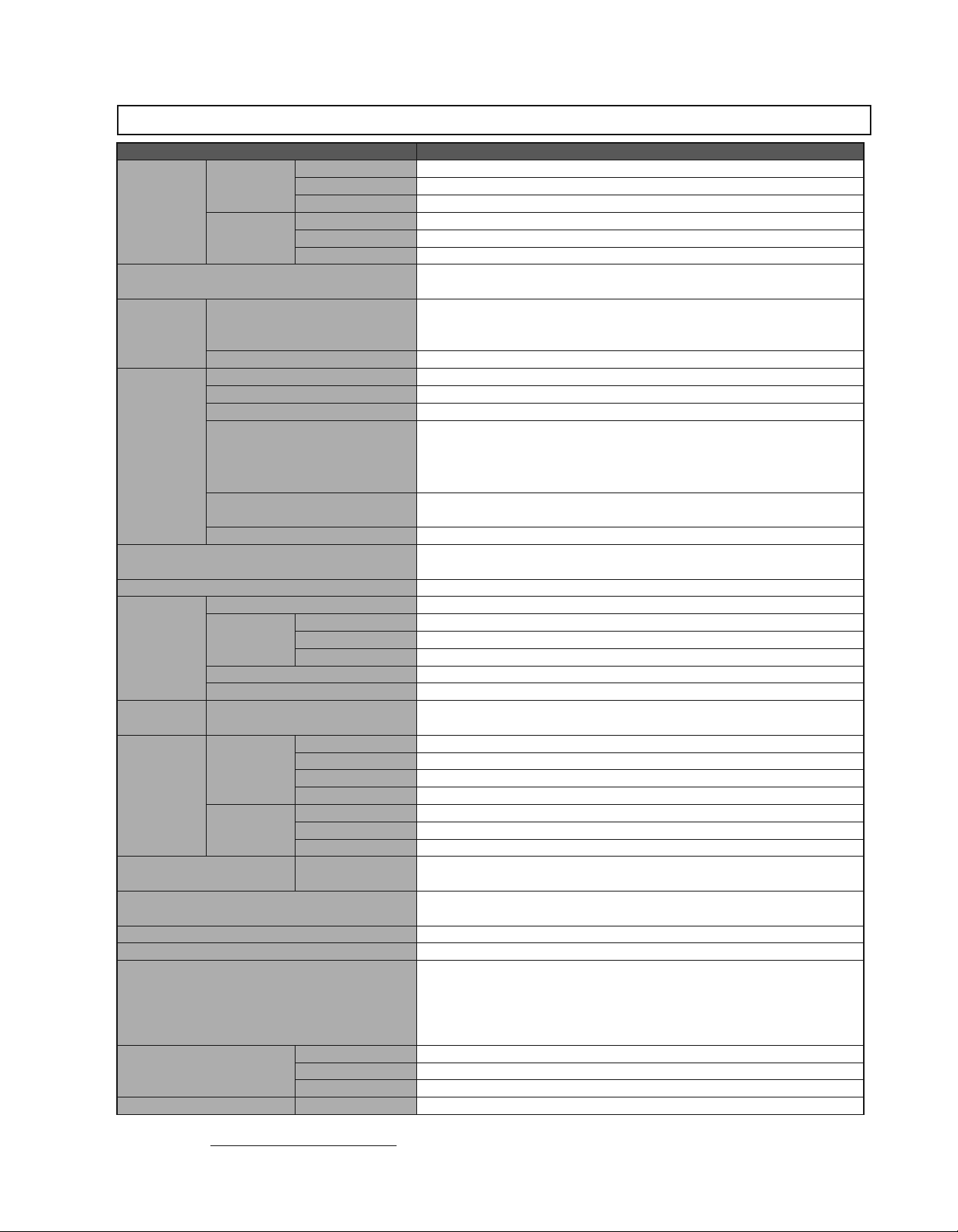

Specifications

Items Specifications

100 V

Main Circuit

Input Power

Supply

Control Circuit

Control Method

Feedback

Operating

Conditions

Compliant Standards

Configuration

Performance

I/O Signals Encoder Output Pulses

Communications

Display Power Charge

Analog Monitor

Protective Functions Overcurrent, Overvoltage, low voltage, overload, regeneration error

Utility Functions Alarm history, JOG operation, origin search, etc.

Regenerative Processing

Safety Functions

Option Card Function Feedback Serial encoder communications input for fully-closed loop control

*: Speed regulation is defined as follows:

Speed regulation =

The motor speed may change due to voltage variations or temperature variation. The ratio of speed changes to the rated speed represent speed regulation due to voltage and

temperature variations.

Rotary Servomotors

Linear Servomotors Serial converter or serial data

Surrounding/Storage Temperature

Ambient/Storage Humidity 90%RH or less (no condensation)

Vibration/Shock Resistance Vibration resistance: 4.9 m/s

Protection class/Pollution degree

Others

Elevation 1000 m or less

Speed Control Range

Speed

Regulation*

Torque Control Tolerance (Repeatability)

Soft Start Time Setting 0 to 10 s (can be set individually for acceleration and deceleration.)

RS-422A

Communications

USB

Communications

No-load motor speed − Total load motor speed

200 V

400 V

100 V

200 V

400 V

Load Regulation

Voltage Regulation

Temperature Regulation

Interface Digital operator, RS-422A port of personal computers etc.

1:N communications

Axis address setting Set by parameters

Function

Interface

1:N communications Compliant with USB1.1 standard

Function

Input /HWBB1, /HWBB2: Hard wire base block signal

Output EDM1: Status monitor (fixed output) of built-in safety circuit

Compliant Standards EN954 category 3 Stop category 0, IEC61508 SIL 2

Rated motor speed

Single-phase 100 to 1

Three-phase 200 to 230 VAC

Three-phase 380 to 480 VAC

Single-phase 100 to 115 VAC

Single-phase 200 to 230 VAC

±

24 VDC

For 100 V, for 200 V, for 400 V, single-phase or three-phase full-wave rectification

IGBT PWM control, sine-wave driven

Serial encoder: 13-bit (incremental encoder)

: 17-bit (incremental/absolute encoder)

: 20-bit (incremental/absolute encoder)

Surrounding temperature: 0 to

Protection class: IP 1X, pollution degree: 2

Do not use SERVOPACKs in the following locations:

·Locations subject to corrosive or flammable gasses

·Locations subject to exposure to water, oil, or chemicals

·Locations subject to dust, including iron dust, and salts

Do not use SERVOPACKs in the following locations:

·Locations subject to static electricity noise, strong electromagnetic/magnetic fields, radioactivity

UL 508C

EN50178, EN55011 class A group 1, EN61800-3, EN61800-5-1

Base-mounted (Rack-mounting available as an option for some models. 6 kW or more models are duct-ventilated.)

1:5000 (The lowest speed of the speed control range is the speed at which the servomotor will not stop with a rated torque load.)

0% to 100% load:

Rated voltage:

25

±

Phase A, phase B, phase C: line driver output

The number of dividing pulse: Any setting ratio is available.

RS-422A port: N

Status display, parameter settings, adjustment functions, utility functions

Personal computers (application: engineering tool SigmaWin

Status display, parameter settings, adjustment functions, utility functions

CHARGE for main circuit power supply input confirmation

One LED (orange)

Analog monitor connector built in for monitoring speed, torque and other reference signals.

Number of points: 2

100 VAC model: External regenerative resistor (optional)

200 VAC SGDV-R70A, -R90A, -1R6A, -2R8A: External regenerative resistor (optional)

200 VAC SGDV-470A, -550A, -590A, -780A: External regenerative resistor unit (optional)

200 VAC models other than shown above: Built-in regenerative resistor

400 VAC SGDV-210D, -260D, -280D, -370D: External regenerative resistor unit (optional)

400 VAC models other than shown above: Built-in regenerative resistor

15%

±

±

10% : 0% (at rated speed)

±

25˚C : ±0.1% max. (at rated speed)

1%

=

15 max. available

× 100%

+

15 VAC

10% to −15% 50/60 Hz

+

10% to −15% 50/60 Hz

+

10% to −15% 50/60 Hz

+

10% to −15% 50/60 Hz

+

10% to −15% 50/60 Hz

+

55˚C, storage temperature: −20 to +85˚C

2

, Shock resistance: 19.8 m/s

0.01% max. (at rated speed)

2

+

)

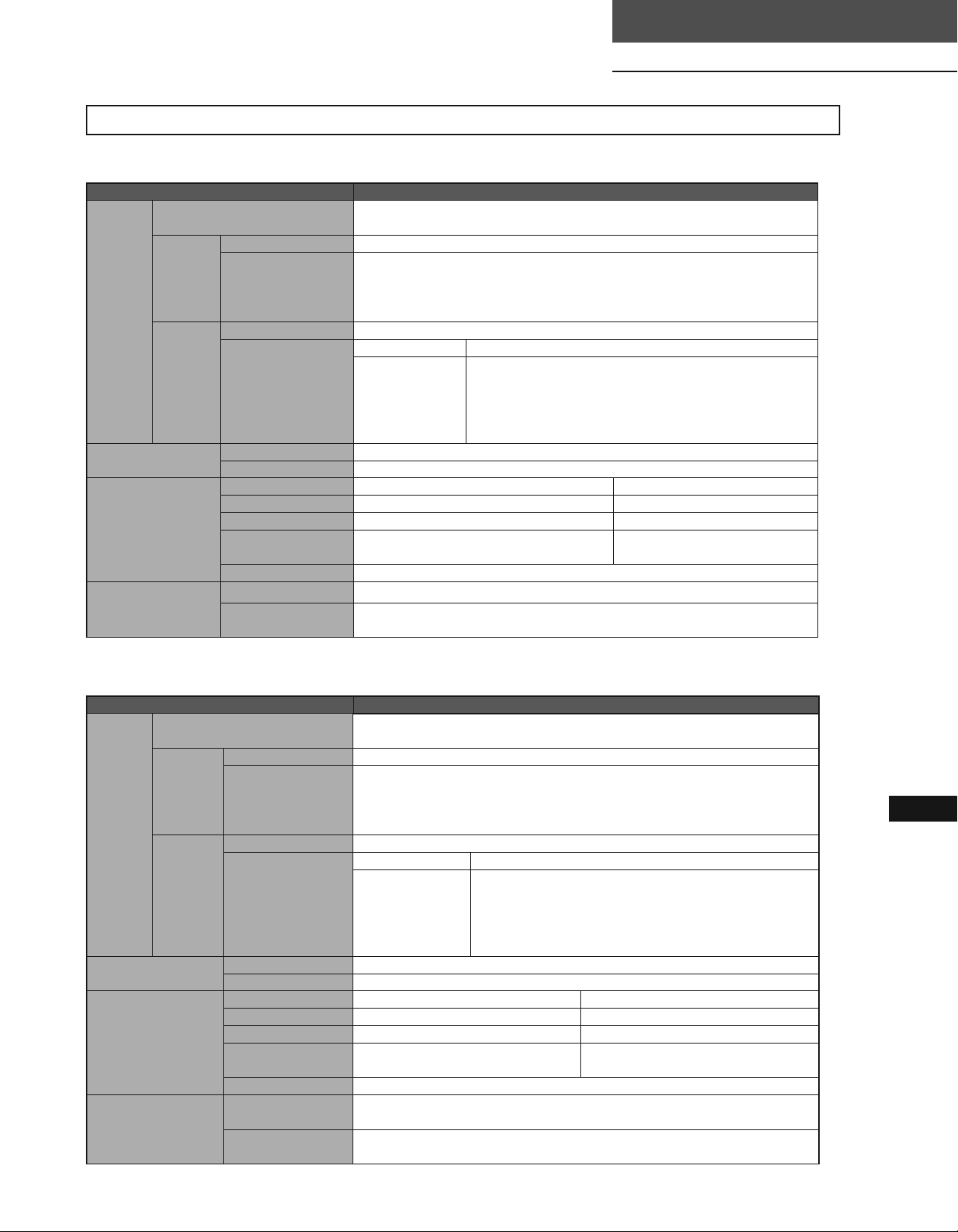

Specifications

Specifications

1Rotary Servomotors

Items Specifications

Encoder Output Pulses

Sequence

Input

I/O Signal

Sequence

Output

Panel Operator

MECHATROLINK

Communications

Command Method

Number of Channels

Function

Fixed Output Servo alarm (ALM)

Output Signals which can

be allocated

Display 7-segment 1-digit LED (red)

Switch Rotary switch: 16 positions, DIP switch: 4 poles

Communications Protocol MECHATROLINK-II MECHATROLINK-I

Transmission Speed 10 Mbps 4 Mbps

Transmission Cycle

Number of Words for

Link Transmission

Station Address 41H to 5FH (max. number of slaves: 30)

Performance Position control, speed control, and torque control through MECHATROLINK communications

Command Input

Phase A, phase B, phase C: line driver output

The number of dividing pulse: Any setting ratio is available.

7 channels

Signal allocations and positive/negative logics can be modified.

Homing deceleration switch signal (/DEC), external latch signal (/EXT1 to 3), forward run prohibited

(P-OT), reverse run prohibited (N-OT),

forward current limit (/P-CL), reverse current limit (/N-CL)

Number of Channels

Function

250

μ

s, 0.5 to 4.0 ms (multiple of 0.5 ms)

Can be switched between

17-bytes /station and 32-bytes / station.

MECHATROLINK commands (for sequence, motion, data setting/reference, monitor, adjustment, and

other commands.)

MECHATROLINK-II Type SERVOPACKs

SGDV-¡¡¡¡11/15

3 channels

Signal allocations and positive/negative logics can be modified.

Positioning completion (/COIN), speed coincidence detection

(/V-CMP), servomotor rotation detection (/TGON), servo ready (/S-RDY), torque limit

detection (/CLT), speed limit detection

(/VLT), brake interlock (/BK), warning (/WARN), NEAR (/NEAR)

2 ms

17-bytes /station

1Linear Servomotors

Items Specifications

Encoder Output Pulses

Sequence

Input

I/O Signal

Sequence

Output

Panel Operator

MECHATROLINK

Communications

Command Method

Number of Channels

Function

Fixed Output Servo alarm (ALM)

Output Signals which can

be allocated

Display 7-segment 1-digit LED (red)

Switch Rotary switch: 16 positions, piano switch: 4 poles

Communications Protocol MECHATROLINK-II MECHATROLINK-I

Transmission Speed 10 Mbps 4 Mbps

Transmission Cycle

Number of Words for

Link Transmission

Station Address 41H to 5FH (max. number of slaves: 30)

Performance

Command Input

Phase A, phase B, phase C: line driver output

The number of dividing pulse: Any setting ratio is available.

7 channels

Signal allocations and positive/negative logics can be modified.

Homing deceleration switch signal (/DEC), external latch signal (/EXT1 to 3), forward run prohibited

(P-OT), reverse run prohibited (N-OT),

forward current limit (/P-CL), reverse current limit (/N-CL)

Number of Channels 3 channels

Function

μ

s, 0.5 to 4.0 ms (multiple of 0.5 ms)

250

Can be switched between

17-bytes /station and 32-bytes / station.

Position control, speed control, and force control through

MECHATROLINK-II communications

MECHATROLINK commands and MECHATROLINK-II commands

(for sequence, motion, data setting/reference, monitor, adjustment, and other commands.)

Signal allocations and positive/negative logics can be modified. Positioning

completion (/COIN), speed coincidence detection

(/V-CMP), servomotor movement detection (/TGON),

servo ready (/S-RDY), force limit detection (/CLT),

speed limit detection (/VLT), brake interlock (/BK),

warning (/WARN), NEAR (/NEAR)

2 ms

17-bytes /station

MECHATROLINK-II Type SERVOPACKs

260

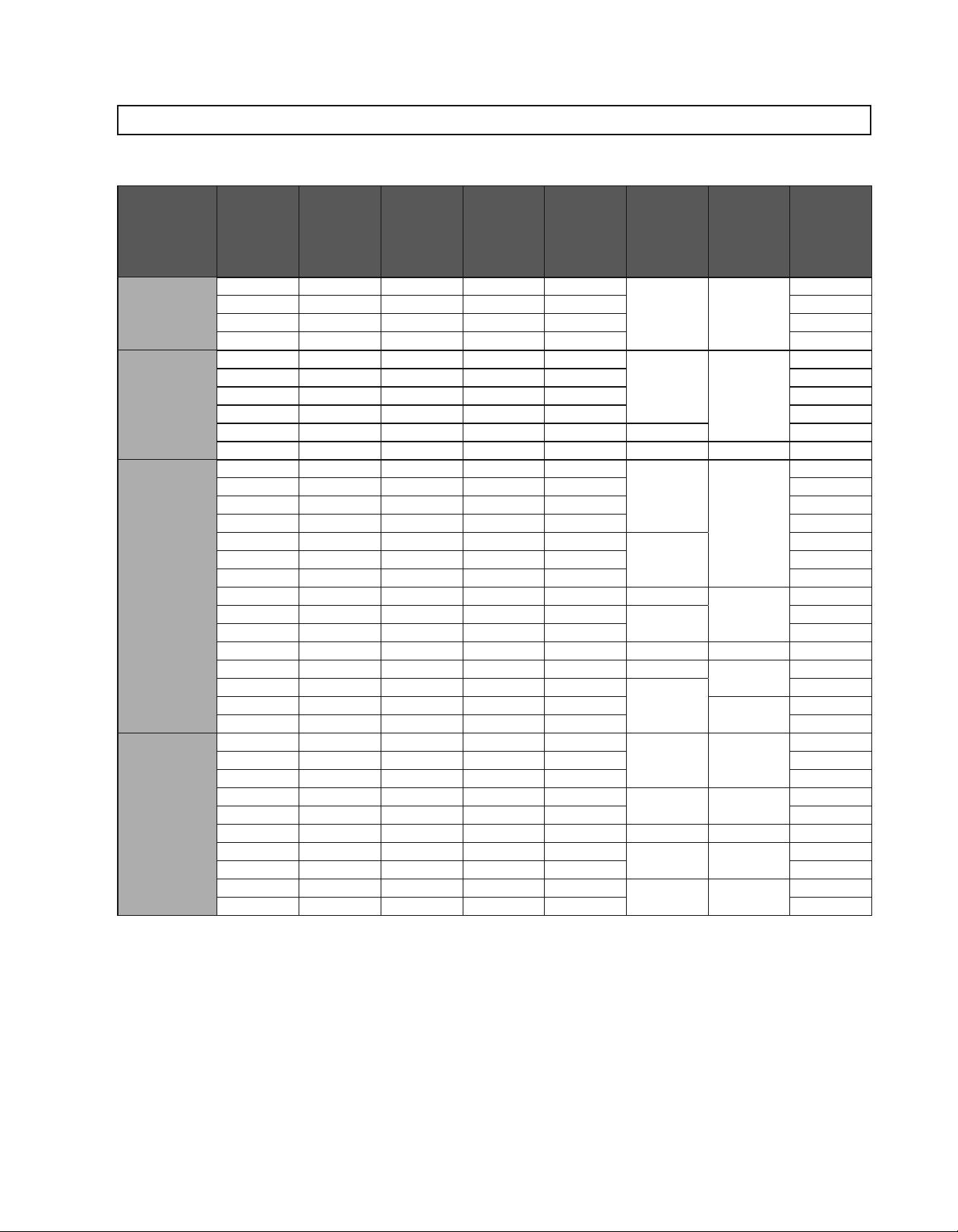

Power Supply Capacities and Power Losses

The following table shows SERVOPACK's power supply capacities and power losses at the rated output.

The following table shows SERVOPACK's power supply capacities and power losses at the rated output.

Regenerative

Power Loss

Main Circuit

Power

Supply

Signal-phase

100 V

Applicable

Servomotor

Max.

Capacity

kW

0.05 R70F

SERVOPACK

Model

SGDV-

Power Supply

Capacity

kVA

Output Current

A

0.2 0.66 5.4

Main Circuit

Power Loss

W

0.1 R90F 0.3 0.91 7.8 24.8

0.2 2R1F 0.7 2.1 14.4 31.4

0.4 2R8F 1.4 2.8 25.6 42.6

0.05 R70A 0.2 0.66 5.2

0.1 R90A 0.3 0.91 7.4 24.4

Single-phase

200 V

0.2 1R6A 0.7 1.6 13.7 30.7

0.4 2R8A 1.2 2.8 24.9 41.9

0.75 5R5A 1.9 5.5 52.7 8 77.7

1.5 120A 4 11.6 68.2 10 22 100.2

0.05 R70A 0.2 0.66 5.1

0.1 R90A 0.3 0.91 7.3 24.3

0.2 1R6A 0.6 1.6 13.5 30.5

0.4 2R8A 1 2.8 24.0 41.0

0.5 3R8A 1.4 3.8 20.1

0.75 5R5A 1.6 5.5 43.8 68.8

Three-phase

200 V

1.0 7R6A 2.3 7.6 53.6 78.6

1.5 120A 3.2 11.6 65.8

2.0 180A 4 18.5 111.9

3.0 200A 5.9 19.6 113.8 161.4

5.0 330A 7.5 32.9 263.7 36 27 326.7

6.0 470A 10.7 46.9 279.4 (180)

7.5 550A 14.6 54.7 357.8

11 590A 21.7 58.6 431.7

15 780A 29.6 78 599.0 647.0

0.5 1R9D 1.1 1.9 24.6

1.0 3R5D 2.3 3.5 46.1 81.1

1.5 5R4D 3.5 5.4 71.3 106.3

2.0 8R4D 4.5 8.4 77.9

Three-phase

400 V

3.0 120D 7.1 11.9 108.7 161.7

5.0 170D 11.7 16.5 161.1 36 24 221.1

6.0 210D 12.4 20.8 172.7

7.5 260D 14.4 25.7 218.6 245.6

11 280D 21.9 28.1 294.6

15 370D 30.6 37.2 403.8 433.8

*1: For the optional JUSP-RA04-E regenerative resistor unit.

*2: For the optional JUSP-RA05-E regenerative resistor unit.

*3: For the optional JUSP-RA18-E regenerative resistor unit.

*4: For the optional JUSP-RA19-E regenerative resistor unit.

Notes:

1 SGDV-R70F, -R90F, -2R1F, -2R8F, -R70A, -R90A, -1R6A, and -2R8A SERVOPACKs do not have built-in regenerative resistors.

If the regenerative energy exceeds the specified value, connect an external regenerative resistor (optional).

2 SGDV-470A, -550A, -590A, -780A, -210D, -260D, -280D, -370D SERVOPACKs do not have built-in regenerative resistors.

Be sure to connect a regenerative resistor unit (optional) or an external regenerative resistor (optional). For selection details, refer to page 293.

3 Regenerative resistor power losses are allowable losses. Take the following action if this value is exceeded.

· Remove the lead or short bar that is short-circuiting the SERVOPACK main circuit terminal B2 and B3.

(SGDV-3R8A, -5R5A, -7R6A, -120A, -180A, -200A, -330A, or 400-V class SERVOPACKs.)

· Install an external regenerative resistor (optional). For selection details, refer to page 293.

Resistor

Control Circuit

Power Loss

W

W

—17

—

17

—

17

8

10

16

*1

22

33

*2

(350)

48

14 21

28 25

*3

(180)

(350)

*4

27

30

Total Power

Loss

W

22.4

22.2

22.1

45.1

97.8

149.9

312.4

390.8

479.7

59.6

130.9

199.7

324.6

261

Loading...

Loading...