Page 1

Linear Series SGL□□/SGDH

USER'S MANUAL

SGLGW/SGLFW/SGLTW Linear Servomotors

SGDH SERVOPACK

YASKAWA

YASKAWA

YA S K A WA

MANUAL NO. YEA-SIA-S800-39.21

Page 2

Copyright © 2004 YASKAWA ELECTRIC AMERICA

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this

publication.

Page 3

About this Manual

Intended Audience

This manual is intended for the following users.

•

Those selecting Σ-II Series servodrives or peripheral devices for Σ-II Series servodrives.

•

Those wanting to know about the ratings and characteristics of Σ-II Series servodrives.

•

•

•

•

Description of Technical Terms

The terms in this manual are defined as follows:

• Servomotor or motor =

• SERVOPACK = Σ-II Series SGDH amplifier.

• Servodrive = A set including a servomotor and servo amplifier.

• Servo System = A servo control system that includes the combination of a servodrive with a host

• Parameter number = Numbers that the user inputs toward the SERVOPACK.

Indication of Reverse Signals

In this manual, the names of reverse signals (ones that are valid when low) are written with a forward slash (/)

before the signal name, as shown in the following example:

• S-ON

• P-CON

designing Σ-II Series servodrive systems.

Those

Those installing or wiring Σ-II Series servodrives.

Those performing trial operation or adjustments of Σ-II Series servodrives.

Those maintaining or inspecting Σ-II Series servodrives.

Linear Σ Series SGLGW, SGLFW and SGLTW linear servomotor

computer and peripheral devices.

/S-ON

=

/P-CON

=

iii

Page 4

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed precautions provided

in this manual can result in serious or possibly even fatal injury or damage to the products or to related equipment

and systems.

WARNING

CAUTION

PROHIBITED

MANDATORY

Indicates precautions that, if not heeded, could possibly result in loss of life or serious

injury.

Indicates precautions that, if not heeded, could result in relatively serious or minor

injury, damage to the product, or faulty operation.

In some situations, the precautions indicated could have serious consequences if not heeded.

Indicates prohibited actions that must not be performed. For example, this symbol

would be used as follows to indicate that fire is prohibited: .

Indicates compulsory actions that must be performed. For example, this symbol would

be used as follows to indicate that grounding is compulsory: .

The warning symbols for ISO and JIS standards are different, as shown below.

ISO JIS

The ISO symbol is used in this manual.

Both of these symbols appear on warning labels on Yaskawa products. Please abide by these warning labels

regardless of which symbol is used.

iii

Page 5

Notes for Safe Operation

Read this manual thoroughly before checking products on delivery, storage and transportation, installation,

wiring, operation and inspection, and disposal of the AC servodrive.

WARNING

• If you have a pacemaker or any other electronic medical device, do not go near the magnetic

way of the linear servomotor.

Failure to observe this warning may result in the malfunction of the medical device.

• Be sure to use nonmagnetic tools when installing or working close to the linear servomotor.

(Example: a beryllium-copper alloy hexagonal wrench set, made by NGK Insulators, Ltd.)

• If starting an operation with the linear servomotor in a machine, set the linear servomotor to

always allow emergency stops.

Failure to observe this warning may result in injury.

• Never touch the linear servomotor or machinery during operation.

Failure to observe this warning may result in injury.

• Before wiring, install the SERVOPACK and the linear servomotor.

Failure to observe this warning may result in electric shock.

• Do not operate switches with wet hands.

Failure to observe this warning may result in electric shock.

• Never touch the inside of the SERVOPACKs.

Failure to observe this warning may result in electric shock.

• Do not touch terminals for five minutes after the power is turned OFF.

Residual voltage may cause electric shock.

• Do not touch terminals for five minutes after voltage resistance test.

Residual voltage may cause electric shock.

• Make sure that the main circuit power cable, the control power cable, and the linear

servomotor main circuit cable are wired correctly.

Failure to observe this warning may result in damage to the SERVOPACK.

• Follow the procedures and instructions for trial operation precisely as described in this manual.

Malfunctions that occur after the servomotor is connected to the equipment not only damage the

equipment, but may also cause an accident resulting in death or injury.

• The SGDH SERVOPACK supports both AC and DC power. If DC power is supplied to the

SERVOPACK without setting Pn001=n1 (DC power input), the internal components of

the SERVOPACK will burn and may result in fire or serious damage.

Before using a DC power supply, be sure to check the parameter Pn001 setting.

• Do not remove the front cover, cables, connectors, or optional items while the power is ON.

Failure to observe this warning may result in electric shock.

• Do not damage, press, exert excessive force or place heavy objects on the cables.

Failure to observe this warning may result in electric shock, stopping operation of the product, or

burning.

iv

Page 6

WARNING

• Provide an appropriate stopping device on the machine side to ensure safety. A holding brake for a

servomotor with brake is not a stopping device for ensuring safety.

Failure to observe this warning may result in injury.

• Do not come close to the machine immediately after resetting momentary power loss to avoid an

unexpected restart. Take appropriate measures to ensure safety against an unexpected restart.

Failure to observe this warning may result in injury.

• Connect the ground terminal to electrical codes (ground resistance: 100 Ω or less).

Improper grounding may result in electric shock or fire.

• Installation, disassembly, or repair must be performed only by authorized personnel.

Failure to observe this warning may result in electric shock or injury.

• Do not modify the product.

Failure to observe this warning may result in injury or damage to the product.

Checking on Delivery

CAUTION

• Always use the linear servomotor and SERVOPACK in one of the specified combinations.

Failure to observe this caution may result in fire or malfunction.

Storage and Transportation

CAUTION

• Do not store or install the product in the following places.

• Locations subject to direct sunlight.

• Locations subject to temperatures outside the range specified in the storage or installation temperature conditions.

• Locations subject to humidity outside the range specified in the storage or installation humidity conditions.

• Locations subject to condensation as the result of extreme changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust, salts, or iron dust.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Failure to observe this caution may result in fire, electric shock, or damage to the product.

• Do not carry the linear servomotor by its cables.

Failure to observe this caution may result in injury or malfunction.

• Do not place any load exceeding the limit specified on the packing box.

Failure to observe this caution may result in injury or malfunction.

v

Page 7

Installation

CAUTION

• When unpacking and installing magnetic way, check that no metal fragments or magnetized objects near

the stator because they may be affected by the magnetic attraction of the magnetic way.

Failure to observe this caution may result in injury or damage to the magnetic way's magnets.

• Do not use the magnetic way near metal or other magnetized objects.

Failure to observe this caution may result in injury.

• Do not place clocks, magnetic cards, floppy disks, or measuring instruments close to the magnetic way.

Failure to observe this caution may result in malfunction or damage to these items by the magnetic force.

• Securely mount the linear servomotor on to the machine.

If the linear servomotor is not mounted securely, it may loosen during operation.

• Do not carry the magnetic way by its antimagnetic cover.

Failure to observe this caution may result in injury by the cover’s edge or the shape of the cover may become distorted.

Cover

Magnetic way

• Install SERVOPACKs, linear servomotors, and regenerative resistors on nonflammable objects.

Mounting directly onto or near flammable objects may result in fire.

• Never use the products in an environment subject to water, corrosive gases, inflammable gases, or

combustibles.

Failure to observe this caution may result in electric shock or fire.

• Do not step on or place a heavy object on the product.

Failure to observe this caution may result in injury.

• Do not cover the inlet or outlet parts and prevent any foreign objects from entering the product.

Failure to observe this caution may cause internal elements to deteriorate resulting in malfunction or fire.

• Be sure to install the product in the correct direction.

Failure to observe this caution may result in malfunction.

• Provide the specified clearances between the SERVOPACK and the control panel or with other devices.

Failure to observe this caution may result in fire or malfunction.

• Do not apply any strong impact.

Failure to observe this caution may result in malfunction.

vi

Page 8

Wiring

CAUTION

• Securely tighten the cable connector screws and securing mechanism.

If the connector screws and securing mechanism are not secure, they may loosen during operation.

• Use power lines and cables with a radius, heat resistance, and flexibility suitable for the system.

• If the SERVOPACK malfunctions, turn OFF the main circuit’s power supply of the SERVOPACK.

The continuous flow of a large current may cause fire.

• Use a noise filter to minimize the effects of electromagnetic damage.

Failure to observe this caution may result in electromagnetic damage to electronic devices used near the

SERVOPACK.

• Do not connect a three-phase power supply to the U, V, or W output terminals.

Failure to observe this caution may result in injury or fire.

• Securely connect the power supply terminals and motor output terminals.

Failure to observe this caution may result in fire.

• Do not bundle or run power and signal lines together in the same duct. Keep power and signal lines

separated by at least 30 cm (11.81 in).

Failure to observe this caution may result in malfunction.

• Use shielded twisted-pair wire or shielded multi-core twisted-pair wire for the signal lines and feedback lines

of the serial converter unit (SC).

The maximum wiring length is 3 m for the reference input line and 20 m for the SC feedback line.

• Do not touch the power terminals for five minutes after turning power OFF because high voltage may still

remain in the SERVOPACK.

Make sure the charge indicator is turned OFF first before starting an inspection.

• Avoid frequently turning power ON and OFF. Do not turn power ON or OFF more than once per minute.

Since the SERVOPACK has a capacitor in the power supply, a high charging current flows for 0.2 seconds when

power is turned ON. Frequently turning power ON and OFF causes main power devices such as capacitors and fuses

to deteriorate, resulting in unexpected problems.

• Observe the following precautions when wiring main circuit terminal blocks.

• Remove the terminal block from the SERVOPACK prior to wiring.

• Insert only one wire per terminal on the terminal block.

• Make sure that the core wire is not electrically shorted to adjacent core wires.

• Do not connect the SERVOPACK for 100 V and 200 V directly to a voltage of 400 V.

The SERVOPACK will be destroyed.

• Be sure to wire correctly and securely.

Failure to observe this caution may result in motor overrun, injury, or malfunction.

• Always use the specified power supply voltage.

An incorrect voltage may result in burning.

• Make sure that the polarity is correct.

Incorrect polarity may cause ruptures or damage.

• Take appropriate measures to ensure that the input power supply is supplied within the specified voltage

fluctuation range. Be particularly careful in places where the power supply is unstable.

An incorrect power supply may result in damage to the product.

vii

Page 9

CAUTION

• Install external breakers or other safety devices against short-circuiting in external wiring.

Failure to observe this caution may result in fire.

• Take appropriate and sufficient countermeasures for each when installing systems in the following

locations.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies including power supply lines.

Failure to observe this caution may result in damage to the product.

Operation

CAUTION

• Do not stand within the machine's range of motion during operation.

Failure to observe this caution may result in injury.

• Before operation, install a limit switch or stopper on the end of the slider to prevent unexpected movement.

Failure to observe this caution may result in injury.

• Before starting operation with a machine connected, change the settings to match the parameters of the

machine.

Starting operation without matching the proper settings may cause the machine to run out of control or malfunction.

• Forward run prohibited (P-OT) and reverse run prohibited (N-OT) signals are not effective during zero point

search mode using parameter Fn003.

• If using the linear servomotor on a vertical axis, install a safety device such as a counterbalance so that the

workpiece does not fall if an alarm or overtravel occurs.

The workpiece may fall during overtraveling.

• When not using the normal autotuning, set to the correct mass ratio.

Setting to an incorrect moment of inertia ratio may cause vibration.

• Do not touch the SERVOPACK heatsinks, regenerative resistor, or servomotor while power is ON or soon

after the power is turned OFF.

Failure to observe this caution may result in burns due to high temperatures.

• Do not make any extreme adjustments or setting changes of parameters.

Failure to observe this caution may result in injury due to unstable operation.

• When an alarm occurs, remove the cause, reset the alarm after confirming safety, and then resume

operation.

Failure to observe this caution may result in injury.

viii

Page 10

Maintenance and Inspection

CAUTION

• When replacing the SERVOPACK, transfer the previous SERVOPACK parameters to the new

SERVOPACK before resuming operation.

Failure to observe this caution may result in damage to the product.

• Do not attempt to change wiring while the power is ON.

Failure to observe this caution may result in electric shock or injury.

• Do not disassemble the linear servomotor.

Failure to observe this caution may result in electric shock or injury.

Disposal

CAUTION

• When disposing of the products, treat them as ordinary industrial waste.

General Precautions

Note the following to ensure safe application.

• The drawings presented in this manual are sometimes shown without covers or protective guards. Always replace

the cover or protective guard as specified first, and then operate the products in accordance with the manual.

• The drawings presented in this manual are typical examples and may not match the product you received.

• This manual is subject to change due to product improvement, specification modification, and manual

improvement. When this manual is revised, the manual code is updated and the new manual is published as a next

edition.

• If the manual must be ordered due to loss or damage, inform your nearest Yaskawa representative or one of the

offices listed on the back of this manual.

• Yaskawa will not take responsibility for the results of unauthorized modifications of this product. Yaskawa shall

not be liable for any damages or troubles resulting from unauthorized modification.

ix

Page 11

CONTENTS

About this Manual- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iii

Related Manuals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - v

Safety Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -vi

Notes for Safe Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii

1 Outline

1.1 Checking Products - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.1 Check Items- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

1.1.2 Linear Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

1.1.3 SERVOPACKs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

1.1.4 Serial Converter Units - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-4

1.2 Product Part Names - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.2.1 Linear Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-5

1.2.2 SERVOPACKs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-6

1.3 Examples of Servo System Configurations - - - - - - - - - - - - - 1-8

1.3.1 Single-phase, 200 V Main Circuit - - - - - - - - - - - - - - - - - - - - - - - - - - -1-8

1.3.2 Three-phase, 200 V Main Circuit - - - - - - - - - - - - - - - - - - - - - - - - - - -1-9

1.3.3 Three-phase, 400 V Main Circuit - - - - - - - - - - - - - - - - - - - - - - - - - -1-10

1.4 Applicable Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.4.1 North American Safety Standards (UL, CSA)- - - - - - - - - - - - - - - - - - 1-11

1.4.2 CE Marking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

2 Selections

2.1 Linear Servomotor Model Designation - - - - - - - - - - - - - - - - 2-2

2.1.1 Coil Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

2.1.2 Magnetic Way - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

2.2 SERVOPACK Model Designation- - - - - - - - - - - - - - - - - - - - 2-3

2.3 Σ-II Series SERVOPACKs and Applicable Linear

Servomotors

2.4 Serial Converter Units Models - - - - - - - - - - - - - - - - - - - - - 2-6

2.5 Selecting Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.6 Selecting Peripheral Devices- - - - - - - - - - - - - - - - - - - - - - - 2-9

2.6.1 Special Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-9

2.6.2 Molded-case Circuit Breaker and Fuse Capacity - - - - - - - - - - - - - - - 2-11

2.6.3 Noise Filters, Magnetic Contactors, Surge Suppressors

and DC Reactors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-12

2.6.4 Regenerative Resistors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-13

2.6.5 Linear Scales - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-14

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

x

Page 12

3 Digital Operator/Panel Operator

3.1 Functions on Digital Operator/Panel Operator - - - - - - - - - - - 3-2

3.1.1 Connecting the Digital Operator - - - - - - - - - - - - - - - - - - - - - - - - - - -3-2

3.1.2 Key Names and Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-3

3.1.3 Basic Mode Selection and Operation - - - - - - - - - - - - - - - - - - - - - - - -3-4

3.1.4 Status Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-6

3.2 Operation in Utility Function Mode (Fn) - - - - - - - - - - - 3-8

3.2.1 List of Utility Function Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-8

3.2.2 Alarm Traceback Data Display (Fn000)- - - - - - - - - - - - - - - - - - - - - - -3-9

3.2.3 JOG Mode Operation (Fn002) - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-10

3.2.4 Zero-point Search Mode (Fn003) - - - - - - - - - - - - - - - - - - - - - - - - - - 3-11

3

.2.5 Parameter Settings Initialization (Fn005)- - - - - - - - - - - - - - - - - - - - -3-12

3.2.6 Alarm Traceback Data Clear (Fn006) - - - - - - - - - - - - - - - - - - - - - - -3-13

3.2.7 Automatic Offset-adjustment of Motor Current Detection Signal

(Fn00E)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-14

3.2.8 Manual Offset-adjustment of Motor Current Detection Signal

(Fn00F) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-15

3.2.9 Password Setting (Protects Parameters from Being Changed)

(Fn010) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-16

3.2.10 Motor Models Display (Fn011) - - - - - - - - - - - - - - - - - - - - - - - - - - -3-17

3.2.11 Software Version Display (Fn012)- - - - - - - - - - - - - - - - - - - - - - - - -3-18

3.2.12 Application Module Detection Results Clear (Fn014) - - - - - - - - - - -3-19

3.3 Operation in Parameter Setting Mode (Pn)- - - - - - - - 3-20

3.3.1 Setting Parameters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-20

3.3.2 Input Circuit Signal Allocation - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-24

3.3.3 Output Circuit Signal Allocation - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-28

3.4 Operation in Monitor Mode (Un) - - - - - - - - - - - - - - - 3-30

3.4.1 List of Monitor Modes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-30

3.4.2 Sequence I/O Signal Monitor Display- - - - - - - - - - - - - - - - - - - - - - - 3-31

3.4.3 Operation in Monitor Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-32

3.4.4 Monitor Display of Reference Pulse Counter

and Feedback Pulse Counter - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-33

3.4.5 Allowable Maximum Motor Speed for Dividing Ratio Monitor

(For the software version 32 or later) - - - - - - - - - - - - - - - - - - - - - - - 3-34

3.4.6 Hall Sensor Signal Monitor

(For the software version 32 or later) - - - - - - - - - - - - - - - - - - - - - - - 3-34

4 Operation

4.1 Trial Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

4.2 Trial Operation Using SERVOPACK Internal References - - - 4-6

4.2.1 SERVOPACK Setup Procedure- - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-6

4.2.2 Setup Procedure Using Linear Servomotors with Hall Sensors- - - - - - 4-6

4.2.3 Setup Procedure Using Linear Servomotors without Hall Sensors - - 4-12

xi

xvi

Page 13

4.3 Trial Operation for Linear Servomotor without Load

from Host Reference - - - - - - - -

4.3.1 Servo ON Command from the Host - - - - - - - - - - - - - - - - - - - - - - - - 4-22

4.3.2 Operating Procedure in Speed Control Mode (Pn000 = n.0) - - 4-24

4.3.3 Operating Procedure in Position Control Mode (Pn000 = n.1) - 4-26

- - - - - - - - - - - - - - - - - - - 4-22

Trial O

4.4

to

.5 Control Mode Selection- - - - - - - - - - - - - - - - - - - - - - - - - - 4-29

4

.6 Setting Common Basic Functions - - - - - - - - - - - - - - - - - - 4-30

4

4.6.1 Setting the Servo ON Signal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-30

4.6.2 Switching the Linear Servomotor Movement Direction- - - - - - - - - - - 4-31

4.6.3 Setting the Overtravel Limit Function - - - - - - - - - - - - - - - - - - - - - - - 4-32

4.6.4 Selecting the Stop

4.6.5 Instantaneous Power Loss Settings- - - - - - - - - - - - - - - - - - - - - - - - 4-35

4.6.6 Motor Maximum Speed (For the software version 32 or later)- - - - - - 4-35

peration with the Linear Servomotor Connected

the Machine

- - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - 4-28

ping Method After Servo OFF - - - - - - - - - - - - - - - 4-34

4.7 Operating Using Speed Control with Analog Reference - - - 4-36

4.7.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-36

4.7.2 Setting Input Signals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-37

4.7.3 Adjusting Offset - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-38

4

.7.4 Soft Start- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-41

4.7.5 Speed Reference Filter- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-41

4.7.6 Using the Zero Clamp Function- - - - - - - - - - - - - - - - - - - - - - - - - - - 4-41

4.7.7 Encoder Signal Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-43

4.7.8 Speed Coincidence Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-45

4.8 Operating Using Position Control- - - - - - - - - - - - - - - - - - - 4-46

4.8.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-46

4.8.2 Setting the Electronic Gear - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-48

4.8.3 Position Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-51

4.8.4 Smoothing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-55

4.8.5 Positioning Completed Output Signal - - - - - - - - - - - - - - - - - - - - - - -4-56

4.8.6 Positioning Near Signal- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-57

4.8.7 Reference Pulse Inhibit Function (INHIBIT)- - - - - - - - - - - - - - - - - - -4-58

4.9 Operating Using Force Control - - - - - - - - - - - - - - - - - - - - 4-59

4.9.1 Setting Parameters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-59

4.9.2 Force Reference Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-59

4.9.3 Adjusting the Force Reference Offset - - - - - - - - - - - - - - - - - - - - - - -4-60

4.9.4 Limiting Linear Servomotor Speed during Force Control- - - - - - - - - -4-62

4.10 Operating Using Speed Control

with

an Internally Set Speed - - - - - - - - - - - - - - - - - - - - - 4-64

4.10.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-64

4.10.2 Input Signal Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-65

4.10.3 Operating Using an Internally Set Speed- - - - - - - - - - - - - - - - - - - -4-65

xv

xii

Page 14

4.11 Limiting Force- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-67

4.11.1 Internal Force Limit (Limiting Maximum Output Force) - - - - - - - - - -4-67

4.11.2 External Force Limit (Output Force Limiting by Input Signals) - - - - -4-68

4.11.3 Force Limiting Using an Analog Voltage Reference - - - - - - - - - - - -4-70

4.11.4 Force Limiting Using an External Force Limit

and Analog Voltage Reference - - - - - - - - - - - - - - - - - - - - - - - - - - -4-71

4.11.5 Checking Output Force Limiting during Operation - - - - - - - - - - - - -4-72

4.12 Control Mode Selection- - - - - - - - - - - - - - - - - - - - - - - - - 4-73

4.12.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-73

4.12.2 Switching the Control Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-73

4.13 Other Output Signals - - - - - - - - - - - - - - - - - - - - - - - - - - 4-75

4.13.1 Servo Alarm Output (ALM) and Alarm Code Output

(ALO1, ALO2, ALO3) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-75

4.13.2 Warning Output (/WARN)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-76

4.13.3 Running Output Signal (/TGON)- - - - - - - - - - - - - - - - - - - - - - - - - -4-76

4.13.4 Servo Ready (/S-RDY) Output - - - - - - - - - - - - - - - - - - - - - - - - - - -4-77

5 Adjustments

5.1 Autotuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.1.1 Servo Gain Adjustment Methods - - - - - - - - - - - - - - - - - - - - - - - - -5-2

5.1.2 List of Servo Adjustment Functions- - - - - - - - - - - - - - - - - - - - - - - -5-3

5.2 Online Autotuning- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-5

5.2.1 Online Autotuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-5

5.2.2 Online Autotuning Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-6

5.2.3 Selecting the Online Autotuning Execution Method - - - - - - - - - - - -5-7

5.2.4 Machine Rigidity Setting for Online Autotuning - - - - - - - - - - - - - - -5-8

5.2.5 Method for Changing the Machine Rigidity Setting - - - - - - - - - - - - -5-9

5.2.6 Saving the Results of Online Autotuning - - - - - - - - - - - - - - - - - - - 5-10

5.2.7 Procedure for Saving the Results of Online Autotuning- - - - - - - - - 5-11

5.3 Manual Tuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-12

5.3.1 Explanation of Servo Gain - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-12

5.3.2 Servo Gain Manual Tuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-13

5.3.3 Position Loop Gain- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-13

5.3.4 Speed Loop Gain - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-14

5.3.5 Speed Loop Integral Time Constant - - - - - - - - - - - - - - - - - - - - - - 5-14

5.4 Servo Gain Adjustment Functions - - - - - - - - - - - - - - - - 5-15

5.4.1 Feed-forward Reference- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-15

5.4.2 Force Feed-forward - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-16

5.4.3 Speed Feed-forward- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-17

5.4.4 Proportional Control Operation

(Proportional Operation Reference) - - - - - - - - - - - - - - - - - - - - - - 5-18

5.4.5 Using the Mode Switch (P/PI Switching)- - - - - - - - - - - - - - - - - - - 5-19

5.4.6 Setting the Speed Bias - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-22

5.4.7 Speed Feedback Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-22

5.4.8 Speed Feedback Compensation - - - - - - - - - - - - - - - - - - - - - - - - 5-23

5.4.9 Switching Gain Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-25

5.4.10 Force Reference Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-26

5.5 Analog Monitor- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-29

xvixiii

Page 15

6 Inspection, Maintenance, and Troubleshooting

6.1 Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.1 Alarm Display Table - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.2 Warning Display- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-4

6.1.3 Alarm Display Table when the Application Module is Used - - - - - - - 6-5

6.1.4 Warning Display Table when the Application Module is Used - - - - - 6-6

6.1.5 Troubleshooting of Alarm and Warning- - - - - - - - - - - - - - - - - - - - - 6-7

6.1.6 Troubleshooting for Malfunction without Alarm Display- - - - - - - - - 6-17

6.2 Inspection and Maintenance - - - - - - - - - - - - - - - - - - - - 6-22

6.2.1 Linear Servomotor Inspection

6.2.2 SERVOPACK Inspection- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-22

6.2.3 SERVOPACK’s Parts Replacement Schedule- - - - - - - - - - - - - - - 6-23

- - - - - - - - - - - - - - - - - - - - - - - - - - 6-22

7 Appendix

7.1 Linear Servomotor Capacity Selection Examples- - - - - - - 7-2

7.2 Calculating the Required Capacity

of Regenerative Resistor

7.2.1 Simple Calculation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-4

7.2.2 Calculating the Regenerative Energy - - - - - - - - - - - - - - - - - - - - - - 7-6

s- - - - - - - - - - - - - - - - - - - - - - - 7-4

7.3 Connection to Host Controller - - - - - - - - - - - - - - - - - - - 7-13

73.1 Example of Connection to MP920 4-axes Analog Module

SVA-01 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-13

7.3.2 Example of Connection to CP-9200SH Servo Controller Module

SVA (SERVOPACK in Speed Control Mode)- - - - - - - - - - - - - - - - 7-14

7.3.3 Example of Connection to MEMOCON GL120/130 Series

Motion Module MC20 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-15

7.3.4 Example of Connection to MEMOCON GL60/70 Series

Positioning Module B2813 (SERVOPACK in Position Control Mode) 7-16

7.3.5 Example of Connection to OMRON’s Motion Control Unit- - - - - - - 7-17

7.3.6 Example of Connection to OMRON’s Position Control Unit - - - - - - 7-18

7.3.7 Example of Connection to OMRON’s Position Control Unit

00-NC221 (SERVOPACK in Speed Control Mode)- - - - - - - - - -7-19

C5

7.3.8 Example of Connection to OMRON’s Position Control Unit

C500-NC112 (SERVOPACK in Position Control Mode)- - - - - - - - -7-20

7.3.9 Example of Connection to Mitsubishi’s AD72 Positioning Unit

(SERVOPACK in Speed Control Mode)- - - - - - - - - - - - - - - - - - - -7-21

7.3.10 Example of Connection to Mitsubishi’s AD75 Positioning Unit

(SERVOPACK in Position Control Mode)- - - - - - - - - - - - - - - - - -7-22

7.4 List of Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-23

7.4.1 Utility Functions List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-23

7.4.2 List of Parameters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-24

7.4.3 Monitor Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-40

7.5 Parameter Recording Table- - - - - - - - - - - - - - - - - - - - - 7-41

xiv

xvii

Page 16

1

Outline

1.1 Checking Products - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.1 Check Items - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.2 Linear Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.3 SERVOPACKs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.1.4 Serial Converter Units - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.2 Product Part Names - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.2.1 Linear Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.2.2 SERVOPACKs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

1.3 Examples of Servo System Configurations - - - - - - - - - - - - - - - - - - - - - - - 1-8

1.3.1 Single-phase, 200 V Main Circuit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

1.3.2 Three-phase, 200 V Main Circuit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

1.3.3 Three-phase, 400 V Main Circuit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1

1.4 Applicable Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.4.1 North American Safety Standards (UL, CSA) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.4.2 CE Marking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1-1

Page 17

1 Outline

1.1.1 Check Items

1.1 Checking Products

1.1.1 Check Items

Check the following items when the products are delivered.

Check Items Comments

Are the delivered products the ones

that were ordered?

Is there any damage? Check the overall appearance, and check for damage or scratches that

If any of the above items are faulty or incorrect, contact your Yaskawa representative or the dealer from whom

you purchased the products.

1.1.2 Linear Servomotors

The location of the nameplate varies depending on the model of the linear servomotor. The nameplate is affixed

on both the coil assembly and the magnetic way.

(1) Coreless SGLGW and SGLGM Linear Servomotors

Check the model numbers marked on the nameplates on the linear

servomotor and SERVOPACK. (Refer to the descriptions of model

numbers in the following section.)

may have occurred during shipping.

CoilassemblyandMagneticway

Nameplate

Servomotor

model

Ratings

OrderNo.

SerialNo.

CORELESSLINEARSERVOMOTOR

SGLGW-40A140B

WA

94 0.8

N

47

O/N

S/N

YASKAWAELECTRICCORPORATIONJAPAN

Ins.

B

1-2

Page 18

(2) SGLFW and SGLFM Linear Servomotors with F-type Iron Core and

SGLTW and SGLTM Linear Servomotors with T-type Iron Core

1.1 Checking Products

SGLFWandSGLFM

SGLTWandSGLTM

Note: The location of the nameplate varies depending on the model and capacity of the linear servomotor.

1.1.3 SERVOPACKs

Coilassembly

Servomotor

model

Ratings

OrderNo.

SerialNo.

Magneticway

Servomotor

model

OrderNo.

SerialNo.

Nameplate

LinearSERVOMOTOR

TYPE

SGLFW-35A120A

200 W

1.3 A

80 N

200 V

2.5 m/s

O/N

S/N

YASKAWAELECTRICMADEINJAPAN

DATE

Nameplate

YASKAWA

TYPE:

SGLFM-20756A

O/N

S/N

MADEINJAPAN DATE

ins.B

1

SGDHfor30Wto5.0kW SGDHfor7.5kW

SERVOPACK

SERVOPACK

model

Applicable

powersupply

Serial

number

MODEL

AC-INPUT AC-OUTPUT

VOLTS

Hz

PHASE

AMPS

S/N

YASKAWAELECTRIC

SGDH-30AE

200-230

60/60

3

18.6

VOLTS

PHASE

AMPS

KU(MP)

412808-15-1

MADEINJAPAN

0-230

3

24.8

3.0(4.0)

Applicable

motor

capacity

1-3

Page 19

1 Outline

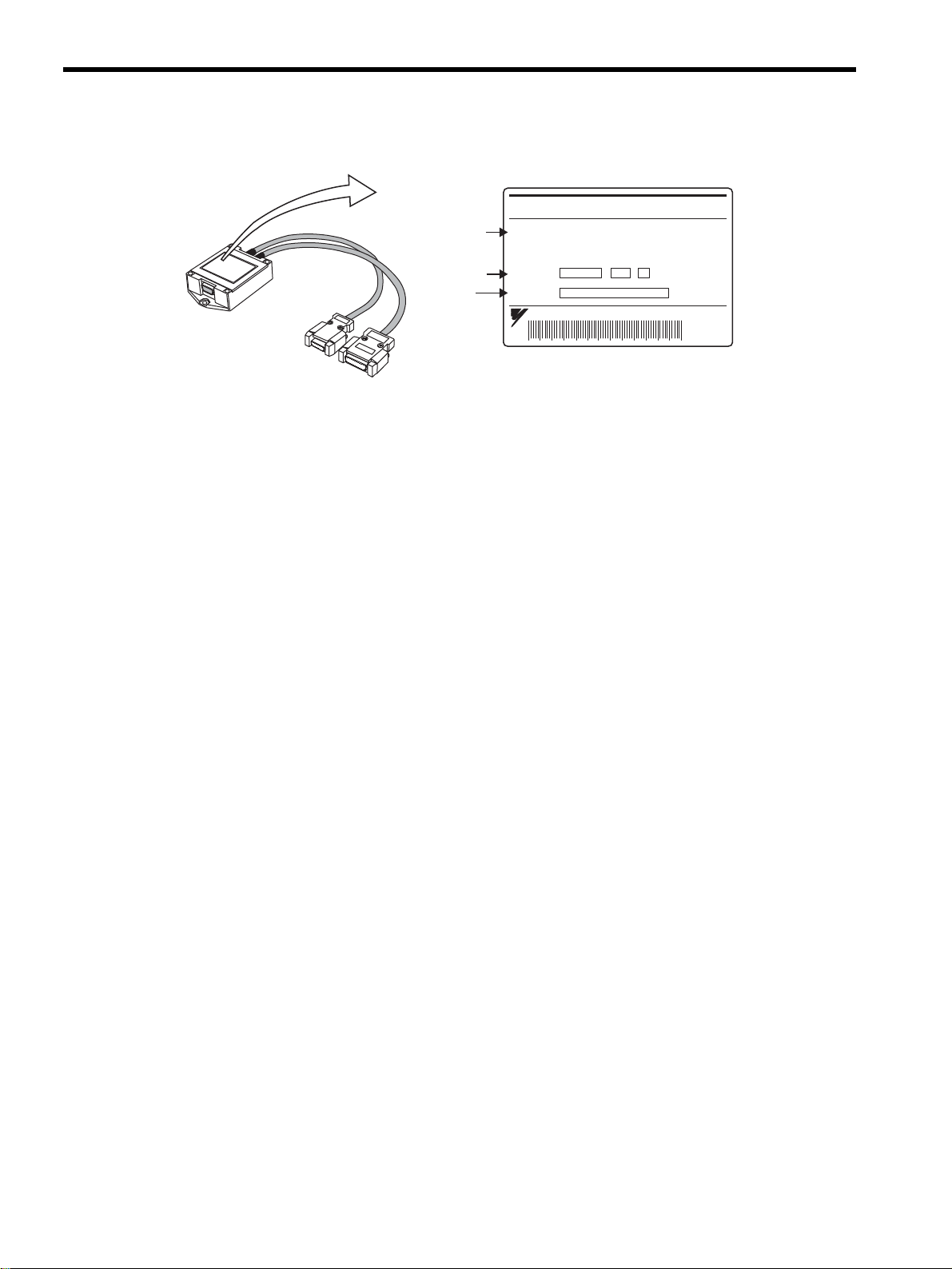

1.1.4 Serial Converter Units

1.1.4 Serial Converter Units

Nameplate

Serial

converter

model

OrderNo.

SerialNo.

SERIALCONVERTER

MODELJZDP-A006-156

For:-

O/N

S/N

YASKAWAELECTRICCORPORATION

--

JAPAN

1-4

Page 20

1.2 Product Part Names

1.2.1 Linear Servomotors

Coreless SGLGW and SGLGM

(1)

Magneticway

Hallsensorcable

Maincircuitcableforlinearservomotor

1.2 Product Part Names

1

Coilassembly

Hallsensorunit

(2) SGLFW and SGLFM With F-type Iron Core

Coilassembly

Hallsensorcable

Hallsensor

unit

Maincircuitcablefor

linearservomotor

SGLTW and SGLTM With T-type Iron Core

(3)

Coilassembly

Hallsensorcable

Magneticway

Spacerfor

installation

Hallsensorunit

Maincircuitcablefor

linearservomotor

Magneticway

1-5

Page 21

1 Outline

1.2.2 SERVOPACKs

1.2.2 SERVOPACKs

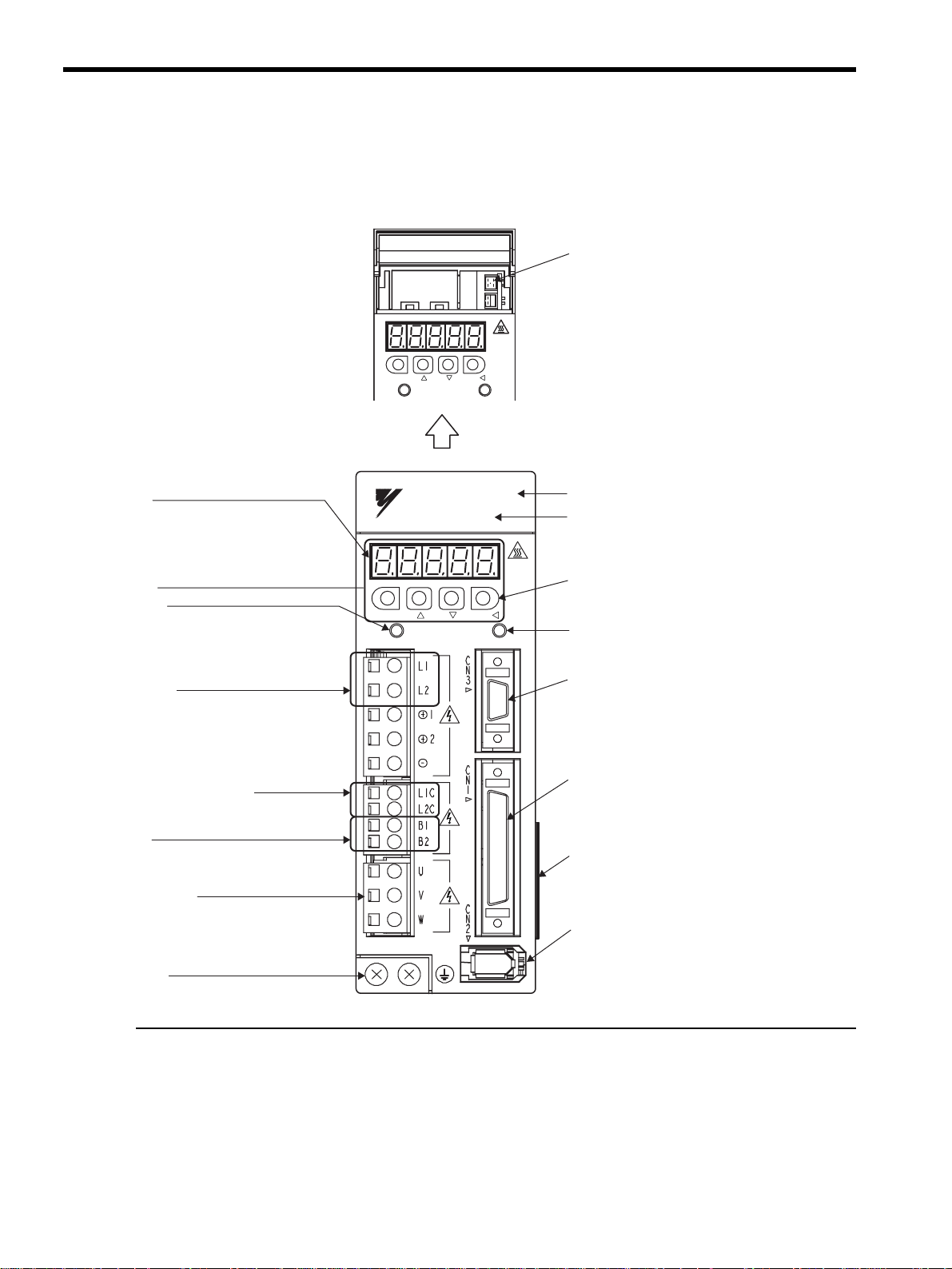

(1) SGDH for 50 W to 5.0 kW

Withthefrontcoveropen

MODE/SET DATA/

CHARGE POWER

CN5Analogmonitorconnector

Usedtomonitormotorspeed,force

reference,andothervaluesthrough

aspecialcable.

Referto5.5 Analog Monitor

Paneldisplay

5-digit,7-segmentLEDusedtodisplay

SERVOPACKstatus,alarmstatus,andother

valueswhenparametersareinput.

Referto3.1.2KeyNamesandFunctions.

Paneloperator

Chargeindicator

Lightswhenthemaincircuitpowersupplyis

ONandstayslitaslongasthemaincircuitpower

supplycapacitorremainscharged.Therefore,

donottouchtheSERVOPACKevenafterthepower

supplyisturnedOFFiftheindicatorislit.

Maincircuitpower

supplyterminals

Usedformaincircuitpowersupplyinput.

Controlpowersupplyterminals

Usedforcontrolpowersupplyinput.

Regenerative

resistorconnectingterminals

Usedtoconnectexternalregenerativeresistors.

Servomotorterminals

Connectstotheservomotorpowerline.

YASKAWA

MODE/SET

YASKAWA

SERVOPACK

SGDH-

CHARGE POWER

DATA/

Frontcover

SERVOPACKmodel

Referto2.3SERVOPACKModel

Designations.

Panelkeys

Usedtosetparameters.

PowerONindicator

LightswhenthecontrolpowersupplyisON.

CN3Connectorforpersonalcomputermonitoring

anddigitaloperator

Usedtocommunicatewithapersonalcomputer

ortoconnectadigitaloperator.

CN1I/Osignalconnector

Usedforreferenceinputsignalsand

sequenceI/Osignals.

Nameplate(sideview)

IndicatestheSERVOPACKmodelandratings.

Referto1.1.3SERVOPACKs.

CN2Encoderconnector

Connectstotheencoderintheservomotor.

Groundterminal

Besuretoconnecttoprotectagainstelectricalshock.

1-6

Page 22

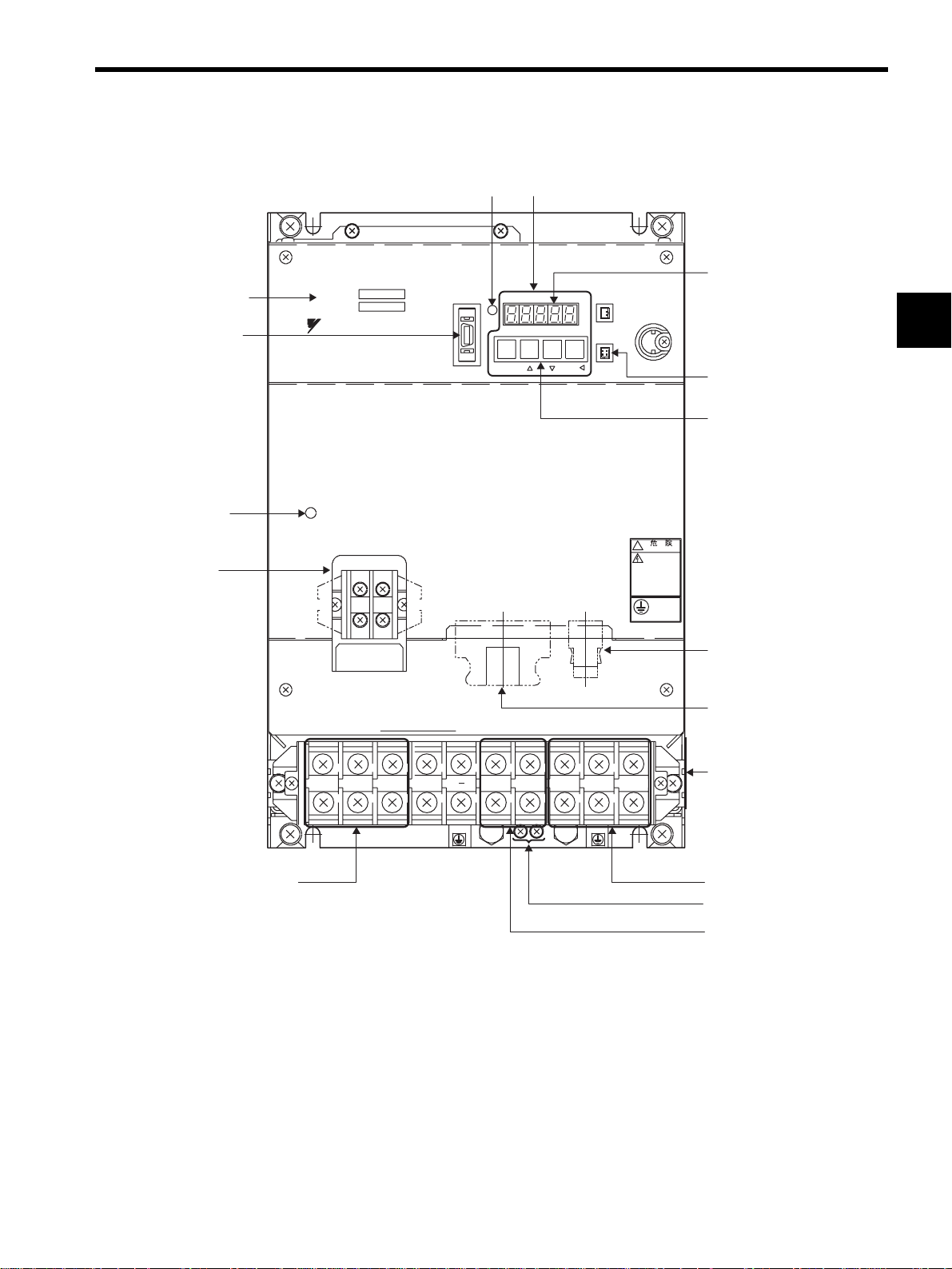

(2) SGDH for 7.5 kW

1.2 Product Part Names

SERVOPACKmodel

CN3Connectorfor

personalcomputer

monitoringand

digitaloperator

Chargeindicator

Controlcircuit

∗

terminal

SERVOPACK 200V

SGDH-

Ve r.

YASKAWA

CHARGE

L1C

L2C

Powerindicator

POWER

MODE/SET

CN3

CN1 CN2

Paneloperator

DATA/

CN8

CN5

BATTERY

!

WARNING

Paneldisplay

1

CN5Analog

monitorconnector

Panelswitch

CN2Encoderconnector

CN1I/Osignalconnector

Nameplate(sideview)

Servomotorterminals:U,V,W

Groundterminal

Maincircuitpowersupply

terminals:L1,L2,L3

L1 L2 L3

+

B2B1

U

VW

Regenerativeresistor

connectingterminals:B1,B2

* Control circuit terminal and regenerative resistor connecting terminals differ the position of the termi-

nal block by the SERVOPACK model.

∗

1-7

Page 23

1 Outline

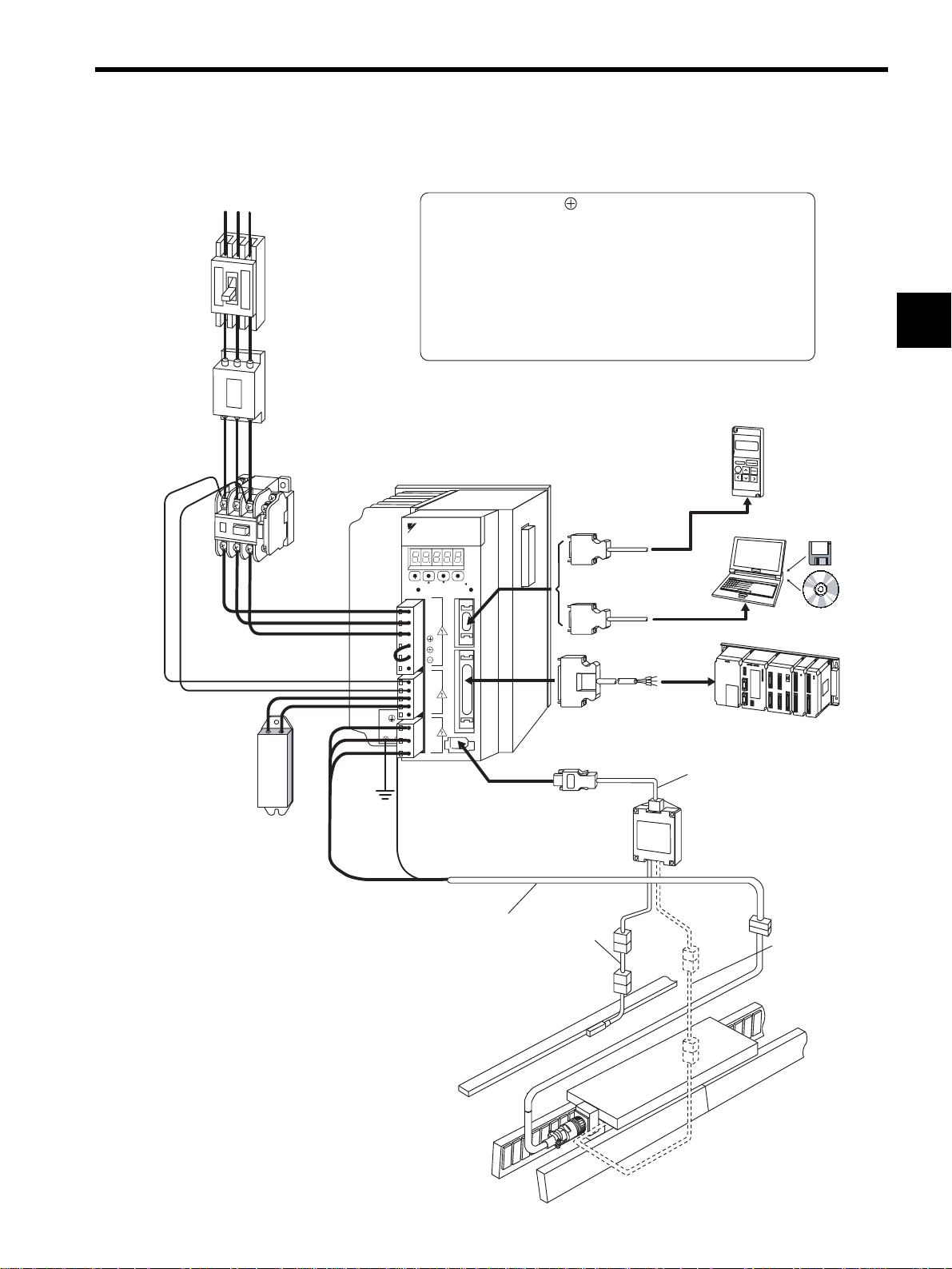

1.3.1 Single-phase, 200 V Main Circuit

1.3 Examples of Servo System Configurations

This section describes examples of basic servo system configuration.

1.3.1 Single-phase, 200 V Main Circuit

Powersupply

Single-phase200VAC

Molded-case

circuitbreaker

(MCCB)

Protectsthepowersupply

linebyshuttingthecircuit

OFFwhenanovercurrent

isdetected.

(Referto2.7.2)

Noisefilter

Eliminatesexternal

noisefromthepower

line.

(Referto2.7.3)

RT

Magnetic

contactor

TurnstheservoON

andOFF.

Installasurge

suppressor.

Referto

2.7.3)

SGDH-AE

SERVOPACK

YASKAWA

SERVOPACK

SGDH-

200V

Digital

operator

(Referto2.7.)

Regenerative

resistor

Connectanexternal

regenerativeresistor

toterminalsB1andB2

iftheregenerative

capacityisinsufficient.

(Referto2.7.4.)

MODE/SET

CHARGE POWER

L1

L2

+1

+2

-

L1C

L2C

B1

B2

U

V

W

Maincircuitcablefor

linearservomotor

(Referto2.6.)

DATA/

C

N

3

C

N

1

C

N

Encoder

cable

(Referto2.6.)

Connectioncable

fordigitaloperator

Connectioncable

forpersonalcomputer

I/Osignalcable

(Referto2.7.1.)

(Referto2.7.1.)

Connectioncable

forserialconverterunit

(Referto2.6.)

Serialconverterunit

(Referto2.5.)

Personalcomputer

Hostcontroller

Connectioncable

forhallsensor

(Referto2.6.)

1-8

Linearscale

(Tobeprovidedby

users.)

(Referto2.7.5.)

Hallsensorunit

CorelessLinearServomotor

Page 24

1.3.2 Three-phase, 200 V Main Circuit

Power supply

Three-phase 200 VAC

Molded-case

circuit breaker

(MCCB)

Protects the power

supply line by shutting

the circuit OFF when

an overcurrent is

detected.

(Refer to 2.7.2.)

Noise filter

Eliminates external noise

from the power line.

(Refer to 2.7.3.)

R S T

*1: The positive terminal for the main circuit is only available for use

in the three-phase (200 VAC, 7.5 kW or more) SERVOPACKs.

Do not use the positive terminals 1 or 2.

*2: Before connecting an external regenerative resistor to

the SERVOPACK, be sure to disconnect the lead between terminals

B2 and B3.

1.3 Examples of Servo System Configurations

1

Regenerative

resistor

Connect an external

regenerative resistor

to terminals B1 and B2

if the regenerative

capacity is insufficient.

(Refer to 2.7.4.)

Magnetic

contactor

Turns the servo

ON and OFF.

Install a surge

suppressor.

(Refer to

2.7.3.)

*2

*1

SGDH-AE

SERVOPACK

YASKAWA

200V

SERVOPACK

SGD

H-

MODE/SET

DATA/

CHARGE POWER

L1

C

N

L2

3

L3

1

2

C

N

1

L1C

L2C

B1

B2

B3

C

U

N

2

V

W

Connection cable for

digital operator

Connection cable for

personal computer

(Refer to 2.7.1.)

I/O signal cable

(Refer to 2.7.1.)

Digital

operator

(Refer to 2.7.1.)

Personal computer

Host controller

Connection cable for

serial converter unit

(Refer to 2.6.)

Serial converter unit

(Refer to 2.5.)

Main circuit cable for

linear servomotor

(Refer to 2.6.)

Linear scale

(To be provided by

users)

(Refer to 2.7.5.)

Encoder

cable

(Refer to 2.6.)

Connection cable

for hall sensor

(Refer to 2.6.)

Linear servomotor with core

1-9

Page 25

1 Outline

1.3.3 Three-phase, 400 V Main Circuit

1.3.3 Three-phase, 400 V Main Circuit

Power supply

Three-phase 400 VAC

R S T

Molded-case

circuit breaker

(MCCB)

Protects the power

supply line by shutting

the circuit OFF when

an overcurrent is

detected.

(Refer to 2.7.2.)

Noise filter

Eliminates external

noise from the power

line.

(Refer to2.7.3.)

Magnetic

contactor

Turns the servo

ON and OFF.

Install a surge

suppressor.

Refer to

2.7.3.)

*1: Use a 24 VDC power supply (To be provided by users).

*2: Before connecting an external regenerative resistor to

the SERVOPACK, be sure to disconnect the lead between terminals

B2 and B3.

Digital

SGDH-DE

operator

(Refer to 2.7.1.)

SERVOPACK

Connection cable

YASKAWA

SERVOPACK

SGD

H-

200V

for digital operator

Personal computer

*1

+

DC power

supply

(24 VDC)

−

Regenerative

resistor

Connect an external

regenerative resistor

to terminals B1 and B2

if the rgenerative capacity

is insufficient.

(Refer to 2.7.4.)

*2

MODE/SET

DATA/

CHARGE POWER

L1

C

N

L2

3

L3

1

2

C

N

1

24V

0V

B1

B2

B3

C

U

N

2

V

W

Connection cable

for personal computer

(Refer to 2.7.1.)

I/O signal cable

(Refer to 2.7.1.)

Host controller

Connection cable for

serial convertr unit

(Refer to 2.6.)

Serial convertr unit

(Refer to 2.5.)

Main circuit cable for

linear servomotor

(Refer to 2.6.)

Encoder

cable

(Refer to 2.6.)

Connection cable

for hall sensor

(Refer to 2.6.)

Linear scale

(To be provided by

users.)

(Refer to 2.7.5.)

1-10

Linear servomotor

wirh core

Page 26

1.4 Applicable Standards

Σ-II Series servodrives conform to the following overseas standards.

1.4.1 North American Safety Standards (UL, CSA)

1.4 Applicable Standards

1.4.2

Model

SERVOPACK • SGDH

* 1. Underwriters Laboratories Inc.

* 2. Canadian Standards Association.

CE Marking

Model

SERVOPACK • SGDH

* TÜV Product Services GmbH

U

R

C

L

US

C

LISTED

∗1

UL

Standards (UL File No.) CSA∗2 Standards

UL508C(E147823)

Low Voltage

Directive

EN50178

EMI EMS

EN55011

class A group 1

CSA C22.2

No.14

EMC Directive

R

US

EN50082-2

or

EN61000-6-2

Certifications

UL

Certifications

TÜV PS

∗

1

Because SERVOPACKs and linear servomotors are built-in type, reconfirmation is

required after being installed in the final product.

1-11

Page 27

2

Selections

2.1 Linear Servomotor Model Designation - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.1 Coil Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.2 Magnetic Way - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.2 SERVOPACK Model Designation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

2.3 Σ-II Series SERVOPACKs and Applicable Linear Servomotors - - - - - - - - - 2-4

2.4 Serial Converter Units Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

2.5 Selecting Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.6 Selecting Peripheral Devices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-9

2.6.1 Special Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-9

2.6.2 Molded-case Circuit Breaker and Fuse Capacity - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11

2.6.3 Noise Filters, Magnetic Contactors, Surge Suppressors and DC Reactors - - - - - - - - 2-12

2.6.4 Regenerative Resistors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-13

2.6.5 Linear Scales - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-14

2

2-1

Page 28

2 Selections

2.1.1 Coil Assembly

2.1 Linear Servomotor Model Designation

This section describes how to check the model and ratings of the linear servomotor. The alphanumeric codes

after SGL- indicate the specifications.

2.1.1 Coil Assembly

40 A 140 A P

Voltage

200VAC

A

400VAC

D

LinearΣSeries

Linearservomotor

ServomotorModel

Code

Specifications

G

Coreless

F-typeironcore

F

T-typeironcore

T

W:Coilassembly

Magnetheight

WGSGL

2.1.2 Magnetic Way

SGL 40 225 A C

GM

D

CableConnectorforMainCircuitCable

Code

MSconnectororconnectormade

−

byTycoElectronicsAMPK.K.

ConnectormadebyInterconnectron

D

Code

P

C

Withhallsensorandforcedcooling

H

Designrevisionorder

A,B,C

Lengthofcoilassembly

Specifications

Options

Specifications

Withhallsensor

Forcedcooling

LinearΣSeries

Linearservomotor

Model

Code

Specifications

G

Coreless

F

F-typeironcore

T

T-typeironcore

M:Magneticway

Magnetwidth

2-2

Designrevisionorder

A,B,C

Lengthofmagneticway

Code

C

Withmagnetcover

-M

Highthrustforce

Options

Specifications Remarks

Onlyforlinearservomotors

withanironcore

Onlyforcorelesstypes

Page 29

2.2 SERVOPACK Model Designation

Select the SERVOPACK according to the applied linear servomotor.

10SGDH-AE

2.2 SERVOPACK Model Designation

RatedOutputofApplicableServomotor(kW)

Code

A5

01

02

04

05

08

RatedOutput

0.05

0.10

0.20

0.40

0.45

0.75

Code

Code

10

15

20

30

50

75

PowerSupplyVoltage

A

D

Single/Three-phase,200V

RatedOutput

Voltage

Three-phase,400V

1.0

1.5

2.0

3.0

5.0

7.5

Code Specifications

-

Base-mounted

-P

Duct-ventilated

-R

Rack-mounted

Code

Forforce,speed,andpositioncontrol

E

Applicableforvariousapplicationmodules

MountingMethod

RatedOutputof

ApplicableServomotor(kW)

0.05to7.5

7.5

0.05to5.0

Model(Fixed)

Remarks

2

2-3

Page 30

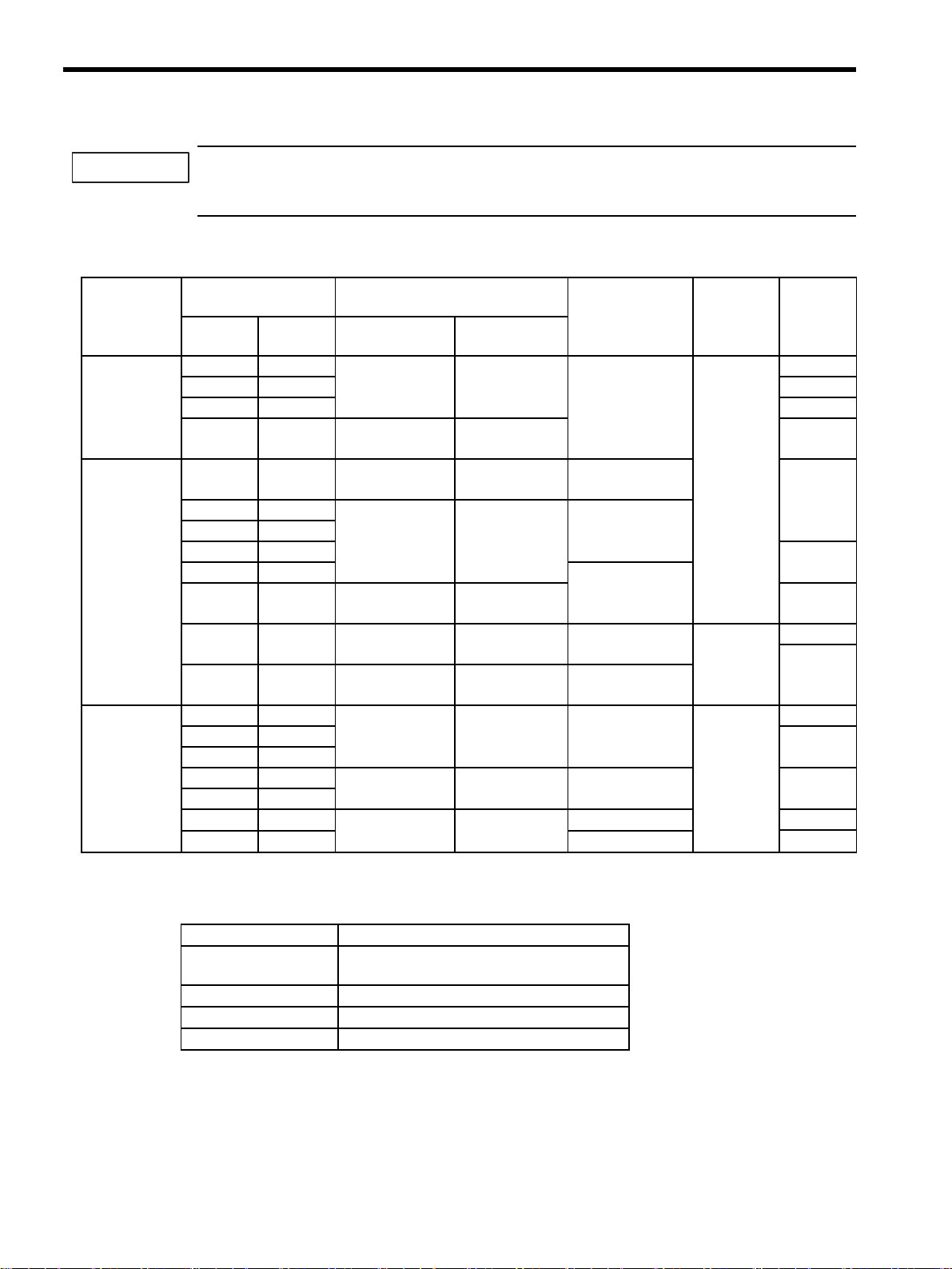

2 Selections

2.3

Σ-II Series SERVOPACKs and Applicable Linear Servomotors

Linear Σ Series Linear Servomotor

SGLGW

(Coreless)

17 models

SGLFW

(With F-type iron core)

12 models

When a

Standardforce

Magnetic

Way is used.

When a

High-force

Magnetic

Way is used.

30A050B

30A080B

40A140B

40A253B

40A365B

60A140B

60A253B

60A365B

90A200A

90A370A

90A535A

40A140B

40A253B

40A365B

60A140B

60A253B

60A365B

20A090A

20A120A

35A120A

35A230A

50A200B

50A380B

1ZA200B

1ZA380B

35D120A

35D230A

50D200B

50D380B

1ZD200B

1ZD380B

Σ-II Series SGDH SERVOPACK

Single-phase

200 VAC

A5AE −−

01AE −−

01AE −−

02AE −−

04AE −−

02AE −−

04AE −−

− 08AE −

− 15AE −

− 20AE −

− 30AE −

02AE −−

04AE −−

− 05AE −

02AE −−

− 05AE −

− 10AE −

02AE −−

02AE −−

02AE −−

− 05AE −

− 08AE −

− 15AE −

− 15AE −

− 20AE −

−−05DE

−−05DE

−−10DE

−−15DE

−−15DE

−−20DE

Three-phase

200 VAC

Three-phase

400 VAC

2-4

Page 31

Linear Σ Series Linear Servomotor

SGLTW

(With T-type iron core)

22 models

Note: The model combinations shown in this table are used when the maximum rated force of the appli-

cable linear servomoter is required. To suppress rises in temperature, larger linear servomotors are

used in some cases. If so, the SERVOPACK capacity can be lowered if using a motor at a lower

force than the rated force. Calculate the required current and select a model with a margin of

approximately 20%. An allowance can be made for up to 1/3 of the combined capacity of the linear

servomotor and SERVOPACK in the table.

20A170A

20A320A

20A460A

35A170A

35A320A

35A460A

35A170H

35A320H

50A170H

50A320H

40A400B

40A600B

80A400B

80A600B

35D170H

35D320H

50D170H

50D320H

40D400B

40D600B

80D400B

80D600B

2.3 Σ-II Series SERVOPACKs and Applicable Linear Servomotors

Σ-II Series SGDH SERVOPACK

Single-phase

200 VAC

− 05AE −

− 10AE −

− 15AE −

− 08AE −

− 15AE −

− 20AE −

− 08AE −

− 15AE −

− 08AE −

− 15AE −

− 20AE −

− 30AE −

− 50AE −

− 75AE −

−−15DE

−−30DE

−−15DE

−−20DE

−−30DE

−−50DE

−−75DE

−−75DE

Three-phase

200 VAC

Three-phase

400 VAC

2

2-5

Page 32

2 Selections

2.4 Serial Converter Units Models

A003JZDP 001

Symbol

A003

A005

A006

A008

SerialConverterUnitModel

Appearance

Applicable

LinearScale

Madeby

Heidenhain

Madeby

Renishaw

Madeby

Heidenhain

Madeby

Renishaw

HallSensor

None

None

Yes

Yes

ServomotorModel

SGLGW-

(Coreless)

Whena

standardforce

magnetic

wayisused.

SGLGW+

SGLGM-M

(Coreless)

Whena

high-force

magnetic

wayisused.

SGLFW-

(Ironcore,

F-type)

ApplicableLinearServomotor

Symbol

30A050B

30A080B

40A140B

40A253B

40A365B

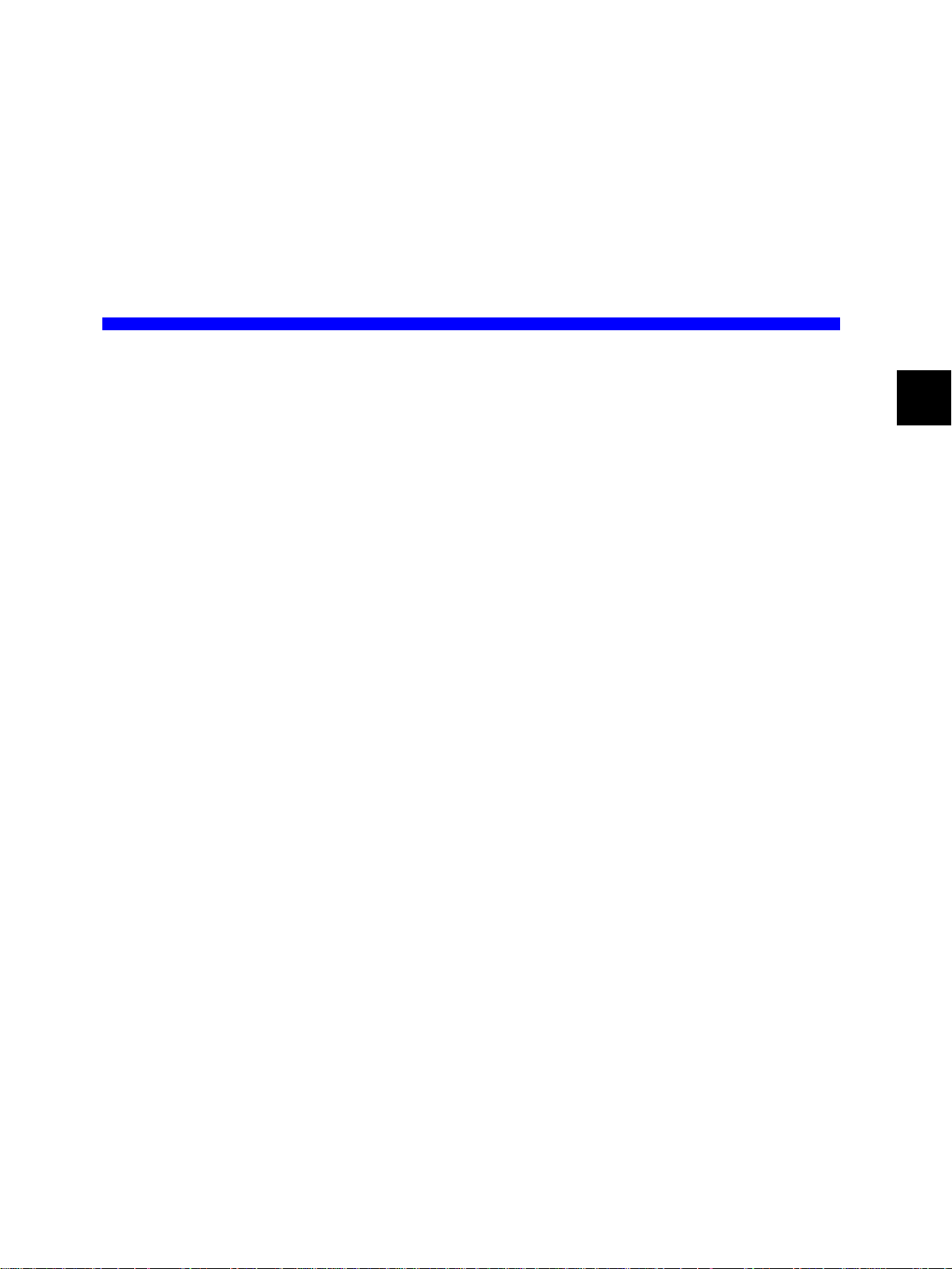

60A140B

60A253B

60A365B

90A200A

90A370A

90A535A

40A140B

40A253B

40A365B

60A140B

60A253B

60A365B

20A090A

20A120A

35A120A

35A230A

50A200B

50A380B

1ZA200B

1ZA380B

50D200B

50D380B

1ZD200B

1ZD380B

158

156

001

002

003

004

005

006

101

102

103

063

059

060

061

062

047

017

018

019

020

181

182

183

184

189

190

191

192

ServomotorModel

SGLTW-

(Ironcore,

T-type)

20A170A

20A320A

20A460A

35A170A

35A320A

35A460A

35A170H

35A320H

50A170H

50A320H

40A400B

40A600B

80A400B

80A600B

35D170H

35D320H

50D170H

50D320H

40D400B

40D600B

80D400B

80D600B

Symbol

011

012

013

014

015

016

105

106

108

109

185

186

187

188

193

194

195

196

197

198

199

200

2-6

Note: When using a 400-V winding linear servomotor with a 200-V SERVOPACK, the parameters in the

serial converter should be changed. Contact your Yaskawa representatives.

Page 33

2.5 Selecting Cables

L1

L2

L3

U

V

W

L1C

L2

B1

B2

B3

1

2

C

N

3

C

N

1

C

N

2

r

YASKAWA

200V

SERVOPACK

SGDH-

MODE/SET DATA/

POWER

CHARGE

CN2

Serialconverter

unit

SERVOPACK

Note:Thefollowingtwomaincircuitcables

areavailableforthelinearservomotor.

MSconnectororconnectormadeby

TycoElectronicsAMPK.K.

ConnectormadebyInterconnectron

2.5 Selecting Cables

2

Linearscale

(Tobeprovided

byusers.)

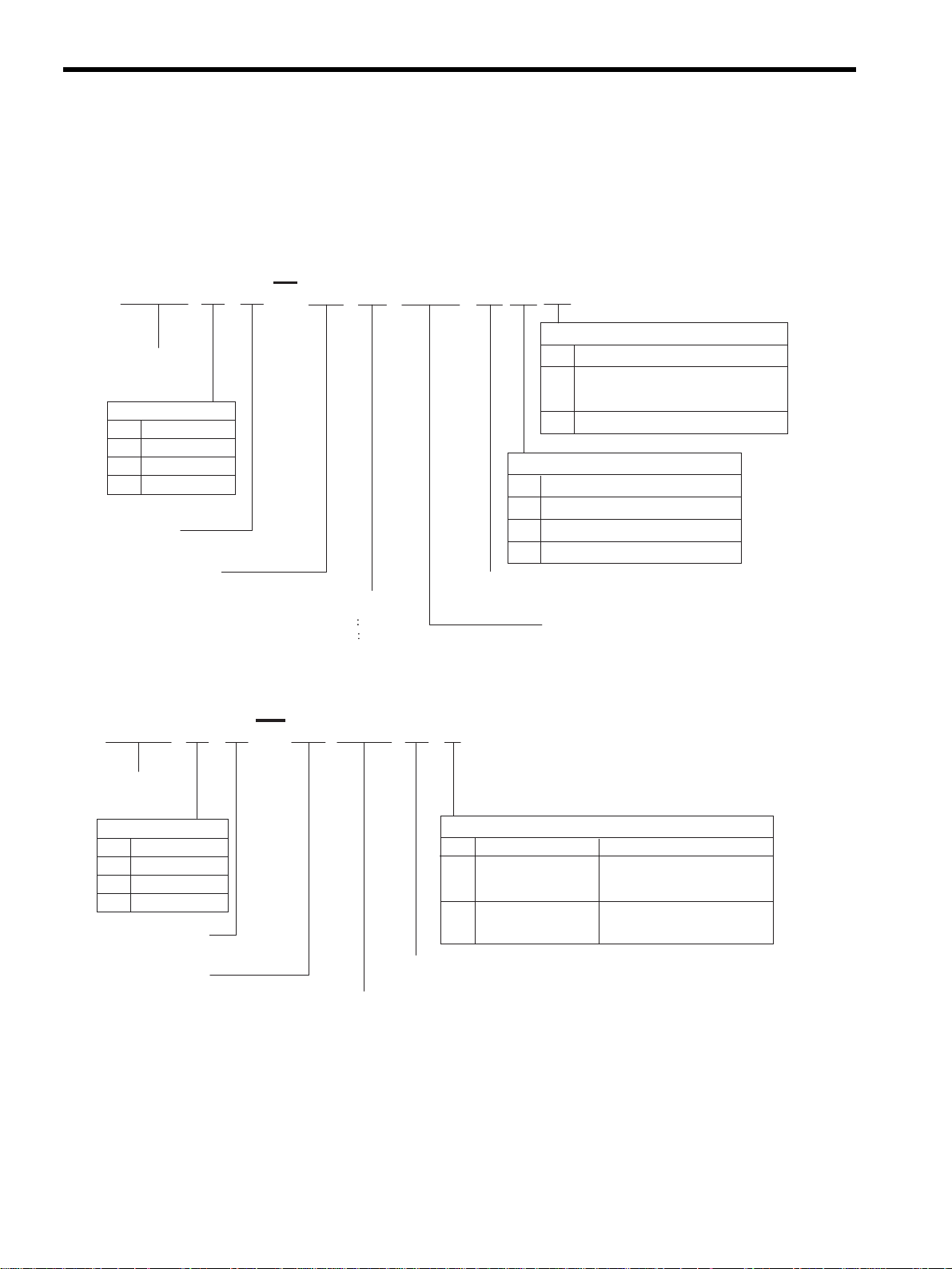

Name Connection

c

Linear Servomotor Main

Circuit Cables

Between SERVOPACK

and linear

servomotor

Linearservomotor

Applicable

Linear Servo-

motor Model

SGLGW-30,-40

and -60

SGLFW-20

SGLFW-35

SGLGW-90

SGLFW-50,-1Z

SGLTW-20,-35

SGLTW-40,-80

Hallsensor

unit

Cable

Length

1 m

3 m

5 m

10 m

15 m

20 m

1 m

3 m

5 m

10 m

15 m

20 m

1 m

3 m

5 m

10 m

15 m

20 m

Cable Type Specifications

JZSP-CLN11-01

JZSP-CLN11-03

JZSP-CLN11-05

JZSP-CLN11-10

JZSP-CLN11-15

JZSP-CLN11-20

JZSP-CLN21-01

JZSP-CLN21-03

JZSP-CLN21-05

JZSP-CLN21-10

JZSP-CLN21-15

JZSP-CLN21-20

JZSP-CLN39-01

JZSP-CLN39-03

JZSP-CLN39-05

JZSP-CLN39-10

JZSP-CLN39-15

JZSP-CLN39-20

SERVOPACK

end

SERVOPACK

end

SERVOPACK

end

Linearservomotor

end

Linearservomoto

end

Linearservomotor

end

2-7

Page 34

2 Selections

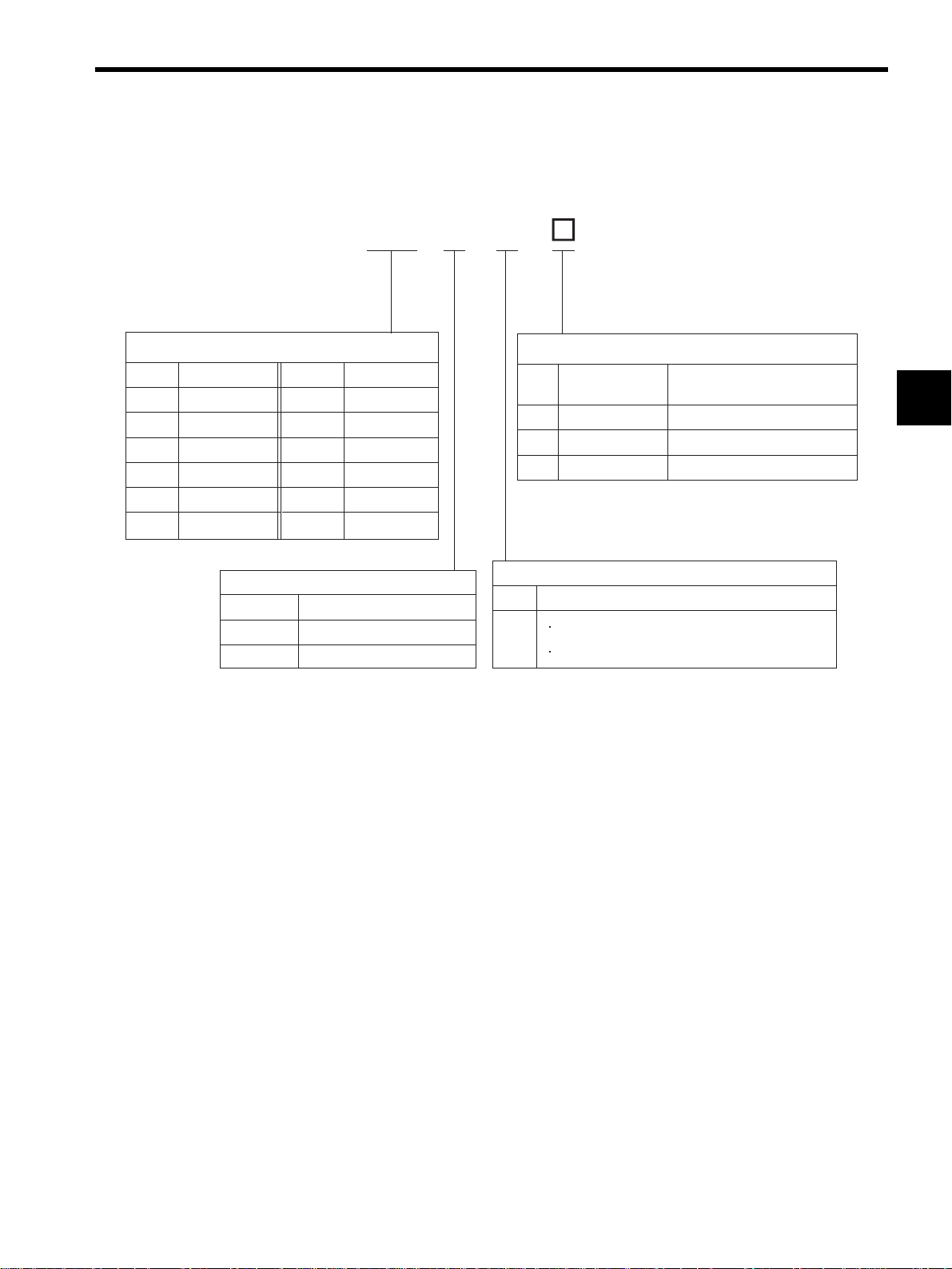

Name Connection

c

Linear Servomotor Main

Circuit Cables

d

Encoder

Cables

Between SERVOPACK

and linear

servomotor

Between serial converter unit and linear scale

e

Connection

cables for serial converter

unit

f

Connection

cables for hall

sensor

Between SERVOPACK

connector CN2 and

serial converter unit

Between serial converter unit and hall sensor

unit

* The main circuit’s cable connector is made by Interconnectron.

A connector is not provided on the linear servomotor end of the main circuit cable, type JZSP-

Note:

CLN39-. The user must provide the connector on the linear servomotor end.

Applicable

Linear Servo-

motor Model

SGLW-

D

For 200 VAC *

SGLW-

D

For 400 VAC *

All models

All models

All models

Cable

Length

1 m

3 m

5 m

10 m

15 m

20 m

1 m

3 m

5 m

10 m

15 m

20 m

1 m

3 m

5 m

10 m

15 m

1 m

3 m

5 m

10 m

15 m

20 m

1 m

3 m

5 m

10 m

15 m

Cable Type Specifications

JZSP-CLN14-01

JZSP-CLN14-03

JZSP-CLN14-05

JZSP-CLN14-10

JZSP-CLN14-15

JZSP-CLN14-20

JZSP-CLN15-01

JZSP-CLN15-03

JZSP-CLN15-05

JZSP-CLN15-10

JZSP-CLN15-15

JZSP-CLN15-20

JZSP-CLL00-01

JZSP-CLL00-03

JZSP-CLL00-05

JZSP-CLL00-10

JZSP-CLL00-15

JZSP-CLP70-01

JZSP-CLP70-03

JZSP-CLP70-05

JZSP-CLP70-10

JZSP-CLP70-15

JZSP-CLP70-20

JZSP-CLL10-01

JZSP-CLL10-03

JZSP-CLL10-05

JZSP-CLL10-10

JZSP-CLL10-15

SERVOPACK

end

SERVOPACK

end

Serialconverterunit

end

SERVOPACK

end

Serialconverterunit

end

Linearservomotor

end

Linearservomotor

end

Linearscale

end

Serialconverterunit

end

Hallsensorunit

end

2-8

Page 35

2.6 Selecting Peripheral Devices

L1

L2

L3

U

V

W

L1C

L2

B1

B2

B3

1

2

C

N

3

C

N

1

C

N

2

L1

L2

L3

U

V

W

L1C

L2

B1

B2

B3

1

2

C

N

3

C

N

1

C

N

2

2.6.1 Special Options

Connectioncable

fordigitaloperator

YASKAWA

200V

SERVOPACK

SGDH-

MODE/SET DATA/

CHARGE

POWER

CN3

Connectioncable

forpersonalcomputer

Digitaloperator

2.6 Selecting Peripheral Devices

Personal

computer

2

YASKAWA

SERVOPACK

SGDH-

MODE/SET DATA/

CHARGE

I/Osignalcable

Hostcontroller

CN1

Analogmonitorcable

CN5

CN8

NS300

CN11

CN6

CN4

NS600

CN7

CN4

CN6

7

8

6

9

0

X

5

4

10

1

3

2

7

8

6

9

X

0

5

4

1

1

3

2

CN11

7

8

6

9

D

0

5

R

4

1

3

2

C

N

11

M

S

N

S

CN6

NS500

6

CN4

CN10

NS100

S

W

200V

Connector

POWER

1

A

R

S

W

2

C

N

6

A

C

N

6

B

C

N

4

CN6A

CN6B

CN4

MECHATROLINK-I

I/FUnit

(NS100)

DeviceNet

I/FUnit

(NS300)

PROFIBUS-DP

I/FUnit

(NS500)

INDEXER

Module

(NS600)

2-9

Page 36

2 Selections

2.6.1 Special Options

c

CN1

I/O Signal

Cables

Name Length Type Specifications

Terminal block and 0.5 m connection

Connector terminal block

converter unit

Cable with

loose wires at

one end

1 m JZSP-CKI01-1 Loose wires at host controller end

2 m JZSP-CKI01-2

3 m JZSP-CKI01-3

JUSP-TA50P

cable

With connection cable (1 m)

d Digital Operator

JUSP-OP02A-2

1 m JZSP-CMS00-1

CN3

e

Connection Cable

1.5 m JZSP-CMS00-2

for Digital Operator

2 m JZSP-CMS00-3

CN3

f

Connection Cable for Personal

2 m JZSP-CMS02

Computer

CN5

g

Analog Monitor Cable

1 m

JZSP-CA01 or

DE9404559

Name Type

MECHATROLINK-I I/F Unit (NS100) JUSP-NS100

Application Module

h

∗

DeviceNet I/F Unit (NS300) JUSP-NS300

PROFIBUS-DP I/F Unit (NS500) JUSP-NS500

INDEXER Module (NS600) JUSP-NS600

* For details, refer to the manuals of each application module.

Only required when using Σ series

Digital Operator JUSP-OP02A-1.

SERVOPACK

end

Operator

end

D-Sub 9-pin (For DOS/V)

SERVOPACK

end

SERVOPACKend

Personal

computerend

Monitorend

2-10

Page 37

2.6.2 Molded-case Circuit Breaker and Fuse Capacity

Current Capacity of the

Main

Circuit

Power

Supply

Singlephase

200 V

Threephase

200 V

Threephase

400 V

SERVOPACK

Model

Power Supply

Capacity per

SERVOPACK

Capacity

(kW)

SGDH-

(kVA)

0.05 A5AE 0.25

0.10 01AE 0.40

0.20 02AE 0.75

0.40 04AE 1.2 8

0.45 05AE 1.4 4

0.75 08AE 1.9

1.0 10AE 2.3

1.5 15AE 3.2 10

2.0 20AE 4.3 13

3.0 30AE 5.9 17

5.0 50AE 7.5 28 67A

7.5 75AE 15.5 41

0.45 05DE 1.1 1.6

1.0 10DE 2.3 3.4

1.5 15DE 3.2 4.6

2.0 20DE 4.9 7.1

3.0 30DE 6.7 9.7

5.0 50DE 10.3 14.9 78A

7.5 75DE 15.4 22.3

* 1. Nominal value at the rated load. The specified derating is required to select an appropriate

fuse capacity.

* 2. Cutoff characteristics (25

°C): 300% five seconds min. and inrush current of 20ms.

* 3. A preventive circuit for inrush current is not built in the 24 VDC control power supply. The

protective circuit must be designed by the customer.

* 4. Make sure the current capacity is accurate. For the SERVOPACK with the cooling fan built-

in, an inrush current flows; 200 % of the current capacity in the table above for two seconds,

when turning ON the control circuit power supply to start the fan working.

Note: Do not use a fast-acting fuse. Because the SERVOPACK’s power supply is a capacitor

input type, a fast-acting fuse may blow when the power is turned ON.

Molded-case Circuit Breaker

and the Fuse (A

Main Circuit

Power Supply

4

7

2.6 Selecting Peripheral Devices

∗1,∗2

)

rms

Control Cir-

cuit Power

Supply

Power Supply

Inrush Current

Main Circuit

0.13 63A 60A

118A

4

∗

0.15

63A

4

0.27

∗

40A

10A

4

∗

0.7

20A

4

1.2

∗

20A

Control Cir-

cuit Power

Supply

60A

24 VDC

(

)

2

3

∗

2-11

Page 38

2 Selections

2.6.3 Noise Filters, Magnetic Contactors, Surge Suppressors and DC Reactors

IMPORTANT

The SGDH SERVOPACK does not include a protective grounding circuit. Install a ground-fault protector

to protect the system against overload and short-circuit or protective grounding combined with the moldedcase circuit breaker.

2.6.3 Noise Filters, Magnetic Contactors, Surge Suppressors and DC Reactors

Main Circuit

Power

Supply

Single-phase

200 V

Three-phase

200 V

Three-phase

400 V

Note: 1. If some SERVOPACKs are wired at the same time, select the proper magnetic contactors accord-

SERVOPACK Model

Capacity

(kW)

0.05 A5AE

0.10 01AE X5071

0.20 02AE X5070

0.40 04AE FN2070-10/07

0.45 05AE FN258L-7/07

0.75 08AE

1.0 10AE

1.5 15AE

2.0 20AE

3.0 30AE FN258L-30/07

5.0 50AE FMAC-0934-5010

7.5 75AE FMAC-0953-6410

0.45 05DE

1.0 10DE

1.5 15DE

2.0 20DE

3.0 30DE

5.0 50DE

7.5 75DE

ing to the total capacity.

2. The following table shows the manufacturers of each device.

SGDH

Recommended Noise Filter

-

Type Specifications

FN2070-6/07

FN258L-16/07

FN258L-7/07

FN258L-16/07

FS5559-35-33

Single-phase

250 VAC, 6 A

Single-phase

250 VAC, 10 A

Three-phase

480 VAC, 7 A

Three-phase

480 VAC, 16 A

Three-phase

480 VAC, 30 A

Three-phase

440 VAC, 50 A

Three-phase

440 VAC, 64 A

Three-phase

480 VAC, 7 A

Three-phase

480 VAC, 16 A

Three-phase

480 VAC, 35 A

Magnetic

Contactor

HI-11J (20 A)

HI-11J (20 A)

HI-15J (35 A)

HI-20J (35 A)

HI-25J (50 A)

HI-35J (65 A)

HI-15JCU (35 A)

HI-20JCU (35 A)

HI-25JCU (50 A)

HI-35JCU (65 A)

Surge

Suppressor

TU-25C240

TU-65C240

Built-in

DC

Reactor

−

X5069

X5061

X5060

X5059

X5068

−

X5074

X5075

X5076

X5077

−

2-12

Peripheral Device Manufacturer

Noise Filter

Magnetic Contactor Yaskawa Controls Co., Ltd.

Surge Suppressor Yaskawa Controls Co., Ltd.

DC Reactor Yaskawa Controls Co., Ltd.

FN, FS type: Schaffner Electronic

FMAC type: Timonta AG

Page 39

2.6.4 Regenerative Resistors

2.6 Selecting Peripheral Devices

SERVOPACK Model

Main Circuit

Power Supply

Single-phase

200 V

Three-phase

200 V

Three-phase

400 V

* 1. For the optional JUSP-RA05 Regenerative Resistor Unit.

* 2. For the optional JUSP-RA18 Regenerative Resistor Unit.

Capacity

(kW)

0.05 A5AE

0.10 01AE

0.20 02AE

0.40 04AE

0.45 05AE

0.75 08AE

1.0 10AE

1.5 15AE 30 70

2.0 20AE 25 140

3.0 30AE 12.5 140

5.0 50AE 8 280

7.5 75AE

0.45 05DE

1.0 10DE

1.5 15DE

2.0 20DE

3.0 30DE

5.0 50DE 32 180

SGDH-

Resistance

Regenerative Resistor

Built-in

(Ω)

−−−

50 60

1

∗

(3.13)

108 70

45 140

2

∗

(18)

Capacity

(W)

1

∗

(1760)

2

∗

(880)

Externally

connected

2

−

JUSP-RA05

−

JUSP-RA187.5 75DE

Note: 1. If the SERVOPACK cannot process the regenerative power, an external regenerative resistor is

required.

2. The following table shows the manufacturers of each device.

Peripheral Device Manufacturer

External Regenerative Resistor Iwaki Wireless Research Institute

External Regenerative Unit Yaskawa Electric Corporation

2-13

Page 40

2 Selections

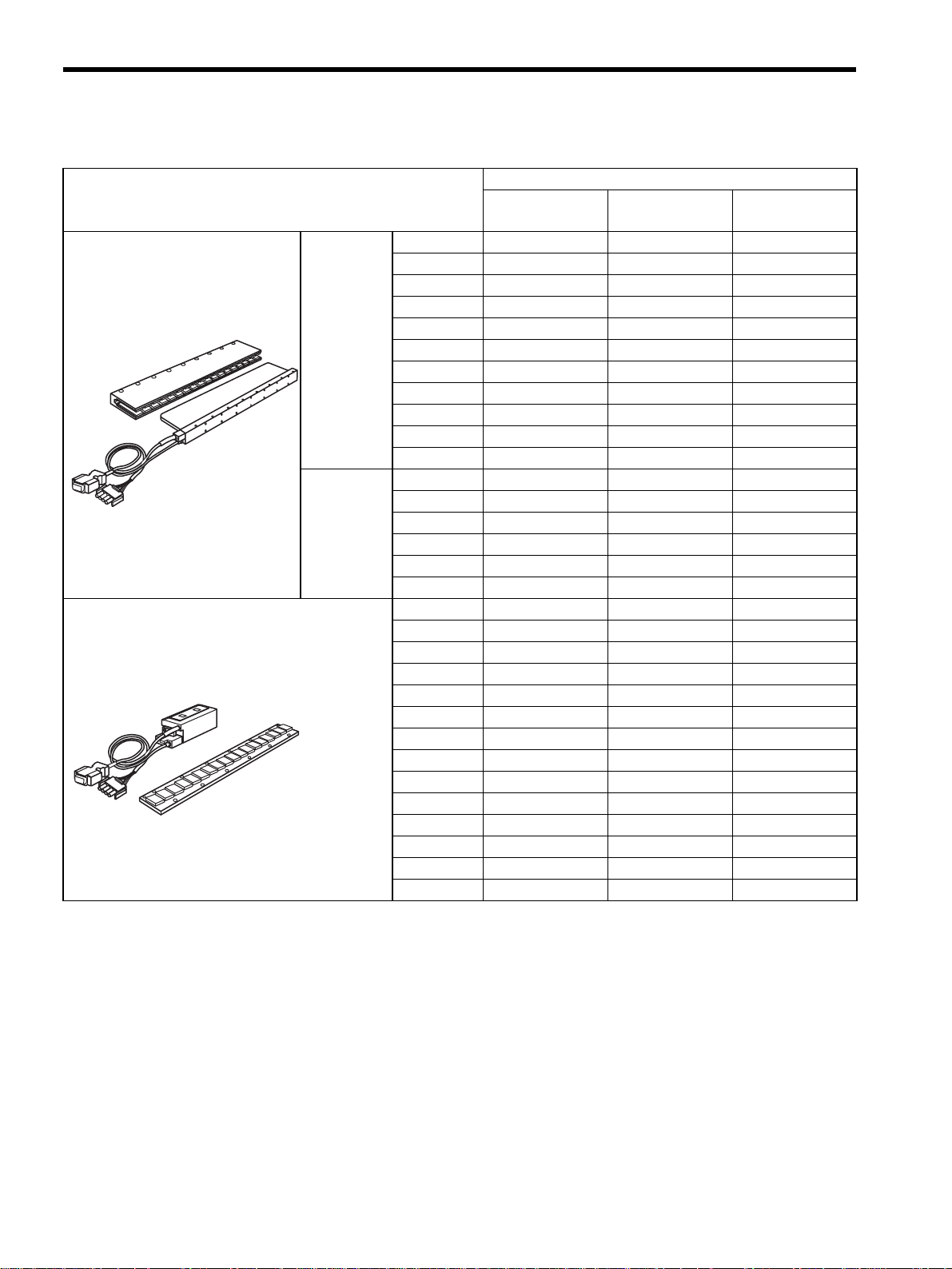

2.6.5 Linear Scales

2.6.5 Linear Scales

Encoder

Manufacturer Type Output Signal

Resolution

m/pulse

(µ

)

Scale Pitch

(µm)

Output

Resolution

Pn281

(

)

1 to 31 5

Renishaw Inc. RGH22B

0.078 20

32 to 63 4

64 to 127 2

128 to 255 1

1 to 63 5

LIDA187

0.156 40

64 to 127 4

128 to 255 2

Heidenhain

Corp.

LIDA487

LIDA489

1Vpp

Analog voltage

0.078 20

1 to 31 5

32 to 63 4

64 to 127 2

128 to 255 1

1 to 31 1.0

LIF181

0.016 4

32 to 63 0.8

64 to 127 0.4

128 to 255 0.2

Note: 1. The linear scale signal is multiplied by eight bits (256 segmentation) inside the serial converter

unit.

2. Using the zero-point signal with a linear scale made by Renishaw Inc. may cause a deviation in

the home position. If so, adjust the setting so that the zero-point is output only in one direction

by using BID/DIR signal.

3. This list does not cover all the applicable types of linear scales. And, the linear scales listed in

the table may not be applicable or available if their specifications have been modified or their

production has been stopped.

Check the most recent catalog of the linear scale manufacturer to select a linear scale that meets

the specifications.

4. Select a linear scale so that the total current consumption of the linear scale, serial converter unit,

and hall sensor is 190 mA max.

5. At parameter (Pn280), set the scale pitch of the linear scale so that it satisfies the following condition. Otherwise, satisfactory control cannot be obtained.

Max. Speed of

Applicable Linear

Servomotor

m/s

(

)

2-14

64000

Pn280(Scale pitch (µm))

Examples

Correct: 1,2,4,8,10,16,20,40

Incorrect: 3,5,12,18

must result in an integer number

Page 41

3

Digital Operator/Panel Operator

3.1 Functions on Digital Operator/Panel Operator - - - - - - - - - - -3-2

3.1.1 Connecting the Digital Operator - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.1.2 Key Names and Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.1.3 Basic Mode Selection and Operation - - - - - - - - - - - - - - - - - - - - - - - - 3-4

3.1.4 Status Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6