Page 1

400V Sigma II Servo Systems

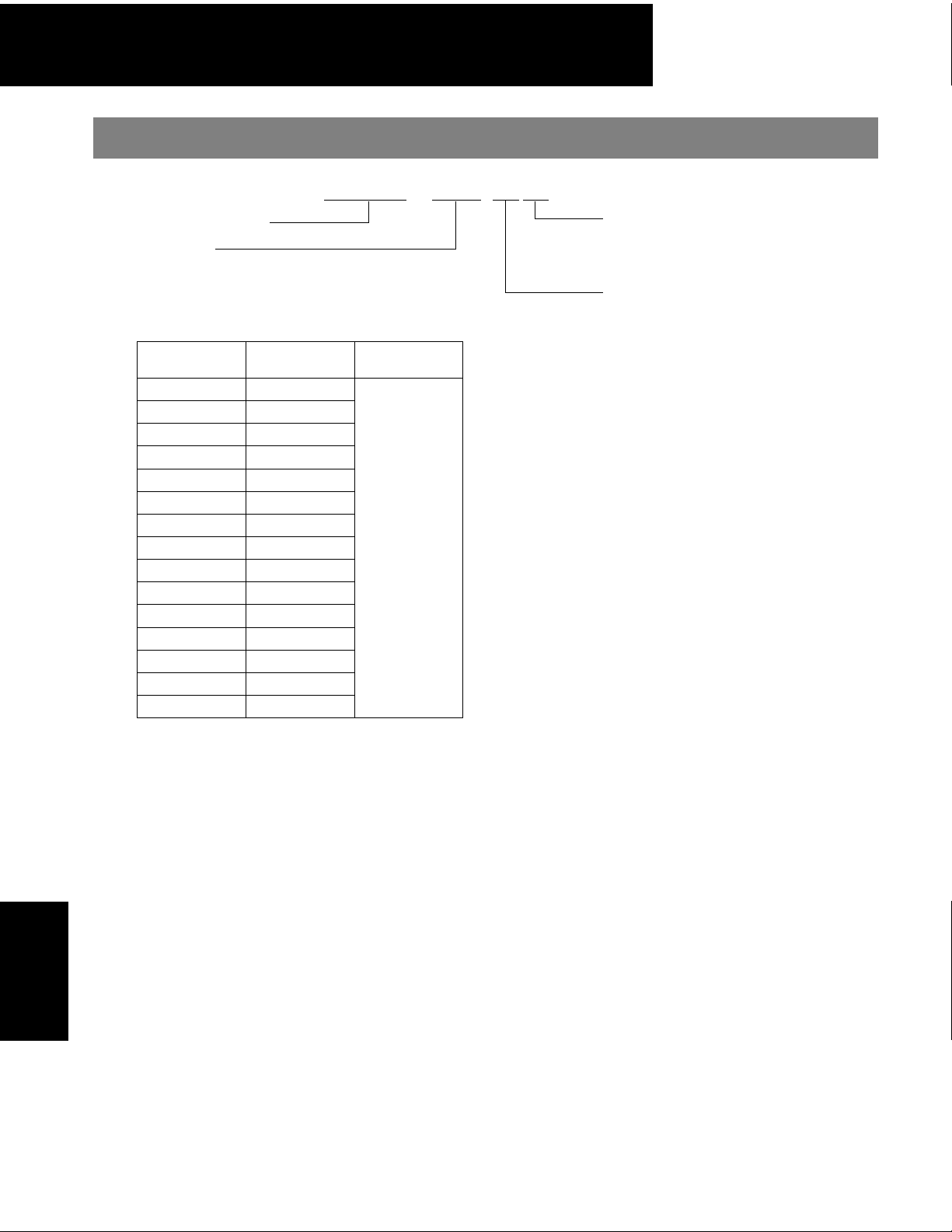

Model Number Designation

Sigma II Series

SGDH Servo Amplifier

Rated Output

Amplifier

Model

05 0.5 (.67)

10 1.0 (1.3)

15 1.5 (2.0)

20 2.0 (2.7)

30 3.0 (4.0)

50 5.0 (6.7)

60 6.0 (8.0)

75 7.5 (10)

1A 11 (15)

1E 15 (20)

2B 22 (30)

3Z 30 (40)

3G 37 (50)

4E 45 (60)

5E 55 (74)

Capacity

kW (HP)

SGDH - D E

Model

E: Speed, Torque, and

Position Control

Power Supply

D: 400V

AC Supply

Phases

3

Servo Amplifiers

SGDH

164

Page 2

400V Sigma II Servo Systems

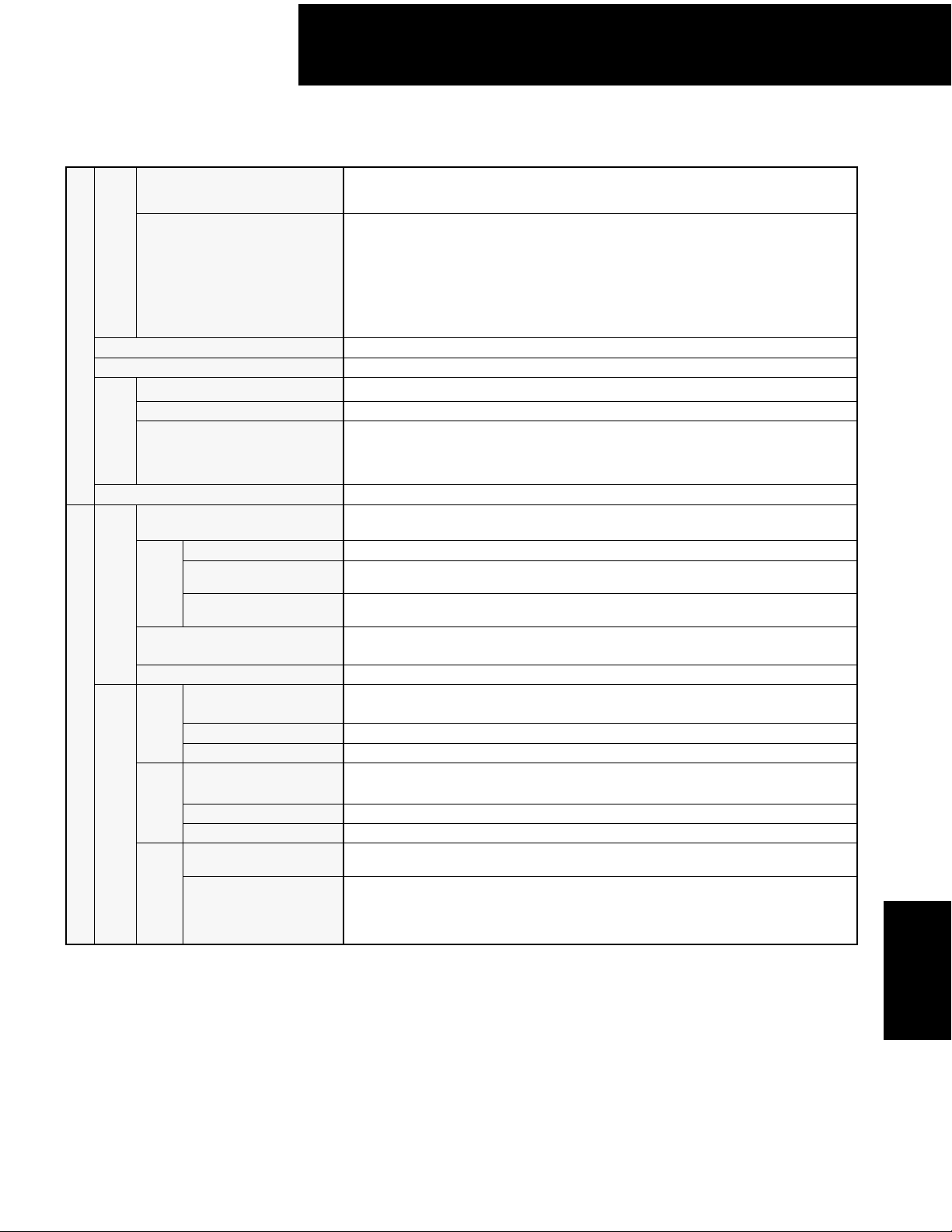

SGDH Amplifier Ratings and Specifications

Supply

Input Power

Control Mode

Feedback

Location

Basic Specifications

Structure

Performance

Main Circuit

Control Circuit

Ambient/Storage Temperature

Ambient/Storage Humidity

Vibration/Shock Resistance

Speed Control Range

Load Regulation

**

Voltage

Regulation

Speed

Temperature

Regulation

Regulation

Frequency Characteristics

Accel/Decel Time Setting

Reference Voltage

Input Impedance

Speed

Reference

Circuit Time Constant

Reference Voltage

Input Impedance

Torque

Reference

Circuit Time Constant

Rotation Direction

Selection

***

***

Three-phase 380 to 480Vac +10% to -15%, 50/60 Hz.

1. 24VDC ±10% to ±15%, 1A (maximum)

2 . 24V

Note: For 22 to 55kW units only, the power supply for the optional dynamic brake

(DB) contactor is made from the control circuit power supply. If DB operation is necessary when the power interruption occurs, maintain the DC24V while the DB operates. If 5 times inertia is attached and a standard DB resistor is used, DB operation

time is approximately 2 to 5 seconds.

Three-phase, full-wave rectification IGBT PWM (sinusoidal commutation)

Serial incremental encoder, absolute encoder

*

0 to 55°C / -20 to 85°C

90% or less (no-condensing)

1. 4.9m/s2 / 19.6m/s2 for 500W to 15kW units

2 . 9.8m/s

Cyclic shock resistance is 29m/s

Base mounted (duct ventilation available as option) and flat mount type

1 : 5000 (The lowest speed of the speed control range is the speed at which the

servomotor will not stop with a rated torque load.)

0% to 100%: 0.01% max. (at rated speed)

Rated voltage ±10% : 0% (at rated speed)

25 ± 25°C : 0.1% maximum (at rated speed)

400Hz (at JL = JM)

Note: 100 Hz (J

0 to 10s (Can be set individually for acceleration and deceleration).

±6VDC (variable setting range: ±2 to ±10VDC) at rated speed (forward rotation with

positive reference); input voltage: ±12V (maximum)

Approximately 14kΩ

—

±3VDC (Variable setting range: ±1 to ±10V) at rated torque (forward rotation with

positive reference), input voltage: ±12V

Approximately 14kΩ

Approximately 47μs

Uses P control signal

±10%, 40W for 22 to 55kw units

DC

2

(1G) / 49m/s2 (5G) for 22 to 55kW units

= JM) for 22 to 55kW systems

L

2

(3G)

DC

(maximum)

Speed Selection

Reference

Speed/Torque Control Mode

Notes: * Use the servo amplifier within the ambient temperature range. When enclosed, the temperatures inside the cab-

Contact Speed

Input Signal

inet must not exceed the specified range.

** Speed regulation is defined as follows:

Speed regulation

*** Forward is clockwise viewed from the non-load side of the servomotor, (counterclockwise viewed from the load

and shaft end).

no-load motor speed - full-load motor speed()

-------------------------------------------------------------------------------------------------------------------------x100%=

Forward/reverse rotation current limit signals are used (first to third speed selection). When both signals are OFF, the motor stops or enters another control mode.

rated motor speed

SGDH

Servo Amplifiers

165

Page 3

400V Sigma II Servo Systems

Ratings and Specifications (cont’d)

Bias Setting 0 to 450rpm (setting resolution: 1rpm)

Feed-forward Compensation 0 to 100% (setting resolution: 1%)

Position Complete Width Setting 0 to 250 reference units (setting resolution: 1 reference unit)

Performance

Sign + pulse train, 90° phase difference 2-phase pulse (phase A + phase B), or

CCW + CW pulse train

+12V (With built-in 1kW resistor)

Phases A, B and C: Line driver output

Phase S: Line driver output (Only when absolute encoder is used)

Servo ON, P control (or forward/reverse rotation in contact input speed control

mode), forward rotation prohibited (P-OT), reverse rotation prohibited (N-OT),

alarm reset, forward rotation current limit, and reverse rotation current limit (or

contact input speed control)

Input

Signal

Positioning Control Mode

I/O Signals

Control SIgnal CLEAR (input pulse form identical to reference pulse)

Built-in Open Collector Power Sup-

ply

Output Form

Output

Frequency Dividing Ratio Any

Position

Sequence Input

Type

Pulse Buffer Line driver (+5V level), open collector (+5V or +12V level)

Signal

Reference

Pulse Frequency Maximum 500/200kpps (line driver/open collector)

*

— Servo alarm, 3-bit alarm codes

Sequence

Dynamic Brake (DB) Activated at main power OFF, servo alarm, servo OFF or overtravel

Regenerative Processing

Overtravel (OT) Prevention

Protection

LED Display POWER, CHARGE, five 7-segment LEDs (built-in digital operator functions)

Analog Monitor (5CN)

Built-in Functions

Servo Amplifiers

SGDH

Communication

Others

Configurable: (Any 3 of these sig-

Output

nals)

Interface

1 : N Communication N can be up to 14 when RS-422A port is used.

Axis Address Setting Set via user parameters

Functions

Positioning complete (speed coincidence), servomotor rotating, servo ready,

current limit, brake release, warning, and near position signals

Incorporated. For 6 to 55 kW units, external regenerative resistor must be

mounted.

Motor decelerates or coasts to a stop, or is stopped by a dynamic brake. This

requires optional dynamic brakes for 22 to 55kW units.

Overcurrent, overload, regenerative error, main circuit voltage error, heat sink

overheat, power open phase, overflow, overspeed, encoder error, encoder disconnected, overrun, CPU error, parameter error.

Built-in analog monitor connector to observe speed, torque, and other reference

signals

Speed: 1V/1000rpm

Torque 1V/rated torque

Pulses remaining: 0.05V/reference units or 0.05V/100 reference units

Digital operator (mount type or hand-held)

RS422A port such as person computer (RS-232C port can be used if some conditions are met).

Status display, user constant setting, monitor display, alarm traceback display,

jogging, autotuning, speed/torque reference signals, other graphing functions,

etc.

Reverse rotation connection, home position search, automatic servomotor ID,

DC reactor connection terminal for high power supply frequency control.

Note: * The built-in open collector power supply is not electrically isolated from the control circuit in the servo amplifier.

166

Loading...

Loading...