Page 1

LEGEND System Components

Dimensions in inches (mm)

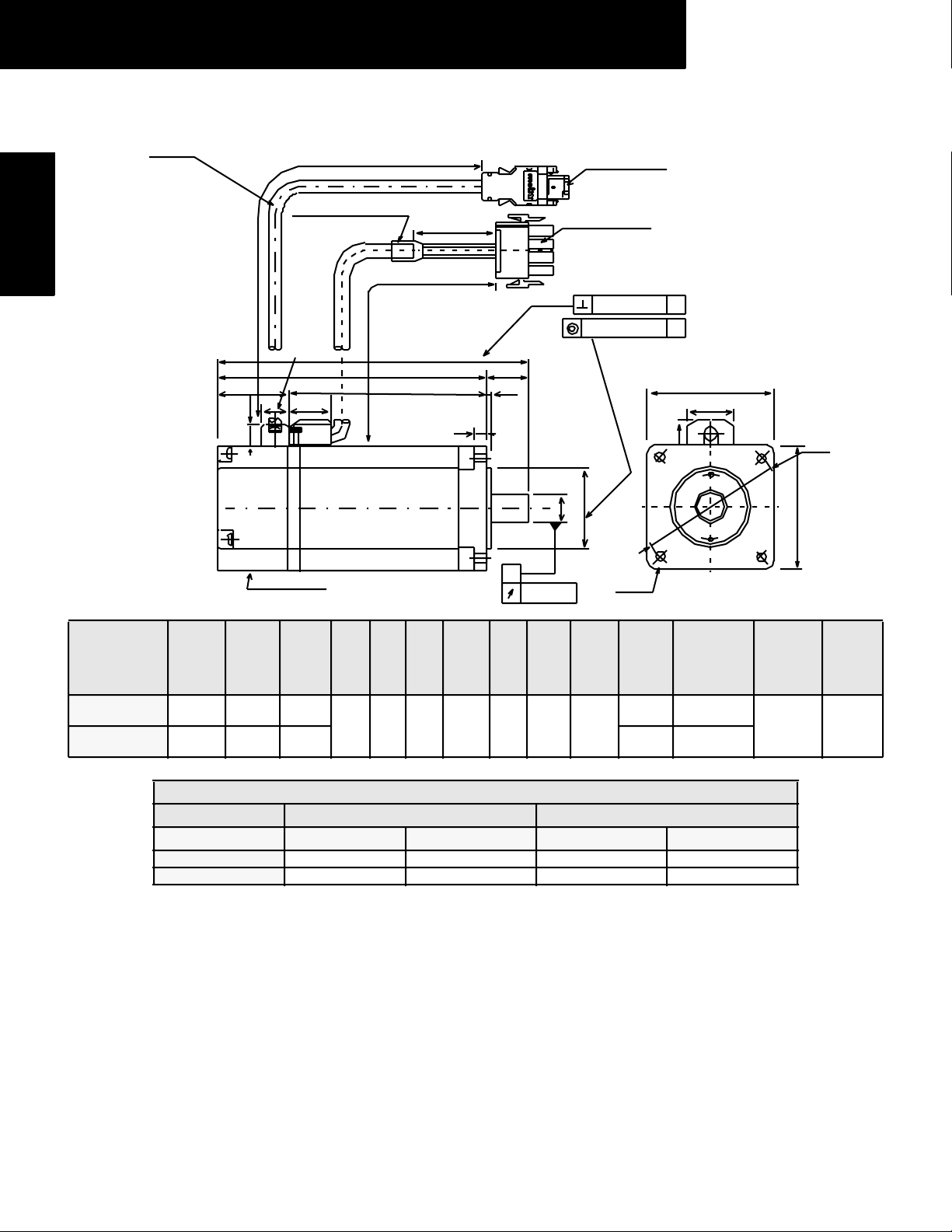

Servomotors

(1) 13-Bit Incremental Encoder, without Brake

• 30W (0.04hp), 50W (0.07hp), 100W (0.13hp)

SGMAH

ENCODER CABLE, Φ0.24 (Φ6)

UL20276

0.87 ( 22)

0.37 (9 .5)

Serial encoder

Ty p e

SG MAH-

A3F2

A3F4

A5F2

A5F4

01 F2

01 F4

†

Some motor dimensions vary for motors with the optional shaft seal: see p. 7 for details.

Encoder Plug

5

3

1

QK U W T L LL LM LR LG LC ΦLA ΦLZ ΦS* ΦLB**

†

Without Keyway

0.55 (14) 0.047 (1.2) 0.079 (2) 0.079 (2)

Without Keyway

0.55 (14) 0.047 (1.2) 0.079 (2) 0.079 (2)

Without Keyway

0.55 (14) 0.07 (1.8) 0.12 (3) 0.12 (3)

Dimension *ΦS **ΦLB

Unit Diameter Tolerance Diameter To l e r a n c e

in

mm

Encoder Connection

Pin Out p u t Wire Color

6

1PG 5V Red

4

2

2 PG 0V Black

3— —

4— —

5 Dat a + Li ght Blue

6 Data - Wh ite /Li ght B lu e

Plug: 55100-0600 (Molex)

Mating connector:

Socket: 54280-0600

11.81 (300) ±1.18 (30)

MOTOR CABLE,

UL1818 or UL3535

0.79 ( 20)

Φ

11.81 (300) ±1. 18 (30) 0.0016 (0.04) A

L

LL

LM

0.098 (2.5)

0.60 ( 15.2)

3.72

2.74

(94.5 )

(69.5 )

4.02

3.03

(102)

4.7

3.72

(119.5)

(94.5 )

0.2362 +0.0000-0.0003

0.3150 +0.0000-0.0004

6.000 +0.000 -0.008

8.000 +0.000 -0.009

0.28 (Φ7)

1.38 (35)

LR

0.30 ( 7.5)

LG

(77)

1.44

(36.5 )

1.73

(44)

2.42

(61.5 )

QK

Y

Y

0.98

(25)

Speci fied Toler ances

Φ

S*

Φ

A

0.0008 (0.002)

0. 20

(5)

Motor Plug

1

d

e

4

Encoder plug

55100-0600

Mot or P lug

350779-1

Cross-secti on Y-Y

Φ

0.0 016 (Φ0.04) A

LC

0. 85 (21.5 )

0.16 (4)

0.17

(4.3)

0.4 3 ( 11)

2-ΦLZ

0.24

(6)

0.31

(8)

1.18

0.315 (F 8)

LB**

Φ

1. 57

(40)

1.81

(46)

1.181 +0.0000 -0.0008

30.000 +0.000 -0.021

Motor Connection

Pin Output Wi r e Co l or

2 Phase U Red

2 Phase V Whi te

3 Phase W Blue

4 FG (Frame Ground) Gr een/Yellow

Plug 350779-1 (AMP)

Pin: 350561-3 or 350690-3 (Nos. 1 to 3)

Ground pin: 770210-1 (No 4)

Mating connector:

Cap: 350780-1

Socket: 350570-3 or 350689-3

W

(30)

T

U

LC

Φ

Output

W (hp)

30

(0.04)

50

(0.07)

100

(0.13)

LA

Approx.

Mass

lb (kg)

0.66

(0.3)

0.88

(0.4)

1.10

(0.5)17(78)

Allowable

Radial

Load

lb (N)

15

(68)

A ll ow a bl e

Thrust

Load

lb (N)

12

(54)

1

Page 2

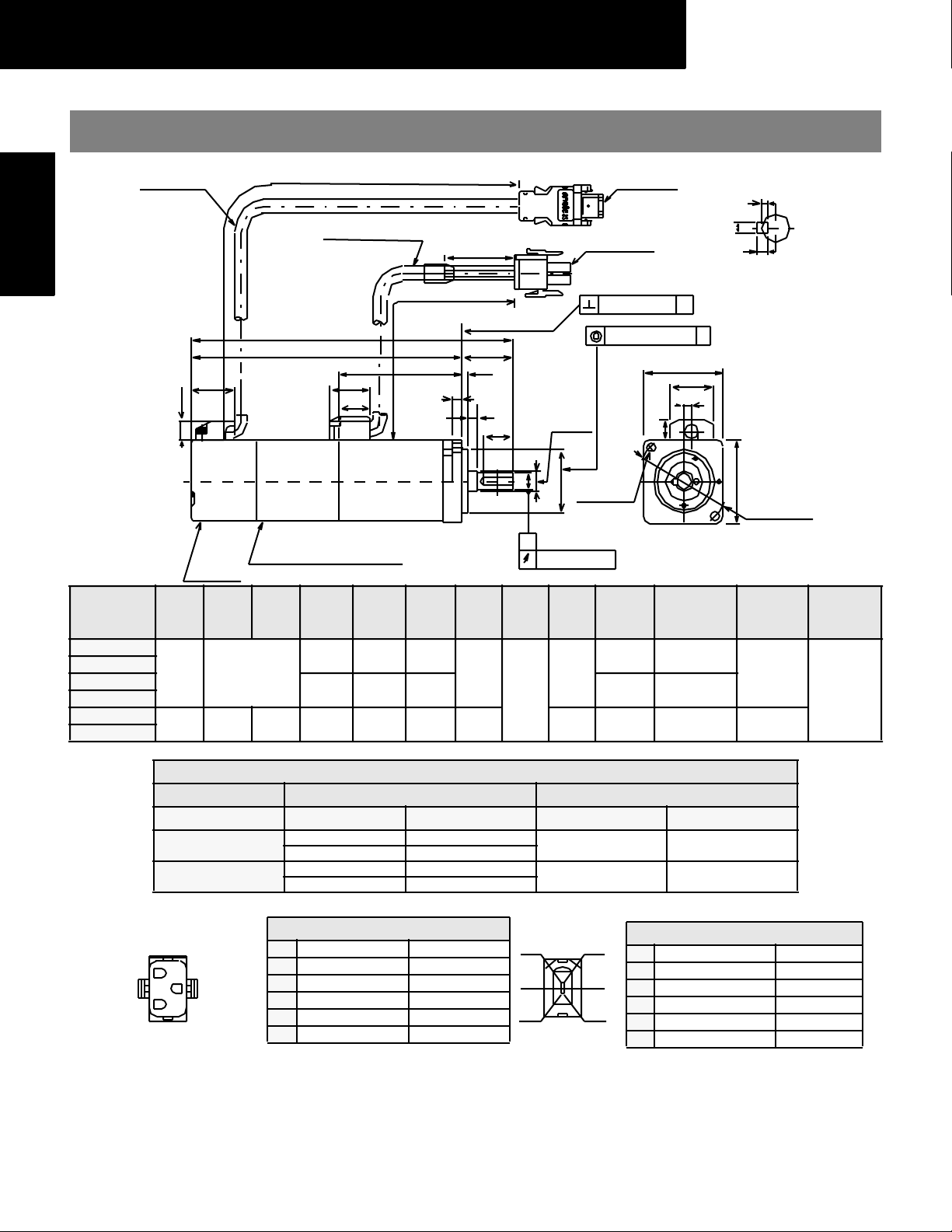

LEGEND System Components

• 200W (0.27hp), 400W (0.53hp), 750W (1.01hp)

Encoder c able, Φ0.24 (Φ6)

UL20 276

11.85 ( 300) ±1.1 8 (30 )

Motor cable

UL 1818, UL3534 or UL35 35

11. 85 (300) ±1. 18 ( 30)

1.38 ( 35)

Encoder plug

55100-0600

Motor plug

350779-1

U

W

T

Cr o s s- se ct i on Y -Y

SGMAH

Servomotors

Type

SGM AH-

02AF4

04AF4

08AF4

0.51 ( 13)

1.04 ( 26.5)

1.04 ( 26.5)

0.37( 9.5)

0.37( 9.5)

Serial e nc oder

Serial e nc oder

0.51 ( 13)

0.79 ( 20)

0.79 ( 20)

L

L

LL

LL

LM

LM

LG

LG

LR

LR

0.12 ( 3)

0.12 ( 3)

QK

QK

Y

Y

Y

Y

A

0.000 8 ( 0.02)

ΦS

ΦS

L LL LM LR LG LC ΦLA ΦLZ ΦS* ΦLB** QK U W T

4.98

3.8

(126.5)

6.08

(154.5)

(124.5)

7.28

(185)

(96.5)

4.9

5.71

(145)

2. 46

(62.5)

3. 56

(90.5)

4. 37

(111)

1. 18

(30)

1. 57

(40)

0. 24

(6)

0. 31

(8)

2.36

(60)

3.15

(80)

2.76

(70)

3.54

(90)

0.22

(5.5)

0.28

(7)

0. 55

(14)

0. 63

(16)

1.97

(50)

2.76

(70)

0. 79

(20)

1. 18

(30)

*

*

ΦLB**

ΦLB**

0.12

(3)

0.12

(3)

0 .0016 (0 .04)

0.0016 ( 0.04)

4-ΦLZ

0. 2

(5)

0. 2

(5)

0.2

(5)

0.2

(5)

A

A

0.43 (11)

Output

W (hp)

200

(0.27)

400

(0.53)

75 0

(1.01)

LC

(21. 5)0.85

Approximate

Ma ss

lb (kg )

2.43 (1.1)

3.75 (1.7)

7.5

(3.4)

ΦLA

LC

Allowable

R a di al

Load

lb ( N)

Allowable

Thrust

Lo ad

lb (N)

55 (245) 17 (74)

88 (392) 33 (147)

* Please see the following table for dimension tolerances.

Specified Tolerances

Dimension *ΦS ** ΦLB

Unit Diameter To lerance Diameter Tolerance

in

mm

0.5512 +0.0000-0.0004 1.9685 +0.0000 -0.0010

0.6299 +0.0000-0.0004 2.7559 +0.0000 -0.0012

14.000 +0.000 -0.011 50.000 + 0.000 -0.025

16.000 +0.000 -0.011 70.000 + 0.000 -0.030

2

Page 3

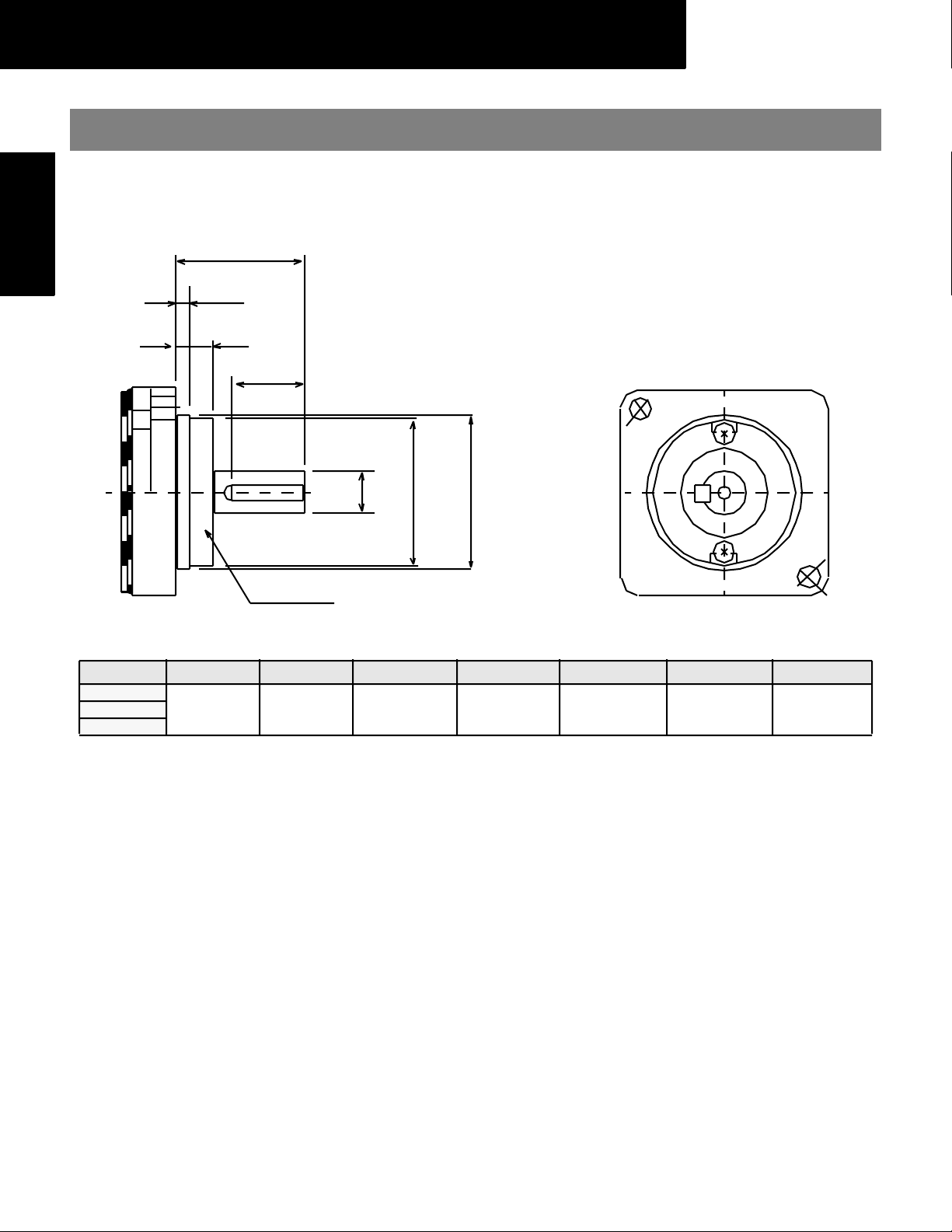

LEGEND System Components

• 200W (0.27hp), 400W (0.54hp) with NEMA 23* Flange/Pilot

Encoder cable, Φ0.24 (Φ6)

Servomotors

UL20276

SGMAH

1.32 (33.5)

0.37(9.5)

Serial e nc oder

11.85 (300) ±1.18 (30)

Motor cable

UL1818, UL3534 or

UL3535

0.51 (13)

0.79 (20)

1.38 (35)

11.85 ( 300) ±1.18 (30)

L

LL

LM

LG

LR

0.06

(1 .6)

A

*

ΦS

0 .0008 (0 .02)

Encoder plug

55100-0600

Motor plug

350779-1

0.0016 (0.04)

Φ0.0016 (0.04)

ΦLB**

4-ΦLZ

A

A

LC

0.85 (21.5)

0.43 (11 )

ΦLA

LC

200

400

Approximate

Mass

lb ( kg )

2.43 (1.1)

3.75 (1.7)

Type

SGMAH-

02AN21

04AN21

1.5

Output

W (hp)

(0.27)

(0.53)

L LL LM LR LG LC ΦLA ΦLZ ΦS* ΦLB**

4.67

(118.5)

5.77

(146.5)

Dimension *ΦS ** ΦLB

3.9

(98.5)

5.0

(126.5)

Unit Diameter To lerance Diameter Tolerance

in 0.5000 +0 -0.00043 1.5000 +0.0000 -0.00098

mm 1 2.7 +0 -0.011 38.1 + 0.000 -0.025

2.56

(65)

3.66

(93)

0.79

(20)

0.24

2.36

(6)

(60)

Specified Tolerances

2.63

(66.7)

0.18

(4.5)

0.50

(12.7)

(38.1)

* For servo application torques: shaft diameter is 0.5in (12.7mm) rather than 0.25 (6.35mm), as is in typical NEMA 23.

Allowable

Radia l

Load

lb (N)

55 (245) 17 (74)

Allo wable

Thr ust

Load

lb (N)

3

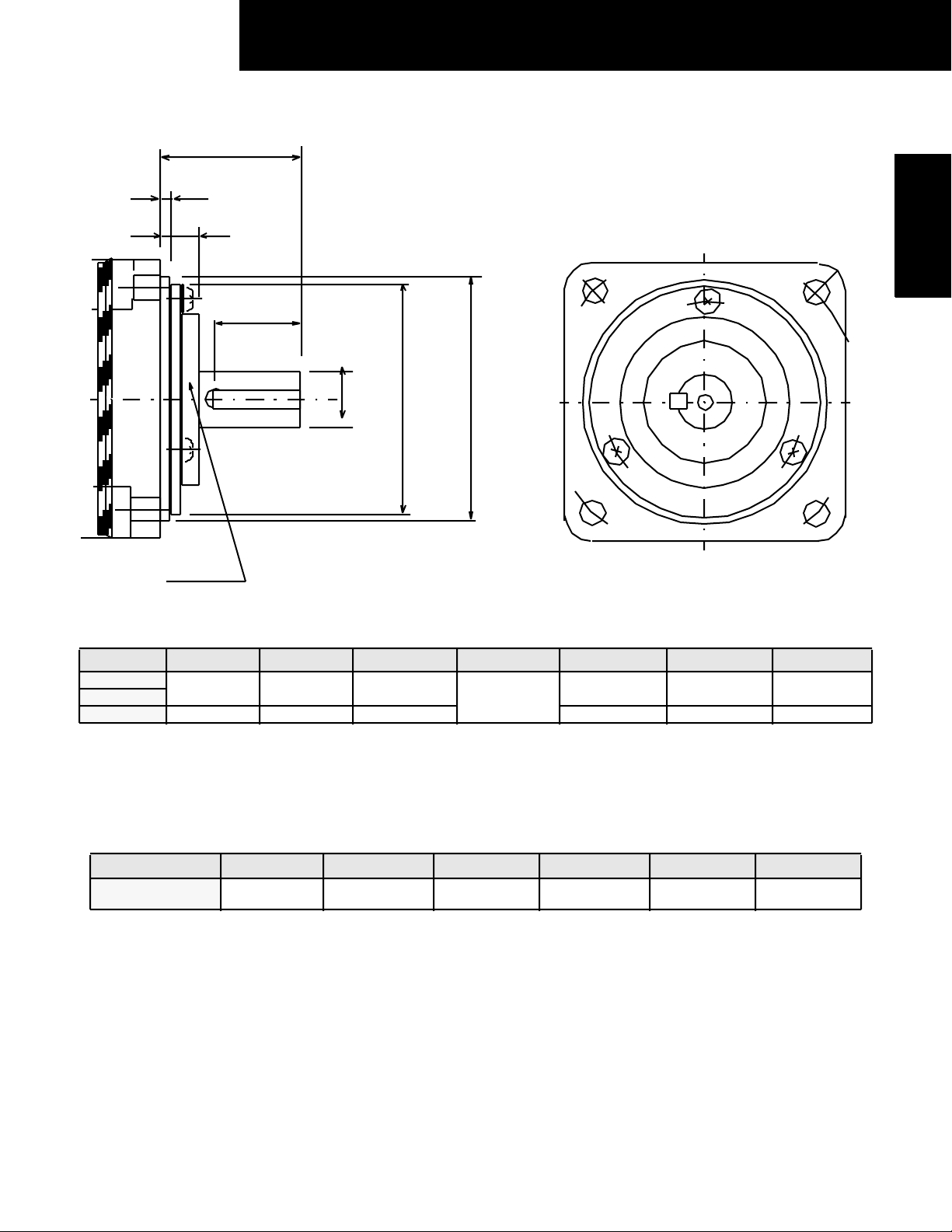

Page 4

LEGEND System Components

• 750W (1.01hp ) with NEMA 34* Flange/Pilot

11.85 (300) ±1.18 ( 30)

1.04

(26.5)

0. 37 (9.5)

Encoder cable, Φ

UL20276

Motor cable Φ0.27 (Φ7)

UL3443

0. 51 (13)

0.28 ( 7)

0.91( 23)

Φ

0.24 (Φ6)

6

Encoder plug

55100-0600

1.38 (35)

11.85 (300) ±1.18 (30 )

L

LL

LM

LR

0.08 (2)

0.63 (16)

LG

Mot or plug

350779-1

S*

LD***

Φ

Φ

Φ0.0016 (Φ0.04)

LB * *

Φ

0.43 (11)

A0.0016 (0.04)

A

LC

0.85 (21.5)

LC

ΦLA

SGMAH

Servomotors

3.35

(85)

A

0.0008 (0.02)

3.87

(98.4 )

0. 28

(7)

0. 63

(16)

4-ΦLZ

2. 87

(73)

2.60

(66)

Output

W (hp)

750

(1.01)

Approx

Mass

lb (kg)

7. 5

(3.4)

Allowable

88 (392) 33 (147)

Radial

Load

lb (N)

Allowable

Thrust

Load

lb (N)

Type

SGMAH-

08AAN21

13-bit ser ial incremental encoder

L LL LM LR LG LC ΦLA ΦLZ ΦS* ΦLB ** ΦLD * **

7.20

5. 75

4. 43

1.46

(37)

0.31

(8)

(183)

(146)

(112. 5)

Specified Tolerances

Dimension *ΦS **ΦLB **Φ*LD

Unit Diameter Tolerance Diam eter Tol eran ce Diameter Tolerance

in 0.625 +0.0000-0.00043 2.874 +0.0000 -0.0012 2.598 +0.0012 -0

mm

15.875 +0.000 -0.011 73.000 ? 66.000 +0.003 - 0

* For servo application torques: shaft diameter is 0.0.625in (15.875mm) rather than 0.375 (9.525mm), as is in typical NEMA 34.

4

Page 5

LEGEND System Components

(2) 13-Bit Incremental Encoder, with Brake

Servomotors

SGMAH

Enc ode r cabl e, Φ0. 24 (Φ6)

UL20276

11. 85 (300) ±1.18 (30)

Encod er pl ug

5 5100-06 00

U

0. 87 ( 22)

0.37(9. 5)

Ser i al enco der

Type

SG MAH-

U W T L LL LM ΦS* ΦLB** QK

A3F2C

A3F4C

A5F2C

0.047

(1.2)

A5F4C

01F2C

01F4C

0.07

(1.8)

Dimension *ΦS ** ΦLB

Connector Specifications:

Motor Plug

31

h

5

d

f

W

T

Cr oss -sec ti on Y - Y

A

Ma ss

1.32

(0.6 )

1.54

(0.7 )

1.76

(0.8 )

0.12

(3)

Mot or ca bl e Φ0.28 (Φ7)

UL 18 28 o r UL35 35

0. 79 ( 20)

0. 60 ( 1 5. 2 )

Holding brake (de-energized operation)

DC Power su pply = 24V

Br ake ho ld in g t orq ue = Mo tor r ate d t or que

0.079

(2)

0.12

(3 )

4.96

(126)

5.26

(133.5)

6.3

(160)

3.98

(101)

4.27

(108.5)

5.31

(135)

1.38 (35)

11. 85 (300 ) ±1. 18 (3 0)

L

LL

LM

0.20 ( 5)

0. 98 (25 )

0. 098 (2. 5)

0.30 (25)

QK

Y

Y

1.44

(36 .5)

1.73

0.24

(6)

(44 .0)

2.42

(61 .5)

0.31

(8)

S*

Φ

A

0.0008 (0.02)

1.18

(30)

Φ

0.315

(Φ8)

LB**

Φ

0.55

(14)

0.55

(14)

Motor pl ug

35 0779-1

0.0016 (0.04)

Φ

2−Φ0.1 7

(Φ

4.3)

Output

(0.04)

(0.07)

(0.13)

0.0016 (Φ0.04)

1. 57 (4 0)

0.8 5 (21. 5)

0. 43 (11)

Approximate

W

(hp)

30

50

100

A

0. 16 (4)

lb (kg)

Specified Tolerances

Unit Diameter To lerance Diameter Tolerance

in

mm

1 Phase U Red

2 Phase V White

3 Phase W Blu e

4 F G (Frame Ground) Green/Yellow

5 Brake T erminal Red

6 Brake Terminal Blac k

Plug: 350715- 1 (AMP)

Pin: 350561-3 or 350690-3 (except No. 4)

Ground pin: : 770210-1 (No. 4)

Mating connector:

Cap: 350781-1

Socket: 350570-3 or 350689-3

0.2362 +0.0000-0.0003

0.3150 +0.0000-0.0004

6.000 +0.000 -0.008

8.000 +0.000 -0.009

Motor Connection

Encoder Plug

5

3

1

1.181 +0.0000 -0.0008

30.000 +0.000 -0.021

En coder Connection

6

1PG 5V Red

2 PG 0V Black

4

3— —

4— —

2

5 Data + Light Blue

6 Data - White/Light Blue

Plug: 55100-0600 (Molex)

Mating connector:

Socket: 54280-0600

1.57 (40)

Φ

1.8 1

(Φ

Allowable

Ra di al Loa d

lb (N)

15

(68)

18

(78)

46 )

A llow abl e

Thrust Load

lb (N)

12

(54)

5

Page 6

LEGEND System Components

• 200W (0.27hp), 300W (0.40hp), 400W (0.53hp), 750W (1.01hp)

Encoder cable, Φ0.24 (Φ6)

UL20276

1.04 (26.5)

Type

SGM AH-

U W T L LL LM LR LG LC ΦLA ΦLZ ΦS* ΦLB ** QK

02AF4C

0.12

04AF4C

(3)

0.2 (5)

08AF4C

Mot or cable Φ0.28 (Φ7)

UL1828 or UL3 535

0.51 (13)

Holdi ng brake (de-ener gized op eration)

DC Power supply = 24V

Brake holdi ng torque = Motor rated torque

Serial encoder

6.54

5.35

(166)

(136)

7.64

6.46

(194)

(164)

9.04

7.46

(229.5)

(189.5)

11. 85 (300) ±1.18 (30)

1.38 (35 )

11.85 (3 00) ±1.18 ( 30)

0.79 ( 20)

0.37 (9.5)

L

LL

LM

2.46

(62.5)

1.18

0.24

(30)

3.56

(6 )

(90.5)

4.37

1.57

(40)

0.31

(8 )

(111)

2.36

(60)

3.15

(80)

LR

0.12 (3)

LG

2.76

(7 0)

3.54

(9 0)

QK

Y

Y

A

0.0008 ( 0. 02)

0.22

(5.5)

0.28

(7)

Encoder plug

55100-0600

Mot or Plug

350715-1

0.0016 (0.04)

Φ

0.001 6 (Φ0.04 ) A

LB**

Φ

S*

Φ

0.55

(14)

0.64

(16)

1.97

(50)

2.76

(70)

A

4-ΦLZ

0.79

(20)

1.18

(30)

U

W

T

Cross-Section Y-Y

LC

0.85 ( 21.5)

Ap pr ox i ma te

Output

W (hp)

200

(0.27 )

400

(0.53 )

750

(1.01 )

Mass

lb (kg)

3.53

(1.6)

4.85

(2.2)

9.48

(4.3)

0.43 (11)

ΦLA

LC

A ll ow a bl e

R a di al

Load

lb (N)

55

(245)17(74)

88

(392)33(147)

Allowable

Thrust

Load

lb (N)

SGMAH

Servomotors

Specified Tolerances

Dimension *ΦS **ΦLB

Unit D iameter To le r a n c e Diameter To l er a n c e

in

mm

0.5512 +0.0000-0.0004 1.9685 + 0 -0.0010

0.6299 +0.0000-0.0004 2.7558 + 0 -0.0012

14.000 +0.000 -0.011 50.000 +0 -0.025

16.000 +0.000 -0.011 70.00 +0 -0.03

6

Page 7

LEGEND System Components

Dimension Modifications for Motors with Optional Shaft Seal

Servomotors

• 30W (0.04hp), 50W (0.07hp), 100W (0.13hp)

SGMAH

LR

LE

LD

QK

S

Shaft seal

Φ

ΦLP

ΦLB

Type SGMAH- QK ΦLB* ΦS* LE LR LD ΦLP

A3

A5

01

* Tolerances for diame ters LB an d S are the same as those fo r moto rs w ith out sh a ft se a ls.

0.55 (14) 1.18 (30) 0.236 (6) 0.10 (2.5) 0.98 (25) 0.30 (7.5) 1.14 (28)

7

Page 8

LEGEND System Components

• 200W (0.27hp), 400W (0.53hp), 750W (1.01hp)

LR

LE

LD

QK

S

Φ

ΦLP

ΦLB

Shaft seal

Type SGMAH- QK ΦLB* ΦS* LE LR LD ΦLP

02

04

08 0.98 (25) 2.76 (70) 0. 63 (16) 1.57 (40) 0.43 (11) 2.60 (66)

0.55 (14) 1.97 (50) 0.55 (14)

0.12 (3)

1.18 (30) 0.39 (10) 1.89 (48)

SGMAH

Servomotors

* Tole ran ces for diamete rs LB and S are the same as th ose for motors with ou t shaft seals.

Torque Reduction Factor for SGMAH motors equipped with a shaft seal:

Servo Motor Model A3 A5 01 02 04 08

Torque Reduction

Factor

For example: The SGMAH-A3 continuous and peak torque rating should be reduced to 70%

of the listed catalog specification.

70% 80% 90% 90% 95% 95%

8

Loading...

Loading...