Page 1

AC Servomotors and Driver

SGMG/SGMS/SGMD/SGM/SGMP Servomotors

SGDB Servopack

YASKAWA

YA S K A WA

MANUAL NO. TSE-S800-16E

Page 2

PREFACE

The rapid progress being made in today’s automation and information

technologies is resulting in a growing need for even more-advanced motion

control for future high-tech equipment. The end result is a need for devices

that can provide more-precise and quicker motion at higher speeds. Servo

control technology makes this possible. Launched by Yaskawa in 1993, the

Σ Series consists of innovative AC Servos that were developed using

leading-edge servo control technology.

This manual covers all products in the Σ Series, which feature superior

functions and performance. This manual was designed to provide

comprehensible information for users who are about to use a servo for the

first time as well as for users who already have experience in using servos.

This manual enables users to understand what Σ-Series AC Servos are all

about and how to design, install, operate, and maintain a servo system.

Keep this manual in a convenient location and refer to it whenever

necessary in operating and maintaining the servo system.

YASKAWA ELECTRIC CORPORATION

General Precautions

S Some drawings in thismanual are shown with the protective cover or shields removed, in order to

describe the detail with more clarity. Make sure all covers and shields are replaced before operating this product.

S Some drawings in this manual are shown as typical example and may differ from the shipped

product.

S This manual may be modified when necessary because of improvement of the product, modifica-

tion or changes in specifications.

Such modification is made as a revision by renewing the manual No.

S To order a copy of this manual, if your copy has been damaged or lost, contact your YASKAWA

representative listed on the last page stating the manual No. on the front cover.

S YASKAWA is not responsible for accidents or damages due to any modification of the product

made by the user since that will void our guarantee.

Page 3

NOTES FOR SAFE OPERATION

Read this manual thoroughly before installation, operation, maintenance or inspection of the AC Servo

Drives. In this manual, the NOTES FOR SAFE OPERATION are classified as “WARNING” or

“CAUTION”.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious personal inju-

ry.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate personal

injury and/or damage to the equipment.

In some instances, items described in

follow these important items.

.

CAUTION

may also result in a serious accident. In either case,

− iv −

Page 4

WARNING

(WIRING)

S Grounding must be in accordance with the national code and consistent

with sound local practices.

Failure to observe this warning may lead to electric shock or fire.

(OPERATION)

S Never touch any rotating motor parts during operation.

Failure to observe this warning may result in personal injury.

(INSPECTION AND MAINTENANCE)

S Be sure to turn OFF power before inspection or maintenance.

Otherwise, electric shock may result.

S Never open the terminal cover while power is ON, and never turn ON pow-

er when the terminal cover is open.

Otherwise, electric shock may result.

S After turning OFF power, wait at least five minutes before servicing the

product.

Otherwise, residual electric charges may result in electric shock.

CAUTION

(RECEIVING)

S Use the specified combination of servomotor and SERVOPACK.

Failure to observe this caution may lead to fire or failure.

(INSTALLATION)

S Never use the equipment where it may be exposed to splashes of water,

corrosive or flammable gases, or near flammable materials.

Failure to observe this caution may lead to electric shock or fire.

(WIRING)

S Do not connect three−phase power supply to output terminals

.

W

Failure to observe this caution may lead to personal injury or fire.

S Securely tighten screws on the power supply and motor output terminals.

Failure to observe this caution can result in a fire.

UV

and

− v −

Page 5

CAUTION

(OPERATION)

S To avoid inadvertent accidents, run the servomotor only in test run (with-

out load).

Failure to observe this caution may result in personal injury.

S Before starting operation with a load connected, set up parameters suit-

able for the machine.

Starting operation without setting up parameters may lead to overrun failure.

S Before starting operation with a load connected, make sure emergency-

stop procedures are in place.

Failure to observe this caution may result in personal injury.

S During operation, do not touch the heat sink.

Failure to observe this caution may result in burns.

(INSPECTION AND MAINTENANCE)

S Do not disassemble the servomotor.

Failure to observe this caution may result in electric shock or personal injury.

S Never change wiring while power is ON.

Failure to observe this caution may result in electric shock or personal injury.

− vi −

Page 6

Manual Contents

This manual providesΣ-Series users with information on the following:

•

An overview of servo systems for first-time users.

•

Checking the product on delivery and basic applications of the servo.

•

Servo applications.

•

Selecting an appropriate servo for your needs and placing an order.

•

Inspection and maintenance.

Manual Structure

All chapters in this manual are classified into one or more of three areas according to their contents: A, B, and

C. Refer to the applicable chapters for the information you require.

A:

Chapters explaining how to select a servo: For users who wish to gain a basic understanding of

Σ

Series products or who need to select an appropriate servo.

B:

Chapters explaining how to design a servo system: For users who are about to design, install, and

operate aΣ-Series Servo Control System.

C:

Chapters explaining maintenance: For users who are going to maintain and troubleshootΣ-Series

products.

Chapter

CHAPTER 1 For First-time Users of AC Servos

CHAPTER 2 Basic Uses of Σ-series Products

CHAPTER 3 Applications of Σ-series Products

CHAPTER 4 Using the Digital Operator

CHAPTER 5 Servo Selection and Data Sheets

CHAPTER 6 Inspection, Maintenance, and Troubleshooting

APPENDIXES

Title Page Area

....................... .........

Provides an overview of servos and theΣSeries.

......................... .........

Describes steps to take when product is received, plus basic

wiring and application methods.

....................... .........

Describes the effective usage ofΣ-Series features according to

application.

.............................. ........

Describes operating procedures forΣ-Series servos, turning

features ON and OFF, setting control constants, etc.

........................ ........

Describes selection methods forΣ-Series servos and peripherals and provides servo specifications.

Describes user maintenance and troubleshooting.

A

Servo Adjustment 539

B

List of I/O Signals 555

C

List of Parameters 561

D

List of Alarm Displays 569

....................................... ........

....................................... ........

....................................... ........

.................................... ........

1

15

51

177

221

........... ........

499

A, B

B

B

B

A, B

C

B, C

B, C

B, C

B, C

INDEX

.............................................................. 573.........

A, B, C

− vii −

Page 7

Basic Terms

Unless otherwise specified, the following definitions are used:

Servomotor:

SERVOPACK: An amplifier (Trademark of Yaskawa servo amplifier “Σ-Series SGDB-jAD

Servodrive: A servomotor and an amplifier (SGDB SERVOPACK)

Servo system: A complete servo control system consisting of servodrive, host controller,

Visual Aids

The following aids are used to indicate certain types of information for easier reference.

.

TERMS

Σ

-Series SGMG/SGMD/SGMS/SGM/SGMP servomotor

SERVOPACK”)

and peripheral devices

Indicates references for additional information.

Technical terms placed in bold in the text are briefly explained in a “TERMS” section at the bottom of the page. The following kinds of technical terms are explained:

Technical terms that need to be explained to users who are not very familiar with

servo systems or electronic devices and technical terms specific toΣSeries Servos that need to be explained in descriptions of functions.

The text indicated by this icon explains the operating procedure using hand-held

type digital operator (Type: JUSP-OP02A-1).

JUSP-OP02A-1

NOTE

The text indicated by this icon explains the operating procedure using mount type

digital operator (Type: JUSP-OP03A).

AΣ-Series Servodrive alone cannot ensure the functionality and performance of the entire

machine control system. It must be combined with an appropriate machine and host controller so that the entire control system works properly. Therefore, carefully read the instruction

manuals for the machine to be used before attempting to operate the servodrive.

− viii −

Page 8

Yaskawa, 1995

All rights reserved. No part of thispublication may be reproduced, stored in aretrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of Yaskawa. No patent liability isassumed with respect to the use of the informationcontained herein. Moreover,becauseYaskawa

is constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information

contained in this publication.

− ix −

Page 9

CONTENTS

CHAPTER 1 FOR FIRST-TIME USERS OF AC SERVOS 1...............

1.1 Servo Mechanisms 2.......................................................

1.2 Servo Configuration 5......................................................

1.3 Features of Σ-Series Servos 11................................................

1.3.1 Servomotor Type 11.................................................

1.3.2 Control Type of SERVOPACKs 11......................................

1.3.3 How to Use the SGDB SERVOPACKs 12................................

CHAPTER 2 BASIC USES OF Σ-SERIES PRODUCTS 15.................

2.1 Precautions 16.............................................................

2.1.1 Notes on Use 16....................................................

2.2 Installation 18.............................................................

2.2.1 Checking on Delivery 18..............................................

2.2.2 Servomotors 18.....................................................

2.2.3 SERVOPACKs 22...................................................

2.2.4 Installing the Servomotor 24...........................................

2.2.5 Installing the SERVOPACK 27.........................................

2.3 Connection and Wiring 30....................................................

2.3.1 Connecting to Peripheral Devices 30....................................

2.3.2 Main Circuit Wiring and Power ON Sequence 34..........................

2.3.3 Connection to Host Controller 36.......................................

2.4 Conducting a Test Run 40....................................................

2.4.1 Test Run in Two Steps 40.............................................

2.4.2 Step 1: Conducting a Test Run for Motor without Load 42...................

2.4.3 Step 2: Conducting a Test Run with the Motor Connected to the Machine 46.....

2.4.4 Supplementary Information on Test Run 47...............................

2.4.5 Minimum Parameters Required and Input Signals 49........................

CHAPTER 3 APPLICATIONS OF Σ-SERIES PRODUCTS 51..............

3.1 Setting Parameters According to Machine Characteristics 54.........................

3.1.1 Changing the Direction of Motor Rotation 54..............................

3.1.2 Setting the Overtravel Limit Function 56.................................

3.1.3 Restricting Torque 59................................................

3.2 Setting Parameters According to Host Controller 64................................

3.2.1 Inputting Speed Reference 64..........................................

3.2.2 Inputting Position Reference 68........................................

3.2.3 Using Encoder Outputs 73............................................

3.2.4 Using Contact I/O Signals 77..........................................

3.2.5 Using Electronic Gear 79.............................................

3.2.6 Using Contact Input Speed Control 83...................................

3.2.7 Using Torque Control 87..............................................

3.2.8 Using Torque Feed-forward Function 94.................................

3.2.9 Using Torque Restriction by Analog Voltage Reference 95...................

3.2.10 Using the Reference Pulse Inhibit Function (INHIBIT) 97....................

3.2.11 Using the Reference Pulse Input Filter Selection Function 98.................

3.2.12 Using the Analog Monitor 99..........................................

3.3 Setting Up the Σ SERVOPACK 100.............................................

− x −

Page 10

CONTENTS

3.3.1 Setting Parameters 100................................................

3.3.2 Setting the Jog Speed 101..............................................

3.3.3 Setting the Number of Encoder Pulses 102.................................

3.3.4 Setting the Motor Type 103.............................................

3.3.5 Adjusting the Encoder Supply Voltage 104.................................

3.4 Setting Stop Mode 105.......................................................

3.4.1 Adjusting Offset 105..................................................

3.4.2 Using Dynamic Brake 106.............................................

3.4.3 Using Zero-Clamp 107................................................

3.4.4 Using Holding Brake 108..............................................

3.5 Running the Motor Smoothly 113...............................................

3.5.1 Using the Soft Start Function 113........................................

3.5.2 Using the Smoothing Function 114.......................................

3.5.3 Adjusting Gain 114...................................................

3.5.4 Adjusting Offset 115..................................................

3.5.5 Setting the Torque Reference Filter Time Constant 115.......................

3.6 Minimizing Positioning Time 117...............................................

3.6.1 Using Autotuning Function 117.........................................

3.6.2 Setting Servo Gain 117................................................

3.6.3 Using Feed-forward Control 119.........................................

3.6.4 Using Proportional Control 119.........................................

3.6.5 Setting Speed Bias 120................................................

3.6.6 Using Mode Switch 121...............................................

3.7 Forming a Protective Sequence 127.............................................

3.7.1 Using Servo Alarm Output and Alarm Code Output 127......................

3.7.2 Using Servo ON Input Signal 130........................................

3.7.3 Using Positioning Complete Signal 131...................................

3.7.4 Using Speed Coincidence Output Signal 134...............................

3.7.5 Using Running Output Signal 136.......................................

3.7.6 Using OL Warning and Alarm Output Signals 138...........................

3.7.7 Using Servo Ready Output Signal 140....................................

3.7.8 Handling of Power Loss 141............................................

3.8 Special Wiring 142..........................................................

3.8.1 Wiring Instructions 142................................................

3.8.2 Wiring for Noise Control 144...........................................

3.8.3 Using More Than One Servo Drive 149...................................

3.8.4 Using Regenerative Resistor Units 151....................................

3.8.5 Using an Absolute Encoder 152.........................................

3.8.6 Extending an Encoder Cable 162........................................

3.8.7 Using SGDB SERVOPACK with High Voltage Line 164......................

3.8.8 Connector Terminal Layouts 166........................................

CHAPTER 4 USING THE DIGITAL OPERATOR 177.....................

4.1 Basic Operations 178.........................................................

4.1.1 Connecting the Digital Operator 178.....................................

4.1.2 Digital Operator Functions 179..........................................

4.1.3 Resetting Servo Alarms 180............................................

− xi −

Page 11

CONTENTS

4.1.4 Basic Functions and Mode Selection 181..................................

4.1.5 Operation in Status Display Mode 182....................................

4.1.6 Operation in Parameter Setting Mode 186.................................

4.1.7 Operation in Monitor Mode 191.........................................

4.2 Using the Functions 194......................................................

4.2.1 Operation in Alarm Trace-back Mode 194.................................

4.2.2 Operation Using the Digital Operator 197.................................

4.2.3 Autotuning 201......................................................

4.2.4 Reference Offset Automatic Adjustment 207...............................

4.2.5 Reference Offset Manual Adjustment Mode 210............................

4.2.6 Clearing Alarm Trace-back Data 213.....................................

4.2.7 Checking Motor Specifications 215......................................

4.2.8 Checking Software Version 216.........................................

4.2.9 Current Detection Offset Manual Adjustment Mode 217......................

CHAPTER 5 SERVO SELECTION ANDDATA SHEETS 221................

5.1 Selecting a Σ-Series Servo 223.................................................

5.1.1 Selecting a Servomotor 223............................................

5.1.2 Selecting a SERVOPACK 233...........................................

5.1.3 Selecting a Digital Operator 235.........................................

5.2 SGM Servomotor 237........................................................

5.2.1 Ratings and Specifications 237..........................................

5.2.2 Mechanical Characteristics 269..........................................

5.2.3 Option Specifications 272..............................................

5.3 SERVOPACK Ratings and Specifications 282.....................................

5.3.1 Combined Specifications 282...........................................

5.3.2 Ratings and Specifications 285..........................................

5.3.3 Overload Characteristics 288...........................................

5.3.4 Starting Time and Stopping Time 289.....................................

5.3.5 Load Inertia 290.....................................................

5.3.6 Overhanging Loads 291...............................................

5.4 Σ-Series Dimensional Drawings 292.............................................

5.4.1 Servomotor Dimensional Drawings 292...................................

5.4.2 SERVOPACK Dimensional Drawings 400.................................

5.4.3 Digital Operator Dimensional Drawings 412...............................

5.5 Selecting Peripheral Devices 414...............................................

5.5.1 Selecting Peripheral Devices 414........................................

5.5.2 Order List 424.......................................................

5.6 Specifications and Dimensional Drawings of Peripheral Devices 442...................

5.6.1 Cable Specifications and Peripheral Devices 442............................

5.6.2 Motor Cables 446....................................................

5.6.3 Connector 447.......................................................

5.6.4 Brake Power Supply 466...............................................

5.6.5 Encoder Cables 469...................................................

5.6.6 Battery for Absolute Encoder 480........................................

5.6.7 1CN Connector 481...................................................

5.6.8 Connector Terminal Block Converter Unit 483..............................

− xii −

Page 12

CONTENTS

5.6.9 Cable With 1CN Connector and One End Without Connector 485...............

5.6.10 Circuit Breaker 486...................................................

5.6.11 Noise Filter 486......................................................

5.6.12 Magnetic Contactor 488...............................................

5.6.13 Surge Suppressor 490.................................................

5.6.14 Regenerative Resistor Unit 490..........................................

5.6.15 Variable Resistor for Speed Setting 491...................................

5.6.16 Encoder Signal Converter Unit 492......................................

5.6.17 Cables for Connecting PC and SERVOPACK 494...........................

CHAPTER 6 INSPECTION, MAINTENANCE, AND TROUBLESHOOTING 499.

6.1 Inspection and Maintenance 500................................................

6.1.1 Servomotor 500......................................................

6.1.2 SERVOPACK 501....................................................

6.1.3 Replacing Battery for Absolute Encoder 502...............................

6.2 Troubleshooting 503.........................................................

6.2.1 Troubleshooting Problems with Alarm Display 503..........................

6.2.2 Troubleshooting Problems With No Alarm Display 529.......................

6.2.3 Internal Connection Diagram and Instrument Connection Examples 531.........

A Servo Adjustment 539........................................................

A.1 Σ-Series AC SERVOPACK Gain Adjustment 540..................................

A.1.1 Σ-Series AC SERVOPACKs and Gain Adjustment Methods 540................

A.1.2 Basic Rules for Gain Adjustment 541.....................................

A.2 Adjusting a Speed-control SERVOPACK 542......................................

A.2.1 Adjusting Using Auto-tuning 542........................................

A.2.2 Manual Adjustment 543...............................................

A.3 Adjusting a Position-control SERVOPACK 546....................................

A.3.1 Adjusting Using Auto-tuning 546........................................

A.3.2 Manual Adjustment 547...............................................

A.4 Gain Setting References 551...................................................

A.4.1 Guidelines for Gain Settings According to Load Inertia Ratio 551..............

B List of I/O Signals 555........................................................

C List of Parameters 561........................................................

D List of Alarm Displays 569....................................................

INDEX 573...........................................................

− xiii −

Page 13

FOR FIRST-TIME USERS OF AC SERVOS

1

1

This chapter is intended for first-time users of AC servos. It describes the basic configuration of a servo mechanism and basic technical terms relating to

servos.

Users who already have experience in using a servo should also take a look at

this chapter to understand the features of Σ-Series AC Servos.

1.1 Servo Mechanisms 2.......................

1.2 Servo Configuration 5.....................

1.3 Features of Σ-Series Servos 11................

1.3.1 Servomotor Type 11..................................

1.3.2 Control Type of SERVOPACKs 11.......................

1.3.3 How to Use the SGDB SERVOPACKs 12.................

1

Page 14

FOR FIRST-TIME USERS OF AC SERVOS

1.1 Servo Mechanisms

You may be familiar with the following terms:

• Servo

1

• Servo mechanism

• Servo control system

In fact, these terms are synonymous. They have the following meaning:

A control mechanism that monitors physical quantities such as specified positions.

In short, a servo mechanism is like a servant who does tasks faithfully and quickly according

to his master’s instructions. In fact, “servo” originally derives from the word “servant.”

TERMS

Servo mechanism

According to Japanese Industrial Standard (JIS) terminology, a “servo mechanism” is defined as a mechanism that uses the position, direction, or orientation of an object as a process variable to control a system to follow any changes in a target value (set point).

More simply, a servo mechanism is a control mechanism that monitors physical quantities

such as specified positions. Feedback control is normally performed by a servo mechanism. (Source: JIS B0181)

2

Page 15

1 . 1 Servo Mechanisms

Servo system could be defined in more detail as a mechanism that:

• Moves at a specified speed and

• Locates an object in a specified position

To develop such a servo system, an automatic control system involving feedback control

must be designed. This automatic control system can be illustrated in the following block diagram:

Configuration of Servo System

Specified position

input

Servo

amplifier

Servo

motor

Feedback part

Detector

Controlled

machine

(load)

Machine position

output

This servo system is an automatic control system that detects the machine position (output

data), feeds back the data to the input side, compares it with the specified position (input

data), and moves the machine by the difference between the compared data.

In other words, the servo system is a system to control the output data to match the

specified input data.

If, for example, the specified position changes, the servo system will reflect the changes.

In the above example, input data is defined as a position, but input data can be any physical

quantities such as orientation (angle), water pressure, or voltage.

1

TERMS

Position, speed, force (torque), electric current, and so on are typical controlled values for a

servo system.

The main technical terms used in this manual are as follows:

1) Servo mechanism

2) Servo

Normally, servo is synonymous with servo mechanism. However, because “mechanism” is

omitted, the meaning becomes somewhat ambiguous. Servo may refer to the entire servo

mechanism but may also refer to an integral part of a servo mechanism such as a servomotor

or a servo amplifier. This manual also follows this convention in the use of the term “servo”.

Feedback control

A control that returns process variables to the input side and forms a closed loop. It is also

called closed-loop control.

3

Page 16

1

FOR FIRST-TIME USERS OF AC SERVOS

3) Servo control system

Servo control system is almost synonymous with servo mechanism but places the focus on

system control. In this manual, the term “servo system” is also used as a synonym of servo

control system.

Related Terms Meaning

Servomotor

SERVOPACK Trademark of Yaskawa servo amplifier “SGDB

Servo drive A servomotor and amplifier pair. Also called “servo.”

Servo system A closed control system consisting of a host controller,

General servomotors or Yaskawa SGMj servomotors. In

some cases, a position detector (encoder) is included in a

servomotor.

SERVOPACK.”

servo drive and controlled system to form a servo

mechanism.

Host controller

Reference

Amplifier

(SERVOPACK)

Servo drive

Servomotor

Servo system

Operate

Controlled

system

4

Page 17

1.2 Servo Configuration

The following diagram illustrates a servo system in detail:

1.2 Servo Configuration

Host controller

(5)

Position or

speed

reference

Servo amplifier

Comparator

(Input)

Position or

speed

feedback

Power

amplifier

Detector

(1) Controlled system: Mechanical system for which the position or speed is to be con-

trolled.

This includes a drive system that transmits torque from a servomotor.

(4)

Motor

drive

circuit

Gear

(2)

(3)

servomotor Drive system

(Output)

(1)

Controlled

system

Position

Speed

Movable

table

Ball screw

1

(2) Servomotor: A main actuator that moves a controlled system. Two types are

available: AC servomotor and DC servomotor.

(3) Detector: A position or speed detector. Normally, an encoder mounted on

a motor is used as a position detector.

(4) Servo amplifier: An amplifier that processes an error signal to correct the differ-

ence between a reference and feedback data and operates the

servomotor accordingly. A servo amplifier consists of a

comparator, which processes error signals, and a power amplifier, which operates the servomotor.

(5) Host controller: A device that controls a servo amplifier by specifying a position

or speed as a set point.

5

Page 18

FOR FIRST-TIME USERS OF AC SERVOS

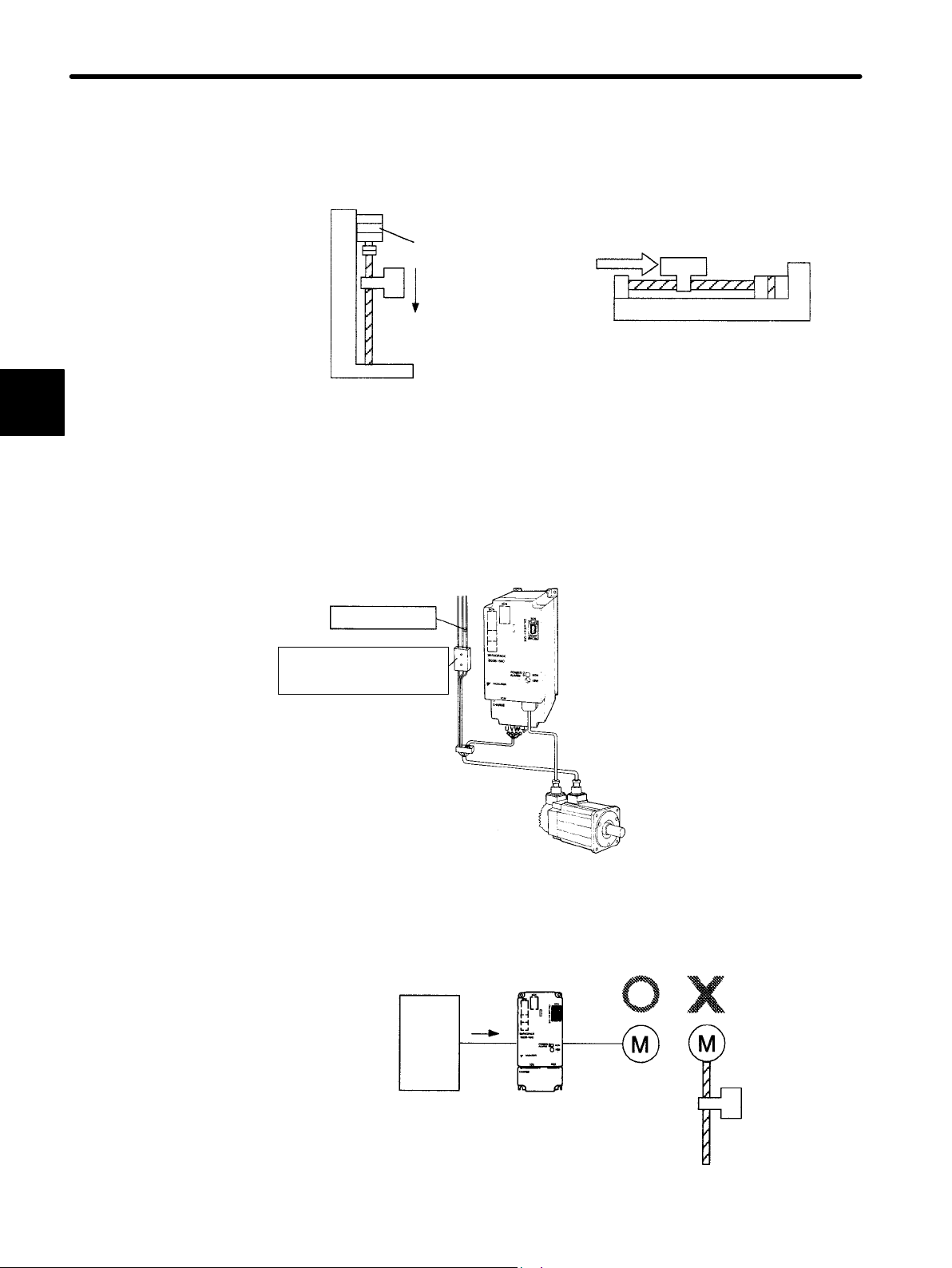

Servo components (1) to (5) are outlined below:

(1) Controlled system

In the previous figure, the controlled system is a movable table for which the position

or speed is controlled. The movable table is driven by a ball screw and is connected to

the servomotor via gears.

So, the drive system consists of:

1

Gears + Ball Screw

This drive system is most commonly used because the power transmission ratio

(gear ratio) can be freely set to ensure high positioning accuracy. However, play in the

gears must be minimized.

The following drive system is also possible when the controlled system is a movable

table:

Coupling + Ball Screw

When the power transmission ratio is 1 :

1, a coupling is useful because it has no

play.

Coupling

Rolling-contact

guide

Ball screw

Rolling-contact

bearing

This drive system is widely used for machining tools.

Housing

Timing Belt + Trapezoidal Screw Thread

A timing belt is a coupling device that allows

the power transmission ratio to be set freely

and that has no play.

A trapezoidal screw thread does not provide

excellent positioning accuracy, so can be

Trapezoidal

screw

thread

treated as a minor coupling device.

Servomotor

Timing belt

To develop an excellent servo system, it is important to select a rigid drive system that

has no play.

Configure the controlled system by using an appropriate drive system for the control

purpose.

TERMS

Drive system

Also called a drive mechanism.

A drive system connects an actuator (such as a servomotor) to a controlled system and

serves as a mechanical control component that transmits torque to the controlled system,

orientates the controlled system, and converts motion from rotation to linear motion and

vice versa.

6

Page 19

(2) Servomotor

(a) DC servomotor and AC servomotor

Servomotors are divided into two types: DC servomotors and AC servomotors.

DC servomotors are driven by direct current (DC). They have a long history. Up

until the 1980s, the term “servomotor” used to imply a DC servomotor.

1.2 Servo Configuration

From 1984, AC servomotors were emerging as a result of rapid progress in microprocessor technology. Driven by alternating current (AC), AC servomotors are

now widely used because of the following advantages:

• Easy maintenance: No brush

• High speed: No limitation in rectification rate

Note however that servomotors and SERVOPACKs use some parts that are subject to mechanical wear or aging. For preventive maintenance, inspect and replace parts at regular intervals.

For details, refer to Chapter 6 Inspection, Maintenance, and Troubleshooting.

(b) AC servomotor

AC servomotors are divided into two types: synchronous type and induction type.

The synchronous type is more commonly used.

For a synchronous type servomotor, motor speed is controlled by changing the

frequency of alternating current.

A synchronous type servomotor provides strong holding torque when stopped, so

this type is ideal when precise positioning is required. Use this type for a servo

mechanism for position control.

1

The following figure illustrates the structure of a synchronous type servomotor:

Rotary disc

Light-emitting

element

Position detector

(encoder)

Light-receiving

element

Armature

wire

Lead wire

Housing

Stator core

Magnet

Front cap

Ball bearing

Shaft

Rotor core

Yaskawa SGMj servomotors are of the synchronous type.

7

Page 20

FOR FIRST-TIME USERS OF AC SERVOS

(c) Performance of servomotor

A servomotor must have “instantaneous power” so that it can start as soon as a

start reference is received.

The term “power rating (kW/s)” is used to represent instantaneous power.

It refers to the electric power (kW) that a servomotor generates per second.

The greater the power rating, the more powerful the servomotor.

1

(3) Detector

A servo system requires a position or speed detector. It uses an encoder mounted on

a servomotor for this purpose.

Encoders are divided into the following two types:

(a) Incremental Encoder

An incremental encoder is a pulse generator, which generates a certain number

of pulses per revolution (e.g., 2,000 pulses per revolution). If this encoder is connected to the mechanical system and one pulse is defined as a certain length

(e.g., 0.001 mm), it can be used as a position detector.

However, this encoder does not detect an absolute position and merely outputs a

pulse train. Zero point return operation must be performed before positioning.

The following figure illustrates the operation principle of a pulse generator:

Phase A pulse train

Phase B pulse train

Fixed slit

Light-receiving

element

Rotary slit

Center of

revolution

Phase A

Phase B

Phase Z

Rotary

disc

Slit

Light-emitting

element

(b) Absolute encoder

An absolute encoder is designed to detect an absolute angle of rotation as well as

to perform the general functions of an incremental encoder. With an absolute encoder, therefore, it is possible to create a system that does not require zero point

return operation at the beginning of each operation.

• Difference between an absolute

An absolute

encoder will keep track of the motor shaft position even if system

and incremental encoder:

power is lost and some motion occurs during that period of time. The incremental

encoder is incapable of the above.

8

Page 21

(4) Servo amplifier

A servo amplifier is required to operate an AC servomotor.

The following figure illustrates the configuration of a servo amplifier:

Servo amplifier

1.2 Servo Configuration

Motor driving AC power

Servomotor

Commercial AC power

Reference

input

Comparator

Feedback

Power

amplifier

A servo amplifier consists of the following two sections:

(a) Comparator

A comparator consists of a comparison function and a control function. The comparison function compares reference input (position or speed) with a feedback

signal and generates a differential signal.

1

TERMS

The control function amplifies and transforms the differential signal. In other

words, it performs proportional (P) control or proportional/integral (PI) control.

(It is not important if you do not understand these control terms completely at this

point.)

(b) Power amplifier

A power amplifier runs the servomotor at a speed or torque proportional to the

output of the comparator. In other words, from the commercial power supply of

50/60 Hz, it generates alternating current with a frequency proportional to the reference speed and runs the servomotor with this current.

Proportional/integral (PI) control

PI control provides more accurate position or speed control than proportional control, which

is more commonly used.

9

Page 22

1

FOR FIRST-TIME USERS OF AC SERVOS

(5) Host controller

A host controller controls a servo amplifier by specifying a position or speed as a set

point.

For speed reference, a position control loop may be formed in the host controller when

a position feedback signal is received. Yaskawa MP920 is a typical host controller.

10

TERMS

MP920

A machine controller. If combined with a servo amplifier

for speed control (maximum 44 axes control), the MP920

can provide position control.

The MP920 also provides programmable controller functions.

Page 23

1.3 Features ofΣ-Series Servos

This section describes the features of Σ-Series servos.

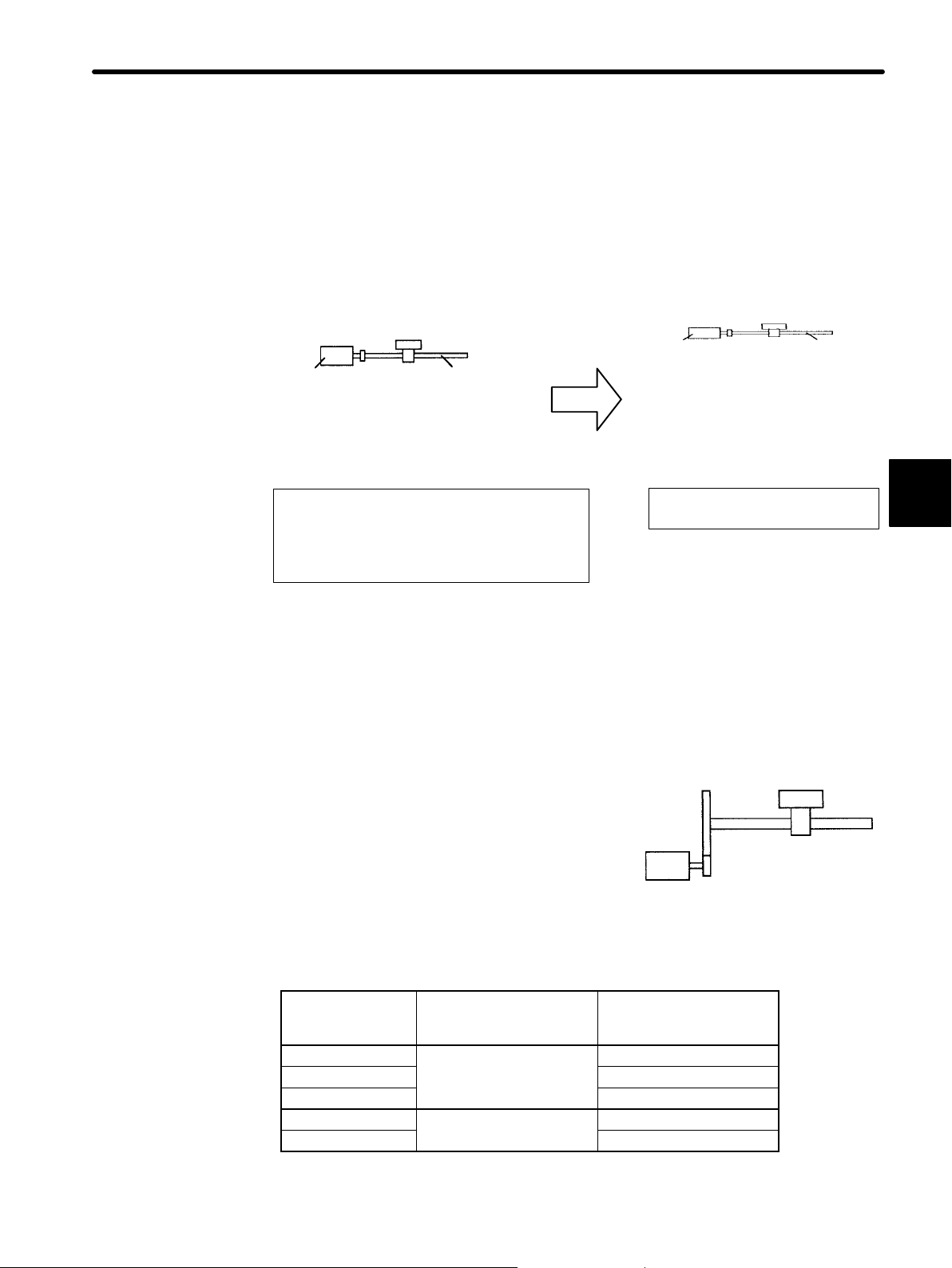

1.3.1 Servomotor Type

1.3 Features ofΣ -Series Servos

Σ-Series SGMj servomotors are synchronous type servomotors and have the following

features:

Rated rotation speed

Maximum rotation speed

SGMG

SGMS 3000 r/min

SGMD 2000 r/min

SGM 3000 r/min

SGMP 3000 r/min

1500 r/min

3000 r/min

1000 r/min

2000 r/min

4500 r/min

3000 r/min

4500 r/min

4500 r/min

1.3.2 Control Type of SERVOPACKs

Rated output

0.45 to 15 kW

(10 models)

0.3 to 6.0 kW

(8 models)

1.0 to 5.0 kW

(6 models)

2.2 to 4.0 kW

(3 models)

0.4 to 0.8 kW

(2 models)

0.4 to 1.5 kW

(3 models)

1

SGMG type

SGMP type

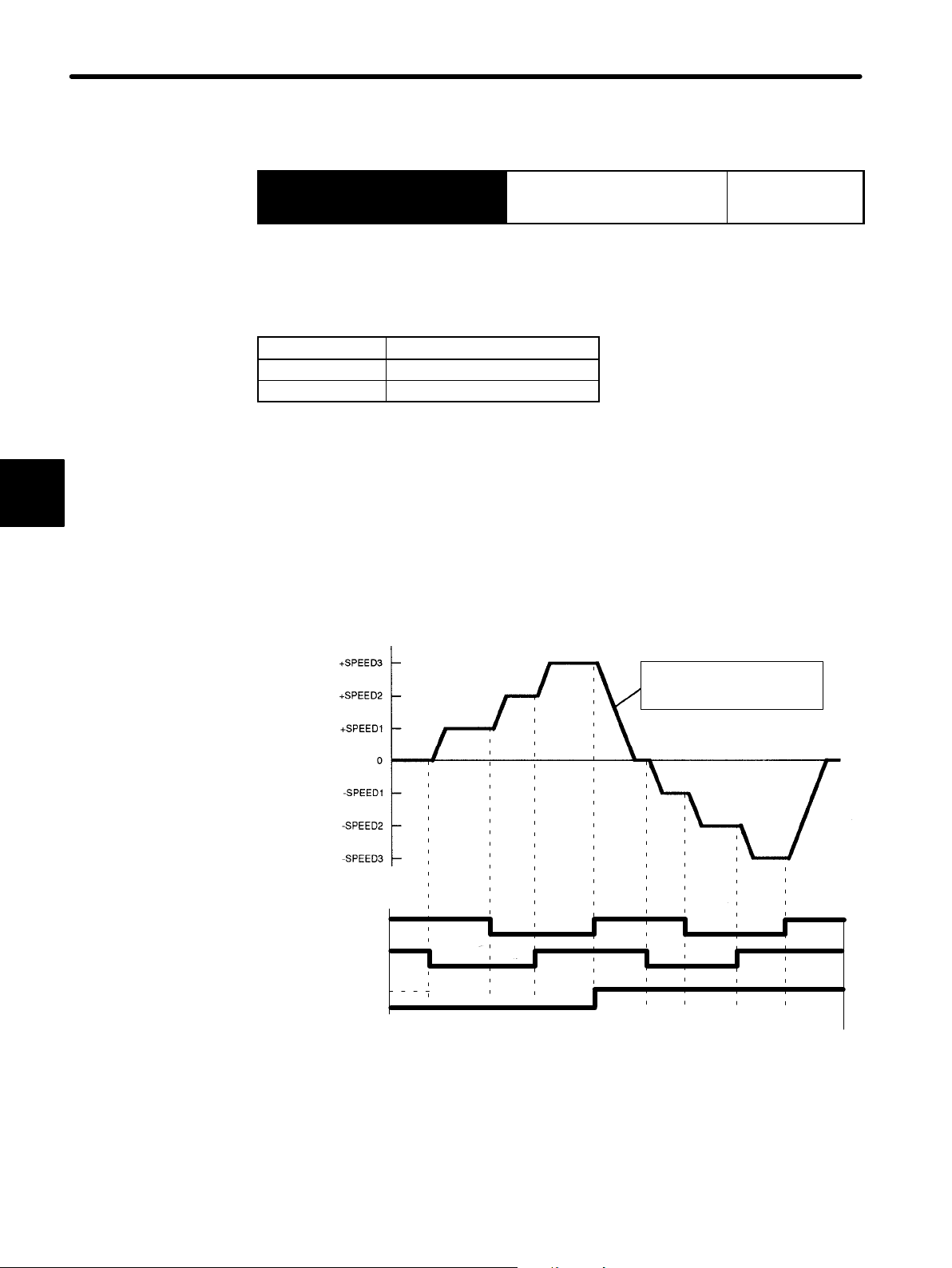

SGDB model SERVOPACKs allow the control of speed, position and torque.

• Speed control (analog reference)

Accepts an analog voltage speed reference.

• Speed control (contact reference)

There are 3 internally set speeds. One of

these is selected as a reference by a contact.

• Position control (pulse reference)

Accepts a pulse train position reference

• Torque control (analog reference)

Accepts an analog voltage torque reference

SGDB SERVOPACK

11

Page 24

FOR FIRST-TIME USERS OF AC SERVOS

1.3.3 How to Use the SGDB SERVOPACKs

1.3.3 How to Use the SGDB SERVOPACKs

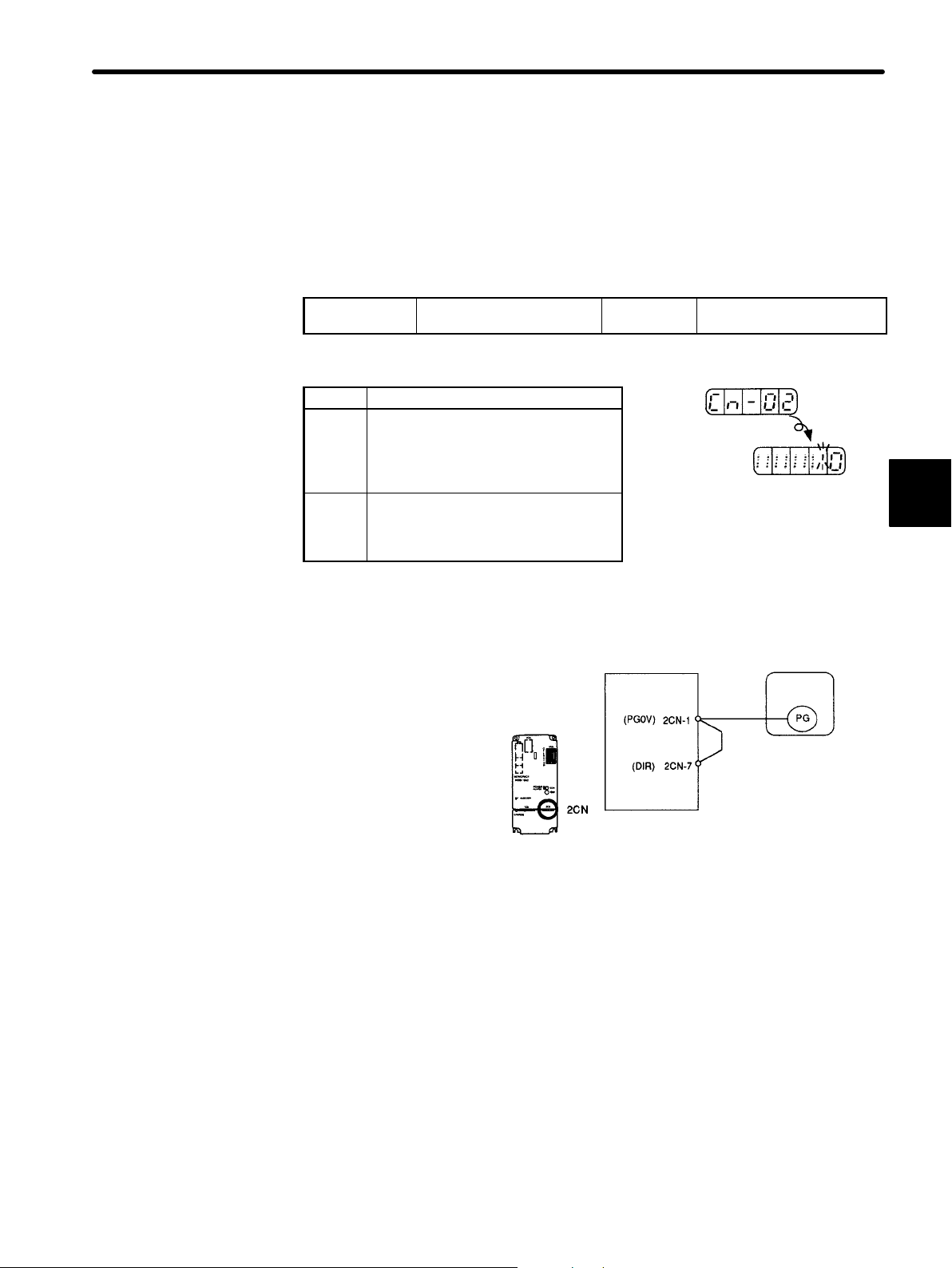

J Using SERVOPACK for Speed Control

The most common use of a SERVOPACK for speed control is shown below:

Host controller

1

Position reference +

Position control loop

Position

feedback

(Analog

voltage)

Speed

reference

Position

Speed

Convert

Position feedback

SERVOPACK

(speed control mode)

Power

amplifier

Servomotor

Torque

(current)

feedback

Pulse train

Encoder

As shown in the above figure, a position control loop is formed in the host controller. The

host controller compares a position reference with a position feedback signal and sends

the processed result to the SERVOPACK as a speed reference.

In this way the host controller can be freed from performing the servo mechanism control.

The SERVOPACK undertakes the speed control loop and subsequent control processing.

12

The Yaskawa programmable machine controller MP920 is used as a typical host controller.

Page 25

J Using SERVOPACK for Torque Control

SERVOPACK for torque control can be used as shown below:

Host controller

Position

monitoring

Position

information

Torque

reference

(Analog

voltage)

Position feedback Encoder

SERVOPACK

(torque control mode)

Power

amplifier

Torque

(current)

feedback

Pulse train

1.3 Features ofΣ -Series Servos

1

Servomotor

The host controller outputs a torque reference to control the SERVOPACK. It also receives a pulse train (position information) from the SERVOPACK and uses it to monitor

the position.

J Using SERVOPACK for Position Control

SERVOPACK for position control can be used as shown below:

Host controller

Position

monitoring

Position

reference

Position

information

Pulse

train

Speed/current loop

Position feedback

SERVOPACK

(position control mode)

Power

amplifier

Servomotor

Pulse train

Encoder

13

Page 26

FOR FIRST-TIME USERS OF AC SERVOS

1.3.3 How to Use the SGDB SERVOPACKs cont.

The host controller can send a position reference (pulse train) to the SERVOPACK to perform positioning or interpolation.

This type of SERVOPACK contains a position control loop.

Parameters can be used to select either of the following pulse trains:

(1) Code and pulse train

1

(2) Two-phase pulse train with 90° phase difference

(3) Forward and reverse pulse trains

The host controller receives a pulse train (position information) from the SERVOPACK

and uses it to monitor the position.

J Setting Parameters

A Digital Operator can be used to set parameters for a SERVOPACK as follows:

• Setting parameters to enable or disable each function

• Setting parameters required for functions to be used

Set parameters according to the servo system to be set up.

14

Page 27

BASIC USES OF Σ-SERIES

PRODUCTS

This chapter describes the first things to do whenΣ-Series products are delivered. It also explains the most fundamental ways ofconnecting and operating

-Series products. Both first-time and experienced servo users

Σ

this chapter.

2.1 Precautions 16.............................

2.2 Installation 18.............................

2

2

must read

2.1.1 Notes on Use 16.....................................

2.2.1 Checking on Delivery 18...............................

2.2.2 Servomotors 18......................................

2.2.3 SERVOPACKs 22....................................

2.2.4 Installing the Servomotor 24............................

2.2.5 Installing the SERVOPACK 27..........................

2.3 Connection and Wiring 30...................

2.3.1 Connecting to Peripheral Devices 30.....................

2.3.2 Main Circuit Wiring and Power ON Sequence 34............

2.3.3 Connection to Host Controller 36........................

2.4 Conducting a Test Run 40...................

2.4.1 Test Run in Two Steps 40..............................

2.4.2 Step 1: Conducting a Test Run for Motor without Load 42....

2.4.3 Step 2: Conducting a Test Run with the Motor Connected to the

Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2.4.4 Supplementary Information on Test Run 47................

2.4.5 Minimum Parameters Required and Input Signals 49.........

15

Page 28

BASIC USES OF Σ-SERIES PRODUCTS

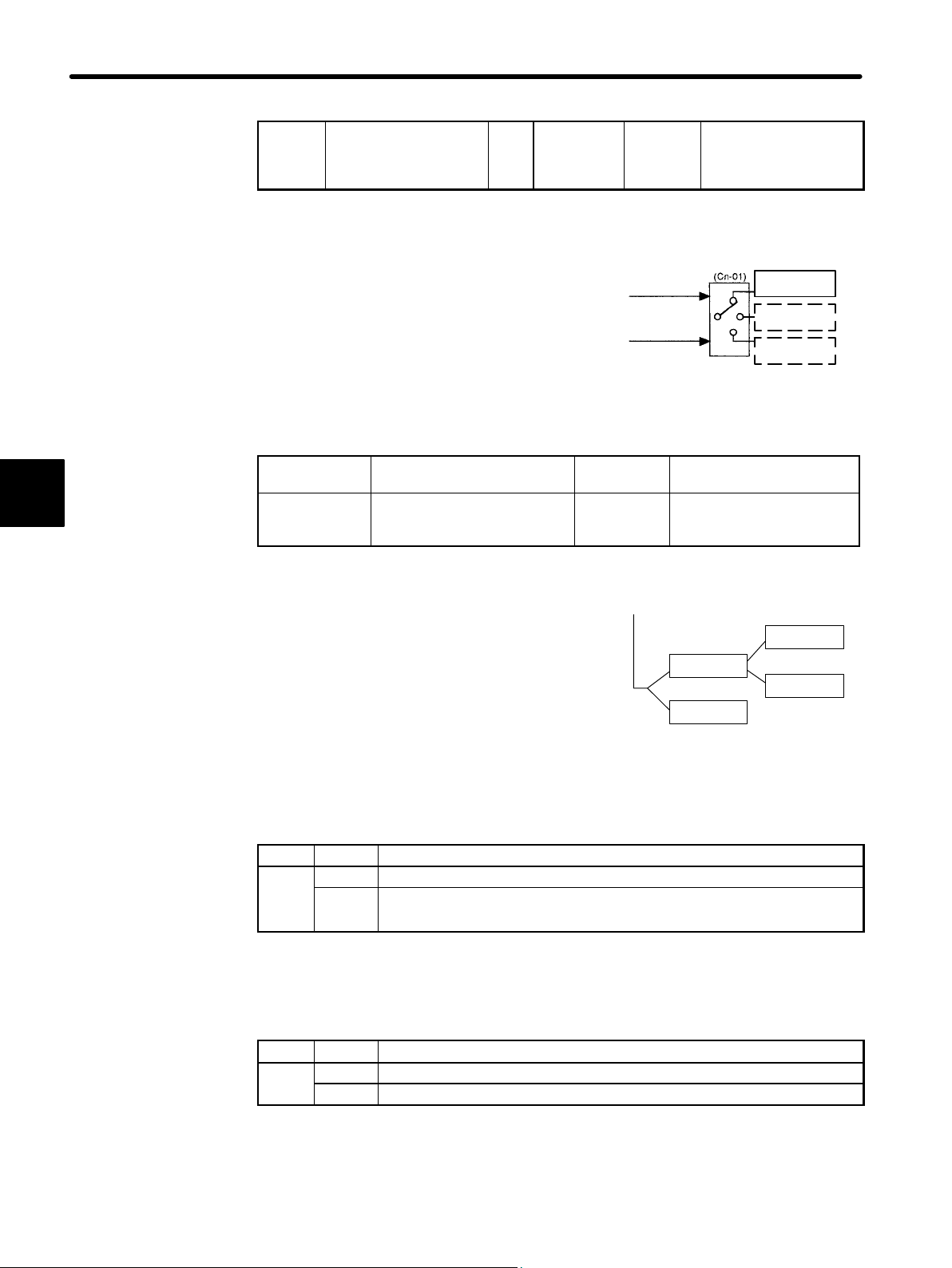

2.1.1 Notes on Use

2.1 Precautions

This section provides notes on using Σ-Series products.

2.1.1 Notes on Use

NOTE Always note the following to ensure safe use.

2

Use 200VAC power supply

Be sure to use the correct type. Do not plug the

servomotor directly into the power frequency supply (Direct connection to the power frequency

supply will damage the servomotor.)

200VAC

power supply

Always use the SGMj servomotor and SGDB SERVOPACK in pairs.

Check whether the combination of applicable motor series of SERVOPACK and of SGMj ( motor

series) is correct or not. Check the setting of parameter Cn-2A (motor selection) and always after

changing its combination. The motor may get

Recheck the setting

of parameter Cn-2A

(motor selection) after

changing its combination.

Refer to Section 3.3.4.

damaged if the combination is not correct.

Do not change wiring when power is ON.

Direct

connection

Damage will result!

16

Always turn the power OFF before connecting or

disconnecting a connector.

(Except for Digital Operator (Types: JUSPOP02A-1, JUSP-OP03A))

OFF

(POWER and

CHARGE lamp)

Always turn the power

OFF before connecting or disconnecting a

connector.

Note that residual voltage still remains in the SERVOPACK even after the power is

turned OFF.

Even after the power is turned OFF, residual electric charge still remains in the capacitor inside the

SERVOPACK. To prevent an electric shock, always wait for the CHARGE lamp to go OFF before

starting inspection (if necessary).

CHARGE lamp

Page 29

2 . 1 Precautions

Always follow the specified installation method.

Provide sufficient clearance

The SERVOPACK generates heat. Install the

SERVOPACK so that it can radiate heat freely.

Note also that the SERVOPACK must be in an en-

50 mm

or

more

vironment free from condensation, vibration and

shock.

Ambient

temperature:

0to55°C

Perform noise reduction and grounding properly.

If the signal line is noisy, vibration or malfunction

will result.

D Separate high-voltage cables from low-voltage cables.

D Use cables as short as possible.

D Ground the SERVOPACK ground terminal with the

resistance 100Ω or less for the servomotor and

SERVOPACK.

D Never use a line filter for the power supply in the

motor circuit.

Casing

SERVOPACK

Signal

Conduct a voltage resistance test under the following conditions.

D Voltage: 1500 Vrms AC, one minute

D Current limit: 100 mA

D Frequency: 50/60 Hz

D Voltage application points: Between r, t, R, S, T

terminals and frame ground (connect terminals

securely).

line

100 Ω or less

Conduct a voltage

resistance test

under the conditions given on the

left.

10 mm

or

more

Servomotor

2

Use a fast-response type ground-fault interrupter.

For a ground-fault interrupter, always use a fastresponse type or one designed for PWM inverters. Do not use a time-delay type.

Fast-response

type

Ground-fault interrupter

GOOD POOR

GOOD

For PWM

inverter

Do not perform continuous operation under overhanging load.

Continuous operation cannot be performed by rotating the motor from the load and applying regen-

Servomotor

erative braking. Regenerative braking by the

SERVOPACK can be applied only for a short period, such as the motor deceleration time.

Do not apply regenerative

braking continuously.

The servomotor cannot be operated by turning the power ON and OFF.

Frequently turning the power ON and OFF causes

the internal circuit elements to deteriorate. Always

start or stop the servomotor by using reference

pulses.

Power

supply

Time-delay

type

SERVOPACK

Do not start or stop by

turning power ON and OFF.

17

Page 30

BASIC USES OF Σ-SERIES PRODUCTS

2.2.2 Servomotors

2.2 Installation

This section describes how to check Σ-Series products on delivery and how to install them.

2.2.1 Checking on Delivery

When Σ-Series products are delivered, check the following items:

2

Check Items

Check if the delivered products are

the ones you ordered.

Check if the motor shaft rotates

smoothly.

Check for damage. Check the overall appearance, and check for damage

Check screws for looseness. Check for looseness by using a screwdriver as

If any of the above items are faulty or incorrect, contact the dealer from which you purchased the products or your nearest local sales representative.

2.2.2 Servomotors

J External Appearance and Nameplate Examples

Remarks

Check the types marked on the nameplates of

servomotor and SERVOPACK (see the table below).

If the motor shaft is smoothly turned by hand, it is

normal. However, if the motor has brakes, it cannot be

turned manually.

or scratches resulting from transportation.

necessary.

Rated output

Servomotor model

18

Σ-II Series Servomotor

Serial number

Manufacturing date

Rated motor speed

Page 31

J Model Numbers

y

y

Standard Servomotors

2.2 Installation

SGM S − 10 A 6 A

Σ Series servomotor

Series name of products

G: SGMS

S: SGMS

D: SGMD

Motor capacity

(See the following table.)

Standard

A: YASKAWA Standard

Encoder specifications

(See the following table.)

Servomotor Capacity (kW)

Symbol SGMG SGMS SGMD

1500 min−11000 min−13000 min−12000 min

03

05

06

09

10

12

13

15

20

22

− 0.3 − −

0.45 − − −

− 0.6 − −

0.85 0.9 − −

− − 1.0 −

− 1.2 − −

1.3 − − −

− − 1.5 −

1.8 2.0 2.0 −

− − − 2.2

j j

Option specifications

B: 90 VDC Brake

C: 24 VDC Brake

S: Oil seal

F: 90 VDC Brake Oil seal

G: 24 VDC Brake Oil seal

Shaft Specifications

A: Standard (straight without key,

with option specification)

B: Straight with key,

shaft end tap (one place)

C: Taper 1/10, with parallel key

D: Taper 1/10, with semicircle key

(For G series 05, 09 type only)

Rated rotation speed

A: SGMG 1500 min

SGMS 3000 min

SGMD 2000 min

B SGMG 1000 min

Symbol

−1

1500 min−11000 min−13000 min−12000 min

30

32

40

44

50

55

60

75

1A

1E

SGMG SGMS SGMD

2.9 3.0 3.0 −

− − − 3.2

− − 4.0 4.0

4.4 4.4 − −

− − 5.0 −

5.5 − − −

− 6.0 − −

7.5 − − −

11 − − −

15 − − −

−1

−1

−1

−1

−1

2

Encoder Specifications

Code Specification SGMG SGMS SGMD

8192 P/R incremental Optional Standard Optional

2

4096 P/R incremental Standard Optional Optional

6

12-bit absolute Optional Optional Standard

W

15-bit absolute Optional Optional Optional

S

NOTE

Refer to Section 5.1.1 Selecting a Servomotor for the SGMP-15A type.

19

Page 32

BASIC USES OF Σ-SERIES PRODUCTS

y

y

2.2.2 Servomotorscont.

Servomotors with Gears

2

SGM G − 05 A 2 A S A R

Σ-Series servomotor

Series name

G: SGMG

S: SGMS

Motor capacity

(See the following table.)

Standard

A: YASKAWA Standard

Encoder specifications

(See the following table.)

Rated rotation speed

A: SGMG 1500 min

SGMS 3000 min

B: SGMG 1000 min

Symbol SGMG SGMS

03

05

06

09

10

12

13

15

20

−1

−1

−1

Motor Capacity (kW)

1500 min

−1

1000 min

− 0.3 −

0.45 − −

− 0.6 −

0.85 0.9 −

− − 1.0

− 1.2 −

1.3 − −

− − 1.5

1.8 2.0 2.0

−1

3000 min

j

Brake specifications

Blank: Without brake

B: With 90 VDC brake

C: With 24 VDC brake

Shaft specifications

(See the following table.)

Gear ratio

(See the following table.)

Gear type (See the following table.)

−1

Symbol

1500 min

30

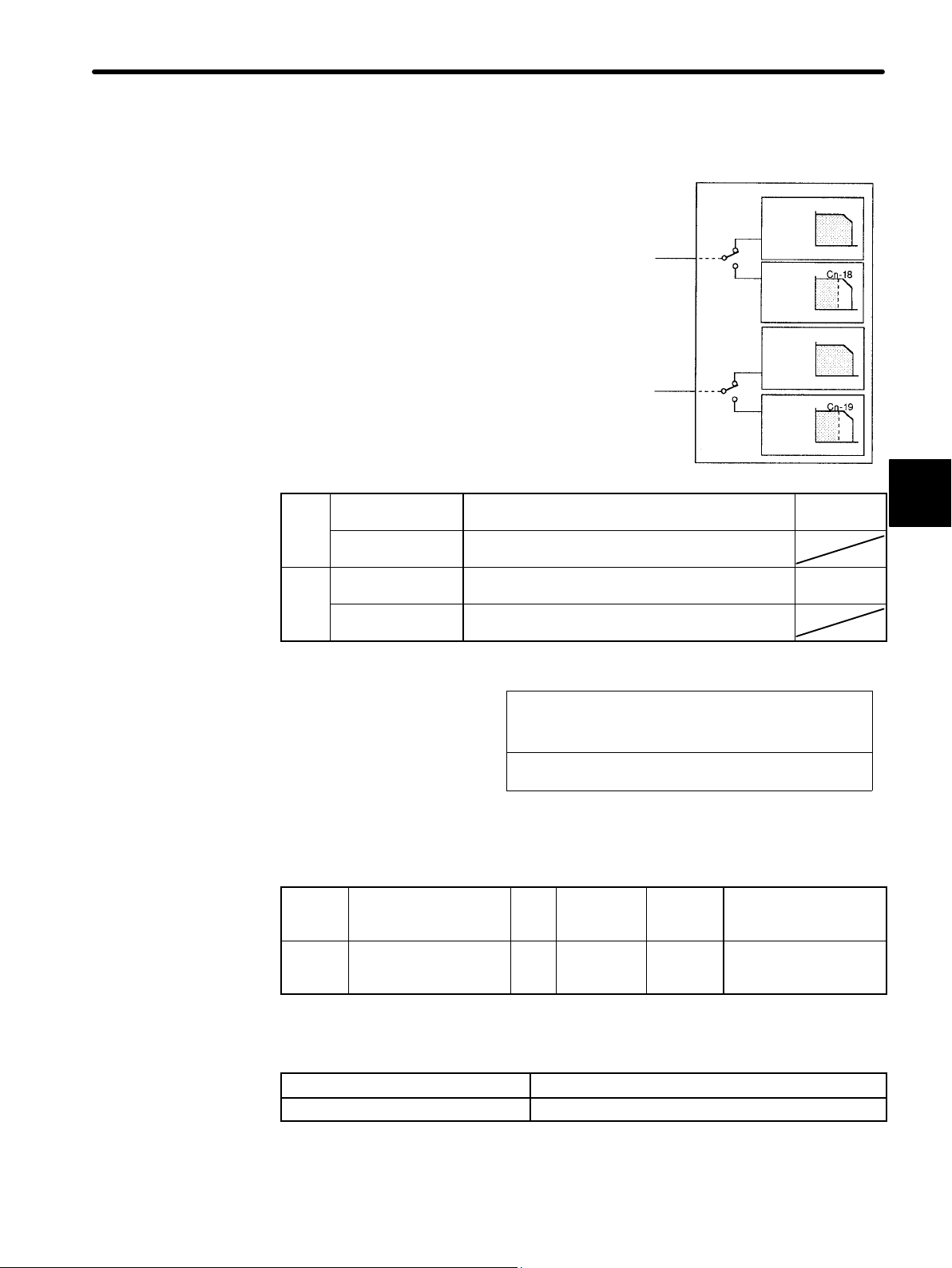

40

44

50

55

60

75

1A

−

SGMG SGMS

−1

1000 min

−1

3000 min

2.9 3.0 3.0

− − 4.0

4.4 4.4 −

− − 5.0

5.5 − −

− 6.0 −

7.5 − −

11 − −

− − −

−1

20

Encoder Specifications

Code Specification SGMG SGMS

8192 P/R incremental Optional Standard

2

4096 P/R incremental Standard Optional

6

12-bit absolute Optional Optional

W

15-bit absolute Optional Optional

S

Gear Type

Code Specification SGMG SGMS

With foot Standard

S

Flange Standard

T

IMT planetary low-backlash gear Standard Standard

L

Page 33

Gear Ratio (Varies with Gear Type.)

Code Specification SGMG SGMS

1/6 S, T*

A

1/11 S, T

B

1/21 S, T

C

1/5 L L

1

1/9 L L

2

1/20 L* L

5

1/29 or 1/33 L, S, T* L*

7

1/45 L* L*

8

* Not all applicable models available.

2.2 Installation

Shaft Specifications (Varies with Gear Type.)

Code Specification SGMG SGMS

Straight, with key L L

K

Straight, with key and tap S, T

R

2

21

Page 34

BASIC USES OF Σ-SERIES PRODUCTS

2.2.3 SERVOPACKs

2.2.3 SERVOPACKs

J External Appearance and Nameplate Examples

SERVOPACK model

2

Σ-Series SGDB

SERVOPACK

J Model Numbers

Σ-Series

SGDB SERVOPACK

Motor capacity

(See the following table.)

Voltage

A: 200 V

Model

D: torque, speed, position control

Applicable motor series

G: SGMG (1500 min−1)

M: SGMG (1000 min−1)

S: SGMS

D: SGMD

P: SGMP

Blank: SGM

Serial number

Applicable power supply

SGDB − 10 A D S −

Output

power

j

22

Option specifications

P: Duct ventilation type

Page 35

Motor Capacity (kW)

2.2 Installation

Maximum Applicable

Servomotor Capacity

Symbol

03

05

07

10

15

20

30

Capacity Maximum Applicable

Servomotor Capacity

Symbol

0.3

0.50

0.7

1.0

1.5

2.0

3.0

44

50

60

75

1A

1E

−

Capacity

4.4

5.0

6.0

7.5

11

15

−

2

23

Page 36

BASIC USES OF Σ-SERIES PRODUCTS

2.2.4 Installing the Servomotor

2.2.4 Installing the Servomotor

Servomotor SGMj type can be installed either horizontally or vertically. However, if the servomotor is installed incorrectly or in an inappropriate location, the service life will be shortened or unexpected problems will occur. To prevent this, always observe the installation

instructions described below.

When using the models with an oil seal, installing the motor with the output shaft up may

cause oil to enter the motor depending on the operating conditions. Check the operating

conditions.

2

NOTE

Before installation

Anticorrosive paint is coated on the edge of the motor shaft to prevent it from rusting during storage. Clean off the anticorrosive paint thoroughly using a cloth before installing the

motor.

Avoid getting thinner on other parts of the servomotor when cleaning the shaft.

Storage:

When the servomotor is to be stored with the power cable disconnected, store it in the

following temperature range:

:

Anticorrosive paint is

coated here

24

Between −20°C and 60°C

Page 37

Installation sites:

The servomotor SGMj type is designed for indoor use.

Install servomotor in an environment which meets the following conditions:

a) Free from corrosive and explosive gases

b) Well-ventilated and free from dust and moisture

c) Ambient temperature of 0 to 40°C

d) Relative humidity of 20% to 80% (non-condensing)

e) Inspection and cleaning can be performed easily

2.2 Installation

If the servomotor is used in a location subject to water or oil mist, the motor can be protected by taking necessary precautions on the motor side. However, if the shaft opening

is to be sealed, specify the motor with oil seal. Install with the electrical connector facing

downward.

Alignment

:

Align the shaft of the servomotor with that of the equipment to be controlled, then connect

the shafts with couplings. Install the servomotor so that alignment accuracy falls within

the range shown below.

Measure this distance at four different positions in the circumference. The

difference between the maximum and minimum measurements must be

0.03 mm or less. (Turn together with couplings)

Measure this distance at four different positions in the

circumference. The difference between the maximum and minimum

measurements must be 0.03 mm or less. (Turn together with

couplings)

2

NOTE

TERMS

If the shafts are not aligned properly, vibration will occur, resulting in damage to the bearings.

When using a pinion gear mounted directly to the motor output shaft, contact your YASKAWA

representative.

Shaft opening

Shaft

opening

Refers to the space where the shaft comes out from the motor.

25

Page 38

BASIC USES OF Σ-SERIES PRODUCTS

()

(

)

()

()

(

)

()

()

()

()

2.2.4 Installing the Servomotor cont.

A precision detector (encoder) is mounted on the opposite-drive end of the servomotor.

To mount a coupling, always protect the shaft from impacts that could damage the detector.

2

Perform a mechanical design so that

thrust load and radial load

motor shaft end falls within the range given in the following table.

Allowable

Motor Type

SGMG-05AjA

-09AjA

-13AjA

-20AjA

-30AjA

-44AjA

-55AjA

-75AjA

-1AAjA

-1EAjA

SGMG-03AjB

-06AjB

-09AjB

-12AjB

-20AjB

-30AjB

-44AjB

-60AjB

SGMS-10A 686 (154) 196 (44)

-15A 686 (154) 196 (44)

-20A 686 (154) 196 (44)

-30A 980 (221) 392 (88)

-40A 1176 (265) 392 (88)

-50A 1176 (265) 392 (88)

SGMD-22A 1176 (265) 490 (110)

-32A 1176 (265) 490 (110)

-40A 1176 (265) 490 (110) 65 (2.56)

SGMP-15A 490 (110) 147 (33) 35 (1.38)

Radial Load

Fr [N(lb)]

490 (110) 98 (22)

490 (110) 98 (22)

686 (154) 343 (77)

1176 (265) 490 (110)

1470 (331) 490 (110)

1470 (331) 490 (110)

1764 (397) 588 (132)

1764 (397) 588 (132)

1764 (397) 588 (132) 116 (4.57)

4998 (1125) 2156 (485) 116 (4.57)

490 (110) 98 (22)

490 (110) 98 (22)

686 (154) 343 (77)

1176 (265) 490 (110)

1470 (331) 490 (110)

1470 (331) 490 (110)

1764 (397) 588 (132)

1764 (397) 588 (132)

Allowable

Thrust

Load Fs

[N(lb)]

LR

[mm(in.)]

58 (2.28)

79 (3.11)

113 (4.45)

58 (2.28)

79 (3.11)

113 (4.45)

45 (1.77)

63 (2.48)

55 (2.17)

applied to the servo-

Reference Drawing

26

TERMS

Note Allowable radial loads shown above are the maximum values that could be ap-

plied to the shaft end.

Thrust load and radial load

2.

1. Thrust load: Shaft-end load applied parallel to the

centerline of a shaft

2. Radial load: Shaft-end load applied perpendicular to

the centerline of a shaft

Motor

Shaft end

1.

Page 39

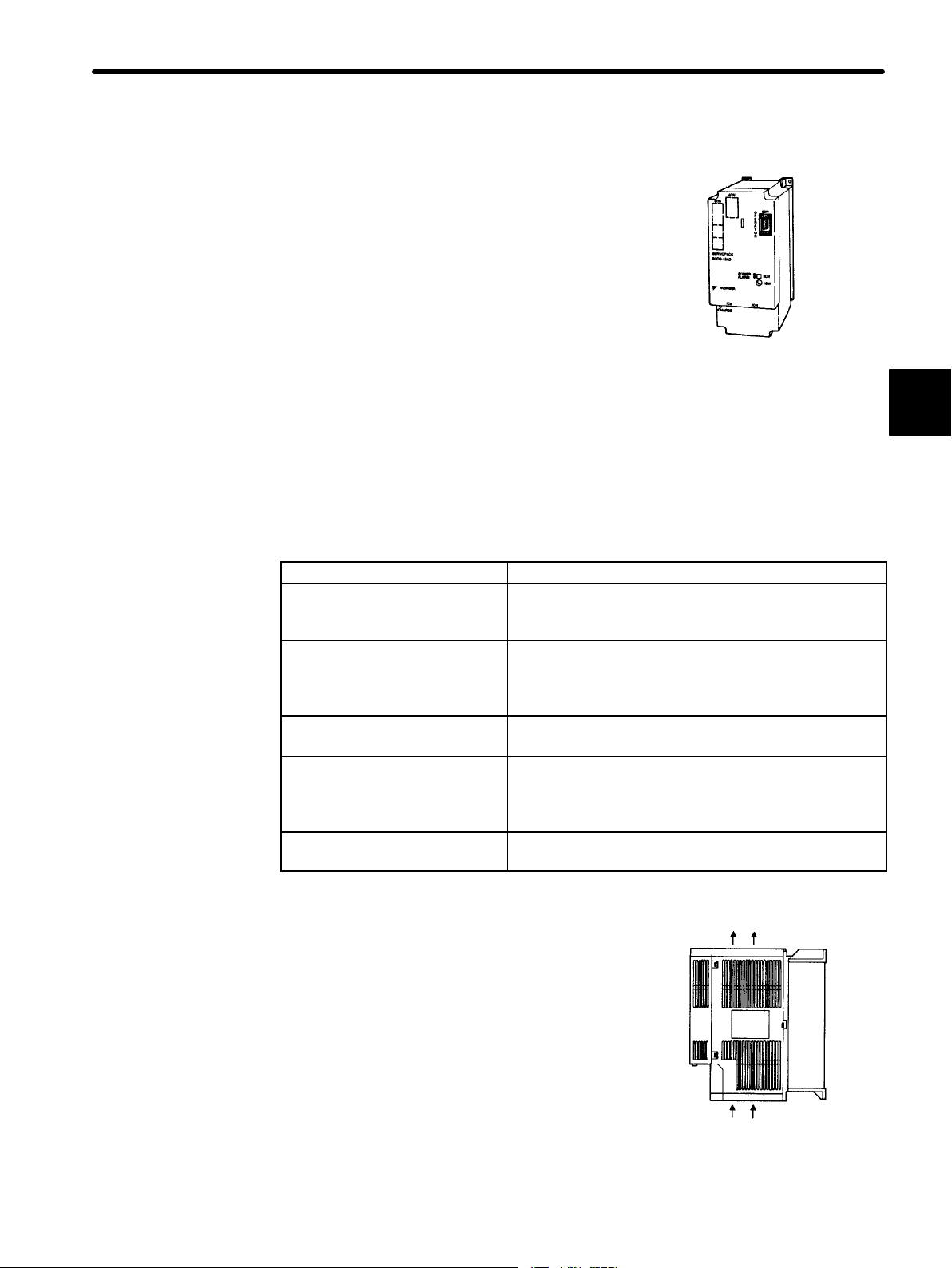

2.2.5 Installing the SERVOPACK

Σ-Series SGDB SERVOPACK is a base-mount type

servo controller.

Incorrect installation will cause problems. Always observe the installation instructions described below.

Storage:

2.2 Installation

When the SERVOPACK is to be stored with the

power cable disconnected, store it in the following

temperature range:

Between −20°C and 85°C

Installation sites:

Situation Notes on Installation

Design the control panel size, unit layout, and cooling

When installed in a control panel

When installed near a heating

unit

When installed near a source of

vibration

When installed in a place

receiving corrosive gases

Others

method so that the temperature around the periphery of

the SERVOPACK does not exceed 55°C.

Suppress radiation heat from the heating unit and a

temperature rise caused by convection so that the

temperature around the periphery of the SERVOPACK

does not exceed 55°C.

Install a vibration isolator underneath the SERVOPACK

to prevent it from receiving vibration.

Corrosive gases do not immediately affect the

SERVOPACK but will eventually cause contactor-related

devices to malfunction. Take appropriate action to

prevent corrosive gases.

Avoid installation in a hot and humid place or where

excessive dust or iron powder is present in the air.

SGDB SERVOPACK

2

Orientation:

Install the SERVOPACK perpendicular to the wall

as shown in the figure.

The SERVOPACK must be orientated as shown

in the figure.

• Firmly secure the SERVOPACK through four

mounting holes.

Ventilation

27

Page 40

BASIC USES OF Σ-SERIES PRODUCTS

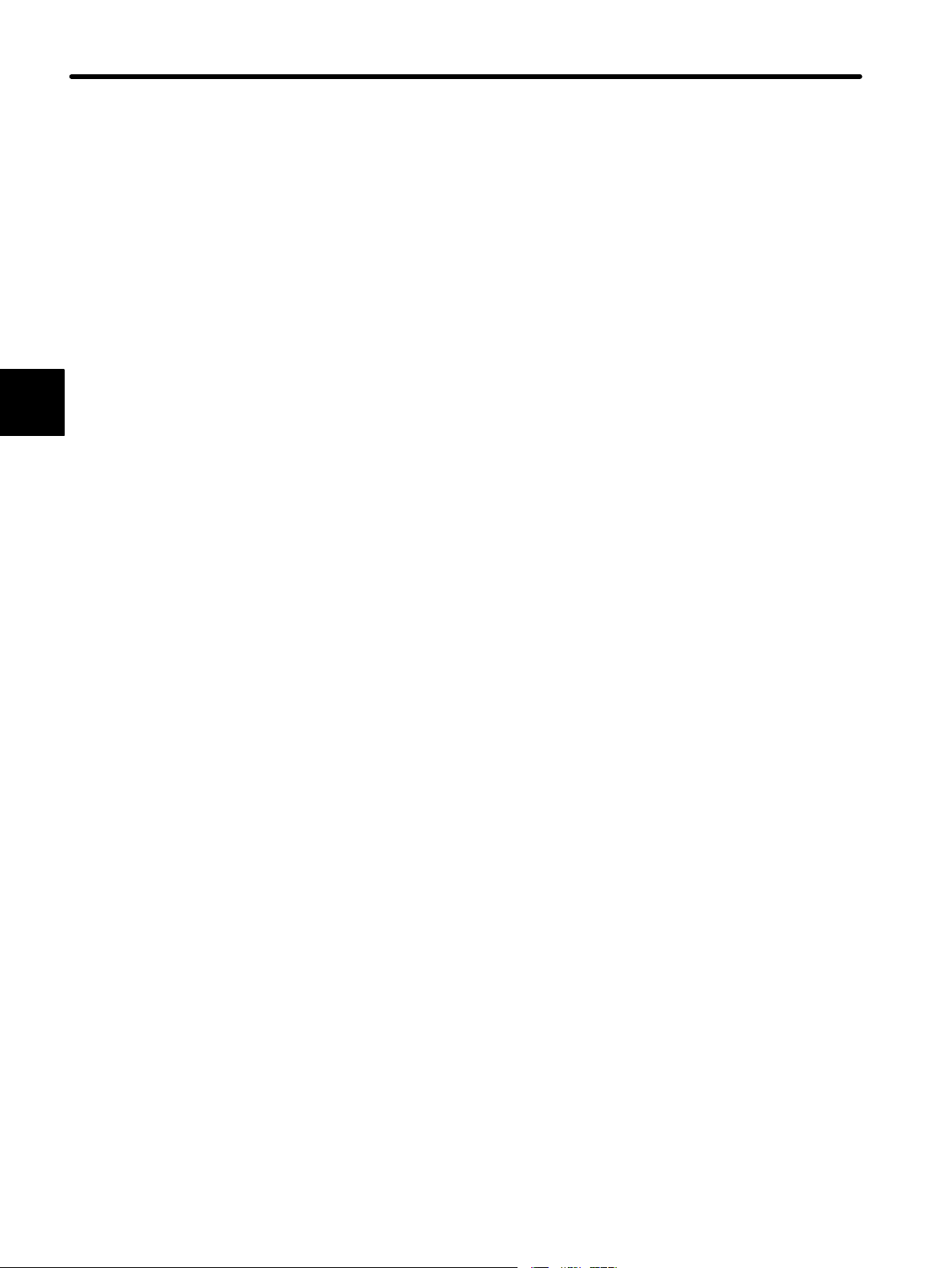

2.2.5 Installing the SERVOPACK cont.

Installation method:

When installing multiple SERVOPACKs side by side in a control panel, observe the following installation method:

2

Fan

Fan

30 mm or more 10 mm or more

Fan

50 mm or more

50 mm or more

a) Install SERVOPACK perpendicular to the wall so that the front panel (digital operator

mounted face) faces outward.

b) Provide sufficient space around each SERVOPACK to allow cooling by fan and natu-

ral convection.

c) When installing SERVOPACKs side by side, provide at least 10 mm space between

them and at least 50 mm space above and below them as shown in the figure above.

Install cooling fans above the SERVOPACKsto prevent the temperature around each

SERVOPACK from increasing excessively and also to maintain the temperature inside the control panel evenly.

28

d) Maintain the following conditions inside the control panel:

• Ambient temperature for SERVOPACK: 0 to 55°C

• Humidity: 90%RH or less

• Vibration: 4.9 m/s

2

• Condensation and freezing: None

• Ambient temperature to ensure long-term reliability: 45°C or less

Page 41

Power loss

Power loss of SERVOPACK is given below:

Power loss for rated output

2.2 Installation

SERVOPACK

type

SGDB-03ADj

SGDB-05ADj

SGDB-07ADj

SGDB-10ADj

SGDB-15ADj

SGDB-20ADj

SGDB-30ADj

SGDB-44ADj

SGDB-50ADj

SGDB-60ADj

SGDB-75ADj

SGDB-1AADj

SGDB-1EADj

Note a) Power loss of regenerative resistor is allowable loss. If the loss exceeds the

Output

current

(RMS value)

A

3.0 18

3.8 27 77

5.7 41 91

7.6 55 105

11.6 80 130

18.5 120 170

24.8 170 22 222

32.9 250

28.2 260 344

46.9 290

54.7 330

58.6 360

78.0 490 520

Power loss

in main

circui

W

t

Power loss

of

regenerative

resistor W

30 20

60 24

-

Power loss

in control

circuit

W

27

30

Power loss

in total

W

68

334

317

357

390

allowable loss, the regenerative resistor inside the SERVOPACK should be

removed and connected externally. Because the model in which the regenerative resistor is externally connected falls into non-standard specification categories, contact YASKAWA for further information.

For this non-standard type, “Y8” is appended to the end of the standard model

number.

2

b) For SGDB-60AD to 1EADj models, the regenerative resistor is placed sepa-

rately. The regenerative resistor unit provided from YASKAWA is described in

Section 3.8.4 Using Regenerative Resistor Units. Its power loss for

SGDB-60ADj is 180W (type: JUSP-RA04), and for SGDB-75ADj and

-1EADj is 350W(type: JUSP-RA05).

29

Page 42

2

BASIC USES OF Σ-SERIES PRODUCTS

2.3.1 Connecting to Peripheral Devices

2.3 Connection and Wiring

This section describes how to connect Σ-Series products to peripheral devices and explains a

typical example of wiring the main circuit. It also describes an example of connecting to main

host controllers.

2.3.1 Connecting to Peripheral Devices

This section shows a standard example of connecting Σ-Series products to peripheral devices and briefly explains how to connect to each peripheral device.

30

Page 43

Connector terminal block conversion unit

1CN connector kit

Cable with 1CN connector and

one end without connector

2.3 Connection and Wiring

Host controller

SERVOPACK is compatible with most P.L.C.

motion controllers and indexers.

See next page

Molded-case circuit

breaker (MCCB)

Used to protect

power supply

line. Shuts the

circuit off if

overcurrent is

detected.

Noise filter

Used to eliminate external

noise from power supply

line.

Types:

LF-350

LF-315

LF-320

LF-380K

Magnetic contactor

Turns the servo

ON or OFF.

Use a surge

suppressor for

the magnetic

contactor.

Molded-case

circuit breaker

Noise filter

Magnetic

contactor

Power supply

3 phase 200 VAC

MP920

Digital Operator

Allows the user to set parameters or operation

references and display operation status or

alarm status. The following two types are

available in addition to personal computers:

Mount type (JUSP-OP03A)

This type can be mounted

directly on the SERVOPACK.

Hand-held type

(JUSP-OP02A-1)

1-meter(3.3ft.)

cable included

Personal computer

Connecting cable type:

DE9405258

2

Brake power supply

Types:

LPSE-2H01 (for 200 V input)

LPDE-1H01 (for 100 V input)

Used for

servomotor

with brake.

Brake

power supply

Regenerative resistor unit

If the capacity of the regenerative resistor

is insufficient, remove the internal resistor

(P-B terminals) and connect it to the P-B

terminals).

For SERVOPACK with capacity more

than 6kW, a regenerative resistor unit is

mounted separately (connected to P1-B

terminals)

Magnetic

contactor

Power

ground

Cable for PG

Connector for

PG

See next page

Regenera-

tive resistor

(option)

31

Page 44

BASIC USES OF Σ-SERIES PRODUCTS

L

h

L

h

2.3.1 Connecting to Peripheral Devices cont.

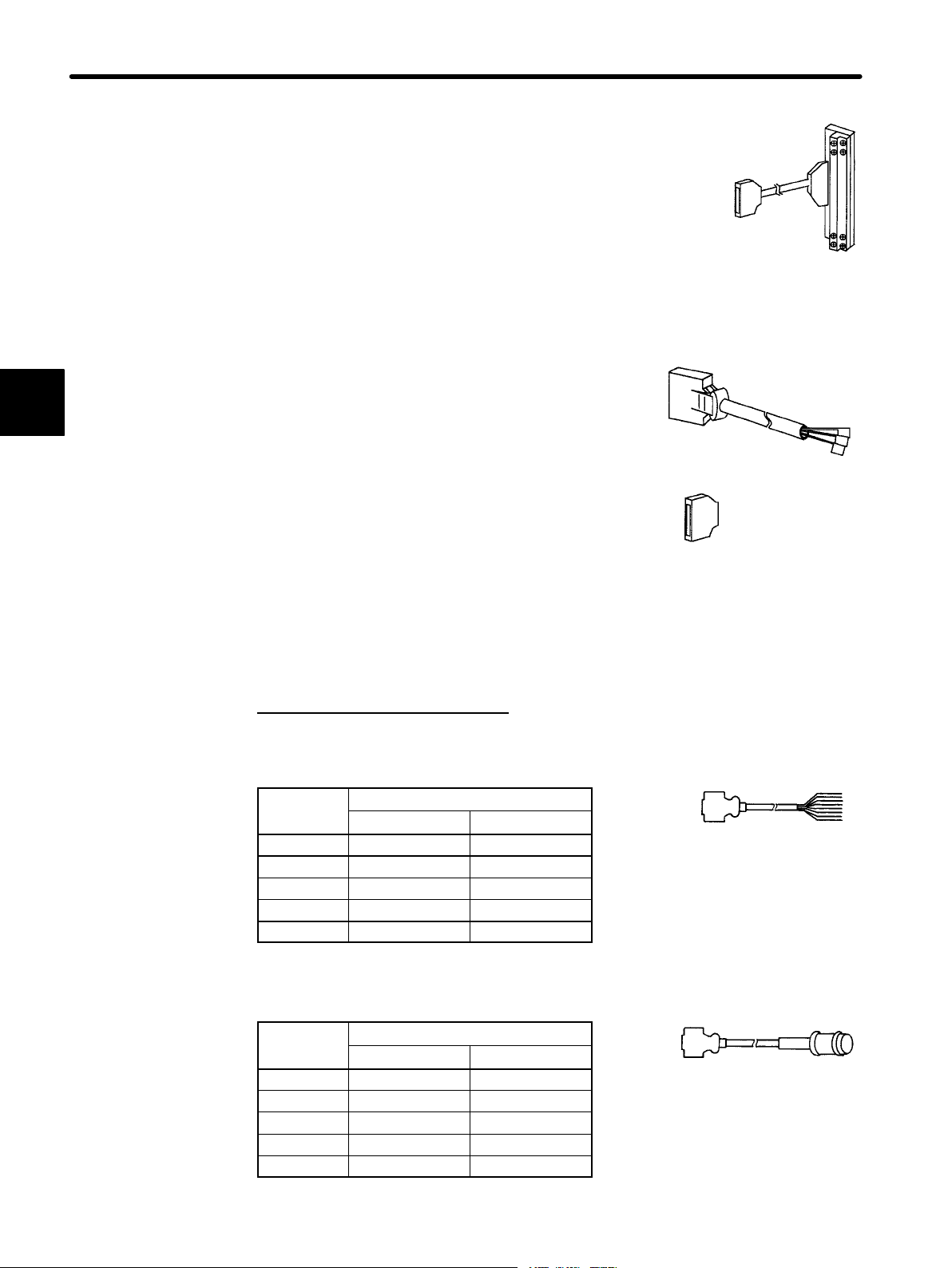

• Connector terminal block conversion unit (Type: JUSP-TA50P)

The terminal block allows connection to a host controller.

• Cable with 1CN connector and one end without connector

1m (3.3ft) DE9406969-1

1CN

0.5 meter cable with

1CN connector

2

2m (6.6ft) DE9406969-2

1CN

3m (9.8ft) DE9406969-3

• 1CN connector kit (Type: DE9406970)

1CN

• Cable for PG

This cable is used to connect the encoder of servomotor to the SERVOPACK.

The following three types of cables are available according to encoder types.

For models SGMG, SGMS,

SGMD

a) Cable with a single connector (without connector on encoder side)

engt

3m (9.8ft) DE9406971-1 DE9406972-1

5m (16.4ft) DE9406971-2 DE9406972-2

10m (32.8ft) DE9406971-3 DE9406972-3

15m (49.2ft) DE9406971-4 DE9406972-4

20m (65.6ft) DE9406971-5 DE9406972-5

Incremental Absolute

Cable type

b) Cable with connectors on both side (straight plug on encoder side)

engt

3m (9.8ft) DE9407234-1 DE9407236-1

5m (16.4ft) DE9407234-2 DE9407236-2

10m (32.8ft) DE9407234-3 DE9407236-3

15m (49.2ft) DE9407234-4 DE9407236-4

20m (65.6ft) DE9407234-5 DE9407236-5

Incremental Absolute

Cable type

32

Page 45

2.3 Connection and Wiring

L

h

L

h

L

h

L

h

c) Cable with connectors on both side (L-shape plug on encoder side)

engt

3m (9.8ft) DE9407235-1 DE9407237-1

5m (16.4ft) DE9407235-2 DE9407237-2

10m (32.8ft) DE9407235-3 DE9407237-3

15m (49.2ft) DE9407235-4 DE9407237-4

20m (65.6ft) DE9407235-5 DE9407237-5

Incremental Absolute

Cable type

For models SGM, SGMP

a) Cable with connectors on both side

engt

3m (9.8ft) DP9320089-1 DP9320088-1

5m (16.4ft) DP9320089-2 DP9320088-2

10m (32.8ft) DP9320089-3 DP9320088-3

15m (49.2ft) DP9320089-4 DP9320088-4

20m (65.6ft) DP9320089-5 DP9320088-5

Incremental Absolute

Cable type

2

b) Cable with a single connector (without connector on SERVOPACK)

engt

3m (9.8ft) DP9320086-1 DP9320085-1

5m (16.4ft) DP9320086-2 DP9320085-2

10m (32.8ft) DP9320086-3 DP9320085-3

15m (49.2ft) DP9320086-4 DP9320085-4

20m (65.6ft) DP9320086-5 DP9320085-5

Incremental Absolute

Cable type

c) Cable without connectors

engt

3m (9.8ft) DP9400064-1 DP8409123-1

5m (16.4ft) DP9400064-2 DP8409123-2

10m (32.8ft) DP9400064-3 DP8409123-3

15m (49.2ft) DP9400064-4 DP8409123-4

20m (65.6ft) DP9400064-5 DP8409123-5

Incremental Absolute

Cable type

• Connector kit (DE9406973)for PG.

Connector on SERVOPACK side only

SERVOPACK

side

2CN

33

Page 46

BASIC USES OF Σ-SERIES PRODUCTS

2.3.2 Main Circuit Wiring and Power ON Sequence

2.3.2 Main Circuit Wiring and Power ON Sequence

The following diagram shows a typical example of wiring the main circuit for Σ-Series

products:

2

Three-phase 200 to 230 VAC (50/60 Hz)

+ 10%

–15%

Main circuit

power

Main circuit power

1MCCB: Circuit breaker (for inverter type)

FIL: Noise filter

1MC: Contactor

1Ry: Relay

1PL: Lamp for display

1SUP: Surge suppressor

1D: Flywheel diode

SERVOPACK

SGDB-jjADj

(Alarm lamp)

The following table shows the name and description of each main circuit terminal:

Terminal

Symbol

R, S, T

U, V, W

r, t

×2

P, B

P1, B

N

Note

P1 terminal is not available for SERVOPACK with power capacity less than 5 kW.

Name Description

Main power input

terminals

Motor connection

terminal

Control power

input terminals

Three-phase 200 to 230 VAC , 50/60Hz

Used to connect motor

Single phase 200 to 230 VAC , 50/60Hz

+ 10

–15

+ 10

–15

%

%

Ground terminal Connected to earth. (For power ground and motor ground).

Regenerative

resistor unit

connection

Normally, external connection is not required.

terminal

Regenerative

resistor unit

connection

Terminal used to connect regenerative resistor for

SERVOPACK with power capacity more than 6 kW.

terminal

Main circuit minus

side terminal.

Normally, external connection is not required.

34

Page 47

NOTE

2.3 Connection and Wiring

Form a power ON sequence as follows:

• Form a power ON sequence so that the power is turned OFF when a servo alarm signal

is output. (See the circuit diagram shown on the previous page.)

• Hold down the power ON push-button for at least two seconds. The SERVOPACK outputs a servo alarm signal for approximately two seconds or less when the power is

turned ON. This operation is required to initialize the SERVOPACK.

Power supply

2

Servo alarm (ALM) output signal

• Do not wire power lines and signal lines in the same duct or bundle them together.

Wire such that signal lines are kept apart from power lines by at least 30 cm.

• Twisted pair wire and multi-core twisted pair shielding wires should be used for signal

lines, encoder (PG) feedback line.

The length for wiring is 3 m maximum for the reference input line, 20 m maximum for the

PG feedback line.

• Do not touch the power terminal even if power was turned OFF.

High voltage may still remain in SERVOPACK.

Perform inspection only after the CHARGE lamp is OFF.

• Avoid frequently turning the power ON and OFF. Since the SERVOPACK has a capacitor in the power supply, a high charging current flows (for 0.2 second) when the power is

turned ON. Therefore, frequently turning the power ON and OFF causes the main circuit devices (such as capacitors and fuses) to deteriorate, resulting in unexpected

problems.

35

Page 48

BASIC USES OF Σ-SERIES PRODUCTS

2.3.3 Connection to Host Controller

2.3.3 Connection to Host Controller

The SGDB SERVOPACK can be connected to the following host controllers. For details,

refer to the technical documentation for the host controller.

• MP920

• GL-Series Positioning Module B2833

• GL-Series Positioning Module B2813

2

Speed/Torque

• OMRON Position Control Unit

• MITSUBISHI Positioning Unit

The following diagrams show connection examples with the host controllers manufactured by OMRON and MITSUBISHI.

J Connection to OMRON Position Control Unit C500-NC222

SERVOPACK for Speed/Torque Control

SERVOPACK

SGDB-jjADj

I/O Power Supply

C500-NC222

(Made by OMRON)

X-axis (Y-axis)

(ON when

positioning is

stopped)

(ON when

proximity is

detected)

36

/S-ON

(T-REF)

X-/A

X-/B

X-/C

* These signals are output for approximately two seconds when the power is turned

ON. Take this into consideration when designing a power ON sequence. Relay 1Ry is

used to stop main circuit power supply to SERVOPACK.

/PAO

/PBO

/PCO

Note The signals shown here are applicable only to OMRON Sequencer

C500-NC222 and Yaskawa SERVOPACK SGDB-VVADV.

Page 49

J

Connection to OMRON Position Control Unit C500-NC112

SERVOPACK for Position Control

2.3 Connection and Wiring

Position

C500-NC112

(Made by OMRON)

CW limit

CCW limit

Emergency stop

External interrupt

Home position

Home position

proximity

Local

Ready

Pulse output

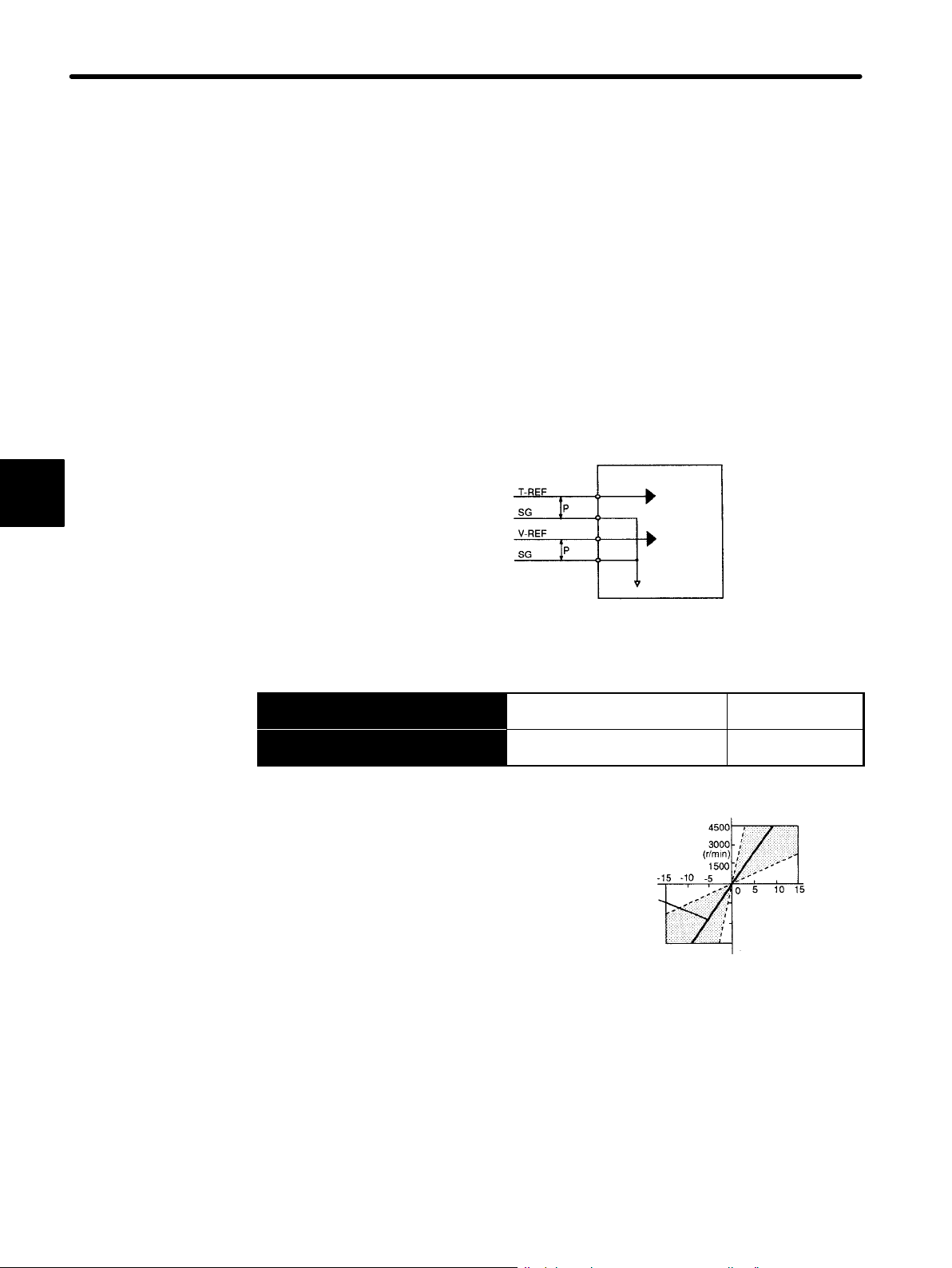

CW + CCW