Page 1

YASKAWA

MACHINE

SERVO

It

CONTROLLER

CONTROLLER

USER'S

llferttfM

i

K'f>:

ri

I?

CP-9200SH

MANUAL

'

wmt

r

YASKAWA

MANUAL

SIE-C879-40.2C

NO.

Page 2

Introduction

This

servo

which

is

Up

to

eleven

of

44

axes

This

manual

examples,

to

Refer

(exterior

of

In

SVA

the

this

document,

the

peripheral

following

The

controller

part

SVA

with

of

the

each

modules

explains

parameters).

Servo

Machine

drawings,

module.

"CP-717"

devicesofthe

is

list

a

user's

Machine

can

axis

able

the

software

Controller

display

lamps,

refers

CP-9200SH.

of

manuals

manual

contains

Controller

be

mounted

operated

be

to

for

CP-9200SH

setting

the

to

for

the

an

CP-9200SH

speed,

with

independently.

SVA

User's

module

Manual

the

switches,

Control

Pack

CP-9200SH.

explanation

(referred

torque,

(basic

(SIE-C879-40.1)

connectors,

CP-717

to

Refer

the

Servo

of

hereinafter

position,

specifications,

(refered

them

and

examples

hereinafter

along

control

as

CP-9200SH)

the

differential

functions,

explanation

for

an

of

connections

as

this

with

module

control

user

with

CP-717).

the

manual.

module)

(SVA

module.

maximum

on

a

programming

of

the

hardware

drives)

Servo

These

are

Related

Manual

Manuals

No.

SIE-C873-16.4

SIE-C877-17.4

SIE-C877-17.5

TOE-C877-17.7

CHE-C879-40

KAE-C879-40

SIE-C879-40.1

SIE-C879-40.3

SIE-C879-40.4

FDS

System

Control

Control

Control

Pack

Pack

Pack

Ultra-high

Super

High-speed

Machine

Machine

Machine

User's

Manual

Installation

CP-

7

CP-717

CP-717

Speed

Machine

Contorller

Contorller

Controller

Manual

Name

Manual

Operation

17

Operation

Manual

Manual

Instructions

Controller

Machine

CP-9200SH

CP-9200SH

Controller

User's

Programming

CP-9200SH/PO-01

(Vol.l)

(Vol.2)

CP-9200SH

CP-9200SH

Manual

Manual

Motion

Controller

1

Page 3

•

For

and

etc.)safety

Be

sure

correct

other

use,

attached

be

Also,

information,

keep

to

be

sure

the

to

sure

read

documents

use

all

the

of

to

and

documents

SAFETY

the

Instruction

thoroughly

equipment

precautions.

the

place

a

at

PRECAUTIONS

and

Maintenance

before

upon

where

use

acquiring

they

may

(installation,

thorough

a

readily

be

Manual,

operation,

knowledge

available

supplementary

this

maintenance,

the

of

for

anyone

manu

inspects

equipment,

using

the

t

devi

#

#

Safety

In

A

A

®

O

In

to

Symbols

this

manual,

DANGER

CAUTION

PROHIBITED

MANDATORY

this

manual,

by

the

user,

Usedinthis

the

following

matters,

are

indicated

Manual

symbols

Danger

O

Indicates

that

Caution

O

Indicates

that

damage.

Prohibited

O

Strong

results

Mandatory

O

Indicates

that

do

next

used

are

where

cases

accompanies

where

cases

accompanies

indication

depending

grounding

that

correspond

not

the

relevant

to

according

erroneous

possibility

the

erroneous

possibility

the

prohibited

of

a

the

on

being

to

items.

descriptions

the

to

handling

deathorserious

of.

handling

medium

of

matter

circumstances.

provided.

be

must

DANGER

a

!

may

may

or

which

a

or

CAUTION

on

lead

lead

light

may

safety.

dangerous

to

a

injury.

dangerous

a

to

injury

otherwise

but

or

should

only

lead

situatio

situatio

matern

seriou

to

adhej

be

2

Page 4

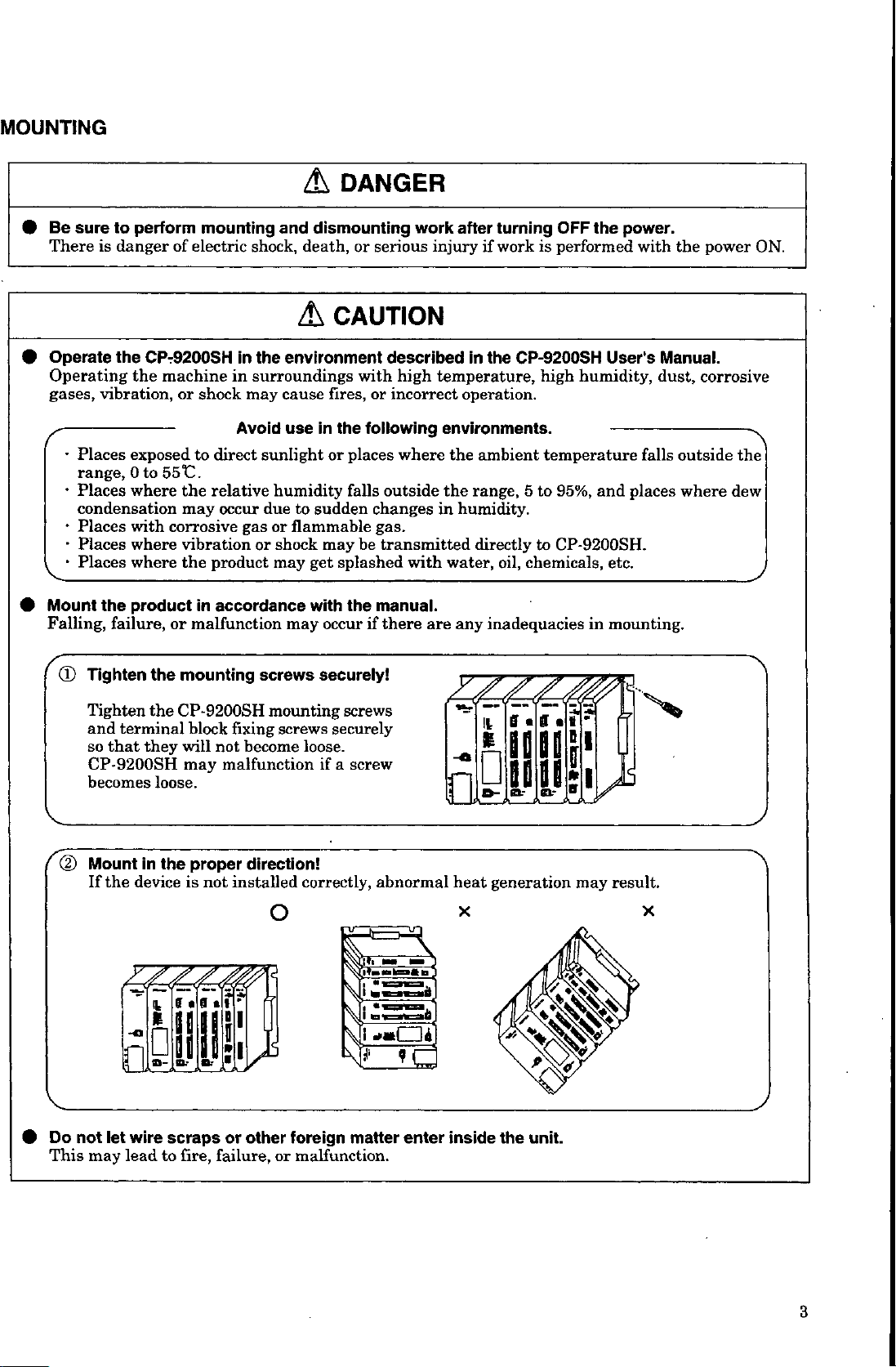

DANGER

A

Be

sure

There

Operate

Operating

gases,

-

Mount

Falling,

is

vibration,

s-

Places

range,

•

Places

condensation

•

Places

•

Places

•

Places

the

(D

Tighten

perform

to

danger

the

CP-9200SH

the

exposed

Oto

where

with

where

where

product

failure,

the

mounting

of

electric

machine

or

shock

to

shock,

the

in

surroundings

in

may

Avoid

sunlight

direct

551C.

the

relative

may

corrosive

vibrationorshock

product

the

in

malfunction

or

mounting

due

occur

gas

accordance

screws

dismounting

and

death,

CAUTION

A

environment

fires,

cause

use

humidity

or

may

may

the

in

or

sudden

to

flammable

may

splashed

get

with

occur

securely!

serious

or

described

with

or

incorrect

following

places

outside

falls

changes

gas.

be

transmitted

the

manual.

there

if

work

injury

high

temperature,

environments.

where

the

in

with

water,

are

after

turning

work

if

the

in

operation.

the

ambient

range,

humidity.

directly

oil,

any

inadequacies

OFF

the

performed

is

CP-9200SH

humidity,

high

-

temperature

5

to

95%,

CP-9200SH.

to

chemicals,

in

power.

with

User's

falls

places

and

etc.

mounting.

the

Manual.

dust,

corrosive

outside

where

power

dew

ON.

>.

the

Tighten

and

so

CP-9200SH

becomes

(D

Mount

If

Do

not

This

may

the

terminal

that

they

loose.

in

the

device

ill

wire

let

lead

CP-9200SH

block

not

will

may

malfunction

the

proper

is

not

scraps

to

fire,

failure,

mounting

fixing

become

direction!

installed

o

or

other

screws

or

securely

loose.

a

if

correctly,

foreign

malfunction.

screws

screw

abnormal

SB

[i

[I

F~rd

matter

enter

heat

x

inside

«

e

it

r.f?

£

IIP

generation

>5

Sr

the

unit.

may

result.

x

3

Page 5

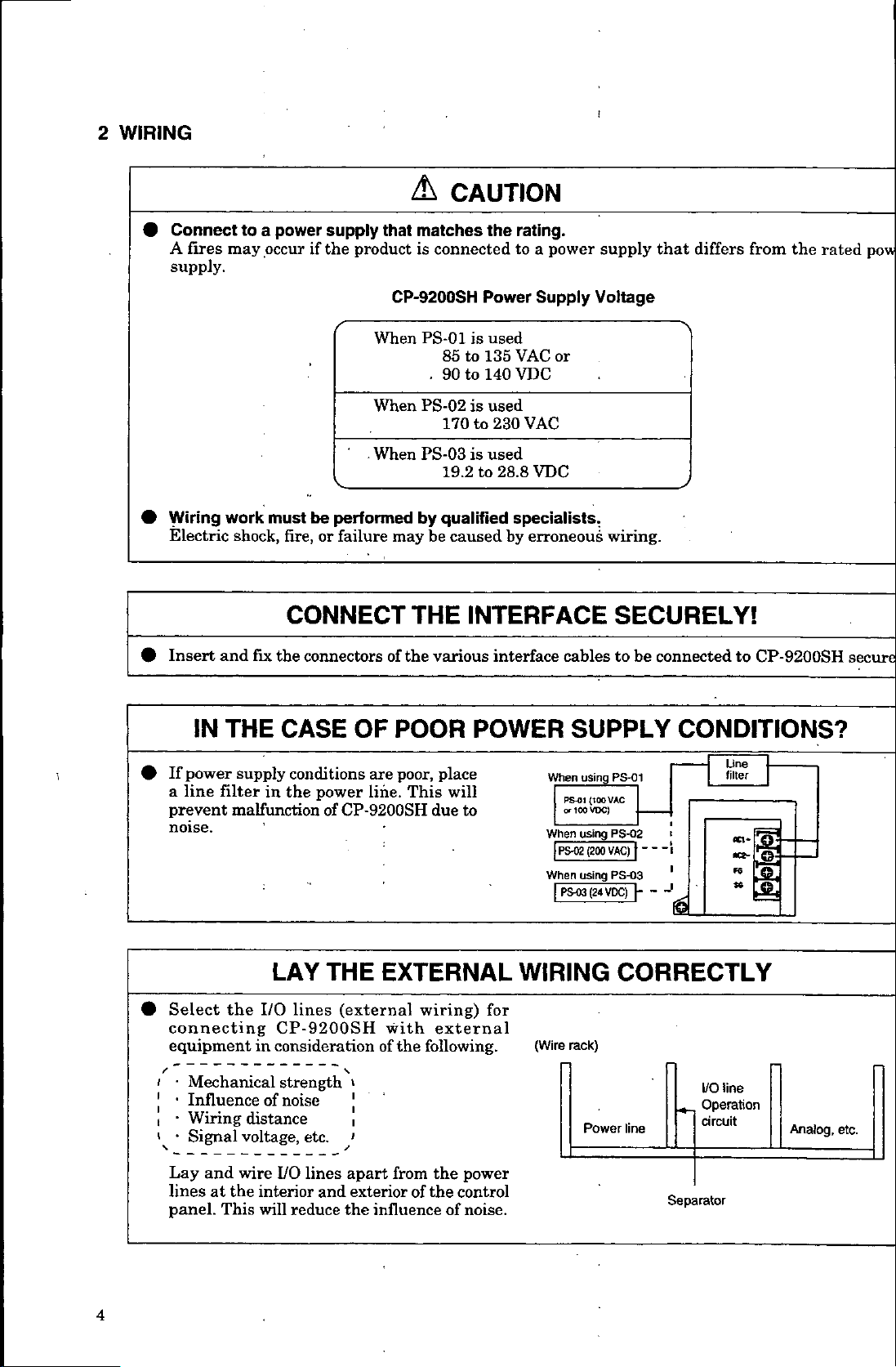

2

WIRING

/h

CAUTION

!

•

•

#

Connect

fires

A

supply.

Wiring

Electric

Insert

to

may

work

shock,

and

fire,

if

be

or

supply

the

power

a

occur

must

CONNECT

the

fix

connectors

that

product

CP-9200SH

When

When

When

performed

failure

may

of

matches

is

connected

PS-01

85

.

90

PS-02

170

PS-03

19.2to28.8

by

qualified

be

THE

the

various

the

rating.

a

to

power

Power

used

is

135

to

140

to

used

is

to

used

is

caused

Supply

VAC

VDC

230

VAC

VDC

specialists.

by

erroneous

or

INTERFACE

interface

supply

Voltage

wiring.

SECURELY!

cablestobe

that

differs

connected

from

the

to

CP-9200SH

rated

pow

secure

THE

IN

If

power

i

#

line

a

prevent

noise.

Select

#

connecting

equipment

•

i

•

[

,

-

•

'

Lay

lines

panel.

filter

malfunctionofCP-9200SH

the

Mechanical

Influence

Wiring

Signal

and

the

at

This

CASE

supply

wire

conditions

the

in

I/O

LAY

lines

power

THE

CP-9200SH

considerationofthe

in

strength

of

noise

distance

voltage,

I/O

interior

reduce

will

etc.

lines

and

OF

POOR

are

poor,

line.

This

EXTERNAL

(external

with

»

1

,

1

from

apart

exteriorofthe

the

influence

place

will

due

to

wiring)

external

following.

power

the

control

noise.

of

POWER

When

When

|

When

I

WIRING

for

(Wire

SUPPLY

using

PS-01

PSÿ1

VAC

\

(100

VDC)

or

t<W

using

PS-02

PS-02

(200VAC)~j

using

PS-03

(24

VDC)

PS-03

I

CORRECTLY

rack)

Power

line

CONDITIONS?

Line

filter

i

1

---

1

'

<6

---

Separator

«*

»

line

I/O

Operation

circuit

3-

<!r

--

Analog,

etc.

4

Page 6

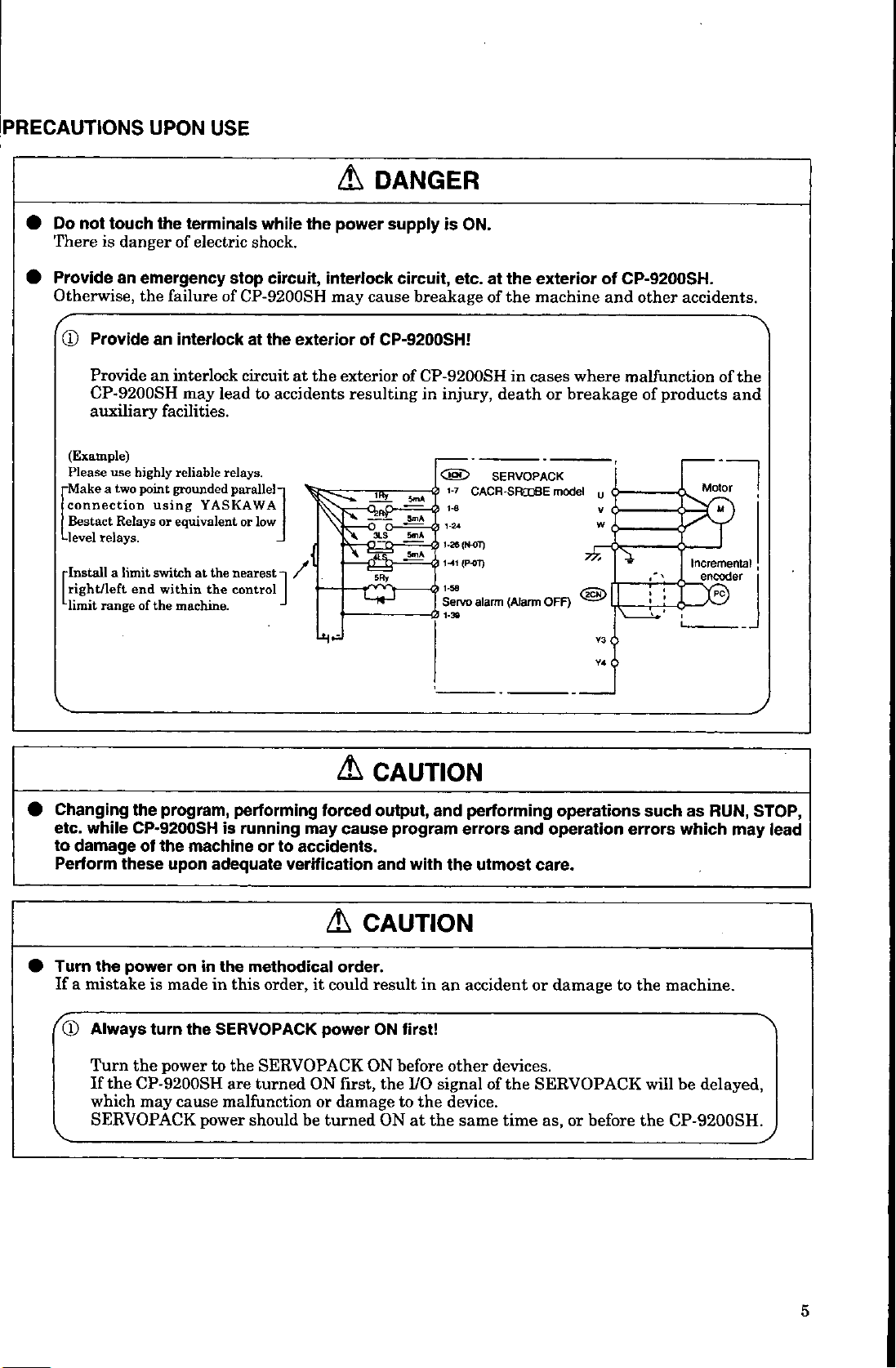

Do

not

There

touch

danger

is

UPON

the

terminals

electric

of

USE

while

shock.

the

DANGER

A

power

supply

is

ON.

Provide

Otherwise,

(D

an

emergency

the

Provideaninterlock

Provide

an

CP-9200SH

auxiliary

(Example)

use

two

a

Relays

relays.

a

limit

range

highly

point

using

switchatthe

end

of

the

Please

connection

Bestact

-level

•Install

right/left

limit

failure

interlock

may

facilities.

reliable

grounded

YASKAWA

or

equivalent

the

within

machine.

circuit,

stop

of

CP-9200SH

the

at

circuitatthe

lead

relays.

to

parallel-

low

or

nearest

control

accidents

-i

J

interlock

may

exterior

/

cause

of

CP-9200SH!

exterior

resulting

w

0

JLS°

\

'

5Ry

L"*

circuit,

breakage

of

CP-9200SH

in

5m*

3m*

5mA

-

J

etc.

injury,

CSD

>

CACR-SRCDBE

1-8

1-24

1-26

(N-OT)

(P-OT)

1-41

1-50

0

Servo

alarm

exterior

the

at

the

machine

of

cases

in

death

SERVOPACK

(Alarm

OFF)

where

breakage

or

model

of

CP-9200SH.

and

other

malfunction

of

0

V

W

Y3

Y4

accidents.

products

Motor

Incremental

encoder

B

M

of

the

and

I

Changing

while

etc.

to

damage

Perform

urn

the

T

If

a

mistake

Always

CD

Turn

the

If

which

SERVOPACK

the

program,

CP-9200SH

the

machine

of

these

upon

power

on

is

madeinthis

turn

the

power

the

CP-9200SH

cause

may

performing

is

running

or

adequate

in

the

methodical

order,

SERVOPACK

the

to

SERVOPACK

turned

are

malfunction

power

shouldbeturned

A

forced

may

to

accidents.

verification

A

order.

it

could

power

ON

or

damage

CAUTION

output,

cause

program

and

with

CAUTION

in

result

ON

first!

before

ON

the

ON

to

I/O

the

at

first,

and

the

an

other

signal

device.

the

errors

same

performing

and

utmost

accident

devices.

of

the

time

operations

operation

errors

care.

damage

or

to

SERVOPACK

or

as,

before

as

such

which

the

machine.

be

will

the

CP-9200SH.

RUN,

may

delayed,

STOP,

lead

5

Page 7

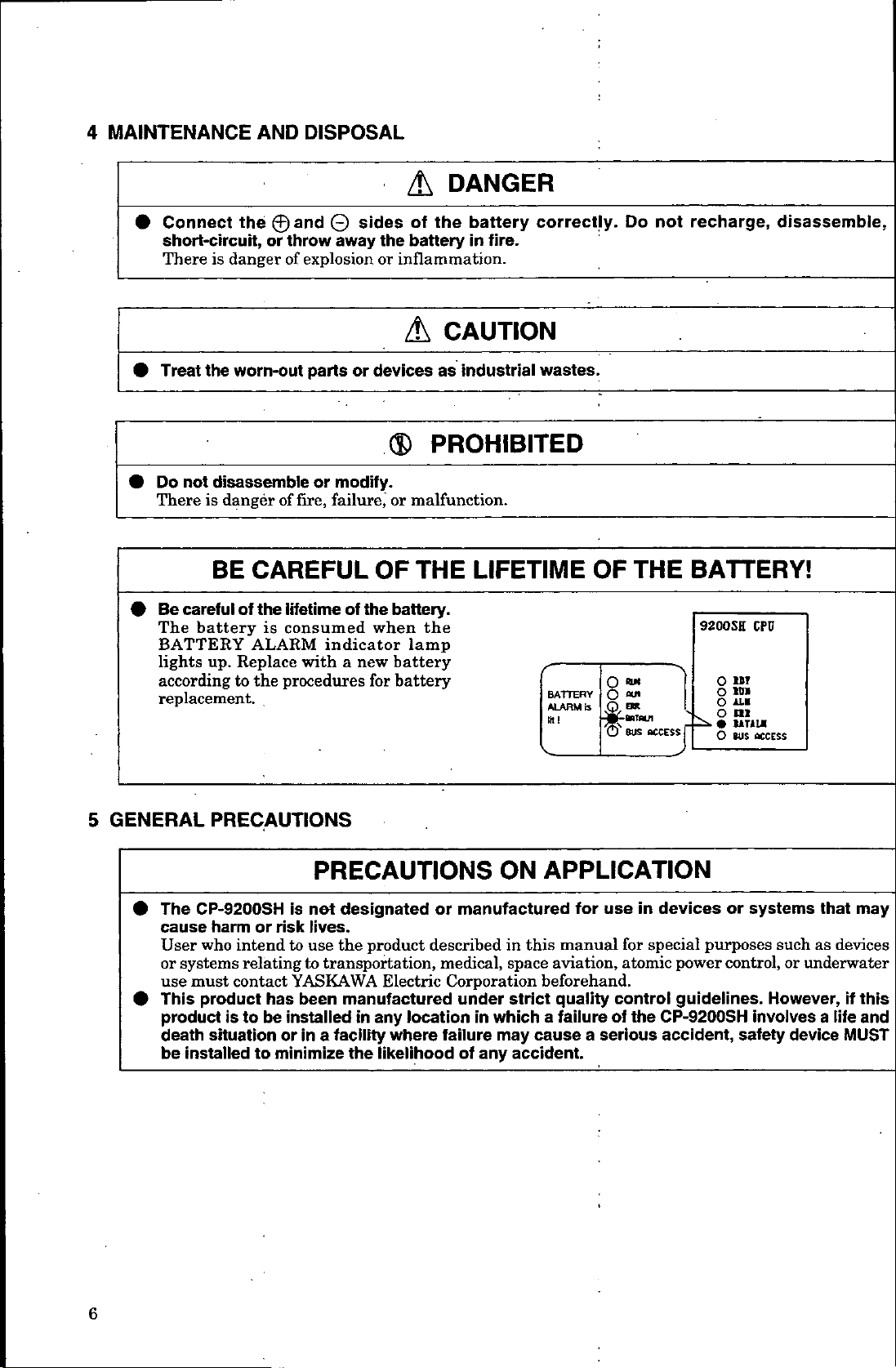

4

MAINTENANCE

AND

DISPOSAL

DANGER

A

Connect

•

short-circuit,

There

Treat

#

Do

•

There

Be

•

The

BATTERY

lights

according

replacement.

danger

is

the

worn-out

disassemble

not

danger

is

BE

careful

battery

Replace

up.

to

the

0and

throw

or

explosion

of

parts

or

of

fire,

CAREFUL

lifetime

the

of

is

consumed

ALARM

the

indicator

with

procedures

sides

©

away

or

modify.

failure,

the

of

a

new

the

of

battery

the

inflammation.

or

A

devices

OF

when

for

as

PROHIBITED

®

malfunction.

or

THE

battery.

the

lamp

battery

battery

battery

in

correctly.

fire.

CAUTION

industrial

wastes.

LIFETIME

BATTERY

ALARM

mi

Do

THE

OF

o

O

*"

is

A™

-jjhBBTOUl

BUS

O'

not

recharge,

BATTERY!

9200SH

ACCESS

•n

O

O

o

O

disassemble,

CFO

11T

10*

n*

111

UT1U

tus

access

GENERAL

5

•

#

PRECAUTIONS

The

CP-9200SH

cause

User

or

use

This

product

death

be

harmorrisk

who

intend

contact

product

is

situation

relating

has

be

to

systems

must

installedtominimize

PRECAUTIONS

is

net

designated

lives.

the

use

to

to

YASKAWA

been

installed

orina

product

transportation,

Electric

manufactured

location

any

in

facility

the

where

likelihood

ON

manufactured

or

describedinthis

medical,

Corporation

under

failure

of

in

any

space

strict

which

may

accident.

cause

APPLICATION

use

for

manual

aviation,

beforehand.

quality

failure

a

serious

a

in

for

atomic

control

the

of

devices

special

power

guidelines.

CP-9200SH

accident,

or

systems

purposes

control,

involves

safety

that

such

as

or

underwater

However,

a

device

may

devices

if

this

life

and

MUST

6

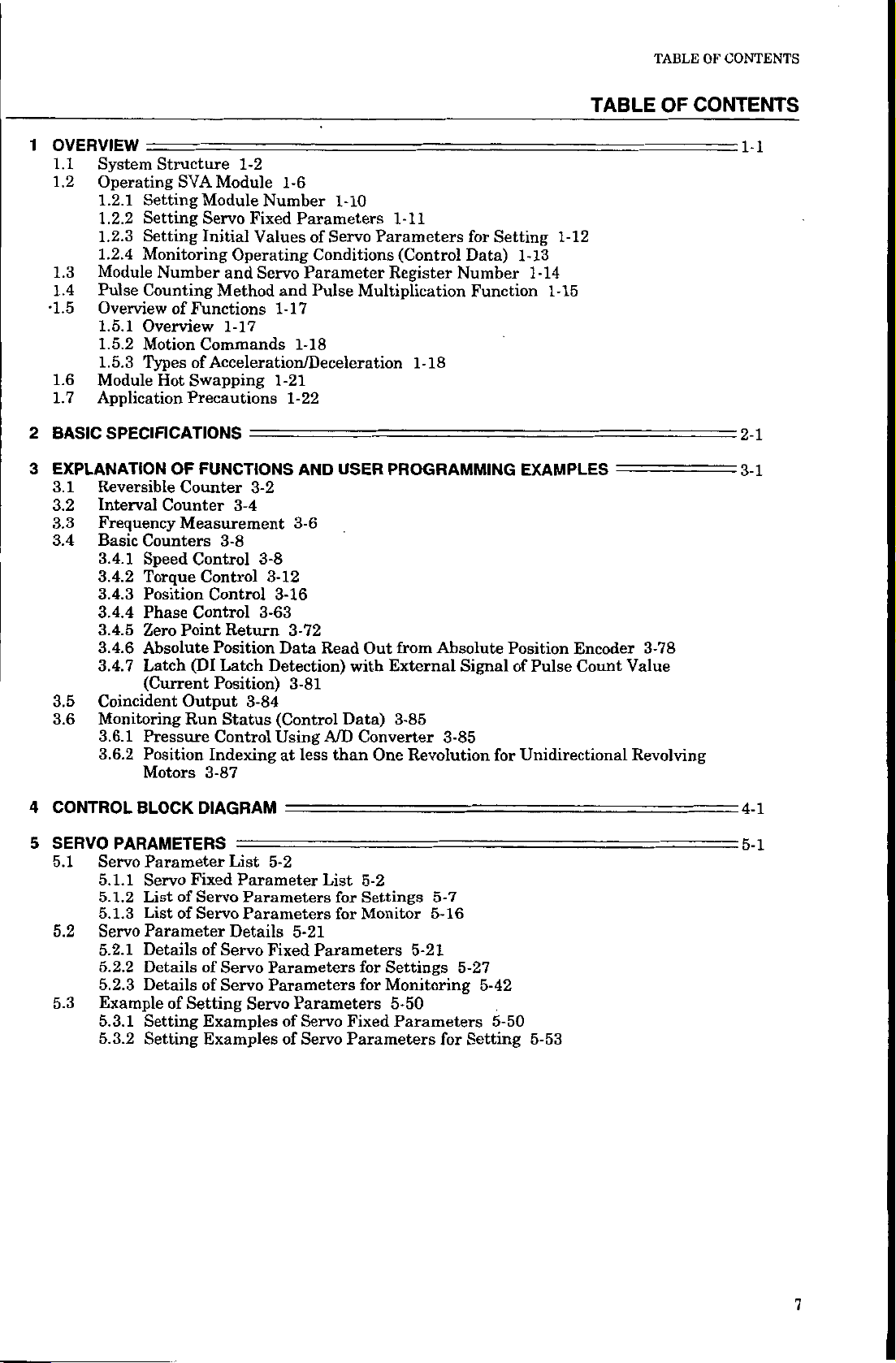

Page 8

TABLE

OF

CONTENTS

1

OVERVIEW

System

1.1

Operating

1.2

1.2.1

1.2.2

1.2.3

1.2.4

Module

1.3

1.4

Pulse

•1.5

2

3

Overview

1.5.1

1.5.2

1.5.3

1.6

Module

Application

1.7

BASIC

EXPLANATIONOFFUNCTIONS

3.1

3.2

3.3

3.4

SPECIFICATIONS

Reversible

Interval

Frequency

Basic

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

3.5

Coincident

Monitoring

3.6

3.6.1

3.6.2

Structure

SVA

Setting

Setting

Setting

Monitoring

Module

Servo

Initial

Number

Counting

of

Functions

Overview

Motion

Types

Hot

Commands

of

Swapping

Precautions

Counter

Counter

Measurement

Counters

Speed

Control

Torque

Control

Position

Phase

Zero

Absolute

Latch

(Current

Control

Point

(DI

Output

Run

Pressure

Position

Motors

Indexing

3-87

Module

Operating

and

Method

1-17

Acceleration/Deceleration

3-4

3-8

Control

Return

Position

Latch

Position)

Status

Control

1-2

Number

Fixed

Values

Servo

3-2

3-8

3-12

3-63

Detection)

3-84

1-6

Parameters

of

Servo

Conditions

Parameter

and

Pulse

1-17

1-18

1-21

1-22

AND

3-6

3-16

3-72

Data

Read

3-81

(Control

Using

at

A/D

less

1-10

Parameters

Register

Multiplication

USER

PROGRAMMING

Out

with

External

Data)

Converter

One

than

1-11

(Control

1-18

from

Absolute

3-85

3-85

Revolution

Setting

for

Data)

Number

Function

Position

Signal

for

TABLE

1-12

1-13

1-14

1-15

EXAMPLES

Encoder

Pulse

Count

of

Unidirectional

OF

3-78

Value

Revolving

CONTENTS

1-1

2-1

3-1

-

4

CONTROL

SERVO

5

5.1

5.2

5.3

BLOCK

PARAMETERS

Servo

Parameter

5.1.1

Servo

of

List

5.1.2

5.1.3

Servo

5.2.1

5.2.2

5.2.3

Example

5.3.1

5.3.2

of

List

Parameter

Details

Details

Details

of

Setting

Setting

DIAGRAM

List

Fixed

Parameter

Servo

Servo

Details

of

Servo

of

Servo

of

Servo

Setting

Examples

Examples

5-2

Parameters

Parameters

5-21

Fixed

Parameters

Parameters

Parameters

Servo

Parameters

Servo

of

of

Servo

5-2

List

Settings

for

Monitor

for

for

for

Fixed

Parameters

5-7

5-16

5-21

Settings

Monitoring

5-50

Parameters

for

5-27

5-42

Setting

5-50

-

=

5-53

4-1

5-1

7

Page 9

APPENDIX

A.

Initialization

A.1

A.2

Absolute

of

Initialization

Initialization

.......

:

Encoder

Procedures

Procedures

A-2

for

Absolute

for

Absolute

-

—

—

Encoder

Encoder

-

(15-bit

(12-bit

~

-

......

.....

—

Type)

Type)

A-2

A-3

—

A

-

—

B.

Differences

B.l

B.2

B.3

B.4

C.

Switching

C.l

C.2.

between

Equivalence

of

List

List

List

When

C.1.1

C.1.2

When

C.2.1

C.2.2

Difference

of

Difference

of

Difference

between

using

Settings

(1)

Servopack

(2)

Interface

(1)

.

(2)

(3)

using

Settings

(1)

Servopack

(2)

Interface

(1)

(2)

(3)

Other

CP-9200SH

Torque

Speed

Other

CP-9200SH

Torque

Speed

CP-9200SH

for

for

for

Torque

Torque

for

A-18

control

control

control

the

for

A-20

Control

Control

Control

for

Servo

Servo

Servo

Tables

Servopack

Servopack

Servo

Control

Series

2

Control

Series

2

SVA

mode

mode

modes

Series

2

Torque

Series

2

SVA

Mode

Mode

Modes

(SVA)

Parameters

Parameters

Parameters

Module

Module

and

Fixed

and

Speed

SGD

Mode

SGD

A-18

18

A-

A-18

DR1

Control

DR1

A-20

A-20

A-20

Parameters

A-17

A-17

Mode

A-19

A-19

CP-9200SH

and

Settings

for

Monitoring

for

Each

for

Control

A-17

A-17

A-19

Control

A-19

(HSC)

CP-9200SH

A-6

A-10

Mode

17

A-

A-4

Servo

A-

12

Controller

A-5

:

8

Page 10

1.

OVERVIEW

1

OVERVIEW

methods

these

explains

items

This

chapter

operating

observe

and

for

the

system

overview

using

the

structural

the

of

SVA

module.

diagrams,

device.

Always

1-1

Page 11

1.1

System

Structure

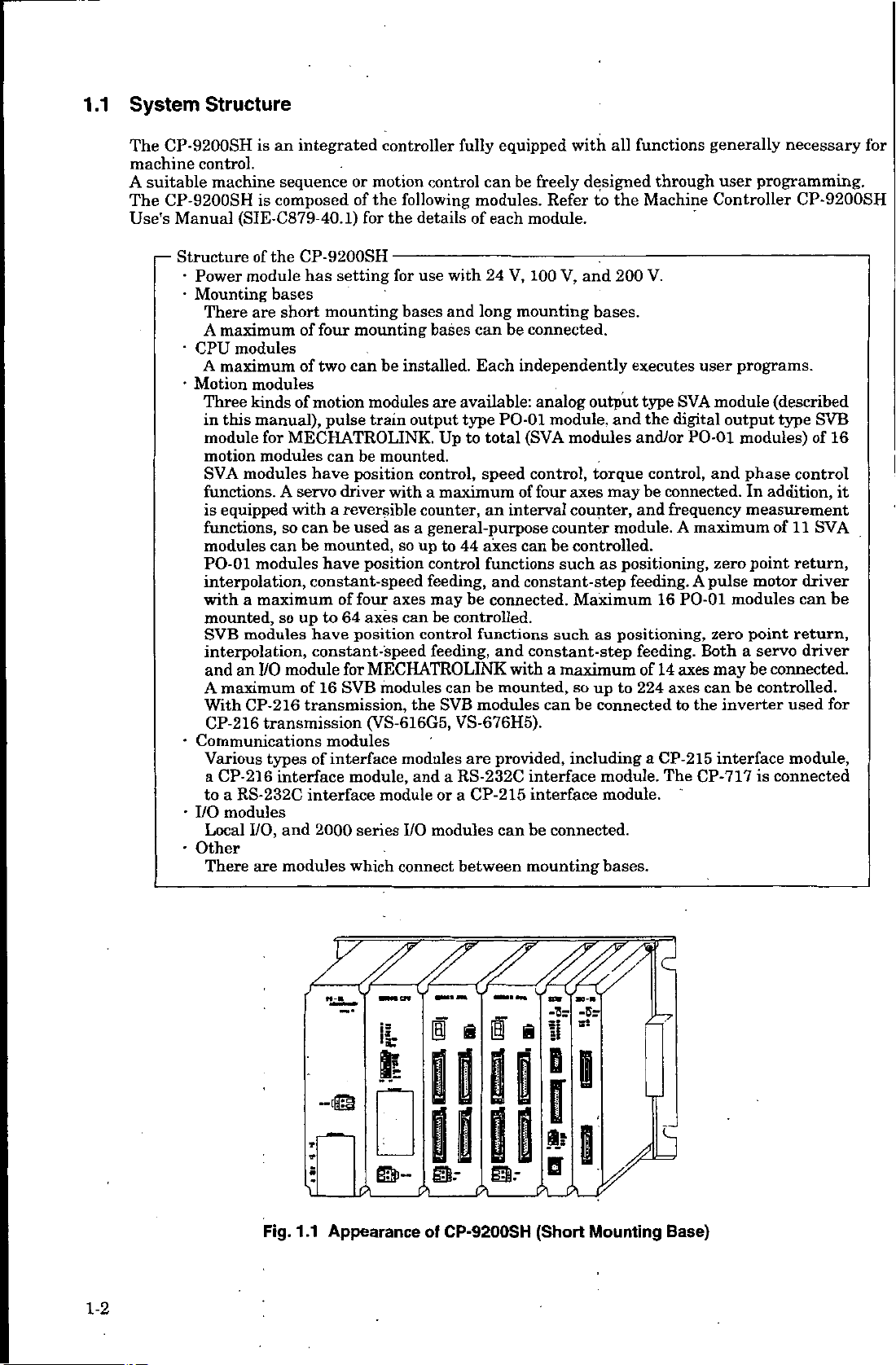

The

CP-9200SH

machine

suitable

A

The

CP-9200SH

Manual

Use's

—

Structure

•

•

•

•

•

is

an

control.

machine

Power

Mounting

There

maximum

A

CPU

A

maximum

Motion

Three

this

in

module

motion

SVA

functions.

equipped

is

functions,

modules

PO-01

interpolation,

with

mounted,

SVB

interpolation,

and

maximum

A

With

CP-216

Communications

Various

CP-216

a

to

a

•

I/O

modules

Local

•

Other

There

sequence

composed

is

(SIE-C879-40.1)

the

of

module

bases

short

are

modules

modules

kinds

manual),

for

modules

modules

A

so

can

modules

maximum

a

so

modules

module

I/O

an

CP-216

transmission

types

interface

RS-232C

and

I/O,

modules

are

integrated

CP-9200SH

has

mounting

four

of

of

two

of

motion

pulse

or

motion

the

of

for

-

setting

mounting

can

modules

train

controller

following

the

details

for

use

bases

be

installed.

output

MECHATROLINK.

be

can

have

servo

a

with

be

can

mounted,

be

have

constant-speed

up

to

have

constant-speed

of16SVB

transmission,

mounted.

position

driver

of

with

reversible

used

position

four

64

axes

position

for

a

as

up

so

axes

can

MECHATROLINK

modules

the

(VS-616G5,

modules

module

series

modules

and

I/O

connect

interface

of

module,

interface

2000

which

fully

equipped

can

control

be

modules.

of

each

24

long

can

V,

mounting

be

with

and

bases

Each

available:

are

type

PO-01

Up

to

total

control,

a

counter,

general-purpose

control

feeding,

may

be

control

feeding,

speed

maximum

an

to

axes

44

functions

and

be

connected.

controlled.

functions

and

interval

with

mounted,

be

can

modules

SVB

VS-676H5).

provided,

are

RS-232C

a

CP-215

or

a

modules

can

between

all

with

freely

designed

Refer

to

module.

-

:

V,

and

100

bases.

connected.

independently

analog

(SVA

control,

of

four

can

constant-step

output

module,

modules

torque

axes

counter,

counter

be

controlled.

such

as

and

may

Maximum

such

as

constant-step

maximum

a

so

up

be

can

interface

interface

be

mounting

connected

including

module.

module.

connected.

bases.

functions

through

Machine

the

200

V.

executes

SVA

type

digital

the

and/or

control,

connected.

be

frequency

and

feeding.

16

feeding.

of

14

axes

224

a

CP-215

A

PO-01

axes

to

module.

positioning,

positioning,

to

The

generally

user

Controller

programs.

user

module

output

PO-01

modules)

and

maximum

zero

pulse

A

modules

zero

Both

a

may

be

can

inverter

the

interface

CP-717

necessary

programming.

CP-9200SH

(described

type

SVB

of

phase

In

measurement

control

addition,

of

11

point

return,

motor

point

be

driver

can

return,

servo

driver

connected.

controlled.

used

SVA

module,

connected

is

for

16

it

be

for

1-2

Fig.

i

Appearance

1.1

IS:

HE

©-

a

I

mr

of

CP-9200SH

mr

!i

U

(Short

-5r

r:

Mounting

y

Base)

Page 12

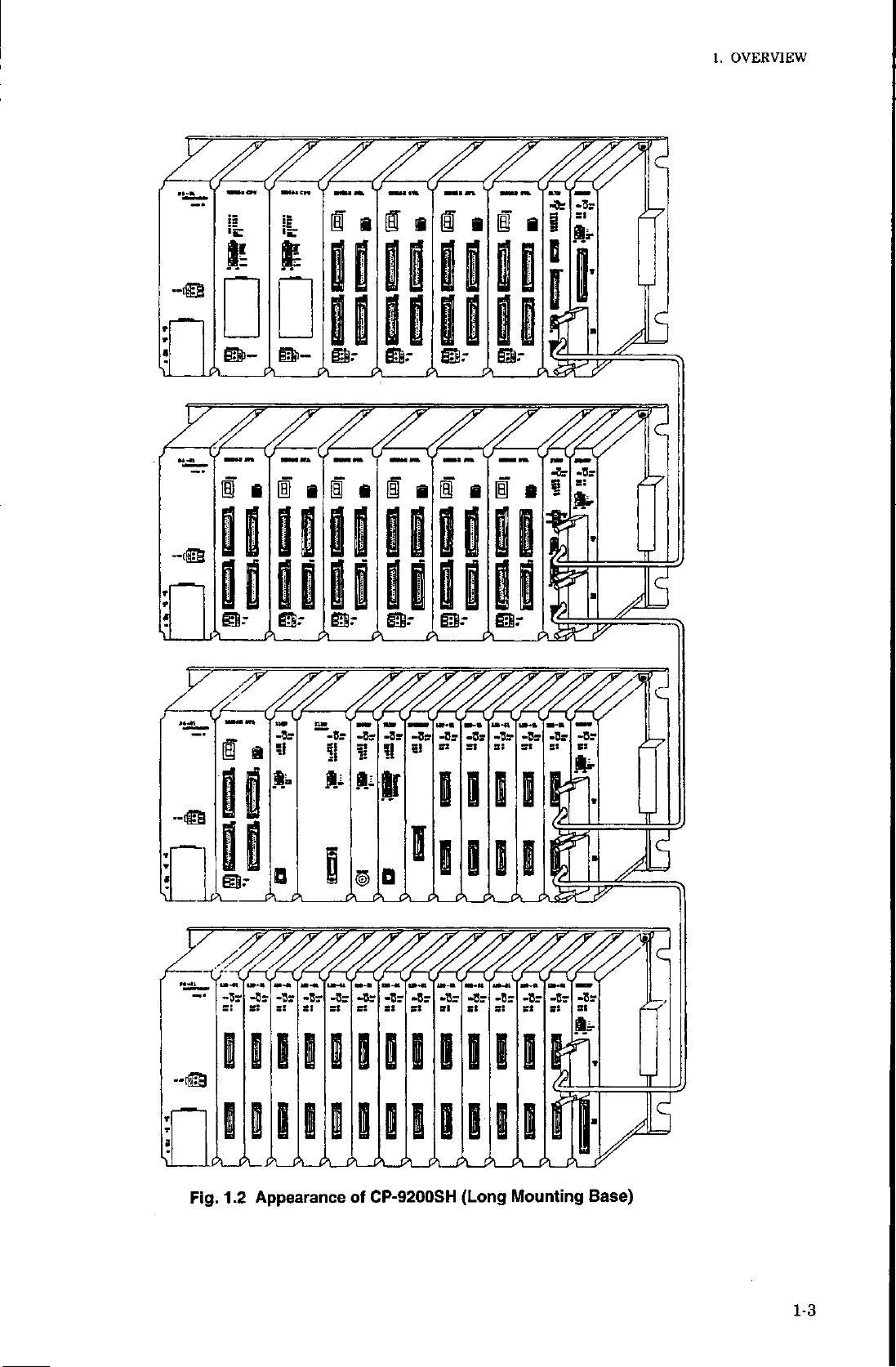

15=

I*

OVERVIEW

1.

z.

a

I

ff

9

i

I

a

1

9

1

f

I

I

1

7

X

a-

A

a.-

A

!*ÿ

a

A A

a.-

A

£-

A A

-«s

?!

IS

*»

U

A A

a--

L/

nm

j*

V

SM*

if*

V

u».«

3*

V

V

S'

V

v

3-

fflJ

-&

-Br

s!

S

3*

3*

3s

c

Jb-

iiiiryj

-©

n

u

—

u.

3s

3*

III

iii

_

A_A

LA

Fig.

1

.2

i.jimte

3s3*3"

I

III

ii

_

_

A__A

A

Appearance

gS

A

3s 3s3*3s

II

in

_

AX>I_X_X_Xÿ_A__AL_AL_Aÿ

CP-9200SH

of

ii

3s

3*

3'

BIB

i>i

(Long

Mounting

3*

if]

ifj>x

3*

Base)

,

Jb-

v

1-3

Page 13

/DO

PI

••

-<3

.

5=?

IX)

Expansion

module

(2000s«nes

VO)

Comrru>

caws

nwUe

CPU

module

1*0000

(0*0000)

*

IW13PF

(OW3PP)

DM)

DO

00

000

IMG

\

8MU023

(CPU#1)

UWO0OO

VWSH7

Expansion

module

(2000

Common

DI/DO

•

-U

5=?

1/0

senes

I/O)

memory

o

ComnuV

cations

nxxUe

CPU

module

1*0000

(CW000)

IVW3PP

(CW13PF)

DM0000

SWBOOO0

\

SWBI0J3

(CPU

MWOOOO

MW27I7

#2)

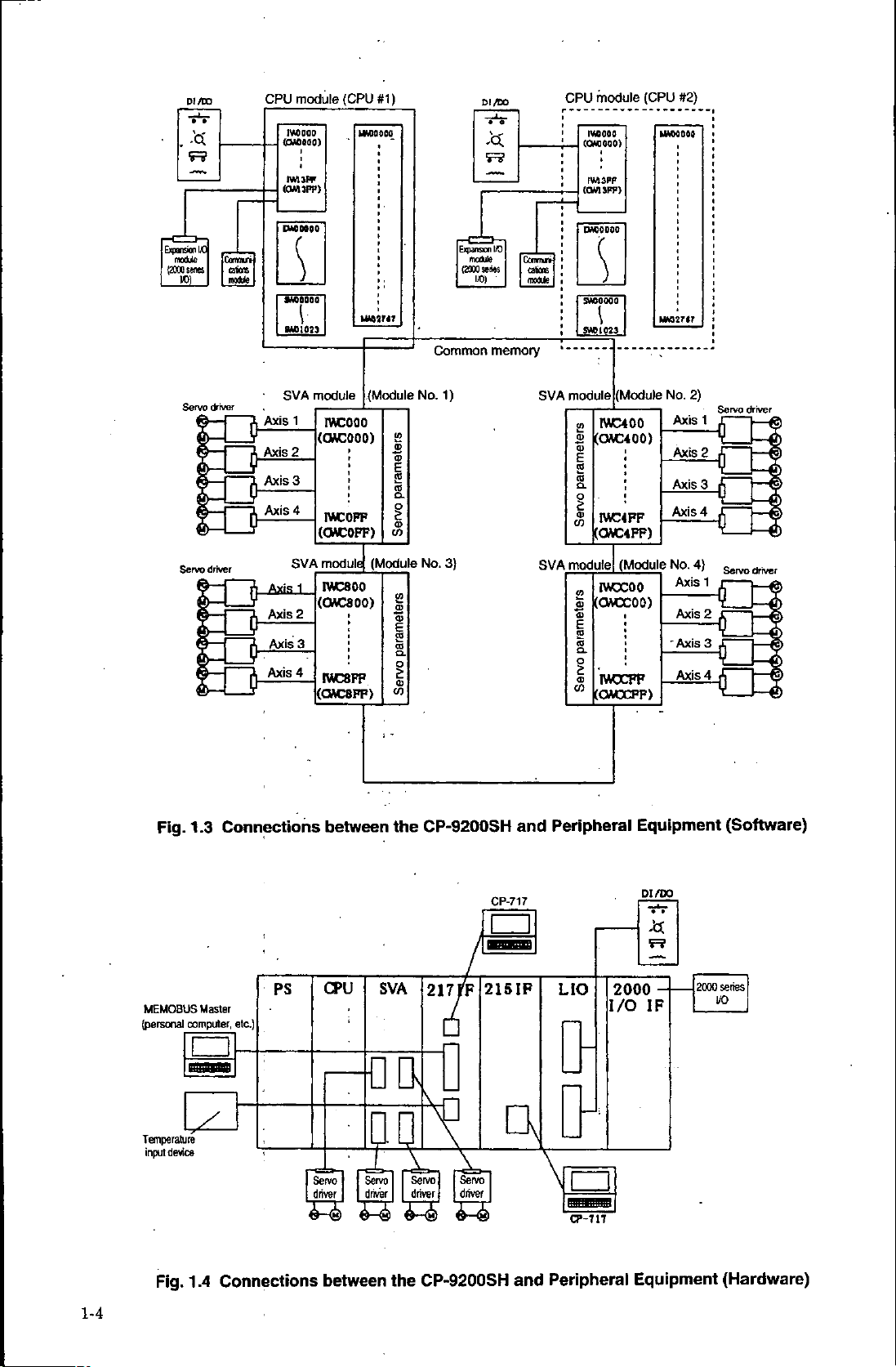

Fig.

Servo

Servo

1.3

driver

driver

SVA

1

Axis

3

Axis

2

3

3

Axis

Axis

3

4

3

SVA

Axis

1

2

Axis

3

Axis

Axis

4

Connections

module

wcooo

(GMCOOO)

MCOFF

(CMC

OFF)

module

IVC800

(QAC800)

MC8FF

(OAC8FF)

between

(Module

S

£

E

2

I

OJ

V)

(Module

2

O)

Q>

E

2

2.

o

£

o

'

1

the

1)

No.

3)

No.

CP-9200SH

SVA

SVA

and

module

IWC400

2?

0)

(CUC400)

a>

E

ro

a.

o

£

<D

MC4FF

to

(CWC4FF)

module!

IWCC00

m

(CWCC00)

5

O)

E

2

to

o

<D

IVrCCFF

C0

(CMCCFF)

Peripheral

(Module

(Module

Equipment

No.

Axis

Axis

Axis

Axis

No.

"Axis

Axis

Axis

Axis

2)

4)

1

2

r

3

L

4

r

1

2

3

4

Q

£J

Servo

driver

Servo

driver

0

(Software)

1-4

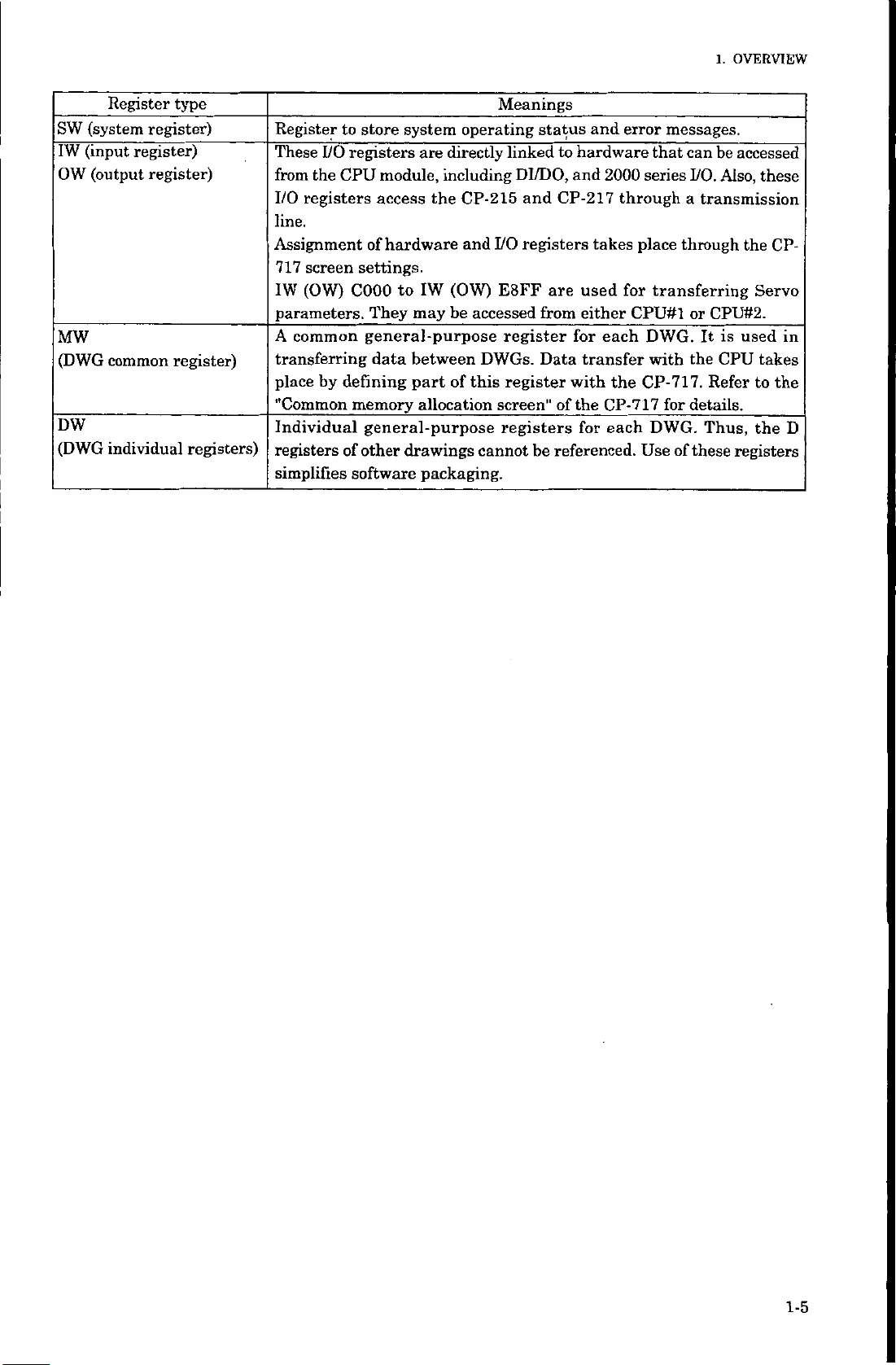

MEMOBUS

computer,

(personal

Temperature

device

input

.4

Fig.

1

Master

etc.)

Connections

PS

CPU

Servo

driver

5-®

between

SVA

tm

X

Servo

driver

&-®

217

Vn

Servo!

j

driver

&-<k

CP-9200SH

the

rF

Servo

I

|

driver

&-<k)

CP-717

[

215

IF

\n

and

LIO

I/O

\

—

CP-717

Peripheral

PI

/DO

»

•

F?

2000

-

IF

Equipment

2000

series

I/O

(Hardware)

Page 14

1.

OVERVIEW

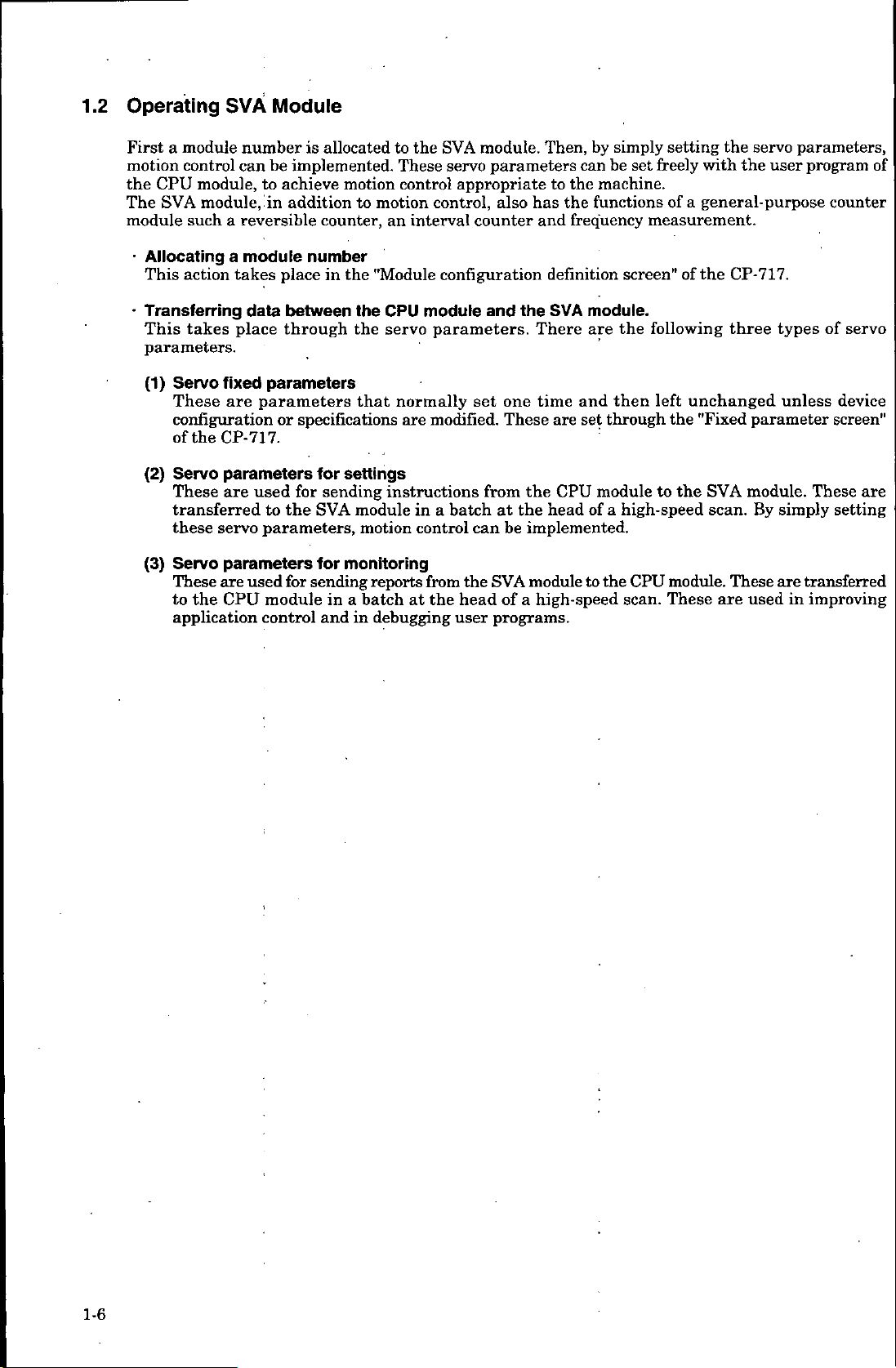

(system

SW

(input

IW

OW

MW

(DWG

DW

(DWG

Register

register)

(output

common

individual

type

register)

register)

register)

registers)

Register

These

from

I/O

to

registers

I/O

CPU

the

registers

line.

Assignment

screen

717

(OW)

IW

parameters.

common

A

transferring

by

place

"Common

defining

Individual

registers

simplifies

of

system

store

directly

are

to

the

IW

may

including

(OW)

be

module,

access

of

hardware

settings.

COOO

They

general-purpose

data

between

of

part

memory

general-purpose

other

software

allocation

drawings

packaging.

Meanings

operating

status

linkedtohardware

DI/DO,

I/O

and

registers

CP-215

and

E8FF

accessed

DWGs.

this

cannot

from

register

Data

register

screen"

registers

be

and

and

2000

CP-217

are

through

takes

used

either

each

for

transfer

the

with

the

of

CP-717

for

each

referenced.

error

messages.

that

series

place

for

transferring

CPU#I

DWG.

with

CP-717.

for

DWG.

Use

be

can

I/O.

Also,

a

transmission

through

CPU#2.

or

is

It

the

CPU

Refer

details.

Thus,

of

these

accessed

these

the

CP-

Servo

used

in

takes

to

the

_

D

the

registers

1-5

Page 15

1.2

Operating

SVA

Module

Firstamodule

motion

the

The

module

CPU

SVA

control

module,

module,

such

Allocating

This

action

•

Transferring

This

takes

parameters.

(1)

Servo

These

fixed

are

configuration

of

CP-717.

the

Servo

(2)

These

parameters

are

transferred

these

servo

Servo

These

the

to

parameters

are

CPU

(3)

application

number

be

can

to

in

reversible

a

module

a

takes

data

place

parameters

parameters

or

used

to

parameters,

used

module

control

is

allocatedtothe

implemented.

achieve

addition

place

between

through

motion

counter,

number

the

in

to

the

the

that

specifications

for

settings

sending

for

the

for

module

SVA

for

monitoring

sending

a

in

in

and

motion

These

control

an

control,

interval

motion

"Module

CPU

module

parameters.

servo

normally

modified.

are

instructions

a

in

control

reports

batchatthe

from

debugging

module.

SVA

parameters

servo

appropriate

also

counter

configuration

and

the

one

set

These

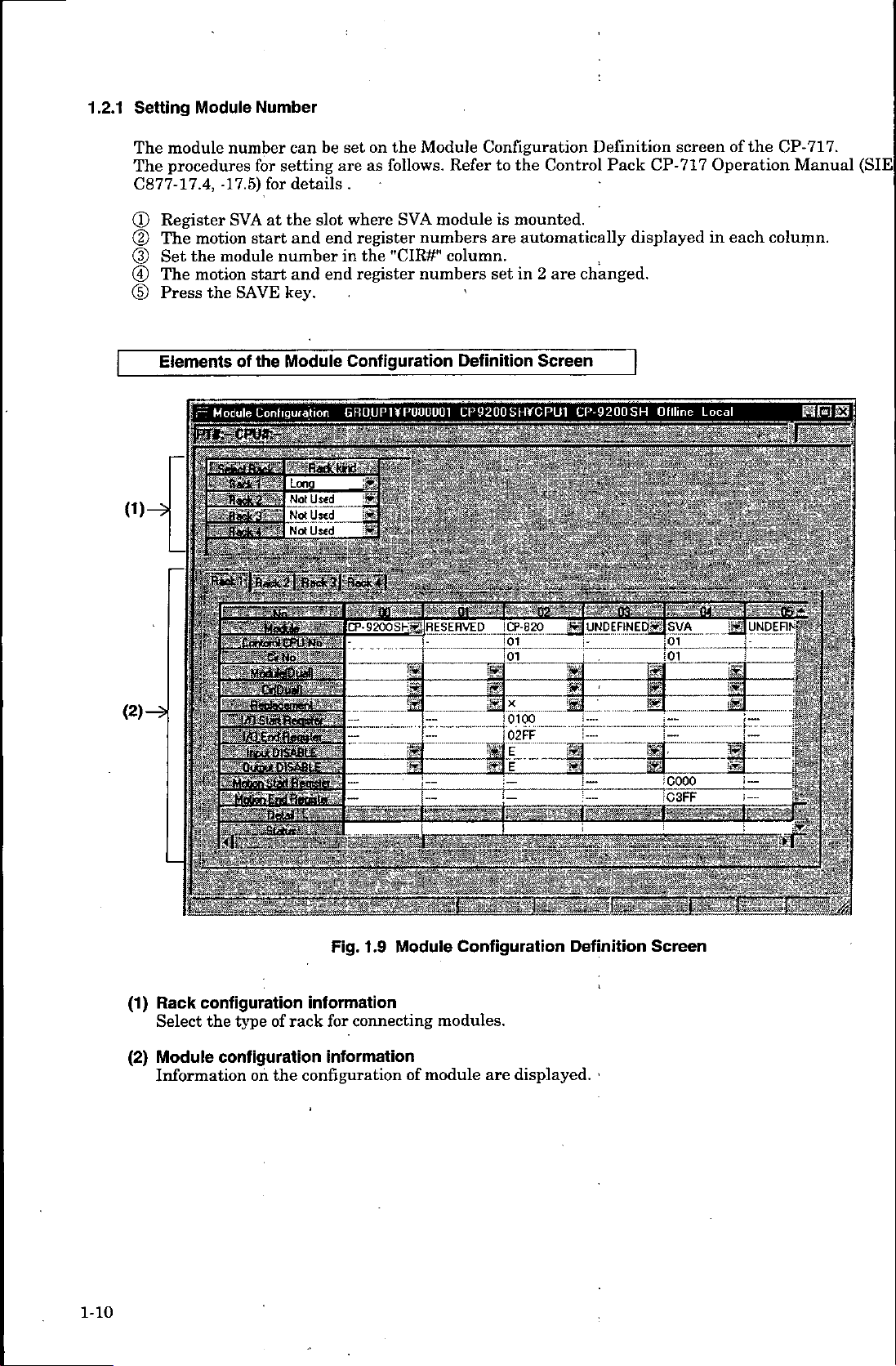

the

from

batchatthe

be

can

the

SVA

head

of

a

programs.

user

simply

by

Then,

be

can

the

machine.

to

has

and

functions

the

frequency

definition

module.

SVA

There

time

are

CPU

head

are

and

then

through

set

moduletothe

of

a

implemented.

the

module

to

high-speed

setting

freely

set

a

of

measurement.

screen"

the

of

following

unchanged

left

the

high-speed

module.

CPU

These

scan.

servo

user

parameters,

program

with

the

the

general-purpose

the

CP-717.

types

three

unless

"Fixed

SVA

scan.

are

parameter

module.

By

These

used

simply

transferred

are

improving

in

counter

of

servo

device

screen"

These

setting

of

are

1-6

Page 16

1.

OVERVIEW

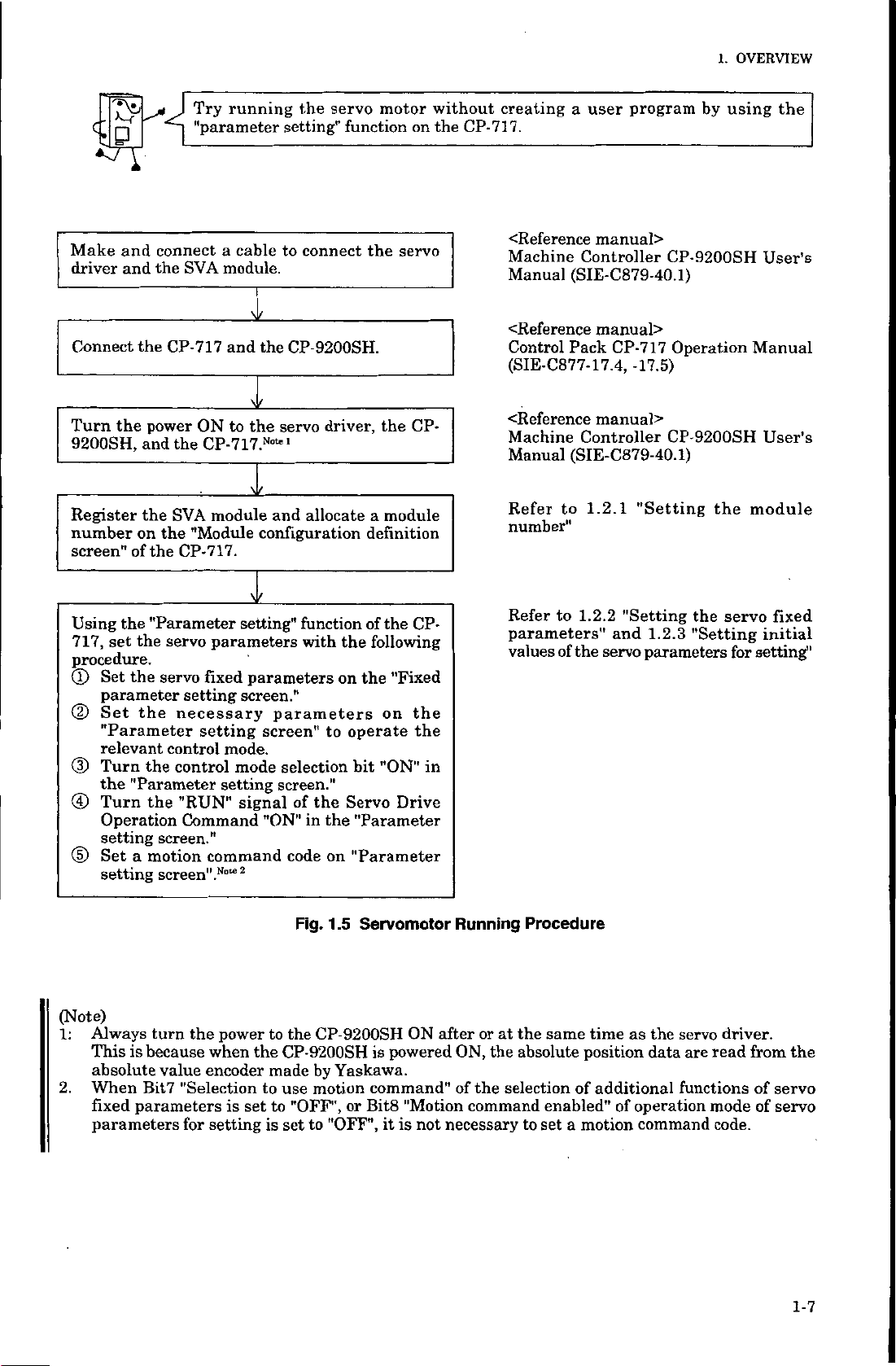

usu

\o

Make

driver

Connect

Turn

9200SH,

Register

numberonthe

screen"

and

and

the

the

power

and

the

of

connect

the

CP-717

the

Try

running

"parameter

a

module.

SVA

and

ON

to

CP-717.Not*

the

SVA

module

"Module

CP-

17.

7

setting"

to

cable

v

the

CP-9200SH.

t

\

the

servo

1

\f

and

configuration

the

servo

connect

driver,

allocate

motor

function

the

the

a

module

definition

on

servo

CP-

without

the

CP-

creating

7

17.

a

<Reference

Machine

Manual

Controller

(SIE-C879-40.1)

<Reference

Control

(SIE-C877-17.4,

Pack

<Reference

Machine

Manual

Refer

number"

Controller

(SIE-C879-40.1)

to

program

user

manual>

manual>

CP-717

manual>

1.2.1

CP-9200SH

Operation

-17.5)

CP-9200SH

"Setting

by

using

the

the

User’s

Manual

User’s

module

Using

set

717,

procedure.

(X)

Set

parameter

Set

CD

"Parameter

relevant

(D

Turn

the

Turn

©

Operation

setting

Set

©

setting

(Note)

Always

1:

This

absolute

When

2.

fixed

parameters

the

"Parameter

the

servo

the

servo

setting

the

necessary

control

the

control

"Parameter

the

"RUN"

Command

screen."

motion

a

screen".

turn

is

because

value

"Selection

Bit7

parameters

for

parameters

fixed

setting

mode.

mode

setting

command

Note

power

the

when

encoder

is

setting

\f

setting"

parameters

screen."

parameters

screen"

selection

screen."

signal

of

"ON"

code

2

the

to

the

CP-9200SH

made

to

use

set

to

"OFF",

is

set

function

with

the

on

to

operate

bit

the

Servo

in

Fig.

"Parameter

the

on

"Parameter

.5

1

CP-9200SH

by

Yaskawa.

motion

or

to

"OFF",

the

of

CP-

following

"Fixed

the

the

on

the

in

"ON"

Drive

Servomotor

ON

powered

is

command"

"Motion

Bit8

it

is

not

Running

after

or

ON,

of

the

command

necessary

Refer

parameters"

values

Procedure

the

at

the

absolute

selection

to

set

1.2.2

to

the

of

same

time

position

additional

of

enabled"

motion

a

"Setting

and

servo

as

of

the

"Setting

1.2.3

parameters

the

servo

are

data

functions

operation

command

servo

for

driver.

read

mode

code.

fixed

initial

setting"

the

from

of

servo

of

servo

1-7

Page 17

U5ÿ

\D

creating

try

Next,

confirmation

test,

a

simple

taking

user

the

program.

simple

speed

We

will

control

discuss

mode

performing

example.

as

an

a

servo

motor

in

the

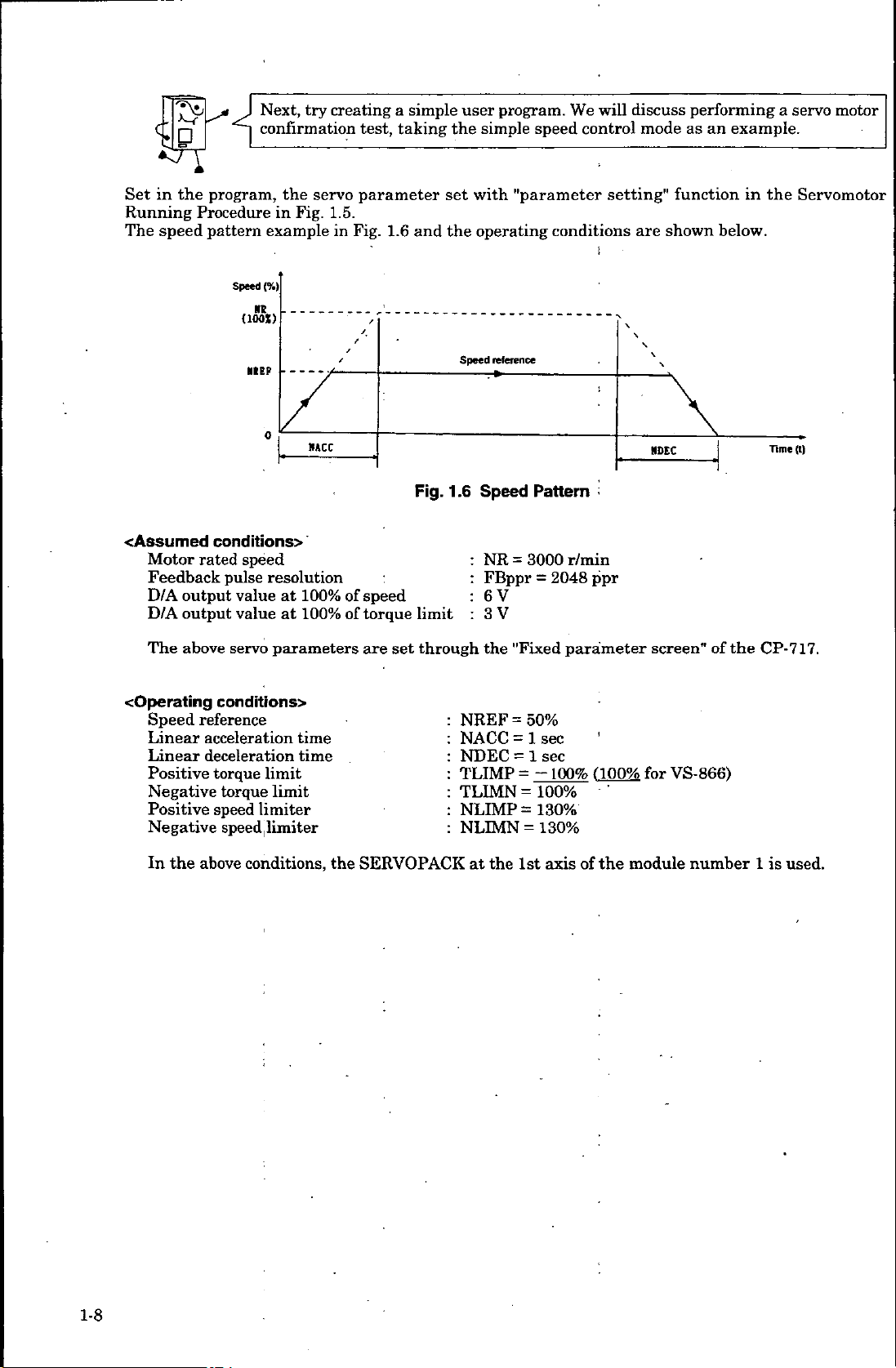

Set

Running

speed

The

<Assumed

Motor

Feedback

output

D/A

D/A

output

The

above

program,

Procedure

pattern

Speed

{1001)

HEP

conditions>

rated

speed

pulse

value

value

servo

the

servo

Fig.

in

example

{%)

0

HACC

resolution

100%

at

100%

at

parameters

parameter

1.5.

Fig.

in

of

of

1.6

speed

torque

are

set

set

the

and

Fig.

1

limit

through

with

operating

Speed

reference

.6

Speed

NR

FBppr

6

V

3

:

V

the

"parameter

conditions

Pattern

r/min

3000

=

2048

=

"Fixed

parameter

setting"

:

ppr

are

»»EC

screen"

function

shown

below.

of

the

in

the

Time

CP-717.

Servomotor

(t)

cOperating

Speed

Linear

Linear

Positive

Negative

Positive

Negative

the

In

conditrons>

reference

acceleration

deceleration

torque

speed

speed

conditions,

limit

limit

limiter

limiter

torque

above

time

time

the

SERVOPACK

NREF

NACC

NDEC

TLIMP

TLIMN

NLIMP

NLIMN

the

at

=

=

=

=

=

=

1st

50%

sec

1

sec

1

-100%

100%

130%

130%

=

'

1100%

axisofthe

VS-866)

for

module

number1is

used.

1-8

Page 18

OVERVIEW

1.

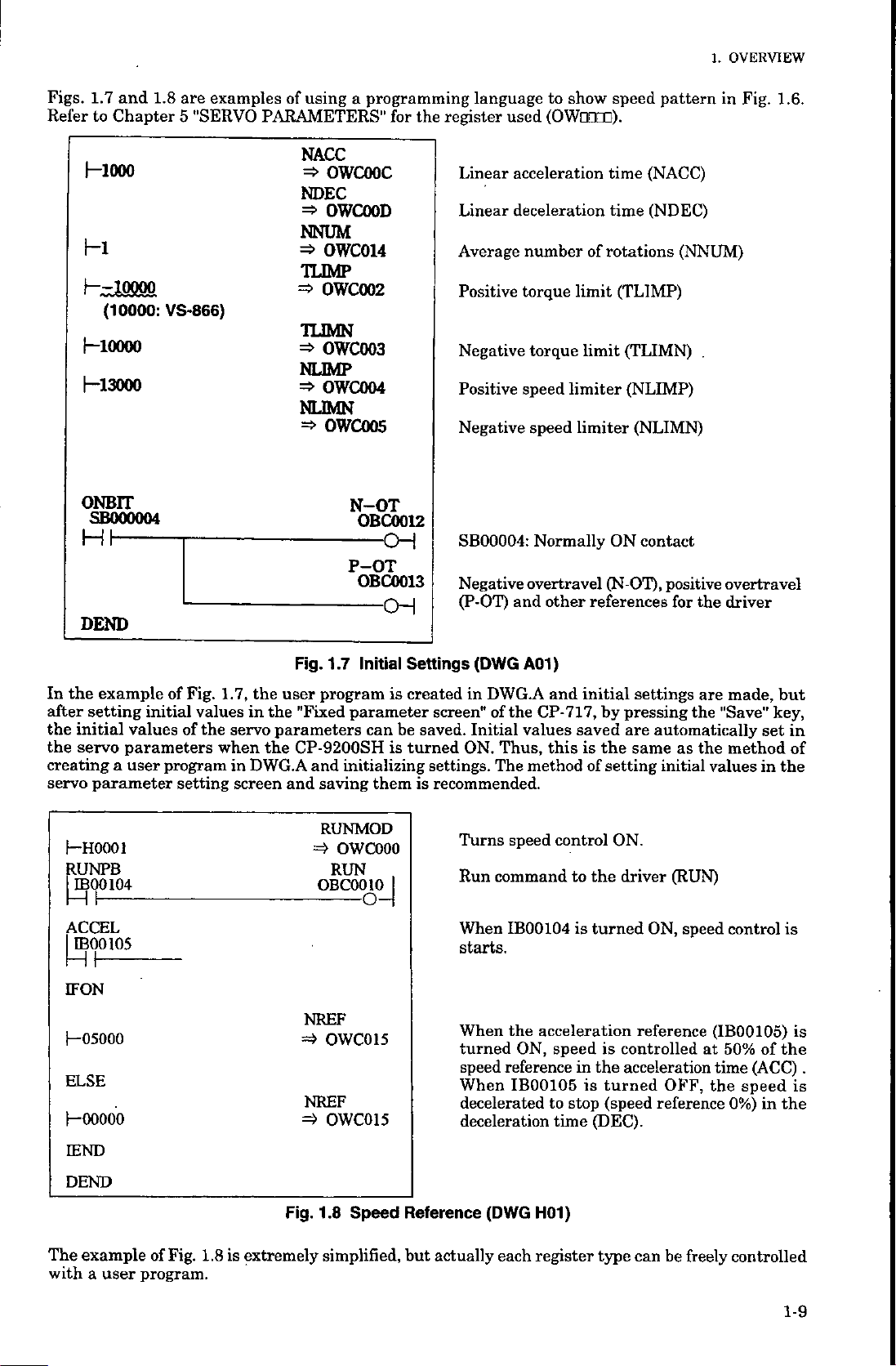

Figs.

Refer

and

1.7

to

Chapter

Hooo

hi

10000

h—

(10000:

—

10000

I

|

13000

—

ONBIT

SB000004

DEND

1.8

are

5

VS-866)

examples

"SERVO

using

of

PARAMETERS"

programming

a

NACC

OWCOOC

=>

NDEC

=s>

OWCOOD

NNUM

=>

OWC014

TUMP

=>

OWC002

UIMN

=>

OWC003

NUMP

=>

OWC004

NUMN

=>

OWC005

N-OT

OBC0012

P-OT

OBC0013

for

OH

the

language

register

Linear

Linear

Average

Positive

Negative

Positive

Negative

SB00004:

Negative

(P-OT)

speed

show

to

(OWODDD).

used

acceleration

deceleration

numberofrotations

torque

torque

speed

speed

Normally

overtravel

and

other

time

time

(TLIMP)

limit

limit

limiter

limiter

ON

(N

references

(TLIMN)

pattern

(NACC)

(NDEC)

(NLIMP)

(NLIMN)

contact

OT),

positive

(NNUM)

.

for

the

Fig.

in

overtravel

driver

1.6.

the

In

setting

after

the

initial

the

servo

creating

servo

f-HOOOl

UNPB

IB

P

ACCEL

I

IB00105

IFON

1-05000

ELSE

(-00000

example

initial

valuesofthe

parameters

a

user

parameter

00104

Fig.

of

values

program

setting

1

.7,

in

servo

when

in

screen

Fig.

the

user

the

parameters

the

DWG.A

and

Initial

1.7

program

"Fixed

parameter

can

CP-9200SH

initializing

and

saving

RUNMOD

=>

them

OWCOOO

RUN

OBCOOlOl

o

NREF

=4

OWC015

NREF

OWC015

=>

Settings

is

created

screen"

be

saved.

is

turned

settings.

is

recommended.

(DWG

in

Initial

ON.

Turns

Run

When

starts.

When

turned

speed

When

decelerated

A01)

DWG.A

of

the

CP-717,

values

Thus,

The

method

speed

command

IB00104

the

acceleration

ON,

reference

IB00105

deceleration

and

initial

by

saved

thisisthe

of

setting

control

the

to

is

turned

speed

is

in

the

is

turned

stop

time

(speed

(DEC).

to

settings

pressing

automatically

are

same

as

initial

ON.

driver

controlled

(RUN)

ON,

speed

reference

acceleration

OFF,

reference

are

the

"Save"

the

values

(IB00105)

at

50%

time

the

made,

key,

set

method

in

control

of

(ACC)

speed

0%)

in

but

in

of

the

is

is

the

.

is

the

END

DEND

The

with

example

user

a

Fig.

of

program.

1.8

is

extremely

Fig.

Speed

1.8

simplified,

Reference

but

actually

(DWG

each

H01)

register

type

can

be

freely

controlled

1-9

Page 19

1.2.1

Setting

The

The

C877-17.4,

Module

module

procedures

Number

number

for

-17.5)

setting

for

be

can

details

set

are

.

on

follows.

as

the

Module

Refer

Configuration

the

to

Control

Definition

Pack

CP-717

screen

the

of

Operation

CP-717.

Manual

(SIE

(D

(D

(3)

©

(5)

0)ÿ

(2)—ÿ

Register

The

motion

the

Set

The

motion

Press

the

Elements

Module

F

i£

,1C—

5

IF

a,

II

it

at

start

start

the

Coni

3''

the

and

number

and

key.

Module

iguiatiori

-

SVA

module

SAVE

of

,

:asd<

s:s

r"r.ua

Contordl

CPU

’C«

:lÿMaifaOita8v7>ÿ

*

•

Ho

c»<Du«n

l/QCntjflaoiiter

OiSASCE

tncui

’

OuiaU

DISABLE

Slat

Register

Motion

where

slot

end

in

end

Configuration

GROUPUf

~

No

..

:

SVA

register

the

"CIR#"

register

module

numbers

column.

numbers

P000001

is

mounted.

are

set

in

'

Definition

9200

CP

S

..

•

automatically

changed.

are

2

Screen

HVCPU1

CP-9200

>

.

-

displayed

Online

SH

-1

.

f.

1

'M

-f

D1

-

'ÿ'g&OSHÿRESERVED

iCP-820

02-

'

'I

SI

UNDEFINEDÿ

Hj

foi

_

[0100

EI=EJ:_

fiK

'"~jT

IpVA

01

:01

i.““

cooo

each

in

Local

nil.

column.

.

..

;

....

.....

-

--

JW

.....

v

‘

1

lijuNDEFlNi

-*

“

t-

vos"*

:

1

a

•

;

j

i

Rack

(1)

Select

Module

(2)

Information

i|

'

configuration

type

on

of

the

the

configuration

Fig.

information

rack

configuration

connecting

for

information

1.9

Module

of

module

v

*F_

Configuration

modules.

are

-

Definition

displayed.

Screen

1-10

Page 20

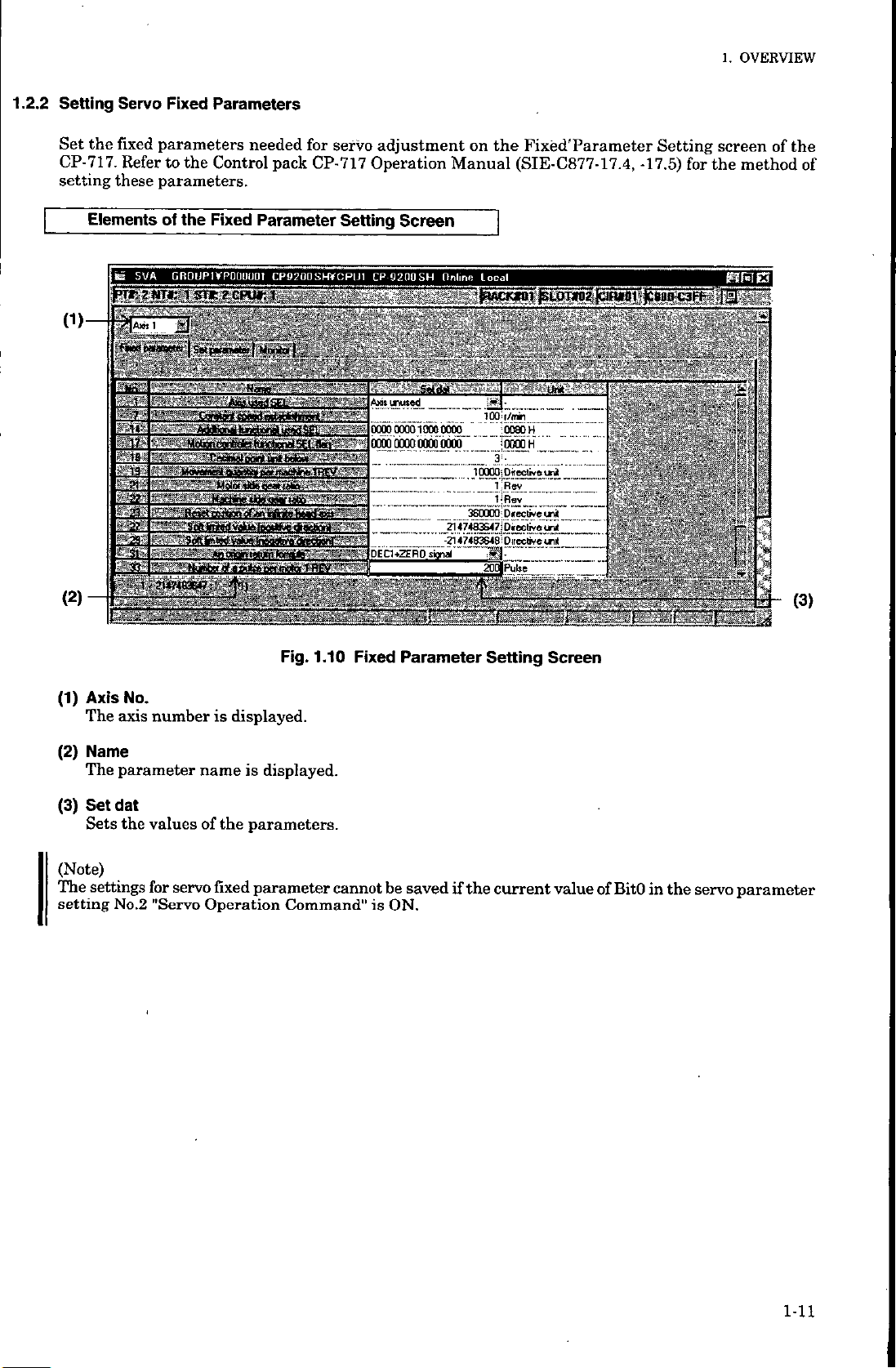

OVERVIEW

1.

Setting

Set

the

CP-

7

17.

setting

Elements

0)

(2)

Servo

fixed

Refer

these

SVA

\ii

rTr-

Axis

I

I

gat*

i-18-

y'22~

mm

a

33

Fixed

Parameters

parameters

the

to

parameters.

the

of

GROUP1¥POUUU01

NTr

2

i

srr

1

needed

Control

Fixed

?

ow

Parameter

mmP

AT

•

;

•

•

•

~

:

V'MoeentMrÿtottfentiSELItaa

*:T’

;

-

.

TSdlifaiiw

_

'

'

Curalirt

-tetWeninl

—

*noBaniepiniloi)iifc~

"

faceuttrisn

tawed

jelneoatÿ

'

'

*

"

”

-

for

servo

pack

CP-717

Setting

CP9200SH*CPU1

1

..

1

'

•

Men

dfecfaart'

.

*

‘

’’

;i

'

-

V

nriatA’rfmnrt

fw

*tmBWiTBEVT~-

*

adjustment

Operation

Screen

CP

9200SH

S

0000

00001000

~

ooooooroixrapoog

‘>

’

.....

-

”c”z"*“"

[rÿi

’

the

on

Manual

Online

‘

0000

.....

:i

Fixed'Parameter

(SIE-C877-17.4,

Local

SI

•

lOOii/inii

u-m

:

4

__

pE:r

'

_

Setting

-17.5)

for

«

screen

the

method

HR

l

Cl

:

of

the

of

:

:::

MMm

mm

..

Is

-

-

jv

-

>

i

.

—

*«

mssssi

iv

;

3-

O)

Axis

(1)

The

(2)

Name

The

(3)

Set

Sets

(Note)

The

settings

setting

No.

axis

number

parameter

dat

the

valuesofthe

for

No.2

"Servo

servo

displayed.

is

is

name

parameters.

fixed

Operation

Fig.

displayed.

parameter

Command"

1.10

Fixed

cannot

Parameter

be

savedifthe

is

ON.

Setting

current

Screen

value

of

BitO

in

the

servo

parameter

1-11

Page 21

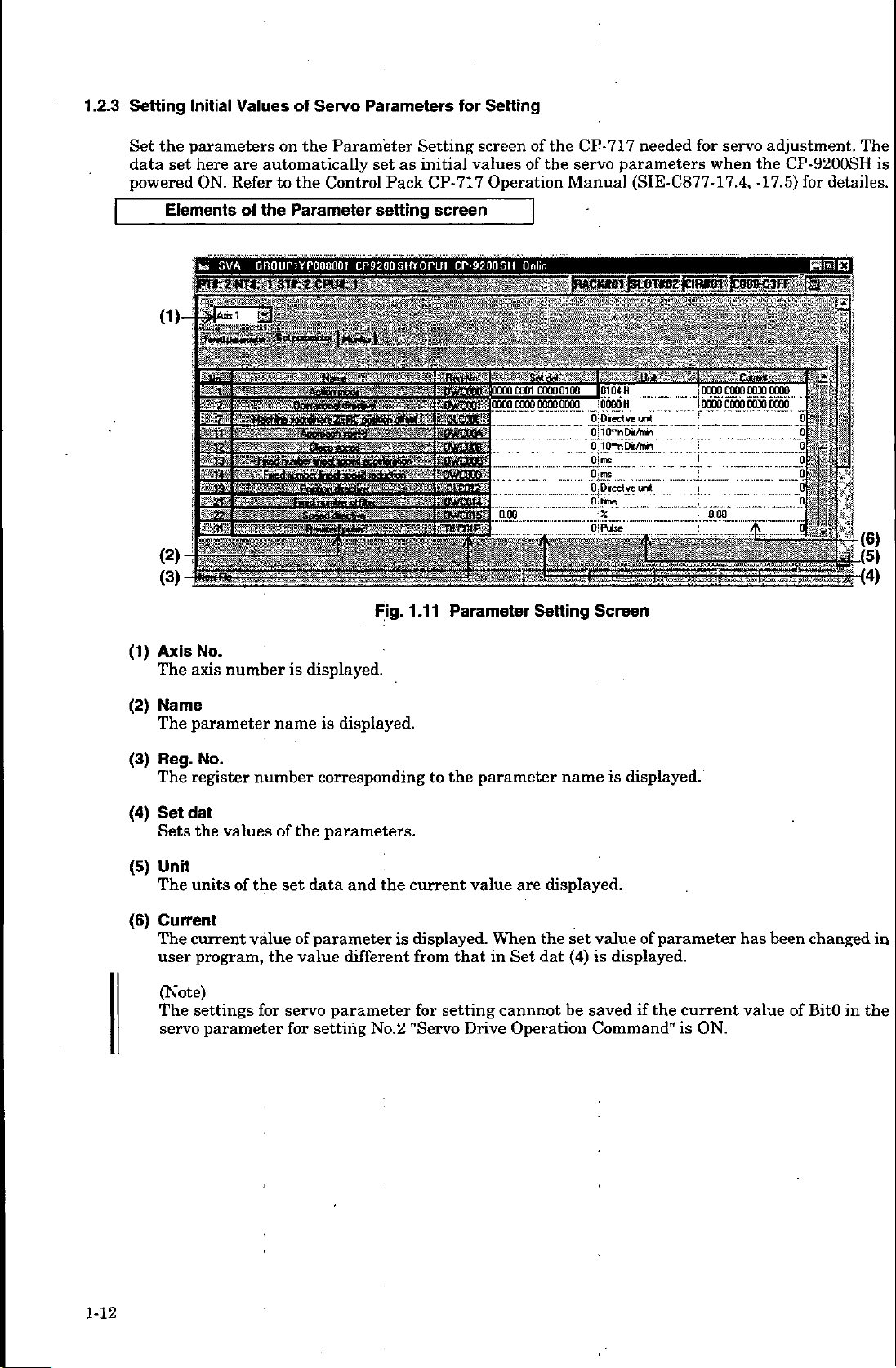

1.2.3

Setting

Initial

Values

of

Servo

Parameters

for

Setting

the

Set

data

set

powered

Elements

(3)

parameters

here

are

ON.

Refer

of

SVA

tes

r~

nr-

777

777:

•

L:

•

7

•

•

•

-F

Rl

1

the

on

automatically

to

the

GROUPJVPOOOOOI

-f,

•

•

Z".;'

Parameter

the

Control

Parameter

m

‘

Setting

initial

as

set

Pack

setting

CP92005I«CPUI

.-•••

1

.11

Fig.

screen

values

CP-717

Operation

screen

CP

9200SH

:-mi/rÿ;8oooci

Mÿm-‘loooc

cum

h&x

cote'

SSB

vmcmr

mmm

Parameter

of

the

CP-717

the

of

servo

Manual

Qrlin

0100

QOOC

-

'I

I01

looooH

.Pis?-

0.

:?

OiPube

ouoi

0000 0000

iido

ccou

-

zzzz*~<

mmm

Setting

Screen

needed

parameters

(SIE-C877-17.4,

-ÿtMt

H

ye

.

'

~

in*

•

-

o<

Direct

z

-

m

is

for

when

servo

-

-URO*

adjustment.

the

CP-9200SH

-17.5)

for

‘

~

F

;

1!

.9

Hi

9

9

0

;F

Jft!

The

detailes.

1

1

-

-

a

Z!

(6)

-

r

.

is

(1)

(2)

(3)

(4)

(5)

(6)

Axis

No.

axis

The

Name

parameter

The

No.

Reg.

register

The

Setdat

the

Sets

Unit

units

The

Current

The

current

program,

user

(Note)

settings

The

servo

number

number

valuesofthe

the

of

value

for

parameter

is

name

set

the

servo

for

of

value

displayed.

displayed.

is

corresponding

parameters.

data

and

the

parameter

different

parameter

setting

No.2

to

current

displayed.

is

from

for

"Servo

the

value

that

setting

Drive

parameter

are

the

When

dat

Set

in

cannnot

Operation

is

name

displayed.

value

set

(4)

is

be

savedifthe

Command"

displayed.

of

parameter

displayed.

current

is

ON.

has

value

been

of

changed

BitO

in

in

the

1-12

Page 22

1.

OVERVIEW

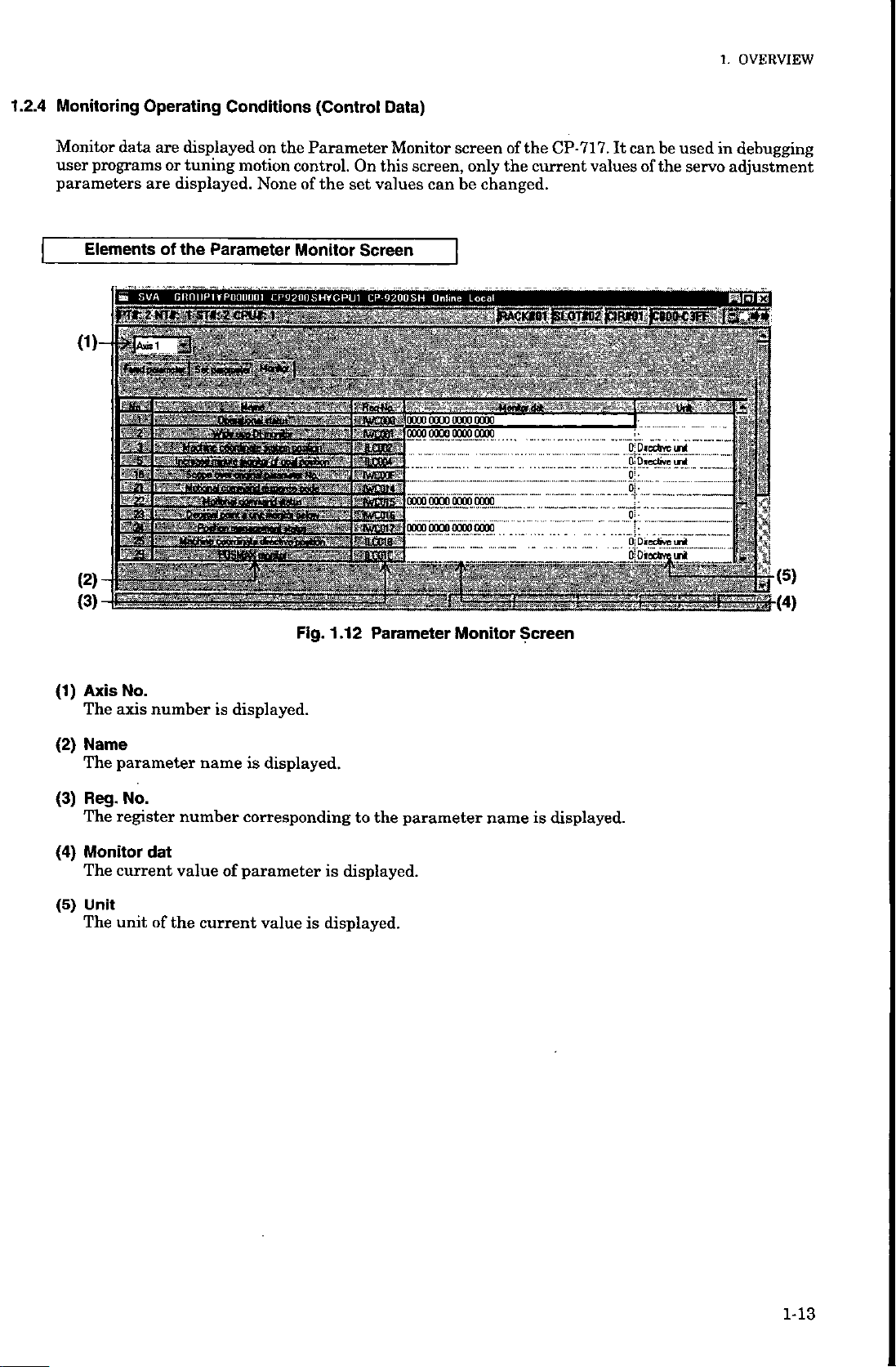

Monitoring

Monitor

user

parameters

data

programs

Elementsofthe

(D

'

>'!

(2)

(3)

Operating

displayed

are

tuning

or

are

displayed.

SVA

GIIQIJPIYPOOUOOI

"tv

-

-

‘

3

3S»inftfei

1

1-

.v

Conditions

motion

Parameter

'’jqv

•

~

OBbiiiiyMltMm1*

-

(Control

the

on

Parameter

control.Onthis

Noneofthe

Monitor

CP9200SHYCPU1

V*

....

.‘rÿr?;

8cn*':~

v

»w?*y

_

Data)

Monitor

values

set

Screen

CP-920QSH

.

.....

>

SWCOOC

|WC8W-

amass

"g.COM

!

’

’

riWCOOF

;:;<wrnn

gwcms

£3WC0tfi-:

?

news

gtCOICi

screen

only

be

changed.

Local

the

screen,

can

m

fiACKIBI

_

|

0000

0000

(TO

rao

ooro

60000660

nmacnoggqogmTr

0000

0000

00000000

oooo

Hetiadik

-

of

the

current

CP-717.

It

values

ElOTOTZ

jCtRMI

...

can

of

jC8P(K3If

0!

be

the

used

servo

debugging

in

adjustment

jjQFi

;

il

1

s

Hgf-(4)

(5)

(1)

(2)

(3)

(4)

(5)

Axis

No.

The

axis

Name

The

parameter

No.

Reg.

register

The

Monitor

The

current

Unit

unit

The

number

number

dat

value

of

the

displayed.

is

is

name

corresponding

parameter

of

current

Fig.

displayed.

is

value

1

Parameter

.12

to

the

displayed.

is

displayed.

Monitor

parameter

name

Screen

displayed.

is

M3

Page 23

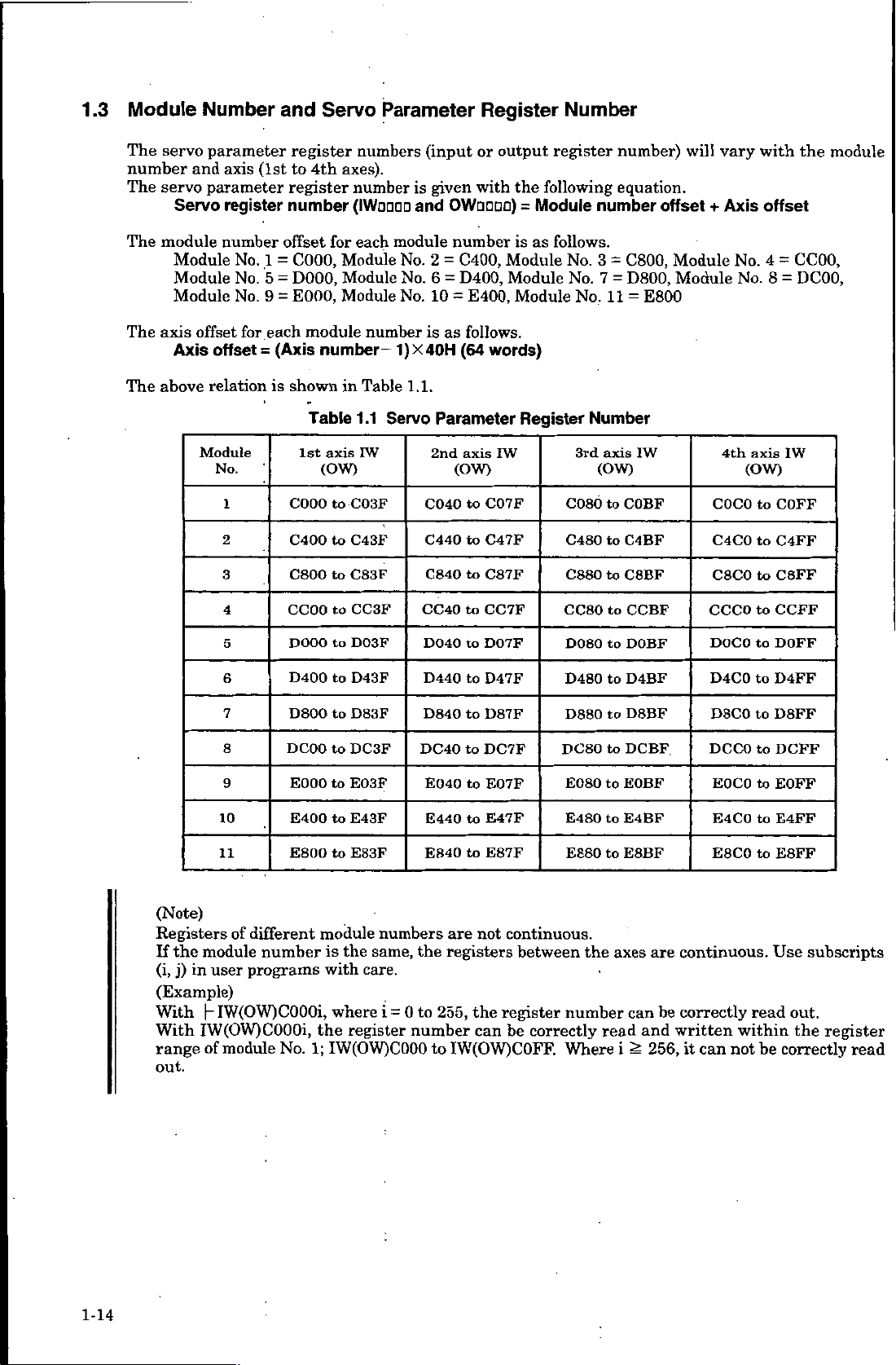

1.3

Module

Number

and

Servo

Parameter

Register

Number

The

servo

number

The

servo

The

module

Module

Module

Module

The

axis

above

The

parameter

and

axis

parameter

Servo

register

number

No.

No.

No.

for

offset

Axis

offset

relationisshown

Module

No.

1

2

3

4

(1st

1

5

9

each

(Axis

=

register

to

register

number

offset

C000,

=

D000,

=

E000,

=

module

Table

1st

C000

C400

C800

CC00

axes).

4th

number

(IWODOD

for

Module

Module

Module

number-

in

axis

(OW)

C03F

to

C43F

to

C83F

to

CC3F

to

numbers

each

module

No.

No.

No.

number

1)X40H

Table

1.1.

1.1

Servo

IW

(input

is

and

given

OWnoao)

or

with

number

0400,

=

2

6

D400,

=

E400,

10

=

follows.

as

is

(64

Parameter

axis

2nd

(OW)

to

C040

C440

to

C840toC87F

to

CC40

output

the

is

Module

Module

Module

words)

IW

C07F

C47F

CC7F

register

following

Module

=

as

follows.

No.

Register

C080

C480

C880

CC80

number

No.

No.

Number

3rd

number)

equation.

3

C800,

=

D800,

7

=

11

=

axis

(OW)

COBF

to

C4BF

to

C8BF

to

to

CCBF

E800

IW

will

offset

Module

Module

vary

Axis

+

No.

No.

4th

COCO

C4C0

C8C0

CCCO

with

axis

(OW)

to

to

to

to

offset

4

=

8

=

IW

COFF

C4FF

C8FF

CCFF

module

the

CC00,

DC00,

(Note)

Registers

the

If

module

(i,

j)

user

in

(Example)

|-

With

IW(OW)C000i,

With

range

of

out.

5

6

7

8

9

10

11

of

DOOO

D400

D800

DCOO

E000

E400

E800

different

numberisthe

programs

IW(OW)C000i,

module

No.

to

D03F

D43F

to

to

D83F

DC3F

to

E03F

to

to

E43F

E83F

to

module

numbers

same,

with

care.

where

i

register

the

IW(OW)COOO

1;

D040

D440

D840toD87F

DC40toDC7F

E040

E440

E840

are

the

registers

to

0

255,

=

number

IW(OW)C0FF.

to

to

to

to

to

to

the

D07F

D47F

E07F

E47F

E87F

not

register

can

D080

D480

D880

DC80

E080

E480

E880

continuous.

between

number

correctly

be

Where

the

to

to

to

to

EOBF

to

to

E4BF

E8BF

to

axes

read

i

DOBF

D4BF

D8BF

DCBF

can

and

256,

continuous.

are

correctly

be

written

it

DOCO

D4C0

D8C0

DCCO

E0C0

E4CO

E8C0

can

read

within

not

to

to

to

to

to

to

to

be

DOFF

D4FF

D8FF

DCFF

EOFF

E4FF

E8FF

Use

subscripts

out.

register

the

correctly

read

1-14

Page 24

1.

OVERVIEW

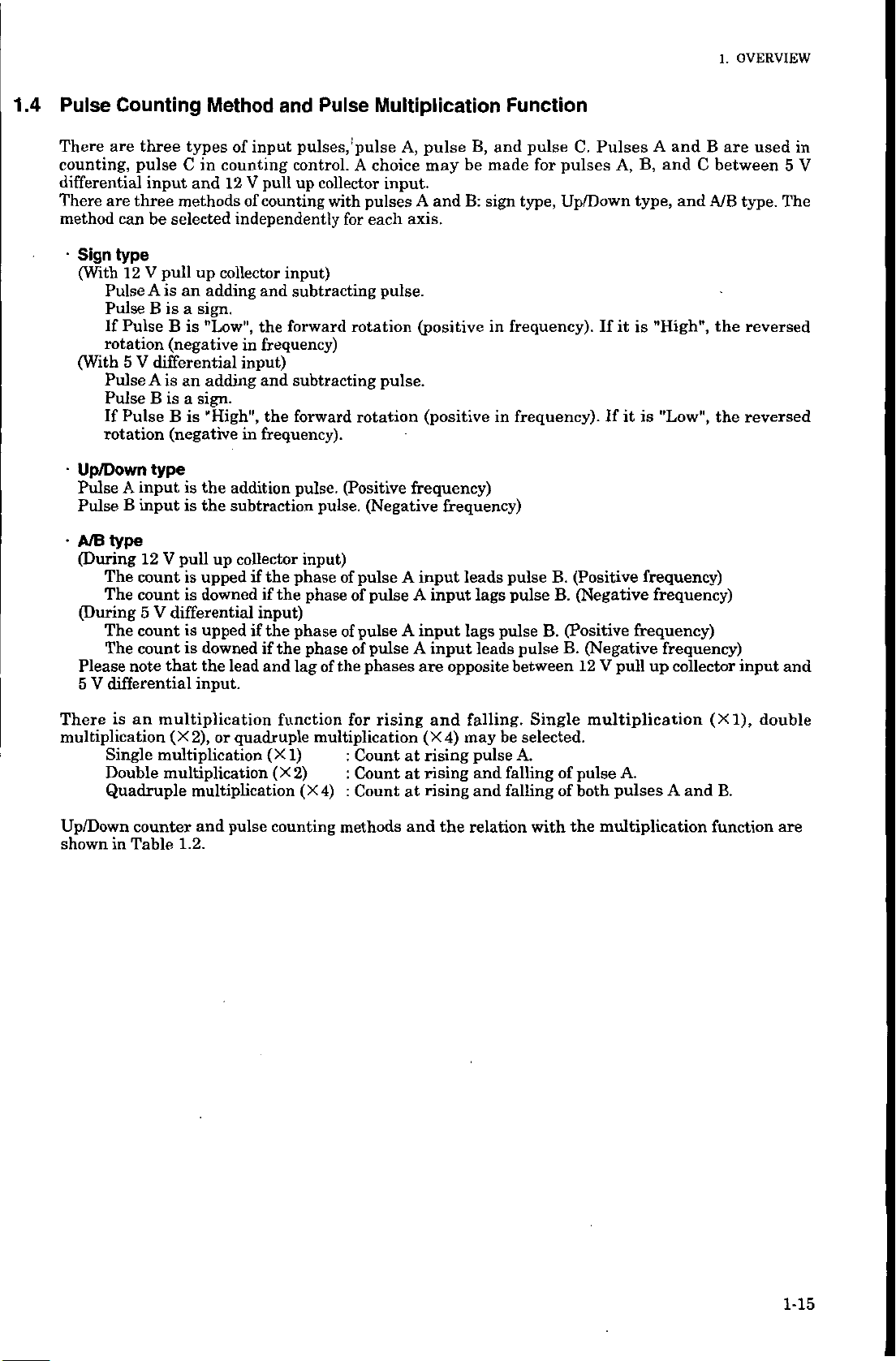

1.4

Pulse

There

Counting

are

counting,

differential

are

There

Sign

(With

can

type

12

method

•

Pulse

Pulse

Pulse

If

rotation

(With

5

Pulse

Pulse

Pulse

If

rotation

Up/Down

A

Pulse

B

Pulse

•

type

A/B

(During

The

The

(During

The

The

Please

differential

5

V

three

pulse

input

three

be

selected

V

pull

is

A

is

B

B

(negative

V

differential

A

is

is

B

B

(negative

type

input

input

12

V

count

count

V

differential

5

count

count

that

note

Method

types

counting

C

in

and

12

methods

up

collector

adding

an

sign.

a

"Low",

is

adding

an

sign.

a

"High",

is

is

the

addition

is

subtraction

the

pull

up

is

upped

is

downed

upped

is

is

downed

the

lead

input.

and

Pulse

input

of

pulses,

control.

V

up

pull

counting

of

collector

independently

input)

subtracting

and

the

forward

frequency)

in

input)

subtracting

and

the

forward

frequency).

in

pulse.

pulse.

if

the

the

input)

phase

phase

collector

if

input)

phase

the

if

if

phase

the

and

lag

of

Multiplication

'pulse

choice

A

input.

pulses

with

each

for

pulse.

rotation

pulse.

rotation

(Positive

(Negative

pulse

of

pulse

of

pulse

of

pulse

of

phases

the

pulse

A,

may

and

A

axis.

(positive

(positive

frequency)

frequency)

A

input

input

A

A

input

input

A

opposite

are

B,

made

be

sign

B:

in

leads

lags

lags

leads

Function

pulse

and

for

type,

frequency).

frequency).

in

pulse

pulse

pulse

B.

pulse

between

Pulses

C.

pulses

Up/Down

(Positive

B.

(Negative

B.

(Positive

(Negative

B.

12

A,

it

If

it

If

pull

V

A

and

B,

and

C

and

type,

"High",

is

is

"Low",

frequency)

frequency)

frequency)

frequency)

up

collector

B

are

between

type.

AJB

the

reversed

the

reversed

input

used

in

5

V

The

and

There

is

an

multiplication

Single

Double

Quadruple

Up/Down

shown

in

counter

Table

multiplication

(X2),

quadruple

or

multiplication

multiplication

multiplication

pulse

and

1.2.

function

(XI)

(X

2)

(X4)

counting

rising

for

multiplication

Count

:

:

Count

:

Count

methods

at

at

at

and

and

(X4)

rising

rising

rising

the

falling.

may

be

pulse

and

and

relation

Single

selected.

A.

falling

falling

with

multiplication

of

pulse

of

pulses

both

the

multiplication

A.

A

and

(XI),

B.

function

double

are

1-15

Page 25

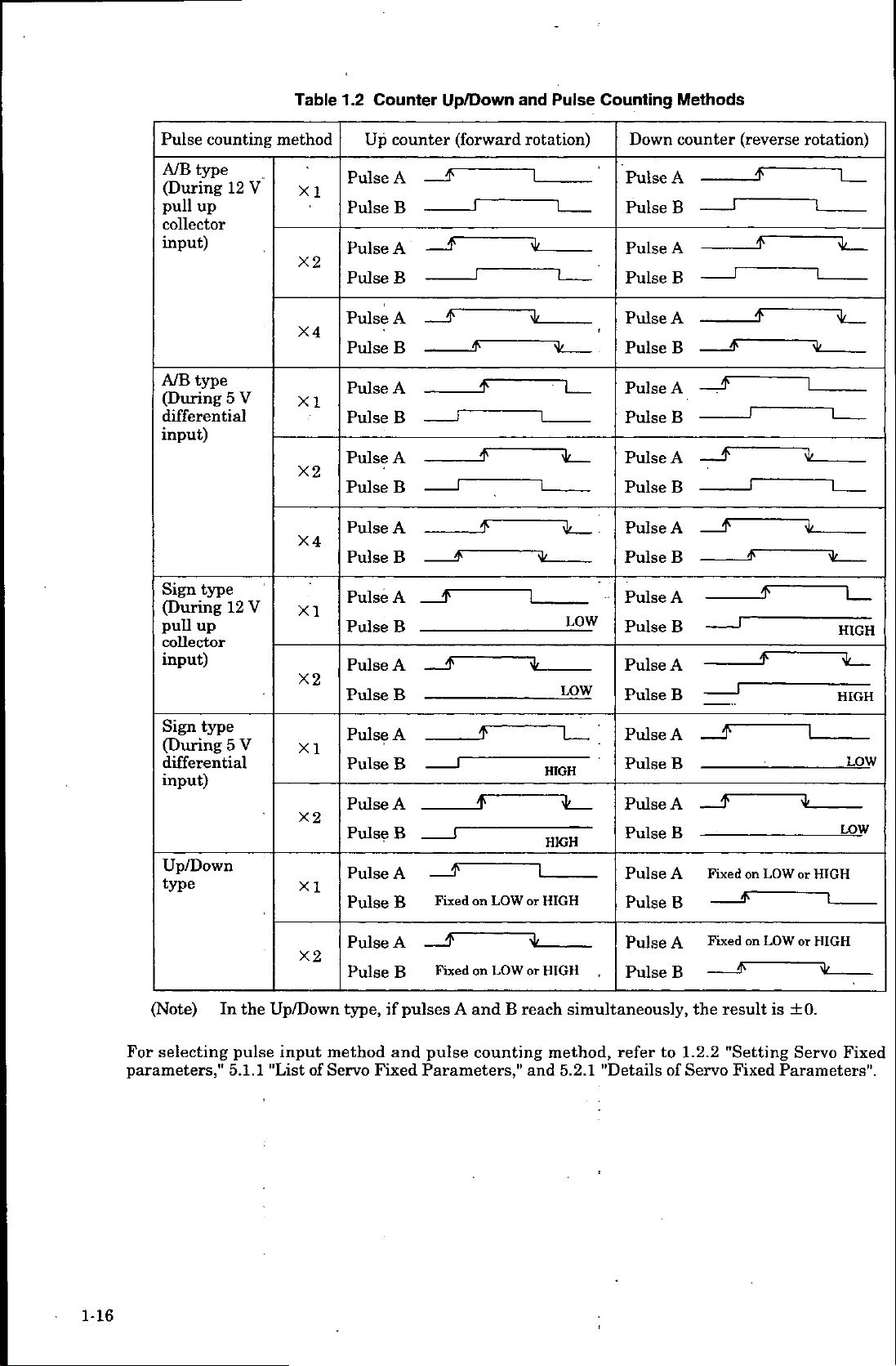

Table

1.2

Counter

Up/Down

and

Pulse

Counting

Methods

counting

Pulse

A/B

type

(During

pull

up

collector

input)

A/B

type

(During

differential

input)

type

Sign

(During

pull

up

collector

input)

12

5

12

V

V

V

method

XI

X2

X4

XI

X2

X4

XI

X2

Up

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

counter

A

—

B

A

—

B

A

—

B

A

B

A

B

A

B

_

A

B

A

—

B

(forward

F

S

$

J

$

5

f

f

jf

rotation)

l

1L

1L

LOW

LOW

Down

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

counter

A

B

A

B

A

B

A

—

B

-

A

—

B

-

A

—

B

A

B

A

B

-ÿr

f

(reverse

jf

S

JF

$

rotation)

_

h

"\k

1

HIGH

HIGH

Sign

type

(During

differential

input)

Up/Down

type

(Note)

selecting

For

parameters,"

5

In

V

the

pulse

5.1.1

XI

X

2

XI

X2

Up/Down

input

"List

of

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

type,

method

Servo

A

B

A

B

A

B

A

B

pulses

if

and

Fixed

I

J

Fixed

—

Fixed

pulse

Parameters,"

f

A

LOW

on

LOW

on

and

B

counting

HIGH

HIGH

or

HIGH

HIGH

or

simultaneously,

reach

method,

and

5.2.1

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

Pulse

,

Pulse

refer

"Details

to

A

B

A

B

A

B

A

B

of

—

-

—

——

Fixed

Fixed

the

1.2.2

Servo

f

f

on

on

result

"Setting

Fixed

1L

LOW

or

HIGH

1

LOW

HIGH

or

±

is

0.

Servo

Parameters".

LOW

LOW

Fixed

1-16

Page 26

OVERVIEW

1.

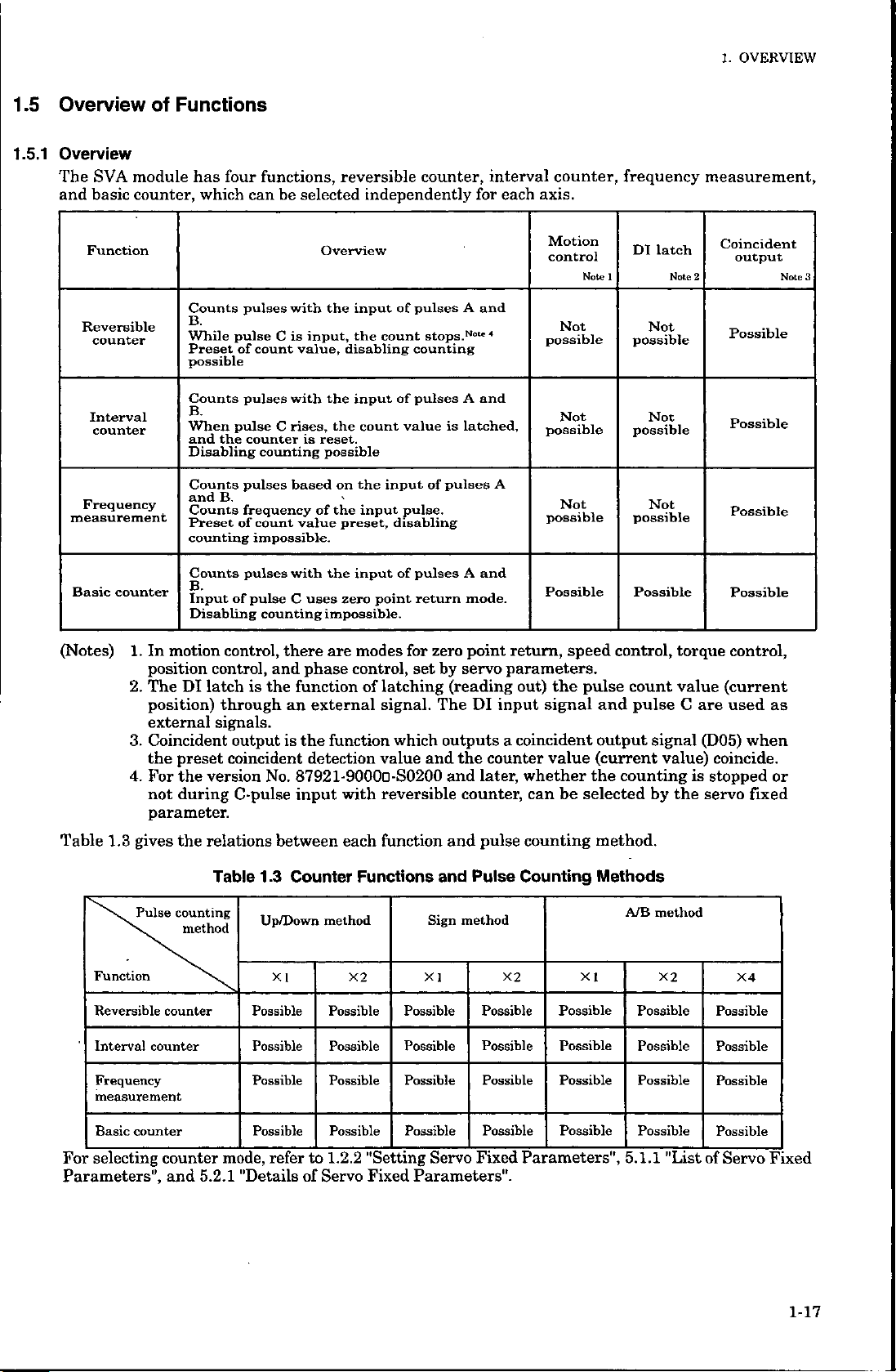

Overview

Overview

The

SVA

and

basic

Function

Reversible

counter

Interval

counter

Frequency

measurement

Basic

counter

Functions

of

module

counter,

four

has

which

Counts

B.

While

Preset

possible

Counts

B.

When

and

the

Disabling

Counts

and

B.

Counts

Preset

counting

Counts

B.

Input

Disabling

functions,

can

pulses

pulse

of

count

pulses

pulse

counter

counting

pulses

frequency

of

count

impossible.

pulses

pulse

of

counting

be

selected

Overview

the

with

input,

C

is

value,

the

with

rises,

C

is

reset.

possible

basedonthe

of

value

with

the

C

uses

impossible.

reversible

independently

input

the

count

disabling

input

the

count

inputofpulses

'

input

the

preset,

zero

disabling

input

point

pulses

of

counting

pulses

of

value

pulse.

pulses

of

return

counter,

A

N°"

stops.

A

latched,

is

A

interval

for

and

4

and

and

mode.

each

A

counter,

axis.

Motion

control

Not

possible

Not

possible

Not

possible

Possible

Note

frequency

DI

1

Not

possible

Not

possible

Not

possible

Possible

latch

Note

measurement,

Coincident

output

2

Possible

Possible

Possible

Possible

Note

3

(Notes)

Table

Function

Reversible

Interval

Frequency

measurement

1.

motion

In

position

2.

TheDIlatchisthe

position)

external

3.

Coincident

the

preset

4.

For

the

during

not

parameter.

gives

Pulse

\

counter

the

counting

method

counter

1.3

control,

control,

through

signals.

output

coincident

version

C-pulse

relations

1.3

Table

Possible

Possible

Possible

there

and

function

an

is

phase

the

modes

are

control,

external

function

of

detection

87921-9000D-S0200

No.

input

with

between

Counter

Up/Down

XI

each

Functions

method

X2

Possible

Possible

Possible

for

zero

by

set

latching

signal.

value

which

The

outputs

and

reversible

function

and

Sign

XI

Possible

Possible

Possible

point

servo

(reading

DI

the

counter

later,

and

counter,

pulse

and

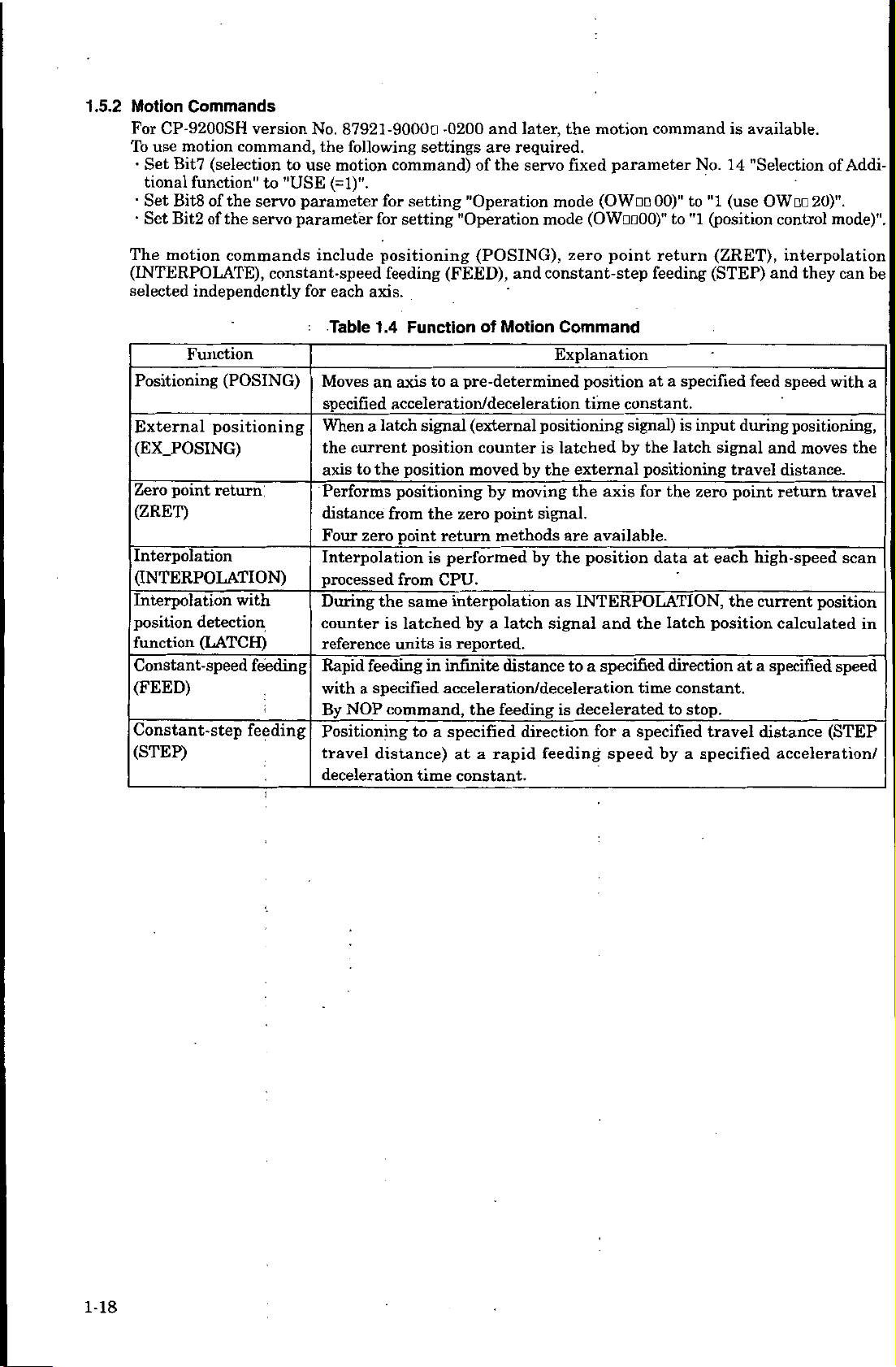

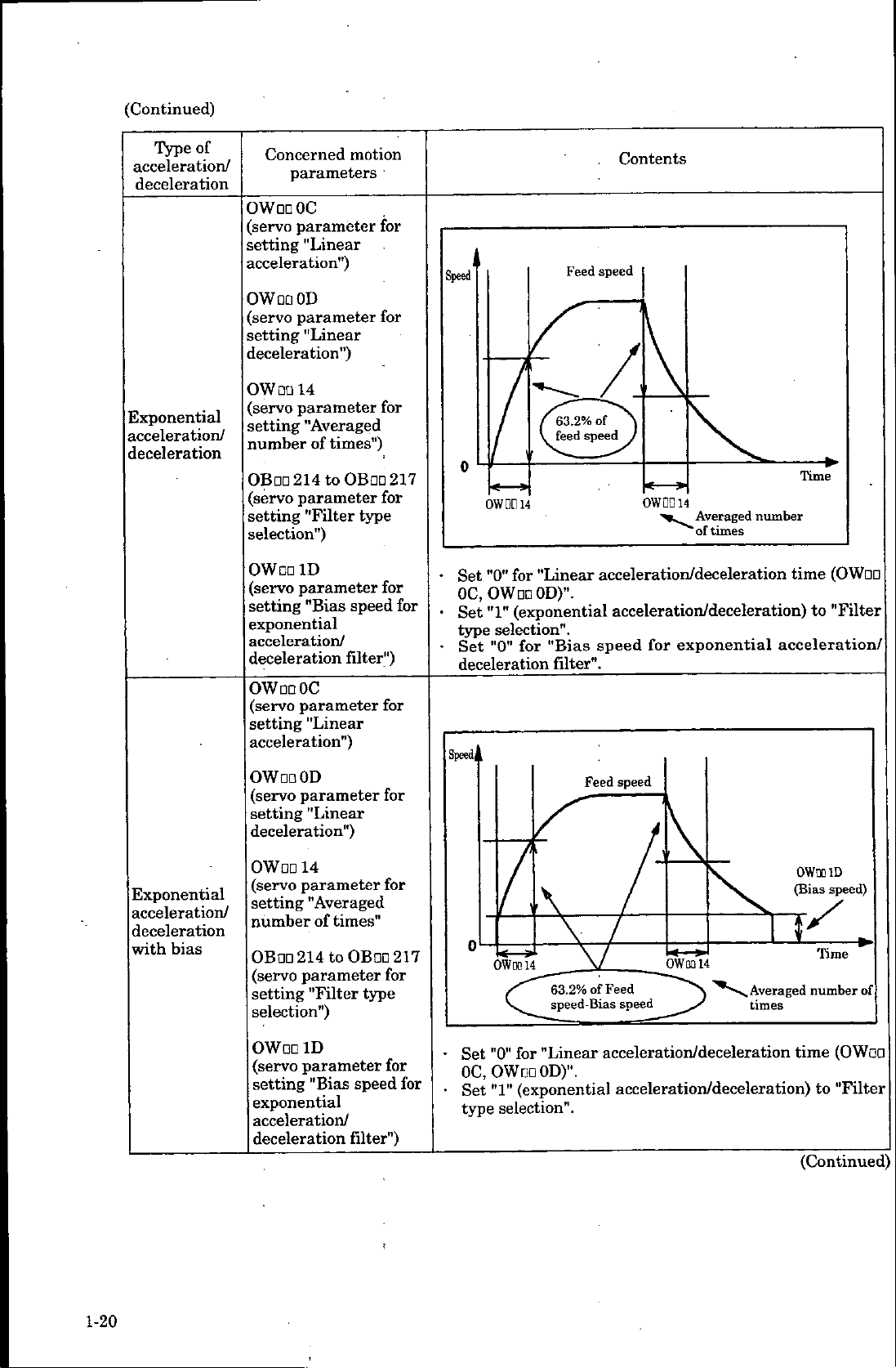

Pulse