Page 1

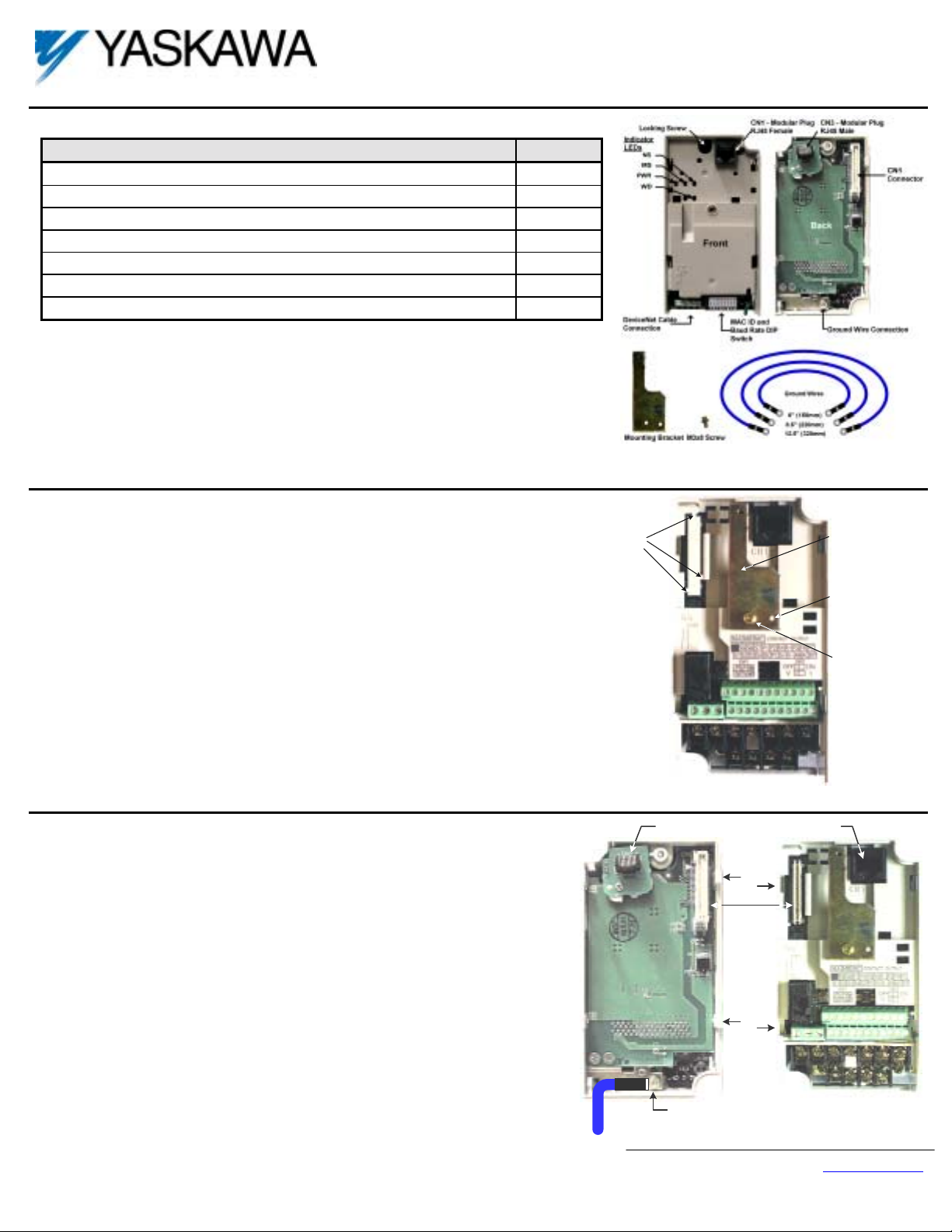

DeviceNetTM Option Card and Ring Kit

CM052

Unpack the V7 DeviceNet Option and verify that all components are present and undamaged.

!

Part Qty .

V7 DeviceNet Option Card and Ring Kit 1

Mounting Bracket 1

M3×8 Screw 1

6” Ground Wire (150mm) 1

8.5” Ground Wire (220mm) 1

12.5” Ground Wire (320mm) 1

Installation Guide (IG.V7.13) 1

Connect power to the drive and verify that the drive functions correctly. This includes running the

!

drive from the operator keypad. Refer to the V7 Technical Manual, TM.V7.01, for information on

connecting and operating the drive.

Installing the V7 DeviceNet Option obscures the I/O, power and motor terminals on the V7 drive. It

!

is necessary to make these connections prior to installing the V7 DeviceNet Option. Check that all

connections have been made and are working correctly before continuing.

Remove power from the drive and wait for the charge lamp to be completely extinguished. Wait at

!

least five additional minutes for the drive to be completely discharged. Measure the DC BUS

voltage and verify that it is at a safe level.

Remove the CN2

protective cover by

carefully clipping

the three tabs

CN2 Cover

Option

mounting

bracket

Prepare the drive for the V7 DeviceNet Option.

!

# Remove the V7 operator keypad and terminal cover.

# Remove the plastic protective cover from over the CN2 connector and install

the option mounting bracket provided on to the drive.

Connect the ground wire provided to the ground connector on the back of the V7

!

DeviceNet Option. Select the ground wire of appropriate length for the drive.

Mount the V7 DeviceNet Option onto the drive

!

# Align the CN1 connector on the back of the option with its mating CN2

connector on the front of the drive.

# Simultaneously align the CN3 connector, the male RJ45 connector, on the back

of the option with the CN1 connector, the female RJ45 connector, on the front

of the drive.

# Align the tabs on the option with their corresponding slots on the front of the

drive.

# Press the option and the drive together until the tabs lock into their associated

slots.

# Secure the option to the V7 drive by tightening the locking screw at the top-

center of the option.

# Connect the ground wire from the V7 DeviceNet Option to ground terminal on

the V7 drive.

E

Ground Wire

CN3 - Male RJ45

Connector

CN1 - CN2

Ground Terminal

Tab

Tab

CN1 - Female

RJ45 Connector

Slot

Slot

Align hole in

mounting bracket

with nib on front of

the V7 drive

Secure mounting

bracket to V7 drive

with M3x8 screw

Yaskawa Electric America, Inc – www.drives.com

IG.V7.13, Page 1 of 5

Date: 07/01/04, Rev: 04-07

Page 2

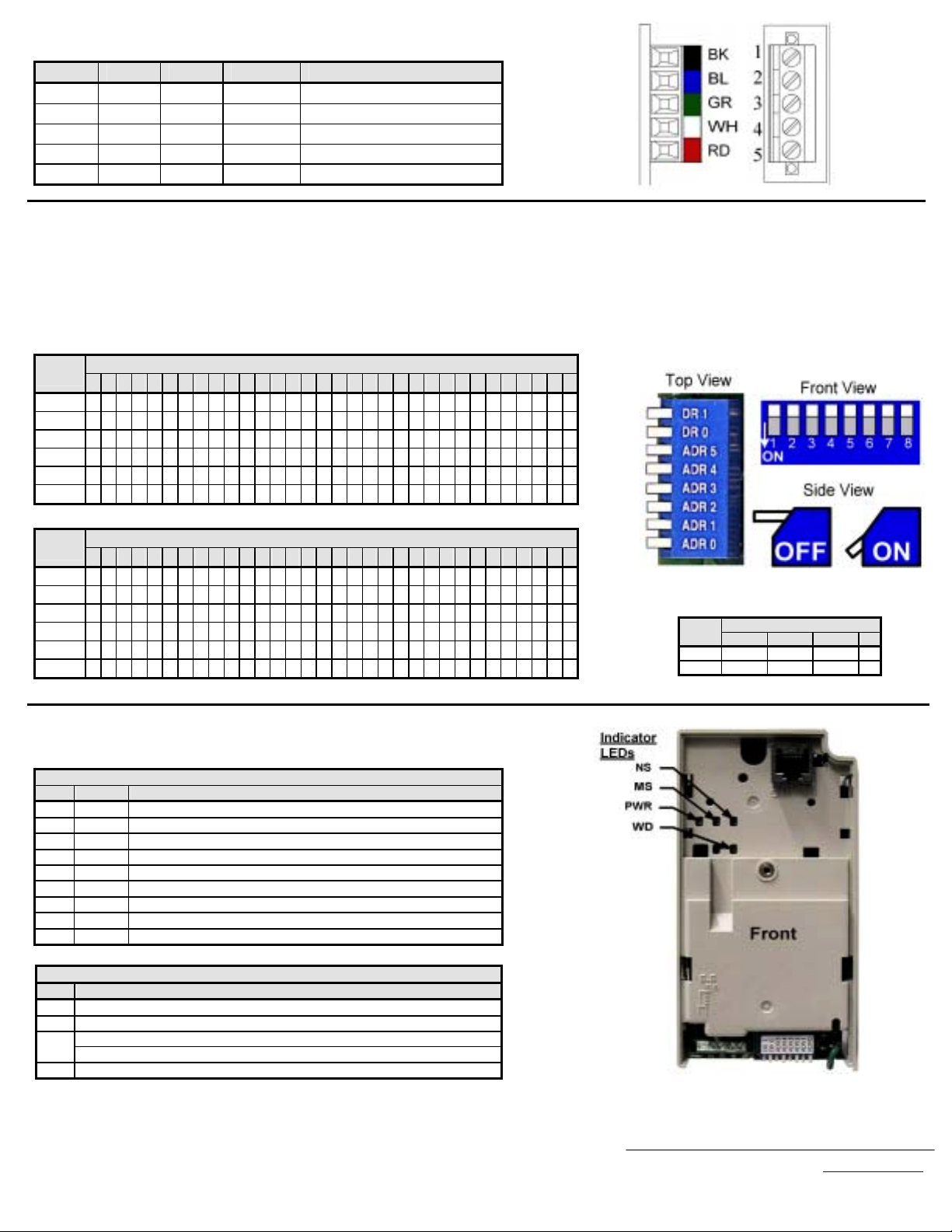

Connect to the DeviceNet network as shown in the figure to the right.

!

Terminal Color Name Wire Color Description

1 Black V- Black Communication GND

2 Blue CAN_L Blue CAN Data Low

3 Green Shield Bare Cable Shield

4 White CAN_H White CAN Data High

5 Red V+ Red Communications +24Vdc

Set the V7DeviceNet Option Baud Rate

!

Set the Baud Rate for the V7 DeviceNet Option to the network baud rate by setting DIP switches DR1 (1) and DR0 (2) as shown in the figure below. The baud r a te must

match the baud rate of the DeviceNet master (PC/PLC/Scanner) in order for the connection to function properly.

Set the V7 DeviceNet Option MAC ID

!

Set the MAC ID of V7 DeviceNet Option by setting DIP switches ADR 5 (3) through ADR 0 (8) as shown in the table below. Each device on the network must have a

unique MAC ID, typically between 3 and 62. Addresses 0 and 1 are usually reserved for DeviceNet masters, address 2 for diagnostic/monitoring equipment and address 63

for vendor specific functions in some systems. Check the network schematic to verify the MAC ID setting.

Sw

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

ADR 5 (3) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0000000000000

ADR 4(4) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1111111111111

ADR 3(5) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0000011111111

ADR 2(6) 0 0 0 0 1 1 1 1 0 0 0 0 1 1 1 1 0 0 0 0111100001111

ADR 1(7) 0 0 1 1 0 0 1 1 0 0 1 1 0 0 1 1 0 0 1 1001100110011

ADR 0(8) 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1010101010101

Sw

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63

ADR 5 (3) 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1111111111111

ADR 4(4) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1111111111111

ADR 3(5) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0000011111111

ADR 2(6) 0 0 0 0 1 1 1 1 0 0 0 0 1 1 1 1 0 0 0 0111100001111

ADR 1(7) 0 0 1 1 0 0 1 1 0 0 1 1 0 0 1 1 0 0 1 1001100110011

ADR 0(8) 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1010101010101

Verify LED Status

!

Refer to the table on the following page for a complete listing of LED states.

LED Power-Up Sequence

LED Color Condition

PWR GREEN Steady

WD RED On for 0.25 sec

WD NONE Off for 0.25 sec

WD GREEN Blink at 0.1ms interval

MS GREEN On for 0.25 sec

MS RED On for 0.25 sec

MS GREEN On for 0.25 sec

NS GREEN On for 0.25 sec

NS RED On for 0.25 sec

LED normal operation Status

LED Condition

PWR GREEN

MS GREEN

FLASH GREEN (no communication)

NS

REEN (communicating)

WD FLASH GREEN

MAC ID

0 = OFF 1 = ON

MAC ID

0 = OFF 1 = ON

Sw

125kbps 250kbps 500kbps N/A

DR1 (1) 0 0 1 1

DR0 (2) 0 1 0 1

Baud Rate

Yaskawa Electric America, Inc – www.drives.com

IG.V7.13, Page 2 of 5

Date: 07/01/04, Rev: 04-07

Page 3

Param Function Data +/- Limits - Description Dflt

Remove power from the drive and wait for the charge lamp to be completely

!

extinguished. Wait at least five additional minutes for the drive to be completely

discharged. Measure the DC BUS voltage and verify that it is at a safe level.

Reinstall all drive covers and the operator keypad.

!

Apply power to the drive and wait for the power-up sequence to complete..

!

Set parameters b1-01 and b1-02 to their appropriate values. Refer to the table to

the right for available b1-01 and b1-02 values.

Install the EDS File and Configure the Drive on the DeviceNet Network

!

The EDS file can be obtained from the CD that was included with the drive or downloaded from www.drives.com

from www.drives.com

separate EDS file for each drive model, verify that the correct EDS file has been installed for the drive model configured. Refer to the documentation that came with the

DeviceNet master configuration tool for information on installing EDS files and configuring a DeviceNet node.

Note: The EDS files located on the CD, CD.V7J7.01, or downloaded from www.drives.com

prior to installation.

to be sure that the latest version is used. Install the EDS file into the DeviceNet configuration tool (i.e. RSNetworx for DeviceNet). There is a

Reference

b1-01

Selection

Operation Method

b1-02

Selection

will be in “zip” format and will need to be un-zipped to a temporary directory

0 Digital Operator

1 Terminals

2 Serial Communication

3

Option PCB (DeviceNet Option)

4 Pulse Input (F7 and G7 Only )

0 Digital Operator

1 Terminals

2 Serial Communication

3

Option PCB (DeviceNet Option)

. It is recommended that the EDS file be downloaded

1

1

Yaskawa Electric America, Inc – www.drives.com

IG.V7.13, Page 3 of 5

Date: 07/01/04, Rev: 04-07

Page 4

LED Status Indicators and Diagnostics

!

LED Display

PWR MS NS WD

Off Off Off Off Power Off

Solid

Green

Solid

Green

Solid

Green

Solid

Green

Solid

Green

Solid

Green

Solid

Green

Solid

Green

Solid

Green

Note: 1: Do not install remove or handle a network card connected to the drive with power applied to the drive. Remove power from the drive and wait for the charge lamp to be

Off Off Solid Red CPU Fault

Flashing

Green

Flashing

Red

Solid Red Off

Solid Red Solid Red

Solid

Solid

Solid

Solid

Flashing

Solid Red

Flashing

Green

Green

Green

Green

Green

Green

completely extinguished. Wait at least five additional minutes for the drive to be completely discharged. Measure the DC BUS voltage and verify that it is at a safe level.

2: When cycling power to the drive make sure that the drive is fully discharged prior to reapplying power.

Off

Off

Red

Solid

Flashing

Green

Flashing

Green

Flashing

Green

Flashing

Green

Flashing

Green

Flashing

Green

Flashing

Green

Flashing

Green

Content Cause Solution

# The drive is not powered

# The option board is not connected

correctly or securely to the drive

# The option board CPU is being

initialized or has a fault

Option Board

Initialization

Recoverable Option

Board Fault

Unrecoverable Option

Board Fault

Baud Rate Setting Fault # DR1 and DR0 are both set to ON

Communication

Timeout

Communication Error # Unrecoverable communication fault

Normal Not

Communicating

Normal

Communicating

# Option board Initialization

# An incorrect DIP switch setting or

other recoverable fault

# An un-recoverable fault

# A master communication timeout

# Connected to a DeviceNet network

but not communicating

# Connected to a DeviceNet network

and communicating normally

# Check the drive main circuit wiring

# Turn power on

# Turn Off drive power

# Check the connection of the option board to the 2CN

connector on the drive

# Turn power on

# Cycle power to the drive

# If the fault persists, replace the option board

# Wait for initialization to complete

# If initialization does not complete within several

seconds, cycle power to the drive

# If initialization does not complete after power cycling

the drive, replace the option card

# Check baud rate setting (DIP switches DR1 and DR0),

then cycle power to the drive

# If the fault persists, replace the option board

# Cycle power to the drive

# If the fault persists, replace the option board

# Set the baud rate switches correctly

# Cycle power to the drive

# Check network termination

# Check network wiring

# Check that the communication bus wiring is separated

from the main circuit wiring

# Check that other device’s MAC ID is not unique per

the network

# Check that the master is configured correctly

# Check that the end termination resistors are correctly

connected to the communication bus

# Check that the communication device is correctly

connected per wiring diagrams

# Check that the communication bus wiring is separated

from the main circuit wiring

# Send explicit message or I/O message from the master

as necessary

-

Yaskawa Electric America, Inc – www.drives.com

IG.V7.13, Page 4 of 5

Date: 07/01/04, Rev: 04-07

Page 5

DeviceNet

TM

Option Card and Ring Kit

CM052

Copies of this Installation Guide along with all technical manuals in pdf format and support files may be obtained from either the CD supplied with the drive or from

www.drives.com

from the ODVA at www.ODVA.

Reference documents:

V7 Technical Manual – TM.V7.01

V7 MODBUS

V7 DeviceNet

V7 DeviceNet

MODBUS

DeviceNet

. Printed copies of any Yaskawa manuals may be obtained by contacting the nearest Yaskawa office. Information on DeviceNet may be obtained

org .

Technical Manual – TM.V7.11

TM

Technical Manual – TM 4320

TM

Option Installation Guide – IG.V7.13

is a registered trademark of Schneider Electric

TM

is a trademark of the ODVA.

YASKAWA ELECTRIC AMERICA INC.

Drives Division

16555 W. Ryerson Rd. New Berlin WI 53151 U.S.A.

Phone: (800) YASKAWA (800-927-5292) Fax: (262) 782-3418

Internet: http://www.drives.com

YASKAWA ELECTRIC AMERICA INC.

Chicago-Corporate Headquarters

2121 Norman Drive South Waukegan IL 60085 U.S.A.

Phone: (800) YASKAWA (800-927-5292) Fax: (847) 887-7310

Internet : http://www.yaska wa.com

MOTOMAN INC.

805 Liberty Lane West Carrollton OH 45449 U.S.A.

Phone: (937) 847-6200 Fax: (937) 847-6277

Internet: http://www.motoman.com

YASKAWA ELECTRIC CORPORATION

New Pier Takeshiba South Tower 1-16-1 Kaigan Minatoku Tokyo 105-0022 Japan

Phone: 81-3-5402-4511 Fax: 81-3-5402-4580

Internet : http://www.yaska wa.co.jp

YASKAWA ELETRICO DO BRASIL COMERCIO LTDA.

Avenida Fagundes Filho 620 Bairro Saude Sao Paolo-SP Brasil CEP: 04304-000

Phone: 55-11-5071-2552 Fax: 55-11-5581-8795

Internet : http://www.yaska wa.com.br

YASKAWA ELECTRIC EUROPE GmbH

Am Kronberger Hang 2 65824 Schwalbach Germany

Phone: 49-6196-569-300 Fax: 49-6196-888-301

MOTOMAN ROBOTICS AB

Box 504 S38525 Torsas Sweden

Phone: 46-486-48800 Fax: 46-486-41410

MOTOMAN ROBOTEC GmbH

Kammerfeldstrabe 1 85391 Allershausen Germany

Phone: 49-8166-900 Fax: 49-8166-9039

YASKAWA ELECTRIC UK LTD.

1 Hunt Hill Orchardton Woods Cumbernauld G68 9LF Scotland United Kingdom

Phone: 44-12-3673-5000 Fax: 44-12-3645-8182

YASKAWA ELECTRIC KOREA CORPORATION

Paik Nam Bldg. 901 188-3 1-Ga Euljiro Joong-Gu Seoul Korea

Phone: 82-2-776-7844 Fax: 82-2-753-2639

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

Head Office: 151 Lorong Chuan #04-01 New Tech Park Singapore 556741 Singapore

Phone: 65-282-3003 Fax: 65-289-3003

TAIPEI OFFICE (AND YATEC ENGINEERING CORPORATION)

10F 146 Sung Chiang Road Taipei Taiwan

Phone: 886-2-2563-0010 Fax: 886-2-2567-4677

YASKAWA JASON (HK) COMPANY LIMITED

Rm. 2909-10 Hong Kong Plaza 186-191 Connaught Road West Hong Kong

Phone: 852-2803-2385 Fax: 852-2547-5773

BEIJING OFFICE

Room No. 301 Office Building of Beijing International Club

21 Jianguomanwai Avenue Beijing 100020 China

Phone: 86-10-6532-1850 Fax: 86-10-6532-1851

SHANGHAI OFFICE

27 Hui He Road Shanghai 200437 China

Phone: 86-21-6553-6600 Fax: 86-21-6531-4242

SHANGHAI YASKAWA-TONJI M & E CO. LTD.

27 Hui He Road Shanghai 200437 China

Phone: 86-21-6533-2828 Fax: 86-21-6553-6677

BEIJING YASKAWA BEIKE AUTOMATION ENGINEERING CO. LTD.

30 Xue Yuan Road Haidian Beijing 100083 China

Phone: 86-10-6232-9943 Fax: 86-10-6234-5002

SHOUGANG MOTOMAN ROBOT CO. LTD.

7 Yongchang-North Street Beijing Economic & Technological Development Area

Beijing 100076 China

Phone: 86-10-6788-0551 Fax: 86-10-6788-2878

YEA TAICHUNG OFFICE IN TAIWAIN

B1 6F No.51 Section 2 Kung-Yi Road Taichung City Taiwan R.O.C.

Phone: 886-4-2320-2227 Fax:886-4-2320-2239

Yaskawa Electric America, Inc – www.drives.com

IG.V7.13, Page 5 of 5

Date: 07/01/04, Rev: 04-07

Data subject to change without notice.

Loading...

Loading...