Page 1

Unpack the

present and undamaged.

LonWorks Option Card

Installation Guide (IG.AFD.20) 1

Verify that the drive is one of the following series: E7, P7, F7, or G7.

The

Apply power to the drive or panel and verify that they function correctly.

This includes running the drive through the drive keypad (or the door

mounted Bypass controls, in case of E7B, E7L, or P7B. Refer to the

appropriate technical manual for information on connections and

operation.

Remove power and wait for the drive charge lamp to be completely

extinguished. Measure and verify the drive’s DC BUS voltage to be at a

safe level.

LONW

ORKS

Option Kit

Part Qty.

(UTC000057)

LonWorks Option Card

and verify that all components are

is only compatible with these drive series.

1

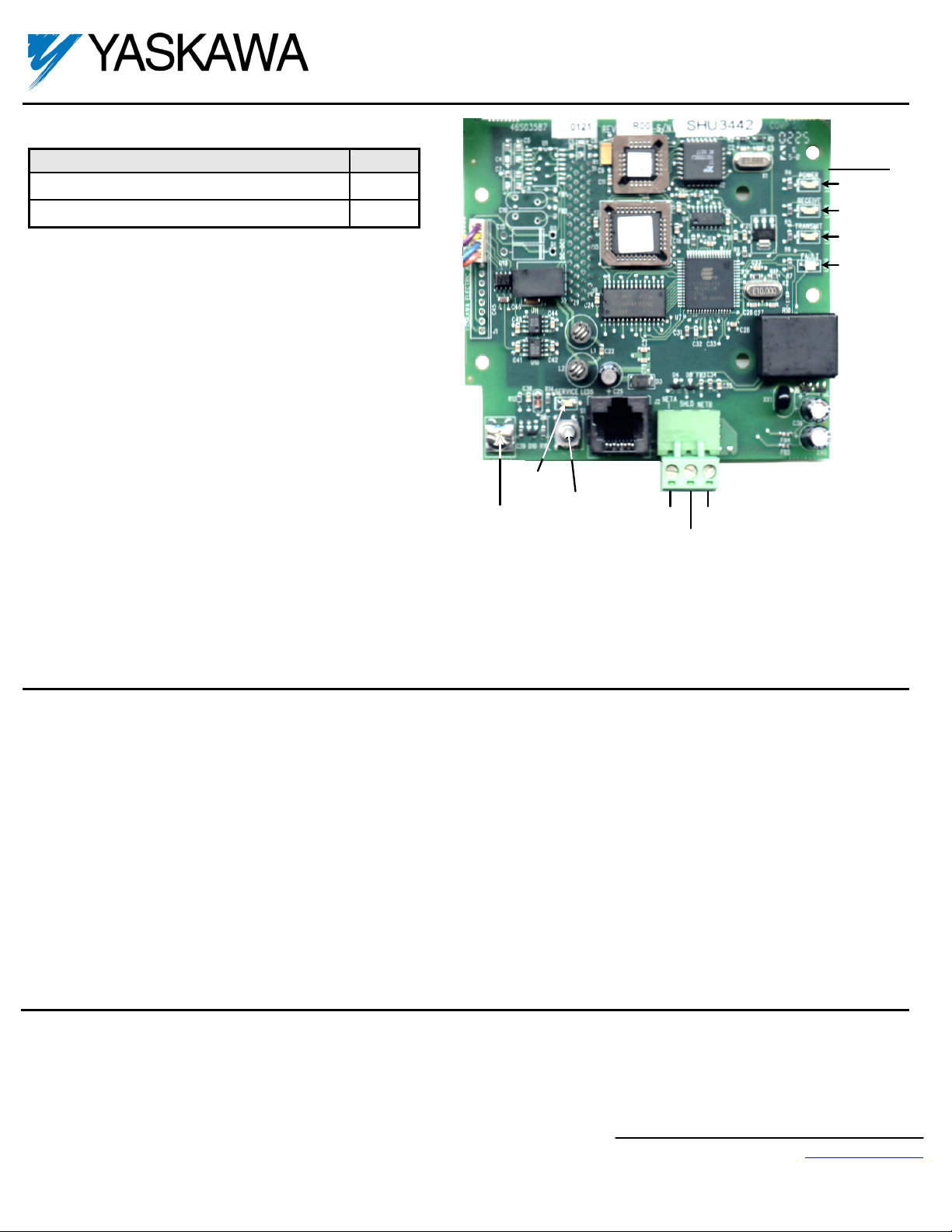

LONWORKS® Option Card

CM048

LEDs

PWR

RECEIVE

TRANSMIT

FAULT

Remove the operator keypad and drive cover(s).

Remove the operator keypad by depressing the tab on the right

side of the keypad and then pulling it out. In E7B, E7C, E7L, P7B,

P7C, or F7C, the keypad may already have been removed and

mounted on the enclosure door.

Remove the drive’s front cover until the entire control card is

exposed. The number of covers and the removal procedure varies

by drive series and capacity. Consult the drive’s technical manual

for details. In E7B, E7C, E7L, P7B, P7C, or F7C, the keypad may

already have been removed and mounted on the enclosure door.

Remove the option card hold-down plug on the left side of the

drive case by carefully compressing the top and bottom until it

becomes free of its holder and then pulling it out.

Mount the

Align the 2CN connector on the back of the

Press the

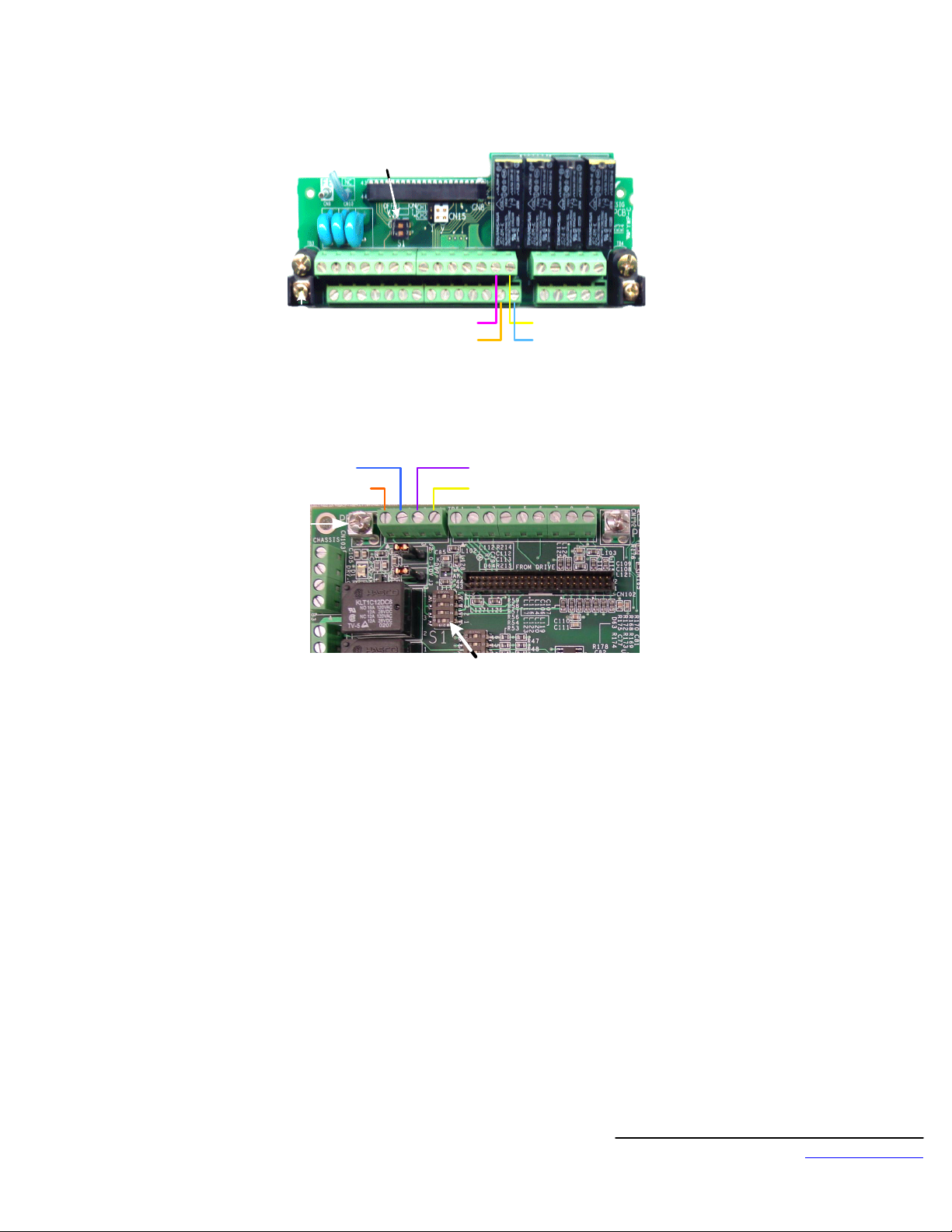

Standard Connection - Route the four wires from the

E7L Connection - Route the four wires from the

A noise free ground is essential for continuous, stable communications. DO NOT USE THE GROUND TERMINALS LOCATED ON THE DRIVE’S

Standard Termination - Set the Termination Switch S1-1 to ON as shown below. This is independent of whether the drive is the first or last device on

E7L Termination - Set the Termination Switch S1 to ON. This is independent of whether the drive is the first or last device on the

LONW

ORKS

Option Card

the two standoffs on the front of the drive’s control board with the two holes on the right side of the

have locked into their appropriate holes.

R+, R-, S+ and S- terminals on the I/O terminal assembly as shown below.

typically mounted on the left inside wall of the E7L enclosure. Connect the wires as shown below.

TERMINAL BOARD OR CHASSIS. If an external, noise free ground is available, connect a ground wire from the ground terminal on the

option Card

the

LonWorks Option Card

to the ground. If no noise free ground is available, leave the ground terminal on the

LonWorks

network.

on the drive.

LonWorks Option Card

firmly onto the drive’s 2CN connector and standoffs until the 2CN connector is fully seated and the drive standoffs

LonWorks Option Card

LonWorks Option Card

with its mating 2CN connector on the front of the drive’s control board. Align

SERVICE

LED

Ground

Terminal

along the left side of the control board and connect them directly to the

to terminal board TB4 on the E7L control card. The E7L control board is

SERVICE

Button

RJ45

net

net

A

B

shield

LONW

ORKS

Option Card.

LonWorks Option Card

LonWorks

un-terminated.

LonWorks

network.

Yaskawa Electric America, Inc. – www.yaskawa.com

IG.AFD.20, Page 1 of 5

Date: 03/02/2012, Rev: 12-03

Page 2

Termination SW

ON

R+ (Purple)

S+ (Orange)

Standard Drive Connection

S- (Blue) R+ (Purple)

S+ (Orange)

R- (Yellow)

Termination SW to ON

E7L Connection

R- (Yellow)

S- (Blue)

Yaskawa Electric America, Inc. – www.yaskawa.com

IG.AFD.20, Page 2 of 5

Date: 03/02/2012, Rev: 12-03

Page 3

Setting the drive parameters

Remove power from the drive and wait for the charge lamp to be completely extinguished. Wait at least five additional minutes for the drive to be

completely discharged. Measure the DC BUS voltage and verify that it is at a safe level.

Reinstall the operator keypad and all drive covers. Apply power to the drive.

Set parameter A1-01 to 2, Advanced.

Set parameters b1-01 and b1-02 to their appropriate values. Refer to the table below for available b1-01 and b1-02 values. Reference Selection

and Operation Method Selection can have different values depending on the application. To control both frequency and run/stop over the network,

set both b1-01 and b1-02 to 2, Serial Communications.

Set parameter H5-01 to 1F (31)

Set parameter H5-02 to 3, 9600 baud

Set parameter H5-03 to 0, No Parity

Set parameter H5-06 to 5, 5ms transmission wait

Set parameter H5-07 to 0, Disabled

Set parameter H5-08 to 0, MODBUS

Parameters H5-04 (Stopping Method at Communications Fault), H5-05 (Serial Fault Detection) and H5-09 (CE Detect Time) should be set according

to the desired drive performance during a communications timeout or failure.

After all drive parameters have been set, power cycle the drive. Communications parameters will not take affect until power has been removed from

the drive until the charge lamp has been extinguished and restored.

For E7L or E7B Bypass-Panel applications, refer to the parameter table and electrical schematic accompanying the unit for parameter and DIP-

switch settings.

Parameter Function Data +/- Limits - Description Default

0 Operator

A1-01 Access Level

1 User

2

2 Advanced

0 Digital Operator

1 Terminals

B1-01 Reference Selection

2 Serial Communication (LONWORKS)

1

3 Option PCB

4 Pulse Input

0 Digital Operator

1 Terminals

B1-02 Operation Method Selection

2 Serial Communication (LONWORKS)

1

3 Option PCB

H5-01 Serial Communications Address 1F 0 – 1F 1F

0 1200 baud

1 2400 baud

H5-02 Serial Baud Rate Select

2 4800 baud

3

3 9600 baud (LONWORKS)

4 19200 baud

ONWORKS)

0

H5-03 Serial Parity Select

0 None (L

1 Even parity

2 Odd parity

H5-06 Transmit Wait

H5-07 RTS Control Select

H5-08 Protocol Select

5 – 65ms 5

5

0 Disabled (L

ONWORKS)

1 Enabled

0 MODBUS (L

ONWORKS)

1 N2 (Metasys)

2 P1 (APOGEE)

0

0

Yaskawa Electric America, Inc. – www.yaskawa.com

IG.AFD.20, Page 3 of 5

Date: 03/02/2012, Rev: 12-03

Page 4

Connect to the

r

Connect the network to the

Network Identification and Node Configuration

LONW

The

option has not been installed on the network. On power up, an un-configured node can be recognized by the SERVICE LED blinking at 2Hz.

Network identification is accomplished with an installation tool. Unique network identities are established by pairing “logical” addresses with a device’s

48-bit Neuron ID.

SERVICE Button

Each option card has a Service Button. If using a configuration tool utilizing this feature, press the Service Button when prompted to do so. When

pressed, a broadcast message is sent which contains the Neuron ID and program ID. This uniquely identifies the node on the network. This method

works best for small networks or with portable installation tools.

Find and Wink

When it is impractical to press each node’s Service Button for installation (e.g. in large networks or a node is physically enclosed), the “find and

wink” installation method is useful. With this method, the installation tool queries the network for all unconfigured nodes. Nodes respond with their

Neuron ID and a logical address is assigned. A “wink” command can then be sent to each logical address. In response to this command, the

TRANSMIT and RECEIVE LED’s will blink rapidly for several seconds. In this manner, the exact physical location of each node can be identified.

Reclaiming a Node

A node can be “reclaimed”, or returned to its unconfigured state, as follows:

Remove power from the drive and wait for the charge lamp to be completely extinguished.

Press and hold the Service Button.

Re-apply drive power, continuing to press and hold the Service Button.

LonWorks

ORKS

Option Card

network.

LONW

ORKS

Option Card

is shipped unconfigured. This implies that the application is loaded and communications parameters are defined but the

as shown.

RJ45 Socket

N

e

t

A

N

S

e

H

t

L

B

D

After approximately 5 seconds, the SERVICE LED should begin flashing at a 0.5 Hz rate, indicating the unconfigured state. This procedure

sets both domain table entries to “undefined” and sets the channel ID to 0.

12345678

N

N

E

E

T

T

A

B

LED Status Indicators and Diagnostics

LED Display

PWR Receive Transmit Fault Service

OFF OFF OFF OFF OFF Power not supplied

ON BLINK BLINK BLINK OFF

ON ON OFF Communications Loss

ON FLASH OFF OFF Normal communications

ON FLASH OFF OFF Normal communications

BLINK

0.5Hz

FLASH

1sON_2sOFF_ContON

Condition Solution

Option is Not Configured

Application missing

Communications not

established

• Configure Option

• Download application image file

• Assign network Identity

• Check that drive has power

• Check option card seating in CN2 connector

• Check drive parameters (refer to table above)

• Check connection between option and drive

• Check network cable connections

Flash each time serial task is complete

Approximately 0.5Hz when drive is at STOP

Approximately 1.0Hz when drive RUN is active

Flash for every 5 netwo

k variables updates

Yaskawa Electric America, Inc. – www.yaskawa.com

IG.AFD.20, Page 4 of 5

Date: 03/02/2012, Rev: 12-03

Page 5

LONWORKS ® Option Card

CM048

Copies of this Installation Guide along with all technical manuals in PDF format and support files may be obtained from either the CD supplied with the drive

or from www.yaskawa.com

may be obtained at

www.echelon.com

. Printed copies of manuals may be obtained by contacting the Yaskawa Help Desk at 800-927-5292. Information on

LonWorks

Reference documents:

E7 Technical Manual – TM.E7.02

P7 Technical Manual – TM.P7.02

F7 Technical Manual – TM.F7.02

G7 Technical Manual – TM.G7.01

F7 Parameter Access Technical Manual – TM.F7.11

MODBUS

LonWorks

YASKAWA ELECTRIC AMERICA, INC.

Drives Division

16555 W. Ryerson Rd., New Berlin, WI 53151, U.S.A.

Phone: (800) YASKAWA (927-5292) Fax: (847) 887-7310

Internet: http://www.yaskawa.com

YASKAWA ELECTRIC AMERICA, INC.

Chicago-Corporate Headquarters

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: (800) YASKAWA (800-927-5292) Fax: (847) 887-7310

Internet: http://www.yaskawa.com

MOTOMAN INC.

805 Liberty Lane, West Carrollton, OH 45449, U.S.A.

Phone: (937) 847-6200 Fax: (937) 847-6277

Internet: http://www.motoman.com

YASKAWA ELECTRIC CORPORATION

New Pier Takeshiba South Tower, 1-16-1, Kaigan, Minatoku, Tokyo, 105-0022, Japan

Phone: 81-3-5402-4511 Fax: 81-3-5402-4580

Internet: http://www.yaskawa.co.jp

YASKAWA ELETRICO DO BRASIL COMERCIO LTDA.

Avenida Fagundes Filho, 620 Bairro Saude Sao Paolo-SP, Brasil CEP: 04304-000

Phone: 55-11-5071-2552 Fax: 55-11-5581-8795

Internet: http://www.yaskawa.com.br

YASKAWA ELECTRIC EUROPE GmbH

Am Kronberger Hang 2, 65824 Schwalbach, Germany

Phone: 49-6196-569-300 Fax: 49-6196-888-301

MOTOMAN ROBOTICS AB

Box 504 S38525, Torsas, Sweden

Phone: 46-486-48800 Fax: 46-486-41410

MOTOMAN ROBOTEC GmbH

Kammerfeldstrabe 1, 85391 Allershausen, Germany

Phone: 49-8166-900 Fax: 49-8166-9039

YASKAWA ELECTRIC UK LTD.

1 Hunt Hill Orchardton Woods Cumbernauld, G68 9LF, Scotland, United Kingdom

Phone: 44-12-3673-5000 Fax: 44-12-3645-8182

®

is a registered trademark of Schneider Automation, Inc.

®

is a registered trademark of Echelon Corporation.

YASKAWA ELECTRIC KOREA CORPORATION

Paik Nam Bldg. 901 188-3, 1-Ga Euljiro, Joong-Gu, Seoul, Korea

Phone: 82-2-776-7844 Fax: 82-2-753-2639

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

Head Office: 151 Lorong Chuan, #04-01, New Tech Park Singapore 556741, Singapore

Phone: 65-282-3003 Fax: 65-289-3003

TAIPEI OFFICE (AND YATEC ENGINEERING CORPORATION)

10F 146 Sung Chiang Road, Taipei, Taiwan

Phone: 886-2-2563-0010 Fax: 886-2-2567-4677

YASKAWA JASON (HK) COMPANY LIMITED

Rm. 2909-10, Hong Kong Plaza, 186-191 Connaught Road West, Hong Kong

Phone: 852-2803-2385 Fax: 852-2547-5773

BEIJING OFFICE

Room No. 301 Office Building of Beijing International Club,

21 Jianguomanwai Avenue, Beijing 100020, China

Phone: 86-10-6532-1850 Fax: 86-10-6532-1851

SHANGHAI OFFICE

27 Hui He Road Shanghai 200437 China

Phone: 86-21-6553-6600 Fax: 86-21-6531-4242

SHANGHAI YASKAWA-TONJI M & E CO., LTD.

27 Hui He Road Shanghai 200437 China

Phone: 86-21-6533-2828 Fax: 86-21-6553-6677

BEIJING YASKAWA BEIKE AUTOMATION ENGINEERING CO., LTD.

30 Xue Yuan Road, Haidian, Beijing 100083 China

Phone: 86-10-6232-9943 Fax: 86-10-6234-5002

SHOUGANG MOTOMAN ROBOT CO., LTD.

7, Yongchang-North Street, Beijing Economic & Technological Development Area,

Beijing 100076 China

Phone: 86-10-6788-0551 Fax: 86-10-6788-2878

YEA, TAICHUNG OFFICE IN TAIWAIN

B1, 6F, No.51, Section 2, Kung-Yi Road, Taichung City, Taiwan, R.O.C.

Phone: 886-4-2320-2227 Fax: 886-4-2320-2239

Data subject to change without notice

Yaskawa Electric America, Inc. – www.yaskawa.com

IG.AFD.20, Page 5 of 5

Date: 03/02/2012, Rev: 12-03

Loading...

Loading...