Page 1

YASKAWA AC Drive GA700

High Performance Type

Initial Steps

Type: CIPR-GA70Cxxxxxxxx

Models: 200 V class: 0.55 to 110 kW

400 V class: 0.55 to 355 kW

To properly use the product, read this manual thoroughly and retain for easy

reference, inspection, and maintenance. Ensure the end user receives this

manual.

MANUAL NO. TOEP C710617 17D

Initial Steps

EN

Page 2

1 General Information

1 General Information

Do not use this manual as a replacement for the Technical Manual. The products and specifications given in this

manual and the manual contents can change without notice to make the product and manual better. Be sure to

always use the most recent version of this manual. Use the manual for the correct installation, wiring, adjustment,

and operation of this product.

This manual is available for download on our documentation website. Refer to the back page of this manual.

2 Qualifications for the Intended User

Yaskawa created this manual for electrical specialists and engineers who have experience with AC drive

installation, adjustment, repair, inspection, and parts replacement. Persons without technical training, minors,

persons with disabilities or mental problems, persons with perception problems, and persons with pacemakers

must not use or operate this product.

3 Safety

Read the safety guidelines carefully before installing, wiring, or operating this product.

◆ Explanation of Signal Words

DANGER

WARNING

CAUTION

NOTICE

Indicates a hazardous situation, which, if not avoided, will cause death or serious injury.

Indicates a hazardous situation, which, if not avoided, could cause death or serious injury.

Indicates a hazardous situation, which, if not avoided, could cause minor or moderate injury.

Indicates a property damage message.

◆ General Safety Instructions

Yaskawa Electric manufactures and supplies electronic components for a variety of industrial applications. The

selection and application of Yaskawa products is the responsibility of the designer of the equipment or the

customer that assembles the final product. Yaskawa is not responsible for how our products are incorporated into

the final system design. In all cases, Yaskawa products should not be incorporated into a product or design as the

exclusive or sole safety control function. All control functions are designed to dynamically detect failures and

operate safely without exception. All products that are designed to incorporate parts manufactured by Yaskawa

must be provided to the end user and include proper warnings and instructions regarding their safe use and

operation. All warnings from Yaskawa must be promptly issued to the end user. Yaskawa offers warranties only

for the quality of our products, in compliance with standards and specifications that are described in the manual.

Yaskawa does not offer other warranties, either explicit or implied. Injuries, property damage, and lost business

opportunities caused by improper storage or handling and negligence oversight on the part of your company or

your customers will void Yaskawa’s warranty for the product.

Note:

Failure to obey the safety messages in the manual can cause serious injury or death. Yaskawa is not responsible for injuries or damage to

equipment caused by ignoring the safety messages.

• Read this manual carefully when mounting, operating, and repairing AC drives.

• Obey all warnings, cautions, and notices.

• Approved personnel must perform all work.

• Install the drive in an area with these conditions.

DANGER

servicing, disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal

capacitor stays charged after the drive is de-energized. The charge indicator LED extinguishes when the DC bus voltage

decreases below 50 Vdc. To prevent electric shock, always wait for at least the amount of time indicated on the warning labels.

When all indicators are OFF, remove the covers before measuring for dangerous voltages to make sure that the drive is safe.

Failure to obey will cause death or serious injury.

WARNING

power supply wiring to main circuit input terminals R/L1, S/L2, and T/L3. Failure to obey can cause death or serious injury.

WARNING

cause death or serious injury from falling equipment.

Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized drive. Before

Fire Hazard. Do not connect power supply wiring to drive output terminals U/T1, V/T2, and W/T3. Connect

Crush Hazard. Only approved personnel can operate a crane or hoist to move the drive. Failure to obey can

EN 2 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 3

3 Safety

WARNING

death or serious injury and will void warranty. Yaskawa is not responsible for changes to the product made by the user.

WARNING

repair the drive. Failure to obey can cause death or serious injury.

WARNING

cause death or serious injury from incorrect equipment grounding.

WARNING

Tighten loose clothing and remove all metal objects such as watches or rings. Failure to obey can cause death or serious injury.

WARNING

than 3.5 mA. The IEC/EN 61800-5-1: 2007 standard specifies that users must wire the power supply to automatically turn off

when the protective ground wire disconnects. Users can also connect a protective ground wire that has a minimum crosssectional area of 10 mm

injury.

WARNING

before starting Auto-Tuning. The drive and motor can start suddenly during Auto-Tuning and cause death or serious injury.

WARNING

machine area and attach covers, couplings, shaft keys, and machine loads before energizing the drive. Failure to obey can

cause death or serious injury.

WARNING

sure that the drive rated voltage aligns with the power supply voltage before energizing the drive. Failure to obey can cause

death or serious injury.

WARNING

near flammable or combustible materials. Attach the drive to metal or other noncombustible material. Failure to obey can cause

death or serious injury.

WARNING

tight can cause incorrect operation and damage to the drive. Incorrect connections can also cause death or serious injury from

fire.

WARNING

Tightening screws at an angle outside of the specified range can cause damage the terminal block or start a fire if the

connection is loose.

WARNING

cause death or serious injury from falling equipment.

WARNING

death or serious injury.

WARNING

protection against contact when using a residual current operated protective device or monitoring device as specified by IEC/EN

60755. The drive can cause a residual current with a DC component in the protective earthing conductor. Failure to obey can

cause death or serious injury.

WARNING

C to comply with the EMC Directive before turning on the EMC filter or if there is high resistance grounding. Failure to obey can

cause death or serious injury.

WARNING

blows a fuse or trips an RCM/RCD. Wait for the time specified on the warning label at a minimum and make sure that all

indicators are OFF. Then check the wiring and peripheral device ratings to find the cause of the problem. Contact Yaskawa

before energizing the drive or peripheral devices if the cause is not known. Failure to obey can cause death or serious injury

and damage to the drive.

WARNING

manual. The drive is suited for circuits that supply not more than 100,000 RMS symmetrical amperes, 240 Vac maximum (200 V

Class), 480 Vac maximum (400 V Class). Failure to obey can cause death or serious injury.

CAUTION

moving the drive. Failure to obey can cause minor to moderate injury.

CAUTION

sure that the heatsink is cool to replace the cooling fans. Failure to obey can cause minor to moderate injury.

NOTICE

to obey can cause ESD damage to the drive circuitry.

NOTICE

equipment sequencing can cause damage to the drive.

NOTICE

Electrical Shock Hazard. Do not make changes to the drive body or drive circuitry. Failure to obey can cause

Electrical Shock Hazard. Only let authorized persons install, wire, maintain, examine, replace parts, and

Electrical Shock Hazard. Always ground the motor-side grounding terminal. Contacting the motor case can

Electrical Shock Hazard. Do not work on the drive or around the drive while wearing loose clothing or jewelry.

Electrical Shock Hazard. The leakage current of drive models 4389A to 4675A, 2xxxB/C and 4xxxB/C is more

2

(copper wire) or 16 mm2(aluminum wire). Failure to obey these standards can cause death or serious

Sudden Movement Hazard. Remove all persons and objects from the area around the drive, motor, and load

Sudden Movement Hazard. Remove all persons and objects from the area around the drive, motor, and

Fire Hazard. Do not use the main circuit power supply (Overcurrent Category III) at incorrect voltages. Make

Fire Hazard. Do not put flammable or combustible materials on top of the drive and do not install the drive

Fire Hazard. Tighten all terminal screws to the correct tightening torque. Connections that are too loose or too

Fire Hazard. Tighten screws against the bit at an angle in the specified range described in this manual.

Crush Hazard. Use a lifting mechanism made to move large drives when necessary. Failure to obey can

Electrical Shock Hazard. Do not cause a short circuit on the drive output circuit. Failure to obey can cause

Electrical Shock Hazard. Use a type B Residual Current Monitor/Residual Current Device (RCM/RCD) for

Electrical Shock Hazard. Ground the neutral point on the power supply of drive models 2xxxB/C and 4xxxA/B/

Electrical Shock Hazard. Do not immediately energize the drive or operate peripheral devices after the drive

Fire Hazard. Install sufficient branch circuit short circuit protection as specified by applicable codes and this

Crush Hazard. Do not hold the drive by the front cover or terminal cover. Tighten the screws correctly before

Burn Hazard. Do not touch a hot drive heatsink. De-energize the drive, wait 15 minutes minimum, and make

Observe correct electrostatic discharge (ESD) procedures when touching the drive and circuit boards. Failure

Do not connect or disconnect the motor from the drive while the drive is supplying voltage. Incorrect

Do not do a withstand voltage test or Megger test on the drive. Failure to obey can cause damage to the drive.

EN

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 3

Page 4

4 Moving the Drive

NOTICE

damage to the drive and connected equipment.

NOTICE

NOTICE

ground terminal of the drive. Failure to obey can cause electrical interference and unsatisfactory system performance.

NOTICE

dynamic braking option to the drive. Failure to obey can cause damage to the drive and braking circuit.

NOTICE

to obey can cause damage to the drive.

NOTICE

cause damage to the drive, phase-advancing capacitors, LC/RC noise filters, and leakage breakers (ELCB, GFCI, or RCM/

RCD).

Do not connect or operate damaged equipment or equipment with missing parts. Failure to obey can cause

Install fuses and an RCM/RCD. Failure to obey can cause damage to the drive.

Do not use unshielded wire for control wiring. Use shielded, twisted-pair wires and ground the shield to the

Review the Braking Unit and Braking Resistor Unit Installation Manual TOBPC72060001 before connecting a

Make sure that all connections are correct after installing the drive and connecting peripheral devices. Failure

Do not connect phase-advancing capacitors or LC/RC noise filters to the output circuits. Failure to obey can

◆ Intended Use

This AC drive is electrical equipment that controls the speed and rotational direction of a motor in a commercial

application. Do not use this product for other functions.

1. Read and understand all safety precautions.

2. Wire and ground the drive as specified by all applicable standards and safety precautions.

3. Tightly attach all parts and protective covers.

4. Always use the product in the correct environmental conditions as specified in this manual.

DANGER

before energizing the drive. Use terminals for their intended function only. Incorrect wiring or ground connections, and incorrect

repair of protective covers can cause death or serious injury.

WARNING

death or serious injury and will void warranty. Yaskawa is not responsible for changes to the product made by the user.

Electrical Shock Hazard. Make sure that all electrical connections are correct and install all drive covers

Electrical Shock Hazard. Do not make changes to the drive body or drive circuitry. Failure to obey can cause

◆ Warranty and Exclusion of Liability

• This product is not designed and manufactured for use in life-support machines or systems.

• Contact a Yaskawa representative or your Yaskawa sales representative if you are considering the application of

this product for special purposes, such as machines or systems used for passenger cars, medicine, airplanes and

aerospace, nuclear power, electric power, or undersea relaying.

WARNING

safety devices to minimize the risk of accidents when installing the product where its failure could cause a life-or-death situation,

loss of human life, or a serious accident or physical injury.

Injury to Personnel. Yaskawa manufactured this product with strict quality-control guidelines. Install applicable

4 Moving the Drive

Obey local laws and regulations when moving and installing this product.

CAUTION

moving the drive. Failure to obey can cause minor to moderate injury.

< 15 kg (33 lbs.) 1

≥ 15 kg (33 lbs.) 2 + using appropriate lifting equipment

Refer to the Technical Manual for information about moving the drive with suspension systems, wires, or hanging

metal brackets.

Crush Hazard. Do not hold the drive by the front cover or terminal cover. Tighten the screws correctly before

Drive Weight Persons Necessary to Move the Drive

EN 4 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 5

5 Receiving

5 Receiving

Please check these items after receiving the drive:

• Examine the drive for damage. Immediately contact the shipping company if the drive is damaged. The

Yaskawa warranty does not cover damage from shipping.

• Verify the drive model number in the "MODEL" section of the drive nameplate to make sure that you received

the correct model.

• Contact your supplier if you receive the incorrect drive model or if the drive does not operate correctly.

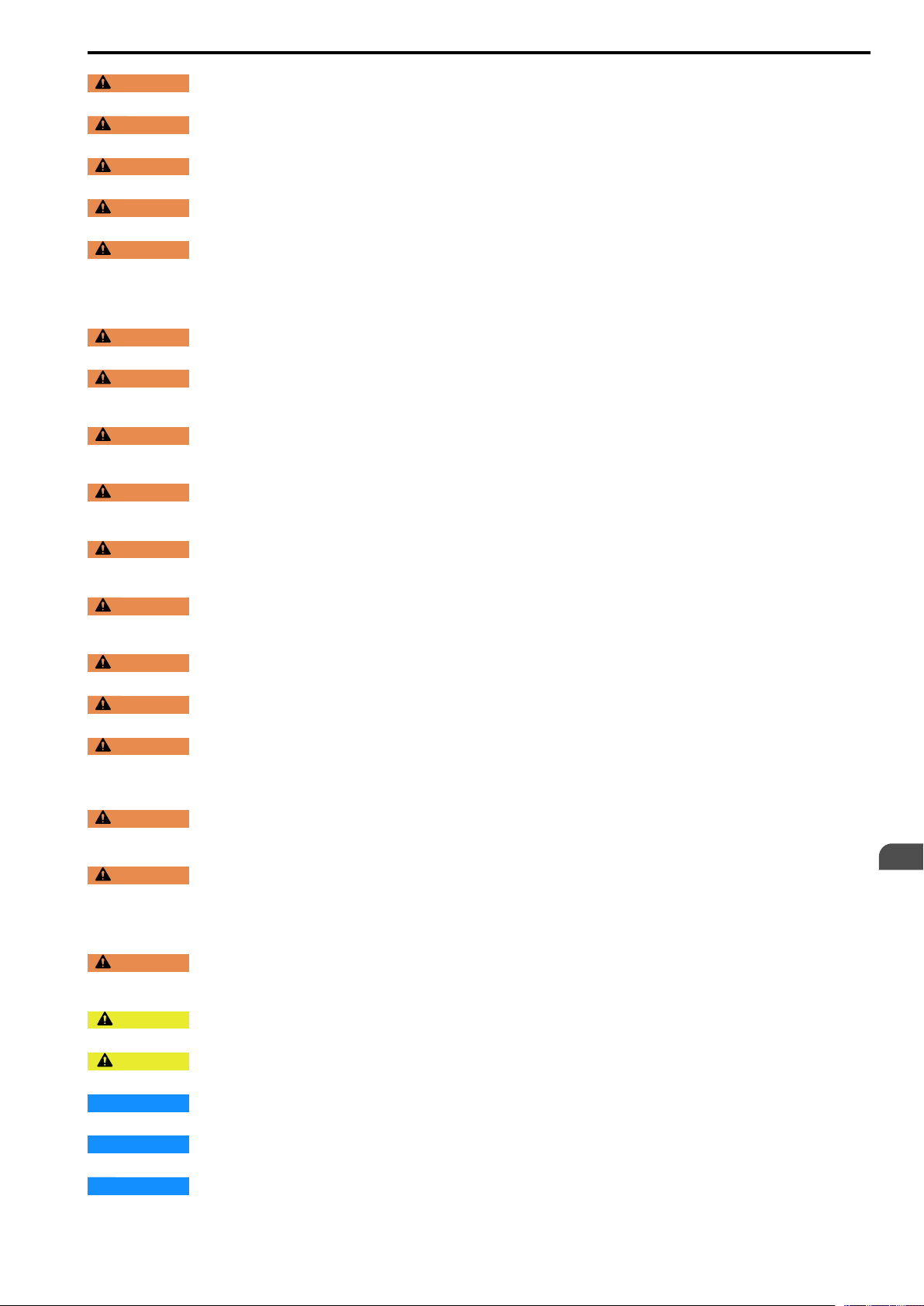

◆ Nameplate

A - Mass

B - Drive software version

C - The address of the head office of

Yaskawa Electric Corporation

D - Accreditation standards

E - Surrounding air temperature

F - Protection design

Figure 5.1 Nameplate Information Example

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 5

G - Serial number

H - Lot number

I - Output specifications

J - Input specifications

K - Drive model

EN

Page 6

6 Keypad

6 Keypad

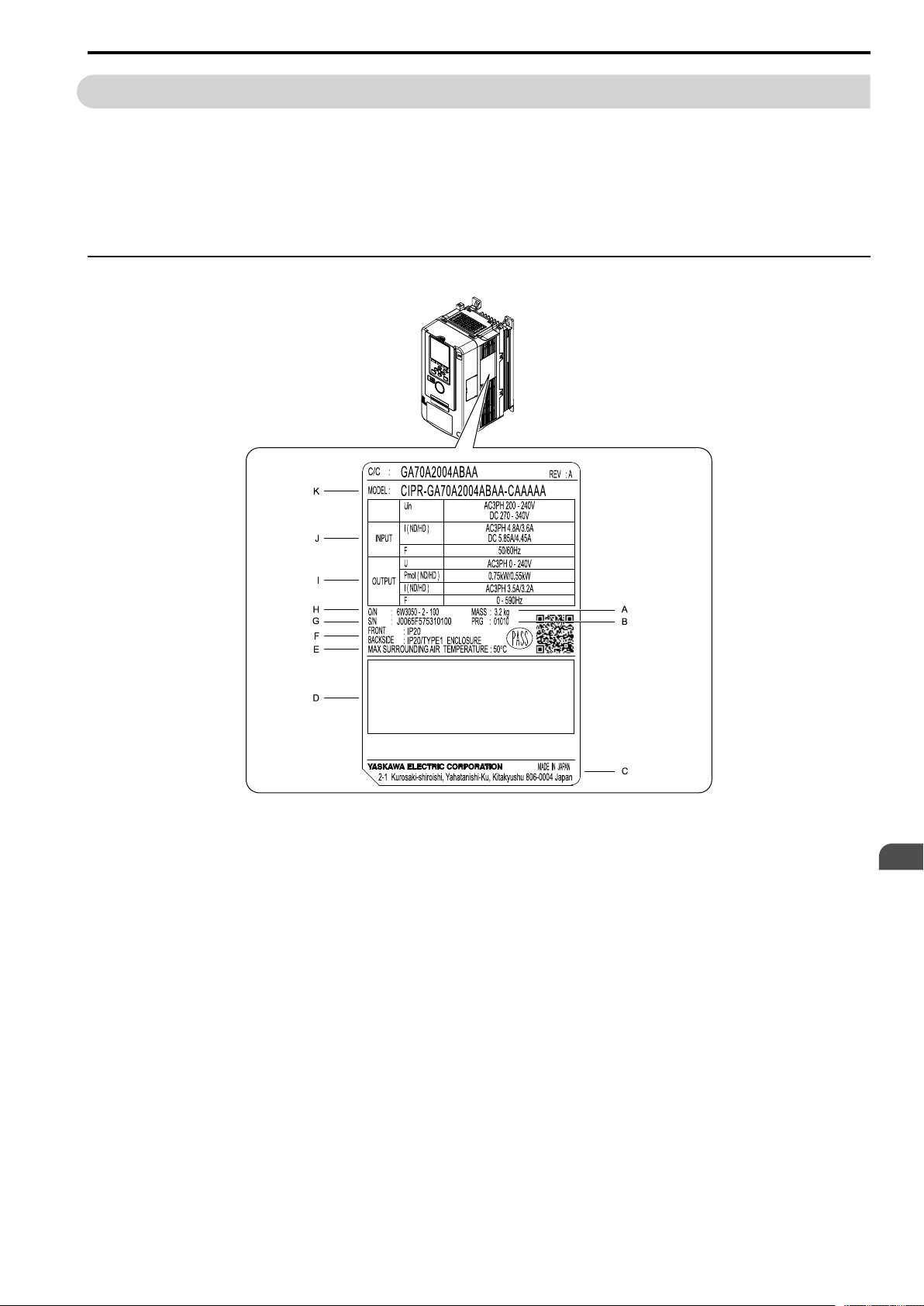

Figure 6.1 Keypad

Table 6.1 Keypad: Names and Functions

No. Name Functions

Illuminates to show that the drive is operating the motor.

The LED turns OFF when the drive stops.

Flashes to show that:

• The drive is decelerating to stop.

• The drive received a Run command with a frequency reference of 0 Hz, but the drive is not set for zero

speed control.

RUN LED

A

ALM LED

B

C

D

microSD Card

Insertion Slot

Function Keys

F1, F2, F3

Flashes quickly to show that:

• The drive received a Run command from the MFDI terminals and is switching to REMOTE Mode

while the drive is in LOCAL Mode.

• The drive received a Run command from the MFDI terminals when the drive is not in Drive Mode.

• The drive received a Fast Stop command.

• The safety function shuts off the drive output.

• The user pushed on the keypad while the drive is operating in REMOTE Mode.

• The drive is energized with an active Run command and b1-17 = 0 [Run Command at Power Up =

Disregard Existing RUN Command].

Illuminates when the drive detects a fault.

Flashes when the drive detects:

• An Alarm

• An oPE parameter setting error

• A fault or alarm during Auto-Tuning

The LED turns OFF when no fault or alarm occurs on the drive.

The insertion point for a microSD card.

The menu shown on the keypad sets the functions for function keys.

The name of each function is in the lower half of the display window.

EN 6 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 7

No. Name Functions

Illuminates to identify when the drive is operating in LOCAL Mode.

The LED turns OFF when the drive is operating in REMOTE Mode.

E

F

G

LO/RE LED

LO/RE Selection Key

STOP Key

Left Arrow Key Moves the cursor to the left.

Note:

• LOCAL Mode: The keypad controls the Run command and frequency reference. Use the keypad to

enter Run/Stop commands and the frequency reference command.

• REMOTE Mode: The control circuit terminal or serial transmission device controls the Run

command and frequency reference. Use the frequency reference source entered in b1-01 [Frequency

Reference Selection 1] and the Run command source selected in b1-02 [Run Command Selection 1].

Switches drive control for the Run command and frequency reference between the keypad (LOCAL) and

an external source (REMOTE).

Note:

• Stop operation in Drive Mode to enable the LO/RE Selection Key. Set o2-01 = 0 [LO/RE Key

Function Selection = Disabled] to disable when switching from REMOTE to LOCAL will

have a negative effect on system performance.

• The drive will not switch between LOCAL and REMOTE when it is receiving a Run command from

an external source.

Stops drive operation.

Note:

Uses a stop-priority circuit. Push to stop the motor even when a Run command is active at

MFDI terminals. Set o2-02 = 0 [STOP Key Function Selection = Disabled] to disable the priority in

.

6 Keypad

Up Arrow Key/Down

Arrow Key

/

H

Right Arrow Key

(RESET)

ENTER Key

I

J

K RJ-45 Connector Connects the keypad directly to the drive.

L Clock Battery Cover Cover for the customer-supplied clock battery.

WARNING

machine area before switching control sources when b1-07 = 1 [LOCAL/REMOTE Run Selection = Accept Existing RUN

Command]. Failure to obey can cause death or serious injury.

RUN Key

USB Terminal Insertion point for a mini USB cable. Use the mini USB cable to connect the drive to a PC.

Sudden Movement Hazard. Remove all persons and objects from the area around the drive, motor, and

• Scrolls up or down to display the next item or the previous item.

• Selects parameter numbers, and increments or decrements setting values.

• Moves the cursor to the right.

• Continues to the next screen.

• Restarts the drive to clear a fault.

• Enters parameter values and settings.

• Selects menu items to move the user between keypad displays.

• Selects each mode, parameter, and set value.

Starts the drive in LOCAL mode.

Starts the operation in Auto-Tuning Mode.

Note:

Push on the keypad to set the drive to LOCAL Mode before using the keypad to operate the

motor.

EN

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 7

Page 8

6 Keypad

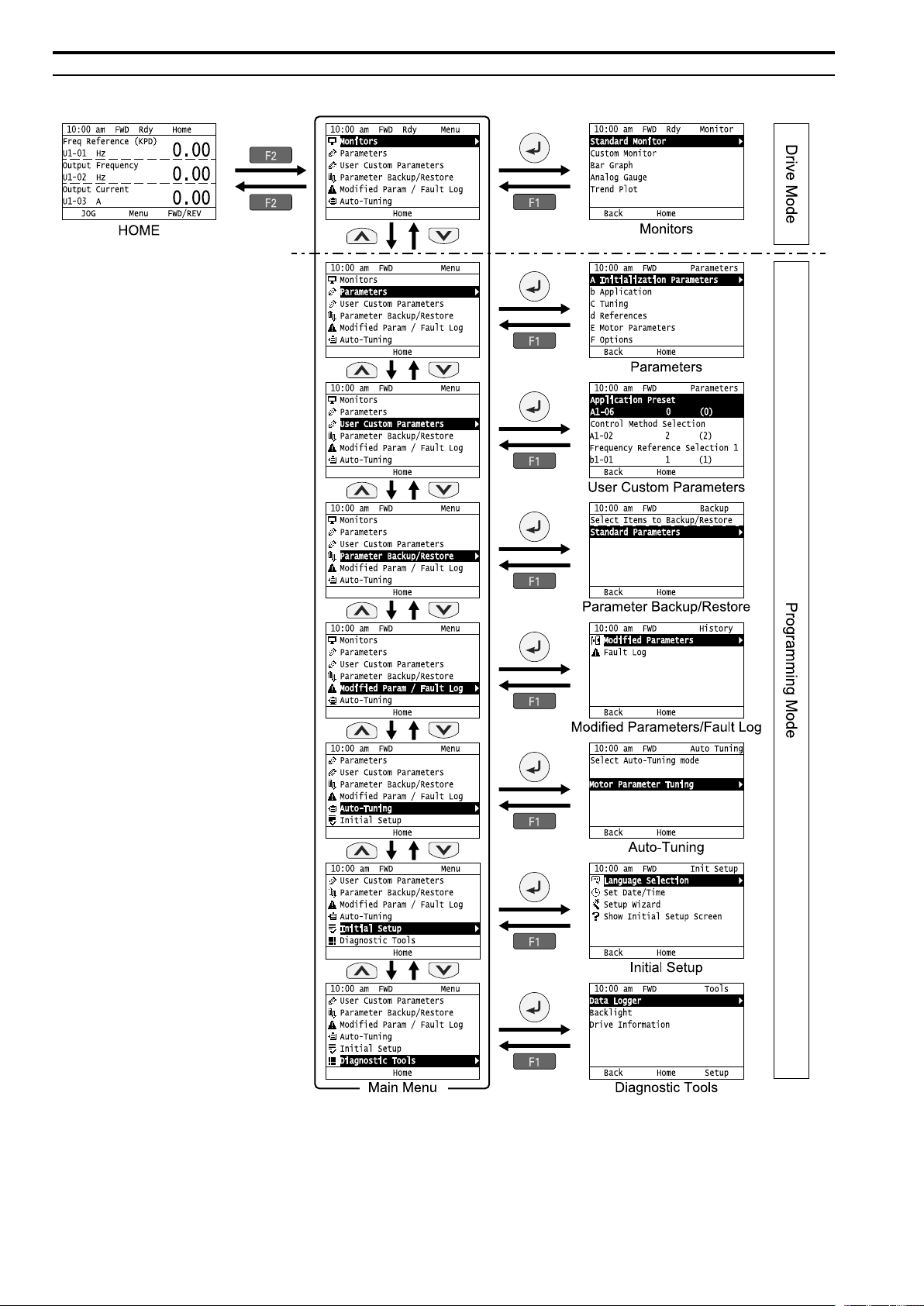

◆ Keypad Mode and Menu Displays

Figure 6.2 Keypad Functions and Display Levels

EN 8 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 9

6 Keypad

Note:

• Energize the drive with factory defaults to show the Initial Setup screen. Push (Home) to show the HOME screen.

–Select [No] from the [Show Initial Setup Screen] setting to not display the Initial Setup screen.

• Push from the Home screen to show drive monitors.

• Push to set d1-01 [Reference 1] when the Home screen shows U1-01 [Frequency Reference] in LOCAL Mode.

• The keypad will show [Rdy] when the drive is in Drive Mode. The drive is prepared to accept a Run command.

• The drive will not accept a Run command in Programming Mode in the default setting. Set b1-08 [Run Command Select in PRG

Mode] to accept or reject a Run command from an external source while in Programming Mode.

–Set b1-08 = 0 [Disregard RUN while Programming] to reject the Run command from an external source while in Programming Mode

(default).

–Set b1-08 = 1 [Accept RUN while Programming] to accept the Run command from an external source while in Programming Mode.

–Set b1-08 = 2 [Allow Programming Only at Stop] to prevent changes from Drive Mode to Programming Mode while the drive is

operating.

Table 6.2 Drive Mode Screens and Functions

Mode Keypad Screen Function

Drive Mode Monitors Sets monitor items to display.

Parameters Changes parameter settings.

User Custom Parameters Shows the User Parameters.

Parameter Backup/Restore Saves parameters to the keypad as backup.

Programming

Mode

Modified Parameters/Fault Log Shows modified parameters and fault history.

Auto-Tuning Auto-Tunes the drive.

Initial Setup Changes initial settings.

Diagnostic Tools Sets data logs and backlight.

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 9

EN

Page 10

7 LED Status Ring

7 LED Status Ring

The LED Status Ring on the drive cover shows the drive operating status.

A - ALM/ERR

B - Ready

LED Status Description

Illuminated The drive detects a fault.

The drive detects:

• An Alarm

• An oPE parameter setting error

A ALM/ERR

B Ready

C RUN

*1 Refer to Figure 7.1 for the difference between flashing and flashing quickly.

Flashing

Illuminated The drive is operating or is prepared for operation.

Flashing

Flashing Quickly

Illuminated The drive is in regular operation.

Flashing

Flashing Quickly

*1

• A fault or error during Auto-Tuning.

Note:

The LED will illuminate to identify a fault if the drive detects a fault and an alarm at the

same time.

OFF

*1

OFF

*1

OFF The motor is stopped.

No fault or alarm occurs on the drive.

*1

The drive is in STo [Safe Torque OFF] Mode.

The voltage of the main circuit power supply dropped, and only the external 24 V power

supply provides the power to the drive.

• The drive detects a fault.

• There is no fault and the drive received a Run command, but the drive cannot operate (such

as when in Programming Mode, or when is flashing).

• The drive is decelerating to stop.

• The drive received a Run command with a frequency reference of 0 Hz, but the drive is not

*1

set for zero speed control.

• The drive received a DC Injection Braking command.

• The drive received a Run command from the MFDI terminals and is switching to REMOTE

Mode while the drive is in LOCAL Mode.

• The drive received a Run command from the MFDI terminals when the drive is not in

Drive Mode.

• The drive received a Fast Stop command.

• The safety function shuts off the drive output.

• The user pushed on the keypad while the drive is operating in REMOTE Mode.

• The drive is energized with an active Run command and b1-17 = 0 [Run Command at

Power Up = Disregard Existing RUN Command].

• The drive is set to coast-to-stop with timer (b1-03 = 3 [Stopping Method Selection = Coast

to Stop with Timer]), and the Run command is disabled then enabled during the Run wait

time.

C - RUN

EN 10 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 11

8 Start-Up Procedure

/

Figure 7.1 LED Flashing Statuses

Figure 7.2 Relation between RUN LED and Drive Operation

8 Start-Up Procedure

1. Install and wire the drive.

2. Energize the drive.

3. Use A1-06 [Application Preset] to initialize the drive for a special application if necessary.

4. Run the Setup Wizard to automatically set these functions:

• Control method selection

• Duty rating selection

• Monitor parameters

• Speed reference source

• Run command source

• Acceleration and deceleration times

5. Run the motor without a load.

6. Make sure that the drive is operating correctly and make sure that the host controller is sending commands to

the drive.

7. Connect the load.

8. Run the motor.

9. Make sure that the drive is operating correctly.

10. Fine-tune and set application parameters, such as PID.

11. Check final operation and make sure that parameter settings are correct.

The drive is prepared to run the operation.

EN

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 11

Page 12

9 Mechanical Installation

9 Mechanical Installation

WARNING

near flammable or combustible materials. Attach the drive to metal or other noncombustible material. Failure to obey can cause

death or serious injury.

CAUTION

moving the drive. Failure to obey can cause minor to moderate injury.

Note:

Observe all necessary conditions to safely and correctly install the AC drive. Refer to the Technical Manual for more information.

NOTICE

electrical devices.

Fire Hazard. Do not put flammable or combustible materials on top of the drive and do not install the drive

Crush Hazard. Do not hold the drive by the front cover or terminal cover. Tighten the screws correctly before

Install the drive as specified by EMC Guidelines. Failure to obey can cause incorrect operation and damage to

◆ Installation Position and Distance

Install the drive vertically for sufficient cooling airflow.

Note:

Contact Yaskawa or a Yaskawa representative for more information about installing drive models on their side.

A - Vertical installation B - Horizontal installation

Figure 9.1 Installation Position

■ Single Drive Installation

Use the clearances specified in Figure 9.2 to install the drive. Make sure that there is sufficient space for wiring

and airflow.

A - 50 mm (2 in.) minimum

B - 30 mm (1.2 in.) minimum on both

sides

Figure 9.2 Installation Distances for One Drive

C - 120 mm (4.7 in.) minimum above

and below

D - Airflow direction

■ Install Drives Side-by-Side

Users can install drive models 2004xB to 2082xB and 4002xB to 4044xB side-by-side.

Install the drives as specified by Figure 9.3. Set L8-35 = 1 [Installation Method Selection = Side-by-Side

Mounting].

Derate the output current to align with the ambient temperature.

Install other drive models as specified by Figure 9.2

EN 12 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 13

9 Mechanical Installation

A - 50 mm (2 in.) minimum

B - 30 mm (1.2 in.) minimum on both

sides

Figure 9.3 Installation Distances for Multiple Drives (Side-by-Side)

Note:

• Align the tops of drives that have different dimensions to help when replacing cooling fans.

• Remove the top protective covers of all drives when mounting UL Type 1 enclosure drives side-by-side.

C - 2 mm (0.08 in.) minimum between

each drive

D - 120 mm (4.7 in.) minimum above

and below

Figure 9.4 Enclosed Wall-Mounted Type (UL Type 1) Installed Side-by-Side

◆ Installation Environment

The installation environment is crucial to ensure proper performance and the expected lifespan of the product.

Ensure the installation environment satisfies the following specifications.

Environment Conditions

Area of Use Indoors

Power supply Overvoltage Category III

Open chassis type (IP20): -10°C to +50 °C (14 °F to 122 °F)

Enclosed wall-mounted type (UL Type 1): -10 °C to +40 °C (14 °F to 104 °F)

• Drive reliability improves in environments without wide temperature fluctuations.

Ambient Temperature

Setting

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 13

• When using the drive in an control panel, install a cooling fan or air conditioner in the area to ensure that the air

temperature inside the enclosure does not exceed the specified levels.

• Do not allow ice to develop on the drive.

• Derate the output current and output voltage to install the drive in areas with ambient temperatures up to 60 °C

(140 °F).

EN

Page 14

9 Mechanical Installation

Environment Conditions

Humidity

Storage Temperature -20 °C to +70 °C (-4 °F to +158 °F) (short-term temperature during transportation)

Surrounding Area

Altitude

Shock

Installation

Orientation

95 RH% or less

Do not allow condensation to develop on the drive.

Pollution degree 2 or less

Install the drive in an area free from:

• oil mist and dust

• metal powder, oil, water, or other foreign materials

• radioactive materials or flammable materials (e.x., wood)

• Harmful gases and liquids

• Low salinity

• Chlorides

Keep wood or other flammable materials away from the drive.

1000 m (3281 ft) maximum

Note:

Derate the output current by 1% for every 100 m (328 ft.) to install the drive in altitudes between 1000 m to

3000 m (3281 ft. to 9843 ft.).

Rated voltage derating is not required:

• when installing the drive at 2000 m (6562 ft.) or lower

• if the drive is grounded with the neutral network when installing the drive at an altitude between 2000 m to

3000 m (6562 ft. to 9843 ft.)

Contact Yaskawa or your nearest sales representative when the drive is not grounded with the neutral network.

• 10 Hz to 20 Hz: 1 G (9.8 m/s

• 20 Hz to 55 Hz:

2004 to 2211, 4002 to 4168: 0.6 G (5.9 m/s

2257 to 2415, 4208 to 4675: 0.2 G (2.0 m/s

Install the drive upright to allow for proper cooling.

2

, 32.15 ft/s2)

2

, 19.36 ft/s2)

2

, 6.56 ft/s2)

NOTICE

electrical interference if components must be near the drive. Failure to obey can cause incorrect operation.

NOTICE

installation and project construction. Put a temporary cover over the top of the drive during installation. Remove the temporary

cover before start-up or the drive will overheat. Failure to obey can cause damage to the drive.

Do not put drive peripheral devices, transformers, or other electronics near the drive. Shield the drive from

Do not let unwanted objects, for example metal shavings or wire clippings, fall into the drive during drive

◆ Removing the Covers

Remove the covers according to the following procedure before wiring the drive.

DANGER

servicing, disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal

capacitor stays charged after the drive is de-energized. The charge indicator LED extinguishes when the DC bus voltage

decreases below 50 Vdc. To prevent electric shock, always wait for at least the amount of time indicated on the warning labels.

When all indicators are OFF, remove the covers before measuring for dangerous voltages to make sure that the drive is safe.

Failure to obey will cause death or serious injury.

DANGER

then remove the covers. Failure to obey could cause death or serious injury.

Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized drive. Before

Electrical shock Hazard. Disconnect the power to the drive and wait for the charge indicator LED to go off,

■ Remove the Front Cover

1. Push the hook on the top part of the keypad and pull forward to remove the keypad.

2. Remove the keypad connector and put it into the connector holder in the direction of the hook on the front

cover.

3. Loosen the front cover screws.

Note:

The number of mounting screws are different for different drive models.

4. Unlock the tabs found on the sides of the front cover.

EN 14 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 15

5. Carefully pull forward to remove the front cover.

9 Mechanical Installation

A - Keypad connector

B - Hook

Figure 9.5 Remove the Front Cover

C - Connector holder

6. Remove the wiring cover before wiring the main circuit terminal.

A - Wiring cover

■ Remove the Terminal Cover

1. Loosen the screws on the terminal cover.

2. Pull down on the cover.

3. Pull forward on the terminal cover to free it from the drive.

EN

Figure 9.6 Removing the Terminal Cover

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 15

Page 16

9 Mechanical Installation

4. Remove the terminal wiring covers for wiring the main circuit terminals.

◆ Reattaching the Covers

Wire the drive, then reattach the covers before operating the drive.

■ Reattach the Front Cover

1. Reattach the wiring cover.

2. Reattach the front cover to the drive with the supplied screws.

3. Remove the keypad connector from the connector holder on the front cover.

4. Put the keypad connector into the connector on the drive in the direction of the hook.

5. Put the bottom part of the keypad into the drive first, then push the top part of the keypad into the drive to

reattach the keypad.

EN 16 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 17

9 Mechanical Installation

■ Reattach the Terminal Cover

1. Reattach the wiring cover.

Note:

• The shape of the wiring cover differs depending on the drive model.

• Detach the cutaway section of the wiring cover by clipping only the areas that apply to the wired terminal. If areas that do

not apply to the wired terminal are clipped, the protective enclosure will not maintain the IP20 protective level.

• Hold the cutaway section of the wiring cover firmly to prevent scattering when clipping this section. There is a risk of injury

from scattering of the cutaway section.

• Process the cross section to prevent the cutaway section of the wiring cover from damaging the electric wires.

• If electrical wires other than those specified by Yaskawa are used, the protective enclosure may not maintain the IP20

protective level, even if the wiring cover is used correctly. Contact Yaskawa or your nearest sales representative for details.

2. Reattach the terminal cover to the drive using the supplied screws.

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 17

EN

Page 18

10 Electrical Installation

10 Electrical Installation

DANGER

servicing, disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal

capacitor stays charged after the drive is de-energized. The charge indicator LED extinguishes when the DC bus voltage

decreases below 50 Vdc. When all indicators are OFF, remove the covers before measuring for dangerous voltages to make

sure that the drive is safe. Failure to obey will cause death or serious injury.

DANGER

before energizing the drive. Use terminals for their intended function only. Incorrect wiring or ground connections, and incorrect

repair of protective covers can cause death or serious injury.

WARNING

can cause death or serious injury.

WARNING

Manual for more information about I/O terminals. Incorrect wiring, incorrect grounding, and unsatisfactory repair of the

protective cover could cause death or serious injury and damage to the drive.

Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized drive. Before

Electrical Shock Hazard. Make sure that all electrical connections are correct and install all drive covers

Electrical Shock Hazard. Correctly ground the drive before turning on the EMC filter switch. Failure to obey

Electrical Shock Hazard. Use the drive terminals only for their intended function. Refer to the drive Technical

◆ Standard Connection Diagram

Wire the drive as specified by Figure 10.1. Users can run the motor only with the main circuit wiring when

operating the drive using the keypad.

WARNING

wiring. Incorrect Run/Stop circuit sequence settings can cause death or serious injury from moving equipment.

WARNING

Momentarily closing a digital input terminal can start a drive that is programmed for 3-Wire control. Failure to obey can cause

death or serious injury from moving equipment.

WARNING

When using a 3-Wire sequence:

• Set the drive for 3-Wire sequence.

• Set b1-17 = 0 [Run Command at Power Up = Disregard Existing RUN Command]

• Wire the drive for 3-Wire sequence.

The motor can rotate in reverse when energizing the drive if these three conditions are true:

• The drive is wired for 3-Wire sequence.

• The drive is set for a 2-Wire sequence (default).

• b1-17 = 1 [Accept Existing RUN Command]

Failure to obey can cause death or serious injury from moving equipment.

WARNING

sequence for the drive. Executing the Application Preset function (setting A1-06 to a value other than 0) changes the I/O

terminal function for the drive and may trigger unexpected operation in equipment. Failure to obey can cause death or serious

injury.

NOTICE

manual. The drive is suited for circuits that supply not more than 100,000 RMS symmetrical amperes, 240 Vac maximum (200 V

Class), 480 Vac maximum (400 V Class). Failure to obey can cause death or serious injury.

NOTICE

a drive duty motor or carefully monitor the motor insulation voltage. Failure to obey can cause damage to the motor insulation.

NOTICE

control circuit operation.

Sudden Movement Hazard. Set the multi-function input terminal parameters before closing the control circuit

Sudden Movement Hazard. Correctly wire the start/stop and safety circuits before energizing the drive.

Sudden Movement Hazard.

Sudden Movement Hazard. Execute the Application Preset function after checking I/O signal and the external

Fire Hazard. Install sufficient branch circuit short circuit protection as specified by applicable codes and this

When the input voltage is 440 V or higher or if the wiring distance is longer than 100 m (328 ft.) be sure to use

Do not connect the AC control circuit ground to the drive enclosure. Failure to obey can cause incorrect

EN 18 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 19

10 Electrical Installation

Figure 10.1 Standard Drive Connection Diagram

*1 Set the wiring sequence to de-energize the drive with the fault relay output. Set L5-02 = 1 [Fault Contact at

Restart Select = Always Active] to de-energize the drive when the drive outputs a fault during fault restart

when using the fault restart function. Be careful when using a cut-off sequence. The default setting for L5-02

is 0 [Active Only when Not Restarting].

*2 Connect peripheral options to terminals -, +1, +2, B1, and B2.

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 19

EN

Page 20

10 Electrical Installation

NOTICE

damage to the drive and peripheral devices.

Do not connect an AC power supply to terminals -, +1, +2, B1, and B2. Failure to obey can cause

*3 Remove the jumper between terminals +1 and +2 when installing a DC reactor.

*4 Models 2110 to 2415 and 4060 to 4675 have a DC reactor.

*5 Set L8-55 = 0 [Internal DB TransistorProtection = Disable] to disable the protection function of the drive

braking transistor when using an optional regenerative converter, regenerative unit, or braking unit. Keeping

L8-55 = 1 [Protection Enabled] can cause rF [Braking Resistor Fault].

*6 Set L3-04 = 0 [Stall Prevention during Decel = Disabled] when using a regenerative converter, regenerative

unit, braking unit, braking resistor, or braking resistor unit. The drive could possibly not stop within the

specified deceleration time when L3-04 = 1 [General Purpose].

*7 Set L8-01 = 1 [3% ERF DB Resistor Protection = Enabled] and set a sequence to de-energize the drive with

the fault relay output when using an ERF-type braking resistor.

*8 Self-cooling motors do not need cooling fan wiring.

*9 Connect 24 V power to terminal PS-AC while the power to the drive control circuit is ON and only the main

circuit is OFF.

*10 Encoder circuit wiring (wiring to PG-B3 option card) is not necessary for applications that do not use motor

speed feedback.

*11 Use a wire jumper between terminals SC and SP or SC and SN to set the MFDI power supply to SINK

Mode, SOURCE Mode, or External power supply.

NOTICE

Do not short circuit terminals SP and SN. Failure to obey will cause damage to the drive.

• SINK Mode: Install a jumper between terminals SC and SP.

Do not short circuit terminals SC and SN. Failure to obey will cause damage to the drive.

• SOURCE Mode: Install a jumper between terminals SC and SN.

Do not short circuit terminals SC and SP. Failure to obey will cause damage to the drive.

• External power supply: No jumper necessary between terminals SC and SN or terminals SC and SP.

*12 The maximum output current capacity for terminals +V and -V on the control circuit is 20 mA.

NOTICE

drive.

Do not install a jumper between terminals +V, -V, and AC. Failure to obey can cause damage to the

*13 DIP switches S1-1 to S1-3 set terminals A1 to A3 for voltage or current input. The default setting for S1-1

and S1-3 is voltage input (“V” side). The default setting for S1-2 is current input (“I” side).

*14 DIP switch S4 sets terminal A3 for analog or PTC input. Set DIP switch S1-3 to the “V” side, and set H3-05

= 0 [Terminal A3 Signal Level Select = 0 to 10V (Lower Limit at 0)] to set terminal A3 for PTC input with

DIP switch S4.

*15 Do not ground the control circuit terminals AC or connect them to the drive. Failure to comply may cause

malfunction or failure.

*16 Connect the positive lead from an external 24 Vdc power supply to terminal PS and the negative lead to

terminal AC. Reversing polarity can cause damage to the drive.

NOTICE

Do not connect reverse terminals PS and AC. Failure to obey will cause damage to the drive.

*17 Use multi-function analog monitor outputs with analog frequency meters, ammeters, voltmeters, and

wattmeters. Do not use monitor outputs with feedback-type signal devices.

*18 Jumper switch S5 sets terminal FM and AM for voltage or current output. The default setting for S5 is

voltage output (“V” side).

*19 Set DIP switch S2 to “ON” to enable the termination resistor in the last drive in a MEMOBUS/Modbus

network.

*20 Use only SOURCE Mode for Safe Disable input.

*21 Disconnect the wire jumpers between terminals H1 and HC and terminals H2 and HC to use the Safe Disable

input.

◆ Wire Gauge and Torque Specifications

Be sure to select the correct wires for the main circuit wiring.

Refer to the Technical Manual for main circuit wire gauges and tightening torques as specified by European

standards and UL standards.

■ Control Circuit Wire Gauges and Tightening Torques

Refer to Table 10.1 and Table 10.2 to select the correct wires and crimp ferrules. Use shielded wire for control

circuit terminal wiring. Use crimp ferrules on the wire ends for more reliable wiring.

EN 20 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 21

10 Electrical Installation

Table 10.1 Wire Gauges

Bare Wire Crimp Ferrule

Terminal

S1-S8, SC, SN, SP

H1, H2, HC

RP, +V, -V, A1, A2, A3, AC

MP, FM, AM, AC

D+, D-, AC

MA, MB, MC, M1-M6

PS, E(G)

Recommended

Gauge

mm2(AWG)

0.75

(18)

Applicable Gauge

2

mm

(AWG)

• Stranded wire

0.2 to 1.0

(24 to 18)

• Solid wire

0.2 to 1.5

(24 to 16)

Recommended

Gauge

2

(AWG)

mm

0.5

(20)

Applicable Gauge

2

mm

(AWG)

0.25 to 0.5

(24 to 20)

Crimp Ferrules

Attach an insulated sleeve to the wire when connecting crimp ferrules. Refer to Table 10.2 for the recommended

external dimensions and model numbers of the crimp ferrules.

Yaskawa recommends the CRIMPFOX 6 crimping tool from PHOENIX CONTACT.

Figure 10.2 Crimp Ferrule Dimensons

Table 10.2 Crimp Ferrule Models and Dimensions

Wire Gauge

2

mm

(AWG)

0.25 (24) AI 0.25-8YE 12.5 8 0.8 2.0

0.34 (22) AI 0.34-8TQ 12.5 8 0.8 2.0

0.5 (20) AI 0.5-8WH,

Model L (mm) L1 (mm) d1 (mm) d2 (mm)

14 8 1.1 2.5

AI 0.5-8OG

■ Line Voltage Drop

WARNING

than 3.5 mA. The IEC/EN 61800-5-1: 2007 standard specifies that users must wire the power supply to automatically turn off

when the protective ground wire disconnects. Users can also connect a protective ground wire that has a minimum crosssectional area of 10 mm

injury.

Be sure to think about line voltage drop before selecting wire gauges.

Select wire gauges that drop the voltage by 2% or less of the rated voltage. Increase the wire gauge and the cable

length when the risk of voltage drops increases.

Calculate line voltage drop with this formula:

Line voltage drop (V) = × wire resistance (Ω/km) × wiring distance (m) × motor rated current (A) × 10

Electrical Shock Hazard. The leakage current of drive models 4389A to 4675A, 2xxxB/C and 4xxxB/C is more

2

(copper wire) or 16 mm2(aluminum wire). Failure to obey these standards can cause death or serious

-3

■ Dynamic Braking Precautions

EN

Connect braking units to drives with these conditions:

• Models with built-in braking transistors use terminals B1 and -

• Models without built-in braking transistors use terminals +3 and -.

NOTICE

tightening torque information before connecting a dynamic braking option to the drive. Failure to obey can cause damage to the

drive and braking circuit.

Review the Braking Unit and Braking Resistor Unit Installation Manual TOBPC72060001 for wire gauge and

Connect a regenerative converter or regenerative unit with terminals +1 and -.

NOTICE

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 21

Do not connect a braking resistor to terminals +1 or -. Failure to obey can cause damage to the drive circuitry.

Page 22

11 Drive Start-Up

◆ Wiring the Main Circuit and Motor

Refer to Figure 10.3 for a view of the drive with line and load wiring.

WARNING

B2 to the ground terminal. Failure to obey can cause death, serious injury, or damage to equipment.

Electrical Shock Hazard. Do not connect terminals R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, -, +1, +2, +3, B1, or

A - Terminal block (TB2-3)

B - Terminal block (TB2-2)

C - Terminal block (TB2-1)

D - DC bus voltage terminals

(configuration changes by drive

model)

E - Drive ground terminals

F - Motor case ground

Figure 10.3 Wiring the Line and Load

G - Three-phase motor

H - Three-phase power supply

I - Fuses and RCD

J - Terminal block (TB1)

K - Terminal block (TB3)

L - Terminal block (TB4)

11 Drive Start-Up

◆ Setup Wizard

Refer to the motor nameplate to record the information in the following table before starting the drive.

Item Value

Motor Rated Power kW

Motor Rated Voltage V

Motor Rated Current A

Motor Rated Frequency Hz

EN 22 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 23

11 Drive Start-Up

Item Value

Motor Maximum Output Frequency Hz

Number of Motor Poles

Motor Base Rotation Speed min

Number of Motor Encoder Pulses ppr

-1

(r/min)

The drive setup wizard prepares the drive for operation. Use the information from the table for Auto-Tuning and

test runs.

1. Energize the drive to show the initial setup screen.

Note:

If the keypad does not show the Initial Setup screen, push [Menu] to show the Menu screen then push to

select [Initial Setup].

2. Select [Set Date/Time] to set the date and time.

Note:

Open the clock battery cover to put in a battery to use the clock functions. Use a Hitachi Maxell CR2016 manganese dioxide

lithium battery or an equivalent battery with the these properties:

• Nominal voltage: 3 V

• Operating temperature range: -20°C to +85°C (-4°F to +185°F)

• Nominal battery life: 2 years (20 °C (68 °F) ambient temperature)

3. Select [Setup Wizard] and follow the instructions shown on the keypad until the setup wizard completes.

The drive and motor are prepared for operation.

◆ Auto-Tuning

WARNING

of the rated frequency of the motor. Make sure that there are no issues related to safety in the surrounding area. Failure to obey

can cause death or serious injury and damage to machinery.

WARNING

Failure to comply could cause death or serious injury and damage machinery.

Auto-Tuning automatically sets parameters on the drive connected to the motor. Some parameters need to be input

individually when Auto-Tuning.

1. Select [Auto-Tuning] then select the Auto-Tuning Mode.

2. Use the information in Table 11.1 and Table 11.2 to select T1-01 [Auto-Tuning Mode Selection] and T4-01

[EZ Tuning Mode Selection].

3. Push to start Auto-Tuning.

Refer to the Technical Manual for more information about Auto-Tuning.

Crush Hazard. When performing Rotational Auto-Tuning, the motor rotates at a frequency that is 50% or more

Sudden Movement Hazard. Disconnect the load from the motor when performing Rotational Auto-Tuning.

EN

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 23

Page 24

11 Drive Start-Up

Table 11.1 Auto-Tuning Mode Selection

Mode T1-01 Application Conditions and Benefits

Recommended tuning mode for the most accurate results. Select this tuning mode

Rotational AutoTuning

Stationary AutoTuning 1

Stationary LineLine Resistance

Mode T4-01 Application Conditions and Benefits

Motor Parameter

Setting

Line-to-Line

Resistance

when:

0

• Users can decouple the motor from the load.

• Users cannot decouple the motor from the load, but the motor load is less than

30%.

Automatically calculates motor parameters for vector control. Select this tuning

mode when:

1

• Users cannot decouple the motor from the load.

• The motor test report data is not available.

Select this tuning mode when:

• The drive and motor capacities are different.

2

• The drive is in V/f Control.

• Replacing the drive and motor.

Table 11.2 EZ Tuning Mode Selection

Sets motor parameters.

0

Select this tuning mode after replacing the drive, motor, and motor cables.

1

A1-02 [Control

Method

Selection]

0

[V/f]2[OLV]

- YES

- YES

YES YES

A1-02 = 8

[EZOLV]

YES

YES

◆ Change Parameter Settings

The procedure below shows how to change the C1-01 [Acceleration Time 1] setting. Use this procedure to set

parameters for other applications

1. Push (Home) to show the HOME screen.

Note:

• The keypad will show [Home] in the top right corner when the HOME screen is active.

• If [Home] is not on , push (Back).

2. Push (Menu).

3. Push or to select [Parameters], then push .

EN 24 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 25

12 Drive Control, Duty Modes, and Programming

4. Push or to select [C Tuning], then push .

5. Push or to select [C1 Accel & Decel Time], then push .

6. Push or to select C1-01, then push .

7. Push or to select the specified digit, then push or to select the correct number.

• Push [Default] to set the parameters to the factory default.

• Push [Min/Max] to move between the minimum value and maximum value.

8. Push to keep the changes.

9. Continue to set parameters or push [Back] to go back to the HOME screen.

12 Drive Control, Duty Modes, and Programming

EN

◆ Drive Control Methods

This section gives information about these basic motor control methods:

• V/f Control (V/f)

• Open Loop Vector control (OLV)

• EZ Vector Control for induction motors only (EZOLV)

Refer to the Technical Manual for information about speed feedback and Permanent Magnet/Synchronous

Reluctance motor control methods.

Use parameter A1-02 [Control Method Selection] to set the correct motor control method for the application.

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 25

Page 26

12 Drive Control, Duty Modes, and Programming

Control Method A1-02 Setting Main Applications

• General variable-speed

• Operating more than one motor from one drive

• When replacing the motor without motor parameter values.

• General variable-speed

• High precision and speed control without speed feedback

• General variable-speed

• No high precision, no speed control, and no speed feedback

V/f

OLV 2

EZOLV 8

(default)

0

◆ Drive Duty Modes

The drive has two duty modes from which to select for the application: Heavy Duty (HD) and Normal Duty (ND).

The duty rating switches to HD2 or ND2 when E1-01 [Input AC Supply Voltage] ≥ 460 V. These specifications are

different between HD1/HD2 and ND1/ND2:

• The input power kVA

• The maximum applicable motor output

• The rated input current

• The rated output capacity

• The rated output current

Refer to Table 12.1 for information about the differences between HD and ND ratings.

Table 12.1 Drive Duty Modes

Duty Rating

Heavy Duty Rating 1

(HD1)

Heavy Duty Rating 2

(HD2)

Normal Duty Rating

1

(ND1)

Normal Duty Rating

2

(ND2)

E1-01 Setting

Input Voltage

• ≥ 200 V and < 240 V

• ≥ 380 V and < 460 V

≥ 460 V and < 480 V

• ≥ 200 V and < 240 V

• ≥ 380 V and < 460 V

≥ 460 V and < 480 V

C6-01

Setting

0

1

Application

• Extruder

• Conveyor

• Constant torque or high

overload capacity

• Fan

• Pump

• Blower

• Variable speed control

◆ Drive Parameters

Refer to the following table when setting the most important parameters.

Note:

Users can change parameters with “RUN” in the “No.” column during Run.

No.

(Hex.)

A1-00

(0100)

RUN

A1-02

(0102)

A1-03

(0103)

b1-01

(0180)

Language Selection Sets the language for the LCD keypad.

Control Method Selection Sets the control method for the drive application and the motor.

Initialize Parameters Sets parameters to default values.

Frequency Reference

Selection 1

Name Description

0: English, 1: Japanese, 2: German, 3: French, 4: Italian, 5: Spanish, 6: Portuguese,

7: Chinese, 8: Czech, 9: Russian, 10: Turkish, 11: Polish, 12: Greek

0: V/f Control, 1: V/f Control w/ PG, 2: Open Loop Vector, 3: Closed Loop Vector,

4: Advanced Open Loop Vector, 5: PM Open Loop Vector,

6: PM Advanced Open Loop Vector, 7: PM Closed Loop Vector, 8: EZ Vector Control

0: No Initialization, 1110: User Initialization, 2220: 2-Wire Initialization,

3330: 3-Wire Initialization

Sets the input method for the frequency reference.

0: Keypad, 1: Analog Input, 2: Memobus/Modbus Communications, 3: Option PCB,

4: Pulse Train Input

Default Carrier

Frequency

2 kHz

2 kHz Swing-PWM

Overload Tolerance

(oL2 [Drive

Overload])

150% rated output

current for 60 s

110% rated output

current for 60 s

EN 26 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 27

12 Drive Control, Duty Modes, and Programming

No.

(Hex.)

b1-02

(0181)

b1-03

(0182)

b1-04

(0183)

C1-01

(0200)

RUN

C1-02

(0201)

RUN

C2-01

(020B)

C2-02

(020C)

C2-03

(020D)

C2-04

(020E)

C6-01

(0223)

C6-02

(0224)

d1-01 to d1-16

(0280 - 0291)

RUN

d1-17

(0292)

RUN

d2-01

(0289)

d2-02

(028A)

E1-01

(0300)

E1-04

(0303)

E1-05

(0304)

E1-06

(0305)

E1-09

(0308)

E2-01

(030E)

Name Description

Run Command Selection1Sets the input method for the Run command.

0: Keypad, 1: Analog Input, 2: Memobus/Modbus Communications, 3: Option PCB

Stopping Method

Selection

Reverse Operation

Selection

Acceleration Time 1 Sets the length of time to accelerate from zero to maximum output frequency.

Deceleration Time 1 Sets the length of time to decelerate from maximum output frequency to zero.

S-Curve Time @ Start of

Accel

S-Curve Time @ End of

Accel

S-Curve Time @ Start of

Decel

S-Curve Time @ End of

Decel

Normal / Heavy Duty

Selection

Carrier Frequency

Selection

Reference 1 to 16 Sets the frequency reference in the units from o1-03 [Frequency Display Unit Selection].

Jog Reference Sets the Jog frequency reference in the units from o1-03 [Frequency Display Unit

Frequency Reference

Upper Limit

Frequency Reference

Lower Limit

Input AC Supply Voltage Sets the drive input voltage. Set this parameter to the nominal voltage of the AC power

Maximum Output

Frequency

Maximum Output Voltage Sets the maximum voltage for the V/f pattern.

Base Frequency Sets the base frequency for the V/f pattern.

Minimum Output

Frequency

Motor Rated Current

(FLA)

Sets the method to stop the motor after removing a Run command or entering a Stop

command.

0: Ramp to Stop, 1: Coast to Stop, 2: DC Injection Braking to Stop,

3: Coast to Stop with Timer, 9: Stop with Constant Distance

Enables and disables reverse operation. Disable reverse operation in fan or pump

applications where reverse rotation is dangerous.

0: Reverse Enabled, 1: Reverse Disabled

Sets the time to start S-curve acceleration.

Sets the time to complete S-curve acceleration.

Sets the time to start S-curve deceleration.

Sets the time to complete S-curve deceleration.

Sets the duty rating of the drive.

0: Heavy Duty Rating, 1: Normal Duty Rating

Sets the carrier frequency for the transistors in the drive.

1: 2.0 kHz, 2: 5.0 kHz (4.0 kHz for AOLV/PM), 3: 8.0 kHz (6.0 kHz for AOLV/PM),

4: 10.0 kHz (8.0 kHz for AOLV/PM), 5: 12.5 kHz (10.0 kHz for AOLV/PM),

6: 15.0 kHz (12.0 kHz AOLV/PM), 7: Swing PWM 1 (Audible Sound 1),

8: Swing PWM 2 (Audible Sound 2), 9: Swing PWM 3 (Audible Sound 3),

A: Swing PWM 4 (Audible Sound 4), F: User Defined (C6-03 to C6-05)

Selection]. Set H1-xx = 6 [MFDI Function Select = Jog Reference Selection] to use the Jog

frequency reference.

Sets maximum limit for all frequency references. This value is a percentage of E1-04

[Maximum Output Frequency].

Sets minimum limit for all frequency references. This value is a percentage of E1-04

[Maximum Output Frequency].

supply.

Sets the maximum output frequency for the V/f pattern.

Sets the minimum output frequency for the V/f pattern.

Sets the motor rated current in amperes.

EN

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 27

Page 28

12 Drive Control, Duty Modes, and Programming

No.

(Hex.)

E2-11

(0318)

H1-01 to H1-08

(0438, 0439,

0400 - 0405)

H2-01

(040B)

H2-02

(040C)

H3-01

(0410)

H3-02

(0434)

H3-03

(0411)

RUN

H3-04

(0412)

RUN

H3-05

(0413)

H3-06

(0414)

H3-07

(0415)

RUN

H3-08

(0416)

RUN

H3-09

(0417)

H3-10

(0418)

H3-11

(0419)

RUN

H3-12

(041A)

RUN

H3-13

(041B)

H3-14

(041C)

H4-01

(041D)

H4-02

(041E)

RUN

Name Description

Motor Rated Power (kW) Sets the motor rated power in 0.01 kW units. (1 HP = 0.746 kW)

Terminal Sx Function

Selection

Term M1-M2 Function

Selection

Term M3-M4 Function

Selection

Terminal A1 Signal Level

Select

Terminal A1 Function

Selection

Terminal A1 Gain Setting Sets the gain of the analog signal input to MFAI terminal A1.

Terminal A1 Bias Setting Sets the bias of the analog signal input to MFAI terminal A1.

Terminal A3 Signal Level

Select

Terminal A3 Function

Selection

Terminal A3 Gain Setting Sets the gain of the analog signal input to MFAI terminal A3.

Terminal A3 Bias Setting Sets the bias of the analog signal input to MFAI terminal A3.

Terminal A2 Signal Level

Select

Terminal A2 Function

Selection

Terminal A2 Gain Setting Sets the gain of the analog signal input to MFAI terminal A2.

Terminal A2 Bias Setting Sets the bias of the analog signal input to MFAI terminal A2.

Analog Input FilterTime

Constant

Analog Input Terminal

Enable Sel

Terminal FM Analog

Output Select

Terminal FM Analog

Output Gain

Sets the functions for MFDI terminals S1 to S8.

Sets the function for MFDO terminal M1-M2.

Sets the function for MFDO terminal M3-M4.

Sets the input signal level for MFAI terminal A1.

0: 0 to 10V (Lower Limit at 0), 1: -10 to +10V (Bipolar Reference), 2: 4 to 20 mA,

3: 0 to 20 mA

Sets the function for MFAI terminal A1.

Sets the input signal level for MFAI terminal A3.

0: 0 to 10V (Lower Limit at 0), 1: -10 to +10V (Bipolar Reference), 2: 4 to 20 mA,

3: 0 to 20 mA

Sets the function for MFAI terminal A3.

Sets the input signal level for MFAI terminal A2.

0: 0 to 10V (Lower Limit at 0), 1: -10 to +10V (Bipolar Reference), 2: 4 to 20 mA,

3: 0 to 20 mA

Sets the function for MFAI terminal A2.

Sets the time constant for primary delay filters on MFAI terminals.

Sets which Sx terminal is enabled when H1-xx = C [MFDI Function Select = Analog

Terminal Enable Selection] is ON.

1: Terminal A1 only, 2: Terminal A2 only, 3: Terminals A1 and A2, 4: Terminal A3 only,

5: Terminals A1 and A3, 6: Terminals A2 and A3, 7: Terminals A1, A2, and A3

Sets which drive monitor Ux-xx to output from MFAO terminal FM.

Sets the gain of the Ux-xx monitor signal in H4-01 [Terminal FM Analog Output Select].

EN 28 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 29

13 Faults and Alarms

No.

(Hex.)

H4-03

(041F)

RUN

H4-04

(0420)

H4-05

(0421)

RUN

H4-06

(0422)

RUN

H4-07

(0423)

H4-08

(0424)

L1-01

(0480)

L1-02

(0481)

L3-04

(0492)

Name Description

Terminal FM Analog

Output Bias

Terminal AM Analog

Output Select

Terminal AM Analog

Output Gain

Terminal AM Analog

Output Bias

Terminal FM Signal Level

Select

Terminal AM Signal

Level Select

Motor Overload (oL1)

Protection

Motor Overload

Protection Time

Stall Prevention during

Decel

Sets the bias of the Ux-xx monitor signal in H4-01 [Terminal FM Analog Output Select].

Sets which drive monitor Ux-xx to output from MFAO terminal AM.

Sets the gain of the Ux-xx monitor signal in H4-04 [Terminal AM Analog Output Select].

Sets the bias of the Ux-xx monitor signal in H4-04 [Terminal AM Analog Output Select].

Sets the output signal level from MFAO terminal FM.

0: 0 to 10 Vdc, 1: -10 to +10 Vdc, 2: 4 to 20 mA

Sets the output signal level from MFAO terminal AM.

0: 0 to 10 Vdc, 1: -10 to +10 Vdc, 2: 4 to 20 mA

Sets the motor overload protection function that uses electronic thermal protectors.

0: Disabled, 1: Variable Torque, 2: Constant Torque 10:1 Speed Range,

3: Constant Torque 100:1 SpeedRange, 4: PM Variable Torque, 5: PM Constant Torque,

6: Variable Torque (50Hz)

Sets the motor overload (oL1) protection time. Usually it is not necessary to change this

setting.

Sets the method that the drive will use to prevent overvoltage faults when decelerating.

0: Disabled, 1: General Purpose, 2: Intelligent (Ignore Decel Ramp),

3: General Purpose w/ DB resistor, 4: Overexcitation/High Flux,

5: Overexcitation/High Flux 2

13 Faults and Alarms

Look at the drive keypad for fault and alarm information if the drive or motor do not operate correctly.

For drive alarms:

• Keypad shows the alarm code

• and ALM/ERR on the LED Status Ring flash.

• The drive will continue to operate the motor. Some alarms let the user select a motor stopping method.

For drive faults:

• Keypad shows the fault code

• and ALM/ERR on the LED Status Ring stay illuminated.

• The drive shuts off output, the fault relay output turns ON, and the motor coasts to stop.

◆ Fault Reset Procedure

1. Remove the cause of the fault or alarm.

2. Push (Reset) or on the keypad while the keypad is showing the fault or alarm code.

This table lists the most frequent alarms and faults with possible causes and solutions.

Refer to the Technical Manual for a full list of faults and alarms.

Code Name Causes Possible Solutions

bb Baseblock A digital input set for the software

CrST Remove RUN Command to

Reset

baseblock function is OFF and the drive

will not accept a Run command.

Tried to reset a fault when a Run

command was active.

• Make sure that the digital input function

selections are correct.

• Make sure that the host controller sequence is

correct.

Stop the Run command and reset the drive.

EN

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 29

Page 30

13 Faults and Alarms

EF FWD/REV Run Command

Input Error

EF1 to EF8 External Fault (Terminal

Sx)

GF Ground Fault A current short to ground was more than

oC Overcurrent • There is a short circuit or ground fault

oL1 Motor Overload The motor load is too heavy. Decrease the motor load.

oL2 Drive Overload • The load is too heavy.

ov Overvoltage • The DC bus voltage is too high.

PF Input Phase Loss Drive input power has an open phase. Correct all wiring errors in the main circuit drive

A forward command and a reverse

command were input at the same time

for longer than 500 ms.

One of the digital inputs caused an

external fault through an external

device.

The digital input settings are incorrect.

50% of the rated current on the output

side of the drive.

The motor wiring or insulation are

damaged.

Too much parasitic capacitance at drive

output.

on the drive output side.

• The load is too heavy.

• The accel/decel times are too short.

• The motor data is incorrect.

• The V/f pattern settings are incorrect.

• A magnetic contactor was switched at

the output.

Operating a general-purpose motor

slower than the rated speed with a high

load.

Cycle times are too short during

acceleration and deceleration.

The motor rated current setting is

incorrect.

• The drive capacity is too small.

• Torque is too high at low speed.

• The deceleration time is too short.

• Stall prevention is disabled.

• The braking resistor is missing or

damaged.

• Motor control is not stable.

• The input voltage is too high.

The drive input power terminals are not

tight.

Too much fluctuation in the drive input

power voltage.

Make sure that the sequence is correct. Do not set

the forward and reverse inputs at the same time.

• Find the device that caused the external faults.

Remove the cause and reset the fault.

• Make sure that the digital input terminal

functions are correct.

• Make sure that the output wiring is correct.

• Make sure that the motor does not have short

circuits or damaged insulation.

Replace damaged parts.

Reduce the carrier frequency in C6-02 [Carrier

Frequency Selection].

• Replace damaged output wiring and motor

wiring.

• Repair damaged machine parts.

• Make sure that the drive parameter settings are

correct.

• Make sure that the output contactor sequence is

correct.

Use a motor with external cooling and set the

correct motor type in L1-01 [Motor Overload (oL1)

Protection].

Increase the acceleration and deceleration times.

Make sure that the motor rated current in E2-01

[Motor Rated Current (FLA)] is correct.

• Examine the load.

• Make sure that the drive is sufficiently large for

the load.

• The overload capability of the drive decreases at

low speeds. Decrease the load or replace the

drive with a larger capacity model.

• Increase the deceleration time.

• Set L3-04 [Stall Prevention during Decel] ≠ 0 to

enable stall prevention.

• Replace the braking resistor.

• Make sure that motor parameter settings are

correct and adjust torque and slip compensation

if necessary.

• Make sure that the power supply voltage meets

drive specifications.

input power.

Tighten the terminals to the correct tightening

torque.

• Measure the voltage from the drive input power.

• Make the drive input power stable.

EN 30 YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps

Page 31

14 Disposal Instructions

There is unsatisfactory balance between

voltage phases.

The main circuit capacitors are

unserviceable.

STo Safe Torque OFF The two Safe Disable inputs are open.

The drive output is safely disabled and

the motor will not start.

SToF Safe Torque OFF Hardware Opening only one Safe Disable input

disables drive output. (Usually inputs

H1 and H2 must open to disable drive

output.)

• One input is damaged and will not

switch off after removing the external

signal.

• The host controller switched off one

input.

• Make the drive input power stable.

• Disable phase loss detection.

• Make sure that the capacitor maintenance time in

monitor U4-05 [CapacitorMaintenance] is less

than 90%.

• Replace the main capacitors if U4-05 is more

than 90%. Contact Yaskawa or a Yaskawa

representative to replace the main capacitors.

Make sure that there are no problems with the drive

input power. If drive input power is correct and the

alarm continues to occur, replace the control board

or the drive. Contact Yaskawa or a Yaskawa

representative to replace the control board.

• Find the problem causing the host controller

safety device to disable the drive.

• If the Safe Disable function does not disable the

drive or if it is not used for the ISO/EN 13849-1

(PL e (Cat.III)), and IEC/EN 61508 (SIL3),

connect a jumper between terminals HC, H1,

and H2.

• Make sure that the wiring from the host

controller is correct and the controller set the two

signals correctly.

• If the signals are correct and the alarm continues

to occur, replace the drive.

14 Disposal Instructions

Correctly discard the drive, packing material, battery, and microSD card as specified by regional, local, and

municipal laws and regulations for this product. (Example: European Waste 16 02 14)

Note:

• Remove the battery and microSD card from the keypad before discarding the drive.

• The battery is not recyclable. Discard used batteries as specified by the battery manufacturer.

• Customers are responsible for microSD card data protection. PC functions that format and delete the data may not be sufficient to fully

erase the microSD card data.

Yaskawa recommends that customers physically destroy the microSD card in a shredder or use data wipe software to fully erase the

card.

EN

YASKAWA ELECTRIC TOEP C710617 17D YASKAWA AC Drive GA700 Initial Steps EN 31

Page 32

YASKAWA AC Drive GA700

High Performance Type

Initial Steps

YASKAWA EUROPE GmbH

Hauptstraβe 185, 65760 Eschborn, Germany

Phone: +49-6196-569-500

E-mail: support@yaskawa.eu.com

Internet: http://www.yaskawa.eu.com

DRIVE CENTER (INVERTER PLANT)

2-13-1, Nishimiyaichi, Yukuhashi, Fukuoka, 824-8511, Japan

Phone: +81-930-25-2548 Fax: +81-930-25-3431

Internet: http://www.yaskawa.co.jp

YASKAWA AMERICA, INC.

2121, Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: +1-800-YASKAWA (927-5292) or +1-847-887-7000 Fax: +1-847-887-7310

Internet: http://www.yaskawa.com

*TOEPC71061717*

In the event that the end user of this product is to be the military and said product is to be

employed in any weapons systems or the manufacture thereof, the export will fall under the

relevant regulations as stipulated in the Foreign Exchange and Foreign Trade Regulations.

Therefore, be sure to follow all procedures and submit all relevant documentation according

to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications and

improvements.

© 2016 YASKAWA Electric Corporation

MANUAL NO. TOEP C710617 17D <3>-0

Published in Japan December 2016

15-11-8_YEU

Original instructions

Loading...

Loading...